BC SALMON INDUSTRY ON EDGE

British Columbians relying on the farmed salmon industry for their livelihood are alarmed at Canada’s decision to phase out 19 farms in the province. Frustrated town mayors speak out on behalf of their communities P. 8

FARMING TECH

RAS for oysters?

Why not. USDA is backing a Maine company that’s pioneering the science of shellfish production using recirculating aquaculture systems (RAS) technology P. 14

BIVALVES

National shellfish outlook

Growers in Canada are improving harvesting processes while minimizing their operations’ impact on the environment. Industry and scientists collaborate to boost shellfish health and lifecycle P. 22

SEA URCHINS

New industry shaping up

New England’s cool waters are ideal for raising sea urchins. Local farmers race to cash in on Japan’s hunger for the highvalue crop P. 32

The success of APEX-IHN® vaccination programs has meant that the risk of IHN is not often spoken about, and yet the potential threat of infection from wild fish remains ever present.

Don’t let IHN become the ‘elephant in the room’, keep protecting your salmon, and your profits, with APEX-IHN®.

Reader Service

Print and digital subscription inquiries or changes, please contact Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Liza Mayer lmayer@annexbusinessmedia.com 778-828-6867

Regular Contributors Ruby Gonzalez, John Nickum, Matt Jones, Lynn Fantom

Advertising Manager Jeremy Thain jthain@annexbusinessmedia.com +1-250-474-3982

Account Manager Morgen Balch mbalch@annexbusinessmedia.com

Media Designer Svetlana Avrutin savrutin@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Aquaculture North America is published six times a year by Annex Business Media. The authority for statements and claims made in Aquaculture North America is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.00+Tax Within North America: $48.00 CAD Outside North America: $62.00 CAD To subscribe visit our website at www.aquaculturenorthamerica.com

PRINTED IN CANADA ISSN 1922-4117 Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 UNITED STATES MAILING ADDRESS Aquaculture North America, 815 1st Ave, #93, Seattle, WA, 98104

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Aquaculture North America are copyright ©2021 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Ad Deadline

The advertising deadline for the May/June issue is March 30th. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the May/June is March 30th. Contact Liza Mayer at lmayer@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

FROM THE EDITOR

Ripple effects

On January 20, I had the opportunity to speak with mayors of five British Columbia communities impacted by Canada’s decision to phase out the salmon farms in the Discovery Islands. The mayors of Campbell River, Port McNeill, Gold River, Port Hardy and the Village of Sayward are fighting for their coastal towns and the lives of real people. People like 24-year-old Kaitlin Guitard, a sea site water-quality technician at Mowi, pictured on the cover of this issue. Like the hundreds of British Columbians relying on the industry for their livelihood, Kaitlin wonders if she’ll still have a job in 18 months. But more than the economic losses, the Vancouver Island mayors worry about the human toll of the farms’ closures. Livelihood is vital for sustaining community wellbeing. Loss of livelihood, especially in the middle of a global pandemic, would be tragic. Communities need these stable, long-term employment opportunities if they are to continue to prosper. Good jobs

ADVERTISERS' INDEX

BY LIZA MAYER

have to be available for their young or these communities will slowly die and eventually become impoverished wards of the state. The mayors were caught off guard by the haste at which Fisheries Minister Bernadette Jordan appeared to have arrived at the decision. They were also left out of the consultation process. In a letter to Minister Jordan, they pointed out the ripple effects of this decision. They are asking that she reassess it, give them the opportunity for input, and give the salmon farmers enough time to decide what to do with the millions of fish intended for some of the farms that will be shut down. They want clarity: What is the oft-quoted “transition plan”? What’s the time frame? Throwing money at the problem isn’t going to cut it, they say. They want full-time, year-round, career-building, lifetime employment with a living wage for their people. They hope the Minister is listening.

Grieg Seafood of Norway says farming in the seas will remain at the industry’s core but land-based farming will play a supporting role

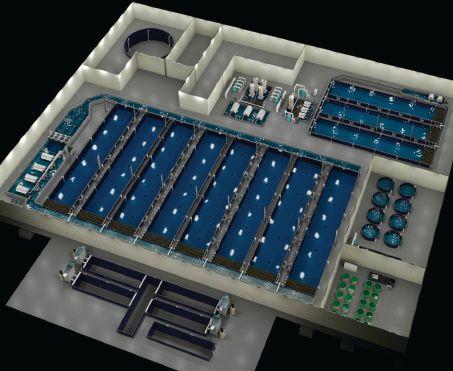

Grieg Seafood enters RAS space Company recognizes land-based farming will play a supporting role

Grieg Seafood has become the first major salmon producer to go into RAS salmon growout.

The Norwegian salmon farmer announced at the start of the year that it has invested in a new land-based salmon producer called Årdal Aqua. The company will produce post-smolt Atlantic salmon using RAS (recirculating aquaculture systems) and, eventually, grow them all the way to market size.

A new land-based facility in Rogaland in Southern Norway will be built this fall for this purpose. It is designed to have 5,000-tonne capacity, but there’s potential to expand that. Initial production target is 3,000 tonnes annually.

Grieg Seafood sees its investment into the new company as a way to learn and refine RAS technology for salmon growouts because RAS is still rife with technological and financial risks.

“We are working hard to improve biology and fish welfare, and to reduce our impact,” said Andreas Kvame, CEO of Grieg Seafood and Chair of Årdal Aqua.

“For a long time, we have invested in

post-smolt, where we keep the fish longer on land before we release it into the sea, as an important part of the solution. With Årdal Aqua we will be able to develop this farming method further. We aim for all of our fish in Rogaland to spend less than one year in the sea.”

Kvame sees a future where RAS technology complements other fish farming technologies. He said ocean-based fish farming will remain the main component of the aquaculture industry but land-based farming will be a “great supplement.”

“We look forward to taking part in the development of this technology. What we know for sure is that the world will need a lot more healthy and nutritious food with the lowest possible impact,” he said.

Grieg Seafood owns one-third of Årdal Aqua; other co-owners also with one-third share each are the smolt and post-smolt company Vest Havbruk, and Stavanger-based investor group Omfar.

The company said it will release information about the investment cost when the design development phase is completed. It estimates an investment cost of $14.27 per kg (NOK120/kg).

Biden urged to make local seafood production a priority

The Stronger America Through Seafood (SATS) movement is urging US President Joe Biden to prioritize domestic seafood production.

In a letter to Biden, SATS asked that aquaculture be included as part of his administration’s oceans and climate policies “to build back a stronger, more resilient America.”

“Aquaculture presents a unique opportunity to build an American seafood future that can bring us through this challenging time and support a diverse workforce, enhance sustainable ecosystems, and guarantee healthful, locally-sourced protein for American consumers,” the group wrote.

“As America begins to rebuild from the devastation of the COVID-19 pandemic, increasing America’s seafood supply through aquaculture will have benevolent rippling effects throughout many areas of the country. Increased aquaculture production will increase demand for American-grown crops, such as soybeans, corn and peas, which can be used in fish feed, and will open up new markets to heartland farmers while lessening dependence on the uncertainty of foreign trade relationships.”

Founded in 2018, the industry coalition includes players in the aquaculture industry, such as Cargill, Pacific Seafoods, High Liner Foods, Innovasea, Blue Ocean Mariculture, and Pacifico Aquaculture.

Fish-free

tilapia feed breakthrough

Faster growth, better FCR worth the slightly higher production costs, say inventors

Scientists at the University of California-Santa Cruz have developed a fish-free feed for tilapia that has shown extensive gains in sustainability, performance, and economic viability.

Instead of fishmeal, the feed uses whole cells from a marine microalgae called Schizochytrium sp. A second ingredient is a protein-rich byproduct derived from a microalgae called Nannochloropsis oculata after the oil, which is used in commercial Omega-3 dietary supplements, has been extracted from it.

“This is an important breakthrough and first proof of concept developing a fish-free feed for tilapia by combining microalgae. This is a potential game changer for shifting aquaculture to more sustainable practices,” said lead author

Pallab Sarker, an associate research professor in environmental studies at UCSC.

He said the tilapia feed is economically viable. “Although fish-free feed cost of $0.68/ kg feed is slightly more expensive compared to conventional feed’s cost of $0.64/kg feed, the economic conversion ratio (feed cost per kg tilapia production) of the fish-free feed ($0.95/kg tilapia) was less than that of the conventional diet ($1.03/kg tilapia) because the tilapia fed on the fish-free diet grew faster with better feed conversation ratio,” he explained.

He and his co-investigator Professor Anne Kapuscinski, a sustainability science and policy expert at UCSC, have already applied for a patent for the feed.

“We hope to work with industry stakeholders and sustainable aquaculture entrepreneurs to bring it to market. We are optimistic about the potential commercial implication of the invention to help expand sustainable economic opportunities for the aquafeed industry and farmed fish producers in the world,” said Sarker.

He acknowledged however that a major challenge is generating consistency in supply of the microalgal ingredients in order to produce quantities on an industrial scale.

A startup called Verdant Seas, which Sarker co-founded, will conduct the commercial trials of the fish-free tilapia feed. Verdant Seas’ mission is to “design blends of marine microalgae to create superior performing aquaculture feeds for tilapia,” according to its website.

US seafood player to acquire BC RAS farmer

Years of hard work and dedication to prove that RAS technology works in small- to medium-sized farms are finally paying off for Steve Atkinson, founder and president of one of British Columbia’s Taste of BC Aquafarms.

Since July 2020, the 100-tonne-capacity land-based steelhead farm has been seeing consistent weekly harvests of 2 tonnes of steelhead weighing upwards of 2kg each.

Now, Miami, Florida-based seafood processing company Blue Star Foods Corp is interested in acquiring Taste of BC Aquafarms. Atkinson and Blue Star Foods have signed a term sheet, subject to certain closing conditions.

“We are very thrilled to partner with the Atkinson family, the founders and operators of Taste of BC Aquafarms, who have been pioneers in RAS farming since 2010. They’ve built a proven and scalable model and we are excited to strategically fund their next level of growth and use our sales platform to market their delicious, sashimi-grade, Steelhead Salmon,” said Blue Star Foods Chairman and CEO, John Keeler.

Yellowtail amberjack created from fish cells then cooked in four ways demonstrated its commercial readiness, said BlueNalu PHOTO: BLUENALU

Lab-grown seafood products to debut in US market this year

A US startup pioneering a technique of producing labgrown seafood products said it expects to introduce a wide variety of cell-based seafood products from its pilot production facility in California this year, starting with mahi mahi, followed by bluefin tuna.

BlueNalu produces whole muscle, cell-based seafood products in the laboratory. “Living cells are isolated from fish tissue, placed into culture media for proliferation, and then assembled into great-tasting fresh and frozen seafood products,” it said on its website.

In January, it secured $60 million in financing, which will fund the next phase of the company’s commercialization plans.

With the help of black soldier fly (inset), Enterra’s facility in Alberta, Canada recycles 130 tonnes of food waste per day and turns it into 10 tonnes of high-protein feed ingredient

Insect-based feed ingredient producer bags $6M grant

A British Columbia company that produces salmonid feed ingredient derived from black soldier fly larvae is scaling up production at its first manufacturing facility with the help of a $6M grant from the federal government.

Enterra Feed Corporation, headquartered in Maple Ridge, BC, made history in 2017 when its insect-based aquaculture feed ingredient became the first of its kind to be approved for the Canadian market.

The company opened its first commercial-scale production facility a year ago in Rocky View County, a municipal district in Alberta, Canada, and has since closed its small-scale production facility in Langley, BC.

The $6-million grant will outfit the 17,500-square-metre production facility with specialized handling equipment and robotics, said Bruce Jowett, director of marketing at Enterra.

“We are at a place where we feel we will reach our full production of 4,000 tonnes by the second quarter of this year,” he said.

Jowett said Enterra is one of only two suppliers of fly larvae as ingredient for salmonid feed in North America, but it is the only one with a production facility in the region.

The company is planning a second manufacturing facility, in Columbus, Ohio, but the pandemic has put the commissioning of that facility on hold. “The building is there, we’re doing all the engineering but our technical people and our entomology experts could not travel down to the United States right now,” said Jowett.

Fish is crucial to food security, but why do policymakers ignore it?

/ BY LIZA MAYER

Scientists and policy experts say fish is largely missing in key global food policy discussions and decision-making because policymakers view fish predominantly as “just a natural resource that provides income and livelihoods.”

The group said fish should instead be viewed as food – and a critical source of unparalleled nutrition at that – so it could move to the front and center of policy discussions.

“Fish has always been food. But in this paper, we lay out an agenda for enhancing the role of fish in addressing hunger and malnutrition,” says Abigail Bennett, assistant professor in the Center for Systems Integration and Sustainability in the Department of Fisheries and Wildlife at Michigan State University.

In the paper titled: “Recognize fish as food in policy discourse and development funding,” Bennett and fellow scientists and policy experts from Duke University, Harvard University, World Bank and Environmental Defense Fund, say that as a result of fish being overlooked, fish is underrepresented in international development funding priorities, including even the World Bank.

They also say that the UN Sustainable Development Goal 2, Zero Hunger, does not mention fisheries or aquaculture by name, nor does it offer specific guidance on fish production systems.

The paper identifies four pillars of suggested action to begin framing fish as food, not just a natural resource:

1.

Improve metrics. There are few metrics to assess and communicate the contributions of fish to food and nutrition security. Governments and researchers can collaborate to develop better tools to raise the profile of fish in broader food and nutrition security policies and investment priorities.

3.

Govern distribution. Availability, access and stability are key features of food and nutrition security. Even though fish is one of the most traded food commodities in the world, there is limited information about its distribution and links to nutrition security. There is also a need to promote equitable distribution of capital and property rights to access fisheries, particularly that recognize the importance of small-scale fisheries and roles women play in fishing and aquaculture sectors.

Promote nutrition-sensitive fish food systems. Current management regimes emphasize the “maximum sustainable yield” for a given fishery. Managing for “optimal nutritional yield” would focus on not just rebuilding and conserving fish populations – an important goal in and of itself – but also on sustainably managing nutrient-rich fisheries.

4.

“Fish as food” framing. Sustainable fisheries and aquaculture are key to feeding the world and alleviating malnutrition, and already provide valuable nutrition and livelihood contributions. Including a nutrition lens when illustrating the multiple benefits of sustainable fisheries production can help to elevate the importance and impact of fish as a key component of the global food system and to ensure that we do not fall behind in global food security targets.

A salmon industry analyst says this uncertainty could make the east coast of Canada, as well as Norway, more attractive as destinations for investments.

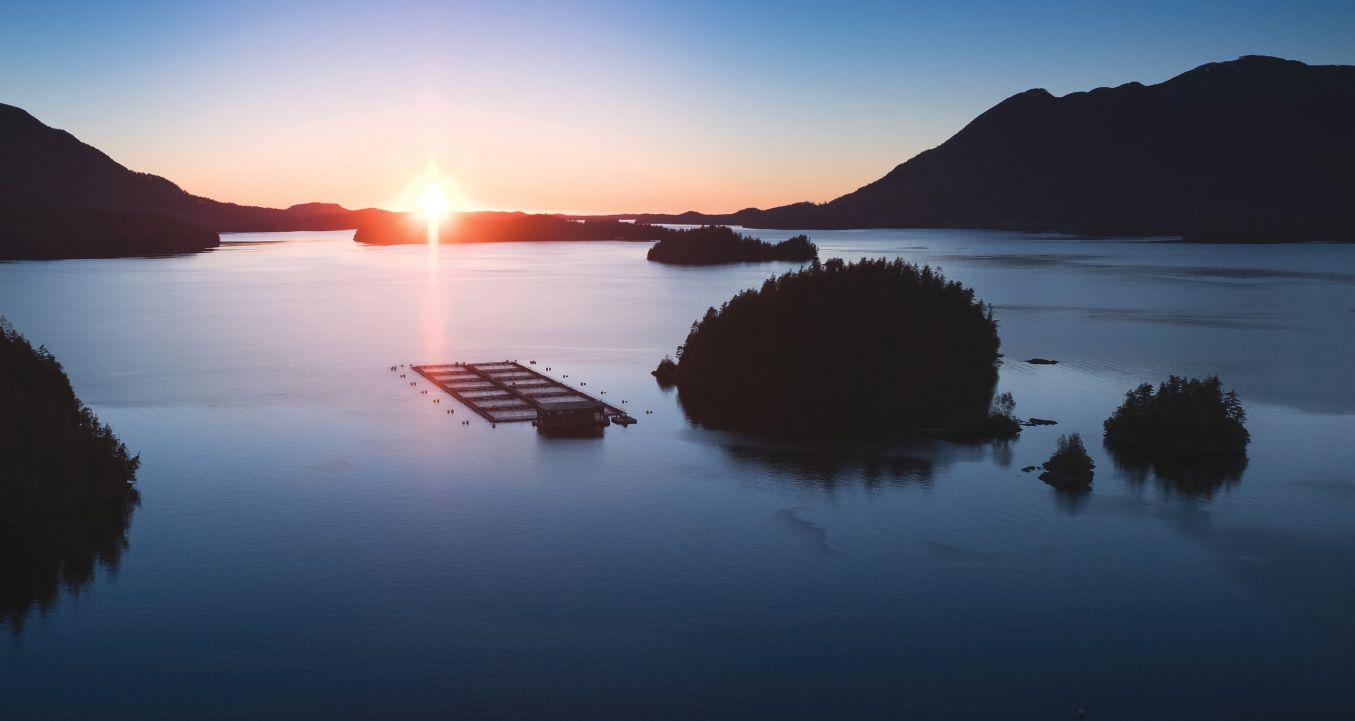

‘WE’RE IN A PANIC MODE’

Frustrated and angry, mayors of five BC

coastal

towns

say decision is a defeat for science, food security and job creation in rural areas

BY LIZA MAYER

There was no shortage of grim news for Port McNeill Mayor Gabriele Wickstrom. Her town of 2,200 people has just come out of a months-long, financially devastating forestry strike in February 2020 when the COVID-19 pandemic hit, dimming hopes of economic recovery.

Wickstrom estimates that roughly 80 percent of Port McNeill’s population depends on

British Columbia’s $7-billion forestry sector for their livelihood. Others rely on the province’s $1.6-billion salmon aquaculture industry.

On December 17, BC’s salmon farming community received bad news: the 19 fish farms in the Discovery Islands will be phased out over the next 18 months because the indigenous communities where those farms are located don’t want them there, said Fisheries and Oceans Canada (DFO) Minister Bernadette Jordan.

The Discovery Islands is an archipelago near Campbell River, the town where almost one-quarter of BC’s aquaculture workforce is based. Three of the world’s leading aquaculture companies – Mowi, Cermaq and Grieg Seafood – have their North American head offices there. The town is also home to two small independent farms, Yellow Island Aquaculture and Salt Stream Aquaculture.

The three global players have some farms in the Discovery Islands: Mowi’s 15 farms account for 30 percent of its annual harvest in BC; Cermaq’s three account for 20 percent of its Canadian production; and Grieg Seafood has one, accounting for 12 percent of its total harvest biomass.

None of those salmon farms are in Port McNeill but the news isn’t any less troubling for Wickstrom. She says the economic benefit that trickles down to neighboring communities like hers – and the losses if the closures move ahead – underscore the magnitude of this decision.

“There’s not a lot of people directly employed in aquaculture but there are a lot of spin-off businesses. In fiscal 2019, Cermaq spent just over $3 million with about 20 individual businesses and contractors in our community. That is just Cermaq, which actually has a smaller footprint than Mowi, so I would say that figure could easily be doubled, maybe even almost tripled,” the mayor says.

Wickstrom is one of five mayors in the North Island region of Vancouver Island who now question their community’s future, especially in a global pandemic.

Like Port McNeill, the Village of Sayward depends mainly on logging. Eleven of the village’s 300 residents work in aquaculture. As important as the jobs are the industry’s

contributions in helping Sayward thrive as a community, says Mayor Mark Baker.

Over the past decade, he says Mowi has contributed $407,000 to the local nonprofit that manages and maintains The Wharf at Kelsey Bay. The salmon producer spent more than $200,000 with local contractors in 20192020, and for years has provided generous supply of salmon during community events, such as Canada Day celebrations, the RCMP bike rodeo and Christmas dinners.

“I know the money doesn’t sound like a lot but given that we have just over 300 people in our community, it is a lot of money,” says Baker.

A defeat for science

“The announcement caught us completely off guard,” says Campbell River Mayor Andy Adams. “It was completely irresponsible and completely contrary to the latest Cohen Commission and very self-serving.”

The Cohen Commission was established in 2009 to address concerns that salmon farms are impacting the wild salmon population in BC’s Fraser River. One of the Commission’s recommendations was to abolish the 19 farms – which are on a salmon migration route in the Discovery Islands – by September 2020, unless there’s proof they pose only a “minimum risk of serious harm to the heath of migrating Fraser River salmon.”

Results of DFO’s own scientific assessment, released this past September, showed the farms present only “minimal risk” to wild Fraser River salmon stocks.

This kind of stipulation from the DFO is one of two new requirements that applicants for new fish farm licences – and renewals of existing ones – must comply with beginning June 2022. The second criterion is consent from local First Nations in whose traditional territories the farm sites are located.

DFO said it consulted with the seven indigenous communities – the Homalco,

Klahoose, K’ómoks, Kwaikah, Tla’amin, We Wai Kai and Wei Wai Kum – in the Discovery Islands in making the decision. When asked by this publication whether consent from indigenous communities trumps science when it comes to policy decisions, Minister Jordan’s Office refused to comment, citing the judicial review of the Minister’s decision filed by Mowi and Cermaq last January.

“I can’t speak enough as to how disappointed we are that the Minister made the decision without taking into consideration the findings of that report,” says Adams.

Uncertainty could

blunt BC’s edge

The lack of clarity around how the DFO Minister weighs her policy decisions could affect investments into the salmon industry in BC, where the federal government/DFO is the primary regulator (provincial governments are otherwise the primary regulators in other provinces).

A study by consultancy firm RIAS Inc says that salmon farmers in BC are willing to invest $1.4 billion in innovation, new technology, and

infrastructure through 2050 if the Canadian federal and provincial governments are able to provide a “predictable policy approach.”

The DFO decision is incompatible with that and raises more questions: “If the federal government along with our Member of Parliament locally are adamant to remove fish farms from the west coast of Canada, does that also pose a threat to all the fish farming and aquaculture industry in Newfoundland and Labrador as well as the rest of the east coast? And are they driving the industry out of the country completely?” asked Adams.

Adams may be justified for asking those questions because the Discover Islands farms’ phase-out echoes a decision made in December 2018 over 17 salmon farms in the Broughton Archipelago in BC. In that move, the BC provincial government and the three First Nations in the Broughtons decided to not renew the leases of 17 salmon farms owned by Mowi and Cermaq. Ten of the farms will cease operations by the end of 2022, while the rest could continue if First Nations-industry agreements and valid DFO licences are in place by 2023.

A salmon industry analyst says this uncertainty could make the east coast of Canada, as well as Norway, more attractive as destinations for investments.

“I think that the companies in Canada are now more eager to grow on the east coast rather than west,” says analyst Christian Olsen Nordby of the European financial services and research firm, Kepler Cheuvreux.

“We have seen that Mowi for example will fight the decision, and they can’t be happy about losing 10,000-12,000 tonnes. Canada has had relatively high costs for a while now and combined with low salmon prices during COVID-19, profitability has been weak. That doesn’t automatically make closed-containment farming extremely attractive because it is expensive. So I understand that the farmers now want to grow volumes on the east coast.”

BC aquaculture tech firm secures fund to facilitate growth

Poseidon Ocean Systems of British Columbia has received $3.9-million (C$5 million) investment from Ontario private equity fund Ag Capital Canada, which it will use to advance engineering and product delivery.

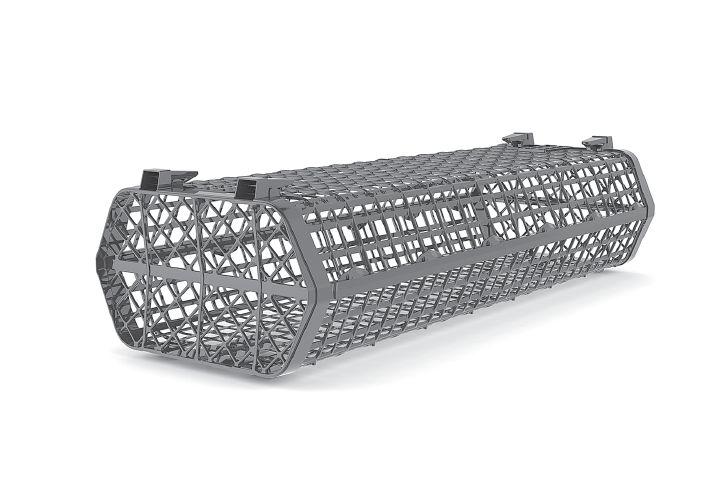

Among these products are the company’s new proprietary technologies Trident Hybrid Steel Cage System and Flowpresso compressor system.

The Trident cage technology has been in development since 2017. Company co-founder Matt Clarke calls it a “ generational leap in fish farm structural design.” Among its attributes are its strength that’s claimed to be up to twice that of existing designs and its ability to handle maximum wave heights of more than six meters.

John Lansink, managing partner at Ag Capital Canada, was impressed at the “amazing” speed at how Poseidon brought technologies to market. “We were able to check all the boxes with this investment. The company is in a growth position, ready to capitalize on a macro trend to meet global protein demand.”

Poseidon expects an additional follow-on investment from Export Development Canada.

He says this will lead to lower total production growth from Canada and more investments directed towards Norway.

“Norway has a more stable growth regime and offshore farming appears more interesting for several farmers rather than geographical expansion. Also land based and post-smolt seems more interesting for many farmers given the relatively low stability from the Canadian government, combined with the relatively high costs in Canada,” Nordby says.

‘Hear us’

Minister Jordan’s Office has neither made any statement nor responded to the countless open letters from the industry and the community asking her to reassess the decision.

“It’s nice to have communication with the seven First Nations (in the Discovery Islands). But there was no consultation, no discussion, with us as the leaders of our communities. We need to be part of the equation in discussions. It’s too important to our livelihoods in our communities,” said Mayor Brad Unger of

Gold River, where Grieg Seafood has been operating a hatchery for the past 20 years.

The hatchery on a former mill site employs 24 employees full-time, including First Nations, says Unger. “They just did a $20M to 25M upgrade of their facilities. On the farm site, there’s 20-plus people working there -full-time jobs, pension jobs, career jobs.”

Unger estimates that Grieg Seafood’s longterm agreement with the village of Gold River brings in tax dollars of between $80,000 and $100,000 a year. “For a small community of 1,300 people, that’s huge,” he says. “That is what keeps our arena, our pool, our recreation facilities going for our community. We’ll lose that, we’re in trouble.”

Mayor Wickstrom says resource-rich regions and communities continually find themselves in a position where municipalities are not included in the conversation, only to be “left picking up the pieces” afterwards.

“We know that in the resource industry things evolve. We understand that, we knew the parameters around that or at least

WAITING FOR ANSWERS

Kaitlin Guitard would be the first to admit that her job as a water quality technician at a sea site farm isn’t a walk in the park. Exposure to all types of weather conditions is the norm, and “whether it’s wind gusts of a hundred km/hr or it’s raining and snowing, you’ve got to have that drive to be able to get out there every single day,” says the 24-year-old.

Kaitlin Guitard, water quality technician at Mowi, wonders what the future holds for her and the hundreds of British Columbians relying on the farmed salmon industry

Still, she considers working at Mowi’s farm on Larsen Island in British Columbia “the best move” she’s made. More than the occasional sightings of dolphins, humpback whales or orcas that are part of the milieu, she says it’s the opportunity to do her part in creating a sustainable food future that resonates with her the most.

“When I was earning my degree in agriculture I learned about sustainable food production. That, and my love of animals, was my main reason for getting into aquaculture,” says the New Brunswick native.

Since moving to British Columbia two years ago, she has immersed herself not just in the province’s beautiful raw outdoors, but also in her coastal community.

“My whole life is this industry, at work and in my personal life. All of the connections that I’ve made, all of the friends that I’ve made are in this community. This is my life now.”

She now feels this stability is threatened by the Canadian Government’s decision to phase out 19 farms in the Discovery Islands in BC. While the farm site where Guitard works is not in the Discovery Islands, it is part of the salmon industry supply chain.

She explained that her worksite is a “specialized nursery.” “We get the fish as soon as they turn into smolts and we grow them until they’re about 500 grams, then we send the fish off to a larger farm where they will grow until

we thought we knew what was going to be happening with aquaculture around the Discovery Islands, but when things change, and change very quickly, it gives us no opportunity to be part of the discussion to even talk about what transition could be like. So when a politician comes in afterwards and talks about ‘transition,’ they’re really only talking about throwing money at the situation.

“We actually want to be part of the conversation that in the long term will save everyone money, and that’s the frustration for us. This is the template that we want to try to lay moving forward for all of our resources: forestry, aquaculture, mining. This continually happens in the province and municipalities are left to pick up the pieces when they’re not included,” says Wickstrom.

Adams emphasized that mayors have direct contact with the communities and therefore know first-hand when people lose their jobs or businesses shutter.

“We, collectively as mayors, are on the frontline hearing (our constituents) and

they’re harvested. With us not having a site to send our fish to, we are could be forced into an early closure ourselves.”

“When I heard the news, I was concerned not only about those farms in the Discovery Islands and their employees, but all of our other operations and the employees in those operations. It’s going to have a huge ripple effect on all other areas of production for the company that I work for and for the our neighboring salmon companies as well,” she said.

“This industry is one of the last of its kind on the island that’s providing secure employment, providing all of the things that it does for individuals for local vendors,” she added.

She joins the 1,500 British Columbians directly relying on the farmed salmon industry for their livelihood in urging the federal government to reassess the decision.

“Why has all of the research and the science that has been done in the last little bit been disregarded?” she wants to ask Fisheries and Oceans Canada (DFO) Minister Bernadette Jordan.

“We as farmers and our hard work and our transparency have been disregarded here. And how come we haven’t heard a response yet? I know these things take time, but there are a lot of jobs on the line. There are a lot of families on the line right now and it just it feels like we’re really just kind of ignored.”

this isn’t just our municipal communities. This includes the First Nation communities throughout the North Island because there are a significant number of employees from those First Nation communities that are also going to be personally, mentally, physically and financially impacted,” he says.

Mayor Dennis Dugas of Port Hardy says he and his fellow mayors are “not against reconciliation with indigenous nations and not against wild salmon.”

“None of us here in our communities are against wild salmon,” he says. “Wild salmon are a big part of who we are but the fish farm industry can provide income and jobs 12

months a year, which fisheries cannot. We want sustainable income for our people. They get good wages from fish farming to support their families. They get benefits that a lot of other smaller companies can’t afford to give: medical services, a pension plan.”

Around 280 Port Hardy residents working at Mowi fish farms and its processing plant in town will be impacted by the phase-out, as will another 50 employed at Hardy Buoys Smoked Fish, which processes Mowi’s harvest, and the 30 that work at Badinotti Net Services Canada, says Dugas.

The boat services operators that transport the fish from the farms to the processing

Next Generation Spawning

•

plant, the crew transport boats that ferry fish farm employees to the farm sites and back, and the mom-and-pop catering businesses and grocers whose livelihoods rely on feeding these workers, would also be impacted.

“Some people ask me: ‘why are you fighting for the fish farming industry?’ Because I’m fighting for 400 people in my community, that’s why!” he says.

“We’re in a panic mode up here,” Dugas continues. “The companies are in a panic mode, as are the people that work in the industry because they don’t know what tomorrow holds. We’re going to create ourselves a situation where social assistance is handed out until they could do something else. Is that the kind of communities that we want to build?”

The mayors say more needs to be done if rural communities are to have a chance of moving forward.

“Just to say that ‘there’s going to be a transition plan’ is not enough. What is that? What’s the time frame for it? Just cutting checks and handing them out isn’t going to cut it,” says Adams.

“We are reaching out to whoever is open to listen or have open dialogue. That’s what we’re trying to do: to try and find out what’s the real end game here.”

SOURCE: BCSFA’S ENVIRONMENTAL FOOTPRINT OF B.C.’S FARM-RAISED SALMON, SEPTEMBER 2016

Farm-raised salmon is greener than chicken, beef

Amidst the debate on salmon aquaculture in BC, science-backed data showing the sustainability of BC farmed salmon is sometimes ignored or forgotten. We reprint results of a 2016 study

Salmon raised in the ocean have the lowest overall cost to the environment, says a research on consumers’ most common protein choices. The research, prepared for the British Columbia Salmon Farmers Association (BCSFA) by Ottawa-based RIAS Inc, looked at the production of salmon versus other major proteins in terms of energy use, greenhouse gas emissions, eutrophication potential, water use and land use.

Results indicate that BC farm-raised salmon is 24-percent less costly to the environment than chicken, while beef has a cost that’s 500-percent greater than salmon raised in an ocean environment.

The study used a life-cycle analysis (LCA), defined by the United Nations Environmental Programme as “a tool for the systematic evaluation of the environmental aspects of a product or service system through all stages of its life cycle.”

“Health professionals agree that salmon is by far the most healthy protein choice for people to eat, this study shows it’s also the most healthy protein for our planet,” said Jeremy Dunn, who was the executive director of the BC Salmon Farmers Association when the study came out. “With the world population estimated by the United Nations to grow by over 2 billion by 2050, governments must consider the full environmental costs of the food we grow and eat.”

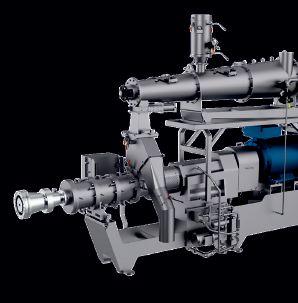

CUSTOM AQUATIC FEED SOLUTIONS ARE WAITING

Surround Yourself with Unparalleled Resources for Extrusion and Drying Systems

Do you know what aquatic feed you need to produce – but unsure of the next steps? Wenger will put unsurpassed technology and process expertise to work, developing flexible solutions specific to your operation. We expertly evaluate and guide the development and processing applications for floating, sinking, shrimp and micro aquatic feeds. Every one of our systems is customized, serving you best by going beyond a standardized approach.

Let us help you solve production challenges now. Email us at info@wenger.com today.

FAST FACTS

Farm-raised salmon ($0.59/kg) has the lowest overall environmental cost of any of the major protein options available to consumers today.

Farm-raised salmon is 24-percent less costly to the environment than chicken ($0.73/kg) to almost 500-percent less costly to the environment than beef ($3.45/kg).

GHG Emissions. Farm-raised salmon produces less GHG emissions than any commercially raised food animal.

Water Use. Farm-raised salmon was found to have consistently lower water use than other types of animal farming, using only a small fraction of the water compared to other species.

Energy Use. Over 90 percent of cumulative energy use for farm-raised salmon is from feed production. Overall, the evidence indicates that the life-cycle energy intensity for farmraised salmon is better than beef.

Land Use. Overall, studies have found that production of feed for farm-raised salmon requires much less land than used in the production of most other species. Over 90 percent of land use for farm-raised salmon is from feed production.

Eutrophication Potential. Evidence suggests that farm-raised salmon has lower potential for eutrophication (defined as the depletion of oxygen in a water body, which kills aquatic animals) than beef.

Salmon is the most efficient of all commercially raised farm-fed animals in converting feed into a kilogram of body weight, an important metric when assessing the sustainability of a food animal production system. Farm-raised salmon has an average feed conversion ratio (FCR) of 1.2:1 compared to chicken at 1.7:1 and beef which can be as high as 9.1:1 – close to 10 times less efficient than salmon.

BCSFA Members produce 75,000 MT of salmon, or about 95 percent of the total provincial harvest of farm-raised salmon.

Source:BCSFA,2016

EU scientists discover higher-value byproducts made from fish waste

Residual fish products that European Union scientists converted into oils, proteins and solids, which they then combined with bacterial strains from the Artic seabed have resulted into “new molecules” that have the potential to be turned into highly valuable raw materials.

The discovery is the latest in the EU-funded research project that’s investigating ways to add value to fish byproducts to reduce waste and enhance the seafood industry’s sustainability.

The researchers said that while fish byproducts, such as offcuts, skin and bones, are already being used in fish oils, fish meal and animal feed, they are worth only $.33 cents/kg on average. Byproducts that could be applied in products fit for human consumption would be worth much higher, they said.

Of the roughy 20 molecules created from the bacteria-residual raw materials combo, one is widely used by pharmaceutical companies in both blood pressure and allergy medications and is valued at $1,000 per gram (NOK 8500) per gram, said Nofima. Scientists from the esteemed research institution lead the project, along with colleagues

“The way forward for the scientists now is about developing the discoveries they have already made. Perhaps in a few years, both new companies and new jobs will have been created as a result of these findings.

Nets, Design, Construction, Service, HDPE Cages, Moorings and Shellfish Gear

from UiT – the Arctic University of Norway.

“The way forward for the scientists now is about developing the discoveries they have already made. Perhaps in a few years, both new companies and new jobs will have been created as a result of these findings,” Nofima said.

OYSTER CULTURE: the newest frontier in agribusiness

USDA backs venture exploring year-round shellfish production using recirculating

aquaculture system

BY LYNN FANTOM

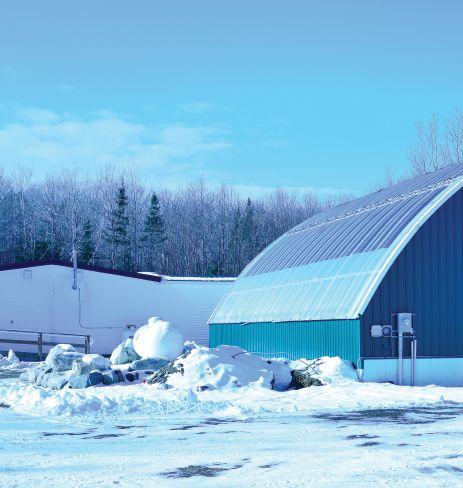

In a building that looks like a solar-powered Quonset hut, the award-winning marine biologist Tap Pryor, one of the commissioners who founded NOAA, is pioneering a non-coastal system to grow Eastern oysters year-round using recirculating aquaculture systems technology.

Maine Shellfish Developers (MSD), founded in 2016 by Pryor and his son, expects production on a pilot scale this spring that will propel progress developing “the newest terrestrial crop,” he says.

The US Department of Agriculture (USDA) apparently agrees there’s potential in those tanks at Waldoboro Business Park in Maine. The agency has supported exploration of this new frontier in agribusiness with two Small Business Innovation Research grants totaling $750,000. The Maine Technology Institute was also an early backer.

At the beginning of 2020, MSD moved to the new inland location after a three-year

“proof of concept” period at the Darling Marine Center, the University of Maine’s research facility on the Damariscotta River. “We wanted to break the umbilical cord of pumping in sea water and instead make our own and recycle it. Once you make that break, then you are entirely terrestrial.”

Like many of the world’s best ideas, this initiative sounds straightforward but represents an array of biological, chemical, engineering, and economic challenges. The goal, after all, is to “domesticate a shellfish,” Pryor says.

“We’re not creating a business. We’re creating an industry,” he asserts. Although Pryor immediately apologizes for sounding “big headed,” he has the bona fides to do so.

The Cornell English major and former Marine captain founded the Oceanic Institute — solely devoted to aquaculture research — while still a graduate student in marine biology at the University of Hawaii. At age 35, he served as a Hawaii State Senator.

Located in a Maine business park, this “Solar Arch” complex is the new, noncoastal home of Maine Shellfish Developers

The oysters he later grew in raceways at his Hawaiian seafood farm won recognition as the “outstanding food product introduced to Europe” at the European Food Fair in 1982.

After holding various university posts, he returned to farming. A land-based microalgae/ oyster aquafarm in the Cook Islands earned him a United Nations SEED award for entrepreneurship in sustainable development.

Now in Maine, the foundation of landbased high-density shellfish culture has been built. “It is a major challenge, but we learned from our trials, it is achievable,” Pryor says.

The

specs

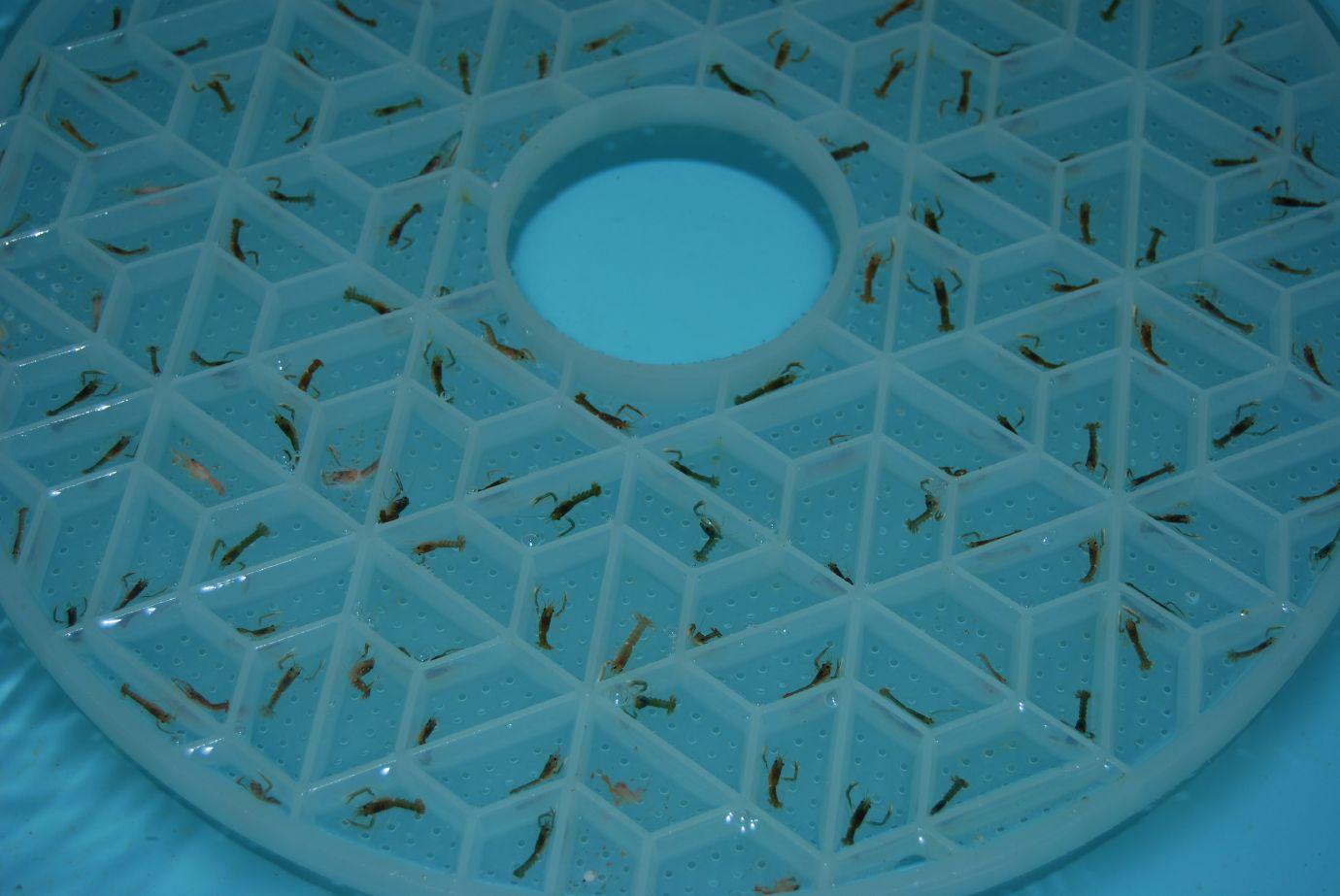

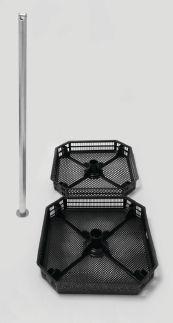

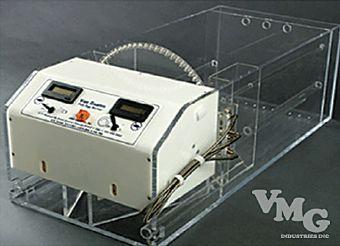

After shutting down for several months last year because of the pandemic, activities resumed in October. Housed in a 60-by-60foot space within what Pryor calls the “Solar Arch Complex,” the beta operation will utilize four circular tanks, filled with custom pie-shaped cages to take full advantage of the 3,400-gallon capacity of each.

Pryor chose energy-efficient AST PolyGeyser Bead Filters to be part of each unit, which he calls “SS-RAS.” That nomenclature,

referring to shellfish, reflects important enhancements to provide oysters with the minerals they need to grow shells — adding calcium and magnesium while extracting phosphate, nitrate, nitrite, and ammonium. The tank and filter together comprise “a basic feedlot,” Pryor says. “We call four of these a Low Volume Model or LVM. Each LVM is rated to harvest about a million oysters annually. Five LVM will comprise

one High Volume Model. The difference is that with an HVM, the cost per unit is halved, thanks to economies of scale.”

Another key consideration related to tank design includes advanced hydraulics. The goal is to ensure circulation “to the last oyster in the last corner of the last cage” to deliver feed to it and remove its waste 24/7.”

In addition to water quality, MSD is focusing on automation. About one-third of the room will be devoted to tumbling, washing, weighing, sorting, and packing. Through automation, these operations can occur 24 hours a day. This “high level of automated animal husbandry” will also significantly cut labor costs, a burden for current-day ocean oyster farmers.

Nutrition

Before MSD becomes a going concern, it must master how to produce feed for the oysters that will be economical on an industrial scale. It is a challenge Pryor approaches with gusto, driven especially by his interest in food waste. He has conducted research using extracts of food waste — from lobster processing, tofu factories, even spent yeast from brewing Allagash beer (of which he is fond) — as the medium to

OYSTER GRADING TECHNOLOGY

SED Vision Grader Fully automated. Cleans, measures, sorts, counts and bags up to 8 per sec. STOP KILLING YOUR OYSTERS!

SED Water Grader for seed and juvenile oysters. Fast but very gentle, significantly lowering mortality rates then dry barrel or shaker graders.

culture microalgae heterotrophically.

But phytoplankton, such as microalgae, is only one course in the smorgasbord MSD is planning for its oysters. The ultimate menu will “emulate the content of the estuary,” Pryor says. “The only way to develop estuarian flavor is to feed oysters estuarian food.”

In addition to phytoplankton, feed will include zooplankton (such as ciliates, which are “like jellybeans to oysters”) and detritus (such as seaweed waste refined so it becomes “bite-size for oysters”). Ocean Organics, which ferments seaweed to make fertilizer, is MSD’s next-door neighbor in the business park and future supplier of fermented seaweed residuals. Already, the two companies share a laboratory.

Aquaculture expert Dr Barry Costa-Pierce, a professor of ocean food systems at the University of New England, knew Pryor at the University of Hawaii and is familiar with the new RAS project. He reinforces the point that oysters like more than microalgae. “We’ve learned a lot about what shellfish actually eat, and it’s a mixture of different types of organisms, not just phytoplankton. That’s good news.”

In fact, it could materially impact MSD’s long-term success. As hatchery operations

Manufacturers of modular Hatchery-in-a-Box solutions for clawed lobster production, utilising our unique technology

SPOTLIGHT

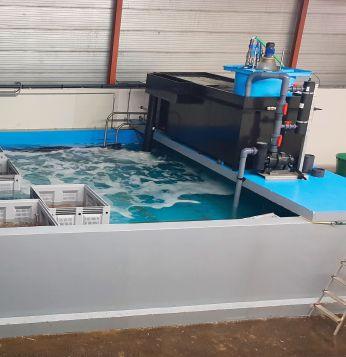

AST PolyGeyser Bead Filters were selected as a key component of the indoor recirculating aquaculture system

know, production of microalgae is expensive: it requires human management, costly reactors or cylinders, and a variety of inputs.

That said, MSD has already laid groundwork for bulk algal culture by hiring Chris Maloney as chief operating officer. Maloney’s credentials date back to the high-flying start-up GreenFuel Technologies, the first algae-to-biofuel company in the world. More recently, he served as a consultant and also director of biology at Bioprocess Algae, which designs, builds, and operates commercial-scale bioreactors to produce microbial feedstock.

Stepping back to survey the broader landscape, Costa-Pierce says, “The implications of this project are really tremendous.” High-density, land-based shellfish aquaculture could open up new markets in

COO Chris Maloney stands among the four 3,400-gallon tanks with a projected annual harvest rate of one million Eastern oysters

noncoastal areas, such as ski resorts and tourist destinations. He points to “phenomenal developments in the Middle East,” where high-end oyster bars are multiplying.

What really gets his attention about MSD’s potential, though, is how it could address social and environmental issues, ranging from NIMBY-ism to permitting complexity to the effects of ocean acidification on shellfish. “It’s a very disruptive technology — if it works,” he says.

In February, the MSD team, including some new members, were ramping up operations in their business park homestead, undaunted by the challenges of the new frontier.

Pryor pauses and adds, “The pens are back in production.”

Lost gear and inventory could have significant financial impact on oyster farms. Through the SmartOysters app, the public can do their bit in reporting found items to oyster farms PHOTO: ©RABBITTI / ADOBE STOCK

Ano-cost solution to the problem of lost farm gear and inventory is now at the fingertips of oyster farmers and the general public.

Following the destruction wrought by Hurricane Sally in the US State of Alabama, developers of the SmartOysters farm management app added a lost-and-found function that allows users to identify gear or inventory that went adrift from farms.

“We’ve seen how oysters growers band together after a severe weather event to help look for and recover lost bags, baskets and cages. We know the significant financial impact that lost gear and inventory could have on oyster farms,” said the app developers.

The SmartOysters app can be downloaded for free from the app store. Anyone who has the app on their smart phone could just scan the item found and its owner will be notified.

The function is enabled by the GPS function in smart phones and can be used even by members of the public who are not registered members of the SmartOyster community.

Josh Neese, the biologist behind the Florida Oyster Trading Co and the first “US lead generator” for SmartOysters, described the lost-and-found function as “a free service that engages the community in helping with aquaculture-related marine debris.”

An additional free service offered by the app is an ecosystem services function. “This is being offered as a free service to NGOs and non-profits engaged in restoration projects. They could use it to quantify such parameters as water volume filtered, carbon removal, and nitrogen sequestered,” Neese added. “It connects the industry to free resources that may benefit the greater good.”

‘FARM-ON-A-BOAT’ idea could disrupt shellfish industry

Cape Cod farmer behind the invention

BY LYNN FANTOM

Past the bobbing sailboats and skiffs along the Cape Cod shoreline, owners of spacious shingle-style homes might spot a pristine white boat with a solar-paneled canopy some 200 yards out in Megansett Harbor. A good guess would be that it’s a tour boat to Martha’s Vineyard or perhaps a research vessel from nearby Woods Hole. But no one would believe it is a self-contained, high-density shellfish farm.

In January, Dr Dan Ward, owner of Ward Aquafarms in Falmouth, Massachusetts, began marketing this vessel, which he created as a solution to many of the problems he has encountered as a farmer himself: the disappearance of real estate available for aquaculture Self-contained, high-density shellfish farm addresses woes of shellfish growers, says

Dr Dan Ward, owner of Ward Aquafarms, has spun off a new company marketing a high-density shellfish farm wholly contained on a boat

orthwest Plastics Ltd. of Port Coquitlam, British Columbia has acquired Go Deep International Inc., a specialist in product development, manufacturing, and distribution of polyethylene-based solutions for the marine industries. Founded in 1973, Northwest Plastics Ltd. (NPL) is one of the largest ISO-certified manufacturers of rotationally molded plastics products in Canada. Go Deep will continue to operate as a wholly owned subsidiary of NPL from its facilities in Saint John, New Brunswick.

Go Deep solidified its position in the industry in the early 1990’s with pressurized floats developed specifically for sub-surface longline aqua farming. Manufactured from high-density polyethylene the floats are purposely

designed as an environmentally friendly replacement for styrofoam buoys increasing efficiencies, enabling entire longline systems to be sub-surface with reduced stress from waves, storms and ice while lessening the visual effect of thousands of buoys on the water.

Since the company’s establishment in 1997 to serve the mussel farming industry in Prince Edward Island, the company has added a variety of products including floatation solutions for oyster growers.

The company also offers lease-marking buoys and solar lights, improved versions based on experience gained manufacturing polyethylene buoys for the Canadian and United States Coast Guards.

“crosswellers” to nourish racks of shellfish

infrastructure, pushback from property owners who don’t want shellfish farms in their backyards, back-breaking toil, high labor costs, the risks of harmful algae blooms, disease outbreaks, and storms.

The Modular Aquaculture Production (MAP) system addresses “all of those problems that are keeping us stuck in this kind of inefficient, low-margin business,” he says, displaying an almost boyish glee at having solved a very hard puzzle. In 2016, he came up with the idea of such a boat — essentially a floating crossweller — and initially funded its development through a USDA grant. Then serial biotech entrepreneur Dr Mark Tepper entered the picture and, in 2019, Ward spun off the project and co-founded Atlantic Aquaculture Technologies with Tepper.

And that’s the other benefit, Ward says. “I’ve had numerous people come to me because they want to invest in aquaculture. They see it as the future.” He pauses, then adds facetiously, “But I tell them: what are you going to invest in? I own plastic bags on a leased beach.”

With a MAP vessel, however, a farmer owns “an actual asset” that may make it easier to secure bank financing or private investment. In turn, it can be sold. Like land-based recirculating aquaculture systems, such a physical enterprise may bring larger-scale institutional investment, something Ward says shellfish aquaculture needs.

As a boat, MAP may also open up more ocean area to aquaculture and ease permitting headaches if authorities license it similar to a fishing vessel.

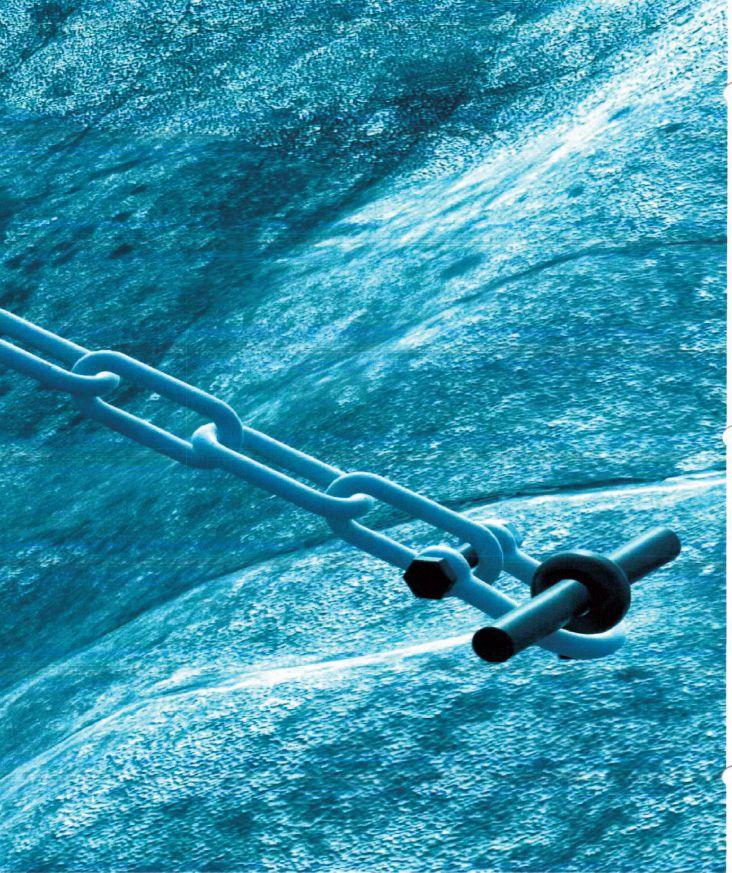

The new shellfish grow-out operation is completely self-contained on the vessel, which has its own solar power and remote monitoring system. A floating platform, which includes the power storage/supply and staging areas, surrounds wells or “modules” where the shellfish are grown on trays within cages. The boat’s single-point mooring features a chain all the way to the surface, so “there’s zero entanglement risk” for whales or sea turtles, Ward adds.

Electronic lifts raise and move the shellfish. In Ward’s operation, that means a 75-percent cut in labor costs and a longer working life for individual farmers. “It’s really a limited number of years that you can work at a commercial level before your body can’t handle it,” he adds. On the vessel, hydraulics comprised of pumps and baffles control the flow rate and direction of sea water, ensuring the entire module of

As a boat, MAP may also open up more ocean area to aquaculture and ease permitting headaches if authorities license it similar to a fishing vessel

SPONSORED CONTENT

Navigating farmers to profitability

Oyster farms are traditionally run on memory, a whiteboard, or even an old school database systems but farmer Ewan McAsh believed there was a better way. Living in the smartphone era meant he could do everything from checking emails to paying bills at the touch of a button, so why not manage the farm remotely?

SmartOysters’ aquaculture and systems specialist Colin Bridges is happy to answer any questions you may have about how your farm business can benefit from SmartOysters or its other platforms.

Reach out at colin@smartoysters.com or via www.smartoysters.com

Let’s Tie One on Together in 2021

Flag Tie Markers

Flag tie markers are another cost-effective way to secure and identify shellfish equipment. They are available in a variety of lengths and marking area sizes to accommodate specific requirements. They can also be hot stamped for identification purposes.

• Lengths from 3” to 18”

• Tensile strength of 120 lbs.

• Available in Blue, Green, Ivory, Orange, Red, Yellow

• Available with blank flags that may be custom printed or Write-on

Cable ties

Cable ties are vastly used in the shellfish industry for securing cages and bags. They are a cost-effective and simple way to ensure equipment is not susceptible to tampering. Available in a wide range of colors, they are also used for identification purposes.

• Lengths from 4” to 60”

• Tensile strengths from 18 lb. to 250 lb.

• Available in 16 different colors, including UV black and fluorescent

• Can be custom printed with company name, date, lot number, etc.

x136

Straight from our Hatchery in Maine

• Retention Screens: 1.0, 1.4,1.6, 2.0 mm.

• Triploid or Diploid, disease free.

• Different genetics suitable for farms from Maine to North Carolina.

For more information: Seed@mookseafarm.com

LIVE ALGAE PASTE

• Frozen with a food-grade cryopreservative to keep cells viable.

• Superior shellfish growth rates.

• 22.5% dry weight.

• For salinities 20-30 ppt.

For more information: Algae@mookseafarm.com

MUSSEL FARMING

• Mussel Socking

• Longline Buoys

• Longline Identification Buoys

LEASE MARKING

• Spar Marker Buoys

• Intermediate Marker Buoys

• Self-Contained Solar Lights

• Floating Bag System Floats • Floating Cage System Floats • Aluminum Cage Systems • Wire Cage Systems • Seed Collectors

SPOTLIGHT ON SHELLFISH

trays receives what it needs. This permits significantly higher stocking density — five times higher for bay scallops and over ten times for Eastern oysters.

In addition to water temperature, the monitoring system also tracks dissolved oxygen, chlorophyll, and salinity. But the key point, says Ward, is that now all of these data are actionable. “Do I need to reverse water flow? Add oxygen? Move to a different area? There are all kinds of things I can do now because the entire farm is one, contained unit.”

In addition to managing environment risks, Ward’s system allows farmers to diversify crops. He has used it to cultivate high-value bay scallops and believes it will be effective with other shellfish, seaweed, and finfish. (Ward, who earned a PhD in environmental science and biology, has published scientific papers on the stocking density of Atlantic cod and diets for summer flounder.)

Ward calculates that the two-module vessel now moored off the coast of Falmouth will produce 500,000 oysters this year, but its capacity could be easily increased if he chose to farm in deeper water. After a year-long trial, he calculates that the system has both higher output and lower operating costs than traditional

lifts raise racks of shellfish from a

includes the power storage and staging areas

methods. “it is eight times cheaper for me to farm using MAP than bottom cages,” he says.

The concept is now market-ready. Although people may want to buy the entire system or a module of trays, Atlantic Aquaculture Technologies is also offering individual trays to smaller farmers or investors. Longer term, Ward muses, a restaurant may want to grow

WAYS INSTANT ALGAE

branded shellfish or a nonprofit might tap the system for nitrogen remediation.

In addition to this spin-off, Ward plans to continue to run his two marinas and Ward Aquafarms — a part commercial operation and part lab. “I use my farm as a research platform to be able to improve methods and techniques in the industry,” he says.

INNOVATIONS MOVING THE SHELLFISH SECTOR FORWARD

From

genetics programs to solar-powered processing, growers are improving the industry

BY JENNIFER BROWN

Genetics research and mechanization are playing a larger role in biosecurity and fish health.

Dr John Buchanan leads the genetics team at the Center for Aquaculture Technologies (CAT) based in Prince Edward Island and San Diego, California. The organization provides the industry solutions involving breeding programs and genetic tools.

In the last five years, Buchanan says much work has been done to build more sophisticated tools and be more thoughtful about breeding programs in the aquaculture industry.

“I think we have reached a critical mass where people are saying let’s build the tools, and they will come,” says Buchanan, president and CEO of CAT. “Our company’s focus is on how to take the examples from

the cattle industry, where people will spend $80 per animal to genotype it because the animal is worth a lot. In aquaculture, we have thousands of animals, so let’s get 90 percent of the efficacy and do it for 25 percent of the cost, and many people will use it. It’s exciting to have these tools that we know work, and that are now cost-effective and available for use in shellfish.”

One of the pressing problems that the R&D center helped address is the herpesvirus, virulent disease in Pacific oyster. “We’ve worked to create some resistance to that in the breeding programs,” says Buchanan.

BC: Addressing oyster mortality

In British Columbia, a selective breeding program is underway to improve resistance to summer mortality syndrome. The three-year project will continue into 2022.

The project’s primary goal is to evaluate the level of genetic resistance to summer mortality in the BC Pacific oyster population and then recommend a selective breeding strategy that promotes resilience.

The project will produce 42 pair-mated families and evaluate their survival and growth rates in the field (at commercial farm sites) and in the laboratory under controlled stress conditions (e.g. temperature, Vibrio infection).

Even a modest reduction in mortality rates would grow the value of the BC shellfish industry by millions of dollars, said the Department of Fisheries and Oceans. Further, the development of a selective breeding program would enhance the industry’s sustainability and help safeguard the resource under the context of a changing marine environment.

Growers are also investing in technology

the gene pools on hand. We will also have a better performing oyster that will get to market faster,” says Mallet.

to help with summer mortality syndrome by moving to shell-sorting devices that help eliminate dead shells.

“The (shellfish) mortality rising, and people are looking at that technology to sort the live and the dead cost-effectively,” says Jim Russell of the BC Shellfish Growers Association.

Work is also underway in the province to better understand the highly contagious norovirus, a leading cause of non-bacterial acute gastroenteritis in humans.

A $300,000-project by the Ministry of Agriculture and Genome BC is looking at genetic markers for the norovirus “to develop an early warning system to identify when norovirus may be present in the growing environment,” says Jim Russell of the BC Shellfish Growers Association.

The project aims to come up with farmbased, real-time monitoring systems that will serve as early detection tools for norovirus. This will minimize human illness associated with consumption of raw oysters.

New Brunswick:

Toward a better oyster

A $3.8-million project with Genome Atlantic and Genome Quebec is about to enter its next phase, according to Marc André Mallet of L’Etang Ruisseau Bar Ltée hatchery, the largest oyster seed supplier in the Maritimes.

The project aims to use genomics to produce the first selectively bred Canadian strain of the Eastern oyster.

“We’ve been working on a genetics program and about to see the fruits of that breeding program as we start selecting for traits we’re looking for,” says Mallet. “We’re starting to put it on a larger commercial scale, and it’s not only for us but for the industry as a whole.”

Mallet says growers are moving towards having a hatchery seed because it guarantees speed and productivity.

“We’re developing a larger gene pool, so if we were ever to have a disease in the Atlantic provinces, we could recover from that with

The project has produced a high-density SNP chip to create a breeding program that will select certain traits to improve productivity and boost profitability.

“Despite COVID, we’re on schedule from the initial plan,” says Dr Louis Bernatchez of the department of biology at the Université Laval in Quebec. “The first trials of this tool will happen in the next couple of months. It’s about getting faster growth for oysters, given we’re at the northern edge of distribution. It takes longer to grow an oyster of the same size as if you were to go down to the Chesapeake Bay.”

PEI: Climate-proofing the blue mussel

Prince Edward Island’s blue mussel production could double over the next 10 years from 50 million to 100 million pounds annually if the performance of blue mussels ( Mytilus edulis ) could be optimized. This is the goal of a genomics-driven initiative by

A project in New Brunswick is using genomics to produce the first selectively bred Canadian strain of the Eastern oyster

Genome Atlantic, the PEI Government and PEI mussel producers.

The $800,000-project will sequence the genome of the blue mussel to establish a modern and sustainable breeding program that will select traits important to growers, such as growth, stress-resistance and temperature resistance.

“The realities of climate change will push several bilogical limits of the blue mussel but genomics will help ensure that PEI mussels can become resilient to new environmental conditions,” said the collaborators in the project.

PEI is the source of 80 percent of all mussels sold in North America. The selective breeding initiative “will allow the Island to retain its dominant position in the mussel industry,” they added.

Solar-powered machine makes for greener, faster ops

A solar-powered oyster sorting machine is installed on D’Eon Oyster Co’s barge in Salt Bay in Yarmouth, Nova Scotia PHOTOS:

CO

On Salt Bay, the D’Eon Oyster Co is processing their oysters much faster these days, aided by the power of the sun as it beams down on Yarmouth, Nova Scotia.

The family-owned farm has installed a solar-powered oyster sorting machine on its barge so the oysters are already graded by the time they are brought ashore.

“We thought it would be cool if we could process the oysters on the water, before hauling them to shore. Then we came up with the idea of a barge, and then things escalated — what if we could have grading equipment on the barge?”

SPONSORED CONTENT

The D’Eons worked with a solar consultant and installed a system developed in Australia that can run for two days on a battery pack. A vision grader on the barge removes the need to measure by hand. The grader sizes each oyster and drops them into the correct bin. Similar technology exist elsewhere but need a barge five times the size of the D’Eons’ 12-by-12-foot barge.

“Many vision graders are big and take up a lot of energy. We have been able to reduce wasteful processes by 25 percent, which allows us to do more with our existing employees,” says Colton D’Eon, the company’s operations manager.

They have also added bacteria-killing LED lights in their processing facility that provide an extra step to ensure cleanliness in the production area.

They have also eliminated the use of zip ties on their oyster bags, replacing them with reusable bungee cords.

– Jennifer Brown

Rugged workboats specially designed for all marine industries

These robust Open Workboats offer great design, quality build and low maintenance. Polarcirkel Open Model boats range in length from 5.8 meters to 8.60 meters, are self-bailing and have rigid PE-100 plastic pontoons filled with polystyrene. Combined with 21-degree V-shaped hull, this design makes a virtually unsinkable boat with unique stability and excellent seaworthiness.

All Polarcirkel boats are tested in extreme weather conditions all over the world and are transport Canada approved. All models are loaded with smart details and unique features for safe operation in tough conditions and we ensure our products have an emphasis on safety and the environment.

AKVA group is a leading supplier of aquaculture technology, promoting well known brand names such as: Wavemaster, Polarcirkel, Fishtalk and Akvasmart. With offices located in British Columbia, Newfoundland and New Brunswick, AKVA group North America can deliver from coast to coast.

CANADA’S SHELLFISH growers eager for markets to return

But there are concerns some restaurant clients could be gone forever

Canada’s shellfish producers are looking forward to once again supply the world with their highly-sought-after product, but some wonder how many of their food service and restaurant customers will survive the pandemic’s devastating impact.

“It’s scary because we can’t predict anything at the moment,” says Mica Verbrugge, owner and operator of Effingham Oyster located in Barkley Sound in Pacific Rim National Park, British Columbia. “With each projection I make, I have to think about whether California or Ontario are going into

BY JENNIFER BROWN

further lockdown. Our biggest worry is the restaurant market. We rely on them so much.”

When restaurants in Asia were ordered to shut down in February 2020, those in the US and Canada were soon asked to close too. The markets collapsed particularly for half-shell oysters, which account for 60 percent of the production in BC, says Jim Russell, executive director of the BC Shellfish Growers Association (BCSGA). “We estimated our members were losing $2.4 million a month in sales. It’s been a marathon and it looks like it will be another six months before any return to normalcy,” he said this past January.

Phone: 604-926-1050

Fax: 604-926-1055

Cell: 604-833-5311

darksea@shaw.ca

growers are looking forward to the time when they can supply the world again with their highly-sought-after product

British Columbia Verbrugge has operated his farm since 2013. He sold his oysters directly to restaurants on Vancouver Island, but to everyone else in Canada and the US he sold through national distributors. His US distributor “just fell off the map.” “We lost that market right away,” he said.

BCSGA’s Russell noted that members of the association reported that Christmas sales were “okay,” but the phones have since stopped ringing again. “It’s still absolutely grim.”

Larger producers with clam and shucked oyster production fared a bit better as some of those products sell at retail outlets. Half-shell

oysters aren’t popular at retail because most consumers aren’t comfortable shucking them.

With 95 percent of BC shellfish product going to restaurants, Verbrugge wonders how many will recover.

“My seed supplier’s sales were down 80 percent this year. This indicates that people didn’t replant this year. I expect many farms will be packing it up,” says Verbrugge, who is also a director with BCSGA. “Hopefully, if things do open up, we’re in a position where we can move a lot of oysters.”

Verbrugge now sells his oysters directly to customers. He says this results in a better product for the customer because cutting out the middle man means it arrives at the destination faster.

“It’s a lot harder to send three boxes here and 20 boxes there, but I don’t see us going back to the big distributors anytime soon. We’ve now learned to do this in Canada, and it’s not that hard.”

He increased the price as the products arrive at their destination faster and fresher.

“For the same delivery cost, we can air freight it to Alberta, and it’s there in 12 hours from the time it leaves the water. It’s a far nicer product and gives restaurants the additional shelf life.”

Verbrugge is preparing for a post-pandemic return of the markets. He is implementing his five-year strategy to mechanize and upgrade the farm. The target is to boost production from 100,000 dozen oysters a year to one million dozen a year. Since 2018, he’s invested in a grading machine from Australia, built a plant, bought refrigerated trucks and built additional rafts and trays.

“We used to do five million seeds a year, and then we jumped up to 15 million,” he says. “We had a massive amount of new production come online this year. We’re too far along to stop. The pandemic definitely slowed us down, but we’ll keep going.”

In March 2020, the federal government launched the Canadian Emergency Wage Subsidy (CEWS) to support entrepreneurs hit hard by the pandemic. Its extension to June 2021 has been “a godsend,” said Russell, because it gives shellfish growers access to funds to pay their staff and do maintenance projects.

Verbrugge availed of it to do clean-ups on the farm to keep his eight employees working. He had to increase wages by 30 percent –– to $22/hour from $17 –– to compete with the amount that unemployed workers were receiving from the government.

BC growers are also beneficiaries of the Department of Fisheries and Oceans Ghost Gear Fund. Over two years beginning in March 2020, they have at their disposal $350,000 to clean up the debris under suspended shellfish farms. Russell says such cleanup efforts help the industry maintain social licence in the communities where farms operate.

Prince Edward Isand

The pandemic dealt shellfish growers in Prince Edward Island and New Brunswick the same blow.

“For most of us selling oysters, one of the biggest shocks was that we don’t have a lot of retail sales. Our primary channel is food

service,” says Jacob Dockendorff of Atlantic Shellfish Products Inc in PEI. Compounding that is the fact that “oysters aren’t take-out friendly or delivery friendly.”

He said PEI shellfish growers were riding a wave of growth before the pandemic. “We were coming out of a really hot period: 30 percent growth year over year for the last two or three years, so we invested in new equipment to deal with the market growth.”

He says the “vibe” is that everyone is waiting it out and expecting a return to normal sometime within the next nine months. “We had a good run, so it was really a shock when the numbers went in reverse. But it’s not always about the numbers; farmers and fisherman are usually prepared for a downturn.”

New Brunswick

In New Brunswick, the disruption of production cycles meant growers had to reorganize growing sites and equipment to ensure they had the space to hold extra inventory caused by the market slowdown, says Nick Brown, a spokesperson for the Department of Agriculture, Aquaculture and Fisheries.

Marc Andre Mallett of Huitres Mallet Oysters in Shippagan, New Brunswick says sales went to zero for a couple of weeks in the first few weeks of the pandemic. As things settled down, he began to see a shift to online sales. “It has definitely

become more customer-based, whereas usually it was all wholesale; that was a challenge, but things have turned around,” he said.

Mallet added that the company is in “full expansion” mode, having just doubled its facilities on land. “Every year, we’re putting new gear in the water to increase our production to sell to market but also to increase our hatchery-produced seed to sell to other growers and our own production as well.”

Two years ago, the company started developing a better wet holding facility to have the product on hand for market-size oysters all-year round. “We have to have bigger availability in case we have bad ice conditions like we’re having right now,” says Mallet.

New Brunswick’s farmed oyster sector grew 96 percent over the last decade, according to the New Brunswick Department of Agriculture, Aquaculture and Fisheries. In 2020, there were 642,644 oyster bags in the water compared to 329,852 bags in 2012. Growth was fuelled by funding initiatives, greater social acceptability, access to additional sites and sustained market demand.

The province also saw an upward trend in farm gate sales (direct to consumer, retailers or restaurants). In 2019, reported farm gate sales reached 35 million oysters, valued at $15.3 million, compared to 17.7 million oysters in 2014 valued at $6.3 million.

The department is working on modernizing local regulations to better support growth and attract more investments in the sector. Brown notes that with several Mi’gmaq oyster companies in operation, the industry offers a unique development opportunity for New Brunswick First Nations.

Nova Scotia

A considerably smaller industry compared to that of its neighbours, Nova Scotia shellfish farmers also were also hit by the pandemic. But the province’s plans to expand the industry has many looking to the years ahead with more optimism.

Water at the planned ‘business park on the sea’ in Nova Scotia has been deemed ‘ideal’ following some tests