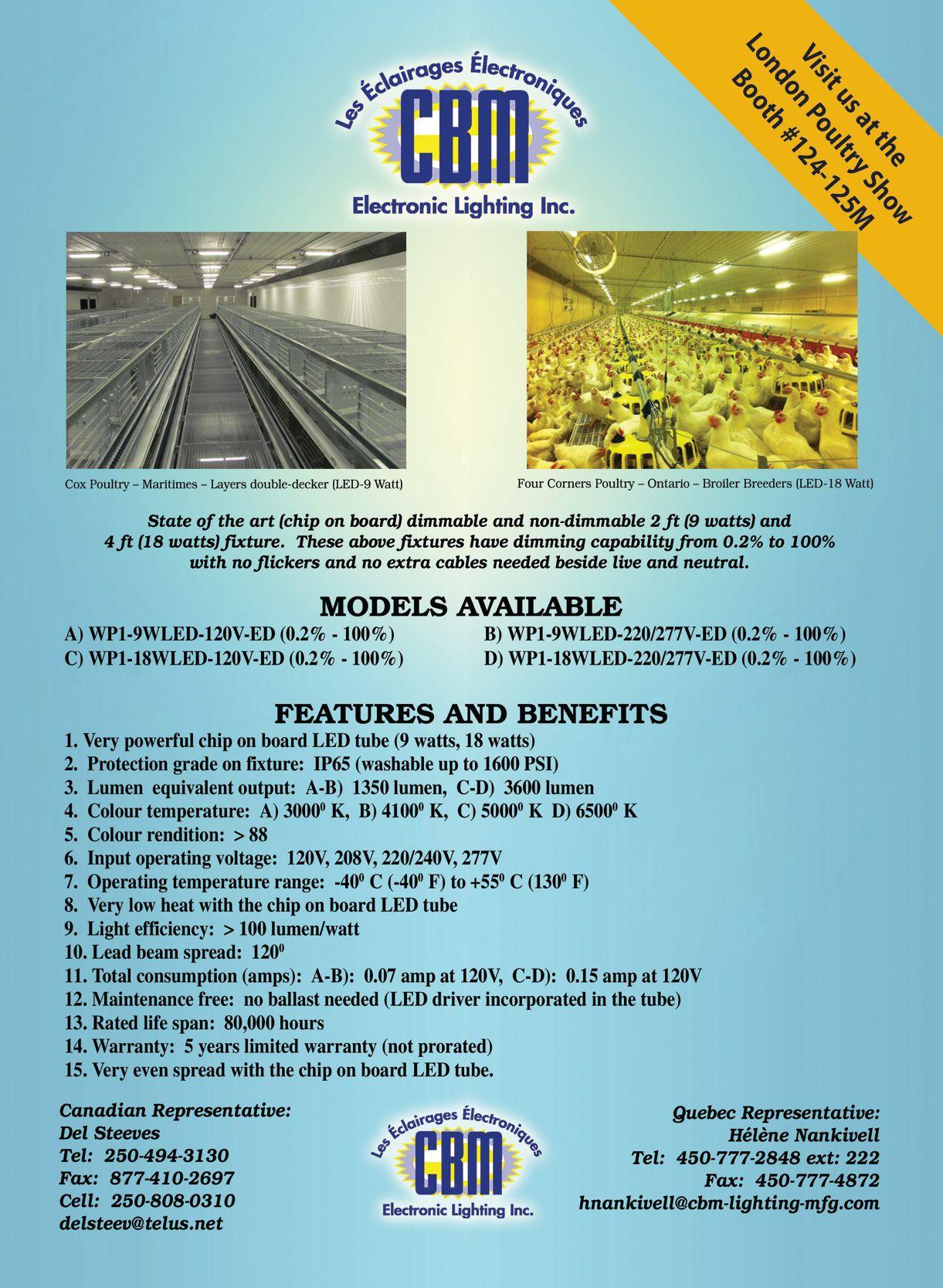

thePassingTorch CFC chair retiring after 13 years thePassingTorch CFC chair retiring after 13 years

thePassingTorch CFC chair retiring after 13 years thePassingTorch CFC chair retiring after 13 years

BY KRISTY NUDDS

Meat is still king, but it’s price might threaten it’s reign.

A recent study commissioned by the American Meat Institute (AMI) and the Food Marketing Institute (FMI) in the U.S. reveals that the price of meat is having a very big impact on the sales volume of meat and poultry products (see page 46).

The Power of Meat: An In-depth Look at Meat Through the Shopper’s Eyes was released at the recent 2012 Annual Meat Conference, held in Orlando, Fla. The study explores shopper perceptions, attitudes and behaviours regarding meat and poultry. It also takes an in-depth look at meat consumption and purchasing patterns.

It’s a very interesting look into the mind of today’s consumer, and the pressures of a faltering economy. Although the study surveyed U.S. consumers, it’s likely a good indication of how consumers are thinking here in Canada.

This is the seventh year the AMI and FMI have commissioned the study, and the authors indicate that grocery and meat shopping continue “to be dominated by finding ways to save.” The economy of the last several years has resulted in shoppers who are “savvy” and have mastered the ability to implement a variety of moneysaving measures, including shopping sales, using coupons, and cooking different meals than they did in the past, including a higher number of meatless meals.

Interestingly, the authors note that shoppers are able to adjust their spending on groceries and meat quite quickly depending on how other economic pressures, such as the price of gasoline, affect them. As a result, consumers will switch between different cuts and types of meats readily, which the authors say is “putting enormous emphasis on sales promotions, price per pound and packaging costs.”

For the first time, the study found that the proportion of shoppers who were savvy

savers (those using coupons or other measures) was equal to the proportion of shoppers who opted to buy less in order to save. Although dollar sales of meat and poultry increased by 2.5 per cent, the study found that the volume of sales decreased by 5.3 per cent across all proteins, as the price of proteins had increased.

Although price was a deterrent for increasing the volume of sales, beef and chicken still remained the most popularly purchased proteins, and consumers preferred to buy it fresh rather than ready-to-eat or heat-and-eat.

What I found most interesting was that a large proportion of consumers indicated that their knowledge of the meats they purchase and how to prepare them is lacking. This group turns to family and friends and the Internet for help, but few ask staff in the meat department of their frequented stores. However, many indicated that they would utilize a “here-how-it’s-done” type of service if it were offered.

This is interesting. Years ago, supermarkets and supercentres (where, according to the study, the majority of consumers purchase meat and poultry) removed in-store butchers in order to cut costs. Now, consumers want them back – but given the increasing price of proteins, and the pressure from consumers to reduce prices on all grocery items, is it worthwhile for a store to do this?

Although poultry farmers have no control over price at the retail level in Canada, providing a “here-how-it’s-done” type of service provides a great opportunity for the marketing boards to engage with consumers directly in the store – not only to demonstrate all the great recipes and cooking techniques they already provide on their websites and in other marketing materials, but also to talk with consumers and answer their questions. In those conversations, questions of price will certainly dominate.

APRIL 2012

Vol. 99, No. 4

Editor Kristy Nudds – knudds@annexweb.com 888-599-2228 ext. 266

Associate Editor Jim Knisley – jknisley@kwic.com

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-429-5193

Sales Assistant Mary Burnie – mburnie@annexweb.com

Production Artist

Brooke Shaw

Group Publisher

Diane Kleer – dkleer@annexweb.com

President

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

PAP Registration #9850 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

Printed in Canada ISSN 1703-2911

Circulation

Subscription Rates

Canada – 1 Year $ 24.00 (with GST $25.20, with HST/QST $27.12)

GST – #867172652RT0001

USA – 1 Year $ 60.00 USD

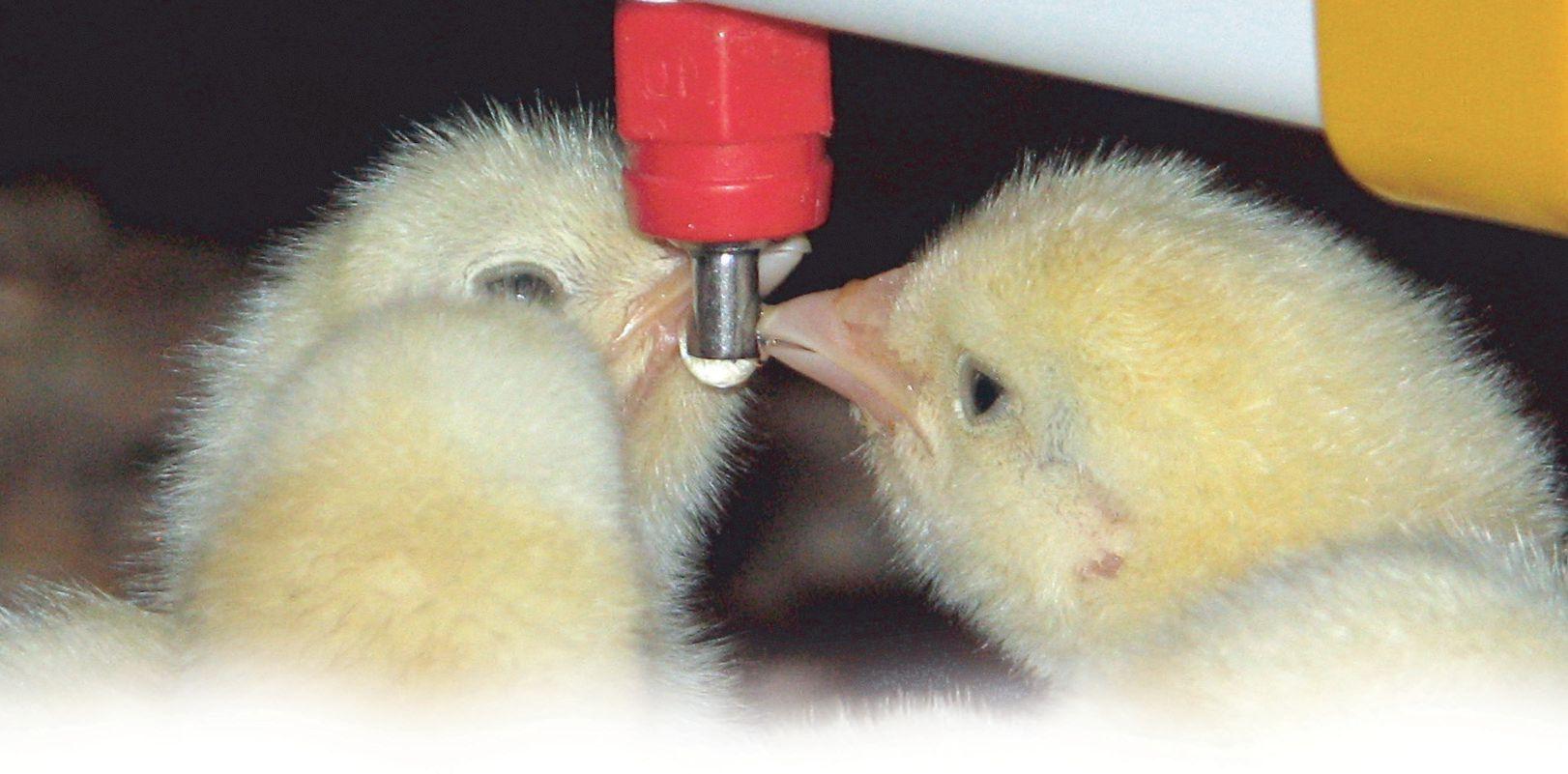

Nothing says like Lubing's is designed to work in today's challenging broiler environment. Because the nipple has been optimized for growth, you will be amazed by the first-week performance and explosive bird growth. offers:

Large body and pin

Acid resistant design

Easy triggering for day-old birds

Low mortality

Increased side-action flow

Larger flow range for jumbo birds

Increased weight gains

Improved feed conversions

To find out more about and it’s outstanding performance, please contact your local Lubing Representative.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

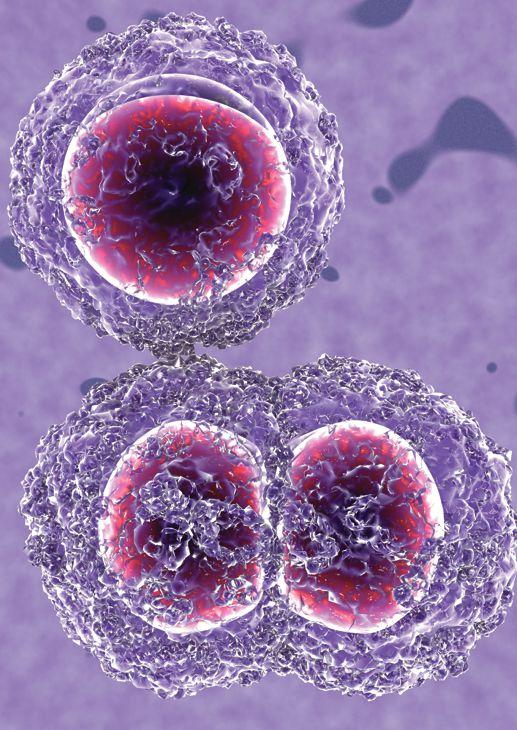

Astrain of the potentially deadly antibiotic-resistant bacterium known as MRSA has jumped from food animals to humans, according to a new study led by the Translational Genomics Research Institute (TGen).

The study, published in the online journal mBio focuses on MRSA CC398, a strain of methicillin-resistant Staphylococcus aureus. The study suggests that MRSA CC398 probably started as a non-resistant (antibioticsusceptible) strain in humans before it spread to food animals where it subsequently became resistant to several antibiotics.

Whole genome sequencing, a cutting-edge testing method in which billions of molecules of DNA are spelled out in exquisite detail, enabled the scientists to trace the likely history of MRSA CC398.

Researchers at 20 institutes joined forces to study 89 genomes from humans and animals spanning 19 countries and four continents.

The study’s international team of scientists found

that the jump of Staph from humans to food animals was followed by the bacterium becoming resistant; first to tetracycline, and then later to methicillin — two important antibiotics for treating Staph infections.

MRSA CC398 is often referred to as “pig-MRSA” or “livestock-associated MRSA” because it most often infects people with direct exposure to swine and other food animals.

“Our results strongly suggest that food animals-associated MRSA CC398 originated in humans as MSSA (methicillinsusceptible S. aureus),” the report concludes. Once in animals, the microbe became resistant to tetracycline and methicillin, likely as a result of the routine antibiotic use that characterizes modern food-animal production, the study said.

Dr. Paul Keim, one of the study’s authors and Director of TGen’s Pathogen Genomics Division, said the study describes evolution in action: “The most powerful force in

evolution is ‘selection.’ And, in this case, humans have supplied a strong force through the use of antibiotic drugs in European swine production.

Dr. Frank M. Aarestrup, Head of the Microbial Genomics and Antimicrobial Resistance unit at the Technical University of Denmark, said the study provided valuable information about the origins and future risks of this MRSA strain.

Dr. Robert Skov, M.D., the study’s Senior Microbiologist and a member of the Department of Microbiological Surveillance and Research at the Statens Serum Institut in Copenhagen, Denmark, said more studies are needed to further assess the risks.

“Further analyses are required to estimate the number of independent genetic events leading to the methicillin-resistant sub lineages, but the diversity of the (MRSA) subtypes is suggestive of strong and diverse antimicrobial selection associated with food-animal production,” Dr. Skov said.

Hand to hand transfers are no longer part of the transportation system for spent fowl in Ontario.

A modular transportation system has been developed for Maple Lodge that utilizes carts to move the birds from their cages to the trucks. The change, which took effect Feb. 13, improves animal welfare and has undergone several months of trials. Under the old system, the hens were carried to crates. Under the new system, a small trolley is rolled into the barn and the

Ihens placed in plastic drawers on the trolley.

The trolley is eight drawers high and 48 inches deep, 18 inches wide and 78 inches tall and taller than a regular pullet cart. Each drawer is almost the same area as a chicken crate.

To accommodate the new system a staging area will be needed at the farm to ensure safety. A loaded cart and a man will weight about 1,000 lbs. so the loading dock must be able to handle the load.

Modified pullet trailers have been developed that will move the carts from the farm to Maple Lodge for processing. The modified trailers can

crates.

n the March 2012 issue, a photo was missing from the sidebar entitled “Open House” on page 11. Canadian Poultry magazine apologizes for the error.

Clark Ag Systems Ltd. hosted an open house at the University of Guelph’s Arkell poultry research station in September 2011 to allow producers and industry representatives to see the Farmer Automatic Portal Rearing System, Loggia system and Layer ECO system. Dr. Tina Widowski and representatives from Clark and Farmer Automatic were on hand to answer questions and show attendees how the systems operate. Pictured here are attendees viewing the Portal Rearing System.

The Alberta Egg Producers have changed its trade name to the Egg Farmers of Alberta to further enhance the positive perception of eggs and the Alberta egg industry.

The organization announced the name change at its annual general meeting on Feb. 28 in Red Deer. Alberta’s egg marketing board said that the rebranding initiative will enable it’s messages to resonate more effectively with the public by reinforcing trust in farmers and reconnecting individuals to the farm.

The Egg Farmers of Alberta represent Alberta’s 150+ registered egg farmers.

APRIL

April 11-12, 2012

The London Poultry Show, Progress Building, Western Fair Entertainment Centre, London, Ont. For more information, visit: www.poultryindustrycouncil.ca

MAY

May 8, 2012

PIC Research Day, Victoria East Golf Club, Guelph, Ont. For more information, visit: www.poultryindustrycouncil.ca

JUNE

June 10-12, 2012

CPEPC Convention, Fairmont le Manoir Richelieu, La Malbaie, Charlevoix, Que. For more information, visit: www.cpepc.ca

JULY

July 9-12, 2012

Poultry Science Association (PSA) Annual Meeting, the Georgia Center, Athens, Ga. For more information, visit: www.poultryscience.org

AUGUST

August 5-9, 2012

XXIV World’s Poultry Congress, Salvador, Bahia, Brazil. For more information, visit: www.wpc2012.com

SEPTEMBER

September 11-13, 2012

Canada’s Outdoor Farm Show, Canada’s Outdoor Park, Woodstock, Ont. For more information, visit: www.outdoorfarmshow. com

Agriculture Minister

Gerry Ritz announced that the Canadian Food Inspection Agency (CFIA) has launched a Statement of Rights and Service for Producers, Consumers and Other Stakeholders and six guides to inspection. The statement and guides will give consumers, producers and businesses an important tool in their interactions with the CFIA by outlining what

the CFIA does, its service standards and what the sector can expect when dealing with the CFIA.

Minister Ritz also announced the CFIA’s new Complaints and Appeals mechanism, which will provide businesses with a more transparent and accessible way to register complaints and appeals.

For more information, visit the CFIA website.

Anew study suggests chicken meat may be a source of E. coli bacteria that is making its way into people and causing infections.

The study looks at strains of E. coli in poultry and compares them to the strains found to have been causing urinary tract infections in women in Quebec.

Senior author Amee Manges of McGill University says the bacteria would be killed if the meat is handled with care and cooked properly, but that isn’t always the case.

She says a comparison of strains from food animals and

September 25-26, 2012 Poultry Service Industry Workshop, The Banff Centre, Banff, Alta. For more information, visit: www.poultryworkshop. com

November 8-9, 2012 Poultry Innovations Conference, London, Ont. For more information, visit: www.poultryindustrycouncil.ca

JANUARY 2013

January 28-31, 2013

International Poultry Exposition (IPE), International Feed Exposition (IFE) and American Meat Institute (AMI) tradeshow, Georgia World Congress Center, Atlanta, Ga. For more information, visit: www.ipe11.org

people suggests poultry and to a lesser extent pork are serving as a reservoir for these bacteria, which can cause blood or urinary tract infections in people, or diarrhea.

Manges says some of the strains being spotted are resistant to multiple antibiotics, a worrying trend.

She says the findings add weight to concerns that the use of antibiotics in food animals is contributing to the rise in drugresistant infections in people.

The study was published in the March issue of the journal Emerging Infectious Diseases - The Canadian Press

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; e-mail knudds@annexweb. com; or fax 519-429-3094.

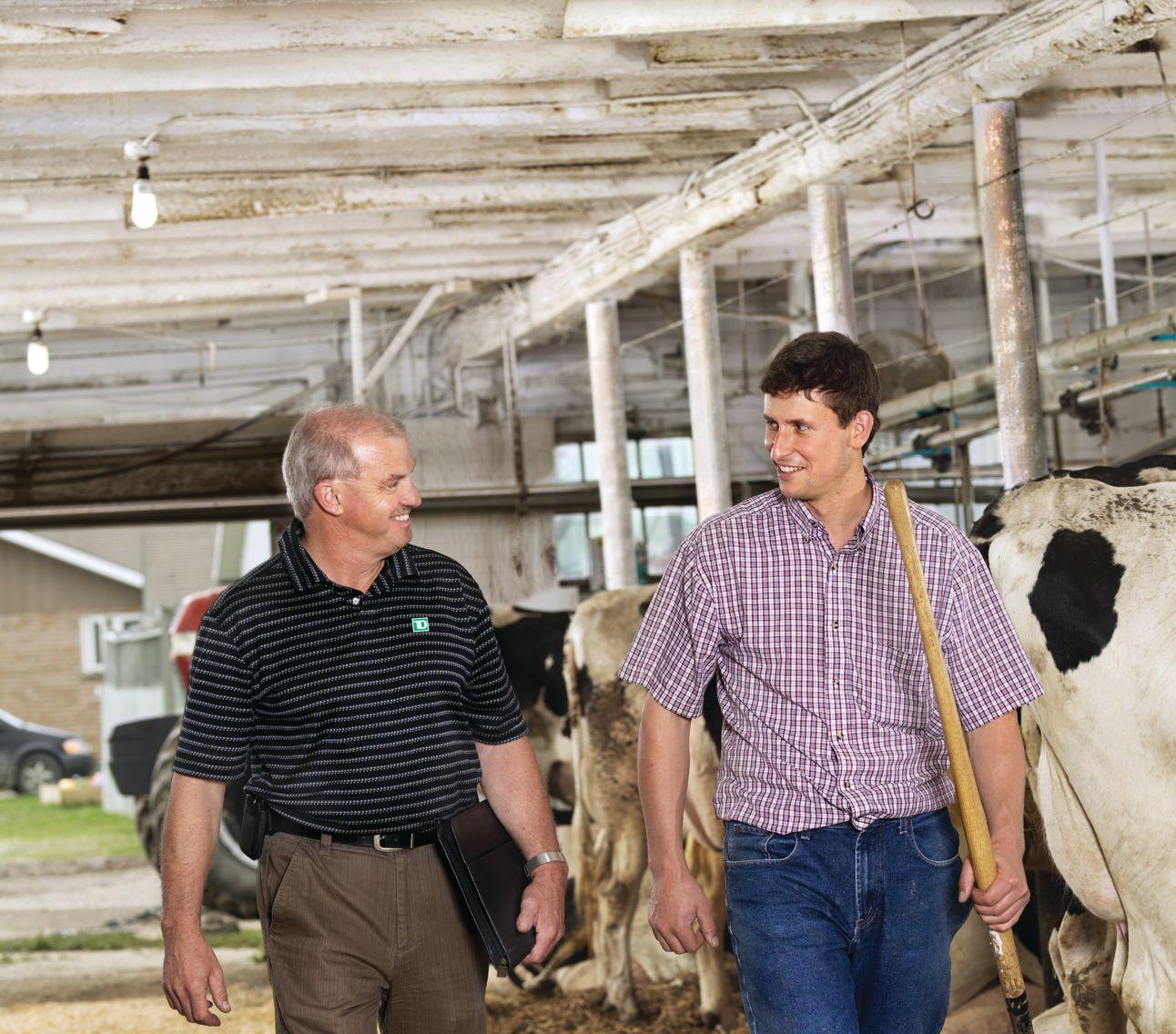

TDiscommittedtohelpingfarmersbuildforthefuture.

Whenthe Martinfamilywantedtoraise theproductivity of their dairy business, they turnedtoDaltonPotter for guidance.DaltonisaseasonedTD Canada Trust Agriculture Specialist andafarmerhimself, andwithhis help,the Martinswere able to buy anewfarm in a primelocation.Our understanding of agricultureand financing,combinedwithapersonalizedapproach,ishowwe’rehelpingfamiliesliketheMartinsgetexactly what they’re lookingfor.

For more information, visit a branch or go to www.tdcanadatrust.com/agriculture

VAL-CO® unveiled its Horizon® Whole House Controller, a new multiple zone automatic control system, at the recent International Poultry Expo (IPE) in Atlanta.

The Horizon Whole House Controller utilizes proprietary logic programs to provide fully automated, 24-hour control of key parameters in the poultry house environment, optimizing temperature, humidity and ventilation, while controlling feed and water delivery. Horizon features a large (17”), intuitive touchscreen interface, making all important house controls readily available and easy to access. Simple, straightforward software guides users in initial application setup and programming. The logic program for automated control can be overridden either at the touchscreen or manually at any time, and the results of all inputs are visually represented on-screen immediately.

The controller provides users with a smooth minimum vent curve, ensuring that all birds, including delicate chicks and poults, are being raised in the ideal temperature and environmental conditions for growth. The system also reduces heating and cooling costs by maximizing energy efficiency and optimizing the use of heaters or fans over multiple zones. Using the VAL-CO patented Innovative Control Logic, the system automatically adjusts minimum ventilation to ideal conditions, taking many factors into account, including outside temperatures and humidity. Wear leveling, to balance tunnel fan motor wear, is also an available and practical option.

System installation or reconfiguration is made easier and faster by the use of fully modular components, which also facilitate quick troubleshooting and allow plenty of work room in enclosed spaces. Remote access via the Internet gives users a means of monitoring their house environments anytime, anywhere – a key feature that helps to deliver peace-of-mind.

Additionally, the Horizon automatic remote monitoring system features dual alarm relays that reduce the risk of nuisance alarms. Scheduled reminders also provide notice whenever regular maintenance should be performed.

For more information, visit: www.val-co. com, e-mail: sales@val-co.com, or visit your local Val-Co dealer.

VAL-CO recently revealed three new additions to its FUZE ProLine Feeding System. The three new features are designed to help owners save costs and maintenance time while generating efficient feed flow and improving overall system performance and reliability.

The FUZE feeder now features a sturdy new pan-to-grill hinge and lock, securely locking the feed pan to the feeder’s “bird-friendly” ergonomic grill. The hinge provides easy access to the pan for faster and simpler cleaning and sanitizing between flocks, which can aid in improving overall flock health and performance.

VAL-CO has also added a new mechanical switch control pan. This feature will help improve control pan performance and make maintenance and servicing of the system easier.

Finally, the new FUZE feeder includes a bird-attracting LED light for the end control pan as a standard feature. Research and best practice has shown that the light attracts birds to the control pan at feeding time, helping to ensure that the feed line remains in a constant fully charged state. The result is consistent and efficient feed flow throughout the system.

For more information, visit: www.valco.com, e-mail: sales@val-co. com, or visit your local ValCo dealer.

Chore-Time’s new CHORE-TRONICS® 3 Controls offer users true buttonless operation with the colour and convenience of touch screen navigation. Additionally, the new controls’ graphing capabilities open a colourful world of data presentation for users, making poultry house data analysis much faster and easier.

Chore-Time’s third generation of its popular CHORETRONICS line of controls features vivid color in a large 10-inch (25 cm) display. Users can employ the intuitive touch screen to navigate from the Current Conditions screen to other screens facilitating control of various house components and display of critical house information in table or graph form. Users more comfortable with mouse operation may use a wired or wireless USB mouse with the new controls.

With the CHORE-TRONICS 3 Controls, a wide variety of information is displayed both graphically and with picture icons on the comprehensive current conditions screen. Details available include the set temperature, the average temperature and the variable speed temperature along with the outside temperature. The current ventilation mode, static pressure, relative humidity and air speed are also displayed as well as the feed and water consumed that day and the current bird weight, for systems equipped with Chore-Time’s bird scales.

CHORE-TRONICS 3 Controls incorporate the features growers have enjoyed in generations 1 and 2 along with the following new features exclusive to generation 3:

Fully integrated ceiling inlet control

Fully integrated bird scale control

Up to 16 controlling sensors

Improved graphing capabilities

External USB port

USB set-up key to back-up and transfer settings

The new generation of control is also designed for easy USB upload of additional features as they are developed and become available. This means that users of the new controls will be able to easily add and take advantage of the additional features under development now and in the future.

Basic graphical information can be displayed on the Control’s screen, or farm managers can use Chore-Time’s C-CENTRAL™ Professional Software for enhanced graphing and data analysis. The controls are capable of displaying graphs for temperature, relative humidity, mortality, water consumption and a wide variety of other data as well as 14 days of history on numerous topics. Graphs can also be used to assist in review of various clock and curve settings.

Chore-Time is also introducing a new larger relay box than was used with previous CHORETRONICS Control generations. The new box saves wall space by incorporating 56 relays in a single box. In many cases this will avoid the user needing two relay boxes in order to have enough relays available. The large interior of the new boxes allows more room for routing wires without the need to squeeze fingers into tight spaces. Each relay bank in the new box includes two strips of four contacts for simple, economical replaceability.

CHORE-TRONICS 3 Controls are part of Chore-Time’s complete line of integrated poultry products including feeders, drinkers, feed conveying, feed storage, ventilation, heating, cooling, nests, controls and software.

For more information, visit: www. choretimepoultry.com, e-mail: poultry@choretime.com, or visit your local Chore-Time dealer.

Big Dutchman recently introduced the Gladiator turkey feeding pan with features designed to reduce feed waste, lower maintenance time, and feed the largest turkeys.

The Gladiator turkey feeding pan is designed to feed the largest and most aggressive turkeys. The “Snap’n Lock” feature secures the dish to the pan body to eliminate “dish drop”, which saves lots of feed, and many manhours of maintenance. The Gladiator’s dish design catches feed as the turkeys eat, which saves feed and then funnels it back in front of your flock, increasing your feed conversions.

The pan is constructed of industrial strength plastic to last through many grow-out periods, and the snap on cap allows for easy installation and simple removal of individual pans when needed. Our patented uses of the shocker wire design gives you the ability to adjust the feed level to the entire line with a simple turn of a crank.

For more information and to view videos and additional photos, visit: www.bigdutchmanusa.com/ gladiator

CPRC held its annual general meeting March 23, 2012, and we felt that this would be a good time to provide an update on some of our activities, programs and initiatives over the past year.

CPRC made a presentation to the House of Commons Standing Committee on Agriculture in November 2011, during the committee’s hearings on the Research and Innovation section of the Growing Forward 2 Program that takes effect in April 2013. We emphasized the value of research to the poultry industry and the importance of the participation of the Government of Canada in those activities. The federal government provides research funding through Agriculture and Agri-Food Canada (AAFC), Natural Sciences and Engineering Research Council (NSERC) and other government agencies, but they also have highly qualified, professional researchers on staff who conduct poultry research projects. Five of the 12 projects in the present Poultry Research Cluster are conducted by scientists with AAFC and Canadian Food Inspection Agency (CFIA). The federal government also has a significant communications system that can disseminate research and innovation information to the poultry industry.

CPRC made a presentation to the Senate Standing Committee on Agriculture and Forestry in February 2012 on the importance of research and innovation to agriculture. We included much of the information from the presentation to the House Standing Committee on the value of research but also provided examples of some CPRC research projects that have had real impacts on the sector. Of the 22 completed projects to date, some have moved on to further research, directed toward adoption by

industry stakeholders, while the results of eight projects have been, or are being, adopted by farmers, processors and input suppliers.

The Poultry Research Cluster, co-funded with AAFC, the PIC, and provincial governments and funding organizations, has entered its final year and preliminary results have already benefited the industry. The cluster approach does not replace single projects but it does have some positive characteristics that make it a strong research tool. A cluster is a science strategy that brings together multidisciplinary teams, or “clusters,” of scientists, to solve complex problems and to create synergies in research efforts. It is a way to make the most of available resources and supports a strong business case for investing in Canadian poultry research.

The present Poultry Research Cluster consists of 12 projects that bring together seven different universities and research organizations and 28 scientists. Research focus for the cluster has been on food safety and quality (e.g., vaccine development, avian influenza, necrotic enteritis) and poultry welfare and behaviour (leg and bone structure, toe-clipping of turkeys, feeding strategies for breeders). Preliminary results for some projects have been featured in previous updates and are available on our website in the research results section.

The draft National Poultry Research Strategy is presently being reviewed and discussed by the poultry production sector, after which it will be made available to other industry stakeholders for comment. This document is very important to both our industry and CPRC as it identifies the issues

that are important to poultry producers and their industry partners, establishing CPRC’s agenda for the next several years.

CPRC has been in existence for just over a decade and approved its first research funding in 2003. The CPRC Board decided that it was a good time to review CPRC’s research funding and processes to try and determine our level of effectiveness and efficiency. The information on the eight projects that have been, or are being, adopted by industry and that were included in the Senate Standing Committee presentation, is taken from the preliminary information generated during the review of research funding.

Some other preliminary information from the evaluation includes:

Since 2005, when the present system was refined, Letters of Intent have been reviewed, assessed and funding approved within three months of receiving them from researchers. More than half have been approved within two months. However, the time needed to complete the review and approval has lengthened in recent years, partly because of the increasing number of proposals received. Of the 22 completed projects to date, 14 per cent were completed on or before the target completion date established by the funding agreement. Half of the completed projects were completed within three months of the target date and almost three-quarters within six months of target date. Research project timelines frequently change as challenges develop in processes and data collection. CPRC has a system in place to identify delayed project completion so we can react accordingly.

More information on the results of CPRC’s evaluation will be available in coming months.

The best of times? Most farmers say yes

BY JIM KNISLEY

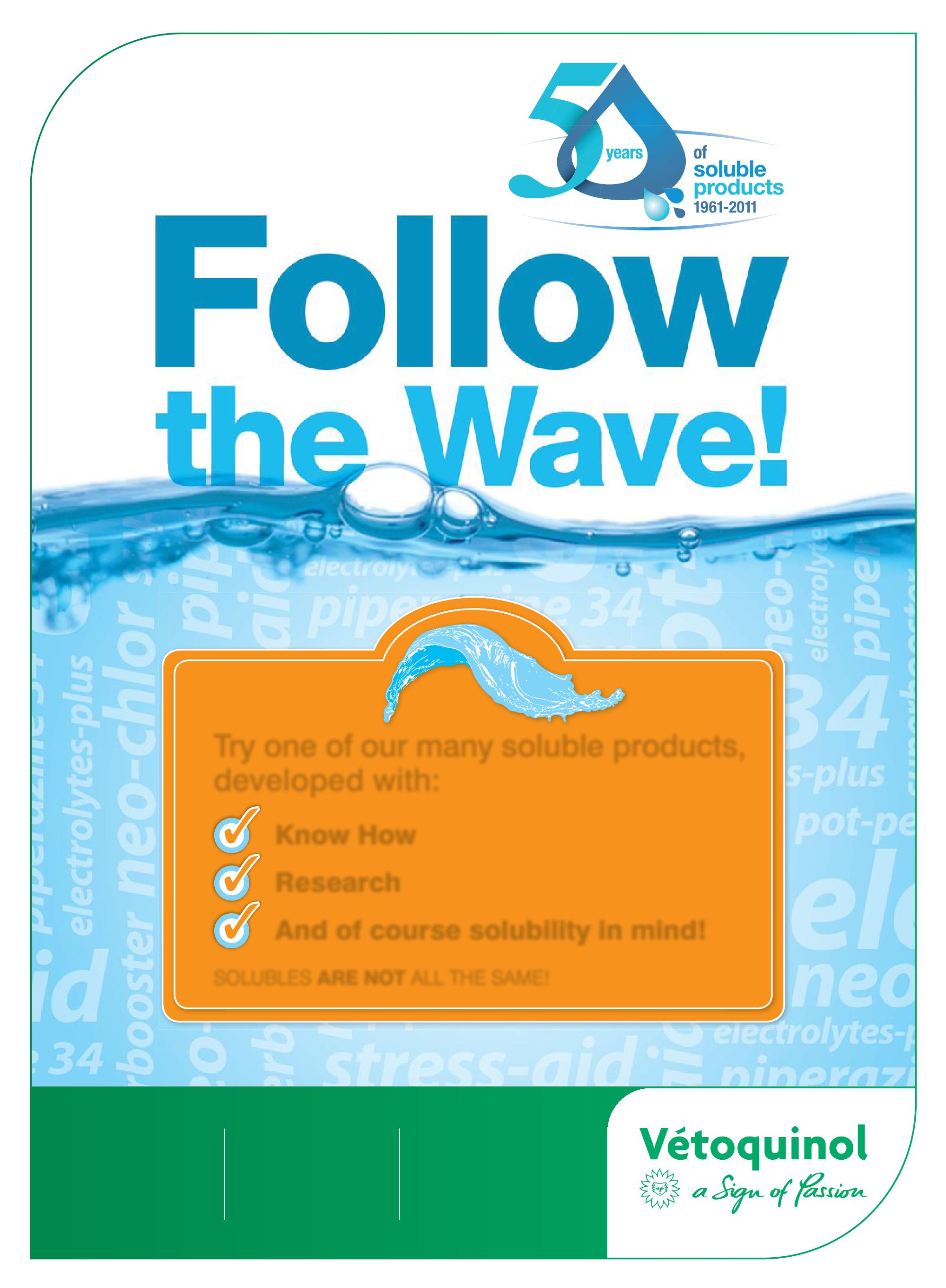

Optimism among Canadian farmers has never been higher than it is today, with all indicators reaching new highs, according to a Farm Credit Canada (FCC) Vision survey.

More than three-quarters of all farmers responding to the survey believe they are better off now than they were five years ago, while eight in 10 believe they will be even better off five years from now. Poultry producers are the most optimistic with eight in 10 poultry producers (80 per cent) saying their farm is better off today than five years ago and agreeing that their farm or business will be even better off five years from now.

The optimism is reflected in farmers’ plans for the future with a majority planning to expand or diversify their operations in the next five years and 80 per cent saying they would recommend careers in agriculture to others.

Over the past five years the level of farmers’ optimism has been increasing. More farmers now say they are better off today than five years ago. In late 2011, when the survey was taken, more than three-quarters of all farmers surveyed (77 per cent) said that their farm or business is better off now than it was five years ago.

As good as things are now, farmers surveyed said better days lie ahead. Eight in 10 producers (80 per cent) expect to be better off five years from now than they are today. The number of producers who

A recent FCC survey shows that more than three-quarters of respondents believe they are better off now than they were five years ago

are optimistic has grown significantly since 2007, the first year the survey was published by FCC.

This increasing optimism is translating into plans for expansion and/ or diversification. More than half (58 per cent) of producers are planning to expand and/or diversify their operations over the next five years, while just 15 per cent say they plan to reduce their operation or exit the industry. The increasing optimism is bubbling into recommendations that others consider a career in agriculture. Advocacy for agriculture is at a new high, according to the survey, with eight in 10 producers saying they recommend a career in an agriculturerelated field, and seven in 10 saying they would recommend a career in primary production.

Although farmers said they would recommend farming as a career, they recognize just how hard it is to get into. Most producers stress that unless you have land or an operation being passed on to you, getting a start in farming is almost out of the picture. They told FCC “that due to increasing machinery costs and land prices, starting a farm from scratch is nearly impossible.”

Producers also said they want Canadian consumers to understand more about their industry, with an emphasis on the production of safe, quality food. The 10 words most frequently mentioned by producers were: safe, food, quality, healthy, important, good, local, sustainable, product and Canadian.

While producers are optimistic, they recognize that major factors are beyond

PRODUCERS TOLD FCC THAT THEY HOPE WHEN CONSUMERS THINK ABOUT CANADIAN AGRICULTURE THEY THINK ABOUT SAFE, QUALITY FOOD, AND THAT IT IS AN IMPORTANT, LOCAL, AND HEALTH INDUSTRY.

their control such as weather and unpredictable economic conditions. They are

also concerned about increasing input and machinery costs and debt loads that could make the upcoming years tough if interest rates increase.

While farmers across Canada are increasingly optimistic, Saskatchewan producers lead the way with 82 per cent expressing optimism compared with 79 per cent nationwide.

Optimism among poultry producers has never been higher than it is now. Eight in 10 poultry producers (80 per cent) agree that their farm or business will be better off five years from now. It is likely that optimism for the future among poultry producers is backed by the fact that 80 per cent of poultry producers feel that their operation is better off today than it was five years earlier.

Poultry producers display optimism

through their plans to expand and diversify their operations. In total, six in 10 poultry producers (59 per cent) plan to expand or diversify, or both. Thirteen per cent of poultry producers plan to reduce their operation or exit the industry, whereas one-quarter (24 per cent) plan no changes.

Advocating careers in primary production is another way poultry producers show they are optimistic about the future. Eight in 10 poultry producers (81 per cent) would recommend a career in primary production, making producers in this sector the most likely to do so among all other sectors. Additionally, 84 per cent would recommend a career in an agriculture-related field. In the past year alone, half of all poultry producers have recommended a career in agriculture (50 per cent) and four in 10 have recommended a career in primary production (44 per cent).

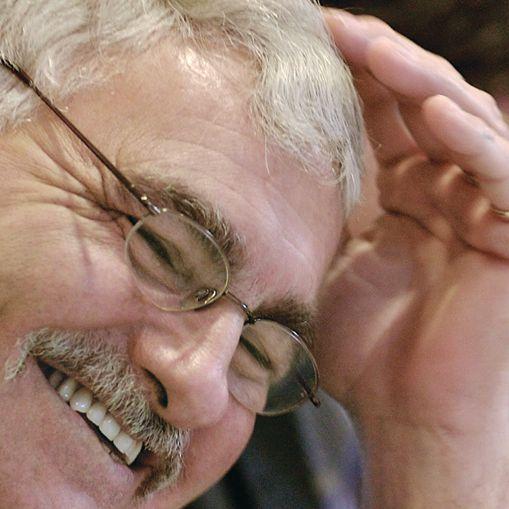

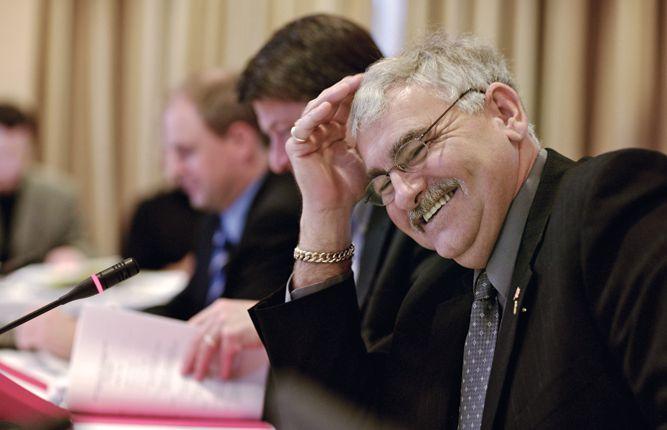

CFC chairman David Fuller is leaving after 13 years to focus on family succession

BY KRISTY NUDDS

The Chicken Farmers of Canada’s (CFC) longeststanding chairman is ready to give up a life of airports, conference calls and meetings to focus on helping his three daughters take over the family farming operation in Nova Scotia.

David Fuller says that change is always good for an organization and that the “time is right” for him to leave the position he’s held since 1999.

“Trying to run a farm and be the Chair of CFC has been more than a fulltime position,” he says.

Now, he’s looking to spend more time with his family, and helping his three daughters — Natasha (along with her husband, Cory Dykens), Stephanie, and Jennifer — take over the farming operation, which produces 1.6 million kilograms of chicken on three farms in the Canning area, in the picturesque New Minas basin.

Fuller began his career in the chicken industry in 1976, when he formed a partnership with his parents John and Betty, who had a broiler and turkey operation. At that time, and throughout the 1980s, chicken production increased and the family acquired additional production quota, expanding the farm to its current size. David and his wife Diane bought out the farm completely from his parents three years ago.

Fuller worked on the farm full-time until 1987, when he began to take on more of a leadership role within the industry. That year, he began serving

David Fuller says his time as Chairman of CFC has had many rewards, despite numerous challenges. But the time is right for him to leave the position and help his daughters take over the family broiler operation

on the Chicken Farmers of Nova Scotia board, as Chair for several years. In 1993, he became Nova Scotia’s representative to CFC, and served on CFC’s Executive committee in 1994 but had to resign that year as the CFNS had asked producers for its support in leaving CFC. Believing that leaving CFC was not the right thing to do, Fuller says he had no choice but to resign from the CFNS as well. His fellow producers supported his position and voted against leaving CFC. Fuller then returned to CFC in 1996.

Fuller says the reason he became so involved in the industry was “it was the opportunity for me to say thank you and hopefully, be able to bring something to the table that would be beneficial for the Canadian chicken industry,” he says.

As a farmer, one of the biggest challenges has been to always make sure that there is stability in the system in

the long-term, which allows farmers to invest with confidence. Stability in the system is a key part of his role as Chair of CFC.

“As Chair, my job was to make sure that the organization looks after the interest of the farmers that we represent, as well the partners that we work very closely with, whether upstream or downstream from the farm, including government,” he says.

He says he has found his experience as chair very rewarding. “To be able to bring the parties together, to build consensus on issues that face our industry as a whole, has been one of the highlights,” he says.

There have been many highlights throughout his tenure at CFC, but the most significant highlight, says Fuller, is the Federal-Provincial agreement that CFC officially finalized in June 2001.

This required getting consensus amongst all provincial commodity boards, provincial supervisory boards, provincial agriculture ministers, as well as the federal agriculture minister. “To be able to put an agreement like that in place that everyone could agree to, that would tell us how we are going to do business in the future as a unit, to me was a highlight, “ he says.

Fuller was also driven by the fact that when he first took the position of chair, he had many that told him he couldn’t get it done. “That was a mistake,” he says. “When you tell me I can’t do something, then I go at it.”

He got involved personally — visiting ministers, talking with them one on one in each province, to make sure that they understood what CFC was doing, and what the scope and the intent of the agreement was.

A challenge, says Fuller, has been the trade file, because it has the potential of having a significant impact on Canadian farmers if it goes badly, regardless of whether a farmer is in supply management or not.

He says he took the file under his wing and was very close to it during his tenure. “It has not been an easy challenge to sit and talk not just with Canadian officials, but officials from other countries to try and build consensus on how to best look after the interests of everyone involved,” he says.

He believes that with the support supply managed industries have from all political parties, whether provincial or federal, shows how important supply management is to Canada and how it is beneficial. “I think our governments clearly understand the benefit of supply management, and that it’s biggest

benefit, to be frank, is that it costs them nothing,” he says.

However, one of the biggest challenges he’s faced is how to convince the media of this, and in particular, that farmers do not set retail prices. He expresses frustration with the fact that despite meeting with numerous editorial boards across the country to try and get this message across, “we just can’t seem to get it there.”

“If Canada gives supply management up, we will not get anything for it,” he says. “People have this assumption that supply management is holding us back, and that is so far off the truth.”

He says although the media likes to say that Canada is unique (with respect to wanting to protect supply management as a sensitive product) but “we’re not.” He points to the U.S. having sensitivities around oranges, sugar, and cot-

ton, and Australia and New Zealand, who claim to be free traders yet have so many barriers put in place, that no one can ship anything into their countries.

Despite the frustration of the trade file, Fuller commends the Canadian government for it’s continual support of supply management. He says it is “unheard of” to have the Prime Minister mention support for supply management on two different occasions during his Speech from the Throne. He also noted that Federal Agriculture Minister Gerry Ritz has been true to his word that supply management is non-negotiable.

A big challenge left unresolved as he leaves his position has to do with differential growth. Since 2007, CFC has been working on provisions for differential growth in its operating agreement under the federal-provincial agreement. In the past few years, growth has “subsided tremendously,” he says.

“We are in a growth market, but it’s minimal,” he says. If the market was experiencing a growth of five per cent a year, it would be easier to achieve consensus amongst stakeholders. Currently, the market is only experiencing one to two per cent growth annually. CFC has been working on several formulas, and will continue to explore ways to allow for differential growth in Canada, he says.

Fuller says he is proud of CFC’s On-Farm Food Safety Program and it’s Animal Care Program, which were developed during his time with CFC. He also notes that CFC’s involvement, along with the other national feather boards and the Canadian Poultry and Egg Processors Council (CPEPC) with the Canadian Poultry Research Council (CPRC) has been a “real opportunity” for the organization.

The SM5 group was also formed during his tenure and he says that “having the ability to sit down with his fellow

members of supply management and talk about issues that face us all has been very rewarding, and to be able to build a team that works closely together is so crucial,” he says.

Fuller says he has learned a lot from CFC on how to be a better farmer, as it has helped him to learn the issues and complexities of the industry. Hearing from other farmers is “eye-opening” he has learnt from them how to do things better. “By communicating with each other you learn things, and that definitely helps you be a better farmer,” he says.

He has also benefitted from being part of the development of two of CFC’s strategic plans (they are developed every five years). The strategic plan is a “roadmap” for the organization to follow, and it uses it to re-verify whether it’s going in the right direction, or whether the members need to sit down and rethink things. “I think it’s absolutely key, and I’ve adopted

it on my own farm,” he says.

Fuller is also thankful for the many rewards and opportunities his time with CFC has brought. “The biggest reward for me in this whole job was the opportunity to meet with not just my fellow farmers, but people throughout the industry as well,” he says.

The opportunity to travel to many different places throughout the world and talk to with farmers and stakeholders in these countries has been something that he has enjoyed and he greatly appreciates.

“The travel that my wife and I have been able to do while I was chairman has been phenomenal,” he says. “We thank everyone from the bottom of our hearts for giving us that opportunity.”

He says that he thinks the opportunity to travel and see more of the “real world” has made them better people. When speaking at a number of different events, one of his key messages has been “that in Canada, we take way too much for granted and we have no idea what it’s really like in a lot of other countries in the world,” he says.

Fuller announced that he would not be seeking re-election at the 2011 annual meeting of Les Éleveurs de volailles du Québec. His last official day as CFC chair was March 20, when the board elected B.C. representative David Janzen as the new chair.

When asked what advice he would give his successor, Fuller says, “always look for commonality and then try to build from the commonality out. If you find the common ground between people or organizations on issues, you will continue to build consensus.”

Fuller says CFC is keeping him on retainer for six months to help with the transition between chairs. The organization will be honouring him at its summer meeting this July in Winnipeg.

Yesterday, today and tomorrow...

Sommers has been a trusted name for standby and PTO power systems in rural Canada for 75 years. Over the generations, we’ve been there to keep your lights on and your equipment running with reliable generator systems personally tailored to your family and business needs.

Times have changed, but Sommers is still leading the next generation of power solutions with advanced features like Sentinel remote monitoring and our new easy-to-buy series of packaged systems.

For now and for your future, count on Sommers for “the power to live better.”

BY KIMBERLY SHEPPARD, RESEARCH CO-ORDINATOR

FEATURED RESEARCHERS:

MANON RACICOT, ARTHUR KOCHER, GUY BEAUCHAMP, ANN LETELLIER, JEAN-PIERRE VAILLANCOURT, UNIVERSITY OF MONTREAL

Hand sanitizing is extremely important to prevent the spread of pathogens — be it from person to person or from farm to farm. But, are all sanitizing methods created equal? Are the convenient alcohol-based gels and wipes as good as (or better than) good old soap and water? Or are they best used in combination? This question is especially relevant to catching crew members, who can heavily contaminate their hands with organic material, then act as mechanical vectors spreading diseases between farms. Hand hygiene is also important to prevent zoonotic agent contamination such as Escherichia coli O157 and Salmonella enteritidis for which health consequences can be serious.

Many studies in human medicine tend to make hand rub with a disinfecting gel a standard for hand hygiene. However, few studies have tested the effectiveness of hand hygiene products on visibly contaminated hands. Dr. JeanPierre Vaillancourt and his research team at the University of Montreal have been evaluating the effectiveness of practical hand sanitization protocols: soap and water, degreasing cream, and hand wipes, all combined with alcohol-based

University of Montreal researchers tackle the question of whether hand sanitizing methods are created equal

hand gel. The use of alcohol-based gel alone was also evaluated. Thirty-two repetitions of each hand-washing protocol were done.

The study was conducted under field conditions, from July to August 2010. A catching crew was followed during normal working hours. To be as close as possible to field conditions, no specific time and quantity were required for washing

or rubbing hands with the different products. An explanation was given on how to perform the four protocols (different steps) without indicating specific time or quantity to use. However, the time spent by each person for each protocol (the time spent to wash hands before applying the alcohol-based gel and the time spent to rub hands with the alcoholbased gel) was recorded using a video

camera and the quantity of alcohol-based gel used was estimated by recording the number of times each participant pressed on the delivery device fixed on the alcohol-based gel container.

Their findings? For the reduction of coliforms after washing, there was no statistically significant difference between protocols when the initial level of contamination was low to moderate. When hands were highly contaminated, the alcohol-based gel alone was less effective than the degreasing cream

combined with the alcohol-based gel. As for the reduction in total aerobic counts after washing, there was no difference between protocols when the initial level of contamination was low. The soap and water with alcohol-based gel protocol was more effective than the scrubbing wipes and alcohol-based gel protocol when hands were moderately and highly contaminated. All protocols were effective in neutralizing Salmonella Reducing the level of hand contamination before using an alcohol-based

gel seems important to ensure effective hand sanitation for highly and moderately contaminated hands. This can be done by using a degreasing cream or soap and water before applying an alcohol-based gel. However, based on the survey done during this study, catching crew members preferred using soap and warm water compared to a degreasing cream. For more information on this study, please visit www.poultryindustrycouncil.ca.

Enterococci are part of normal intestinal gut flora of animals and humans. Many studies have shown that enterococci from animal origin could represent an antimicrobial resistance genes reservoir for the human community. Little is known about the molecular antimicrobial resistance profiles from avian enterococci in Canada. Enterococci have numerous genetic elements that contribute to the dissemination of antimicrobial resistance traits that are mostly transferred by a highly efficient “pheromone-responsive” system. This system enables contact between donor cell and recipient cell during conjugation. In addition to reducing antimicrobial use, the poultry industry would benefit from new methods of prevention or reduction of spread of AMR.

Dr. Marie Archambault and her research team at the University of Montreal have been working toward providing evidence for the development of new tools to help the poultry industry prevent the emergence and spread of AMR. To this end, they have conducted a study to characterize the antimicrobial resistance determinants and investigate plasmid colocalization (presence of two

substances in the same site) of tetracycline and macrolide genes in Enterococcus faecalis and Enterococcus faecium from broiler chicken and turkey flocks in Canada. This study also investigated new ways to reduce the transfer of antimicrobial resistance through interference in the pheromone-responsive conjugation. They hypothesized that the horizontal transfer of antimicrobial resistance in avian isolates of enterococci could be reduced using a polyclonal antiserum AS44-560.

Their findings? A total of 387 E. faecalis and E. faecium isolates were recovered from poultry cecal contents from five processing plants. The percentages of resistant E. faecalis and E. faecium isolates, respectively, were 88.1 and 94 per cent to bacitracin, 0 and 0.9 per cent to chloramphenicol, 0.7 and 14.5 per cent to ciprofloxacin, 72.6 and 80.3 per cent to erythromycin, 3.7 and 41 per cent to flavomycin, 9.6 and 4.3 per cent (highlevel resistance) to gentamicin, 25.2 and 17.1 per cent (high-level resistance) to kanamycin, 0 and 0 per cent to linezolid, 2.6 and 20.5 per cent to nitrofurantoin, 3 and 27.4 per cent to penicillin, 7 and 12.8 per cent to salinomycin, 46.7 and

38.5 per cent (high-level resistance) to streptomycin, 95.6 and 89.7 per cent to tetracycline, 73 and 75.2 per cent to tylosin, and 0 and 0 per cent to vancomycin.

One predominant multidrug-resistant phenotypic pattern was identified in both E. faecalis and E. faecium (bacitracin, erythromycin, tetracycline and tylosin). A significant reduction in the pheromone-responsive horizontal transfer of bacitracin resistance in E. faecalis could be achieved in vitro with a polyclonal anti-AS44-560. Overall, results indicated that the intestinal enterococci of healthy poultry could be a reservoir for quinupristin-dalfopristin, bacitracin, tetracycline, and macrolide resistance genes. For more information on this study, please visit www.poultryindustrycouncil.ca.

BY TIM NELSON, EXECUTIVE DIRECTOR

It’s music to our ears when a producer tells us that he can’t wait for the next regional producer update, which we host with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) at vari-

Canadian Trial Demonstrates the Performance Improvements of Vaccination with VAXXITEK® HVT + IBD.

In one of the largest Canadian field studies of its kind, more than one million broilers were vaccinated with VAXXITEK® HVT+IBD over four periods from June 2010 to February 2011. 1 At the end of the trial, the conclusion was clear. Vaccination with VAXXITEK HVT+IBD resulted in a substantial improvement, particularly in livability, number of condemnations and profitability.

Here’s what satisfied customers are saying:

We started using VAXXITEK shortly after its launch and noted a big improvement in chick quality right from the start. Our customers reported fewer condemns and reduced mortality. Now we have customers asking for VAXXITEK-vaccinated chicks. We’re extremely happy with the results.

“

Ernie Silver, Hatchery Manager, Western Hatchery, Abbotsford, BC

April 25 26, 2012

University of Alberta, Edmonton

For more information visit: www.settingthestageforsuccess.wordpress.com

To register: www.regonline.ca/nationalhatcheryworkshop

Workshop Presenters Include:

Sander Lourens, Wageningen UR, Netherlands

Nick French, Aviagen

Donna Hill, HatchTech

WEDNESDAY APRIL 25, 2012

The Stage is Set: the big picture

Setting for Success: managing egg storage

The Heat is on: adjusting embryonic metabolism for hatching success

Squeaky clean. Does egg hygiene really matter?

Short periods of incubation during long egg storage: what happens to hatchability?

Multi stage vs. single stage….embryonic profiles

How do you measure chick quality?

Warming up to your chicks: incubation effects beyond the hatchery doors

Measuring performance–what matters to you?

THURSDAY APRIL 26, 2012

Shake, rattle and roll: the effects of transportation

Incubation temperature and breeder flock age effects on chick bone development

Incubation temperature and breeder flock age effects on chick immune function

Get your hands dirty! Hatch residue break out: doing it right and making it matter!

Will I survive? How poor hatching flocks impact incubation

Too hot, too cold, or just right: chick holding temperatures and subsequent broiler performance

Hitting the ground running: post hatch chick management.

Beyond the navel gaze: checking out the big picture.

$270 per individual

Includes continental breakfasts and lunches.

More than 1 attending from your company?

Receive a $35 discount on all registrations when you register at the same time. Student Registration only $50!

Students are invited to present research posters.

ous locations throughout Ontario.

The focus of the regional poultry producer updates is to bring producers and industry together to talk about current issues and provide a local forum for the exchange of information. Looking at attendance, we seem to have hit our stride with the last round of updates held in February. Thanks to all of our presenters who provided great information in a clear, concise manner peppered with real-life stories that we all could relate to.

Here are the attendence numbers: Belleville, 55, London, 120, and Jordan, 51, for a total of 226.

Of the 226, 50 per cent were poultry producers.

Topics included:

the poultry health update from the regional poultry vets, what they have been seeing with respect to disease this winter; an update from the banks (TD and RBC), who shared their thoughts on current market trends; an update from the provincial poultry specialist on the use of the new pullet carts; and updates on the effect of heat stress, fly control and much more.

Some highlights:

Crystal Mackay from Farm and Food Care Ontario spoke about the newly released poultry transport decision tree, “Should This Bird be Loaded?”, and why it was created and this led to a lively exchange of questions and answers. Producers were able to pick up copies of the ”Should This Bird Be Loaded?” laminated information sheet, which is a quick reference guide that can be inserted in barn binders. A poster version of this guide (great for displaying on barn entrances), as well as a more detailed handbook were also available and were scooped up.

Bill Groot-Nibbelink, livestock regulatory affairs specialist with OMAFRA, gave an update on the pending deadline for certification of incinerators, and listed which companies are hoping to have their Environmental Technology Verification Program (ETV certificate) by March 27.

George Cornelissen shared his story of installing a geothermal unit (water furnace) on his property to heat his barns. George talked about the cost, installation and cost savings that he is now experiencing with this alternative heating system.

These days are run for producers and we rely on you for great ideas for speakers and topics.

We run regional think-tanks with producers to discuss what they would like to hear and all are welcome to attend. The more input into the planning sessions, the better the updates. So why not join us at one of those or if you have a topic you would like to share with others at a regional producer update please don’t hesitate to contact us for information on how to get it into the agenda. Phone the PIC at 519-837-0284 or e-mail pic@poultryindustrycouncil.ca.

The next round of updates will be held in November.

Don’t hand them over to necrotic enteritis-The Profit Killer!

BMD® Helps Improve Your Bottom Line By:

Reducing subclinical and clinical disease, resulting in greater productivity and decreased morbidity/mortality

y

Ensuring the absorption of nutrients from feed through preserving the integrity of the gut wall and controlling necrotic enteritis1

1 Miller SH, Skinner J, Davis SW. Efficacy of Probiotic and/or BMD ® in the Feed for Control of Necrotic Enteritis Caused by Clostridium perfringens in Broiler Chickens. Pfizer Global Poultry. Data on file. King/Alpharma is now part of Pfizer Inc. The integration of King/Alpharma and Pfizer entities may be pending in various local jurisdictions and integration may be subject to completion of various local legal and regulatory obligations. All content in this message is subject to works council and/or union consultations, if applicable, and other legal requirements where appropriate.

BY JIM KNISLEY

Controlling flies in and around poultry barns can be a challenge, but if the flies aren’t controlled the farmer may face an even bigger concern – government officials buzzing around the barn.

Daniel Ward, an engineer with Ontario’s Ministry of Agriculture, Food and Rural Affairs (OMAFRA), told 120 farmers gathered for a producer update in London, Ont., that legislation protects farmers from nuisance complaints so long as they are following “normal farm practice.”

Flies are one of the seven nuisances listed under the Farming and Food Production Protection Act (FFPPA) and Nuisance Complaints. The others are: noise, odour, dust, light, vibration and smoke.

A normal farm practice is defined as that which is consistent with proper, acceptable customs and standards of similar operations or uses innovative technologies according to proper advanced farm management practices.

Complaints usually come from neighbours, and OMAFRA staff will investigate by talking to the farmer and the neighbours. The officials will try to mediate the dispute and 98 per cent of cases are resolved through mediation with agricultural engineers of environmental specialists.

If mediation fails the case can go to the Normal Farm Practices Review Board for a hearing. “Hearings are a last resort as they are time consuming and often result in a

OMAFRA engineer Dan Ward says there are three basic approaches to fly control: barn and site management, biological controls and chemical control. These can be used alone or in combination.

winner/loser, which can make for difficult neighbourhood relationships,” said Ward.

The board, which is a quasi-judicial body, will decide if the farm practice from which the dispute arose is normal, not normal and must stop, or can be normal if specific conditions are met.

But for a complaint to get that far is very rare.

To deal with flies the key thing is to “know the enemy,” by understanding the fly life

cycle and the ideal environment they seek, he said.

Flies seek moist, dark areas to lay their eggs and the eggs must remain moist to hatch. Although they will lay eggs in areas with moisture between 20 and 80 per cent, 60 to 80 percent moisture is their ideal.

Flies also like it warm and with ideal moisture and warm summer temperatures they can reach the pupae stage in five to seven days and mature is less than two weeks. In the most favourable conditions it can take “10 to 14 days egg to egg,” he said. In cooler temperatures the cycle can

Used year-round in your flocks, Coccivac® vaccine can help achieve simple, sustainable and profitable prevention against coccidiosis. Resistance is not an issue, so Coccivac frees birds from the stress associated with in-feed anticoccidial rotation and shuttle programs. You and your feed company can focus on improving nutrition and better gut health.

To make the transition to Coccivac, go to www.becauseitworks.ca, talk to your veterinarian or speak to your Merck Animal Health representative.

take up to 30 days.

Fly larvae require a nutrient-rich environment such as rotting vegetation, garbage, spilled feed or manure, which is why flies lay their eggs in those areas.

And a small fly problem can explode almost overnight if it is not dealt with immediately. A single adult fly will lay an

average of 500 eggs in its short life and there can be as many as 10 generations of flies in a year. The arithmetic is frightening. In the unlikely event all survive generation to generation, one fly lays 500 eggs, so if they all survive those 500 flies would become 250,000 and the 250,000 would become 125 million.

…if trace mineral safety for your layers is not as simple as cracking a few eggs?

While consumers are demanding more poultry, they are also demanding safety. Do you know where your trace minerals come from? We do. Alltech’s Poultry Advantage program brings you local manufacturing in the heart of Canada and guarantees safe and traceable minerals everyday through our state of the art Q+ program. Be Alltech Farm Proud with the advantage, the Poultry Advantage

So, who cares about safety in your trace minerals? Remember…

“The population can just go crazy,” Ward said.

Even in the real world where most don’t survive it can easily become a big problem that must be controlled.

To deal with flies Ward said there are three basic approaches: barn and site management, biological controls and chemical control. These can be used alone or in combination, he said.

But no matter the approach the key is to break the fly cycle because “adult flies only represent a quarter of the problem.” “Even if you kill all the adults there are more flies coming,” he said.

Barn management sounds like the simplest solution but it takes a lot of time, he said. It involves: eliminating water leaks; increasing ventilation rates to ensure the manure and litter are too dry for eggs or larvae to survive; cleaning up feed spills and water leaks immediately; regularly mowing vegetation around the barns; cleaning up spilled manure; and keeping dead stock disposal sites operating properly and clean.

The bottom line is that barn management involves more work walking the barn and dealing with wet litter, extra bedding to dry up wet spots and a higher ventilation rate (extra electricity) to dry the barn.

Biological control is an option that uses the fly’s natural enemies to control the population. The most common biological controls are parasitic wasps and a fungus.

The advantage of biological controls is the flies are unlikely to develop resistance.

But “you need to know where and when to use these products to achieve the best fly control results.”

Call 1-800-285-8617 to learn how to become Alltech Farm Proud through Alltech’s Poultry Advantage Program. Alltech.com | AlltechNaturally | @Alltech

“You need to plan ahead, they’re not a quick kill,” he said. In effect, you need to put the biological controls in place when you think a problem is coming, not after it has arrived.

The wasps are not what most people think of as wasps. They are tiny – about the size of a fruit fly.

The wasps do their work before flies

Dear chicken farmers,

Over the past 13 years, you have given me the privilege of experiencing this great nation from a number of different perspectives. From coast to coast, I have learned so much from the industriousness, innovation and imagination of my fellow Canadian chicken farmers and indeed, of all the partners in our great industry

As I look back I think we need to remind ourselves why Supply Management is necessary for the entire chicken industry. The supply management system for the production of chicken is the result of an agreement among farmers and among governments on the desire for a system in the interests of us all.

Why was this partnership formed?

1. To provide price stability

2. To ensure such price stability and adequacy by the management of supply

3. To preserve a structure of independent family farms

4. To preserve a share of the industry for all regions

5. To achieve these goals without government subsidies

It is a privilege to be a farmer within this system. It is a privilege that we have to earn by working tirelessly to make the system work on a sustainable basis. It is a privilege that we have to earn through partnership and by looking out for each other not just our own self interests.

By “looking out for each other”, I refer to the many issues that we have to face on a daily basis. How we address these challenges will determine if they are stepping stones, or stumbling blocks.

Over the years we have built a system that is advantageous to both the consumer and all sectors of the industry, but in order to continue our success, and maintain the employment and economic spin-offs, it is crucial that we work closely together and address our industry issues for the betterment of the entire Canadian chicken industry

As well, there will be challenges to our system from those who choose not to understand it and from those who believe the supply management systems restrict Canada at any trade talks. We need to continue to monitor all trade talks whether they are multilateral or bilateral agreements. We need to continue to explain to all of our politicians the value of our system. The old saying – United We Stand, Divided We Fall – is what we always need to keep in the back of our minds.

After 13 years at the helm of this dynamic organization, I have decided to step back. I do so with the confidence that there is strong leadership and commitment on the CFC Board of Directors to lead our industry forward. I have met wonderful people over the years – people who have helped build our industry to where it is today. At every stop, I have been welcomed with the hospitality for which Canadians have always been known. So, to you, I say, “Thank you” I’ve had an incredible ride. My request of you is that you continue to support and act, as I have done, in the best interest of farmers across Canada

Sincerely, y

David Fuller Chair of CFC, 1999-2012

reach the adult stage. When the flies begin the process of changing over from larvae to a pupae the wasp stings and deposits her eggs inside fly pupae. These eggs begin to grow and feed on the developing fly, stopping it from hatching.

The wasps have produced good results, but he repeated that they work best if you anticipate the potential for a fly problem.

The Beauveria bassiana fungus has a spore that attaches itself to the adult fly or fly larvae. The spore has a feeding tube that goes into the fly or larvae. It does not, however, work on pupae because the outer shell is too hard.

Using either the wasps or the fungus involves paying for the products, labour to walk the barn and distribute the product (in the case of wasps) or multiple spray applications during growout for the fungus.

Wasps are also perishable with a limited shelf life. In effect, you should order as needed, he said.

“These are knockdown products,” he said. They will kill adult flies on contact. Most

offer some residual effect and will be viable for up to 30 days. In effect the chemical will land on a surface and if the fly lands on that surface it will pick up the chemical and die.

But none of the products can be used in barns as an aerosol when birds are present. “Their use is limited to fogging the barn before cleanout to gain control of a bad situation or surface application in a barn after cleanout and disinfection and before introduction of the birds,” he said.

If you plan to use a chemical control, read the label, because you need to use the correct rate. You should also rotate between active ingredients. Both of these actions are necessary to reduce the danger of flies developing resistance to the products.

Another option is a combination of bait stations and traps. These tend to be low cost, but involve lots of labour to replenish baits or traps, he said.

Beat beetles. Darkling beetles are evil little creatures. They wreak havoc on your facilities, spread bacteria and disease and irritate the most important part of your business. Your birds. So don’t hold back, hit them with Tempo®. A fast and powerful way to control darkling beetles. With rapid knockdown and prolonged residual activity, Tempo® boosts the comfort of your birds. And your bottom line. Learn more at BayerLivestock.ca.

The second largest acreage in history is predicted, but if it doesn’t materialize, supplies could be tight

BY JIM KNISLEY

The question heading into the coming crop year seems to be which rollercoaster markets will be on – the Comet or the kiddie coaster – and whether it will be a stomach-churning wild ride or much less exciting mild ride.

The release of the February United States Department of Agriculture (USDA) supply and demand forecast, grain markets moved up as tighter than earlier predicted supply/demand pressures were forecast. Despite the prospects of the second largest acreage in history in the offing the possibility of weather-fueled wildness later in the year remains.

If the large corn crop anticipated for this year doesn’t materialize, supplies could be tight.

For example, the USDA forecasts crop-year ending corn supplies at just over 800 million bushels. This is less than half the carryover at the end of the 2009 crop year and 25 per cent lower than at the end of the 2010 crop year.

The stocks-to-use ratio is projected at 6.3 per cent, the lowest level since 1995/96, when the stocks-to-use fell to 5.0 per cent. But unlike 1995/96, corn held by farmers for delivery to ethanol plants is expected to account for a significant portion of 2011/12 ending stocks.

The USDA says that U.S. corn prices are expected to hit a record as stocks continue to tighten.

But next year the situation could change dramatically. The USDA’s proj-

2012 could be a bumper year, but the weather and weakening ethanol demand could change that

ects corn acres at 94 million for 2012-13. With average yields and no dramatic change in use corn ending stocks for 2012-13 would come in at 1.6 billion bushels — double this year’s.

The USDA forecast the amount of corn for feed at 5.225 billion bushels, up significantly from this year. Corn for ethanol was held at about 5.0 billion, and exports were increased to 1.875 bil-

lion bushels from 1.7 billion this year.

The farm gate corn price is expected to average $5.00 per bushel for 2012-13 compared with $6.20 for 2011-12.

The USDA baseline projection calls for a record 14.235 billion bushel corn crop, above the previous record 13.1 billion and pegged the yield per acre at 164.0 bushels, above last year’s 147.2 bushels per acre.

Meanwhile, the USDA forecast soybean seeding at 74.0 million acres and a crop of 3.215 billion bushels, the third largest on record.

Morgan Stanley said corn prices could face a short-term hiccup from weak ethanol margins and less demand.

“The outlook for US domestic demand near term may begin to falter in coming weeks as poor ethanol margins and growing inventories should begin to pressure plants to slow production,” Morgan Stanley said.

The bank forecast corn use by ethanol plants at 50 million bushels less than the USDA projection.

Despite this Morgan Stanley anticipates an average price of $6.60 per bushel in 2011-12, well above the USDA forecast.

Morgan Stanley said: “We remain most constructive corn out of all of the agricultural commodities.” The bank cautioned that “prices need to move higher to justify the demand rationing currently implied by the USDA balance sheet.”

Meanwhile, Rabobank said, in an earlier report, that 2012 grain markets are ‘down, not out.’

World grain inventories remain near historical lows, and that should mean continued high prices. But it won’t be a steady, strong bull market and at times in the next 12 months it may seem like a bear market with lower prices going forward.

Rabobank analysts said here’s downward pressure from weakness in overall world economies, but the potential remains for major demand growth from emerging nations and rising populations around the world. Throughout the next year, commodity prices could seesaw as one or the other gains weight.

“We believe the long-term bull run in agri-commodities remains, but expect prices across the complex to ease from their recent record highs, continuing their downward trajectory in place since mid-2011,” according to a Rabobank report. “Elevated price levels must persist in order to encourage farmers to continue expanding production to keep pace with demand growth and allowing global inventories to rebuild. Agri-commodity demand should remain robust in 2012 as consumptive growth in emerging-market economies continues to drive the agri-complex.”

Rabobank analysts expect lower year-over-year prices for 2012 versus 2011 but forecast they’ll still remain at profitable levels.

For soybeans, prices are also expected to drop but “remain historically elevated.”

“We anticipate lower-than-average stock levels of many agri-commodities to support prices; while harvests are expected to be large, encouraged by the high prices, the supply response is still catching up to demand.”

The University of Georgia, in its annual forecast, says Georgia’s poultry producers will face another difficult year. Poultry farmers slashed the number of chickens they were growing in 2011 and are expected to continue scaling back production in 2012 because limited corn supplies have made chicken feed so expensive that farmers have had trouble selling their poultry at a profit.

Mike Giles, president of the Georgia Poultry Federation, said this year farmers hope that producing fewer chickens will raise prices back to profitable levels.

“Looking ahead to 2012 we’re hopeful that market conditions will improve,” Giles said. “But the price of corn isn’t likely to come down significantly.”

USDA projections forecast 2012 US broiler production at 36.5 billion pounds. This would put 2012 production below the 2011 record of 37.2 billion pounds.

After a good 2010 for chicken processors, “2011 was a very bad year” for processors, according to the CPEPC Highlighter.

“Driven by increasing feed costs and aided by (broiler) allocations that were too aggressive to allow the market to absorb the increased cost, the gross processor margin fell below the healthy range early in the year and has remained there ever since.”

However CPEPC believes that, due in part to cuts made to production for the last half of 2011, the Canadian industry is ready for reasonable growth in 2012, consistent with population growth and with CFC’s medium-term growth rate of one percent.

However, “moving into 2012, CFC has allocated the first two periods at two percent over base. In addition,

the unresolved issue of differential growth among provinces is adding additional pressure to the allocation system and to the live supply volume,” the Highlighter reports.

“Live costs, driven by feed costs, reduced at year end and going into 2012 are expected to reduce further in the short term before leveling out. This alone will not be enough to get processors’ gross margins back to reasonable, sustainable levels – we will also need supply to be set at levels that will allow for an increase in market prices,” CPEPC says.

Meanwhile Canadian processors hope that reductions in U.S. broiler production will improve prices in the U.S. market “which will have a knock on effect on the Canadian market as well.”

“We desperately need 2012 to be a recovery year,” CPEPC said.

Market conditions in the Canadian turkey industry improved in 2011 compared to the recent years.

For the whole bird market, despite the live price increase, processors sold approximately the same volume as 2010 and wholesale prices increased to offset live price increases, according to the Highlighter.

The improved market conditions convinced the industry to increase the whole- bird allocation for the next control period starting in April.

Market conditions have also improved in the Further Processing (FP) market. Inventories of toms and breast meat have dropped and prices of breast meat and thigh meat have increased. The demand is still not exceptionally strong but because of the storage stock decrease, processors requested an additional 2.5 million kg for further processing.

Canadian poultry producers can likely look forward to a less exciting year than grain producers. Thanks to the costof-production formulas, they should adapt to whatever ride grain markets embark upon and if consumer confidence strengthens poultry demand could increase making for good, if not thrilling, year.

Your partner with innovative, unique and effective Alternative poultry production equipment solutions!

SALMET, one of the Zimmerer Family group of companies established for nearly 50 years, a Global supplier of a wide range of innovative and unique poultry production concepts with emphasis on bird friendly welfare solutions. The Zimmerer Family, are in Germany also one of the leading producers of Barn, Organic and Free Range egg production on their own farms. Salmet’s wide range of products are tested in the field on their own farms before being promoted for Global sales. All Salmet equipment are manufactured in their own factories.

With Alternative egg production systems, Barn, Free Range and Organic. Salmet offer a unique rearing system “PediGrow2” appropriate for successful egg production in Salmet innovative production concepts; High Rise 3 - known as a compact and effective production and management system, Combi Barn - perching and nesting system, High Rise 1 - with double floor system and our AllinOne system. Standard nesting systems with slats for deep pit systems or manure belts under slats are also available.

All Salmet products are compliant with welfare regulations and with our expertise we Share our knowledge.

More information please visit our website www.salmet.de

BY TONY KRYZANOWSKI

The plan by a company called EnergyWorks to build a $30 million thermal gasification plant near Gettysburg, Penn., to process manure generated by the state’s largest egg producer is one of those ideas that seems to have “can’t miss” written all over it.

The EnergyWorks plant is being built on a site adjacent to four Hillandale Farms egg-laying facilities located within the Susquehanna River basin, which is part of the Chesapeake Bay watershed. It will produce syngas that will be used as a fuel source to generate steam to drive a turbine to produce just over three megawatts of electric power. The gasification process will also produce between 13,000 and 16,000 tons of ash byproduct annually that will be marketed as an animal feed supplement because of its beneficial mineral content. All told, the process will dispose of about 240 tons of poultry manure per day.