ALBERT KAHN

ALBERT KAHN

Guided by the legacy of our founder, Albert Kahn, and a passion for architecture and engineering, Kahn commits to putting our clients first and delivering a remarkable product. Having designed over 45,000 projects around the world, Kahn’s expertise starts with architecture, engineering, interior design, landscape architecture, program management, and master planning, and spans through commissioning, business and management needs, strategic facilities planning, value and sustainability analysis.

It has always been our clients who inspire the work that we do. Known for award-winning designs and historic projects, the professional team at Albert Kahn Associates, Inc. takes pride in its ability to collaboratively create environments distinct to the needs of each client.

Our multi-disciplinary teams approach each project from a unique perspective to ensure that you are equipped with the very best solution.

We relentlessly explore fresh ideas, pushing boundaries to provide solutions that redefine possibility, captivate, and set new benchmarks in design and experience.

We use design-thinking to continually question and uncover the heart of the challenge.

Only once we fully understand can we infuse ingenuity into every aspect of our work, fostering unique and imaginative solutions that transcend convention and inspire awe.

We foster an inclusive culture where every individual is valued, embraced, and empowered. We operate with an open and approachable demeanor, ensuring clear communication and a seamless collaborative experience, to create an environment of trust and ease that resonates throughout every engagement. This commitment extends externally as we design spaces that not only reflect this ethos but also invite a profound sense of connection and ownership, enabling all to find their place within our creations.

For nearly 130 years, Albert Kahn Associates, Inc. has committed to designing and engineering innovative facilities that surpass the needs of our clients.

ALBERT KAHN ASSOCIATES HAS DESIGNED OVER

45,000

PROJECTS AROUND THE WORLD

We are driven to question the status quo in search of creative and long-lasting solutions that solve your unique challenge. We engage our clients in the design of the built and natural environments to foster genuine belonging and leave a positive impact on our world.

Albert Kahn’s expertise starts with architecture, engineering, interior design, program management, and master planning, and spans through commissioning, business and management needs, strategic facilities planning, and sustainability analysis.

COLLABORATION Our team believes the best solutions are discovered when a team works together. Through collaborative working relationships with internal and external team members, our clients experience a synergy unique to our enjoyable working culture. Through years of collaboration, our team understands the nuances of your market, as well as the key relationships, to assure your project runs smoothly.

COMPLEX PROJECTS Our team’s most successful projects are the most complex in the industry. Our experienced team loves to solve problems. Organized around a multi-discipline team means we look at each challenge from a variety of angles, discovering the best solution to align with the specific priorities of each client. Our depth of cross market technical skills allow our team to have deeper thinking and more innovative solutions, providing results unmatched by our competition.

MACRO TO MICRO Our team’s depth of expertise allows our professionals to see solutions others don’t. Through years of successfully leading clients through major and minor projects, our team understands that the big picture of a master plan is best realized from the thorough understanding of the micro details that make each component most efficient and successful. When the components are analyzed and combined in the most effective ways, our clients realize efficiencies and flexibility that result in better, more efficient operations.

SPEED TO MARKET Our team has a unique advantage when it comes to speed to market. It is in our DNA to fast track projects. Our team is nimble to adjust the decision making process to meet the client’s delivery goals. We know which decisions need to be made quickly to expedite the desired results. We continue to amaze and delight our clients with our ability to deliver quality in a short time frame.

PROCESS UNDERSTANDING Successful design and planning maintains a fundamental element; stop and listen. As planing design and management professionals, our job is to understand our clients experiential and operative objectives and then and then express these goals through design. We accomplish this by conducting interactive research and discovery to determine key elements which enhance the overall process, your expectations are defined from the start,and our team’s goal is to exceed those expectations.

As a full-service Architecture and Engineering firm, Albert Kahn offers a multi-disciplinary team that is equipped to handle every aspect of your project. The desires of our clients come first and guide the project based on budget, program requirements, and the overall nature of the project. This approach, coupled with highly qualified project teams, assure that Kahn’s design solutions are unique and specific to each client’s desired objectives.

Condition Assessment Report

Existing Facilities Evaluation

Site and Utilities Analysis

Code Analysis

Construction Documents

Value Analysis

Historic Preservation

Building Envelope

Structural Analysis

Structural Engineering

Mechanical Systems

Mechanical Engineering

Electrical Engineering

IT Systems Engineering

Programming & Planning

Site Design

Interior Design

Landscape Architecture

Sustainable Design Design

Strategic Facilities Planning

Program Management

Commissioning

Decommissioning

Asset Optimization

Conceptual Estimate

Environmental Surveys

Urban Planning & Design

Land Planning

Campus Planning

Site Master Planning

Albert Kahn is dedicated to creating transformative, industrial facilities designed to support the dynamic needs of today’s manufacturing and production environments.

We focus on designing industrial spaces that serve as efficient, climate-controlled environments where workers can operate in comfort while dealing with sensitive materials. Our approach redefines industrial facilities as productive and safe environments, thoughtfully designed to optimize workflows, ensure stability, and prioritize employee well-being. We understand that today’s workforce expects facilities that are both highly functional and considerate of worker comfort.

Kahn’s industrial designs emphasize the importance of climate control to maintain product integrity and create comfortable workspaces. With features like precision HVAC systems, air quality management, and zoned temperature controls, our designs ensure that sensitive materials are protected while keeping workers comfortable and safe. This approach reduces environmental stress, increases productivity, and supports the seamless operation of complex manufacturing processes.

To further enhance the industrial environment, we incorporate elements that support worker wellness and comfort. Features such as ergonomic workstations, break areas, and fitness spaces provide workers with the ability to recharge and care for their health throughout the day. Personal control options, where feasible, for temperature and lighting enable workers to adjust their immediate surroundings, enhancing focus and reducing fatigue.

Our industrial facilities are designed with flexibility in mind to accommodate diverse workflows. Modern manufacturing spaces must cater to various stages of production and assembly, so we create adaptable layouts with designated zones for assembly, testing, storage, and quality control. This flexibility allows workers to move smoothly between tasks, improving efficiency and supporting collaborative and individual work as needed.

Recognizing that today’s workforce values accessible and supportive amenities, we integrate thoughtful additions such as break rooms, on-site dining areas, and outdoor spaces for relaxation. Our locations are often chosen with accessibility in mind, ensuring convenient proximity to public transit, secure bike storage, and ample on-site parking to support an easy commute for employees.

Kahn’s use of durable, high-quality materials not only enhances the aesthetics of industrial spaces but also ensures longevity and ease of maintenance. By incorporating sustainable, resilient finishes, we create facilities that meet rigorous operational demands while promoting environmental responsibility. Our approach combines durability with warmth, resulting in spaces where employees feel valued and engaged in their work environment.

Albert Kahn’s work on Ford’s Driving Dynamics Lab remedied the workflow and efficiency challenge Ford experienced with related departments scattered across a vast campus. It created unity and cohesion between product engineers and test technicians while improving the overall employee experience.

The Driving Dynamics Lab (DDL) is the first building to rise out of Ford’s commitment to sustainably upgrade their engineering campus. DDL is designed to attract and retain the best and brightest designers and engineers ensuring that the surrounding communities retain their distinction as a hub for skilled professionals. Constructed in two phases, East and West, the facility co-locates multiple departments and test functions.

DDL East is three stories with the first floor including a vehicle garage, test lab, and shop space. The second floor includes labs, fabrication shops, storage lockers, equipment rooms and an employee café. The third floor includes engineering offices and test track observation areas. DDL West is a single-story building featuring tire and durability laboratories, shipping and receiving, storage,

vehicle autonomous technology laboratory, outdoor patio area, facility entry, and core support areas. The facility also features the most advanced NVH testing facility Ford has constructed to date, a Hybrid Test Chamber capable of acoustic and environmental temperature testing on an AWD chassis dynamometer.

The most recent addition to DDL is the Low Travel Driving Simulator (LTDS). The LTDS is a nine-axis electric actuated driving simulator utilizing a partial vehicle buck and a motorized test stand to recreate vehicle functions in a simulated environment. The simulator incorporates a 280 degree projection screen encircling the vehicle buck. An elevated and tiered observation room allows unfettered viewing and control of the test simulations.

Albert Kahn’s expertise in designing highly technical, heavily regulated, environmentally sensitive and complex facilities was exemplified through the work done on Volvo’s first North American Headquarters Office and Manufacturing facility.

Ridgeville, South Carolina

Volvo Cars, the Swedish auto manufacturer, awarded planning and design of their first North American Headquarters Office and Manufacturing Facilities to the design-build team of Yates Constructions-Albert Kahn Associates. This campus of six major buildings in Ridgeville, South Carolina will produce 100,000 new S60 models for worldwide distribution.

The facility includes a Body Assembly and Robotic Welding Shop, Finish Operations Shop, Utility Building, Fluids Building, and Guardhouses – all designed with responsible, sustainable practices as a high priority.

As Volvo’s master architect, Kahn also provided the architectural design features of the paint shop, as well as the mechanical/electrical design for the paint shop utilities and wastewater building.

The high-tech, functional aesthetic draws from the “ form follows function design philosophy using a collaborative workplace model to promote quality, productivity, and elimination of waste. “ Lean ” Master Planning, Programming, Design, and Construction was employed in a collaborative design-build approach to bring the production process on-line in an amazingly short period of time.

Albert Kahn’s design of Volvo Car University sets a new benchmark in sustainable, low-impact architecture, achieving LEED Gold certification while creating an inspiring, nature-connected space that supports Volvo’s mission toward an all-electric future.

The Design-Build team of Kahn-HITT completed the first Volvo Car University. Volvo’s University plays a critical role in the movement toward fully electric vehicles for a more sustainable future. The building contributes to this sustainable vision; its LEED Gold certification bolsters the program’s mission and creates a healthy and inspiring environment for employees.

Project goals emphasized low-impact and sustainability through energy and water efficiency, renewable energy, and space for green vehicles. The connection to nature is established through natural daylight, outside views, 100% fresh air ventilation, living garden walls, natural materials, and more.

Communication was essential. The integrative effort required all disciplines, consultants, and the construction team to work together and maintain open discussions to achieve LEED Gold.

The building is across from Volvo’s Assembly Plant. Embodying the brand, the refined exterior highlights the Scandinavian functional design with a color palette inspired by Volvo’s color standards, which links the building to the adjacent campus.

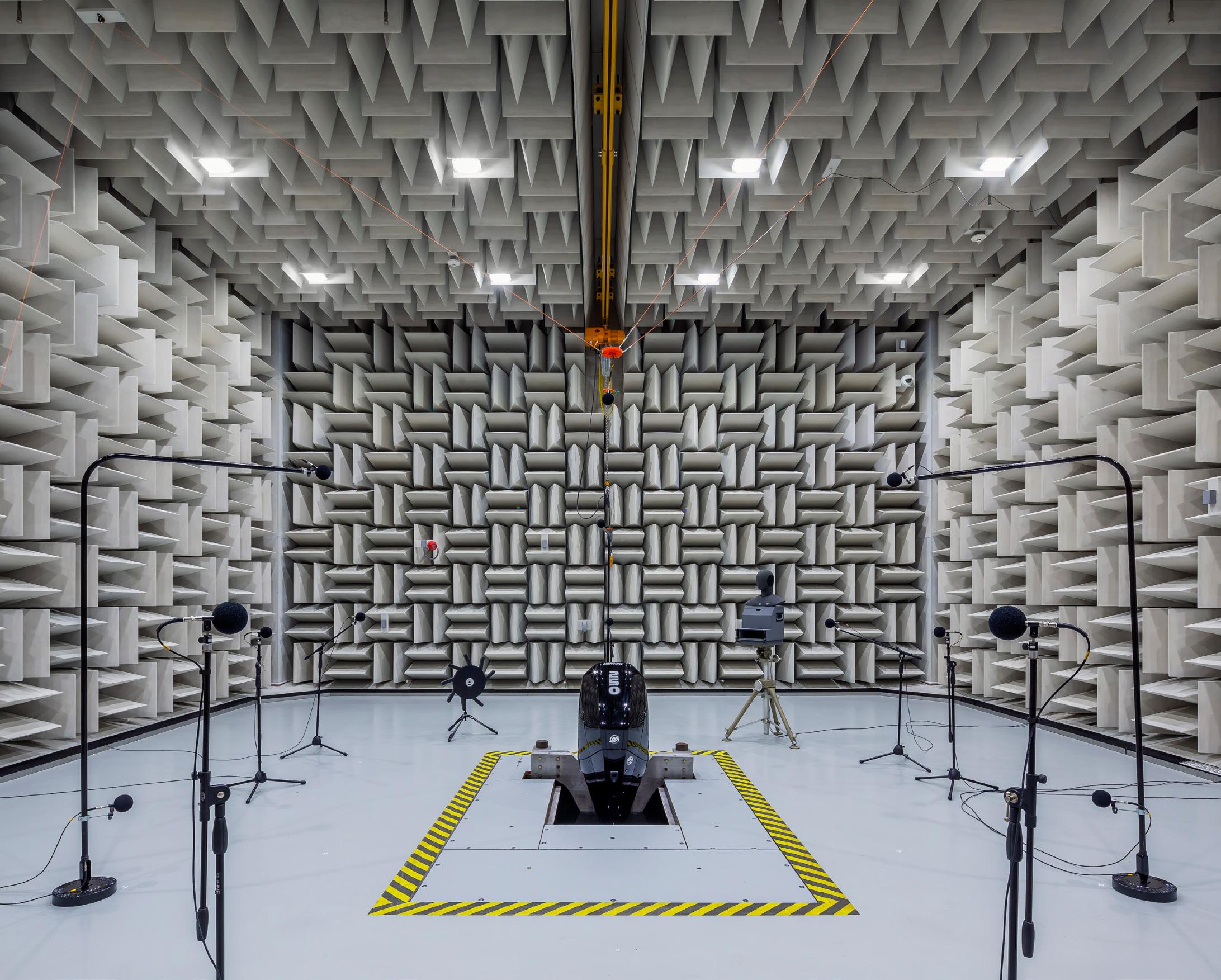

Albert Kahn’s innovative approach to acoustical design and engineering created a state-of-the-art NVH testing facility for Mercury Marine, setting a new standard for performance and transforming their campus with an iconic, collaborative workspace.

Fond Du Lac, Wisconsin

With expertise in acoustical design and engineering, Kahn was contracted to design a Noise Vibration Harshness (NVH) engine testing facility for Mercury Marine.

Mercury Marine recognized that the relentless increase in product technology and motor horsepower drove the need for a next generation facility. Kahn proposed a solution to isolate the vibration noise: an encased testing facility within an office building.

The first floor features engineering spaces with an isolated, independent testing facility negating outside noise infiltration. Within a glass façade, the second floor houses office workspaces utilizing furniture concepts that promote collaboration among the teams.

Not only were the technical needs of the client met, but as with all Kahn projects, the final building transformed their corporate image and became an icon on the campus.

Albert Kahn leveraged its expertise in vehicle manufacturing facility design to create a comprehensive concept for Vinfast’s new Automobile Manufacturing Campus, setting the foundation for a state-of-the-art, greenfield production hub that embodies efficiency, innovation, and strategic site integration.

Cat Hai, Hai Phong, Vietnam

Albert Kahn Associates (Kahn) was engaged by Vinfast for our extensive knowledge in the process of vehicle manufacturing, especially on greenfield sites. The project scope included conceptual design and preliminary design for their new Automobile Manufacturing Campus containing a Press Shop, Body Shop, Paint Shop, General Assembly, Engine Shop, Associated Logistics Area, Office Facility and a 700,000 square meter Supplier Park. Services included conceptual and preliminary design consisting of defining project goals criteria, establishing schedule and budget.

The Kahn team also reviewed site use and improvements, selection of materials, building systems, equipment, construction methods and methods of project delivery. The deliverable was a set of drawings, outline specs and other documents illustrating the scale and relationship of project components.

Albert Kahn’s design for this expansive railcar manufacturing facility seamlessly integrates high-performance industrial operations with sustainable features, creating a collaborative environment that meets rigorous production standards while achieving LEED® Silver certification goals.

With all manufacturing and administrative functions under one roof, both workers and management come together in a high performance, collaborative industrial environment. This 3/4-mile-long building creates an aesthetic and operational bridge among functions, but also meets the specific process and operational requirements of the manufacturing process for railcars.

The facility incorporates many sustainable design features, such as the use of curtain wall, clerestory and roof monitor glass. Energy efficient glass combined with a mechanically assisted natural ventilation system significantly reduces energy consumption and provides workers with access to daylight.

Other key features involve harvesting rainwater from roof and hard surface areas for use in site irrigation; reduction of weld process fumes through advanced fume hood ventilation technology; and utilizing indigenous, droughttolerant plant materials. With LEED® Silver certification serving as the goal for this project, this facility flexibly embraces and balances the needs of workers, the natural landscape, and the surrounding community.

Albert Kahn Associates is committed to designing spaces that prioritize sustainable practices, aiming to create facilities that support both human health and environmental resilience. Central to Kahn’s philosophy is a tailored Sustainable Design Work Plan for each project, aligning building performance with site-specific factors to reduce environmental impact from the start. With over two decades of cross-disciplinary sustainable design expertise, Kahn’s approach is comprehensive, spanning from energy and water efficiency to materials selection, ensuring each aspect of a project works toward sustainability goals.

Kahn’s participation in the AIA 2030 Commitment reflects its dedication to reducing carbon emissions, guiding every project through sustainability analyses and environmentally conscious design workshops. This early-stage focus allows Kahn to provide clients with a range of design and engineering solutions that support long-term sustainability, while also emphasizing costeffective lifecycle performance.

Kahn prioritizes efficient site use by assessing natural resources, topography, and climate, supporting designs that leverage local conditions. Open spaces are planned to accommodate climate needs and minimize environmental disruption, with thoughtful measures to manage stormwater, reduce heat islands, and enhance energy generation through renewable resources.

To conserve water, Kahn integrates low-flow plumbing, recycles greywater, and eliminates the need for traditional irrigation by using native landscaping and capturing HVAC condensate. Advanced water-saving technologies are incorporated to reduce overall water consumption in building operations.

The design process optimizes building orientation and massing to manage solar heat gain and energy loss. High-performance building envelopes, energyefficient systems, and green roofs maximize energy efficiency, often supplemented by renewable energy sources. Smart technology, such as automated building management systems, helps lower operational energy needs.

Materials are carefully selected for their environmental impact, sourcing regionally and recycling construction waste where possible. Recycled and locally-sourced materials reduce transportation emissions and support the regional economy.

Indoor air quality is maintained with CO2 sensors and low-emission materials, while systems are in place to control pollutants and prevent airborne contaminants. Green cleaning and pest management practices are also part of maintaining a healthy environment for occupants. Kahn’s integrated approach ensures that sustainable design principles are embedded in every aspect of a building, from initial site planning to long-term operational strategies, fostering resilient, eco-friendly environments for generations to come.