Better returns, more income

Colin Breukelman reflected on his decision, saying,

‘The ESA 3000 exceeded my expectations in every aspect. It not only improved the litter condition and flock performance but also had a direct positive impact on my bottom line. The investment in ESA 3000 heat exchangers was undoubtedly one of the best decisions I’ve made for my poultry production.’

by Brett Ruffell

The B.C. chicken industry has been thrust into a pricing controversy, drawing national attention. While mainstream media largely aligns with critics of the proposed 10 per cent price hike, I thought it was essential to delve into the chicken industry’s perspective. The ongoing debate surrounding potential chicken price hike in the province has prompted the B.C. Chicken Marketing Board to advocate for a nuanced examination of its pricing model.

Woody Siemens, the executive director of the B.C. Chicken Marketing Board, provided me with valuable insights into the intricacies surrounding the proposed price adjustments and addressed concerns about the industry’s efforts to lower input costs. He acknowledges the historical reliance on Ontario’s pricing model and the need for a shift due to the unique challenges faced by B.C.’s chicken producers, particularly concerning the cost of feed grain.

Siemens emphasizes the importance of addressing B.C.’s high production costs, driven by factors such as feed grain differentials and land expenses. “We recognize that B.C. is a high-cost production province, and our current pricing model does not adequately cover the expenses incurred by growers. If growers can’t recover their costs, they won’t be able to stay in business

long term,” he explains.

In response to criticism from Restaurants Canada and other industry stakeholders, Siemens clarifies that the B.C. Chicken Marketing Board regulates prices only up to the farm gate, focusing on ensuring fair compensation for farmers. Acknowledging the concerns critics have raised, the chicken industry expert states, “We did engage in wide and vigorous consultation, including hatcheries, the hatching commission, processors, all under the Farm Industry Review Board supervisory review.”

“If growers can’t recover their costs, they won’t be in business long term.”

He addresses the question about the industry’s efforts to lower input costs, acknowledging ongoing attempts between growers, feed mills, and nutritionists. He says, “There’s been ongoing efforts to optimize and control costs, especially considering the challenges we face in B.C. with feed grain differentials.” Emphasizing the limitations, Siemens notes, “While attempts to explore alternative solutions, such as adjusting feed compositions, have been made, inherent constraints exist due to limited accessibility to certain feed markets, unlike our counterparts in Ontario.”

Additionally, Siemens shed light on the transparency of the

B.C. Chicken Marketing Board’s pricing proposal. He says, “Our pricing proposal, based on the cost of production up to the farm gate, is fully transparent to all stakeholders and the public. The same level of transparency cannot be stated by the rest of the value chain from primary processors, further processors, distributors, restaurants, retailers, and others who all can add in unknown levels of cost and margin.”

Meanwhile, Restaurants Canada is urging the B.C. government to prevent the proposed 10 per cent increase. Mark von Schellwitz, vice president, Western Canada at Restaurants Canada, highlights the significance of competitively priced B.C. chicken for the province’s foodservice industry.

He says, “The soaring cost of this widely consumed and versatile meat protein could prove detrimental to restaurants of all sizes in British Columbia, where chicken forms an essential part of menus and dietary preferences.”

A recent survey by spark*insights showed that 78 per cent of B.C. residents would be concerned if chicken prices rose by 10 per cent. The potential impact of this price surge could lead to a substantial shift in consumer behavior, with 48 per cent of respondents indicating they would purchase less chicken and 24 per cent stating they would stop buying chicken altogether.

Moving forward, as the debate over B.C.’s chicken price hike persists, achieving a delicate equilibrium between industry sustainability and consumer affordability is paramount.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer Brooke Shaw

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada - Single-copy $10.00

Canada – 1 Year $33.15

Canada – 2 years $56.61

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Reducing emissions

Supplying high-quality eggs

Canadian egg farmers are passionate about providing fresh, high-quality eggs while taking care of their animals, communities and the environment. Find out how egg farmers are shaping a brighter future. eggfarmers.ca/sustainability

Protecting our animals

Following rigorous standards

Supporting the future of our food system

Canadian authorities reported the first instance of highly pathogenic avian influenza (HPAI) in a commercial poultry flock in Alberta for 2024. The Canadian Food Inspection Agency (CFIA) officially confirmed the virus’s presence in a commercial flock situated in Mountain View County, Alberta, on February 19. CFIA did not disclose details regarding the specific type of flock or the number of affected birds.

A critical pump station that came dangerously close to being overwhelmed by floodwaters in British Columbia in November 2021 will receive almost $80 million in upgrades to provide future disaster protection, Premier David Eby said in February. With the looming threat of climate change, Eby said protecting Fraser Valley residents, farmlands and economically important transportation infrastructure must be addressed ahead of future floods. Record rainfall in late-2021 killed thousands of poultry and livestock min the region.

Lawrence MacAulay, Minister of Agriculture and Agri-Food Canada, recently announced an investment of over $97 million under the Agricultural Clean Technology (ACT) Program. This funding is set to bolster 162 projects nationwide, empowering farmers with cutting-edge clean technologies to enhance efficiency and reduce environmental impact. The ACT Program is designed to support farmers and agri-businesses in developing and adopting the latest clean technologies.

Event shatters records with 1,432 exhibitors, 31,353 attendees, and global acclaim.

The 2024 International Production & Processing Expo (IPPE) marked a triumphant year, achieving significant milestones by hosting 1,432 exhibitors across 620,850 square feet of exhibit space.

This success resulted in the establishment of two new records for the renowned event. As the world’s largest annual gathering for the feed, meat, poultry, and egg industries, IPPE also secured its position among the top 25 largest trade shows in the United States.

CANADA emerged as the leading contributor outside the U.S., constituting 14.9 per cent of registered attendees.

The event, sponsored by the U.S. Poultry & Egg Association, American Feed Industry Association, and the Meat Institute, drew attention with its impressive scale and industry representation.

With 31,353 registered attendees hailing from the poultry and egg, meat, and animal food sectors, the 2024 IPPE witnessed robust participation.

Notably, a record-breaking 9,063 international visitors, representing 133 countries, contributed to the event’s global significance.

Canada emerged as the leading

contributor outside the U.S., constituting 14.9 per cent of registered attendees. Latin America maintained its strong presence, accounting for 45 per cent of international visitors, consistent with previous years.

Reflecting on the event’s success, the organizing entities—U.S. Poultry & Egg Association, American Feed Industry Association, and the Meat Institute—expressed their satisfaction and excitement.

In a joint statement, they stated, “We are very pleased and excited about our strong attendance numbers and this year’s record-breaking trade show floor. The turnout for the 2024 IPPE was outstanding, and the feedback from attendees has been extremely positive regarding time spent on the trade show floor, education sessions offered, and opportunities to connect with colleagues and vendors. We expect next year’s IPPE to build on this success to ensure we continue to provide the best possible experience for attendees and exhibitors.”

The Chicken Farmers of Ontario (CFO) has responded to the surge in Ontarians seeking emergency food support by contributing a substantial $100,000 donation to Feed Ontario’s Full Shelves Campaign. Murray Opsteen, chair of Chicken Farmers of Ontario, emphasized the unwavering commitment of Ontario’s chicken farmers, stating, “Food banks across Ontario have seen a widespread increase in visitors since 2020. Ontario’s chicken farmers remain committed to ensuring a steady, reliable supply of safe, nutritious, locally grown chicken for Ontario food banks.”

Opsteen further announced the CFO’s monetary donation to Feed Ontario’s Full Shelves Campaign, citing the CFO Cares:

noted, “Through the CFO Cares: Farmers to Food Banks Program, Ontario’s chicken farmers donate chicken contributing to over 1 million meals each year. With Ontario food banks experiencing increased pressure, I am thrilled to announce this monetary donation of $100,000 to Feed Ontario’s Full Shelves Campaign.”

The CFO Cares: Farmers to Food Banks program facilitated this substantial donation through existing funds recovered from the program’s successful initial funding. Andrea Veldhuizen, CFO Board Director for CFO Cares & District 4, expressed gratitude, stating, “Chicken Farmers of Ontario is grateful for this opportunity to donate to Feed Ontario’s

to step up and do what we can to tackle hunger in our communities.”

Veldhuizen highlighted the persistent focus of the CFO Cares program on addressing the chicken protein needs of food banks with the greatest need. The donation was made possible through the CFO Cares: Farmers to Food Banks program, ensuring a steady supply of chicken to Ontario food banks.

Feed Ontario, dedicated to ending poverty and hunger, welcomed the support from several community partners, including Chicken Farmers of Ontario, Dairy Farmers of Ontario, Food Basics, Metro, and Toyota Canada, amounting to over $800,000 in additional support for the Full Shelves

By Crystal Mackay

The term collaboration shows up in many places such as strategic plans, vision statements, and media soundbites. But what does it really mean and how would you put collaboration to work on the job or in life?

Let’s flashback to our first experiences with collaboration – group projects at school. Do you remember those? These could be very painful exercises in frustration or incredibly fruitful depending on the individuals in the group. From a young age, I learned the value of group dynamics, and how it was easier to work with some people than others.

Fast forward to our world today. The issues and opportunities for individuals, organizations, the poultry sector, and the entire food system are so immense it’s almost impossible to fathom how to successfully navigate them on our own. At a time when human resources, time, and money are all at a premium, we need to continue to think smarter to achieve bigger results.

Enter the term and need for collaboration. It’s easier said than done, as the supply chain was built for competition, not collaboration. Collaboration

“At a time when human resources, time, and money are all at a premium, we need to continue to think smarter to achieve bigger results.”

requires leadership and strategic intent to make it happen. It is often much easier and faster to work on your own plans and work, particularly at the beginning.

So why is collaboration worth the extra effort? Evidence clearly shows that efforts that work collaboratively lead to greater resources, recognition, and rewards, particularly when facing competition for finite resources. Let me share a few examples.

I’m a hard-wired collaborator. I identified the need for a whole food system approach to earning public trust in food and farming in my Advanced Agricultural Leadership Program project many years ago. One farmer, one company,

or even single sector voices were too tiny and fragmented at a time when the rural-urban gap was growing and pressures against production practices were mounting.

The same collaborative spirit went into creating the Canadian Centre for Food Integrity (CCFI). The United States food companies and farm groups formed the US Center for Food Integrity in 2007.

Could we not learn from their investment, research, and model and use it to research Canadian attitudes on public trust in food? After three years of thinking, discussing, and development with many stakeholders, the Canadian Centre for Food Integrity was launched in 2016 with a whole food system approach.

Fierce competitors in the marketplace come together to invest and learn around the same tables with the pre-competitive spirit of collaboration needed for leadership and shared goals.

I recall in some of those early meetings a few individuals shared they had never been in a room with their competitors and customers and government representatives having such open discussions before.

These are just two examples of many that demonstrate collaboration takes work. It takes strategic intent and sometimes a mindset shift, for individuals and organizations. Where competition focuses on individual achievement, collaboration emphasizes teamwork and collective success.

Take a minute and review your efforts. Where and how do you spend your time working? Review it with the collaboration lens – is there anything you could do better and bigger together?

Don’t be afraid to stretch yourself and think outside your normal borders and partners. In addition to the greater achievements, you might also find some more positive energy and fun as unexpected bonuses we can all appreciate and benefit from!

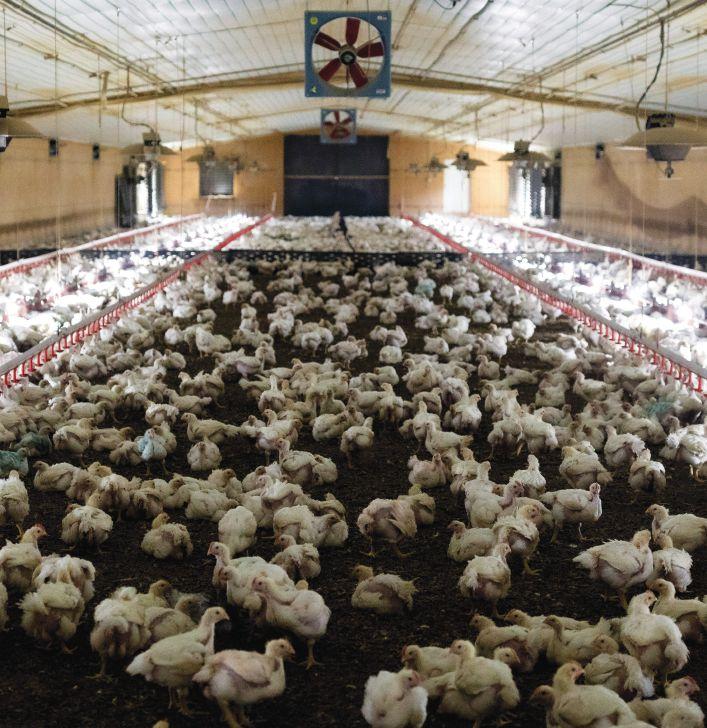

Inspired by nature, gradient lighting is transformative for broiler welfare.

By Melanie Epp

It’s commonly known that intensity, wavelength and duration of lighting influence broiler activity, feed and water intake, and overall productivity. It’s also well known that light intensity impacts animal welfare and mortality. However, there’s little research that supports current lighting recommendations and, until recently, few studies have looked at how lighting impacts broiler welfare.

A recent study, led by Seong Wook Kang, director of the poultry experiment station at the University of Arkansas, examined lighting preferences in broilers. The commercial-scale study, which was conducted at Tyson Foods’ Broiler Welfare Research Farm in Springdale, Ark., revealed that broilers do have lighting preferences, and giving them choice offers several benefits, including improved feed conversion ratio, reduced fear response and fewer welfare issues. Their findings could be a game changer for broiler welfare on a global scale.

While the vast majority of commercial broiler barns provide uniform lighting conditions, in nature, Red Jungle Fowl live at the edge of and in rainforests where light filters through the canopy unevenly. Drawing inspiration from nature, Kang wanted to know if non-uniform artificial

light could be used as a tool to promote broiler welfare and performance.

In 2016, he sought to answer this question through a series of pen trials. Intrigued by the results, Tyson Foods offered up its Broiler Welfare Research Farm to test the effects of gradient lighting in commercial-scale barns. Karen Christensen, Senior Director of Animal Welfare at Tyson, worked closely with Kang

on the project.

Broilers are diurnal in nature, which means they eat when the lights come on and rest when the lights are off. In most poultry barns, lighting programs offer 16 hours of light and eight hours of darkness. When the lights came on, the birds would immediately move to the feeders.

In his initial experiments, in order to stimulate eating, Kang installed lighting

directly over the feeders. He noticed the birds would move off to dimmer areas for active rest once they were satisfied and wanted to know if he could manipulate lighting further for their benefit.

In the commercial-scale study, one-dayold broilers were housed in four commer-

mortality, leg health and performance. He also measured brain welfare indicator genes.

In his first observations, Kang noted the birds fought a lot more in the brightly-lit houses. Overall performance fell as well. In the variable-light house, where the flock was given a choice, Kang observed more uniformity. The birds also

“Before, the house was not exciting enough,” said Kang. “Conditions were too uniform. Providing different lighting conditions lets them choose where they want to go – bright or dark areas.”

But it wasn’t just lameness that saw improvement. In fact, daily physical activities, footpad condition, fear response to novel objects, body weight and feed

pacted by the variable-light intensity lighting program. Additionally, lighting

tensen, was eager to participate in the study with Kang. Recommendations around lighting programs were varying

cause we didn’t care what the light intensity was, but we absolutely wanted to make sure it’s right for the bird,” Christensen said. “There just didn’t seem to be a lot of great research as to where some of those numbers came from.”

According to Christensen’s observations, there was a palpable difference in the behaviour of the birds under the different lighting programs. The birds in the variably-lit houses were visibly calmer, she said.

“The birds were quiet,” she said. “But the other interesting part is that they were not just sitting and they’re not just resting. They’re actively eating around the feeders. They’re playing in the transition area between the water lines where it’s still fairly bright. And then we see them moving to the dimmer areas where they are resting and feeling safe.”

But it wasn’t just the stillness and calm, or the movement that surprised her. There were also obvious holes where birds had been dustbathing.

“We really feel that’s a comfort behaviour,” she said. “That is only going to happen at that level when they’re feeling really safe and secure.”

Not only did the researchers see better leg health, but they also noted improvements in feed efficiency, which is counterintuitive given the increased movement observed.

“We’ve seen those metabolic changes that favour the feed line lights, so it really kind of puts the whole picture together,” she said.

Variable lighting made simple

While there are many suppliers of lighting

options, Tyson opted to go with Optient lighting, developed by ONCE by Signify. Optient is a modular LED lighting solution that uses a patented twist-and-hook system for simple installation in any poultry house. Christensen said the lighting solution is robust. Tyson put it through ammonia testing to ensure it could last at that height above the litter, and they are pleased with the result. In fact, Tyson believes so much in the benefits of gradient lighting that they made the decision to transition 3,100 of their broiler houses. While it’s a huge project, their customer partners believe in as well and support the transition.

“Optient is really changing the game for the boiler industry,” said Gabrielle House, Poultry Scientist at Signify. “It’s a simple solution that can promote that freedom of choice and optimal performance in commercial boiler houses.”

Taken together, the variable-light intensity lighting program offers several benefits to broiler producers. Research shows that the lighting system promotes volunteer natural behaviours and physical activity, which may improve footpad condition and leg health of birds.

Performance data including the increased daily weight gain and the lowered feed conversion ratio, as well as the results of brain welfare indicator gene expression showed the beneficial effect of the variable-light intensity lighting program on the performance and welfare of commercial broilers.

Optient lighting is now available in Europe, North America and Latin America.

Research Breakthrough: Recent studies led by Seong Wook Kang at the University of Arkansas unveiled groundbreaking insights into broiler welfare by exploring lighting preferences.

Commercial-Scale Study: Conducted at Tyson Foods’ Broiler Welfare Research Farm, the study demonstrated that broilers exhibit lighting preferences. Providing them with choices resulted in improved feed conversion ratio, reduced fear response, and fewer welfare issues.

Inspiration from Nature: Kang drew inspiration from the uneven lighting conditions in nature, particularly the Red Jungle Fowl living in rainforests. Mimicking this non-uniform light in barns proved beneficial for broilers.

Trial Details: Commercial broiler houses with gradient lighting options were tested, revealing that broilers in variable-light conditions exhibited calmer behavior, reduced fighting, and improved overall performance.

Positive Impact: Broilers given the choice between well-illuminated areas and shaded spots showed better leg health, reduced fear responses, increased dustbathing holes, and improved feed efficiency.

Lighting Programs: The study compared different lighting programs, including 5 lux, 20 lux, natural light (480 lux), and variable light (2–5/40 lux).

Variable lighting not only enhanced welfare but also reduced lighting costs by 70%.

Industry Adoption: Tyson Foods embraced Optient lighting, developed by ONCE by Signify, for its modular LED solution. The company is transitioning 3,100 broiler houses to this innovative lighting system.

Global Availability: Optient lighting is now available in Europe, North America, and Latin America, providing broiler producers worldwide with a simple solution to enhance bird welfare and optimize performance.

Danish group designs greener way to process poultry manure. By Jane Robinson

The evolving carbon market is driving innovation for how to effectively capture the building block of greenhouse gas as the world moves closer to net zero emissions. A Danish group has designed a greener way to process poultry manure, capturing carbon to create a cleaner agricultural fertilizer – with possibilities beyond the farmyard.

Lars Bojsen and his son Peter operate Springkilde, a large family farm near Horsens, Denmark. Their operation includes 150,000 laying hens and about 150 hectares of cropland.

Always looking for new options to process the manure generated on the farm, they connected with a local manufacturing firm that was starting to design and build a flash pyrolysis system to process waste material into biochar. They were so intrigued about the possibilities that they became one of the first customers and then joint owners in a new venture called Frichs Pyrolysis.

“There are a lot of systems doing carbon capture, but they generally require a lot of energy,” says Soren Bruun, CEO of Frichs Pyrolysis. “What we’ve created is a process that produces energy, while doing carbon capture. It’s like a Swiss-army knife – a multi-purpose system that delivers a way to capture and store carbon, produce an energy surplus, and recirculate minerals (phosphorus).”

The company is in the process of building a new flash pyrolysis unit on the Bojsen’s farm that will have the capacity to process up to 15 tonnes of dry matter per day. They’ll process the farm’s manure, provide a site where they can collaborate with researchers at the University of Southern Denmark to gather experience and productivity data on the system, and provide a showpiece for promoting the flash pyrolysis system. The project is supported by the European Union’s NextGenerationEU program.

“We need to know the carbon credits created with the system,” says Peter Bojsen. “We are thinking on a global carbon scale

and whatever we can do to capture carbon, we need to do it – and pyrolysis is one way to accomplish that.”

Pyrolysis uses high heat to convert biomaterial into carbon-rich biochar. Here’s how the process will work for the system at Springkilde. Manure (or any biomass) must be prepped to go into the pyrolysis reactor. This involves drying it down to 80 to 90 per cent dry matter – poultry manure is about 25 per cent dry matter. The dried down manure is then put through a hammermill to create a consistent maximum three-millimetre particle size needed for the pyrolysis process.

The flash pyrolysis reactor heats the manure to 800°C for two to three seconds without oxygen to create biochar and industrial gas from poultry manure. The amounts will vary depending on the biomass material.

The resulting biochar from poultry manure creates a concentrated fertilizer that contains up to 90 per cent pure stable car-

bon. “This carbon can’t be broken down by bacteria to produce CO2, and when it’s applied to the soil it remains stable for a very long time,” says Bojsen.

The other important component in the biochar is phosphorus. “Through the pyrolysis process, phosphorus from the biomass/manure remains in the biochar and is more stable, more bioavailable and more moveable from areas with a lot of animal production to areas with less,” Bruun says.

Gas produced through the pyrolysis process runs through scrubbers before being used, stored, or sold. About 10 to 15 per cent is needed to power the system, leaving excess available for farm generators or to be upgraded and sold through natural gas networks. Nitrogen – the other component in the original poultry manure – is removed from the biochar and contained in the resulting gas component.

“The work with the University of Southern

“What we’ve created is a process that produces energy, while doing carbon capture.”

Denmark will help us evaluate the inputs and outputs and refine the whole process,” Bojsen says. “The university is particularly interested in the gas produced through the process because we already have the complete gas infrastructure in place.”

The new flash pyrolysis system at Springkilde is expected to be running in the early part of 2024. They’ll be using two different sources of biomass – poultry manure and straw – to work with the new system. With a much higher dry matter content, straw doesn’t need to be dried down as much as

manure, but also provides fewer nutrients in the resulting biochar.

Agriculture is a natural starting point for the flash pyrolysis system. “Dairy also represents a big benefit for the system from a CO 2 emission perspective,” Bojsen says. “The system also makes sense in areas with a land imbalance compared to the manure produced, like the Netherlands.”

After agriculture, Frichs Pyrolysis will set its sights on other industries needing new innovations to handle biomass. “Municipal waste is another opportunity, but we need proof of concept in agriculture before moving into the next market,” says Bruun.

This year marks an important milestone for Canada’s hatching egg sector when it comes to on-farm food safety practices. It’s the 20-year anniversary of the Canadian Hatching Egg Producers’ (CHEP) quality assurance program – Canadian Hatching Egg Quality (CHEQ). It’s also the year that new updates to the program are in place to ensure the sector keeps supplying safe and high-quality hatching eggs to the entire value chain.

Viki Sikur has been involved in on-farm food safety for her entire career at CHEP. As the national food safety officer, she was responsible for developing the initial CHEQ program in 2004, and ensures the program is kept up to date. CHEQ is managed by CHEP and implemented by provincial hatching egg boards across the country.

“When we started working on a quality assurance program, we were part of a larger Canadian approach about on-farm food safety, and there was a tremendous benefit to having a coordinated, common response to growing consumer demands around food safety,” Sikur says.

She’s particularly proud of the fact that CHEP’s pro -

gram was developed by producers, for producers from the unique broiler hatching egg perspective, led by the HACCP Technical Committee and reviewed by the Canadian Food Inspection Agency (CFIA).

“Broiler breeders are very highly tuned birds that require a special kind of management to produce healthy, fertile eggs for the broiler sector,” she says. “The fact that we have created a program that is rigorous, technically sound and practical, is critical for compliance.”

The biggest changes to CHEQ came into effect in November 2023 and were mostly related to new hatchery regulations required by CFIA. The changes didn’t come as a surprise for Sikur as they are components that their producers were already working towards.

“There is now mandatory Salmonella testing at the end of every flock cycle,” Sikur says. “Before this came into effect, all our member provinces had Salmonella enteritidis monitoring programs because we knew the regulation was coming, and so we were ready.”

The second change is the requirement that all producers implement a preventative control plan (PCP). For

CHEQ and food safety that covers activities including biosecurity and pest control. “CHEQ already has components to address these two new requirements –testing and PCPs – because we saw these changes coming and did our homework,” Sikur says.

As part of CHEQ’s commitment to continually improving its program, there were a few other changes to the program that have also taken effect, based on input and feedback from producers.

“We looked at biosecurity given the instances of highly pathogenic avian influenza over the last few years and clarified some requirements,” she says.

There were other requirement changes around water testing, medication usage and corrective action. And after 20 years, they updated some of the language for CHEQ to reflect technology changes, including the ability to demonstrate compliance with electronic farm records.

“We occupy a key point in the poultry supply chain, at the breeder level. Safety controls at our level is particularly important because our eggs hatch out and go on to become exponentially more broiler chicks,” says Sikur. “So, when we talk about pathogen control at the breeder level, it becomes that much more important down the line.”

Over the years, Sikur has put a lot of thought into the “what’s the benefit to me” for producers and the CHEQ program. “If we want to see progress in food safety for our sector, CHEQ is the way to do it,” she says.

• Rigorous, yet practical, requirements for on-farm food safety are vital for broiler breeders because of their position at the “start” of the poultry supply chain, and remove the need for additional programs.

• The documentation required in CHEQ for medication, pest control, etc., can reduce duplication, and better records can lead to better productivity.

• CHEQ is “our” program with a process in place to make improvements that reflect current science, industry practices and feedback from provincial boards.

Like every segment of the Canadian agriculture industry, the hatching egg producer sector looks for ways to encourage and recruit young farmers to get involved in leadership roles in the industry. Since 2002, the Canadian Broiler Hatching Egg Producers’ Association (CBHEPA) – the national producer association – has offered an annual program for farmers 39 years of age or younger.

The program gives producers the opportunity to tour primary breeder facilities in the U.S. – Aviagen and Cobb – and learn more about the hatching egg industry and broiler breeder management.

Starting this year, CBHEPA is collaborating with CHEP to offer a new professional development component to the Young Farmers Program. The new option is designed to help develop leadership skills for younger producers who may come up through the ranks.

“We want to help widen the world for young producers by helping them gain more experience about their industry and learn what the national agency does,” says Teddy Markey, communications and government relations advisor at CHEP. “They have the chance to learn about the issues CHEP deals with, develop networks across the country and participate in board meetings at the provincial and national levels.”

With the new professional development option, young farmers applying to the annual program can choose to be part of the tour component, the professional development component or both. The first participants in the new part of the program will be chosen this spring.

“The federal government occasionally contacts CHEP looking for young farmers to participate in working groups or advisory councils, and this expanded program will give us a pool of producers to draw on that could represent the industry and be better prepared to participate in federal initiatives,” says Markey.

For more information, visit chep-poic.ca.

In a new Canadian Poultry webinar series, experts shared insights on top diseases affecting poultry, offering strategies for protection and economic resilience.

By Lilian Schaer

Diseases are top of mind concerns for poultry producers and a leading cause of negative economic impacts on-farm.

That’s why, this past winter, Canadian Poultry tapped a series of experts to address four of the top diseases currently affecting the industry and highlighting their causes, the on-farm impact and what producers can do to protect their flocks.

Here are the key takeaways they offer for producers.

Inclusion body hepatitis

Inclusion body hepatitis (IBH) is caused by a Type I adenovirus. In Canada, IBH mainly affects meat birds like broilers, and the best way to protect against the virus is vaccinating breeder flocks as there is no live vaccine for broilers.

As birds get older, they become more resistant to IBH, so while outbreaks at three to five weeks of age are common, the level of mortality is much lower than if the outbreaks happen in the first couple weeks of life, when mortality can be 10 to 30 per cent in affected flocks.

How hard an outbreak will hit a flock

depends on various factors including whether transmission is vertical or horizontal; what level of maternal antibodies are transmitted; the age of birds at the time they’re exposed to the virus; what type of vaccine is used and how old the breeder flock is; and how much older IBH virus might still be circulating in a farm’s environment from previous outbreaks.

“What’s unique about adenovirus, unfortunately, is that the serotype causing the outbreak must be present in the vaccine used to vaccinate broiler breeders in order to create immunity that can be passed on to offspring,” Sanei notes.

“We would like broiler breeders to have active immunity via natural infection before they come into production, so they

The OptiGROW nipple is specifically designed to present water to day-old broiler chicks for the best possible start, and will deliver fresh water throughout the grow-out for the largest possible broilers.

Made with a stainless steel triggering pin and chemical resistant thermoplastic body so you can depend on a reliable drinker for many flocks.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

transmit antibodies via passive immunity to their offspring; the other way is to vaccinate to induce maternal antibodies and immunity.”

Ontario had a significant IBH outbreak in 2009, primarily caused by serotypes 11 and 8a and after the industry collectively decided to vaccinate all breeder birds, cases subsided significantly. This was a successful approach until 2016, when 8b emerged as a new serotype that is more virulent than the other two as well as being immunosuppressive.

Even when vaccinated, maternal antibodies will wane by 18 to 20 days of age and flocks can still be susceptible to IBH outbreaks, Sanei cautions. This is especially true of the more pathogenic 8b strain, which means producers should also protect their flocks against infectious bursal disease (IBD).

“In my opinion, all broilers need a dose of IBD vaccination at the hatchery followed by monitoring of bursa samples at three to four weeks of age to make sure vaccine is working,” he advises. “Monitoring and diagnostics are critical here as you don’t want IBD and IBH at the same time, especially not 8b.”

Infectious laryngotracheitis (ILT) is a contagious viral upper respira-

tory disease primarily of chickens that can cause mortality and production losses. It infects both small non-commercial chicken flocks and larger commercial flocks.

Caused by a herpes virus, outbreaks happen sporadically in most provinces, except in B.C. where the disease is considered endemic and outbreaks happen regularly, particularly in the Fraser Valley where the poultry population is quite dense.

Although birds of all ages are susceptible, ILT typically affects birds older than four weeks. In long-lived birds like breeders and layers, outbreaks tend to occur around peak of lay, so it will cause a decrease in egg production. In affected flocks, 50 to 70 per cent of birds will end up sick, with mortality as high as 10 to 20 per cent. Birds that recover from the disease remain ILT carriers for life and can become sources of infection for future outbreaks.

The incubation period can be six to 12 days, meaning a flock has been infected for some time before clinical signs are detected. Those signs include difficulty breathing, coughing blood, and red, irritated, or blood-filled tracheas, although in mild cases they could be limited to conjunctivitis.

“Call your vet if you see clinical signs, so that birds can be sent to a lab where they will sample tissue to look for the herpes virus,” Carrier says.

Although there is no treatment for the disease once its present in a flock, Carrier says the single biggest action producers can take to protect their birds is to practice good biosecurity and to strengthen those measures if there is an outbreak nearby.

As well, vaccination for all long-lived birds will reduce the severity of lesions and reduce loss. An injection given in the hatchery provides life-long protection against ILT as well as Marek’s disease; vaccination can also be administered by eye drops on the farm.

Commercial broiler flocks aren’t usually vaccinated against ILT except in British Columbia. In Ontario and Quebec, vaccination is recommended for producers inside a 10-km risk zone around an outbreak for at least two flocks following the last case in the region. Most small flocks aren’t vaccinated, which causes preventable losses, Carrier notes.

“No vaccine is 100 per cent effective, but it will help reduce the severity of clinical signs and mortality, reduce the negative impact on productivity and reduce virus shedding,” he says. “Vaccination alone is insufficient; you also need good biosec-

urity and good sanitation. Reciprocally, biosecurity and sanitation alone may be insufficient, so vaccination makes a difference.”

Enterococcus cecorum (E. cecorum) is an old foe presenting new challenges for the poultry industry. It’s a commensal bacterium of the gut microbiota in adult chickens that in Canada usually starts presenting in birds at two to three weeks of age.

Affected birds will show lameness and jumping on one leg, causing a high cull rate. Less commonly now in Canada, it can also present as kinky back in older birds resulting in paralysis. It is very hard to treat, and there are no vaccines available.

E. cecorum tends to reoccur in the same barn sporadically, and as an organism that thrives in cold, humid conditions, it is hard to eradicate from the environment. There are still a lot of unknowns, such as where it comes from, what the causes are and why some birds and barns are affected repeatedly while others are not.

Dr. Lanthier first started seeing cases of pathogenic E. cecoru in antibiotic-free broilers over a decade ago. There are many potential risk factors, but through his work with producers and consultations with industry colleagues, he has developed a short

826 Nanticoke Creek Parkway, Jarvis, Ontario, N0A 1J0

Call us on: 519-587-2667

Or visit our website: www.mellerpoultry.ca

The Chainovation chain feeding system can be used for a wide range of applications, enabling the most effective set-up for every type of poultry house (breeders rearing, production and layers). The Chainovation chain feeding system, developed in cooperation with breeding associations, is an extremely reliable system. Feed can be distributed at various speeds (max. 3000 kg/hour) through the feed trough, giving all the birds almost simultaneous access inside the poultry house and promotes animal welfare and animal health.

list of the top three that influence pathogenic E. cecorum infections.

These include preventing heat stress in newly hatched chicks, ensuring early access to feed, and cleaning and disinfecting water lines.

According to Lanthier, chicks in their early days are very sensitive to their surroundings and if they’re in an environment that’s too hot for them, it is easier for bacteria to move from their intestines into the blood stream.

Kevin Amini, technical services veterinarian, Boehringer Ingelheim Animal Health Canada

This means it’s important to ensure uniform light and temperature conditions, as well as a quiet, calmer environment.

Giving chicks immediate and consistent access to feed and water in their early days is also critical. This gives them a steady stream of nutrition during a key period of bone and gut development. Over the first seven days, chicks should never be without feed at any time.

“Aim for 100 per cent of chicks to have consistent access to feed. Evaluate frequently and fix if you see problems,” he advises. “The harder we work on this, the closer we will be to a solution for E. cecorum.”

Good cleaning and disinfection between flocks, as well as leaving more than 14 days of downtime before new birds are placed will help break disease cycles. Thoroughly cleaning water lines is critical, yet often overlooked.

“Waterlines are a most important point as they’re the highway to the chicks’ intestines for E. cecorum and a great reservoir for the virus. Overkill on waterlines will be worth your time and money,” he says.

And finally, keeping a healthy barn environment will help control other diseases

that can place additional stress on a young flock.

Infectious bursal disease (IBD) is a highly contagious disease of young broiler chickens that suppresses their immune system and is responsible for major economic losses in the poultry industry worldwide.

It is a stable, hardy virus that is easily transported on vehicles, people, insects, birds, and rodents, and can survive in poultry barns even when thorough cleaning and disinfection protocols are followed.

There are two major serotypes of IBD, but only Serotype 1 is important to the industry as it is pathogenic to broilers and includes standard and antigenic variant strains.

It’s the antigenic variant strains that are causing the majority of IBD- related problems in North America. There are no clinical signs, but they cause the bursa to atrophy, which causes immunosuppression and can result in secondary infections.

In Canada, the most prevalent IBD field strains are NC171 and SA08 and 586, but classic strains stemming mostly from vaccines are also found.

“All pathogenic types of Serotype 1 will cause immunosuppression in chickens and if the bursa is infected by IBD virus and damaged before 14 days of age, the immunosuppression becomes permanent,” he says.

Five main tools are used to diagnose and monitor IBD. The gold standard, notes Amini, is histopathology (by scoring the bursal pathology), but bursa to body weight ratio, PCR and sequencing and

“Vaccination alone is insufficient; you also need good biosecurity and good sanitation.”

• Use vaccination as a control if it’s available.

• Thorough cleaning and disinfection between flocks will give fresh birds a better start.

• A healthy barn environment will control other diseases that can stress a young flock.

• Good biosecurity is always important to minimize the risk of problems entering a barn.

blood testing are also used.

Producers are also encouraged to closely monitor flock performance to watch for indicators of IBD, such as:

• increased bird mortality from other diseases;

• an overall increase in the condemnation rate;

• particularly high air sacculitis condemnations;

• an increase in the proportion of under-performing flocks; and

• diagnosis of other immunosuppressive diseases, like Marek’s disease, reovirus or inclusion body hepatitis and others.

Although biosecurity is important for overall poultry health, it is not a practical solution for IBD virus because of its hardiness and easy transmission. That’s why IBD is controlled primarily through vaccination programs; however, thorough cleaning and disinfection helps lower the viral load between flocks, giving vaccines a better chance at working.

Young broiler breeders are vaccinated with modified live or vector vaccines. Breeder hens are also immunized so they will transfer high levels of antibodies to their offspring that will offer protection for one to three weeks. Broiler flocks are vaccinated with modified live, immune-complex or vector vaccines.

“The timing of live vaccination is crucial; if it is done too early while maternal antibodies are still high, the live vaccine virus is neutralized, and if it is given too late, there will be an immunity gap and infection can occur,” he explains.

By Treena Hein

As with so many new technologies in agriculture, the story of REVEAL Layers can be summed up quickly.

A hardware-software platform replaces a manual or more labour-intensive process, enabling much more data to be collected and analysed, resulting in much more accurate (and in many cases real-time) decisions.

These decisions may quickly improve or help maintain optimum crop or livestock performance and/or welfare, support sustainability through reduced use of resources, and help increase producer efficiency and profitability. Information, as they say, is power.

In the case of Cargill’s REVEAL Layers technology, launched at the 2024 International Production and Processing Expo (IPPE) in January, the focus is on body condition evaluation in laying hens to adjust feed recommendation as needed for optimum egg production. It’s the first time that NIR (near-infrared light) scanners have been used in this type of application.

“In many livestock animals, it’s well-established that there’s a direct connection between body condition and performance,” explains Rob Payne, the director of poultry nutrition for Cargill.

“In egg production, if a hen is too thin, she won’t achieve optimum egg production, so

producers may overshoot a bit with volume of feed or energy content of feed. However, if we overshoot, the hens may store excess fat, which can also have negative impacts on egg production. In addition, feeding too much food or making mistakes in the ration component also means potentially wasted resources and/or lower profitability.”

For many years, companies like Cargill have tried to get a sense of body condition for layers through extrapolating the findings of a small number of necropsies to the entire flock. This of course means the bird must be euthanized before measurement.

Additionally, the cost of necropsies severely limits the number of birds examined

to a very small number in the flock, usually about ten hens once or twice a year in a barn of tens of thousands.

“That sample size is not very representative, but it’s been our primary method available to assess body condition and fat pad measurement for the entire flock,” Payne says. “It’s not a very accurate way of assessing volume and composition of feed to maximize egg production, especially as a flock ages. So, we started looking at the technologies that are available.”

Cargill considered using DEXA (bone densitometry) scanning technology, but the equipment is large, and the animal needs to be kept still (sedated) during the scan. But today’s NIR scanners are handheld, easy to use, and once calibrated correctly provide accurate measurements of fat pad size. Fat, muscle, bone, and other tissues all have a unique fingerprint in NIR used in these types of applications, Payne explains.

“NIR is very suitable. It provides a non-invasive, rapid way to scan the body condition of many more birds in a flock. We can also scan many times over the lifetime of a flock to do age-related body scoring analysis and adjust feed accordingly to keep hens in ideal body condition along the way.”

Cargill chose to develop the technology with layers first as daily performance data – number of eggs collected from a flock per day – is readily available. However, the firm hopes to develop similar REVEAL applications for other production species, for example broilers in the future.

The NIR scanner is applied directly on the skin of the hen, and multiple scans are done over a short period of time (30 to 60 seconds). It doesn’t take long to learn how to hold the scanner correctly, Payne says. Depending on size and layout of the barn,

ideally one to two per cent of the hens would be scanned, but as few as 100 per barn can already provide more observations and thus more confidence in assessments than is possible with necropsy results.

As the scans are completed, the results are uploaded in real-time to the user’s mobile phone and analysed by the REVEAL Layer application. “With this number of hens scanned, REVEAL’s software provides a good sense of whether, for the entire flock, fat pads are within an optimal range,” Payne says.

“We’ve so far found that there generally needs to be some adjustment to the ration to help optimize body condition, and we see may see egg production change for the better in fairly short order.”

Like using the scanners, Payne says it does not take long for producers or nutritionists to learn what the REVEAL analysis means and to apply it in changing the ration. The

• Nests at the front for excellent egg quality thanks to the short egg travel distance

• 24 birds per compartment

• Increased height reduces coccidiosis

• Backwall between the compartments for easy access to the birds

• Choice between perforated, solid or wire partitions

ALBERTA William Vis: 204-781-4699 BRITISH COLUMBIA Dave Coburn: 778-752-9279 MANITOBA Calvin Hiebert: 431- 205-3365

ONTARIO Andy Stokman: 519-777-1495

ONTARIO Clarence Martin: 519-669-2225

ONTARIO SERVICE Steve Poppe: 519-348-8483

QUEBEC Stephane Chouinard: 450-266-9604

SASKATCHEWAN Greg Olson: 306-260-8081

flock may need to be moved up and down a phase, he notes, or a small change may be needed in feed energy level or feed volume.

Flock tests so far

In developing and confirming reliability of the technology, Cargill worked with multiple flocks in Cargill and customer facilities in the US, Spain, Netherlands, France, Turkey, and China.

Payne and his colleagues have learned a lot about adjusting the ration to support improved body condition/egg production already, he says, but there’s much more learning ahead. “In some ways it’s validated the nutrition program we have in North America, and it’s shown us we need to tweak feed for various reasons,” Payne says. “The findings from the other parts of the world are very similar.”

Specifically, Payne first explains that most research on body condition has focussed on the peak production phase of 25 to 55 weeks.

“We’ve seen using REVEAL to help confirm that our nutrition program during peak production is properly formulated and the volumes are correct, and I think that’s true for most nutrition programs,” he says. “REVEAL has also validated our program before peak production and how we get hens to peak weight faster than other programs.”

However, Payne and his team would like to collect more data on aging hens and how feed can be adjusted to maintain peak production longer. “A lot of producers in North America are carrying hens out 100 weeks and there isn’t much research on this,” he says.

“We’ve so far only calibrated and analysed from 20 to about 80 weeks, and we want to lengthen that. There also isn’t much research about body condition in pullets, and we’d like to broaden to that too. We’ve only scratched the surface so far.”

REVEAL Layers has also shown Cargill that more feed adjustment relating to genetics is

likely in order. “We already have some differences in our feeding programs now related to brown egg and white egg hens,” Payne says. “We know brown egg hens tend to be more robust and eat more, and we’ve always adapted for that. But we know there are differences in the pullet stage and it appears that no one has collected data about that.”

Regarding housing, Cargill has collected data in conventional cage housing and cage-free flocks. “We have seen different body composition profile in cagefree and caged hens, which could allow us to better adapt our feeding programs for different housing systems,” Payne says.

“Our data includes about 30 cage-free flocks in the US, and we’ve analysed a few in France that are similar to the enriched housing that’s quite popular in Canada. We will continue to collect data as time goes on.”

REVEAL Layers is now being launched globally with North America being one of the first regions the technology is offered. Payne notes that it’s logical for Cargill to build adoption in flocks owned by its nutrition consulting customers first – Cargill provides nutrition consulting for approximately 25 per cent of the layers in North America – but that this technology is available for use by any egg production company interested in being able to monitor bird health and egg production more closely by partnering with Cargill.

The cost of REVEAL Layers, including a NIR scanner and the analysis, is relatively low and is less than the cost for a benchtop NIR used for ingredient analyses, which makes this a very feasible and practical solution for most, if not all, egg producers, Payne says.

ROI will depend on how well a flock’s body condition is kept to optimum, farm size, number of weeks flocks are kept, genetics and other factors. And Payne stresses that REVEAL Layers is meant to be used as a standard ongoing practice,

as the components of feed ingredients never stay the same, because egg production changes over the life of the flock, management practices, genetics and housing can change, etc.

Additional innovation

REVEAL Layers is far from the only innovation relating to information technology that Cargill has recently developed or is now developing.

FlockWise is another development for the layer industry that Cargill has recently rolled out. This tool helps layer producers track weekly egg production and performance. This allows anyone who benefits from seeing such data –live production managers, nutritionists, veterinarians – the opportunity to review and compare data across flocks, house to house, etc.

For nutritionists, such information allows important real-time access to how the hens are performing, so that they can make proactive feeding and nutrition decisions to maintain that performance.

Technology Breakthrough: Cargill’s REVEAL Layers utilizes NIR scanners for real-time body condition analysis in laying hens.

Data Precision: Handheld scanners offer swift, non-invasive assessments, providing accurate insights into fat pad size and composition.

Optimizing Feed: Real-time results enable precise feed adjustments, ensuring peak egg production and sustainable flock health.

Global Rollout: Launched globally, REVEAL Layers is one of Cargill’s latest innovations in poultry care.

Cost Efficiency: The comprehensive REVEAL package, including the NIR scanner and analysis, is cost-effective, making it accessible for all egg producers.

Sustainability Impact: By promoting optimal body condition, REVEAL contributes to sustainability goals and increased profitability.

Industry-Leading Approach: Departing from traditional necropsies, REVEAL captures more data, offering a technological leap in poultry farming.

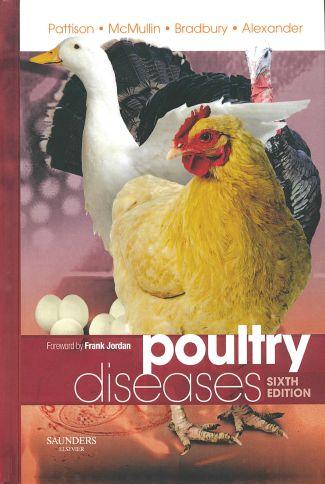

Now in its sixth edition, Poultry Diseases is once again fully revised with the addition of vital new material. It remains the standard reference work on health and disease for those involved in the poultry industry, government, and veterinary education.

Following a familiar structure, readers of the sixth edition gain concise but major reviews on current knowledge of general and diseasespecific topics discussed over 45 (5 new) chapters in seven sections.

Dunvegan, Ont.

Chicken Little Farm, under the Haerle family’s leadership, has unveiled a cutting-edge barn, signaling a new era for the business. With a rich 50-year history, they transitioned from dairy to laying hens decades ago. Now, with Markus and Roxane at the helm, joined by sons Christopher and Mathew, the producers have modernized their operation.

The decision to build a new barn arose from the need to modernize facilities and align with evolving housing regulations for laying hens. Markus Haerle emphasizes, “The main reason was to get in line with new housing regulations.” The looming 2036 deadline to phase out conventional housing prompted a proactive approach to address the changing landscape and create space for the next generation on the farm.

Housing 21,000 birds, the barn utilizes Nuform building technology, providing structural integrity without additional cladding. A Systel heat exchanger system from France enhances energy efficiency, operating without additional heating for four weeks. The enriched layer cage system from Hellmann prioritizes bird welfare, and tunnel ventilation with a water curtain system ensures environmental sustainability. In Markus Haerle’s words, “There’s nothing hidden behind the discussion around an enriched cage; it performs the way it’s supposed to.”

A unique coccidiosis vaccine that balances the safety and efficacy needed for poultry that are raised without antibiotics, or in management programs to reduce resistance against anticoccidials.

S T R EN G T H EN Y OU R

R OILE R F L OC K

Reduce mortality

Reduce E. coli associated lesions

Potential to reduce antibiotic use