US catfish farmers have to contend with oversupply in 2019

BY LIZA MAYER

The big story in catfish aquaculture in two years ago was that US farm-raised catfish production was able to meet demand for the first time since 2013. A year prior to that, in 2016, the industry saw annual sales of catfish farmed in the United States reach $386 million, a 7.2-percent growth over the average annual sales during the last five years. How times have changed. US farmers are now faced with oversupply, falling prices and an uncertain 2019.

Encouraged by record live catfish prices in 2016, farmers in the catfish-producing states – Alabama, Arkansas, Louisiana and Mississippi – raised more fish by building new ponds and increasing density in existing acreage.

“Some four or five years ago we didn’t have enough fish, people weren’t producing the fish because prices were down, and we couldn’t meet the demand,” recalls Sid Nelson, chairman of the Alabama Catfish Producers. “But when prices came back up, in 2015 and 2016, there was a pretty good expansion. A lot of the Mississippi farms went back into production. Some of them renovated ponds to make them more efficient and raise more fish per acre. Some went into producing hybrid catfish – the blue channel cross – you produce more per acre with that. So we produced more but it was just more than the market would stand.”

continued on page 8

Canada’s efforts to improve its aquaculture sector while protecting wild salmon populations have gained traction with a whole raft of strategies announced in December. Among them are initiatives that will clarify the complicated regulatory framework governing the industry, enhance aquaculture risk management, and explore alternative technologies for aquaculture.

The closure of fish farms situated in wild salmon migration routes in the Broughton Archipelago in British Columbia was also announced. We round up these landmark developments in Canada’s aquaculture industry on pages 4-7.

New markets, climate change, and growing pains marked the past year, will shape 2019

BY MATT JONES

was a busy year for the US farmed shellfish industry, filled with challenges, opportunities, and innovative ideas and techniques. American shellfish farmers have fought against regulatory hurdles and changing weather patterns while earning victories that will aid the industry in the future. But the industry’s growth could lead to a greater challenge of a saturated market that requires industry-wide cooperation.

COASTAL VIEWPOINTS

Official government statistics on the value of the industry are several years out of date, but Bob Rheault, executive director of the East Coast Shellfish Growers Association, estimates the industry is worth roughly half a billion US dollars per year. The west coast produces more than the east, while exact figures for the southern gulf coast are hard to come by. Rheault says the east coast saw a sturdy increase in production by existing producers and a steady influx of new entrants.

continued on page 12

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Aquaflor® is now approved for use in all freshwater-reared finfish at dose rates of up to 15 mg/kg*. It’s cleared for use in recirculating aquaculture systems, too.

S o whether you raise trout, tilapia, bass, catfish or even baitfish or ornamentals, you can turn to Aquaflor for managing the toughest bacterial diseases of farm-raised fish.*

For the full story, call our fish-health specialist, Kasha Cox, at 662.907.0692 or visit our new website at Aquaflor-USA.com.

It just keeps getting better AQU AF LOR

* In the USA, Aquaflor is approved for use at 10-15 mg/kg in freshwater-reared salmonids for the control of mor tality due to furunculosis associated with Aeromonas salmonicida and coldwater disease associated with Flavobacterium psychrophilum; in catfish for the control of mor tality due to enteric septicemia of catfish associated with Edwardsiella ictaluri; and in all freshwater-reared finfish for the control of mor tality due to columnaris disease associated with Flavobacterium columnare At 15 mg/kg, Aquaflor is also approved in freshwater-reared warmwater finfish for the control of mor tality due to streptococcal septicemia associated with Streptococcus iniae. LABEL CLAIMS NOT APPROVED IN CANADA.

CAUTION: Federal law restricts medicated feed containing this veterinary feed directive (VFD) drug to use by or on the order of a licensed veterinarian.

© 2015 Intervet Inc., doing business as Merck Animal Health, a subsidiary of Merck & Co. Inc All rights reserved. MAH-AQF-38

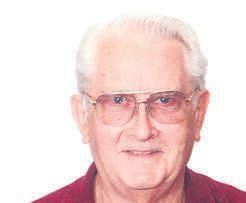

Global seafood company Marine Harvest has gone back to its roots by changing its name to MOWI – the name it started with more than 50 years ago when it was founded by Norwegian aquaculture pioneers.

The company will launch the MOWI brand into selected markets. The branded product line – yet to be announced –“will provide customers added value in taste, convenience, nutrition and traceability,” the company stated in a release.

Alf-Helge Aarskog, Marine Harvest CEO says a new product line carrying the MOWI brand will be announced in the coming months

“I am really excited that we are now taking the company to the next level. Through implementing our MOWI branding strategy, we can communicate our integrated value-chain from feed to the consumer’s plate,” said Marine Harvest CEO Alf-Helge Aarskog. “We are looking forward to announcing our new MOWI product line in the coming months.”

“MOWI is an inspirational name that recalls our pioneering spirit that has developed over the past 50 years,” Aarskog added. “Since the first salmon was farmed in 1964, we have grown into a global fully integrated company, including breeding, feed, farming, processing and sales. Throughout the past 50 years, we have always remained true to our core value – the care we have for our people, our fish, our customers and the environment.”

Upon shareholders’ approval, the name change will take effect from January 1, 2019.

Global farmed salmon production is expected to grow roughly 5 percent in 2018 to 2.4 million tonnes over 2017, with Norway remaining in the lead with 1.2 million tonnes, according to projections by Kontali, a provider of aquaculture data.

But while the growth is slightly higher than the 3 percent average per annum growth since 2013, it is still below the 7 percent annual growth seen from 1993 to 2013, noted Steven Rafferty, head of consultancy and design firm Global Maritime. The company designed the world’s first offshore farm, Ocean Farm 1, now in operation in Norway.

Addressing the audience at the National Policy Conference hosted by the Canadian Aquaculture Industry Alliance in Ottawa, Canada in October, Rafferty said production of salmon requires new technologies to overcome constraints to growth, such as sea lice and other diseases.

“If the salmon industry is to grow, new methods are required,” he said. He noted that in Norway, “the government is giving new concessions to new innovations and technologies, not to traditional methods.” Norway’s plan is to increase its current salmon production three-fold by 2030.

Anutrition researcher says human diet needs more shellfish because it has some of the most important essential nutrients humans need.

Professor Baukje de Roos, deputy director of the Rowett Institute at the University of Aberdeen in Scotland, discussed the major health benefits of seafood and highlighted the contribution of shellfish to a healthy diet at the conference of the Association of Scottish Shellfish Growers in Oban, Scotland.

Other farming producing countries can learn from Norway so they do to not fall behind in the new ways of farming, said Rafferty. He believes offshore and land-based farming will add production volume in the coming years, but support from central and local governments and from the largest farming companies is needed to make that happen. Investment and innovation, and improved infrastructure in some areas are also needed, he said.

Mussels, oysters, and king scallop roe contain Omega-3 levels between 1.1 and 2.4 grams per 100 grams of flesh, similar to oily fish such as mackerel, herring and salmon, de Roos was reported as saying by Seafoodsource. Omega-3 fatty acids help to protect against stroke and lower the risk of mortality from coronary heart disease.

“Micronutrients such as selenium, iodine, and zinc are also found in abundance in shellfish and all have important functions,” de Roos said. “Oysters in particular are high in zinc and would be a good addition to the diet of anyone with a deficiency.”

SUPPORTING YOUR SUSTAINABILITY GOALS AND NUTRITIONAL NEEDS

Darling Ingredients is a leading global supplier of animal nutrition solutions for aquaculture. We offer consistent, nutritional and reliable ingredients for the best aqua feed.

With a keen understanding of today’s markets, and through our trusted brands DAR PRO Ingredients and Sonac, we can provide you with essential proteins that will enhance the quality and value of your product.

food,

Seventeen Atlantic salmon farms operated by Marine Harvest and Cermaq in British Columbia’s Broughton Archipelago – a wild salmon migration route – will be phased out between 2019 and 2023.

The Province of BC and the ‘Namgis First Nation, the Kwikwasut’inuxw Haxwa’mis First Nation and Mamalilikulla First Nation, who own the traditional territories in which the farms operate, arrived at the decision following months of discussion.

“The success of this process shows that when the provincial government and First Nations work together in the spirit of recognition and respect, taking into consideration the concerns of the federal government and industry, we can deliver results in the best interests of all who live and work here,” said Premier John Horgan.

Marine Harvest Canada, which owns 11 of the 17 farms, and Cermaq Canada, which owns the rest, have greed to the decision, said the provincial government in a statement.

“Our Nations, together with many British Columbians, have been raising serious concerns about this industry for decades. We are grateful that governments and industry are finally starting to listen and work with us to find solutions that aim to protect and restore wild salmon and other resources,” said Chief Robert Chamberlin, Elected Chief Councillor of the Kwikwasut’inuxw Haxwa’mis First Nation and First Nations’ Chair of the steering committee. “There is much that still must be done, but these recommendations are a significant positive step in a better direction.”

John Paul Fraser, executive director of the BC Salmon Farmers Association, says the “historic agreement founded on reconciliation... creates new opportunities between industry and First Nations in the Broughton Area.”

The 17 farms will be phased out on a tenure-by-tenure basis between 2019 and 2023. Some farms will be immediately decommissioned while some will remain in operation for various terms (two to four years).

By the end 2022, 10 farms will have ceased operations. The remaining seven farms will cease operations unless First Nations-industry agreements and valid Fisheries and Oceans Canada (DFO) licences are in place by 2023.

“Consent” by First Nations and a stipulation from the DFO that the farm won’t endanger BC wild salmon are the new criteria that businesses applying for new fish farm licences or seeking to renew existing licences have to comply with beginning June 2022.

“We see the implementation of the recommendations as a positive step toward building mutual goodwill, trust, and respect as we work to earn First Nations consent of our operations in their territories,” said Diane Morrison, managing director, Marine Harvest Canada.

As pat of the agreement, a First Nations-led monitoring and inspection program to oversee those farms during the transition will be implemented. “We are committed to participating in the creation of the Indigenous monitoring and inspection program which establishes transparent oversight of our operations,” said David Kiemele, managing director of Cermaq Canada.

Spawning salmon. Shutting down fish farms in BC’s Broughton Archipelago is a ‘simplistic’ answer to the question why wild salmon populations are fluctuating, says the Atlantic Canada Fish Farmers Association Credit: Adobe Stock

Fish farmers in Atlantic Canada say the Canadian Government’s decision to shut down fish farms in BC’s Broughton Archipelago is a “simplistic” answer to the question why wild salmon populations are fluctuating.

The Province of BC and the three First Nations who own the traditional territories in which the farms operate announced in December that 17 Atlantic salmon farms in BC’s Broughton Archipelago – a wild salmon migration route – will be shut down between 2019 and 2023.

They believe the establishment of a “farm-free migration corridor in the Broughton” will help reduce harm to wild salmon.

‘No one really knows exactly why wild Pacific salmon populations are fluctuating,’ says Susan Farquharson, executive director of the Atlantic Canada Fish Farmers Association

“We reject the assumption that removing salmon farms from coastal BC waters will save wild Pacific salmon. It’s a simplistic notion that is not based in scientific evidence and does a disservice to the identification of the complex issues facing wild salmon on the west coast. The fact is, no one really knows exactly why wild Pacific salmon populations are fluctuating,” Susan Farquharson, executive director of the Atlantic Canada Fish Farmers Association, said in a statement.

She added that the Cohen Commission has listed more than 20 activities affecting pacific salmon, including climate change (marine and fresh water), loss of habitat, predators, non-point sources of contaminants, forestry, and cumulative effects.

At the launch of the International Year of the Salmon in Vancouver in October, DFO Emeritus Scientist Dr Dick Beamish says filling in the knowledge gaps in the factors affecting wild salmon abundance is the aim of a $1.1-million research expedition in the Gulf of Alaska in 2019.

The expedition could result in new research that will make the discoveries scientists need to actively forecast salmon abundance, he said. “We still don’t know the mechanisms that allow us to accurately forecast salmon,” Beamish acknowledged.

Farquharson noted that “Atlantic Canadian salmon farmers are leading the way in wild Atlantic salmon conservation activities, such as partnering in the Fundy Salmon Recovery Program with First Nations and all levels of government.”

Editor Liza Mayer Tel: 778-828-6867 lmayer@annexbusinessmedia.com

Advertising Manager Jeremy Thain Tel: 250-474-3982 Fax: 250-478-3979

Toll free in N.A. 1-877-936-2266 jthain@annexbusinessmedia.com

Art Director Svetlana Avrutin, Mark Ryan savrutin@annexbusinessmedia.com

Regular Contributors Ruby Gonzalez, Treena Hein, John Nickum, Matt Jones, Tom Walker

Group Publisher Scott Jamieson sjamieson@annexbusinessmedia.com

President & CEO Mike Fredericks

RETURN UNDELIVERABLE

Circulation Manager Barb Adelt Tel: 416-442-5600 ext. 3546 badelt@annexbusinessmedia.com

Subscriptions Angie Potal apotal@annexbusinessmedia.com Tel: 416-510-5113 Fax: 416-510-6875 or 416-442-2191

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2384

A subscription to Aquaculture North America (six issues) is $37.00+Tax within Canada, $37.00US

CANADIAN ADDRESSES TO: Aquaculture North America. CIRCULATION DEPT. 111 Gordon Baker Road, Suite 400, North York, ON M2H 3R1

United States Mailing Address Aquaculture North America, 815 1st Ave, #93, Seattle, WA, 98104

Canada’s seafood farmers will see the implementation of a number of initiatives this year that are aimed at improving the country’s aquaculture sector and further protecting threatened wild salmon populations.

“The Government of Canada is committed to making aquaculture more effective, efficient and environmentally sustainable,” stated Jonathan Wilkinson, Minister of Fisheries, Oceans and the Canadian Coast Guard. “Together, with Indigenous, environmental and industry partners, we will lead the way towards a more prosperous and sustainable aquaculture industry.”

The Canadian government is pledging up to $153 million to an initiative aimed at accelerating innovation and economic growth in marine-based industries. The fund will be matched dollar for dollar by the private sector in the Atlantic Canada-based Ocean Supercluster, a group of businesses, post-secondary institutions and non-profits working together to accelerate innovation and sustainable economic growth from Canada’s oceans. Cooke Aquaculture and Cuna del Mar, an aquaculture private equity firm, are among the participants.

“We are incredibly excited to have the contribution agreement signed and are eager to enter a new stage of the Ocean Supercluster,” said Kendra MacDonald, chief executive officer of Ocean Supercluster.

The funding agreement means the supercluster can move forward with activities to harness emerging technologies to strengthen Canada’s ocean industries such as marine renewable energy, fisheries, aquaculture, oil and gas, defence, shipbuilding and transportation.

It is projected that this supercluster will create more than 3,000 jobs and add more than $14 billion to Canada’s economy over 10 years.

Who’s in charge of Canadian aquaculture? In British Columbia, where Atlantic salmon farming brings in over $1.5 billion annually to the province’s economy, the Canadian government is the primary regulator. Provincial governments are otherwise the primary regulators in other provinces, with involvement of the Fisheries and Oceans Canada (DFO) in a number of aspects.

Jonathan Wilkinson, Canada’s new federal minister responsible for regulating the aquaculture industry, acknowledged in December the complicated regulatory framework governing the industry.

“Aquaculture in Canada is a bit complex in terms of jurisdiction across the country,” he said at the conclusion of the two-day 2018 Canadian Council of Fisheries and Aquaculture Ministers (CCFAM) meeting, which brought together ministers with statutory responsibilities over fisheries and aquaculture in federal, provincial and territorial levels.

The push for a Federal Aquaculture Act by Canada’s seafood farmers aims to simplify the framework. The ministers expressed support for and commitment to the proposal. The Aquaculture Act, they said, “gives expression of the legitimacy of aquaculture as legitimate user of the marine environment.”

“We have directed our officials to develop federal legislation that will respect federal, provincial and territorial jurisdictions and provide greater clarity for industry. That federal legislation will ensure Canada’s aquaculture sector is

a global leader in producing quality aquaculture product in an environmentally sustainable manner.

“In taking advantage of these opportunities, we are working together to solve the challenges ahead that will make Canada respected throughout the whole world

salmon farm workers heading to the boat that will take them to the farm. CCFAM ministers say the Aquaculture Act “gives expression of the legitimacy of aquaculture as legitimate user of the marine environment”

when it comes to sustainable products from the ocean,” Wilkinson, CCFAM chairman, told the press.

Part of the Aquaculture Act would be a commitment of and a recognition by all parties “that we need to have greater commonality of standards across the country;

•

that we need to be working towards ensuring that we are enhancing transparency in terms of how things are done; and providing greater certainty to the industry that investments in different parts of the country will be done on similar terms,” he said.

Wilkinson said however that this in no way means that the federal government will usurp the regulatory authority of provinces where the provincial government is the regulator. “There’s no intention on the part of the federal government to invade jurisdiction. There are mechanisms through which we can ensure that provincial jurisdiction where the provinces are the primary regulators will continue to apply. But greater consistency in a country like Canada is good for industry and is good for ensuring environmental sustainability. And it also allows us to convene a conversation that allows us to discuss things like best practices to ensure were doing everything that we can that to grow the industry in an environmentally sustainable way.”

The Canadian Aquaculture Industry Alliance (CAIA) welcomed the support of the ministers to advance the legislative development process for an Aquaculture Act in Canada.

“The timely development and passage of a federal Aquaculture Act is the most important and overriding need for the sustainable and competitive growth of aquaculture in Canada,” explained Timothy Kennedy, CAIA president & CEO. “There is such incredible opportunity for this young and innovative sector in Canada. This important support from the ministers is very much appreciated and will provide a fresh look at seafood farming in Canada. Canada remains the world’s only major farmed seafood producing country without modern national legislation specifically designed to govern a responsible and sustainable aquaculture industry.”

While the ministers recognized seafood farmers are

are

amongst the most sustainable producers

happy to compete to be even better”

already doing global best practices, there appears to be an intention to make regulations stricter under an Aquaculture Act. Kennedy welcomed them, saying: “We are already amongst the most sustainable producers in the world, and are happy to compete to be even better.”

CAIA said it and its members “stand ready to

collaborate with federal, provincial, territorial and Indigenous and non-government partners to draft and modernize federal legislation, regulations and programs keeping Canada’s seafood farming business competitive, sustainable, innovative and growing.”

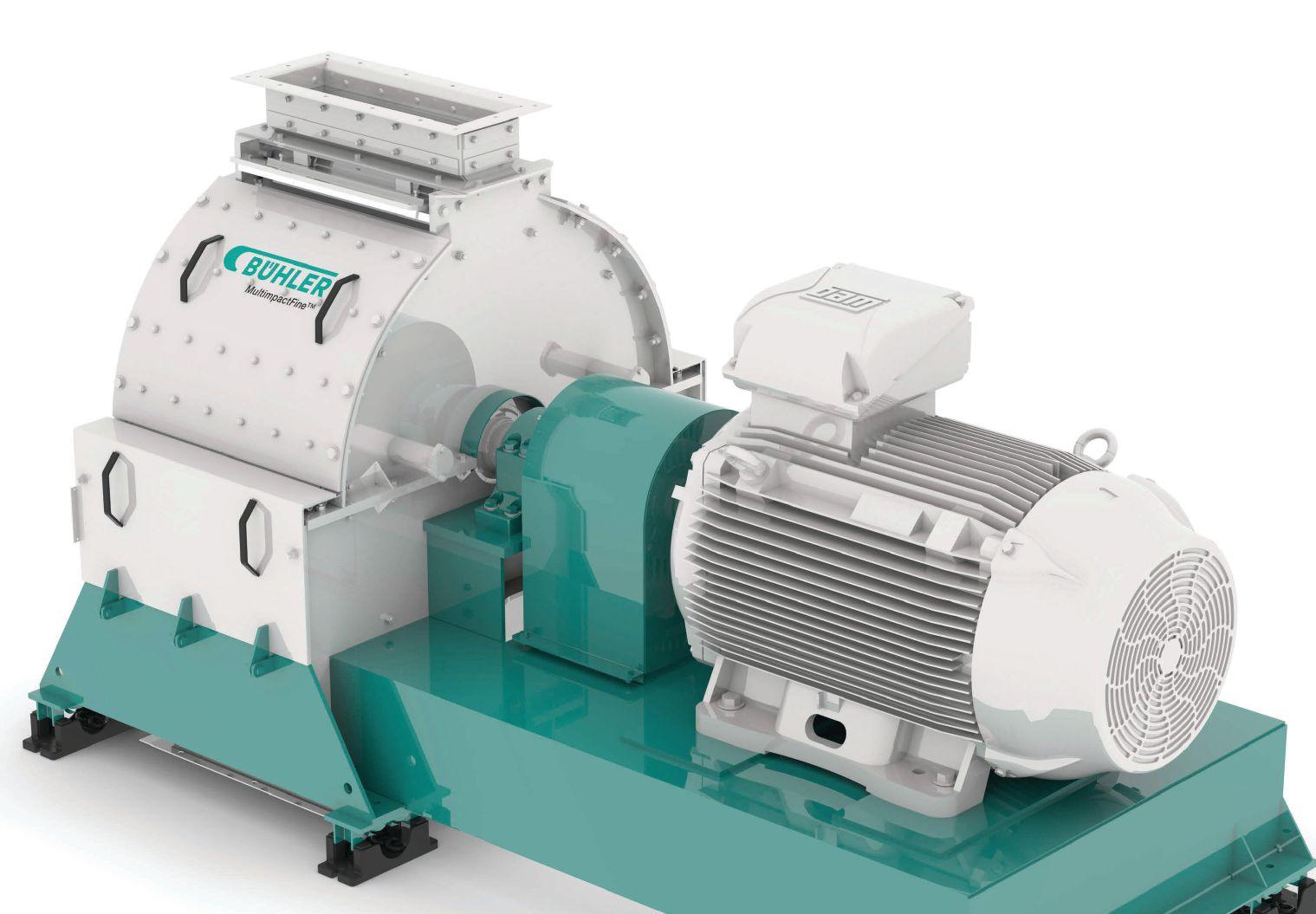

The heavy-duty MultimpactFine™ hammer mill uses proven, innovative technology to combine high-capacity grinding with uniform particle size distribution. From coarse to fine grinding to extrusion, drying and coating Bühler offers a complete line of flexible processing solutions that result in exceptional quality of floating and sinking aquafeed pellets.

Have a question? Let’s talk about it. buhler.minneapolis@buhlergroup.com www.buhlergroup.com

continued from cover

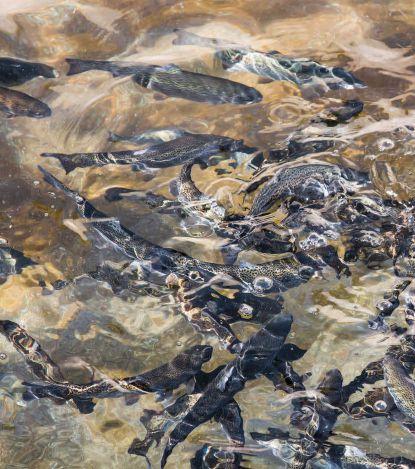

Live catfish prices have come down from their highs in 2016. The industry expansion from two years ago has left the industry with more fish than the market could absorb

Credit: The Catfish Institute

“The last year-and-a-half has been pretty bad,” acknowledged Townsend Kyser III, president of the Catfish Farmers of America. There was an oversupply caused by a lot of production increase and a warm winter in 2016 that allowed farmers to feed a lot more feed thus growing a lot more fish. If we have a 310-million-lb market and we raise 340 million lbs, the 30 million lbs of excess production takes about two years to work through the marketplace,” he says.

Compounding the oversupply problem is the addition of big fish in the mix – catfish weighing beyond the

maximum ideal of 4 lbs that processors want. In a slow market, catfish processors that have their own ponds begin to process their own fish first and buy from other farmers only when needed. Delay in getting the fish to market means they spend another year or so in the pond where they continue to feed and get too big, consequently driving down the price paid to farmers, explains Nelson.

In 2017, the average price for “premium” catfish weighing 1 to 4 lbs was $1.2 per lb, while “very large” fish weighing over 4 lb was only $0.71 per lb on average, according to the Catfish Economic Outlook presentation of Terry Hanson, professor and extension specialist at Auburn University.

“Big catfish give us problems. They depress the price,”

are the biggest problem for the US

industry

Nelson says. “Processors pay less for those they can’t process if they are over a certain weight. And hybrids too, they grow so much faster so this adds to that problem.”

Another challenge – although lately to a lesser extent –are imports of catfish-like products from Vietnam and catfish from Thailand. Since the 2001 implementation of a bilateral trade agreement between the United States and Vietnam, imports have taken some of the market from US farm-raised catfish. 2017 saw for the first time a decline in imports – by 18 percent to 228 million lbs from 279 million lbs in 2016 – according to the US Census Bureau. “Yes it is a little bit better than it’s been but they’ve stolen a lot of our markets with under-priced Vietnamese-

Live prices in 2018 reached a high of $1.03 per lb and a low of 94 cents per lb, down from 2017’s average range of $1.05 - $1.20 per lb, data from The Catfish Institute show

government-subsidized fish. Its been hard to win those markets back,” says Kyser.

For Nelson, Asian imports are the biggest problem for the industry. “In early 2000 we were a 650-million-lb industry as processed, dressed fish. In 2018 we were at 320 million lbs; we’ve been this size for the past six to eight years now. All of that came about because of imported fish. They came in and undercut the price. That knocked the industry down by about half. That’s definitely the biggest problem.”

“All we ask for is to test them under the same strongest tests we US farmers are subjected to,” he adds.

In the third quarter of 2018, certification of Asian imports began, according to Kyser, but he is skeptical about the quality of inspections those imports are subjected to at the source.

Kyser explains: “As the letter of law reads, they (exporting countries) have set up their own inspection program that are inspecting fish like they are supposed to, but I find it difficult to believe that they were able to put together in three months a program similar to ours that took us 18 months to set up, considering that the USDA was already upand-running as an organization.

“I can’t believe a third-world country will be able to set up so quickly something that we have been doing for years with meat, poultry, pork, and for 18 months for catfish. I find difficult to believe that their standards are the same.”

He acknowledged however that the imports are re-inspected at the US border “and tested for residues which we know they’ve been using.” “We are watching that closely,” he adds.

BUY AMERICAN

Kyser and Nelson encourage American consumers to specifically ask for “US FarmRaised Catfish,” which is The Catfish Institute’s generic brand. At supermarkets, Vietnamese catfish are labelled “pangasius,” “tra” or “basa” because they are a different species of catfish than the kind grown in the US (channel catfish). And to be aware of any “white fish” that cannot be linked to a source.

“Down here, on the menus now on the gulf coast, there’s white fish. If you look at white fish, it’s a fish grown in really cold water. That’s not what they’re getting there. White fish is nothing but a generic name for any kind of white fish they put on our plate. And most of it is pangasius. Consumers don’t know what it is. They know it as a

clean white ocean fish when it’s actually a farm-raised Asian fish,” says Nelson.

Kyser admits it’s hard to sell US farmraised catfish as a premium product beyond the traditional southern markets where catfish has been part of the culture - Lousiana, Arkansas, Missouri, Alabama, Mississippi and Texas, and a bit in Chicago and Los Angeles, California.

Both he and Nelson opined that processors have become complacent in promoting catfish into new markets partly because for a couple of years – 2014-2016 – there was supply shortage and therefore there was no need to promote to try to expand the market.

“The other problem is that different areas prefer different fish. Cod and pollock are more popular in the northeast, and in the northwest, salmon is way more popular, and catfish is just more popular in the south. If you’re going to come across fried cod on the menu in the south, it probably won’t go over very well because people around here are used to eating catfish, the same as if you go further south, it will be hard to get people to eat catfish,” Kysers observes.

The current reality in the US catfish farming industry is, unfortunately, not new. “Business had always been volatile for 50 years but the swings are getting greater and the margins are getting smaller, and your exposure and the cost of doing business is growing,” says Kyser. “It’s three to four times the risk now than there was 30 years ago and if there’s no reward for the risk there’s no sense in taking it. Two to three bad years could destroy a lifetime of building equity.”

Live prices in 2018 reached a high of $1.03 per lb and a low of 94 cents per lb, down from 2017’s average range of $1.05 - $1.20 per lb, data from The Catfish Institute show.

Despite the challenges, Kyser sees a glimmer of hope.

“You really could flip a coin in 2019,” he says. “I say that because there’s conflicting reports about what the swimming inventory of the industry is. One side of the coin is if the inventory is still too high and the fish is still too big then the price is still going to stay where it is. Other reports say yes there’s a lot of feeding out there but that feeding is maintenance-feeding larger fish and not growing a new crop. If there’s no new crop coming out from under last

year’s crop, then fish are going to be short. And you can really flip a coin because you can find arguments in either direction.

“I tend to want to believe that a lot of the feed that was fed was keeping a crop that was already there and not growing any fish under for 2019 so it will create a little bit of a shortage. Not shortage in the marketplace but a shortage to drive the price up a little bit for the farmers.”

“I don’t think we’re going to get a lot of relief in 2019,” says Nelson. “We have a lot of fish in the ponds, which is going to hold the price down. Hopefully it doesn’t go down anymore. There’s not enough time to generate more demand because it takes awhile to do that. So I don’t see a

lot of relief in 2019. Hopefully we make a little money but we’ll see.”

Meanwhile, some farmers are already thinking of exit strategies, both men say.

“There’s no expansion right now absolutely. There are a lot of people looking at exit strategies. If the industry does not get a turn for the better it will probably shrink a little bit more,” says Kyser. He notes that while farmers in the Mississippi delta could go back to planting crops, those in Alabama cannot. “I’m not sure what we can do with the ponds in Alabama. Our land is too hilly and it would be cost-prohibitive to reform the land to try to grow grain because grain is down as well.”

We understand the critical role Aquaculture has in advancing sustainable and responsible fish farming practices. At Dura-Cast, we manufacture a variety of durable open top and cone bottom

Benchmark Holdings, a specialist in manufacturing nutrition and health products for aquaculture, has won a case against Marine-Tech International (MTI) in Thailand for patent infringement.

The patents relate to the company’s hatching and enrichment technologies for artemia, which are used as live feeds in marine finfish hatcheries.

The Sheffield, UK-based biotech company filed a complaint at the Intellectual Property and International Trade Court in Bangkok in 2017 following unfruitful dialogue with MTI. The court awarded damages to Benchmark in November and ordered MTI to cease using Benchmark’s patented technology.

Hatching and enrichment technologies for artemia, which are used as live feeds, were at the center of the patent-infringement case Credit: Adobe Stock

The Kampachi Company says it expects its operation in La Paz, Baja California Sur, Mexico to see its first harvest of 4-6 lb King Kampachi (Almaco jack) this March after receiving $5 million in investments from asset manager Althelia Funds’ Sustainable Ocean Fund (SOF) in November.

The firm’s offshore grow-out pens are currently stocked with around 200,000 fish. It plans to market the sashimi-quality marine fish to restaurants and retailers in Mexico, the United States, Japan, and Europe.

“This investment by Althelia validates the scalable, environmentally-sound attributes of offshore kampachi production,” said Neil Anthony Sims, co-founder and chief scientific officer of The Kampachi Company.

This marks the first investment for SOF, which is a new Althelia Funds vehicle that’s

The Kampachi Company’s offshore growout pens in Mexico are currently stocked with around 200,000 fish Credit: The Kampachi Company

focused on investing in “scalable, impactaligned businesses to drive improvement in ocean ecosystems.”

AquaBounty expects to start commercial production of its genetically modified salmon this year Credit: AquaBounty

Massachusetts-headquartered AquaBounty Technologies says it expects to start commercial production of its AquAdvantage genetically modified salmon early this year after receiving a loan that will help to complete its production facility in Canada.

The facility, located in Rollo Bay, Prince Edward Island, has the capacity to produce 250-metric tonnes of salmon. The site includes an R&D hatchery and a broodstock facility.

The $1.6-million loan (C$2 million) was secured from the PEI provincial government.

“This facility will demonstrate the superior economics that AquAdvantage brings to land-based recirculating aquaculture systems. We are very grateful for the support we have received and continue to receive from the Province of Prince Edward Island,” said Ronald Stotish, AquaBounty CEO.

Roughly 20-30 technical jobs will be created once the facility is in operation, the company said.

In Indiana where it has another facility, the company has began raising traditional Atlantic salmon while waiting for approval from the US Food and Drug Administration (FDA) to import AquAdvantage salmon eggs. Stotish says this will enable the company to make any necessary adjustments to its processes or standard operating procedures while waiting for the FDA to lift the import restriction.

Meanwhile, expenditures have driven AquaBounty’s losses to widen in the first nine months of 2018 to $7.96 million from $6.6 million in the corresponding period of the previous year. The spending includes pre-production and production costs at the Indiana farm and R&D activities at the Rollo Bay hatchery, the company said.

“On the east coast, we’ve been seeing a very rapid expansion of oyster culture,” says Rheault. “Clam culture’s been pretty flat, even though prices have recovered a little bit from when prices collapsed about 20 years ago.”

Margaret Pilaro, executive director of the Pacific Coast Shellfish Growers Association, says the most significant development on the west coast has been the adoption of the Army Corps of Engineers Nationwide Permit number 48 in Washington State, where the majority of west coast shellfish farming occurs. Getting issues surrounding the permit resolved was a 10-year effort.

“What that now means is that our farms for shellfish aquaculture have permits, and that helps us to understand if there’s a path forward for more opportunities for shellfish aquaculture or to expand existing farms,” says Pilaro. “That’s exciting, and something that we may see more of here in 2019, now that the permit has been solidified.”

Another major development for both coasts has been the agreement to resume shellfish trade with the European Union on a limited basis – Massachusetts and Washington will be allowed to trade with the EU in 2019. Around a decade ago, the US Food and Drug Administration declined to allow Great Britain to export shellfish to the US over norovirus concerns. In what Rheault sarcastically describes as “a remarkable feat of acting like adults,” the EU retaliated by disallowing US shellfish exports.

who wish they had access to that market.

“2019 will probably see us working to ensure that other states are afforded that same opportunity,” says Pilaro. “There’ll be attempts to level the playing field and open it back up for the other states as well.”

CLIMATE CHANGE IMPACTS

One of the most talked about issues of 2018, in any sector, is the impact of climate change, as seen in extreme weather patterns and powerful tropical storms. These storms can have widereaching impacts on the industry. For instance, when an important sewage treatment plant in Newark was flooded during Hurricane Sandy (as with most sewage treatment plants, it was situated in a low-lying area), it was six months before they sold another shellfish out of New Jersey, says Rheault. “I think that’s going to become more common,” he says.

“In the south-east especially, there’s really been some harm to the industry by these really intense hurricanes,” says Bill Mook, owner of Maine’s Mook Sea Farm. “If you want to talk about the year in review, you can’t ignore that, both in North Carolina and Florida.”

Mook, along with six other producers representing both coasts, decided to tackle this issue by forming the Shellfish Growers Climate Coalition (see sidebar).

NATIONWIDE STANDARDS LACKING

Credit: Thierry Chopin

Rheault says that while he hasn’t seen too much interest from Massachusetts in selling to Europe, there is some jealousy on the part of operators in other states

One of the most enduring challenges for the industry is inconsistency of regulations and standards across various states. Timothy Londregan, owner of Connecticut’s Niantic Bay Shellfish Farm, says that the permitting process is much easier to comply with in some states than others. The adoption of relatively new equipment like tumbler

The increasing acidity of seawater, known as ocean acidification, should serve as a wake-up call to the industry, says Bill Mook, owner of Mook Sea Farm. One of the effects of the phenomenon is the diminishing size and falling population of oysters, according to a study carried out by Scottish and Australian scientists on Sydney rock oysters in New South Wales.

“Everybody felt ocean acidification is a problem that’s only going to get worse, but it’s also not the only thing that’s related to climate change that is impacting us and starting to cost our businesses,” says Mook. He and fellow shellfish farmers behind Fishers Island Oyster Farm, Taylor Shellfish Farms, Island Creek, Rappahannock Oyster Co, Hama Hama Co and Hog Island Oyster Co decided to do something about it. “The feeling was that we should start to address, to the extent that we can, the root cause of the problem, which is greenhouse gas emissions,” he says.

Over the course of a series of discussions in early 2017, the group decided that the best approach would be to find a politically neutral nonprofit that can lead a national effort. Thus was born the Shellfish Growers Climate Coalition, led by The Nature Conservancy. The organization was deemed the ideal partner because it has presence in every state and can call on members of the coalition to testify to climate-change impacts on the state level.

baskets or floating bag culture, which are helping drive the growth of the industry, is slow moving.

“In Connecticut, you can do anything you want, but it has to go through the full-blown process,” says Londregan. “If there were standards established, if what you propose fits the standards, then that’s one hurdle already cleared.”

Londregan is also frustrated by the inconsistency in funding for state aquaculture programs. The Connecticut Department of Aquaculture, in his experience, lacks the capacity the keep the industry moving.

“I have a product, I’m ready to sell, I have the capacity, but I need the green light from you guys,” says Londregan. “The green light should be on, but it’s off because there’s not enough staff to do all the paper work, to do all the testing, to even have a boat in our part of the [Long Island] Sound. They fully support me, but they’re being pulled in five different directions and they can only go in one.”

While the growth of the oyster farming industry is encouraging, Rheault is concerned about the possibility of market saturation. He’s already seen it happen with clams, tilapia, catfish, and salmon – we learn how to grow a product, the market gets flooded and the price drops.

“I’ve been singing this song for 30 years,” says Rheault. “It’s been my recurring fear that we might crash the price of oysters.”

The solution, Rheault says, is to master marketing. As marketing skills and shellfish farming savvy don’t necessarily go hand-in-hand, he believes forming a cooperative will be the answer. That way, one skilled professional can handle marketing for a collective of producers. Such is the idea behind Panacea Oyster Coop (see ANA, March/April 2018), a Florida cooperative that brings oyster farmers together to share experiences, get support and have a guaranteed place to sell their product, at a guaranteed price.

As more inexperienced participants join the industry, product quality can become an issue, however. Bill Dewey, director of public affairs for Washington’s Taylor Shellfish Farms, says that some new entrants don’t understand the importance of maintaining quality. For that reason, he’d like to see the adoption of nationwide standards for quality and size, such as those in the EU.

“The industry there is 10 times the size of that in the US,” notes Dewey. Nationwide standards may seem like a

pain to comply with, but they’ve driven the EU market to grow to the extent that is has, he says.

Promoting the industry and increasing market share by attracting people to consume shellfish products is also key to the industry’s future. “I don’t know how effective we are at creating new shellfish lovers every day,” admits Pilaro. “That’s part of what we want to try to do.”

Mook, however, believes that such efforts should be an industry-wide task. “I believe it’s possible but it’s going to take spending money on marketing, and not just companies promoting their own brands, but really encouraging people to eat more of these products,” he says.

“It’s what I call an endorsement coalition,” says Mook. “The idea is to give The Nature Conservancy access to people with real stories that are experiencing real impacts of climate change in their businesses now. The feeling is also that in this day and age in politics, businesses carry more weight than non-governmental organizations. For us, it’s a way to feel like we’re doing what we can to address the root problem that has now been underlined in red ink.”

Aquaculture in US federal waters is inevitable, but there are important regulatory issues that will have to be addressed before that can happen. One issue is licensing of veterinarians, who play an essential role in aquaculture operations. Veterinary licenses are administered by individual states, but under whose jurisdiction do they fall under in federal waters?

The American Veterinary Medical Association (AVMA) sought to answer this at a meeting in November in Rosemont, Illinois, with 50 representatives from 17 states and other stakeholders.

“Looking at a veterinarian doing work on animals that are in federal waters, outside of state jurisdiction, we saw a regulatory issue that needed to be talked about,” says Dr Warren Hess, assistant director of AVMA’s Division of Animal and Public Health. “More importantly, this needed to be communicated to the states that might be facing this, to make them aware of the fact that we do have a gap here.”

Veterinarians are licensed at the state level, but what will happen when aquaculture moves into American federal waters? The AVMA held a meeting this November in Illinois to discuss the issue Credit: Adobe Stock

The AVMA offered several recommendations to attendees. In the absence of a federal license, a veterinarian operating in federal waters should be licensed in at least one state. They should be accredited by the US Department of Agriculture (USDA)’s veterinarian service as a Category 2 veterinarian, which will allow them to work with federal and interstate movement papers for any animal species. They should have taken some accreditation modules for aquaculture. And the USDA’s Animal and Plant Health Inspection Service should be the animal health authority for animals in federal waters.

The issue will only impact a small handful of veterinarians initially because companies will be hiring only highly qualified and experienced veterinarians in the early days of aquaculture in federal waters, Hess notes. But the issue will have to be addressed before the industry can properly be established in federal waters.

“It really becomes a gap,” says Hess. “It is an area where veterinarians may feel more vulnerable, because they’re thinking: ‘there’s no licensing body to back me up. If things fall back to either one or more of the states in which I’m licensed because of an issue in federal waters, how is that state going to react to it?’ Every state has a different policy or rules or legislation on what actions they might be able to take on a veterinarian who may not have been doing things correctly outside of their jurisdiction. There is no straightforward answer, but we’re trying to patchwork some things together to make states and veterinarians feel more comfortable knowing there’s a general agreement on how these things should go forward.”

Discussion groups at the November meeting suggested other potential solutions, such as the creation of a federal governing body that would be responsible for licenses in federal waters. Hess says the AVMA will present their recommendations at the United States Animal Health Association’s annual meeting in October 2019.

– Matt Jones

Ahe ability to adapt and innovate is crucial in ensuring the future of the marine ingredients industry.

This was the message of IFFO’s President Eduardo Goycoolea at this year’s IFFO conference in Rome. Goycoolea spoke amidst renewed pressure for the industry to embrace more sustainable practices, and the push for aquaculture to reduce its reliance on marinederived fish feed ingredients.

“As an industry you have adapted your products to ensure the success of the aquaculture industry, but as resources continue to become scarcer, more innovation will be needed. There are huge opportunities in producing further new marine ingredients from our oceans, your future is in your hands, be true to your name,” he told conference attendees.

Dr George Chamberlain, president of the Global Aquaculture Alliance, said marine ingredients are “the gold standard” but agreed with Goycoolea that “supply needs to increase through by-products and the development of new innovative sources.”

‘Marine snow’ could be key component in eel farming

In the latest push to perfect the technology to make eel farming commercially viable, Japanese scientists are looking at “marine snow” as potential diet for the slippery creature.

The so-called marine snow is the decaying sea detritus –comprised of dead plankton and other decaying organisms – found at the bottom of oceans.

If baby eels, or elvers, could survive on this diet harvested from the sea, that would be the next breakthrough in the efforts toward commercial production of fully farmed eels, Prof Takashi Sakamoto of Tokyo University of Marine Science and Technology told The Financial Times

Japan is on a quest to make eel farming – from egg to maturity – commercially viable. The nation is the world’s largest consumer of the slippery fish but shortage of eel from the wild has caused a spike in prices.

The RAS2020 creates a highly-controlled environment that supports healthy fish growth. The patented design allows fish to swim naturally against the current and reduces handling. This decreases fish stress, improves growth rates, and ensures a quality final product.

We are ready to help you. Our team of global aquaculture experts will help you maximize fish quality and production yield, while delivering a cost-effective and environmentally responsible solution.

Freshwater is used to treat amoebic gill disease (AGD) in salmonids but when it poses a logistical challenge, hydrogen peroxide treatment may be used. The effectiveness of the results, however, depends on the water temperature.

The study, Effect of hydrogen peroxide as treatment for amoebic gill disease in Atlantic salmon (Salmo salar L.) in different temperatures, estimated the effectiveness of different doses of hydrogen peroxide to treat AGD-infected Atlantic salmon at a range of seawater temperatures.

Researchers Martinsen K.H., Thorisdottir A., Lillehammer M. of NOFIMA and VESO Vikan

laboratory found that the treatment was most effective at a low temperature of 8°C, which was tested with hydrogen peroxide doses of 1.5, 1.8 and 1.2 g/L.

Treatments were performed in tanks with aerated seawater (33‰ ± 2‰). Doses were decreased as the temperature increased.

At 8°C, subsequent development of AGD infection was delayed substantially by roughly 8.5 weeks, compared to 1.7 weeks at 12°C and 1.5 weeks at 17°C.

AGD is a pathogenic disease in salmonids caused by Neoparamoeba perurans. It attacks the respiratory system of the fish, causing lesions or white and gray mucoid spots on the gill surface, which lead to reduced gill function. Infected fish are lethargic and exhibit reduced swimming activity, increased respiratory rate, reduced feed intake and reduced growth.

The development of the disease is dependent on seawater temperature and salinity, making AGD a problem for the farmed salmon industry in areas with high salinity and seawater temperatures.

“Both freshwater and hydrogen peroxide treatment may cause mortalities as the fish is already weakened by the disease and the treatment itself can cause additional stress to the fish. Neither treatment seems to be fully effective, as AGD reappears in treated fish, both under natural and controlled experimental conditions.”

“Hydrogen peroxide as treatment for AGD was shown to be successful for all combinations of doses and temperatures tested. The gills partially recovered following treatment and further development of the disease was delayed. However, all groups developed the disease again after treatment, suggesting that fish were not cured,” the authors wrote.

The same was observed in the freshwater treatment.

“Both freshwater and hydrogen peroxide treatment may cause mortalities as the fish is already weakened by the disease and the treatment itself can cause additional stress to the fish. Neither treatment seems to be fully effective, as AGD reappears in treated fish, both under natural and controlled experimental conditions.”

They concluded, “repeated treatments are, therefore, necessary, sometimes several times during a life cycle.”

“Furthermore, it is important for both economic considerations and fish welfare that the method used is both effective and gentle on the fish,” said the authors.

–

BY TREENA HEIN

If you’ve been to Eastern seaboard, you may have heard of Captain Clam. His name is Edward Stilwagen and hard clams have been part of his life since he was very young, in the 1940s, when they were worth only 2 cents apiece. Stilwagen is now 80 and has been the proud owner of Atlantic Clam Farms since 2000, when he started the business. “I was an engineer in the 60s in New York City, but I wanted to be out in the sea,” he shares. “I quit and started selling seafood to restaurants, then one thing led to another and I got more involved in the industry.”

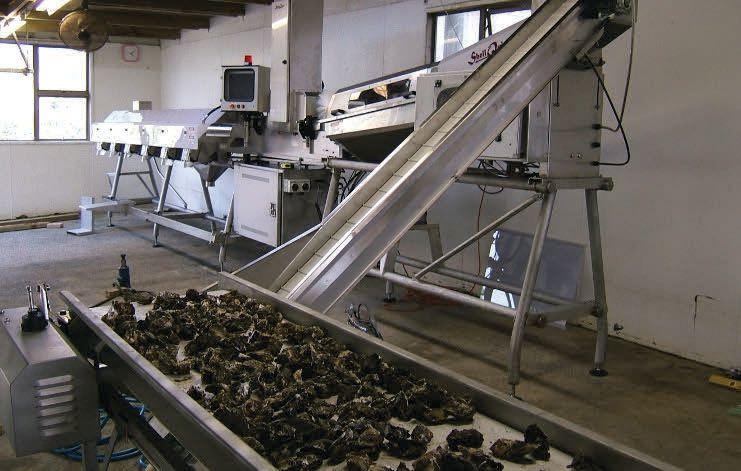

In the 80s he invented a clam sorting and counting machine and sold a lot of them. “They’re used all over the world. I got to know everyone in the industry that way. I sold that business in the 90s and then got into boat and general marine manufacturing,” he says.

Clam harvesting usually involves vessels trawling the ocean floor, but this dredging is in some ways destructive. Stilwagen invented a system wherein a minimal jet of water first loosens the clams and a vacuum system sucks them up onto a conveyor into the boat. The clams are then cleaned of various small sea bottom tag-alongs, baby clams and extraneous shell material, which are all returned to the ocean. The clams are then sorted and counted into bags on the boat and come to shore ready for market. Stilwagen says his system is very gentle on the ocean floor and works very well.

It was perfected just in time. In 1999, Stilwagen heard about some clam farm lots available for lease off the coast of Greenwich Connecticut in Long Island Sound and purchased them. “The leases are in perpetuity as long as you pay,” he says. “You pay every year what you paid the first year.”

He runs his two boats over 4,000 acres in total – 3,000 leased from the state and another 1,000 from Greenwich –harvesting about 15 million clams on average annually with the help of 10 employees. The boundaries of lease lots were marked with buoys and flags years ago, but the industry has now turned mainly to using GPS since Stilwagen started.

Atlantic Clam Farms sells a small amount of its inshell live hard clams to three area restaurants, but most of them go to a large wholesale distributor that sells them in Connecticut and adjoining states. Stilwagen says the smaller ones are eaten mainly raw on the half shell, and larger ones are usually cooked in various sauces.

In 1960, Stilwagen explains that the great south bay in Long Island was largely devoid of clams. Then an enormous “set” took place and by 1964, the harvest was really high. In fact, at that time, the area accounted for 50 percent of US production. Two clams can produce five million offspring and clams need three to five years to grow. Stilwagen notes that the harvest goes up and down every year, depending on natural conditions mostly related to food. He says hard clam harvest is sustainable as long the clams are reproducing as they should.

Fuel prices have increased over the years, but Stilwagen says it’s not a very large operating cost, and that clam prices have also gone up. “In the 1940s, they were two cents a piece and now I get 30 to 35 cents for the small ones and 12 to 15 cents for the big ones,” he reports. “The smaller ones are in greater demand. There really isn’t much competition. There are not enough clams for demand. Everything always sells.”

One challenge is land-based pollution found in rain runoff (which negatively affects clam quality), but it’s a situation that Stilwagen says is handled very effectively in a team fashion. “It depends on the year and there really hasn’t been a big increase in rain over the years, but if there’s a lot of rain, the Connecticut Aquaculture Department will shut down the beds for a while,” he explains. “Three inches closes everything for about two weeks, for example. After some time, they do a water test and then test some clams and oysters and lift the ban when all is okay. But I’ll tell you, the water is much cleaner now than it was in the 80s and 90s. We have a Harbor Watch and if there is polluting going on, they will find the source and shut it down. They have been very beneficial for the whole industry and we support them financially to do this work, and other groups do as well.” Stilwagen says the state government is quite supportive of the industry, and that Connecticut is one of the few states that allows machinepowered clam harvesting. He never has a problem finding employees.

80-year-old Edward Stilwagen farms over 4,000 acres in the Long Island Sound, which bring in over 15 million clams annually

Credit: Tyler Sizemore, Greenwich Time

However, respect for Mother Nature is needed. “The saltwater environment is rough on machinery, and you can run into a rock, storms, ice in the winter,” he says. “We harvest every day and you have to criss-cross and never wipe out a whole area. There are hot spots with a lot of clams growing faster and other spots that need more time. It’s a wonderful resource, and you just have to protect it and respect it. You can’t physically see what’s down there, being in a diving suit is no use as there is no visibility, so harvesting properly is a matter of experience.”

Besides his experience, Stilwagen attributes his success to being friends with everyone in the industry and also to his engineering background. “We all get along and we help each other,” he says. “It’s a good place to be. I’ll never starve. I’ll always have clams to eat. My favourite is eating them in the half-shell with a little horseradish. They’re really good.”

Tying salmon farming to the United Nations 2030 Sustainable Development Goals (UN SDG) and selecting the right technology could neutralize biases against farmed salmon, suggests an industry executive.

Farmed salmon fits the profile of the protein source per the UN SDG 2, Zero Hunger.

Among fish, farmed salmon has the highest protein content. Its carbon footprint of 9.8 percent, edible yield of 68 percent, and its feed conversion ratio of 1.15 is the lowest compared to other proteins.

“When we look at the farmed animals that we currently eat, we are definitely able to consume more of the fish and produce it in much less space,” said Rachel Major, business development representative at Deep Trekker.

Major cited statistics during her presentation at Aquaculture Canada 2018, titled Aquaculture for global health: Sustaining the United Nations Sustainable Development Goals with remotely operated vehicles. The annual production of 3.2 million tons of farmed salmon lags far behind other proteins, with beef production at 60 million tons per year, chicken at 107.1 million tons, and pork at 118.3 million tons.

UN SDG 14 Life Below Water focuses on the conservation of the oceans, seas and marine resources. However, at times, it seems to be incongruous with fish farming practices, said Major. This is where technology comes in.

Aquaculture has been called out for the perceived negative impact to the environment, particularly in terms

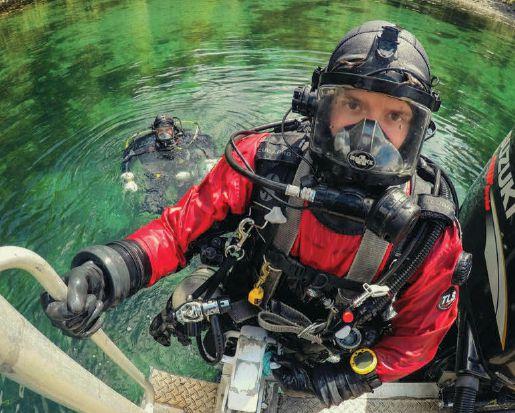

Deep Trekker’s DTG2 remotely operated vehicle provides site managers and fish farmers the

cages, moorings and stock health from the surface of the farm. With increasing demand for sustainable protein, developing technologies in support of aquaculture is critical Credit: Deep Trekker

of water pollution and fish escapes. Remotely operated vehicles (ROVs) are an option that could minimize fish farming’s impact on the environment.

“Now more than ever before, underwater robots are making it possible to protect the environment, giving fish farmers eyes under the waves and allowing them to monitor water conditions effectively and in an environmentally savvy way,” Shannon Regan, communications specialist at Deep Trekker, told Aquaculture North America (ANA)

Visual monitoring of the fish feeding behaviour allows farmers to reduce overfeeding and waste. From what they see on the sea floor, they also get to make informed decisions on fallowing or recycling the pen to protect the ocean environment, Major said.

Feed represents about half of the operational cost for the

farmers so being able conserve and minimize wastage of the feed is crucial.

Attachments to the DTG2 ROV, their most popular product, such as the laser scaler and mort retrieval system are used to monitor and perform preventative maintenance and ensure the integrity and cleanliness of the farm environment. The cost of a diver to perform similar tasks is two to three times more than a single purchase of a DTG2 ROV, Regan said.

“The difference between running a sustainable operation and one that can poses risks to the surrounding environment depends on how often fish farms are inspected. It is recommended that farms are inspected on a daily basis,” she said.

– Ruby Gonzalez

Aplanned aquaculture project in a coastal community in Newfoundland, Canada may require immigration from outside the province to fill job vacancies, but contrary to media reports, that will be a last resort, a partner in the project told Aquaculture North America (ANA)

Businessman Paul Antle, whose firm Pluto Investments is a partner in the Marbase Marystown project, was quoted in a CBC article that indicated that the project may have to look beyond the province for workers.

“It’s one thing to create the jobs; it’s another thing to fill the jobs,” Antle told CBC Newfoundland. “That’s why immigration is so important for this province…I don’t think we have enough, and our economy can’t sustain the drag on the human resource base that we have. We need more people.”

Antle told ANA his comments were taken out of context, and that their agreements with local unions dictate that they must follow a specific “pecking order” in the hiring process.

“Any employment for skilled trades, we’re first going to look at the existing seniority lists of the union members, number one,” says Antle. “If positions are not filled, then we can go outside and hire from the community at large. We have promised, for example, the town of Marystown where we’re located that we will do our best efforts to hire locals before we go any further. If the skill sets are not available in Marystown then we’ll reach out to other communities close by, in the rest of the Burin Peninsula.”

If workers can’t be found in the local area, then they will look to the rest of the province, then the rest of Canada. Only after all other avenues have been exhausted would they look at hiring from outside of the country. Antle says that the comments CBC used were from an interview he had given several weeks before the article was posted.

The project is expected to generate 50-100 jobs in the first year, and over 200 in the following years. Antle says that there is an open dialog with both Memorial University’s Fisheries and Marine Institute and the College of the North Atlantic, looking at ensuring that locals have ample opportunity to obtain any necessary training.

A former shipyard in Marystown has lain dormant for some time, and the municipality is in the process of purchasing it. It will then be leased to Marbase Marystown, a joint venture of Pluto Investments and Norway’s Amar Group. The facility is planned to be a fully integrated service hub for the aquaculture industry in the Atlantic region.

– Matt Jones

Made in the USA and distributed globally to the aquaculture market by Sivat Services, these blowers include:

• Options for multiple electrical configurations and for extreme duty special coatings.

• Large line of accessories: intake filters, inlet/outlet mufflers, sound attenuation cabinets, pressure regulators, moisture separators and VFD’s Invest in the best equipment for your RAS facility.

Mussels are being wired with sensors on Canada’s East Coast to monitor water quality and potentially protect marine life, including salmon.

Mussels have a distinct response when exposed to toxic algae, Luc Comeau, Canadian fisheries scientist with the Department of Fisheries and Oceans, told the CBC. He added that the sensors capture and recognize the mussels’ shell movement.

“If something is strange in the environment, they will behave strangely,” Comeau told the news outlet.

The testing ground is a floating monitoring station at the Cooke Seafood salmon farm in Halifax, Nova Scotia.

The sensors monitor movements 10 times a second, using only solar panels. The data produced is so extensive that the Dalhousie University department of computer science has been brought on to help sort through it all.

The consequences of algal blooms going unnoticed could mean feed and growth changes for the salmon.

Cooke Seafood has invested $2 million into the research.

Wisconsin Sea Grant received funding from the National Oceanic and Atmospheric Administration’s (NOAA) National Sea Grant College Program to examine and overcome three critical barriers to the growth of land-based Atlantic salmon production in the Great Lakes region.

The findings from this study will help ensure the best standard operating procedures for quality and efficiency and will be available to all commercial producers of salmon harvested from RAS, said The Freshwater Institute.

“Land-based closed containment operations using RAS technology offer an economically viable, sustainable, and local means of aquaculture production. The Freshwater Institute is proud to partner on this work and to contribute scientific research and development to support the growing land-based aquaculture sector and facilitate domestic agricultural economic contribution, job growth, and food security,” said Brian Vinci, director of the Freshwater Institute.

The $245,000 in federal funds that Wisconsin Sea Grant received is a portion of $11 million in grants that NOAA allocated for 22 projects aimed at advancing aquaculture in the United States.

Researchers in the Wisconsin project will focus on two key issues that have hampered the continuing growth of the land-based salmon industry in the US: fish health and fish flavor.

“Land-based salmon aquaculture is growing by leaps and bounds in North America. This research study is very exciting because it is really going to help the industry. We are working in close concert with private partners that are doing this type of aquaculture right now,” said Greg Fischer of the University of Wisconsin-Stevens Point Northern Aquaculture Demonstration Facility (NADF), who will serve as the project’s leader and research team organizer.

The walleye (Sander vitreus) is a favorite food fish and sport fish of millions of Canadians and Americans residing in the Great Lakes region and northern Great Plains. The flesh – white, firm, and mild in flavor – is very pleasing to most palates. Although the walleye is not a great fighter, it is a very popular sport fish because of its favorable characteristics as a food item. The opening of the walleye fishing season is almost a state holiday in places such as Minnesota and Wisconsin. When I was a teenager in Minnesota many years ago, the start of the walleye season was an acceptable reason for skipping school for thousands of youngsters and their families in our area. Given nearly reverent respect for walleyes across much of North America, it’s reasonable to ask: “Why hasn’t the walleye become a major species for aquaculture?”

Before I offer some speculative answers to that question, I think a brief review of walleye biology and the history of walleye culture is warranted. Walleyes are considered to be a coldwater fish, which means they thrive in waters with temperatures lower than 24C, preferably less than 20C. Walleyes are basically carnivorous; they prey on others, including smaller walleyes. First-feeding walleyes typically feed on rotifers and cladocerans, however, one report from Ohio showed heavy consumption of diatoms (a group of algae). In the wild, walleyes begin feeding on smaller fish by the time they reach 10 to 15 cm in length and are completely piscivorous by the time they are 20 cm in length, although a thesis study in South Dakota showed that fingerling walleyes continued to feed on dense populations of large daphnids up to a length of 20 cm. When I first began studies on intensive culture of walleyes in the 1970s, experienced fishery biologists advised me to forget about it because walleyes would rather eat each

other than pellets of formulated feeds.

Traditional walleye culture, as practiced at state and federal hatcheries, consisted of either feeding first-feeding fry slurries of rotifers and/or zooplankton in tanks or troughs, or stocking them into fertilized ponds that were managed for dense zooplankton populations. In all cases, pond culture began no later than the time the fingerlings reached 10 cm. The fingerling walleyes were generally stocked into public lakes by the time they reached a length of 20 cm. The first indications that walleye might accept pellets of formulated feeds came from Ontario in the early 1970s. This breakthrough stimulated research on all aspects of intensive culture by scientists and hatchery managers across the northern United States and southern Canada. Detailed discussion of the hypotheses tested, the results analyzed, conclusions developed, and recommendations produced are far too lengthy for a brief op-ed style article, such as this one. Readers interested in such details should obtain a copy of “Biology, Management, and Culture of Walleye and Sauger” (Bruce A. Barton, Editor, American Fisheries Society, 2011).

Rearing walleye under intensive culture systems to market sizes of approximately 1 kg can be done, but it has proven to be a task filled with many strange twists and turns in addition to a proclivity for eating their siblings. Research conducted by one of my graduate students in the late 70s, Luciano Corrazza, found a surprising link between their behavior and the intensity of light and the background color of the rearing tank: walleye fry are intensely photopositive and were so strongly attracted to the walls of the culture tank that they attached to the walls and did not feed. Neutral, gray-colored walls and uniform

BY JOHN G. NICKUM

distribution of feed particles solved this problem. The behaviors and mechanics involved with initial filling of the fry’s gas bladders provided another set of issues that culturists have not experienced with traditionally cultured species such as trout and salmon.

A recent presentation by Gregory Fischer of the University of Wisconsin-Stevens Point’s Northern Aquaculture Demonstration Facility may bring the longheld dreams of walleye enthusiasts to fruition. Fischer and his colleagues found they could rear walleye and hybrid walleye to market size (some fish reached 1 kg in 12 months) in an intensive culture system based on water recirculation and a domestic broodstock. They were able to successfully manipulate spawning and hatching, then rear the resulting offspring to full market size.

Whether or not the systems and techniques developed by the researchers in Wisconsin, Iowa, Ohio, New York, and Minnesota will lead to economically successful production of walleyes, hybrid walleyes, saugeye, and/or zander, remains to be seen. Systems that are biologically and technically feasible are not always economically feasible. For example, one of my former students developed a cage culture system to produce fresh walleyes for local markets in Iowa; however, cheaper, imported products from capture fisheries based in Lake Winnipeg and Lake Manitoba flooded the market and drove him out of business.

Walleye aquaculture that’s biologically and technically successful appears to have been developed. Whether or not walleye culture can be economically successful remains to be determined. Yet another question is the potential effect of global warming – the warming waters could force walleye entrepreneurs to move further and further north.

Photo titled “Releasing some chinook fry in Surrey!” by contestant Fernando Lessa bested other entries in the International Year of the Salmon Photo Challenge in the North Pacific. The competition, which ran under the theme “Salmon and people in a changing world,” is part of the

celebration of 2019 as the International Year of the Salmon (IYS). A highlight of IYS is a $1.1M research expedition in the Gulf of Alaska co-funded by the BC Salmon Farmers Association. The expedition aims to fill knowledge gaps in the factors affecting wild salmon abudance.

Research from AquaFish Innovation Lab (AIL) at Oregon State University shows that women are underrepresented in aquaculture-related research paper authorship. This can have an impact on their careers as publication credits are an important factor for promotions, funding, and tenure positions for academic researchers.

Academic papers are often a team effort but there is no set process for determining what order the authors’ names should appear when published. Authorship order can make a big difference to academics’ careers as it can be an indicator of status in the discipline, according to Morgan Chow, Gender Specialist at AIL. She noted that authors who are listed first or last generally see the most credit. Women are underrepresented both in those first and last positions, as well as in papers with a single-listed author.

While US Department of Education statistics show women account for roughly 50 percent of the graduating classes in agriculture, biological and natural sciences, the research on gender authorship reveals that the percentage of women authors was low: 13.8 percent and 15.7 percent in JSTOR (Journal Storage) and the International Aquaculture Curated Database, respectively, and a scant 3.7 percent in Web of Science. While Chow’s research establishes this statistical trend, other researchers are examining in a wider context why women are underrepresented in research authorship. A 2015 study published by Elsevier titled Gender in the Global Research Landscape, for example, analyzed research performance and gender over 20 years, 12 geographies and 27 subject areas.

“It’s getting increased attention because it’s important, and it’s a very timely to talk about this and it’s important to find robust ways to really understand what’s happening,” says Chow. “It’s also challenging, especially with a discipline like aquaculture. Our effort is just that one piece of many other studies that are trying to consider how academic institutions or other structures may or may not propagate these gender inequities.”

– Matt Jones

Offshore is the most promising option for expanded sustainable seafood production in the United States but ‘smart policy’ is needed to advance it, according to a new study.

The study, Opinion: Offshore aquaculture in the United States: Untapped potential in need of smart policy, said less than two percent of the US exclusive economic zone is needed for offshore finfish aquaculture development in order to produce the country’s current seafood requirements.

But “the US needs a “more unified policy framework that specifies how permitting will work across agencies and jurisdictions, while creating clear and rigorous standards to protect ocean ecosystems and other ocean uses,” said the authors.

“Scientifically informed, proactive spatial planning should drive this process by identifying prime locations for aquaculture

development—locations that will be productive and profitable while minimizing negative environmental, social, and economic impacts,” the authors said.

They defined offshore aquaculture as typically referring to farming beyond the near-shore and inshore coastal zone, with waters that are more than 20 meters deep.

Spatial planning could include prepermitting for locations, for example, conducting site or regional environmental impact assessments rather than the permit-by-permit approach currently used. This, the authors said, will boost efficiency and cut costs. Part of spatial planning is analyzing the set of existing and projected impacts on the environment.

They stressed that while the US has some of the highest offshore aquaculture production potential in the world, its

Nordic Aquafarms said it will seek certification from the Aquaculture Stewardship Council as a sustainable seafood producer once its 40acre land-based Atlantic salmon farm becomes operational.

Risks to the environment and local waters are top concerns among residents of Belfast, Maine where the company plans to construct the facility.

At the company’s recent “public informational meeting” attended by roughly 180 area residents, company president Erik Heim corrected notions that the recirculating aquaculture system (RAS) project is “experimental.”

“If anybody thinks we’re experimenting with wastewater treatment, this is not the case; this is proven technology. If you look at the environmental technologies being employed here, they are not unique to aquaculture. These are wastewater treatment systems that are used across many industries. We did not invent them,” he told the residents. Mitsubishi, a global player in wastewater treatment, is supplying major parts of the facility in terms of wastewater treatment, he added.

He said Nordic Aquafarms is in fact “willing to invest more than other players in the industry to create a cleaner type of operation.”

“What we are spending a lot of our time on is the fish farming concept that’s behind that and that’s more about how we work to optimize fish welfare and quality in these systems as they scale up,” Heim said. He said land-based aquaculture projects need to be scaled up to make financial sense. For that to work, investment in infrastructure, fish processing and hatchery operation are needed, and that is what the company is doing, he said.

marine aquaculture production is low.

The US imports 90 percent of its seafood consumption, according to NOAA. The US imported six billion lbs of seafood in 2017, valued at more than $21 billion. Exports were at 3.6 million lbs valued at $5.4 billion, resulting in a $15.6-billion seafood trade deficit.

“This failure to realize offshore aquaculture potential is partially attributable to reasonable concerns over environmental impacts and the lack of a streamlined, objective, and predictable policy framework for offshore aquaculture permitting and regulation,” they said.

•

• Preassembled, skid-mounted Life Support System with multiple options

• Full system monitoring available

• Salt water and fresh water versions available to suit any species e.g. crab, lobster, geoduck, tilapia and more

- R-value insulation option to reduce energy costs.

De Vaudreuil, Boucherville, Quebec Canada J4B 1K7 - Ph: +1 (450) 449-6400 www.dc-inter.com dctank@dc-inter.com

from

funds for effluent-treatment

from

Three aquaculture operations in British Columbia, Canada expect to enhance their environmental sustainability with the funds they received in December from the federal government.

The three companies received a portion of the $1.1 million in funds from the Fisheries and Aquaculture Clean Technology Adoption Program, which helps businesses deploy clean-technology solutions.