A ‘Product of the United States’ label on its land-based-farmed salmon will help the Norwegian company capture 10 percent of the US market, believes its CEO

BY MATT JONES

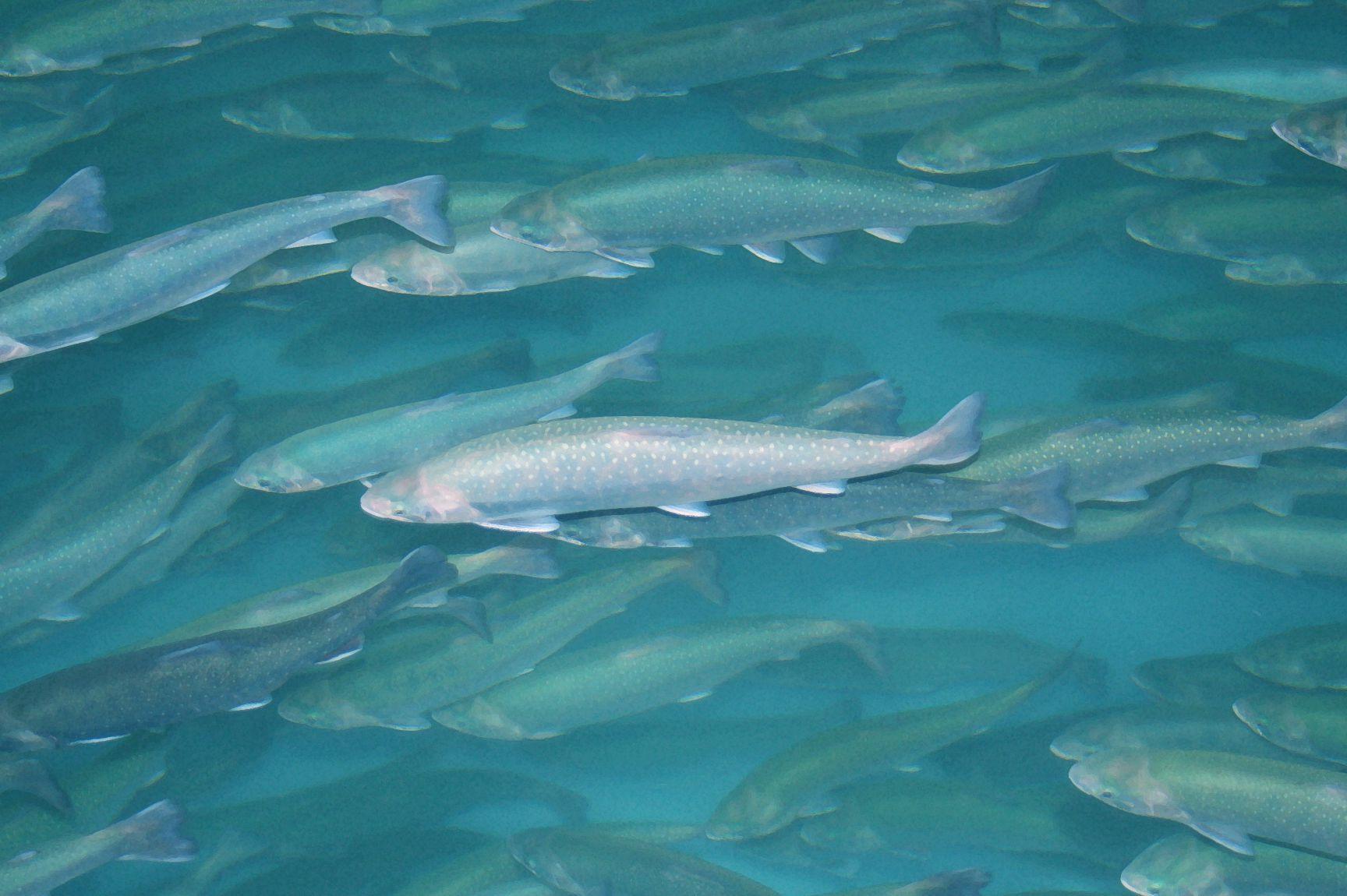

Atlantic Sapphire is well into the construction of the Miami version of their Bluehouse – an all-in-one aquaculture production facility that houses every stage, from hatching broodstock to processing of the harvest. As CEO Johan Andreassen watches his vision for an American Bluehouse take shape with each passing day, he keeps his eyes on a larger prize – a giant US market that imports the vast majority of its consumed salmon.

“I think the consumption of salmon here can double over the next 10 years, if done properly,” says Andreassen.

‘We are in a messaging war’

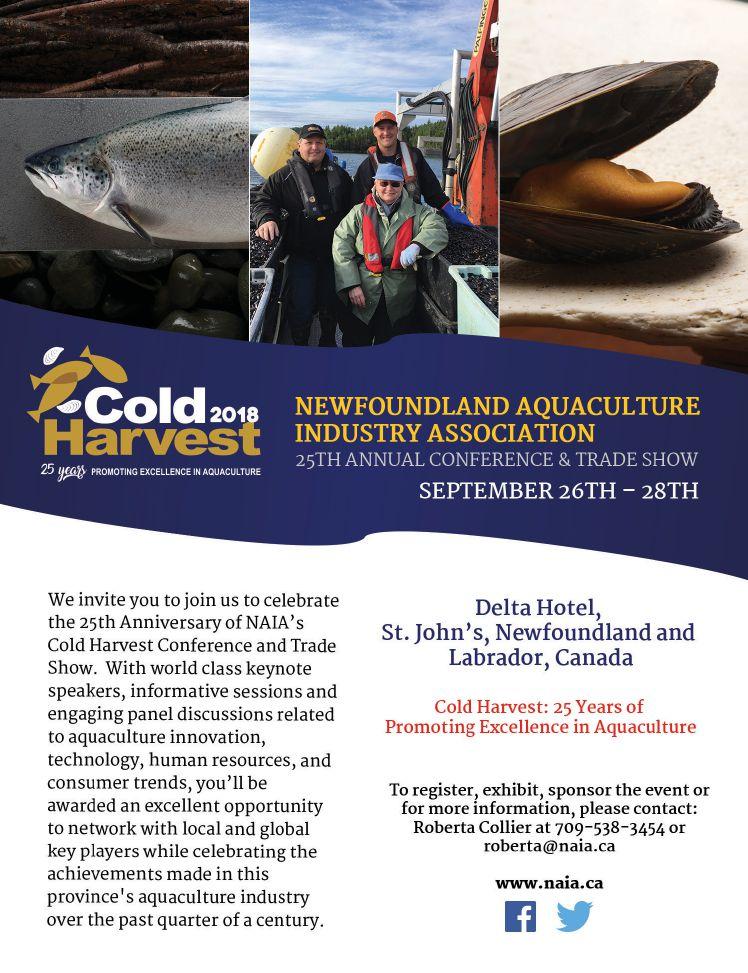

Public perception of aquaculture was a trending topic at Aquaculture Canada 2018 held in Quebec City in May. The message that everyone in the industry has a role to play in today’s so-called “messaging war” was a common theme in a number of presentations. Other hot button topics discussed were developments in recirculating aquaculture systems (RAS), and improving farming practices and sustainability through new technology.

Organized by the Aquaculture Association of Canada, the four-day conference was held under the theme “Aquaculture Innovation for Sustainable Future.” Liza Mayer recaps the highlights beginning on page 10.

Passionate farmers and technical experts are undaunted by challenges in their quest to buoy Alabama’s fledgling shrimp industry

Alabama is a distant third behind Texas and Florida in farmed shrimp production. Early production issues included proper amendment rates, nutritional research, acclimation procedures and post-larvae stocking. Some of these issues are still being researched as survival problems have resurfaced

BY LIZA MAYER

Talk about turning lemons into lemonade. What does one do with abundant underground saltwater that’s too salty for human consumption? Ask Gregory N. Whitis, an aquaculturist at the Alabama Fish Farming Center. In 1998, Whitis and others thought the water could potentially be used to farm saltwater shrimp so they began the journey to build Alabama’s shrimp industry.

With him from the start were Bart Green and David TeichertCoddington, who both had extensive experience in international shrimp culture. “We have salinities in west Alabama as high as 9.8 so they saw some potential with Pacific white shrimp (Litopenaeus vannamei),” says Whitis.

continued on page 22

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

You take pride in your operations and the health of every fish matters. Infectious Hematopoietic necrosis (IHN) is highly dangerous and unpredictable and now, more than ever, it is imperative that your fish stocks are protected. With one small dose of Apex-IHN you can help protect your fish against this deadly disease by stopping it before it starts.

Amajor study examining the fish-eating habits of pregnant women has found that they are not linked to autism or autistic traits in their children.

Scientists at the University of Bristol looked at the assumption that mercury exposure during pregnancy is a major cause of autism using evidence from nearly 4,500 women who took part in the Children of the 90s study.

Using analysis of blood samples, reported fish consumption and information on autism and autistic traits from one of the largest longitudinal studies to date, researchers found no links between levels of mercury in the mothers and autism or autistic traits in their children. The only adverse effect of mercury found was poor social cognition if mothers ate no fish at all, especially for girls.

“Our findings further endorse the safety of eating fish during pregnancy. Importantly we’ve found no evidence at all to support claims that mercury is involved in the development of autism or autistic traits,” said lead author and founder of the Children of the 90s study Professor Jean Golding.

“This adds to a body of work that endorses the eating of fish during pregnancy for a good nutritional start to life with at least two fish meals a week.”

Massive study finds no link between the fish-eating habits of pregnant women and autism in their children

Credit: Adobe Stock

Efforts to combat sea lice infestations through natural means have advanced with the first spawning of farmed ballan wrasse in captivity.

Wild ballan wrasse has been used in salmon farms in Scotland for years as a non-chemical way of controlling sea lice infestations, but reliance on wild catch is unsustainable.

The milestone in the culture of the so-called “cleaner fish” has been reached at a hatchery in Machrihanish, Scotland — a joint venture between Marine Harvest and Scottish Sea Farms.

Wrasse eats sea lice that attach themselves on salmon. Efforts to culture the cleaner fish have reached a milestone with the first spawning of farmed ballan wrasse in captivity

Although the wrasse produced at the hatchery will go to the companies’ salmon farms, the industry will benefit from the research. “The research we have done here is for everybody. We have close links with Norway and other hatcheries in Scotland and the information can be disseminated all around the industry. It is a joint industry project and we welcome the opportunity, if need be, to supply larvae to hatcheries,” says hatchery manager Paul Featherstone.

There are plans to expand the existing facility over the next few years, and the expansion could enable the hatchery to produce 1.5 to 2 million wrasse annually, says Featherstone.

“This is a total win-win situation,” says John Rea, director of Scottish Sea Farms, in a film about the role of wrasse in salmon aquaculture. “Our fish are better off by having this partner in their nets alongside them. It means we have a much lower environmental footprint than we’d otherwise have; the medicine bill is reduced. It makes salmon more suitable.”

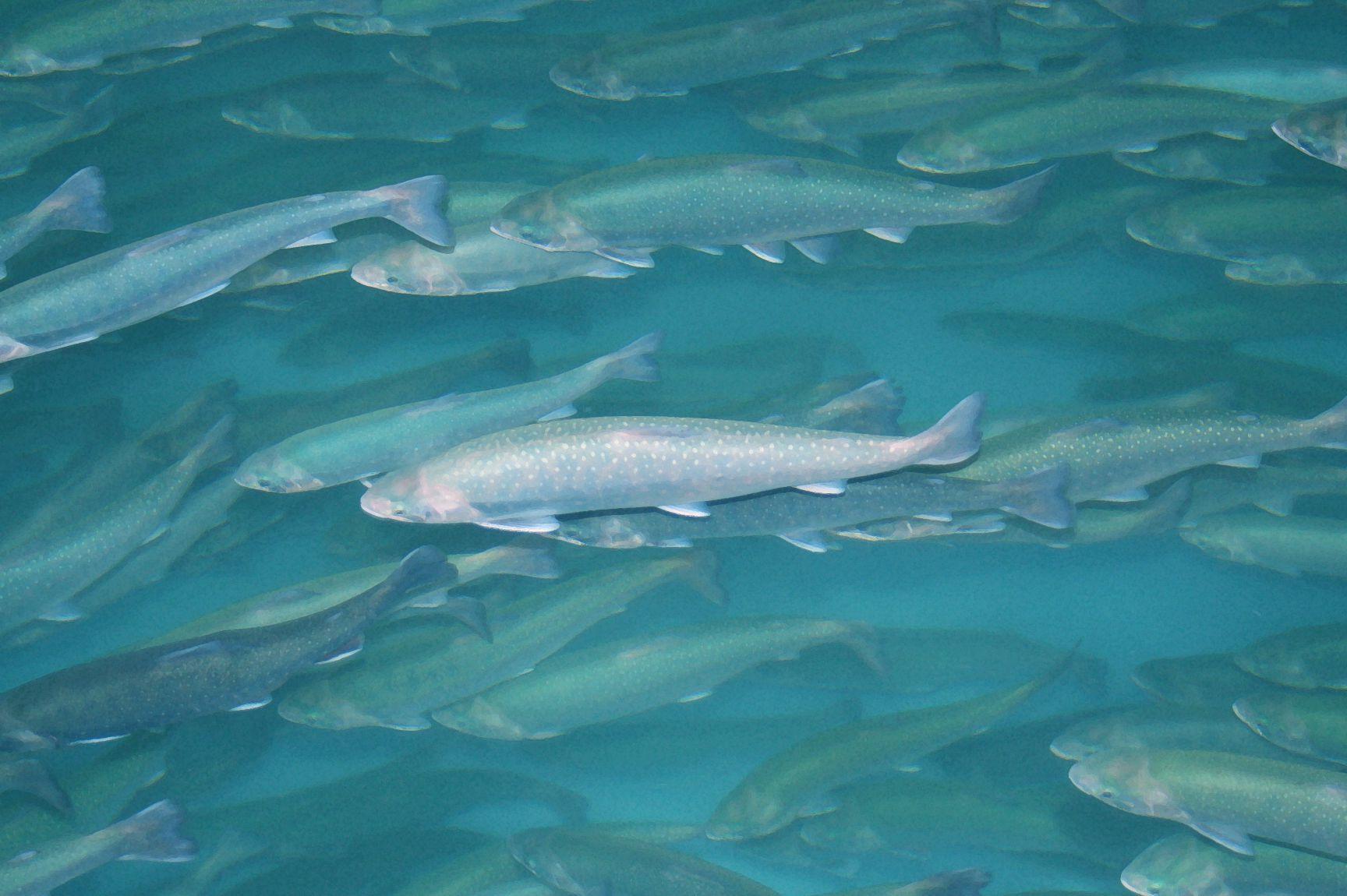

Farmed salmon has the lowest overall cost to the environment compared to other major animal proteins, says the Global Salmon Initiative (GSI) in its latest sustainability report.

Farm-raised salmon has shown to be one of the most eco-efficient forms of protein production, ranking low (9.8) in terms of carbon footprint than any commercially raised food, such as chicken (43.2), pork (56.7) and beef (337.2).

Due to an increase in the use of nonmedicinal approaches and sharing of best practices in sea lice management, the use of medicinal sea lice treatments has gone down by 40 percent over the past five years among GSI members, the report said. GSI members comprise 17 salmon farmers around the world, which account for over 50 percent of the global farmed salmon sector.

The report added that continued innovations in the sourcing and efficiency of feed ingredients have enabled GSI members to reduce their use of fish oil and fishmeal by 16 percent and 15 percent (calculated per forage fish dependency ratio), respectively.

The sustainability report provides consumers and stakeholders a lens through which they can measure the salmon industry’s performance. It is the fifth year GSI members have released the report since the initiative’s launch in August 2013.

GSI’s 17 members operate in eight countries – Australia, Canada, Chile, Faroe Islands, Ireland, New Zealand, Norway, and the United Kingdom — and over 40 percent of their production is now certified to the Aquaculture Stewardship Council (ASC) standard.

Liza Mayer Tel: 778.828.6867 lmayer@annexbusinessmedia.com Advertising Manager Jeremy Thain Tel: 250-474-3982 Fax: 250-478-3979 Toll free in N.A. 1-877-936-2266 jthain@annexbusinessmedia.com Art Directot Svetlana Avrutin savrutin@annexbusinessmedia.com

Regular Contributors Ruby Gonzalez, Treena Hein, John Nickum, Matt Jones, Tom Walker

Production of farmed fish puts less strain on our ecosystem than terrestrial livestock production because the amount of cropland required to feed fish is less than what livestock require, says a new study.

Researchers from UC Santa Barbara’s National Center for Ecological Analysis and Synthesis (NCEAS) examined how much land would be required to grow the seven most common crops used to feed both terrestrial livestock and farmed fish.

For instance, a cow requires anywhere from six to 30-plus lbs of feed to gain one lb of biomass, while most farmed fish need just one to two lbs of feed to do the same. This efficiency translates into much less cropland required to grow feed for the fish that people eat, the study said.

Livestock production will need to grow by 52 percent to feed the world’s 10 billion people in 2050 but replacing that with fish could spare land twice the size of India from the pressures of agriculture, says the study.

“The expansion of agriculture across the world is driving most species extinctions and the dramatic loss of ecosystems,” said Claire Runge, a research scientist at University of Tromsø - The Arctic University of Norway, told UCSB’s The Current. “Aquaculture offers one way to reduce some of this pressure on our natural landscapes, wild places and wildlife.”

While aquaculture is not a panacea for sustainable food production, “the potential is ripe to really do it right,” says lead author Halley Froehlich, a postdoctoral researcher at NCEAS. These include strategic siting of farms and adoption of sustainable feed practices, she said.

“We hope that awareness of how much land can be spared with a fish-rich diet helps individuals make the change,” said co-author Ben Halpern, director of NCEAS. “Similarly, we hope our results put more ‘fish on the bones’ of policy arguments to make more systematic changes.”

Asalmon farmer’s idea to raise fish in what would have been the world’s largest ship was rejected by Norway because it reportedly wasn’t innovative enough.

In May, Norway’s Directorate of Fisheries informed Pure Atlantic it is rejecting its application for 45 salmon farming development licenses because the plan did not bring significant innovation to the industry, Reuters reported.

The 521-metre vessel envisioned by Pure Atlantic was designed to produce 50,000 tonnes of salmon a year but Norwegian authorities were unimpressed with the plan

The 521-metre vessel envisioned by Pure Atlantic was designed to produce 50,000 tonnes of salmon a year. Development licenses are part of an initiative by authorities to spur growth in Norway’s salmon production.

Aprobiotic supplement that has been proven to boost larval oyster survival by 20 to 35 percent is ready for manufacturing but the path to commercialization may not be that easy.

Probiotic OY15, a benign strain of Vibrio bacteria found in the oyster gut, was developed by microbiologist Diane Kapareiko and her team at NOAA Fisheries Milford Laboratory in Milford, Connecticut. Their goal was to help oyster hatchery managers boost the survival of Eastern oyster (Crassostrea virginica) larvae and seed, and improve their defenses against bacteria.

But while it is a promising drug, Tom Hashman, director of business development for Envera, said there are hurdles for getting the Food and Drug Administration to approve any probiotic, and a Vibrio-based bacteria might present additional hurdles.

This particular Vibrio strain is confirmed benign and has shown it can be a “good” bacteria that boosts the oyster’s immune system and is safe for humans to handle; however, harmful Vibrio strains known to be human pathogens can cause serious illness and be fatal if an immune-compromised person ingests them or is infected through a cut in their skin while swimming in seawater.

Kapareiko says a partner is now being sought to produce the probiotic on a commercial scale. “If it were to go commercial, in a perfect world, if we had a company that said yes and went forward with commercializing it, it could possibly be another couple of years before it reaches the market,” she said.

‘Much-needed maintenance break’ halts supply of

K

uterra LP, the land-based Atlantic salmon farm on northern Vancouver Island in British Columbia, says market supply of its fish will resume in early summer 2019.

In June, it delivered to the market its last harvest and then halted the farm’s operations to give it a “much-needed maintenance break.”

“We’ve been making changes to our facility as we go, but the next changes have to be done with some of the tanks emptied. Examples of these important changes are overhauling a key part of the water filtration system, upgrading the cooling system, and salt-proofing key components to protect against the level of salinity in our water,” said Garry Ullstrom, CEO.

t was a long time coming but Delaware’s shellfish aquaculture program has officially kicked off with the planting of the first oyster seeds in Sussex County’s Rehoboth Bay.

IThe idea for the state’s shellfish aquaculture program was born in 2012. “We see this as a significant first step in the development of the new shellfish aquaculture industry,” said Shawn M. Garvin, Secretary of the Department of Natural Resources and Environmental Control, which administers the program.

“We are making great strides in the Inland Bays in improving water quality and the ecology, and shellfish aquaculture contributes to achieving those goals. It is very encouraging to see this first seeding of what will become the foundation for commerciallygrown oysters and hard clams in Delaware,” Garvin added.

Aside from the leaseholder that made the initial planting of the oyster seeds, the program has so far received 23 lease applications, the department said. Applications for shellfish aquaculture leasing are continuously being accepted and evaluated by the Division of Fish & Wildlife.

The new shellfish aquaculture program is expected to boost Delaware’s economy. Oysters planted this spring will be available for sale in a year or two.

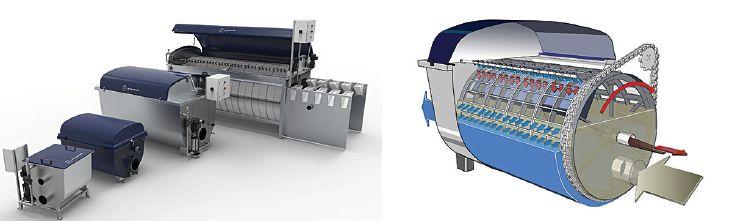

Cooke Aquaculture is boosting its sea-lice management tools with addition of the Thermolicer technology — a Norwegian invention that uses warmwater baths to remove sea lice.

“The Thermolicer exploits a vulnerability of sea lice that we know do not tolerate sudden changes in water temperature. Sea lice are immediately sensitive to sudden temperature changes. By suddenly heating the lice, it will fall off the fish,” said Tore Laastad of Steinsvik, which designed the technology.

Blacks Harbour-based Cooke Aquaculture said trials of the

technology last summer proved it to be 98 percent effective at removing the lice without harming the fish. It has since equipped one of its vessels — the Miss Mildred — with the technology and brought it into service recently.

“This is an exciting evolution in sea lice management for us. Thermolicer is a simple and effective treatment that further reduces our need to use chemicals or medicines,” said Joel Richardson, Vice President, Public Relations for Cooke Aquaculture. He added that it is the first time that the Norwegian technology is being used in Atlantic Canada to combat sea lice.

Researcher suggests noise pollution could affect reproductive behavior and stress levels of fish

stablishing an aquaculture operation requires attention to a wide variety of factors, but noise pollution is typically not among those considerations. Kieran Cox, a PhD student at the University of Victoria in BC, hopes the potential impacts of noise will soon become a regular part of the conversation. Cox conducted a meta-analysis on previous scientific research on the impacts of noise on fish. His analysis looked at impacts on fish in general, but many of the conclusions apply to the aquaculture industry and should be taken into consideration.

ECox found there are five broad categories of noise that could impact fish –anthropogenic, biological, environmental, tones and music. Exposure to these types of noise could have a variety of harmful impact on fish, including alterations to reproductive behavior, increased stress levels (measured through increased cortisone) and an increased hearing threshold, meaning that it takes more noise for sound to register. Fish in the wild and those in open-net pen scenarios could be affected by noise generated by boats and other equipment, in addition to noise from other ocean life. Fish within land-based systems could see impacts from the pumps and other machinery that keep the tanks functioning.

“We should be thinking about noise within these systems,” says Cox. “Concerns will not be limited to just fish health; from an industry perspective feed efficiency is a big concern. So if the noise in the environment is causing fish to eat less effectively, the industry should be aware of that.”

Fish within land-based systems could see impacts from the pumps and other machinery that keep the tanks functioning.

Cox hopes that further, more specialized research may look into whether controlling noise exposure could impact growth rates positively. Stress is known to impede growth rates, and his meta-analysis

If the noise in the environment is causing fish to eat less effectively, the industry should be aware of that, says Kieran Cox, a PhD student at the University of Victoria in BC

shows that noise can be a cause of stress for fish. While he initially found studies looking at the impacts of music on fish to be somewhat comical, he says he now thinks they could be implemented as part of a stress-reducing sound system within aquaculture facilities, to decrease random background noises that commonly cause startle responses. “Within land-based facilities, it should definitely be something that they should be considering, especially from a fish health standpoint,” says Cox. “They want the best product and noise could be playing a larger role than they realize.”

— Matt Jones

Alot, according to results of a poll conducted by the Aquaculture Stewardship Council (ASC).

The organization said majority (92 percent) of ASC-certified fish and shellfish farmers who responded to the survey found that ASC certification enhanced their reputation; 90 percent benefited from meeting buyers’ preference; and 87 percent gained access to new market opportunities.

An ACS certification verifies that the product was raised in an environmentally and socially responsible manner. To date, more than 600 farms have been certified, the majority of which are in Europe and Asia, and 11,000 different products are available on the market bearing the ASC consumer label. ASC surveyed farms certified to all eight ASC Farm standards and got a 21-percent response rate.

In addition to the aforementioned benefits, the farmers said they valued the opportunity to reduce their environmental impact, and three quarters had become more aware of sustainability issues related to feed use.

More than one third of them found that their use of antibiotics and therapeutic medicines had decreased, while a quarter reported that their feed conversion ratio had lowered, thus reducing their feed costs and their environmental impact. Notable improvements in water

CEnhanced reputation is one of the major benefits that fish and seafood farmers said they got from being ASC-certified

quality and a reduction in fish mortalities were also linked directly to working through the ASC certification process, the organization said.

“Overall the survey showed us that we are doing a lot of things right. Our farm partners are important stakeholders and these findings are also an opportunity for us to further improve our offering,” said ASC CEO Chris Ninnes.

keep out, say BC First Nations leaders

oastal First Nations leaders have told the Shepherd Conservation Society to stay off their traditional territories and partners’ farms this summer.

Leaders and members from three First Nations spoke about the importance of aquaculture at a gathering in Campbell River, BC, in June.

Tlowitsis Chief John Smith arguably delivered the strongest message, advising activists to stay off their traditional territories: “You are

not invited here,” he said.

Foreign members of the activist group have harassed salmon farms for the last two summers despite pleas for them to leave, Smith said. The activists contend that “under marine law they can come anywhere they want,” Smith added.

Farm-raised salmon is BC’s highest valued seafood product, the province’s top agricultural export, and generates over $1.5-billion towards the province’s economy, resulting in over 6,600 jobs.

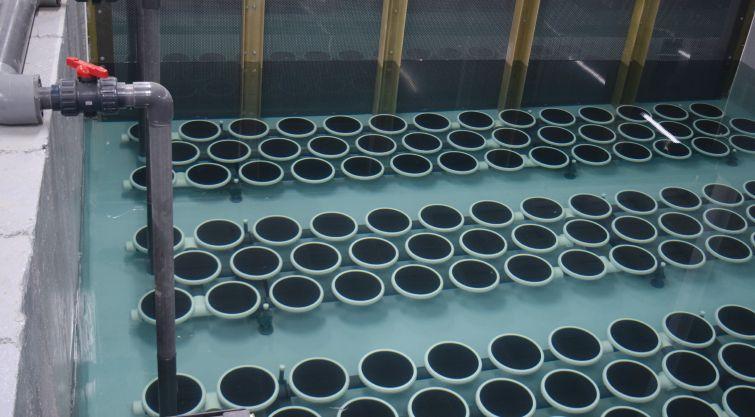

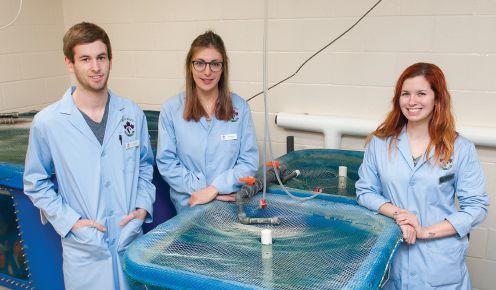

This aquaculture touch tank is part of the mobile lab project aimed at promoting aquaculture education, training and employment opportunities in North Carolina

How a recirculating aquaculture systems (RAS) work will be just one of the things students in North Carolina can learn through a mobile aquaculture lab currently being built in the state.

Project proponents North Carolina Sea Grant (NCSG) and Carteret Community College (CCC) expect the lab to promote aquaculture education, training and employment opportunities in the state.

The lab, which is scheduled for completion by the end of June, is part of a larger project called Building the Marine Aquaculture Career Pipeline. As part of the project, NCSG has taken part in several events where they brought touch tanks and animals to schools. But CCC Aquaculture Department Chair David Cerino says this new lab will be on another level.

“It’s a flatbed trailer on which we are going to put a touch tank that can transport animals and quickly set it up so those animals can go into smaller trays for interaction. There will be a RAS system that will have fish in it, with all the components of a RAS system so we can explain what each part does and highlight that aspect of aquaculture.”

The mobile lab will also display different types of gear and information on different aquaculture techniques as well as monitors for visual presentations. The modular lab can have new elements added, as necessary.

“I do a lot of work in high schools in North Carolina to educate students about the opportunities in marine aquaculture,” says Jane Harrison, Coastal Economics Specialist with NCSG. “I can go in and give a power point presentation, but if they can’t see what these creatures really look like and get their hands on them, it’s not as effective.”

Another aspect of the project is developing curriculum for teaching about aquaculture. Harrison says that she hopes the mobile lab might inspire some teachers to create permanent aquaculture labs at their schools.

— Matt Jones

AquaBounty is closer to its dream of bringing its genetically modified salmon to US consumers.

The company said it has received approval from the US Food and Drug Administration (FDA) to raise AquAdvantage Salmon at its land-based contained facility near Albany, Indiana.

AquAdvantage Salmon is an Atlantic salmon that has been genetically modified to grow to market size in about half the time of a traditional

The FDA previously approved AquaBounty’s New Animal Drug Application (NADA) on November 19, 2015, for the production, sale, and consumption of AquAdvantage Salmon in the United States. That approval specified that all production facilities for the product would require separate site-specific approvals. To conform with this requirement, the company submitted a supplementary NADA to the FDA requesting approval to grow AquAdvantage Salmon at its farm site near Albany, Indiana.

The Indiana facility as currently configured has a production capacity of 1,200 tons per year and was designed to allow significant expansion. But while AquaBounty’s Indiana facility is now approved, it cannot proceed with the commercial production of AquAdvantage Salmon until the FDA issues official product-labeling guidelines.

“We still have work to do before we can start production, but we take great pride in this latest accomplishment,” said CEO Ron Stotish.

Astudy examining black soldier fly (BSF) as fish-feed ingredients found no adverse effect on the growth performances, feed utilization, apparent digestibility and whole body composition of farmed Atlantic salmon fed with feed containing BSF meal and oil.

This means protein meal and oil from BSF shows “great potential” as a source of nutrients for the fish, said Dr Ikram Belghit and her team from the Institute of Marine Research, University of Bergen and Norwegian University of Life Sciences, all in Norway, and Marche Polytechnic University in Italy.

In the study, published by Elsevier BV, the researchers added insect meal and insect oil to the diets of freshwater Atlantic salmon. The BSF larvae used were either grown on media containing organic waste streams or media partially containing seaweed.

A typical industrial diet is composed of a 50:50 ratio of protein from fishmeal and soy protein concentrate, and lipids from fish oil and vegetable oil at a 33:66 ratio. In the formulated experimental diets, insect meal replaced 85 percent of the dietary protein and/or insect oil replaced all the vegetable oil.

“Using insect ingredients in the fish feeds did not affect the voluntary feed intake, indicating no negative effect on palatability of the insects-based diets for the Atlantic salmon,” the researchers said. “Even at inclusion levels of 600g of insect meal per kg diet, no negative effect

a source of nutrients for Atlantic salmon, says study

on growth performances or feed conversion ratios were observed.”

Insects have been catching the attention of aquafeed producers as alternative ingredients for fish feed because they do not use arable land, they can grow well on organic waste and they produce high-quality protein and fat. The most promising insect species for feed purposes are the common housefly, yellow mealworm and BSF. BSF larvae are rich in protein, which is about 40 percent of its dry weight, and have a well-balanced essential amino acid profile, similar to the amino acids of fishmeal.

-

D

ay 1 keynote speaker Dr Alison Van Eenenaam of UC Davis Department of Animal Science talked about the importance of genetics in promoting sustainability. A cattle breeder by trade, Van Eenenaam discussed the use of genetic editing, also known as precision breeding, to improve sustainability in the cattle industry. The carbon footprint of a glass of milk today is one-third of what it was in 1944 because of breeding innovations via genomic selection, she said.

Precision breeding could also be used to improve yields in animal protein production. “Aquaculture will be number two in the projected increased demand [for protein] in the developing world in the next 20 to 30 years. The choices are to increase the number of animals or make the animals more productive,” she said.

It will be easy to do precision breeding in aquaculture “because fish has eggs,” she added. Some examples of how genetic editing can be applied in aquaculture include developing resistance against infectious salmon anemia virus and F. columnare infection in farmed salmon and catfish, respectively, or increasing muscle yield of farmed carp.

As in other major industry conferences recently, public perception of aquaculture was a trending topic. “We are in a messaging war,” said Day 2 keynote speaker Andrew Gruel, head chef and CEO of Slapfish, a restaurant franchise serving sustainable seafood across the United States. He noted how Americans know that salmon and other seafood are the healthiest protein, yet they consume only 16 lbs of seafood per year compared to 60 lbs of chicken and 60 lbs of beef.

CHEF ANDREW GRUEL

Answering his own question regarding why US consumers are “confused about seafood,” he said consumers are faced with a barrage of messages about farmed fish being “a bad thing.” He suggested tapping the power of social media but cautioned that content has to be “real, authentic and drool-worthy.”

CEO AND FOUNDER, SLAPFISH RESTAURANT GROUP

Credit: Lauren Gruel

“We need to educate everybody, not change behaviors,” said Gruel. “Let’s take what we know and communicate in this war on messaging. What we can do is to spread the word

in small groups. If everybody can agree on one thing in this room, we tweet the same thing with the same hashtag, hundreds of people will see it,” he suggested.

Tim Kennedy, executive director of the Canadian Aquaculture Industry Alliance, encouraged participants to communicate about aquaculture and sustainability in aquaculture. “We know sustainability means increasing transparency, building on the good record we have and consistently doing better. Continue to draw back to the big picture and on why you got involved in the sector. You have great capacity to become ambassadors; you can speak effectively about the sector and for each other,” Kennedy told conference delegates.

Jenny Weitzman, an IDPhD student of Marine Affairs Program at Dalhousie University, noted that stakeholders play a role in communicating with the media and in how that story is told. Her review of Canadian media’s reporting of the industry over a twoyear period showed 45 percent was negative; 28 percent was positive; and 27 percent was balanced or neutral. “There’s an opportunity to leverage the media in a positive way to debunk those facts, to help shape the way people see aquaculture,” she said.

Phil von Finckenstein of Maple Leaf Strategies spoke about fighting fake news on the industry. “Fighting fake new starts with you,” he told the people in the room. He noted the need to disseminate fresh and engaging content. “It is incumbent on all of us, especially those with knowledge, to engage and spread the facts. Get a game plan, make it a goal to fact-check posts, get engaged, become part of the debate.”

To reach a wider audience in social media, key hastags to use are #salmon #seafood,#fish and #fisheries, not #aquaculture, he suggested.

Apacked room during each session on recirculating aquaculture systems (RAS) validates the emergence of the technology as a potential solution to some of the industry’s challenges.

Daniel Stechey of Canadian Aquaculture Systems said the aquaculture industry is “not there yet” in terms of seeing efficiencies in RAS. Stechey, who discussed the essential elements of RAS design and management, acknowledged there is a lack of standardization in land-based aquaculture unlike in traditional production systems and in net pen aquaculture. To get the technology to move forward, “as a sector we need to get over the inconsistency in land-based aquaculture because it hinders the sector’s growth, creates confusion and inefficiency,” he said. Asked during the Q & A

BILL ROBERTSON PRESIDENT, RETHINK INC

who would work on that standardization, Stechey said the industry will naturally gravitate toward the most efficient.

Bill Robertson, president of industry consulting firm ReThink Inc discussed the merits of small-scale RAS (defined as less than 400 tonnes). “RAS systems do not have to be very large to make sense economically,” he said, but stressed that the operator “needs more than just technology.” “Access to the right information and supporting infrastructure is critical,” he told the audience.

Anumber of speakers noted the growing interest in Canada’s “other weed” — seaweed, that is.

In Nova Scotia, interest is growing in seaweed cultivation as an alternative to mussel farming, said Dr Isabelle Tremblay of the Aquaculture Association of Nova Scotia.

“Mussel farming is no longer economically viable in some areas in Nova Scotia because of biofouling and predation problems. Some mussel leases are underutilized. Seaweed cultivation is a potential new industry,” Tremblay said. Several activities have been held in the province since 2014, such as workshops on planning and evaluation of seaweed cultivation. This summer people from Nova Scotia will go to Quebec to visit a research institution, commercial hatchery, seaweed producers and processing plant to learn more.

DR STEPHEN CROSS

INDUSTRIAL RESEARCH

CHAIR FOR SUSTAINABLE AQUACULTURE AT NORTH ISLAND COLLEGE IN BC

Credit: North Island College

There is likewise growing interest in coastal British Columbia in seaweed, said Dr Stephen Cross, Industrial Research Chair for Sustainable Aquaculture at North Island College (NIC) in BC.

Shellfish hatcheries are interested in seaweed for mitigation of ocean acidification issues while First Nations communities are interested in cultivating brown algae (Saccharina latissima) in small-scale individual farms that fit in with their capacity. He sees cooperative-style operations, where production will be pooled and share a common processing facility, as economically viable.

A kelp-growing study by partners BC Salmon Farmers Association and NIC shows good potential in growing seaweed within salmon farm tenures. Forty-four fish farms are well suited to co-culture seaweed with salmon, Cross said.

At the moment, seaweed harvest in the province is mostly from the wild, totaling roughly 800 to 1,000 MT per year.

Cross sees “incredible production and market opportunity” in seaweed farming because the province has the most of the most diverse seaweed species in the world — 633 in all; the province’s 20,000 km of coastline is physically diverse and has pristine water quality; and the province has a large Asian population, a ready market for seaweed.

Cross believes consumer acceptance of seaweed in the West will boil down to marketing. “Asians have eaten it for thousands of years, it’s part of their culture and diet. Here, it’s ‘Eww, seaweed? It think it’s a matter of education,” he told Aquaculture North America (ANA).

MECHANIZATION AND ACCESS TO FUNDING HAVE HELPED NEW BRUNSWICK

OYSTER AQUACULTURE TO GROW DRAMATICALLY

Credit: Gnb.ca

New Brunswick’s oyster farming industry has grown 36 percent over the past five years due to mechanization of farming processes and access to funding, according to M.J. Maillet of the province’s Agriculture, Aquaculture and Fisheries department.

The province measures the industry’s growth in terms of oyster bags in water, which, in 2017 stood at 518,000. Latest sales figures show the industry sold 23 million units (pieces of oysters) in 2016 at farm gate value of $9.1 million.

Maillet says the use of the single floating bag as well as cages that house a number of oyster bags per cage are the most popular growing techniques among the province’s 90 oyster companies. These techniques allow the bags and cages to be flipped, which addresses the biofouling found on the oysters and gear. “This was revolutionary. Scraping barnacles manually was not the way to grow the industry,” she said.

Another development that made a difference was access to funding, enabling growers to invest in, for instance, grading machines, and build the proper infrastructure such as warehouses, enabling work to continue even in inclement weather. “It’s basic but it’s something we didn’t see a few years ago,” said Maillet.

New Brunswick’s new shellfish aquaculture development strategy aims to grow the industry by 10 percent, meaning 30 million oysters, $12 million in farm gate sales, and $6.4 million in exports by 2021 (Aquaculture North America, Jan/Feb 2018, page 3).

With a VAKI Biomass Daily frame placed permanently in each ASK US!

Visit PentairAES.com/VAKI today for more about how the VAKI Biomass Daily can improve your operations.

PENTAIRAES.COM +1 407.886.3939

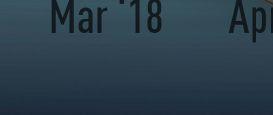

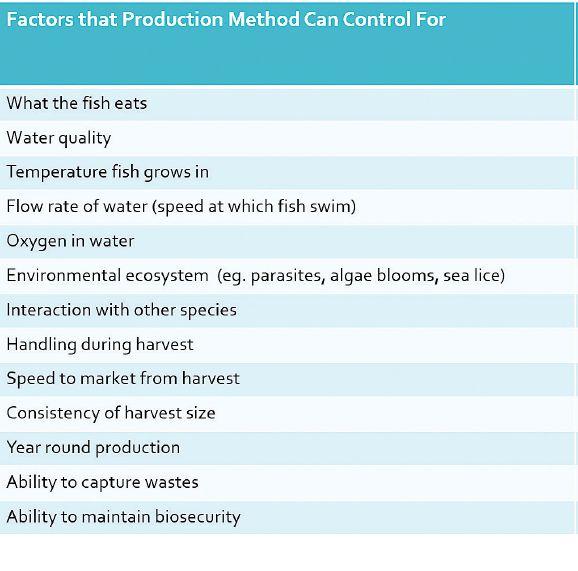

BY SAMUEL CHEN

When Aquaculture North America (ANA) first asked me why my family got involved in farming seafood on land using recirculating aquaculture systems (RAS) and what potential benefits we saw, I had to take a step back because not only are there multiple levels to the answer, the answer has also been evolving over time as we continue learning about RAS.

From a macro-business perspective, the forecast of protein shortage as global population grows supports the business case for exploring alternative methods of protein production. When we look at the most efficient converters, we should be either eating insects or seafood. We chose to focus on seafood, beginning with salmon and shrimp, the two most consumed species in North America. We believe that no matter the method, seafood production is significantly more efficient and greener than livestock production. It is also the healthier option.

Before answering the question about why RAS, we come to the inevitable question about why we didn’t start off in net-pens or other traditional production systems, such as outdoor raceways or ponds. It was not because we believed net pens were inherently unsustainable. Rather, we wanted to look at disruptive technologies that allowed for production closer to markets, are less dependent on environmental conditions, have less environmental impact and allow for greater quality control.

The company is preparing for an increased demand for salmon. It plans to exponentially expand the Miami Bluehouse in size and scope as it moves through different phases. Phase one is due for completion by the yearend and will see its first harvest – 9,484 metric tons of head-on and gutted (MT HOG) salmon – by the second quarter of 2020. Phase two will add 20,000 MT HOG by 2023. Phase three will add another 60,000 MT, for a total production of nearly 90,000 MT HOG, by 2026. The initial 384,000-square-foot facility in phase one will grow to four million square feet by phase three. The 100 direct jobs and economic impact equivalent of 2,700 jobs in phase one is predicted to grow to 21,000 indirect jobs by phase three.

While the idea of including every step of the seafood value chain under one roof is unique, it’s not a new idea, says Andreassen. “If you look at everything from broodstock through hatch, through parr, pre-smolt, smolt, post-smolt, what we are doing here is exactly the same as the entire salmon industry. Then we grow-out the fish to five kilos, that’s basically what we are innovating and what we are doing differently from anybody else. Once the fish is five kilos, it goes into a slaughterhouse and a processing facility that’s also exactly the same technology and concept that is widely used throughout the industry.”

By housing the supply chain in one facility, the product can reach the market quicker and fresher. But this also means much more planning on the front end for Atlantic Sapphire to avoid potential issues.

While recirculating aquaculture systems (RAS) are much more secure and have a smaller risk of virus issues than other facilities, Andreassen states emphatically “nothing is virus-proof.” The original Bluehouse in Denmark served as a dry run where most of the kinks in this type of facility were ironed out. In 2012, there was a furunculosis bacteria outbreak. And once such a virus gets into a recirculating system, it’s a significant problem because the water keeps recirculating. That’s why it’s so important to have protocols and protections in place to begin with.

“You have to have a very, very thorough pre-treatment of the water, and high hygienic standards, and procedures on all the stuff that you’re bringing into the farm. Most of the people that are producing fish on land, they’re using water from a pipe into the ocean or they’re piping water from rivers or streams and those are not biosecure. You have fish, you have algae and you have living organisms in the intake water. In the case of South Florida, we’re using a deep-laying artesian aquifer that’s 2,000 feet below, where the water is completely biosecure. So that’s a huge edge that we have here.”

To deal with the furunculous issue in Denmark and avoid such issues in Miami, Atlantic Sapphire designed a new water treatment system with a double firewall for pathogens. They also improved their bio security routines. Another risk factor, for any farming situation, is hydrogen sulfide intoxication, which the Danish Bluehouse experienced last year. In response to that, the company updated the design of their bio filters, developed a new sensor to measure H₂S and made changes across the system to prevent sedimentation.

Due to such intense precautionary measures

“We have hatched and raised 28 generations of salmon on land so far since 2010 and the lessons we learned along the way will be applied on the 2018 version of the Bluehouse.”

– Johan Andreassen, CEO, Atlantic Sapphire

Atlantic Sapphire CEO Johan Andreassen surveys the ongoing construction of the company’s ‘Bluehouse’ in Miami, Florida

required, some larger salmon farmers do not feel that RAS technology is ready to operate in larger scale production. But Andreassen feels such concerns are unwarranted.

“Broodstock salmon have been raised land-based for 20 years, right? It’s not a question of whether it’s feasible to get the salmon to grow to a large size in a land-based environment. Obviously, when you do commercial food fish production, you have higher densities and you need to dimension the technology accordingly, so it can keep a higher volume of game per cubic meter of tank volume.”

No matter what the challenges, Andreassen feels it will be worth the benefits their approach will bring to aquaculture production. Citing how open-net pen farming was recently banned in Washington State, for example, he notes that the Bluehouse concept addresses all of the issues associated with that type of salmon farming, including microplastics. “I think microplastic is going to be one of the largest [problems]. I call it the next CO₂.”

More than that, however, is the fact that consumers are becoming more concerned about the origins of their food and how it comes to their plate. Having the entire supply chain under one roof means that question is much more easily answered.

“I also think that once we have the ‘Product of the United States’ [label] on our products, it will appeal more to a lot of consumer groups here,” says Andreassen. “We have a very open philosophy. We want to create trust amongst the consumers so we have designed our farm in a way we can have tours. People can see exactly how the fish are being raised so we can create that confidence that what we’re doing is good both for the fish, for the environment and for the consumer.”

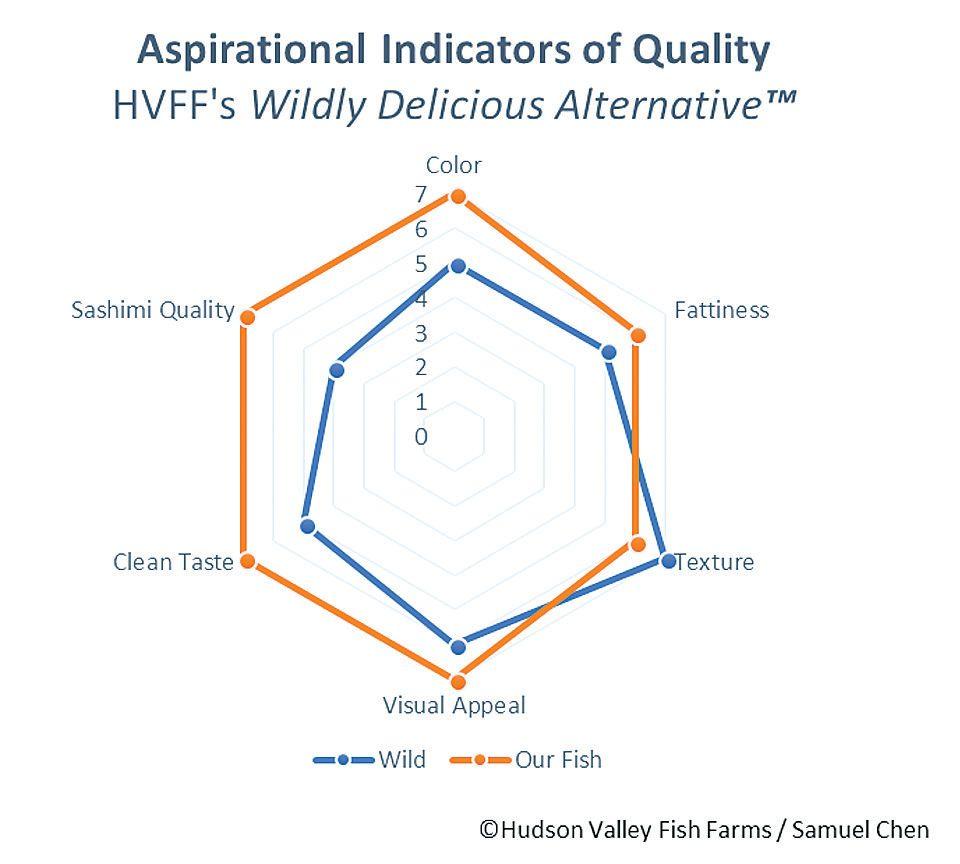

Figure 3 shows indicators of quality that we at Hudson Valley Fish Farms aspire for. We worked with various chefs to discuss “ideal” taste and texture profiles. To reach this ideal, we adjusted fish diet, their exercise rate at different life stages, and water temperature in the tanks. We tried various harvesting methods to reduce handling and stress in fish. (Compared to over two decades of R & D efforts for Wagyu to become the much-desired beef cattle that it is today, we in aquaculture are on only on the cusp of learning how to grow seafood this way.)

The jury’s still out as to which axiom will apply when adopting RAS; will it be “the early bird gets the worm” or “the second mouse gets the cheese?” Either way, I believe investing in RAS is worth it if you’re “the right kind of person.” The right person being the one with deep-enough pockets, has foresight and is willing to have sleepless nights.

Samuel Chen helped launched Hudson Valley Fish Farms, shepherding it over the past five years from regulatory approval, to the build, production and marketing of the first three crops of production. He developed the farm’s relationships with the industry, scientific community and market. During his tenure at the farm, Samuel has also been the business lead for six commercial shrimp pilots in indoor systems. He recently left HVFF to return to his home in British Columbia, where he now serves as consultant on the business of seafood and RAS.

Efforts to restore the population of wild Atlantic salmon in the Inner Bay of Fundy between Nova Scotia and New Brunswick has reached a milestone as wild-hatched offspring are leaving their home rivers for the first time and migrating to the Bay of Fundy to feed.

The parents of the young salmon were collected from the wild as juveniles and raised to maturity in a Cooke Aquaculture conservation farm on Grand Manan Island.

The Fundy Salmon Recovery Project is a collaboration between industry, academia, provincial and federal governments and First Nations.

A visually appealing fish and short time to market are just some of the pluses of raising fish on land, says America’s sole producer of RAS-raised European seabass

BY TOM WALKER

It’s been a while in the making, but Great American Aquaculture of Waterbury, CT has test-marketed some of its first fish and expects to be in full production by the end of the summer.

Sold under the brand Ideal Fish, the branzino (European seabass) raised in land-based RAS have found a positive reception, says founder Eric Pedersen.

In side-by-side tastings with imported product raised in open-net pens in the Mediterranean Sea, he says Ideal Fish stood out. “We have had really strong reviews,” says Pedersen.

He says Ideal Fish are, at most, sold within 24 hours of harvest. The Mediterranean product, he says, could have taken up to a week to arrive and it will have been handled several times along the way. “Ours is a bright shiny fish that’s visually appealing and identified by our brand on the gill tag. The tag has a QR code for full traceability, allowing

the customer to see when the fingerling came into our plant right up to when it was harvested and shipped. This is what customers want now.”

Branzino is a high-value and popular fish in the US, with 17 million lbs imported in 2017, mostly from Greece and Turkey. Pedersen says it’s what attracted him to the species, and the higher price point should allow him to recoup the extra costs of raising them on land.

He aims to produce 140-150 tonnes or around 330,000 lbs of fish annually. With a target weight of around 1&1/8 lb, that will be about 5,500 fish a week. “Our sweet spot is a little larger than the 400-gram size the European market wants. We have designed our production for an even supply throughout the year,” says Pedersen.

BRANZINO ADAPTING TO RAS

Fingerlings are flown in once a month from Europe, primarily from a French hatchery. They are transferred to the first of four rooms, each with three nursery/quarantine tanks of 40 cubic meters. Each month they move up through the system with one room of tanks going off to grow-out and one new shipment coming in. “We keep the nursery densities fairly low; somewhere below 25 kg per cubic meter,” he says. For grow-out, the fish are distributed across 12 92-cubic meter tanks, and are moved up to a maximum density of 80 kg per cubic meter.

“We’ve had very good luck with these fish. They are adapting to RAS, but you have to feed them well, or they will be cannibalistic.”

Pedersen says grow–out period is eight or nine months once they are out of the nursery. “We harvest about a quarter of a tank at a time,” he says. Fish go off to smaller purging tanks for a week, are chill-killed, processed and packed in 10-lb boxes on site and shipped directly.

A small customer list of only one or two dozen means the company only needs one truck and perhaps a small van. Being situated half way between Boston and New York gives them access to the largest seafood market in the US.

““We are a local farm-to-table distributor. We have sized our production so that if we wanted, we could sell it all in New York City.”

The state of Connecticut has other assets besides location. “The state welcomes and supports manufacturing and has a lot of infrastructure in place to sustain that,” says Pedersen. Indeed, Ideal Fish is in a converted warehouse, water comes from a robust municipal system and water discharge goes to a municipal treatment plant. The company pays for the waste treatment, but it didn’t have to build the plant.

Pentair Aquatic Eco-Systems is a financial and engineering and equipment partner in the company. It custom-designed the RAS system to suit branzino. “This is the first commercial-scale saltwater RAS system that Pentair has built,” says Pedersen. “We did a lot of research into the specific water chemistry needs of branzino, the stocking densities and water flow rates, to ensure top-quality fish. They can take a lot of credit for getting me to where I am now.”

Synthetic sea salt is used to prepare a brine mix that is housed in six 8,500-gallon reservoirs. The entire water system is roughly a million gallons, with around 2-percent discharge/day. Heating costs are minimal. “Electricity is approximately 20-25 percent of production costs before fixed costs,” he says. Branzino sleep about six hours a day, allowing the company to conduct some electrical tasks at night, such as running foam fractionators, when electricity costs are lower. “We can adjust our use times to avoid peak demand charges.”

The water is room-temperature and the pumps from the system keep things pretty warm. Branzino thrives in 26ºC in the nursery and 23-24ºC in grow-out.

The fish are fed a specially formulated marine diet that contains about 50 percent protein and all BAP-certified fishmeal and fish oil. With an FCR of 1.5, branzino are not quite as efficient converters as salmonids, Pedersen acknowledged.

The de-watering technology that Ideal Fish uses to process their solids takes out more than 50 percent of the salt content and that, they believe, will allow them to run an 8,000-sq-ft decoupled aquaponics system. “There’s huge demand for local organic salad greens and culinary herbs throughout the winter. This will be a fall project for us and we expect this product to contribute substantially to our business.”

The company also plans to build a local cluster of four or five plants about 10- to 15-minute drive from each other to mitigate risks and take advantage of economies of scale for supplies, and manpower, where technical staff work in more than one facility.

Farming more than one species is also a possibility, Pedersen says, to diversify the company’s revenue source and protect itself from price swings. “There is some great work being done with red snapper and we are looking at yellow tail and arctic charr as well,” he says.

•

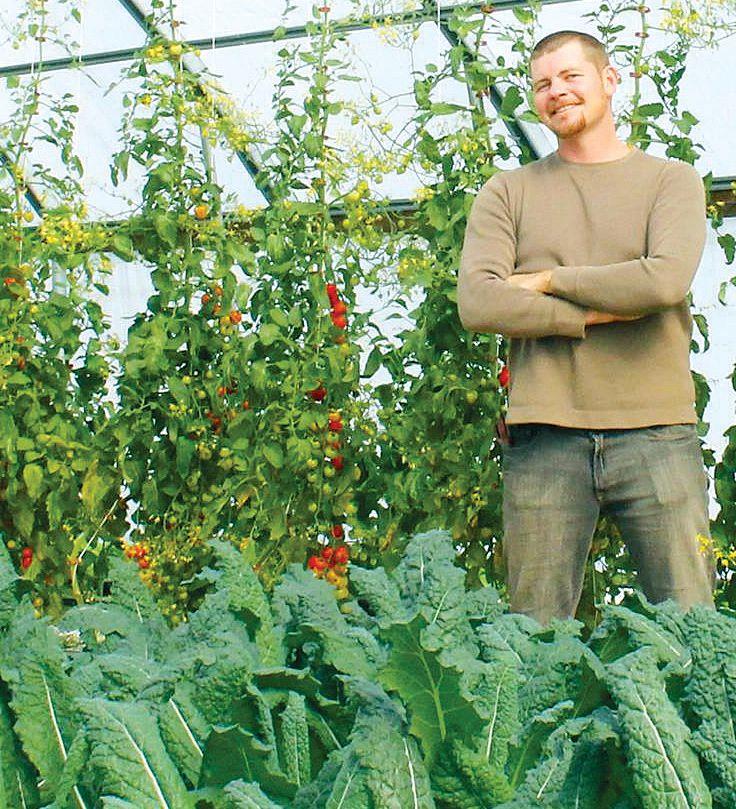

an aquaponics serve as a catalyst to bring sustainable salmon production out of net pens and into land-based RAS facilities? Ryan Chatterson, who owns an aquaponics operation called Chatterson Farms with his wife Katie in Clermont, Florida, certainly believes so.

Earlier in his career, Chatterson spent 10 years working at Aquatic Eco-Systems (now Pentair), where he assisted in thousands of aquaponic projects ranging from backyard systems to large commercial designs. He is also the founder and president of Aquaponic Engineering and Design, a custom design and consulting company. At Aquaculture America 2018 in Las Vegas recently, he listed many reasons why aquaponics now broadly makes more sense than ever for land-based farming of salmon and other fish.

At this point in history, humanity has an increased understanding of how to concentrate nutrients from the waste of fish and other livestock, he notes, at the

same time sources of phosphorus around the world are being depleted. Chatterson also explained that better automation in hydroponics is now making investment in aquaponics more attractive than ever. Another important point is that increasingly, aquaculture operations are having to pay to remove wastes from fish farm effluent, which aquaponics minimizes or makes unnecessary. Chatterson also noted that certification using RAS fish waste as organic nutrient source has recently been upheld in the United States, making it possible to market the produce at a premium organic price.

Chatterson told the audience: “Why go through all the trouble of adding an aquaponic component to your aquaculture business? Well, you can diversify your revenue stream. You’re spreading risk across multiple profit centres. Money is coming in the door back fast to fuel

that business, within six to eight weeks of start-up…Investors like to hear that.” Aquaponics, he said, also increases your profit margins, as the profit margin from the greens is quite large.

In terms of the monetary value of fish waste, Chatterson presented many calculations (on trout, since he does not farm salmon). He says that if 50 kg of feed is fed per day to RAS-growing rainbow trout with a 1.2 feed conversion rate, the result would be 15,208 kg/year (or 33,458 lbs/year) of rainbow trout. At $2.64/kg (or $1.20/lb), that’s a potential gross profit of $40,150/year before costs.

Using the wastewater from the same setup can result in 112,000 heads of lettuce per month (or 39,000 kg). Bibb lettuce, Chatterson said, was priced wholesale at $2.27/lb in 2016, which would provide a monthly gross profit of $195,220 or a yearly gross profit of $2,342,640 before costs. In the same situation, about 3,900 tomato plants can be supported, providing a harvest of 6,400 to 12,000 kg (14,000

to 26,400 lbs) of tomatoes on average per month at $3.34/kg ($1.52/lb), amounting to a potential gross profit of $252,000 to $580,800 a year.

Chatterson lastly pointed out that making fish waste a part of one’s story in the form of aquaponics is good PR.

“It gives your firm the ability to make legitimate ‘green’ claims and can set you apart from your competitors, and the ‘green’ nature of aquaponics might also open up new opportunities for borrowing or grants,” he said.

He advises RAS operations that don’t want to grow plants to convert fish waste into dry organic fertilizer, liquid hydroponic concentrate or concentrated soil inoculant.

“Just don’t flush that ‘liquid gold’ down the drain,” Chatterson says. And even though it may not seem that aquaponics will be a solution for everyone, “market research should still be done as it might be a game-changer for your business,” he suggested.

— Treena Hein

Whole Oceans is building a land-based Atlantic salmon farm in a former paper mill in the state. Repurposing the paper mill has saved the company a lot of money, according to head of Business Development Ben Willaeur. “Paper-making also involves high intensity water usage and the intake and discharge saltwater so the infrastructure already exists. That reduced our costs tremendously,” Willaeur says.

The farm will create 50-60 jobs directly, as well as a number of indirect jobs through construction or byproduct utilization. The facility is the first of many being planned by Whole Oceans in Maine. CEO Rob Piasio hopes the company could eventually capture 10 percent of the domestic salmon market.

“We’ll achieve that goal by growing numerous farms in different locations in Maine; that will get us to 50,000

metric tons of capacity, or more,” says Willaeur. “But it’s a long-term goal. That could take 20 years, or more, but it’s ultimately something that may happen much sooner than expected.”

While acknowledging that the 50K MT capacity is a very large number relative to what is currently being grown in RAS facilities within and outside the US, Willaeur believes it is something the market can bear. “There is, I think, going to be an awareness that the consumer will bring when they become more familiar with the quality that RAS fish possess in terms of their taste, but also in terms of the fact that they’re taking pressure off an endangered wild species and really have controlled food and water quality.”

Market demand is promising. Whole Oceans says it has already pre-sold 100 percent of its projected inventory. Willaeur downplays competition among RAS producers; instead, he speaks highly about the work done by contemporaries such as Nordic Aquafarms and Atlantic Sapphire in this sector. He believes the market has more than enough room for everyone.

“The industry is dynamic enough that we find most participants consider themselves as partners rather than competitors. Everybody wants each other to be successful. There’s a lot of knowledge-sharing in terms of the growth of the technology and the innovation that’s occurring.”

That collaboration is part of why Willaeur and Piasio, both Maine natives, would like to see the state become a global hub for RAS technology. That hub would be formed both through partnerships with both the industry and academia. The knowledge base of RAS systems incorporates everything from chemistry to biology, electrical and mechanical engineering and international procurement.

“There’s just a myriad of diverse centers of knowledge that we would be looking to recruit, and looking to acclimate specifically to our work. We feel that academic institutions in this state are rising to the occasion and are very interested in producing integrated academic offerings, partnering with industry partners within the state.”

Burrowing shrimp infestation will devastate oyster growers’ businesses and habitat for dungeness crab and eel grass if the ban on the pesticide imidacloprid remains, according to oyster growers in Washington State.

The Washington Department of Ecology said imidacloprid is “too risky for Washington’s environment” and is now in the process of reviewing public comment on the ban.

Members of the Willapa-Grays Harbor Oyster Growers Association (WGHOGA) use the pesticide to kill burrowing shrimp that destroy oyster beds. They accused the department of basing its tentative denial on “unsound science.”

In a letter to Rich Doenges, who manages water quality in the Southwest Region for Ecology, the group outlined how the department “ignored multiple field studies” that support the continued use of the pesticide.

“Ecology has cast aside objective, rational science, and has instead chosen a

predetermined path that will not address the grave economic and ecological harm caused by this shrimp infestation,” the letter stated.

Willapa Bay shellfish farmer Brian Sheldon doubts the public comments will alter the department’s intention to ban the pesticide. He said the ban will lead to the collapse of about 70 percent of the habitat growers need to produce shellfish. “With that goes Dungeness crab nursery area and eel grass habitat,” he said.

“ We’ve spent many years to find an alternative, everything from mechanical methods where you basically destroy the ground to get to the shrimp and we tried different culturing methods like offbottom — that will buy you some time but eventually the shrimp density gets so large that the structure to support that culture technique fails.

“We’ve tried sonic waves, electrical shocks, and concreting over the oyster beds, but nothing is realistic and they do more damage than the pesticide. There’s nothing on the horizon right now that works,” he lamented.

“As we remain mired in administrative process, it is important to keep in mind that the burrowing shrimp infestation continues, devastating not only WGHOGA members’ farms, but publiclyowned tidelands, degrading the ecological quality of what has been an extraordinary resource and place in Southwest Washington,” the letter said.

sea-lice counts at some of Cermaq’s Canadian farms tainted the company’s sustainability record in Q1

Cermaq reported robust survival rates and declining use of antibiotics in its salmon in the first quarter of 2018 but excessive sea lice levels at some of its Canadian farms have ruined the otherwise rosy picture.

Average sea lice levels at Cermaq sites worldwide were within regulatory limits, it said, except for “a few sites in Canada where the levels exceeded the regulatory limit and have continued doing so.”

As a result, the company decided in May that it would no longer sell Aquaculture Stewardship Council-certified salmon from those farms in British Columbia until it has resolved the situation.

On its Q1 sustainability performance, Cermaq said survival rates ranged from

92.5 - 97.3 percent on a 12-month rolling basis, with the highest level achieved for trout in Chile.

In fish health performance, use of antibiotics in Q1 was reduced by 70 percent in Chile compared to the same quarter last year. In Canada, the use was “further reduced” to 9 grams of antibiotics per tonne of salmon harvested within the quarter. The fish harvested by Cermaq Norway in the quarter did not receive any antibiotics, it added.

Cermaq also reported one incident of escapes in Chile, where 6,284 fish, weighing 2.9 kg each on average, escaped its operations due to ripped nets.

The company started publishing quarterly sustainability results in early 2016.

continued from cover

Around that time, local catfish farmers Rafe Taylor and Richard Odom Jr were exploring alternative species that have a greater profit potential than catfish. They stocked a former catfish pond with post-larvae shrimp.

“They had a one-acre pond and they managed to grow 1,500 lbs of shrimp. They were big shrimp, beautiful shrimp. And they grew at about two grams per week, which is pretty phenomenal growth,” says Whitis.

But soon they faced the biggest stumbling block — survival was poor. Poor survival rate would become a sad refrain for shrimp farmers in the state. Alabama’s first commercial farm dedicated to shrimp, Greene Prairie Aquafarm, experienced the same problem.

“David [TeichertCoddington] gave up his job with the Alabama Cooperative Extension System and partnered up with Dr Rudy Schmittou and built Greene Prairie Aquafarm back in 2000. It took a lot of money to do this but they bought the farm,” says Whitis. It costs roughly $9,000-$10,000 an acre just to get a farm started. “That’s your investment costs, not your operating costs,” he says.

But Greene Prairie Aquafarm also saw shrimp die immediately after stocking. Survival dropped to 20 percent.

“We started off with a lot of fanfare. A lot of folks were interested in shrimp but the survival issues whittled out a few of them and then we lost a few more,” says Whitis. Not one to give up easily, the men kept going with their mission. “The potential was there and we recognized that,” he says.

Teichert-Coddington compared his water with diluted seawater and found that Alabama’s inland salty water was deficient in potassium and magnesium. After adding K-Mag — a fertilizer that contains potassium magnesium and sulfur — and muriate of potash fertilizer, mortality ceased almost overnight.

An Alabama Cooperative Extension System result demonstration also showed similar results for one particular producer: K-Mag improved survival. “It wasn’t really statistically clear, but the trend was the K-Mag did a little bit better than the other treatments,” says Whitis.

Another shrimp farmer treated his pond with high volumes of K-Mag last year and the results “blew the records of everybody else in Alabama.” The farmer harvested 4,900 lbs of shrimp per acre at a 1:19 feed conversion ratio. Survival rate at his farm was 62 percent — high compared with the average survival rate of less than 40 percent in Alabama.

Alabama farmed shrimp for sale at Western Supermarkets in Birmingham, AL. Most big buyers of shrimp are pricefocused so farmers find it hard to get good prices for their produce, says Whitis Credit: Gregory N. Whitis

“These are phenomenal results because we treated this pond with K-Mag at a very high dose. So we’re hoping we can do that again this year,” says Whitis.

With only six shrimp farmers, Alabama currently ranks behind Texas and Florida in terms of farmed shrimp production. The state’s four existing farms in 2017 totaling over 173 acres produced an estimated 304,572 lbs that year, which is a drop in the bucket compared to 3.8 million lbs of farmed shrimp produced in the United States overall.

“In this country — Texas, Florida and Alabama where shrimp are raised — everybody has experienced low survival. We do not know if it’s a genetic problem or what, but everybody across the board is experiencing low survival right now,” Whitis says.

While the addition of K-Mag in shrimp ponds has shown positive results in boosting survival rates, it is not a cure-all for Alabama’s fledgling shrimp industry.

“We’re really lacking a critical mass here,” says Whitis. “We need closer seed stock supplies. Our feed comes all the way from Louisiana. Our catfish feed producers are not going to make us the shrimp feed anytime soon. We have one processor in Alabama, in Bayou La Batre, which is about 90 miles away. Even for my farmer in Lowndes County in central Alabama, he had problems getting bulk ice. So, little things like that add up and make things really difficult when you’re trying to get the industry going.”

Another stumbling block is the reality that big buyers of shrimp are price-focused. “Just because you grow them doesn’t mean you’re going to be able to sell them. Most of these big buyers of shrimp are still shopping price. They could care less about these shrimp being locally grown, antibioticfree, family farm. They’re still shopping price. It’s very hard to move shrimp in large numbers at a really good price. I’ve got one farmer now that’s got 30,000 lbs of shrimp in inventory that he doesn’t know what he’s going to do with.”

Whitis acknowledged that shrimp farming in Alabama is not a profitable business given the current problems farmers are facing. It boils down to poor survival rates.

“If you have survival rates below 40 percent, the handwriting is on the wall. You’re not going to be able to stay in business long. That’s why we have to get the survival issue figured out. If we don’t improve it in the next couple of years this industry will die.”

Thankfully, what Alabama has is technical expertise, he says. “We’ve got Auburn University nearby and that expertise is incredible.”

Auburn University fisheries and aquaculture professors Allen Davis and Claude Boyd provide technical expertise, and Teichert-Coddington is himself now an expert in shrimp culture. Whitis and the other experts continue to assist producers with water quality issues and treatments to boost survival rates. “We’re not giving up on it,” says Whitis.

Marine Harvest’s operational earnings and profit fell by 28 percent and 15 percent, respectively, but the Norwegian salmon producer remains optimistic.

“The demand for salmon has increased globally this year, compared to the end of 2017. This has led to high prices and a good result for Marine Harvest in the first quarter,” says CEO Alf-Helge Aarskog.

The company’s operational revenues were EUR 862 million ($1 billion) in the first quarter of 2018, while profit was EUR 179.1 million in Q1 of 2018 ($212.8 million).

The Consumer Products segment posted a significant increase in operational earnings—EUR 20.9 million ($24.8 million) up 29 percent compared to EUR 12.9 million ($15.3 million) year-on-year.

“I am encouraged by Marine Harvest Consumer Products and its seasonally record high results. It is also very satisfactory that our organic farming operations in Marine Harvest Ireland have achieved record high first quarter results on strong demand and reduced costs,” says Aarskog.

A US startup has raised $3.5 million in seed funding to further develop its computer-vision technology for aquaculture.

Silicon Valley-based Aquabyte says its software platform helps fish farmers collect feeding data with underwater 3D cameras to determine ideal feed quantity. As feed accounts for 50 percent of fish farming costs, the technology will help boost yields and profit for farm owners, it said.

“By installing these cameras in fish farm pens, the technology watches the fish and determines the size of fish/biomass in order to determine the optimal feed quantity. Through the application of its machine learning algorithms, Aquabyte anticipates that this more efficient feeding over a fish’s lifetime could result in as much as a 20- to 30-percent decrease in feed cost, which would be tens of billions of dollars saved,” it said in a statement.

Venture capital firms Costanoa Ventures and New Enterprise Associates helped raise the $3.5-million seed fund, as did Princeton University and other strategic US and Norwegian investors, the company said.

The Silicon-Valley manufactured Aquabyte will first be deployed in Norway.

The Canadian province of New Brunswick is investing up to $1.9 million in support of Cooke Aquaculture’s effort to create 100 new jobs in the province over the next five years.

The amount will benefit Cooke in the form of payroll rebates of up to $990,000; a forgivable loan of $810,000; and a non-repayable contribution of $100,000. The investment is being made through government-owned corporation Opportunities NB, which administers the province’s economic development activities.

Among the new jobs will be marine site workers, technicians and managers, logistics experts and truck drivers. They are expected to contribute $25 million in payroll over five years and $80 million toward the province’s GDP over that same period.

“Opportunities NB and the Government of New Brunswick remain outstanding partners for us as we continue

to grow,” said Glenn Cooke, company CEO. “These new employees are needed to help us reach our latest growth targets and we are very pleased to be able to add so many of them as part of our operations in rural New Brunswick.” Cooke is based in Blacks Harbour, NB, where it already has more than 1,300 employees throughout the province.

A startup that’s developing aquaculture feed made with byproducts from the whisky distilling process has attracted roughly $671,600 (£500,000) in investment.

The company, MiAlgae, uses byproducts from the distilling process to grow Omega 3-rich algae for feeding farmed salmon.

Douglas Martin founded the company while a masters student at the University of Edinburgh in 2015-16. He said he wanted to revolutionize the animal and fish feed industries with microalgae that come from whisky.

The investment, in equal shares from Equity Gap, the Scottish Investment Bank, the investment arm of Scotland’s enterprise agencies, and the University’s venture fund Old College Capital, will enable the company to expand its team and build a pilot plant for its technology at a whisky distillery.

“This investment will fund the initial scale-up steps and de-risk our commercial facility. It certainly sets us on track to achieve our ambitions,” Martin said.

Small BC aquaculture company producing innovations that make sense from environmental, economic and production perspectives

BY RUBY GONZALEZ

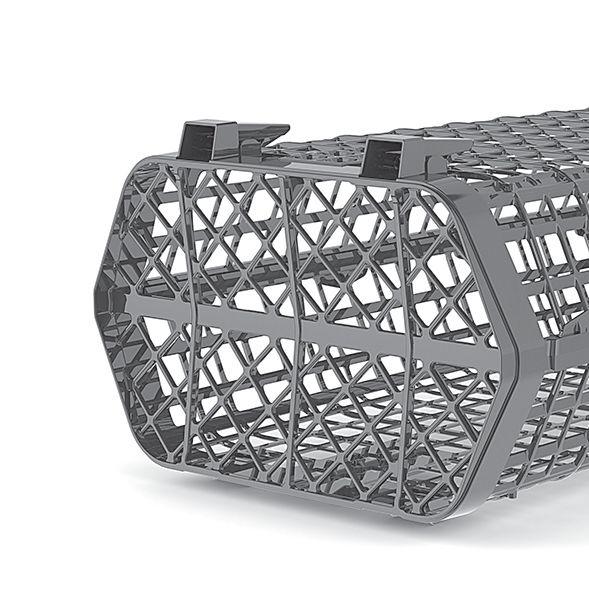

Ingenious companies around the world are accelerating innovations at an unprecedented pace to make fish farming more sustainable. One of them is AgriMarine TechnoIogies Inc (ATI), a developer of marine aquaculture containment systems. ATI is a subsidiary of AgriMarine Holdings Inc, a portfolio company of Torontobased Dundee Corporation.

The British Columbia company is busier than usual these days, says AgriMarine Director Sean Wilton. “We have lately been working on a lot of closed containment systems because it’s starting to look like there’s a sweet spot in the industry where you get a crossover of functional benefits with cost. The cost of (floating) containment is obviously higher than net pens but lower than in land-based,” he told participants at the Aquaculture Innovation Workshop in November.

The company’s product is featured on menus as “Lois Lake Steelhead” and is available throughout BC and Alberta at specialty restaurants, fishmongers and grocery stores

AgriMarine has been at the forefront of salmonid closed containment aquaculture for nearly two decades and pioneered the development of marine-grade floating closed containment systems for over 10 years. In 2014, it formed ATI to focus on delivering its market-ready sustainable technology solutions to clients around the world.

ATI has less than 10 employees, which is relatively small in the world of technology innovators. But while the competition has started getting bigger — in both the size of their deployed systems and their engineering and R&D budgets — Wilton believes “bigger is not always better.”

The greatest challenge for any smaller innovator, he says, is to stay relevant once they have proven the value of their technology to larger players in the industry.

“We are meeting this challenge by leveraging both the depth of our practical experience and our flexibility and responsiveness that we enjoy being a smaller private company,” Wilton says.

The company’s marine containment systems offer solutions for sea lice, toxic algae blooms, low dissolved oxygen water and high temperatures.

“Our floating closed containment technologies, both tanks and raceways, address all of these issues in the same fundamental manner. We use solid or impermeable wall structures in the rearing containment vessels to isolate the husbandry environment from the ambient surface-water conditions,

and draw cleaner, cooler water largely free of algae and sea lice from depth to supply the fish with as close to ideal culture conditions as are available,” he told Aquaculture North America (ANA)

REAL-WORLD RESULTS

In 2012, AgriMarine acquired West Coast Fishculture (Lois Lake) Ltd, a finfish farm in Powell River, BC, which produces 1,200 MT of steelhead annually. Starting out as a net-pen operation, it added closed containment because high water temperatures in the summer led to high mortality rates. There are currently six tanks deployed, displacing approximately 18,000 cubic meters of water and accounts for three quarters of the farm’s standing biomass. Plans are underway to transition fully to closed containment.

AgriMarine’s floating, semi-closed containment systems optimize the rearing environment for the steelhead, says Wilton. “Having our own farm and our own engineering group in-house allows us to learn and live what it takes to use floating closed containment in a real-world commercial environment. We have direct feedback from end users to designers and back again, and this is giving us a very rapidly developing practical knowledge base of the technology and its use,” he says.

He adds that sea lice are not an issue in the steelhead farm. “There are no sea lice in the lake. Our challenge is that it gets too warm in the summer. Key for us is the ability to isolate culture temperature from the ambient water around us so we bring cooler water up from depth of about 30 meters below our tanks.”

Having our own farm and our own engineering group in-house allows us to learn and live what it takes to use floating closed containment in a realworld commercial environment.

— Sean Wilton

This allows water in the tank to be maintained at 13 to 14˚C whereas the surface water temperature is as high as 26.5 ˚C outside the tanks. As the farm transitions to all contained systems, the tanks are operated alongside nets, allowing them to collect comparative data. Traditionally, net pens in freshwater lakes see marked spikes in mortality levels during the summer. In contrast, AgriMarine’s tanks and raceways have seen greatly reduced mortality rates that are in line with industry norms at saltwater marine sites.

Two tanks were delivered to a Norwegian specialist postsmolt producer over 2016/2017. The client has completed two crop cycles and reports excellent health and accelerated growth with both cohorts reaching target weight seven weeks ahead of schedule.

The company’s tanks are certified to the Norwegian NS9415:2009 construction standard — a very rigorous set of technical standards and quality control procedures enforced for all marine equipment in Norway.

“We believe we were first to achieve NS9415 certification for our floating tank technology two years ago and in some ways are still leading as we have more commercial production cycles through our technology than anyone we know of,” Wilton added.

“Combined with government incentives for Green Sites and other R&D support measures in other countries, some competitors have taken the lead in deployment footprint and we have to keep innovating to make sure those large well-funded engineering teams don’t catch up or pass us technologically as well,” he says.

BY JOHN G. NICKUM

Credit: Biotechnology Innovation Organization

AquAdvantage salmon are remarkable products of nature and genetic engineering. They are basically Atlantic salmon, but “snippets of genetic code” (DNA) taken from ocean pout (Zoarces americanus) and Chinook salmon have been added to eggs of the Atlantic salmon (see image). The result is Atlantic salmon that are essentially normal, except for the fact that they grow much faster and are little more cold-tolerant than their un-modified siblings. Their normal characteristics notwithstanding, AquAdvantage salmon have been controversial and have faced one challenge after another from environmental and consumer activists.

The latest controversy for AquaBounty involves an application to the Food and Drug Administration (FDA) to produce AquAdvantage salmon at a facility in Albany, Indiana. FDA has recently granted its approval, so the primary hurdle remaining for production at the Indiana facility previously owned by the Bell Fish Company is to develop acceptable labeling guidelines for the fish. Separate FDA approval for production at the Indiana site was required even though AquaBounty was given FDA approval to sell AquAdvantage salmon in the United States in 2015.

AquaBounty grows the genetically engineered fish in land-based recirculation aquaculture systems; therefore, there is no connection to natural waters and native fishes in the production area. Eggs are produced from fish held in secure facilities in Canada, primarily Prince Edward Island. Production facilities there and in Central America have been operating for several years without any environmental incidents, nor interactions with wild fish populations. Nevertheless, opposition to production of AquAdvantage salmon remains active, environmental activists, food safety activists, and wild fish protectionists remain vocal.

Controversy does not have to have bases in facts and reality to exist and thrive. Personal beliefs and parochial interests are typically the “fertilizers” that nourish controversies that lack factual support. The common “wisdom” that there are “two sides to every story” facilitates arguments even when one side has no evidence to support it.