ABOUT THE COVER

AAPEX 2025

The Venetian Expo & Caesars Forum Las Vegas 4 – 6 November 2025 www.aapexshow.com

SEMA Show 2025

Las Vegas Convention Center 4 – 7 November 2025 www.semashow.com

Automechanika Shanghai

National Exhibition and Convention Center (Shanghai)

26 – 29 November 2025 www.automechanika.messefrankfurt.com

Automechanika Dubai

Dubai World Trade Centre 9 – 11 December 2025 www.automechanika.messefrankfurt.com

PRI Show 2025

Indianapolis, Indiana, USA 11 – 13 December 2025 www.performanceracing.com/tradeshow

Australian Auto Aftermarket Expo 2026

Melbourne Convention & Exhibition Centre 14 – 16 May 2026 www.autoaftermarketexpo.com.au

Collision Repair Expo 2026

Melbourne Convention & Exhibition Centre 14 – 16 May 2026 www.collisionrepair.com.au Wayne

Acme Impex Pty Ltd

42 Francis Greenway Drive

CHERRYBROOK NSW 2126

Midway Auto Port

117 North Road RYDE NSW 2112

Ph: 02 9878 2592

Ph: 02 9007 0407 E: nirav.desai@acmeimpex.co.nz

Aussie 4X4 Centre

1/11 Blackburn Drive PORT KENNEDY WA 6172

Ph: 0417 539 111 E: info@aussie4x4centre.com.au

AutoPlus Bayswater

758 Mountain Highway BAYSWATER VIC 3153

Ph: 03 9729 5755

AutoPlus Dandenong

14 Lonsdale Street DANDENONG VIC 3175

Ph: 03 9706 9636

AutoPlus Fawkner

1369 Sydney Road FAWKNER VIC 3060

Ph: 03 9357 3340 E: fawkner@autoplus.com.au

Bosch Car Service Wallan

10A Innovation Street WALLAN VIC 3756

Ph: 03 5669 1614 E: admin@vw-tech.com.au

BSC Auto Electrical

3/55 Anderson Road SMEATON GRANGE NSW 2567

Ph: 02 4627 3871 E: info@bscautoelectrical.com.au

Das Auto Haus

1/21 Bessemer Street BLACKTOWN NSW 2148

Ph: 0484 561 649 E: msaautomotivegroup@gmail.com

Gallagher

2/74 Gheringhap Street GEELONG VIC 3220

Ph: 03 9021 7700 E: Dean.OHalloran@ajg.com.au

Jack Beedhams Exhaust & Brake Centre

208 Anzac Avenue REDCLIFFE QLD 4021

Ph: 07 3283 1000 E: jackbeedham@bigpond.com

Jax Tyres & Auto Forrestdale

U6/6 Remisko Drive FORRESTDALE WA 6112 Ph: 08 6384 1200 E: rajesh.kumar@jax.com.au

MDR Automotive

51A Oborn Road MOUNT BARKER SA 5251 Ph: 08 8464 0084 E: info@mdrautomotive.com.au

Melling Mechanical

444 Rouse Street TENTERFIELD NSW 2372

Ph: 02 6736 3555

E: workshop@mellingmechanical.com.au

CHAIRMAN

E: midwayautoport@live.com.au

Quicktech

117 Industrial Road OAK FLATS NSW 2529

Ph: 02 4257 9771 E: lawrence@quicktech.com.au

Rapid Tune Airport West

95A Matthews Avenue AIRPORT WEST VIC 3042

Ph: 02 9338 7757 E: airportwest@rapidtune.com.au

Rapid Tune Clyde North

2-8 Palladium Circuit

CLYDE NORTH VIC 3978

Ph: 03 5902 7000 E: Clydenth@rapidtune.com.au

Rapid Tune Strathpine

10 Dixon Street STRATHPINE QLD 4500

Ph: 07 3495 0229

E: inventerholdings@rapidtune.com.au

Repco Authorised Service Edithvale (Edithvale Motors)

222 Nepean Highway Edithvale VIC 3196

Ph: 03 9773 1722 E: info@edithvalemotors.com.au

Repco Authorised Service Webberton (Allround Mobile Mechanic)

6 Boyd Street WEBBERTON WA 6530

Ph: 0475 686 490

E: allroundmobilemechanic@gmail.com

Rotor Sport Development

2/8 Cornwall Road INGLEBURN NSW 2565

Ph: 02 9618 6103

E: rororsportdevelopments@gmail.com

Tyre Plus Newport

45 Mason Street NEWPORT VIC 3015

Ph: 03 9391 0666 E: newport@tyreplus.com.au

Ulladulla Diesel Services

9A Wilfords Lane MILTON NSW 2538

Ph: 02 4454 2646

E: ulladulladieselservices@outlook.com

United Fuel Injection PO BOX 141 GUILDFORD WA 6935

Ph: 0483 0288 08 E: kringrose@unitedfuel.com.au

DIRECTORS

Australia has a productivity problem. Our national productivity growth has flatlined, wage growth is stagnating, and businesses – particularly small and medium enterprises – are being asked to do more with less.

In this climate, the search is on for practical, shovel-ready reforms that can help unlock productivity gains across the economy. One such lever is hiding in plain sight: Australia’s Motor Vehicle Service and Repair Information Sharing Scheme.

Right to Repair (R2R) is more than a consumer rights issue. It is a productivity reform with proven economic benefits. And now that the Federal Minister responsible for the scheme has been assigned the Productivity portfolio, the time has come to elevate R2R from niche policy to centre stage.

When the Motor Vehicle Information Scheme (MVIS) law was introduced in 2022, it was rightly lauded as world-leading, and one that we were very proud to champion on behalf of our industry. The law gave independent mechanics the legal right to access the same service and repair information as car dealerships – leveling the playing field and restoring choice to consumers. But its economic benefits are just as compelling.

According to independent research commissioned by the AAAA, since the introduction of the MVIS:

• 65 percent of independent repairers report improved productivity, with less time wasted searching for repair data and more vehicles serviced each day;

• 61 percent report increased revenue, and 55 percent report higher profitability—clear signs that better information access leads to better business performance;

• The number of vehicles turned away by independent workshops has dropped by 40 percent, enabling more work to be done locally.

These are not abstract gains. They represent real improvements in workshop efficiency, consumer access, and market competitiveness – exactly the kinds of changes that drive national productivity growth.

Yet these gains are only partial. The scheme, as it stands, is working well for larger workshops and brand specialists but is being undercut by structural barriers that continue to lock out smaller, multi-brand repairers. These include:

• The lack of a universal scan tool standard, forcing technicians to purchase or rent brandspecific diagnostic equipment that can cost up to $510 per day;

• The exclusion of telematics data, which is essential for diagnosing and calibrating modern vehicles, particularly those equipped with Advanced Driver Assistance Systems (ADAS);

• The failure to formally recognise data aggregators, used by 87 percent of independent workshops, as critical delivery channels for multi-brand repair information;

• The complexity and cost of navigating over 60 separate OEM portals, each with its own subscription model, access rules, and tooling requirements. These issues are more than inconvenient – they are productivity killers. In an industry where time is money, these inefficiencies reduce throughput, inflate costs, and create two classes of repairers: those with the capital to participate fully, and those locked out by design.

What’s worse is that these problems have simple, internationally tested solutions. In the United States, Massachusetts law mandates access to real-time telematics and prohibits the use of proprietary diagnostic tools to block independent repair. In Europe, Regulation 2018/858 requires all automakers to provide full diagnostic and repair data – including telematics – in standardised formats. These laws recognise what Australia must now act on: that productivity in the digital age depends on open access to information.

The AAAA has put forward a series of practical, cost-neutral reforms that would lift the scheme’s productivity dividend. These include:

• Mandating a universal pass-through diagnostic standard (SAE-J2534), enabling repairers to use non-proprietary tools;

• Requiring OEMs to license all relevant repair data to data aggregators, to ensure efficiency and affordability;

• Bringing telematics and dynamic ADAS calibration data within the scope of the scheme, reflecting how vehicles are repaired today.

Taken together, these reforms would not only expand consumer choice and reduce repair costs – they would unlock a wave of small business productivity across Australia. And with over 27,000 independent workshops servicing millions of vehicles each year, the multiplier effects would be significant.

If the government is serious about lifting productivity, Right to Repair must be seen for what it is: a targeted, proven and largely noncontentious reform that improves business efficiency, enhances market competition, and helps put downward pressure on the cost of living. We now have a Minister responsible for both Productivity and Right to Repair, and the opportunity to lead on this reform has never been greater. The legislative foundations are in place. The scheme is working – but not yet for everyone. With minor changes, we can maximise its productivity potential and ensure that every Australian mechanic can get on with the job of keeping our economy moving.

Chief Executive Officer

It is an exciting time to be part of the Capricorn Community as we set our sights on the next 50 years of working together and backing one another

As Capricorn marks 50 years, Capricorn Group CEO Brad Gannon is looking ahead with energy and optimism

AAAA notes that with some reforms, this scheme can become a productivity powerhouse

The Australian Automotive Aftermarket Association (AAAA) has called on the Federal Government to unlock the full productivity potential of the Motor Vehicle Information Sharing Scheme, describing it as a “ready-made economic reform hiding in plain sight.”

While the scheme is already delivering major benefits for independent repairers and consumers, AAAA Chief Executive Officer Stuart Charity has warned that key structural barriers must be addressed for it to help meet Australia’s pressing productivity challenges.

“With national productivity growth stagnating, we should be backing reforms that are already working,” Stuart said.

• Vehicles being turned away due to lack of access to data has dropped by 40 percent, enabling more work to be completed locally.

“These are not theoretical improvements – this is productivity in action,” Stuart said.

It is an exciting time to be part of the Capricorn Community as we set our sights on the next 50 years of working together and backing one another. Last month, we proudly launched our ‘2030 Powering Forward’ strategy – a plan built on shared values and collaboration. More will be shared over time. A key part of this strategy is continuing to connect Members with trusted Preferred Suppliers who understand the day-to-day needs of automotive businesses.

Capricorn’s Ecommerce Partner program is growing, with Members now able to shop online with JB Hi-Fi Business in Australia and Partmaster in New Zealand. These partnerships make it easier for Members to get what they need, while still enjoying the Capricorn benefits they know and trust. If you want to find out more about Capricorn member benefits, visit our website.

Every year we bring our Community together at the Capricorn Gala Dinners and Trade Shows – these events are a highlight of the year, offering a chance to connect with the Capricorn Community, explore new products, and celebrate our shared achievements. This year they will be held on 13 September (Melbourne), 20 September (Sydney), 11 October (Auckland), 25 October (Perth), 8 November (Gold Coast), and 15 November (Adelaide).

We’re also excited to be hosting Career Expos/ Showcases at the Queensland and South Australia events – a fantastic opportunity for apprentices to meet potential employers and explore career pathways in the industry. Tickets are available now for Capricorn Members via myCAP, our online platform. I hope to see you there.

For more on Capricorn Society membership, visit www.capricorn.coop

“The Motor Vehicle Information Sharing Scheme is delivering real gains – higher workshop efficiency, lower costs for consumers, and stronger competition.

“But it could do so much more if a few key roadblocks were removed.”

The AAAA has urged the Government to strengthen the scheme by adopting a series of practical and cost-neutral reforms, including:

• Mandating a universal diagnostic tool interface such as SAE-J2534;

• Expanding the scheme to include access to critical telematics data and ADAS calibration systems;

• Ensuring fair access for data aggregators used by the vast majority of workshops;

Research conducted by Fifth Quadrant on behalf of the AAAA highlights the scheme’s measurable impact:

• 65 percent of workshops report improved technician productivity since the scheme was introduced;

• 61 percent report increased revenue, and 55 percent report higher profitability;

“We have independent repairers doing more work in less time, with better results for consumers and more competitive pricing across the board.”

AAAA also welcomed the addition of Productivity to the portfolio of Assistant Minister for Competition, Dr Andrew Leigh, describing it as an opportunity to lead a second phase of reform that will benefit small business, regional communities, and working families.

“Dr Leigh has a strong track record of championing evidence-based policy, and the data is clear: Right to Repair is working. Now let’s finish the job,” Stuart said.

“With the right reforms, this scheme can become a productivity powerhouse – not just for our industry, but for the entire economy.”

The Australian Automotive Aftermarket Association is the only independent national body representing and supporting the automotive aftermarket industry.

AAAA members are manufacturers, suppliers and retailers of automotive parts and accessories, tools and equipment and providers of service, repair and vehicle modification.

To learn more about the AAAA head to www.aaaa.com.au

“We’ll have to void your warranty if you don’t service with us.” “You must use genuine parts.” “Only our technicians are trained to do it properly.”

These are the kinds of statements Australians hear every day when they purchase a new car — especially if that car is electric. They sound official. Legal. Final. But often, they’re not just misleading – they are wrong.

Welcome to the world of warranty creep, where car manufacturers stretch the boundaries of warranty conditions to control the post-sale market, lock out independent workshops, and limit consumer choice.

What is warranty creep?

Warranty creep refers to the gradual expansion of warranty conditions – often through fine print or verbal pressure at the dealership – that appear to limit a consumer’s rights.

It typically involves:

• Requirements to use only “genuine” parts;

• Claims that servicing and repairs must be done by authorised dealers;

• And, increasingly, “extended warranties” that sound generous but are only valid if the customer stays within the dealer network. It is a quiet but effective strategy which undermines Australia’s independent repair sector, and it is on the rise.

The “extended” warranty trap

Several carmakers are now offering extended warranty programs of up to ten years, but with significant strings attached.

• Nissan advertises a 10-year extended warranty, but access to the full term is conditional on servicing at Nissan dealerships.

• Mitsubishi’s 10-year warranty comes with the same requirement.

• MG promotes a 10-year/250,000 km warranty – again, tied to dealership servicing for the full duration.

These warranties are promoted as “peace of mind,” but what they actually do is restrict consumer choice and discourage independent servicing. For many customers, this link between warranty and dealership loyalty isn’t made clear until after purchase.

Under the Australian Consumer Law (ACL):

• You are entitled to have your vehicle serviced by any qualified mechanic;

• You do not have to use “genuine” parts – only parts that are fit for purpose;

• A manufacturer cannot void your warranty simply because you choose an independent workshop.

These rights apply to all vehicles – petrol, hybrid, or electric.

As the ACCC puts it: A warranty does not override your consumer guarantee rights, which apply regardless of what the manufacturer says or whether you use a dealer for servicing.

And yet, we continue to see warranty documents and marketing materials that suggest otherwise.

This creates confusion, reinforces a false sense of obligation, and places unfair pressure on consumers.

This isn’t about protecting vehicle safety or ensuring quality work. It is about controlling the post-sale ecosystem.

As vehicles become more complex – particularly with software-driven systems and EV platforms –access to data, software updates, and diagnostics is as valuable as access to the physical parts.

Warranty conditions are increasingly used as leverage to:

Lesley Yates,

AAAA Director of Government Relations and Advocacy info@aaaa.com.au

• Restrict access to service and repair information;

• Withhold scan tool compatibility and telematics data;

• And lock customers into dealer networks by creating fear and uncertainty about their rights.

Industry surveys show that more than 40 percent of consumers believe they will lose their warranty if they don’t service with the dealer – a belief that benefits carmakers but is not supported by the law.

What comes next — and what we’re doing about it

At the Australian Automotive Aftermarket Association, we’ve raised our concerns directly with the ACCC, and we’ll continue to press for action.

We strongly object to the rise of extended warranties that are conditional on dealership servicing.

They may look like generous offers, but in practice they mislead consumers, reduce competition, and lock out independent service providers who do high-quality work.

We’ve warned regulators that unless they intervene, this tactic will become even more widespread – especially as EVs and softwarecontrolled vehicles become the norm.

Independent workshops have a critical role to play here – not just in providing competitive and skilled servicing, but also in helping educate customers about their rights.

When trusted local mechanics explain what the law really says, it empowers consumers to make confident, informed decisions.

Because at the end of the day, fair competition, honest information, and freedom of choice are worth protecting – and we intend to keep fighting for them.

If you would like to offer your thoughts on this subject, please email advocacy@aaaa.com.au

A recent special event tackled the topic, ‘How Does a Car Work?’

More than 60 women from across the automotive industry gathered at the Australian Automotive Aftermarket Association (AAAA) headquarters in July for a sold-out event designed to demystify the workings of a car and build confidence across every corner of the aftermarket.

Hosted by AAAAWomen, the event ‘How Does a Car Work?’ combined relaxed networking with hands-on education, creating a warm, welcoming space where attendees could ask questions, get clarity, and learn the fundamentals of vehicle operation, with no prior knowledge required.

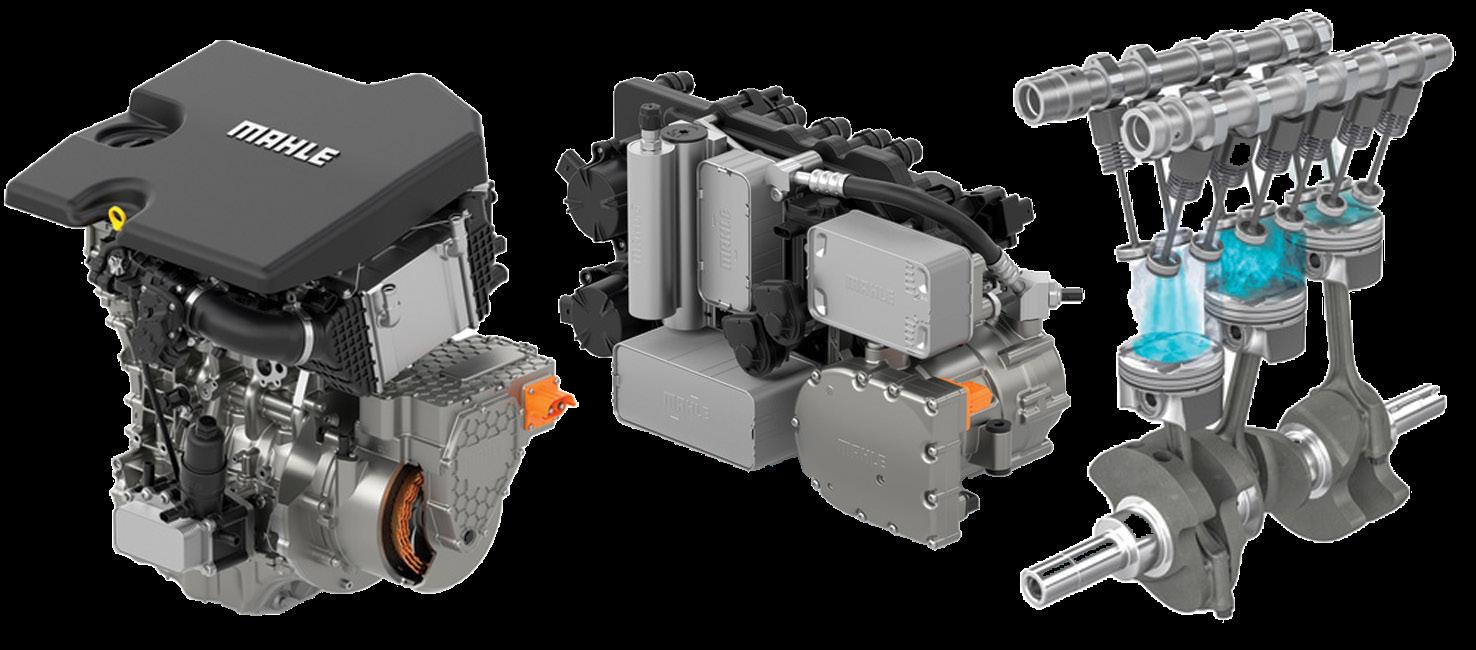

Guided by Auto Innovation Centre (AIC) Managing Director, Luke Truskinger, the interactive session walked through how vehicles turn fuel or electricity into forward motion.

“This wasn’t just a technical workshop – it was an empowering night,” AAAAWomen Steering Committee member and MC for the event, Ange Wall, said.

“So many women told us they’d been nodding through car talk for years.

“Now they feel more equipped to join the conversation – and that’s what this is all about.”

Luke used plain language, engaging visuals, and real-world examples to explain the basics of internal combustion and the role of key components.

“Being asked to present content that I love to an audience who was eager to learn was an absolute pleasure,” Luke said.

“As a certified car nerd, I love talking about the origins of the car and where the technology has come from and why they are the way they are now. A foundational understanding of this is essential to understand how a car works.”

“The best part of the night for me was just how engaged the participants were. They really

brought along their inquisitive nature and plenty were armed with questions they had wanted to get answers to for some time,” added Ange.

“This was the first event of its kind and we were nervous about how it would go but as soon as it started I could tell it would be smooth sailing.”

The group did a theory session in the AAAA training room before going down to the workshop in groups to see a couple of brand new vehicles mid-teardown. Having vehicles and components to talk around complemented the theory and flushed out even more questions.

Attendees came from all parts of the aftermarket – parts interpreters, merchandisers, auto service advisors, marketers, product managers, and head office staff – all with a shared interest in understanding the technical side of the vehicles they support every day.

“This is about giving women across the aftermarket industry the language and confidence to be heard,” AAAAWomen Committee Member and AAAA Director of Government Relations, Lesley Yates, said.

“Whether you’re working front of house or in head office, understanding how the mechanical systems work – even just the basics – makes a real difference.

“It gives you the confidence to speak up, ask questions, be part of the conversation and be more effective in your role.”

Attendees learned how energy from fuel or electricity becomes momentum; the fundamentals of internal combustion and hybrid power; the role of components like pistons, camshafts, crankshafts, valves and more; common mechanical terms explained in plain English; and how to confidently talk about vehicle issues with colleagues, customers, or suppliers.

Held in AAAA’s dedicated training space, the AIC workshop was transformed into a learning lab,

while the upstairs space buzzed with connection over drinks and snacks.

Photos from the evening captured the energy of the crowd, from note-taking and curious questions to moments of shared laughter.

“This was the first time I felt like I could ask the ‘dumb questions’ – and they weren’t dumb at all,” said one participant.

“I finally understand how all the moving parts work together! Now I don’t just sell the parts – I get why it matters.”

This event is part of a broader slate of AAAAWomen initiatives aimed at connecting, educating, and celebrating the women who power Australia’s $58B aftermarket industry.

With Connection Circles, national networking events, and potential future tailored sessions, AAAAWomen is creating a vibrant and visible community of support and shared growth.

Following the success of ‘How Does a Car Work?’, the team is already exploring follow-up sessions and new topics based on attendee feedback, including future events in Sydney and a repeat of this session in 2026.

The Australian Lubricant Association is championing excellence in the lubricant industry

After the landmark success of its inaugural conference in 2024, the Australian Lubricant Association (ALA) says it is proud to announce its second annual conference, set to take place on Tuesday September 3 in Melbourne.

Established to foster collaboration, knowledgesharing and advocacy within the Australian lubricant sector, the ALA says it has become a unifying force in the lubricant industry.

It says that last year’s event was more than just a conference, stating instead that it was a turning point which brought together more than 80 lubricant professionals, technical experts, OEM partners, additive companies, distributors, and regulators for a full day of insight, innovation, and networking.

The feedback was clear: there is a real hunger for connection and collective advancement in the industry.

ALA says delegates praised the quality of speakers, the breadth of topics, and the rare opportunity to engage with peers from across the value chain, all under one roof.

Now, the ALA states the enthusiasm and

momentum generated have set the stage for an even bigger and more ambitious follow-up in 2025. This year’s conference will offer a dynamic program designed to address the most pressing trends shaping the sector today.

From emerging technologies and formulation challenges to regulatory shifts, sustainability imperatives, and supply chain dynamics, the agenda will cover a wide spectrum of topics relevant to lubricant professionals at every level.

Thought-provoking keynote presentations from leading industry figures featuring diverse voices from across the sector will be coupled with focused networking opportunities that foster real collaboration.

As the lubricants industry evolves in response to the energy transition, electric mobility, circular economy models and digital innovation, the ALA says it is committed to ensuring its members remain informed, connected and future-ready. This event is not just for major manufacturers or suppliers, it is for anyone involved in the formulation, application, distribution, testing, or regulation of lubricants. Whether you’re working

in automotive, industrial, commercial, marine, or agricultural sectors, ALA says your voice and your experience are vital to the conversation.

Whether you’re a returning delegate or considering attending for the first time, the ALA encourages you to mark your calendar for Tuesday September 3 and join it in Melbourne to be part of a growing, thriving community dedicated to advancing excellence in lubrication.

For more information about the conference, sponsorship packages, membership opportunities or to register, email info@lubeassoc.com.au or visit www.lubeassoc.com.au

The digital agency has delivered an award-winning eCommerce platform driving global growth for Ironman 4x4

Ironman 4x4, a Melbourne-founded manufacturer of rugged off-road vehicle components, has taken a major leap forward in its global expansion efforts with the rollout of a fully integrated, enterprisegrade eCommerce platform.

This award-winning project, which earned the 2025 iTnews Benchmark Award for Best Retail Project, was delivered in partnership with digital agency Soul+Wolf and Netsuite Implementor, PKF Digital. It involved a bespoke integration of Shopify Plus and Oracle NetSuite, streamlining operations across multiple continents while significantly improving the B2B ordering experience for distributors.

With a legacy dating back to 1958 (formerly Jacob Spring Works), Ironman 4x4 has grown from local suspension specialists into a recognised global brand serving recreational drivers and military fleets alike.

Yet, as demand for its products grew internationally, outdated technology began to constrain the business.

Until recently, the company relied on a decades-old ERP system and disconnected global operations, resulting in manual processing, inconsistent user experiences and missed opportunities for automation.

“Our mission was clear: digitally transform Ironman 4x4 to improve global efficiency and enhance the customer experience, particularly for B2B clients,”

Soul+Wolf Co-Founder and Managing Director, Marco Rosano said.

The new platform was built on Shopify Plus with a fully customised B2B ordering interface and seamless NetSuite integration.

Designed to handle the complex data needs of a multinational parts supplier, the solution now delivers real-time visibility across key business data points – inventory, pricing, vehicle compatibility, warranty claims and more – via a single source of truth.

To mention just a few, users can now pull real-time data on customers, companies, vehicles, products, stockists, inventory, complex pricing rules, warranty claims, and general enquiries.

Since go-live, Ironman 4x4 says it has recorded a 20 percent increase in B2B orders within the first two months, with marked improvements in operational efficiency, order accuracy, and user satisfaction. Beyond functionality, the platform was engineered for growth. Each regional store – Australia, USA, Thailand and beyond – is tailored to the buying behaviours and market conditions of that geography.

While Australian users are guided through an interactive “build-your-vehicle” catalogue designed to drive in-store sales, US customers are served through a full direct-to-consumer (D2C) online shopping experience.

The back-end system accommodates multilanguage, multi-currency needs, and even allows B2B clients to place international container-load orders where required.

With SEO improvement as a key focus of the migration, Ironman 4x4 also achieved a record high 23 percent increase in Google search visibility, driven by an enhanced user experience and streamlined content management capabilities. With further rollouts planned across Asia and Europe, Ironman 4x4 says its digital revamp sets a compelling benchmark for other aftermarket suppliers seeking to modernise legacy systems and scale both locally and globally.

If you have questions about how to elevate your eCommerce experience, Soul+Wolf invites you to contact its team on hello@soulandwolf.com.au, call on 03 7018 8138, or visit www.soulandwolf.com.au

To explore Ironman 4x4’s newly launched site, visit www.ironman4x4.com.au

The event has been lauded as a rewarding business and engaging lifestyle experience for global and local automotive participants

Automechanika Ho Chi Minh City has been deemed a successful event and rewarding platform for business activities, workshop engagement, and entertaining attractions by participants.

This international affair featured 401 exhibitors from 16 countries and regions, and 17,075 visitors from 48 countries and regions.

It served as a two-way gateway for connecting with local OEMs, manufacturers, distributors, traders, wholesalers, retailers, and end-users facilitating business deals, market exploration, brand building and investment opportunities.

To support this collaboration, specialised zones helped attendees grasp the chance to explore technologies and innovations that address trends such as energy transition, digitalisation, connectivity, sustainable practices, and more throughout the value chain.

“The past few days spotlighted the direction in which the market is heading and showcased Vietnam’s vibrant and prosperous automotive industry, which is both embracing and catching up to global trends,” Overseas Director of Yorkers Exhibition Service Vietnam, Akai Lin, said.

“This makes it all the more important that we can provide a platform to host international leaders who can offer solutions to keep Vietnam aligned with development and support a robust automotive ecosystem. Automechanika Ho Chi Minh City has evolved into a comprehensive meeting point for global and local pioneers to network, learn, and enjoy distinct experiences through business activities, workshops, and entertainment.”

Organisers state that participants commended how the fair supported collaboration between local and global industry players.

There was no shortage of opportunities for this,

with buyers ranging from countries and regions including Cambodia, China, France, Germany, India, Indonesia, Japan, Malaysia, Myanmar, South Korea, Singapore, USA, and more. Over 60 one-on-one business matching sessions were lined up in the event.

Much of the spotlight at the fair centred on the energy transition, EVs, and related technologies, reflecting trends in the Vietnamese market.

Expanding on forward-looking innovations was the Automotive Mobility Solutions Zone and Conference, which presented upcoming trends in the auto sector in Vietnam and global markets. Developments in logistics efficiency, supply chain operations, new energy vehicle (NEV) adoption, digital solutions, and more, were particularly noteworthy over the three days. Participants praised the opportunities for growth and possible partnerships.

Other specialised zones contained industryleading companies and include the Parts and Components, Electrics and Electronics, Automotive Repair and Maintenance / Body and Paint / Care and Detailing / Oils, Lubricants and Fuels / Accessories and Customising areas presenting advanced technologies in these sectors. The showcases also catered to regional lifestyle trends by displaying the best in Modified Cars, and Outdoor, Camping, Campervan and Caravan.

Also receiving positive feedback was the fringe programme, which consisted of forums for idea sharing, innovative discussions, skill development, and relaxed networking events.

As part of this, the Collision Repair Training Workshop was recognised as a one-of-a-kind event. Participants, including academia and workshop professionals, appreciated the

opportunity to explore and learn the latest techniques and tools for diagnostics and repair, and modern workshop practices by engaging in live demonstrations.

Connecting with end-users was also a source of inspiration at the fair, with autoFEST@HCMC delivering engaging and entertaining experiences designed to celebrate a variety of cultures within the automotive sector.

For example, the Drift and Stunt Show showcased the skills of world-class drifters, and the autoFEST@HCMC Music Party provided a lively atmosphere for fairgoers to connect with one another in an energetic setting for new generations and the future talents of the value chain.

Additionally, the EMMA Vietnam – Car Audio and Modifications Competition and Auto Service Day acted as entry points for industry newcomers.

The next edition of Automechanika Ho Chi Minh City will take place from 18 to 20 June 2026. The trade fair is co-organised by Messe Frankfurt (HK) Ltd, Chan Chao International Co Ltd and Yorkers Exhibition Service.

For more information, please visit www.automechanika-hcmc.com or email the organisers at autoasia@hongkong.messefrankfurt.com

The launch comes amidst Penrite Oil 100 Years of Australian ownership and manufacturing celebrations

Penrite Oil says it is proud to announce the official opening of the Penrite Training Centre, which took place on 27 June 2025.

Located at the Penrite head office in Dandenong South Victoria, the event was marked by a special ceremony attended by key members of the Dymond family, including Margaret, Toby, Nigel, Jon, Roland, and Julia Dymond.

The facility is dedicated to the legacy of John ‘JD’ Dymond and Mark Dymond, as part of the celebration of Penrite’s 100 years of Australian ownership and manufacturing.

The Penrite Training Centre is designed to provide a world-class space for its team, customers, and industry partners.

With a capacity to host up to 80 people seated, the centre is fully equipped with modern tools and resources to offer both theoretical and practical learning experiences.

Key features of the Penrite Training Centre:

• Comprehensive product showcase: a full range of Penrite’s high-quality lubricants, fluids, greases, additives and equipment is prominently displayed, providing a hands-on learning experience with the brand’s extensive product line.

• Award displays: the centre proudly showcases all major awards Penrite has received over the years, underscoring its legacy of excellence in the automotive sector.

• Hands-on training: featuring a car hoist, engines and other practical tools, the training centre is fully equipped for hands-on automotive training, ensuring that participants

Lovells has launched a new flagship centre to ‘future proof’ its 95 year legacy

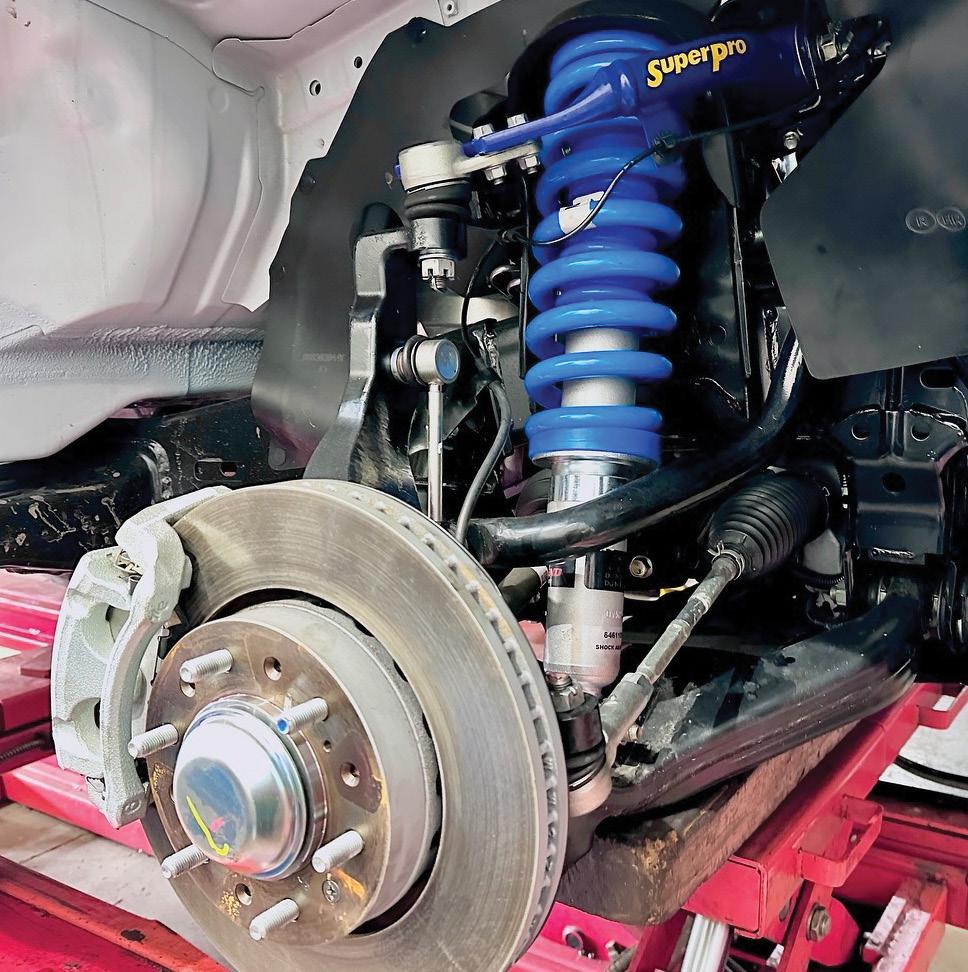

As part of its 95th anniversary and long-standing commitment to innovation, Lovells Group has announced the launch of a new state of-the-art flagship engineering, manufacturing and retail centre in Newcastle, New South Wales.

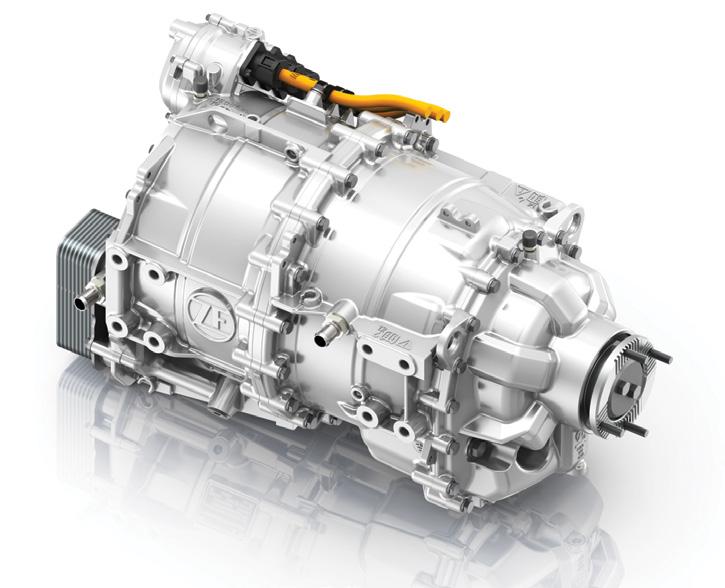

The upcoming 5000m2 facility, adjacent to Lovells’ main manufacturing site, will complement Lovells’ existing R&D hub in Edwardstown, South Australia, and form a critical part of the company’s national innovation ecosystem – supporting the development of next-generation products across electric vehicles (EVs), emerging drivetrain technologies, and advanced suspension platforms.

The investment, valued at $12 million, will create 24 new specialist roles across engineering, advanced manufacturing, product design, and compliance, also absorbing the existing Lovells Special Products manufacturing and design facility.

The centre will offer dedicated capabilities for advanced product fatigue, corrosion and performance testing and evaluation; vehicle dynamic stability analysis; fitment engineering for both OEM and aftermarket applications; and design and manufacture of electro-technology solutions for EV, ET (electric truck) and EB (electric bus) charging systems.

“Our new Newcastle R&D Centre reinforces our commitment to local innovation, advanced engineering, and our role in supporting the future

of transport,” Lovells Group Managing Director, Simon Crane, said.

“Together with our Edwardstown site and The Bend testing facilities in South Australia, this centre will ensure Lovells remains on the cutting edge of suspension, load-carrying, and towing system development.”

As part of its commitment to future research and design capabilities, Lovells Industrial Systems is also transitioning its production facilities to induction heating to support a broader strategy focused on cutting emissions, improving energy efficiency, and phasing out gas use.

The company plans to have three induction units operational by the end of the year and is aiming to achieve a fully gas-free operation within three to four years.

“Induction heating gives us faster, more precise control, allowing us to heat suspension spring steel – which makes up around 40 percent of our output, far more efficiently than gas,” Simon said.

“It is a critical step in futureproofing our facility and cutting our reliance on fossil fuels.”

The new centre builds on Lovells’ South Australian investment, where the company recently launched a $1 million facility in Edwardstown, employing 20 specialists and supporting dynamic testing, retail, and product development for local and international markets.

can engage directly with the products and tools used in the industry.

“This Training Centre represents a significant milestone for us as a fully Australian -owned company,” Penrite Oil Chief Executive Officer, Toby Dymond, said.

“It honours the enduring legacies of my father John ‘JD’ Dymond and my brother Mark Dymond and provides an excellent environment for our partners to learn, engage and grow together with Penrite.”

For more information about the Penrite Training Centre or to schedule a visit, please contact Penrite Oil on 1300 PENRITE or alternatively log an enquiry at www.penriteoil.com.au/contact

For more from Penrite, visit www.penriteoil.com.au

Lovells says this broader national footprint underpins its ability to simulate the most extreme road and climatic conditions for customers around the world.

“Lovells is a company built on innovation,” Simon said.

“This new R&D centre in Newcastle will drive our next chapter of product leadership, especially as we develop solutions tailored for EVs and next-gen vehicle platforms, while staying true to our 95-year foundation of Australian manufacturing excellence.”

From Australia to the Arctic Circle, Lovells exports to more than 30 countries – including diverse markets such as the USA, Saudi Arabia, Norway, Greece, Kazakhstan, and Thailand.

Consisting of a newly simplified structure of two divisions, Lovells Industrial Systems offers design, engineering, manufacturing, and procurement of products, which are then sold and distributed through Lovells Automotive Systems.

The entire Lovells operation is supported by corporate and manufacturing operations located in Newcastle, New South Wales.

For more information, visit www.lovells.com.au

The final free event in a three-city roadshow will be held in Melbourne on September 8

Automotive eCommerce specialist, Zellis, in conjunction with other exhibitors, is currently midway through a free to attend three-city Auto Parts Retail Innovation Summit.

Following events in Brisbane on July 21 and Sydney on 13 August, Melbourne will host the third and final event in this Summit schedule, featuring four expert-led panel sessions between 5.30pm and 8.30pm on September 8.

The premier event is designed to connect and empower automotive parts and accessories sellers across Australia and New Zealand.

Whether you sell in-store, online, or both, Zellis says this summit is your opportunity to tap into expert insights, connect with like-minded peers, and discover the tools and strategies you need to

accelerate your business in today’s fast-evolving automotive retail landscape.

The four sessions will cover:

1. Market opportunity deep dive: explore the current and future landscape of the automotive parts and accessories market in Australia and New Zealand, including emerging trends, consumer behaviour, and growth drivers.

2. Building brand and customer experience: discover how to craft a compelling brand, deliver exceptional customer experiences, and build loyalty. Topics include user experience (UX) best practices, customer engagement strategies, and retention tactics.

3. Conversion and fitment optimisation: learn how to optimise product fitment data, improve conversion rates, and streamline data management and configuration. Hear from leading experts on driving more sales through smarter product presentation.

4. Fulfilment, shipping and global scale: understand the critical link between checkout experience and delivery. Gain practical tips on reducing cart abandonment, enhancing delivery experiences, and scaling your ecommerce presence internationally with localised logistics strategies.

Zellis says attendees can expect to gain actionable insights to grow their business, to learn from successful industry leaders and solution providers, network with fellow automotive retailers and sellers, and be ready to stay ahead of evolving retail and ecommerce trends.

Whether you’re just getting started or looking to scale, Zellis says the Auto Parts Retail Innovation Summit is your roadmap to success in 2025 and beyond.

Spots are limited so Zellis encourages interested parties to reserve their seat today.

For more information and to register, visit https://events.bizzabo.com/723652/home

Free live online training courses, short e-learning courses, and face-to-face trainings are available

MAHLE Lifecycle and Mobility is expanding and restructuring its range of training courses for trading partners, workshops, and fleet operators.

“The need to create opportunities for advanced training for technicians in workshops and employees in wholesale is increasing,” MAHLE Management Committee member and Head of MAHLE Lifecycle and Mobility, Philipp Grosse Kleimann, said.

“With the inauguration of our new Global Training Center in Stuttgart, we have successfully begun the worldwide expansion of our refined training structure.”

The facility has over 1,300 sqm of training space, five fully equipped workshop workstations, and offers enough space to train up to 15 partners simultaneously under practical conditions.

MAHLE will use the Stuttgart model to set up new training centers in other countries, such as France and Italy.

The improved training structure also includes the MAHLE training portal. Interested parties can use this online platform to book training courses but additionally access technical user knowledge across the entire MAHLE portfolio – from spare parts to workshop equipment.

“We see ourselves as a supplier of spare parts and workshop equipment, but also as a strong partner for the workshops with a comprehensive package of solutions that combines consulting, service and training,” Philipp said.

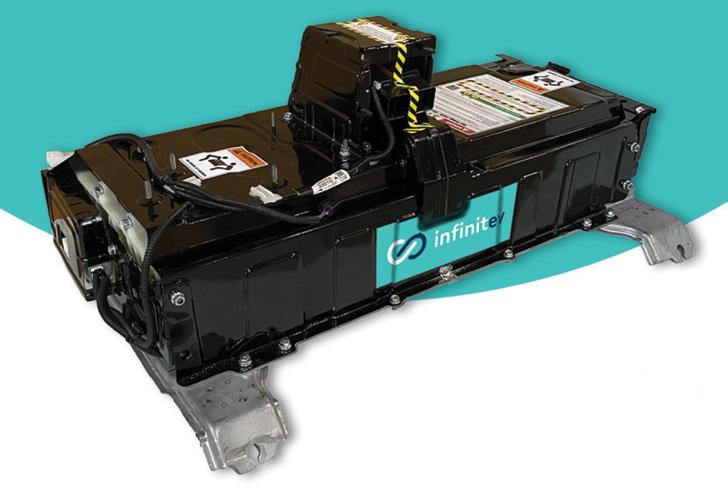

The growing influx of alternative drive types, such as battery-electric or hybrid vehicles, in the independent spare parts market is extending the scope of tasks in workshops to include vehicle diagnostics, cooling circuit maintenance, and work on battery systems.

MAHLE says this is the reason why its spare parts and service division chose the strategic location of the training center right next to the technology group’s development and test center for traction batteries.

“At MAHLE Lifecycle and Mobility, we are increasingly utilising our internal competence to respond early to future developments in the independent spare parts market,” MAHLE Lifecycle and Mobility Director Global Service Solutions, Felix-Matthias Walter, said.

“We are actively looking for proximity to workshops and wholesalers to find out where the greatest need for further training lies.”

The improved MAHLE training portal is expanding the range of training courses for workshops as

well as service providers and offers targeted and flexible opportunities for advanced training for every knowledge level.

Technicians and wholesale partners can choose between free live online training courses, in which qualified trainers are directly available for questions and exchange, and short e-learning courses to impart basic knowledge or provide more in-depth technical knowledge.

In addition, visitors to the portal can book faceto-face trainings quickly and easily and access over 120 technical documents such as damage brochures or oil quantity manuals.

The training offer is available in German, English, Polish, and Portuguese. More languages are currently being prepared.

The training portal can be accessed online at www.training.mahle.com

The MTAA congratulates Frank Agostino on Order of Australia Honour

The Motor Trades Association of Australia (MTAA) says it is proud to congratulate Frank Agostino on receiving the Medal of the Order of Australia for his exceptional service to the automotive industry and community.

As former Chair of MTAA, Frank has been instrumental in advancing the interests of motor traders across Australia.

His leadership and vision have helped shape national policy and strengthen the automotive sector’s voice at the federal level.

Frank’s journey from apprentice mechanic to industry leader exemplifies the entrepreneurial spirit that drives Australia’s motor trade sector.

His extensive business portfolio and commitment to excellence have set a benchmark for industry professionals nationwide.

Beyond his commercial success, Frank’s dedication to charitable causes, including Variety – the Children’s Charity, and Anglicare SA, reflects the values of community service that MTAA champions amongst its members.

“Frank’s contribution to the motor trades industry has been extraordinary. His strategic leadership as Chair of MTAA helped navigate critical industry challenges and positioned our sector for future growth,” MTAA Interim Executive Director, Rod Camm, said.

“This Order of Australia recognition is richly deserved for someone who has dedicated his career to advancing our industry whilst giving back to the community.

“We’re proud to call Frank a valued colleague and leader.”

This recognition is a well-deserved acknowledgement of his significant contributions to our sector and the broader Australian community.

For more from the MTAA, visit www.mtaa.org.au

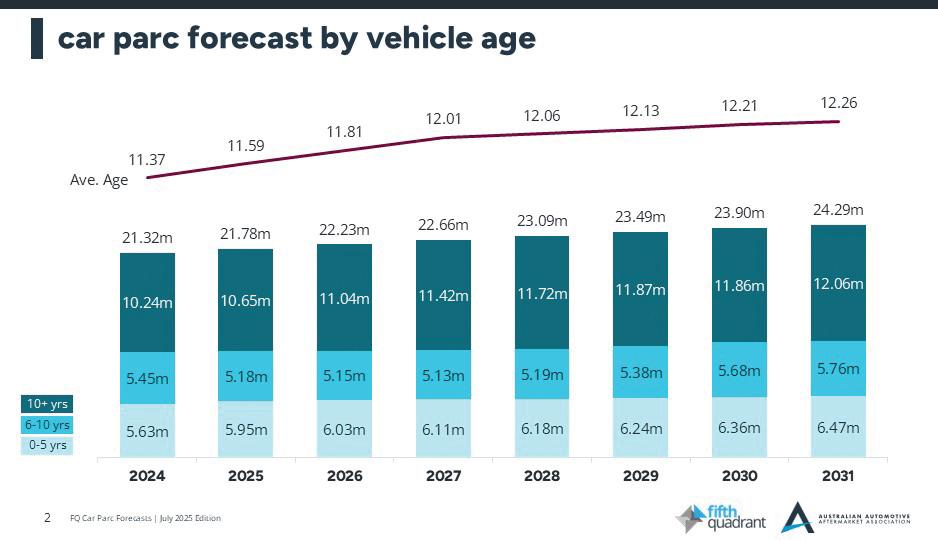

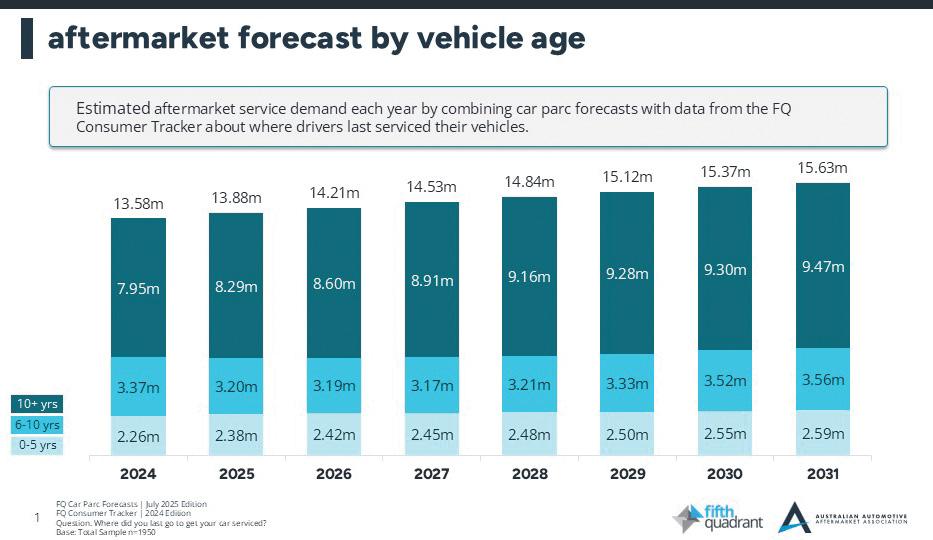

The growing car parc offers a significant opportunity to the Australian aftermarket Australia’s car parc is projected to grow from 21.8 million vehicles in 2025 to 24.3 million by 2031, but for aftermarket workshops, the real story isn’t just about growth, it is about how this expanding fleet is aging and what that means for servicing demand.

The latest edition of the Fifth Quadrant market forecasts reveals a fundamental shift in car parc composition, which will impact where vehicle owners will seek maintenance and repairs in the years ahead.

An aging fleet creates opportunity By 2031, the average age of vehicles in the Australian car parc will reach 12.3 years, with more than 12 million vehicles over 10 years old still on our roads.

This aging trend disrupts traditional dealership relationships, with vehicle turnover creating a natural break point, and driving cars to aftermarket providers for cost-effective maintenance.

But, older vehicles also bring complexity that demands more from workshops as they work to manage aging electronics, complex powertrains, and cumulative wear issues.

Meanwhile, workshops can’t ignore the steady flow of newer, more technologically advanced vehicles moving into the six-10 year category.

The numbers tell a compelling story

Historic vehicle servicing trends gives us a clear idea of the typical distribution of vehicles by age between dealership and aftermarket workshops.

The Fifth Quadrant Consumer Tracker in 2024 reports that aftermarket providers captured 54 percent of drivers’ last scheduled service visits and 63 percent of tyre servicing visits.

Based on this, we can estimate overall aftermarket service demand, projecting it to grow from 13.6 million vehicles in 2024 to 15.6 million by 2031.

What’s particularly striking is how the 10-plus year segment drives most of this growth, expanding to almost 10M vehicles at the end of the decade.

This older segment represents the aftermarket’s sweet spot, where vehicles have aged out of dealer warranties, but are still playing an important role within their household.

The dealership challenge

While these trends favour aftermarket growth, dealerships aren’t retreating quietly.

Capped price servicing, extended warranties, and bundled service plans are retention tools that are being deployed increasingly aggressively as they seek to retain customers beyond traditional thresholds.

These dealership incentives work because they address consumer price sensitivity while offering transparency and perceived value.

For the aftermarket, this means cost advantages alone won’t guarantee customer loyalty.

What this means for workshops

The opportunity is clear: 15.6 million serviceable vehicles by 2031, with growth concentrated in older segments where aftermarket providers excel. But capturing this growth requires planning:

• Technology capabilities: diagnostic tools that handle both the aging electronics in older vehicles, and the sophisticated systems in newer ones.

• Skills development: technicians capable of handling ‘most makes / most models’ to effectively service growing vehicle diversity.

• Value communication: clear articulation of expertise, convenience, and long-term relationship building to compete with transparent dealer pricing and bundled incentives.

The growing car parc offers a significant opportunity to the Australian aftermarket.

Workshops that invest in capabilities, skills, and customer relationships will have the opportunity to define their sweet spot and capture their share of this expanding, aging fleet.

This column was prepared for AAA Magazine by Fifth Quadrant, the AAAA’s partners in the AAAA Aftermarket Dashboard which is delivered to AAAA members each quarter.

For more information about its services, visit www.fifthquadrant.com.au or contact Ben Selwyn on ben@fifthquadrant.com.au

CoolDrive supported the Auto Electrical category and had key personnel on site to supply advice and expertise

CoolDrive Auto Parts has reaffirmed its commitment to Australia’s automotive industry by supporting the 2025 WorldSkills Australian National Championships and Skills Show, which was recently held in Brisbane.

As Australia’s largest vocational education and skills excellence competition, the WorldSkills National Championships brought together the best emerging tradespeople from across the country to demonstrate their technical capabilities, passion, and commitment.

CoolDrive, a long-time advocate for technical training and hands-on learning, played an active role in supporting this prestigious event.

At this year’s Championships, CoolDrive supported the Auto Electrical category by supplying highquality Jaylec components and its General Manager of Training and Development, Scott Williamson, offered on-site advice and expertise.

Industry partner REDARC also provided valuable support, reinforcing the importance of collaboration in fostering skilled professionals.

Competitors in the Auto Electrical category were

assessed across areas reflective of real-world workshop tasks, including schematic drawing and development, the installation of off-grid recreational power products, diagnostics for body control systems and spark ignition engine management, and starting and charging systems.

A new addition to this year’s competition was a focus on electric vehicles, with participants tasked with depowering, repowering, and fault-finding EV systems.

Reece Gallagher from Northern Rivers Auto Electrical claimed the Gold Medal in the Auto Electrical category, while in the Automotive Mechanics category, Edie Thurtell, who was mentored by CoolDrive Technical Trainer Clint Flower, clinched Gold.

“The WorldSkills competition really does highlight the exceptional calibre of talent emerging through vocational training, as well as the dedication of those who mentor and guide them,” Scott Williamson said.

“Our involvement in WorldSkills reflects CoolDrive’s ongoing commitment to championing the next

Autobarn has revealed a brand refresh and ‘All for the drivers’ brand platform via Spinach

With a rich and storied history, Autobarn is this year celebrating its 40th birthday.

To mark the occasion, Autobarn says it called on integrated Melbourne agency Spinach to reinvigorate the brand and reclaim its place in the hearts of minds of drivers.

With 144 stores across the country and an easyto-use online store, Autobarn, part of BAPCOR Limited, says it is Australia’s trusted destination for all things automotive.

“We have the products our customers need and want, but where we truly win is our friendly, passionate experts,” BAPCOR Executive General Manager, Retail, Megan Foster, said.

“We needed to remind our customers what sets us apart. Having worked with Spinach in the past, we knew the team, the quality of their work and their unique style of getting in the trenches.

“That made them the perfect partner for this important piece of work.”

Together, Spinach and Autobarn say they dug deep into the category with a combined, dedicated team that set out to deliver a reinvigoration that would set the brand on course for the next 40 years and create a north star the whole business could head toward.

Using the insight that Aussies love to take care of their cars – not just the revheads – and tapping into the warmth and approachability of the business, the brand platform ‘All for the drivers’ was born.

Appealing to a diverse demographic with women making up half of the customer base, the positioning acts as an inclusive rally cry, challenging the conventions of a category that often speaks primarily to traditional car enthusiasts.

The refreshed brand and positioning are front and centre in a campaign including a 60-second TVC that will roll out across social channels in addition to 30 and 15-second versions set to appear on linear, BVOD and digital channels.

The ambitious campaign features a cast of Autobarn team members and was shot on location at a drive-in during the depths of Melbourne winter.

“To have the whole of the business so enthusiastically embrace and participate is something I’ve not encountered during my 25 years in advertising,” Spinach Executive Creative Director Dom Megna, said.

“This level of passion drives everything forward, and we love the result.”

generation of automotive professionals. Through programs that support skill-building, innovation, and passion, CoolDrive will continue to empower this future talent.

“We extend our congratulations to each and every competitor - reaching the national stage is a remarkable achievement, and we’re proud to support them along the way.”

Next up for Reece, Edie, and the other winners from the WorldSkills Australia National Championships will be WorldSkills Shanghai 2026, which is set to take place from 22–27 September 2026.

For further information on CoolDrive Auto Parts, please visit www.cooldrive.com.au

In the coming months, ‘All for the drivers’ will flow through to retail executions, events and more.

“The Autobarn brand relaunch has been a long time in the making, and now we’re finally here with an amazing finished product,” BAPCOR General Manager, Marketing, Simon Davenport, said.

“There’s so much excitement and anticipation across the business to see it come to life.

“Our refreshed positioning goes straight to the heart of our customer pledge, to be customer-obsessed and support all car owners on their automotive journey, no matter who they are or what their needs may be.”

To view the new campaign, visit the Autobarn YouTube channel.

The new partnership is designed to support automotive apprentices and increase awareness of trade career opportunities

MTA Training and Employment, the Motor Trade Association SA/NT’s registered training and group training organisation, has partnered with REDARC Electronics to promote automotive electrical technology as a trade and increase student awareness of career opportunities in the trade.

The industry-leading partnership will initially run for three years and was formalised through a signed memorandum of understanding (MOU) in May.

Through this partnership, REDARC Electronics will provide MTA Training and Employment with equipment to support automotive apprentice electrical training at the MTA Training and Employment Centre in Royal Park.

MTA SA/NT Chief Executive Officer, Darrell Jacobs, shared his excitement about the partnership.

“This partnership highlights how collaboration between training organisations and industry can

address skills shortages and strengthen career pathways,” Darrell said.

“We have seen substantial growth in our dual trade apprenticeships which pair light or heavy vehicle with automotive electrical trades.

“Since their launch in 2024, 73 South Australians have commenced dual trades, and this partnership will further support this growth.”

Darrell explained how The MTA SA/NT will also utilise its industry leading Schools Pathways Program to continue to highlight the opportunities.

“Through this partnership with REDARC, we will work closely with schools across South Australia to continue to promote automotive electrical as a career choice,” Darrell said.

REDARC has more than 45 years of experience in the design, development and manufacture of a range of electronics built to work in some of the toughest conditions and environments on the planet.

RACV is alerting Victorians to a rising trend in car thefts using on-board diagnostics (OBD) ports

Thieves are increasingly using electronic devices to access vehicles via their OBD ports, enabling them to start and steal cars without the owner’s key.

Victoria Police data has shown that 20 percent of car thefts in 2024 were stolen using this method.

“By connecting unauthorised devices to a vehicle’s OBD port, a thief can communicate directly with the car’s engine control unit, allowing them to program a new key or even start the engine without the original key,” RACV General Manager Motoring Products, Jeff Ames, said.

In addition to OBD port-related theft, RACV is also warning motorists of ‘relay theft’ – where thieves use a device to amplify a signal from your car key, tricking a car to unlock and even start.

“As vehicle technology advances, so do the methods employed by criminals, so it’s crucial for motorists to be aware of these tactics and take appropriate steps to protect their vehicles,” Jeff said.

RACV recommends the installation of OBD port locks to prevent push-start car theft. An OBD lock works by physically securing the OBD port, preventing unauthorised access.

“An OBD lock is a simple, yet effective tool that can significantly reduce the risk of theft by blocking access to the port,” Jeff said.

In general, OBD port locks are easy to install yourself. OBD port locks are cheap and readily available from auto shops and vehicle anti-theft websites.

You will need an OBD lock kit, a screwdriver, and possibly a socket set, depending on your vehicle model. Follow this step-by-step guide to ensure a successful installation:

• Turn your vehicle off and remove any keys

• Locate the OBD port in your car, usually found under the dashboard near the driver’s seat

• Gently remove any panels or coverings over the OBD port

• Secure the lock in place over the OBD port, following the instructions provided with your OBD lock kit

• Reattach any panels or coverings you removed earlier.

You can test the installation by attempting to connect to the OBD port with a diagnostic tool. The lock should prevent access, confirming that your installation was successful.

“We are passionate about investing in the future of automotive technology and its workforce,” REDARC Group Chief Executive Officer, Anthony Kittel, said.

“This partnership with the MTA is a significant step, allowing us to equip apprentices with the latest auto-electrical technology and showcase the value of high-quality Australian-made products.

“It is about fostering the next generation of skilled professionals who will drive innovation and ensure a robust and capable workforce for years to come.”

For more information, visit www.mtasant.com.au and www.redarc.com.au

In addition to installing OBD port locks, RACV recommends the following precautions:

• Secure your keys: always keep your vehicle keys in a safe place, away from doors and windows, to prevent relay attacks. Ensure you also keep your valuables out of sight.

• Install physical deterrents: use steering wheel locks or wheel clamps as visible deterrents to potential thieves.

• Stay informed: regularly update your vehicle’s software with a registered mechanic and be aware of any manufacturer recalls or security updates.

“By staying vigilant and implementing these security measures, vehicle owners can significantly reduce the risk of theft,” Jeff said.

For more information on car theft prevention, visit www.racv.com.au

Megabus provides the following tips for Tyre and Mechanical Workshops seeking to improve cash flow

For Tyre and Mechanical workshops, cash flow is the lifeblood of your business. While growing sales is always a goal, it is equally important to ensure the money owed to you actually arrives on time. Bad debts often reveal themselves too late, after the work is done and the invoice goes unpaid. As the saying goes, “An ounce of prevention is worth a pound of cure.”

Managing your trade accounts proactively, both new and existing, helps ensure consistent cash flow and reduces the risk of unpaid invoices.

Megabus recommends that you consider some practical strategies to help you take control, such as the following:

• Start smart with new customers: always request references and assess credit history before offering 30-plus day terms. Perhaps, you can also begin with COD, seven- or 14-day terms until you have established trust.

• Set credit alerts: configure your system to notify you when a customer reaches their credit limit.

• Take timely action: do not hesitate to change

an account’s status, such as placing it on hold while you follow up on overdue amounts.

• Stay visible: send regular account statements (weekly if needed) to keep customers aware of their outstanding balances.

• Keep records: log every collection effort in your system, including date, contact person, and promises made regarding payment.

• Encourage early payment: offer small discounts for prompt payments as an incentive.

• Reward loyalty: consider providing product or service discounts to trade customers who consistently meet order volume targets.

• Avoid disputes: make it mandatory to record order numbers with each sale to prevent disputes on overdue transactions.

• Simplify statements: if customers operate multiple locations, consolidate their accounts into one overall statement to make management easier.

• Self-serve: give your trade customers the option to order via an online portal, available 24/7 for their convenience.

Megabus says pivoting to these strategies can reduce the risk of bad debt and ultimately strengthen your cash flow, freeing you to focus on what really matters: running and growing your business, not chasing overdue invoices. For more information, visit www.megabus.com.au

ACS has been working with the team from Mighty Car Mods since 2022

The team from Mighty Car Mods have recently announced its new partnership with performance clutch specialists, Xtreme Clutch.

A division of Australian Clutch Services, the Xtreme Clutch brand is a leading supplier of performance clutch kits and components for performance street and motorsport use throughout both Australia and Europe.

Marty and Moog from Mighty Car Mods started their YouTube journey back in 2007, filming DIY car projects on Marty’s mother’s driveway.

Fast forward to 2025, and Mighty Car Mods is one of the largest automotive shows in the world, with more than 3.9 million subscribers and a global audience of enthusiasts following their videos and events.

Mighty Car Mods have been using the Xtreme Clutch product range for several years for their project cars.

“We first got in touch with Xtreme Clutch a few years back for a big power H6 Subaru build, we needed a twin plate that would support 400kw+,” Marty said.

“From there a few more builds came up that needed clutches both big and small in scale.

“The parts worked great and we’ve since used them consistently over the following years.

“We’re excited they’ve come on board as an official sponsor, which opens the door for some bigger and better (manual!) projects.”

Mighty Car Mods will be working with the Australian Clutch Services team on a variety of new projects to be released in the near future.

“We’re excited to welcome Marty and Moog to

our cutting-edge Adelaide head office, where they’ll get an exclusive first look at our newest performance upgrades and dive deep into our custom clutch program, one they’ve used in previous projects,” Australian Clutch Services Customer Service Manager, Dion Coulls, said. “We have some thrilling projects in the works and look forward to showcasing these to our customers across both local and international markets.”

The Xtreme Clutch brand is the performance street and motorsport division of Australian Clutch Services and incorporates a comprehensive range of specially designed and engineered performance clutch upgrades for all popular makes and models.

Alongside the heavy duty 4x4 brand, Xtreme Outback, the Xtreme Clutch range is distributed

around the world via an extensive international distribution network.

These upgrades have been developed over several decades in-house at Australian Clutch Services in Adelaide and the company says they have become renowned for offering a variety of different upgrade options for each vehicle to match the performance goals and driveability requirements.

The new partnership with Mighty Car Mods will showcase the extensive variety of upgrades available for enthusiasts around the globe.

“We have been working with the team from Mighty Car Mods since 2022 and they have been great ambassadors for our brand throughout the enthusiast market,” Australian Clutch Services Marketing Manager, Hayden Jarrett, said.

“With the Xtreme Clutch brand growing internationally and our XClutch brand continuing to evolve in the US, Mighty Car Mods is the ideal team to partner with to showcase our street and motorsport performance upgrades.”

To coincide with the announcement, Xtreme Clutch has also launched an updated website with a more enhanced user interface and design.

“We have freshened up our website to coincide with our new partnership which allows us to add a range of new technical support channels and information to our customer base,” Hayden said.

“We will continue to develop this website alongside our ClutchPro, Xtreme Outback, ACS and AG Clutch websites to ensure our customers have access to the technical specifications and information required to support their decisionmaking process.”

For more information on the Xtreme Clutch range of products, please visit www.xtremeclutch.com.au or call 1800 CLUTCH.

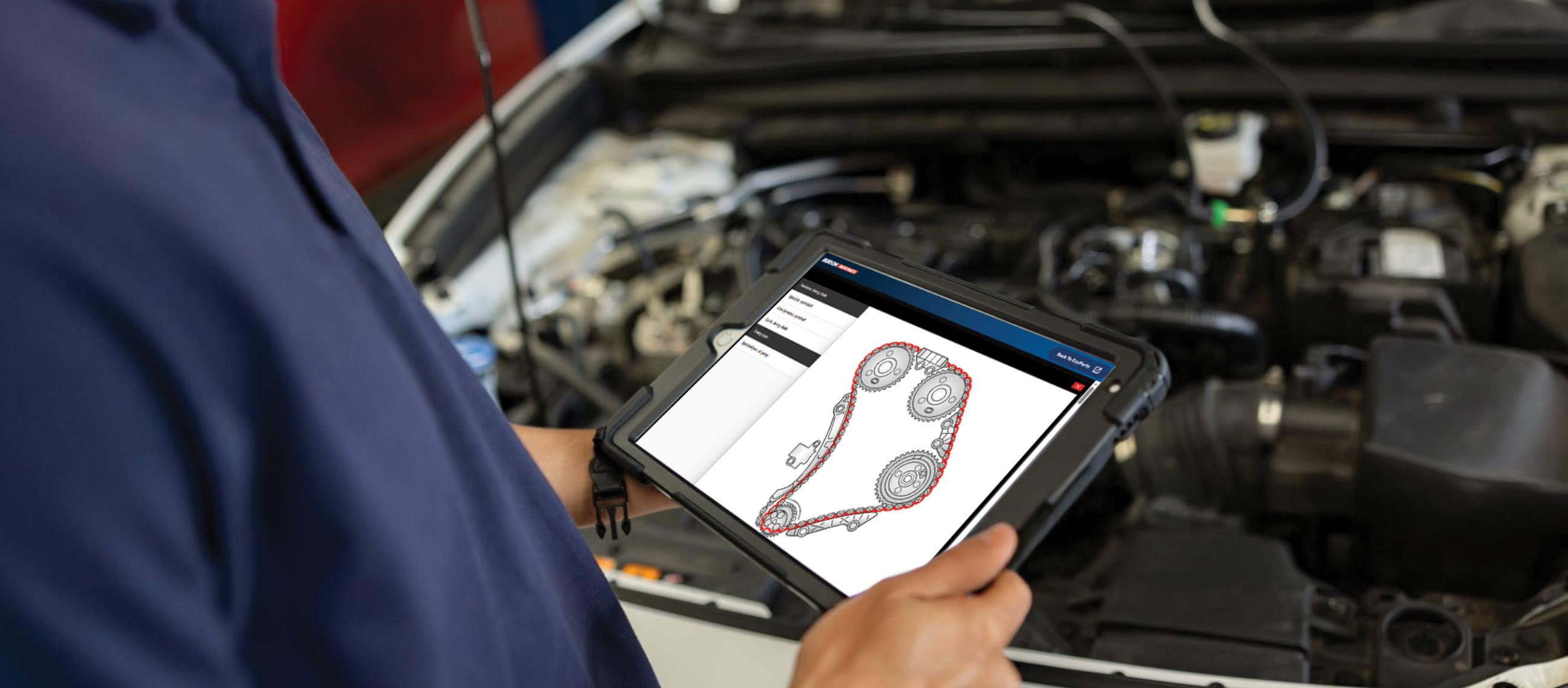

The newest addition to Burson Auto Parts’ EzyParts platform

In today’s fast-paced automotive industry, efficiency isn’t just an advantage, it is essential for success.

As vehicles become increasingly complex and customer expectations grow, workshop owners and mechanics face mounting pressure to deliver precise repairs faster than ever before.

Burson Auto Parts says this is where EzyData comes in, as “the ultimate workshop information system.”

The challenge of modern automotive repair

“Vehicles just aren’t getting any simpler to work on, and it is only going to get harder,” Burson Auto Parts Head of Digital Operations and Network Support, Tim Tummons, said.

Today’s cars are packed with complex electronics, cutting-edge computer systems, and intricate mechanical components that vary significantly between manufacturer makes and models.

The traditional approach of flipping through thick repair manuals or searching through YouTube or Google consume valuable time.

“We know that time spent hunting for the right repair data costs workshops more than they realise; in lost productivity, lost income, and unnecessary frustration,” Tim said.

The industry needs a solution that bridges the gap between searching for information and getting the answer needed to start diagnosis, repair, and maintenance.

“That’s why EzyData was designed with one purpose in mind, to make our customers’ lives easier by helping them find the answer to their problem – fast,” Tim adds.

EzyData: where information meets innovation

As the latest offering from EzyParts, EzyData is linked directly from the Vehicle Workbench within EzyParts, meaning gaining access to the right information has never been easier.

By consolidating vast amounts of vehicle data into a single, intuitive interface, EzyData eliminates the frustration of information hunting and empowers technicians to focus on what they do best; fixing cars.

Powered by the HaynesPro vehicle database, EzyData offers a treasure trove of data across a wide range of vehicle makes and models, which is constantly updated with the latest additions to the market.

From the moment a registration number is searched in EzyParts, EzyData delivers a wealth of vehicle-specific information that would traditionally require multiple sources, and ultimately, a significant amount of time invested to gather it.

By identifying both the cause and solution of an issue, Burson Auto Parts says EzyData empowers technicians to work faster and smarter, with less guesswork and more confidence in every repair.

Everything you need in one place

EzyData is conveniently integrated within EzyParts, Burson’s online ordering platform.

Burson Auto Parts says this powerful combination creates an uninterrupted workflow that seamlessly takes users from problem identification to parts procurement, without needing to switch between multiple tabs in a browser.

“By bringing accurate, up-to-date vehicle information straight into EzyParts, we’re helping technicians work faster, make smarter decisions, and ultimately be more profitable,” Tim said.

Comprehensive vehicle intelligence at your fingertips

From endless adjustment data such as torque settings, cylinder firing orders and brake disc thickness, through to manufacturer recall reports, EzyData provides workshops with everything they need to know about a particular vehicle.

Thanks to Technical Service Bulletins (TSBs) and VESA guided diagnostics, technicians can simply follow manufacturer-certified, step-bystep instructions on how to identify, diagnose, and resolve issues, tailored specifically for the vehicle they’re working on.

To complement these written procedures, EzyData offers visual guidance with over 100,000 technical drawings and wiring diagrams.

These detailed schematics help technicians understand complex systems at a glance, reducing interpretation errors and speeding up the repair process.

With EzyData, workshops can avoid outsourcing complex jobs and do it themselves, ranging from Advanced Driver Assistance Systems (ADAS) recalibration to knowing precisely where fuse, relay and control units are located.

Transforming workshop operations

The impact of EzyData extends far beyond individual repairs.

“Being able to go from a rego to reliable technical data in seconds changes the game for workshop efficiency,” Tim said.

“It means technicians can plan the job properly, avoid surprises mid-repair, and get it right the first time.

“Instead of wasting time second-guessing themselves, they can keep jobs moving and even go beyond basic service schedules.”

Workshop owners can also gain better visibility into job requirements, enabling more efficient resource allocation and job scheduling.

EzyData’s user-friendly interface ensures that accessing this wealth of information doesn’t require extensive training or technical expertise. The user interface is designed to feel intuitive,

allowing technicians to focus on getting to the solution rather than navigating complex software interfaces.

The future of automotive service

EzyData represents more than just a technological upgrade, says Burson Auto Parts.

It states EzyData represents a fundamental shift toward smarter, faster automotive service, enabling workshops to deliver superior service while improving their operational efficiency and profitability.

The ability to quickly access accurate, comprehensive vehicle specifications isn’t just a convenience – it is a competitive necessity in an industry where quick turnaround, accuracy, and customer satisfaction determine success.

In a world where knowledge is power, Burson Auto Parts says EzyData puts that power directly into the hands of automotive professionals, stating, “it is more than just data, it is about setting up workshops for long-term success.”

“Whether it’s attracting and retaining great technicians, supporting staff development, or simply staying competitive, having the right tools in place makes all the difference,” Tim said.

“The question isn’t whether workshops can afford to adopt this technology, but whether they can afford not to.”

For those “ready to embrace the future of automotive service and repair,” Burson Auto Parts says it now offers a 30-day free trial of EzyData. For more information, visit www.burson.com.au

When a truck carrying brake discs was involved in an accident on its way to Italian car maker Alfa Romeo, local company Brembo seized the moment to start manufacturing and supplying parts to the sports car manufacturer

Brembo was established in 1961 as a small mechanical workshop by Emilio Bombassei, his sons Alberto and Sergio, and his brother-in-law, Italo Breda, just a few miles from Bergamo, Italy.

During the early years, Brembo focused on mechanical work for third parties such as Alfa Romeo and Pirelli, but it was also servicing sectors outside of automotive with mechanical repairs.

In 1964 a fortuitous event changed the fate of the company: a truck from England transporting brake discs for Alfa Romeo overturned.

At the time, Alfa was one of the very few car makers, especially in Italy, to fit its models (such as the Giulia 1300) with the new disc brakes.

Fearing that the discs had been damaged in the accident, Alfa Romeo asked Brembo to repair them.

Realising that the English-made products were not so sophisticated after all, Brembo proposed the idea of producing them directly in Italy, and at a more competitive price.

In 1965 Brembo had a total workforce of 28 employees. However, the company’s small size did not prevent it from exploring a variety of different applications for disc brake technology.

From the late 1960s throughout the 1970s, Brembo produced disc brake systems for trams, buses, earthmoving machinery and even cable cars, including the Sugarloaf Mountain cable car overlooking Rio de Janeiro in Brazil and the Mont Blanc cable car.

Beginning in 1972, Brembo invested heavily in growth, production and research.

The result of these efforts led to the development of Brembo’s first complete disc braking system, which would equip the classic Italian motorcycle, the Guzzi V7 Special.

The comparison tests demonstrated the performance benefits of the disc brake applied to

the bike, and the success of the Moto Guzzi and Brembo duo forced the competition to conform.

In 1975, Ferrari owner Enzo Ferrari called on Brembo to supply the most iconic car in Formula 1 – an event which the company notes provided definitive affirmation of Brembo’s technological supremacy and quality.

This milestone marked the turning point that allowed Brembo to enter the racing world and provided an exceptional test bench for cuttingedge technological solutions that would transform new products for both its OEM and Aftermarket business.

Fifty years later, Brembo is a key player in the world of racing and claims it has long been the choice for teams competing in the most demanding motorsport championships worldwide, contributing to over 700 titles.

Earlier this year the company also announced its entry into the world of mountain bike competitions alongside the Gravity Team of Specialised Bicycles, further expanding its horizons.

At the beginning of the 1980s, Brembo focused on the development of products and innovative technological processes, concentrating on the highperformance car segment; ultimately deciding to manufacture calipers in material that was innovative for that period – aluminium.