ALTERNATIVE HOUSING SUPPLEMENT

EGG PRODUCER’S

Vencomatic Group offers a full range of innovative equipment for poultry farms accross North America.

We are proud to be a global leader in cage-free solutions that are flexible, practical and high-performing.

Our poultry experts provide expert advice on barn layout, bird management, climate management and egg handling.

More information: www.vencomaticgroup.com or please contact your local dealer.

BLR Solutions

QC - T: +1 450 772 2929 jfbourbeau@blrsolutions.ca

Jonkman Equipment Ltd.

BC - T: +1 604 857 2000 info@jonkmanequipment.com

Penner Farm Services

AB - T: +1 403 782 0675

MB - T: +1 204 326 3781 info@pennerfarmservices.com

Pols Enterprises Ltd. ON - T: +1 905 708 5568 sales@polsltd.ca

Ruby360 Ltd. ON - T: +1 888 218 7829 sales@ruby360.ca

Western Ag Systems

SK - T: +1 306 222 4881 wayne@westernagsystems.com

JONKMAN JE Equipment

CAGE-FREE LIGHTING STRATEGIES

BY ERIKA PREWITT

Lighting is a crucial component to properly managing any poultry housing system. It’s even more crucial when managing a cage-free layer house. Our goal is well-trained pullets and layers that go back into the system at night so that, when the time comes, they lay their eggs in the nest instead of on the floor.

So, how do we train pullets or layers to come up off the floor when it’s time for lights out? A strategic lighting sequence and duration is at the heart of this. I know there are many different opinions of this sequence, but I’m going to give you my go-to approach.

Start the dim down training process as soon as you can at the pullet stage. You want them well accustomed to it by the time they get to the layer house. Have good communication with your pullet grower if you are not raising them yourself. You will want to match both the lighting sequence and light intensities in both houses when first moving birds. Come up with a plan that both of you can agree on.

Don’t change the sequence when first housing the pullets in

the layer barn from what they are used to. This can confuse the birds and affect how well they enter the system at night.

Don’t change the foot-candle drastically either from the pullet to the layer barn at move-in time. This can cause the birds to become very flighty if they are used to a dim pullet house and are then moved to a very bright layer house. Try to have the houses be no more than one to 1.5 fc different. Ask your genetic company if they have a specific recommendation for your breed. To start your dim down sequence at night, any lights underneath the system should be shut off first. Don’t bother dimming lights underneath the system – they should simply go from on to off. This helps move the birds out from underneath the system and into the aisle, and additionally move into the system. Remember, do not allow birds access underneath the system until they are fully trained to move into the system at night. This goes for both pullets and layers. Even if birds cannot access underneath the system yet, lights should be on at 100 per cent intensity. Next, here are three different

Erika Prewitt is aviary systems specialist with Big Dutchman. In this column, she shares cage-free management tips for egg producers.

strategies for your consideration.

1. Begin dimming the ceiling and the system lights together. Dim for about five minutes. After that, pause the system lights and continue to dim down the ceiling lights. When ceiling lights are at zero per cent, continue dimming down the system lights until they turn off also. This method works well in any sort of aviary system.

2. The opposite of strategy one. Begin dimming the ceiling and system lights together. But this time, hold the ceiling lights. Dim the system lights first and then finish dimming the ceiling lights. I only use this strategy in limited environments. For example, if you have a very tall aviary system and the ceiling light illuminates the top tier better than the system lights, so it has three or more tiers and no system lights on the upper tiers.

3. The third method is ideal if your controller can’t pause. In this case, I begin by dimming the ceiling lights first for about 10 minutes followed by dimming the system lights for 20 minutes. This is the easiest method to follow, and I often use it for producers new to cage-free.

THE SMOOTHEST TRANSITION

The current best resources and thorniest challenges for making the transition to enriched or free-run layer housing.

BY TREENA HEIN

Making any major transition in a farming business is difficult, especially when it directly involves production. But at this point, the transition to enriched or free-run layer housing for Canadian egg farmers should be easier than ever before.

There are more sources of help available and overall industry experience relating to how to achieve smooth transitions has never been stronger. However, some challenges still exist that can complicate the process or otherwise cause a bumpy ride if not circumvented effectively.

While there are still 13 years left before transitions must be underway, in reality, it’s eight years. That is, in 2031, conventional cages will have to be retrofitted to provide 90 square inches per bird instead of the present 67 square inches, and spending the required sizable sum to do that

ABOVE:

Some producers find it difficult to decide whether to go with enriched housing, as shown here, or cage-free.

makes little sense when the same farmer would need to spend again to transition to new housing within five years.

In any case, at this point we present to you a list of the most important current opportunities and resources for producers, as well as a look at various potential pain points for those farmers whose transition out of conventional cages still lies ahead.

OPPORTUNITIES

1. Support

A large percentage of Canadian egg producers have already transitioned at least one barn to alternative housing, so there is now quite a large pool of people now available from whom to seek out for advice.

“To me, speaking to other producers is one of the most important steps for a farmer to take prior to building,” says Harley Siemens, vice president at Siemens Farms in Rosenort, Man., which was started by his grandparents Pete and Laura Siemens in 1955 and taken over by his father Kurt.

“Listening to sales reps and builders is great, but to

To me, speaking to other producers is one of the most important steps for a farmer to take prior to building.

get firsthand experienced knowledge from a farmer is invaluable. To take this one step further is to get out and tour those farmers’ facilities. Understanding the reasons in how others built their barns will surely help on our own project.” Siemens and his father talked to peers across Canada.

He suggests asking these farmers for each and every reason they chose their style and brand of housing and rejected others. Also, ask about transition tips and what they’ve learned about management practices.

In addition to speaking to housing company representatives and barn builders, smart farmers facing transition also attend poultry shows. “The London poultry show, Midwest poultry show and Atlanta poultry show are great events where farmers can see lots of equipment in a short amount of time,” Siemens explains. “It really got our ideas flowing and helped us picture what our barns could look like.”

2. Funding

Whether you’re doing a retrofit or new barn build, there are various funding programs that help defray the cost. Everyone in the industry can likely name the main one, the Poultry and Egg On-Farm Investment Program (PEFIP), a compensation scheme created by the federal government to compensate farmers for market access given up in trade agreement negotiations. Under the program, each farmer is entitled to a certain amount of funds for the quota they had at the time agreements were finalized.

“PEFIP is open to producers in all provinces and territories, but the disclaimer is that the funding is based on quota holdings on January 1st, 2021,” adds Jonathan Giret, CEO at Elite Agri Solutions in Glencoe, Ont., which provides help with applications and more. “Anyone that entered the industry after that date is ineligible.”

Giret notes that rollout of PEFIP is going well. “There are delays in processing, but claims are getting approved consistently,” he reports. “The key is to get started. The more organized the farmer is the easier it will be to submit a claim. If you’re not going to start today, then consider hiring someone. Carrying the interest payments on projects for another year typically outweighs the fees many consultants would charge.”

3. Research

There’s now a large body of research around alternative housing type and features (for example, nest box placement and curtain style), including preparing pullets for these systems. Check out past issues of Canadian Poultry magazine for articles on lighting systems, bird welfare, ventilation, rearing pullets for aviaries, pullet behaviour and much more.

In making the decision about housing, there is, of course, the revised Code of Practice for the Care and Handling of Layers, released by Egg Farmers of Canada and the National Farm Animal Care Council in 2017. It includes research from Canadian scientists such as Dr. Tina Widowski, Egg Farmers of Canada Chair in Poultry Welfare and Professor at University of Guelph. She and other poultry scientists are pleased that producers have a very solid base of research on bird welfare, costs, air quality and many other factors to make informed decisions about tradeoffs relating to housing.

CHALLENGES

1. Type of housing

At the same time, the choice to transition to enriched or free-run housing may be difficult for some producers. For those under contracts, remaining barn transition decisions are straightforward. However, in the bigger industry picture, there’s uncertainty

around whether various retailers and restaurant chains will stick to their cage-free pledges.

“When spending millions of dollars, farmers want to be assured that they are making the right decision,” Siemens says. “I think some are waiting it out to hopefully get a clearer picture of what the future may look like in egg production. This issue is the hardest one to predict.”

In 2017, the Siemens family built three new barns (one pullet and two layer) with aviary free-run housing. Siemens is also president of another Manitoba egg operation named Manova, which is owned by his family and three other family shareholders. In 2022, one of the operation’s conventional barns was converted to aviary free-run as well, due to Siemens already having experience with that housing.

2. Timing of retrofit or build

Barn builds and retrofits are currently more expensive than they have been in the past. Some producers without an urgent need to replace housing could wait a few years to proceed with a new barn build or swap out their housing, but waiting also means higher ongoing energy and heating costs due to old ventilation and heating systems. It also means a longer time with flocks exposed to lower levels of bird welfare, which impacts production.

LEFT:

Events like the National Poultry Show in London, Ont., are great opportunities for farmers to see lots of equipment in a short amount of time.

“The numbers are high for building new and its tough to justify building something new when what you have is working,” Siemens notes. “With that said, the interest rate today is substantially higher than two years ago.”

He adds that farm succession is another issue that can make the decision on timing of transition very tough. “With no clear direction of who is going to take over the farm, it makes it tough to make a huge investment,” he says.

A good first step is to book appointments with housing company representatives, your banker, accountant, family members and so on to discuss the pros and cons of how long to wait to book a build/retrofit.

3. Sourcing pullets

Pullet sourcing is also a challenge in transitioning, one that requires action to make the transition smooth. “If you are moving from conventional to enriched, the hurdle is not big, as the same pullet barn should be able to supply your new facility,” Siemens notes.

“When moving to free-run, those birds need to be trained in that type of environment to be able to succeed in the layer barn. I would suggest being in contact with your chick supplier and if they know of any barns available for room or of any producers thinking of suppling free-run farmers. If you grow for yourself then you will have to retool your pullet barn as well.”

MOVING FORWARD

Siemens’ overall advice to address all of these opportunities and potential pitfalls? Do your best to educate yourself and then choose the system that will make you the best farmer you can be. “There are many reasons that can prevent us from moving forward, but we have to look at the positives and focus on how great of an industry we are a part of,” he says. “We can take pride in supplying Canadians with high quality, affordable food.”

The VALLI BABY AREA is ideal housing for the intensive rearing of pullets, with all main components built right in, while the VALLI COLONY SPACE allows you to customize your multi-tiered configuration from 3 - 12 floors.

Valli-Italy operates on the premise of passion and quality to ensure each producer receives the ideal system for their operation.

BONE BENEFITS

Measuring the impact of aviary rearing on bone health in pullets.

BY JANE ROBINSON

Of all the aspects researchers are evaluating to help laying hens adapt to alternative housing, very little is known about the effect of aviary rearing systems on bone health. A collaboration between human and poultry researchers is now applying state-of-the-art technology to another piece of the puzzle to give producers useable insights into open housing designs and decisions.

Dr. Bettina Willie is a professor in the Faculty of Dental Medicine and Oral Health Sciences at McGill University in Montreal, and joined the university in 2015. She’s a bioengineer with a lab at the Shriners Hospitals for Children-Canada, where she uses high resolution imaging to study bone fragility in young children.

“I became interested in laying

hens as a relevant animal model for my work in children because hens are the most efficient land animal at being able to move calcium from their bones to daily egg shell production,” Willie says. “I knew the findings in chickens will be highly transferrable to human health.”

When Willie looked for poultry researchers to collaborate with, she connected with Dr. Tina Widowski, professor in Animal Biosciences and Egg Farmers of Canada Chair in Poultry Welfare at the University of Guelph. Willie joined Widowski’s multi-disciplinary research project looking at the impact of aviary rearing on various aspects of pullets, including behaviour and physiology.

Willie and a McGill colleague Dr. Svetlana Komarova (see sidebar) brought their expertise in human bone research to the poultry project.

Dr. Bettina Willie of McGill University brought her expertise in human bone research to a multi-disciplinary poultry project.

CREATING A BONE HEALTH BASELINE

“Bones constantly adapt to maintain their strength and integrity to support different daily activities,” Willie says. “We investigated how rearing birds in different styles of commercially available aviaries affects bone health and structure in whiteand brown-feather pullets.”

Willie and her PhD graduate student Isabela Vitienes conducted two research projects using state-of-the-art 3D imaging and equipment – that has never been used in poultry research – to examine the bone’s response to mechanical stimuli.

They started by determining if the bones of white- and brown-feathered pullets differ depending on the style of aviary they are reared in, to provide baseline information of bone health.

Pullets were raised at the University of Guelph’s Arkell

PHOTO CREDIT: DR. BETTINA WILLIE

Research Station in three aviary styles, representing commercially available systems that provide varying levels, perches and ramps for birds to move about in. The researchers evaluated bone health at 16 weeks of age after birds had time to adapt to the different environments.

To measure a baseline of bone health, Vitienes inserted sensors onto the leg bones of pullets to measure bone mechanics. Sensors tracked the amount of strain put on the leg bone during normal daily activities in the rearing environments – walking, running, perching, jumping, etc.

“One of the things we looked at was which activities best stimulate the bird to build bone mass,” Vitienes says. “We wanted to determine, for example, if birds need more vertical or horizontal space to get the level of physical stimuli they need for healthy bone formation.”

The depth of detail – including bone thickness, volume and curvature –provides indicators of fracture risk and overall bone health that affect the longterm health and wellness of laying hens.

WHITES WIN AGAIN

What they found wasn’t entirely unexpected. Compared to conventional cages, aviary rearing improved the bone structure of white-feathered birds, but not brown feathered. “We have seen similar results in several parts of this projects,” Widowski says. “We know that white-feathered birds benefit the most from the complexity of aviaries because they are the only ones that use the space. And we saw that in the improved bone structure.”

The brown-feathered birds don’t benefit because they aren’t using the space. “It’s like giving people access to a gym – the only ones that benefit are those that use it,” Widowski says.

ANY AVIARY STYLE IS A PLUS

When Willie and Vitienes looked for differences in bone structure between the aviary styles, they didn’t find any significant differences. “We see that aviary rearing improves bone compared to conventional cages, but there was no difference between the different style of aviaries,” Willie says. “Thus, the

level of complexity does not appear to be important for bone health, since all three aviaries we examined reached the necessary threshold of providing access to bone-stimulating activities.”

This also jives with what Widowski sees in other aspects of aviary rearing – any style of aviary will benefit birds compared to conventional cages.

WILL WORKOUTS BUILD BONE STRENGTH?

The second project involved applying a mechanical load to one of the pullet’s leg bones. This artificial activity – performed for a few minutes, five days a week over a two-week period – was intended to represent more activity than the baseline measured in the first project. They were seeing how the bone responds to mechanical loading by giving the birds a workout to see if that extra activity might change/improve bone structure.

We see that aviary rearing improves bone compared to conventional cages.

While the results aren’t in yet, Willie and Vitienes will be using micro CT imaging to compare the two leg bones – the one that got the added workout, and the one without – to see if there are differences in the bird’s ability to build bone based on the environment they are raised in, as well as genetic strain differences.

“We are hoping to be able to report which feather colour and aviary rearing style results in birds that better respond to access to exercise with stronger bones,” Willie says.

BUILDING A WHOLE BIRD PICTURE

“Bone health is so important for bird welfare,” says Widowski, who recognized the unique opportunity to pair her poultry research knowledge with Willie and Komarova. “Being able to collaborate with human bone experts, and the sophistication of their facilities

and equipment, is helping build a much more complete picture about the what’s important in aviary rearing for the overall health and wellbeing of pullets.”

KEEPING CALCIUM IN CHECK

Dr. Svetlana Komarova, a biophysicist and professor in the Faculty of Dental Medicine and Oral Health Sciences at McGill University, is filling in another piece of the bone health picture for genetic strains of pullets raised in different aviary housing. Komarova is looking at the metabolism of calcium and phosphorus in pullets – the building blocks of bone. “We are trying to determine if the different aviary rearing environments change the way pullets are able to regulate calcium and phosphorus,” Komarova says.

She was drawn to the project because of the similarity in bone physiology between chickens and humans – and the possibility for cross-species learning between the work that Widowski is leading and her own research on human bone physiology at the Shriners Hospitals for Children-Canada – one of the largest pediatric orthopedic hospitals in the Canada.

Birds depend on calcium for many functions in the body. But egg production in hens brings a competing need for calcium. “We want to understand the fundamental mechanisms of how pullets are using calcium and phosphorus, and whether early rearing life can make a difference in the lifelong health of the birds,” Widowski says.

Komarova is analyzing blood samples from white- and brown-feathered birds raised in the three aviary styles at the University of Guelph for indicators of bone health. Her results, expected soon, will provide another piece of the picture to determine how to ensure birds are raised in environments that make them as healthy as possible from rearing through the lay period.

This research is funded by the Canadian Poultry Research Council as part of the Poultry Science Cluster which is supported by Agriculture and Agri-Food Canada as part of the Canadian Agricultural Partnership, a federal-provincialterritorial initiative.

RETROFITTING OLDER LAYER BARNS

New multi-tier aviaries accommodate low clearances in aged poultry houses.

BY FRANK LUTTELS

For growers looking to transition from caged to cage-free egg production, most experts recommend using a multi-tier, or European style, aviary. That’s because this type of aviary offers the best combination of excellent bird welfare, optimum bird density, low labour requirements and a superior long-term return on investment.

While the high return on investment is attractive to growers, some have been challenged by low clearances in their existing houses. As a result, the adoption of multi-tier aviaries has been limited. Fortunately, some of the latest advancements in aviary design have addressed this issue.

CLEARANCE CHALLENGES

When converting an existing poultry house to cage-free egg production, some growers have been unable to fit multi-tier aviaries under their pitched roofs, especially along sidewalls where the clearance is lowest. And, if the aviaries do fit, they may not provide enough space between the aviary and the roof to provide an adequate amount of ventilation needed to maintain a healthy environment.

MULTI-TIER MODIFICATIONS

As more North American growers transition from caged

to cage-free eggs, engineers have taken note of the height challenge and begun developing solutions to modify multi-tier systems to better fit low-clearance houses. A new solution is to merge the bottom and middle levels, creating a two-tier aviary that’s less than 84 inches tall.

Despite the shorter size, the two-tier aviary maintains many of the same advantages of the original three-tier design. Additionally, it meets cage-free requirements worldwide.

There are two keys to the high performance of the two-tier model: perches are kept on the upper level; and water is still located in front of the nests.

The top level with perches and feeding systems provides an ideal sleeping environment. This helps provide good ventilation and eliminates hot spots in the house.

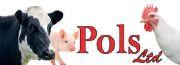

An illustration of an aviary system that can be adapted to an older poultry house with a lower ceiling.

In the morning, the birds will wake up, feed on the upper level and get thirsty. Then, they move to the lower level to find water. After drinking, the birds naturally find their way to the nests to lay eggs.

Instead of a lower level with feeding, these two-tier aviaries have a manure belt under the nest level with a wide platform in front of the nests.

Not only does this design provide ample space for natural bird activities, but it also keeps a clean environment with minimized ammonia levels, thanks to the manure belt.

To match the width and varying heights of a building, multiple aviary configurations can be used in one poultry house.

For instance, a two-tier system can be used along the walls, where clearance is lowest. Then, a three-tiered aviary can be used in the centre of the house, where the roof peak provides more room.

Properly trained birds enjoy moving across the aisles from one level to the next, resulting in excellent welfare and high performance.

Growers who implement this system find that birds use it instinctively well, minimizing hot spots and floor egg issues that are common with other aviary types.

Frank Luttels is layer product manager for Chore-Time.

• self-training from day 1

• easy-to-operate

• excellent monitoring

• smooth transition to aviary laying system

Saskatchewan

Greg Olson

Tel: +1 (306) 260 8081

Ontario

Clarence Martin

Tel: +1 (519) 669 2225

Danny Gilbert

Tel: +1 (506) 470 7370

Manitoba

Calvin Hiebert

Tel: +1 (204) 346 3584 Ontario Andy

+1 (519) 777 1495

British

Dave Coburn

Tel: +1 (778) 245 2765

William Vis

+1 (204) 781 4699 Quebec

Stéphane Chouinard Tel: +1 (450) 266 9604

Multi-tier true aviaries

Enriched colony systems

Single-tier aviaries

Aviary rearing systems

Big Dutchman offers proven and industry-leading layer and rearing systems that can deliver great production results for your farm. Contact your local distributor or sales representative today to discuss a system that works for you.