Enrichable and Fully Enriched Systems Layer and Pullet Systems Standard Height and Lo-Profile Standard Depth and Extra Deep Options

Contact: Jim Currie

( 519 ) 868 - 1882

( 204 ) 346 - 3584

Enrichable and Fully Enriched Systems Layer and Pullet Systems Standard Height and Lo-Profile Standard Depth and Extra Deep Options

Contact: Jim Currie

( 519 ) 868 - 1882

( 204 ) 346 - 3584

By LIANNE APPLEBy

It wasn’t a huge surprise when the verdict came. Anticipation had been building since September of 2012, so it was just a matter of time until the validation confirmed it. I found out via text from my Dad: “Did u ere? It was Dick 3 in Leics.” Relevant to me because I grew up less than 20 miles away from the impromptu gravesite of King Richard III, who perished at the Battle of Bosworth in 1485. Deformed folly of Shakespearean mockery, he died with a great big hole in his head. I probably tromped all over him at some point on my many trips to Leicester.

Confirmation of the skeleton’s identity was the fruit of technology. The fact that, five centuries later, two direct descendants were tracked down and asked to provide DNA samples was amazing. The detail that one of them was Canadianborn Michael Ibsen, is a convenient segue to come back to this side of the Atlantic.

I don’t need to unroll some parchment and make a proclamation that traceability is a buzzword in Canadian agriculture. Yet not all agree it’s a good thing. Proponents tend to regale the benefits when we’re talking international trade. Innovators and suppliers of traceability technology love it, and early-adopters are trying to stay ahead of what they see as inevitable legislation – the guillotine of mandate will be dropped someday, so why not start now? The rest of us need a little more convincing, but usually fall into the categories of early or late majority. The laggards will have a few choice words and only do it when there is no alternative.

My point is that traceability too, has been brought to us by technology. Five hundred years ago, when Richard III was dealt the final blow, probably by a halberd (an axe blade topped with a spike), he had no clue that his body would be identified

centuries later by fancy processes called “genetic fingerprinting” and “radio-carbon dating.”

The fact is, progress doesn’t wait for late-adopters. Change is the only constant and if progress didn’t happen, this magazine wouldn’t have existed for 100 years, because on-farm practices would be stagnant.

As you read on, and peruse this month’s articles, reflect on their common link of forward-thinking and how it can benefit your farm operation. And remember, technology can only help you if it’s available to you at your time of need.

Think about what you could be implementing on-farm that may not be needed now, but could be very advantageous when the time, season or legislation comes.

Today, what the Baird purported to be Richard III’s last words are infamous. Shakespeare was illustrating that the value of things can change suddenly if you don’t have them at hand when you need them (in his drastic example, a simple thing such as a horse to ride became more important than having a kingdom to rule). Without his trusty steed, Surrey, Richard III found himself at a terrible disadvantage and lost his life – and the throne – to King Henry vII.

Maybe it’s not exactly life or death, but I’ll lay a gauntlet down that the absence of a particular technology in the right situation could seem as unnerving as Richard III’s comprehension of imminent defeat at Bosworth. n

APRIL 2013 Vol. 100, No. 4

Editor

Lianne Appleby – lappleby@annexweb.com 888-599-2228 ext. 266

Associate Editor

David Manly – dmanly@annexweb.com 888-599-2228 ext. 261

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424

888-599-2228 ext 237 • fax: 888-404-1129

Sales Assistant

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Brooke Shaw

Group Publisher

Diane Kleer – dkleer@annexweb.com

President

Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

REtuRN uNDELIVERABLE CANADIAN ADDRESSES tO CIRCuLAtION DEPt., P.O. BOx 530, SIMCOE, ON N3Y 4N5. e-mail: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation e-mail: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GSt $31.50, with HSt/QSt $33.90) GSt – #867172652Rt0001

uSA – 1 Year $ 66.00 uSD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2013 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

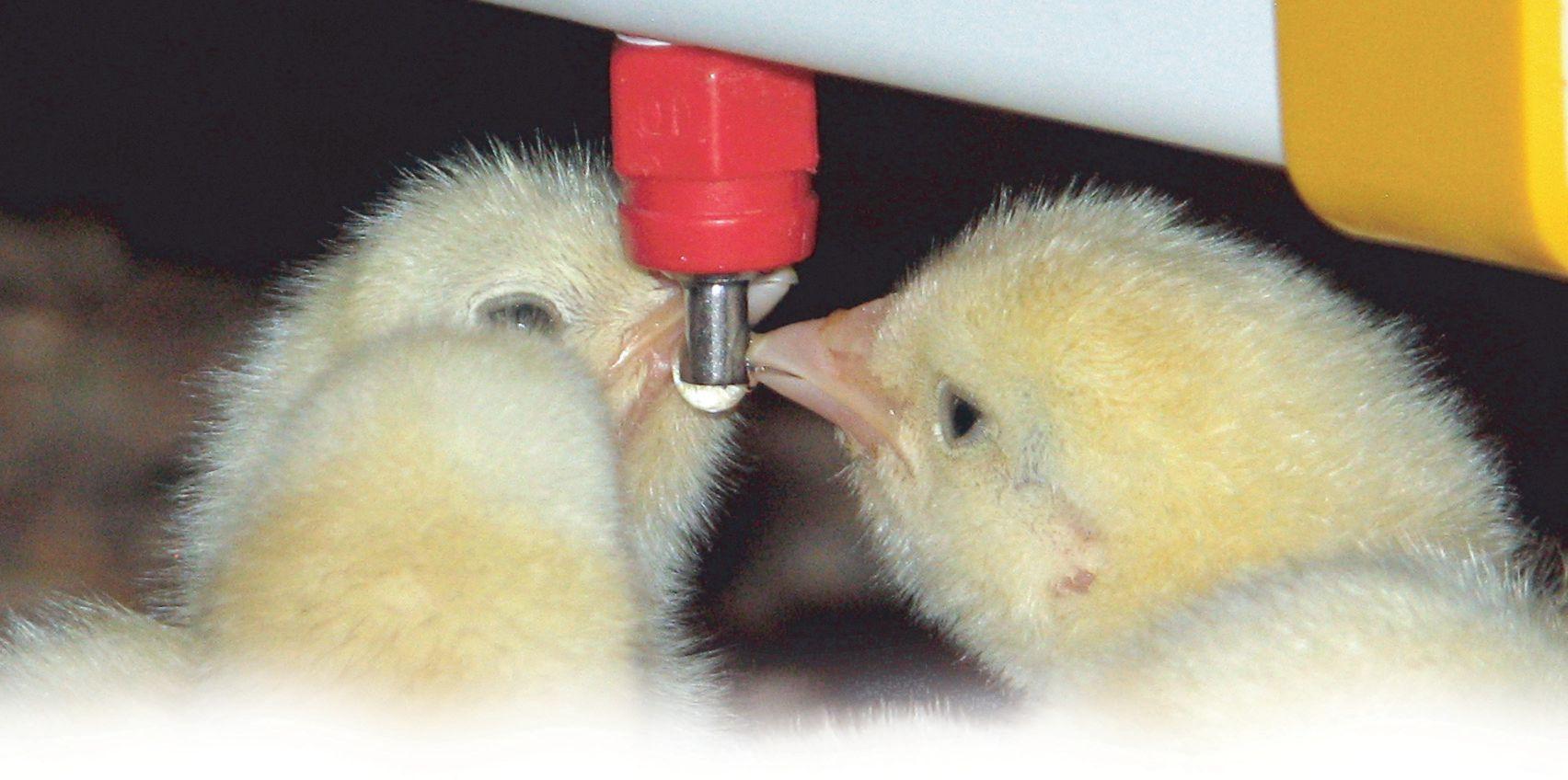

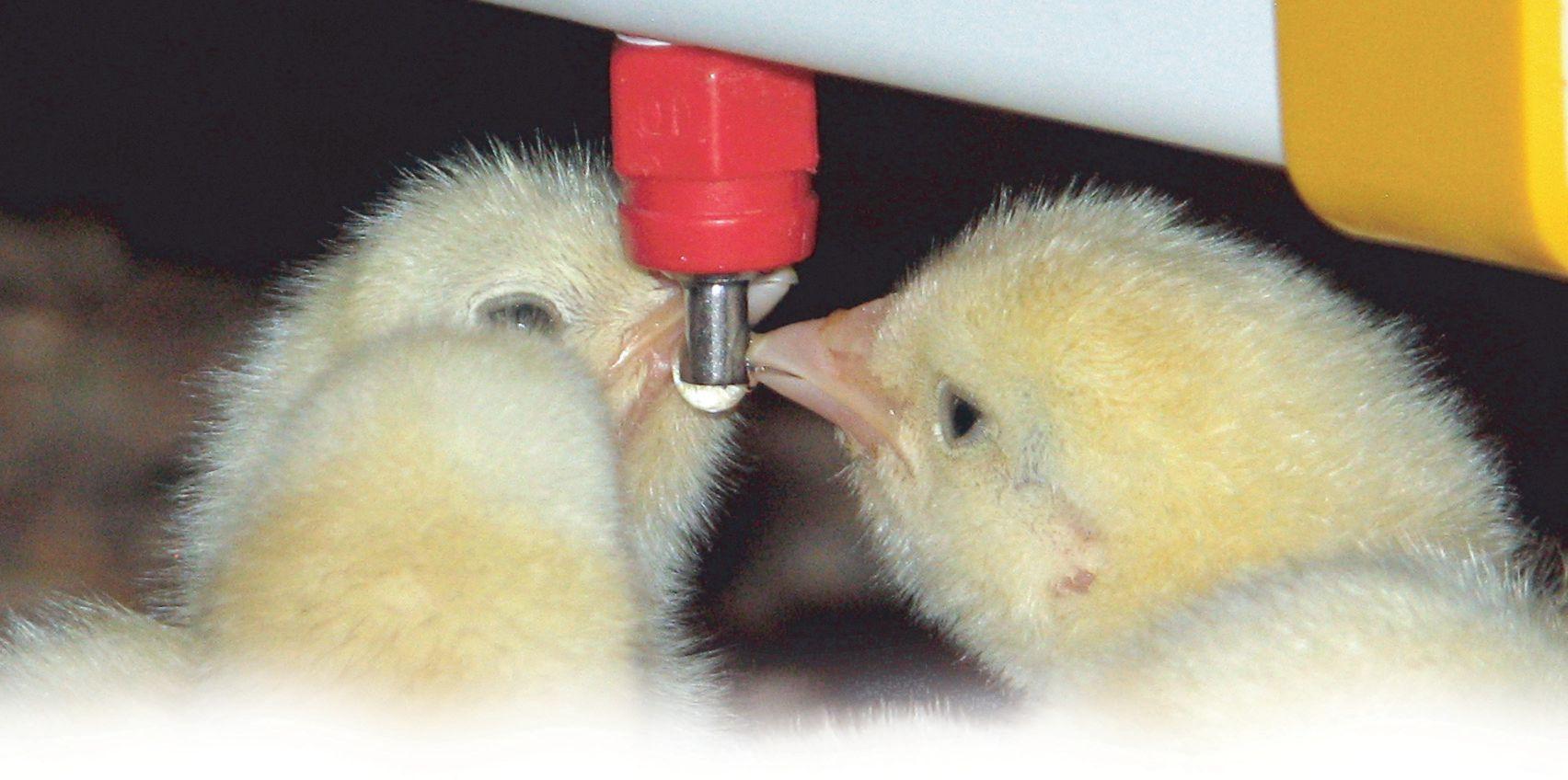

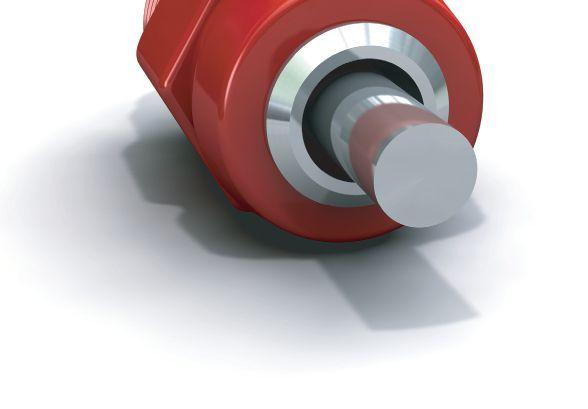

Nothing says specktacular like OptiGROW!

Lubing's all-new OptiGROW Nipple is designed to work in today's challenging broiler environment. Because the nipple has been optimized for growth, you will be amazed by the first-week performance and explosive bird growth. OptiGROW offers:

Large body and pin

Acid resistant design

Easy triggering for day-old birds

Low mortality

Increased side-action flow

Larger flow range for jumbo birds

Increased weight gains

Improved feed conversions

To find out more about OptiGROW and it’s outstanding performance, please contact your local Lubing Representative.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd. London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Les Equipments Avipor Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

Canada’s food safety system remains among the best in the world, but events such as the XL Foods Inc. beef recall that occurred in September and October of 2012 underscore the importance of ongoing review and continuous improvement.

As a result, the Government of Canada has appointed an Independent Expert Advisory Panel to conduct a review of events and circumstances related to the XL Foods Inc. E. coli O157:H7 investigation and recall.

The review team includes recognized scientific, public health, and industry experts. The team consists of Dr. Ronald Lewis (Chair), Dr. Ronald Usborne, and Dr. André Corriveau.

The review will carry out the following:

(i) examine the events, circumstances, and factors that contributed to the E. coli outbreak in XL Foods Inc.

products, including the design, implementation, and oversight of food safety preventative control programs, inspection policies and protocols, and information exchange between the Canadian Food Inspection Agency and its food safety system partners, including XL Foods Inc. and foreign regulators;

(ii) consider whether the Canadian Food Inspection Agency or XL Foods Inc. could reasonably have detected the contamination prior to beef products entering into distribution and commerce; and

(iii) review the effectiveness of the response of the Canadian Food Inspection Agency, in light of the additional resources provided to it since 2006 by the Government of Canada, in conjunction with the response of its food safety system partners, including XL Foods Inc. and foreign regulators, to the E. coli outbreak, including but not limited

to the effectiveness of their prevention, detection, recall response, incident management, and investigative activities, as well as their collaboration and communication with one another, the public, and stakeholders for the purpose of ensuring consumer safety.

Based on the findings and conclusions, the team will make recommendations, within the existing resources of the Canadian Food Inspection Agency, to strengthen prevention strategies and regulatory oversight. In keeping with the Government’s commitment to transparency, the final report and any recommendations will be made public once completed.

For more information on the panel review team please visit www.inspection.gc.ca/ food/consumer-centre/foodsafety-investigations/ xl-foods/advisory-panel/ eng/1360360148 361/1360360313541.

Three new reports released by Agriculture and AgriFood Canada indicates a positive outlook for farmers in 2013.

“The forecast for 2012 reflects that farm incomes are once again at an alltime high,” said Agriculture Minister Gerry Ritz.

The three new reports, the Farm Income Forecast for 2012 and 2013, the Medium Term Outlook, and the Farm Income, Financial Conditions and Government Assistance Data Book 2012, provide an overview of the financial and market outlook for the sector and offer a benchmark for producers, industry stakeholders, and governments as they plan for the years ahead.

Some highlights are:

The Farm Income Forecast report highlights that farmers are prospering from continued high commodity and

One Earth Farms Corp., a subsidiary of Sprott Resource Corp. (SRC) has acquired Toronto based Beretta Farms Inc., a purveyor of hormone free and antibiotic free natural and organic branded meat products in Ontario and British Columbia, in consideration for cash and shares in One Earth Farms. In connection with the transaction, Mike Beretta will join the executive

livestock prices. The sector will once again report recordhigh income levels for 2012 and can count on a continued positive outlook for 2013.

When the final figures are in for 2012, net cash income for the entire sector is expected to rise 14 per cent to $13.1 billion, which is a new record income level, and remain at a near record in 2013 of $12.9 billion.

While performance varies by sector, the average net operating income for Canadian farms is expected to reach a new record of $74,190 in 2012, 17 per cent greater than the 2011 level and 50 per cent above the 2007–11 average. The net worth of an average farm is forecast to grow by 8 per cent in 2012 to reach $1.8 million.

The average total income of farm families, which includes family income from all farm and non-farm sources, is projected to reach $127,106 in 2012,

committee of One Earth Farms as the Chief Operating Officer.

Commenting on the transaction, CEO for One Earth Farms, Larry Ruud said, “I am pleased to welcome Beretta Farms to the One Earth Farms family. Mike and Cynthia Beretta are market visionaries with a passion for farming and the marketing of natural and organic meat products. The Beretta Farms supply chain and consumer brands perfectly complement the One Earth Farms source of beef from our more than 17,000 animal herd of top quality natural and organic cattle. With Mike and Cynthia remaining actively involved in the day to day operation of the business, this

eight per cent above 2011 levels.

Over the medium term, strong global demand, particularly from major emerging economies, will underpin continued strong prices and growth for the sector.

Assuming normal weather conditions, Canadian grains and oilseeds prices are expected to moderate from 2012 peaks but remain at higher than historical levels over the medium term. While cattle and hog sectors will see modest growth, a strong Canadian dollar and higher feed grain prices will remain challenges going forward.

For more information on the Farm Income Forecast for 2012 and 2013, the Medium Term Outlook, and the Farm Income, Financial Conditions and Government Assistance Data Book 2012, please visit www4.agr. gc.ca/AAFC-AAC/displayafficher.do?id=1177676316971&lang=eng.

combination gives One Earth Farms an integrated business model and broadens our reach from the farm to the end consumer where there is increasing interest in naturally raised meats, food traceability and best practices in animal care.”

Mike Beretta added, “Cynthia and I are delighted that we can continue the growth and evolution of our business through this partnership with One Earth Farms. The fit between the Beretta brand, our customer base of prestigious retailers and the organic and natural cattle supply of One Earth Farms make this joint entity an ideal platform for growth.”

APRIL

April 10-11, 2013

London Poultry Show, Progress Building, Western Fair District, London, Ont. For more information, visit: www.westernfairdistrict.com

mAy

May 7, 2013

Poultry Industry Council Research Day, victoria Park East Golf Club, Guelph, Ont. For more information, visit: www. poultryindustrycouncil.ca

JuNE

June 16-18, 2013

CPEPC/CMC Convention, Fairmont Banff Springs Hotel, Banff, Alta. For more information, visit: www.cpepc.ca

June 19-21, 2013

Canada’s Farm Progress Show, The Co-Operators Centre, Regina, Sask. For more information, visit: www.myfarmshow.com

JuLy

July 21-25, 2013

Poultry Science Association (PSA) annual meeting, Town & Country Resort & Conference Center, San Diego, Calif. For more information, visit: www.poultryscience.org

sEPTEmBER

September 10-12, 2013

Canada’s Outdoor Farm Show, Canada’s Outdoor Park, Woodstock, Ont. For more information, visit: www.outdoorfarmshow.com

Ziggity Systems Inc. has recently restructured its Ontario, sales and service distributor channel for poultry watering systems. All Ziggity authorized sales, service, parts and warranty support will now be exclusively handled by Clark Ag Systems of Caledonia (www.clarkagsystems.com) and J. Dean Williamson Ltd. of London (www.jdwpoultry.com).

“Both these firms are long-standing associates of ours and offer producers the best options, knowledge and service in regard to our

watering systems,” said the company. “Clark Ag Systems has a strong understanding of Ziggity Systems and producer needs because it operates its own broiler farm, among other things. J. Dean Williamson also provides a wealth of knowledge, having been in the poultry industry for more than 60 years. We are pleased to have them as our Ontario anchors for Ziggity Systems, and we urge all Ontario users of our watering systems to contact them for any sales or service needs.”

oultry producers can reduce bacterial cross-contamination in poultry cages by treating the cages with forced air that’s been heated to 122 degrees Fahrenheit, according to a study by U.S. Department of Agriculture (USDA) scientists.

While being transported in coops on trucks, poultry that have bacteria such as Campylobacter can contaminate, through their feces, other poultry that are free of pathogens. Those disease-causing bacteria can then be passed on to the next group of birds during the next trip, and so forth, unless the cycle is broken.

The researchers tested the use of hot flowing air to speed the process of drying soiled or washed cages to lower or eliminate detectable Campylobacter on cage flooring.

When the hot flowing air was applied to fecally soiled transport cage flooring samples for 15 minutes after a water-spray wash treatment, Campylobacter levels declined to an undetectable level. Static heat at similar temperatures was not nearly as effective, and unheated flowing air was moderately effective, but less so than hot flowing air.

October 1-3, 2013 XXXVIII Poultry Service Industry Workshop, The Banff Centre, Banff, Alta. For more information, visit:poultryworkshop.com/ index.php

November 7-8, 2013 Poultry Innovation Conference, Best Western Lamplighter Inn, London, Ont. For more information, visit: www. poultryindustrycouncil. ca/training-and-events/ innovations-conference/

JANuARy 2014

January 28-30, 2014 International Production and Processing Expo (IPPE) 2014, Georgia World Congress Center, Atlanta, Ga. For more information, visit: www. ippe14.org

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; e-mail lappleby@annexweb.com; or fax 519-429-3094.

Poultry producers understand that the success of their industry depends on the health and wellbeing of their flocks – and they have always been committed to giving their poultry what they need to thrive. Historically, those needs have been defined under parameters such as production performance and freedom from disease. Significant strides continue to be made in both of those areas, but there is also growing interest in understanding how the welfare of poultry is impacted by the production systems in which they are placed and what birds need to further enhance their welfare. A thorough understanding of this impact becomes increasingly important as concern for the welfare of food animals continues to rise in Canada and around the world.

Welfare in the poultry industry is consistently identified as a major research area and has been included in the “National Research Strategy for Canada’s Poultry Sector” (for a copy of this document, search for “strategy” in the CPRC website). In response to a need for a more coordinated poultry welfare research program, the Poultry Welfare Centre was established in 2009 as part of a four-way agreement between the CPRC, Poultry Industry Council, Agriculture and Agri-Food Canada (AAFC) and the University of Guelph. A lot has been going on at the Centre ever since, both in terms of capacity building and research activities.

Dr. Stephanie Torrey, an AAFC Research Scientist co-located at the Centre is leading a team of researchers from Guelph, Saskatchewan and the Scottish Agricultural College in investigating the welfare and produc-

tion implications of alternative broiler breeder feeding strategies. Successful implementation of this research could allow the industry to preserve the reproductive potential of its breeder stock, while mitigating the welfare impacts of restricted feeding.

Dr. Tina Widowski, a professor in the Department of Animal & Poultry Science at Guelph, was named the Egg Farmers of Canada Research Chair in Poultry Welfare in 2011. She is involved in a number of research programs, one of which is looking at the effects of the rearing experience and housing system of parent laying hens. The program examines the behaviour and stress susceptibility of their offspring to determine if these epigenetic effects differ among commercial strains.

A recent addition to the Centre is Dr. Alexandra Harlander-Matauschek, who moved in January to Guelph from the University of Bern, Switzerland, and is interested in continuing her past work on feather pecking in laying hens. She is embarking on a study to determine if common commercial strains of layers differ in locomotory skill development and their ability to adapt to complex production environments, such as aviaries. Results from this research, coupled with those from Dr. Widowski’s work, will help the layer industry select birds that are appropriate for the production system in which they are placed and adjust management practices to help prepare young birds for those environments. Drs. HarlanderMatauschek, Torrey and Widowski are also collaborating on a study looking at the impact of ammonia on the welfare of layers, broilers and turkeys.

These are just a few examples of

the research led by members of the Poultry Welfare Centre, who also help teach and train the welfare scientists of the future. The Welfare Centre is part of a larger group at Guelph known as the Campbell Centre for the Study of Animal Welfare (CCSAW; Dr. Widowski is the Director) including 40 associated faculty members with expertise ranging from biological sciences to humanities and economics. The CCSAW is the largest group of its type in North America and is an extremely valuable resource that fosters collaboration and information exchange among researchers from all across Canada and beyond.

Behaviour and welfare science is an essential part of Canada’s poultry research strategy and researchers at the Poultry Welfare Centre are working with scientists across the country in all aspects of animal research to help us understand what our poultry need and how best to provide it.

For more details on these or any other CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ont., K1R 7S8, phone: 613566-5916, fax: 613-241-5999, e-mail: info@cp-rc.ca, or visit us at www. cp-rc.ca. n

The membership of the CPRC consists of Chicken Farmers of Canada, Canadian Hatching Egg Producers, Turkey Farmers of Canada, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

B Y L IANNE

unless I’m distracted, when I step on an “up” escalator, I think about The Honourable Eugene Whelan. If I do, you can bet that a wry smile crosses my face.

As editor of a magazine focused on an industry that operates under supply management, it would be shameful not to acknowledge that Mr. Whelan, the father of our very marketing system passed last month. But, as a writer, how does one pen an original column that the audience hasn’t read or heard a hundred times before in the many tributes that have been used as introductions, the biographical profiles that have been printed in agricultural journals, and the countless interviews Mr. Whelan himself gave during his lifetime?

How do you do that if you weren’t even born when Mr. Whelan was fighting on behalf of producers and you didn’t really “know” him?

Ah, but I did encounter him. Twice. And I felt and saw first-hand the effect he had on people.

A student at the University of Guelph, I met him initially in Leamington on a tour of a canning plant. I’d heard so much about him that his Stetson might well be a halo. What could I have said to him that he didn’t already know? Not much.

I went with unoriginal. “Hello, Sir. It’s an honour to meet you.”

“Don’t call me Sir. Call me Gene.”

“Yes, Sir.”

That went well, I thought, afterwards.

Years later, in March of 2005, at the

roy maxwell (centre) interviews the honourable eugene Whelan (left) and the honourable John Wise (right) at the 2005 chicken Farmers of ontario annual general meeting. see the Back Page for more.

Chicken Farmers of Ontario (CFO) Annual General Meeting, it was announced that former federal Agriculture Ministers, Mr. Whelan and his former colleague, The Honourable John Wise, had agreed to serve as Honourary Co-Chairs of FarmGate5 in support of Ontario’s dairy and poultry farmers.*

My job, as an employee of CFO, was to make sure that Mr. Whelan was in the ballroom after lunch, so that when he was introduced, he was waiting in the wings. Easy peasy.

Anyone who has been to a convention at the DoubleTree hotel near Toronto airport, knows the layout. The main conference Plaza ballrooms are separated from the guest room block by a long, narrow breezeway. It’s only about 300 feet long, but it is a good haul when you’re in a rush.

I was in a rush.

Mr. Whelan was in a dining room at the opposite end of that breezeway and I had just less than seven minutes to track him and get him to where we needed him. So, I ran.

“Eugene Whelan is a giant and champion of ours. He’s the father of supply management and I had a chance to meet him, not too long ago at the 40th Anniversary of Egg Farmers of Canada. He had as much passion for the industry now as he did back in 1972.”

–

Dave Janzen, chair of Chicken Farmers of Canada

Finding him wasn’t the issue. The green Stetson was easy to locate. The problem was, a sea of faces surrounded it, and all of them were alight with smiles and laughter. Mr. Whelan was in the middle of what looked to be a good story.

That was definitely not helpful.

I stood watching for a few seconds and then thought “I have to,” so I barged up to everyone and broke up the revelry.

“Excuse me, Mr. Whelan, Sir. I need you to come with me.”

That look…oh yes. The look you give when someone has just done something so nervy that they don’t even realize how nervy it was.

I wasn’t quite sure which way this was going to go.

But then, quite companionably, he looped his arm through mine and told me to lead the way. Like I said … easy.

But, did I really know who I had on my arm? Did I realize at the time that Mr. Whelan had served as the Liberal MP for EssexWindsor in southwestern Ontario from 1962 until 1984? Yes, I knew that. Or that he served as Agriculture Minister under thenPrime Minister Pierre Trudeau from 1972 through 1984, except for nine months in 1979-80 when the Conservatives took office? Sure I did.

Did I know he was so popular? Nope!

Trying to get Mr. Whelan to that room three furlongs away was akin to getting water back into a faucet. No sooner had he told me to lead the way, than a producer delegate stopped him, wanting to shake his hand and chat for a while. I fended that person off, only to get another few feet before yet another glad-hander stopped us again.

And so it went. In the space of that cursed mile of carpet, I would bet that Mr. Whelan was stopped at least twenty times. Frankly, I had never seen anything like it with any politician and probably won’t again.

At one point in the segmented journey, still arm-in-arm, he looked down at me and said, “Are you going to be in trouble?”

I replied “No, Sir. But at this moment in time, it is highly inconvenient that you are so popular.” And he chuckled.

The only thing left now was to navigate the small escalator that would take us up one floor to the plaza foyer.

The escalator at the hotel is narrow, single-file only, and it only goes one way – up or down. It was moving up so I chose to use it

“As long as I can remember,

with

my father, you

did not say anything against Eugene. With old farmers, he was their hero. To this day, my father is still so respectful and supportive of him and has never forgotten what he did.”

– Paul Vanderzanden, Turkey Farmers of Ontario.

and stood aside to let Mr. Whelan on.

“No, ladies first,” he insisted.

So I stepped on, a few feet behind someone. And then I turned around to talk to him – but there was just a great fat clump of air where he should have been standing, on the stair below me. Instead, he was still at the bottom, talking to another delegate who wanted a few moments with him. The escalator carried me upwards and away from him and I watched helplessly as he fell into easy conversation with this new devotee.

In blind panic I started trying to step back down the escalator until someone stepped on and blocked my way. I gave up then, and resignedly let the thing take me to the top. I had to laugh. What else was there to do?

The minute I stepped off that escalator, though, I ran around to the stairs, down the zigzags (what was wrong with a simple straight staircase anyway and who designed them?) and finally, caught up with Mr. Whelan, still engrossed in spirited conversation with a congregation who, at that precise moment, were Public Enemy #1 through #9, as far as I was concerned. Reunited, we set off again, only to be confronted again by more fans at the top of the escalator. Alas, by this time, we were close enough that more escorts materialized to help me and eventually, Mr. Whelan did make it into the room…fashionably late.

But as I surrendered him to higher-ranked handlers, I stopped in the doorway and thought about what had just happened. Even as he was led to the stage, people in the room were stopping him to shake his hand, slap him on the back and have their oneminute audience. I was astounded. How does a politician get to be that popular? In agriculture?

The fact is, The Honourable Eugene Whelan was a farmer’s advocate – and farmers knew it. His reputation preceded him, and time spent with him was a privilege.

As a rookie, on that day in March of 2005, I realized a lot about the man under that legendary green hat and just how much farmers appreciated his efforts. His legacy lives on in the form of supply management, but the personal memories he left with people will also be treasured.

What an extraordinary man. How fortunate I am to have been able to take a leisurely afternoon stroll with him.

*For more on this, see The Back Page, by Roy Maxwell. n

BY TERRY ALBRECHT, FIsCHER FEEDs

Hen management is one of the most difficult areas that has been discussed or looked at in the 30-plus years that I have been involved in the poultry industry. And it does not appear to be getting any easier.

The most difficult part to achieve is to be sure that the reduction in feed to the female takes place at the correct time, so as not to affect the egg mass and therefore production. It is important that farmers maintain control of egg size in the later stages of life, since studies have shown that it can affect production, shell quality and fertility – which can ultimately reduce the number of chicks per hen housed.

Therefore, the goal of the producer should be to keep eggs from becoming too large, but keep track and control the flock’s production.

In this article, we will touch on areas that can possibly help control hen egg size by doing quick daily checks, as well as tabulating weekly egg size averages for your flock.

Nutritional specification can partially control egg size, but it should be balanced with making sure that the birds receive the correct nutrition needed to maximize peak egg production during its peak egg mass.

“The most important nutrients for

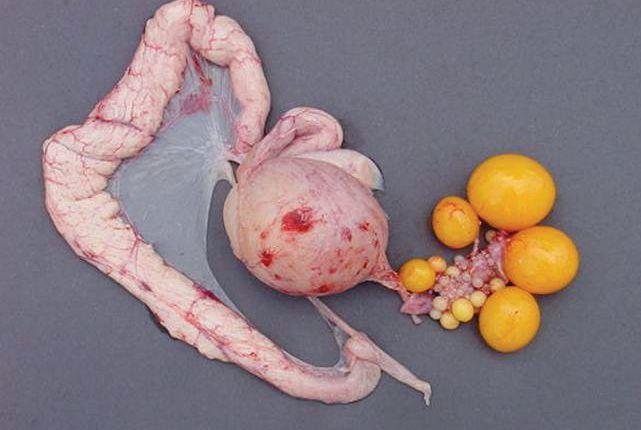

Figure 1 – although it is possible to control late egg size by manipulating nutrition, such an approach should be exercised with caution so that egg production is not adversely affected.

control of egg size are linoleic acid, protein and specific amino acids,” according to Emma Fleming, the Technical Transfer Manager for Aviagen Inc. “Reducing the level of one, or a combination of these nutrients, in the diet will or can reduce egg size. However, this type of reduction is not recommended much before 40 weeks of age as this can reduce egg production (egg mass). Therefore an introduction of a second stage breeder diet at approximately 45 weeks of lay has been beneficial in some flocks in helping to control late egg size but in some cases it may be already too late.”

Reducing the linoleic acid content of the hen’s diet could be beneficial, but it is worth noting that this is more difficult to achieve in maize-based diets than in wheat-based diets. Lowering the total protein in the diet may also help, but a reduction in dietary protein can also reduce egg numbers as well as egg size (see Figure 1).

But, the most significant amino acid affecting egg weight is methionine, and reducing it can help in controlling late egg size. However, it must be repeated

Continued on page 20

across canada, traceability pilot projects are helping the poultry and egg industries understand how to move forward

BY TREENA HEIN

Full traceability is not yet mandatory in Canada, but the benefits to the agricultural industry as a whole are many. Whether it involves ready-to-cook seasoned poultry pieces, tomatoes or grain, it’s all about safeguarding our health in times when food safety incidents occur – and presenting an image of Canada’s agricultural industry as responsible and responsive.

As you may know by now, traceability of any food product is a matter of keeping track of three key pieces of information. Product Identification is one – identifying animals, food products or components of food products as individuals, lots or batches. Premises Identification involves a record of where each component of the food product or the animal originated, and Movement Recording involves tracking identified products as they move between identified premises. Read on for an update on what’s happening with poultry and egg traceability across the country.

On a national scale, Agriculture and Agri-Food Canada (AAFC) initiated a federal, provincial and territorial Traceability Task Team (TTT) in 2005. In addition, an Industry-Government Advisory Committee (IGAC) on traceability was formed, which includes representatives of more than 20 agricultural industry organizations. Working together, the TTT and IGAC created the vision of the National Agriculture and Food Traceability System (NAFTS), and the development of traceability systems is supported through the Canadian Industry

in February 2012, the eFc Board of directors approved the canadian egg industry traceability system (ceits) standard.

Traceability Infrastructure Program (CITIP). Both Egg Farmers of Canada (EFC) and Chicken Farmers of Canada (CFC) have been a part of this.

Under Growing Forward, NAFTS has provided funding for industry-led projects including Systems Development activities (e.g. strategic assessments, industry systems development, pilot projects) and Industry Systems Implementation activities (e.g. technology adoption, testing, and data collection). Under this program, each project is eligible to receive up to a maximum of $2,000,000, but CITIP is no longer accepting applications and the program will end on Mar. 31, 2013. The Growing Forward II policy framework will continue the development and implementation of traceability started under Growing Forward.

In February 2012, the EFC Board of Directors approved the Canadian Egg Industry Traceability System (CEITS) standard. “This voluntary national standard

spells out minimum requirements for tracking and tracing laying hens and eggs,” says EFC Communications Officer Gregory Kampf. “We’re currently working with our provincial egg board partners and other industry stakeholders on implementation. Basically, anyone who implements the standard will be meeting the NAFTS performance targets.” The standard requires data management systems that can work with systems such as the one used by the Canadian Food Inspection Agency, premises identification and movement tracking. Printing on an egg is not required to meet the standard, but there must be some method in place of tracking where the eggs came from (in Quebec however, it is mandatory for graders to print a unique producer code and province of origin on each egg.) Flocks are to be given a permit number at the hatchery and it is added to along the way. EFC has developed a compliance audit process to

Andrew & Robert Franke

& Cattle

Jolene Bolding

TD Agriculture Specialist

TD is committed to helping farmers build for the future.

The Franke twins rst came to us in 2001 with an ambitious plan to grow their grandparents’ farm. Though they were barely over 20, their TD Agriculture Specialist quickly recognized their potential and backed their plan. Over the years, Jolene has been there for every major nancial decision affecting the farm, helping it grow to thousands of acres and over 250 head of cattle. A personalized approach to agriculture nance, like Jolene’s, is something all TD Agriculture Specialists bring. Maybe it’s time you brought one to your farm.

ensure participants who wish to part of the CEITS meet the standard.

“As well, EFC and several Canadian egg industry stakeholders visited the UK in fall 2012 to learn about traceability,” notes Kampf.

A current CFC objective on traceability is to formalize current data sharing agreements between provincial boards and governments to build on the success of the traceability data that is collected, says Steve Leech, CFC’s Food Safety, Animal Care & Research national program manager.

Most of the current traceability programs in all provinces are winding down, and a new suite will be introduced under Growing Forward 2 in April 2013; however, some initiatives will also continue through the funding renewal.

Premises identification (PID) initiatives are handled provincially, with Alberta, Manitoba and Quebec having mandatory systems. In March 2012 in Ontario, Angus GeoSolutions Inc. (AGSI) was chosen by the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) to develop, implement, operate and expand the new Provincial Premises Registry (PPR). The firm that built and was administering premises identification – OnTrace – lost out to AGSI in a recent tender process.

To register your premises under PPR, you are asked to provide the Assessment Roll Number (your tax assessment number from the Municipal Property Assessment Corporation). If you cannot provide this, you will need to provide GPS co-ordinates, municipal address or Legal Land Description (Lot, Concession Number and Township).

The President and CEO of AGSI, Chris

Cameron, says that there has been a good response this year from operations within different commodity groups, as well as from independent business owners. “We’ve had a 40 per cent increase in registrations over the previous total since we took over,” he says. “That’s partly a result of commodity organizations encouraging their members to get it done.”

Cameron says his company provides a very secure system, so farmers can be reassured that farm location and other information kept in the PPR is safe from hacking. “We handle information for credit card companies, Elections Ontario, insurance companies and so on,” he says. Cameron adds that his company will pursue being part of the expansion of traceability in Ontario into product ID and movement tracking.

To move forward on that front, OMAFRA has introduced The Traceability Foundations Initiative (TFI), a three-year

“All areas of my production have improved since I started using drySTART®!”

Johnny Heemskerk of Heemskerk Farms Ltd. owns and operates a broiler chicken unit in Norwich Ontario, where he has been farming since 2001. Johnny averages 21,000 per crop and has 5.8 crops per year.

Johnny has been using drySTART® on the floors of his chicken barns since 2011. He was using straw and was finding that it would stick and cake to the floors. After watching the drySTART® information DVD, he decided to give drySTART® drying powder a try. Once he tried it, Johnny said, “The difference was like night and day, the manure did not stick to the floors, which greatly reduced clean-out times and the birds looked a lot healthier and cleaner.”

Johnny uses drySTART® on both concrete and plywood floors. He applies drySTART® followed by a layer of straw. Some things Johnny has to say about the benefits of using drySTART® are: “All areas of my production have improved since I started using drySTART®. My birds are a lot more even and I have less condemns, clean-out times are a fraction of what they used to be and my hydro bill is less because I do not have to use my fans as much to keep the barn dry.”

Johnny has found great success in using drySTART® and looks forward to continuing to see the benefits in his chicken barns.

joint federal-provincial funding program that may provide up to 75 per cent cost-share funding (maximum of $5 million) to support voluntary, industry-led information-sharing networks that will enhance traceability. Projects selected for funding through Intake 2 (this year’s round) of the TFI “will support the design and implementation of Information Sharing Networks across sector organizations and value chains…leading to effective information sharing systems that include premises identification, animal/ product identification and movement recording.” Projects will develop/enhance information sharing that meet identified business objectives and achieve measurable outcomes that align with TFI program objectives.

A fee-free pilot project to track the inter-provincial movements of all animals, even those in labs and zoos, called Zone Canada (www.zonecanada.ca) is

being piloted at the Manitoba-Ontario border, an initiative of the Canadian Animal Health Coalition. All transport vehicles carrying animals across the border are expected to stop and report to the site at the West Hawk Lake, where manifests accompanying the animals are checked for accuracy. Senders and receivers of animals are also asked to report to the Zone database within which a confidential electronic Zone movement record is created, and can be accessed quickly in an emergency.

Manitoba has focussed its traceability efforts in the poultry industry on PID uptake. In BC, under the province’s Enterprise Infrastructure Traceability Program established in 2009, cost-share funding (75 per cent, cap $20,000) is available. However, the single poultry industry applicant in 2011-2012 withdrew, and there were no poultry applicants in 20122013. Similarly, no poultry industry com-

modity groups or businesses in Alberta have accessed the Alberta Ministry of Agriculture and Rural Development programs during the past two years. These include the RFID Technology Assistance Project, which provides software and hardware for feedlots, the Traceability Pilot Program for exploring traceability technology solutions and the Traceability Training program.

In Saskatchewan, there is no traceability project funding that is suited to the poultry industry at present. In New Brunswick, current traceability programs include Enterprise Infrastructure (purchase and installation of equipment necessary to implement traceability systems, including animal/product handling systems, training, data recording and handling systems) and Pilot Projects. Pilot projects have also been funded through Nova Scotia’s Traceability Infrastructure program. n

Sommers has been a trusted name for standby and PTO power systems in rural Canada for over 75 years. Over the generations, we’ve been there to keep your lights on and your equipment running with reliable generator systems personally tailored to your family and business needs.

Times have changed, but Sommers is still leading the next generation of power solutions with advanced features like Sentinel remote monitoring and our new AGLINE series of packaged systems.

For now and for your future, count on Sommers for “the power to live better.”

Continued from page 14

increased egg sizes later in life can affect production, shell quality and fertility of the birds.

again that there is a fine balance between supporting persistent egg production and controlling late egg size when altering nutrient concentrations in the feed.

Therefore, while it is possible to control late egg size by manipulating nutrition, such an approach should be exercised with caution to minimize adversely affecting egg production.

An effective tool to help stay on a consistently balanced diet but control egg size is to calculate the energy available from your feed, as well as your weekly production rate of decline after peak production, which is based on the grams of feed being fed to the bird weekly.

When the flock has reached its peak and starts to show a decline in egg mass, the hen is very close to the optimal time for feed reduction. With constant monitoring, you can help control egg size and keep production more stable during her weekly declines in production (see Figure 2).

One of the largest issues in egg production for the female is stress – namely water, nutrition, light and disease. The effects can be dramatic or very slight, but it will be noticeable if you are recording weights.

To troubleshoot flocks that are showing issues with their production and egg sizes, the FLAW (Feed, Lights, Air and Water) system can be incredibly useful.

Feed = Change every four days as a nutritional response. Light = Alter every 10 days as a response to egg size, but it may result in short-term weight loss as well as long-term egg size gain. This has not been seen in all flocks, but has been noted in the past.

Air = Change every 24 – 48 hrs. For every two degrees below 65 degrees, you can lose approximately 8 k/cal of energy solely in the feed.

Water = Be sure to change every 24 hrs.

stArt oF production

But how do we maximize the accuracy of weighing eggs?

1. Always weigh eggs same time every day.

Only weigh gathered eggs, excluding double yolk eggs.

3. Always weigh the eggs in the same place, and never on another table or belt.

Be sure to weigh eggs a full tray at a time if possible, and be sure to use a light tray – I always used the fiber tray, as they are light and most scales can handle that weight and still be accurate.

If you weigh the eggs in a different place every time, there will be no consistency to your egg weights, you will lose accuracy and confuse the egg weight data on how your flock is doing.

It is also important to weigh at least 90 eggs per day (or approximately three trays) to give an accurate egg weight measurement. Remember to also average out the weight to an individual egg average at the end of the week. If sending eggs to a hatchery, only weigh those eggs in order to receive an accurate starting measurement.

Once your eggs have been weighed and averaged, how do you make adjustments to your feed based on egg size?

As long as you have been collecting the data on a weekly basis, when the birds arrive at 23 weeks of age, a simple calculation can be done: Egg weight X Production % = Egg mass.

For example, at age 30 weeks, a flock has an observed average egg weight of 59 grams with a production percentage of 88 per cent. Therefore, using the formula above, the egg mass peak equals 51.92 grams.

Once the flock has hit its peak egg mass and you observe a drop in production and an egg weight increase the following week, it may be time to reduce the feed on the flock.

Continuing with the above example, if the production drops to 87 per cent and the egg weight goes to 59.5 grams during the second week, the peak egg mass will drop to 51.76.

Looking at the reduction, a decision must be made based on the energy of your breeder feed and the amount the

VAL-CO® is a leading manufacturer of high-quality systems for commercial poultry and egg production, creating new and exciting products based on innovative thinking, technical research, and field experience. By controlling the manufacture of all the components, VAL-CO engineers its products to work together as complete systems, each expertly designed and produced with a distinct focus on the customer. Our worldwide presence and commitment to providing leading products and technical service make VAL-CO your key business partner whose performance you can count on.

production dropped that week. To do this, you first must know the energy of your feed, and for this example, we will use 2850 k/cal.

To calculate the energy per bird you must take your feed rate per bird and multiply it to the energy of your feed per bird.

Example: 159 grams per bird X

2.850 energy of feed per bird = 453 k/cal of energy per bird being fed at week 31.

If your production drops one per cent at the end of week: Take the drop

in production from that week (1 per cent) and multiply by 1.8 k/cal, which gives 1.8 k/cal to be reduced for that week.

453 k/cal – 1.8 k/cal = 451.2 k/cal per bird.

When 451.2 is divided by 2.850 energy of feed (based on the energy in the feed being supplied to the flock), you get 158.32 grams per bird. Therefore, you were feeding 159 grams initially, so the next week you should only be feeding only 158.32 grams (a drop in feed rate of .68 grams of feed per bird for that week based on the drop in production and energy required).

What if your production drops two percent at the end of a week?

Take the production drop percentage and multiple by 1.8 k/cal to get 3.6 k/cal of energy to be reduced per bird. Therefore: 453 k/cal – 3.6 k/cal = 449.4 k/cal per bird.

Finally, if you divide 2.850 energy of feed from 449.4 kcal/bird, you end up with a total of 157.68 grams per bird, a total drop in feed rate of 1.31 grams per bird.

It needs to be pointed out that while 1.8 k/cal is a constant base energy value number, all the other values can change based on egg weight, production of the flock and the energy in your feed ration.

This calculation should be done on a weekly basis to tell when it is time to start reducing or increasing feed and by how much. In essence, you are letting the production of the flock and the energy of your feed dictate how much should be reduced on any given week.

It should be noted that it is possible to notice egg weight improvements by simply weighing the eggs, watching the trends and keeping an eye out for flaws in production.

There are no silver bullets in this industry that are a given, but nothing ventured, nothing gained. n

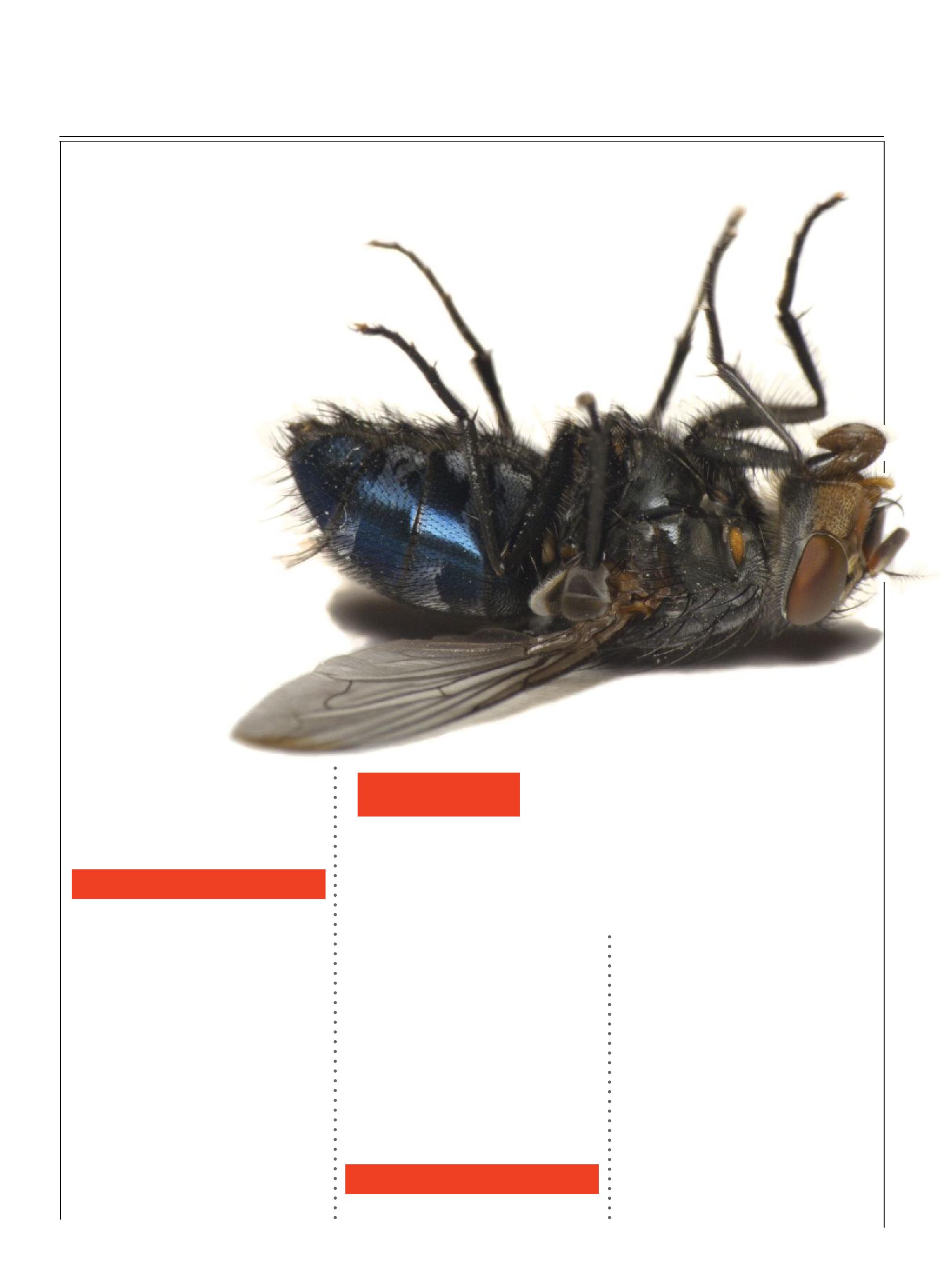

Flies are a nuisance to every farmer, but can be controlled if the proper steps are taken

BY MARC LALONDE, BIOsECURITY TECHNICIAN, véTOqUINOL CANADA

Flies are everywhere and can cause increased stress to both animals and workers. As urban development rapidly stretches into agricultural areas, the demand for effective fly control has become a large concern, especially in large numbers, where flies can cause considerable annoyance to the farmer and surrounding neighbours. Poultry barns are the perfect breeding ground for flies, since they offer perfect conditions like heat, moisture and plenty of organic material. Fly control should be a regular and important part of managing any poultry farm.

The housefly develops in multiple stages: egg, larva, pupa and adult. Female flies will lay their eggs over three or four days in batches of about 150 eggs on various types of moist, decaying organic materials. Manure can contain as many as 3,500 eggs per kilogram!

The larvae, known as maggots, are white and will grow in the manure until they are ready to transform into an adult via the intermediate stage – the pupa. This stage in the fly’s growth cycle occurs in dry areas and the pupae are brown-red in color. In the barn, visible adult flies represent only 15 per cent of the population, whereas eggs, larvae and pupae that are hidden in the

inteGrAted pest mAnAGement

there are four steps in integrated pest management to help reduce the concentration of flies in your barn: prevention, surveillance, intervention and evaluation.

manure account for the other 85 per cent.

Like most insects, flies are capable of surviving winter inside barns that offer moderate climate conditions. Under ideal conditions, the life cycle of a fly can be as short as seven to 10 days when heat and moisture are high. Flies are active from the beginning of spring, will be present until winter arrives and are capable of traveling for many kilometres, but will usually stay within one kilometre of their breeding sites.

IPM consists of controlling pests at an

acceptable level, because eradication of flies is almost impossible due to the nature of poultry operations. There are four steps in integrated pest management: prevention, surveillance, intervention and evaluation.

Integrated pest management means having a good knowledge of the pest that is infesting the barn. Identifying what pest is infecting your barn, in addition to their favourable conditions and behaviours are important first steps because different flies can have different biologies.

Don’tforgettopick-up my$25gift-card afterpurchasing$500 worthofVetoquinol’s cleanersordisinfectants.

AprilMustpurchasebetween1standJuly31st,2013

Surveillance

Installing a means of detection on the farm to evaluate the fly population will help to determine the threshold needed for intervention. Monitor flies with sticky sheets or spot cards, which are white 3‘’ x 5’’ cards, typically placed in fly resting areas. Install a minimum of five cards and count vomit or fecal spot on the cards weekly in a log-book to record results. A count of 100 or more spots per card indicates a need for intervention.

Intervention

Apply, when needed, a combination of different means of physical, chemical, biological, and mechanical interventions to best control or eliminate fly populations.

Almost 85 per cent of the fly population in a barn is in the manure and bedding, and thus it is necessary to act not only on the adult flies, but also on the developing juveniles through management of the litter and manure. Flies reproduce in wet manure, feed and bedding, so wet areas in the barn must be limited wherever possible. With a life cycle as short as seven to 10 days, twice weekly removal of wet organic material will help to break the life cycle.

Stockpiling of manure near the barn is not recommended, as it may attract more adult flies, so the removal of manure from the proximity of the barn is the best solution. Composting the manure can also kill developing juveniles, but the pile must be tarped

to allow the temperature to rise to 50 C (120 F), and for better composting results, the manure pile should be turned every three to four days

As for the bedding, coarse sawdust is a better moisture absorbent than straw. It will create dryer litter and therefore fewer opportunities for flies to lay their eggs. When straw is used, the moisture level is higher; giving flies a better environment to reproduce in.

Flies reproduce in damp areas in the litter, especially under water lines, so proper maintenance is key to avid leaks. ventilation is another factor that can help in the process of controlling flies through adequate air circulation that keeps the litter dry.

Another physical control method is to install fine window mesh on the air

• Engineered to Current Building Codes

• Custom Designed to Your Specification

• Barn Straightening, Renovations

• Additions

Tel: (519) 666-0453

Fax: (519) 666-2430

David Kloosterman P. Eng.

intakes in order to prevent flies from infiltrating the barn. Additionally, removal and disposal of dead birds and broken eggs on a daily basis will help to reduce fly reproduction. Around the barn keep grass short – this will remove resting areas that are cooler for the flies and it will also maintain good airflow in the barn to help dry the litter.

Chemical Control

Insecticides are products that are used to help in the control of insects. There are many insecticides on the market and by nature these products are hazardous – therefore, precaution is needed at all times. Follow label instructions for proper use of products. Appropriate protective gear should always be worn when handling and applying these products.

Fogging

In cases of heavy infestation of the barn at the end of a production cycle, fogging can be used to eliminate adult fly populations. This is critical because flies reproduce quickly, so it should be started immediately after birds are loaded. Flies will hide during barn cleanout and re-infest the barn when conditions allow. Be sure to close all doors, stop ventilation and fog the barn with a fast acting pyrethrin-based insecticide to eliminate adult flies. Finally, be sure to leave for two hours and ventilate the barn before re-entry.

A residual insecticide should be applied inside the barn when the cleanout is finished to ensure a residual activity for several weeks by applying the insecticide until run-off on walls, posts and ceilings. A common practice is to mix the insecticide with a disinfectant, but this should not be done unless both labels permit this concurrent use. The chemical reaction between insecticide and disinfectant may result in a solution that is unsafe, or with one or both ingredients being neutralized. For best results, applications should be done separately; start with disinfection and finish with insecticide.

Fogging a residual insecticide is not as effective as spraying directly on walls because there is often not enough solution in the fogger to ensure maximal surface coverage, and this can promote the development of fly resistance to insecticides. Insecticide active ingredient rotation is also necessary to prevent resistance from occurring.

Another option during barn cleanout is to apply a residual insecticide on the outside walls of the barn as well. Apply insecticide only when the label allows for exterior application in accordance to municipal regulations. This application will offer additional treated surfaces for flies to come in contact with. However, this application should not be done while birds are in the barn because the mist will be taken in by the ventilation system.

Granular bait contains an insecticide, an attractant (usually sugar) and sometimes a synthetic pheromone. Some baits are coloured blue, because it is the color flies can see best. Be sure to spread out fly bait stations within the barn and apply the stations at a rate of 250g/ 100m2. The stations should also be put out at the beginning of the fly season and renewed once a week throughout warm weather near where flies congregate such as resting areas, windows and lights. Fly bait stations are available from manufacturers, but it is also possible to build stations with fine window mesh or plastic jugs. When setting up fly bait stations, take caution not to contaminate feed and water when doing so.

The use of biological control agents in fly management programs is an alternative to chemicals, with different parasitic insects available on the market. Please refer to distributors and users for information.

Mechanical

Capturing and preventing the infiltration of houseflies in barns is another means of control. There are different formats of sticky sheets and cords that can be used in the barn and when placed in the right areas and in appropriate quantities, these traps will reduce the population, especially when placed in the spring. It is possible to enhance the attractiveness of traps by adding an attractant such as sugar, molasses or fly pheromones. Installing a fine mesh on air intakes will also prevent the infiltration of flies into barns.

Lastly, evaluate the efficiency of your chosen interventions (efficacy, quality, quantity, cost, labor, etc.) in order to recall the events and to be able to analyse them. Keep records of your interventions in a dedicated logbook and make adjustments as needed.

A control program is successful if flies are kept at, or below, acceptable levels. It is difficult to determine just what factors have the greatest effect on flies, but combining different means of control will often be necessary. An early start in spring will give better results when summer heat and moisture arise.

You can also request the services of a vétoquinol Biosecurity Technician to schedule a farm visit and help educate your staff and yourself on flies and how to control them. The technician can set up a specific biosecurity program for your property that is effective and simple to follow, as well as be a great resource to help you tackle the unique problems on your barn as they arise. n

a farmer and his birds couldn’t be happier after a switch to biomass hot water heating

BY ANDRé DUMONT

When René

Gélinas undertook a conversion to biomass heating in 2010, he investigated every aspect, recalculated everything and questioned the recommendations of experts. In the end, only one detail had escaped him: just how much better his broilers would do.

The new biomass-based heating system is exceeding expectations. ‘’I’m making almost more money with better bird performances than I’m saving by using biomass instead of propane,’’ says the owner of Ferme Thomchyrs, in SaintBoniface, Quebec.

Gélinas and his wife Lise Grenier operate five broiler houses and farm 350 acres with three henhouses on one side of the road, two on the other, along with a grain-drying bin, two garages and a family house. And yet, all of this is linked to a single hot water distribution system, without energy and water pressure loss.

Right from the start, Gélinas figured he’d better do a bit of investigation into the process on his own. Different contractors had differing advice about pipe diameters; and he also had serious doubts about the suggestion that he should insulate the pipes himself.

‘’I checked everything, from the beginning to the end,’’ he said. “But it’s a good thing I did my own research, otherwise I would have had major problems

this éconoserres 4,125,000 BtU boiler heats water to 90 c before circulating it to five broiler houses, two garages, a grain dryer and the family house.

with hot water distribution.’’

Gélinas had spoken to a farmer who knew he hadn’t insulated his pipes properly, because the ground above remained snow-free in the winter, which needed to be avoided at all costs.

Surfing the Internet, he found Urecon pre-insulated pipes. The 6,000 feet he ordered from the Danish company were shipped by boat.

‘’When the piping got here, we had no idea how to unroll it!’’ Gélinas remembers. ‘’I called a drainage contractor. He suggested I start by unrolling it in a field and let it sit under the sun. He saved my life! Afterwards, it was really easy to install.’’

After that, trenches were dug between all the buildings and the pipes; electrical

wiring and security alarm wires were also laid and buried.

The 4,125,000 BTU (or 1210 kW) boiler is from Chauffage éconoserres, a company from the Beauce region, south of Quebec City. An auger feeds the boiler in real time, bringing the biomass in from a large shed. Gélinas uses mostly chipped demolition wood and hardwood residue from a sawmill that sells to furniture manufacturers. When Canadian Poultry visited, downgraded barley seed was also being fed into the biomass mix.

The boiler can take biomass with anywhere from five to 30 per cent humidity – but the dryer the material, the more

efficient the combustion.

‘’Everyone is calling to offer biomass!’’ Gélinas says. With offers coming in from everywhere, supply is surpassing demand and Gélinas figures that at current low prices, it is not worth investing in equipment to fetch biomass from his own woodlots.

Still, biomass is not for everyone, Gélinas believes. Installing a boiler and hot water piping requires a great financial investment: One must purchase the feedstock and store it, keep an eye on combustion and perform regular maintenance tasks – for some, propane and pellets are still the simpler choice.

Boiler maintenance at Ferme Thomchyrs takes about four hours, every three weeks. ‘’I have more maintenance to do than with propane burners, but I also have less problems with my broilers. I spend less time around my birds, therefore I can allot more time to my heating system.’’

Gélinas had calculated he would need eight to ten years of energy savings to recoup the $500,000 (after subsidies) he put into his new heating system. He hadn’t thought that the system’s profitability would be improved by better technical performances among all of his broiler lots.

The chickens seem to prefer the ‘’two-speed’’ hot water system. Radiant tube heaters stretch the whole length of the houses, distributing soft and even heat. ‘’Birds get under the tubes and stretch their wings. They are comfortable,’’ Gélinas says.

When the winter’s coldest days arrive, suspended forced air hot water heating units kick in and eliminate the use of oxygen-burning propane. Because of that, birds can breathe better and grow in a healthier, drier environment.

This results in better weight gain and less mortality of the birds. For every lot, there’s a little more money going in the farmer’s pocket.

Gélinas is so thrilled with the enhanced comfort his broilers are enjoying that he recommends all poultry farmers consider hot water heating, whatever the energy source may be. However, he warns that each boiler and each hot water distribution system must be perfectly adapted to the size and the specific needs of the farm.

But what if biomass heating one day becomes more expensive?

‘’Tomorrow morning, I can produce my own biomass using my woodlots,” he adds. “And if I don’t like biomass anymore, I keep my hot water system and switch it to propane, oil, electricity or... solar!’’ n

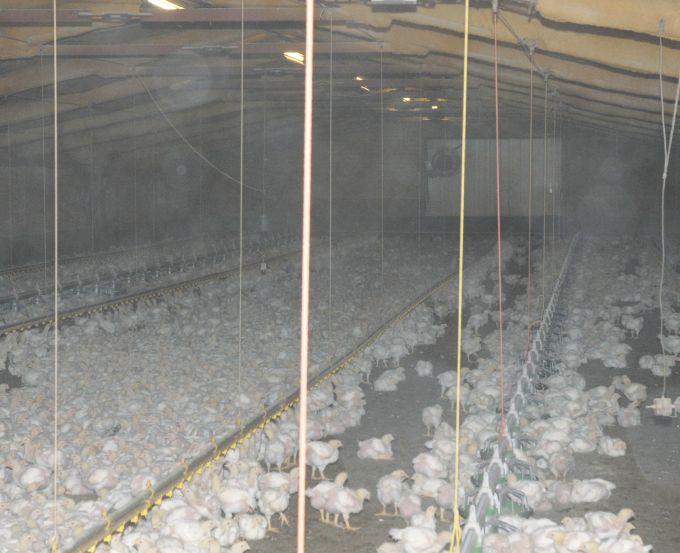

learning how to observe and understand chickens will allow for better management of bird health, welfare and production

BY J.H. (KOOs) vAN MIDDELKOOP, PHD

Poultry keeping is all about the chickens.

Providing a comfortable house for them and looking after them properly is a basic requirement, and it is also important to work economically and neatly. Bird-focused poultry farming is all about how to house and care for chickens in the best possible way, so the focus is always on: What is a chicken and what are its needs in terms of health, welfare and production?1

Everyone can learn how to observe and understand chickens better so they can manage their birds’ health, welfare and production. Some people have a natural ability to observe and understand chickens, while others have to go to a lot of trouble to learn, but everyone improves with practice.

Many people are so involved in the farm that they no longer notice irregularities because they are so used to seeing them on a day-to-day basis. Open your mind to new things. Be critical and don’t be afraid to change.

An important question a good entrepreneur regularly asks himself is: Am I

somethinG’s WronG

By paying attention to your birds, you can see signals when something is wrong, like if the ventilation is inadequate.

getting the best out of everything? Or could I be getting even more?

trAin yourselF to looK And see

Proper care of your birds begins with critical observation and awareness. Take a (sometimes literal) step back. You cannot look with awareness if you are busy doing something else. Stop and think about the signals your birds are showing and the longer you spend on perfecting the art of watching, the more subtle signals you will be able to pick up on. It takes skill to notice faint signals before

the consequences reveal themselves.

The main thread running through this so-called “bird-focused poultry farming” ideal is: Look, think and act.

There are three basic questions poultry farmers must keep asking themselves: What am I observing? Why is this happening? And what should I do?

If you only look at technical aspects such as laying percentage, growth or feed and water consumption, you run the risk of missing important signals and being

overtaken by events. You can pick up on these signals from the chickens themselves and from their appearance, behaviour, manure and eggs.

Start your inspection by observing the whole flock and asking yourself some key questions: How are they spread out in the floor space? How are they using the different parts of the house? Are they avoiding certain places? Are there differences between birds? Are these uniform?

Pick up some birds that seem different and take a closer look, as well as some birds at random. Irregularities are not always evident and need context, so look at the individual chicken and the flock as a whole as well. Put a chair in the house and sit on it for a few minutes at regular intervals to observe birds. Only then can you pick up on irregular behaviour.

During rearing, a lot of attention must be paid in preventing problems with flock uniformity with regards to feeding. The chain feeder needs to be constantly monitored and all birds should be able to go to feed at the same time.

Use what you see to improve your flock management. The following questions must be asked about everything you see:

• What am I seeing, hearing, smelling or feeling? What is the signal?

• Why is this happening? What is the explanation?

• What should I do? Can I leave it or should I take action?

A genuine signal will be repeated by the birds, but be sure to think about what it is and how it relates to the current circumstances. For example, try to determine what is the behaviour behind a signal by monitoring how often it occurs both during the day and at night. Do not be afraid to find out by asking other farmers, colleagues and advisers. Does it happen often? At different times,

to different birds? Does it happen on other farms?

unclAssiFied notAble obserVAtions

Not every signal you notice will necessarily cause harm – such benign signals are known as Unclassified Notable Observations (or UNO). When you see such observations, it is very important that you find out why they occur.

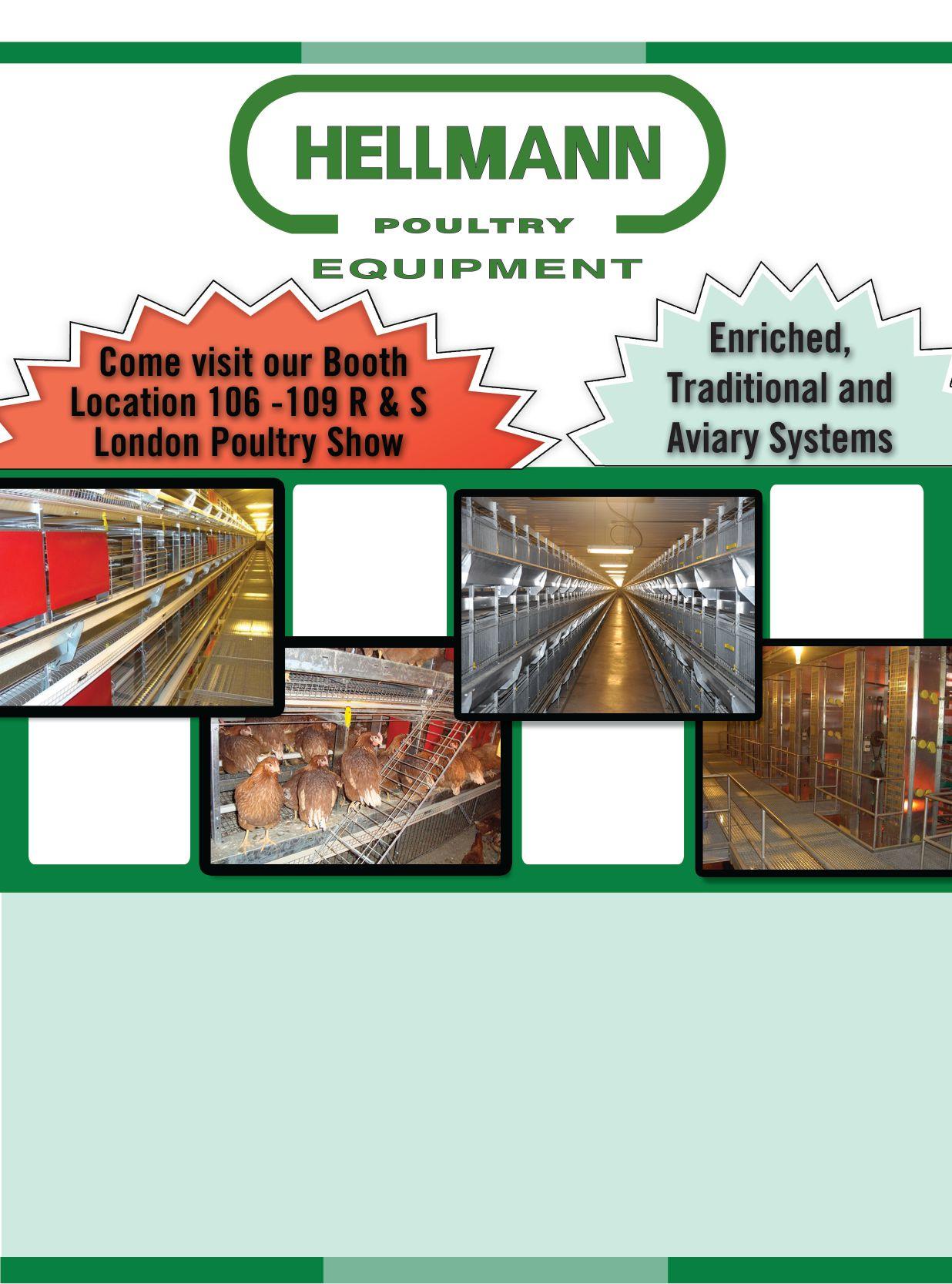

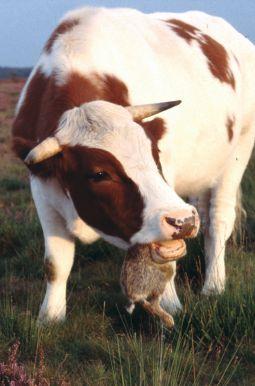

A clear example – a bull eating a rabbit. There was not just one bull, but many. They did not eat the rabbits because they lacked education or because they did not know they were supposed to be vegetarians.

So, why did they do it?

The answer is that they had to eat the rabbits to compensate for the lack

of phosphorus in the area where they were grazing!2

From the individual: If you lift up a chick by the wings, its feet should point downwards. If the chick is holding its feet up, it is giving you a clear message that it is experiencing the early signs of stomach pain.

From an egg: A normal egg laid in the nest is what you want, but if an egg is laid on the floor, do not blame the hen or yourself. Feel the egg to determine whether or not the egg has a smooth shell: if it is not smooth, it is not just a floor egg, but due to disease or genetics, will not produce a chick.

As well, different shell damage can result from poor nest quality or such

factors as incorrect egg collecting.

Open your mind to new things to increase the pleasure of working with chickens and improve the results. Take time to learn to observe, understand and translate your observations into a better and more productive operation. n

1. Poultry Signals, 2011, ISBN 978-908740-079-8. Authors: M. Bestman, M. Ruis, J. Heijmans and J.H. van Middelkoop.

2. PhD study, Wageningen University, Netherlands, 1194. Foraging in a Landscape Mosaic, 161 pp. M.F. Wallis de vries.

Wet litter can directly affect bird health, but there are additives that can be placed in feed to help

BY DAvID TROTT, WALLENsTEIN FEED & sUPPLY

In commercial poultry operations, controlling litter moisture is essential to maintaining animal health, welfare and production performance. Poultry litter consists of bedding material, excreta, feathers and spillage, and it also has a dynamic moisture content affected by management, bird health and nutrition. Since the cause of wet litter is multi-factorial, it is critical to constantly monitor heating and ventilation systems to remove the large amount of water excreted into the litter each day.

Changes in water intake and excretion caused by microbial or dietary intestinal challenges can quickly have a major impact on litter moisture. For example, coccidia infections damage the gut directly and can lead to necrotic enteritis and wet litter if not controlled with the use of anti-coccidials in the feed. Diarrhoea and wet litter can also result from intestinal challenges by bacteria Antibiotics can be used to treat bacterial infections and therefore reduce wet litter – however, the focus of this article is to discuss non-antibiotic feed additives when there is a non-specific microbial intestinal challenge.

Dietary intestinal challenges in poultry production are often the result of highnutrient dense diets formulated to maximize the entire flock’s production. In addition, commercial poultry are tremendously

david trott, a poultry nutritionist, says that promoting gut health is an important tool for maintaining dry litter in poultry production systems.

uniform and there is a tendency to overformulate diets in order to meet the nutrient requirements of the least efficient birds within a flock in order to maintain production. Access to feed and water is essential for each bird to obtain nutrition and maintain water balance, but the dietary intestinal challenges in the most efficient birds can potentially result in more water excretion and wet litter. Some feed additives are used with the objective of directly drying litter moisture by maintaining water balance of birds. However, most of the feed additives discussed have indirect effects on drying litter through improved nutrient availability and gut health.

The majority of commercial feed formulations contain added enzymes from fungi or bacteria to improve the availability of nutrients and reduce the prevalence of antinutrients. Phytase is the most common feed enzyme as it improves the phosphorous, calcium and mineral availability of grains, and may also improve nutrient availability by digesting the anti-nutrient, phytate.

Other feed enzymes, such as xylanase, target fibers of plant cell walls called non-starch polysaccharides (NSPs), which reduce nutrient availability, by increasing

gut viscosity or caging nutrients within cell walls. The use of xylanase enzymes when feeding wheat-based diets to poultry is well accepted and essential for reducing gut viscosity. Adding xylanase to corn-soy diets is thought to release the caged nutrients from cell walls, as well as improve gut health by digesting anti-nutrients and providing nutrients that promote a beneficial gut flora.

To promote drier poultry litter with feed enzymes, the nutrient density of poultry diets should be reduced – specifically reductions in crude protein and sodium, which have the biggest impact on litter quality. The challenge with using feed enzymes is to appropriately reduce nutrient density without risking loss in production. According to recent research, it may be viable for a producer to order extra feed enzymes on top of current formulations to dry poultry litter. This “super-dosing” of enzymes may work by removing anti-nutrients and promoting a healthy gut-flora, but this is not currently a common commercial practice.

Clay-based products are typically used as litter amendments for managing poultry litter, but they may also be helpful when fed to poultry. Two products approved for use in feed as pelleting aids include sodium bentonite and diatomaceous earth. Bentonite, or montmorillonite clay, has a high water absorption capacity and high cation exchange capacity. When used as a litter amendment, sodium bentonite absorbs excess water and prevents caking of the litter. Bentonite added to feed is thought to have the additional benefits of slowing feed passage and improving feed efficiency, and it is approved for use up to 20 kilograms per tonne (kg/t).

Diatomaceous earth is the fossilized remains of phytoplankton or diatoms and is characterized as an adsorbent, anti-caking agent and dewormer. Diatomaceous earth is also sometimes used as a poultry litter amendment to help control fly larvae and darkling beetles, and is well accepted in organic

“Long hours. It’s what we do.”

As

The Alltech on farm program is designed to help you along the way. Contact us and see what we can do…. together.

production systems. As a feed additive, diatomaceous earth may also provide the additional benefits of slowing feed passage and improving feed efficiency along with absorbing anti-nutrients and toxins. Similar to bentonite, diatomaceous earth can be used up to 20 kg/t of feed and has been shown to result in poultry excreta

with drier consistency.

For clay products, the drier litter is thought to be a result of slower feed passage more efficient absorption of nutrients; however, the high dosage of 20 kg/t could potentially bind nutrients or dilute the nutrient density of the feed too much. The effectiveness of clay-based products

We see the numbers that connect us. We see the number of visits our veterinarian, Dr. Helen Wojcinski, makes to improve your flock performance. We see the countless hours of training and experience that come with Helen wherever she goes.

Together by understanding the numbers, we understand the industry. Strength in Numbers.

11 years of formal Animal Health education

10 0,000 miles travelled to visit customers each year

16 industry presentations delivered per year

120 people trained through Hybrid Hatchery Workshops

drying poultry litter at dosages lower than 20 kg/t is possible, but has not been reported.

Betaine, or trimethylglycine, is a nonessential nutrient named in the 19th century after it was discovered in sugar beets. It is also naturally occurring in grains fed to poultry, with the highest levels found in wheat. Osmolytes such as betaine affect the water balance or osmotic pressure of cells and tissues by regulating the movement of water through the cell. When betaine is supplemented in poultry diets, it is quickly absorbed by intestinal cells and balances the osmotic pressure of the gut containing high concentrations of inorganic salts after a meal. In other words, water loss is reduced and the integrity of the intestinal cells is maintained.

Commercial sources of betaine are a by-product of sugar production from sugar beets, and are available as feed additives. Betaine added at 1 kg/t of feed has been shown to be effective at relieving heat stress in poultry, treating fatty liver disease in layers and treating wet litter in turkeys. Betaine seems to be effective at maintaining intestinal water balance and drying poultry litter when wet litter is a result of over-formulation of nutrients. It has also been shown to reduce the intestinal damage caused by coccidiosis in broilers.