Bacterial diseases in a post antibiotic era

Broiler litter management

Dynamics and patterns of U.S. poultry meat trade between 2012 and 2022

a 2024 Zootecnica International –January 2024 –POSTE ITALIANE Spa –Spedizione in Abbonamento Postale 70%, Firenze

1

The new feeders of the «Gió» range, specifically developed for great poultry farms, thanks to the easiness in the regulation of the feed and to the absence of grill (that avoid chicks perching) have many advantages: they are easy to use and their cleaning is extremely easy and fast too, leading to an overall reduction in labour costs.

CODAF Poultry Equipment Manufacturers • Via Cavour, 74/76 • 25010 Isorella (Brescia), ITALY Tel. +39 030 9958156 • Fax: +39 030 9952810 • info@codaf.net • www.codaf.net

for the rearing phase (first 30 days of life)

for the growing phase (no anti-waste ring)

EDITORIAL

Food wastage is an ever-present topic. In the 1960s, families threw away 40% of the food purchased (even when the refrigerator was now present in almost all homes) and even in the budgets of the large-scale retail trade, food waste took on a significant role.

Since 2000 it has increasingly declined, reflecting the growing economic crisis which has led to greater attention being paid to food waste.

Poultry farming, in this context, has proven to be the food sector that is most attentive in responding to changing consumer needs, new lifestyles and growing demands in terms of healthiness and sustainability.

Poultry products are the most requested worldwide, not only because there are no religious barriers that limit their use, but also because, as is well known, they are the cheapest for the consumer.

The attention to the pursuit of less waste has also become notable on the part of the catering industry, which not only uses increasingly technologically targeted equipment to reduce wastage but also invest time and money in increasing the overall knowledge of the product by those tasked with preparing and cooking the product.

I have the privilege of having my son Jacopo who is a chef in a starred restaurant and, thanks to him, I am kept informed on news within the sector. For some time now the famous Michelin stars have been dyed green to reward those who are also virtuous towards the environment.

We must be proud to operate in a very important sector for human nutrition. We should also become ambassadors of news that help us to better understand and appreciate the sacrifice of many professionals involved in this sector.

BREEDAZA THE RATIONING SYSTEM FOR BROILER BREEDERS AND LAYERS

Leader in livestock feeding systems

ADJUSTABLE ANTI-COCK GRID

NO OBSTACLE INSIDE

EASY ACCESS TO FEED

System designed for equal, controlled and immediate distribution throughout the line.

The obstacle-free linear trough feeder allows an easy access for the animals which can easily spot the feed.

Easy cleaning and no residual feed inside the trough.

MADE IN ITALY www.azainternational.it

QUALITY

VIDEO

I WANT AZA!

SUMMARY WORLDWIDE NEWS ......................................................................... 4 COMPANY NEWS 8 FIELD CASE Effect of multienzyme on late-phase hens fed with corn-soy-based diet 10 DOSSIER Bacterial diseases in a post antibiotic era ...................................................... 16 FOCUS Broiler litter management .............................................................................. 20 MARKETING Dynamics and patterns of U.S. poultry meat trade between 2012 and 2022 ....................................................................... 26 MANAGEMENT Vision-based dynamic density estimation of laying hens for piling- up prevention ........................................................... 32 NUTRITION Nutritional strategies to mitigate coccidiosis 36 Precision feeding of egg- and meat-type pullets 38 MARKET GUIDE 44 UPCOMING EVENTS 47 INTERNET GUIDE ............................................................................48 26 16 20

IFIF and FAO continue to strengthen

collaboration on critical issues to ensure safe and sustainable feed and food

The International Feed Industry Federation (IFIF) and the Food and Agriculture Organization of the United Nations (FAO) held their 22nd annual meeting to further strengthen their collaboration on critical issues to ensure safe, nutritious and sustainable feed and food.

The meeting was officially opened by Mr. Thanawat Tiensin, Director Animal Production and Health at FAO, together with Mr. Ruud Tijssens, IFIF Chairman. They welcomed the IFIF delegates representing over 80% of global compound feed production and reiterated their commitment to this longstanding partnership and agreed to continue to strengthen their work together to tackle the challenges facing the feed and food chain.

Mr. Tiensin, Director Animal Production and Health at FAO, reaffirmed the importance of collaboration between the public and private sector, as well as other stakeholders, to support evidence-based key role of the feed and livestock sector in sustainable livestock transformation. Mr. Tiensin reiterated that “livestock production is a vital part of our agrifood systems, providing essential nutrients for all and enhanced livelihoods and economic opportunities for billions of people around the world.” Mr. Tiensin highlighted that “FAO advocates improving efficiency is essential to producing more with less. Animal Feed is a vital part of this, as efficiency can be pursued by optimizing feed conversion, reducing feed loss and waste and enhancing nutrient utilization, all of which can reduce pressure on biodiversity and land and water resources,

as well as decrease greenhouse gas emissions and mitigate environmental degradation.”

Mr. Tijssens, IFIF Chairman, underlined that “the animal feed industry plays a crucial role in supporting sustainable livestock production by leveraging innovation and efficiency. Animal nutrition supports animal health and welfare, as well as productivity and allows farmers to produce more with less and optimize environmental resources.”

Mr. Tijssens added that “together with the dedicated colleagues at the FAO we contribute to building a solid science-based approach to support safe and sustainable animal nutrition to bring quality and affordable food to a growing world population, producing more with less and even better under diverse production systems. The high quality of exchanges and cooperation towards the United Nations Sustainable Development Goals (SDGs) continue to build on our achievements and together with all IFIF members I am pleased our relationship with FAO continues to strengthen year to year.”

Daniela Battaglia, Livestock Production Officer at the Animal Production and Health Division of the FAO, said “FAO and IFIF have a long standing partnership and this meeting addressed a number of critical issues of common interest, such as the need for capacity development to ensure feed safety and the importance of collaborating to tackle the containment of antimicrobial resistance (AMR). FAO is committed to work with the private sector and the feed operators and believes that they can valuably contribute to make the livestock and food sectors more responsible and sustainable and to achieve important goals such as public health, and animal health and welfare.”

Source: IFIF

4 - worldwide newsWORLDWIDE NEWS

CORTI

ARTICLES ACCESSORIES

for breeding

PP Belts

• Egg collection

• Manure drying system

• Manure belt collection

• PP woven egg belts

• PP hole egg belts

4002 H

• 360 degrees opening

• Highly strong and durable material

• “SOFT” action

4006 H

• 360 degrees opening

• Highly strong and durable material

• “EXTRASOFT” action

4626

• Suitable for fattening turkeys

• Perfectly dry bedding

• Simultaneous watering of 2 and more animals

INFINITY

• Essential design

• No chicks in the pan!

• Regulation of minimun and maximum feed level

• Available in caged broilers version

4901 N

Pressure regulator with bypass

ZOOTECNICI

Corti Zootecnici Srl | Via Volta, 4 21020 Monvalle (VA) Italy| www.cortizootecnici.it |

The role of animal source foods in healthy and sustainable diets

Speaking at the recent IEC Global Leadership Conference in Lake Louise, Dr Ty Beal, Research Advisor at the Global Alliance for Improved Nutrition (GAIN), provided expert commentary on the role animal source foods can play in combatting the global issues of malnutrition and environmental sustainability. Dr Ty Beal began by providing an overview of the state of malnutrition worldwide, incorporating undernutrition and overweight/obesity. “We see it’s widespread in all countries,” he explained. “No country is without a high burden of both of these issues. I think that’s important to highlight – we have malnutrition across the world.” As well as illustrating levels of stunting and obesity, Dr Beal explored the prevalence of common micronutrient deficiencies across regions. While 9 out of 10 women are lacking in essential nutrients in many lower income countries, such as India and Cameroon, there is also prevalence in high income countries. For example, 1 in 2 women in the UK, and 1 in 3 in the US are lacking in at least one micronutrient. Furthermore, Dr Beal emphasised the shortage of protein in the food supply, especially in lower income countries: “A billion people consume inadequate protein.”

Why we need animal source foods

Next, the expert speaker reviewed the consumption of animal source foods worldwide, identifying South Asia & sub-Saharan Africa as areas with very low intake. As such, these regions showed an increased risk for undernutrition, especially in early childhood; resulting in stunting, which can have “life-long, lasting effects”.

Dr Beal also recognised the importance of recent efforts to encourage more sustainable, healthy diets, but explained that certain popular proposed diets, such as EAT-Lancet, possess inadequacies when it comes to essential nutrition: “Once you get this very highly plant-based diet, you start to see the increased risk for deficiencies of certain nutrients.” With this in mind, Dr Beal explored the unique nutritional contribution of animal source foods, including eggs, and how they can help combat malnutrition worldwide. “Animal source foods are rich in nutrients that are often lacking, for example iron, zinc, vitamin B12 and choline,” he explained.

In addition, he highlighted the importance of bioavailability: “If you have the same quantity of these nutrients in plant sources versus animal source foods, it’s not actually providing the same amount of absorbable nutrient.” For example, Dr Beal explained that vitamin A is around 12 times more bioavailable when found in animal sources, than when derived from plant source foods. Looking specifically at eggs, the speaker likened them to a multi-vitamin, since they have “a moderate amount of a lot of nutrients”. Furthermore, he stated that while one egg is only 4% of the energy requirements for the average adult, the daily value is much higher than 4% for many of the nutrients, showcasing their nutrient-density.

Planet-positive production

Having established the role of animal source foods in healthy diets, Dr Beal went on to explore their impact on sustainability. He identified key areas of discussion around food production, including land use, water consumption and biodiversity. While recognising challenges in these areas, he argued that sustainability can be achieved with the right production methods. “When produced at the appropriate scale, and in accordance with local ecosystems in the right context, and using the best practices, we really can have sustainable production,” Dr Beal concluded. “So we can have healthy diets that include animal source foods and plant source foods in the right amounts, produced in the right ways.”

Source: International Egg Commission

6 - worldwide newsWORLDWIDE NEWS

Multi-country outbreak of Salmonella Enteritidis in chicken meat and chicken meat products

Between January and October 2023, 14 EU/EEA countries, the UK and the US reported 335 cases related to this outbreak.

Chicken meat and chicken meat products (kebab) are the likely source of a multi-country outbreak caused by three types of Salmonella

ECDC’s latest Rapid Outbreak Assessment.

DRINKING FOR TURKEY EASYLINE 2.0

Consisting of a system with the pendulum as the main element, which ensures a perfect water supply at all times.

Bacteria similar to those causing the outbreak have been detected in samples of chicken meat and chicken kebab. While food traceability data points to producers located in Poland (7 producers) and Austria (1 producer), no microbiological evidence of a contamination at their facilities has been found.

Scientists expect that new cases are likely to occur in this multi-country outbreak as the source has not yet been identified. EFSA and ECDC experts recommend further investigations to identify the potential locations within the chicken meat production chain where the contamination

• The pendulum is activated every time the animal moves it with its head to drink.

• The new pendulum with two nipples guarantees even grater reliability of the drinker, both in terms of durability and ease manintenance.

• Cleaner litter and the best results in both the rearing and finishing phases at every age of the turkey.

WORLDWIDE NEWS

!lanigirO

+39

Via Marco Polo, 33 - 35011 - Campodarsego (PD) ITALIA

0499202290

- lubingsystem.com - info@lubing.it

Breeder management in Focus at latest Aviagen European Conference

European customers gain key knowledge on optimizing Ross bird health, welfare and sustainability.

Aviagen® European customers came together in the historic city of Edinburgh from Oct. 23-25 for an exclusive Breeder Focus Conference. The primary goal was to give them management insight into optimizing the health, welfare, and sustainability of their Ross® breeders.

Together, attendees explored several critical topics with the presenters, including Aviagen’s latest research and development efforts, updates on breeding for welfare and sustainability, and a range of breeder management subjects.

They also discussed the latest findings from European trials, highlighting Aviagen’s commitment to strengthening bird welfare through the simultaneous evaluation of various environmental variables. Global Technical Transfer offerings were also in the spotlight as an ongoing effort to empower customers with the knowledge necessary to heighten their success.

The conference brought together customers representing 20 European countries, making it a unique gathering that collectively accounted for more than half of Europe’s poultry breeder sector. It provided a valuable opportunity for attendees to engage in dynamic discussions and receive updates on Parent Stock (PS) management, such as rearing, production and male management, nutrition, biosecurity, and practical advice on hatching egg storage.

Aviagen EPI Regional Technical Manager Sascha Kuer said: “We were proud to have our customers together here in Edinburgh, the home of Ross, for our Breeder Focus seminar 2023. It was rewarding to hear their feedback on the content quality and that they were happy for another opportunity to get together with fellow breeder growers.”

Veterinarian Stefan Weier from Rothkötter Gruppe, Germany, highlighted the importance of networking at the event. “I benefited greatly from the insight of both the speakers and my peers in the industry.”

Erik Wolterinck, General Manager, Schotman Hatcheries, The Netherlands, added: “It was interesting to learn about the genetic development of Ross birds and how efficiency can be optimized through feed and nutrition. I also appreciated the insight into market developments, particularly in slower-growing breeds.”

“Our best takeaway was to see what goes on within Aviagen, the background that we don’t normally see,” reflected John Nicholls, Flock Farmer Manager, Avara Foods, UK

“Breeder Focus has been a resounding success in championing the success of our customers, fostering collaboration, addressing industry challenges, and building confidence in our commitment to achieving excellence in poultry breeding,” concluded Aviagen’s Stuart Thomson, Head of UK Sales & Tech/Regional Technical Manager, Northern Europe

8 - company newsCOMPANY NEWS

New Conventional Series, a new generation of Petersime’s conventional incubators

The continuous improvement mindset that characterizes Petersime has pushed us to rethink our Conventional Series with the aim to further optimize its performance, simplify its operation and boost overall profitability. The result is a new generation of Petersime’s conventional incubators with significant improvements in design and features.

Conventional Series: robust and reliable

While top-notch incubators may be an obvious choice for certain hatchery owners, others may look for a less hefty investment that will still guarantee outstanding performance in all circumstances, from day one until the end of the equipment’s lifetime. The Conventional Series is Petersime’s answer: it is the ideal solution for hatchery owners who are looking for conventional multi-stage or single-stage incubators that stand for strong, reliable performance, trusted quality, and ease of operation. Over the past decades, the Conventional Series has built a proven track record of excellent performance. Today, we are pleased to announce a new generation of the range that will bring your hatchery’s performance and profitability to the next level.

New generation of conventional incubators

Along with improving incubator design, Petersime’s focus is also to make incubators more intelligent. This is reflected in the new generation of our conventional incubators. “The previous Conventional Series was already best in class for producing top-grade chicks, poults or ducklings, even in less-than-ideal circumstances,” says Ives

Vanstechelman, Product Specialist at Petersime. “The new generation builds on that quality by being even more performant thanks to a new controller with data connection. Plus, it has added benefits that further enhance the machine’s user-friendliness.”

Vision+ controller

The first enhancement is the new Vision+ controller with data connection. Vision+ makes it possible to connect Petersime’s conventional incubators to the intelligent Eagle Trax™ hatchery software, which opens the way for improvements of the overall productivity and profitability of your hatchery operations. For customers who do not require this advanced technology, we offer the Analog controller for easy incubator parameter control.

Digital calibration

Calibration checks are needed to maintain optimal incubator performance. The new Conventional Series works with digital calibration: its easy-to-use calibration tool ensures a quick and accurate temperature and humidity calibration. This improvement further enhances user-friendliness for operators of all experience levels.

180° panoramic windows

The new incubator design features full panoramic windows. This gives the added advantage of having an instant overview of what is happening inside the setters and hatchers. No matter if multi-stage or single-stage operation is your preferred incubation system, Petersime’s new Conventional Series has the right incubators for you to optimize your profitability and product quality. Want to know more about the range and all its features and benefits? Please don’t hesitate to contact us: our sales team is ready to answer all your questions.

www.petersime.com/contact/i-am-interested

- january 2024 - 9 COMPANY NEWS

The new Vision+ controller makes it possible to connect conventional incubators to Petersime’s intelligent Eagle Trax™ hatchery software.

R.J.R. Mosaso1, J.R.V. Conejos1 and M.J.C. Ang

2

1 University of the PhilippinesLos Baños CAFS-IAS

2 University of the PhilippinesLos Baños CVM -DBVS

Effect of multienzyme on late-phase hens fed with corn-soy-based diet

Eggs are the most affordable animal protein; thus, there is a surging increase in the number of laying flocks, especially in developing countries. The current trend in the Philippines is extending flock age beyond recommended egg production for economic purposes but decreasing egg quality. To save costs, farmers use low-quality ingredients, which negatively impact the performance and health of laying hens. Therefore, this study aims to evaluate a multienzyme product in terms of hen performance, egg quality, gut morphology, and bone strength.

10 - field reportFIELD REPORT

Introduction

With the recent Covid-19 pandemic disrupting the regular supply chain in agriculture and threatening food security, it is imperative to look for innovative ideas to meet the population’s food demand. The agriculture sector is pressured to offer sustainable, economical, and ethically-produced animal protein. Egg, a cheap and relatively easy-to-produce commodity, is one of the best candidates for such protein. Thus, there is a surging increase in layer population, especially in developing countries where food security is still an issue. The Philippine Statistics Authority (2021) reported that a record high of 605,786.16 metric tons or 12.721 billion pieces of eggs were produced in 2020, a 4% higher compared to 2019. To sustain the egg production requirement and to lower the cost of farming, the current tactic in the Philippines is to extend the flock age beyond breed recommendations. However, due to

formance at this stage of the hen are different from when it is at peak production. In nutrition, various approaches can be implemented to decrease cost, which includes using cheaper alternative feed sources and altering nutrient specifications to reduce expensive inputs. With cheaper source materials, higher ANFs are expected while alteration of specs needs formulation adjustment that will still meet nutrient standards. Both can be addressed via the addition of feed additives. Feed additives are a well-studied aspect of nutrition for improving hens’ production. Enzymes, and enzyme cocktails, are among the most prevalent nutritional feed additives in poultry for the last decades. It is widely accepted that the enzymes’ nutrient-liberating ability can help birds enhance performances and lower production costs. Indirectly, it can be one of the actions to support our growing population’s food demand by assisting the farmers in producing eggs efficiently and economically. This study investigates the effect of multienzyme supplementation on reduced energy diets on late-phase hens’ egg production, quality, gut morphol-

11 - january 2024FIELD REPORT

Garibaldi, 54 •

Tel. (+39) 0375 / 95135 • Fax (+39) 0375 / 95169 • Manu re re moval belt s • Manu re belt wi th hole s for dr yi ng system s info@barbieri-belts.com www.barbieribelts.com BELTS and ROP ES for AV ICULTURAL USE BE LT S

Barbieri srl Via

26040 Scandolara Ravara (CR) Italy

Methods

Three hundred and twenty-four (n=324) Dekalb hens 96 weeks of age were randomly allotted to one of the 3 dietary treatments in a completely randomized design (CRD). Each treatment had 27 replicates with 4 hens/ cage. The trial was 16 weeks, with feed and water provided ad libitum. The cage specifications were: 46 cm x 47 cm x 33 cm (L x W x H). All cages were in a well-shaded and naturally-ventilated facility experiencing a temperature of 25.3-26.6 °C and humidity of 85-86%.

The 3 dietary treatments were a) Treatment 1 ( T1), positive control, b) Treatment 2 ( T2), 90 kcal ME reduction, and c) Treatment 3 ( T3), T2 plus multienzyme (350 g/ tonne). Formulations among the treatments were isonitrogenous with the same level of EE, CF, and Ca, and P. The diets were based on the Dekalb guide manual and in mash form (0.5 to 3.0 mm). Nutrient specs standards are as follows: ME 2750 kcal/kg, CP 17.5 g/kg, EE 3.8 g/kg, CF 2.8 g/kg, Ca 4.3 g/kg, and P 0.6 g/kg. The multienzyme product Natuzyme ® (BIOPROTON) contains

the following at varying concentrations and activities: phytase (1,876,000 u/kg), xylanase (11,539,000 u/kg), alpha-amylase (760,000 u/kg), beta-glucanase (742,000 u/ kg), cellulase (6,924,000 u/kg), protease (271,000 u/kg) and pectinase (74,000 u/kg). Initial and final body weight (BW) and average daily feed intake (ADFI) were recorded. All eggs produced were also recorded for Hen Day egg production (HDEP), Hen-housed egg production (HHEP), Average Egg Weight (Ave. EW), egg mass (EM), and FCR. Twenty-seven (27) eggs per treatment were randomly selected to be measured for Shell width (SWd) and Shell length (SL) and eventually Eggshell Shape Index (SWt/SL x 100). The eggs were broken and subjected to Egg Analyzer (ORKA Food Technology LLC, Utah, USA) to determine the Haugh unit (HU) and albumen height (AH). At the end, twelve (12) hens from each treatment were sacrificed for gut morphology and bone-breaking strength assessment (BBS). Cross sections (4um) of the gut’s ileum were stained by H&E (villi and crypt measurements) and Periodic-Acid Schiff (goblet cell counting) The left tibia was excised and subjected to strength de -

12 - field reportFIELD REPORT

Parameters Unit T1 T2 T3 SEM P Value Ave Daily Gain (ADG) g 85.03 49.60 176.73 1.04 0.93 Hen Day Egg Production (HDEP) % 74.45a 64.80 b 72.78a 6.66 <0.001 Hen Housed Egg Production (HHEP) % 69.42a 62.23 b 70.90 a 5.64 <0.001 Ave.Egg Weight (Ave EW) g 65.31a 62.76 b 65.83 a 1.20 <0.001 Egg Mass (EM) g 48.63 a 40.84b 47.67a 4.59 <0.001 Ave Daily Feed Intake (ADFI) g 132.70 a 127.23 bc 123.00 c 11.46 0.0102 FCR egg mass 2.80 b 3.25a 2.66 b 0.28 <0.001 Haugh Unit (HU) 67.65b 67.49 b 69.22a 2.77 0.05 Albumen Height (AH) mm 5.42b 5.34b 5.62a 0.31 0.0033 Shell Width (SWd) mm 44.87a 44.10 b 45.06a 0.45 <.0001 Shell Length (SL) mm 58.85a 58.17b 59.11a 0.59 <.0001 Albumen Weight (AW) g 47.42a 45.32b 48.07a 1.38 <.0001 Egg Shape Index (ESI) % 76.21 75.99 76.23 1.04 0.71 Bone Breaking Strength (BBS) N 0.20 c 0.20 b 0.26a 0.05 0.0116 Villus Height (VH) um 566.34a 419.87b 553.90 a 86.54 0.01 Crypt Depth (CD) um 119.53 110.76 133.94 15.76 0.06 VH/CD ratio um 4.84 3.83 4.21 0.98 0.18 Goblet Cell Count (GCC) #goblet/ umVilli 0.13a 0.07b 0.13 a 0.03 0.01

Table 1 – Parameters for hen performance, egg quality, gut morphology, and bone breaking strength.

termination using the Universal Testing Machine. All data were analyzed using the General Linear Model (GLM) procedure of Statistical Analysis System software version 9.2. The model assigned cages as a random effect, while dietary treatments were the fixed effect.

Results and discussion

In this study, there were no changes in body weight gain between treatments (P=0.9313). The current research aligns with the previous study in multienzymes that body weight is not affected regardless of decreased ME kcal. In this study (16 weeks) and that of Lee et al. (2014), the trial period may be too short to elucidate the long-term effect of reduced energy on BW. Feed intake showed a different pattern as the T1 gave the best results among the 3 diets (P=0.0102), which may be related to lower dietary crude fat and crude fiber as per proximate analysis (not shown). This translates to lower heat increment; thus, T1’s hens would eat more to compensate for the heat needed. Also, the results did not conform to the theoretical idea that hens with reduced ME (T2) would tend to eat higher amounts of feed to compensate for energy requirements. The HDEP, HHED, egg weight, egg mass, and eventually, the FCR (T3) were all at par with the standard diet (T1) (P>0.05), even with decreased energy. T2, as expected, was reduced in all parameters except higher FCR.

In egg quality, T3’s Haugh unit (P=0.0464) and albumen height (P=0.0033) were of superior results. Factors affecting albumen height were not fully understood, but Scott et al. (2001) suggested that it may be due to the involvement of the multienzyme’s phytase-releasing P. This could be the reason why T3 showed better results than T1 and T2 as there were no reduction in P inclusion rate in the formulation of the diets. Thus, multienzyme’s phytase in T3 diet would further increase P availability. In eggshell width (SWd) (P=<0.0001) and eggshell length (SL) (P=<.0001), all gave good results for multienzyme-supplemented (T3) as it was consistent with the T1. The T2’s egg sizes decreased, and so did the width and length. Nevertheless, the eggshell shape index (ESI), a ratio of SWd and SL, was uniform among the groups (P=0.6406). The result implies that even if width and length is reduced in T2, the hens produced an egg shape as proportioned as possible regardless of treatment conditions.

In gut morphology, the villi mean (553.90um) of T3 was not statistically different from T1 (566.34um), and both

13 - january 2024FIELD REPORT

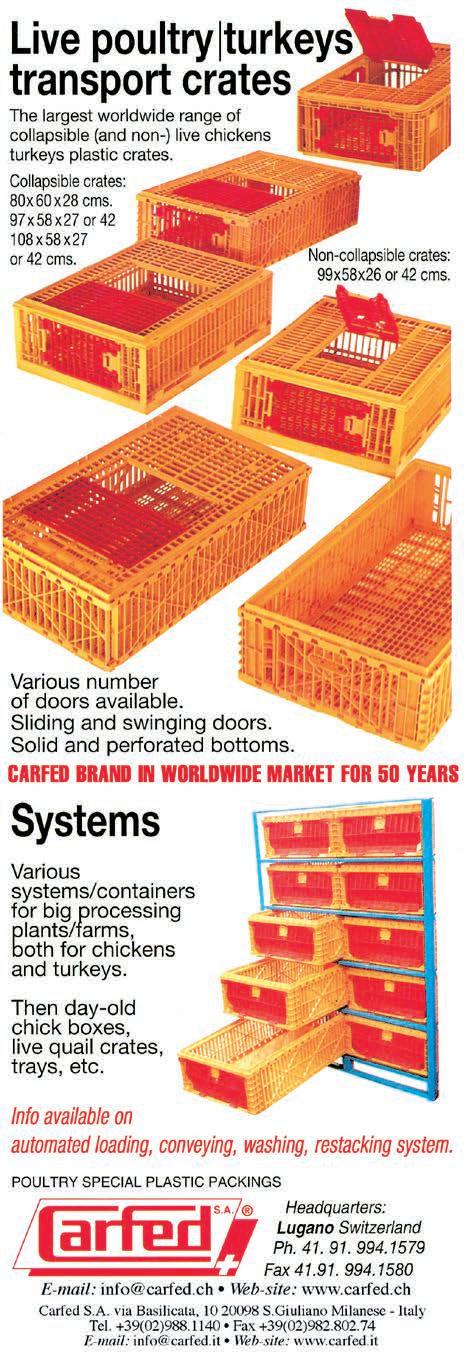

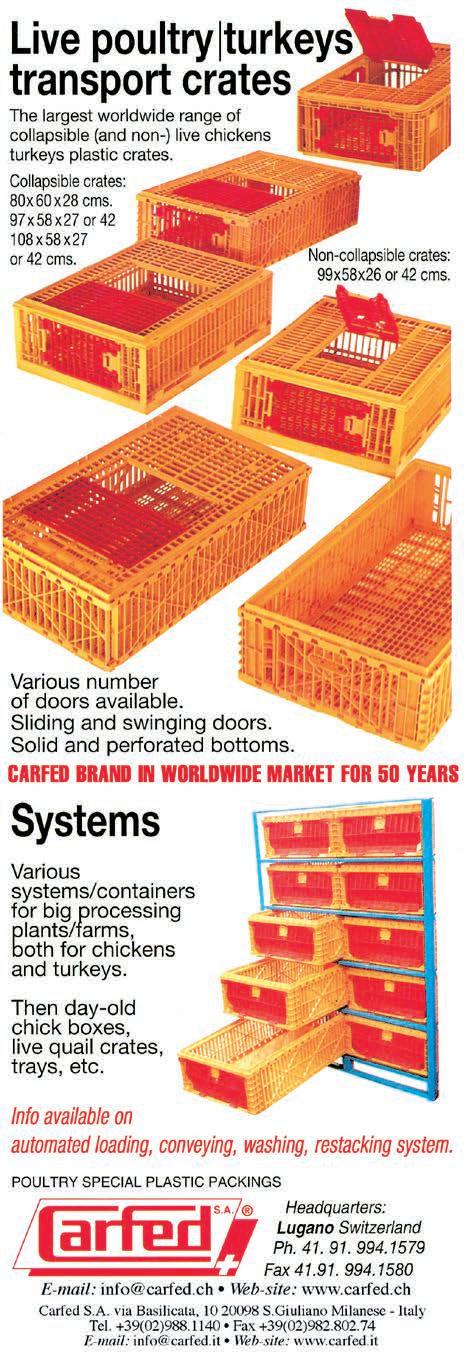

CARFED INTERNATIONAL LTD Italian headquarters: Piazza Oberdan 3, 20129 Milano (Italy) Italian warehouse: Via Basilicata 10, 20098 San Giuliano Milanese (Italy) Ph.: +39 02 9881140 – Fax: +39 02 98280274 Email: carfed@carfed.it – Website: www.carfed.it UK headquarters: Ground Floor, One George Yard, London EC3V 9DF, England, UK Ph.: + 44. 20. 7660.0987 – Email: carfed@carfed.co.uk

were superior over T2 (419.87um) at P=0.0134. In opposition, both crypt depth and VH/CD ratio were not significantly different among diets (P>0.05). The enzyme’s action of enhancing nutrient availability in the gut lumen causes the response of increased villi length. A longer villus result is good indicator of a healthy and well-absorbing gut. Previous studies showed similar results regarding ileal crypt depth, where there was no change. In contrast, a high crypt depth value is unwanted as crypts are ‘villi factory’ where an increase in length indicates a faster turnover rate of cells to produce new villi. Thus, this translates to more unhealthy cells needed of immediate replacement and is pathologic in nature. In goblet cell counting (GCC), the T3 result was at par with T1, and both were statistically significant over the T2 (P=0.0093). The consistent result of T3 with T1 is the ideal and implies that there were no gut problems. A high density of goblet cells is unwanted as it also suggests an increase in goblet cell proliferation and consequently decreases rate of enterocyte formation, thus, lower absorptive capability.

In bone breaking strength (BBS), T3 showed superior results compared to T1 and T2 at P=0.01. As mentioned, all diets followed Ca and P standard, but when egg production varies, the bone reserves utilization will also vary among treatments thereby affecting BBS. In T2, it was statistically higher than T1 at P=0.021 because T2 hens

did not need reserves as production also decreased in frequency. Thus, more Ca and P are still present in the bones of T2, making it ‘harder’. Meanwhile, in T1, the group is still in good production and giving decent egg sizes which still demands high Ca and P. Thus, T3 needs bone reserves as the standard Ca and P feed inclusion rate may be inadequate. This explains better BBS for the enzyme-supplemented diet (T3), even if T1 and T3 had the same egg production and sizes. Minerals liberated by multienzyme’s phytase are adequate or even excess in T3 that it did not need the bone reserves thereby addressing production demand while maintaining bone strength.

Thus, supplementing late phase hen’s diet with a multienzyme at 350g/tonne and a 90 ME reduction was able to maintain or outperform the positive control in terms of hen performance, egg quality, gut morphology, and bone health. Furthermore, no adverse effects on feed intake and body weight gain occurred. Therefore, the product is advantageous for farmers planning to extend flock age without sacrificing egg production and quality and promoting animal welfare through improved bone strength.

References are available on request

From the Proceedings of the Australian Poultry Science Symposium 2023

14 - field reportFIELD REPORT

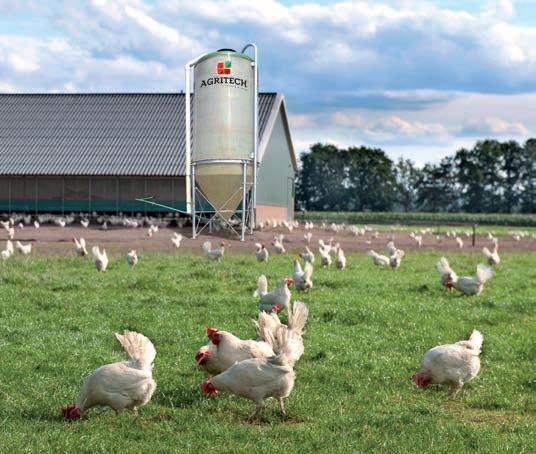

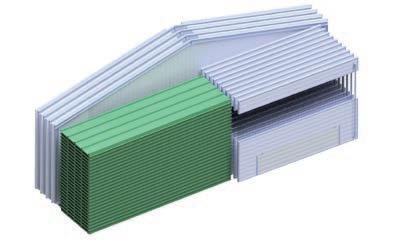

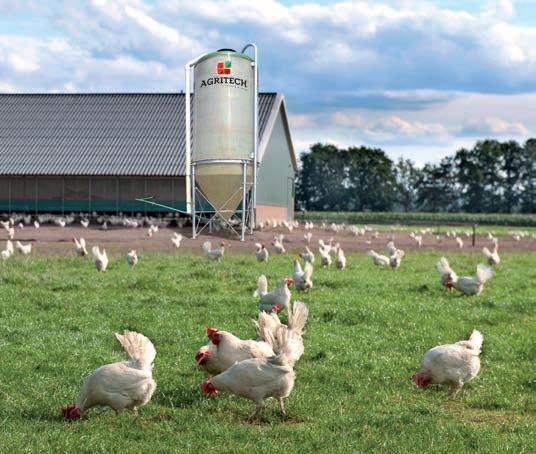

Mobile Poultry Shed

60 m2 Surface Mobile Poultry Shed. Professional design, made in Italy, suitable for free range poultry breeding.

5 unassembled sheds in one truckload

Agritech s.r.l.

Via Rimembranze, 7

25012 Calvisano (BS) Italy

Tel. + 39 030 9968222 r.a.

Fax + 39 030 9968444

commerce@agritech.it

www.agritech.it

15 - january 2024FIELD REPORT

Bacterial diseases in a post antibiotic era

For many years, bacterial diseases of poultry have been kept under control through the administration of antimicrobials. Due to the well-known issue on antimicrobial-resistance (AMR) in humans, many countries have adopted a “One-Health” approach to face this problem by promoting the so-called “prudent use” strategy that have significantly concurred to reduce the antimicrobial consumption in farmed animals, poultry included.

This trend is evident in Europe where the sales of veterinary antimicrobial agents collected in 25 countries reveal a decline of 46.5% (from 161.2 mg/PCU to 86.2 mg/PCU) from 2011 to

16

Luca Bano

DOSSIER - dossier -

Microbiology and Veterinary Diagnostic Laboratory, Istituto Zooprofilattico Sperimentale delle Venezie, Treviso, Italy

©cookfamilyfarm.com

2021 (ESVAC, 2022). This tendency has been observed also in the US where the domestic sales of medically important antimicrobial drugs approved for use in food-producing animals decreased of 33% from 2012 to 2021 and of 69% and 13% in chicken and turkey productions respectively, from 2016 to 2021 (FDA, 2022).

The above-mentioned results seem to indicate that we are moving to a post antibiotic era, but deep differences exist around the world. Indeed, in spite of the reduction politics adopted in some countries, the global antimicrobial consumption in food producing animals estimated at 99,502 tonnes in 2020 is projected, based on the current trends, to increase by 8% to 107,472 tonnes by 2030 (Mulchandani et al., 2023). The majority of the hotspot areas of antimicrobial use (AMU) intensity were found in Asia (67%). Africa, Oceania, and South America, despite low absolute AMU, were predicted higher relative increases of AMU by 25%, 16%, and 14% respectively. Unfortunately, 6 out of the 10 largest meat producers in the world do not report AMU to the public (Brazil, Russia, Mexico, Argentina, India, Viet Nam) and, among them, Brazil is the largest expor ter of poultry in the world (FAOSTAT, 2021). In this scenario, in addition to the actions taken by the governmental authorities of each country, the increase of antibiotic-free meats may contribute to curb AMU.

The production of “antibiotic-free” and “no-antibiotic ever” meat chickens represents a large part of the market in some countries but those productions are more difficult to realize for other poultry species. Indeed, the majority of meat chicken productions is globally more standardized than ducks, goose, laying hens, turkeys, guinea fowls

and quails sectors in terms of housing systems, genetics, age at slaughter and nutrition. In particular, poultry species with a long production cycle have a highest probability to be exposed to bacterial diseases and, as a consequence, to be treated with antimicrobials.

According to the FAO recommendations, the three main measures to prevent infectious diseases in a farm are good animal husbandry, effective biosecurity and vaccinations (Magnusson et al., 2019). In poultry, good husbandry includes all-in/all-out system, adequate space allowance with no over-stocking, good lighting and air quality through appropriate ventilation, correct temperature (by age) and good quality/quantity of feed. Biosecurity is the set of behaviours/procedures aimed to prevent the introduction and diffusion of infectious diseases in the farm (Magnusson et al., 2019). Although many effective vaccines are available in the market to prevent viral diseases of poultry, few vaccines are registered for bacterial diseases and its efficacy is affected by the large antigenic variability of the circulating strains.

The first step toward a post-antibiotic era is the ban of the growth promoters with antimicrobial properties. This action has been adopted by many countries during the last decades with distinctions for some molecules and animal species (Rahman et al., 2022).

The strategies that can concur to reduce or substitute antimicrobials in poultry include:

• eradication of the disease in the parents flocks (eg. pullurosis, micoplasmosis, salmonellosis);

• vaccination to prevent bacterial diseases (eg. colibacillosis, necrotic enteritis, micoplasmosis,

17 - january 2024DOSSIER

Royal Pas Reform Integrated Hatchery Solutions www.pasreform.com pas2020_adv-Zootecnica-180x61mm.indd 1 25-02-2020 11:16

fowl colera, riemerellosis, salmonellosis, fowl typhosis) or viral diseases that can predispose to the bacterial diseases (chicken anaemia, Gumboro disease, Marek disease, infectious bronchitis, pneumovirus infections, haemorrhagic enteritis);

• improve the chick quality (eg. onphalitis, runting and stunting syndrome);

• enhance the gut health (necrotic enteritis, dysbacteriosis, Enterococcus cecorum skeletal infections).

Those actions should be implemented primary in gran-parent flocks that are at the top of the poultry pyramid from which the selection of antimicrobial resistant bacteria can easily spread to the offspring at the hatchery. For this reason, antimicrobial

treatments of parent flocks should be absolutely avoided or limited and a monitoring plan for AMR applied in this poultry category.

Once the above mentioned preventive actions have been implemented, the occurrence of a bacterial diseases in poultry flocks should be treated according to the “prudent use” principles and antimicrobial stewardships that many institutions (public and private) have produced around the world. The scope of the “prudent use” in veterinary medicine is to preserve the effectiveness of antimicrobials considered “critical” for the treatment of some threatening diseases of humans, according to the World Health Organization (WHO, 2019).

As a consequence, the administration to animals of critical important antimicrobials (CIAs) should be

avoided or adopted af ter a clear laboratory diagnosis coupled with an antimicrobial susceptibility test (AST) that demonstrates that antimicrobials considered of first choice are not effective against the bacterial pathogen isolated. This process gives responsibilities to the veterinary diagnostic laboratories that have to provide reliable results in particular as regards AST. In this area, the main problem is the lack of interpretation criteria of the in vitro results that can be predictive of the effectiveness of the therapy in the field (clinical break-points). Indeed, only the clinical-breakpoint of enrofloxacin to treat E. coli infections is available in poultry (CLSI, 2023). In conclusion, the poultry sector is contributing to face the AMR issue in many countries but this action should be harmonized around the world. It is clear that no single good practice will be enough to further reduce the use of antimicrobials in poultry and that education at different levels can be the keystone of the changing process. To further sustain this process, researchers can contribute by developing effective vaccines, on-farm diagnostics, microbiome regulators and precision livestock farming tools. The definitive elimination of antimicrobials in the poultry production is probably unrealistic but everyone, at different levels (institutions, farmers, practitioners, researchers, breeding and pharmaceutical companies, feed producers), can actively contribute.

References are available on request

From the Proceedings of XXII WVPA Conference, 2023

18 DOSSIER - dossier -

19 - january 2024 -

Broiler litter management

To reduce the susceptibility of chickens to infectious disease, the poultry production environment (particularly the litter) plays a critical role in fostering immune system and overall flock health. The efficiency of poultry production as well as animal welfare is greatly affected by the conditions inside the poultry house. One crucial factor which directly affects poultry performance and welfare is litter management.

Xuan Dung Nguyen, Graduate Research Assistant, Department of Animal Science, University of Tennessee, USA

Tom Tabler, Professor, Department of Animal Science, University of Tennessee, USA

The U.S. is among the world’s largest poultry-producing countries. Two major products include meat from broiler and turkey production and table eggs from commercial layer operations. The combined value of these two products exceeded 35 billion dollars in 2020. Poultry production provides an affordable and important source of protein consumed in the U.S and a livelihood for 1 million citizens. Approximately 18% of U.S. poultry products are exported. In Tennessee, broiler production is the most important poultry sector.

The poultry industry is now facing numerous challenges including the impact of infectious diseases and a growing demand for higher welfare standards. To reduce the susceptibility of chickens to infectious disease, the poultry production environment (particularly the lit-

20 FOCUS - focus -

science

©Popular

ter) plays a critical role in fostering immune system and overall flock health. The efficiency of poultry production as well as animal welfare is greatly affected by the conditions inside the poultry house. One crucial factor which directly affects poultry performance and welfare is litter management. Some of the important factors in litter management include moisture control, ammonia control, litter depth and type of bedding. Maintaining a good quality litter is a management challenge for poultry producers particularly because “No Antibiotics Ever” (NAE) programs are now widely used by integrators.

Concerns when using built-up litter

Reusing poultry litter is a very common and cost-effective litter management technique used by broiler producers; however, reusing litter over multiple flocks may cause issues if the litter is not managed appropriately. For instance, reusing litter means that challenges for the previous flock, such as high ammonia volatilization rates,

disease pressure and high moisture content, can be carried forward to the next flock. In particular, maintaining good air quality in the presence of built-up litter can be a management challenge.

The high price and decreasing availability of quality bedding materials add to the challenge of managing built-up litter. Pine shavings are an ideal bedding material, but competing markets for this product are driving the price up and making it difficult for poultry producers to afford to use it. Therefore, the industry is looking toward some alternative bedding materials such as miscanthus grass. Another possible alternative bedding material in the future could be hemp bedding. Hemp can absorb four times its weight because of its natural folding structure, and it displays high rates of both moisture adsorption (7.43 mg/min) and moisture release (12.5 mg/min); however, hemp is more expensive than pine shavings and lacks data, making it hard for producers to currently utilize this alternative. Pathogen build up is another concern when using built-up litter. Typically, the optimal conditions

- january 2024 - 21 FOCUS

Eurosilos Sirp srl Isorella (BS) Tel. +39 030.9958205 contatti@eurosilos.it www.eurosilos.it WE KEEP YOUR VALUE SAFE Italian manufacturer of fiberglass silos, tanks and augers. Follow us We are Social

for chickens to grow in a poultry house are the same optimal conditions for the growth of pathogens. Thus, poor built-up litter management can lead to the overgrowth of pathogens. Producers must work to keep pathogen numbers below a disease pressure threshold that the flock can tolerate.

Moisture content

Moisture is a key factor influencing litter quality in broiler houses. Litter moisture is affected by multiple factors including the broiler house environment (temperature, ventilation rate and humidity) and litter properties (bedding material, new vs. built-up litter, litter depth and moisture content). Poor litter moisture control can cause severe footpad dermatitis (Figure 1), which affects the performance and animal welfare of chickens. Previous studies recommend an upper threshold of 25% moisture litter moisture. Levels higher than 25% also increase the ammonia concentration in poultry houses, which can affect bird health and welfare. Maintaining litter moisture concentrations below 25% is not always possible especially during wither weather.

Determining exactly how much moisture is in broiler litter requires some laboratory assistance. Litter samples are collected from various locations in the poultry house, and a composite sample is sent to the lab for analysis. There, they first weigh the poultry litter as is. Then, the litter goes through a drying process, typically 24 hours. After the drying process, the poultry litter is weighed again, and the weight reduction is going to be the water content loss. From that, they can calculate the litter moisture content.

An alternative way to assess litter moisture is a rule of thumb described by Michael Czarick that performed by squeezing handful of litter firmly:

• if the litter stays in a ball, it is too wet;

• if the litter sticks together slightly, the moisture content is acceptable;

• if the litter does not stick together at all, it is too dry.

Growers should check the moisture content regularly. By reusing the poultry litter from the previous flock to the next flock, the moisture content in the litter will be added to daily by the birds through respiration and manure deposition. To compensate for this increase in moisture, ventilation rates must be properly maintained, especially during winter.

“No antibiotics ever” production

No Antibiotics Ever (NAE) production requires much better management; however, NAE often shows that used litter may be more beneficial with NAE production. On one hand, reusing poultry litter may increase disease challenges.

On the other, if producers properly manage reused litter, it will build up good microbiota which can be beneficial to our birds. NAE production means your chickens do not have a protective shield from antibiotics anymore; therefore, litter management is critical. You do not want your litter to build up pathogens because your chickens are now more susceptible to infectious diseases.

Disease control and proper mortality management are two of the important management factors that producers should emphasize for NAE flocks. There has been a steep learning curve associated with removing antibiotics from poultry production. We now know that NAE production requires:

• optimum stocking density,

• good litter management,

• ideal housing environment,

• quality pre-starter feed,

• good water quality and a sound water sanitation program.

Wintertime litter management

Winter litter management is discussed in detail in Litter Management. Some challenges in winter months are cold outside air, a brood chamber at 90-92 °F for baby chicks, minimum air flow rates that make a uniform temperature distribution difficult to achieve and expensive propane that producers must burn to keep their flocks warm.

During wintertime, producers must balance between the expense of heat loss and ventilation to remove ammonia and moisture.

22 FOCUS - focus -

Figure 1 – Footpad dermatitis caused by wet litter.

Failure to balance heat loss and ventilation properly could mean:

• high NH3 concentrations

• increased pathogen growth/disease challenge

• high litter moisture concentrations.

Moisture is the key factor influencing litter quality during winter. There are two major sources where this moisture comes from: the first one is the birds. Birds consume ap proximately two pounds of water for each pound of feed consumed. 80% of this water is added back to the house environment in the form of manure and respiration. Sec ond is the brooders. For each gallon of propane burned, 6.8 pounds (0.8 gallons) of water is produced. Produc ers must control this moisture with ventilation, and the amount of ventilation needed will vary continuously. The ventilation rate needs are necessary to ideally keep am monia at less than 25 ppm and maintain relative humidity in the 50-70% range

Pathogen control

During wintertime, litter pathogen concentrations tend to increase when ammonia and moisture control is poor. To address this problem, some common methods are:

• Pasteurization – uses heat to kill microbial disease organisms.

• Composting – well-known and commonly used method.

• Windrowing – reliable and cost-effective way to reduce pathogen load;

• – it is not true composting because composting takes a longer time;

• – heat buildup in windrows can kill the majority of pathogens.

Windrowing is an attractive litter management practice that is a reliable and cost-effective way to reduce the pathogen load in built-up litter. It is not true composting because the windrows are in place for only a short time between grow outs, but when done correctly heat build up in the windrows will kill many microbial pathogens. Windrowing can be challenging to manage (Figure 2). For instance, litter moisture must be adequate (25-30%), or the windrow will not heat properly. If the windrow doesn’t heat, the windrowing process has done little good, and time and diesel fuel are wasted. There also must be enough downtime between flocks to windrow properly.

- january 2024 - 23 FOCUS

INNOVATION IN VENTILATION +45 75771922 • mail@dacs.dk • www.dacs.dk Across the entire pressure range, and at any speed, any airflow, and any supply voltage MagFan comes out top of the chart in Bess Lab testing, by a wide margin!

Given enough time to do it correctly, and with the right moisture content for the windrow to heat to around 130140 °F, many of the pathogens in the litter can be killed. Depending on the litter moisture content, it may be necessary to leave the caked litter in place to have enough moisture to make the windrow heat. Consult your service technician about leaving or removing the caked litter before windrowing. The initial windrow should be built within two days following flock departure and allowed to remain windrowed for three days. Then, turn the first windrow and create a second windrow that will similarly remain in place for three days. After three days, level the second windrow. Allow the litter 4 days to dry and cool after the windrows have been re-spread before applying a litter amendment. Otherwise, the amount of ammonia emitted by the litter can rapidly overwhelm the litter amendment, rendering it ineffective. Litter over 6 inches deep is difficult to windrow because of the amount of material in the house. Windrowing works best at litter depths of 3-6 inches.

Litter treatments

There must also be enough downtime between flocks to windrow properly. Less than 10 days is not long enough to properly windrow litter. Especially after applying windrowing, it is important to use litter treatments to manage ammonia levels. Some litter amendments can also reduce pathogen loads built up in used litter. However, some amendments can increase the nitrogen (N) content in the litter, and the conversion of nitrogen (N) compounds in manure to NH3 is a source of environmental concern. Ammonia is a serious animal welfare and economic threat to the poultry industry and must be managed as such. Most litter treatments are acidifiers, and growers should follow manufacturers’ recommendations, guidelines and precautions for their safe use and handling. Commonly available litter treatments include:

• PLT (sodium bisulfate)

• Alum (aluminum sulfate)

• Poultry Guard (claylike particles soaked in sulfuric acid)

• Klasp (iron sulfate)

• Liquid A7 (sulfuric acid and aluminum sulfate).

Indoor parameter assessment

Ammonia, humidity, temperature and carbon dioxide are the critical influencing factors of poultry production and animal welfare. To properly assess these parameters, producers must acquire measurement devices such as humidity and ammonia sensors. In some cases, when growers are exposed to ammonia over a long period of time, they may not be as sensitive to noticing high levels of ammonia inside the house as others. However, these measurement devices are always considered support tools, they do not replace the role of producers in properly managing poultry farms. Nothing can work better than the human senses. Previous authors promote the “5-gallon bucket” method as the best way to assess the indoor environment of the poultry house. Basically, you find a 5-gallon bucket and sit down in the poultry house. Watch the birds. See how they respond to ideal conditions. Learn how they behave when they are too hot, too cold, etc. They can tell you what’s wrong if you learn how to recognize what they are telling you. You can only learn these things by being in the chicken house. The house controller cannot grow the chickens for you. The controller can assist you, but you must grow the chickens. And the only way to do that successfully is for you to be in the chicken house.

Summary

There are two take-home messages that you should always keep in mind:

• litter moisture and ammonia control are critical to maintaining productivity and bird welfare.

• No Antibiotics Ever production has made litter management a much more critical issue.

Trade names are for educational purposes only and do not imply endorsement by the UT Institute of Agriculture or the University of Tennessee Department of Animal Science.

By courtesy of The University of Tennessee Institute of Agriculture and UT Extension

References are available on request

24 FOCUS - focus -

Figure 2 – Windrowing litter in poultry houses.

- january 2024FOCUS Leader in livestock feeding systems QUALITY MADE IN ITALY www.azainternational.it I WANT AZA! Only one winching system for two lines with more space in the shed. Designed from one-day old to slaughtering age. Automatic feed level setting with the window opening system. DUO THE SUITABLE COMBINED FEEDING AND DRINKING SYSTEM No chick inside the pan. Automatic feed level setting with the window opening system. ONE SECOND immediate opening and closing of the bottom pan for complete and fast washing. FULLY AUTOMATIC AUTOMATIC ADJUSTMENT MIXTA THE FEED PAN FOR TURKEYS, DUCKS AND MIXED CYCLES CLACK ONE SECOND TO CLOSE CLICK ONE SECOND TO OPEN EASY CLEANING Flexible rubber shock-proof cone

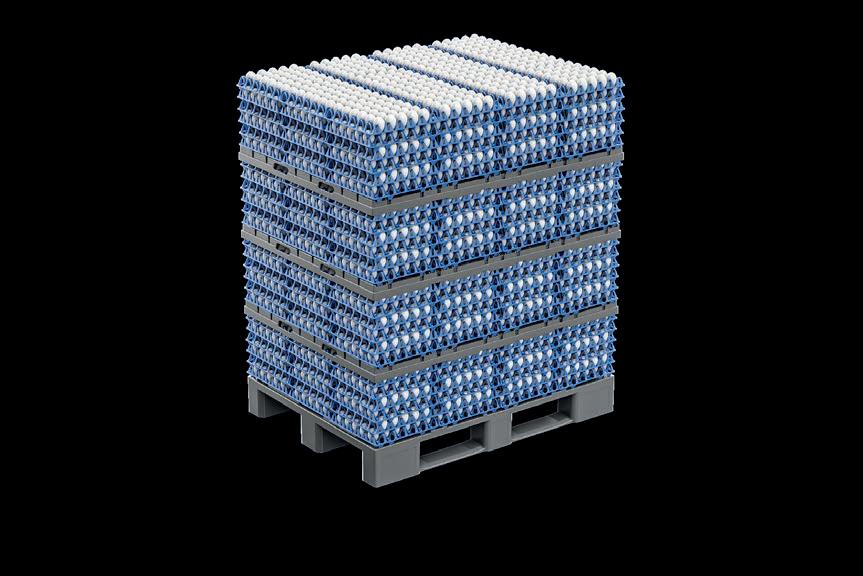

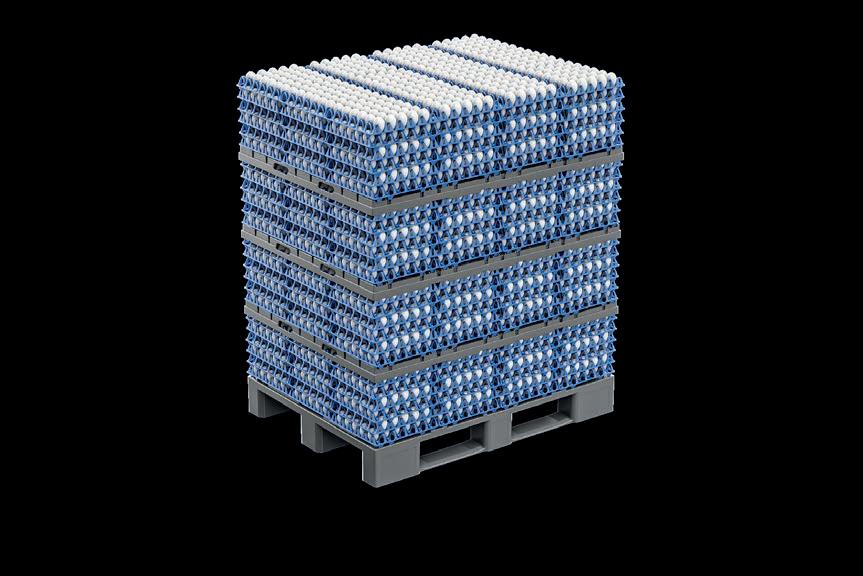

Dynamics and patterns of U.S. poultry meat trade between 2012 and 2022

Brazil, the USA and some EU member countries are dominating global poultry meat trade. Until 2007, the USA was leading in broiler meat exports, then it lost its first place to Brazil. In turkey meat trade, the USA still rank in first place, but have lost market shares since the middle of the past decade to Poland, Germany, Italy and Spain. As will be shown, the massive outbreaks of the Avian Influenza virus in 2015 and 2022 played an important role in the dynamics and trade patterns of U.S. poultry meat exports.

Stable volume but losing market shares in broiler meat exports

With the exception of 2015, the USA exported over 3 mill. t of broiler meat. Figure 1 shows that in most of the years, the volume even surpassed 3.3 mill. t. The value of the exports fluctuated, however, between only 2.8 billion $ in 2015 and almost 4.3 billion $ in 2022. This fluctuation reflects the dynamics in the average value per exported tonne.

Hans-Wilhelm Windhorst

The author is Professor

Emeritus

of the University of Vechta, Germany

In 2015, the AI outbreaks mainly affected the egg and turkey farms in Minnesota and Iowa and reduced their production volume

considerably. Although no outbreaks occurred in the centre of broiler meat production in the Southeast, the export volume decreased by almost 443,000 t between 2014 and 2015 and it took several years before the former volume was reached again. The decline was a result of the import ban on U.S. poultry meat, as pronounced by 30 countries. The share of the exports in production fell from 14.3% in 2014 to 11.9% in 2015. Table 1 documents the exports to the ten leading countries of destination in 2014, 2015 and 2022. Russia and China did not permit any imports in 2015 because of the AI outbreaks, exports to Angola fell by 90,000 t

26 MARKETING - marketing -

or 39%, to Cuba by 38,000 t or 26%. In contrast, exports to Hong Kong, Viet Nam and Canada increased. The value per exported tonne of broiler meat decreased by 15% between 2014 and 2015 and even 23% in 2016. The sharp decline was a result of the continued ban by several countries and a surplus on the global market. The low average price on the global market was a consequence of the Covid-19 pandemic. The lockdown of restaurants and outlets of the system gastronomy not only in the USA, but also in many other countries, caused an oversupply and forced the exporting companies to accept lower prices. The average value per tonne decreased from 1,226 $ in 2014 to 1,046 $ in 2015 and 946 $ in 2016.

In 2021 and 2022, the export volume remained stable despite the AI epidemic in 2022, but decreased in the first quarter of 2023 because of import bans. It is worth noting that the export value increased by 520 mill. $ in the two years under consideration. AI outbreaks in Europe and Asia resulted in a tight market situation, which permitted higher prices. The value per exported tonne of broiler meat climbed from 1,127 $ in 2021 to 1,295 $ in 2022. Russia, a major importing country in 2014 was no longer member of the top ten countries of destination in the following years because of the ban on export as pronounced in 2014. The ban was one reason but also the remarkable progress of Russia’s broiler industry, which not only reached full self-sufficiency but also permitted exports. Although the exports reached the same volume in 2022 as in 2012, the USA lost market shares in global

2012 and 2022 (design: A.S. Kauer based on USDA, FAS data).

poultry meat trade. In 2012, the country shared 28.5% in the global export volume; the share fell to 24.3% in 2021 and, according to preliminary data, to only 21.2% in 2022.

27 - january 2024MARKETING

2014 2015 2022 Country Export Share (%) Country Export Share (%) Country Export Share (%) Mexico Angola Canada Cuba Russia China Taiwan Hong Kong Iraq Georgia 695.7 230.9 162.8 143.7 138.2 118.0 115.2 104.9 88.5 87.8 21.0 7.0 4.9 4.3 4.2 3.6 3.5 3.2 2.7 2.6 Mexico Canada Taiwan Angola Hong Kong Cuba Guatemala Viet Nam Iraq Philippines 668.1 181.3 174.5 140.7 132.6 105.9 104.2 77.2 73.3 71.7 23.3 6.3 6.1 4.9 4.6 3.7 3.6 2.7 2.6 2.5 Mexico Cuba Taiwan Philippines Angola Canada China Guatemala Viet Nam Congo Braz. 663.8 272.7 236.6 188.8 178.3 151.4 138.6 128.4 116.9 83.9 20.1 8.3 7.2 5.7 5.4 4.6 4.2 3.9 3.5 2.5 10 countries 1,885.7 57.0 10 countries 1,729.5 60.3 10 countries 2,159.4 *65.4 Total 3,309.9 100.0 Total 2,867.0 100.0 Total 3,301.3 100.0

Table 1 – The share of the ten leading countries of destination in U.S. broiler meat exports in 2014, 2015 and 2022; data in 1,000 t (source: USDA, FAS).

[bill. $] 0,0 1,3 2,5 3,8 5,0 [mill. t] 2.5 2.8 3.0 3.3 3.5 20122013201420152016201720182019202020212022 Export volume Export value [$/t] 100 400 700 1.000 1.300 20122013201420152016201720182019202020212022 Average value

* sum does not add because of rounding

Figure 1 – The development of U.S. broiler meat exports by volume and value between

Higher impacts of AI outbreaks on exports than on turkey meat production

Turkey meat production fluctuated between 3.39 mill. t in 2012 and 2.99 mill. t in 2022. In 2015, more than 160 outbreaks in turkey farms resulted in a loss of 7.5 mill. birds, which either died from the infection or were culled to prevent a further dissemination. Production decreased from 3.30 mill. t in 2014 to 3.17 mill. t in the following year or by 4.0%. The relative decrease may be astonishingly low, but as most of the outbreaks occurred in the first half of the year, farms were restocked after several weeks of quarantines and production was restarted (Windhorst 2016). The situation was different in 2022. The 217 outbreaks spread over the whole year and caused a loss of 9.7 mill. turkeys, either by the infection or by pre-emptive culling. Production of turkey meat decreased from 3.23 mill. t in 2021 to 2.99 mill. t in 2022 or by 7.4% (Windhorst 2023).

Figure 2 documents the development of the export volume, the value of exports and the average price per tonne, which could be achieved on the global market. The AI epidemic in 2015 and the ban on imports of poultry meat as pronounced by 30 countries resulted in a decline of the export volume from 351,400 t in 2014 to 239,900 t in 2015 or by 31.7%.

The share of the exports in the production volume fell from 10.6% to 7.6%. The value of exports decreased from 766.3 mill. $ to 589.0 mill. $ or by 23.1%. The lower relative share in the export value than in the export volume is a consequence of the tight market situation and higher prices for turkey meat on the international market. The average value per tonne increased from 2.181 $ to 2,455 $. In the following years, the average price fell again to 2,160 $ in 2017.

The 2022 outbreaks had massive impacts on the export volume and on the export value. The different timeline of the epidemic and the lasting bans on imports of U.S. turkey meat are reflected in the decline of the export volume from 248,400 t in 2021 to 184,800 t in 2015 or by 25.6%. In contrast, the export value decreased by only 23.9 mill. $ respectively 3.6%.

The difference is a result of the sharp increase in the average value per tonne from 2,340 $ to 3,479 $ due to the tight market situation not only in the domestic but also on the global market. With only 6.2%, exports in 2022

had the lowest share in production for years. Even in the first quarter of 2023, export volume and value were lower than in the fourth quarter of 2021.

Considerable fluctuations in the composition and ranking of leading countries of destination

The two AI epidemics in 2015 and 2022 had considerable impacts on the composition and ranking of the leading countries of destination. Figure 3 documents the changes between 2014 and 2015 respectively 2021 and 2022.

In 2015, Mexico remained in an unchallenged first position despite a reduction of its imports by 73,300 t or 32.4%; nevertheless, the share in the U.S. exports remained stable. China’s imports fell from 25,752 t in 2014 to only 289 t in 2015. When the first AI outbreaks were documented in the USA, China immediately closed its borders. The drastic reduction of the imports was to some

28 MARKETING - marketing -

[mill. $] 0 200 400 600 800 [1,000 t] 0 100 200 300 400 20122013201420152016201720182019202020212022 Export volume Export value [$/t] 0 1,000 2,000 3,000 4,000 20122013201420152016201720182019202020212022 Average value

Figure 2 – The development of U.S. turkey meat exports by volume and value between 2012 and 2022 (design: A.S. Kauer based on USDA, FAS data).

degree compensated by an increase of Hong Kong’s imports by 4,500 t. It is surprising that Japan imported about 1,200 t more in 2015 than in the preceding year because the country normally pronounces a ban as soon as an AI case is documented in the country of origin. Perhaps the meat came from stockpiles operated by the USA in Asia to continue supplying in the event of an AI outbreak. With the exception of Gabon and Panama, all other countries of the top group reduced their imports, some, as the Philippines and Benin, considerably (Table 2).

The AI epidemic in 2022 caused a decrease of the turkey meat exports by 63,563 t or 25.6%. The highest absolute decline showed Mexico with 39,000 t, the Dominican Republic with 3,100 t, Benin with 3,000 t and China with 2,000 t. The highest relative decrease was record-

ed for the Dominican Republic with 52.9%, China with 32.7% and Benin with 32.6%. A stable respectively even increasing import volume showed Canada and El Salvador. Figure 3 documents the heavy dependency of the U.S. turkey industry on Mexico’s imports. Over the whole decade under consideration, Mexico’s share in U.S. exports ranged between 60% and 70%. An important role also played other Central and South American countries, countries in East Asia and Benin.

Figure 4 shows the great fluctuation in the export volumes of the three most important Asian countries of destination and Benin between 2012 and 2022. In the early years of the past decade, China ranked second among the leading importing countries, but the AI outbreaks in 2015 reduced the import volume drastically and fell to

* sum does not add because of rounding

29 - january 2024MARKETING

2014 2015 2022 Country Export Share (%) Country Export Share (%) Country Export Share (%) Mexico China Canada Benin Philippines Japan Hong Kong Panama Dom. Rep. Colombia 226,517 25,752 8,815 6,521 6,403 5,976 5,941 4,681 4,347 4,204 64.5 7.3 2.5 1.9 1.8 1.7 1.7 1.3 1.2 1.2 Mexico Hong Kong Canada Japan Panama Benin Dom. Rep. Gabon Jamaica Philippines 153,188 9,486 7,663 7,113 4,999 4,581 4,246 3,434 3,333 3,052 63.8 4.0 3.2 3.0 2.1 1.9 1.8 1.4 1.4 1.3 Mexico Canada Benin China Guatemala Jamaica Panama Dom. Rep. El Salvador Costa Rica 129,718 6,444 4,062 3,981 3,286 3,126 2,898 2,820 2,456 2,446 70.2 3.5 2.2 2.2 1.8 1.7 1.6 1.5 1.3 1.3 10 countries 299,157 85.1 10 countries 201,0 9 5 *83.8 10 countries 161,237 87.2 Total 251,404 100.0 Total 239,930 100.0 Total 184,837 100.0

Table 2 – The share of the ten leading countries of destination in U.S. turkey meat exports in 2014, 2015 and 2022; data in 1,000 t (source: USDA, FAS).

MADE IN ITALY WEB R www.valli-italy.com quality you can depend on Area Baby Area Bellavita Castello Casa Piramide Plus Vita VLV Plus Via Cimatti, 2 47010 GALEATA FC -ITALY ALTERNATIVE SYSTEMS

almost zero until 2019. After a year of recovery, it declined again but did not completely plunge in 2022. In the first quarter of 2023, China did not import turkey meat from the USA any longer. Beside the AI outbreaks, rising political tensions may also have played a role. In some years (2016 to 2019), Hong Kong partly compensated for China’s declining imports, but from 2020 onward, im -

ports decreased considerably and were only of minor importance for the U.S. turkey industry.

The development of Japan’s imports are worth noting. The AI outbreaks in 2015 did not result in a sharp decline but in an increase of the import volume in 2016 and 2017. In the following years, it fell constantly, however, and was over 90% lower in 2022 than in 2017. In the first quarter

of 2023, Japan imported only about 170 t from the USA, which indicates continuing low import volumes. Benin’s imports fluctuated considerably in the decade under consideration. The AI outbreaks obviously had impacts on the import volume, as it fell considerably in 2020 and 2022. As the country is exporting large amounts of it imports to other African countries, the decisions of these countries may have played a decisive role in Benin’s import behaviour.

Summary and perspectives

The massive AI outbreaks in 2015 and 2022 had far-reaching impacts on U.S. poultry meat exports. Broiler meat production was less affected than turkey meat because of the differences in the timelines and the regional patterns of the outbreaks. As broiler growing is concentrated in the Southeast and in the Mid-Atlantic states, the AI epidemics had only minor impacts on broiler meat production.

The massive reduction of the export volume in 2015 was mainly a result of the banning of imports, as pronounced by 30 countries. It took several years, until the former volume was reached again because several countries prolonged their ban into 2016 and even 2017. The strong competition of Brazil, Turkey and some EU member countries will only permit a small increase of the exports over the 2022 volume. In contrast, the timelines and regional patterns of the AI outbreaks in turkey farms in 2015 as well as in 2022 had drastic impacts on turkey meat exports. The sharp decline in 2015 was also mainly a consequence

30 MARKETING - marketing -

[1,000 t] 0 13 25 38 50 20122013201420152016201720182019202020212022 Benin China Japan Hong Kong

Figure 3 – The share of the ten leading countries of destination in U.S. turkey meat exports in 2021 and 2022 by volume (design: A.S. Kauer based on USDA, FAS data).

14.9% 1.2% 1,3% 1.7% 1.8% 2.5% 7.3% 64.5% Mexico China Canada Benin Philippines Japan Hong Kong Panama Dom. Rep. Colombia Others Total: 351,404 t 2014 1.7% 1.9% 1.2% 15.1% 1.2% 1.2% 1,4% 1.5% 1.8% 1.9% 2.4% 2.4% 3.0% 68.1% Mexico Benin Canada China Dom. Rep. Guatemala Haiti Jamaica Panama Peru Others Total: 248,369 t 2021 16.1% 1.3% 1.4% 1.4% 1.8% 1.9% 2.1% 3.0% 3.2% 4.0% 63.8% Mexico Hong Kong Canada Japan Panama Benin Dom. Rep. Gabon Jamaica Philippines Others Total: 201,065 t 2015 12.8% 1.2% 1.3% 1.5% 1.6% 1.7% 1.8% 2.2% 2.2% 3.5% 70.2% Mexico Canada Benin China Guatemala Jamaica Panama Dom. Rep. El Salvador Costa Rica Others Total: 184,837 t 2022

Figure 4 – The development of U.S. turkey meat exports to selected countries between 2012 and 2022 (design: A.S. Kauer based on USDA, FAS data).

of import bans, but in the following years, the former volume of 350,000 t could not be reached again.

The Economic Research Service of the USDA assumes that turkey meat exports will persist at the low level of 2022 with less than 200,000 t until 2024 and perhaps even longer. Several EU member countries and Brazil have been able to stabilize their position in global turkey meat trade and are a big challenge for the U.S. turkey industry.

Data source and references

FAO database: https://www.fao.org/ faostat/en.

USDA, ERS: Livestock, Dairy, and Poultry Outlook: May 2023. https:// www.ers.usda.gov/publications/ pub-details/?pubid=106570.

USDA, FAS: Brazil: Poultry and Products, Semi-Annual. GAIN Report BR2023-0005. https://www.fas.usda. gov/data/brazil-poultry-and-products-semi-annual-7.

USDA, FAS: China: Poultry and Products, Semi-Annual. GAIN Report CH2023-0020. https://www.fas.usda. gov/data/china-poultry-and-products-semi-annual-8.

USDA, FAS: Russia: Poultry and Products Annual. GAIN Report RS2020-0042. https://www.fas.usda. gov/data/russia-poultry-and-products-annual-4.

USDA, NASS: Poultry production and Value. 2022 Summary. https:// usda.library.cornell.edu/usda-esmis/ files/m039k491c/wm119387d/7p88dx55s/plva0423.txt.

Windhorst, H.-W.: Brazil and USA: Ongoing competition on the global chicken meat market. In: Zootecnica International 41 (2019), no. 6, p. 16-19.

Windhorst, H.-W.: Economic impacts of the AI-outbreaks in the USA in 2015. A final evaluation of the epizootic disaster. In: Zootecnica International 38 (2016), no. 7, p. 34-39.

Windhorst, H.-W.: Two waves, different routes and changing dynamics. The Avian Influenza outbreaks in the USA in 2022. In: Poultry World 39 (2023), no. 2, p. 8-11.

Eagle Trax™

Hatcheries have a wealth of valuable data available. Unlocking the potential of that data presents a major opportunity to improve the overall performance of hatcheries as well as of the entire value chain. With Eagle Trax™, Petersime offers the first intelligent hatchery software that turns data into maximum poultry performance. Eagle Trax™ allows you to digitise, analyse and optimally use data to advance ever more in hatchery efficiency, productivity and chick quality.

With Eagle Trax™, your hatchery will always maximise the genetic potential of each hatching egg and deliver predictable output of the most profitable day-old chicks for everybody involved in the poultry value chain.

Let’s keep in touch!

www.petersime.com

31 - january 2024MARKETING

The intelligent hatchery software that turns data into maximum poultry performance Scan for more information: © Petersime 2023All rights reserved. Visit our booth at IPPE in Atlanta, USA 30 Jan - 1 Feb, 2024 Hall B, 4045

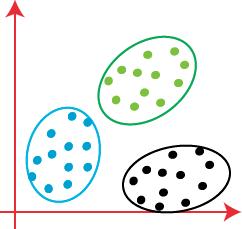

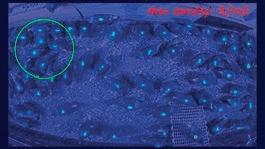

Vision-based dynamic density estimation of laying hens for pilingup prevention

M. Cheng1, L. Yu1, R. Shephard2, Q. Wu1, R. Jenner 3 and J. Zhang1

1 School of Electrical and Data Engineering, University of Technology Sydney

2 Herd Health Pty Ltd

3 Rosetta Management Consulting Pty Ltd

Piling-up is a behaviour that can be common in laying hens on commercial egg farms, which can result in smothering and mass mortality events. Authors propose to provide early warning of pileups by automated video monitoring of bird density and activity in real-time. This will allow farmers to receive early warnings and take necessary measures to prevent negative impacts.

We have designed an auto-monitoring system using computer vision and machine learning to allow automated and dynamic estimates of local flock densities under both indoor and

32 MANAGEMENT - management -

outdoor environments suitable for use on commercial egg farms. This automated monitoring system provides a low-cost intervention to pile-ups, and potentially other behavioural problems on egg farms, with egg production and animal welfare benefits and the added benefit of more efficient labour utilization.

Introduction

The welfare of all farmed livestock is of importance to the consuming public. Australian consumers especially have some concerns about welfare within more intensive animal production systems, such as commercial egg farms. Most consider cage- free and free-range production systems to be more `natural` and associate this with ‘good’ animal welfare. Commercial egg farms experiencing smothering and mortality events as a result of pile-ups experience reduced egg production and risk social licence from compromised animal welfare. Pile-ups occur when a group of hens increasingly cluster together within a small space, which can progress to smothering and death. Recurring pile-ups seem more prevalent on some farms and in some sheds. Birds that do not die can suffer in other ways including heat stress, injury and increase fear responses. Risk factors for pile-ups include several environmental factors (including light and temperature), shed infrastructure, genetics and sudden disturbances resulting in the mass movement and/or attraction.

The monitoring of bird welfare is a challenging task on large egg farms that have tens of thousands of birds per shed. For this reason, an increasing number of Precision Livestock Farming methods have recently been developed. Specifically, density estimation technologies provide the potential for non-intrusive and continuous monitoring and management support on egg farms by providing effective auto-analysis focused on animal welfare and egg production.

In this paper, we present our applied computer vision and machine learning techniques that operate within a video-based monitoring system to enable dynamic estimates of the local density of birds at any time and place. Using low-cost equipment, the system can work continuously giving real-time information. This means that high-density ‘problem’ areas can be effectively detected without labour, and mitigating steps taken in response in a timely fashion.

Method

Our system is based on crowd counting and automated region analysis from video streams. To effectively estimate the flock density, a top-view video camera is mounted to capture the video footage, as illustrated in Figure 1 Such a view setting can avoid occlusion and enlarge the observation area. The video camera is connected to a desktop, which provides backend computation and communication. The live video feed is analysed in real-time, providing the essential density estimates and monitoring to prevent pile-ups.

The backend computational model is data-driven, which requires image data collection and manual annotation. To do this, we set up two cameras on a commercial egg farm in Windsor, NSW to collect video data. One camera was mounted in the shed, and the other was mounted on a pole in the open area outside the shed with the cameras covering 15m2 and 40m2 for indoor and outdoor environments respectively. Af ter annotation of each observable bird on sampled images, we built a simple crowd-counting model as described by Wang et al. Given an image, the model outputs a density map of the same size, where the value of each pixel represents the probability of an object instance, i.e., a bird in our case.

The summation of the values across the whole density map is the total number of observable instances. However, alone, it cannot identify the specific region within

33 - january 2024MANAGEMENT

Figure 1 - The camera setting.

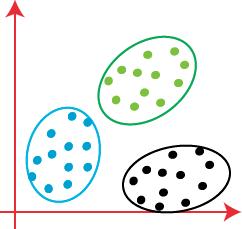

Figure 2 - An illustration of k-means on 2D coordinates.