INNOVATIVE THINKING HAS DRIVEN US FOR THE PAST 80 YEARS.

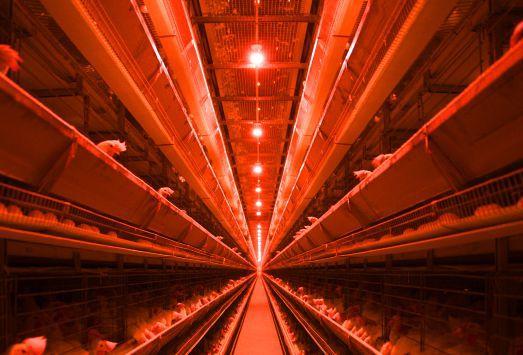

It’s that seasoned wisdom that has made Big Dutchman the undisputed leader in poultry feeding, housing and management. In recent decades we’ve focused much of our pioneering spirit on CAGE-FREE and ENRICHED SYSTEMS and management.

THE RESULTS SO FAR? Worldwide more hens call our cage-free environments home. We also offer the most options in the industry— backed by a team of highly qualified, experienced experts, eager to help you configure the system that meets your farm’s unique requirements!

Learning from egg producers with experience in enriched colony and aviary housing systems.

BY TREENA HEIN

While the vast majority of Canadian egg producers still use conventional housing, some have had enriched colony or free-run housing systems in place for several years. These farmers have, therefore, had the time to get to know these systems and learn how to best manage flocks within them. Canadian Poultry checked in with three such producers, one free-run, one enriched colony and one that uses both, to hear their lessons learned and best management tips.

Gislain Houle is the owner of Le Meunier du 8 Inc egg farm in Saint-Germain-de-Grantham, Que. (white and omega-3 brown eggs). He’s also first vice president of the Fédération des Producteurs d’oeufs du

Québec. Houle has a pullet barn and two free-run aviary barns, one renovated five years ago for 34,000 hens and one renovated two years ago for 28,000.

To maximize the performance of hens in terms of the housing itself, Houle says the most important thing in aviaries is to keep manure levels low on the floor. “You don’t want them laying eggs on the floor, and the hens will do that if the manure gets too thick,” he observes.

“You want to keep manure at two inches at most. In the new barn, I have an automatic manure removal system and in the older barn I remove manure about once a week using a shovel and wheel barrow.”

Houle raises and trains his own pullets to navigate aviary housing so that they are well prepared at 19 weeks of age to do well in the layer barn. “It’s important for success to have

Gislain Houle, Saint-Germainde-Grantham, Que.

well-trained pullets,” he says. “With my pullets, at five weeks we start opening their cages and it takes two to five weeks to get them used to the aviary pullet training system; to get used to going up into the system and sleeping on the perches, eating and drinking and so on. Then once they are in the layer barn, they will perch in there at night and lay their eggs up there in the morning before they come down to the floor.”

In terms of feeding, Houle notes that consumption is higher in an aviary system because the birds expend more energy in moving around more. “We had to reduce the salt content in the feed,” he adds, “as you have a dryer manure if the salt content is lower. We had the feed tested every year and adjusted it down a bit each time. Some companies also add feed additives to feed to keep the manure dryer.”

Houle uses a dimmer to slowly decrease the light level over about 90 minutes every evening, giving the birds adequate time to go up inside and perch.

Light is increased in the morning over about 30 minutes. However, he cautions that watching every new flock to make sure the timing is right is a must.

He also monitors daytime light levels with every new flock to make sure they are low enough to prevent pecking. “You have to watch your flock and adjust, and you have to be more attentive to your flock in general with an aviary,” Houle says. “If you watch the birds every day, you will notice any small problems with pecking or other problems, and deal with them before they become large problems.”

Houle’s barns have a large air exchanger that keeps the humidity levels low and no other source of heat is required. He says that while the dust levels are higher than in a conventional cage barn, the temperature and ventilation control is similar and works well.

With regard to bird health, Houle says management practices in aviaries are similar to those used in conventional cage systems. But the producer adds that the birds in an aviary system are definitely healthier. “They grow more feathers,” he says, “and look great.”

Tonya Haverkamp operates her family’s layer farm near Listowel, Ont., where enriched cage housing was installed in one barn in 2017. The family has 41,000 hens in

enriched and the remainder in conventional cages. They also raise pullets on the farm.

Haverkamp notes that cleaning and maintenance in the enriched system is similar to conventional cages, as is ventilation and water systems. In terms of light, the sunrise and sunset dimming patterns are also similar.

“However, our daytime lighting in the enriched barn is lower than conventional, about 60 per cent of maximum versus about 80 per cent,” she says. “We noticed there were pecking issues at the start of the flock and lowering the lights eliminated it.”

While she was a bit nervous that the hens would lay eggs in the nesting boxes, Haverkamp says they took to it right away. “Overall, about 95 per cent of eggs are laid in the nesting boxes,” she notes. “We had to adjust the belt advancement so that the eggs don’t pile up too much. We advance it at 6:30 am, 10:00 am and 3:30 pm.”

Feed consumption is a bit higher in enriched over conventional because the hens are more active, she observes, and the farm’s feed company upped the calcium for pullets going into the enriched system to ensure their bones would be stronger.

Haverkamp says their next flock will get cocci vaccinations because the hens in the first flock ingested manure from their scratch pads and got ill. She cleans the manure belts twice a week.

“Enriched cage production is pretty foolproof really,” Haverkamp concludes. “If you’ve raised in conventional cages, this will be no problem.”

“You have to watch your flock and adjust, and you have to be more attentive to your flock in general with an aviary.”

- Gislain Houle

“We noticed there were pecking issues at the start of the flock and lowering the lights eliminated it.”

- Tonya Haverkamp

Burnbrae Farms, a national family owned egg business (brown and white eggs) that’s the sole egg supplier for McDonald’s Canada, has been transitioning to enriched cages and free-run aviary for some time.

The Burnbrae Poultry Operations team says that while litter needs to managed properly in both types of alternative housing to minimize dust and prevent disease (which can be the result of birds having access to manure), maintaining better ammonia and dust levels is more of a challenge in aviaries.

They also note that there’s more risk of hens contracting coccidiosis in aviary housing, so vaccination is important. Lastly, the Burnbrae team observes that alternative housing systems will continue to improve “as more farmers install it and provide feedback to equipment suppliers.”

• Variety of configurations for all sizes of operations.

• Multi-tiered design combines bird comfort with peak density.

• Eggs are safely and automatically collected.

• Tipping nest floor self-cleans for more hygienic eggs.

• Perches are over the system for better manure management.

• Compact designs offer speeds from 18,000 to 80,000 eggs/hr.

• High-performance with 30-cell trays and modern egg transport systems.

• Low-maintenance, low operating costs.

• Automated palletization is also available.

• Retain up to 80% of exhaust-air heat.

• Preheat incoming air for bird comfort and performance.

• NEW EcoWash system for easy and efficient maintenance.

• Lower energy costs.

• Reduce dust and ammonia levels.

Vencomatic has been leading the way in cage-free solutions for more than 30 years. As North American producers make the move to cage-free egg production, we have the equipment and the expertise to help you make the transition.

The housing system choice is as individual as the producer.

BY MADELEINE BAERG

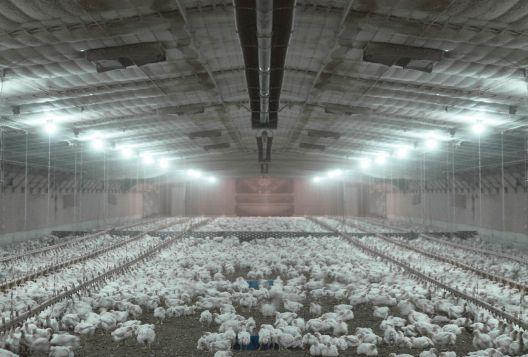

Across the country, egg producers looking to comply with the phase-out of conventional layer housing are facing a big decision of whether to invest in aviary or enriched housing. For many producers, the choice is challenging: not only do both systems provide management benefits and drawbacks, the single most critical factor – future consumer demand – remains a huge wildcard.

“I don’t think anyone has as a crystal ball on what the future will hold,” says Amy Carter, general manager of Clark Ag Systems, which distributes Farmer Automatic and Tecno layer housing systems across Canada. “In Europe, they’ve gone predominantly cage-free but the consumer demand in Canada is just not there.

“I think there are many producers holding tight right now (rather than investing in new housing) because over the last year it changed. We

“If I had to be a chicken, 100 per cent I’d want to be

in an enriched system.”

saw a lot of cage-free barns going up a year ago and now we are seeing the demand swing to enriched systems instead.”

Part of the decision comes down to dollars and cents, as cage-free eggs capture approximately 15 cents more per dozen than their conventionally caged equivalent, so long as a producer can find a market that will take them.

“If the egg farmers can get a premium for cage-free eggs, they will go most likely for a cage-free system, even If the aviary equipment is more expensive and the management is more time-consuming,” says Andreas Moors, area sales manager for Hellmann Poultry. “At the end, it will pay off.”

Certain market indicators suggest cage-free eggs are simply a matter of ‘when’, not ‘if’. Germany recently legislated cage-free for 100 per cent of its egg production. Many other European countries produce primarily cage-free eggs. Though North

America tends to trend behind Europe in welfare regulations, major companies here have been on board for the past couple years.

In September 2015, McDonald’s Canada announced it would switch to exclusively cage-free eggs within 10 years. Six months later, retailers representing 90 per cent of Canadian grocery dollars followed suit. In response, demand for cage-free layer systems spiked.

However, consumers’ willingness to pay a premium on cage-free eggs has so far failed to gain the traction industry expected, leaving many egg producers uncertain of next steps and causing sales of aviary systems to slow. And, adds Ron Wardrop, Canadian sales manager with Big Dutchman, “there is added production cost (to cage-free production) so most people are leaning away from cage-free systems.”

Clark Ag Systems’ president Brad Mandryk foresaw that consumers wouldn’t be as

ready to commit to change as the major companies. “It didn’t surprise me at all. A lot of the large producers in the U.S. are really slowing the process of converting solely towards the cage-free concept.

“Even the egg board was cautiously concerned about where demand was going to go. It was the special interest groups pushing cage-free eggs and, though people are becoming much more conscious about animal welfare, it comes down to price. The consumer is not necessarily willing to pay for cage-free in the grocery store.”

Of course, current demand is just one factor. With layer systems typically lasting 20 or 25 years, installing a system that meets future consumer demands is as important as installing something that best suits today’s needs. Though the new Code of Practice for the Care and Handling of Pullets and Laying Hens supports enriched cages, the future of this housing system may be uncertain as activists lobby to ban any form of cage.

“You have to ask: If I put in an enriched system, is demand going to hold for 20 years or is everything going to shift to cage-free systems?” Carter says.

Hellmann’s Moors agrees. “Even if the farmer has today no benefits with having an aviary system, they seem to be better prepared for the future, as changes to the existing rules and stricter regulations can suddenly come up. That means farmers will be on a safer side with a cage-free system.”

If regulation were to outlaw even enriched cages tomorrow, experts say existing cages would likely be grandfathered for some years, just as conventional cages were when the most recent code of practice was released. However, market demand is fickle: Should the market change, unpopular raising systems could produce unmarketable eggs even if those eggs meet regulations.

“We know markets can change very quick. We have experienced a complete changeover in Europe and

especially in Germany, where it’s almost 100 per cent impossible to buy cage eggs in a supermarket,” Moors adds.

The shift is even evident in unexpected parts of the world: Moors says Hellmann is now even getting requests for aviary systems from companies operating in countries with virtually non-existent animal welfare regulations.

Carter says demand for aviary systems has slowed at Clark Ag Systems over the past year, while demand for enriched housing has risen. Wardrop’s seen the same trend, saying demand for aviary systems makes up about 30 per cent of Big Dutchman’s Canadian business currently, down significantly from a couple of years ago.

You have to ask: If I put in an enriched system, is demand going to hold for 20 years or is everything going to shift to cage-free systems?

Moors, in contrast, says demand for Hellmann’s aviary systems continues to grow. Last year, aviary systems comprised approximately 20 per cent of the company’s total Canadian sales. This year, it expects that number to rise to 25 to 30 per cent before growing to approximately 35 per cent of total sales over the next two years.

Aside from marketability, farmers should consider several other key factors when deciding whether to implement an aviary or enriched housing system. Cage-free and enriched housing systems both offer productivity when managed properly. However, proper management is different when hens are confined to cages rather than

allowed to roam. A cage-free system will not suit farmers who prefer automation and simplicity over hands-on management.

“Some customers, when they see pictures of aviaries, they say: ‘No way will I ever do that system,’” Moors says. “If they are used to cages for 40 years and then they see a house with all the birds flying everywhere, they think it’s too much work. But others are pioneers who really look forward to doing it. They want the system even if they’re not forced to do so. They’d do it even if there was no market premium.”

Hens destined for cage-free systems must be raised in aviary-style pullet barns in order to learn to move through the system, jump to perches, find feed and water, and co-exist within a very large flock. Helping them learn to opt for nest boxes for laying is a time-consuming, labour-intensive process, notes one producer.

“You need to teach them how to move so in the morning when you turn the lights on, the birds are in the system and near the nest instead of on the floor,” says David Lefebvre, professional engineer, director of operations for Ferme St-Ours Inc., and proud seventh generation on the family farm.

Teaching layers starts in the pullet barn where, for about 30 days after opening the aviary system, staff must go through the barn each night, lifting pullets off the floor and placing them into the system.

In a 20,000-bird pullet barn, Lefebvre says he would expect to lift hundreds of birds every night the first week after opening the system. Once birds move over to the layer barn, he’d expect just a few layers would need to be lifted into the system each night for the first week.

Operating a cage-free system is more costly than enriched housing in terms of infrastructure costs, not only because the same square footage can house fewer birds but also because the system requires more intensive air control and management infrastructure

compared to an enriched system. As well, because pullets destined for aviary systems need to be raised in aviary-style pullet barns, the additional costs begin even before laying begins.

While airflow is important in any system, effective and efficient heating and ventilation systems are critical in an aviary. Manure becomes part of the ground litter rather than being regularly removed, so drying and cleaning the air fundamentally impacts bird health and productivity.

Management and costs aside, many egg producers spend significant time analyzing which system will provide better welfare and comfort for their laying flock.

Big Dutchman’s Wardrop argues that cage-free does not necessarily mean a better existence. “If you really care about the welfare of the bird, enriched is better. The regulations for enriched cages were drawn up very scientifically instead of emotionally. The government and associations did a really good job of taking the welfare of the bird into the whole concept. If I had to be a chicken, 100 per cent I’d want to be in an enriched system.”

Not everyone agrees. Lefebvre has hands on experience with all systems,

as his farm currently operates 12 organic barns each containing 5,000 layers, two enriched system barns containing 31,000 layers each, two aviary system barns containing 20,000 layers each, 20,000 cage-free broiler breeders and one conventional system barn of 16,000 layers. They also rear all their layer pullets in cagefree systems.

“I do really like the atmosphere you have in (cage-free) barns. It seems like you enter into the world of the birds; it’s really special. But an enriched system also perfectly responds to the layers’ needs,” he says.

Farmers ask Clark’s Carter virtually every day which system she’d install if she were choosing between caged and cage-free.

It’s a question she simply can’t answer. “Farmers are really doing their homework on what it takes to run enriched versus cage-free,” she notes. “A lot of farmers have crops and other demands on their farms so that has to be considered. And, talk to your grader and see where demand is coming from. Ultimately, it is a family decision on which system you choose.”

Egg Farmers of Canada provides fresh egg industry news to help you stay informed about topics that affect our industry. Visit eggfarmers.ca to subscribe and learn more.

SUBSCRIBE to our e-newsletter for news and updates.

After deciding on aviary or enriched, producers still face many other important questions.

BY MADELEINE BAERG

Once producers make a final decision between whether they want to build cage-free or enriched housing for their flock, what next? Every farm is unique and every barn is custom designed, so decisions of all kinds still lie ahead.

The very first decision a producer needs to make is how many birds a barn is going to house. In most cases, that decision makes itself given that the majority of producers opt for maximum efficiency.

“Numbers really dictate everything: your barn size; your ventilation requirements; your housing,” says Brad Mandryk, president of Clark Ag Systems, which distributes Farmer Automatic and Tecno layer housing systems across

Canada. “Do you want to maximize your current quota and bird densities? Most producers would say yes.”

Second, producers need to decide whether they plan to build new or to retrofit an existing barn. While retrofitting can often save construction dollars, investing major system upgrade money into a facility that is the wrong size or has major flaws can end up costing in the longer-run.

Building a new barn allows a producer to customize the size, shape and layout to any system they desire. Retrofitting an old barn is more complicated and, in certain cases, existing infrastructure will dictate what kind of system and numbers are possible.

“It’s all about the space you’ve got,” says David Lefebvre, professional engineer and

director of operations for Ferme St-Ours Inc. “In an existing building you can’t do whatever you want. An aviary system needs a precise building width and usually needs a lot of ceiling height. There are many different aviary systems and some can fit in a lower-roofed building but it’s not the best.”

Farmers also need to determine which company to partner with for the system construction. Various companies approach the design process differently: Some design a system from start to finish to make the process easy for producers, while others ask for significant producer input along the way.

“Ultimately, producers have significant control on the very critical decisions they have to make. Although the standards

Building a new barn allows producers to customize the size, shape and layout to any system they desire.

of code of practice have to be met with the way a barn is laid out, there are lots of big decisions,” says Amy Carter, general manager of Clark Ag Systems.

“While they very much ask for our expertise to put together a design that works, it’s important that farmers look at the different systems that are out there, consider the different management techniques and go out and visit other farmers. While they look to us for insight, most farmers are very engaged and want to be part of the process.”

Regardless of company, every installation is customized to a producer’s needs. “Every company that sells cages, we’ll all customize equipment to a producer’s needs. If it’s in an existing facility, we’ll work with that. If it’s in a new facility, we’ll show them how to maximize space. There’s never two quotes that are the same,” says Ron Wardrop, Canadian sales manager with Big Dutchman.

“In Finland, they prefer wooden nests because (they think) birds like wood more than metal,” says Andreas Moors, area sales manager for Hellmann Poultry. “For that market, we started to supply wood nests. As a middle-sized company with short decision paths, we can offer a flexible production that allows us to work with a customer if they have unique requests, so long as our design team says the request is not interfering with overall quality or design.”

In certain cases, choosing one company’s product over another may come down to what you’ve already got in place. For example, some parts of Hellman Poultry’s cage equipment (motors, drive units, feed corners, control units and sometimes other components) can be re-used within a Hellmann’s aviary system, Moors says. That can translate to significant cost savings. If you currently have equipment in decent repair, it’s a good idea to check with that manufacturer first to see if repurposing might be possible.

The design process starts with a calculation of space based on the number of birds desired. Typically, the floor space, ceiling height and flock size determine the number of tiers in an enriched system and the layout in an aviary. Because in certain cases a producer may have a choice of how many tiers to install, keep in mind that managing a single tier is easier than managing multiple tiers, experts say.

In most cases, manure is not completely removed from an aviary’s aisle-ways until the hens are retired, though some producers are now opting for deep pit systems to allow manure to drop below hen level. Because manure increases both moisture and dust, managing air moisture quality must be a major priority.

Ventilation also plays a huge role in how any barn is designed. From simple to complex, there are many concepts. While ventilation is critical in any laying barn, Lefebvre recommends investing in a heat exchanger for an aviary.

“Layers that are comfortable will lay you eggs. If you give them a good environment, they will lay more eggs. It’s not an obligation to install but it’s a good thing: an investment that offers payback. If you install a heat exchange system, you’re going to be able to ventilate more for the same energy cost, giving you better air condition and drier manure.”

For maximum ventilation, Lefebvre recommends tunnel ventilation that ventilates a barn from front to back and generates higher air speed in summer.

And, he points out, this kind of ventilation system allows easier trapping of light from outside.

Researchers and equipment companies continue to work to improve how birds are housed in both enriched and cage-free systems. Because both are fairly new, experts are making great strides forward.

“There is a lot of research going on at the university level right now around what is the best environment for animal welfare. The (current designs for both aviary and enriched systems) have come a long way from where they used to be,” Clark’s Mandryk says.

Perches are a case in point. Today, they come in round, square and mushroom-style and can be made from various materials. At this point, decisions will be based on a producer’s preferences and a poultry equipment dealer’s recommendations. However, researchers, including some at the University of Guelph, continue to test different perch designs and may soon offer additional insights.

Lighting needs to be a key priority in all systems. In multi-tiered enriched housing systems, a top tier can get adequate light from aisle/ceiling mounted light sources. However, lower tiers will suffer from

Brunner, Ont., producer Josh Gerber is a long time farmer but only a recent convert to egg production. At this time last year, he was poring over catalogues, walking miles around farm-show floors and chatting up every poultry system dealer he could find. By fall, he was building his first layer barn and, as of January this year, he was the proud owner of his first flock.

Gerber considered both aviary and enriched housing systems but ultimately chose the latter. “I opted for a caged system mostly because of management: it’s a lot easier to manage an enriched barn than a cage-free system. Floor eggs are a problem and dust in a cage-free system is a big thing too,” he says, adding that he believes the welfare of the birds is better in an enriched system.

The producer also worried that market demand would not be strong enough to carry more cage-free eggs.

Gerber recommends that any producer considering switching to a new production system should spend significant time learning from other producers. “I found that other producers are not shy at all. They’ll help you with any questions; take you through their barns. I found that incredibly helpful.”

The single biggest message he suggests others keep in mind is to invest for the long-term. “When you’re buying equipment for your barn, it’s not like you’re buying a car or a tractor. If you don’t like it in two years, you can’t trade it in.”

You’re focused on delivering high-quality eggs. So are we.

For over 50 years, Farmer Automatic has engineered better performing systems for your best eggs. Like the new Loggia 3 Layer Aviary – offering additional living space with a third tier for greater density.

One of the biggest decisions is whether to retrofit or build anew.

heavy shadowing.

As Big Dutchman’s Wardrop explains, the downsides of inadequate lighting include a harder time adjusting to the system, lower feed intake and poorer nest acceptance. Luckily, LED technology allows lighting to be small and cool enough that it can be mounted right inside cages themselves.

“We’ve seen a real spike in in-system lighting versus when enriched housing first came out,” Carter says. “That came down to testing. Enriched systems are a lot taller, a lot deeper and have a lot more birds in a colony than a conventional cage.

“That offers up different challenges because you want to be very uniform in your lighting. Your lighting program is very important for both the birds’ behaviour and their productivity.”

While the new code of practice outlines minimum nesting space requirements, producers may benefit from additional nesting space. “Something researchers are really looking at right now is the even distribution of birds laying eggs. Is it better to have just the required number of nesting spaces?” Carter says.

“We don’t necessarily go by the code on minimum nest space requirements. We tend to suggest increasing nest space to provide uniformity and distribution of eggs which minimizes egg undergrads.”

In any aviary system design, Lefebvre recommends looking closely at how all the systems are managed. “In an aviary system, there are as many designs, as you can imagine, and they are all different. Even a single company can propose many kinds of systems.

“Ask, ‘Where is the feed? Where are the water lines? Where are the nests? How easy would it be for a bird to lay in that nest?’ I don’t think multiple short perches or

fewer long perches make a big difference. But it is important to ask, ‘Is it easy for birds to jump from perches evenly from one side to the other?’”

He recommends choosing a system where you can easily see and touch all the components and where you can see the birds everywhere in the system.

Given that certain companies used to offer enrichable conventional cages, some farmers wonder if they can start with enriched housing and convert it to cage-free when necessary by simply removing the doors and installing enrichments like exterior perches. Though this transition may theoretically be possible with certain systems, Wardrop recommends against it.

The problem, he explains, is that an enriched system’s aisles are typically around 40-inches wide, whereas a cage-free system requires aisles that are 60-inches across.

“If you take the doors off and have a 40 inch aisle, (a cage-free system) is just never going to run really well,” he says. “We try to talk producers out of doing it.”

Carter, on the other hand, says meeting customers’ requests for flexibility is possible. “(We) are seeing an increase in producers wanting to have the flexibility in their barn design to convert from an enriched cage system to an aviary style system. With effective planning that takes into consideration the conversion from enriched to aviary, we see that productivity, welfare and management are not compromised.”

Most importantly and at every stage in the process, remember to ask questions and make open communication a priority.

“We’re seeing a lot more really good interaction between egg graders and producers and equipment dealers. We’re seeing that communication process ramp up dramatically,” Mandryk says. “There’s a real partnership approach between all the parties and that’s really good.”

And we’re ready for our next 50 years, with innovations designed in Germany and manufactured close to home. Bringing you the quality you expect faster than ever.

learn more, contact

Systems at (800) 263-6410

Advice on how to best light your new layer housing system.

BY TREENA HEIN

More poultry producers are switching to LED lights in their layer barns for the power savings, versatility, durability and brightness they offer in comparison to all other options. Lighting is important in broiler, turkey, pullet and layer production, but especially important in egg production these days because of the new systems hens are being housed in. It’s all about making sure, in these new housing set-ups, that egg laying in the nest boxes is maximized.

With that aim in mind, lighting goals for all the new layer housing systems options are similar – keep it even, keep the nest boxes fairly dark, and keep corners, walls and feed/ water sources bright. But while these objectives apply for all types of lighting, installation of LEDs require

some new thinking.

“As LEDs are being phased in, producers need assistance with figuring out what intensity on the controller is actually producing the illumination level desired,” notes Sarah Pelissero, a sales and service provider with McKinley Hatchery in St. Mary’s, Ont., who spends a great deal of time providing layer lighting consultation.

Something Pelissero says producers have to get used to with LEDs is new numbers. That is, the brightness that would have been provided with compact fluorescent lights at a controller reading of 100 per cent might be 50 or 60 lux, but the same controller reading with LED lights could provide 100 or 150 lux, depending on the bulb being used.

Producers should also keep in mind that because LEDs don’t draw as much power, lighting arrangements that may have

In aviary aisles, LEDs should be used in broad distribution to evenly light the floor.

used multiple controllers/slaves to provide enough power for incandescents may offer too much power for LEDs. “For example, a system with four rows of lights may have had two rows per controller/slave, whereas with LED bulbs, one slave/controller could be used, depending on the setup and power load,” Pelissero explains.

“Having too much power going to the LEDs makes it difficult to dim the bulbs properly, as there is less resistance on the line. This can be managed with the help of a good electrician.”

In terms of LED use in aviaries, Ian Rubinoff, technical services veterinarian with Hy-Line International, notes there are many different system brands that are all constructed a little differently.

He says most aviaries have at

✓ 116.25 Sq. In. Per Bird

✓ Curtained Nest w/ Nest Pad 10 Sq. In. Per Bird

✓ 5.9” Perch Space Designed To Imitate Natural Habitat

❖ Chain Feeding – Floor & Cage

❖ Multi Level Perch Systems

❖ Manure Conveyors, Scrapers & Augers

✓ Built In Claw Shorteners

✓ 3.9” Feed Trough Space

✓ Scratch Pad 4.8 Sq. In. Per Bird

✓ Access to Multiple Nipple Drinkers

❖ Quail & Rabbit Cages

❖ Pullet Rearing Cages

❖ Custom Equipment for Research

least four different sub-environments that must be considered in regards to lighting. In the aisles, LEDs should be used in broad distribution to evenly light the floor. Underneath the system, consistent lighting is also important to prevent laying. He adds some producers find using a colour spectrum different than the rest of the house is effective in keeping hens from laying there. Sufficient light is also important in feed and water line areas, especially at the beginning of the flock cycle. Lastly, nests should be the darkest area of the system.

“It is ideal if all four areas have their own controls and dimmers,” Rubinoff says. “Using lights going on and off at different times is a good way to help pull the birds onto the floor during the day and move them back into the system in the evening.”

Tanya Streifel, marketing manager at Minnesota-based lighting provider Once, agrees. “By dimming or increasing the intensity,” she says, “we are able to essentially tell the birds where to go within the system.”

With regards to enriched colony systems, Pelissero notes

that when this housing was new to the egg industry, LEDs were installed in the aisles in dropped fixtures from the ceiling. However, today, most colony housing has ‘in-system’ central LED tubes (a string of bulbs) in each tier. There are positives or negatives to both, she notes, but whether it’s aisle lighting or central tubes, the light must be even, with the nest area darkest and the scratch/perching areas brightest.

With in-system LED lighting, producers also need to make sure they are getting even lighting on each side of the cage area, she notes, and aisle lighting can be added to address this (or turned on when a worker is present if needed).

“With aisle lights,” Pelissero adds, “you have the added factor of uniformity from top tier to bottom tier as well as along the row. Bulb placement and spacing is very important.”

In free-run houses, Rubinoff says that, depending on the width of the building, there will usually be two rows of lights on each side.

For flexibility, the lights should be wired so the outside lights are on one dimmer and the inside lights are on another,

with the goal being consistently brighter light on the outside over the litter area and less light near the nests.

Pelissero notes that with LEDs in free-run barns it’s challenging getting the right intensity at bird height, at feeders and waterers, with no shadows or dark corners.

Streifel echoes that sentiment. “Making sure that the corners have adequate light is especially important. Birds will quickly learn to like those dark corners, pile or lay floor eggs.”

No matter the housing system, Streifel emphasizes that using the correct light spectrum is very important. “Layers require a red-light spectrum, which can decrease time to peak production by stimulating ovulation via the release of reproduction-stimulating hormones and targeting sexual maturity,” she explains.

“The sunrise and sunset simulation [offered in our systems] eliminates the stress inputs of switching lights on and off abruptly, calming the birds and lowering stress and mortality while supporting immune response.

“By dimming or increasing the intensity, we are able to essentially tell the birds where to go within the system.”

“It is recommended to incorporate scientifically tested photoperiods and light colour spectrums,” she concludes, “to achieve optimal results.”

However, Pelissero believes that LEDs generally don’t dim as well as conventional lighting systems do, so she says if you’re a producer who uses dimming of your lights as a management tool to calm birds, you’ll have to do some rethinking. “In our barn, we do use dimmers, just not as much as most do, only if necessary, and we also keep our barn brighter than many other egg producers,” she notes.

“I think my best advice overall is to realize every barn situation is unique. LED use is not cookie cutter. It’s about learning as we go and reading our birds.”

Cindy Huitema

Cindy Huitema is an egg farmer from Haldimand County, Ont. In her now-concluded blog, she shared her journey transitioning from conventional hen housing to an enriched system.

Over the past year, I’ve been documenting my family’s journey converting from conventional housing to an enriched system on canadianpoultrymag.com. Thankfully, the new barn is up and running. Based on our experience, my husband Nick and I compiled some key takeaways. While we installed enriched housing, the following tips could apply to any type of hen housing.

Begin researching at least two years in advance, as the actual building process will take a full year. Also, you need a Nutrient Management Plan before getting a building permit in Ontario. I suggest leaving yourself plenty of time for the permit process as I’ve found it can take a while.

From the outset we made a month-by-month timeline. However, this went off kilter by our third month. Contractors can have a hard time committing to a timeline and this can often put you behind.

We had issues getting our concrete work complete, which made some of our construction run into the winter months. Avoid this and plan to have the barn closed in by December, thus making it easier to do the inside work when outside temperatures turn frigid.

Find reputable contractors familiar with layer barn builds. This will save time as they will have done the type of work with farmers in the past with similar equipment.

Make use of the most recent technologies and advancements in the industry. Our profession and the world of technology are always changing. Using what is most modern will help you to keep up. For instance, we decided to get in-house lighting in the enriched houses. This makes it easy for us to see the birds at hen care check time, saving us time and allowing us to see at a glance any issue that may have occurred since our last check. We still have lights on the ceiling as well for any

You can have your budget and may have padded it some, but things always end up costing more than anticipated.

maintenance and whenever we feel the need for more light.

Make use of industry contacts, such as feed salesmen, hatchery personnel, grading station experts and others. These people deal with farmers from a broad geographic region and can be a great resource. They can also give advice from outside of your particular farm situation and can be unbiased with input.

You can have your budget and may have padded it some, but things always end up costing more than anticipated. This is partly due to unexpected or uncontrollable factors driving up costs. For instance, you cannot anticipate the weather. I never watched the weather so closely as I did this past year, especially in the winter. I was constantly checking to see what temperature the carpenter guys would be working in, whether it would be too cold for them to come, if the wind would hamper working conditions and other factors.

Be prepared for a year of doing more than your usual egg barn routine, working harder and having more stress as a result. Both Nick and I found the barn build interesting and exciting. However, my husband handled the stress a lot better than I did. Although both of us admit that we were overworked, overtired and outdone during portions of the build.

At Clark Ag Systems, we see the shift to Enriched and Aviary housing and we are prepared to offer you CHOICE. The experience and knowledge of Clark paired with two reliable companies is a winning combination. We offer over 100 years of combined trust with Farmer Automatic and Tecno Poultry Equipment, to give you the best fit for your farm.