ECO Unit creates a healthy air ow with additional heating and cooling. You can maintain an even house temperature all year round.

• 35% lower ammonia levels

• Better FCR

• Better litter

• Circulate up to 30,000 m3 of air an hour

• Recovers up to 80% of heat

• Easier cleaning with automatic cleaning options

• Earn back your investment in < 5 years *

• Save up to CAD $ 18,000 ** per year on your total energy cost

* Based on CAD $ 1.95/kg/GLP, 7 ocks p/y ** Based on CAD $ 1.95/kg/GLP, 7 ocks p/y @35K birds

BLR Solutions

QC - T: +1 450 772 2929 jfbourbeau@blrsolutions.ca

Eric Gri n Agri. Equip. Ltd.

NS - T: +1 902 542 0160 andrew@ericgri nagriequip.ca

Penner Farm Services

AB - T: +1 403 782 0675 MB - T: +1 204 326 3781 webuildfarms@pennerfarmservice.com

Pols Enterprises Ltd. ON - T: +1 905 708 5568 sales@polsltd.ca

United Agri

BC - T: +1 604 859 4240 webuildfarms@unitedagri.com

Western Ag Systems

SK - T: +1 306 382 0700 webuildfarms@westernagsystems.com

by Brett Ruffell

There’s something special about knowing the food on your table and the products in your home were made right here in Canada. And these days, that feeling is stronger than ever. With recent tariff threats and ongoing trade tensions with the U.S., many Canadians are making a conscious effort to support homegrown products. A new survey shows that 63 per cent of Canadians are actively seeking out Canadian-made goods, and over half are even checking labels to avoid U.S. products.

“Now is the time for Canadian poultry farmers and processors to highlight what makes our products stand out.”

For poultry farmers, this shift could be a game-changer. Consumers are increasingly looking for clarity on where their food comes from, and our industry has a great story to tell. Canada’s poultry sector already operates under some of the highest food safety and animal welfare standards in the world, and we’ve long been leaders in sustainability. Now, more than ever, consumers are looking for that assurance when they shop.

But here’s the catch – understanding what “Made in Canada” and “Product of Canada” actually

mean isn’t as straightforward as it should be. The survey revealed that many Canadians assume a “Made in Canada” label means a product is mostly Canadian. In reality, only 51 per cent of the total direct costs of producing that item need to be Canadian. In contrast, “Product of Canada” requires at least 98 per cent Canadian content. Once consumers learn this, the preference for “Product of Canada” skyrockets from 23 per cent to 66 per cent.

This confusion presents both a challenge and an opportunity. As an industry, we need to ensure consumers recognize the value of truly Canadian poultry products – whether it’s fresh chicken, turkey, eggs, or further-processed items. Labeling clarity is key, and industry groups like Egg Farmers of Canada have done a great job educating consumers on how to identify Canadian products. But there’s still work to do across the sector.

Now is the time for Canadian poultry farmers and processors to highlight what makes our products stand out. Strong messaging and consumer education efforts will help ensure that when Canadians choose to buy local, they’re truly supporting Canadian farmers. And given the current momentum, there’s never been a better time to make that push.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep.

Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager

Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer Lisa Zambri

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada - Single-copy $10.00

Canada – 1 Year $33.15

Canada – 2 years $56.61

Canada – 3 years $78.54 (plus applicable taxes)

USA – 1 Year $93.33 CDN

Foreign – 1 Year $105.57 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2025Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

We process roughly 7,000,000 eggs per day and needed many curves, inclines and declines, and LUBING delivered a system that exceeded our expectations.

Brennan Dowsett - Herbruck’s Poultry Ranch

Our egg conveying systems safely transport a large volume of eggs from the nest to the processing area, which is why the majority of all eggs produced in the North America are riding on a LUBING egg conveying system.

Our conveying systems are flexible, and can be adapted to nearly any configuration with curves, angles, heights and distances.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

Tim Hortons has introduced scrambled eggs made with 100 per cent Canadian freshly cracked eggs as part of its expanded breakfast menu. The new Scrambled Egg Loaded Wraps, available nationwide, feature three varieties: Sausage, Bacon, and Scrambled Egg & Cheese. Each wrap includes a hash brown and signature sauce. Tim Hortons continues to support Canadian egg farmers by sourcing eggs that meet the strict standards of the Egg Quality Assurance (EQA) program.

The 2025 International Production & Processing Expo (IPPE) saw strong attendance with 30,502 registered attendees and 1,385 exhibitors covering 598,373 square feet of exhibit space. The event, held in Atlanta, attracted 8,909 international attendees from 129 countries, with Canada representing the largest international contingent. IPPE organizers received positive feedback on the event’s educational sessions, networking opportunities, and trade show experience, and plan to build on this success for next year’s event.

With egg prices soaring, the Trump administration is shifting its approach to avian influenza, focusing on vaccines and stronger biosecurity instead of mass culling. The new strategy aims to reduce economic impact from the disease, which has led to shortages and price hikes. Agriculture officials are working to improve perimeter protections around poultry farms and explore vaccination, though challenges remain in balancing food security with trade concerns.

The federal government says it has purchased 500,000 doses of a bird flu vaccine as a proactive measure, pointing to guidance that says highrisk people should be prioritized for the shot, such as farm workers exposed to infected animals.

The Public Health Agency of Canada says risk to the general public is low and that broad vaccinations are not recommended, citing guidance from the National Advisory Committee on Immunization on the use of GSK’s human vaccine against avian influenza.

The shot is meant for people who may be at increased risk, such as those who have ongoing contact with infected animals.

“While the current risk to the public remains low, individuals with higher-level exposure to infected animals are at increased risk and should take appropriate precautions,” PHAC said in a statement.

Provinces and territories are set

to receive 60 per cent of the available doses and will decide how to use them, PHAC said, while the remainder will be kept in a stockpile.

NACI, which provides guidance on vaccine use in Canada, said the vaccine – called Arepanrix – can be offered as a two-dose series to individuals six months of age and older in specific circumstances.

It identified several groups considered at higher risk “in a non-pandemic context,” including: people who handle live avian influenza virus in laboratory settings; people with ongoing contact with infected birds or other infected animals or their environments, and people who work or live on farms with geographic or other connection to farms experiencing outbreaks.

Health Minister Mark Holland said in PHAC’s release that buying the vaccines is among the government’s “proactive steps” to prepare for the threat of H5N1 spread.

BY HANNAH ALBERGA,

Infectious disease experts say the avian flu case that infected a 13-year-old in British Columbia shows “worrisome” signs that the virus could be mutating to more easily infect humans, but that the treatment approach taken can help inform future cases.

In a letter published in the The New England Journal of Medicine Tuesday, Canadian health officials identified changes in the viral genome sequence of specimens collected from the teenager who tested positive for avian flu and was treated in Vancouver.

The case study says the teen was taken to a pediatric intensive care unit with respiratory failure and pneumonia on Nov. 8, endured a long hospital stay, and recently was taken off of supplemental oxygen on Dec. 18.

B.C. health officials said in a statement to The Canadian Press Thursday that the patient has not

been discharged from BC Children’s Hospital, but that she is no longer in intensive care. They said they still don’t know how the teen got infected.

The report in The New England Journal of Medicine said the girl, who has a history of mild asthma, first went to the emergency room with a fever and conjunctivitis on Nov. 4.

A genome sequence taken eight days after the onset of her symptoms showed three mutations in the specimen, including in genes that “facilitate viral entry into cells in the human respiratory tract and enable viral replication,” the case study says, adding evidence of the change is “worrisome.”

Physicians initiated a multiprong approach, giving the teen all three of the approved antiviral treatments available for avian flu, in addition to intubation and ventilation.

APRIL

Apr. 2, 2025

PIP Innovation Showcase, Webinar poultryinnovationpartnership.ca

Apr. 7-9, 2025

Restaurants Canada Show, Toronto, Ont. rcshow.com

Apr. 8-10, 2025

PEAK 2025, Minneapolis, Minn. midwestpoultry.com

Apr. 9, 2025

Canadian Poultry Egg-Centric Learning Series, Webinars canadianpoultrymag.com

A genome sequence from a 13-year-old in British Columbia showed mutations that could make the avian flu more likely to bind to human airway receptors.

Apr. 17, 2025

PIC’S Agricultural Advisors Day, Wellington, Ont. poultryindustrycouncil.ca

Apr. 28-May 2, 2025

Shell Egg Academy, Virtual Event shelleggacademy.org

MAY

May 7, 2025

PIP Innovation Showcase, Webinar poultryinnovationpartnership.ca

May 7-9, 2025

Animal Nutrition Conference of Canada, Niagara Falls, Ont. animalnutritionconference.ca

May 22, 2025

PIC’S Research Impacts, Virtual & Elora, Ont. poultryindustrycouncil.ca

May 28-30, 2025

ANAC AGM and Convention, Canmore, Alta. anacan.org

By Treena Hein

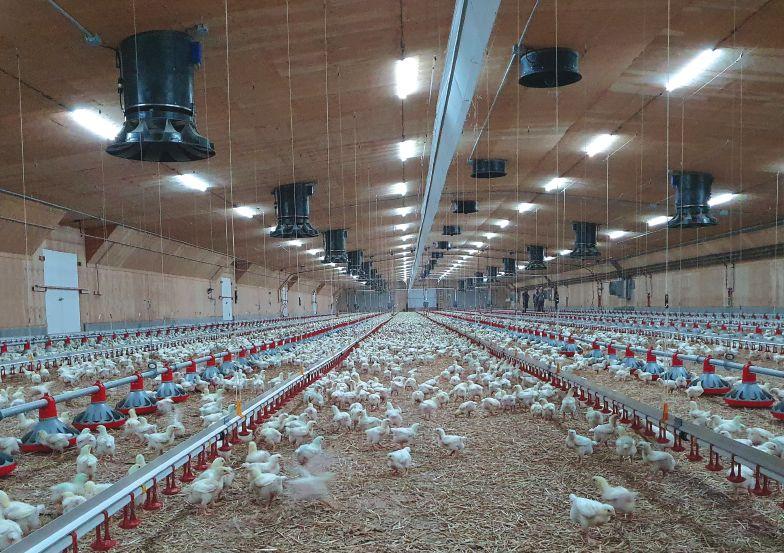

Ventilation is far from a stagnant aspect of poultry production in Canada, with new technologies powering further improvements in bird health and trimming costs while lessening environmental impact. To tease out the trends, we contacted leading firms for details on trend rationales, how to sidestep potential challenges and what’s next.

There is now a larger focus in Canada’s poultry sector on ensuring the entire barn environment is more uniform throughout the year to maximize bird health. “Better mixing of barn air, whether through stir fans in broilers or centrifugal mixing fans in layers, has made a big impact on litter quality, foot pad quality and lower condemnations,” explains VAL-CO’s general manager Sean Francey.

“In layers, it has really reduced feed use as it has helped to minimize cold spots in housing systems that otherwise require birds to consume additional feed for compensatory heat gain during colder months.”

Giulia Simioni, marketing manager at Munters, adds that with the trend towards building larger Canadian poultry barns, applying traditional ventilation methods designed for smaller barns may result in ventilation falling short. “During periods of minimal ventilation, fresh air may struggle to reach the center of the building,” she says, “leaving pockets of temperature variation which can chill the birds.”

No matter the barn size or housing type, a proper ventilation design is required. Si-

mioni notes that some large fan models optimize airflow over others. Better models reduce the number of fans needed to ensure drier litter, lower ammonia, less illness and optimum bird growth. And where supplemental fans are required, they further help achieve uniform conditions.

Indeed, according to Simioni, Computational Fluid Dynamics is now revolutionizing barn ventilation design, a type of highlevel modeling that enables custom airflow analysis for optimized fan placement, inlet positioning and overall ventilation configuration.

James Black, Canada regional sales manager for SKOV, notes that with the current increases in avian influenza cases, “we’re seeing increased interest in filtered barns that would normally be reserved for parent and grandparent type barns.”

As we know, filtering incoming air and

pressurizing the building to create a positive airflow that effectively blocks unwelcome airborne microbial guests. “Pioneering this concept in the U.S. hog industry, Munters has demonstrated the potential of this technology, and its positive pressure application in chicken houses is now under intense scrutiny,” she reports. “However, this vision faces some practical hurdles.”

One is cost. Simioni explains that “the initial investment in such a system can be significant, and the ongoing maintenance of the filters adds to the cost. Perhaps the biggest challenge, however, lies in the lack of a standardized approach.

Designing and implementing the correct ventilation equipment for positive pressure filtration requires careful planning and expertise, making it a complex undertaking for producers. While the potential benefits of this technology are clear, overcoming these challenges will be crucial for its widespread adoption.”

Up until now, most producers chose one ventilation system and stuck with it, reaping its benefits and dealing with its detractions. However, more producers are now choosing to combine multiple systems to achieve better ventilation year-round.

As Doug Martin explains, tunnel ventilation has been around in Canada for many years, yet a note of concern is improperly designed systems. “Many farms are now combining tunnel ventilation with evaporative cooling systems to lower barn temperatures even further,” says Martin, Canadian sales manager at Cumberland.

“This is especially useful during heat waves when traditional ventilation alone isn’t enough.” He adds that “systems that switch between tunnel ventilation in the summer and sidewall ventilation in the winter, and even attic ventilation for those in-between days, allow for year-round efficiency.”

Eric Longtin, VP of sales and operations at Agrimesh Technologies, agrees that “a hybrid approach – combining tunnel ventilation for summer cooling and cross ventilation for even air distribution in colder months – offers the best year-round efficiency.”

Black notes that combi-tunnel barns work very well, as do well-designed cross ventilation systems in the Canadian climate, “although, in both situations, adding in a form of evaporative cooling is one of the best additions to make the system excel. Either a pad cooling system in a tunnel barn, or high-pressure cooling in a sidewall system, is like air conditioning for the birds and makes the more-frequent heat waves we see each summer easier to get through.”

For Niels Dybdahl, owner at DACS (producer of the MagFan), “a well-specified minimum ventilation system in conjunction with a tunnel system is in my opinion the best solution for the Canadian poultry sector. The minimum ventilation system should be able to ventilate the house up until outside temperatures is no more than 2°C below set-point temperature. At this point, the introduction of air through the tunnel doors only does good to the birds.”

Although they have special ventilation needs, specialty producers have had to make do with systems designed for their conventional counterparts. However, tailored solutions emerging for niche production systems, providing easier management for farmers and better conditions for birds.

Simioni explains that the ventilation challenges of free-range and organic systems, because of the open access to the outdoors, are made worse with traditional negative pressure systems.

“Neutral pressure buildings can offer a solution,” she says, “pushing fresh air in while helping to keep warm air from entering through outdoor access doors, ensuring even ventilation.”

However, she notes that this requires a shift in thinking. “While beneficial for animal welfare, implementing neutral pressure requires careful planning and new technologies.”

Dybdahl notes that “as soon as the doors in a negative pressure-driven houses for free-range and organic birds open, then the airflow pattern collapse and the air pass uncontrolled to the house via the doors. This uncontrolled airflow damage litter and harm birds.

“Ventilation units like the Corona air intake maintain the airflow pattern in the house when doors open. This because these

systems are equipped with a fan and therefore, they can maintain zero static pressure in the house and thereby maintain the airflow pattern.”

For free-range housing, SKOV also offers a ventilation system with incoming air and exhaust air being equal, and one that uses natural convection.

Mindy Brooks, director of marketing at Chore-Time, reports that “we’re really seeing a push for direct drive fans that have variable speeds to replace belt drive fans. One of the biggest benefits with direct drive fans is that you’re eliminating a lot of the maintenance that’s required on belt drives.

“Add to that the ability to run direct drive fans at varying speeds, giving you more control over airflow and temperature with the greatest efficiency when fans are running at 60 to 80 per cent speed.”

Exacon President Mark Relouw notes that “electronically commutated (EC) direct-drive variable-speed motors, available now for fans up to 72 inches, are an emerging solution for significant electricity savings.”

Martin explains that because EC motors adjust their speed based on conditions inside the barn, they reduce energy use without sacrificing airflow. “This trend,” says Martin, “has really allowed for a completely new fan layout to optimize performance.”

A

He adds that modern high-efficiency fans move more air with less power by using better blade shapes and materials, and in addition, fans that use permanent magnet motor technology provide energy-efficient performance at all fan speeds and static pressures.

In Canada, it’s becoming more common to see additional ventilation sensor types in poultry barns, among them CO2NH3 and air pressure. However, fans themselves are also getting their own sensor arrays.

“Systems available today monitor fan power, RPM and motor temperature,” says Relouw. “They provide failure alerts, activate backup fans and simplify wiring by requiring only high-voltage connections to fans and low-voltage communication wires to controls.”

Monitoring and acting on sensor data is of course increasingly achieved by software. Indeed, Black says advancements in using AI in controller technologies is among the biggest trends in ventilation.

Longtin also sees the integration of AI as a growing trend. “Unlike fixed-stage systems, AI continuously adapts environmental factors such as feel-like temperature, CO2NH3 and oxygen levels in real time,” he explains.

“This ensures optimal bird welfare while lowering energy costs. Additionally, proactive weather monitoring powered by AI allows growers to anticipate drastic temperature changes outside that could impact energy usage.”

That is, by analyzing weather patterns and adjusting barn conditions in advance, systems such as those offered by Agrimesh help maintain optimal barn conditions “while preventing sudden spikes in energy consumption,” says Longtin, “further enhancing efficiency and sustainability.”

As Canadian poultry barns evolve, ventilation technology is driving improvements in efficiency, bird health, and sustainability. Here are some key figures shaping the future:

30% - Potential heating cost reduction with advanced ventilation and heat recovery systems.

10-15% - Lower ammonia levels reported on some farms, leading to improved air quality and bird performance.

40% - Reduction in energy consumption with modern, high-efficiency fans compared to traditional models.

80% - Maximum heat recovery from barn air using heat exchangers, significantly cutting fuel use.

2-5% - Potential improvement in feed conversion rates when airflow is optimized to reduce bird stress.

Each year, CABEF helps students to pursue rewarding agri-food careers through seven $2,500 scholarships. We’re looking for the future leaders who will help this industry meet tomorrow’s challenges.

Do you know someone who needs to fund their future in agri-food? Tell a student today.

Scholarship application deadline is April 30, 2025

Want to help support the next generation of agri-food leaders?

Become a “Champion of CABEF.” This program allows your organization to directly sponsor a deserving student. Contact CABEF at info@cabef.org.

By Jane Robinson

What if there was a simple and effective way to clean up outside air before it entered the barn to improve air quality in the barn and bird health?

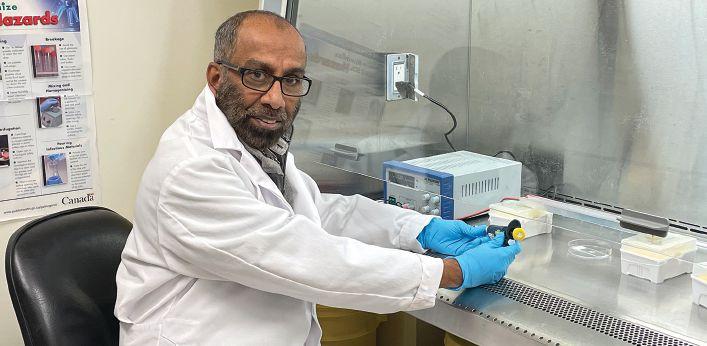

Dr. Lifeng Zhang, his graduate student Angelo Alluag and research assistant Myra Martel at the University of Saskatchewan are evaluating two technologies that are showing great promise. They are using ionization – a green technology that adds electrical charges to air or water droplets – to deactivate potential pathogens and hopefully offer a new approach to help reduce the spread of avian influenza.

The team are partway through a three-year project that is assessing the performance of the two systems for reducing the pathogen load of incoming air under lab conditions, then testing the better performing one under barn conditions and finally doing a cost analysis to look at the economics on a commercial scale.

“Airborne pathogens are a significant risk to poultry health and productivity,” says Zhang, a professor of chemical and biological engineering. “And we know that barn ventilation systems can introduce bacteria and viruses, including the

That’s the main driver behind the research project – to find innovative air protection technologies for poultry barns that focus on reducing pathogens before they enter the barn.

The research project includes collaboration with an interdisciplinary at the university including Dr. Karen Schwean-Lardner from Animal and Poultry Science, Dr. Huiqing Guo from Mechanical Engineering, Dr. Bernardo Predicala from Prairie Swine Centre and Dr. Shelley Kirychuk from the Department of Medicine.

Both technologies work in a similar way using electric charges to deactivate pathogens by disrupting the membrane around the pathogens – one system uses and charges water droplets and sprays them into the air, and the other directly charges

the contaminated air.

For the first phase of the project, they created prototype models to compare the ability of each system to clean up inlet air before trying them out in a poultry barn. “We want to see which one is more suitable for protecting inlet air and ability to filter out pathogens including potentially avian influenza,” says Zhang.

The electro-nanospray system has been tested by the team in swine barns and has shown promising results for purifying the air inside the barns. The system works by using a very small amount of water to diffuse into the air and react with potential pathogens or water them down to be less harmful. The nanosized water droplets also carry electrical charges and reactive oxygen to help decontaminate the air.

The <b>electrostatic particle ionization system</b> directly charges the particles in the air that

are then able to capture airborne pathogens and deactivate them. “We are essentially deactivating or killing pathogens –viruses and bacteria – to clean up the incoming air,” says Zhang.

There are very promising signs for both technologies so far that are showing 80 to 90 per cent reduction efficiency – the measurement used to evaluate the effectiveness of the system at removing particulate matter of a certain size.

“We’re most concerned about removing super small particles that are below 10 microns,” says Zhang. Airborne avian influenza molecules fall into this size category. And while they couldn’t test the systems on the virus for biosecurity reasons, they tested the ability of the systems to remove E. coli and Salmonella molecules that are similar in size to the influenza virus.

“Our previous studies looked at larger particle sizes, but we want to be sure that our technology can capture and find influenza and other fine particles that are as small as one to two microns before they get in the barn,” says Zhang.

From an energy efficiency angle, the team also looked at how well the systems removed particulate matter when they were switched on and off, versus running them continuously. The results looked good here too. It seems the systems don’t need to run all the time to effectively remove particulate matter – an important finding for energy saving.

“We are still in early stages of the research, but the longer-term goal would be to integrate the technology into existing ventilation control systems in barns,” says Zhang.

They will also be comparing the energy consumption of both systems to understand the economics of the technology. “This is effective technology for improving air quality that we don’t expect will be very expensive to install into existing ventilation systems,” says Alluag.

There are still some results to consider before the team decides which air-purifying system to take into phase two.

“We’re very excited to see the effectiveness of these two technologies and the potential application to treat inlet air and prevent viruses and pathogens from entering the barn,” says Zhang. “After collecting some additional data on how effectively the systems deactivate pathogens – what we call biocell deactivation – we will move forward with one of the systems to test in poultry barns at the University of Saskatchewan.”

They’ll also be looking at the impact of Canadian winter weather on the systems. And then the options for getting the technology on farms, including connecting with industry and manufacturers to gear up to a commercial scale for broiler, layer and turkey operations.

“We anticipate that this ionization-based technology will effectively reduce airborne pathogens at the ventilation inlet,” says Alluag.

Proper air quality is essential for a healthy and productive poultry house. Engineered for superior climate control and ventilation, AirMaster Blue provides high air performance, minimal energy consumption, and an optimized aerodynamic design.

Equipped with advanced control technology and a durable, corrosion-resistant design, they offer long-lasting performance while reducing maintenance.

Reach out to one of our authorized distributors to learn more.

With rising energy costs and a push for sustainability, some poultry farmers are turning to solar air heating.

By Melanie Epp

As energy costs mount and a focus shifts to sustainable production, Canadian poultry farmers turn to innovative solutions to heat their barns efficiently. One such technology, SolarWall, is gaining ground for its ability to lower heating expenses while improving ventilation and air quality. Victoria Hollick, a representative of SolarWall, explains how the system works, its benefits, and why more farmers are adopting it.

SolarWall is a unique solar air heating system that uses perforated, dark-coloured metal panels made from 26-gauge steel that absorb solar energy and heat incoming air before it enters the building. The panels are installed on the exterior walls of barns. Using solar energy to heat incoming air reduces reliance on conventional heating methods such as propane or natural gas, and leads to significant cost savings.

The process reduces reliance on conventional heating methods such as propane or natural gas, leading to cost savings. “Heating and ventilation are some of the largest energy expenses for poultry barns,” said Hollick. “Our technology preheats incoming air, reducing fuel consumption and providing fresh, warm air essential for proper humidity and temperature levels.”

The SolarWall system functions under negative pressure, which means air is drawn through the perforations into the collector panel where it is heated before entering the barn.

“Instead of drawing in outside air at -10°C, for example, the system can heat it to around 10°C, reducing strain on conventional heating systems,” she explained.

Although counterintuitive, solar wall technology continues to work during Canada’s harsh winters.

“Even in snowy conditions, SolarWall remains effective because its surface stays warm enough to prevent snow accumulation,” said Hollick. “Additionally, sunlight reflection off the snow increases solar gain, further enhancing efficiency.”

For poultry farmers, SolarWall offers several advantages beyond energy savings, though. According to Hollick, the technology maintains optimal temperature, enhances bird welfare, lowers greenhouse gas emissions, and improves air quality inside barns.

Since it filters incoming air, some producers believe the system also improves biosecurity. Filtration reduces contaminants such as dust and feathers, and possibly even airborne pathogens, which could protect flocks from viral diseases such as avian influenza.

Several factors contribute to the growing adoption of solar wall technology among Canadian poultry farmers.

Rising energy costs have made alternative heating solutions more attractive, while government incentives, such as the federal solar tax credit, provide financial support for installation.

“There is a renewed focus on sustainability, and farmers are looking for proven, cost-effective ways to reduce their carbon footprint,” said Hollick. “With hundreds of installations across Canada, producers are seeing first-hand how SolarWall lowers costs and improves efficiency.”

The ease of installation also makes SolarWall appealing. According to Hollick, “The system is straightforward to integrate, whether for new construction or retrofitting existing barns. In some cases, farmers can even install it themselves, further reducing costs.”

Adopting SolarWall technology doesn’t necessitate the construction of a whole new building. The technology can be retrofitted to existing poultry barns by mounting the panels onto exterior walls.

Lowy Gunnewiek, an Alberta-based engineer who has helped involved in several SolarWall installation projects, said the job is straightforward enough that farmers can take it on themselves with minimal effort.

“It’s quite simple to install,” he said. “Farmers can mount the system onto a wood-framed support structure and tie it into the existing ventilation system. In most cases, warm air is drawn into the attic through existing inlets, making integration straightforward.”

One challenge in retrofitting SolarWall is adapting airflow to existing ventilation setups. Some older barns may require additional ducting or modifications for proper air distribution.

“Every barn is different,” said Gunnewiek. “Some have multiple exhaust fans, and integrating SolarWall means ensuring adequate air intake to balance the system.”

Despite these challenges, retrofitting is worthwhile. SolarWall not only reduces heating costs but also enhances summer cooling, he said.

Lowers Heating Costs: Heats incoming fresh air an average of 10 degrees C to 30 degrees C above ambient. It has a solar energy conversion rate up to 80 percent.

Healthier Livestock: Improved ventilation and indoor air quality lowers bird mortality and enhances animal well being.

No Cold Drafts: Acts as a barrier against cold winds, ensuring better comfort.

Humidity Control: Reduces moisture and aids in drying after cleaning, creating a healthier environment.

“The system acts as a thermal shield, preventing excessive heat build-up on barn walls,” Gunniwiek said. “At night, it helps cool the barn by facilitating heat radiation to the sky, reducing stress on birds during hot months.”

He’s also seen producers use excess heat to dry manure, a move he said extends its benefits beyond winter heating.

Part of the challenge of getting producers to adopt solar wall technology is that they’re often unable to visualize the end result, said Gunniwiek.

While he’s able to offer visuals to show how the retrofit will look aesthetically, the results they really want to see happen in the barn. Proper ventilation and reduced ammonia levels, for instance, create a healthier environment, allowing birds to convert feed into growth more effectively.

“When ammonia levels rise, birds experience respiratory stress, which impacts their feed intake and overall growth,” Gunnewiek said. ‘With

SolarWall maintaining better air quality, poultry farmers see improved feed efficiency and reduced waste.”

Ben Entz, an egg farmer from Brownlee, Sk. and owner of Huron Poultry, installed SolarWall in 2019 during the construction of a brand new barn. With plans to expand, he initially had fewer birds in a large space, making heating a challenge.

“We built a big barn but only had it half full, so we needed a way to supplement heat efficiently,” said the producer. “That’s where SolarWall came in.”

During extreme cold, Entz has seen impressive results. “Yesterday, it was minus 32°C outside, and the SolarWall raised the attic temperature by 18 degrees,” he explained, adding that the pre-warmed air allows for better ventilation without overworking conventional heaters. This, he said, significantly reduces his heating costs.

At 4,100 square feet, the SolarWall system at the Huron Colony delivers a maximum airflow of 41,000 CFM, providing heated air

for the layer barn. Each year, the wall captures approximately 176,591 kWh of solar energy and recaptures an additional 10,900 kWh from building heat loss, leading to total annual energy production of 187,491 kWh. This translates into a substantial reduction in natural gas consumption – 22,052m ³ annually, based on an 80 per cent burner efficiency rate.

Beyond savings, Entz has also noticed substantial improvements in air quality and bird health. “Before SolarWall, ammonia levels were high enough to – v sting your eyes,” he said. “Now, the fresh air system keeps ammonia so low that it doesn’t even register on audits.”

Another unexpected benefit has been improved biosecurity. “CFIA inspectors have commented on how SolarWall acts as a filter, preventing airborne contaminants like feathers and dust from entering the attic,” he said. “That’s an extra layer of protection we didn’t anticipate.”

In summer, SolarWall provides additional advantages by preventing heat build-up on barn walls. This is done by creating a shadow, which keeps the barn cooler in the evenings, Entz said.

Finally, Entz said one of the greatest benefits of the SolarWall system is that it enables him to continue bringing fresh air into the barn during windy snowfall without running the risk of filling his attic with snow. This provides extra peace of mind, as he’s seen built up snow cause barn collapses before.

With its ability to cut heating expenses, improve barn conditions, and support sustainability goals, SolarWall has proven to be a valuable investment for some Canadian poultry farmers.

As more producers recognise its benefits, experts expect solar air heating adoption to grow across the industry.

1. Energy cost savings: Solar wall technology reduces reliance on propane and natural gas, significantly lowering heating expenses.

2. Improved air quality: Preheated fresh air lowers humidity and ammonia levels, benefiting bird health and productivity.

3. Sustainability: Solar energy reduces greenhouse gas emissions, supporting environmental goals.

4. Year-round benefits: Solar wall technology prevents excessive summer heat build-up and aids in night-time cooling.

5. Government incentives: Federal and provincial programs offer financial support for solar energy adoption.

Location

Arthur, Ont.

Sector

Layers

The business

Stickney Poultry, a second-generation farm near Arthur, Ont., was founded in the 1980s. In 2022, Anneke Donkers-Stickney relocated to a new 80-acre farm, upgrading to enriched housing for her 68,000 laying hens. She operates two barns, each with 34,000 birds, supported by one full-time and two part-time employees.

The need

The shift was driven by updated industry standards. “My old barn was nearly 30 years old and no longer met requirements,” Donkers-Stickney says. The 2017 Egg Farmers of Canada mandate required new barns to adopt enriched systems, prompting her investment in a full farm overhaul.

The barn

Each barn is equipped with the Tecno enriched sys te m, sourced from Clark Ag Systems, designed with perches, nesting boxes, and a dual nest box layout to minimize competition. “Birds move naturally, improving welfare,” Donkers-Stickney explains.

Having two nests per area ensures more even nest distribution, reducing crowding and stress. The design also prevents eggs from rolling out, lowering the risk of shell damage and maintaining egg quality.

An egg packing system from Moba streamlines egg collection, processing 32,000 eggs per hour and cutting labor time from five hours to three. “The system is efficient and gentle on the eggs, reducing cracks and maintaining a high percentage of Grade A eggs,” Donkers-Stickney notes.

To manage waste efficiently, on-farm manure storage allows for annual cleanouts instead of weekly hauling, reducing labour and costs. “Manure is stored in a Poultry

way that controls moisture and odor, making handling easier,” she says.

Custom feed, sourced from Donkers-Stickney’s family feed mill, supports bird health with optimized nutrition. The birds also benefit from an enhanced ventilation system, which ensures consistent airflow, reduces ammonia buildup, and maintains a stable barn climate. “Good air quality is key to bird health and egg production,” the producer adds.

The enriched system, advanced technology, and improved barn design provide a more efficient, sustainable, and bird-friendly environment. Donkers-Stickney worked with Agrotec Construction to build the barns. “It’s more efficient, better for the birds, and gives me greater control. Absolutely worth it,” she says.

View more photos at canadianpoultrymag.com

serving Southwestern Ontario since 1985

and cold stress threaten poultry health – here’s how to manage both.

By Lilian Schaer

In Canada, excessive heat and humidity in the summer is contrasted by deep cold in the winter, and although poultry facilities are designed to keep birds in a consistent environment year-round, dramatic extremes can be hard to manage.

Without sweat glands, poultry rely on panting, ruffling feathers or holding out wings to cool themselves down – but both heat and cold stress will affect bird health and performance.

Western Canada’s infamous heat dome in 2021, for example, caused significant mortality as well as impacting health and production. With severe and extreme weather events seemingly becoming more common, producers should be prepared to deal with whatever Mother Nature throws their way.

Raymond Funk of Summit Technologies addressed the issue in a presentation at last year’s Western Poultry Conference, highlighting what producers can do to combat both winter humidity and summer heat stress.

Humidity is a challenge in the winter, Funk noted. That’s because 60 to 70 per cent of a barn’s moisture comes from bird respiration and feces, but unvented heaters also add moisture.

According to Funk, decreasing relative humidity inside a barn follows a simple principle of bringing in dry cold air and warming it up before bringing it down to the bird level on the floor or at the manure belt to pick up moisture before ventilating it out.

Cold air is very dry, and its moisture-holding capacity increases as it warms.

“It’s incredible how dry prairie air is in the winter and all we have to do is warm it up. If we take air in -34°C at 100 per cent humidity and warm it up to 32°C, you’re down to single digit relative humidity (in the barn),” he explained.

However, this can cause some barns to be

too dry when producers are starting chicks, so some barns now include high pressure misting lines on stir fans to bump up humidity during the first week or two of chick life. Funk noted some producers are now starting birds at 40 to 50 per cent relative humidity before decreasing as the chicks mature.

To keep relative humidity in check, Funk suggested using stir fans to help get warm air from the ceiling to the floor or across manure belts. Using zone control for heaters and inlets creates microclimates inside a facility; setting up stir fans to work in

loops will help keep heat inside each zone. For better control of the interior barn conditions, Funk recommended using only one out of every three inlets in winter, however, or having a different set of inlets for that season; if all inlets are just left open a tiny bit, it simply amounts to controlled leakage of expensive heat.

Monitoring CO2 levels is an inexpensive way to determine a barn’s overall air quality; these should not go over 1,000 ppm in winter and be less than 5,000 ppm on a longer term, he noted.

Relative humidity sensors are crucial to managing ventilation rates accurately. Using a relative humidity curve helps the dry barn environment at the start of a flock slowly gain moisture to reach the birds’ ideal point and keep humidity build-up under control as the flock grows by speeding up fans or running heaters.

Extreme summer heat and humidity

Father’s Day 2022 is a day many in the Manitoba poultry industry remember for the impact it had on their flocks, recalled Funk. Temperatures were 31°C to 37°C most of the afternoon and into evening with relative humidity at approximately 35 per cent. In the evening, temperatures dropped to 31°C, but relative humidity rose to 49 per cent and stayed high from 8:00 pm to 4:00 am. Many birds were lost, and production was affected.

As barn temperatures rise, birds will reduce their feed consumption to limit heat gain from digestion and breathe more rapidly, pushing moisture into the air.

One of the most practical and feasible ways to lower the interior barn temperature is by increasing air movement to remove heat and moisture. This includes setting stir fans to 100 per cent speed and pointing them in the best direction to get air to the

Stress caused by extreme heat will affect bird production and health. Here are some tips to prepare and manage your flock for such events:

• Birds need extra water during extreme heat, so make sure your barn's system is robust enough to meet the added demand. Any misting or evaporative cooling systems you may have will also need water during this time, so consider installing a larger storage tank for example to make sure the facility can keep up.

• Keep water temperature between 18 and 21°C, test automatic waterers to make sure they're working and consider flushing water lines to keep them cool, and measure the water flow rate to ensure birds can get the water they need.

• Check for signs of heat stress: panting, wing spreading, squatting close to the ground.

• Consider using electrolytes as some vitamins and minerals, like sodium, potassium, or Vitamins E, D, A and C can have a positive impact on heat stress.

• Keep feed correctly balanced and highly digestible during summer and ensure birds can feed during cooler times of the day.

• Limit bird handling, avoid transporting flocks during extreme heat if possible and slow down your movements when walking through the birds.

Meller Poultry Equipment Inc.

826 Nanticoke Creek Parkway, Jarvis, Ontario, N0A 1J0

Call us on: 519-587-2667

Or visit our website: www.mellerpoultry.ca

MELLER POULTRY EQUIPMENT

AUTHORIZED DEALER VDL JANSEN

birds, as well as adjusting the position of inlets. In a typical crossflow ventilation design, exhaust fans and inlets are spaced along sidewalls for even airflow and heat removal.

Tunnel ventilation is another way to increase airspeed in the barn and will create a wind chill effect on the birds. According to the Ontario Ministry of Agriculture, Food and Agribusiness (OMAFA), research has shown that an airspeed of two metres per second (400 ft per minute) creates a wind chill effect of 3.7°C for the birds.

This wind chill effect from the fast-moving air running down the length of the barn will let both birds and people in the barn feel cooler. Research in Ontario has also shown that tunnel ventilation will also reduce energy costs as fewer fans are needed to create the same level of cooing in the barn.

In an example of a 60’ x 400’ barn with 10’ walls, Funk said using conventional cross ventilation results in air speed of 90 feet per minute in the barn whereas a combination of cross and end wall fans creates air speed ranging from 75 feet per minute at one end the bar to up to 600 feet per minute at the other.

Tunnel ventilation, by comparison, create a consistent en-

Authorized dealer VDL Jansen VDL Agrotech

The nest systems of VDL Jansen are long proven in the market, and known for their nest acceptance and egg quality. Our nest is designed to stimulate natural behavior of the hens and have them produce a maximum number of high quality eggs. Available nest area can be optimized by using single or double-tiered nest boxes, whereas a flat roof facilitates for some extra useable area to achieve an optimum bird density in the barn. Our perch frames provide sufficient space for placement of extra perch and feed trough length in the barn. As the perch frames can be winched during clean out, cleaning is easy and more efficient.

• Excellent nest acceptance

• Optimal nest capacity

• Made of durable materials

Meller Poultry Equipment

Call us on: 519-587-2667

Or visit our website: www.mellerpoultry.ca

vironment of 600 feet per minute throughout the entire barn; adding drop curtains to within nine feet for the floor increases air speed by another 20 per cent to 787 feet per minute.

Evaporative cooling systems like cool cells or misting can also be used alongside tunnel ventilation to cool barns.

Water will evaporate from cool cell pads placed along the side of a barn and can produce up to 11°C of cooling in addition to the cooling from the tunnel ventilation. Thus, they can be very effective in high temperature areas.

Misting systems are a more economical alternative to cooling cells and can more easily be retrofitted into older barns. They can add up to 7°C of additional cooling to tunnel ventilation.

Both options, however, will add humidity to the air, which can add to bird stress.

According to Funk, air placement and speed are always the first choice and need to be at correct levels – sometimes it’s simply too humid to cool.

It's also important to keep birds well hydrated and comfortable during extreme cold. Here are some ways to do that:

• Ensure your external water lines don't freeze.

• Have a heating system adequate for your size of barn and keep it well maintained. Check your fuel supply to make sure you won't run out during a cold event.

• Install a generator and ensure it is in proper working condition.

• Reduce drafts, install covers over summer fans and check and adjust inlets as needed.

• Keep additional bedding on hand; birds may also need additional feed to keep their body temperatures up.

• If shipping, clear snow and ice from your driveway and barn areas and try acclimating birds to cooler temperatures before catch.

• Monitor snow load on your barns and remove icicles and snow loads if needed.

Paint and landscape fabric are evolving into potential weapons.

By Ronda Payne

New control methods against the spread of AI (Avian Influenza or HPAI) are coming from unexpected sources. Alberta-based research into simple supplies found in the tool or garden shed – like paint and landscape fabric – reveals how these everyday items may join the arsenal poultry farmers can layer onto their biosecurity and other management practices.

Antiviral paint and UV light

Dr. Faizal Careem, a professor with the Faculty of Veterinary Medicine with the University of Calgary has several projects in the works that have the potential to help control AI in poultry barns. The first is using UV light with anti-viral paint which often contains titanium dioxide as a virus-fighting ingredient.

“What we thought was to apply the paint to the walls and the ventilation. Or even the anterooms,” Careem says. “When they deposit on the walls, there is the possibility those viruses will be inactivated. That is the goal. To inactivate the virus within the incoming air or

whatever falls out of the air.”

The titanium dioxide in the paint is “self-renewing” according to Careem, meaning painted surfaces could remain effective in fighting viruses for several years. Some countries use this type of paint as an air purifier because the titanium dioxide is activated by UV light and can convert viruses into harmless compounds and elements.

He feels the biggest benefit will come from painting anterooms and the insides of ventilation inlets, then focusing UV light in those areas.

“Those surface coatings are available in the market. Because of that, we bought some of them and tested them in the lab,” he explains. “We exposed them to UV, and we saw a significant reduction of the active virus.”

Painting surfaces once every few years is a manageable activity given the potential benefits. As the research on the paint and UV light explores how long the paint remains active and what level of UV light is required, Careem will learn what balance of each is needed to provide control without harm.

“There’s an initial cost, but you don’t need to do it annually,” he says of painting and installing lights. “In terms of the paint, I don’t think there is any harmful effect. It purifies the air. It can get rid of the odour as well. That’s an added advantage as well.”

But the UV light needs to be better understood in terms of the levels that activate the free oxygen radicals in the paint versus levels that cause harm to humans or poultry. With partial funding from Egg Farmers of

Canada, work in barns to explore the benefits of the paint and the requirement of UV light is underway.

“When it comes to the UV light, there’s a certain range that is detrimental to humans and detrimental to animals,” he says.

“There are other ranges that are beneficial to the poultry. We need to target specific areas. We don’t know which range is very effective. Those things we need to figure out. We need to specify if it is 220 nanometers or 300.”

Understanding how the virus makes its way into poultry barns is paramount to gaining the upper hand. Careem started taking samples from ventilation outlets on top of barns after flocks were euthanized.

“We are invited only at the time of euthanasia. After euthanasia, we collect a sample. We go to those outlet areas and sample the air,” he says. “It’s very tough for the producers. We can’t go and bother them too much.”

Once the flock is euthanized, the fans are turned on to blow the barns out. Careem takes samples of this outflow of air for testing.

His study’s bad news has been good news for Alberta poultry producers. So far, the study has very limited data because there was only one farm available for air sampling in 2024 and none (at the time of writing) in 2025.

“The funding is from the provincial government, so we couldn’t go to neighbouring provinces,” he says.

While samples are limited, he has found the genome for the wild bird virus in outflows of air that were tested.

“It can be active virus or inactive virus,” he says of the genome identified. “One thing we need to determine is if those viruses are active or inactive. Infectious or not.”

Samples have been sent to the Winnipeg lab for testing, which is the only Canadian lab able to work with HPAI.

In addition to collecting samples of the air leaving the barn, Careem has been sampling water and dust.

“We’ve seen the virus in the poultry house dust. That is an indication that it is floating around,” he says. “Also, we collect water.”

By sampling the animals, air, dust and water, Careem will have a better idea of how the virus is moving throughout the barn. This can lead to better control methods for the future.

Farmers are innovators, so it’s not surpris-

“That is the goal. To inactivate the virus within the incoming air or whatever falls out of the air.”

Your local Georgia Poultry store is the place you count on for service and repairs. We feature GrowerSELECT® parts as cost-effective replacements for all types and brands of live production equipment. Stop by a store, shop online, or call us today.

ing that a study in the summer of 2022 was developed after growers asked if landscape fabric could be beneficial if used as a filter in the fight against AI and if it would have negative effects on ventilation systems. Thania Moraes, an extension technician at Poultry Innovation Partnership (PIP), a group of Alberta industry partners, took on the work to determine the outcomes.

“PIP decided to do a short trial to assess the impact of landscape fabric on ventilation systems,” she says.

“We measured the static pressure, the air speed and the smoke clearance time inside the barn with no landscape fabric or with the air inlets covered with landscape fabric.”

While the assumption was that reducing dust flow into barns would reduce the potential risks of AI access to barns, this hypothesis was not part of the study.

Both three-ounce and five-ounce weights of landscape fabric were tried and as expected, they increased the static pressure rates, reduced the airspeed and increased smoke clearance times.

However, while the pilot trial increased the static pressure to above the ideal range, the trial conducted at a commercial barn used two-ounce landscape fabric and saw values of static pressure (as well as airspeed) within acceptable ranges.

“Because the results of the pilot trial showed that the landscape fabric considerably reduced ventilation efficiency, we used a thinner landscape fabric to cover the air inlets at the commercial facility,” says Moraes.

“This trial happened during a time when avian influenza was seriously impacting the poultry industry in Alberta and a quick, emergency protection was needed,” Moraes explains.

“The trial happened for a short time and there were no birds in the barn. The landscape fabric was applied to the air inlets with duct tape and was not intended to be a permanent solution.”

Whether landscape fabric is an effective barrier for AI and determining practical uses in commercial settings will require more testing and data.

Break the fly reproduction cycle with regular introductions of fly parasites. These natural enemies attack and kill flies where they feed and breed: in the manure!

Effective: Control flies before they mature and breed. Safe: For humans and other animals. Deadly for flies. Natural: Unlike pesticides, no harmful side effects. Economical: Comparable or less cost than pesticides.

In addition, it highlights the main benefits of using probiotics in poultry production, such as maintaining gut health and integrity, reducing gut inflammation, modulating the immune system, preventing bacterial lameness, preventing reproductive tract infections, combating various enteric pathogens and improving performance. The chapters of this book illustrate various studies, which show the efficacy of probiotics in reducing livestock and poultry diseases, potentially reducing the need for antibiotic intervention, in addition to improving production performance.

By Crystal Mackay

and projects.

This call to action from Food Day Canada has never rung truer. Remember the 100-mile diet? Well, it’s time for the 4,634-kilometre diet to step into the spotlight.

The buy local movement started small and grassroots at local shops, farmers’ markets and direct farm sales. Why would people buy local? The list was long, including supporting your neighbour, local businesses, and community, with less food miles and better freshness, while you got to know your food stories.

Reporters would often call and ask me about my thoughts on ‘ocal food and family farms. I would always ask them a few questions in return, including how they defined those things. Is local next door, your province, or your country? My answer was all the above.

What do you think is the difference between a consumer and a citizen? For example, citizens say what they think and how they would act in surveys. That same person as a consumer demonstrates with their actions and what they choose to buy. And the reality is consumers always have price at the top of the list.

The 2024 Public Trust Research from the Canadian Centre for Food Integrity (CCFI) found the cost of food and availability of healthy food in the top five issues for Canadians, along with cost and access to healthcare and inflation. Cost of food concerns are real and time-tested. It has been a top five issue since the CCFI research started in 2016.

Many of us have proudly shared that we grow and produce some of the best food in the world for dec-

Buying Canadian isn’t just a choice –it’s a commitment to supporting our farmers, economy, and national identity.

ades. Is that message getting through? Do people care? It comes with the challenge of abundance – if you are hungry, you only have one problem. People can criticize our food with their mouth full. Or even worse, they don’t think about their food or who produces it at all. Trust in our food is not the issue, apathy is.

Backpackers proudly display the Canadian flag on their bags while traveling abroad – even if they aren’t Canadian. People around the globe see Canadian bacon named on restaurant menus, even when it isn’t from Canada. Why? Our Canadian brand is strong and deep around the world. But what about here at home?

When it comes to what we buy and choose at the grocery store or what restaurants might choose to serve us

– let’s move from sometimes towards always and more often. Everyone with a marketing, advertising or communications budget or social media channel, personal or professional –it’s time to get Canada on the menu and in your message channels loud and clear.

Can we eat our way out of trade chaos? Absolutely not. But with easier access across provincial borders and Canadian focus, we can make a difference.

The sentiment for buy local is and should be loudly Canadian, with a big flag all over it. This is not the time for our usual Canadian humble ways. Let’s live and act the words of our incredible national anthem with our fabulously Canadian 4,634-kilometre diets.

For a list of helpful resources and ideas around buying Canadian food, view the online version of this article at canadianpoultrymag.com

With Avian Influenza posing an increased risk to the poultry sector, improving barn entrance design has emerged as a crucial biosecurity measure. Epidemiology reports from the CFIA highlight its effectiveness in preventing disease transmission on farms.

By adopting enhanced biosecurity measures, the poultry sector can significantly reduce the risk of Avian Influenza outbreaks and safeguard flock health.

S T R EN G T H EN Y OU R

B R OILE R F L OC K

Reduce mortality

Reduce E. coli associated lesions

Potential to reduce antibiotic use