Building Information Modelling (BIM) technology for Architecture, Engineering and Construction November /December 2022 >> Vol.123 Exciting new tools for AEC workflows IMAGE COURTESY OF KREOD New model architect January / February 2023 >> Vol.124 FREE INSIDE Workstation special report How Kreod benefits from fabrication-level detail with 3DExperience Catia

Intel® Arc™ Pro A40 GPU unites fluid viewports, the latest in visual technologies, and rich content creation in a condensed half height, half length form factor. • Ray Tracing Hardware Acceleration • Dedicated AI Acceleration • Industry First AV1 Hardware Encode • 6GB High Speed Memory • Software Certifications • Up to 4x Displays, with Audio Support and Latching Mechanism • Single Slot, Tiny Form Factor • Premium Components • Extended Warranty Professional Graphics Begins Here Intel.com/ArcProA40 © Copyright 2022 Intel Corporation. All rights reserved. Intel, the Intel logo, and other Intel marks are trademarks of Intel Corporation or its subsidiaries. Intel Arc Graphics is a trademark of Intel Corporation in the U.S. and/or other countries. Other names and brands may be claimed as the property of others.

CONSULTING

MARTYN DAY martyn@x3dmedia.com

CONSULTING

STEPHEN HOLMES stephen@x3dmedia.com

tony@x3dmedia.com

ADVERTISING

steve@x3dmedia.com

U.S. SALES & MARKETING DIRECTOR DENISE GREAVES denise@x3dmedia.com subscriptions MANAGER ALAN CLEVELAND alan@x3dmedia.com accounts CHARLOTTE TAIBI charlotte@x3dmedia.com FINANCIAL CONTROLLER SAMANTHA TODESCATO-RUTLAND sam@chalfen.com

Industry news 4

Hexagon acquires digital twin firm LocLab; V-Ray 6 for Revit connects with Enscape; Intel launches raft of new CPUs, plus lots, lots more

Fabrication-level modelling with Kreod 10

With attention to detail, understanding of fabrication and Catia, the high-power MCAD system, Kreod is looking to empower the ‘Digital Master Builder’

Snaptrude in Revit workflows 16

With Snaptrude v1.0 now available, we examine how the BIM modeller can be used to augment Revit workflows and boost project collaboration

Vectorworks 2023 24

Support for scan-to-BIM with Apple’s RoomPlan and quality checking via Solibri Inside, are among the new features in this annual update

SimpleBIM: part 2 28

Confronting the challenges of working with structured BIM data

Veras AI 32

We explore this AI-based renderer for BIM models created in Revit

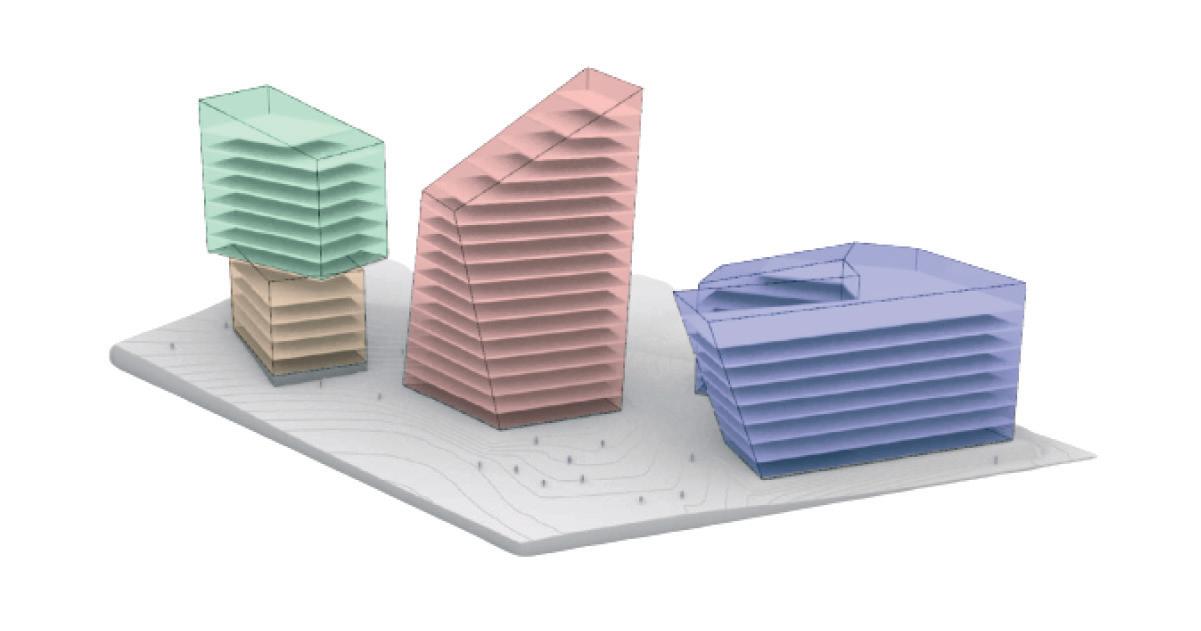

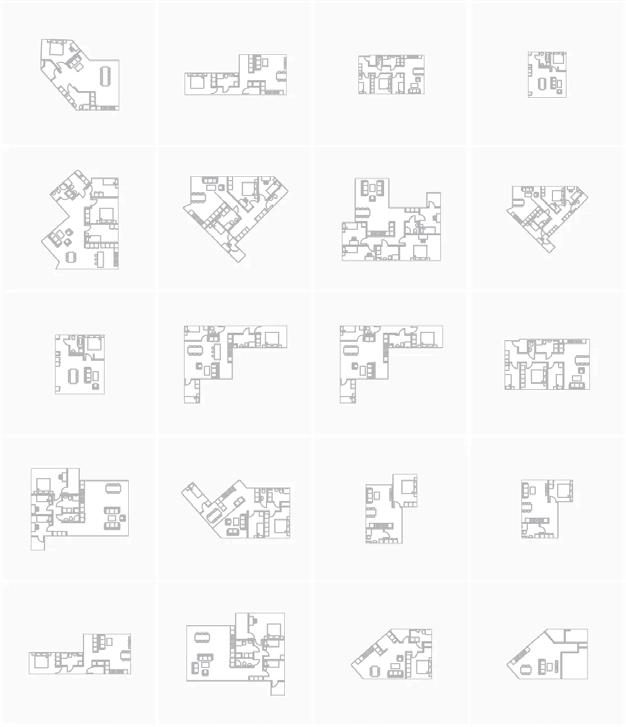

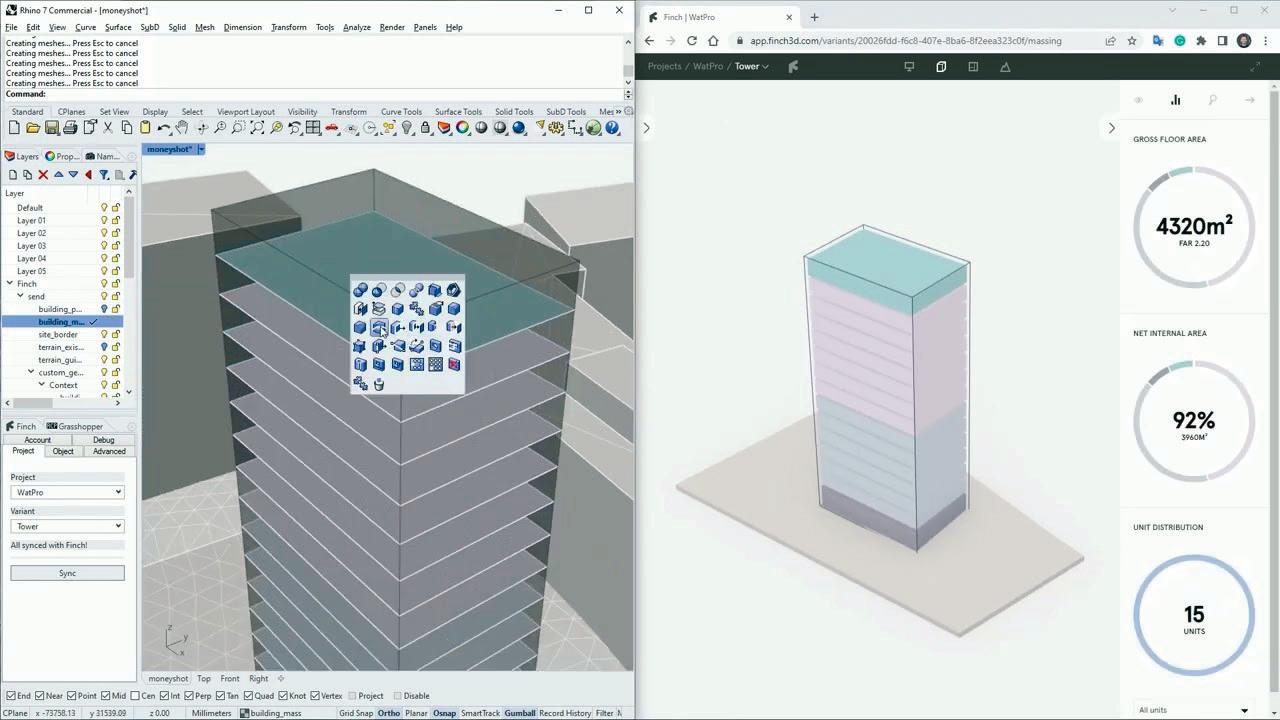

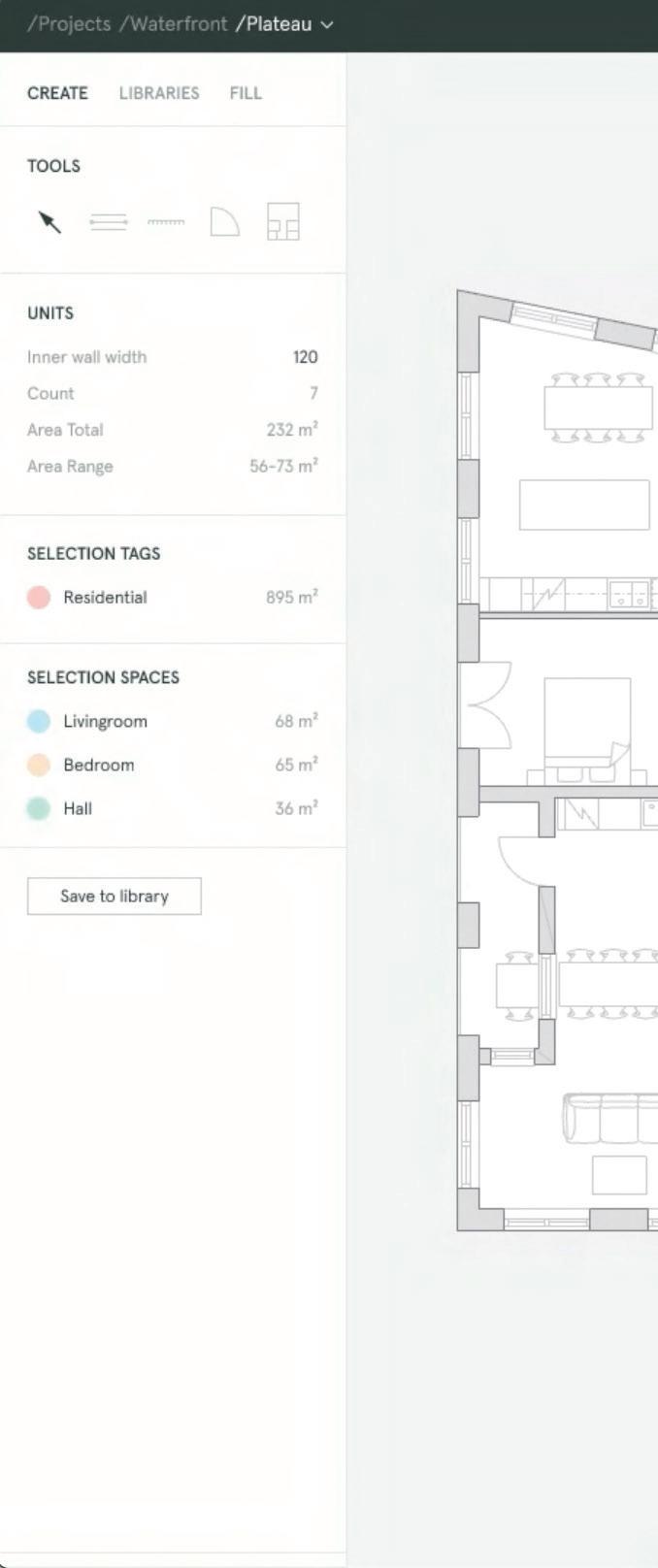

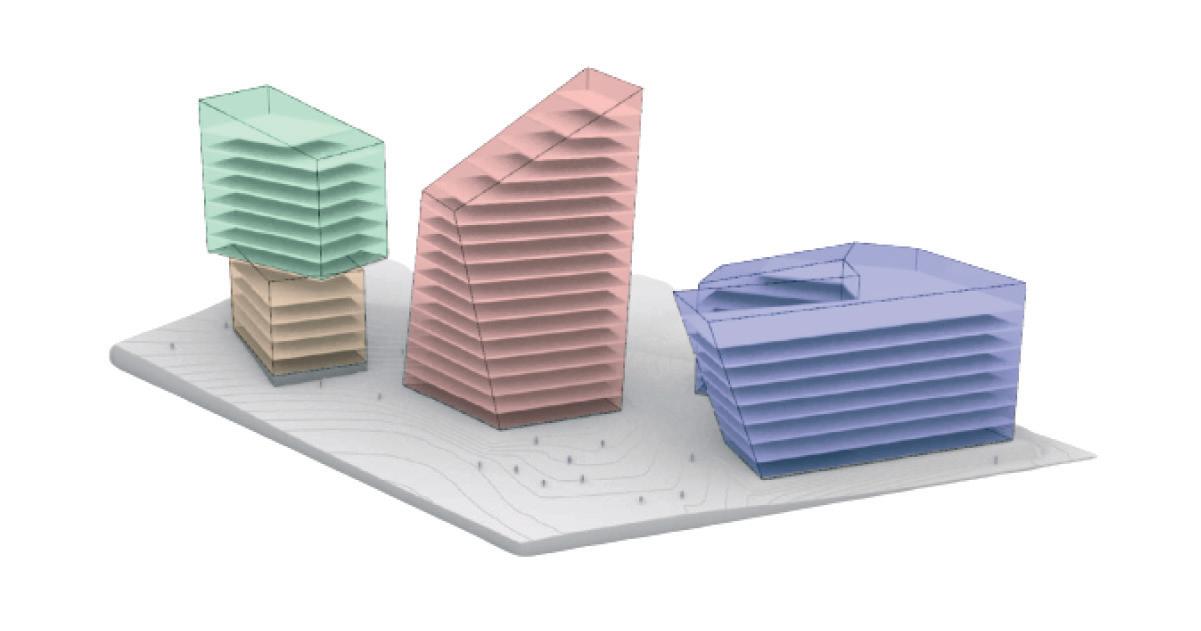

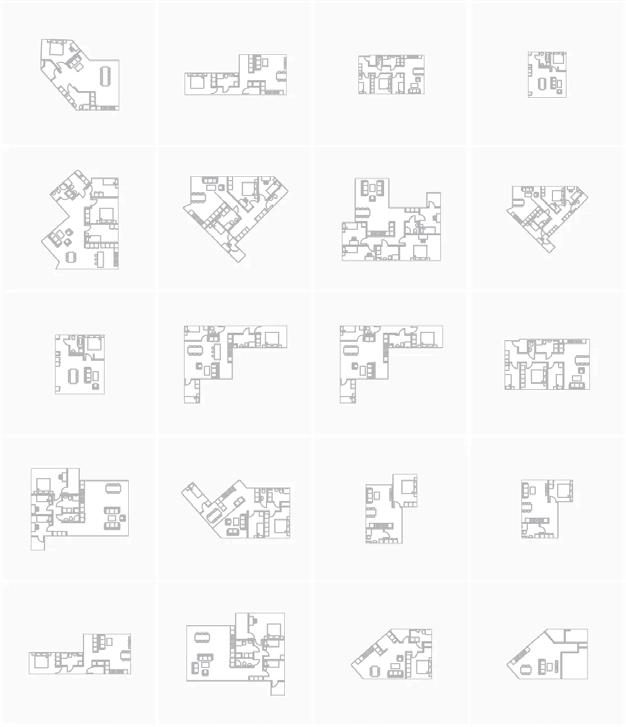

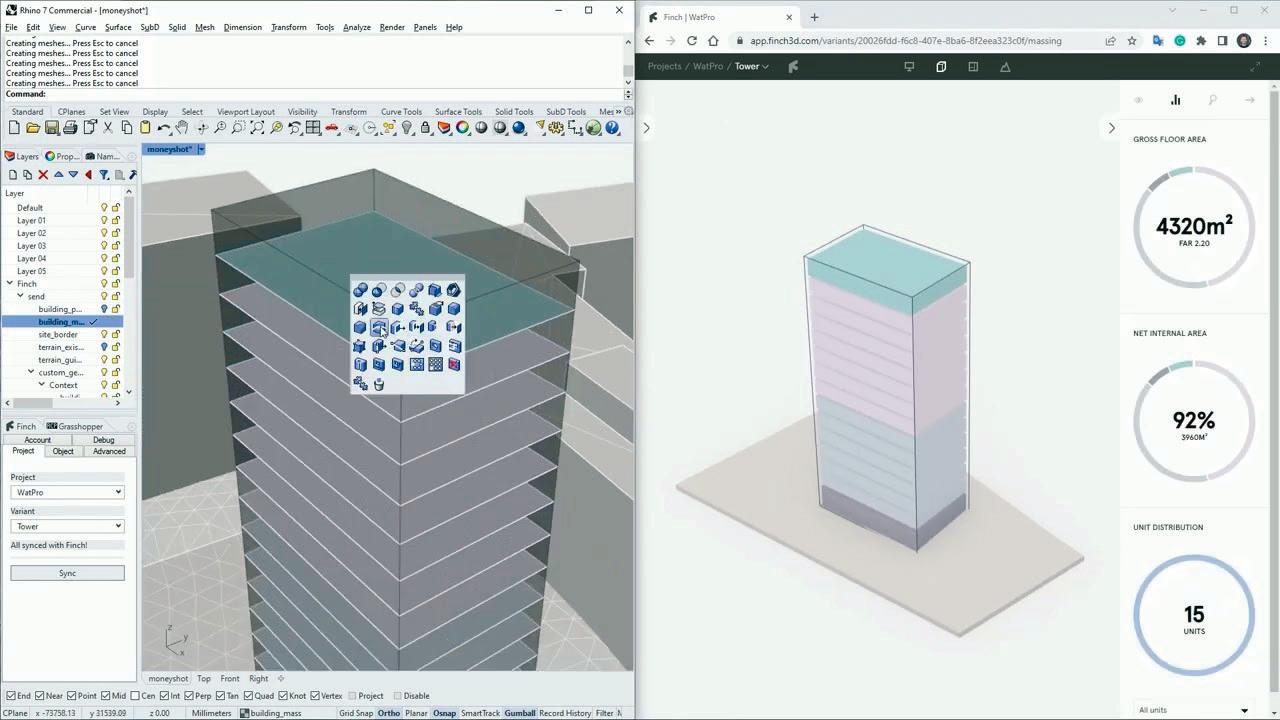

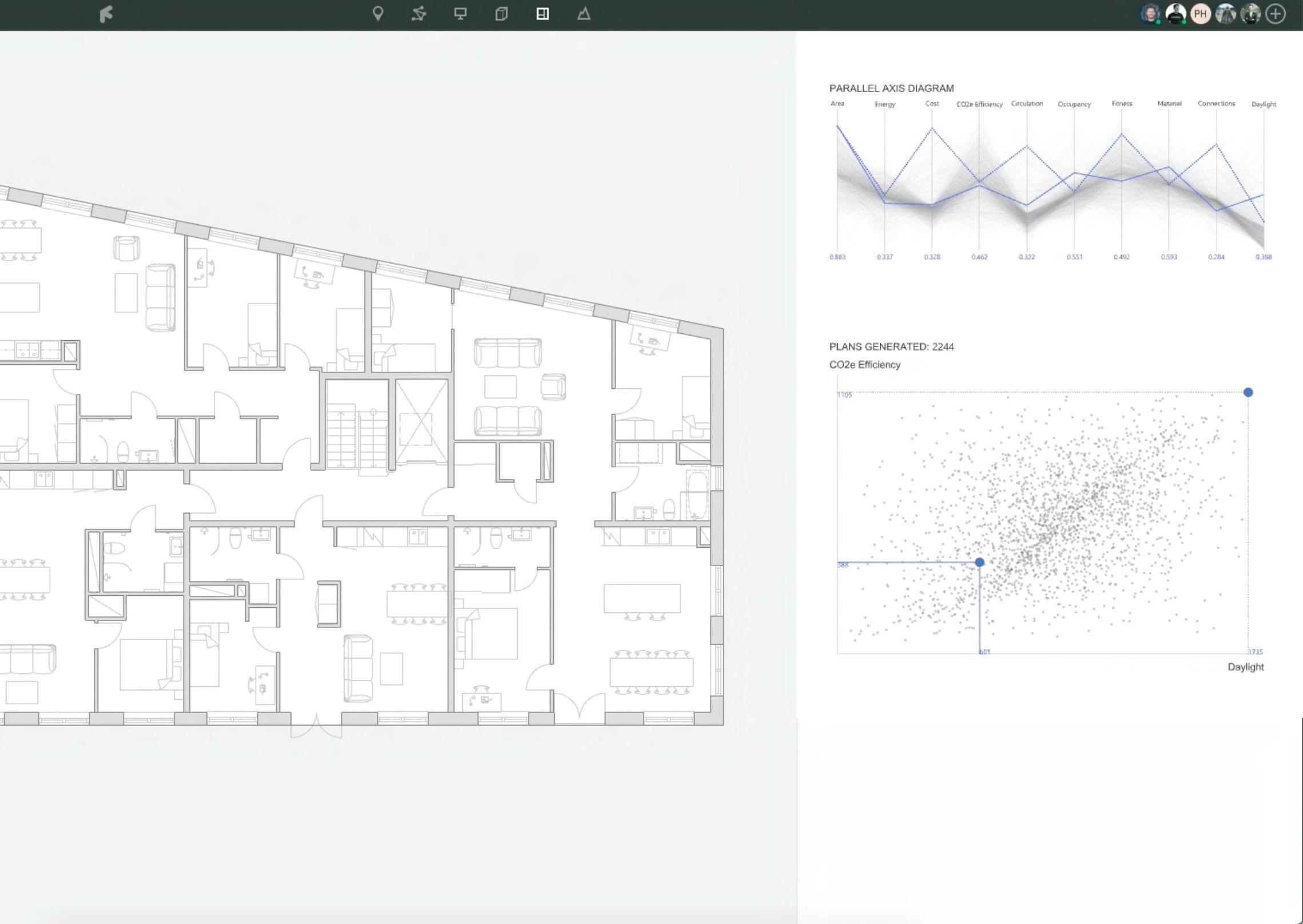

Finch3D 34

This parametric design tool automates floor plan generation, provides feedback and optimises designs for code compliance

Cadsoma 36

Cadsoma aims to become the global web shop for CAD developers to promote and sell their specialised software

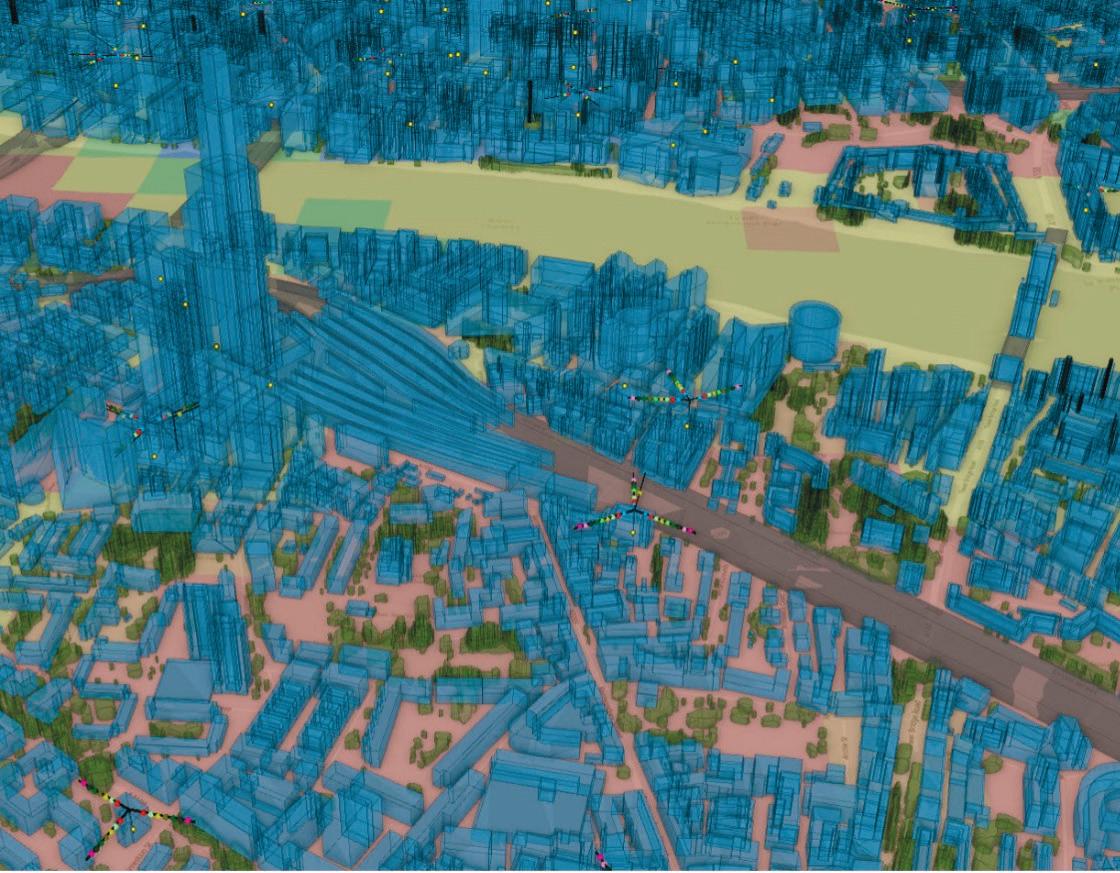

Network connection 39

Vodafone’s network planning digital twin is helping engineers be ‘smarter and faster’

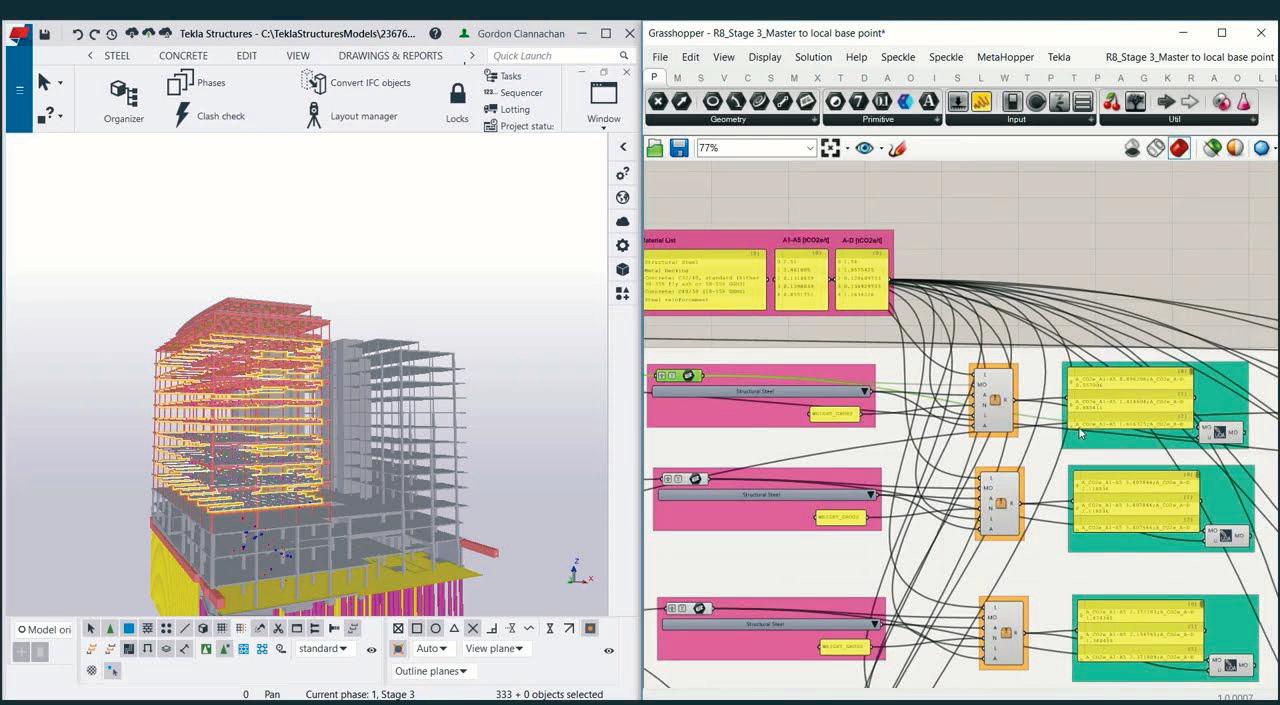

Parametric automation 41

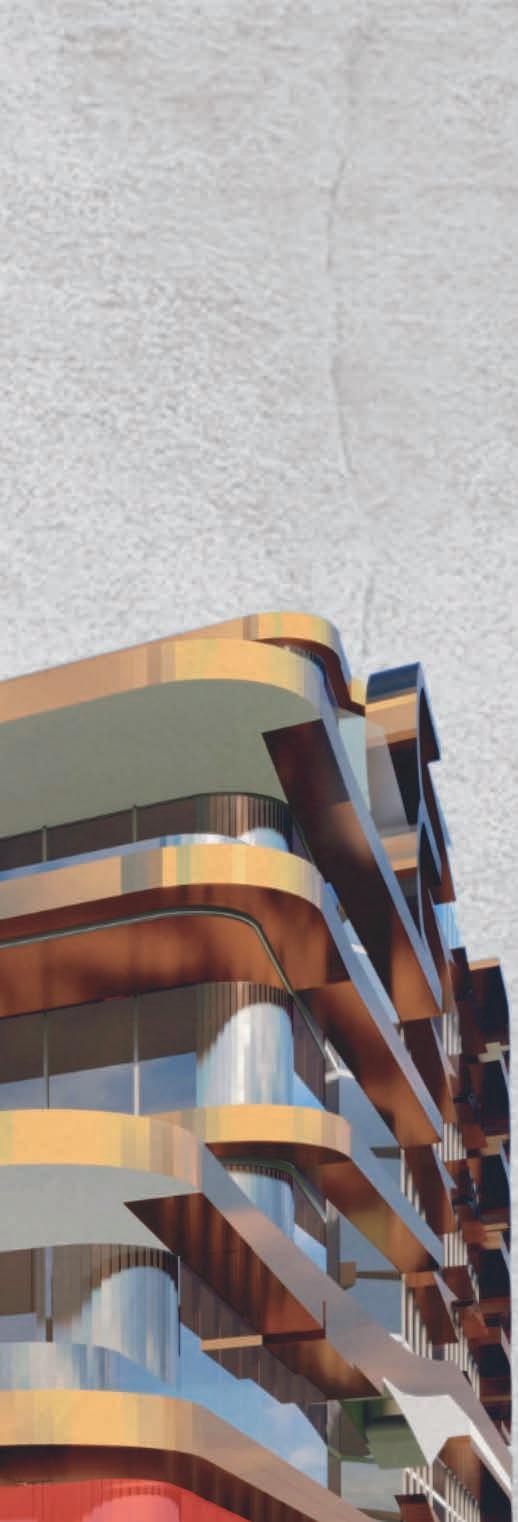

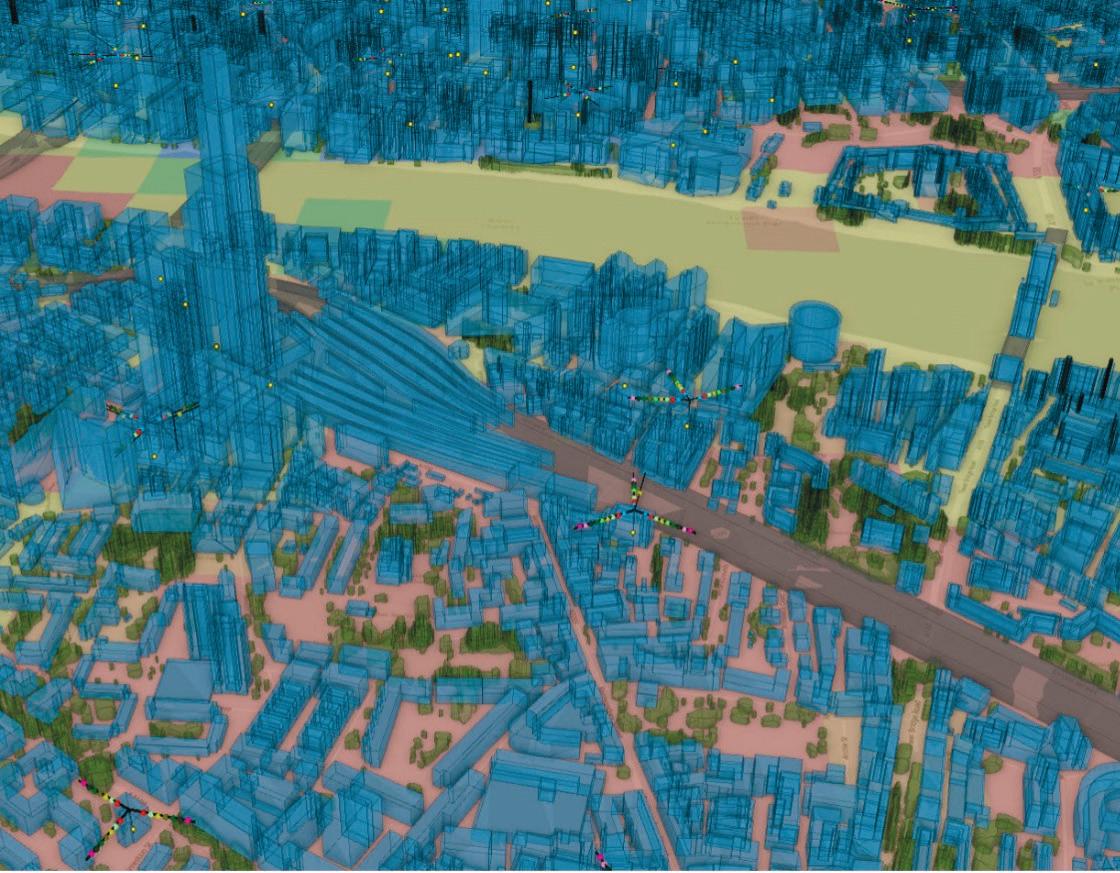

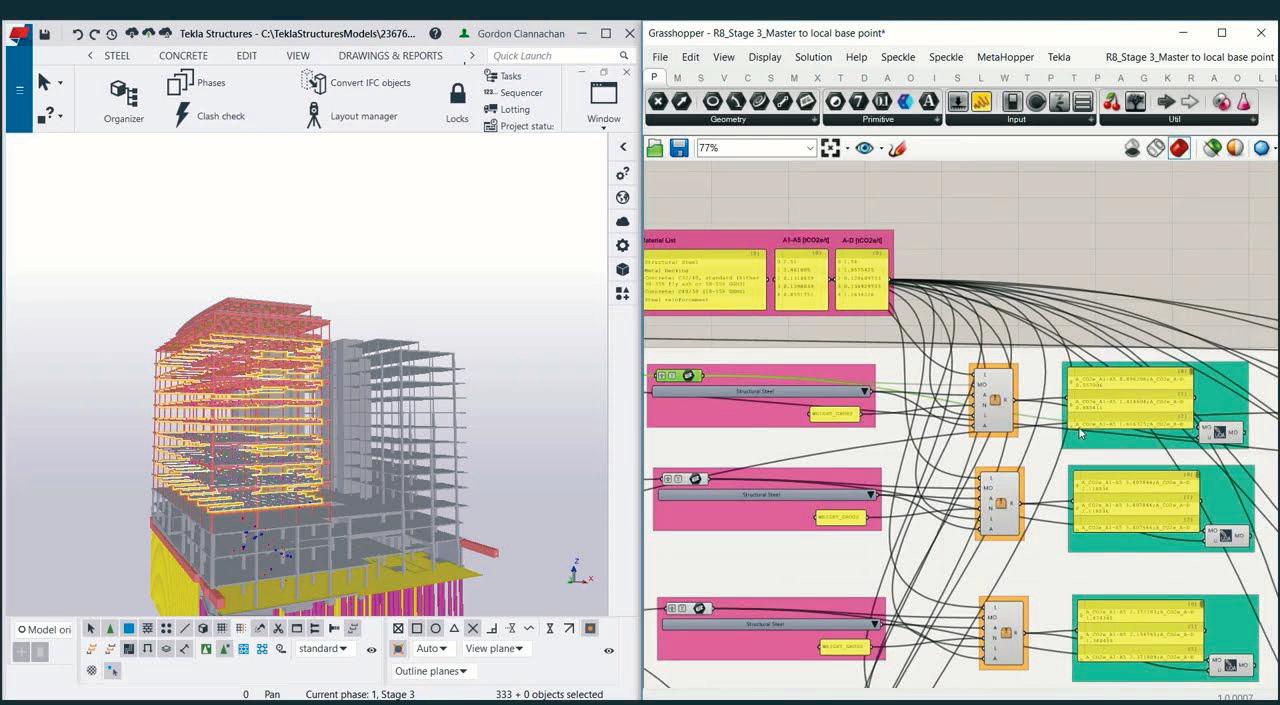

Arup went all-in on parametric design for a mixed-use complex in King’s Cross

3 www.AECmag.com January / February 2023

FREE SUBSCRIPTIONS Register your details to ensure you get a regular copy register.aecmag.com editorial MANAGING EDITOR

Building Information Modelling (BIM)

technology for Architecture, Engineering and Construction

GREG CORKE greg@x3dmedia.com

EDITOR

EDITOR

advertising GROUP MEDIA DIRECTOR TONY BAKSH

MANAGER STEVE KING

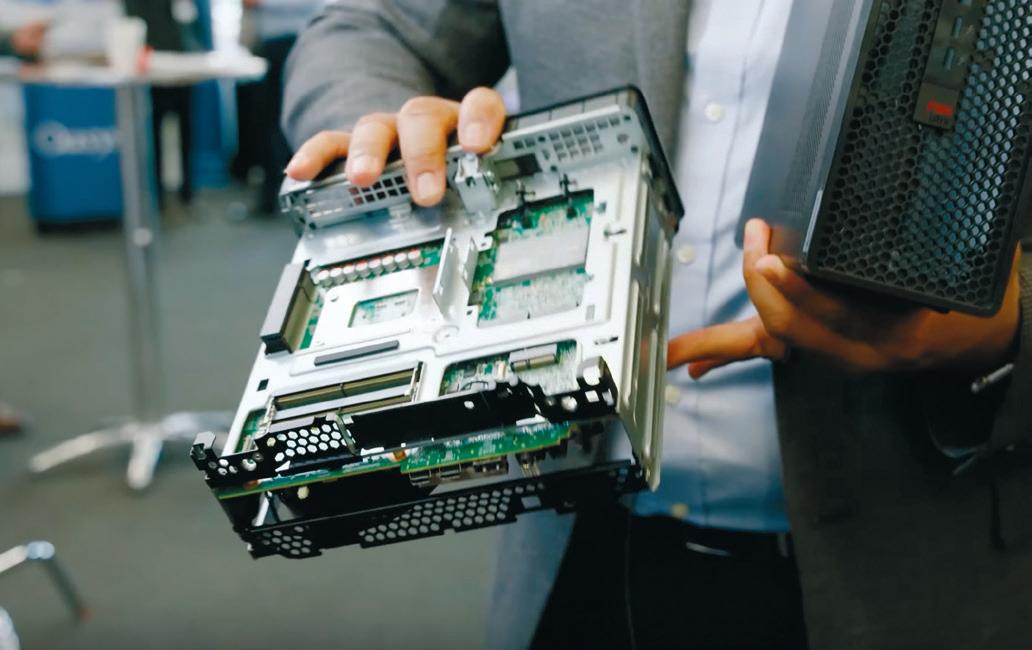

AEC Magazine is available FREE to qualifying individuals. To ensure you receive your regular copy please register online at www.aecmag.com about AEC Magazine is published bi-monthly by X3DMedia Ltd 19 Leyden Street London, E1 7LE UK T. +44 (0)20 3355 7310 F. +44 (0)20 3355 7319 © 2023 X3DMedia Ltd All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged. Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors in articles or advertisements within the magazine. 32 Workstation special report www.develop3d.com December January workstationspecialreport With impressive performance hardware tracing in, low profilepro card transform workflows small desktop workstations,writes Corke Price VAT): GB) GB) www.nvidia.com Small (SFF) tions DellPrecision have extremelypopu lar designers engineers because significantly than standard desktop towers. because their slender they been to ‘low-profile’ with half height Historically, low-profile cards have much‘entry-level’ perfectlygood for CAD, lacking performance and for demanding worksuch real-timevisualisationand ray rendering. This changed year the introduction RTX This powerful profile only delivered performance ever before, introduced technology theentry-level Previously, getprofessionalNvidia withhardware tracing you needed class other difference between previous low-profile offerings that double board, taking motherboard. This accommodate beefier type better where hot directly exhausted of workstations ever — SFFs, ultra-compact workstations such HP G9 WS18) it’s just workstations. also fitted standard and, purchasedseparately,it with height height bracket. first A2000 GB GDDR6 At launch suggested this light intended workflows. After datasets quickly especially resolution. recently,however, released version, the models identical with Mini DisplayPort minimal matt black enclosure.power 70W the designed operate PCIe with applications. CAD software Inventor, Solidworks delivered. Compared Nvidia A4000, SPECapc Solidworks benchmarkscores droppedoffat resolution, we perfectly smooth viewport 26.4 Frames when testing large 2,300 49 trianglesnow assembly RealViewenabled. workflowsthingsstarted down little. showed performance resolution, droppedoffconsiderably especially some our demanding tests. VRED Professional antialiasing to ultra-high Unreal Engine with tracing reached digits. rendering, RTXA4000 faster V-Ray, Solidworks rendered Camaro model (100 withde-noising) perfectlyacceptable seconds. As aside, testinghighlighted importance selecting right driver. Newer not better. Solidworks Visualize was slower driver was 516.94 verdict With impressive performance hardware tracing, Nvidia RTX A2000 completely transformedandultra-compactworkstation. an expandinto visualisation, dedicated like or ray tracers arestarting their CADviewports. forget the version GB better —now future. RTX GPU for you design seriously. RTX better suited demanding workflows,especially 4Kresolution. these full boards full towers. have heart pint-sizeddesktop,then nothing there that close. NvidiaRTX RTXA2000(12GB) visualisation, consider comes Solidworks slowed resolution Inventorhardly cheaper. Nvidia T1000 GB) Nvidia possibilities entry-level workstations applications WS34_D3D_DEC22FEB23_Nvidia-RTX-A2000.indd www.develop3d.com workstationspecialreport six in HP finally redesigned chassis iconic workstation. better significantly enhanced performance, much about diminutivedesktop, GregCorke 2016, broke mould with desktopworkstation was significantlysmaller any major Sincethen favourite DEVELOP3D. original Mini The edition new all-metal Simple form, essentially rectangular prism with corners distinctive mesh, which drawn then at The beauty HP G9 size mere horizontally vertically kept with included And keep brand, the Z the can rotated degrees. even VESA mounted and with wireless keyboard mouse free working environment. integrated Intel there’s need Ethernet. idealmachine constrained home — there beenplenty those last years. 10mm design, that significantlymore performance.‘Alder 12th Intel Core replace‘Comet 10th withimprovedthermalmanagement, can support 125W up Core i9-12900K. However, important note these the ‘Raptor 13th Intel CPUs, seen special so little wider choice single lightly workflows, the machine around 14-20% slower fastest Core For machine that’simpressive. But highlymulti-threaded workflows like rendering start notonly fewerE-cores top-end i9processors, CPU clock high, particularly loads. Rendering Keyshot, example, only 30 for drop 4.10 3.48 although then maintained that frequency for Notably, therewashardly noise throughout. Considering thermal challenges packing standard components small chassis, quite achievement, especially workstations be noisy times. thingsslowed particularly resolution. Here, GB would much better An to Nvidia A2000 would into entry-levelvisualisationterritory. Opening case seconds rear release button slide top small chassis make servicingstorage,you’ll remove GPU. the memory, unscrew In machine SODIMM sockets already but spare for second inside. 280W adapter. Speaking itdrew mere 160W plug rendering. Considering size, HP Mini equipped ports. are Type one Type (charging) on and USB the along 1GbE Flex port you add choosing from 2.5GbE LAN Thunderbolt HDMi. HP done excellent updating impressive workstation. industrial design excellent, acoustics improved,and taken forward terms performance. there compromises be While does in threadedand lightlythreadedworkflows, falls with cores can’t with towerswhen topower cooling. if workflows that there’s tough either maximise performance minimise impact your HPZ2MiniG9 i7-12700K From Microsoft warranty years labour reviewed available, T1000 £1,499www.hp.com/ zworkstations WS18_19_D3D_DEC22JAN23_HP.indd workstationspecialreport Vs WS04_05_06_07_08_09_10_D3D_DEC22JAN23_Intel_AMD.indd WorkstationspecialreportforCAD,BIM,visualisationandbeyond BATTLEOFTHECPU 13thGenIntelCoreversus AMDRyzen7000for CAD-centricworkflows MINIWORKSTATIONS Powerfulmachines,pretty onyourdesktoporhidden behindadisplay WhatdoIntel’slong awaiteddiscreteGPUs meanforCADandviz? Slimline laptops 20mm review Vs WS01_AEC_JANFEB23_Cover.indd

Hexagon acquires digital twin firm LocLab

independent of human intervention.”

“The foundation of any smart digital reality is the underlying 3D model. If not already part of one of our solutions or readily available via our content program, it can be time and resource-intensive to create,” continued Rollén. “LocLab’s semi-automated modelling process with AI-based object recognition from video data and its enormous library of 3D digital content offers tremendous time savings and cost efficiencies.”

“The integration of LocLab’s 3D digital content with HxDR, our cloud-based storage, visualisation, and collaboration platform, will drive HxDR’s expansion as a leading digital reality platform within transportation, construction, urban planning, and many other industries,” continued Rollén.

Hexagon has acquired LocLab, a German company that uses proprietary workflow technology and AI-based object recognition to help automate the creation of reality models for digital twin applications.

LocLab’s in-house developed ‘toolchain’ can utilise several data input formats with a view to balancing speed, cost and accuracy. This includes terrestrial videogrammetry, survey data and point clouds, although the company states that photographs or videos are only required at a minimum.

When creating 3D models of buildings and infrastructure assets, the AI software compares detected objects with LocLab’s

object library of 3D elements (street objects, building components, rail equipment, etc.) to semi-automate the creation of a ‘semantically enriched’ 3D model (i.e. adding context and descriptive elements).

“We continue to advance the utility and potential of the digital twin. We call it the Smart Digital Reality,” says Hexagon president and CEO Ola Rollén. “Like any digital twin, it provides an intuitive 3D hub for data management and information. But it has traits not always associated with digital twins: it’s datarich, kept up to date in real-time, and workflow-driven, making it seamlessly accessible. And most importantly, it’s autonomously intelligent, meaning it can implement physical world actions

“Altogether, LocLab’s capabilities nicely complement our leading reality capture and software portfolio while also offering LocLab global scalability opportunities through our expansive sales and partner network.”

■ www.loclab-consulting.com

Trimble acquires Ryvit to connect construction workflows

Trimble has acquired Ryvit, an integration Platform-as-aService (iPaaS) provider for the construction industry. Ryvit builds connections between commonly used applications and data sources, enabling information sharing both within and across organisations. According to Trimble, it allows project teams to use the right information to make the right decisions at the right time.

“The construction industry today is stymied by disparate data and technology solutions that don’t connect with one another, making it difficult to share information across departments and amongst project teams,” said Pete Large,

senior VP, Trimble Construction sector.

“Ryvit provides a platform for software solution providers and construction stakeholders to rapidly build and deploy workflows, enabling the automatic flow of critical information across organisations and teams in real time.”

According to Ryvit, AEC firms can connect ‘virtually anything’ – cloud, on-prem or custom apps, databases and stores, IoT streams, unstructured documents, partner APIs and more.

The platform includes connectors for a broad range of applications and data sources covering areas such as asset management, change orders, expense management, project management,

procurement and more.

Trimble states that integrations will continue to be supported as part of Trimble Construction One, a connected, cloud-based construction management platform, with the primary offerings from Ryvit undergoing a rebrand to Data Xchange and App Xchange.

Data Xchange represents the contractor tools that allow end users to configure and manage their data flows between connected systems.

App Xchange serves as the developer’s command centre for connecting systems, building pre-configured dataflows, and onboarding new customers.

■ www.ryvit.com

4 www.AECmag.com January / February 2023

News

V-Ray 6 for Revit connects with Enscape ROUND UP

RealityScan iOS

RealityScan from Epic Games / Capturing Reality is now available to download for free on iOS.

RealityScan is a 3D scanning app for mobile devices that uses cloud processing to turn smartphone photos into high-fidelity 3D models ■ www.capturingreality.com

Spaces expands

Cerulean Labs, the developer of Spaces, the sketch-based conceptual design tool for the iPad, has announced its Series Seed investment round led by Shadow Ventures. The company has also established Cerulean Labs U.S. Inc. as its global headquarters in Atlanta, Georgia ■ www.spacesapp.io

Bird’s eye view

Evercam 4D View is now powered by Bentley Systems’ iTwin, allowing construction professionals to ‘easily switch’ between a BIM model and live camera view of the construction site to help project teams better understand the construction sequence and communicate project plans ■ www.evercam.io

AEC investment

Hensel Phelps has launched a new investment company that specialises in construction innovation and technology. ‘Diverge’ works directly with innovation partners and technology startups to source, evaluate, invest and deploy new construction innovations ■ www.diverge.vc

HVAC-Twin

CCTech’s HVAC-Twin has joined Bentley Systems’ powered by iTwin program. The software allows engineers to add sensor data, make connections, and start visualising data such as temperature, occupancy, and CO2 levels—to diagnose and improve the performance of HVAC systems ■ www.cctech.co.in

Revit automation

Ideate Automation, a scripting solution that runs BIM tasks in the background, now allows users to batch-export Revit sheets and/or views to DWG file format, export model health data from a Revit file and display it in Power BI, plus more ■ www.ideatesoftware.com

V-Ray 6 for Revit includes a new link to Enscape, making it easier for architects and viz specialists to collaborate on photorealistic visualisations at any part of their process — without losing design intent.

What starts in Enscape can now be rendered and edited in V-Ray 6. With support for Enscape environments, materials and compatible 3D assets, what the visualisation team receives is a 1:1 version of what the architect designed. Even custom skies created in Enscape are automatically transferred.

Since clouds can have a big impact on the look of an outdoor scene, V-Ray 6 introduces a new procedural cloud system, built on Enscape technology. Instead of spending hours browsing through HDRI libraries, or adding skies later in Photoshop, artists can now easily simulate a variety of cloud types and weather conditions — from partly cloudy

to overcast. According to the developers, the new system is not only memory efficient, but a powerful way to create dynamic timelapse presentations and streaming streaks of sunlight.

V-Ray 6 for Revit also includes a new V-RayDecal capability that can project textures onto multiple surfaces and materials, all while working as a native Revit family. Users can not only adjust its position, size and angles, but project displacement through it. A key application for this is to bring more realism to cracked walls, stains, road marks and more.

Meanwhile, Chaos Cloud Collaboration is designed to make it easier to share work and collaborate with internal/external stakeholders. Users can share images and image panoramas straight from the V-Ray Frame Buffer and get feedback from reviewers, with a view to speeding up the approval process for everyone involved.

■ www.chaos.com/vray/revit

Symetri partners with One Click LCA S

ymetri, a provider of solutions for design, engineering, construction and manufacturing firms, has formed a new partnership with One Click LCA, a developer of construction Life Cycle Assessment (LCA) and Environmental Product Declaration (EPD) software.

In addition to a global technology reseller agreement, the agreement includes a technology partnership which allows Symetri to use One Click LCA’s database

as part of Symetri Technology.

According to Mikko Viertola, CTO, the aim is to enable Symetri’s customers to make carbon-smart material selections for both buildings and building products.

Building LCA is a science-based methodology for quantifying the lifetime environmental impacts of a building. One Click LCA has been designed to make the assessment easy by embedding the methodology into a tool.

■ www.symetri.co.uk

6 www.AECmag.com January / February 2023

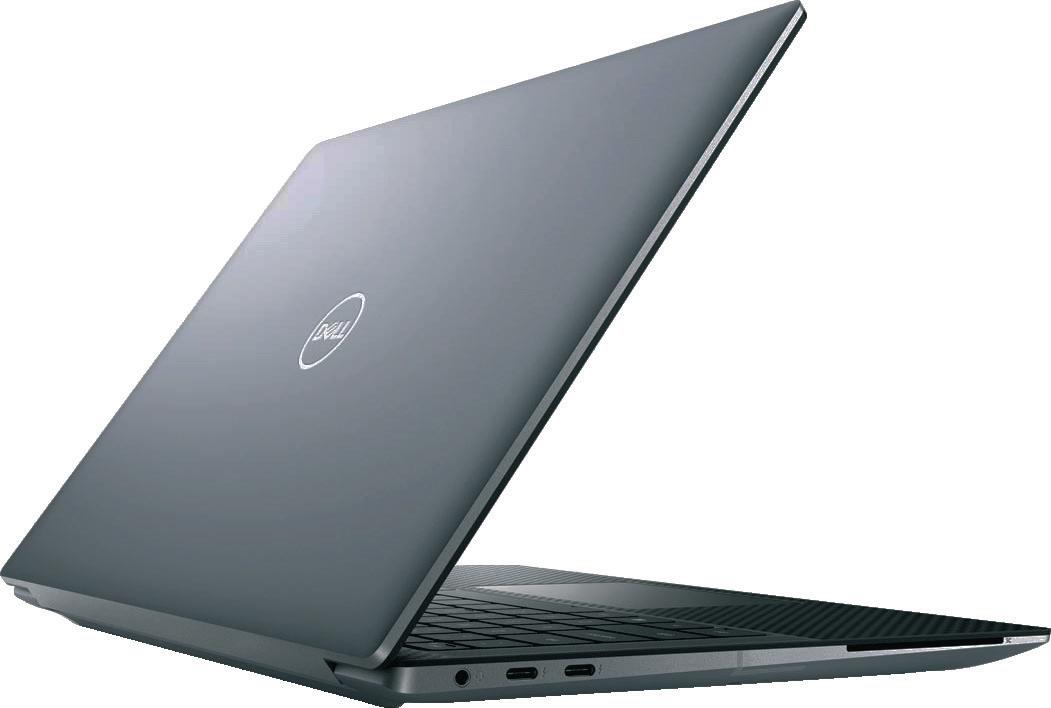

Intel launches raft of new CPUs for mobile and desktop

NBS acquires Schumann International

NBS, the construction technology platform, has acquired specification consultancy Schumann International. According to NBS, the expansion will allow it to further support its specification and manufacturer customers with additional specification writing services, design management and BIM.

The consultancy, to be known as NBS Schumann, will provide a specification consultancy service to NBS customers via the NBS Chorus platform.

Intel has kicked off 2023 with a raft of new product announcements as well as a teaser for its forthcoming workstation processors. This includes 13th Gen Intel Core mobile processors, new 13th Gen Intel Core desktop processors and Intel Xeon W processors (Sapphire Rapids).

At CES, Intel announced its entire mobile 13th Gen Core processor lineup, including its HX-series for high-end mobile workstations. The big news is Intel has added more cores to its mobile chips with up to 24 (8 P-cores and 16 E-cores) for the HX-series and up to 14 (6 P-cores and 8 E-cores) for the H-Series and P-series.

According to Intel, the Intel Core i9-13950HX will perform up to 24% better in AutoCAD, up to 17% better in Revit, up to 12% better in Autodesk

Inventor, and up to 79% better in Blender (rendering), compared to the previous generation Intel Core i9-12900HX. Expect to see mobile workstations with these chips in the coming months.

On the desktop, Intel has expanded its family of 13th Gen Intel Core processors with new 35W and 65W models that look well suited to budget conscious CAD users. Intel also launched the ‘special edition’ Intel Core i9-13900KS, with a record 6.0 GHz max turbo frequency out of the box.

Finally, Intel has shared brief details of its forthcoming Intel Xeon W-2400 and Intel W-3400 Series workstation processors (codenamed Sapphire Rapids). Due to launch on February 15, expect to see desktop workstations with these long awaited chips in the months that follow. ■ www.intel.com

Construction software market consolidates

The BIM software market is continuing to see significant Merger and Acquisition (M&A) activity, according to Cambashi in its latest January 2023 BIM Software Market Update.

“The construction industry is used to disruption. It was already starting to experience disruptive elements before the global pandemic and, as the effects of the pandemic have unfolded, there has been a significant increase in corporate restructuring and M&A activity in the industry,” said David Land, senior consultant, Cambashi.

The report states that ‘BIM Design’ software providers are now expanding into the areas of ‘BIM Construct’. Cambashi reveals that there has been a clear convergence between the software vendors within the ‘BIM Construct’ and ‘BIM Operate’ market areas, with partnerships and acquisitions enabling larger players to gain access across the entire BIM lifecycle.

Providers involved in M&A activities include: Autodesk, Nemetschek, Bentley, Hexagon, MRI, Procore, Schneider, SpaceIQ, Thinkproject and Trimble.

■ www.cambashi.com/bim

“Construction is becoming more global, technology is evolving, and new legislation is arriving. This complexity means that our customers increasingly require specialist expertise to support their specification process,” said Russell Haworth, CEO of NBS and Byggfakta Group UK. “We’ll be able to provide our customers with additional bandwidth and knowledge as and when they need it.”

■ www.thenbs.com/nbs-chorus/schumann

Solibri links to BIM 360

Users of Autodesk BIM 360 now have access to a direct integration with BIM quality assurance software, Solibri Office, to help validate the quality of their BIM models, and easily share changes, issues or resources with relevant stakeholders.

Users will be able to open IFC files that are stored in BIM 360 directly from within Solibri, without the need to download and maintain multiple local files.

The link will help Skanska Norway maintain one central storage area for its BIM files.

■ www.solibri.com

7 www.AECmag.com January / February 2023 News

Facility monitoring added to Autodesk Tandem

Building product selection

Revgen.tool is a new cloud platform from cove.tool designed to make it easier for building product manufacturers to ‘market products, attract qualified leads, and drive revenue’. The solution is said to provide manufacturers with verified advanced building performance engines to help drive informed product decisions earlier in a project’s lifecycle.

Autodesk has added the ability to integrate near real-time monitoring and historical operational data to its digital twin platform, Tandem. The aim is to provide insights into how systems come together and how a building performs.

According to Autodesk, owners will be able to track office occupancy trends and strategise to mitigate peak energy demand; adjust building systems to tune performance and optimise temperature, humidity, and employee comfort; or spot anomalies ahead of equipment failures to minimise downtime and costs.

Tandem’s facility monitoring gives users access to preconfigured views of operations data in context. The responsive 3D models ‘come to life’ with heat mapping capabilities so owners can begin to explore questions like: what course correction is needed to achieve sustainability goals? Which systems, equipment, and materials perform better than others across the portfolio? What future planning and design decisions will maximise ROI?

Autodesk Tandem Facility Monitoring is currently in beta. ■ www.intandem.autodesk.com

NCC invests in BIM quality assurance

Nordic construction company

NCC has agreed a multi-year contract with BIMcollab to use its BIM quality assurance solutions, including BIMcollab Cloud for issue management and BIMcollab Zoom for model checking.

NCC intends to use the software to help ensure model quality in every step of development, engineering, and construction of all projects.

toolset within its VDC (Virtual Design & Construction) departments to clash-detect and validate BIM models on geometry and information accuracy. Combined with analytics tools, the company also plans to make use of the added value for current and future projects by having a more informed viewpoint on design and potential issues.

“We will implement BIMcollab Zoom as the main tool for design collaboration and clash detection of the company, and BIMcollab Cloud to centralise communication, manage and analyse issues. Now we will have a more streamlined and standardised workflow,” said Karl Liberg, lead specialist VDC at NCC Building Sweden.

www.bimcollab.com

revgen.tool enables manufacturers to highlight product performance within a project and market their products to meet specific needs. Powered by ‘advanced analytics’, it filters through thousands of building designs within architecture 3D models, including BIM, to help teams identify the best match for their products.

At the same time, AEC teams have access to the data they need in real-time to identify the right products for a project.

■ www.cove.tools

Hexagon acquires Projectmates

Hexagon AB has acquired Projectmates, a SaaS-based, owner-focused provider of enterprise construction project management software.

The Texas-based company’s configurable and centralised platform is designed to enable owners to keep all working documents and projects within a construction program up to date and in one place – from the planning stages through closeout and handover to the facilities management team.

■ www.projectmates.com

www.AECmag.com

News

Start designing for free! No installation required. snaptrude.com A r c h i t e c t C o n s u l t a n t D e v e l o p e r A modern, collaborative building design software on the cloud.

Ideas to BIM in a snap!

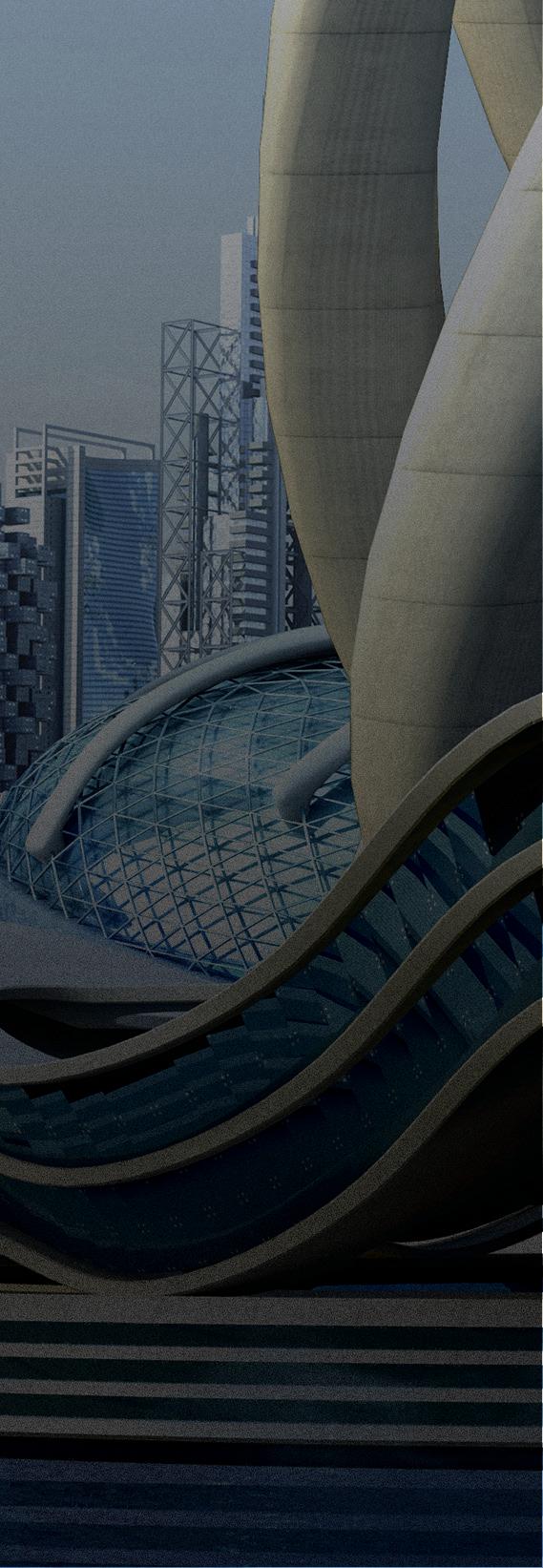

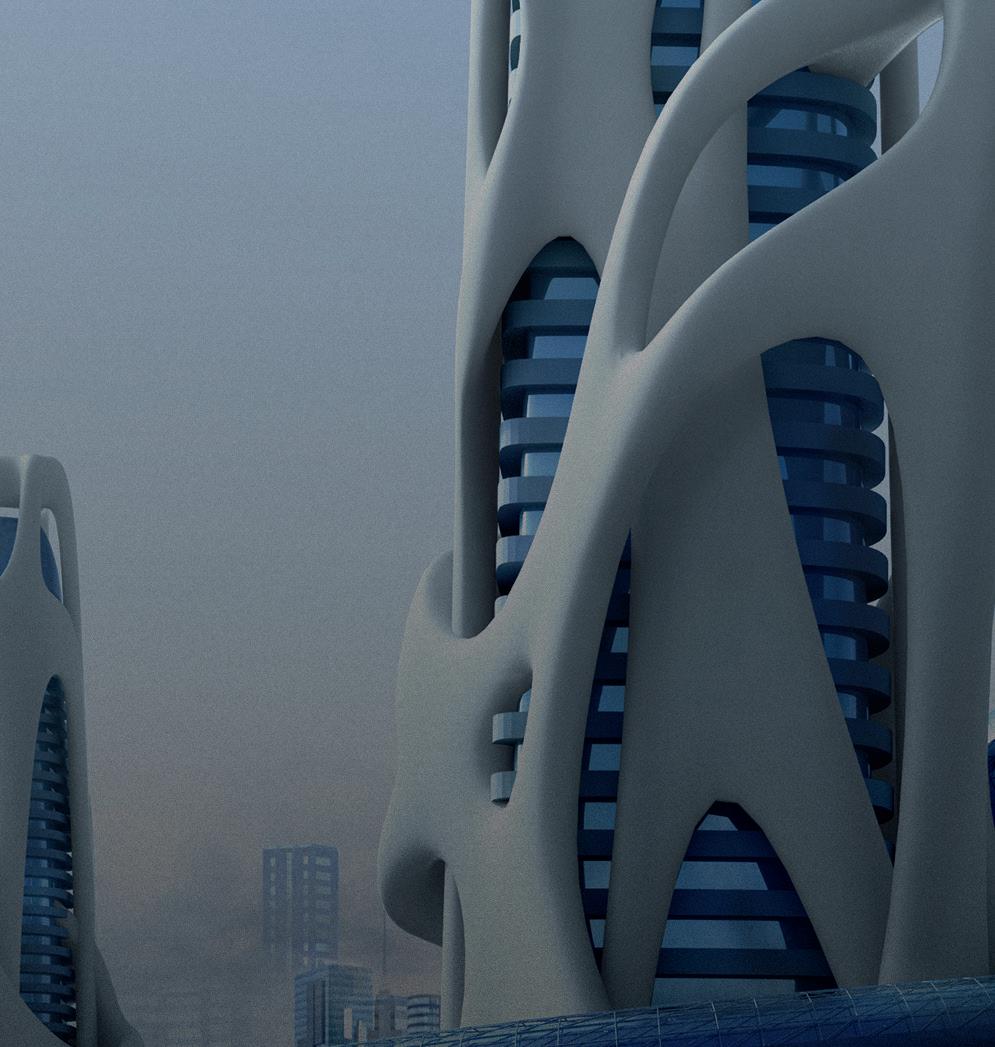

New Model Architect

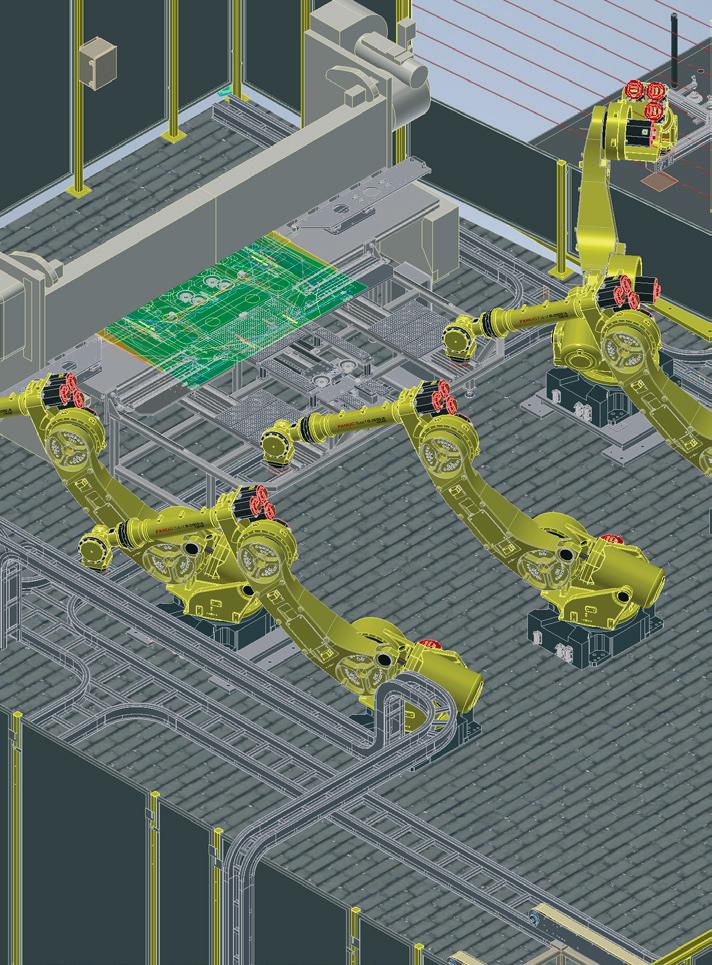

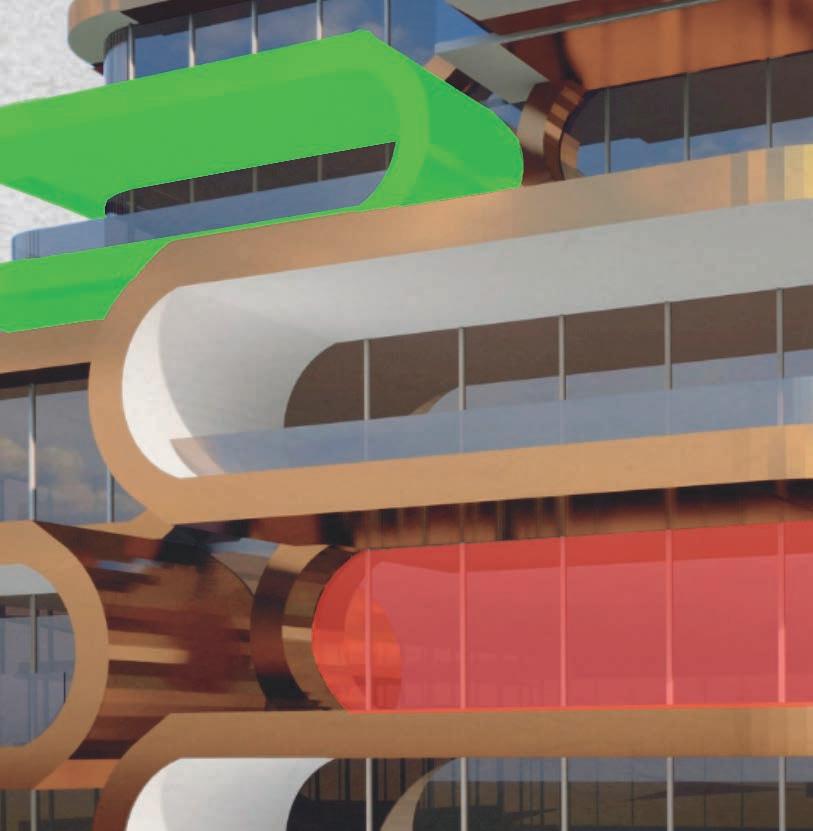

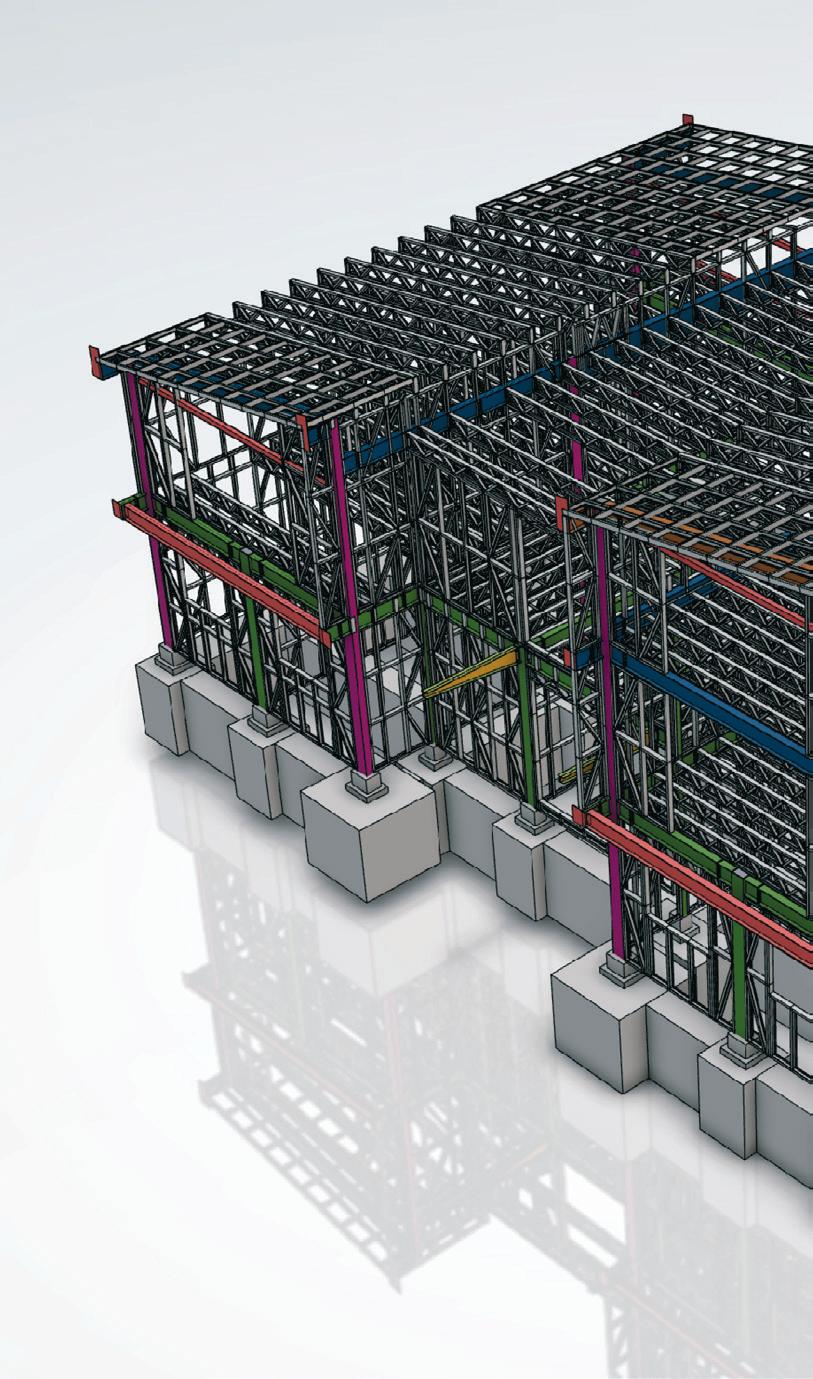

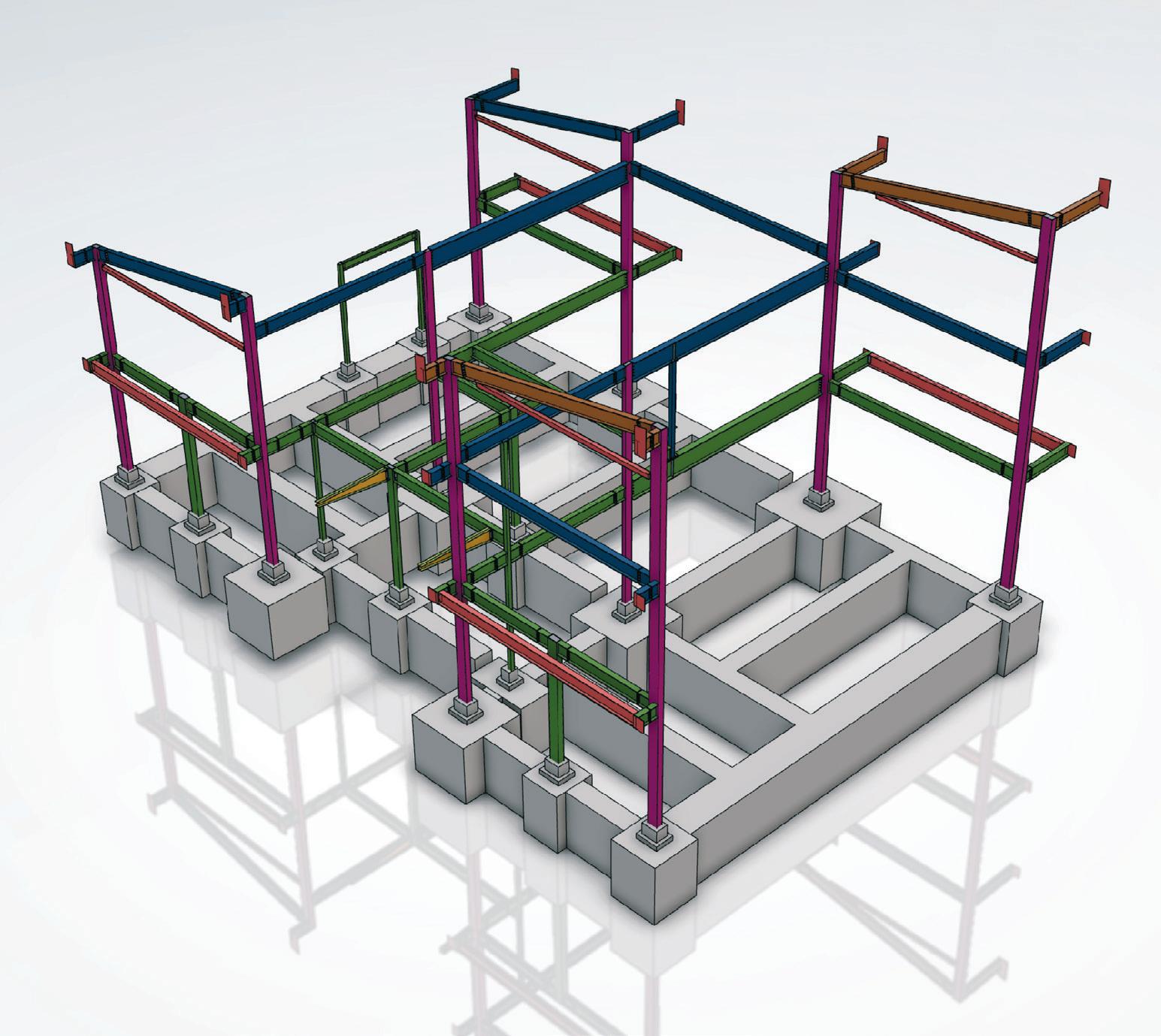

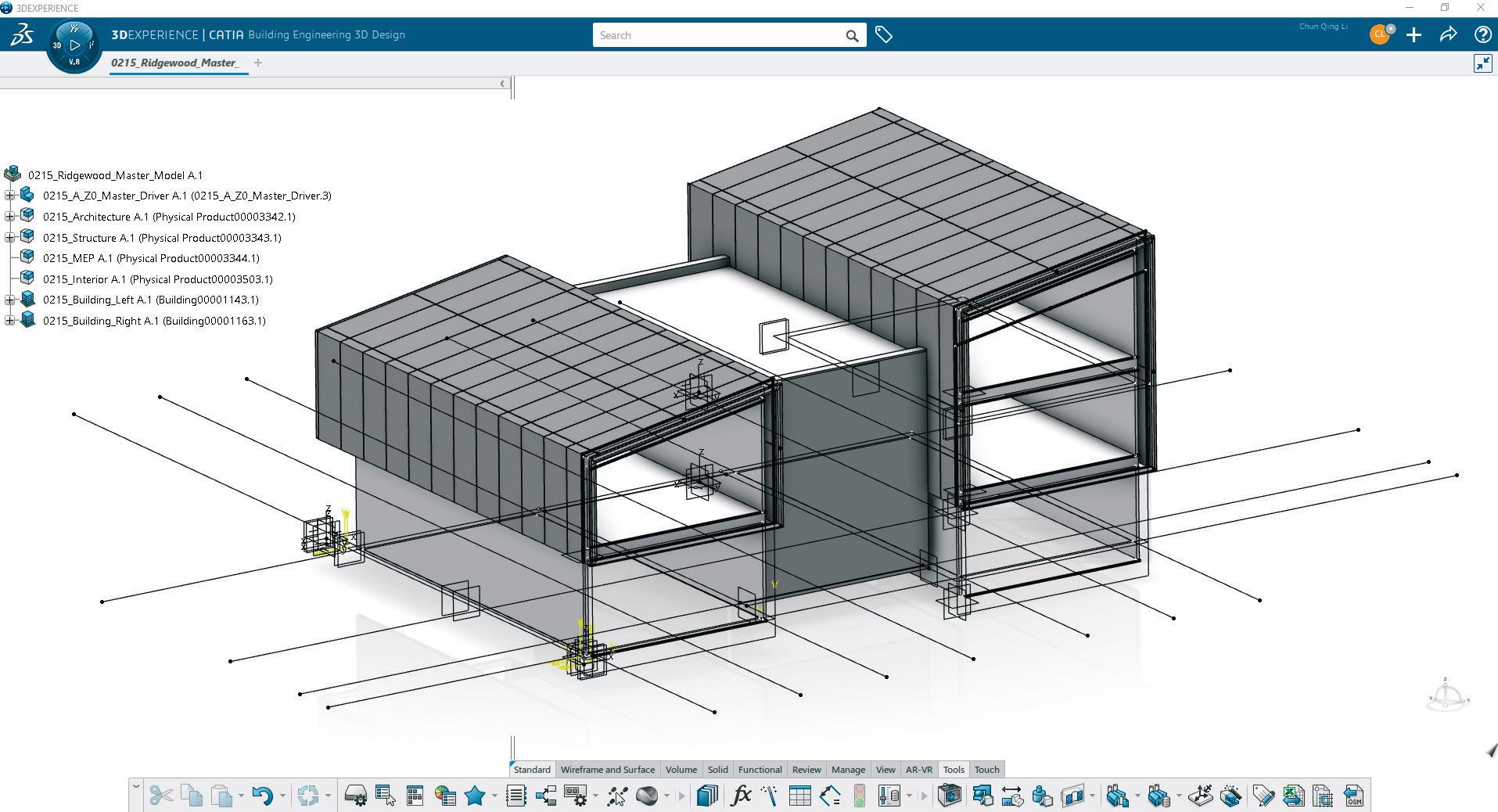

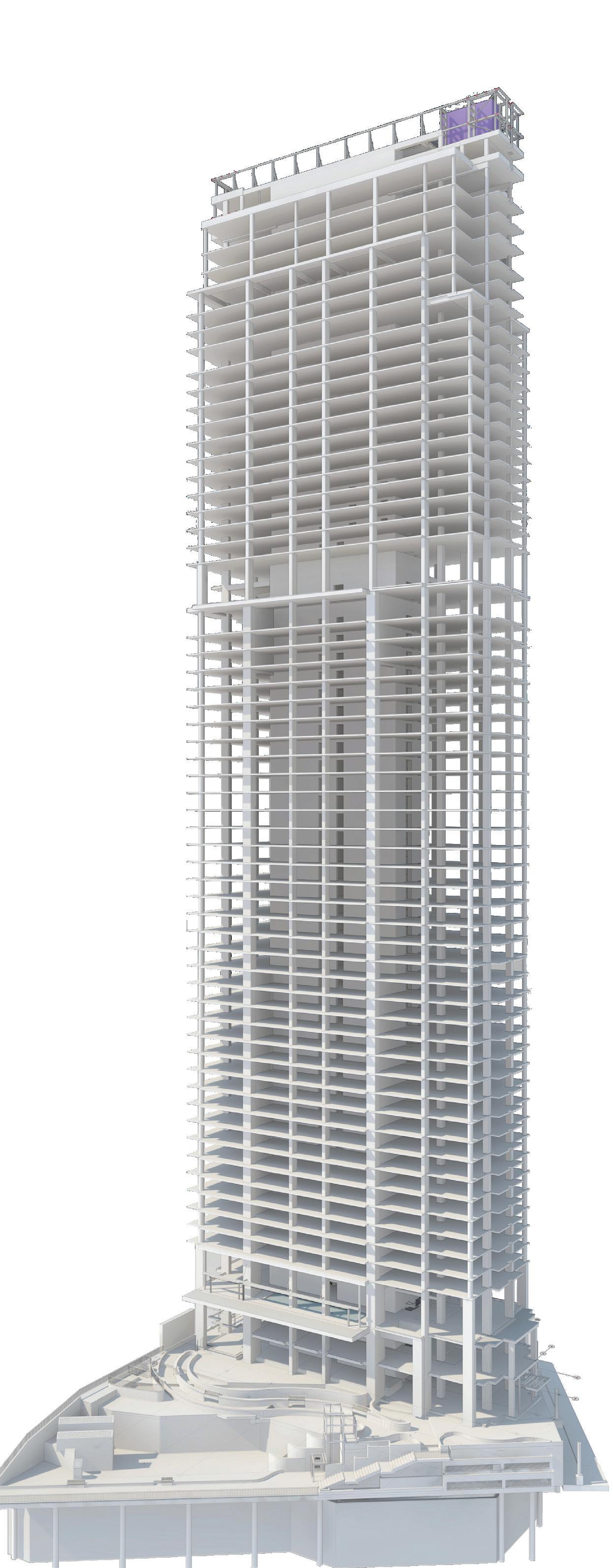

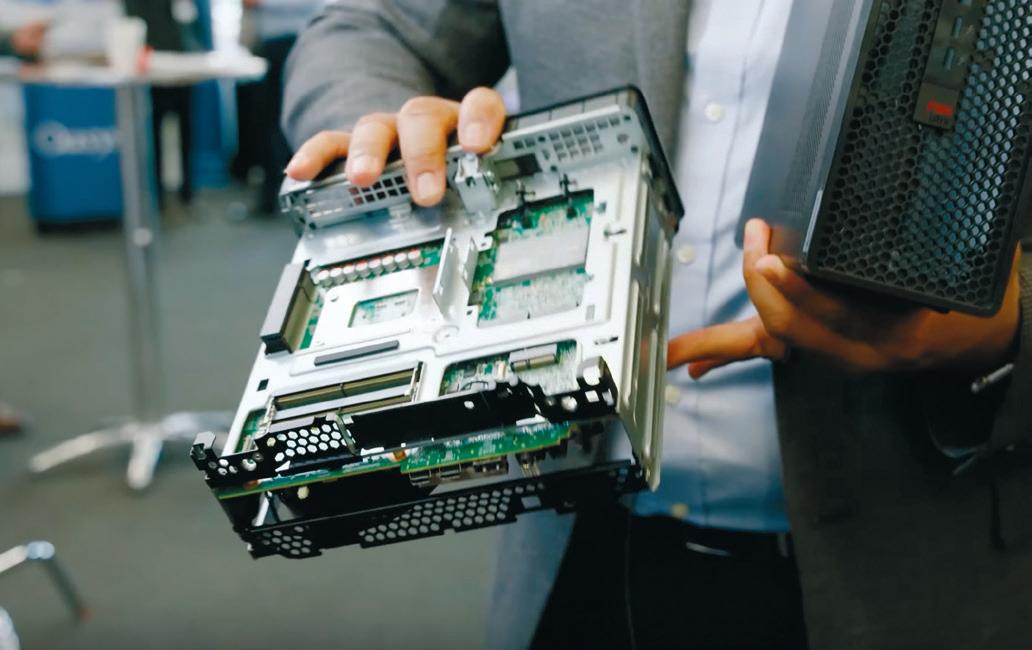

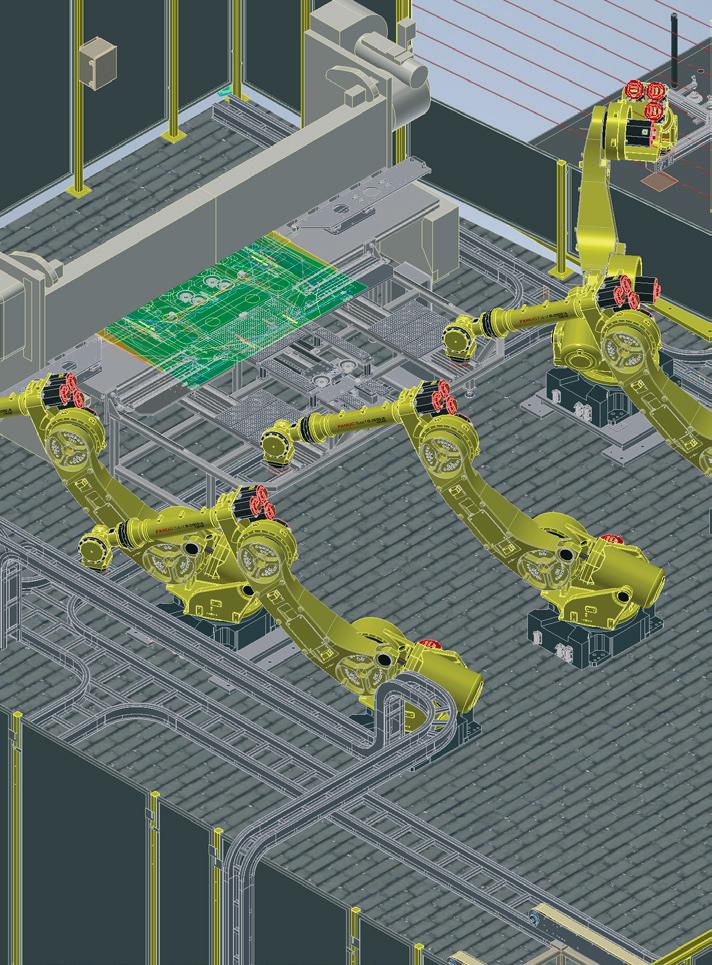

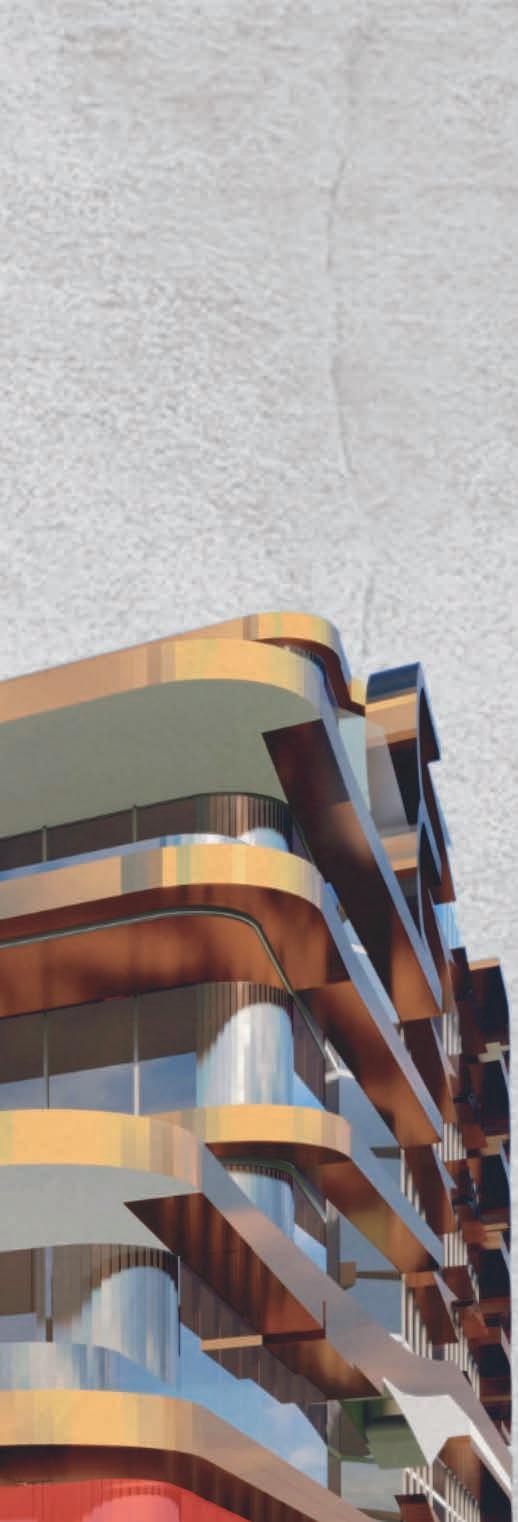

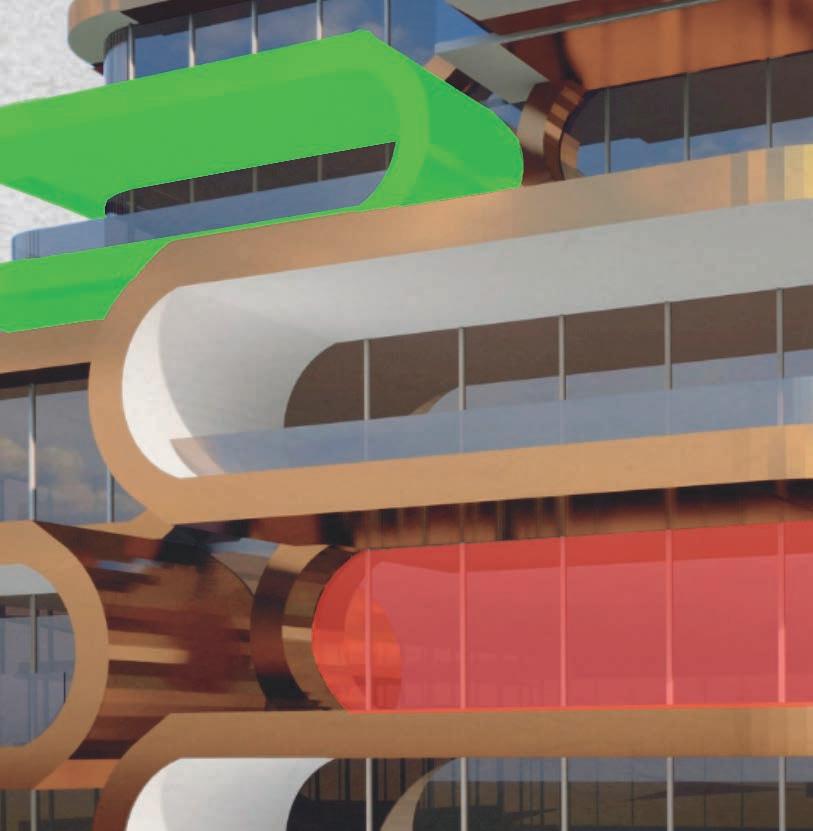

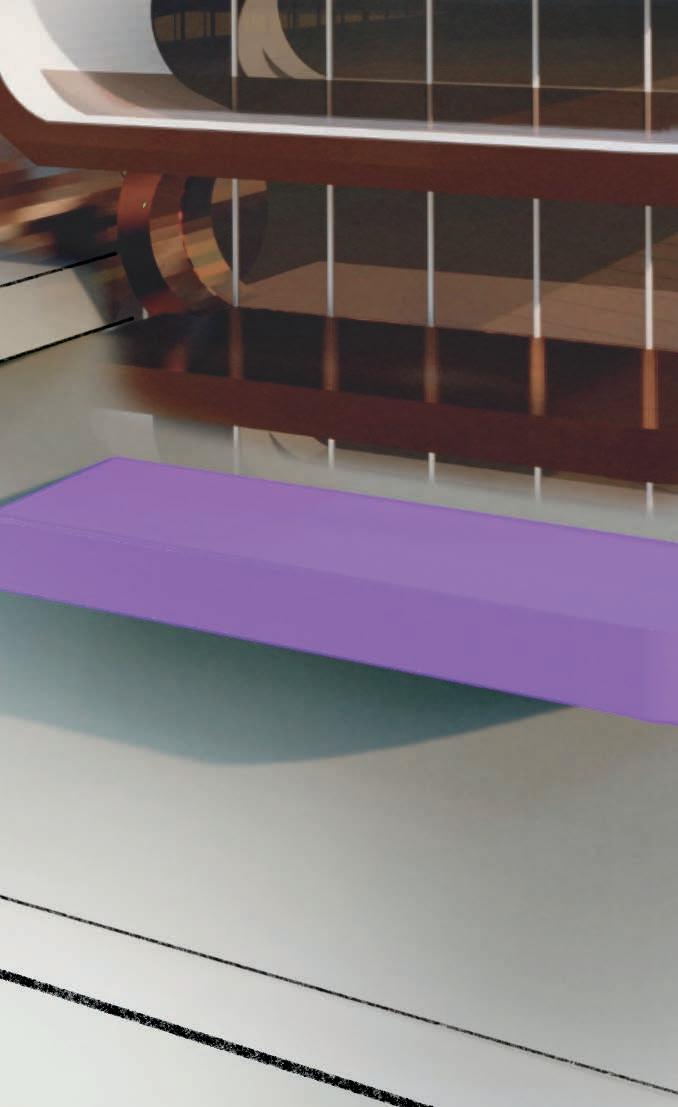

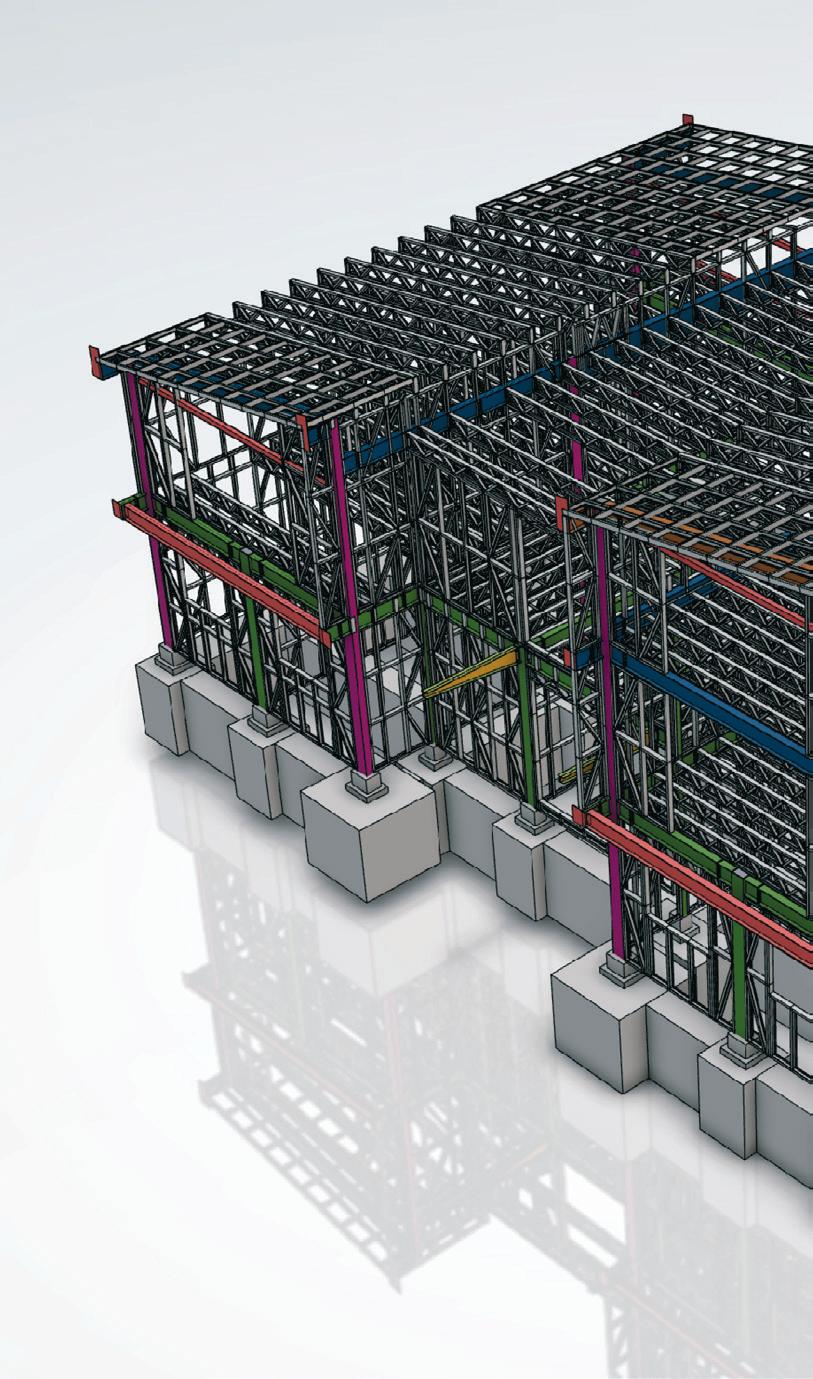

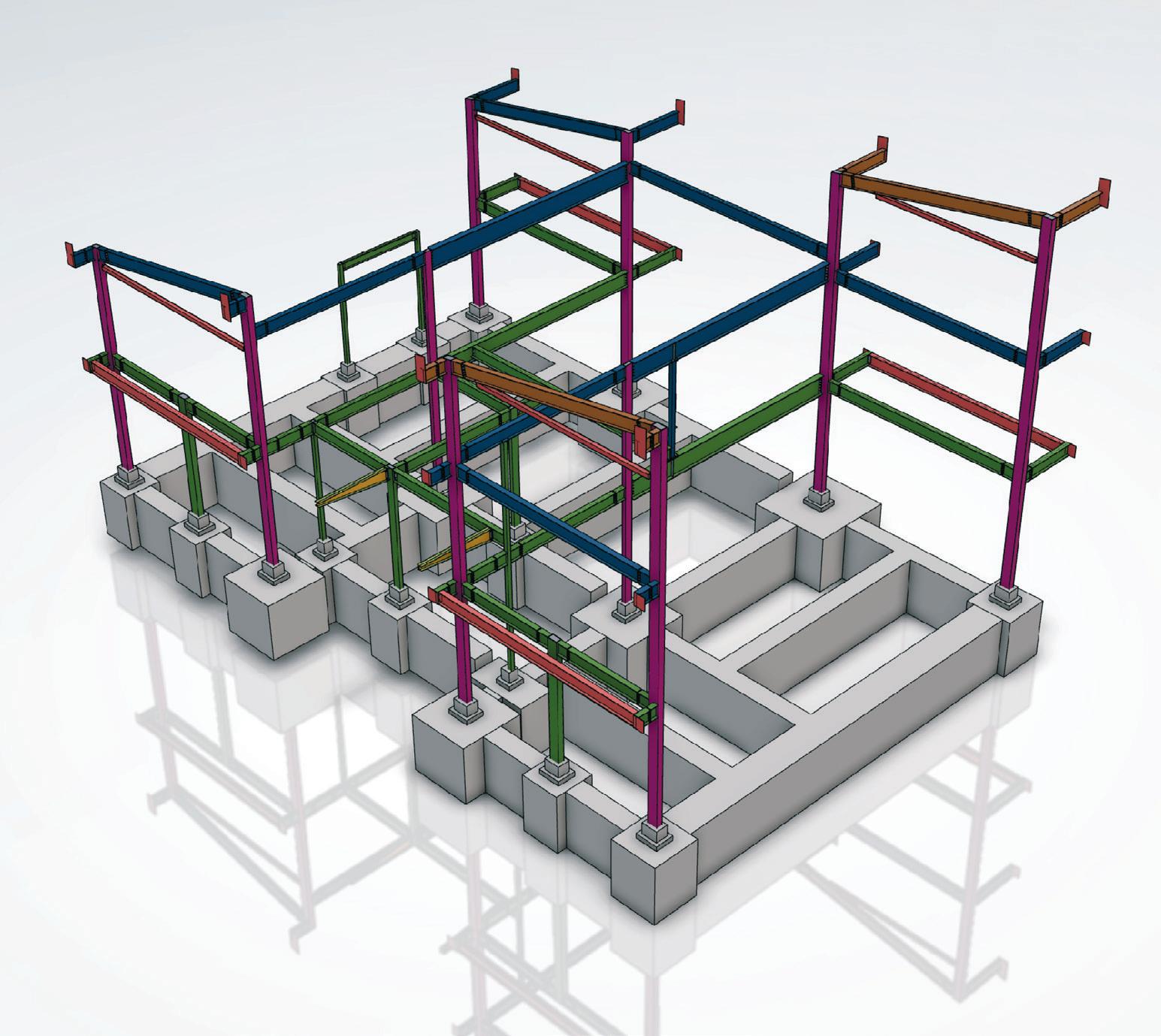

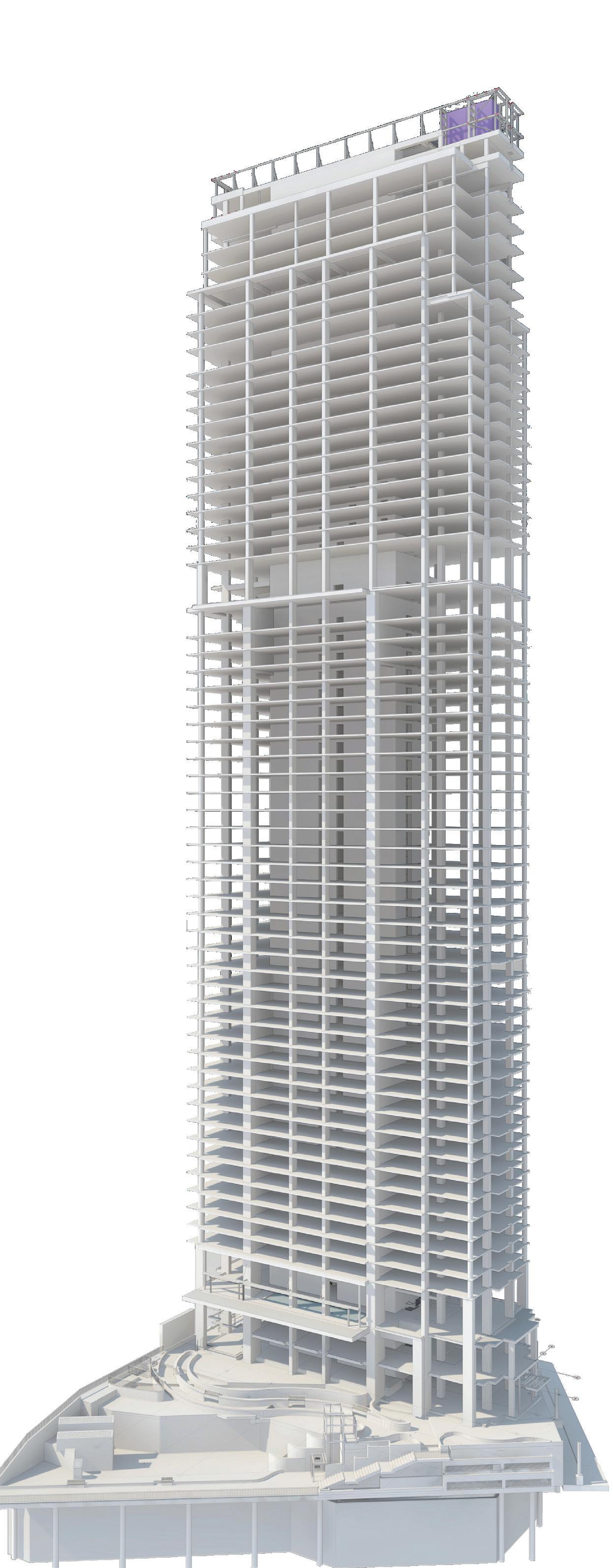

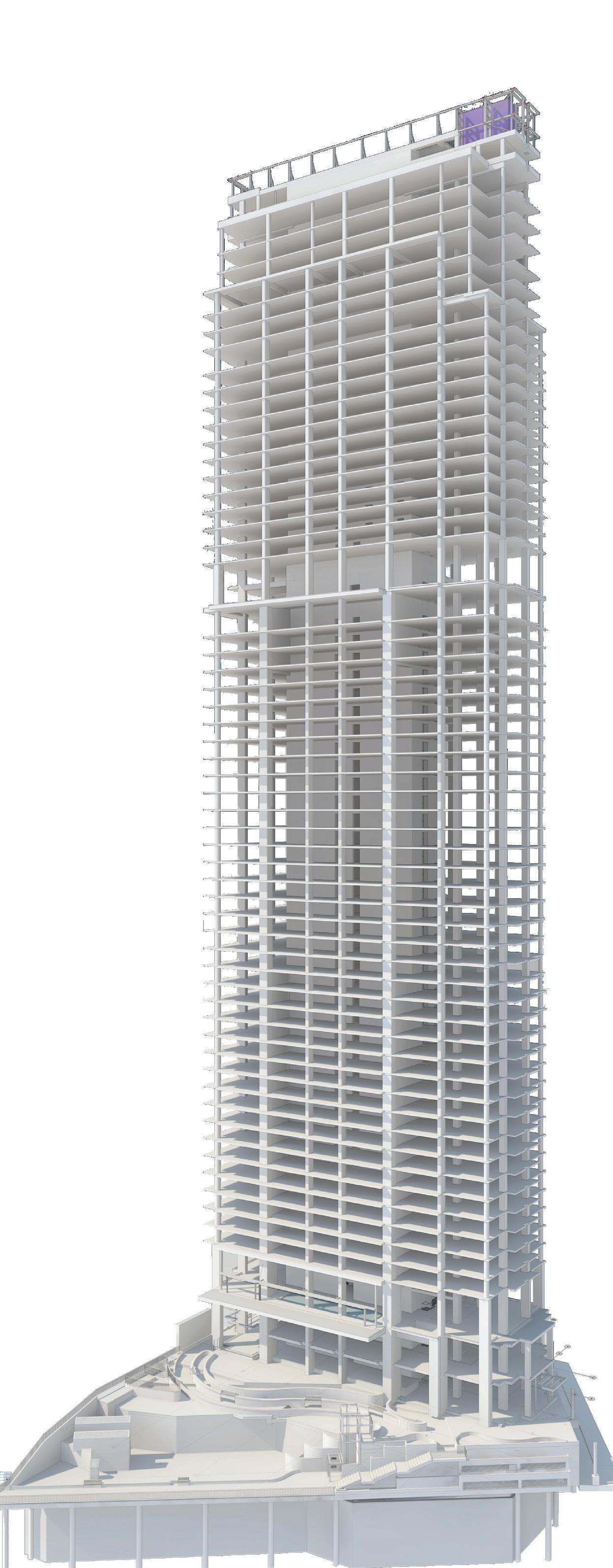

BIM has brought benefits, but it did not bring about the revival of the traditional ‘Master Architect‘ role for the profession. With attention to detail, understanding of fabrication and a high-power mechanical CAD (MCAD) system at his disposal, Kreod’s Chun Qing Li feels like he’s getting there

We are often told that history repeats itself. As a species, we seem doomed to keep reinventing the wheel. For the uninitiated, a recent discovery may look like the Next New Thing. For us older folks, those of us who have been around the sun a few too many times, the distinction between what’s ‘new’ and what’s ‘old’ tends to blur. And that, I guess, is why somebody invented marketing!

Architectural design was once a predominantly 2D exercise, accompanied by some physical models. When 2D CAD came along, we merely replicated the process on a personal computer. Then we had BIM, which puts 3D modelling first, to produce drawings and then PDFs. Ultimately, the deliverable has not changed — just our way of getting there.

But today’s BIM systems rarely collect enough detail to pass along to the next stage in the workflow: manufacturing and fabrication. In other words, a chasm persists between BIM data and manufacturing data.

In other forms of manufacturing — think of cars, aeroplanes, consumer

goods and so on — a designer’s 3D model is accurate and modelled at 1:1 scale. And it is connected to a digital process, in which a number of other systems are involved, in order to generate assemblies (right down to the nuts and bolts, a bill of materials (BoM) and a wide variety of product manufacturing information. Business systems such as enterprise resource planning (ERP) software are integrated too, to produce costings and assess availability of parts.

To date, a small number of architectural and construction firms have either augmented or ditched their BIM tools and adopted modelling software that is more commonly used in manufacturing in order to model at 1:1 scale, with high component detail. In this way, such firms are able to use design information beyond the design phase, to link it to fabrication, and to make it more accessible to downstream processes. In the process, they are in some ways becoming ‘master architects’.

Enabling designto-construction

There may still be 2D drawings on the factory floor, but the production of these is often wholly automated by core CAD systems. And these days, it’s not uncommon to see models get accessed at the point of manufacturing, too.

This begs the question: How might the AEC industry establish a ‘digital thread’ that extends further into the end-to-end process, delivers productivity benefits along the way, and helps firms manage the risks inherent to design and construction?

One such firm is Kreod, a London-based architectural and transdisciplinary practice, established 2012 by Chun Qing Li. The firm has built a reputation for the quality of its residential and commercial designs, and within the CAD community, it is particularly acknowledged for its approach to harnessing digital engineering and manufacturing.

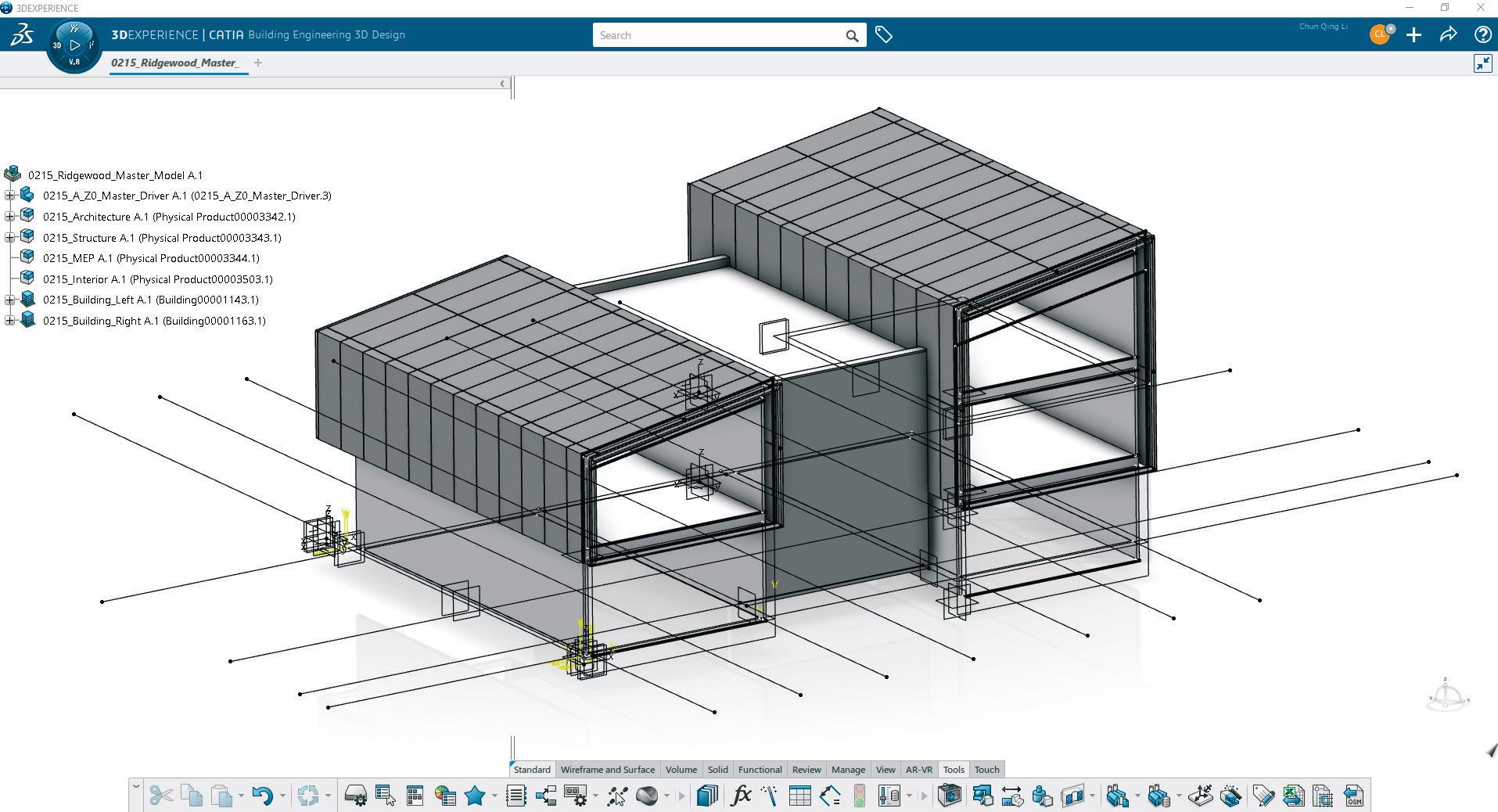

Li has, almost single-handedly, promoted the benefits of using high-end manufacturing software in AEC, replacing BIM with 3DExperience Catia from Dassault Systèmes (DS) (see box out page 12)

Through using the base software and

Cover story

‘‘

Kreod models every component in detail, right down to fabrication level, in order to truly understand not just design intent but also constructability, cost and all the connection details

’’

What is 3DExperience Catia?

3DExperience Catia is a long name for a big CAD system. Catia is the flagship modelling ecosystem from French developer, Dassault Systèmes (www.3ds.com). As CAD systems go, the current version, V6, is the Ferrari of the manufacturing CAD world. Indeed, it’s used by Ferrari and its F1 team, as well as Porsche, BMW, and Toyota. In aerospace, both Boeing and Airbus are customers. Catia covers individual part models, assemblies (of parts), very high-end surface modelling, Finite Element Analysis, Structural Analysis, generative design, sheet metal folding, rendering and so on. The design tool is connected to other DS brands, Enovia (collaboration), Delmia (supply chain planning) and Simulia (simulation), amongst others.

The 3DExperience part of the name relates specifically to its ability to operate beyond the desktop and to work in the cloud, connecting to other parts of organisations with web-based model and business process management tools. This is commonly known as PLM (Product Lifecycle Management) in manufacturing circles.

Catia is not commonly seen in AEC firms. It’s viewed as an exotic choice. However, some exceptional practices are famously associated with its use. These include Frank Gehry, ZHA (Zaha Hadid Architecture) and more recently, Lendlease. We’ve also heard rumours that Laing O’Rourke might be experimenting with it as part of the company’s ongoing research into modern methods of construction.

Before Catia, Gehry had trouble getting his buildings built, because contractors would add a big

developing in-house applications such as Kreod Integrated DfMA Intelligent Automation workflow (typically shortened to KIDIA), the company prides itself on the accuracy of its models, its bills of materials and, ultimately, the financial success of its sustainable projects. By modelling everything at a fabrication level of detail, Kreod has made great strides in minimising risk.

It is also tackling the issue of procurement, at a time when rapid raw material price inflation is contributing to escalating build costs and, in some cases, forcing projects to be put on hold. One of the

innovations that the Kreod team has developed is a web service for onboarding clients. This details the materials required for their project, along with live associated costs. In this way, clients stay informed about budget issues and can even make decisions around when to buy certain materials for a job. For the first time, clients can actually tap into the supply chain themselves, as opposed to having to rely on traditional contracts and hoping it all works out.

At the same time, by shunning established BIM tools, Li has seemingly opted to perform the equivalent of climbing the

percentage to the estimates, arguing that 2D drawings left too much to the imagination. When he switched to sending Catia models, all bids came in within 1% of each other.

Kreod is thus following in famous footsteps. In doing so, it has opted to build its own layers of functionality to enable the rapid detailed modelling of architectural and construction elements, down to every nut and bolt.

Chun Qing Li is looking to bring all the knowledge his team has amassed in design to fabrication modelling to offer on demand, online service to the market. Watch this space.

north face of the Eiger. It’s only after talking with him that you get a real sense of what has driven him to bypass the predefined walls, doors and windows of ‘Lego CAD’, and make geometry and manufacturing his key drivers in selecting a design system.

Kreod models every component in detail, right down to fabrication level, in order to truly understand not just design intent but also constructability, cost and all the connection details.

With each project, if the company is using a new supplier, or a new process, project leaders will visit the fabricator

12 www.AECmag.com January / February 2023

The Cleveland Clinic Lou Ruvo Center for Brain Health in downtown Las Vegas Nevada by Frank Gehry Image by Bobby Dagan

Marseille: a Bouygues construction site for an international school complex by architect Rudy Ricciotti

Kreod Olympic pavilion

The Kreod Olympic pavilion (London 2012) was designed to showcase modern design and innovative construction techniques. The unique form of the structure was made possible through the use of cuttingedge CAD technology, enabling it to be manufactured in modular form with minimal waste material. Prefabricated sections were quickly and accurately assembled, ensuring that construction could be completed within a tight timescale before the games began.

Innovative manufacturing processes such as laser cutting, vacuum casting and CNC machining enabled the creation of the intricate details that are a feature of the finished structure. During the build process, precision CNC tools cut individual components from a range of materials, including aluminium, stainless steel and composites. These were then handwelded together to create frames for a lightweight shell covered with wood panelling. The high accuracy of modelling and CNC-cut parts meant that each part fits perfectly, despite a wide range in variances.

Chan Qing Li describes his approach to creating the Kreod Pavilion as follows: “Our vision was to provide an exciting showcase for some of London’s most dynamic designers working in 3D-printed structures; making full use of contemporary technologies, while still meeting all relevant safety regulations.”

Kreod’s Olympic Pavilion demonstrates the potential of combining modern design and manufacturing technologies with digital building processes, offering a practical example of how custom structures can be created faster.

and invest time in understanding the fabrication process and limitations that they must consider during the design stages. The level of communication the firm builds up with its trusted suppliers means that design communication is dependable and can be model-based.

A fair amount of experimentation

On our visits to other leading architects, we certainly see a fair amount of experimentation with manufacturing CAD systems. While director of innovation at Aecom, Dale Sinclair was increasingly using MCAD tool Inventor over BIM tool

Revit, to model modular projects destined to be manufactured off-site. Sinclair looks to have carried that vision with him to WSP, where he also heads up innovation.

Revit was Aecom’s weapon of choice, but the level of detail at which the firm needed to model for fabrication would have led to huge models, impacting Revit performance and potentially making the system unusable for this purpose. By contrast, MCAD tools are optimised to run with models comprising tens of thousands of parts. Very high-end systems can handle even more.

This approach may not be for the faint-

hearted — but it is for the engineeringminded. It also suits those AEC professionals who want to use digital tools to be involved in the whole end-to-end, design-to-build process. The upside for clients, meanwhile, is that firms that model in detail and know a great deal about fabrication costs upfront are better placed to offer a full-service, singlepoint-of-contact approach, managing everything from design to delivery.

The industry is very slowly waking up to the connection between choice of design tool and project outcomes. At present, that awareness tends to be limited

13 www.AECmag.com January / February 2023 Cover story

to those who increasingly see fabrication as being where the industry needs to focus. And, as discussed, fabrication considerations need to take place early in design processes.

This forward-thinking mindset is not dependent on the size of a firm. It can be seen both at Aecom (50,000 employees) and Kreod (fewer than 10 employees).

AEC Magazine contributor and Foldstruct CEO Tal Friedman refers to it as ‘Fabrication Information Modelling’ or ‘FIM’ (www.tinyurl.com/FIM-AEC) , where designs are created with built-in knowledge of eventual production methodology. Li prefers the tried-andtested DfMA (design for manufacturing) label, but ultimately, we are talking about the same thing.

The big problem is that there is no

commercial turnkey system to provide this. Every manufacturer has varying capabilities. In 2017, Bouygues paid Dassault Systèmes to custom-build a system to automate the stripping of models from Revit into their component parts in order to build an optimised, manufacturable model, with drawings, full costings and lean project management using Dassault Systèmes’ 3DExperience environment. Bouygues is looking to expand this system to include sustainability analysis and optimisations, too.

Maybe this is the way the industry will go, with traditional, federated workflows for some sectors, using off-the-shelf BIM tools, while others adopt bespoke systems to fully automate assembly models and drive fabrication.

Looking at what we have today, along

Q&A with Chun Qing Li of Kreod

AEC Magazine: While there are a number of mature BIM applications out there, you have chosen to go with a CAD system more popular in high-end manufacturing. That’s meant developing your own layers of functionality — so what on earth made you do that?

Chun Qing Li (CQL): I feel that, as architects and designers, we have been kind of hijacked by the software companies. Because we are creative people, we have different mindsets to engineers, and the software companies develop tools created by software engineers who don’t necessarily understand how we work. We always have to bend ourselves and learn their logic. In my experience, it’s counterproductive. The tools we have as off-the-shelf solutions for AEC just don’t make any sense to me. For example, with BIM, we spend a whole load of time modelling a beautiful, 3D datadriven design, but ultimately end up delivering 2D PDFs. It just defeats the whole purpose.

with where we need to go tomorrow, if AEC is to embrace a completely digital end-to-end process, it seems unlikely that today’s 2D-focused BIM tools can evolve to keep pace.

Kreod may have eschewed the comforts of ‘Lego BIM’, opting instead for the certainty of extreme detail - but in the process, it has brought upon itself a great deal of additional modelling work. That said, the more work Kreod does here, the bigger its own library of parts, so there will be payoffs.

It will be fascinating to see what software and services Kreod decides to bring to market in order to assist the industry. From our conversation with Li (see boxout below) , it’s clear he likes to have a lot on his plate. In return, he’s giving the industry plenty of food for thought.

■ www.kreod.com

AEC Magazine sat down with Chun Qing Li, founder & CVO of Kreod, to learn more about his non-conformist approach to BIM workflows and discuss his views on how and why the industry needs to change

AEC Magazine: But how much of that is down to the technology failing to map to dumb contractual constraints and deliverables?

CQL: Everything’s driven by the principal contractors. While architects may be using Graphisoft [Archicad], Revit and other

interesting packages, in construction, they are still beholden to 2D drawings. That’s the thing, and the contractors mainly use 2D packages and specifications. I feel a sense of urgency that we need to change this, but obviously my company is very small, and I don’t have a marketing budget to educate the industry! When I started developing the software, I tried to convince developers and contractors that there was a better way of doing things, but they said that they didn’t want to be guinea pigs. So, I started my own construction company. Now, we are building things and we are our own guinea pigs!

We started with our own architecture firm, and from our in-house development work, we launched a multi-tech start-up to share our solutions, the first of which was an intelligent automation tool. This will eventually enable us to bring to market a complete platform that will integrate design with procurement and supply chains. This system will be able to get prices immediately, instead of relying on a QS (Quantity Surveyor) benchmark estimate. When we launch our platform, clients will be able to access our system and pick, choose and buy products from the catalogue.

As to contracts, based on all our in-house process development, we have introduced what we call ‘open book contracts’, so that when we talk to a client, we are incredibly open with

materials costs, down to the brick, as well as all the preliminary costs and even our profit margin.

AEC Magazine: You sound very frustrated looking at the AEC workflows that have been adopted and codified?

CQL: The RIBA Sequential Work Methods have a linear format which necessitates sequential focus on phases, one at a time. Each stage must be completed before the next is initiated, leading to a drawn-out development process with intensive design alterations, delaying projects and having financial implications for all involved. Linear workflows, by their very nature, build in risk, not eliminate it. From a commercial perspective, I understand that the method makes it easier to break down payment phases, but I think you can simplify the whole workflow.

In manufacturing, they have refined the process. They produce 3D models that are manufacturing-ready. They do assembly sequencing, as in how you put things together, while we as an industry, we produce hundreds or thousands of drawings, bundle them up and throw them over the fence!

Our specific workflow, which we call KIDIA (Kreod Integrated DfMA Intelligent Automation) is specifically designed to eliminate the need for repetitive work. It enables an early and accurate calculation of cost by

14 www.AECmag.com January / February 2023

automatically creating the necessary manufacturing/fabrication code and bill of materials (BOM). KIDIA not only expedites RIBA Stages 2, 3 and 4, but can also potentially save up to 90% of the time spent doing it, all while eliminating or reducing risk, which can be seen in our contractor quotes.

AEC Magazine: Some may say that it’s extreme, opting for an MCAD system versus a BIM platform that was custom made for architects?

CQL: I think that the whole process has to be integrated on a single platform. Otherwise, you end up using all sorts of applications: Rhino, Grasshopper, SketchUp, AutoCAD, Excel spreadsheets and Revit. And the best the industry could do to join them up was IFC, which is a lowest common denominator format.

I guess like most of us, toolswise, I have been on a journey. I started off using MicroStation and Generative Components (GC), then moved on to Rhino and Grasshopper. Then I started to get into geometry rationalisation and teamed up with a professor of mathematics from ETH Zurich who did it all in C++, no CAD system required!

Experience is essential. On the Olympic Pavilion project, I was the lead designer, the client, the contractor and the project manager! I had to do everything, apart from structural engineering. After rationalising the

geometry, I built what I called at the time a ‘building manufacturing model’, though I found out later it’s called DfMA. I found a second-hand robotic arm and started experimenting with cutting and assembling wooden frames for the pavilion. For the metal frame, I collaborated with a steel fabricator and took a highly collaborative approach, which was great. I learned so much.

AEC Magazine: How on earth did you fund the Pavilion as a personal project?

CQL: I pitched everyone! I had a fulltime job. I think I spent £2,000 on stamps, writing to a lot of people and companies. I just sold the idea and made it possible!

AEC Magazine: How did you get involved with Dassault Systèmes and the 3DExperience Catia platform?

CQL: Frank Gehry was the pioneer. He developed Gehry Technologies, with his own Catia tools for architectural designs. For us, this is a financial decision, a commercial decision, to go and find the best platform which can go all the way to fabrication and then develop on top of it. The 3DExperience platform is very powerful and can handle lots of complex information. It’s why it’s so popular in aerospace and automotive. Initially, when I first contacted

DS around 2010, they said they didn’t really work with one-manbands or students. They worked with multi-billion dollar engineering and aerospace firms and that was the end of the conversation! Later, things bounced back, especially as they created an on-boarding programme for start-ups and started to see potential for their applications in AEC.

AEC Magazine: So how do you think this is going to play out? AI is starting to appear at the edges and some systems will take polylines and deliver fully detailed 3D models, with drawings for fabrication. Are we going to see more design/ build firms? Will we need fewer architects?

CQL: I use the term ‘Digital Master Builder’ from the traditional meaning, dating back to the mid-sixteenth century, where architectural designers were closely involved in the whole construction process. We have self-restricted the role of architects to just delivering design intent. Back in the day, architects used to lead the process, but now we lack broad industry competence and there is a general lack of interest in understanding the construction side of the business. There’s a shift in the way we work, where the principal contractor is now playing a major role in the entire process. Through our plans for

development, I want to give more power to the architects. They will be the designers that will understand the costs. That’s how we sell our schemes. We need to widen our spectrum, not just be the producers of couture drawings with beautiful line weights. Buckminster-Fuller asked Sir Norman Foster how much his building weighed? We need to be more like BuckminsterFuller, who was obsessed with the relationship between weight, energy and performance — of “doing the most with the least”. And, of course, customers want to know the cost. We need better tools to do this.

AEC Magazine: You have started a lot of different firms with different aims. What can you tell us about them?

CQL: There’s a reason we started these companies, for architecture, software development, and especially construction, because in each, I need to build, to demonstrate and deliver. From our experience, we can convince more customers to use our technology or consultancy. That’s the notion. Ultimately, we have to do something to better serve architects and developers and the key is to integrate the whole process. To provide more transparency, with design costs understood, which means there will be less need for damage control at critical points in any build.

15 www.AECmag.com January / February 2023 Cover story

‘‘

Kreod may have eschewed the comforts of ‘Lego BIM’, opting instead for the certainty of extreme detail - but in the process, it has brought upon itself a great deal of additional modelling work ’’

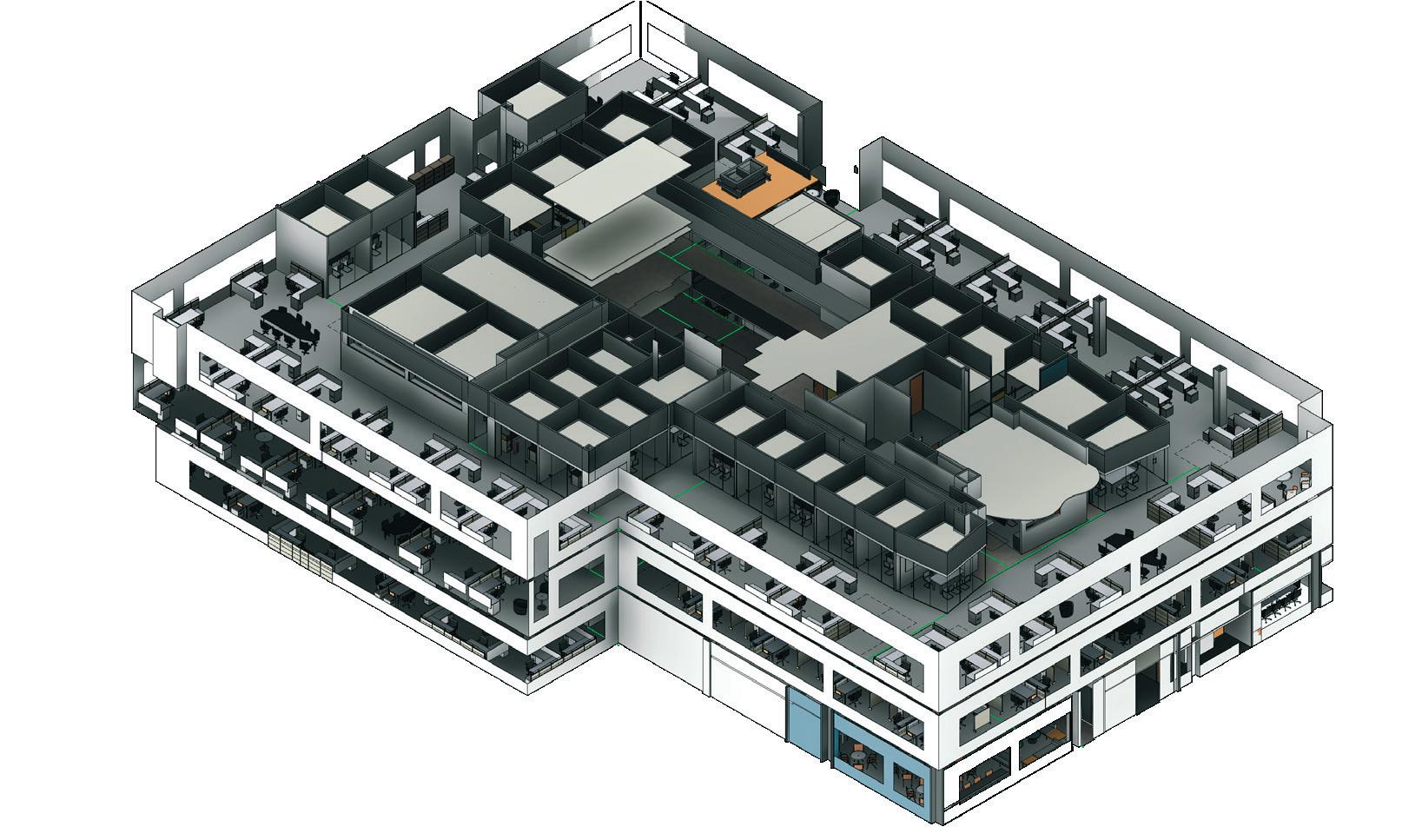

Snaptrude in Revit workflows

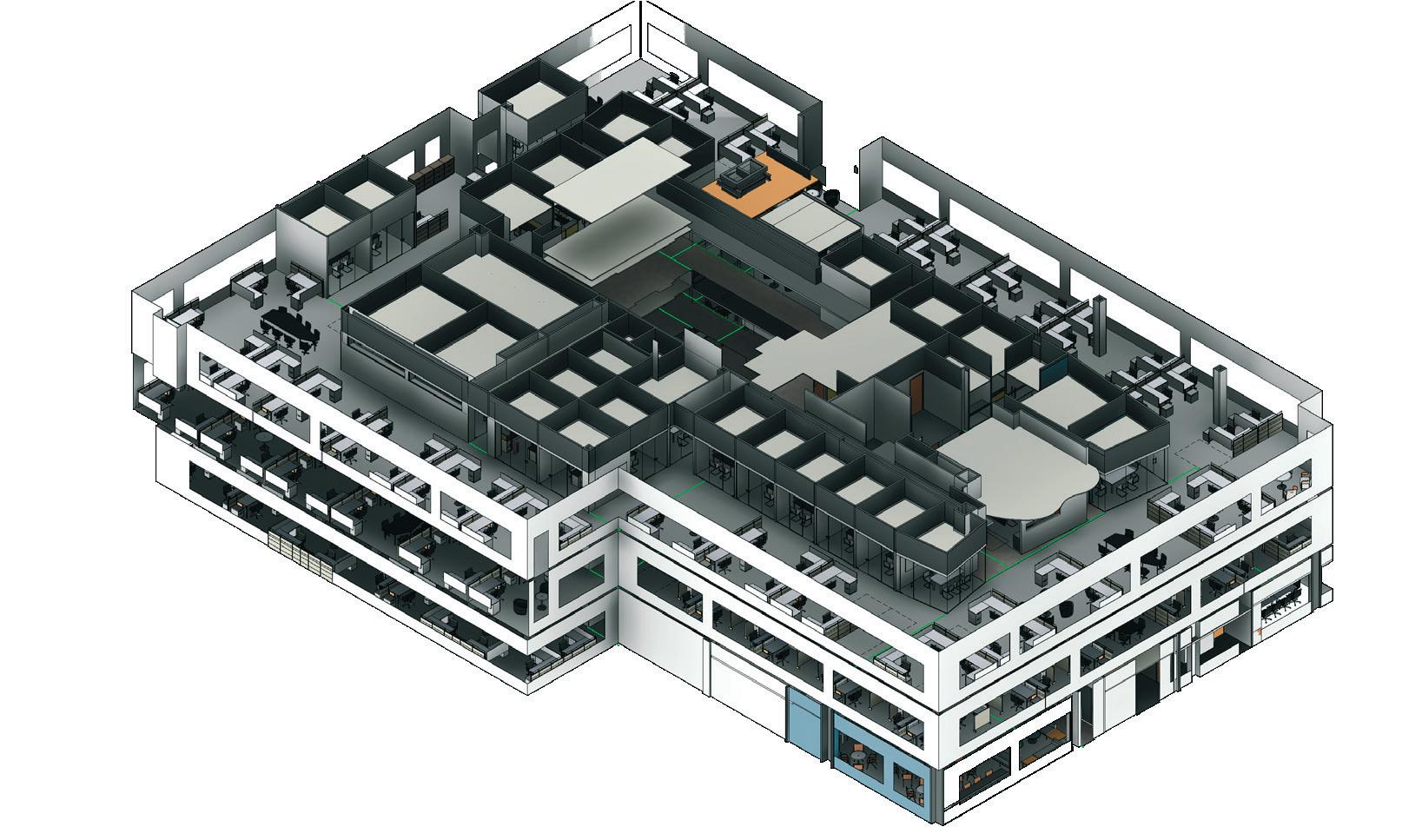

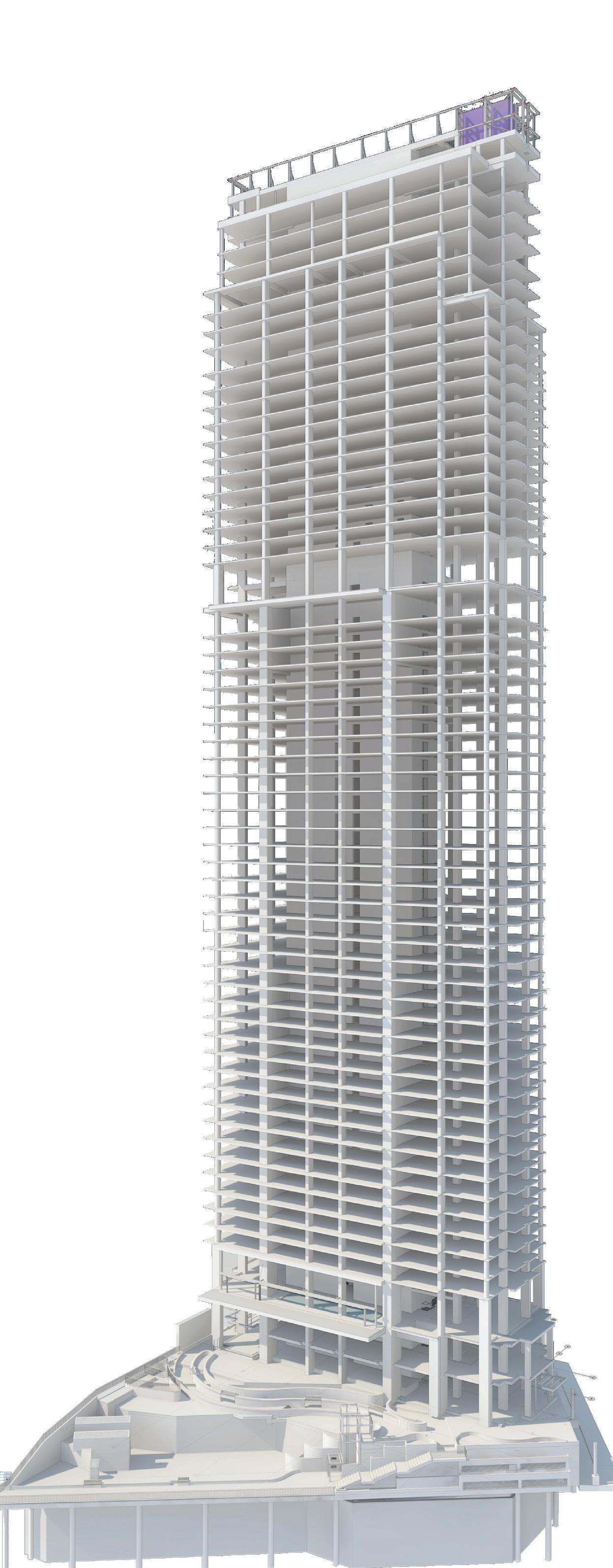

For those not already in the know, Snaptrude is a new, parametric, cloud-based BIM modelling package attempting to give Revit and other established BIM tools a run for their money.

Released at the end of 2022, Snaptrude v1.0 can be used as a BIM modelling tool in itself, but in its first incarnation, it also serves as a collaboration companion and cloud extension for putting Revit models in the hands of all project stakeholders. And, as such, it packs quite a punch.

This focus on collaboration makes a lot of sense. Design-to-construction is a complex process involving many stakeholders, but despite recent advances in cloud and web technologies, legacy tools and

formats continue to hold the AEC industry back. These lead to misunderstandings, project delivery delays and costly repercussions.

A huge array of collaborative tools and common data environments (or CDEs) are already jockeying to fill in the gaps for AEC professionals. But many lack depth and can only offer the most basic model-sharing and mark-up capabilities. Frequently, firms in this sector end up relying on multiple CDEs to get work done, all with their own strengths and weaknesses.

Choices here include Autodesk BIM 360, which comes in a bewildering array of versions, with an equally bewildering array of names. While BIM 360 is a pow-

erful permissions-based, centralised filesharing service, users complain about set-up complexity, the user interface, a steep learning curve and costs.

A great deal of the ‘web’ connectivity in Autodesk BIM 360 happens behind the scenes, with desktop users unaware of how data moves between servers in the background. While predominantly used for document revisioning, sharing, aggregation and viewing, certain features of BIM 360 already compete with capabilities also offered by Revizto, Solibri, Verifi3D, Dalux and Trimble Connect, to name but a few.

Snaptrude provides a new way to deploy real-time co-authoring capabilities, similar to those seen in other industries where Google Docs and Figma are used. This eliminates the complexity of a workflow based on files, caches, copies, and project folders.

It was designed with the core beliefs in mind that collaboration is a fundamental part of all BIM workflows and that realtime, multi-user collaboration is essential for the AEC industry to remain productive and efficient in the digital, cloudenabled age.

During its beta development phase, the company received valuable feedback from enterprise customers. These included office space provider WeWork, which has created its own intuitive design interface that enables architects to collaborate with clients and other stakeholders.

The Revit-Snaptrude bi-directional link enables users to seamlessly transfer

16 www.AECmag.com January / February 2023

With Snaptrude v1.0 now available, Martyn Day examines how the BIM modeller can be used to augment Revit workflows and boost project collaboration

Software 1

1 Users can gather design feedback through in-model mark-ups

2 Snaptrude supports Revit Library components and users can save furniture families, types, standard doors, and windows, as well as material textures, into their Snaptrude library with any necessary parameters

3 Snaptrude rendered model

4 The bi-directional link to Revit is managed by the Snaptrude Manager add-in for Revit

models between the two products, granting them the ability to securely share them with clients in a permission-based environment using a URL link.

Furthermore, users can gather design feedback through in-model mark-ups, allowing clients to view a model in a highdefinition, real-time rendered 3D viewer, either on their desktop, tablet or mobile device. And since Snaptrude provides a data-rich BIM authoring environment, architects can even make design changes in Snaptrude, provided they have the right permissions, and reconcile them back into Revit without losing any parametric data or relationships.

Snaptrude Manager

The bi-directional link is managed by the Snaptrude Manager add-in for Revit. Once installed and authenticated, it can quickly and easily send a Revit model to a shared Snaptrude team workspace or a personal workspace on Snaptrude’s servers. It is possible to import models partially using the ‘Section Box’ in Revit, in order to selectively define which subset of a model’s geometry needs sharing. Uploaded models can be organised in folders according to the project, version, stage or according to a company’s own organisational standards, just like in Google Drive.

The Snaptrude Manager currently works for Revit versions 2019 through 2022, and the company will soon be launching an update to support Revit 2023, allowing you to stay up-to-date

17 www.AECmag.com January / February 2023

3 2 4

with the latest version.

As a native BIM environment, having deep knowledge of the embedded information enables Snaptrude to be used to study project metrics in real time, such as cost and programme-area changes. Because of its inherent BIM modelling capabilities, Snaptrude eliminates the need to switch between Revit and a model viewer with each change order, as well as the need to rework the model to evaluate the impacts of design changes. Once all design updates have been finalised, project teams can obtain a client’s sign-off directly on the Snaptrude model and send the updated data back to Revit.

Accessing Revit data

Historically, Snaptrude worked with Revit using the Autodesk Forge RVT conversion tool, which was charged on a per-file transaction basis. The company then experimented with Speckle and Dynamo to extract data from Revit sessions. By implementing the Speckle-to-Revit converter (https://speckle. systems), which converts Revit data to

Speckle’s own database format, the geometry and parametric data could be extracted to Snaptrude.

However, the team discovered there was lots of essential information missing. As a result, Dynamo was used to extract the missing geometric information to enable Snaptrude to generate accurate walls, slabs, floors and so on. While an improvement, texture mapping was still missing, which led to the use of Revit’s own API. Snaptrude not only extracts 3D but also 2D geometry from Revit.

Under the hood, Snaptrude uses BREP algorithms and vertical or horizontal profiles, associated parameters and advanced algorithms to reconstruct elements such as walls, floors and slabs from the Revit data. Its robust algorithms can also handle more complex elements like stacked or curtain walls, compound ceilings, staircases, and objects with cut-outs.

Snaptrude’s boolean algorithms are also able to handle walls, ceilings and

other elements with holes or voids. Furniture, furniture systems, assemblies, model groups, nested families, casework, railings and so on are all imported in such a way that the user can query either individual items or a larger group.

Once data is reconstructed into native parametric Snaptrude objects, the user can perform any operation as they would on an original Snaptrude project. Walls can be extended, doors can be moved, or furniture added, for example.

The net result, Snaptrude claims, is that despite being a cloud-based application, it opens RVT files between 10% and 20% quicker than desktop Revit and manages to deliver more frames per second (FPS) when manipulating the same geometry, despite being on the cloud (this is especially true in models with multiple copied objects).

So far, performance is currently optimised for Revit models up to 500 MB, according to Snaptrude, but the company will be concentrating on performance over the coming months, with larger files and better graphics performance with technologies such as the latest version of Web GPU.

When changes need to be brought back into Revit, Snaptrude uses its own RVT exporter which was originally built on Autodesk Forge and is now a

18 www.AECmag.com January / February 2023

‘‘

Snaptrude is a BIM modelling tool but also serves as a collaboration companion and cloud extension for putting Revit models in the hands of all project stakeholders. And, as such, it packs quite a punch

’’ Software

The Revit-Snaptrude bidirectional link enables users to seamlessly transfer models between Revit and Snaptrude

Are you looking for growth opportunities? CADSOMA | CAD Solution Marketplace Be one of the first – sign up as a reseller on cadsoma.com Hello CAD developers!

Revit add-in. To accelerate the process, Snaptrude maintains element ID tags with the original Revit model and just sends back the components that have been edited.

For any given Revit model, Snaptrude is able to compare the number of objects in the Revit model to those imported into Snaptrude, providing firms with the assurance of data accuracy. Users can also access export logs that contain a list of all model changes made within the Snaptrude environment, ensuring accountability for edits. In addition, Snaptrude’s support teams are on hand to help to create BIM implementation plans, manage material and object libraries on their platform and provide on-site training to streamline workflows.

Library components are also supported, so users can save furniture families and types, standard doors and windows and material textures into their Snaptrude library with any necessary parameters. These saved objects and textures can be reused when importing models from Revit, ensuring data consistency and visual accuracy. When reconciling back into Revit, families created, placed or modified on Snaptrude are recreated by mapping them to textures and RFAs (file extensions assigned to Revit Family Files) in the user’s Revit library, allowing for a seamless transition.

Collaboration between disciplines is made easier through support for importing linked Revit models. For instance, when importing an architectural model, users can include any linked structural, MEP, landscape or other models. This includes structural columns and capitals, lighting fixtures, electrical devices, security systems, HVAC components, vegetation and more. Linked models can then be reviewed, locked or hidden as needed for further analysis.

Snaptrude’s development team has been working closely with early beta customers to guarantee that all the necessary Revit family types are imported and customise parameter sets if needed. This is especially important as every firm has a distinct approach to BIM workflows or family creation.

Looking ahead

With any young product like this, there are always big holes to fill, such as drawings. Any next-gen BIM modeller may tackle the significant challenge of developing geometry capability, but the output still has to fit into existing workflows and deliver the ultimate low-tech contractual obligation — drawings.

So far, Snaptrude has avoided this aspect, but in the next few months, the team will connect Snaptrude to an already mature and unique cloud-based DWG editor, and will offer auto-dimensioning and other drawing productivity enhancements.

The team is also set to address earlystage conceptual mass modelling, more detailing tools, push/pull modelling and branching (developing alternative designs in one master model).

I can still remember having my first Zoom call with Snaptrude CEO Altaf Ganihar back in 2019. During this session, I saw a quick demo of Snaptrude’s formative capability for parametric sketching of 3D rectangles.

It really is amazing to think of what the product can do now as compared to back then. This is incredible product development velocity, in an industry where design tools have often lacked aspiration.

However, there is still a long way to go. The decades of development and inclusion of edge cases embodied by existing BIM tools will take a long time to match. For those looking for alternatives to their daily BIM workhorse, there is still no magic bullet. All new BIM start-ups have to provide the basics, and deliver them better, before they can advance.

This is where Snaptrude is being smart, as the company has not only nailed the basics, but also offers something currently unique in a shipping BIM product — it’s based on the cloud and has had built-in collaboration from the start.

So why should a Revit customer consider adding Snaptrude to their tech stack? The simple answer is that Snaptrude takes your Revit models and makes them available to other project members and clients, via the cloud.

Unlike any other tool, it does not only offer viewing, but also live collaborative editing, which can be re-synchronised back to the original Revit model. It’s even possible to start projects in Snaptrude and, when the need for detailing outgrows current capability, you can send the model to a new Revit session. In this respect, Snaptrude can be considered as SketchUp with BIM knobs on.

As mentioned, one of the early adopters of Snaptrude has been WeWork. The company needed a tool that it could use to sit down with clients, either face-toface or online, to discuss and live edit interior designs of its managed workspaces. Here, it’s possible to see a valuable extension to WeWork’s Revit workflows, leveraging the unique capabilities that Snaptrude offers.

It’s going to be exceptionally interesting to see what further capabilities Snaptrude will be able to offer the BIM community in two to three years’ time. With the knowledge that automated cloud 2D drafting (DWG) and further performance increases are expected within months, Snaptrude’s velocity only looks set to increase.

■ www.snaptrude.com

20 www.AECmag.com January / February 2023

‘‘

Software

Unlike any other tool, Snaptrude does not only offer viewing, but also live collaborative editing, which can be re-synchronised back to the original Revit model ’’

Models can be viewed on desktop, tablet or mobile device

We offer you the platform – you do the business. Publish your first plugin in the CAD Solution Marketplace and start selling! Selling CAD plugins has never been easier CADSOMA.COM It’s here! Independent CAD marketplace Use your own PayPal or Stripe account for billing Promote your CAD plugins

Snaptrude Q&A with CEO Altaf Ganihar and product lead Amritha Krishnan

AEC Magazine recently had the opportunity to sit down with two of the executives leading Snaptrude’s development and find out more about where they see the product going.

AEC Magazine: In the AEC sector, performance is key, as well as accuracy of data interoperability. So is it fair to say that the challenge here is not only delivering BIM in the cloud, but also dealing with the size of models and the fact that not everyone models in the same way?

Altaf Ganihar (AG): We have optimised the product. In 2019/2020, we struggled with large-scale projects, but that gave us an opportunity to look back at the kernel and the rendering optimisation to handle those large-scale projects. And honestly, the best thing was last year having WeWork become a customer. They pushed us to the limits of what can be done in optimisation, Revit interoperability, and the way that people model. I think there are people in our team who can write papers on just how many ways users model walls in Revit!

On the cloud, you can open multiple large files. Here, I have 15 large models and they can all be manipulated smoothly – and I am running these Revit models all on my Apple Silicon MacBook. There’s still a lot of room for optimisation. We have a three-man graphics team, with a leader who is ex-Sony PlayStation development, that focuses only on visuals and 3D optimisation.

Amritha Krishnan (AK): We are able to support the entire model system from the base Revit file, as well as linked models, which can all be brought together into Snaptrude as an architectural model, with the linked MEP and structural models.

AG: Performance-wise, Revit’s biggest problem is that it’s singlecore, and so therefore loads the geometry linearly. We parallelise it, even though we are on the web. We have done a lot of optimisation, so our loading speed is much faster. And even performance-wise, we get almost the same FPS or slightly better FPS. even though we are on the web.

AEC Magazine: Data compatibility obviously exceeds importing. Do you get everything out of the RVT file?

AG: For interiors, 100%. We are good. Look at the WeWork use case,

which is commercial interiors. We now have multiple customers in that segment, and all of them are able to get 100% fidelity. If there are any gaps, since we know the Revit API, we can work with the customer. It might take a couple of weeks to figure it out, but we have our BIM implementation plan for enterprise customers, where we will sit with your Revit modelling team and we will make sure they match up.

For MEP, we’re treating it as geometry, but we categorise it as MEP. So users can filter, select and do all of those things. We recently tried doing a clash detection experiment on a weekend hackathon and it worked well on our MEP elements. But for the moment, we treat it as geometry, rather than a parametric BREP mesh. In our plan, Q3 this year is when we will start the work to apply parametrics to MEP data.

AEC Magazine: Potential users might be concerned about unauthorised editing. While Snaptrude can be used as a straightforward viewing tool, could the editing capability prove to be a double-edged sword for users?

AK: You can’t edit anything while it is locked, but anybody who has admin or creator access can basically decide if the rest of the team should be able to unlock the model or specific geometry — or not. There is built-in accountability across the team. When we bring in a link file, by default, they’re locked. That was one of the key requirements of our customers: that linked models should be locked and non-editable.

AEC Magazine: The ability to share portions of models is exciting, although the issue here is whether there will be common geometry between workspaces. So the big question there might be who owns a wall that extends beyond a workspace, for example?

AG: Yes, you can separate models by people as well. I can lock a certain portion, so I am the owner of it. Somebody else can lock another portion, as the owner of it. Everything can be locked. Subsequently, the data also updates the cost information areas. We implemented it by object right now. So, you can select the geometry and lock it for yourself, so nobody else can touch it, but it might also be zone-based, as you’re saying, ‘This is your zone, this is my zone’.

AK: I think that’s precisely what we are looking to handle this year, in collaboration, to improve the logistics. Zone-based gets tricky, because nothing fits perfectly.

AEC Magazine: BIM is not just about geometry but also, with Revit, support for families. How do you deal with that?

AK: Yes. Take, for instance, wall families. Select a wall in Snaptrude and you can see its object properties. It shows that it has been created with a certain name and parameters in Revit, all that all comes in. If you go further into edit structure, you can see that the components are set up exactly the way you would layer the wall up in Revit. So that same principle applies to most of our architectural elements: walls, slabs, flooring, ceilings. When it comes to nested stack walls, nested families, these are handled slightly differently. Using an asset family, for example, Snaptrude tells me that the name of the family is ‘Group 15’ in Revit and the same naming is applied in Snaptrude. If you want to see all the objects inside the group, just click on it, and you get to see.

AEC Magazine: While concentrating on Revit fidelity, I guess the issue might be getting trapped into Revit’s way of working, which in some cases, might be more for historic reasons than a sound basis for future-looking methodologies?

AK: I think our approach to parametric modelling on Snaptrude will be similar to our approach for space planning on Snaptrude. We are taking a fresh approach, while at the same time accounting for the fact that people are used to doing things a certain way in SketchUp or any other modelling tool. So, it would be a similar kind of thought process that we’re applying to parametric modelling and we are quite excited about where that’s going to go.

So, as an example, take a mass and think of it as a component of furniture and you’re designing that furniture family. I can copy it, copy the array. Once I come out of it, that array naturally becomes a parameter. I can go back and change the

distance between two instances, as well as the number of copies. Every option I choose, like split, cut or join, is a parameter of that family. And you can choose which to expose and which to hide. That is the approach. It’s basically like SketchUp, but you can go back and change any of the steps in that stack of operations.

AEC Magazine: Looking at the bidirectional link between Revit and Snaptrude, I guess it can’t work with just RVT files on their own? You need to have a Revit licence?

AG: We do exchange through a Revit plug-in only for now, in terms of import, because anybody who has a Revit file and wants to only collaborate will have a Revit subscription. But it means it’s possible to also share the model with others who don’t have Revit subscriptions or skills.

AEC Magazine: People model in so many different ways in Revit, is that a problem?

AG: A BIM implementation plan is so helpful. It’s less about supporting new geometry types. It’s just about seeing the client’s modelling process, to check they’re not modelling in an unusual way. In one case, we had two teams, and one had a very precise way in which they were modelling, the other team modelled walls with plaster and paint as not part of the wall. They were, in fact, modelled as separate walls. They asked us to combine those walls and load it as one wall while Snaptrude was reconciling it. It wasn’t a geometry issue or a Revit issue, but above all, a modelling issue.

22 www.AECmag.com January / February 2023 Software

CEO Altaf Ganihar (left) and product lead Amritha Krishnan (right)

Software

Vectorworks 2023

Vectorworks has been busy with a major update to its flagship product.

Recent releases of Vectorworks have been both important and tricky. New features needed to be added to the core BIM tool, in Windows and Apple Intel. Behind the scenes, meanwhile, some major rearchitecting has been undertaken, not least with a whole new port to Apple Silicon.

In the latest release, 2023, the BIM feature updates continue. And, post-launch, Vectorworks has added two exciting new capabilities: first, Scan-to-BIM, supporting Apple’s brilliant mobile RoomPlan Technology; and second, quality checking via Solibri Inside.

But first, let’s look at the sales strategy for this product. Vectorworks comes in four flavours, all built on the same core technology. These are: Architect, Landmark (for landscapers), Spotlight (for media and entertainment/stage design), and Fundamentals (a basic version).

With the 2023 version, new Vectorworks licences can only be bought by subscription — more on that later. Subscriptions for Architect, Landmark and Spotlight cost £123/month or £1,230 billed annually (which works out as £102/month). A Fundamentals subscription costs £88/month or £880 billed annually (£73/month).

When you compare these prices to a single licence of Revit — £2,940 yearly or £366 per month, according to the Autodesk website — then Vectorworks’ various professional flavours look like good value for money.

Top 2023 features

Moving on to features and functions, the Wall Tools command is now a combined wall tool. In other words, it supports the editing of curtain wall frames and walls with a single in-context tool. There are now additional options for wall insert of objects, which can be centrally located or locally overridden when needed. It’s also possible to align inserted components, even if they’re in different styles. Construction drawings have been improved with the inclusion of additional fields to the Profile offsets and Wall

Closure Wrappings dialogue.

Push/ Pull modelling has been beefed up with a new Offset Edge tool, which lets you offset edges and edge loops from planar and non-planar faces. It also includes an automatic Push/Pull mode for nonplanar faces of 3D objects, reducing the steps to model unique 3D solid objects. This is very powerful. It will not only improve modelling times but also enable complex solids to be generated very easily, while maintaining a full history of the complex solid. This is the kind of capability seen in mechanical CAD systems.

The Shaded Render mode has been improved to support an unlimited number of light objects, glow textures, environmental lighting and reflections. This provides a real-time preview for a better understanding of a project while it’s being designed and helps predict the render output better. The new reflected textures and ‘lit fog’ support are really cool.

Section Viewports can be generated six times faster than in the previous release and using 80% less system memory, thanks to the Vectorworks Graphics Module. This moves calculations and processing to the background. Viewport updates are snappy and don’t lock up the application.

Cloud Presentations for clients have been enhanced to enable users to create and customise boards and virtual tours in Vectorworks Cloud Services. In virtual tours, there is increased compatibility with file types, such as 3D models, videos, images and PDFs, as well as the ability to create text and hyperlink-based pins.

Vectorworks 2023 now takes full advantage of Maxon’s Redshift Everywhere initiative, which supports Redshift render styles regardless of the type of hardware in use. Redshift is no longer limited to using just the GPU, but also the CPU for processing image work.

The new BCF Manager and interface is a lot quicker for loading, creating editing and managing issues during coordination. With powerful data filtering capabilities and support for BCF 3.0, Vectorworks now supports BCF

exchange by file or web workflows using BCF web services.

A new elevation benchmark tool can be used for annotation as well as a design tool. It can be placed in the model space and used as a visual aid when modelling. Elevations can be placed on different design layers and reference the layer height above the ground plane or associated to storeys or different ground levels. Once included, they can also be used to change story heights. A number of styles can be applied, and there are lots of options for the way that the information is displayed.

Data Reporting, meanwhile, creates detailed reports and quantity take-offs for building objects, using a new set of reporting functions for walls, slabs, roofs and railing/fence objects and their defining components.

In terms of data exchange, Vectorworks now supports more Revit object types and provides better organisation of imported file data. You can also reference a Revit file directly.

IFC files give faster, more reliable results on import, with additional filters applied to objects upon import. They have access to class, storey and other criteria-based mapping for alignment with Vectorworks data.

DWG and DXF files, meanwhile, have also seen import/export improvements with a new, simplified export dialogue. When importing, you can now select which layers and objects to include.

And when it comes to site grading and GIS, new Site Modifier modes, including Aligned, Pathway Path and Boundary Path, enable site designers to create more complex grading projects. There are new ways to account for drainage, vehicular/ pedestrian use and better control via contour drawing and editing. GIS and georeferencing integrations automate the placing of referenced files using GIS settings from a master document.

Cloud and mobile enhancements

In January 2023, Vectorworks announced key updates to Vectorworks

24 www.AECmag.com January / February 2023

The 2023 version now offers users support for scan-to-BIM with Apple’s RoomPlan and quality checking via Solibri Inside, as Martyn Day reports

1 The new Offset Edge tool lets you offset edges and edge loops from planar and non-planar faces

2 Vectorworks 2023 includes improved BIM issue management

3 Using Apple’s room scanning framework, RoomPlan, the Vectorworks Nomad mobile app can now produce models with classified geometry, such as walls, windows, openings and doors, which can be imported directly into a Vectorworks model

Cloud Services and the Nomad mobile app. Utilising Apple’s innovative technology, the development team has increased performance and streamlined reality capture workflows.

The existing Photos to 3D Model feature in Vectorworks Cloud Services has been replaced with a new framework, in order to take advantage of Apple’s new photogrammetry API on macOS, known as Object Capture. Job submissions now incorporate this framework on the cloud infrastructure, desktop app, web portal and Nomad mobile app.

The net result is higher success rates and the ability to create more optimised geometry in less time. The service now captures any additional metadata that is generated by supported iOS devices. This is used by the algorithm to recover actual object size and orientation, a capability that was not previously possible.