GOW HASTINGS ARCHITECTS

PERSPECTIVE

Understanding embodied carbon through whole building LCA.

RESHAPING EXPECTATIONS

Gow Hastings Architects transforms everyday spaces into meaningful architectural experiences.

HARDER, BETTER, FASTER, STRONGER

Building enclosure systems take innovation to the next level.

WONDER WALL

Exploring the evolving art and science of curtain and window wall systems in Canadian construction.

Metal roofing and cladding experts turn to Canadian-made to stabilize supply and enhance quality.

Innovative surfaces, seamless curves, and versatile designs redefine modern kitchens.

Fast-changing electrical and communications systems drive new challenges and solutions.

Tariffs and politics test the reinforcing steel industry, but business stays strong.

Lighting

and connection.

by GIOVANNA BONIFACE, RAIC Chief Commercial Officer

Understanding embodied carbon through whole building LCA

Architects and design professionals across Canada now have access to a new on-demand course exploring Whole Building Life Cycle Assessment (LCA). Developed in partnership by the Royal Architectural Institute of Canada (RAIC), the National Research Council of Canada (NRC), and experts at Ha/f Climate Design, the free 12-module training provides practical skills and foundational knowledge to integrate LCA into design practice.

As climate concerns intensify, there is a growing demand for architects and allied professionals to understand the carbon impact of their design decisions. LCA offers a structured method to assess the full environmental impact of a building, from material extraction and manufacturing through to demolition and disposal. This training aims to support a national shift toward low-carbon and regenerative design practices.

The RAIC’s on-demand course is open access, allowing learners to move through the content at their own pace through the RAIC’s Learning Management System. The training includes modules on embodied carbon; LCA theory, tools, and standards; how to apply LCA across different phases of a building’s life cycle; and case studies.

The course was designed with flexibility in mind to accommodate the needs of professionals across disciplines, including architects, engineers, landscape architects, technologists, and sustainability consultants.

Students and early career professionals are also encouraged to participate. By making the course freely available, the RAIC and NRC hope to eliminate barriers to access and ensure widespread adoption of LCA practices across the country.

The program initially launched with in-person workshops between September 2024 and May 2025 in cities including Ottawa, Toronto, St. Andrews, Winnipeg, Regina, Vancouver, Calgary, Halifax, and Montreal. These sessions combined lectures with hands-on group exercises and provided participants with experience in using LCA tools. Feedback from the sessions has helped shape the current online modules, which are now available to the broader public.

“Life Cycle Assessment is a vital skill for the future of the profession,” said Jonathan Bisson, FIRAC, president of the RAIC. “We are proud to provide complimentary access to training that supports environmental leadership in architecture and the broader AEC industry.”

This training initiative reflects a shared commitment to accelerating climate action within Canada’s built environment. By empowering professionals to assess and reduce the carbon footprint of their projects, the RAIC, NRC, and Ha/f Climate Design are helping drive the transition to more sustainable and resilient communities.

To access the training and learn more, visit the RAIC website and register for the course through the RAIC Learning Management System.

“Really, this course is incredible because we don’t appreciate the intrinsic energy in our profession.”

— DANIEL PEARL, Architecte Senior OAQ, LEED AP Professeur titulaire, École d’architecture, Université de Montréal, Assoc. Principal Cofondateur L’OEUF

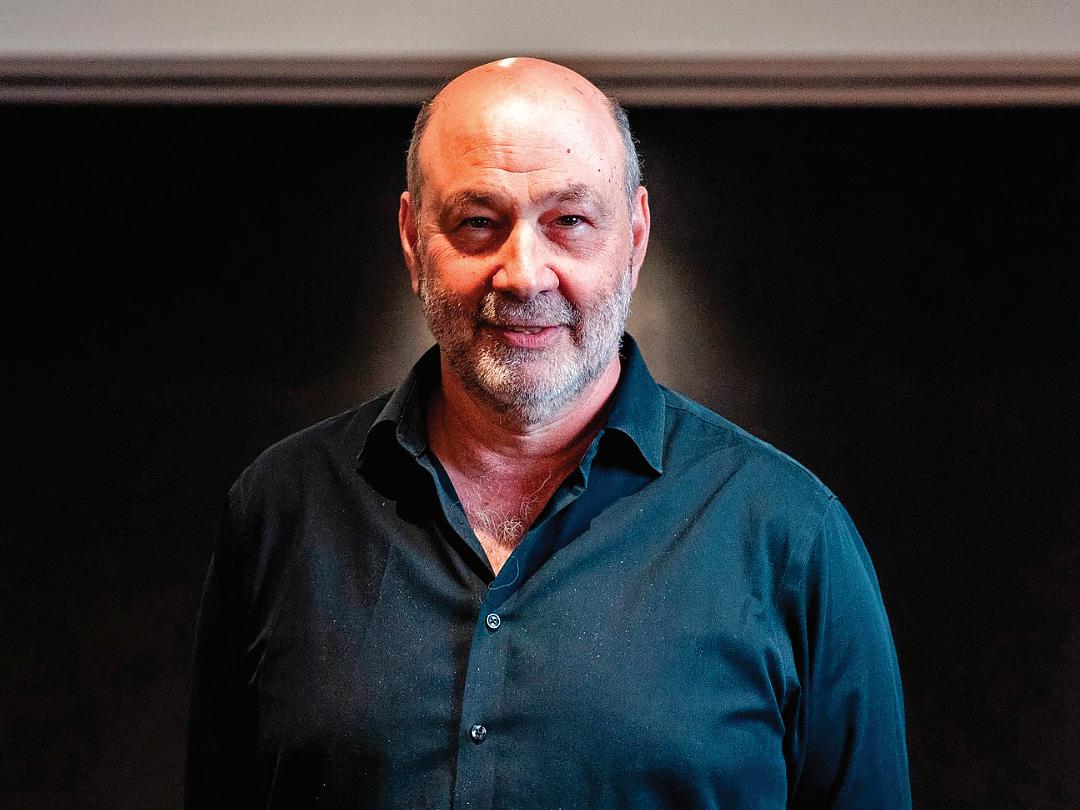

RESHAPING EXPECTATIONS

Gow Hastings Architects transforms everyday spaces into meaningful architectural experiences

by NATALIE BRUCKNER | photography courtesy GOW HASTINGS ARCHITECTS

W“hile we believe good design is practical and grounded, it can also be uplifted, with a sense of awe or wonder, a bit of whimsy, and where possible, a hint of joy.” This quiet but unmistakable principle runs through the work of Toronto studio Gow Hastings Architects. Rather than a formal mission statement, it reflects the team’s belief that architecture, even at its most pragmatic, has the capacity to move us, to elevate our experience, and offer delight, often in places we least expect.

Originally founded in 2002 by Valerie Gow and Philip Hastings, the studio emerged from a shared desire to reimagine how public spaces could feel. The two met as classmates at the University of British Columbia’s School of Architecture and Landscape Architecture before building their early careers in Vancouver and London, England, contributing to large-scale cultural and institutional work. While working abroad on projects for clients such as the Universities of Oxford and Hertfordshire (and, in Philip’s case, on landmarks like the Royal Opera House and Somerset House) they began to see a future for

themselves back in Canada: one that involved not just designing spaces, but reshaping expectations.

The first opportunity came not in a museum or gallery, but in a school at Humber College. It would become the first in a series of collaborations with Ontario’s post-secondary institutions, setting the tone for the work to come.

While Gow Hastings did not initially set out to specialize in education, they quickly became known for it, as well as for offering what was, at the time, a relatively unique integration of architecture and interior design.

Those early years of Gow Hastings Architects were marked by a deliberate embrace of the overlooked, with early projects including broom closets, service corridors, and temporary classrooms. “A pattern that quickly emerged was our ability and agility to work on small-scale projects, critical to the functioning of public institutions, in spaces that few other architects sought,” recalls Valerie Gow. “But we treated them with equal care and attention.”

These small, often transient interventions became a kind of architectural sketchbook, forming the foundation of a practice that believes no space is too minor to matter.

“Those early, small-scale projects also taught us how to do a lot with very little; tight budgets, tighter timelines,” adds Philip Hastings.

Early experience with public projects proved formative for Gow Hastings, teaching them to navigate the complexities of public procurement and engage directly with decision-makers. Before the days of formalized processes, Valerie and Philip hustled door-to-door, personally connecting with clients at colleges and universities – a labour-intensive approach that earned them a deep understanding of facilities management and institutional intricacies.

As their portfolio expanded, so too did the scale and visibility of their projects. “For example, at Toronto Metropolitan University [TMU], what started out as a storage space renovation turned into a new identity and celebrated campus presence for the Department of Architectural Science, making it a focal point of the school,” explains Gow.

Elsewhere, at Humber College and later George Brown’s Centre for Hospitality and Culinary Arts, Gow Hastings helped redefine culinary education spaces, transforming stainless steel infrastructure into participatory, open-concept kitchens. Their hands-on experimentation with stainless steel, led by then-intern Stephen Wenzel (now associate), sparked a spirit of play and innovation that continues to influence the studio’s work. These projects, informed by early lessons in economy and ingenuity, helped to craft an approach that is precise, pragmatic, and always human-centred. This groundwork led to a trusted reputation at Humber College, where their ongoing renovations and campus stitching earned them the nickname “village architect.”

While their core principles took shape during their time at their first office – a shared workspace at 51 Wolseley, housed in a converted garment factory in downtown Toronto – the studio culture truly found its home in 2010. That year, Gow Hastings moved into a warm, bright, converted 1920s residence near Casa Loma, a space where leadership and teamwork work side by side, embodying the spirit of togetherness that defines the studio.

When it comes to their work, the team concur that two overarching questions have guided Gow Hastings: What can architecture offer? And how can it respond with purpose and meaning?

A standout example is the revitalization of Fleming College’s A-Wing (2018) and B-Wing (2022), where heavy, enclosed 1970s buildings were transformed into vibrant, light-filled spaces. Perforated coloured metal panels and transparent glass pavilions now invite socializing and informal learning.

“This project marked a turning point, expanding our work from interiors to exterior envelope design. It reflects our studio’s four Ps: People, Purposeful, Practical, and Playful,” says design director Jim Burkitt, a former UBC classmate who came onboard in 2005.

At the Université de l’Ontario français (2021) campus the Gow Hastings team got together and reimagined corridors and lobbies as dynamic “third spaces” optimized for gathering, teaching, and movement. By transforming traditionally overlooked areas into vibrant hubs, the project showcases their talent for crafting collaborative spaces that enrich campus life despite spatial limitations.

Building on this commitment to flexible, community-oriented design, Conestoga College’s School of Hospitality & Culinary Arts (2024) demonstrates their ability to create efficient, adaptable spaces that celebrate culinary education. By positioning teaching labs as public-facing stages, the design connects the school to the street, fostering a lively and inviting atmosphere.

Indigenous-led projects have become another vital part of Gow Hastings’s portfolio. The Spirit Garden at Nathan Phillips Square (2024) stands as a landmark example of their evolving role as facilitators in Indigenous design, first established on the Seneca Odeyto Indigenous Centre, both in collaboration with Two Row Architect. Rather than imposing a vision, they prioritized listening and translating, enabling Indigenous artists and communities to create a space dedicated to healing, teaching, and reconciliation.

Beyond their many impactful projects, Gow Hastings’s commitment to purposeful design is matched by a dedication to their people, evident in the studio’s vibrant and inclusive culture. “You would be met with a lot of smiles,” says Chi Nguyen, senior graphic designer, when asked what people encounter when walking into their studio. “We are a happy bunch, according to a recent office survey, who come from diverse cultural, design, and education backgrounds, well-balanced and represented across the spectrum.” That balance, and the spirit behind it, is reflected in everyday moments, whether it’s Friday beer and chips, seasonal walk-and-talks, creative workshops, or what the team affectionately call NARF: non-architecture related fun.

Even Pepper, their goldendoodle – formally known as head of security and chief happiness officer – adds to the studio’s creative energy, offering a lighthearted presence in daily life. This welcoming, supportive spirit extends into how Gow Hastings nurtures future talent. Mentorship is central to their identity, with co-op students from client schools such as TMU and the University of Waterloo regularly working alongside senior staff. In this way, the studio not only designs learning environments but also operates as a vibrant learning space itself.

Building on their dedication to education and community, Gow Hastings looks ahead with excitement to new horizons beyond Ontario. Their first out-ofprovince project – a culinary school for Vancouver Community College in British Columbia – marks a significant step in expanding their impact. Central to their approach remains meaningful collaboration with Indigenous communities, continuing the spirit exemplified by The Spirit Garden and Odeyto. These projects have sown seeds of inspiration that are blossoming in new work like the Scanlon Creek Nature Centre (SCNC), set for completion in 2026.

“We see SCNC as the type of compelling work, rich in meaning and impact, in our future. Above all else, moving forward, regardless of future industry changes or disruptions, we remain steadfast about what drives us: projects with deep purpose from the ground up,” says Hastings. A

Fleming College A-Wing, Sutherland Campus

Université de l’Ontario français Campus

The Spirit Garden at Nathan Phillips Square

Department of Architectural Science, Toronto Metropolitan University

Build Smarter. Build Faster.

Build with Prefab Precast Concrete.

In response to Canada’s housing crisis, prefab precast concrete durable, and cost-effective, as each component is manufactured i concrete offers higher quality, making it a resilient and sustainable option to address Canada's mid – to high–rise housing shortage.

Learn more about the advantages of using prefab precast concrete for your next project.

Let’s build fast, resilient housing together!

| 877.937.2724 For more information on housing with prefab precast concrete, visit: www.cpci.ca/publications or scan the QR Code to download your free copy of any CPCI Technical Publications.

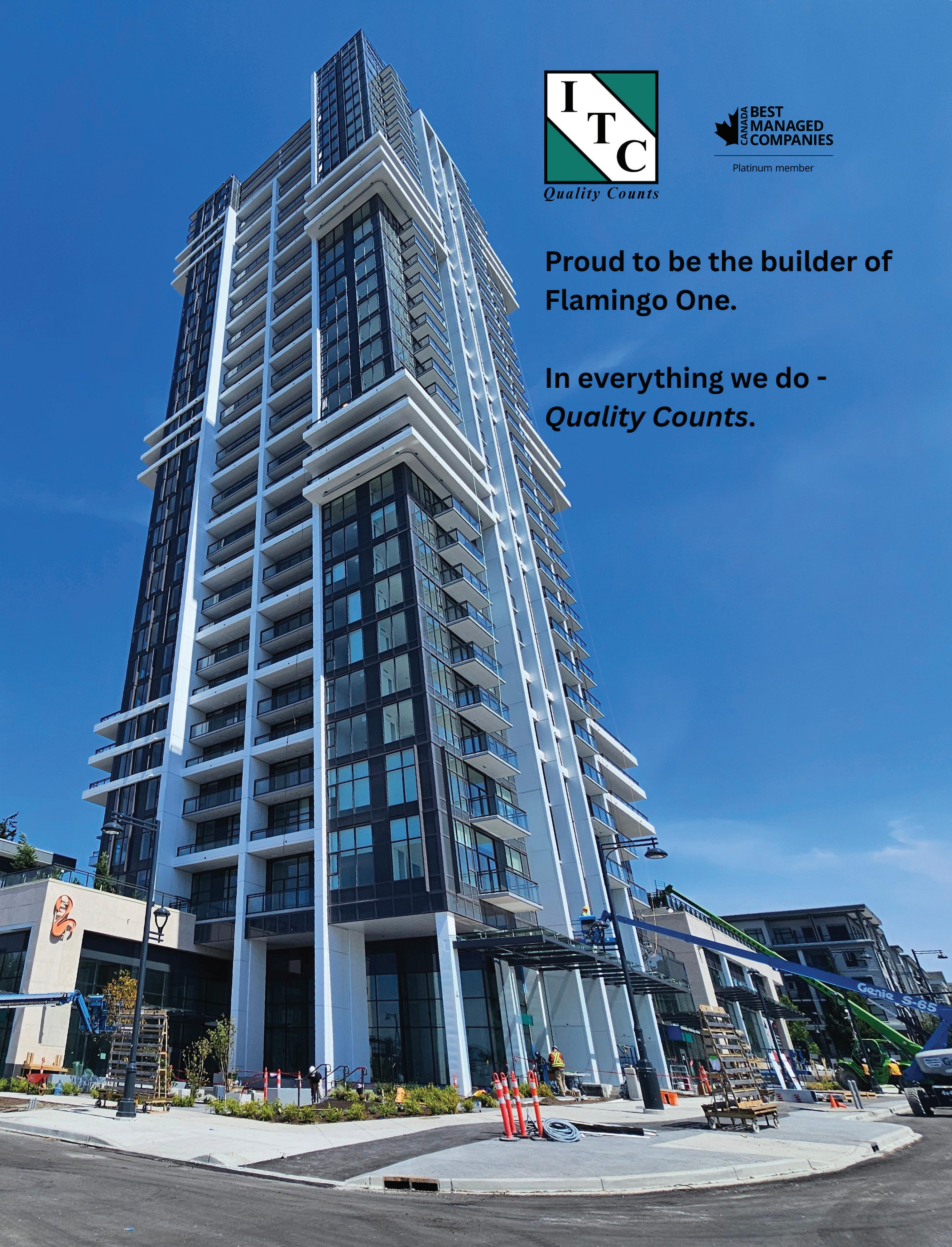

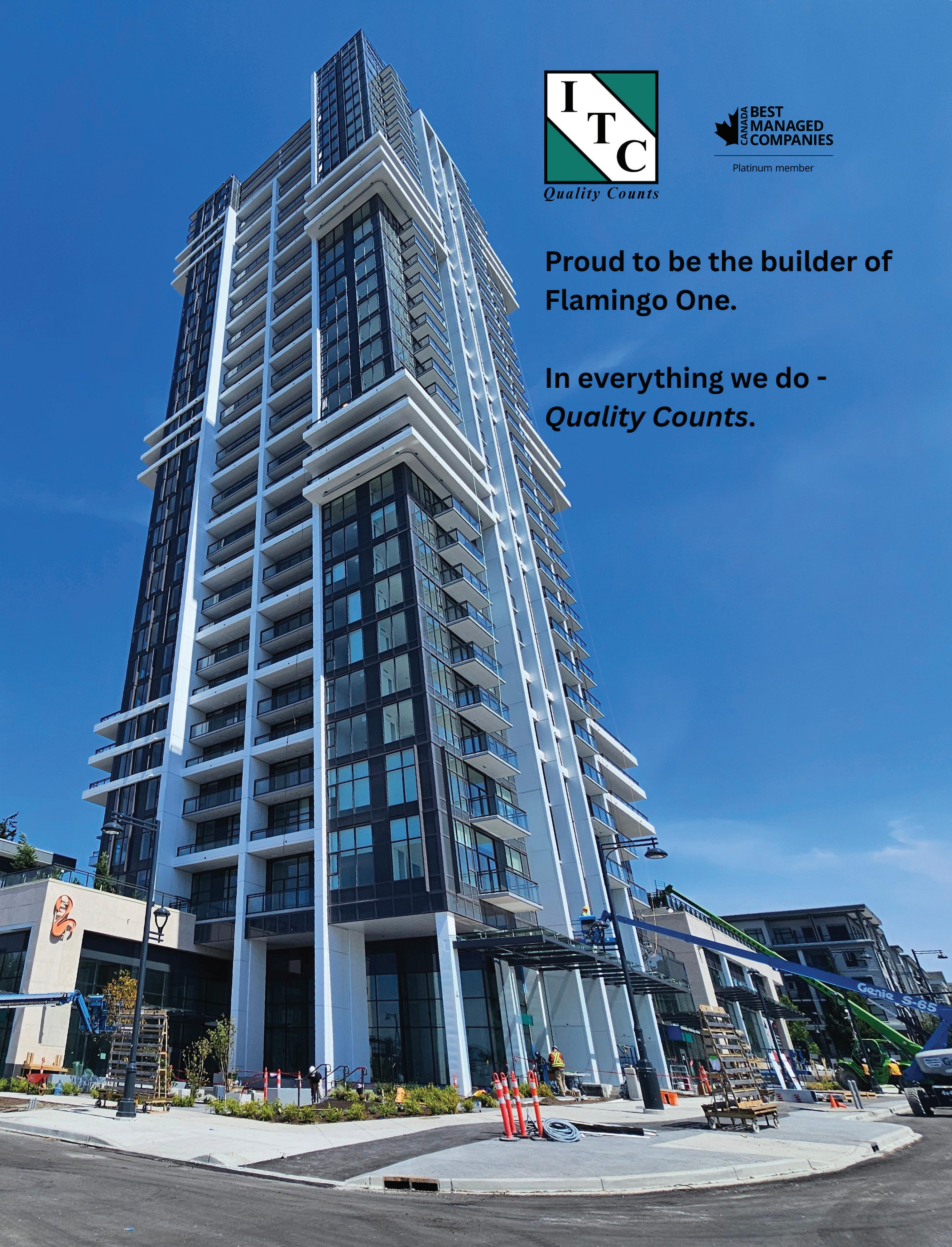

Harder, Better, Faster, Stronger

Building enclosure systems take innovation to the next level

by ROBIN BRUNET

Necessary innovation may be the best way to describe the technological advances emerging in the building enclosure systems sector, with new products driven by government-mandated energy efficiency performance improvements across North America. Flynn Group of Companies exemplifies the spirit of product innovation — one example being a system it spent six years developing: Speedwall, a factoryassembled, complete exterior wall system. Built on an aluminum chassis based on Flynn’s 6450 unitized curtain wall system, Speedwall modules are fully self-framed, sealed, and insulated at Flynn’s manufacturing facility, with all windows, doors, and exterior cladding pre-installed.

The aluminum framing features a male–female connection with dry gaskets, enabling quick installation and creating an air and water seal without the need for exterior-applied sealant. The frame is fully insulated from the outside by attaching an insulated metal panel using stainless steel fasteners, minimizing conductive components through the insulation and resulting in a high-performing, thermally broken system.

Joe Baz, product manager at Flynn Canada Ltd., says, “Speedwall effectively addresses two problems faced in Canada and in our construction industry. First, our industry is grappling with a severe shortage of skilled workers due to an aging workforce and fewer young people entering the field. Second, Canada is in a housing crisis, and it’s been calculated that 3.5 million new housing units need to be built by 2030 to restore affordability.”

Speedwall proved it can contribute to solving these problems when the British Columbia Institute of Technology (BCIT) needed new student housing and engaged architects Perkins&Will to design a 12-storey building using mass timber construction. Dubbed the Tall Timber Student Housing (TTSH) project, the building envelope needed to be rapidly installed, and it had to be high-performance, with minimal sound transmission, and zero moisture issues.

Speedwall’s performance and installation methods were confirmed at the BCIT TTSH project, where up to 12 modules were installed daily, covering between 2,000 and 3,000 square feet of wall area. The rapid installation enclosed mass timber quickly, and also met the project’s objective of achieving a TEDI target of 15.

Installation of a Speedwall module at the BCIT TTSH project.

UNCOMPROMISING QUALITY

Your project deserves more than materials—it deserves a partner who values your time, budget, and vision. Our affordable precast systems deliver the durability and design flexibility you need while keeping costs under control. From first pour to final install, we’re with you every step of the way.

For those who bemoan the fact that such modular systems would result in fewer jobs on site, Baz points out that “significant job creation occurs elsewhere. Large modular factories create jobs for factory workers, maintenance staff, manufacturing leads, managers, and shipping staff. Added back-end work involves drafters, BIM modellers, engineers, procurement teams, business development teams, and administrative roles.”

Flynn’s Speedwall has been dispatched to various construction sites in Ontario (primarily for low-income housing) and other parts of Canada.

“Speedwall will be in high demand for a wide variety of building projects,” Baz says. “It’s a great way to future-proof buildings, since it achieves a high effective R-value for exterior walls, improving building efficiency, and reducing energy required for heating and cooling. Additionally, in terms of manufacturing Speedwall itself, we use materials with low embodied carbon to reduce the system’s overall carbon footprint. This focus on performance and reducing embodied carbon directly impacts reducing overall carbon emissions in buildings.”

Mitrex’s technological innovation is unique to the industry: its building-integrated photovoltaics (BIPV) façades aren’t just an effective replacement for building envelopes, they also capture the power of the sun, thanks to their robust aluminum honeycomb core and a layer of high-efficiency solar cells. “Our manufacturing facility in Etobicoke uses thicker glass, better lamination, and other elements that would be too expensive for the type of panels you typically see in large-scale solar farms. Hence, we offer a lifetime warranty of 60 years for the product, with energy generation after 25 years being 80 percent,” says Danial Hadizadeh, CEO of Mitrex. While reinventing the building envelope, Mitrex also ensured that durability would be a hallmark of its UL-certified cladding, and videos show an automobile driving over a single suspended patch of thin cladding panel without the panel incurring any damage.

Hadizadeh reports that the BIPV facades have slowly been making inroads in the commercial sector for five years now. A project that brought widespread exposure to the technology is the 22-storey Loyola Residence at Saint Mary’s University, which was recently honoured at the Clean50 Top Projects Awards. Built half a century ago, Loyola faced heat retention challenges, leaks, and structural issues. Instead of simply replacing the worn-out concrete, the university opted to use BIPV across the building’s entire south-facing wall, serving as part of the building’s structure as well as generating clean energy.

Safe removal of the existing precast concrete was one of the early steps in the construction process. Next, the wall had to be prepared to accept the BIPV facade. This required enhanced insulation, waterproofing, and running electrical conduit. It was decided that a row of windows (also integrated with PV) should be added to the design, bringing natural light to an interior stairwell. Installation of the panels was rapid, mainly because they could be installed from swing staging. As for electrical power generation, Loyola is designed to exceed 100,000 kilowatt-hours annually.

Hadizadeh regards 2025 as a banner year for the BIPV facades (a new line also incorporates LEDs in the facades), as the product shifts from being new and unproven to increasingly sought after in the mass-market realm. “We have many projects on the go this year across Canada, and coming up are three airport projects: two in the U.S. and one in the Middle East,” he says.

Yet another building enclosure system marketed as “revolutionary” comes from Huntsman Building Solutions, well known for manufacturing industryleading spray polyurethane foam (SPF) and coatings for roof, attic, foundation, wall, and under slab applications.

Huntsman Building Solution’s D-Max Wall assembly is changing how buildings are insulated;

it enables builders to meet stringent energy requirements while reducing construction costs and improving job site productivity. Huntsman Building Solution’s Heatlok Soya HP spray foam is the assembly’s core feature and serves as insulation, air barrier, and vapour barrier – the three key elements required for a building envelope.

D-Max eliminates the need for scaffolding or hydraulic elevators, with spray foam applied from inside the building, avoiding weather-related delays. Essentially, the walls are assembled after installing regular steel studs; instead of exterior sheating being placed directly on these studs, a horizontal Z-girt creates a gap between the studs and the exterior sheeting to be filled with spray foam, cutting the thermal bridges.

D-Max’s effectiveness is reflected in the certifications it has received, including U-value calculations in accordance with ASTM C1363 and ASHRAE 1365RP, Greenguard Gold (for low VOC emissions and better indoor air quality), CAN/ULC S134 (for fire resistance), CAN/ULC S742 (for air barrier systems), and ASTM E331 (for water penetration).

Providing an efficient building enclosure package that offers rapid construction and performance exceeding thermal requirements is a focus of the Canadian Precast/Prestressed Concrete Institute. Its managing director, Brian Hall, points out this can be achieved with prefab double-wythe precast concrete insulated panels featuring pre-installed, integrated windows.

Hall explains that such panels “combine the durability and thermal mass of precast concrete with the energy efficiency of insulation and the practicality of factory-installed windows.” They provide both the exterior cladding and rain screen function of the wall system, along with the load-resisting structure for the external cladding and interior of the wall, facilitating quick enclosure of a building without the need for scaffolding or hoarding.

Further, the prefab precast window panels usually include aluminum framing and glass. “They are pre-assembled, caulked, vapour- and air-tested at the fabrication facility before shipping to the job site,” Hall says. “As a complete building enclosure system, they are designed to manage air and moisture while enhancing energy efficiency and streamlining façade installation.” R-values range from R-5 to R-50 and can be increased by increasing the insulation thickness between the two concrete wythes.

Speedwall building enclosure at the BCIT TTSH project.

Building-integrated photovoltaics façade at the Loyola Residence.

D-Max wall assembly at the Quartier Élévation Phase 2 project.

In addition to streamlining construction and enhancing energy efficiency, the panels improve the overall quality and longevity of any building. “These prefab wall panels have been effectively specified for various construction applications, including data centres, mid- to high-rise residential buildings, and educational facilities, retail, commercial, governmental – including blast-resistant structures – industrial/warehouse, correctional facilities, and more,” Hall says.

In Brandon, Manitoba, Greenstone Building Products is also responsible for prefabricated building envelope technology that enables projects to be completed faster. The Insulated Composite Envelope (ICE Panel) is an engineered combination of expanded polystyrene (EPS) and galvanized steel: a much lighter and stronger building envelope. A premium option from Greenstone is a panel that replaces EPS with graphite polystyrene, which provides a superior R-value.

These panels are made to eliminate thermal bridging, and their effectiveness as an envelope has led to their use in everything from urban residential and commercial buildings to projects in the far north, such as the Arctic Bay 8-Plex residence in Nunavik.

In terms of admixtures that support building enclosure systems, Euclid Admixture Canada offers the new Eucoshield, a ready-to-use liquid

admixture. It is intended as an integral finishing aid that reduces rapid moisture loss from the concrete surface by binding internal water in the pore structure. While Eucoshield works well with all cement and supplementary material types, it is especially effective with concrete containing Type IL (GUL) and other blended cements. It is also particularly useful when concreting operations must be performed in direct sun, wind, high temperatures or low relative humidity.

Finally, earlier this year, Holcim completed the separation of its North American business in the U.S. and launched Amrize, an independent public company providing building solutions from foundation to rooftop.

During the transition, Gaco – a leading provider of coatings, adhesives, and sealants and formerly part of Holcim Building Envelope – undertook a strategy to unify its entire portfolio under the Gaco name. Its extensive product lines, which include everything from roof restoration to floor coatings, are now organised into seven distinct sub-brands.

The sub-brands include: GacoFlex (roof restoration, coatings, and roof foam); GacoFloor (floor and safety traffic coatings); GacoSeal (general construction and building envelope sealants); GacoBond (general construction and building envelope adhesives); and GacoIndustrial (industrial and specialty adhesives, coatings, and sealants). A

BUILDING THE FUTURE

Installation of prefab precast window panels.

SCIENCE APPLIED TO WOOD

Sansin Precision Coat™. High performance wood protection for mass timber structures.

Sansin Precision Coat products offer unparalleled beauty and durability in an environmentally friendly formula. Warrantied for up to 20 years, Precision Coat factory finishes deliver the color, transparency and performance that architects, engineers and builders can count on.

Contact us about our specification program so we can help you achieve the perfect finish and protection, every time.

Sewell’s Boathouse | Horseshoe Bay, British Columbia, Canada

Photographer: Ema Peter

PRECAST CONCRETE QUALITY ASSURANCE!

THE CPCQA CERTIFICATION PROGRAM

CPCQA

The Canadian Precast Concrete Quality Assurance (CPCQA) Certification Program prequalifies precast concrete manufacturers who fabricate structural, architectural and specialty precast concrete products, including concrete pipe and underground utility and drainage products.

Manufacturers adhere to the CPCQA certification program requirements, and to the applicable requirements of the CSA, PCI, ASTM, and Provincial Standards.

THE CPCQA CERTIFICATION PROGRAM OFFERS KEY BENEFITS TO ARCHITECTS, CONTRACTORS, ENGINEERS, GOVERNMENT AUTHORITIES AND OWNERS.

Endorsed by the Canadian Concrete Pipe and Precast Association (CCPPA) www.ccppa.ca and the Canadian Precast/Prestressed Concrete Institute (CPCI) www.cpci.ca

For more information, scan the QR Code or visit www.precastcertification.ca

Project: Champagne Quarry Park, Calgary, AB

Architect: Gibbs Gage Architects

WONDER WALL

Exploring the evolving art and science of curtain and window wall systems in Canadian construction

by NATALIE BRUCKNER

Driven by rising demand for energy efficiency, visual appeal, and durability, curtain wall and window wall systems are playing a bigger role than ever in high-rise and mixed-use construction across Canada. In response, industry experts are delivering solutions that not only meet architectural design goals but often exceed performance and code requirements.

One company navigating this landscape with a clear strategy is GlasCurtain. Over the past 12 months, conversations around supply chains and tariffs have intensified, and, according to managing director Peter Dushenski, as a 100 percent Canadian manufacturer with a fully domestic supply chain, GlasCurtain has been able to hold its prices steady and maintain consistent lead times, even amidst ongoing geopolitical uncertainty. “We made a strategic decision in 2010 to keep manufacturing local, and today’s conditions have validated that choice,” he says.

One system in particularly high demand is Thermaframe 9 PH, which Dushenski calls “a very pleasant surprise.” He adds: “It’s the world’s highest thermally performing curtain wall, according to the Passive House Institute in Germany, but it still costs more up-front. That tells us clients and architects are now prioritizing high-performance envelopes – especially for Net-Zero, Passive House, and Step/Stretch Code projects. The long-term benefits of low-carbon fibreglass framing are too compelling to ignore.”

A standout project is the upgraded Yawkey Building at Boston Medical Center, GlasCurtain’s first U.S. installation. The design team, RDH Building Science with Tsoi Kobus | DLR Group, selected Thermaframe 9 PH as the only system that met both thermal and aesthetic criteria.

“The new Stretch Code in Massachusetts is extremely demanding, essentially shadowing Passive House, so our fibreglass-framed system was the ideal fit,” says Dushenski. “And with current geopolitical tensions, USMCA-protected tariff-free systems like ours are a safer, smarter bet than European alternatives.”

This focus on high-performance, sustainable curtain wall solutions is echoed by the experts at Phoenix Glass. Jim Lebedovich, president of Phoenix Glass, notes a clear shift over the past year toward energy efficiency and modern aesthetics driving curtain wall design choices.

“Energy efficiency has driven the demand for more sustainable and aesthetically modernized curtain wall systems,” Lebedovich says. “Installations are very simple, and when executed correctly, they are bulletproof for any air infiltration and water penetration requirements.”

Thermally enhanced curtain wall systems, in particular, have seen a sharp rise in demand, becoming the go-to choice for commercial and institutional projects. “The performance and flexibility of these systems is very appealing to all consultants for their own various reasons,” he explains. “Curtain wall addresses all parties’ concerns for the envelope and design when putting a project together.”

One project that exemplifies these advancements is the upcoming UBC Sauder Powerhouse School of Business Expansion. Lebedovich notes that the design integrates high-performance curtain wall systems with a visually

striking envelope. “It will showcase the best that curtain wall has to offer,” he says. “Complex curves mixed with faceted geometry and co-ordination with exterior wall cladding will provide for a great achievement when complete.”

MODULAR MOMENTUM

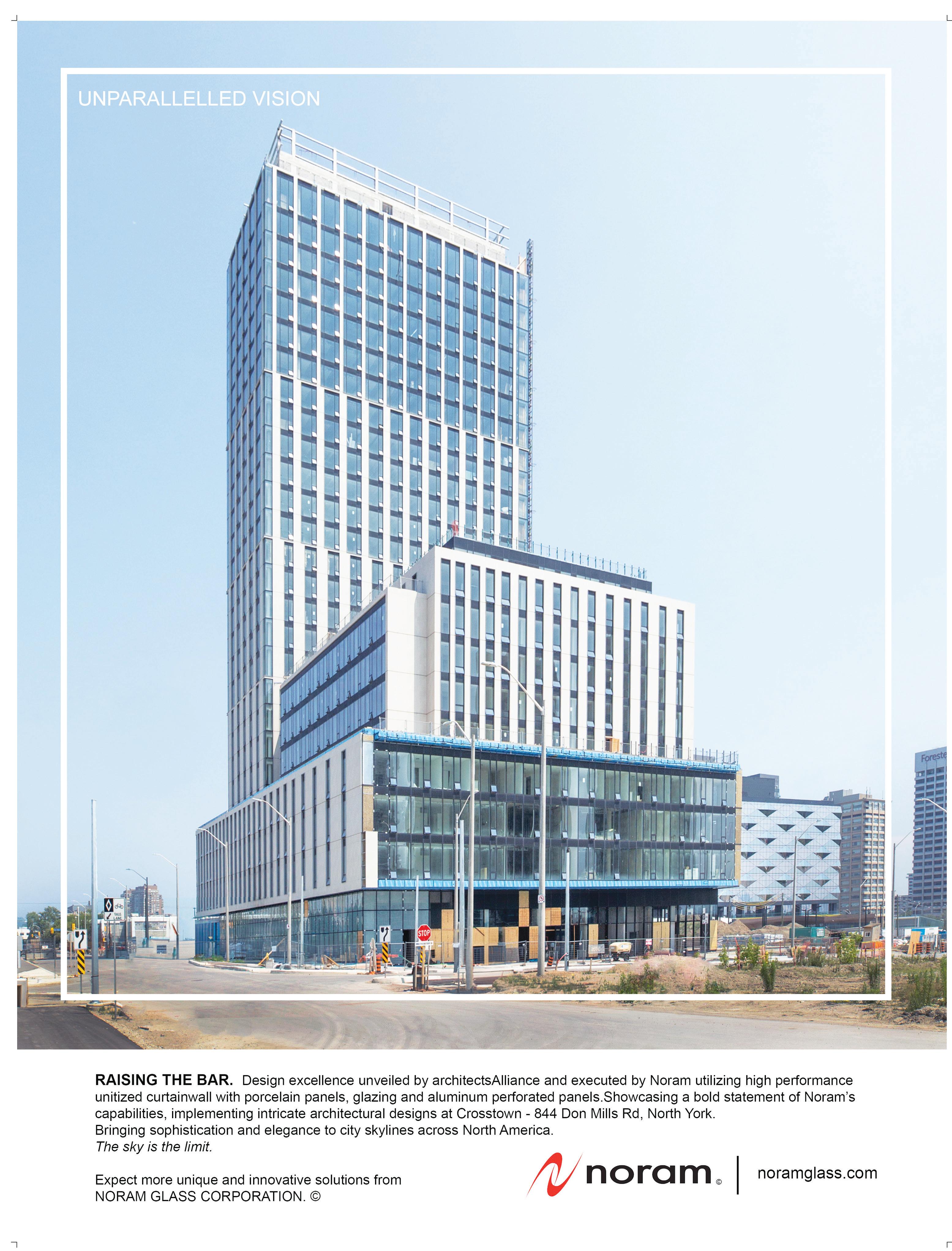

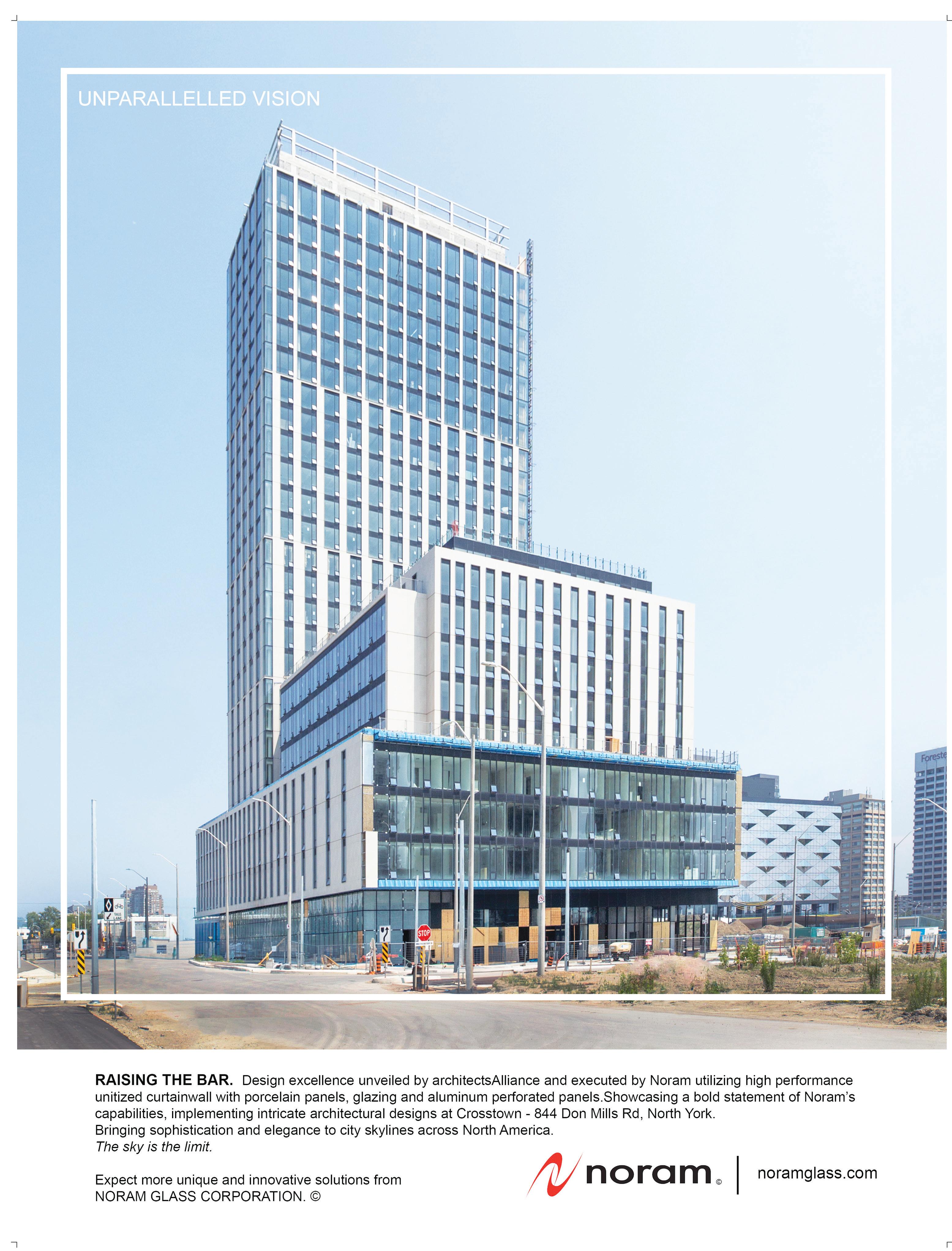

Over the past year, the industry has also seen a growing shift toward unitization and modularization in building facades, according to Noram Glass. The trend is largely driven by the need for improved quality control, faster installation times, and reduced site labour.

“We’re also seeing increased demand for higher-performing envelope systems, particularly with the integration of triple-glazed and vacuum-insulated glass units,” adds Ted Redlarski, president.

One project his team has recently worked on is Crosstown, where Noram transitioned from a traditional construction approach to a fully modular and panelized facade system.

Luxe

Lansdowne, Richmond, B.C.

“The pivot streamlined construction timelines, but also significantly improved quality and installation efficiency. It’s a great example of how adopting a modular mindset towards future projects can unlock both new design flexibilities and construction speed, particularly in large-scale developments,” says Redlarski.

With market demand for faster construction speeds and larger, more complex facade systems, the embrace of unitization and modularization is on the horizon. There are exciting growth opportunities ahead, and with the right planning and innovation, the experts at Noram see these challenges becoming opportunities to redefine how buildings are delivered.

ENERGY CODE IMPACT

Building on the industry’s focus on sustainability, Michael Bousfield of Cascadia Windows & Doors points out that evolving energy codes – especially those encouraging reduced glazing area – are pushing designers to create more strategic, efficient building envelopes.

“This is inspiring innovations when it comes to prefab wall systems,” Bousfield says. “Prefab wall manufacturers are now adopting some of the same principles as curtain wall systems. Curtain walls are stick-built on site, or, more frequently than ever before, fabricated in a factory, brought to site, craned into place, and structurally attached. Prefab wall panels are doing the same thing, just scaled up.”

He points to local mass timber leader Intelligent City (BC) and steel framing specialists Centura Building Systems (BC) and Unitiwall (Ontario) as examples of companies driving the prefab shift.

“We recently supplied windows to a mass timber prefab project,” Bousfield adds. “The windows were more like large punched openings, similar to inserting operables into curtain wall. But now entire panels, the size of a flatbed truck, come with windows already integrated.”

As for what’s next for Cascadia, Bousfield says, “We’re developing a window wall system that can fully wrap a high-rise in a single, integrated envelope, whether it’s all glazing or a blend of vision and opaque elements. It opens up a lot of design flexibility.”

DESIGN INNOVATION

While commercial projects emphasize performance and efficiency, residential design is increasingly focused on expansive glazing, greater accessibility, and smart technology. Christine Marvin of Marvin highlights how large, accessible windows and automated systems are transforming homes into more connected, light-filled spaces. “Smart home innovations such as automated windows and door systems, like Marvin Connected Home, seamlessly integrate technology to bring more light, air, and views into homes,” she explains. Features like responsive sensors and customizable schedules also give homeowners more control over their environment.

A collaboration between Marvin and architect Paul Lewandowski on the “Notch House” in New Hampshire’s White Mountains highlights this shift. “With Marvin’s Modern collection in mind, the project became an opportunity to maximize gorgeous views with large expanses of glass,” Marvin notes. Floorto-ceiling windows with slim profiles and minimal trim blur the line between indoors and out.

These windows also serve a practical purpose. “Some of the Modern collection’s largest offerings were brought in for the project, including three almost-96-square-foot units,” Marvin explains. Despite the region’s harsh conditions, from hot summers to strong winter winds, the fibreglass construction offered the strength and durability the project required.

Innovation remains a central focus for Marvin, not just in product development but in how they support the design and building community. “In 2024, we reimagined our Boston Brand Experience Center to include the Marvin Connected Home, our fully integrated automated window and door solution,” says Marvin. “By creating a hands-on environment, we’re helping professionals explore how smart technologies can shape more responsive, connected living spaces for their clients.”

As energy codes evolve and buildings aim for higher performance, managing solar heat gain and façade thermal efficiency has become essential – especially on south- and west-facing elevations with extensive glazing, says Zhen Liu of Silex. While aluminum remains durable and widely used, its high conductivity can increase energy loss if not properly addressed.

Thesis Headquarters, Portland, OR

Crosstown, Toronto, ON

Legacy Park Elementary School, Weyburn, SK

ENGINEERED FOR PERFORMANCE. DESIGNED FOR CANADA. TRUSTED BY PROS.

CONTACT US TODAY

PARTNER WITH SILEX FOR YOUR NEXT PROJECT!

ÉCOLE WATERFORD SPRINGS SCHOOL

Your trusted choice across Canada for high-performance, energy-efficient fiberglass windows and doors.

PRODUCT FEATURES

Thermally stable fiberglass frames for long-term performance

Custom sizes and finishes

Easy Maintenance

Triple-pane glazing for superior energy efficiency

“Excessive solar heat gain is often due to improper low-emissivity [low-E] glazing, not necessarily the frame material,” Liu explains. “Still, frame conductivity significantly affects envelope performance.” Canadian-made fibreglass systems are gaining traction for their superior thermal insulation, lower conductivity, and ability to deliver energy efficiency without compromising structural integrity or design flexibility.

Beyond performance, cost and sourcing are shaping material choices. With rising aluminum prices and growing interest in local procurement, fibreglass window and curtain wall systems offer shorter lead times, price stability, and reduced embodied carbon – all while meeting or exceeding energy code requirements.

Liu notes that Silex fibreglass systems exemplify this shift, with low-conductivity profiles and clean lines making them a popular choice for Passive House, Net Zero, and other high-performance projects.

CURTAIN WALL UPGRADES

LiteZone Glass Inc. has earned recognition for its innovative ability to upgrade older curtain walls originally designed for one-inch insulated glass units (IGUs) to accommodate LiteZone® R17 4.4-inch IGUs. Many older curtain wall systems are designed to accommodate much thicker, more energy-efficient LiteZone® units. By retaining the existing structural back section of the curtain wall and adding an adapter to extend the thermal break, these upgrades can easily fit the thicker LiteZone® glass units. During the process, all gaskets and seals are replaced, and insulation can be added to the spandrel areas. The result is a costeffective renewal that transforms outdated, energy-inefficient curtain walls into highly efficient systems.

“This upgrade requires no modifications to the existing curtain wall framing and can reduce energy loss through the glass by up to 90 percent compared to traditional double-pane IGUs,” explains Greg Clarahan, president and CEO.

Additionally, worn-out perimeter heating systems often found beneath windows can be removed during the upgrade, freeing up valuable floor space for more practical uses. Thicker, higher-performing LiteZone glass units can be

installed within existing curtain wall systems without altering the glass pockets. This is achieved by inserting a spacer to fill the one inch glass pocket against the offset exterior glass pane, using an aluminum tube as an interior glass stop, and applying a silicone heel bead to create an airtight interior seal.

Passive House, low carbon and other highly sustainable

LiteZone R17

4.4-inch

insulated glass units.

AI INTEGRATION

With increasing focus on AI and robotics, Starline Windows is embracing these technologies to transform installation practices and improve job site safety.

Chief operating officer Lesley Noland reveals the company has been developing a robot arm installer as part of its ongoing push toward safer, more efficient construction practices. “We have a robot that we’ve spent the last year designing to drill holes in concrete,” she says.

The new technology is being trialed as a way to automate one of the most physically demanding and hazardous parts of the job. Drilling into concrete exposes workers to harmful silica dust and requires sustained heavy labour. While the robotic system is still in its early stages and requires close supervision, it represents a leap toward safer job sites and streamlined workflows.

For Noland, automation isn’t about eliminating workers and instead is about empowering them. “It’s not replacing jobs, it’s just augmenting them and making it so that the monotonous stuff isn’t bogging you down all day,” she explains.

As robotics and AI become more embedded in building practices, Starline’s investment in emerging technology underscores a broader shift in the construction industry.

EPD TRANSPARENCY

Transparency is, of course, key in today’s push for greener building practices and Innotech Windows + Doors is setting a strong example in this regard.

Earlier this year, Innotech Windows + Doors released third-party verified Environmental Product Declarations (EPDs) and Health Product Declarations (HPDs) for its core product lines: the Defender 76TS and 88PH+ window and door systems. These documents, based on a cradle-to-grave Life Cycle Analysis conducted by Vertima and audited by the Athena Sustainable Materials Institute, offer a transparent view of environmental performance and embodied carbon impact.

“In an era of greenwashing, transparency is non-negotiable,” says Troy Imbery, president of Innotech Windows + Doors. “EPDs and HPDs are part of our broader commitment to performance, sustainability, and truth in environmental claims.”

Beyond compliance, these disclosures serve as a roadmap for reducing environmental impact through smarter material choices and improved manufacturing processes. Imbery explains, “Until recently, sustainability focused largely on operational carbon and reducing energy use. Now, embodied carbon is just as important. It’s changing how we define responsible building practices.”

As low-carbon design becomes standard practice, Innotech’s initiative reflects a broader shift across the industry, where forward-thinking manufacturers are identifying environmental hotspots in their products and operations to drive meaningful sustainability improvements. A

Lake Superior Administration and Visitor Centre, Nipigon, ON

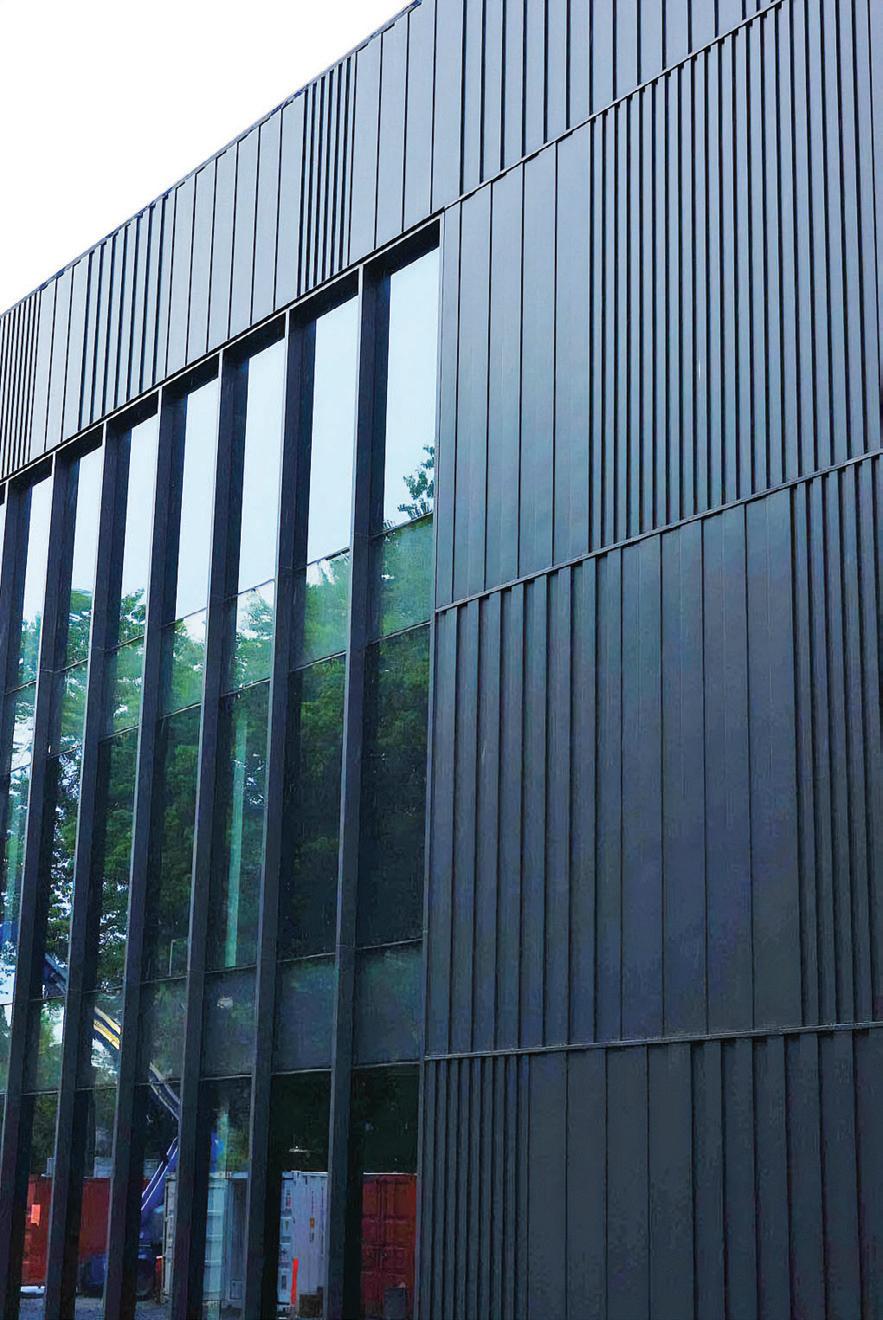

Elbows UP

Metal roofing and cladding experts turn to Canadian-made to stabilize supply and enhance quality

by ROBIN BRUNET

Sean Lepper, senior vice-president at Behlen Industries, summarizes the uncertainty that has dogged the metal roofing and cladding sector in 2025: “It seems like Canada is being threatened by 25 percent tariffs on steel one day, then 50 percent the next. I suspect the speculation about how hard steel will ultimately be affected will end in the new year – the tariff could wind up being about 10 percent, as has been the case in the U.K.”

Lepper adds, “All I can say is we at Behlen rely on an all-Canadian supply chain. This has helped our business enormously, and the few odds and ends that aren’t Canadian we can easily obtain offshore.”

When asked to explain why relying on a Canadian supply chain has helped business, Lepper replies, “While the tariffs issue has created a lot of difficulty in planning, as well as uncertainty around projects going forward, we’re benefitting from the surge of renewed patriotism and people wanting to ‘buy Canadian.’ We’ve been fielding a much greater volume of inquiries for our product.”

The inquiries are for Behlen’s two key products: Frameless and Rigid Frame building systems. For the former, the entire building is manufactured from heavy-gauge engineered panel — galvanized, galvalume, or stainless steel, depending on requirements — with an exclusive roll-formed corrugation process that provides the structural integrity. The wall system uniformly transfers the load to the foundation, eliminating the need for heavy foundations, piers, and piles. As hundreds of projects have demonstrated, the system can incorporate windows, overhead doors, glass, wood, precast masonry, and cladding materials to provide creative design flexibility.

Behlen’s Rigid Frame buildings offer solutions for complex projects, featuring appealing building envelope options such as Artspan insulated metal panels, which are a trending choice over cladding due to their superior thermal performance. These

panels are available in an assortment of profiles and colours for walls and standing seam roofs.

Lepper is cautiously optimistic about the new government in Ottawa. “If they’re true to their word and act on their promise to green-light so-called ‘nation-building’ projects, that will be huge for companies like ours because our focus is on providing structures for the mining industry,” he says.

Meanwhile, Lepper says, “We’ve got a great backlog of projects that will keep us busy through the rest of this year. But we are hoping for good things from Ottawa. Bill C-5 alone, which enacts free trade and labour mobility in the Building Canada Act, could be a game changer for our industry.”

Despite challenges, the landscape for opportunities in Canada’s metal roofing and cladding sector seems robust and even extends to a noticeable increase in new talent recruitment.

Robert Scales, director of education and training at the Roofing Contractors Association of British Columbia (RCABC), says, “We’re definitely still seeing record numbers of registered apprentices in the Architectural Sheet Metal Worker (ASMW) trade in B.C., and demand isn’t slacking. The RCABC Educational Foundation delivered more training seats for Architectural Sheet Metal Workers in 2024/25 than in any previous year.”

Further, the association has received requests from as far away as Saskatchewan to register apprentices in B.C. Meanwhile, in eastern Canada, Nova Scotia’s architectural cladder program, which was modelled on B.C.’s ASMW program, is reporting brisk business — all of which suggests that young apprentices expect a bright future in their chosen trade.

Cascadia Metals, a leading supplier of premium coil and sheet products – and innovations such as Cascadia Tex pre-painted steel, which delivers 3D visual effects – recently took a unique approach to inspiring the next generation of metalworkers. Cascadia’s Delta, B.C., branch donated over

10,000 pounds of various types of steel to Seaquam Secondary School for students in the machining and welding program. Some of the thicker metal donated is enabling students to practice welding different joints, similar to what BCIT students learn in the Welders’ Foundation program. With the thinner metal, Grade 8 students are making sheet metal pencil cases, while Grade 9 and 10 students are making sheet metal toolboxes.

This has enabled the school to divert money away from what would have been an expensive procurement of raw materials and invest instead in welding helmets and enough hand tools to equip eight welding booths, instead of the single booth it operated until last year. “We’re committed to investing in the future of our communities,” says James Gregoire, Cascadia’s assistant operations manager. “By donating materials to Seaquam Secondary School’s metal shop, we’re helping students explore their passion for craftsmanship while developing valuable, hands-on skills.”

The cautious optimism about the future of the industry, despite headwinds, is reflected in the large number of new products and technologies coming from cladding specialists. Case in point: Exterior Technologies Group, established in 2004 to address a gap in the Canadian market for high-performance exterior cladding solutions.

A recent example of how Exterior Technologies bridges that gap was provided by partner Kalzip, which developed an aluminum standing seam cladding system for the Boulevard Club’s west wing expansion in Toronto. This system was chosen for both the roof and exterior walls, and Kalzip rollformed the aluminum sheets on site to ensure a seamless installation. Over 2,600 square metres of 0.5-millimetre-gauge sheets were used, featuring a high-albedo reflective finish. The beauty of this lightweight system is that, at the end of the building’s life, the sheets can be “unzipped” and reused or recycled.

Rigid Frame dairy barn, Pennwood Dairy, Steinbach, MB.

Many products emerge from Longboard Architectural Products Inc.’s 350,000-square-foot aluminum extrusion plant in Abbotsford, B.C. For exteriors, they include cladding, screens and enclosures, and soffits. Interior products include ceilings, walls, and partitions.

But by far Longboard’s most popular product is wood-grain siding and soffits, powder-coated and treated with a wood-grain texture that looks like the real thing, even close up — and is amazingly resilient.

Chris Thomas, vice-president of sales and marketing for Longboard, says, “Over a decade ago, we supplied the John Paul II Pastoral Centre in Vancouver with a lot of our product, including wood-grain aluminum cladding, and we give

potential clients tours of the facility because even today the materials look brand new.”

More recently, Longboard supplied wood-grain aluminum soffits for the new Amazon building in Vancouver that extend indoors for a unique architectural appearance. It even supplied wood-grain boards to create a massive ‘bird’s nest’ sculpture within Vancouver’s Alberni Tower. “We cite this simply to show the versatility of the product,” Thomas says.

Sébastien Lainesse, general director of Honco, says that despite the reinstatement of tariffs on Canadian imports, “our company continues to demonstrate strong financial health. This resilience is the result of a deliberate diversification strategy implemented over the past several years, allowing

us to expand our activities across other regions of Canada and into international markets.”

Lainesse points out that by prioritizing U.S.based steel suppliers, Honco minimizes tariff exposure and avoids the volatility of global supply chains. Full ownership of critical supply chain components, including garage door hardware, also enables greater cost control and shields clients from the material price surges affecting much of the construction sector.

Lainesse continues, “Looking ahead, we anticipate a more challenging environment for the Canadian construction sector over the coming year, with longer project lead times and a modest market growth rate of approximately 1.3 percent.

Wood-grain aluminum soffits, Amazon building, Vancouver, B.C.

Multi-Sports Complex, Collège de Lévis, Lévis, QC

“Nonetheless, our medium-term outlook remains positive, with expectations for a more robust recovery by 2027. At the same time, we are seeing a significant increase in demand for resilient, high-performance buildings designed with sustainability and lifecycle environmental impact in mind. Honco buildings are uniquely positioned to meet this demand.”

Honco’s latest projects in Quebec include the Laval University Tennis Centre, valued at approximately $40 million, and set to establish Laval University as a leading destination for racquet sports. The new facility will feature 16 tennis courts, evenly split between eight indoor and eight outdoor courts. “To enhance the athlete and spectator experience, the centre will include a central show court with seating, a public plaza, and recreational and dining spaces,” Lainesse says.

Another new project is the multi-sport complex at Collège de Lévis, also valued at about $40 million. This facility features a high-quality, multi-purpose indoor stadium designed to support school, community, and public health–focused sports activities. The complex includes an indoor synthetic field, as well as two outdoor synthetic fields, which can be subdivided into three seven-a-side fields suitable for a wide range of sports.

Companies such as Arcnova are busy this year providing solutions for all types of structures. Arcnova specializes in architectural panels and metal roofing, with engineering, fabrication, and installation all handled in-house – providing greater control over the supply chain. The company is currently overseeing more than a dozen projects, ranging from educational and extended care facilities to residences and storage buildings.

For The Quad Phase 3 in North York, Arcnova’s ACM panels provide a sleek, modern look with excellent weather resistance for the project’s two distinctive buildings, while the metal siding enhances the buildings’ structural integrity and long-term resilience. Arcnova’s early involvement in the project ensured the final outcome aligned with ARK architectural’s design vision and practical requirements. Similarly, Arcnova’s ACM panels give Queen’s University’s McArthur Hall project a sleek, contemporary appearance while offering excellent durability and low maintenance.

Upcoming for Arcnova is the Queen’s University Agnes project, set to begin later this year. This boldly designed addition to the university campus will feature a unique combination of metal siding and terracotta sunshades, creating a visually striking appearance. The metal siding will provide durability and a modern aesthetic, while the terracotta sunshades will be strategically integrated to enhance energy efficiency by reducing solar heat gain.

Finally, substandard knockoff products from China have long been a problem for Canadian manufacturers. This includes siding, where cheaper versions often look as good as legitimate alternatives but quickly fade and fail to meet performance standards.

At NewTechWood, a corporate realignment in which the company regained control of inventory and distribution marks an important step toward mitigating the prevalence of offshore products. “Initially, relying on a distributor enabled us to grow faster, but now that we’ve assumed control of our inventory, we’ve actually been able to reduce our prices by up to 30 percent,” explains NewTechWood owner Michael Richard. “We’re now considered mid-range in price, and this not only opens up many markets but also gives clients the opportunity to afford our tough, fade-resistant siding rather than compromising on quality.”

Additionally, Richard and his team have been working for the past few years to make all their siding products CCMC-certified. “We expect the certification to be finalized later this year, which will make us the first company in Canada using composite materials for siding to be certified,” he says. A

NewTechWood’s fluted siding in Teak.

Cooking Up A Storm

Innovative surfaces,

seamless

curves, and versatile designs redefine modern kitchens

by LAURIE JONES

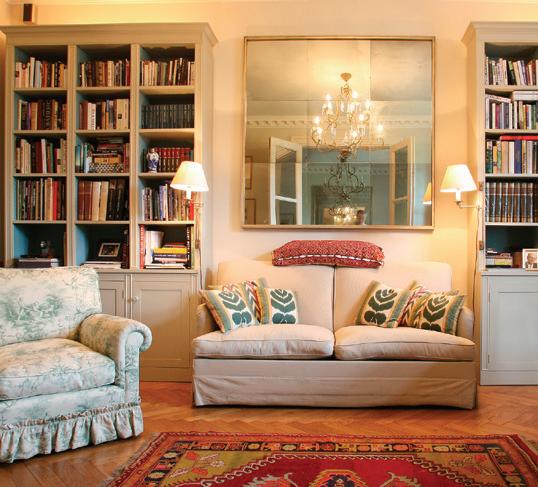

Bold designs, elegant colour palettes, and a sense of relaxation are defining kitchen trends this year, as manufacturers and suppliers unveil a wide range of options for designers and clients alike.

Silestone by Cosentino proudly unveils Bronze Rivers, the latest addition to its Suma colour series – a collection known for offering elegant, marble-inspired surfaces at an accessible price point. This new design features a white marble base enriched with dynamic veining in earthy gold and grey tones, delivering a timeless yet contemporary aesthetic. “This is an exciting addition to our Suma colour series, which includes our more affordable marble-look selections,” says Jesús Carreño Carrillo, general manager for B.C.

Previously available in four designs – Siberian, Persian White, Linen Cream, and Motion Grey – the Suma series is celebrated for its versatility. “Whether the design concept is classic, rustic, or contemporary, the Suma series brings warmth and brightness to any space,” adds Carreño Carrillo. Bronze Rivers, the fifth colour in the series, offers a refined, natural look that complements a wide range of interiors while maintaining affordability.

Caesarstone has introduced its new ICON line, a groundbreaking new category of advanced fusion surfaces that are entirely crystalline silica-free and crafted using a proprietary blend of innovative, responsibly sourced, and recycled materials.

“Caesarstone ICON is a transformative moment for our brand and the industry,” says Ken Williams, president, Caesarstone Canada. “This innovative formulation is the result of years of research, development, and an unwavering

commitment to progress.” The ICON collection introduces a new level of visual sophistication. Engineered for both beauty and performance, these surfaces feature enhanced transparency, rich dimensionality, and a tactile esthetic that captures and reflects light like never before.

New designs from the ICON Collection feature Clearlight – a bone-white base threaded with delicate, chalk-like veining; Wild Storm – an opalescent grey marbling and golden-brown, foam-like streaks; and Ocean Sage – a smoky grey background with dark, seaweed-toned veins.

Bronze Rivers marble-inspired surfaces from Silestone by Cosentino.

Ocean Sage – part of the ICON collection from Caesarstone.

FENIX® innovative material is anti-fingerprint and highly resistant to scratches, making it ideal for kitchens fenixforinteriors-na.com

J0029 BIANCO MALÉ J0748 BEIGE ARIZONA

Formica Group introduced its new patterns and woodgrain designs to its Formica Laminate portfolio. Designed to meet the evolving needs of modern interiors, this latest offering – including eight new woodgrains and six new patterns – delivers a curated selection of organic textures and dynamic patterns, ideal for a broad range of commercial and residential spaces.

“These updated laminate designs reflect our commitment to delivering designforward, highly functional surfacing solutions,” says Meghan Howell, North American design and creative director at Formica Group. “These new styles were developed to inspire creativity while supporting the practical needs of modern design. We’re excited to share a collection that brings warmth, texture, and realism into design environments across all industries.” The collection provides broad applicability, from casework and furniture to feature walls and cabinetry.

The Woodgrains line features Natural White Oak, Fumed Maple and Silver Maple, Brun Refined Hickory and Natural Refined Hickory, Coco Tamarind, Ash Riftwood, and Natural Riftwood.

The Schluter countertop system offers functional and aesthetically pleasing designs in their tiled countertops, incorporating a variety of components that work seamlessly together, with various profiles to suit any kitchen. The Schluter Rondec-CT and Schluter Schiene-Step serve as edge protection and transition elements, providing a polished and elegant finish to the countertop edges while safeguarding them from damage.

“The double-rail design of the Rondec-CT profile allows for an inset of tile to match the counter tile or act as an accent,” says Tod Valickis, global product manager. “On the other hand, Schiene-Step is specially designed to create a smooth metal edge, offering a visually appealing and durable edge protection, and eliminating the need for bullnose tile.”

Cove-shaped profiles like Schluter Dilex-AHK are used at counter-to-wall transitions, replacing grout lines for a hygienic and easy-to-clean solution. These profiles eliminate excessive grout lines, offering a seamless and visually appealing transition between the countertop and the wall.

CLEVER CABINETRY

NIICO Millwork Group, makers of bespoke and custom cabinetry, are proud of their ability to create products from doors to cabinets, with hand-selected woods and matching grains, all the while meeting the current trends such as rift white oak. “We follow the trends in Europe, particularly in Italy, which give us an insight into coming styles that we can bring back to North America,” says Joseph Marcantonio, vice president, operations.

Marcantonio explains they use different types of raw logs, and select particular veneers depending on the size of the job. “We are particular about choosing high-quality grades of the wood. Then we do all the grain matching for the cabinetry in the kitchen and other spaces in the home. We look at both the vertical and horizontal grain matching – which is called an architectural layup –then we try to achieve a nice flow and character of the beams of the wood to flow throughout the kitchen, or the whole room.”

Marcantonio notes that NIICO Millwork Group was acquired by Cortina Kitchens and moved to a brand-new facility in North York, Ontario, featuring an 89,000-square-foot manufacturing space. The company will soon open a 6,000-square-foot showroom in the Castlefield Design District in Toronto. This will be the largest and one-of-a-kind showroom in the Greater Toronto Area, designed in collaboration with Michael Lambi of Michael Lambi Interiors.

When space is a premium asset, which applies to many new builds, particularly apartments, corner cabinetry storage tricks are greatly welcomed. The Rev-A-Shelf Cloud two-tier organizer by Richelieu increases shelf space for blind corner cabinets, with optional soft close. The Cloud unit was designed for either right- or left-cabinets where the door opens the opposite way. It is available in 15-, 18-, or 21-inch openings, and the shelf can support up to 45 pounds. Available in grey, maple, or Orion grey surface, the Cloud unit features a round wire design.

Another useful option from the Richelieu collection is the Opla-Top table extension mechanism. This aluminum unit is hidden inside a small cabinet, waiting for a topper supplied by clients or customers. With a width of 17 ¾ inches to 35 7/16 inches, the unit works for a variety of surface requirements.

OPENING DOORS

In today’s homes, flexibility is everything, and Blum’s Revego pocket system delivers it in a way that’s both elegant and effortless. “This pocket system allows entire spaces – like kitchens, offices, living rooms, laundry rooms, and bedroom areas – to completely disappear behind sleek, full-height doors,” says Lucy Traetto, marketing representative. “With just a gentle push, the doors slide into discreet pockets, opening up the room when needed and closing it off just as easily for a clean, minimalist look.”

Traetto notes what stands out is how Revego is available in both single- and double-door versions, making it incredibly adaptable for different layouts.

“Because it’s a fully integrated, preassembled system, installation is surprisingly straightforward – something very important when planning complex interiors.”

Blum has clearly thought through every detail, from the smooth motion to the handleless design using Tip-On technology. “It’s a clever solution for open concept living, especially when you want to keep things hidden but still easily accessible,” says Traetto. “Revego isn’t just about hiding clutter, it’s about creating versatile, well-designed spaces that can change throughout the day. It’s a perfect example of how thoughtful hardware can support modern living in a beautifully understated way.”

CUTTING-EDGE HARDWARE

Grass Canada Inc.’s selection of innovative hardware continues to provide customers with cutting-edge designs to accommodate a changing path requiring lean production, minimal inventory, and minimal hardware from suppliers. “Our goal is to provide clients with a very simple format for production for cabinet shops to be able to do two applications with one runner or slide,” says

Woodgrains line in Natural White Oak from Formica.

Vionaro drawer system from Grass Canada.

Blum’s Revego pocket system.

Opla-Top table extension mechanism from Richelieu.

George Pavlov, Ontario sales manager. “This has been our biggest story for over 10 years, to be able to empower shops, whether they are working with wood or steel drawers, without having to incur large amounts of inventory.”

The products Grass notes include drawer options ranging from 11 inches to 30 inches, and slides able to handle 40 kilos to 70 kilos. “This gives designers the ability to be versatile with wider drawers, bigger applications, and larger drawer fronts. We can go from 72 to 250 millimetres, or 10 inches to 30 inches, which could be incorporated in everything from kitchens to commercial designs.” He adds that while the company has offices all over the world, Grass Canada primarily deals with the Canadian market. “In the past, we did millwork for American installations, including universities, and had tremendous feedback for providing quality materials.”

Häfele’s Twenty Five collection features simple, clean lines, smooth curves, and illustrious finishes. For kitchen upgrades, the 81-piece design collection of handles, knobs, and pulls blends easily into modern, midcentury, and industrial designs.

Adding to the ambiance of sleek design options for kitchens is Häfele’s Elemental Base Pull-Outs. This high-quality wood accessory is welcomed by both designers and installers, as its smooth-moving drawer slides can be incorporated into traditional kitchen designs. Available for both open-shelf storage and canister options, Elemental can be applied to both face frame and frameless cabinets.

DOWN WITH DESIGN

The Gemini Acero concept kitchen from Laminam and Andrea Federici brings extraordinary application potential to ceramic surfaces. With panels, doors, countertops, internal accessories, and drawer linings, the Gemini collection brings a sense of continuity.

One of the unique features of Andrea Federici’s kitchen is the use of twO by Laminam surfaces, with a thin, two-millimetre thickness that allows them to be curved, transforming the ceramic slab from a two-dimensional material to a three-dimensional one.

An example of this versatility can be seen in the design of the front portion of the kitchen, which features a dual curve clad entirely with a two-millimetre slab, and thanks to the lightweight nature of twO, the drawer and door fronts are also covered with this material.

Additional uses of the Gemini Acero in different thicknesses include countertops, the cutlery rack, drawer linings, and even a spice organizer box.

With a blend of design talent and state-of-the-art products, Cuisigam partnered with Fenix Nero Ingo to renovate a family home in Quebec. The client wanted to incorporate black material for cabinets with wood inserts; at the same time, they wanted the kitchen to be functional, airy, and include significant storage space.

Fenix Nero Ingo’s ultra-matte effect and soft-touch texture provides a modern yet warm look. The product is durable, fingerprint resistant, and matches perfectly with stainless steel appliances.

“At Cuisigam, we love Fenix materials” says Sacha Lajeunesse, interior designer and co-owner of Cuisigam. “It’s soft touch, durability, anti-fingerprint properties, and the ability to thermally repair micro-scratches on the surface make them unique. For our team, Fenix surfaces are truly the industry’s best matte products.” A

THE QUIET EDGE

DOOR ACOUSTICS SYSTEM

This low-profile hardware and retractable seal system for wood doors up to 100 kg (220 lbs) offers effective sound attenuation while blocking odours, drafts, and light. Ideal for pocket and wall-mount sliding doors, these smooth automatic seals create a quiet interior perfect for office spaces and residential kitchens. Open the door to a peaceful environment.

Twenty Five Collection – Knurling

Twenty Five Collection – Mola

The Big Switch

Fast-changing electrical and communications systems drive new challenges and solutions

by NATALIE BRUCKNER

From smart buildings to sustainable energy, the electrical and communications systems sector is evolving fast, and complexity is rising just as quickly.

With everything from feasibility to future-proofing on the table, expert guidance is more critical than ever.

That’s where the experts at WSP are stepping up by helping clients make sense of a rapidly expanding landscape of options, technologies, and expectations.

“The solution can be as easy as hiring a consultant for a feasibility study, or a digital vision for their organization,” explains Ross Taylor, national leader, Smart Places at WSP in Canada. “That can create a starting point from which they can evaluate further options, and investments.”

Taylor adds that they’re hearing from some clients that a proper consultation process isn’t always taking place, which means they may not be getting full value from their investment in SMART.

He cautions that technology for technology’s sake doesn’t lead to successful outcomes for clients.

“To allow for proper budgeting, early engagement with the client is necessary to explore technologies,” Taylor explains. “It can be particularly challenging, but important, to uncover workflow issues that could benefit from technology enhancements, especially when working with non-technical client stakeholders.”

A key challenge that Taylor is seeing lies in ensuring project planning accounts for the broader context from the outset, something he says is often missed in the industry. “Many projects aren’t greenfield developments and therefore involve additions to existing buildings, campus expansions, or partial renovations, which means we need to consider how new technologies will integrate with the surrounding built environment and existing infrastructure,” he says. While WSP aims to leverage innovation to address these challenges, Taylor adds that delivering a seamless user experience remains equally important, particularly as people move between new and existing areas.

INNOVATION INSIGHT

While WSP highlights the need for thoughtful planning and integration from day one, MCW underscores the importance of pairing innovation with proven, practical systems that stand the test of time. New technologies are often seen as a silver bullet to solve all our problems, but experts at MCW say that market proven, reliable, appropriate, and maintainable systems actually provide the real world solutions that most buildings rely on.

“Modernizing electrical systems is essential to fully leverage renewable energy while reducing operational costs and carbon emissions,” says Graham Lovely, partner at MCW Consultants Ltd. “We specialize in designing and upgrading building systems that seamlessly integrate with clean energy solutions, ensuring long-term sustainability and resilience.”

Lovely adds that upgrading electrical systems is not just about reducing carbon emissions, it is about optimizing energy use, lowering operational costs, and strengthening infrastructure. “With increasing

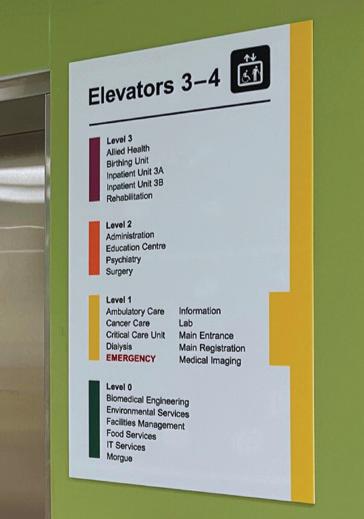

Ksyen Regional Hospital, Terrace, B.C.

PL AY I NG TOGETHER TO GIVE SUPPORT FOR BC’S KIDS

On behalf of the organizing committee, we would like to thank all participants and supporters of the 30th Annual Building for Kids Golf Classic benefiting BC Children’s Hospital, which took place on Thursday, July 17, 2025.

The tournament brought together friends, colleagues, and industry partners for a day of friendly competition and networking at Morgan Creek Golf Course in Surrey, BC. With perfect summer weather and an enthusiastic field of 148 golfers, the atmosphere was nothing short of celebratory.

This year’s tournament successfully raised $240,000, adding to the tournament’s cumulative total of $4.6 million to date. Funds raised will support the Heart Centre at BC Children’s Hospital, ensuring kids with heart conditions have access to the best care possible.

Also thank you to Award Magazine for providing this ad each year to thank all participants and sponsors. For a full list of supporters and to learn more about the event, please contact golf committee chair: Gavin Yee at GYee@ventanaconstruction.com.

Phoenix Truck & Crane

Thinkspace Architecture Planning

Interior Design Ltd.

Jani-King Vancouver-Fraser Valley

Bobcat of Vancouver

STRIVE Recruitment

Escape Fire Protection Ltd.

Midvalley Rebar

Northern Building Supply Ltd

Thermo Design Insulation Ltd.

Ontario’s electricity demand expected to surge by 75 percent by 2050, aging power infrastructure faces increasing strain. Meeting this challenge requires innovative solutions that deliver reliable, low-carbon energy to support growing urban and building electrification needs. AtkinsRéalis, a leader in engineering and nuclear technology, is driving one such solution through its $450-million contract with Ontario Power Generation to deliver the Darlington New Nuclear Project’s first small modular reactor (SMR). The 300-megawatt BWRX-300 SMR will power approximately 300,000 homes with clean, stable electricity. AtkinsRéalis is providing comprehensive engineering, project management, and licensing expertise to ensure the project’s success by 2030. By advancing this kind of technology, AtkinsRéalis is helping modernize Ontario’s energy grid and enabling architects and planners to design future-ready, sustainable communities powered by innovative, resilient energy infrastructure.

Complementing this big-picture approach, Pratus Group, in partnership with Quasar Consulting Group, is focused on the next critical piece of the puzzle: optimizing how individual buildings manage and use power to drive efficiency and reduce environmental impact. As electrical demand intensifies, Pratus is helping clients confront the biggest environmental contributor: how buildings source and use power.

Their work spans diverse sectors, including data infrastructure and health care. At UTSC’s Myron and Berna Garron Health Sciences Complex, Pratus is guiding LEED v4 and energy performance compliance, aligning design with the university’s Tri-Campus Energy Standards. Meanwhile, the Mission Flats project deploys rapid infrastructure upgrades to support 5MW of high-density computing, balancing aggressive timelines with mechanical precision and energy modelling.

Another example is FirstOntario Centre in Hamilton that is being transformed into a premier sports and entertainment venue. Pratus is delivering mechanical and electrical best practice commissioning services to ensure the upgraded systems – including hospitality, structural, and circulation enhancements – operate at peak performance.

MEETING ICAT DEMAND

In B.C., the demand for Integrated Communications and Technology (ICAT) systems has grown steadily, particularly in the public and entertainment sectors. MCW Consultants has observed three key trends shaping the industry: the increased adoption of security systems with built-in cybersecurity policies, a growing preference for unified platforms that simplify monitoring across multiple systems, and a rising demand for higher-speed applications using Category 6A and fibre media.

MCW Consultants ICAT team has been actively involved in a range of projects that reflect these trends. This includes upgrades to video surveillance and access control at three casinos, new structured cabling and security systems for the Langley Indoor Soccer Field and Vancouver Aquatic Centre, and communication design services supporting multiple initiatives at YVR Airport.

The shift toward faster, more secure, and integrated systems isn’t just a trend. It’s a response to evolving operational needs, as clients across industries prioritize efficiency and resiliency in their technology infrastructure. A

Reinforcing Growth Nationwide

Most, if not all, people in Canada’s reinforcing steel industry recall that in 2018, when 25 percent tariffs on steel and 10 percent tariffs on aluminum were imposed by Washington, the Canadian steel and aluminum sectors experienced a downturn.

So even though the latest wave of tariffs – and Ottawa’s decision to impose counter-tariffs – came as no surprise, rebar specialists again prepared for headwinds, the overall sentiment being that North America needs steel and aluminum regardless, and tariffs will only add costs to consumers.

The good news is that renewed patriotism in Canada seems to have bolstered domestic steel manufacturing. In April, ArcelorMittal Dofasco’s activity peaked at 46 percent, reflecting efforts to stabilize production lines in response to market pressure. Algoma Steel’s activity peaked at 57 percent in February,

Tariffs and politics test the steelreinforcing industry, but business stays strong

by ROBIN BRUNET

indicative of its strategic alignment with anticipated upgrades in housing and infrastructure development initiatives. Also, the Ivaco Rolling Mills plant showed consistent productivity, maintaining an impressive activity level above the mean up until May.

But Canada manufacturing alone isn’t able to absorb the negative impact of tariffs. The question is, how severely will the rebar sector be impacted this time out?

Ron McNeil, CEO and co-founder of LMS Reinforcing Steel Group, says, “We’re in a difficult situation for fixed-price contracts, and it’s difficult to predict prices, to say the least. However, Washington is only one element of the challenging market we find ourselves in. B.C. is weak, Alberta is somewhat better due to growth in rental construction, and overall, there are some opportunities in infrastructure. But some sectors are undergoing a normal down cycle – one result being thousands of new condo units going unsold due to high costs and product saturation.

Cutting rebar on the Oakridge South redevelopment project.

“It’s something we simply have to ride out, and I’ve been in this business long enough not to make predictions about what could happen, either positively or negatively. We’re fortunate to be keeping busy, and our efforts to support new talent via our academy are paying off. We’ll keep looking for new ways to attract newcomers, just as we will be ready to take advantage of project opportunities that arise despite the current circumstances.”

The nearly complete Pattullo Bridge and Oakridge South redevelopment are just two of LMS’s multi-year projects. The academy McNeil refers to is LMS Academy, an in-house school developed by McNeil and his colleagues to support team members pursuing continued education. The academy supports new hires as well as apprentices preparing for the Red Seal exam, and offers trade-specific instruction, extensive safety training, specialized courses for ongoing development, and leadership and management training.

Duane Kotun, director of administration at Sherwood Steel in Edmonton, agrees that the current state of tariffs poses challenges to the rebar sector. “Most of our steel is sourced domestically, but as we speak in June, domestic suppliers have already raised their rates by about 12 percent.

“However, we’re performing about the same as last year, which, along with 2023, were our best years ever. School projects continue to be solid, and we’re in the midst of working on three water treatment plants in Alberta, one of which required 700 metric tonnes of rebar.”