TECHNOLOGIES POSITION

Architectural Design Position +Technical Detail Study Purpose

TECHNOLOGIES POSITION: Advancing Glulam and Creating a better controlled environement

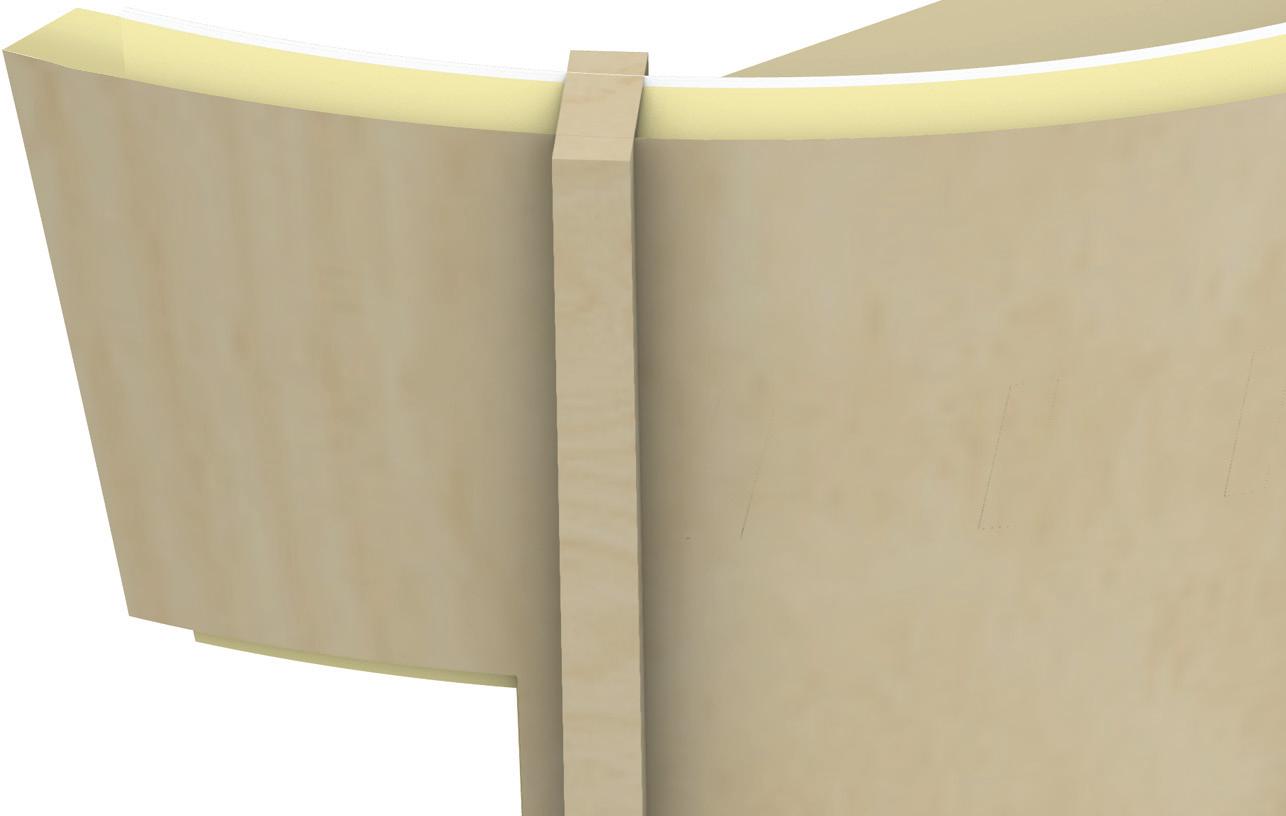

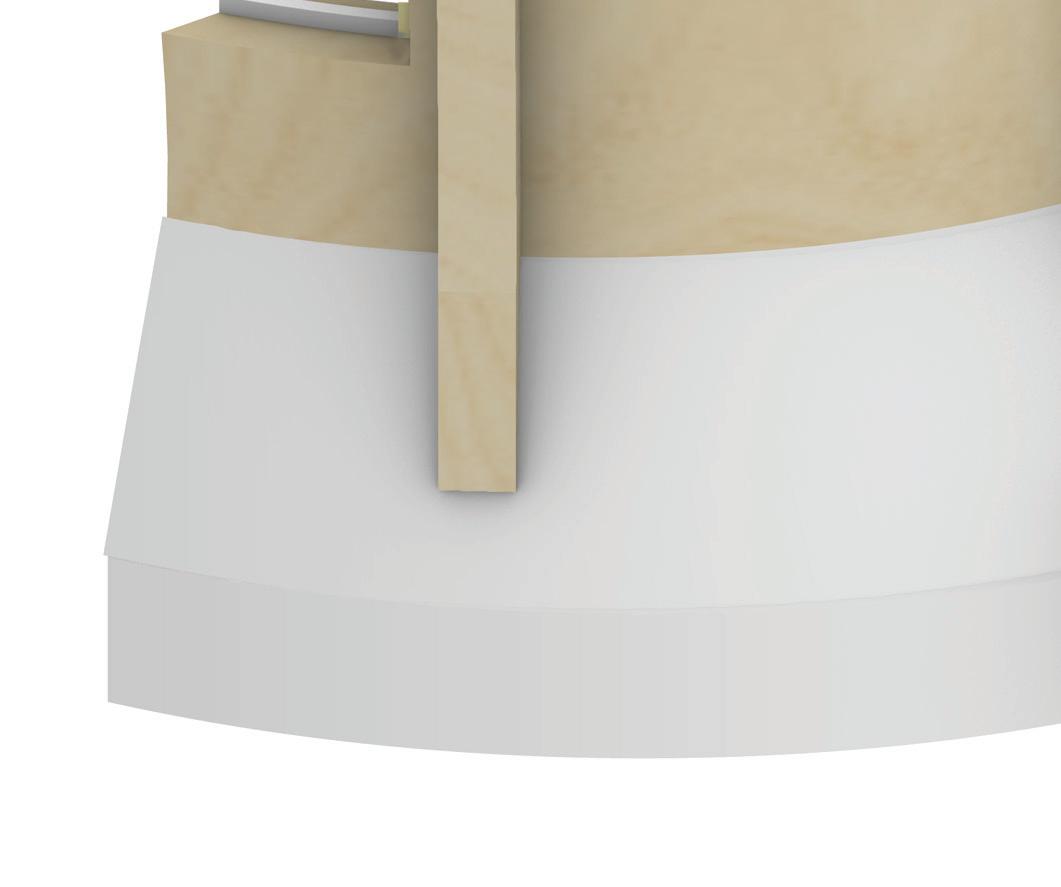

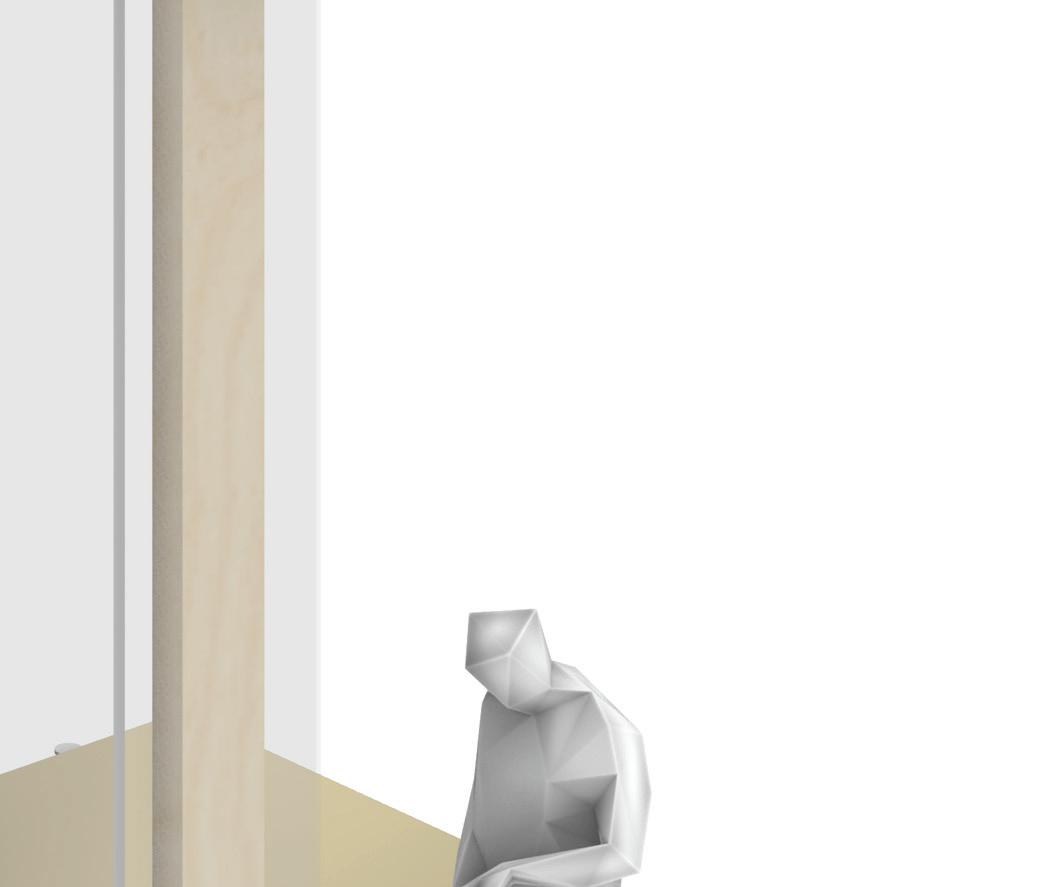

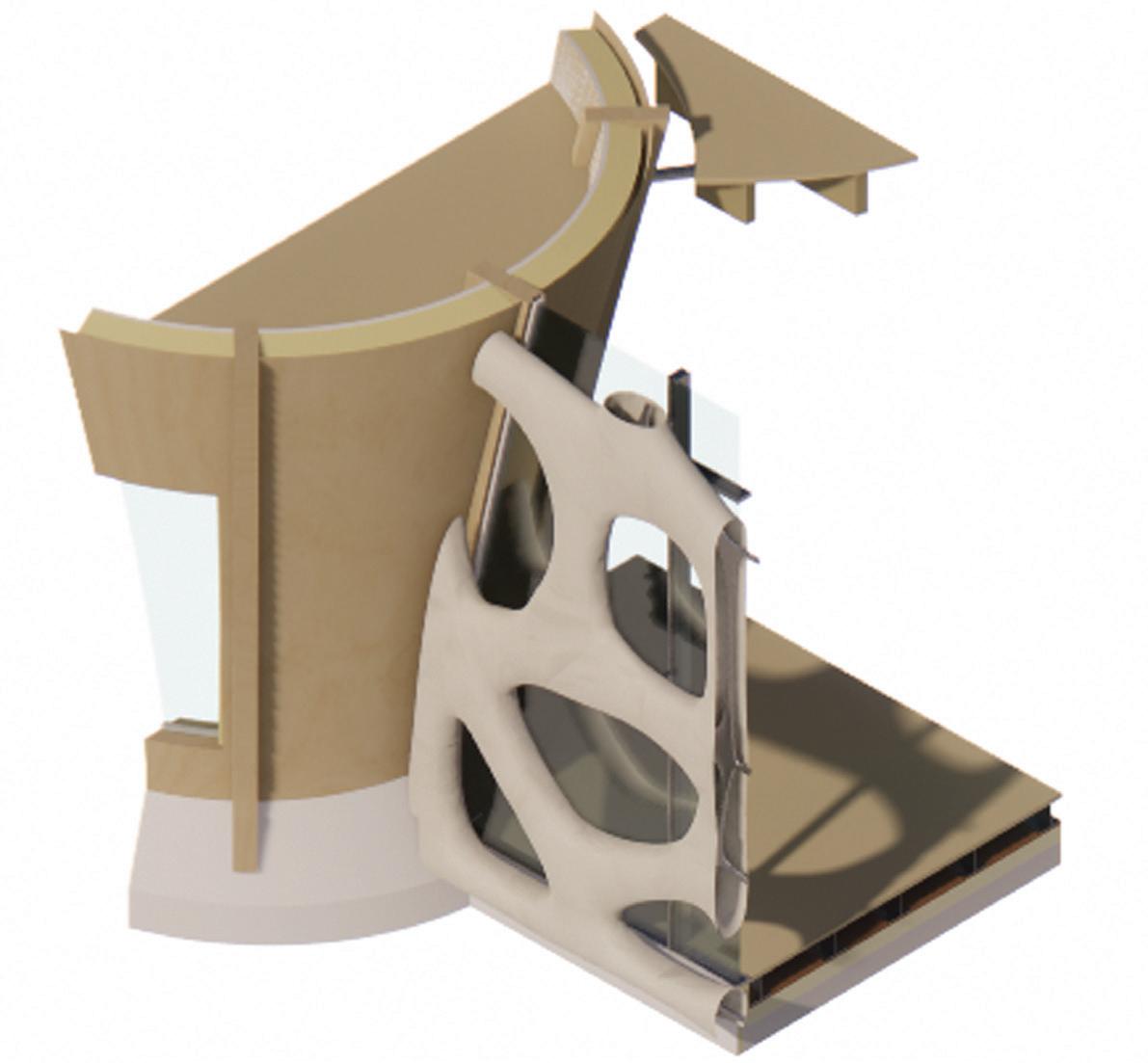

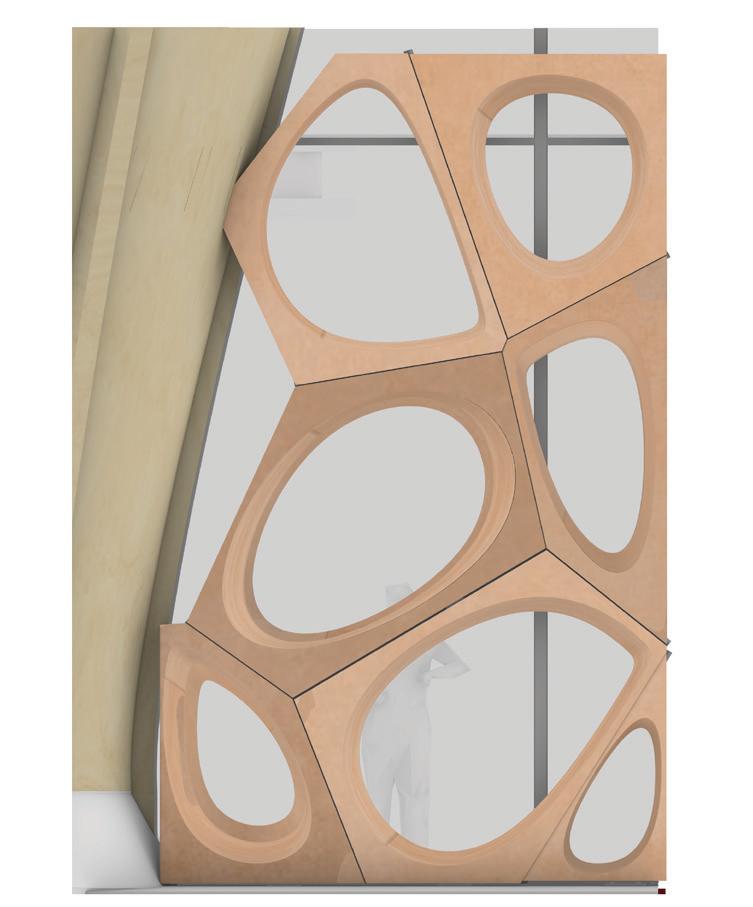

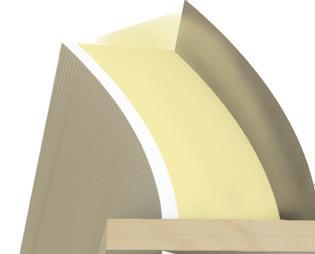

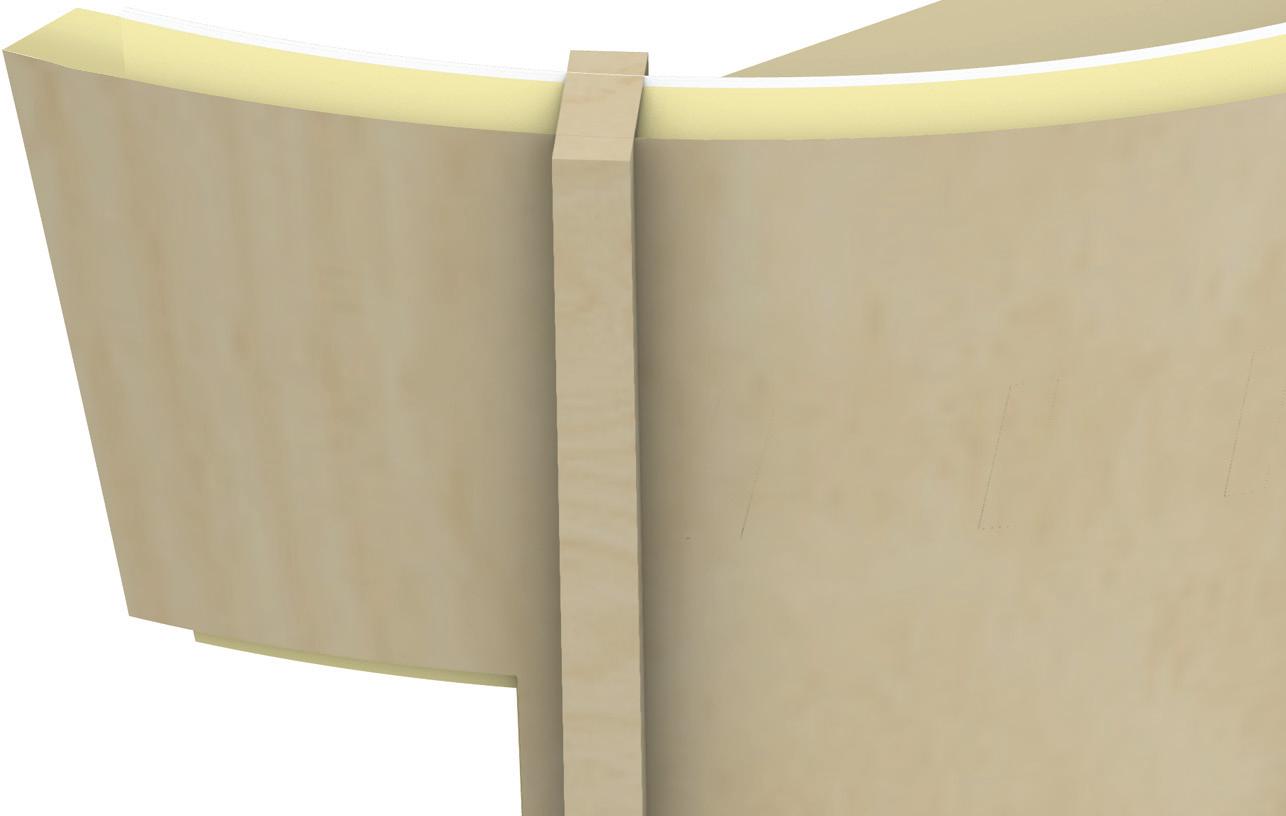

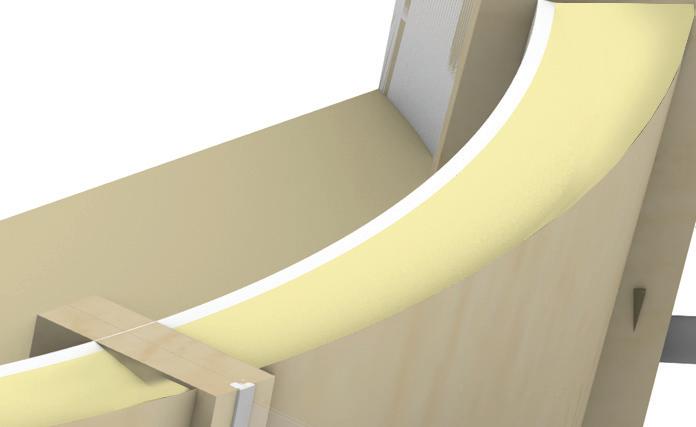

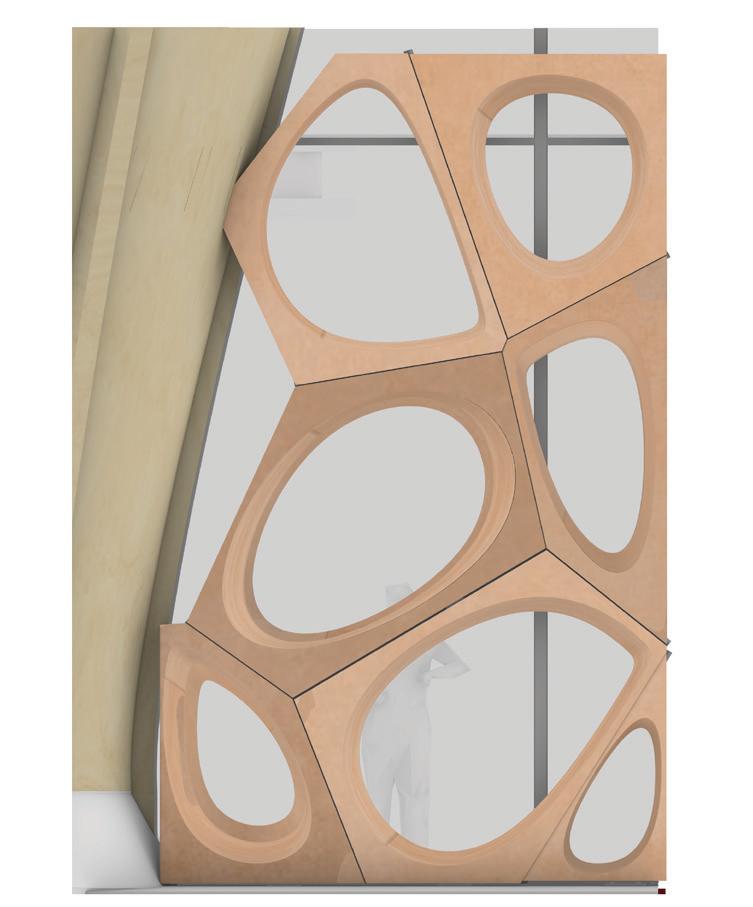

The project explores the impact of glulam structure on pacients affected by mental health and their cognititve response to a well controlled environment. Developed as a phylosophy of tectonics, the structure is an integrative part of the function, aiming to create an unstandardized healthcare setting. Therefore, the structural system is composed of pre-fabricated elements. The envelope system- glazed wall- acts as a shell for the structure (the three cone structures which accommodate the therapy spaces). Given the large amount of glazing, for the prototyping stage shading devices will be explored to regulate the microclimate and reduce operational costs for heating/ cooling. The iterations will explore different types of shading devices based on their capacity to create a controlled environment and their aestethic value.

MATERIALS

CLIMATE CHANGE

MATERIALS (NET ZERO EMBODIED CARBON)

The building system considers climate emergency with regards to both embodied carbon and operational carbon. The carbon footrpint is reduced through the use of local timber and minimal use of concrete for basement and ground floor slabs (+ foundations). The use of local materials minimises operational carbon footrpint caused by tranportation while encouraging ethical sourcing. Prefabricated components allows future building reuse and material (components) up-cycling.

NET ZERO OPERATIONAL COSTS AND WELLBEING

The aim for the prototyping stage is to design a shading device in order to regulate microclimate and decrease the operational carbon costs.

SUSTAINABLE LIFE CYCLE COST

Given the robustness of detailing, glulam structures have a life span of over 100 years; however, due to high humidity, glulam may be exposed to decay due to wet rot, which can be stopped through timber isolation, additional solid sticks/rods. To add, designed as prefabricated components, the structure allows dissably and transportation to a different site.

BUILDING AND LIFE SAFETY

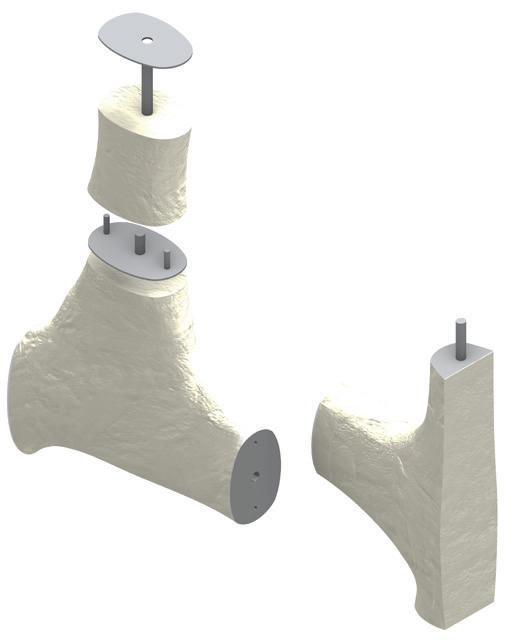

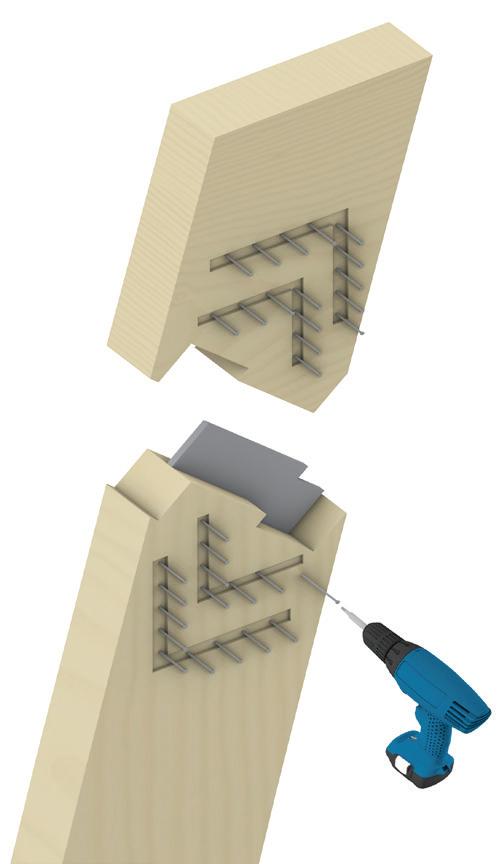

Given its dimensional stability, glulam does not bend or twist, needing minimal reinforcement. Yet, for stability steel elements are used: bolts, steel plates and drift pins. Furthermore, reinforcement may be increased through additional FRP (fibre reinforced polymer) materials (for stifness) allowing possible reduction of cross section.

FIRE SPREAD PREVENTION

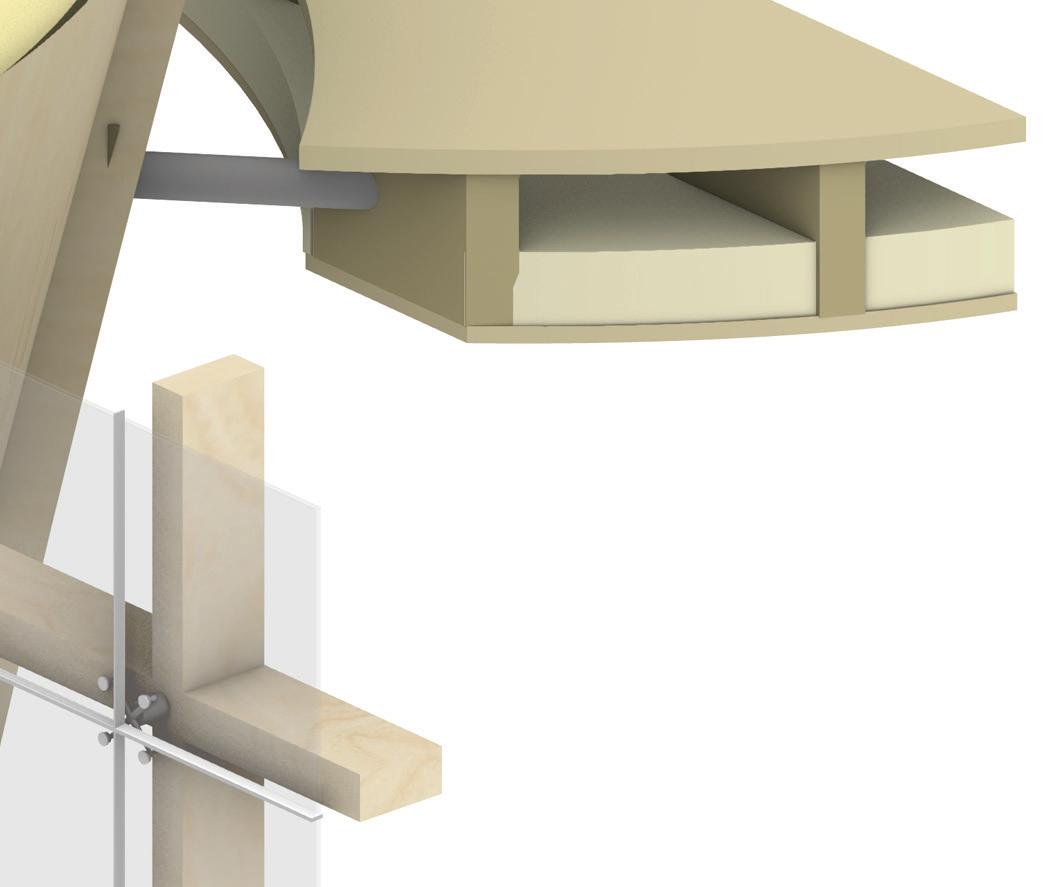

Timber offers a distinct advantage in case of fire as it chars on the outside, while retaining its strenght. To prevent fire spread and smoke penetration, fire stops and cavity barriers are placed in the external cavities and at the slab edge- galzed wall interface. Given the regulations in England, the cavity barriers are designed to have a minimum of 30 minutes integrity and 15 minutes of insulation, 15mm wide and spaced at 10m. Compartment floors achieve 90 minutes fire resistance.

CONSTRUCTABILITY

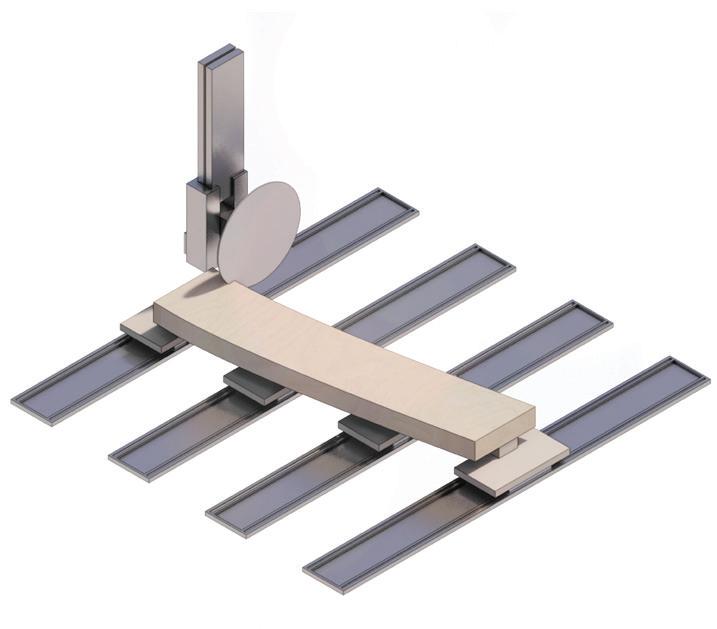

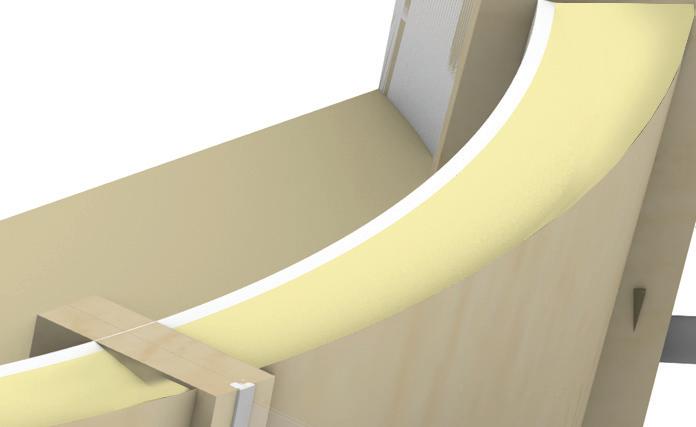

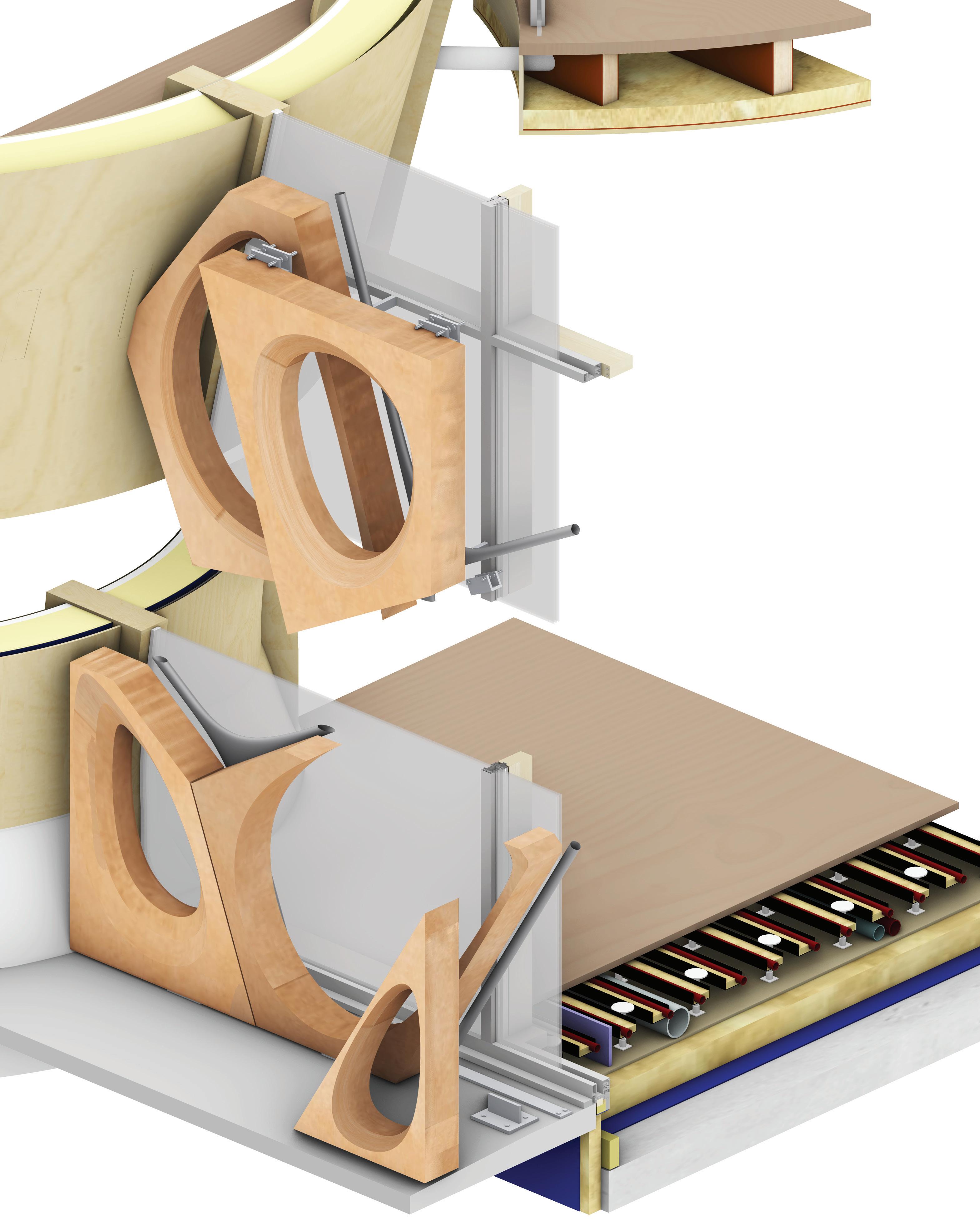

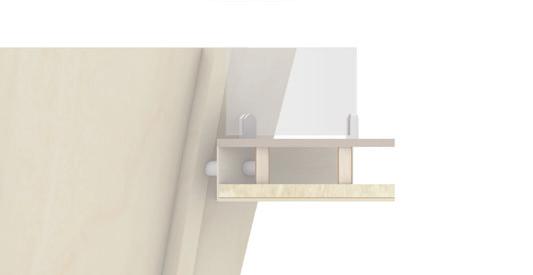

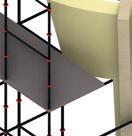

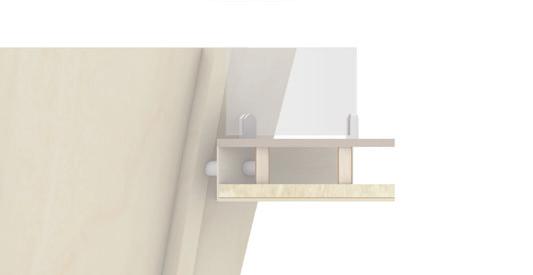

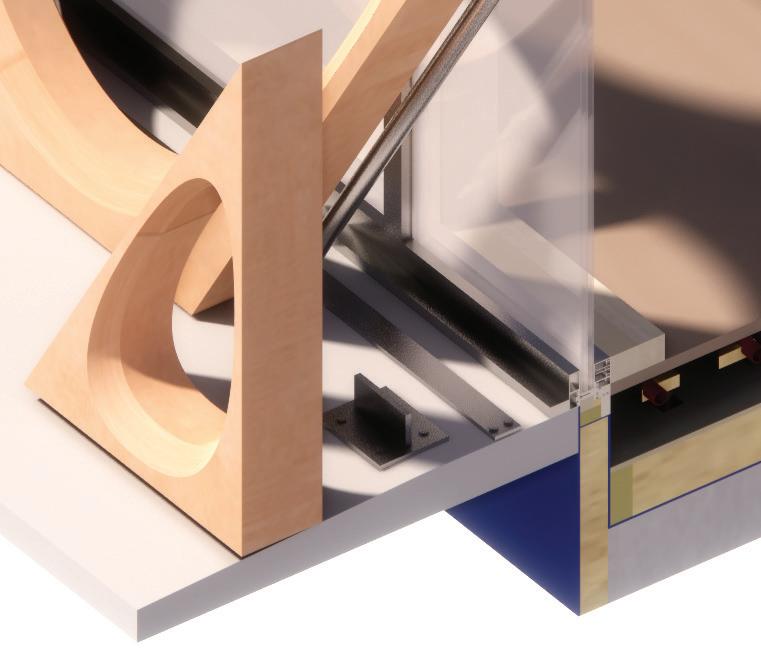

A. Spider bracket system for fixing the double-glazed window panels. Spider brackets being commonly used for single glazed units, they require an additional seal

ASSEMBLY FROM STANDARDIZED COMPONENTS

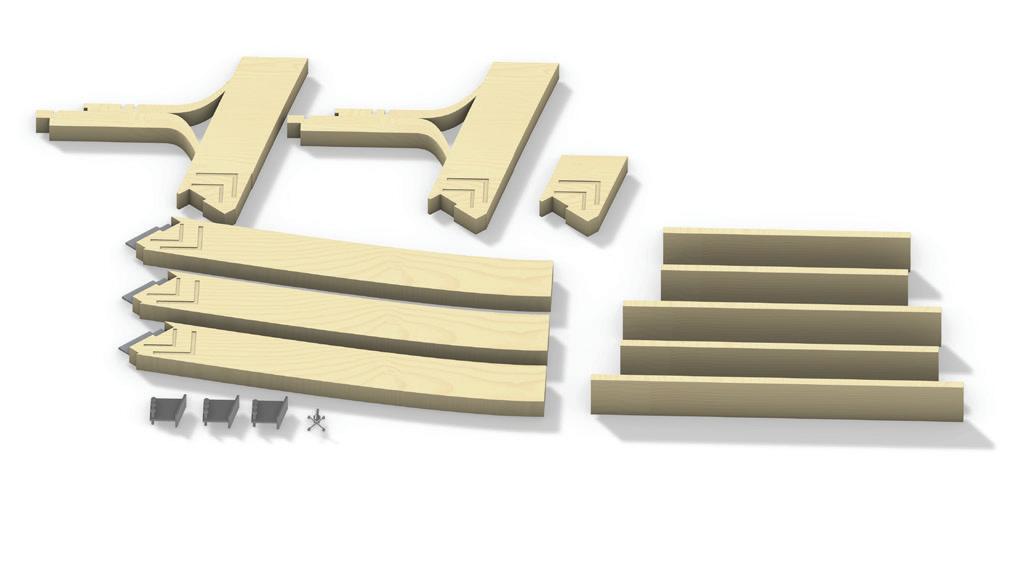

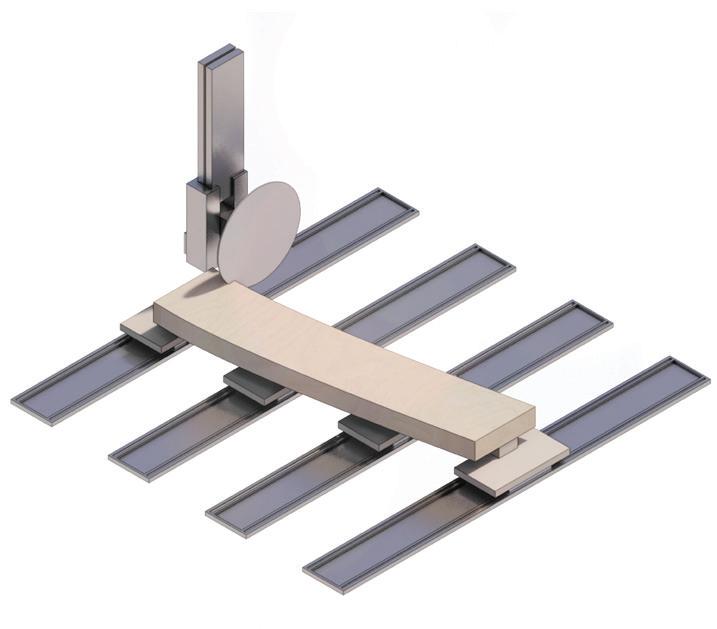

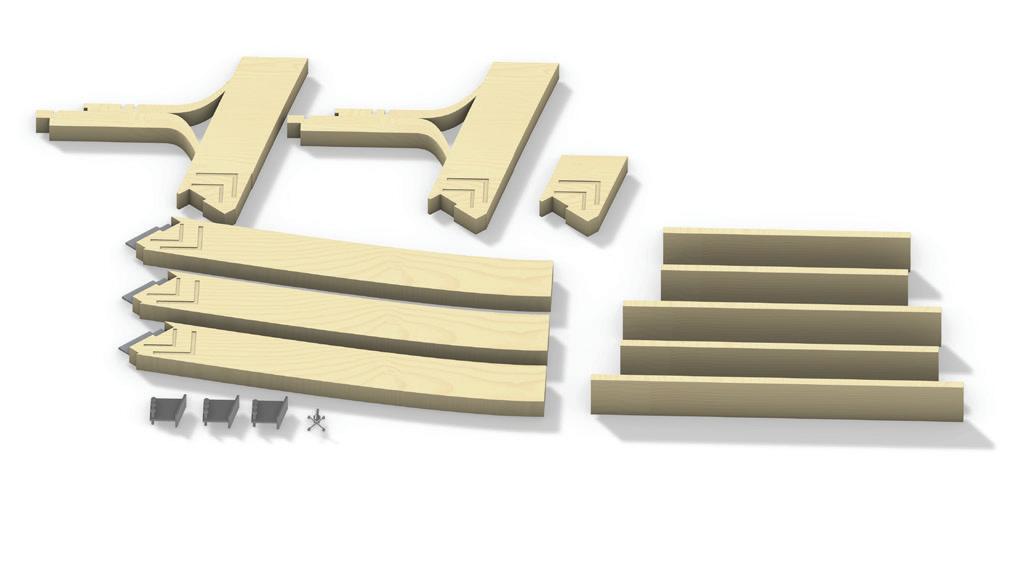

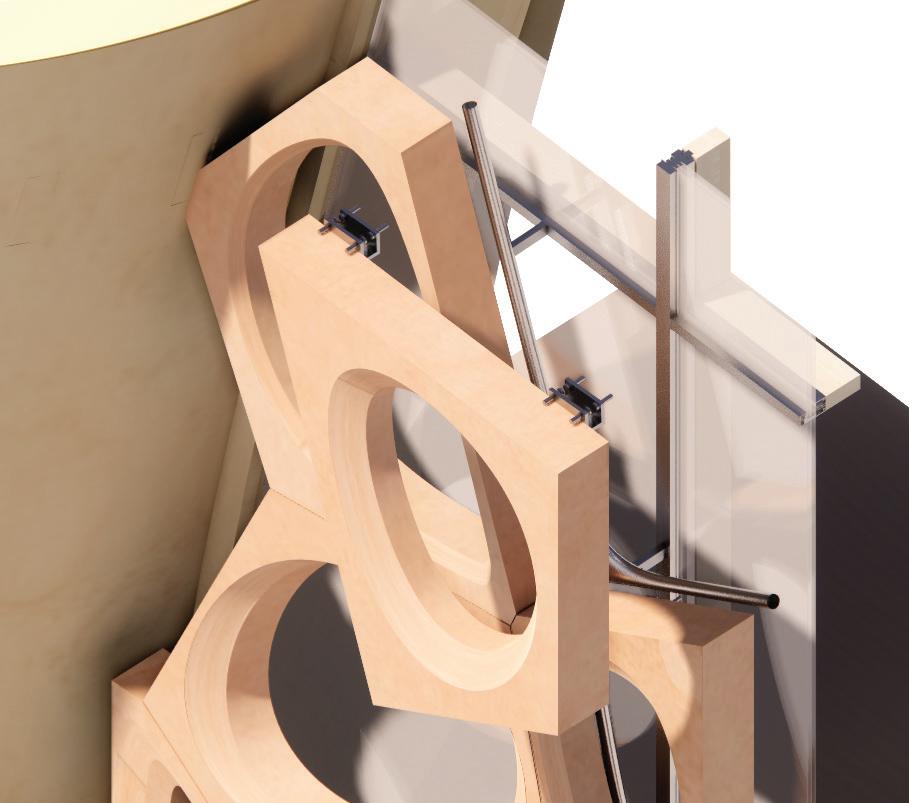

The building system consists of a series of pre-fabricated components, with in-built nodal and steel connections, which can be easily assembled on site. For the envelope, the double-glazed panels are assembled on site and fixed with aluminium spider brackets.

Each structural system and floor will be assembled by using a set of standardised components. The use of steel connection allows the quick assembly and dissasembly, if construction may be relocated elsewhere.

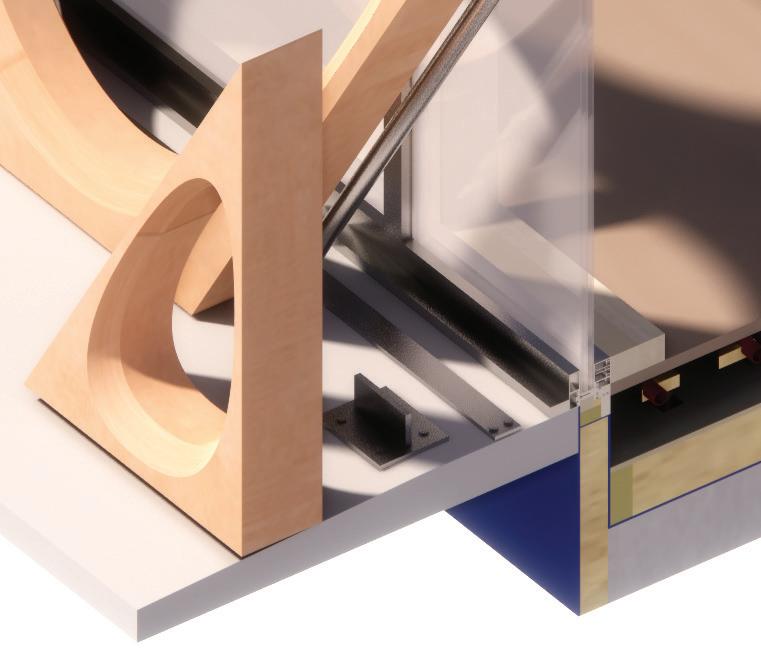

Developed around tectonics, the build-up employs different timber species (oak and beech), based on their strenght, elasticity and aesthetic value. For the envelope system, a glazed wall was chosen, due to its seamless finish and up-cycling strategy, being easy to dissmentle and reuse.

TOOLS

LORRY Components and construction materials transported to site using a lorry. The elements being locally sourced and pre-fabricated, they may be brough to site at once (excluding the transportation of glazed wall elements).

CRANE

Given the size of glulam components, they are fit into place with a crane. For the glulam columns (180x480mm), beams and other prefabricated elements, a mobile crane is required as the load does not allow them to be carried. A mobile crane is chosen as the size of the building and the use of pre-fabricated elements reduces the labour time. Component based structure allows craining of individual elements on site.

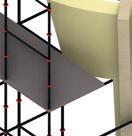

SCAFFOLDING

Given the floor to floor hight (4500mm) scaffolding is required to fix the insulation and the additional required layers (DPM, VCL, OSB board and external and internal finishes).

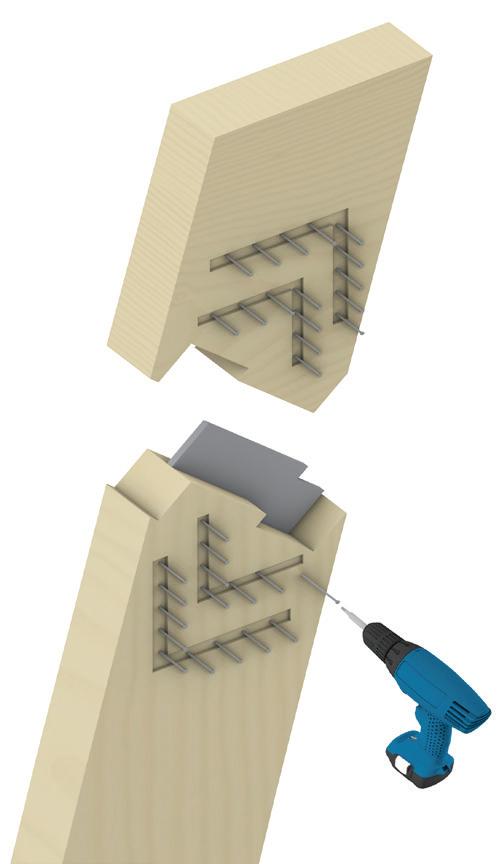

SCREW DRIVERS For the glulam components which support high loads, in-built steel connections require the use of screw drivers on site, to fix the elements with bolts and pins. To add, the glazed wall panel requires screw drivers to fix the spider brackets.

PROCESSES

I. Prefabricated components with in-buit connections are manufactured, precisely cut to size, reducing possible timber waste.

II. Glulam components are assembled and fixed with steel connections to stiffen the structure. Nodal in-built connections are used for the majority of the joins, where additional stiffning is not required.

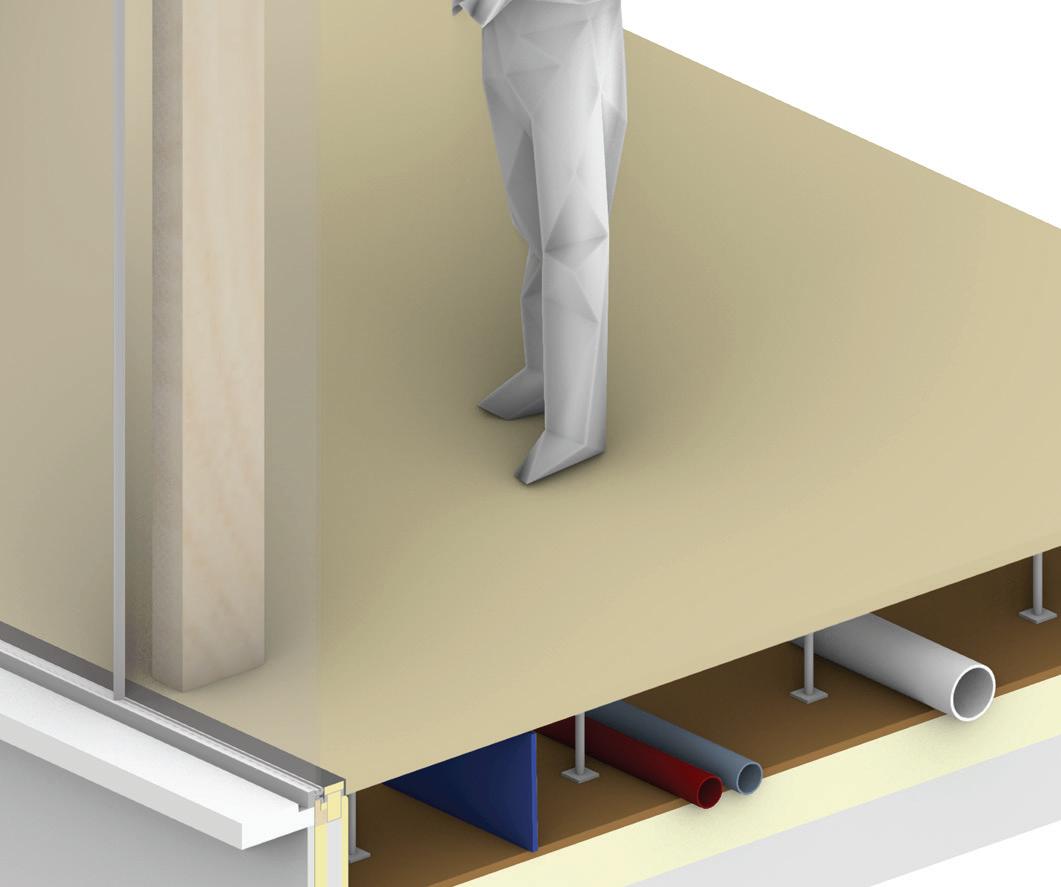

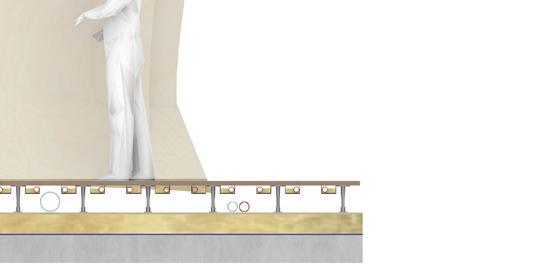

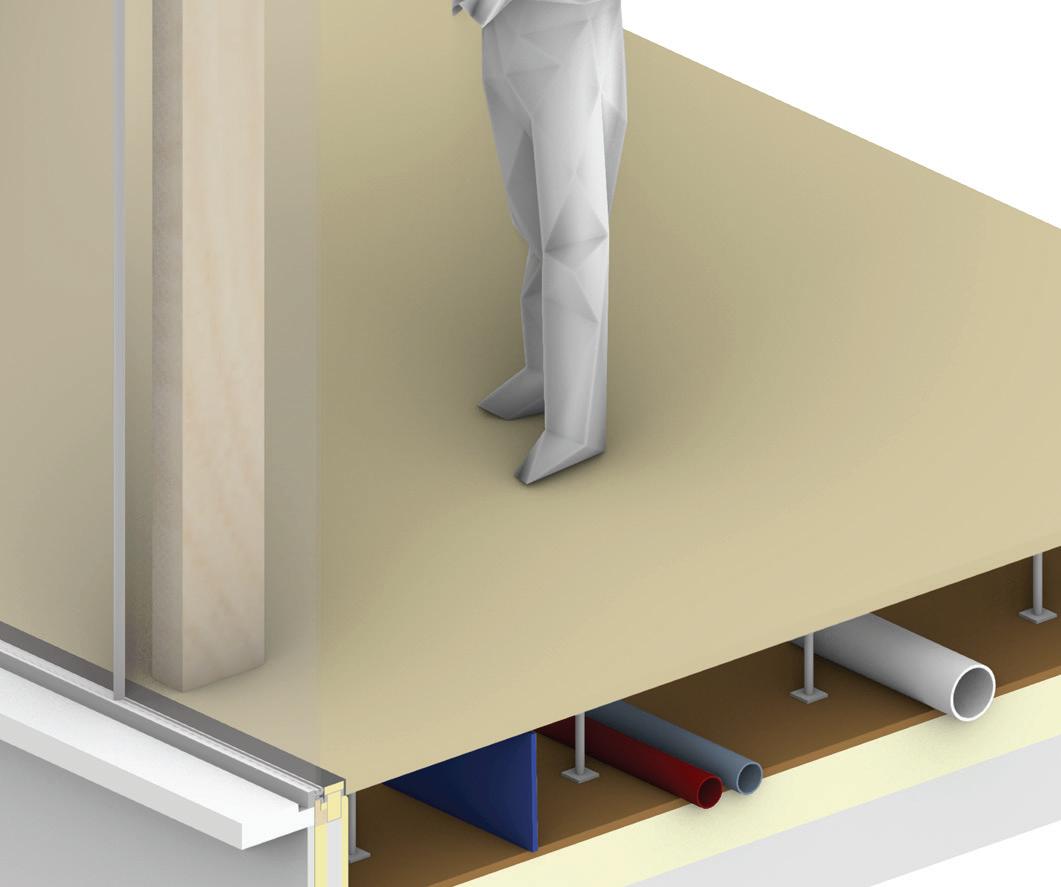

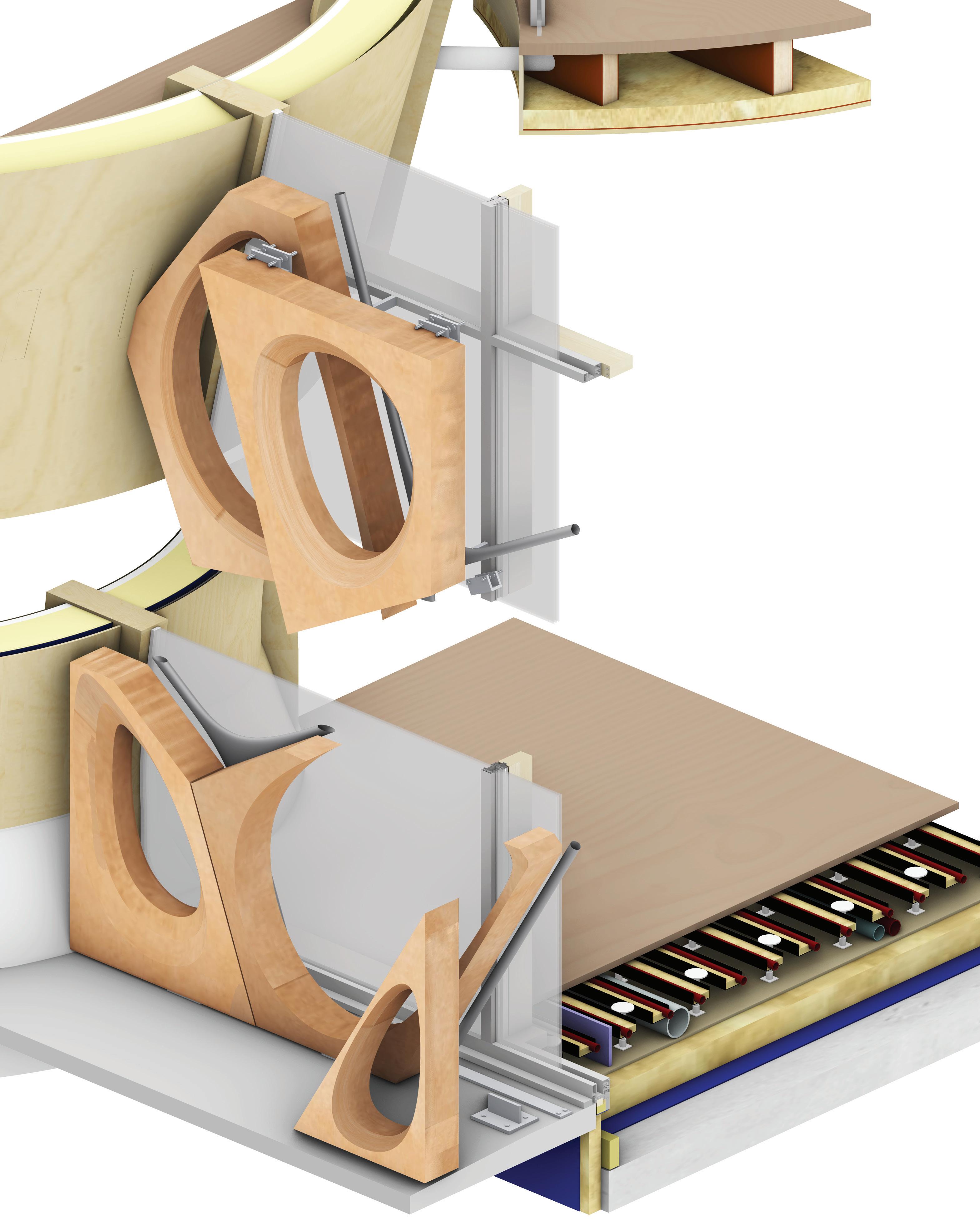

IV.The glazed panels are fixed with spider brackets and services are distributed in the 300mm raised floor void.

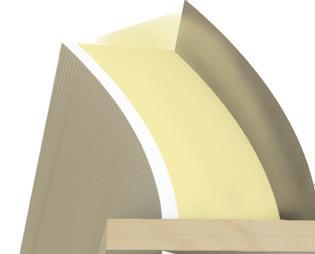

plywood finish OSB board vapour control layer 180x400mm glulam columns 250mm wood fibre insulation damp proof membrane 25x50mm timber battens timber cladding

D C. Glulam Column and Post Junction (external) C

Oak Tree (Gulalm columns, Engineered oak flooring) Beech Tree (Laminated Veneer, Timber Joists) B. Glulam Column and Glazed Wall Junction

seal integrated into the glualm column) E. Column- Beam Connection (glulam beam and laminated timber junction) -joint through nodal connection and additional lamination “I believe that the heterogeneous nature of wood is one of its greatest strengths, and yet it is often overlooked in modern design.[...] We must re-evaluate our approach to wood and embrace its full potential as a dynamic and versatile material that can enrich our built environment in so many ways.” - Kengo Kuma STABILITY

(Window

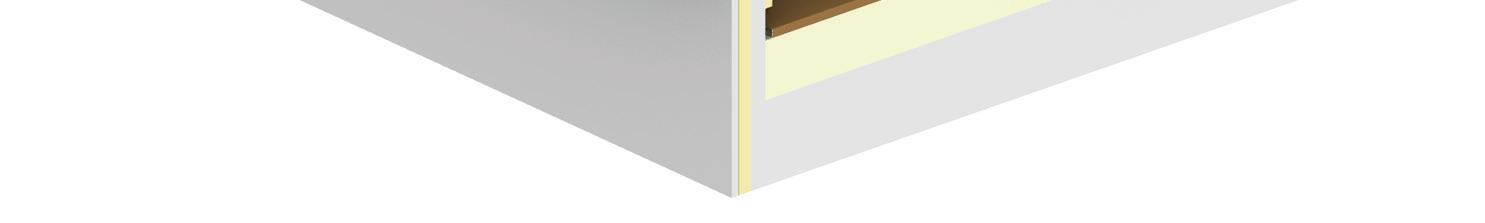

B D.Glulam ColumnFloor Connection (internal): T-shape steel, bolts, glulam column FIRE STOP CAVITY BARRIER ROCK WOOL STRUCTURAL INSULATION acts as a cavity barrier spaced at 10m SLOTTED-IN STEEL Scaffolding U value Envelope Rso: 0.06km2/W Rsi: 0.12km2/W R1(wood fibre insulation 0.25m, 0.043 W/m2k): 0.17km2/W R2 (plywood 0.008m, 0.05 W/m2): 6.25km2/W R3 (timber cladding 0.018m, 0.1 W/m2k): 5.55km2/W U Value= 0.08W/m2k (fits within the passivhaus

STAGE I: Material Sourcing and Manufacturing of Glulam and Timber Components STAGE II: Laying RC slab and assemblying Glulam structure STAGE III: Damp Proof Membrane, Insulation and Vapour Control Layer; Timber Joists are placed STAGE IV: Window panels and raised floor installed (Services fitted at this stage) A

standards)

01 Manchester School of Architecture | BA Hons Architecture- Technologies 3- Part C- Design Project | Alexandra Muntean Shading device ( to be developed in the prototyping stage) Screw Driver for bolted site connections

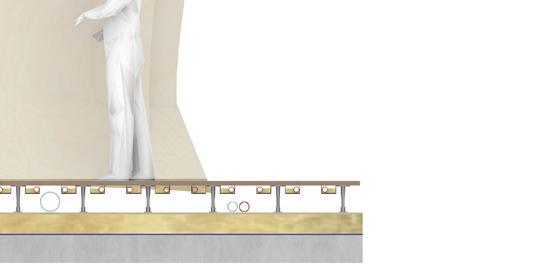

South Facing Building Fragment Engineered Oak Floor 300mm Raised Floor (raised floor pedestals) Timber Protection Layer Vapour Control Layer Damp Proof Membrane 215mm Concrete Floor DETAIL COMPARTMENT FLOOR to achieve 90min fire resistance Glulam columns fixed on T-shaped steel plate Timber Joist- Column Connection -joint inforced with steel elements-

WALL BUILD-UP GROUND FLOOR BUILD-UP RIBA SUSTAINABLE OUTCOMES

STAGE V:Timber Cladding and Finishes

Crane for glulam components Analysed Fragment

E

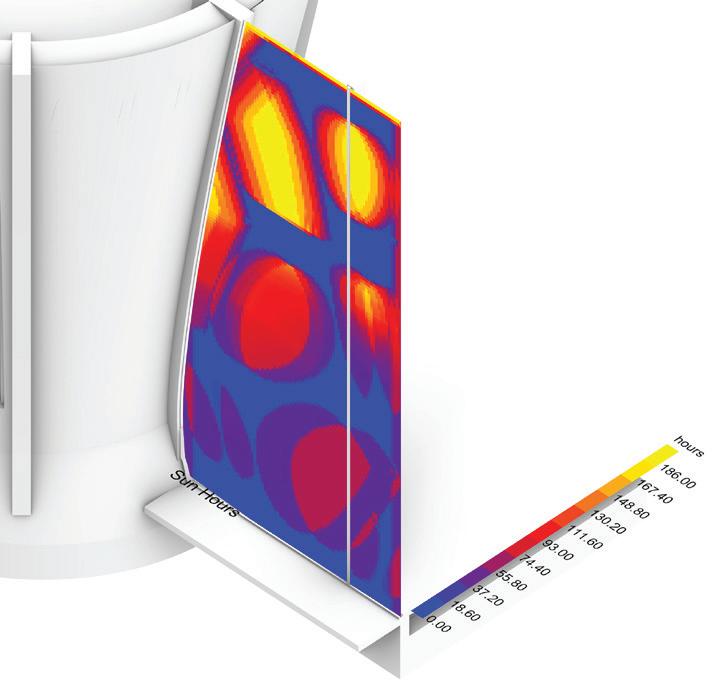

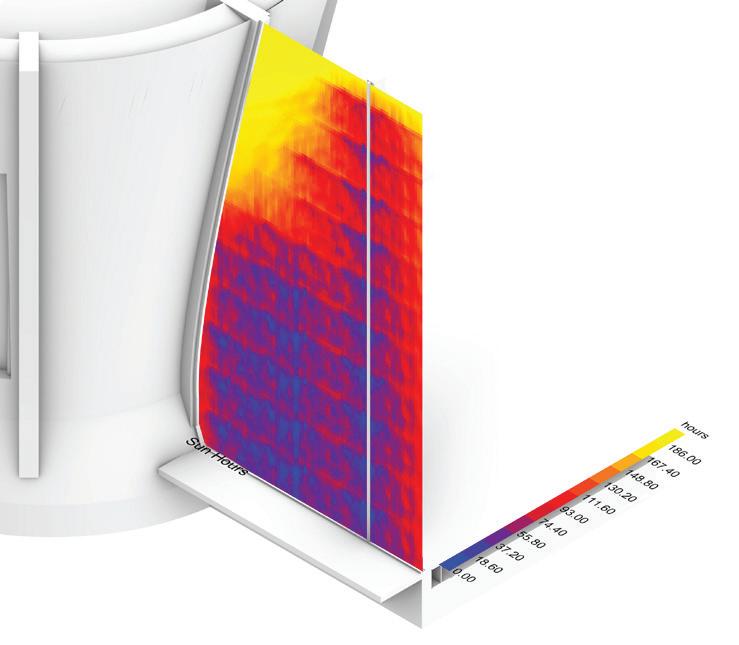

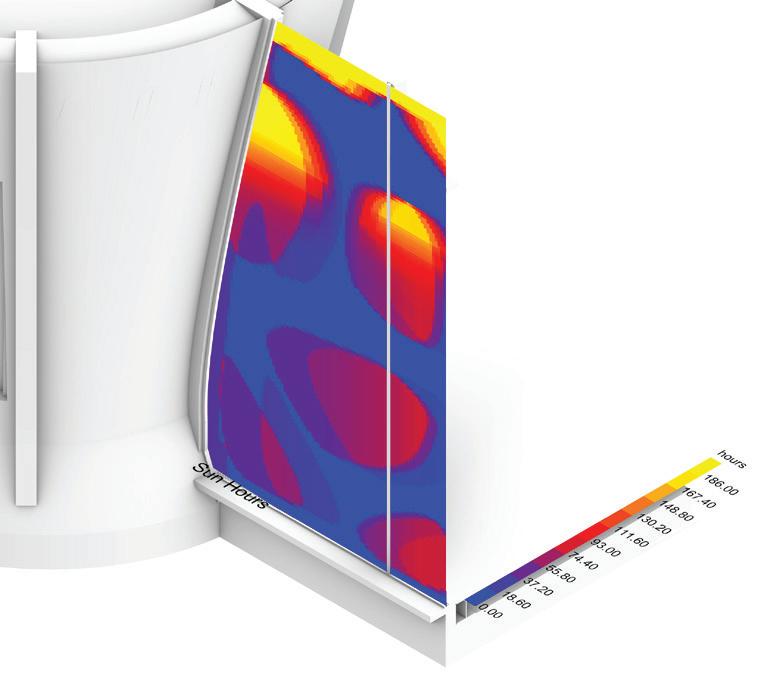

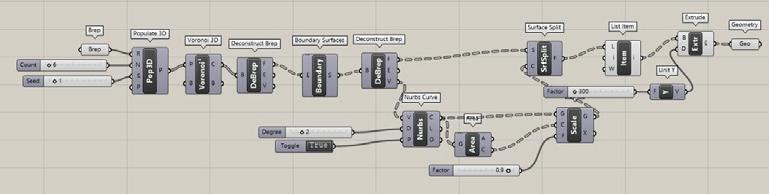

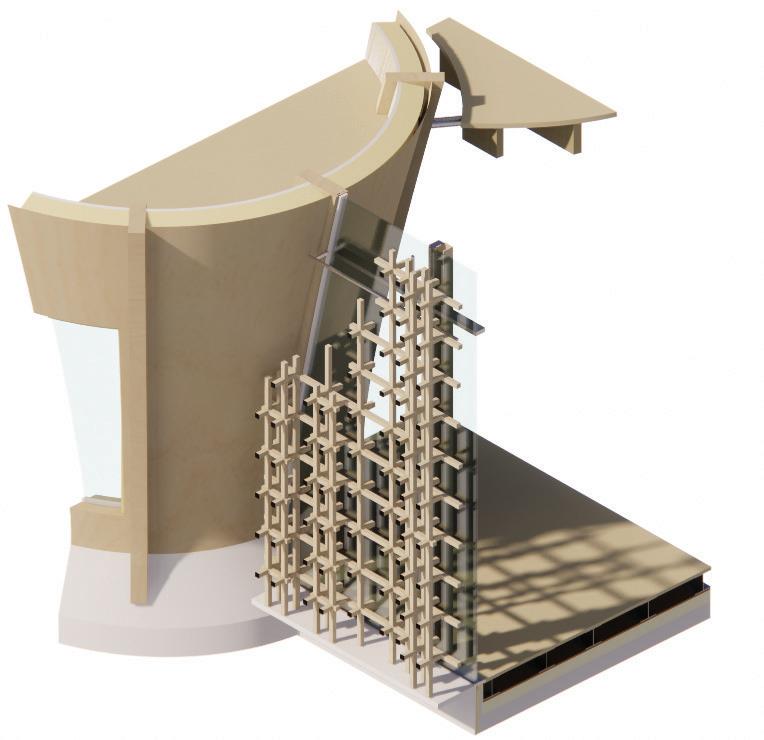

Iterative Testing | Record of Process

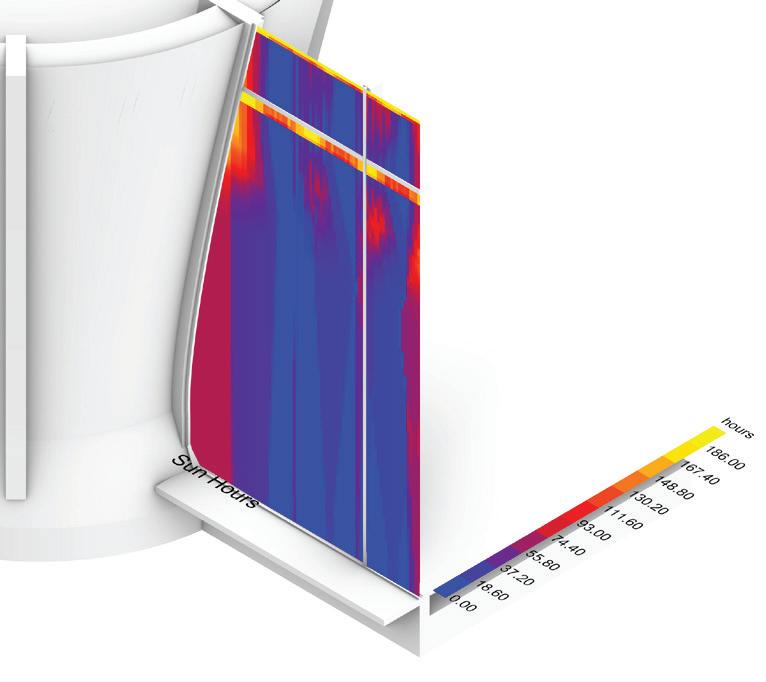

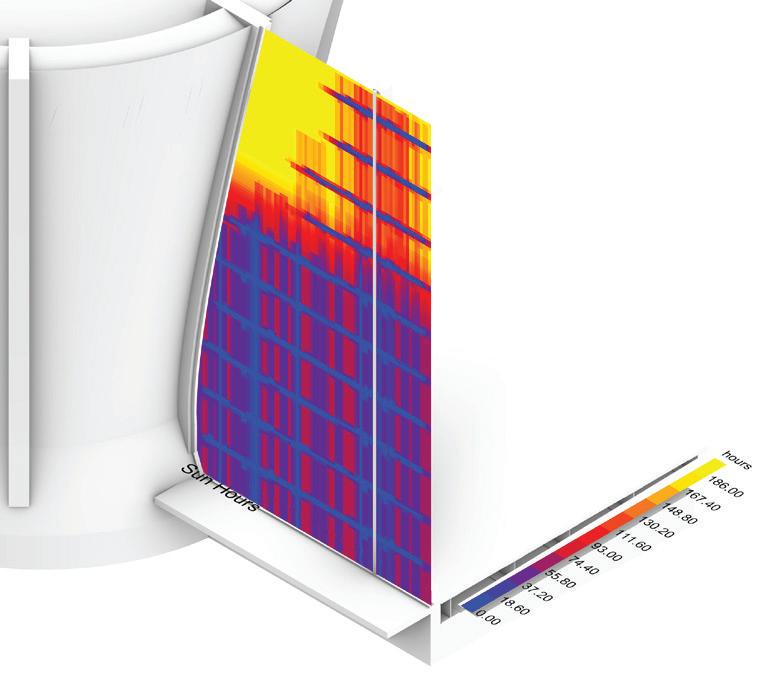

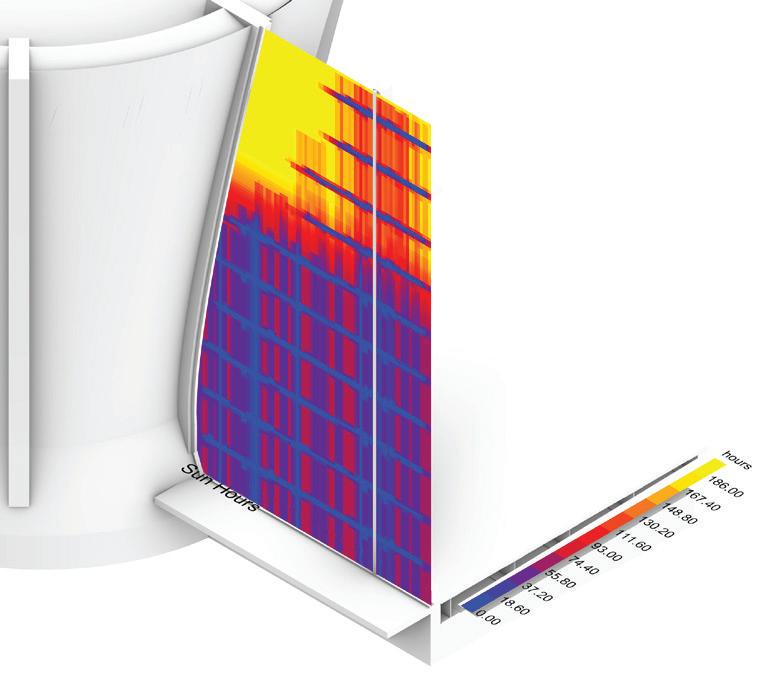

The aim of the prototyping stage is to design a shading device to reduce operational cost and regulate microclimate. Given the large amount of glazing, sun shading is needeed. A series of fixed and operable shading devices are analysed, considering solar radiation, internal quality and constructability. The iterations consider the use of prefabricated components and the use of carbon negative, local materials.

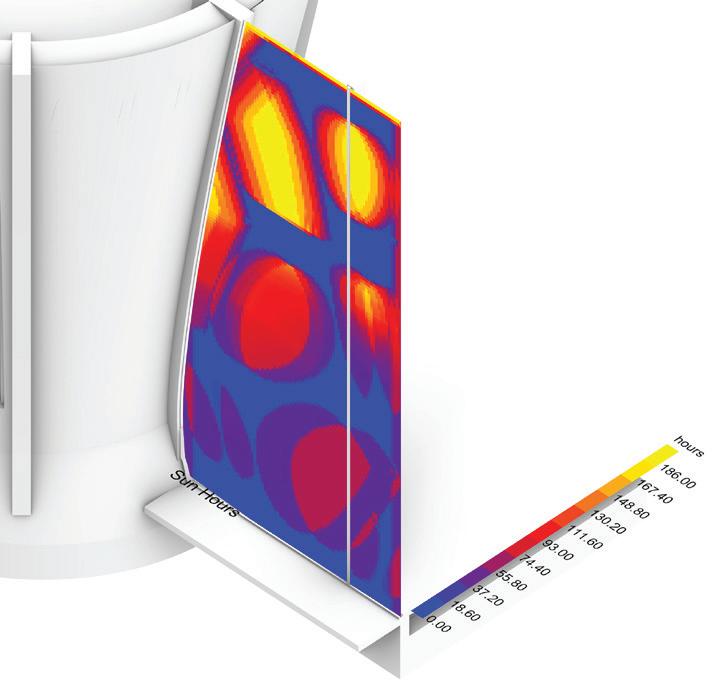

ITERATION 1 | Climate Performance

Chidori Joinery Shading Panel

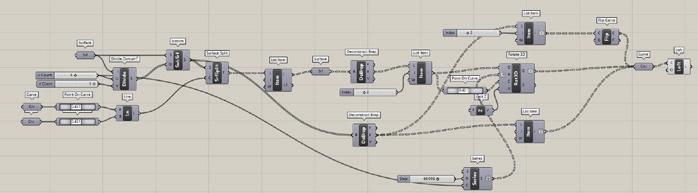

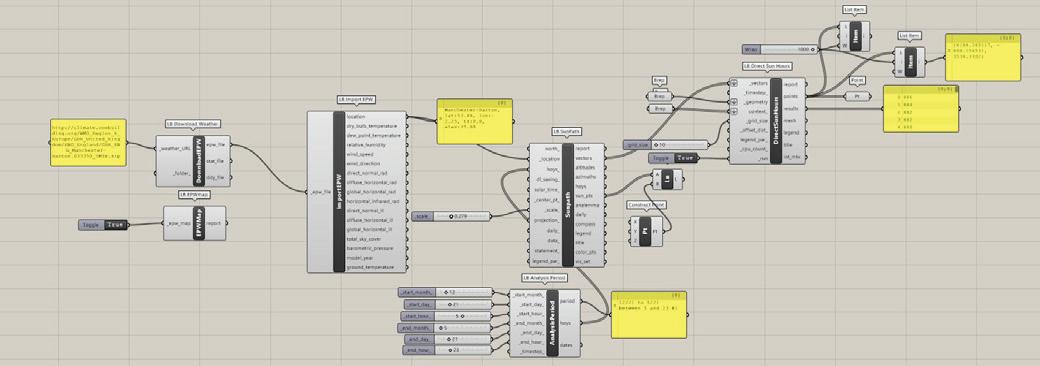

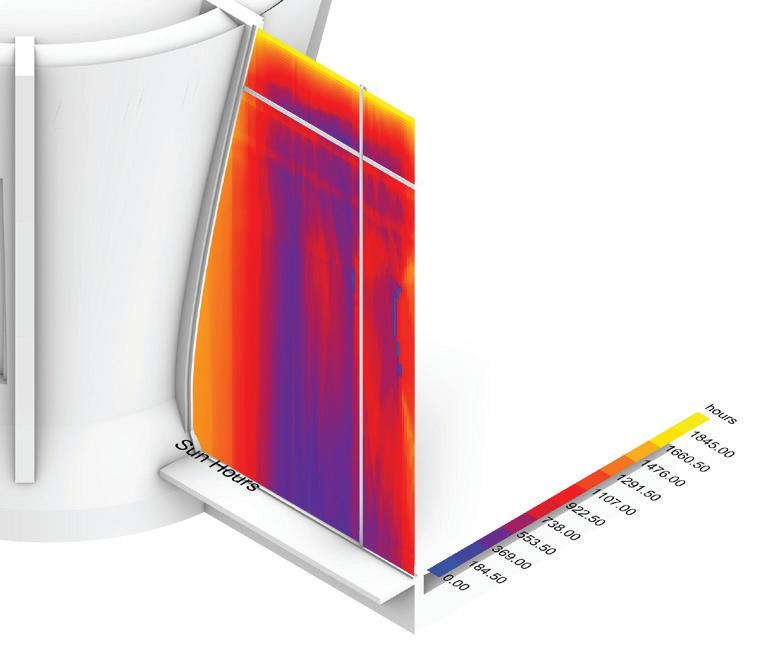

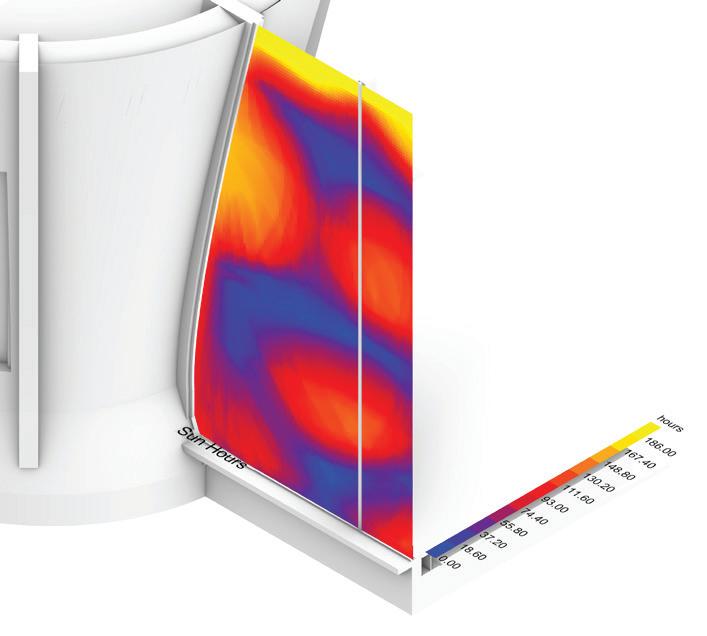

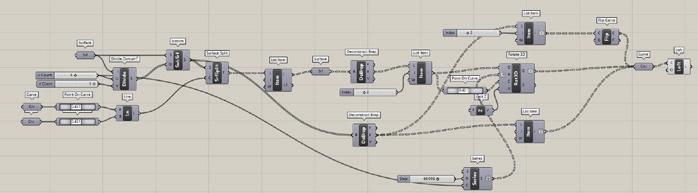

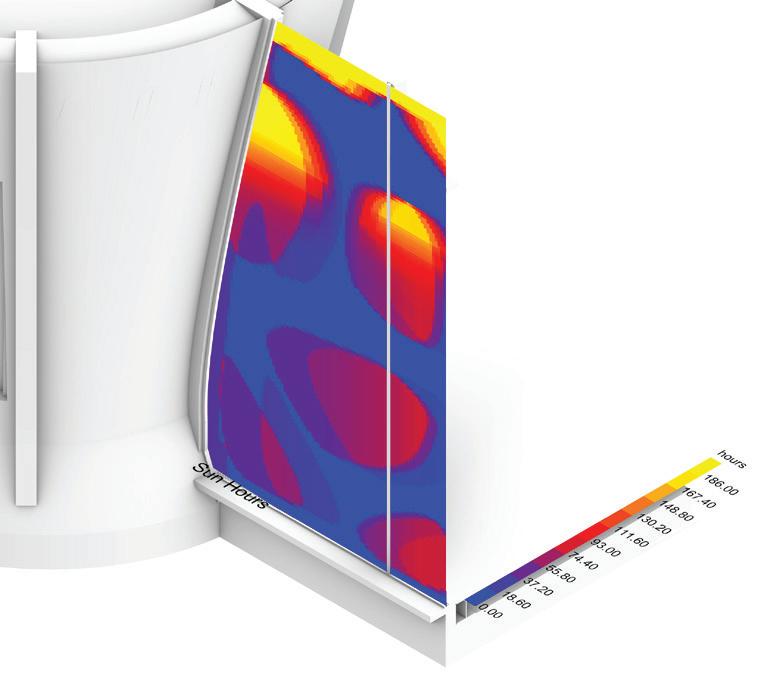

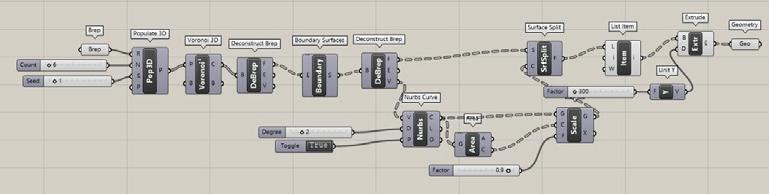

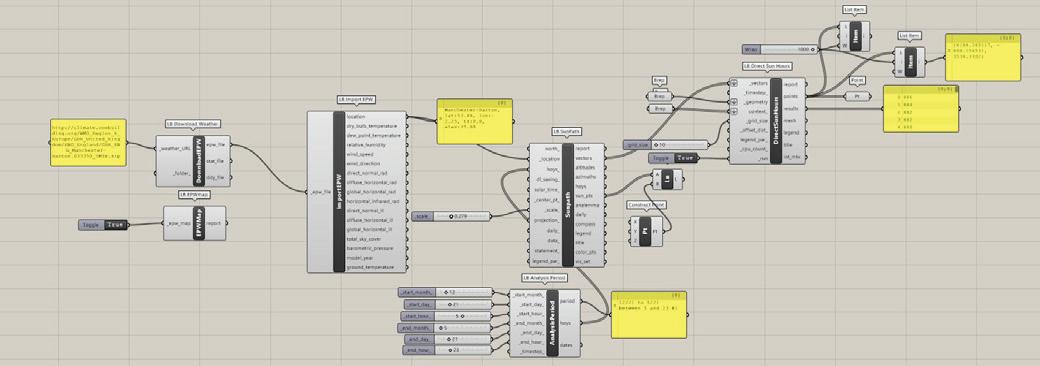

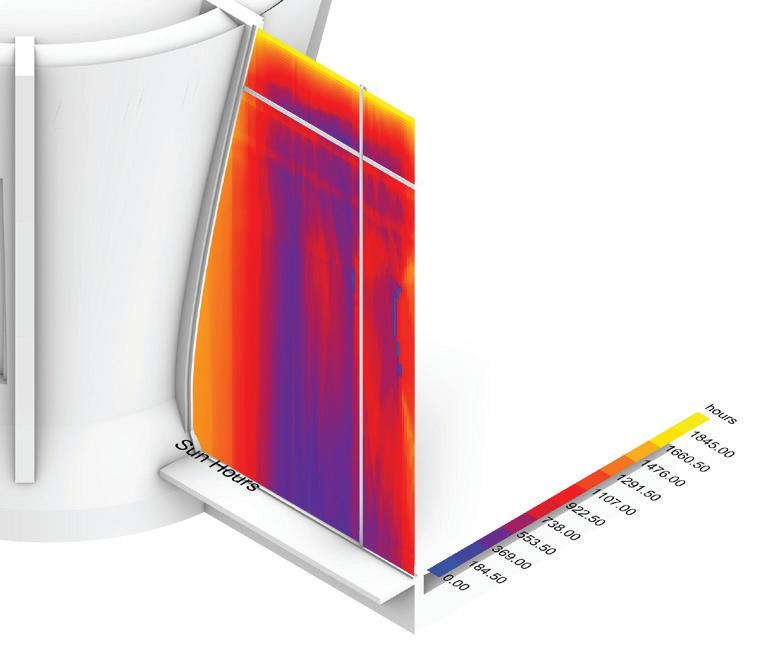

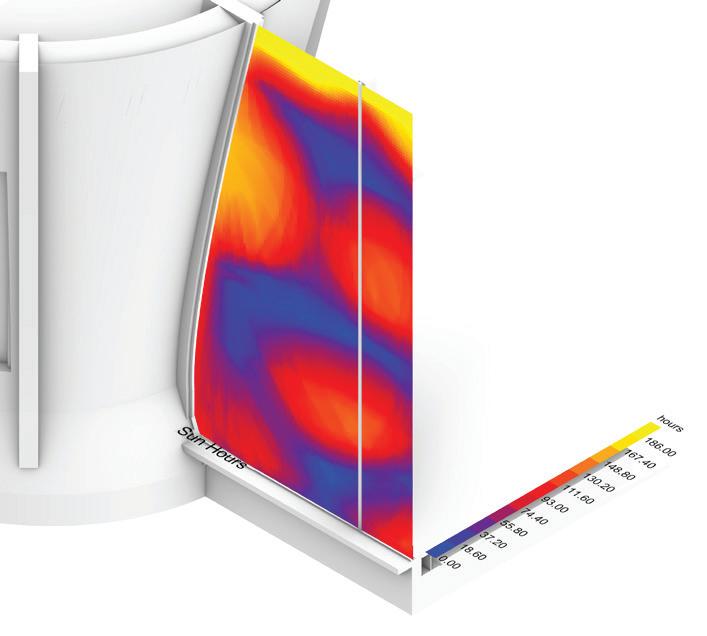

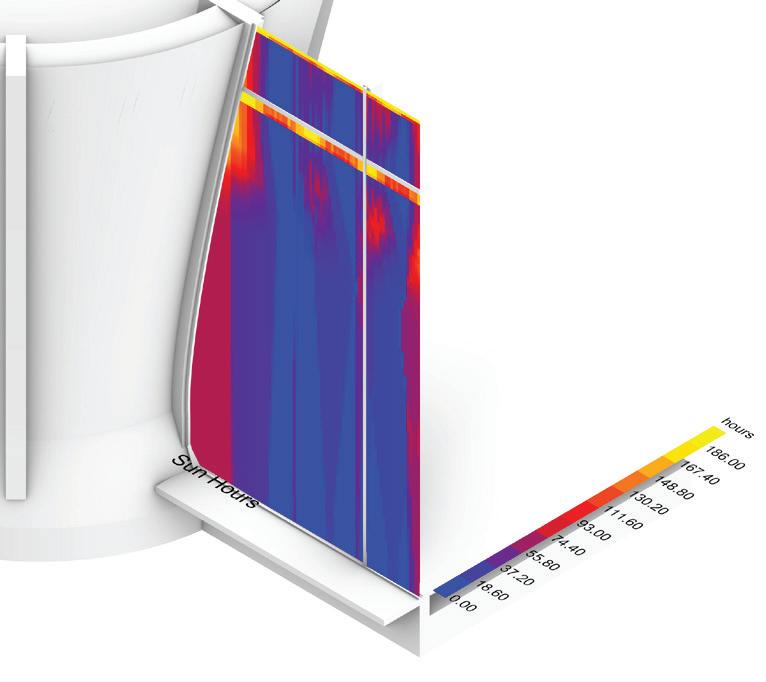

To analyse the performance of the shading device, grasshopper was used for form development. For the solar radiation analysis ladybug was used to test the radiation level on the facade, analysing the performance during summer and winter solstice.

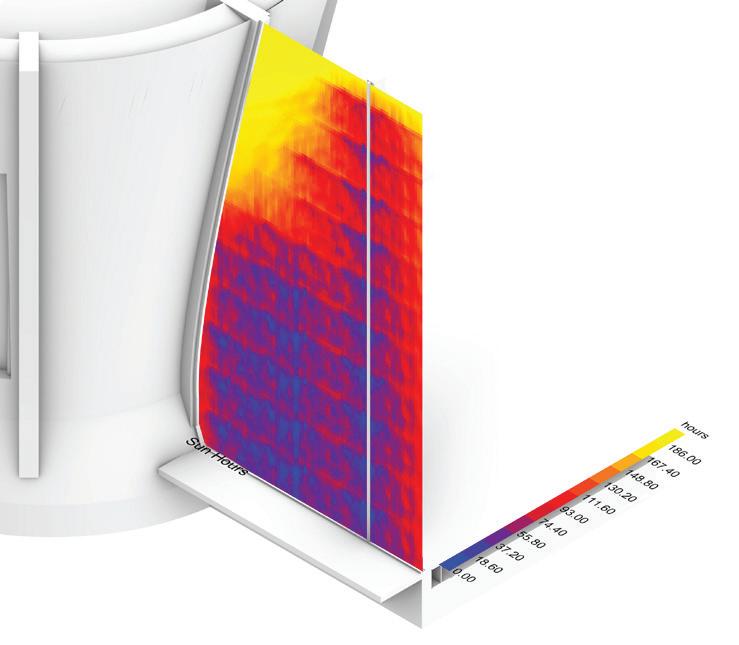

ITERATION 2 | Climate Performance

Vertical Timber Operable Louvres

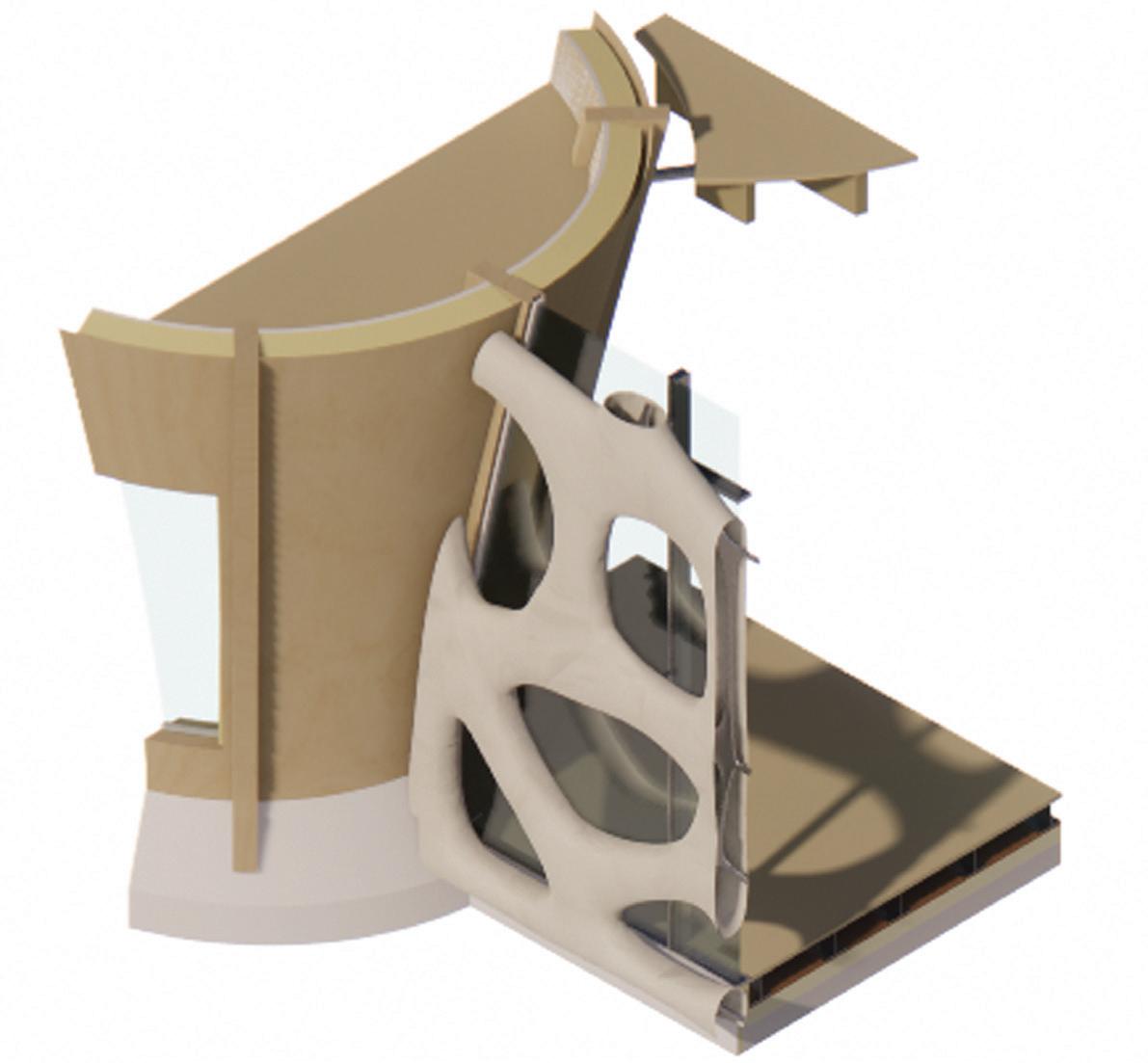

ITERATION 3| Climate Performance

Mycelium Shading Panel

ITERATION 4 | Climate Performance

Terracotta Shading System

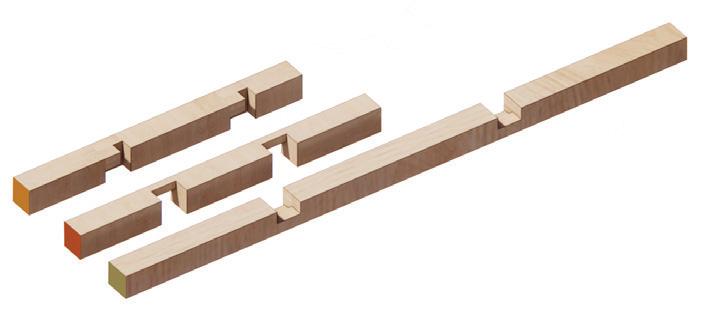

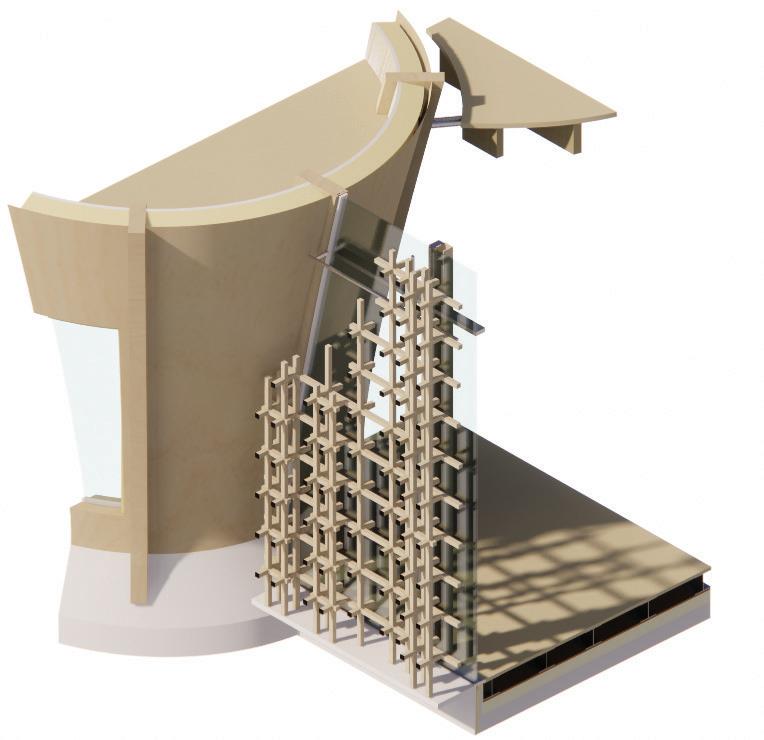

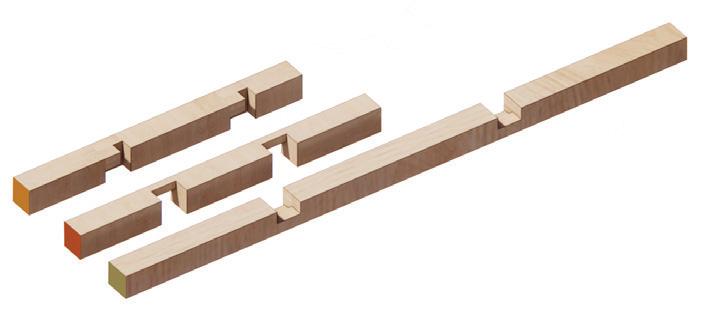

Inspired by the chidori Japanese joinery technique, the shading device is fixed (non-operable), composed of small 70x70mm timber sticks assemled through nodal connections, resulting in a stable, yet intriguing structure.

During summer, a good amount of shading is provided, yet not enough, resulting in an uneven coverage.

For this iteration, a manually operable vertical louvres system was tested. Having a pivot arm, the louvres may be opened or closed depending on the sun agle. It provides a well controlled environment, being easily adaptable to seasonal changes.

The use of biodegradable materials for sun shading is explored. The mycelium blocks are durable, as well as a great thermal and acoustic insulation (considering the noise coming from the ring road next to the site). To add, it allows the growth of microorganism.

The hsading panel tested in the previous stage is further developed. Another natural material is chosen- terracotta- due to its thermal mass capacity and insulation properties. Some of the small cavities may be filled with planting and bee habitat modules.

The vertical louvres provide an even amount of shading during summer, protecting the facade from extreme sun (glare and overheating). It achieves a great performance, creating a well controlled environment.

The large amount of small openings allow light into the space during winter, while preventing extreme winds to overcool the building.

During winter time, the louvres may be opened to allow light into the space (as the anlysis presents the louvres closed, lot allowing enough light into the space). At night time the louvres may be closed, to prevent overcooling, dicreasing the energy demand.

The mycelium panels provide a good amount of shading, preventing glare and overheating. Despite the massive mycelium structure, the radiation on the facade is quiet even, resulting in a well controlled microclimate. At winter, the shading panel prevents overcooling and allows enough light into the space. However, there is a considerable change in terms of radiation, as differences on the upper and lower areas are registered.

The use of smaler opening resulted in a better controlled environment, reducing glare. To add, by changing the panel thickness the radiation on the facade is improved. During winter, there are no major changes registered. However, there is a more even radiatio achieved. Furthermore, the climate performance is improved through the use of terracotta components with high thermall mass and insulation quality

The use of thin timber battens create an intriguing internal lightning, allow light into the space while preventing glare. Yet, the visual comfort may be affected by the heavy shadow patterns created, obstructing views.

CONSTRUCTABILITY

The panel consists of three types of timber planks which are coonected through nodal joins, technique used in tradional Japanese craftmanship. The joineries result in a stable structure; they do not require any nail or glue fixing. Yet to prevent the glazed panels from lateral loads and any hazards, the timber structure may be fixed to the curtain wall with steel brackets. To add, the nodal connections and prefabricated elements allow the easy assembly and disassembly of the shading device.

REFLECTIONS ON CONSTRUCTIBILITY

The vertical louvres filter the light, preventing glare, while keeping the connection with the outside. The operable louvres allows them to open and close depending on the sun angle and the activities that take place in the space.

CONSTRUCTABILITY

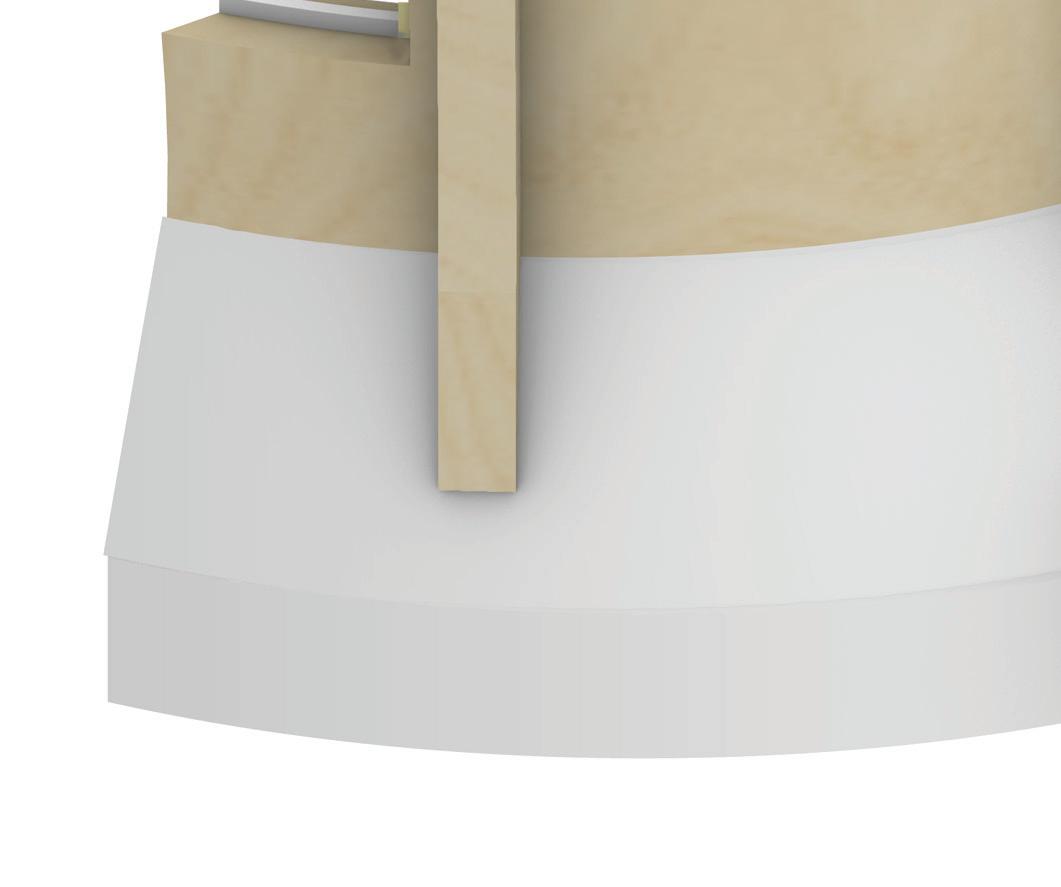

To be able to fix the shading device, the glazed wall system had to be changed with a curtain wall system (as for the other iterations as well) to which the timber louvres are fixed to an aluminium extruded pivot arm with brackets.

The organic mycelium panel stimulate the cognitive response of the pacients to natural materials and light. The organic shape creates interesting patterns on the floor, while the openings in the facade allow views to the outside.

CONSTRUCTABILITY

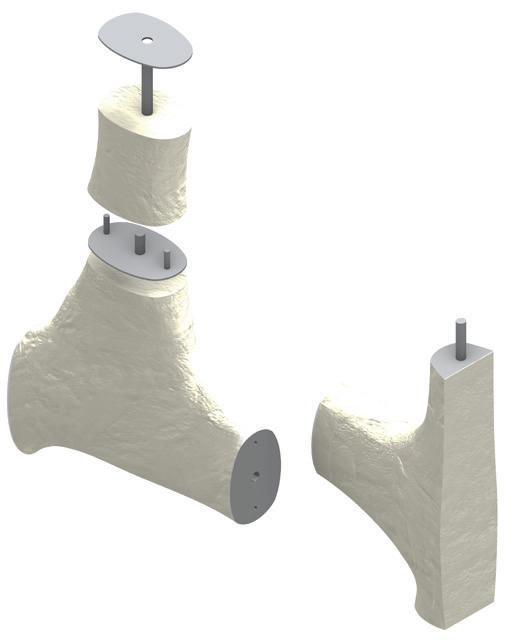

The shading system is composed of pre-fabricated mycellium elements (blocks) fixed with aluminium plates and pins. An additional aluminium structure is used for stability and protection of the glazed panels from lateral loads (wind).

aluminium plate mycellium block aluminium pins

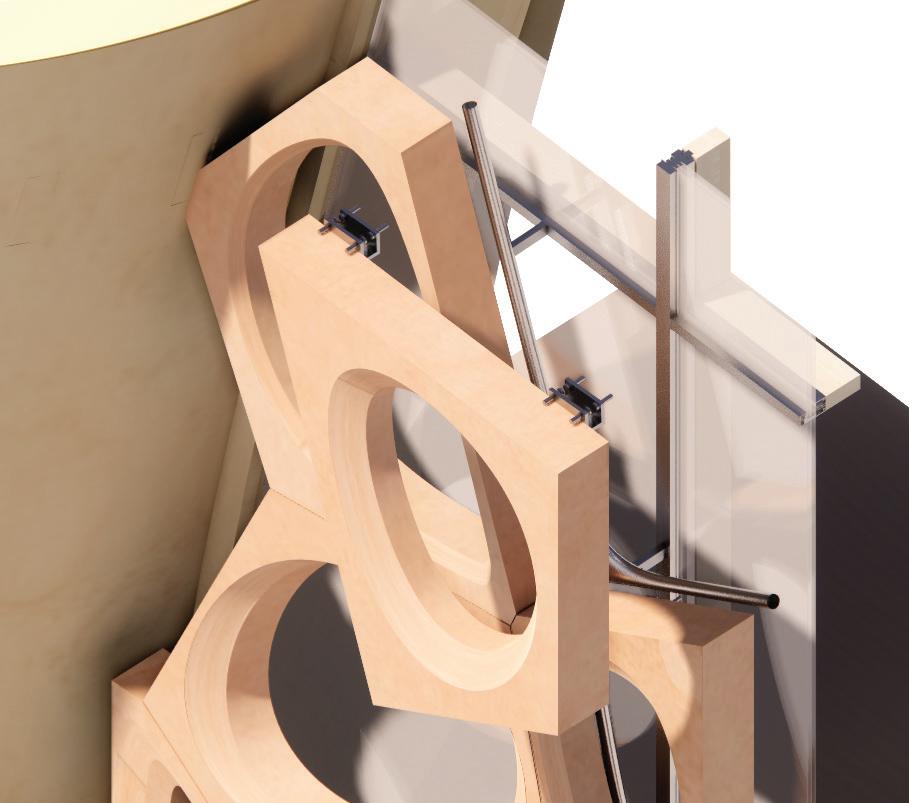

Terracotta shading system composed of small prefabricated elements assemnled with steel pins.

Some cavities may be closed and used for planting or bee habitat (on the upper part).

Small changes were made as for the qaulitative testing; smaller openings increase the visual comfort, eliminating glare. The terracotta prefabricated components allow the interplay of smaller and larger openigs based on the facade orientation (eg. on the south side more smaller components, while on the eastern facade, larger openings are provided).

WINTER SOLSTICE

ITERATION 5 | Climate Performance &

Constructibility: Thermal Bridges

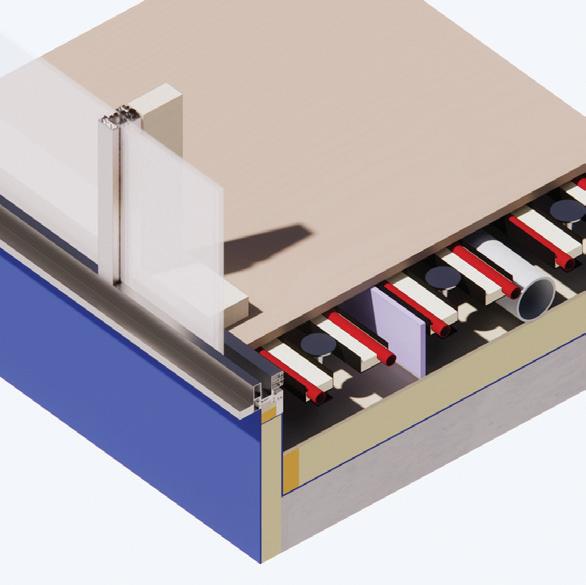

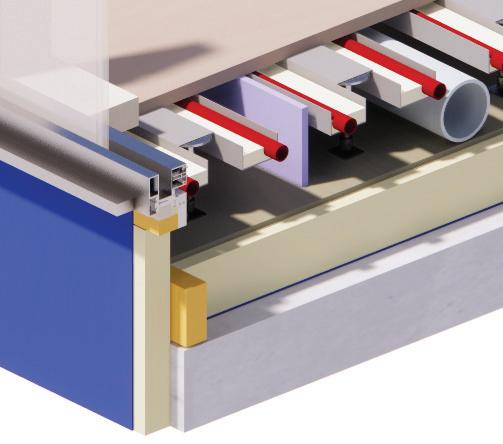

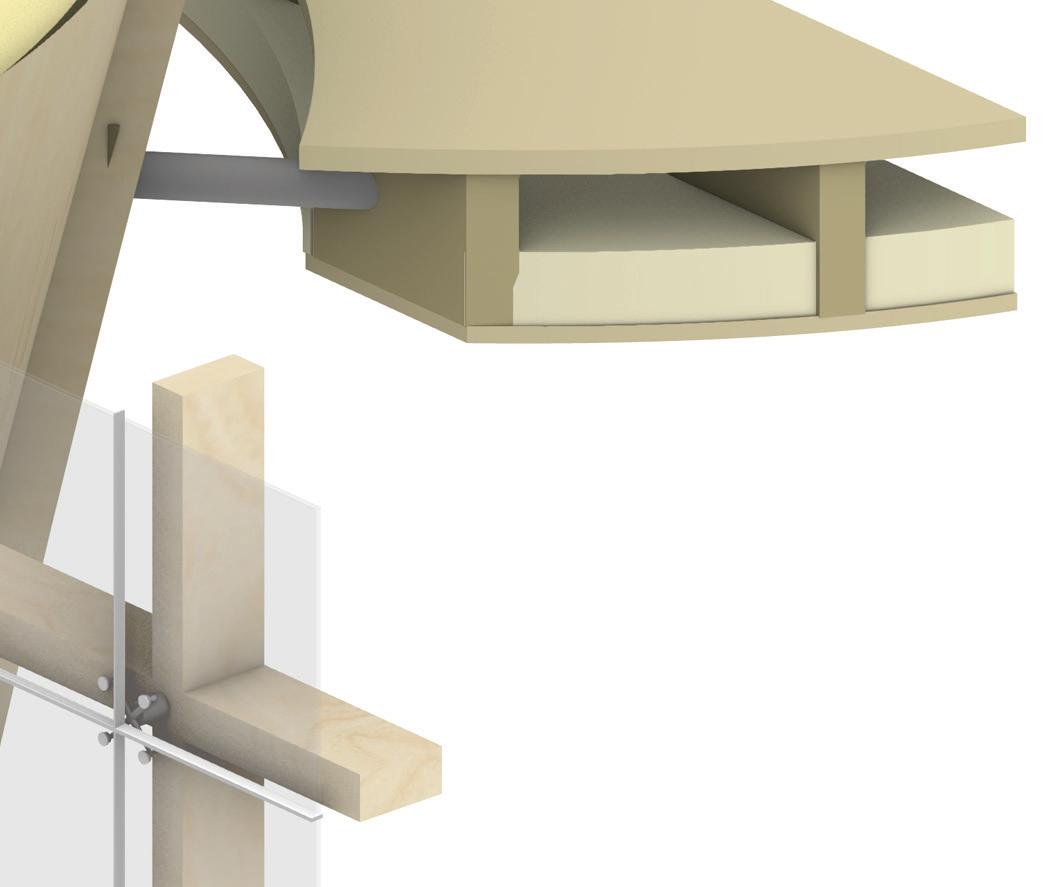

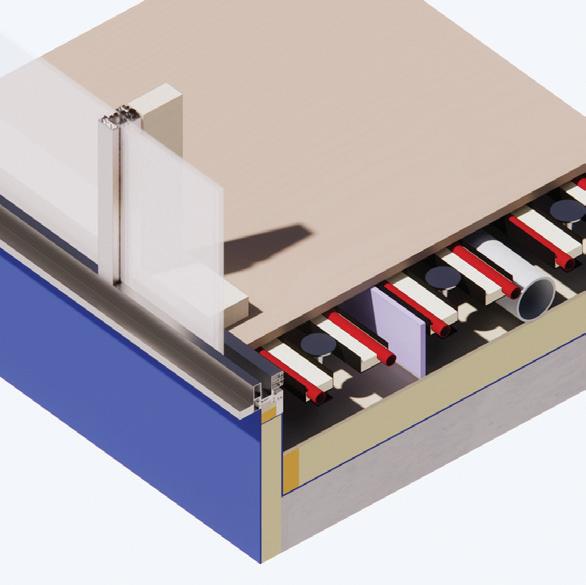

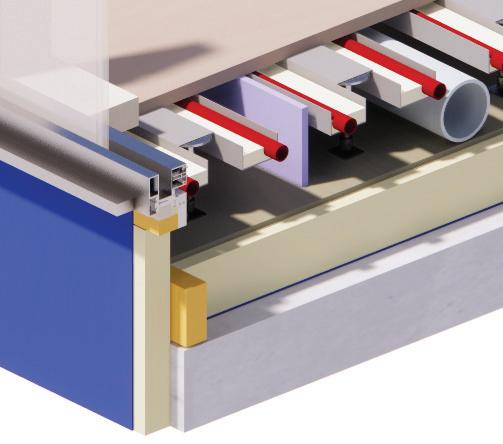

To minimise themal bridges structural insulation and timber battens are added; for thermal comfort underfloor heating (UH) pipes. To add, for the curtain wall, timber mullions are used for a better thermal performance.

7. Cavity Barrier

8. Ventilation Pipe FLOOR TO CURTAIN WALL THERMAL INSULATION

REFLECTIONS ON BUILDING AND LIFE SAFETY CONCLUSIONS

Terracotta is a stable material which does not need much reinforcement. Channel brackets and knife plates may be added to support vertical and lateral loads. To add, an additional metal frame is added behind the shading panels to prevent any hazards (glass breaking) when exposed to extreme lateral loads (harsh winds).

Furthermore, the use of prefabricated components minimises any hazards and accidents on site, given the minimal number of tools and connecting elements needed (Screw drivers, knife plates, aluminium plates, channel brackets).

To prevent any fire spread on the facade, non-combustible materials were chosen. Terracotta has a high fire resistance, being 100% non-combustible and in case of long exposure to fire it may crack.

There was also explored the constructability of the ground floor. Given the void of the raised floor (300mm) cavity barriers with a thickness of 15mm are spaced at 10m apar together with structural insulation and wire mesh.

After testing four types of shading systems, the fourth iteration will be further developed on the technical detailig stage. The terracotta shading system responds to the primary aim of creating a well controlled environment as well as the quality of internal spaces. The use of organic material simulate the occupants’ cognitive response, while the use of robust materials highlights the longevity of such scheme. To add, the use of pre-fabricated components, not only allows a easy and fast assembly, but also the amount of openings based on different interplays of components (smaller-larger openings).

PROTOTYPING

Veronoi Facade | GH Script Curtain Wall System Solar Adaptive Louvres | GH Script 02 Manchester School of Architecture | BA Hons Architecture- Technologies 3- Part C- Design Project | Alexandra Muntean

SUMMER SOLSTICE WINTER SOLSTICE

FACADE RADIATION ANALYSIS FACADE RADIATION ANALYSIS FACADE RADIATION ANALYSIS FACADE RADIATION ANALYSIS QUALITATIVE ANALYSIS QUALITATIVE ANALYSIS QUALITATIVE ANALYSIS QUALITATIVE ANALYSIS

AIM METHODOLOGY Ladybug Script

SUMMER SOLSTICE WINTER SOLSTICE SUMMER SOLSTICE WINTER SOLSTICE SUMMER SOLSTICE SUMMER SOLSTICE WINTER SOLSTICE 1 2 3

The use of shading

implied a new glazing system: curtain walling to which the shading panels are fixed with steel or aluminium bracket system. To achieve a better climate per-

panels

formance and to lower the energy demand, triple glazing is used.

HEAT

1 2 3 4 5 6 7 8

RAF

UH

1. Structural Insulation 2. Timber battens 3. RAF Pedestal 4.

Bracket 5. Grooved Insulation 6.

Pipes

Veronoi Facade | GH Script FIRE PREVENTION STABILITY TERRACOTTA PANEL SYSTEM

STEEL SUPPORT

PREFABRICATED

TERRACOTTA

CONSTRUCTABILITY- Designed for Longevity

The proposal represents a scheme designed for longevity due to the massive glulam structure, having a life span of approximately 80 years. Therefore, the shading device was designed as a durable sheme; given the prefabricated components, in case of replacement, individual elements can be replaced instead of larger scale repairs. Furthermore, the fixing system does not require advanced tools, being an accessible assembly method.

BUILDING AND LIFE SAFETY

FIRE PREVENTION

Terracotta is a durable material and 100% non-combustible (class A1), making it a perfect material for facade, given the restrictie fire regulations. For the upper and ground floors, fire protective layers (wire mesh), cavity barriers and structural fire proof insulation blocks are added.

STABILITY

For stability a series of prefabricated elements are used to support the load bearing elements and lateral loads (wind). An aluminium frame is placed behind the terracota blocks for both stability( channel brackets fixing) and for the protection of the curtain walling in case of strong winds.

CLIMATE PERFORMANCE

The terracotta panels allow light into the building while preventing glare. Having thermal mass properties and insulation properties, the shading panels help regulate microclimate and cancel noise from the ring road.

REFLECTIONS ON TECHNOLOGIES POSITION & DESIGN INSIGHT

The facade detail synthesizes the technological finding is terms of constructability, climate performance and building and life safety in order to advance my design proposal and create a better controled environment for the occupants. The technical details highlights the two main sections of the facade, the ground connection and the connection on the upper level, to the curtain wall system.

The technical detail helped me in finding both a design and technical solution for the facade as the initial fragment was overexposed to sun, which would have resulted in an increased themal and visual discomfort. The iterative process refined the design language, having a heuristic approach in defining key parameters which resulted in defining the final scheme: facade radiation, qualitative and contructability analysis.

Designed around longevity(durable materials) and dissasembly (material reuse or relocation of structure), the scheme is composed of prefabricated elements which facilitate the assembly, while it reduces waste, given the precesition at manufacturing.Furthermore, the main components can be deisassebled and used elsewhere (on a different site)

Following the approach of Coofox and Buro Happold team, the facade can be transformed in the main biophilic element of the design scheme: the void in the terracotta componenents can be closed and transformed in bee habitat (on the upper level due to safety reasons) or planting modules. In this way the facade will not only be a threshold between the exterior and interior, but also a connector between the occupants and nature, improving their health condition.

TECHNICAL DETAIL Integrative Systems | Design Conclusions 03 Manchester School of Architecture | BA Hons Architecture- Technologies 3- Part C- Design Project | Alexandra Muntean 1 2 3 4 5 6 7

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

UPPER PANEL SYSTEM FIXING DETAIL FIRST FLOOR DETAIL RAISED FLOOR DETAIL 2D DETAIL GROUND FLOOR BUILD-UP (peeled back layers) 3D DETAIL

FIRST FLOOR BUILD-UP (peeled back layers) SHADING COMPONENT FIXING (UPPER LEVEL) SHADING COMPONENT FIXING (GROUND LEVEL) Knife Plate (fixed with bolts) Aluminium Plate Channel Bracket 1 2 3 4 5 6 7 8 9 10 11 12 13 14 THE FACADE TERRACOTTA PANELS TRIPLE GLAZING REDUCES THERMAL MASS PROPERTIES OF THE SHADING PANELS HEATING BUILDING & LIFE SAFETY (Stability) CLIMATE PERFORMANCE SHADING PANEL- CURTAIN WALL CONNECTIONS (G. Floor Detail) UPPER PANEL SYSTEM 1. Timber Mullion 2. Curtain Wall Transon 3. Triple Glazed Window Panels 4. Extruded Aluminium Arm 5. Aluminium Frame 6. Channel Bracket 7. Terracotta Shading Component FIRST FLOOR 8. Laminated Protection Glass 9. Stainless Steel Clamp 10. Engineered Oak Flooring 11. 100x400 Timber Joist 12. Fire Protection Wire Mesh 13. 100mm High Density Mineral Insulation 14. 15mm Plasterboard Ceiling GROUND FLOOR 15. Timber Mullion 16. Aluminium-framed curtain wall; 17. Timber Batten (thermal pad) 18. Structural Insulation 19. 90mm Rigid Insulation 20. Damp Proof Membrane 21. Engineered Oak Flooring 22. L Shape Fixing Bracket 23. RAF Bracket 24. RAF Pedestal 25. Grooved Insulation 26. Underfloor Heating Pipes 27. Cavity Barrier 28. Ventilation Pipe 29. Timber Protective Layer 30. 150mm Wood Fibre Insualtion 31. 215mm Reinforced Concrete Slab 1 2 3 4 5 6 7 9 10 11 12 13 14 15 16 17 18 19 20 21 23 24 25 26 27 28 29 30 31

(CONSTRUCTABILITY)

BEE HABITAT PLANTER MODULE SOUTHERN FACADE