HYDRO

Picture: zek

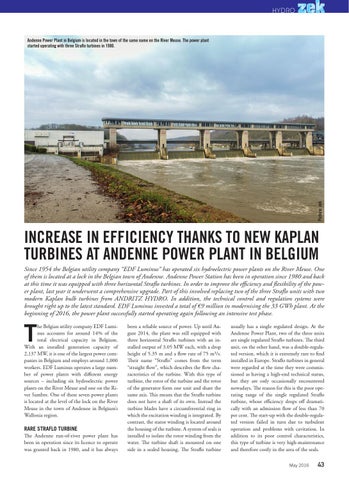

Andenne Power Plant in Belgium is located in the town of the same name on the River Meuse. The power plant started operating with three Straflo turbines in 1980.

INCREASE IN EFFICIENCY THANKS TO NEW KAPLAN TURBINES AT ANDENNE POWER PLANT IN BELGIUM Since 1954 the Belgian utility company “EDF Luminus” has operated six hydroelectric power plants on the River Meuse. One of them is located at a lock in the Belgian town of Andenne. Andenne Power Station has been in operation since 1980 and back at this time it was equipped with three horizontal Straflo turbines. In order to improve the efficiency and flexibility of the power plant, last year it underwent a comprehensive upgrade. Part of this involved replacing two of the three Straflo units with two modern Kaplan bulb turbines from ANDRITZ HYDRO. In addition, the technical control and regulation systems were brought right up to the latest standard. EDF Luminus invested a total of €9 million in modernising the 33 GWh plant. At the beginning of 2016, the power plant successfully started operating again following an intensive test phase.

T

he Belgian utility company EDF Luminus accounts for around 14% of the total electrical capacity in Belgium. With an installed generation capacity of 2,137 MW, it is one of the largest power companies in Belgium and employs around 1,000 workers. EDF Luminus operates a large number of power plants with different energy sources – including six hydroelectric power plants on the River Meuse and one on the River Sambre. One of these seven power plants is located at the level of the lock on the River Meuse in the town of Andenne in Belgium’s Wallonia region. RARE STRAFLO TURBINE The Andenne run-of-river power plant has been in operation since its licence to operate was granted back in 1980, and it has always

been a reliable source of power. Up until August 2014, the plant was still equipped with three horizontal Straflo turbines with an installed output of 3.05 MW each, with a drop height of 5.35 m and a flow rate of 75 m³/s. Their name “Straflo” comes from the term “straight flow”, which describes the flow characteristics of the turbine. With this type of turbine, the rotor of the turbine and the rotor of the generator form one unit and share the same axis. This means that the Straflo turbine does not have a shaft of its own. Instead the turbine blades have a circumferential ring in which the excitation winding is integrated. By contrast, the stator winding is located around the housing of the turbine. A system of seals is installed to isolate the rotor winding from the water. The turbine shaft is mounted on one side in a sealed housing. The Straflo turbine

usually has a single regulated design. At the Andenne Power Plant, two of the three units are single regulated Straflo turbines. The third unit, on the other hand, was a double-regulated version, which it is extremely rare to find installed in Europe. Straflo turbines in general were regarded at the time they were commissioned as having a high-end technical status, but they are only occasionally encountered nowadays. The reason for this is the poor operating range of the single regulated Straflo turbine, whose efficiency drops off dramatically with an admission flow of less than 70 per cent. The start-up with the double-regulated version failed in turn due to turbulent operation and problems with cavitation. In addition to its poor control characteristics, this type of turbine is very high-maintenance and therefore costly in the area of the seals. May 2016

43