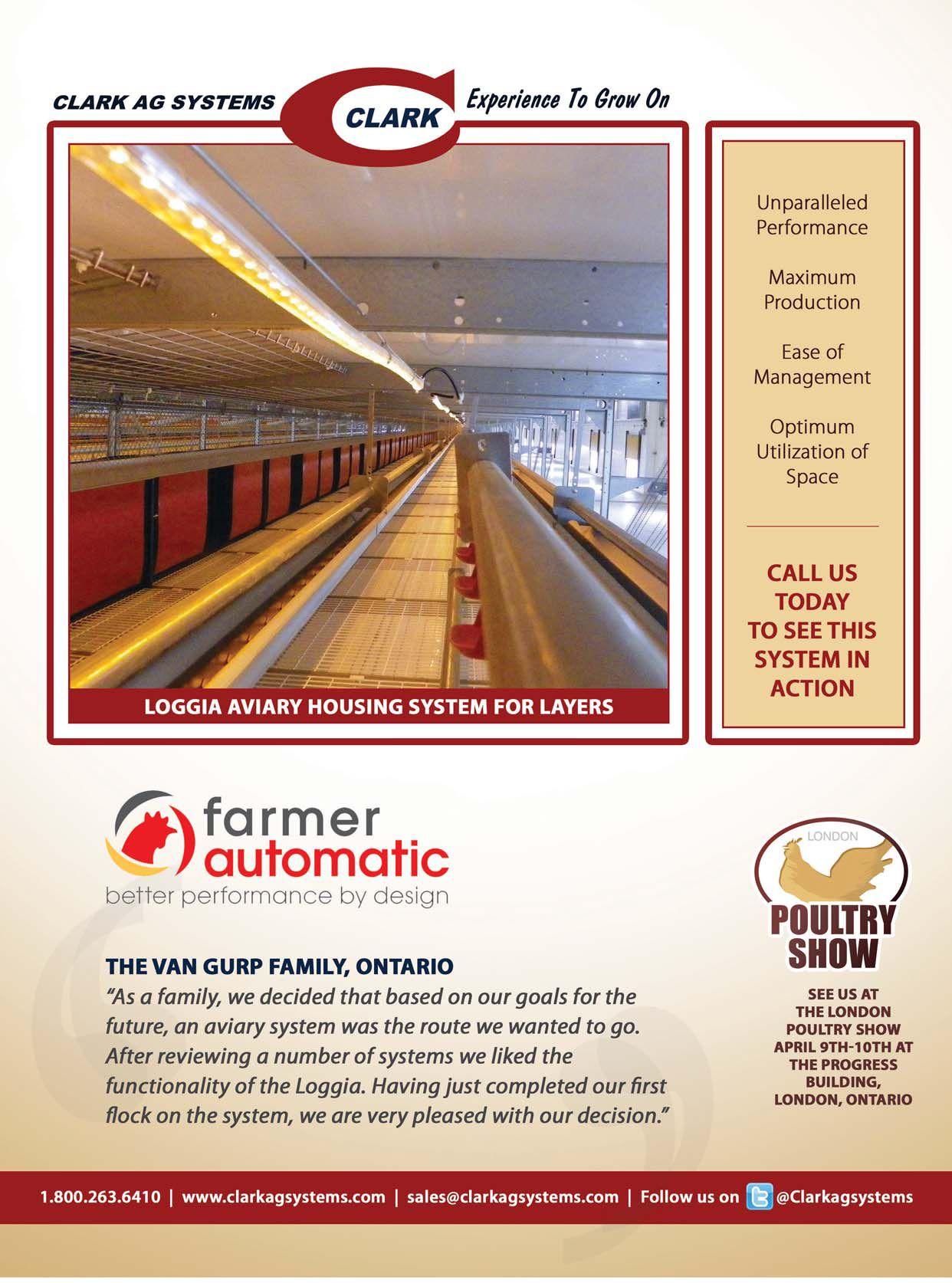

Multiple Tier Layer & Pullet Aviaries Floor Systems Free Range Systems

Choice of Elevator or Egg Lift Collection Systems

Enrichable and Fully Enriched Systems Layer and Pullet Systems Standard Height and Lo-Profile Standard Depth and Extra Deep Options

MARITIMES

Contact: Doug Schofield Cell: ( 902 ) 680-5731

EASTERN ONTARIO & QUEBEC

Contact: Stephane Chouinard Cell: ( 450 ) 266 - 9604

WESTERN & CENTRAL ONTARIO

Contact: Jack Lepelaars

Phone: ( 519 ) 348 - 8483 MANITOBA

Contact: Calvin Hiebert Cell: ( 204 ) 346 - 3584

WESTERN CANADA

Contact: Greg Olson Cell: ( 306 ) 260 - 8081

NORTH AMERICA (HEAD OFFICE)

Contact: Jim Currie

Phone: ( 519 ) 453 -3913 Fax: ( 519 ) 453 -3996 email: hellmannpoultry@bellnet.ca

BY KRISTY NUDDS

Since I hold the job title of editor I suppose it’s only natural that I pay great attention to words and their meaning.

Now that I am a mother, certain words capture my attention immediately. One of these is the word “wholesome”, particularly when it’s used in relation to food that I might feed my daughter. It’s an old-fashioned word and I can’t help but get a mental picture of June Cleaver cooking for the Beaver. If something is “wholesome”, then it must be good for you, right?

This line of thinking is what the World Society for the Protection of Animals (WSPA) is relying on with a new promotion for its cage-free egg campaign. In mid-February the organization announced celebrity Canadian chef Christine Cushing has partnered with it in an effort to get Canadians to choose cage-free over conventionally raised eggs.

Cushing says in a WSPA release “when I’m cooking, I always start with the very best ingredients. And I know that raising hens in cramped cages can’t produce the best eggs. Cage-free hens have space to move around, spread their wings, and be what they are — healthy, happy chickens, producing healthy, wholesome eggs. To me, it’s a clear and easy choice.”

The Oxford Dictionary defines wholesome as follows: 1) conducive to or suggestive of good health and physical well-being and 2) conducive to or characterized by moral well-being.

In the quote cited, how the word “wholesome” is used infers good health, even though the WSPA really means to

infer that “wholesome” is a moral choice.

That’s why I take offense to Cushing’s statement, and I think egg farmers should too.

Eggs are heralded as the “gold standard” for protein and have too many nutritional benefits to list in this small space. With the exception of eggs coming from hens with access to pasture (which alters the fatty acid profile), cage-free and cage eggs are the same nutritionally (in terms of protein, vitamins, minerals, etc.).

When an organization like the WSPA uses a celebrity spokeperson to get its message across we need to take notice. Cushing has a big reach. According to her website, she has cooking shows on both the Food Network and the Oprah Winfrey Network (OWN) and is the resident chef on the Marilyn Denis show, a daily talk show on the CTV television network.

If consumers want to make the choice based on morality, that’s their personal choice, but I don’t think they should be made to believe choosing one over the other will effect their health.

It’s known that although consumers, when polled, say they will choose one type of production method over another, when push comes to shove, they often choose the cheaper option. But will they when it’s no longer a moral question but one of health?

APRIL 2014 Vol. 101, No. 3

Editor

Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424

Account Coordinator

Mary Burnie – mburnie@annexweb.com

Media Designer Gerry Wiebe

Group Publisher Diane Kleer – dkleer@annexweb.com

President

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

Printed in Canada ISSN 1703-2911

Circulation

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

As easy as 1, 2, 3. and still maintaining exceptional litter conditions.

To find out more about the new please call us at or write to

Technical and performance details are available at

bottom Largebottompipin attract b

Large bottom pin that holds a drop of water to attract day old birds to nipple / great starts / average first week mortality below 1%.

Greater side flow allows all birds to eas a start.

Greater side flow with minimal triggering force allows all birds to easily trigger the nipple and get off to a great start.

Both, vertical and flow ability

h

Both, vertical and side action, deliver the Opti-mum flow rates and ability to grow a 4 lb small bird up to a 10 lb Jumbo bird with the same nipple. After hundreds of house updates, customers are consistently seeing improved weight gains of up to 1/2 lbs/bird with dry litter conditions!

Scan code for details

Hybrid Turkeys announced March 7 that it suspended four employees and has mandated video monitoring and veterinary review of all turkey euthanasia on its farms in response to an animal activist video.

The video was filmed by a staff member of the activist group Mercy for Animals who was hired to be an egg gatherer. This activist was the same person responsible for the undercover video filmed at an Alberta egg farm last October. She had changed her name prior to applying for the job at Hybrid.

The video depicts the four suspended employees using blunt force trauma (including a shovel) to euthanize two sick birds, procedures that violate Hybrid Turkey’s animal welfare policy.

“Based on multiple levels of audits and third party inspections, we believe this to be an isolated incident,” says David

Libertini, Managing Director, Hybrid Turkeys in a company statement.

“Hybrid has zero tolerance for animal abuse,” Libertini said. “We are conducting an independent third-party investigation to review the incident as well as our company’s animal welfare program, training and quality practices.”

Hybrid will become the first turkey producer in North America to employ mandatory video monitoring and veterinary review of all turkey euthanasia.

“Euthanasia is not easy to do or watch at the best of times. Hybrid has just recently launched a new, easier-to-use tool plus training for this euthanasia method. ” says Dr. Helen Wojcinski, Manager Science and Sustainability for Hybrid Turkeys.

As well the company has initiated a cooperative research agreement on more effective and humane forms of euthanasia with the world renowned

Campbell Centre for the Study of Animal Welfare, University of Guelph.

Hybrid Turkey said in a statement that it’s animal welfare standards exceed national industry standards and regulatory rules and are based on scientific research, veterinary advice, ethical and practical knowledge gained through years of experience.

Following the statement by Hybrid Turkeys, the Turkey Farmers of Canada said in a release that “the respectful treatment and welfare of turkeys is a top priority” and it commended Hybrid Turkeys “for taking action by implementing corrective and additional measures and initiating an independent investigation.”

The U.S.-based National Turkey federation stated that Hybrid demonstrated “leadership and an understanding that turkey consumers throughout North America expect the highest standards of animal care in turkey production.”

Mr. William (Bill) Bearss joined the Ontario Broiler Hatching Egg and Chick Commission as Chair on March 5, 2014.

Mr. Bearss has spent his entire career in the agri-food / agri-business sector including time in the “feather” industry. He is no stranger to the

Ontario chicken value chainserving six years as the General Manager to the board of the Chicken Farmers of Ontario during which time Bill had regular interaction with OBHECC board members and staff.

Bill gained an appreciation for the issues and concerns of the hatching egg and chick sector. He also had an opportu-

nity to build positive relationships with some of the key players in both the farm and hatchery areas. As President of numerous industry and service organizations Bill gained valuable experience in governance, facilitation, conflict resolution, meeting efficiency and other related boardroom skills. Bill also has an extensive background in the financial and investment profession.

APRIL 2014

April 9-10, 2014

London Poultry Show

Progress Building, Western Fair District, London, Ont. For more information, visit: www.westernfairdistrict.com

MAY 2014

May 6, 2014

Research Day

Egg Farmers of Alberta (EFA) has announced the launch of a new environmental program, the first of its kind for egg farmers in Canada. The Producer Environmental Egg Program (PEEP) is intended to help egg farmers better identify their impacts on the environment and facilitate the use of best practices. This will

help to ensure that resources are being managed in a sustainable manner.

The PEEP assessment is focused on key impact areas such as energy use, water consumption and manure management, which helps farmers identify and address environmental risks and opportunities, to improve their carbon footprint.

Portions of PEEP have been derived from the Environmental Farm Plan (EFP), which is a more exten-

sive program available to all agricultural producers across Alberta. EFA believes that the key to effective environmental management is through a systematic approach to planning, controlling, measuring and improving environmental performance. EFA will be able to track industry-wide trends and significant changes in egg farming practices over time, using a pioneering attitude to contribute to the long-term sustainability of Alberta’s egg industry.

Hosted by the Poultry Industry Council, 1 Stone Rd., Guelph, Ont. For more information, visit: www.poultryindustrycouncil.com

JUNE 2014

June 15-17, 2014

CPEPC/CMC Convention

Westin Harbour Castle Hotel, Toronto, Ont. For more information, visit: www.cpepc.ca

June 18-20, 2014

Agriculture Minister Gerry Ritz announced an investment of $4 million to the Canadian Poultry Research Council (CPRC) on February 18.

The research will focus on helping the poultry processing industry remain competitive, while addressing consumer concerns about poultry welfare and environmental preservation. This will include developing new vaccines, finding viable alter-

natives to the use of dietary antibiotics in chicken production, reducing the environmental footprint of poultry farms and providing poultry farmers access to high-calibre training opportunities.

This investment builds on research funding previously received through Agriculture and Agri-Food Canada’s (AAFC) Canadian AgriScience Clusters Initiative as part of Growing Forward. This investment is made through the Industry-led Research and Development stream of AAFC’s AgriInnovation Program, a five-year, up to $698-million initiative under Growing Forward 2.

Roelef Meijer, chair of the Canadian Poultry Research Council says that Canada’s poultry industry has made embracing innovation part of the industry’s vision in recognition of the need to be dynamic and to foster efficiency for farmers and its industry partners. He says the funding will “enable researchers to find more immediate answers to industry issues and to provide important information to farmers, stakeholders and consumers.”

More information on the funding and how it will be disseminated is provided in more detail in the CPRC Update on page 14.

Canada’s Farm Progress Show

Evraz Place, Regina, Sask. For more information, visit: www.myfarmshow. com

JULY 2014

July 8-9, 2014

North American Manure Expo

Springfield, Mo.

For more information, visit: www.agannex.com/ manure-manager/manureexpo.com

Chick-fil-A, an Atlantabased restaurant chain announced that it plans to serve only chicken raised without antibiotics within the next five years.

The chain said it’s working with suppliers to build up an adequate supply for its nearly 1,800 restaurants. It is asking suppliers to work with the U.S. Department of Agriculture to verify that no

antibiotics are administered to the chickens at any point.

Although the company says that the switch to chickens raised without antibiotics would likely result in higher prices for customers, it is working with suppliers to ensure the impact is “minimal.’’

The company’s suppliers include Tyson, Purdue and Pilgrim’s Pride.

three-year research agreement between Cobb-Vantress, Inc. and The Roslin Institute, at the University of Edinburgh, will facilitate collaboration on avian disease resistance, genome analysis and genome preservation.

Cobb is putting almost $1 million into avian research programs at The Roslin Institute (which has a new National Avian Research Facility (NARF)) to identify innovative ways to improve avian health and to develop technologies to understand and preserve the current and heritage poultry genomes.

One of the applications of this joint partnership is an effort to develop new technology enabling pedigree or heritage lines to be maintained without the need to physically maintain the bird stock. In addition, several projects will investigate DNA markers in the genome, targeting some of the more difficult to select for traits such as avian immunity, disease tolerance and disease resistance.

The collaboration will support research by graduate students and is for an initial three years, with potential for renewal.

JULY 2014

July 14-17, 2014 Poultry Science Association (PSA) annual meeting Texas A&M University, Corpus Christi, Texas.

For more information, visit: www.poultryscience. org/psa14 or e-mail: psa@ assochq.or

2014

September 9-11, 2014

Canada’s Outdoor Farm Show

Canada’s Outdoor Park, Woodstock, Ont.

For more information, visit: www.outdoorfarmshow.com

OCTOBER 2014

October 7-9, 2014 XXXIX Poultry Service Industry Workshop

The Banff Centre, Banff, Alta. For more information, visit: www.poultryworkshop.com

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; e-mail lappleby@ annexweb.com; or fax 519429-3094. Please write ‘Event Submission’ in the subject line.

consider w here are many things to Th

iderwhen creating quality space for your flock, n, a fresh and even sup uch as proper ventilation suc ensupply of feed and water, quality nest placement... just to name a few ter, perch space, and n litt afew. We focus on providing quality space for your flock so they can thrive and have a healthy and highly productive life.

The RZ Mask offers Agriculture workers a clean air solution with its comfortable fit and advanced filtration.Made from neoprene material and equipped with an Active Carbon filter, the RZ Mask filtrates up to 99.9 per cent of dust and allergens while absorbing odours. The mask covers the nose and mouth and can be worn for extended periods of time. With its versatility, the mask has seen application within

agriculture work, livestock and allergy protection. The RZ Mask comes in over 20 designs and colors and retails for $29.95 on RZMask.com. For more information, tel: (888)-777-9422 or e-mail: Sales@rzmask.com.

Features:

Will guarantee a reduced icing, and all mechanical parts will stay in function

Reduces energy costs massively by ongoing forced ventilation (no cycle timer) Spreads the temperature uniformly inside the stable, minimum ventilation rates can be achieved to the requirements of the animals

At outdoor temperatures below -10°C / -14°F, ice can form at the air intake blocking them. Normally this leads to false airflow and bad result. To solve this problem, traditionally, intakes are opened and closed via a cycle timer, which in fact means Increasing heating costs and higher mechanical efforts. Therefore Reventa® developed a new kind of air-intake (ZEW Polar) to maintain a perfect air flow also under very cold conditions. Due to the incomparable design of the ZEW Polar it is avoided that cold incoming air and

warm and humid air will get in direct contact. In combination with a high insulation factor we can guarantee an extremely reduced icing on the air-Intake.

Before the first sales release the ZEW Polar was tested in Reventa’s test center at -33°C / -27°F without any negative effect on the mechanical function. Results from the market, the ZEW Polar was already tested under extremely circumstances in a broiler barn in Siberia at -33°C / -27°F outside temperature confirmed our first experiences.

Reventa is one of the major suppliers for ventilation systems and components in Europe and they will show their Full Line product range for the agriculture ventilation business from April 9-10, 2014 on the London Poultry Show in London Ontario, Canada on booth 115S.

May 20-22, 2014 on the “VIV Europe” in Utrecht in Hall 11 on booth F066.

For more information, visit: www.reventa.de or e-mail: info@reventa.de

Super Radiant Products recently introduced the SRP EvenGROW™ heater, specifically engineered for poultry houses and agricultural applications.

The unique SRP EvenGROW model ALTX two stage heater’s patented design provides even heat for low learance applications. The principal advantage is the softening of the radiant output over a much longer length of tube with an end-end variance of less than 15 per cent and a bottom clearance of only 36 inches. Add SRP’s “Flapper” hinged vent terminal to prevent cold air filtration when the heater is not operating. Available in rates from 40,000 to 100,000 btu/hr, lengths from 30 to 50 feet, natural gas or LPG. This combined with SRP’s 100 per cent efficient reflector radiates all the heat directly where it is needed without hot spots. Results are maximum bird comfort, optimum production and greater return on investment.

For more information tel: (800)-527-HEAT (4328) or visit: www.superiorradiant.com

TD is committed to helping farmers build for the future.

Dave Jefferies and his sons, Roland and Ernie, know a thing or two about farming. So, when it was time to expand the business, they naturally chose a bank that knew how to help. At TD, they found Agriculture Specialist Vince Puchailo, who helped implement a succession plan that involved Dave’s brother. Vince’s understanding of the complex process even impressed the lawyers handling the sale. A personalized approach to agriculture finance, like Vince’s, is something all TD Agriculture Specialists bring. Maybe it’s time you brought one to your farm.

From the very first moment

an egg is laid until it reaches its final destination, a commercially produced egg travels a long and tough journey. On this journey it faces numerous impacts and possible contamination sources. Vencomatic Group focuses on perfecting every detail of this journey, calling it the “Egg way”. Their poultry and technical specialists evaluate and optimize every little step to protect the eggs from damage or contamination. Vencomatic Group strongly believes that optimizing the Egg way is the only way to maximize profit for poultry producers with today’s tight margins.

Extensive research shows that carrying an egg from the nest to the hatchery or the retailer can be managed perfectly if you have the knowledge of every single move the egg experiences along its way. Vencomatic presents several innovations to successfully ensure the Egg way in a perfect condition, such as:

A perfect egg way starts with a healthy hen laying a maximum number of eggs. A global problem and risk for the hen’s health is red mite, which causes major economic losses resulting from suboptimal productivity. The revolutionary Q-perch (patent pending) is the only true environmental and bird friendly way to eliminate the problem of red mite. Resting on this

innovative perch, birds are safe from red mite. As red mites do not get the chance to feed on the hens, the population never develops and the use of pesticides is history.

At the heart of many Vencomatic systems is the laying nest. The Vencomatic nest is based on Vencomatic Group innovations, such as the Vencomat, the tipping floor and the egg belt. Innovations that make the difference along the Egg way ensuring outstanding egg quality. The wellknown Vencomatic nest is integrated in the Bolegg Gallery, a new aviary system that combines user friendliness with a clever and economic design.

For Vencomatic Group, the Egg way ends in the broiler house with on-farm hatching (patented). Previously on-farm hatching was only available with the Patio system, with the X-Treck this is now possible in traditional floor houses. The X-Treck enables direct posthatch feed and water access and eliminates the stressful events of chick handling and transportation, providing an optimal start for chicks on the farm.

For more information, visit your local Vencomatic dealer or visit: www.vencomaticgroup.com or e-mail: marketing@vencomaticgroup.com

Worksaver, Inc. offers the ETG-26 Dual Tine Grapple Rake for use on 30-80 horsepower front loaders or skid steers with the “Universal” attaching system. The ETG-26 features two upper grapples that are 20 inches wide, lower tines are spaced 10 inches apart, overall width is 72 inches. The tine grapple is ideal for, piling, loading brush and handling other materials while leav-

ing dirt behind. The upper grapple design provides clamping force to hold material securely, featuring greaseable pivot points for long service life and a shield plates to protect the hydraulic cylinders. A low profile design offers great forward visibility for superior control in close quarters and easy access to skid steer or loader seat.

For more information, contact Worksaver, Inc. tel: (217)-324-5973, fax:(217)234-3356, visit: www.worksaver.com or e-mail: sales@ worksaver.com.

Ventrac unveils the newest addition to their product lineup, the Ventrac 3400. The 3400 is designed to fill the gap in the marketplace for a piece of equipment that finds the middle ground between a commercial zero-turn mower and a compact tractor, and is ideal for large acreages.

The company says the 3400 is a great blend between a zero turn and a compact tractor, blending the maneuverability and visibility that a

The 3400 tractor maintains the same professional quality craftsmanship as all other Ventrac tractors, with features that include hydrostatic allwheel drive, a center-pivotingarticulating frame, power steering, and patented hand controls. The 3400 is available in two engine options, the 3400L gas engine and the 3400Y, diesel engine. Equipped with a patented tandem drive train, the 3400 efficiently transfers power to where it’s needed for unparalleled performance and power.

The Ventrac 3400 features over 15 commercial grade attachments. The Ventrac mount system allows operators to change attachments quickly and efficiently, mov-

ing from job to job with ease. Standard on the 3400 is Ventrac’s patented S.D.L.A. control, which allows for easy control of Speed, Direction, Lift and Auxiliary function all with one hand. A forward and reverse foot control pedal is also standard for operator option. The extra-large deluxe comfort seat with adjustable slide rails will provide many hours of riding comfort for operators.

Features of the Ventrac 3400 include:

All-Wheel Drive

Compact 40.5” Width

Articulating and Oscillating Frame

Patented Tandem Drive Train

Commercial Design

20 Degree Continuous

Slope Rating

Patented SDLA Hand Controls

Digital Speedometer and Fuel Gauge

Tight Turning Radius

Industrial Grade Engines

Excellent Visibility

Over 15 Front Mounted Attachments

Heavy Duty Welded Steel Frame

Power Steering

Adjustable Tilt Steering Column

Industry Leading Ventrac Mount System

Adjustable Weight Transfer System

Onboard Electronic

Diagnostics Panel

Fold Down Roll Bar

Sealed Electrical System

Easy Engine Access Hood

Forward and Reverse Foot

Control

Deluxe Comfort Seat

Many accessories are available on the 3400, allowing operators to customize the unit to fit their needs. These include:

Fully Enclosed Cab

Tree Shield Kit for Tree

Farms

Tire Options — All Terrain or Turf

Rear Weights

Strobe Light

Directional Flasher

Work Lights

12 Volt Switch and Plug

Suspension Seat

Arm Rests

Horn

Salt Spreader

Seed/Fertilizer Spreader

2-N-1 for Front Hitch

Capabilities

Block Heater (3400Y only)

Back Up Alarm

The model 3400 is backed with a two year commercial and three year residential warranty.

For more information visit: www.ventrac.com/products/3400

be used on

Ziggity Systems Inc. is now offering an easy and economical way for producers with ChoreTime® poultry watering systems to upgrade to highperformance Ziggity drinkers without replacing their existing system.

Producers just need to unscrew the existing Chore-Time® nipples, remove the metal pin from the saddle, screw on the Ziggity saddle adapter, and then snap in a Ziggity TL drinker. TL drinkers feature Ziggity’s latest state-of-theart technology, primed to deliver the amount of water birds need without spillage when managed properly, thus keeping litter and pits dry, reducing ventilation costs, and improving flock performance.

For more information about these and other Ziggity products, visit your local Ziggity dealer or www.ziggity. com. For best management practices and other helpful information for achieving best results, visit: www.poultrywatering.com.

Minister Gerry Ritz announced that Agriculture and Agri-Food Canada (AAFC) will contribute $4 million to Canadian poultry research under the AgriInnovation Program (AIP), part of Growing Forward 2. The announcement was made at Kay House at the Arkell Poultry Research Station, University of Guelph on Feb. 18. Funding will support a Poultry Science Cluster, which CPRC will administer. CPRC was the recipient of funding for research for a previous Poultry Science Cluster under the first Growing Forward program that concluded March 31, 2013.

A “cluster” brings together multidisciplinary teams of scientists to solve complex problems and to create synergies in research efforts. It is a way to make the most of available resources and supports a strong business case for investing in Canadian poultry research. Pooling intellectual and financial resources to address issues of common interest is a powerful way to maximize the impact of our collective investment in research.

Total funding of almost $5.6 million, including industry contributions of $1.45 million and the balance from government, will support 17 research activities on four themes that reflect industry priorities as identified in the National Research Strategy for Canada’s Poultry Sector, available at www.cp-rc.ca under the Research tab. Cluster research themes include: , as they impact poultry health and/or zoonosis (four activities).

that enhance avian immune function and mitigate the impact of infectious pathogens while displacing the need for traditional antimicrobials (four activities).

throughout the production chain, as impacted by early immune function, bird harmony within various alternate farm production systems, bird stocking density, and the effects of temperature extremes during live bird transport (five activities).

as

impacted by emissions of particulate matter, ammonia and greenhouse gases and their effect on poultry, poultry workers and the industry’s environmental footprint (four activities). Anticipated outcomes of the Cluster research include:

As an extension of work accomplished in the first Poultry Science Cluster, an increased understanding of the biology of necrotic enteritis (NE) and continued progress towards an effective vaccine that can be used to complement current NE-management strategies

Optimization and validation of a prototype avian influenza vaccine and vaccine delivery method developed in the first Cluster

Multimedia training tools on biosecurity principles and measures made available to Canadian poultry producers

Demonstration of several alternatives to traditional antimicrobials used in the poultry industry

Information for the egg layer industry on the impact of genetics and management on productivity and general wellbeing of hens in alternative production systems

Information for the broiler industry on strategies to monitor foot pad dermatitis and mitigate its effects

Information for the turkey industry and development of best practices

regarding stocking density in the production setting and management of conditions during live transport

Further reductions of the environmental footprint of commercial poultry production

The 17 research activities will be conducted by 59 researchers from 24 organizations. These organizations include 11 universities (four international); five government departments (federal and provincial) representing both agriculture and human health; and eight companies involved in poultry research. Each research activity is led by a Principal Investigator from a Canadian university.

The Poultry Science Cluster provides capacity to resolve many current issues facing the poultry industry. The unique cooperation among scientists, industry partners and government departments across Canada will synergize efforts to address these issues. The scale of the Cluster allows for basic research and more near-term, applied studies that will provide both immediate answers and future information for the poultry and food industries, as well as factors impacting consumer wellbeing.

For more details on these or any other CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ontario, K1R 7S8, phone: (613) 566-5916, fax: (613) 241-5999, email: info@cp-rc.ca, or visit us at www.cp-rc.ca.

The membership of the CPRC consists of Chicken Farmers of Canada, Canadian Hatching Egg Producers, Turkey Farmers of Canada, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

Cobb geneticists have recognized the importance of efficiency in converting feed into meat for more than 30 years. Cobb broilers have always been known for their high meat yield, efficient feed conversion and excellent growth rate. This assists the customer’s goal of achieving a targeted weight with competitive advantages of lower cost. At Cobb we invest 12-14% of our annual sales revenue in research and development. This investment enables Cobb to continue leading the way in delivering consistent continuous genetic progress year over year.

BY SHAWN CONLEY

Iused to wonder what the “ISO 9000” or “ISO 14001” banners hanging in front of businesses meant. Being a part of the management team at a few companies, I quickly realized that these were best practices and benchmarking accreditations. Many companies have this status, and generally speaking, even those companies that don’t apply the same principles on some level. From equipment manufacturers to feed suppliers, climate controller companies, processors and live production, they are everywhere in our industry. They are utilized in all industries to establish a framework for management and to measure performance throughout processes to ensure that small problems don’t balloon into larger ones. Best practices, if properly developed and used, can prevent many problems, and benchmarking performance will help identify and minimize any problems that do develop.

It’s OK to have an opinion about what works on your farm, but it’s better to observe and truly figure it out. Building a template for your farm / business is a process, and takes comprehensive analysis of performance and methods used to reach the performance levels already attained. Constant tracking of data, which may include feed and water consumption, weight gain, medication and supplement use, heater run time, ventilation rates, humidity, ammonia, carbon dioxide levels, and labour, among other things, is the first and most important step. If accurate and detailed records

Benchmarking and following best practices on farm can help reach performance levels set out by companies or help you surpass them

aren’t kept, it is impossible to analyze your system. A great way to illustrate this concept is through the example of weight loss. I was not able to lose weight because when I was working out a lot, I would not track my eating habits, and vice-versa. But doing both at the same time showed results quickly and maintained them.

The concept of benchmarking is defined as comparing your performance

metrics to other similar organizations, or other similar industries to figure out how and why yours are better or worse. In our industry, Agri-Stats is currently the standard for collecting and comparing performance data. It is a good place to see how your operation compares to the average of U.S. poultry companies. It does not, however, provide an in-depth analysis of the data and what it really means, and it is really only applicable at

the company level. At the farm level, the processor / hatchery, breeding company, and equipment companies can provide this data and analysis in a way that benefits the farm. They have done the research necessary or collected enough data over time to establish recommendations for use of equipment, supplements, ventilation and heat.

Basically, best practices are a set of recommendations assembled to obtain the best results based on current knowledge. That doesn’t mean that once they are established, they won’t change; one of the great things about them is that they evolve as a company learns. But they provide a great starting place for farm management, and a place to reset to if there are recurring performance issues. The highest performing farms generally

meet or exceed these guidelines. Water treatment is an excellent example. It has become common knowledge in our industry that we look for a 6.5 pH, and use a volt meter to measure oxidative reduction potential, targeting a level of 650. This number appears in most company’s best practices, and getting a higher number generally will result in even cleaner water. There are other examples where being right on target is the key. If a drinker company recommends 25 to 30 birds per cup, this is because they have done exhaustive studies to get to that number. Going under may result in insufficient water levels in the cup, going over will result in reduced water consumption due to lack of space. Both those scenarios can, in turn, lead to reduced feed consumption, which leads to lower average daily gain, which means less pay at the end of the flock because you had to house the

birds longer to get to target weight, or they shipped on time with lower yield. A third example would be the application of vaccines, antibiotics or probiotics. Applying these through the water can cause many problems. No withdrawal period, not pulling the chlorine in time or not administering in the correct time period can lead to reduced efficacy, or even total failure of the product, opening up the opportunity for disease challenges.

If a processor / hatchery / company has provided best practices guidelines, it is in your best interest to follow them as closely as possible. They do not develop them to create more work on the farm but to assist the farmer in producing the best performing, healthiest animals possible. Lighting and heating are the prime examples of this. Companies invest a lot of time and resources into figuring out the best ways to manage these variables.

Light intensity and time can affect birds in many ways; for example, it may influence feeding or cause aggressive behaviour such as picking, which we know can lead to mortality, and cost a ton of money – especially late in a flock.

Heating is so complicated because there are so many options. Setting up a

turkey brooder may take up to 60 BTUs per square foot, whereas a finisher is only 40, and a broiler house, 50. That number can be higher if not using radiant heat, but your company, the heater company or the primary breeder likely has a heat profile detailing the heat requirements of your bird (which can

even vary by breed!). How does this cost money? Too few BTUs, and you are using feed to heat the birds and risking disease; too much, and you risk having birds flip, dehydrate or constantly move because of extreme repeated temperature fluctuations.

Following best practices for air quality is extremely important. Ammonia, carbon monoxide, carbon dioxide, humidity and dust can hurt not only the birds, but farmers and labourers. Dust levels are hard to quantify, but it is clear that dust is not good for birds or humans with extended exposure. The other four components are easier to quantify using handheld and computer linked measuring tools. In general, targeting ammonia levels under 25 ppm, carbon monoxide under 10, and carbon dioxide below 2500, with humidity under 60 per cent is a pretty solid guideline. High carbon dioxide leads to decreased weights and low activity, while carbon monoxide is similar, but with the added negative of increased mortality. Ammonia’s effects are well known, including opportunistic respiratory infections, blindness and footpad damage. Humidity leads to ammonia and also makes it difficult for birds to cool themselves because respiratory heat exchange is a major part of the process.

It is very obvious that all of the best practices discussed can affect bottom line and animal welfare to a great extent. Following best practices and constantly researching and reviewing them to make improvements is extremely important. If you, your company, your feed formulator, hatchery, primary breeder, processor, or equipment manufacturer has assembled these recommendations for you, they have put a lot of work into it because they know the importance of getting it right. And believe this —they appreciate your feedback to make the best practices better and want nothing more than to see you succeed. When the farm does better, everyone does.

“All areas of my production have improved since I started using drySTART®!”

conc n rete e a and p plywood fl floors r . H He e ap p l pliies s dr ySSTAARTT® fo f llow d ed b by y a layer of straww. Soome m thinggs s Johnnny y h has s t to o

si

BY DAVID MANLY

One of the most important procedures on a farm for protecting the health of both livestock and farmers is the maintenance of strict biosecurity protocols. But following them takes time, money and effort for little or no immediate benefit. On the other hand, however, a disease outbreak can occur with little warning, and it is those procedures that become immensely important, potentially saving individual producers many thousands of dollars, or industries millions. Biosecurity is akin to buying insurance – you hope you never need it, but if you do, you hope you have it.

The risk of an incident is low, but constant vigilance is the best way to decrease the risk as much as possible. Now there is a new Canadian monitoring program that might be able to assist in mitigating disease spread.

Tim Nelson, CEO of the Livestock Research Innovation Corporation (LRIC), has developed a program known as “Be Seen Be Safe,” which monitors the comings and goings of people and vehicles on and off farms and other agricultural properties that could be at risk through an application downloaded onto a smartphone or GPS-enabled device.

The purpose of Be Seen, Be Safe is simple, says Nelson – “It’s a cost-effective smart and simple tool to help mitigate disease spread and stop small disease outbreaks becoming catastrophic.”

This project was developed to fill a need in the Canadian agriculture system for

“Be Seen Be Safe”, developed by LRIC CEO Tim Nelson, is a new tool that monitors the coming and going of people and vehicles on and off farms

an easy-to-use, accurate, and inexpensive method of tracking visitors who travel to farms and associated properties, and may be inadvertently carrying a disease organism with them. The system utilizes real-time surveillance in order to mitigate the post-outbreak spread of a disease by predicting its movement and enabling a managed response.

The U.S. Food and Agriculture Organization spells out the need for the development of such a system in its Manual on Livestock Disease Surveillance and Information Systems. According to Nelson, the manual states: Surveillance can assist with early detection of disease. The sooner a

disease is found before it makes progress along the epidemic curve, the better.

It is much easier to tackle a disease problem in a small corner of a country where it is only necessary to deal with a small animal population, than to get to grips with a developing epidemic that is spreading on many fronts. Surveillance has other roles, as well. One of these is monitoring the spread of a disease in order to manage it effectively. Knowing how fast a disease is spreading, in which directions it is going and the size of the populations threatened is a key factor in resource mobilization.

While the old method of maintaining visitor logbooks, if used correctly and updated often, is most likely fine at an individual farm level, combining the information into useful data across multiple farms during a serious disease outbreak is impossible, says Nelson. In that case, a faster and automated system

was needed to track outbreaks across the entire industry. The Poultry Industry Council has been trying to find a smart, cheap solution such as this for a number of years, he added, but the technology simply wasn’t available until now.

“This program complements good biosecurity protocols; it doesn’t replace

them. But to err is human and as a result good biosecurity is simply not done properly 100 per cent of the time. Be Seen Be Safe takes the human element out of keeping visitor records and enables ‘real-time’ movement analysis of disease fomites [people and vehicles], and it’s innovative, nothing like this currently exists anywhere in the world as far as we can ascertain.”

The Be Seen Be Safe app is quickly downloaded through a mobile phone or loaded onto a GPS-enabled device, and the setup is simple: Sign up, enter your user profile information and that is it. The program runs silently in the background and automatically tracks movement in and out of properties that have previously signed up with the program. Every property that is registered within the system has an invisible fence known as a “geofence” around it. The “fenced” boundary is set up remotely via satellite and logs each Be Seen Be Safeenabled device as it enters and exits each property or location. No other locations are monitored or logged in the system. “It’s no different from the visitor record books currently in use. It simply automates the recording process and makes the records useful in time of emergency,” says Nelson. In addition, all records are password protected, and the information reported does not contain any personal information, simply movement into and out of locations on the system.

When a Be Seen Be Safe-enabled device enters or leaves a property, it records the movement and logs it in a central database. “The device user receives a message telling him/her that he/she has entered or [exited] a Be Seen Be Safe enabled property, and the property owner/manager simultaneously receives notification of who has entered or left the property,” says Nelson.

During an emergency, Be Seen Be Safe can quickly analyze visitor information obtained from a property that has been positively identified as infected. The program then plots the movement of visitors

to that property throughout its infectious period, looks at where they came from and where they went in order to identify potentially infected secondary properties.

“These secondary properties can be instantly put on various levels of alert,” says Nelson. “Or, in cases where there is a vaccine for a specific disease, stock could be vaccinated against it, such as with foot and mouth disease. The drivers of potentially infected vehicles could also be notified instantly through the Be Seen Be Safe system and requested to take extra precautions to ensure their vehicles are cleaned and sanitized before going onto other at-risk properties.”

In certain scenarios, regulators may want to establish a “control zone” around an infected property within a few hours of the initial property being declared infected. “Be Seen Be Safe can instantly enable that virtual boundary to signal enabled devices as they enter the three-kilometre

quarantine zone,” says Nelson. “Those devices then receive predetermined alert notifications such as instructions to stop and call a disease hotline number.”

New technology is often associated with a monetary cost, which for this program is approximately 32 cents per property per day, while downloading the application for the mobile devices and GPS systems is free. “It’s inevitable that some farmers will see it as simply another cost, so it could take a while for all stakeholders to recognize its benefit, adopt the technology and help build a reliable network. But industry, the progressive producers and those looking to automate and simplify their visitor records will drive it,” says Nelson. “However, we are building other management tools that the system will trigger which we hope will help the system get traction on a greater number of properties much sooner.”

Nelson hopes that once the technol-

ogy gains a foothold in Ontario, it can then spread across Canada and perhaps into the U.S., so that every farmer and producer could reap its benefits.

“The sooner Be Seen Be Safe has a network up and running, protecting farms, stock and crops, peoples livelihoods and industry sustainability, the better,” he adds.

“In the meantime, we have a largescale proof of concept pilot just starting up and once that’s done we’ll be showing industry how the system works and what it can potentially save for the little it costs. After that, it is all systems go to prevent the spread of disease.”

For more information on Be Seen Be Safe, visit: www.beseenbesafe.ca

For more on poultry health, v sit www.canadianp ultry g.c p y vi t www.canadianpoultrymag om m

BY KAREN DALLIMORE

The needs of the poultry industry are changing and Chicken Farmers of Ontario (CFO) is investing in enhanced capabilities and capacity to deliver that change. That investment began with the introduction of the CFO Flock Manager program in 2013.

Flock Manager is an online reporting system that has created a more efficient way of filing the familiar Form 3’s and 6’s that broiler farmers have always submitted to report flock production and marketing. The electronic filing system simplifies the process, eliminating legibility issues, reducing the number of incomplete forms by forcing data entry in required sections of the form, and significantly speeding up the transfer of information.

“It used to be a seven- to 10-day gap with the form ‘in the mail,’ ” said Cathy Aker, CFO’s manager of quality and risk management. While the system will eventually be used by all farmers, Aker said that the early adopters have been critical in helping to shape and refine the reporting system.

So how has it worked so far?

Mike and Leonie Vander Meer and their son Daniel operate a broiler farm in Wellandport, Ont. When they first heard of the opportunity to participate in CFO’s Flock Manager electronic form trials, Mike was a little hesitant – he didn’t spend a lot of time with a computer – but Leonie said, “No, we should do this.”

“The first attempts at electronic filing with Flock Manager involved at lot of phone calls,“ Leonie remembers, “and a bit of technical frustration in the wee hours of the morning as the

Ontario chicken farmer Mike Vander Meer using CFO Connects - Trace, a new online reporting system

by Leonie Vander Meer

chickens ship out somewhere between midnight and 8 a.m.”

Mike and Leonie soon discovered that the program worked better with Fire Fox than Internet Explorer. Webinars were available to help coach them though the forms and in the early stages they appreciated the opportunity to provide suggestions for refining the forms. They have since purchased a tablet in order to be more mobile. It took only a few crops for Mike to become comfortable with using Flock Manger on the tablet on his own.

Leonie encourages those still hesitating to attempt the electronic filing to try it, as it is easier to grow along with

the program than playing “catch up” later on.

Tim Klompmaker is a chicken farmer from Peterborough County, farming there since 1984. He is also the CFO board director for District 9 and chair of the Farm Operations and Sustainability committee. Klompmaker was involved in Flock Manager at the committee level at CFO, but as a farmer he became involved when his processor, Farm Fresh Poultry Co-operative, agreed to participate in the traceability pilot project.

From his farmer perspective, Flock Manager was about helping to eliminate the need for paper forms and allowing the quick and efficient flow

Producers need to focus on what matters in a poultry facility — bird, litter and system performance, not counterproductive “concepts” and “standards” that prove to be myths (see sidebar).

Fact: Drier litter will produce better results than wet litter. So producers should manage their watering systems to deliver the right amount of water to the birds while maintaining ideal litter conditions

Arbitrary directives and standards regarding column pressure, water usage or drinker flow rate usually ignore bird behavior and house conditions. Using these standards often leads to excessive drinker discharge that creates wet litter, ammonia release, pododermatitis, breast lesions and a host of other problems, but NOT better bird performance.

The best solution is to manage the watering system based on litter readings, not column pressure or water usage. Get detailed information on how to accomplish this at the website below.

Key Directive: Manage your watering system to maximize performance, which requires delivering ample water to your birds without creating spillage and wet litter conditions.

Videos and other proof that support these statements are at the website below.

Water meters do NOT measure water consumption.

Truth: Water meters measure usage, which includes water consumed AND spilled.

Evaluating drinkers based on flow rate is NOT a valid concept.

Truth: A drinker flow rate test is an invalid procedure that does not predict actual water consumed by birds. As such it can not be an effective management tool.

Increasing drinker discharge may NOT increase water consumption.

Truth: Water consumed is limited by beak size. Discharging more water than the beak can hold simply causes spillage.

Excessive drinker discharge does NOT always cause wet litter.

Truth: Aggressive ventilation, heating, etc. can mask significant spillage, keeping litter artificially dry.

of information electronically between CFO, farmer, processor and hatcheries. From a risk management perspective the new program would allow for quick access to information and the ability to react promptly in the case of a disease outbreak.

As a farmer, Klompmaker sees Flock Manager as “a work in progress.” He recalls that, just the way their schedule worked out, they were both shipping from one farm the first week of the program and placing chicks at their other farm. “We were basically the guinea pigs for the program so it was timeconsuming initially,” he said, but as far as adapting to the new program it was a relatively easy transition since the online forms are not significantly different from the paper forms.

With his director hat on, Klompmaker would like to expand the program so that as much reporting as

possible will be done online, including but not limited to the On Farm Food Safety Assurance Program (OFFSAP) and Animal Care Program (ACP).

In July 2013, Paul Bakker used Flock Manager for the first time. He was “pleasantly surprised,” especially with the 24-hour support line provided by Earl Thomson. “There will always be some bugs,” said Bakker, who farms near Belwood, Ont.

His involvement as a member of the processing co-operative Farm Fresh Poultry, a company that has now gone entirely paperless for the Form 3 and 6, helped him to decide to become involved early. To him, Flock Manager was “long overdue.” Bakker doesn’t consider himself to be super tech savvy but he is familiar with computers. “It’s just clicking buttons,” he said, so it wasn’t a big jump for him to handle the computerized version of the familiar forms.

When he first started with Flock Manager he found himself going back and forth to the barn while entering all the information, but now it’s streamlined – he just passes it off to the driver and it’s done.

“There’s nothing I’d change,” said Bakker. All of the information is in drop down boxes on the computer screen, making selections easy. He reports that the interface is intuitive and very simple, and the support team can fix things in real time, 24/7. If you’re sitting on the fence about Flock Manager, “go in with an open mind,” said Bakker, who is now up to speed after only two or three flocks.

As of February 2014, almost 250 Ontario broiler farmers are using the Flock Manager system.

Cathy Aker reports that at the processor level, those committed to using Flock Manager wouldn’t look back. Maximizing output drives the bottom line, said Aker, and now Canadian Food Inspection Agency vets can access information instantly online, reducing delays at the plant. In that respect, Flock Manager will help to streamline the inspection process.

As the program evolves, Aker predicts further “tweaks” to Form 6, which starts with the farmer but is then passed along to the driver. “We’ve had varying levels of success,” she reports, largely because of different comfort levels of the drivers with using mobile electronic devices to input the data. The first solution involved texting the information using an older-style flip phone, but there were issues when big fingers met small keys. She is confident that a new transporter portal data entry system will work better.

Even though it is still relatively new, the Flock Manager system is currently undergoing a “rebranding” and will be known as CFO Connects – Trace, part of a complete system which will streamline, standardize and automate all operations. This new platform will help CFO reach its goal of simplifying how business is done in the chicken industry.

Broad

Disinfectant

The Veenhofs looked to Europe to upgrade their air intake and ventilation system and found the results they wanted

BY TREENA HEIN

Joanne and Keith Veenhof both grew up on farms, and after spending some years of their adult lives away from farming, they felt the call to return to it.

“Joanne grew up on her parents’ broiler farm, and I was raised on a dairy farm,” says Keith. “The breeder industry appealed to both of us, as Joanne was familiar with chickens, and I was familiar with the similarities between dairy and breeders, namely the concepts of body scoring and feeding for production.”

The Veenhofs decided in 1999 to buy a breeder farm in Wainfleet, Ont. It had a flock size of 9,500, which they’ve grown to 15,000 hens. They grow their own pullets (day-old to 20 weeks), and pullets for another farm on the opposite cycle. Their five children all help in the day-to day running of the operation, after school and on weekends.

Every year since starting their operation, Joanne and Keith have made improvements to the pre-existing buildings that would improve production results and boost energy savings and efficiency. “Among the early improvements we made was the addition of heat to the barns for better egg production in winter months,” Keith explains. “As a consequence, we found we could reduce feed consumption. We also changed exhaust fan controls from individual

Joanne and Keith Veenhof are always making improvements to their breeder operation, and European ventilation was the answer to their air quality needs

two-speed controls and two-speed fans to central control and variable speed fans. We found our air quality improved, and energy consumption went down.”

The Veenhofs also replaced their circulation fans with lower-energy draw fans, and upgraded the wiring in those fans to allow variable speed. “Whenever possible, we tried to change energy use to 220 volt in feed motors, auger drives, and so on to give us maximum flexibility,” Keith says. “Our next improvement was compact fluorescent lights to

reduce energy consumption, and now in the new barn we have gone to LED lighting.”

In the time leading up to the construction of that new 84 x 400 foot single-storey breeder barn, finished in January 2012, Keith and Joanne tried to attend as many open houses as they could to check out the latest options and speak to fellow producers. LED lighting was an obvious choice, but there was digging to do in order to decide about other aspects. “The area of

most note for us was the variety of ventilation systems available out there, and we gathered a lot of feedback from other producers regarding how their systems changed air quality, and in turn, production results,” says Keith. “In our plans for the new barn, we had some definite ideas as to what we hoped to achieve. Ideally, we hoped for improvement in production results, air quality, running costs and capital costs, in that order. And air quality is very important as it’s one of the largest factors affecting production.”

In doing their research, the Veenhofs started browsing European poultry magazines, looking at articles concerning ventilation. “Articles concerning open houses at breeder barns were of particular interest and we noticed that all these barns used the same air intake system,” Keith explains. “The way they move air in the barn is quite a bit different from what we would normally see in Canada. When we contacted the manufacturer (Tulderhof, based in the Netherlands), we asked if they could show us barns that had this system. We were told that we would have to come to Europe, as they did not have a distributor in North America at that point.” When the Veenhofs arrived in Europe, they were shown several breeder operations that were using this system and the couple was impressed. “This system appealed to us, as it met all three of

our criteria,” Keith says. Their custom-built barn therefore included a Tulderhof 3300 Flash system, which Keith says is comparable in terms of capital cost to other air intake systems. The running cost of the inlet system in itself also doesn’t use any more or less energy than other systems, he notes, but because there are no circulation fans needed, and the exhaust is designed for maximum cubic feet per minute, energy use is minimized through these avenues. “I would summarize by saying that it’s designed to maximize productivity for the amount of money invested,” Keith says. “The way the air enters the barn, mixes, and then exits gives more control over the quality of the air in the barn, and in turn helps achieve production results.” After finishing their first flock in October 2012 in the new facility, the Veenhofs were able to draw some firm conclusions about the Flash 3300. “There was a sharp learning curve regarding the use of the ventilation and its capabilities but it’s manageable for sure,” Keith says. “The most surprising change was the energy usage. Comparing to four years of flocks of roughly the same size and at the same time of year, we found that electricity use was roughly cut in half.” Production results for that run and all runs since were average, a normal flock with normal mortality and normal chicks per

hen housed, but in 2013.

The Veenhofs were impressed enough to install Flash 3300 inlet systems during the retrofit of their old barns in 2013, when they changed them from breeders to breeder pullets. “We are currently using these barns in a crossflow configuration and are quite pleased with the results so far,” Keith says, “but we have never grown pullets before so we have nothing to compare to.”

Poor air movement inside the house can cause cold spots or draught, condensation of incoming air, and worst of all, ice forming on the air inlets or even inside the house, says Jorn Rinia, Tulderhof marketing and sales manager. Predominant wind directions also play a role in the air movement inside a poultry barn, as well as the amount of air that passes through.

Rinia says that while traditional inlets don’t offer the ability to steer incoming air to different areas inside the barn, Flash inlets feature adjustable spoilers, which allow much more precise steering of the air, in addition to an insulated vertical plastic slide for air amount regulation. “Since the air steered in the direction it’s needed before it enters the barn, there is very little condensation on, or freezing of, the inlet,” says Rinia. “This makes them ideal for houses in countries like Canada with extreme winter weather.”

The small amount of condensation is due to the rope closure, but the company offers a spring closing option to avoid this. Freezing doesn’t occur because the gliding system is inside the barn. Jorn adds that the Flash air inlet is the ideal inlet for the Canadian barn style (flat ceilings) and it fits perfectly between the wooden studs.

The Flash concept, which was first marketed in 2008, can

Keith Veenhof says with the flash inlets, the way the air enters the barn, mixes, and then exits gives more control over the quality of the air in the barn, and in turn helps achieve production results

be used in every type of barn, and Rinia says it is able to achieve an ideal climate even in barns 30 metres wide. “In Europe, we have mostly sold the system in layer barns, and starting in 2010, we were really busy in Europe with the banning of battery cages,” he explains. “We didn’t have much time for building export markets, but now we have.” In a layer barn, the Flash 3300 allows you to send the same amount of air flow over the nests, which means the birds are comfortable and there will be fewer ground eggs, says Rinia.

Cost return is usually achieved within about a year, with most of the savings from reduced fan usage, if cross ventilation was accomplished by fans. The louvers (spoilers) are adjusted manually once and the inlets are controlled with a computer and a winch. “The system is also able to create a 1/3 or 1/4 minimum ventilation where only one out of four inlets are open,” says Rinia. “We will assist you to set up the louvers in the right position, do smoke tests and set in the right curves on your computer, advise you on making the barn airtight and so on.”

Rinia also notes that more and more producers in Europe and beyond are facing regulations which dictate the provision of daylight for their birds. To deal with this, Tulderhof offers transparent air inlets which, like the company’s non-transparent version, easily fit in a light street or row of connected windows.

BY PETER HUNTON

Egg and poultry producers, along with many other people, have been forced to support the production and use of a variety of alternative energy sources.

As we buy motor fuel (either gasoline or diesel) in most countries today, we are consuming a proportion of “renewable” energy in the form of biofuels. Most common are ethanol and biodiesel, made respectively from corn (or another cereal grain) or vegetable oil. These developments took place following the oil price crises in the late twentieth century, and in response to the threat of global warming over the past 30 years.

Driving through the countryside, we cannot fail to notice, at least in some parts of the world, large investments in wind and solar energy. These are in response to the same motivation responsible for the wide use of biofuels. Neither of these sources of energy is economically viable without major subsidies, and we have only to study the situation in Ontario to realize how inefficient these installations are.

In a well-researched new book*, Douglas Auld, from the University of Guelph, traces the history, and outlines the production technologies, behind the rise of biofuels in the modern developed world. He also raises serious questions as to the capability of these products to accomplish much, if anything, in the

In his book Accountability Denied: The Global Biofuel Blunder, University of Guelph professor David Auld outlines in many cases, the proclaimed benefits of ethanol and biodiesel use, in terms of CO2 emissions, has been exaggerated

way of mitigating global warming due to greenhouse gas emissions.

Governments in Europe and North America have shown tremendous zeal in encouraging ethanol production (particularly in Canada and the U.S.) and biodiesel production (particularly in Europe). Production facilities have been subsidized, and biofuel inclusion rates in commercial motor fuels have been mandated, among other market distorting techniques. These actions have been based on the need for energy security, and the supposed benefit of reduction in greenhouse gas emissions. The fact that the substrates

used to produce these biofuels are also in demand for animal feed or human food was apparently given very little weight in the decision making process. But without these subsidies, it is clear that biofuel use in transportation, and the production of electricity and heat would be minimal. Not only do biofuels compete for sources of substrates, but the inevitable increase in corn and other crop production leads to a wide range of possibly unintended consequences. Rising production may cause increased nitrogen run-off, greater use and residuals from herbicides and pesticides, and higher use of scarce water. It may also lead to increases in the value of agricultural land and ultimately, higher cost of production. If forests are

destroyed to create more crop land, there is a consequent and permanent reduction in carbon dioxide sequestration, which may more than offset any reduction in CO2 emissions expected from the eventual use of the biofuel.

Closer to home, poultry and egg producers can easily note the steep rise in feed

prices associated with the rise of the cornbased ethanol industry. These translated into general increases in the price of all food by a minimum of one to two per cent.

Water use occurs not only in growing the

We see the numbers that connect us. We see the number of birds our th physical selection manager, John McCurdy, selects to improve your flock performance. We see the countless hours of training and experience that p per orm come with John wherever he goes. come

Together by understanding the numbers, we understand the industry. Tog

Strength in Numbers

1 756 640 legs selected

9 005 500 kilograms of turkeys lifted

26 years with Hybrid

16.6 billion kilograms of turkeys influenced at the commercial level

crop substrate but also in the actual biofuel production process. In Auld’s book, data are quoted showing that refining crude oil to yield gasoline requires a maximum of 6.2 gallons of water per gallon of gasoline, while as much as 325 gallons may be used in the ethanol production process. While Canada has abundant supplies of fresh water, other countries do not, and as the real cost of water increases, this may limit the attractiveness of biofuel production.

Biofuels are not as efficient as the fossil fuels they replace, as shown in the following table: Fuel

(source: Auld, 2013)

The major reason for having second thoughts about ethanol and biodiesel, according to Prof. Auld, is that in many cases, the proclaimed benefits of their use, in terms of CO2 emissions, has been exaggerated. For example, early claims for the benefits of ethanol from corn, included only the energy used in processing corn into ethanol, while the energy used to produce the corn was ignored. The same holds true for biodiesel. If the Life Cycle Production Analysis is used to compare corn-based ethanol with gasoline, the best possible outcome in terms of greenhouse gas emissions is a reduction from 4.1 to 3.5 g CO2/mBTU.

There are, however, several methods of biofuel production that do not involve all, or in some cases, any, of these shortcomings. Among these, cellulosic ethanol and biogas production from animal and human waste are the most interesting. Cellulosic ethanol is produced from fibrous material in contrast to starch-containing grain. Substrates include forestry and lumber waste, corn stover, and fibrous crops such as switch

grass. None of these competes directly with the production of food crops. Switch grass would normally be grown on marginal land unsuitable for cereal or oilseed crops. The volume of substrate required to produce cellulosic ethanol is much greater than for the corn or wheat based product, and current technology is extremely expensive. In addition, there are inevitable costs associated with moving the substrate from its origin to the processing facility. However, future developments may bring it within the mix of energy sources.

The process of anaerobic fermentation of excreta to yield biogas is well known. The type of facility can range from single household systems (Auld states that there are 4 million such installations in India alone) to large-scale plants capable of dealing with waste from thousands of cattle, or hundreds of thousands of poultry. In addition to producing biogas, which can subsequently be used to generate heat or electricity, these systems reduce the emissions of methane, which is the most powerful of all greenhouse gasses in terms of permitting global warming. Even these technologies are expensive in terms of cost of producing useful energy. Small scale facilities may be relatively inefficient and may be located far from the places where energy is needed. Connecting to an electricity grid is also expensive and may require subsidies to encourage development.

Known reserves of fossil fuels continue to expand. According to the website www.poodwaddle.com, known reserves will last for over 47 years at current consumption rates. We can assume that more reserves will be found. Furthermore, if just a fraction of the money currently spent in subsidizing solar, wind power, ethanol and biodiesel use was spent on improving energy conservation and developing cellulosic ethanol and biogas production, fossil

fuel reserves would last much longer. While it has to be assumed that at some time in the future, fossil fuel reserves will be exhausted, and alternatives become economically viable and necessary, this is not likely to occur during the lifetime of most people now living. The world’s economy has plenty of time to

evolve before a fossil fuel-free existence is necessary.

* Douglas LA. Auld (2013)Accountability Denied: The Global Biofuel Blunder

BY SANDRA AVANT, AGRICULTURAL RESEARCH SERVICE, USDA

Anumber of poultry industry groups are using a less costly method to collect avian influenza virus samples, thanks to U.S. Department of Agriculture (USDA) scientists.

At the Agricultural Research Service’s (ARS) Southeast Poultry Research Laboratory (SEPRL) in Athens, Ga., scientists conduct studies not only to identify various avian influenza virus strains, but also to determine their origin and whether current tests and vaccines are effective against them. In addition, the scientists investigate the best methods for collecting virus samples from poultry for testing.

In the United States, all meat chickens and turkeys must be tested for avian influenza before processing. Sample collection is an important component of this process.

A certain number of swab samples, taken from inside the birds’ mouths, are needed per flock to get a reasonable virus sample, according to microbiologist Erica Spackman, who works in SEPRL’s Exotic and Emerging Avian Viral Diseases Research Unit. The current method used to determine if virus is present works well, but requires placing only one to five swab samples in a tube.

Spackman found that improvements could be made by switching the type of swab used and increasing the number or swabs in each tube.

“One of the most important variables is

Microbiologist Erica Spackman reviews results of a reverse transcription polymerase chain reaction test to determine whether there is virus in a sample and to generate material for gene sequencing.

the number of swabs required—the sample size we take from inside the mouth of the chicken or turkey to see if the virus is there,” Spackman says. “We need to collect a certain number of swab samples per flock to get a reasonable virus sample.”

Swab samples are collected from the same flock and put into tubes for testing. Traditionally, each tube contains 1-5 swab samples. The idea was to determine whether more swab samples could be pooled together into a single tube without inhibit-

ing or affecting the sensitivity of the test.

Spackman found that putting 1, 5, or 11 swab samples in the same tube did not affect testing. A similar experiment with Newcastle virus samples had the same results.

This research, which was published in BioMed Central Veterinary Research in 2013, supports the USDA’s priority of promoting international food security.

ARS is USDA’s principal intramural scientific research agency.

EFC has partnered with Canada’s top energy provider to reduce its environmental impact

KIM

The Egg Farmers of Canada (EFC) has started 2014 on a new foot – one that leaves a smaller footprint.

Alison Hebbs, manager of corporate and public affairs, says the organization has partnered with Bullfrog Power, Canada’s top green energy provider, to source renewable energy for the national office in Ottawa.

“We’re really excited to be partnering with such a leader in the green energy movement,” says Hebbs.

As part of the partnership, Bullfrog Power’s generators will put 100 per cent green electricity and 100 per cent green natural gas onto the energy grid – matching the amount of electricity and natural gas currently used by the EFC for its 13,000-square-foot office space. Annually, this will mean 27.81 megawatt hours of electricity and 96.98 gigajoules of natural gas, Hebbs says.

Bullfrog Power’s electricity comes from a mix of wind and low-impact hydro power, and the natural gas from methane-capture projects at landfill sites across Canada. At least 50 per cent of the green energy is sourced directly from the region surrounding the EFC office.

Hebbs says the energy use is verified annually by Deloitte to ensure an accurate amount of energy from clean,

EFC has partnered with Bullfrog Power to source renewable energy for its national office, building on the initiatives individual farmers are already undertaking, like egg farmer Glen Jennings who’s sourcing 75 per cent of the power used for his N.S. egg operation from wind turbines.

renewable sources is produced to displace that on the grid from polluting sources.

Sourcing the green energy through Bullfrog Power will cost EFC approximately $12,500 more per year, based on their energy usage. Hebbs says these dollars get invested into building new renewable energy projects, expanding capacity.

“It’s a tangible return,” she says.

“We’re helping to invest so more and more green energy can be put into the grid for the long run.”

Bullfrog Power also helps partners like EFC communicate about environmental issues with their team through activities such as lunch and learns. “So over time our employees will learn more and raise our overall environmental consciousness as an organization,” Hebbs says.

The full colour photographs make this an invaluable tool for all those for whom a knowledge of poultry anatomy, diseases and other conditions is required.

Following the success of the first edition, this second edition has been extensively updated and augmented, to better reflect the requirements of its readers. The author has replaced a large number of the diagrams with labelled photographs and expanded the anatomy section to allow a clearer and better understanding of the subject.

The diseases of poultry section has also been updated and now includes photographs of some of the conditions following a basic introductory explanation of the disease process and the body’s response. The Parasites section has also been improved by the addition of photographs.

Importantly, the author has added a guide to performing post mortem examinations on suspect birds.

The partnership with Bullfrog Power is a natural extension of EFC’s Office Green Initiative , which encourages staff and board members to be more efficient with resources. The organization has gone paperless for meetings, traded plastic bottles for filtered water, uses environmentally friendly cleaning products, and offers battery and egg carton recycling programs.

“This commitment to social responsibility is inherent in our industry,” says Hebbs, “and we’re trying to nurture that culture from our family farms through to the staff at the national office.”