Creo 12 CAD system is now infused with more industry-leading composite capabilities, expanded Model-Based Definition (MBD), real-time simulation and streamlined workflows to make it even easier for you to deliver your best designs in less time.

EDITORIAL

Editor

Stephen Holmes

stephen@x3dmedia.com

+44 (0)20 3384 5297

Managing Editor

Greg Corke

greg@x3dmedia.com

+44 (0)20 3355 7312

Consulting Editor Jessica Twentyman jtwentyman@gmail.com

Consulting Editor Martyn Day martyn@x3dmedia.com

+44 (0)7525 701 542

DESIGN/PRODUCTION

Design/Production

Greg Corke

greg@x3dmedia.com

+44 (0)20 3355 7312

ADVERTISING

Group Media Director Tony Baksh tony@x3dmedia.com

+44 (0)20 3355 7313

Deputy Advertising Manager

Steve King steve@x3dmedia.com

+44 (0)20 3355 7314

US Sales Director Denise Greaves denise@x3dmedia.com

+1 857 400 7713

SUBSCRIPTIONS

Circulation Manager Alan Cleveland alan@x3dmedia.com

+44 (0)20 3355 7311 `

ACCOUNTS

Accounts Manager Charlotte Taibi charlotte@x3dmedia.com

Financial Controller

Samantha Todescato-Rutland sam@chalfen.com

ABOUT

DEVELOP3D is published by

X3DMedia 19 Leyden Street

London E1 7LE, UK

T. +44 (0)20 3355 7310

F. +44 (0)20 3355 7319

© 2025 X3DMedia Ltd All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors in articles or advertisements within the magazine

Ican’t remember a previous issue of DEVELOP3D in which I used the word ‘hack’ as much as I have done in this one. I’ve never ‘hacked’ a sack, a pony or a computer, but I’ve definitely hacked a physical product to create something that better fits a need or purpose. This type of hacking is a key skillset of product designers and engineers. Increasingly, the fast iteration of physical prototypes – whether through card, foam, 3D-printed parts or simply clay overlaid on a surface – plays an intrinsic part in getting better products to market faster, as we see in this issue.

Our cover story looks at BOA Technology, where physical prototyping is key not only to creating its ratcheting technology for shoes, clothes and accessories, but also to readying its product to survive the very manual world of footwear manufacturing.

Equally, the team at Reekon Tools, creator of tech-packed digital tape measures, tells us about the use of hacking together quick prototypes to get them into the hands of testers. This was a key part of its workflow to downsize a product and create a newer, smaller version that comes with no compromise.

Elsewhere, I recall how I recently headed to a hackathon for product development software people. At this event, my lack of ability to do anything with code put me at a distinct disadvantage, but it did gave me a good idea of the passion of those behind the software, and an urge to get more customers involved.

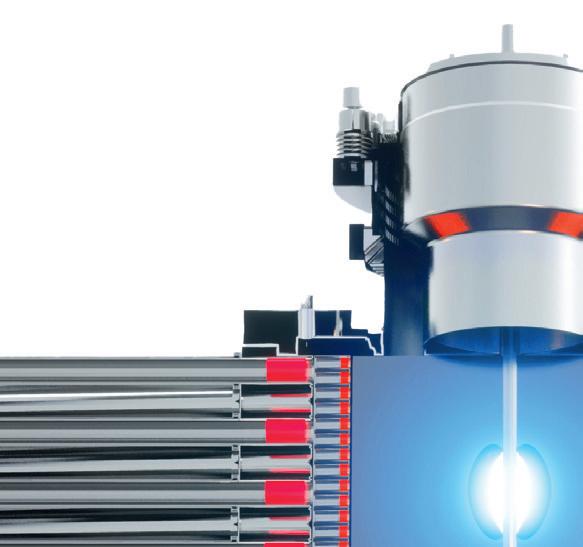

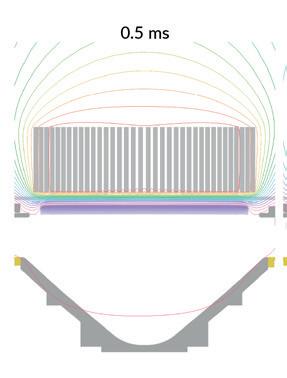

Something that can’t necessarily be hacked is nuclear fusion. In this issue, we learn how General Fusion is taking steps closer to making fusion-generated domestic energy supply a commercial reality, with multiphysics simulation helping unlock fast and safe iterations of its Magnetized Target Fusion technology.

A busy summer has seen the DEVELOP3D team travel to multiple events, from which we bring you all the key headlines. SJ got a glimpse of what an AI-enhanced design renaissance might look like at the nTop Computational Design Summit; while Martyn hopped over to Siemens’ user event in Amsterdam, where the constituent parts of the company’s vast and growing portfolio are finally starting to speak the same language.

So get ready to turn the page and hack on through.

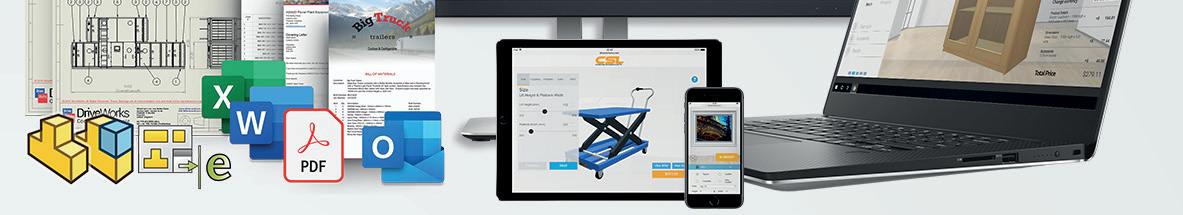

DriveWorks is flexible and scalable. Start for free, upgrade anytime. DriveWorksXpress is included free inside SOLIDWORKS or start your free 30 day trial of DriveWorks Solo.

Entry level design automation software included free inside SOLIDWORKS®

Entry level SOLIDWORKS part and assembly automation

Create a drawing for each part and assembly

Find under the SOLIDWORKS tools menu

Modular SOLIDWORKS® automation & online product configurator software

SOLIDWORKS® part, assembly and drawing automation add-in

Automate SOLIDWORKS parts, assemblies and drawings

Generate production ready drawings, BOMs & quote documents automatically Enter product specifications and preview designs inside SOLIDWORKS

Free online technical learning resources, sample projects and help file

Sold and supported by your local SOLIDWORKS reseller

Try examples online

Set up once and run again and again. No need for complex SOLIDWORKS macros, design tables or configurations.

Save time & innovate more

Automate repetitive SOLIDWORKS tasks and free up engineers to focus on product innovation and development.

Eliminate errors

DriveWorks rules based SOLIDWORKS automation eliminates errors and expensive, time-consuming design changes.

Complete SOLIDWORKS part, assembly and drawing automation

Automatically generate manufacturing and sales documents

Configure order specific designs in a browser on desktop, mobile or tablet

Show configurable design details with interactive 3D previews

Integrate with SOLIDWORKS PDM, CRM, ERP, CAM and other company systems

Scalable and flexible licensing options

Sold and supported by your local SOLIDWORKS reseller

Connect sales & manufacturing

Validation ensures you only offer products that can be manufactured, eliminating errors and boosting quality.

Integrate with other systems

DriveWorks Pro can integrate with other company systems, helping you work more efficiently and effectively.

Intelligent guided selling

Ensure your sales teams / dealers configure the ideal solution every time with intelligent rules-based guided selling.

Power boost for HP ZBook Fury G1i Pro laptop, Blackwell GPUs launch for compact workstations, Autodesk invests in Toolpath and more

Comment: David Heiny of Simscale on the AI race

Comment: Liucheng Guo of TG0 on systems thinking

Visual Design Guide: Nuance Audio’s ‘hearing glasses’

COVER STORY BOA Technology’s superior snug fit

Awards: DEVELOP3D Top 5 New Designers

Event report: Siemens Realize Live 2025 in Amsterdam

Interview: PTC’s Brian Thompson on Creo 12

Laurence Marks on smoothed-particle hydrodynamics

Event report: nTop Computational Design Summit

General Fusion’s bold vision for power generation

Made to measure: Reekon Tools unveils T1M device

Bumper harvest: Vertical farming at IGS

Getting smart people in a room is a proven way to tackle software challenges, but let’s include more customers in the problem-solving process, writes Stephen Holmes

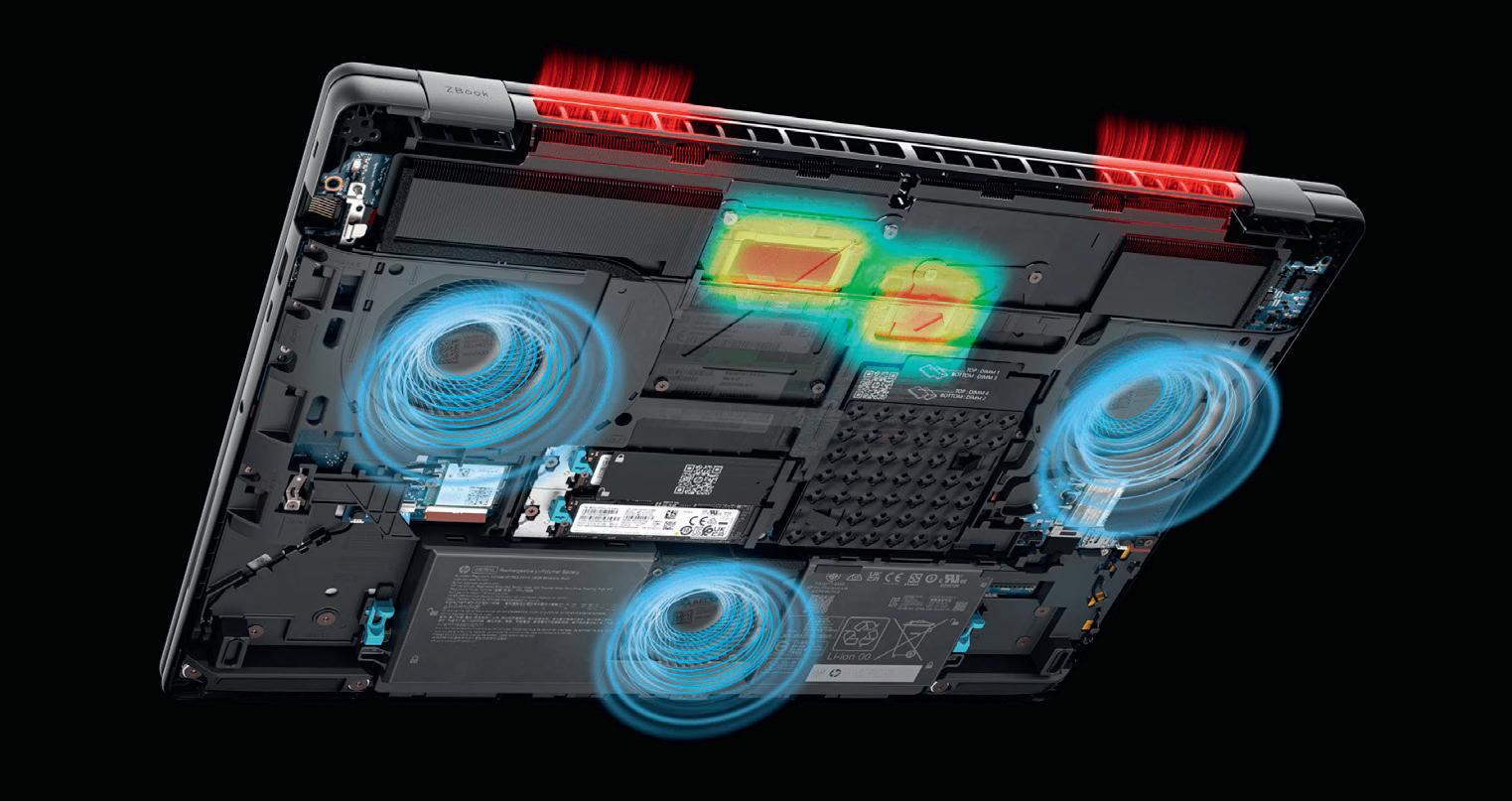

HP has revealed more details about the HP ZBook Fury G1i, the latest generation of its high-end mobile workstation, now available in a new 18-inch form factor alongside the familiar 16-inch model.

According to HP, the ZBook Fury G1i delivers a significant performance boost over its predecessor, the ZBook Fury G11, thanks not only to its choice of next-gen Intel Core Ultra 200HX Series 2 processor and Nvidia RTX Pro Blackwell GPU, but also its higher power envelope.

The 16-inch model now supports up to 170W Thermal Design Power (TDP), while the 18-inch pushes that even further to 200W, compared to just 145W in the G11. To manage this additional thermal load — and to maintain optimal acoustics — HP has introduced a new ‘hybrid turbo-

bladed’ triple-fan cooling system. Naturally, power delivery also gets a boost: the 16-inch model peaks with a 280W PSU, and the 18-inch with a 330W unit, both up from 230W in the G11.

The ‘Arrow Lake’ Intel Core Ultra 200HX Series 2 processor is considered ‘desktop class’, and the top-end Core Ultra 9 285HX features 8 Performance cores, 16 Efficient cores, and a Max Turbo Frequency of 5.5 GHz on the P-cores. Its integrated Neural Processing Unit (NPU) delivers 13 TOPS — typical for Arrow Lake chips — but this falls short of the 40 TOPS requirement for Microsoft’s Copilot+ AI PCs.

However, in high-end mobile workstations like this, the bulk of AI workloads are expected to be handled by the discrete GPU, such as the top-tier Nvidia RTX Pro 5000 Blackwell (24 GB). www.hp.com

HP’s new triplefan cooling system will be key to maintaining the equilibrium between thermals, acoustics, reliability and portability

Lenovo has refreshed its ThinkStation P2 and P3 desktop workstation line-up with four new ‘Gen 2’ models featuring Intel Core Ultra 9 (Series 2) processors and, later this year, Nvidia RTX Pro Blackwell GPUs.

The mainstream workstations span a variety of form factors, including compact towers, small form factor, and micro.

The ThinkStation P3 Tower Gen 2 is the most expandable and is ‘AI-ready’. It features an Intel Core Ultra 9 with integrated NPU and, by Q3 2025, will offer up to an Nvidia RTX Pro 6000 Blackwell Max-Q Workstation Edition GPU (96 GB). www.lenovo.com

AMD has launched the Ryzen Threadripper Pro 9000 WX-Series and Threadripper 9000 Series processors, based on AMD's Zen 5 architecture. Both chips boast high core counts, high memory bandwidth, and are built for multi-threaded workloads such as simulation and rendering.

The Threadripper Pro 9000 WX-Series is built for workstations, offering up to 96 cores and support for eight channels of memory. The Threadripper 9000 Series targets high-end desktop users, with up to 64 cores and quad-channel memory. www.amd.com

Lenovo has introduced Lenovo Access, a new high-performance remote workstation solution that it claims delivers superior performance and a more seamless user experience than traditional public cloud or VDI services.

According to Lenovo, Lenovo Access delivers flexibility, performance, and security for remote workers, without compromising user experience. In short, users get a desktop workstation-like experience wherever they work, even when using demanding 3D applications.

Lenovo’s solution includes a series of ‘easily deployable’ reference architectures, or ‘Blueprints’, which pair Lenovo workstations with software and services.

The first Blueprint is powered by seven rack-mounted Lenovo ThinkStation P3

Ultra SFF workstations in a 5U shelf, running the Mechdyne TGX remote graphics protocol.

According to Lenovo, the set-up offers a real-time responsive screen, as well as control sharing, where multiple users can collaborate for design review and training. www.lenovo.com

Lenovo Access Blueprint powered by seven rackmounted Lenovo ThinkStation P3 Ultra SFF workstations

AMD has introduced the Radeon AI Pro R9700, a new workstation-class GPU with 32 GB of memory, built on AMD’s RDNA 4 architecture. The card has a big focus on AI and with double the memory of its consumer counterpart can be used for local inference, finetuning and other data-heavy workflows. It features 2nd Gen AMD AI accelerators which are said to deliver up to 2x the throughput of the previous generation. Naturally, the card can also be used other GPU-accelerated workflows, such as visualisation and simulation.

The Radeon AI Pro R9700 is available from multiple manufacturers including ASRock, Asus and Gigabyte. www.amd.com

Autodesk has become the latest company to invest in Toolpath and its software that integrates AI and CAM with the goal of optimising tool selection and toolpath strategies.

The value of this strategic investment hasn’t been revealed, but Autodesk joins other investors including Kennametal, ModuleWorks and Leaders Fund in its support for Toolpath’s AI-powered manufacturing platform.

This platform analyses machining processes and the parts a process will make, providing manufacturers with the insights they need to make better decisions around which jobs to quote, how to estimate costs and how to optimise machining operations.

Toolpath covers workflow steps from initial job evaluation to machining plans, thanks to its applied AI and proprietary Part Comprehension Engine.

The company was founded in 2021. Its CEO is Al Whatmough, who led Fusion at Autodesk for a decade prior to leading Toolpath. “I know first-hand the craftsmanship, innovation and sheer engineering excellence that exists within Fusion,” said Whatmough, “and I’m thrilled to be working again with friends at Autodesk to create the next generation of outstanding tools for machining.”

According to Stephen Hooper, VP of design and manufacturing cloud solutions at Autodesk, the funding will support the growth of Toolpath’s engineering team and market presence. Autodesk customers will benefit from the addition of closed-loop, fully automated workflows in Autodesk Fusion.

“Looking ahead, combining Toolpath’s technology with Autodesk’s Manufacturing Data Model would enable Fusion users to automatically analyse manufacturability, plan machine strategies and send complete programmes to Fusion,” he said.

“The goal here is to streamline and elevate the user experience, harnessing AI to automate and augment critical aspects of the production process.”

In 2022, Autodesk invested in UK-based start-up CloudNC, also an AI-enabled CAM company.

According to Hooper, CloudNC offers “differentiated support” to that offered by Toolpath, but both companies address “specific persona requirements, creating a separate but comprehensive suite of solutions that supports manufacturers across the board.”

www.autodesk.com

Toolpath embeds AI in the CAM process, optimising operations, tool selection and toolpath strategies

CoLab has released AutoReview, a new AI system that automatically reviews 2D drawings and 3D models to ensure that quality standards are met and errors are reduced, without requiring design engineering teams to spend valuable time on repetitive manual checks www.colabsoftware.com

Vizcom has added a new feature, Modify, an AIpowered way to iterate on concepts without needing to redraw sketches. Instead of producing a new drawing from scratch, users can adjust existing designs using intuitive controls that include sliders, toggles and real-world inputs www.vizcom.ai

Chaos is expanding its Cosmos library of highquality 3D assets by around 400%, adding almost 30,000 assets including vegetation, vehicles and furniture and offering a new AI material generator, in order to give projects a more realistic, polished and designforward look www.chaos.com

Xencelabs has announced its latest Pen Display 24+, which adds Calman Ready colour calibration technology to an already stacked product.

Billed as an industry-first for pen displays, this capability introduces full colour accuracy and hardware-level calibration, underlining Xencelabs’ ambition to attract professionals reliant on colour-critical workflows.

The colour calibration process is streamlined by automatic features. Users connect a Portrait Display C6 HDR5000 or compatible colorimeter to Calman Professional software, which can bypass complex OS-level adjustments and software interferences, ensuring true-tolife colours meeting standards such as Adobe RGB, DCI-P3, Rec. 709, Rec. 2020 and sRGB.

As well as colour space support, the Pen Display 24+ supports Pantonevalidated palettes and SkinTone-certified realism. The Super AG Etching glass surface provides optimal tooth, and the pen pressure curve was developed with feedback from professional artists. www.xencelabs.com

Pen Display 24+ is said to be the first drawing display with built-in Calman Ready capability

Materialise and Synera have announced a partnership that will enable Synera users with access to Magics SDK to deploy additive manufacturing agents that handle design-to-print tasks autonomously, helping to scale throughput while simultaneously reducing manual effort and costs www.materialise.com

Spatial has released Analogue 2, a nextgeneration collaborative design platform built natively for the Apple Vision Pro, enabling creative teams to work together in full 3D context – reviewing, iterating and finalising high-fidelity projects in real time, with no code required www.spatialinc.com

Nvidia has announced two new low-profile workstation GPUs, the Nvidia RTX Pro 4000 Blackwell SFF Edition and the Nvidia RTX Pro 2000 Blackwell, designed to accelerate a range of professional workloads, including CAD, visualisation, simulation and AI.

Both are expected to appear in small form factor and micro workstations later this year, including the HP Z2 Mini G1i and Lenovo ThinkStation P3 Ultra SFF.

The RTX Pro 4000 SFF and RTX Pro 2000 feature fourth-generation RT Cores and fifth-generation Tensor Cores with lower power in half the size of a traditional GPU.

Compared to its predecessor, the RTX

SFF Ada, Nvidia claims the RTX Pro 4000 Blackwell SFF delivers up to 2.5 times faster AI performance, 1.7 times higher ray tracing performance, and 1.5 times more bandwidth, while maintaining the same 70-watt maximum power draw. It also gets a memory boost, increasing from 20 GB of GDDR6 to 24 GB of GDDR7.

Compared to the RTX 2000 Ada, the RTX Pro 2000 Blackwell is said to deliver up to 1.6 times faster 3D modelling, 1.4 times faster CAD performance, and 1.6 times faster rendering. It also promises a 1.4 times improvement in AI image generation and a 2.3 times boost in AI text generation. Memory has also been increased, rising from 16 GB of GDDR6 to 20 GB of GDDR7. www.nvidia.com

Dell has launched its longawaited Dell Pro Max family of high-performance laptops, comprising eight models across 14-inch, 16-inch, and 18-inch form factors. In line with Dell’s recent re-branding, the range is organised into three tiers: Dell Pro Max 14/16, Dell Pro Max 16/18 Plus, and Dell Pro Max 14/16 Premium.

Most models feature a choice of Intel Core processors paired with Nvidia RTX Pro Blackwell Generation GPUs. The entrylevel Dell Pro Max 14/16, however, is also available with AMD Ryzen AI processors, combining integrated Radeon graphics with an NPU capable of delivering over 50 TOPS — making it the first Copilot+ PC in the Dell Pro Max family.

The performance crown goes to the Dell Pro Max 16/18 Plus, equipped with a choice of silicon up to the Nvidia RTX Pro 5000 Blackwell GPU and 55W Intel Core Ultra 9 285HX processor.

Meanwhile, the Dell Pro Max 14/16 Premium blends mobility with design with a choice of GPUs up to the 45W Intel Core Ultra 9 285H vPro Enterprise processor and Nvidia RTX Pro 3000 Blackwell GPU. www.dell.com

Samsung has added two new high-capacity models to its high-performance workstation-class range of SSDs: the 9100 Pro 8TB and the 9100 Pro 8TB with Heatsink.

The new models are designed to deliver improved thermal efficiency and sustained peak performance and follow the 1TB, 2TB, and 4TB versions launched earlier this year.

Sequential read/write speeds reach up to 14,800 MB/s and 13,400 MB/s respectively, while random read/write speeds go up to 2,200K IOPS and 2,600K IOPS, making them well-suited to intensive workloads such as simulation and 3D scanning. www.samsung.com/ssd

The Nvidia RTX Pro 6000 Blackwell Server Edition GPU is coming to enterprise servers from Cisco, Dell, HPE, Lenovo and Supermicro. According to Nvidia, this will help speed the transition from traditional CPU systems to accelerated computing platforms. The 2U servers will accelerate enterprise workloads spanning content creation, data analytics, graphics, simulation, agentic AI, industrial AI and physical AI. www.nvidia.com

UK-based subscription workstation platform

Computle has secured a £500k pre-seed investment from technology veteran Mark Boost, who takes a minority stake in the company. The funding will support Computle’s development of its remote workstation service for creative, architecture and engineering teams. Founded in 2020 by technology architect Jake Elsley, Computle claims to deliver 30% to 50% cost savings compared to alternative solutions. Unlike virtualised remote workstation solutions, Computle provides each user with a dedicated workstation over a 1:1 connection. Every custom-built blade workstation includes its own CPU, GPU, NVMe storage, and RAM, and can be configured using an online tool. www.computle.com

See What’s Possible with Cloud-Native CAD

Legacy CAD and PDM tools were built for another era—one of files, crashes, installs, and endless IT overhead. But today’s engineering teams move faster, scale globally, and expect more from their tools.

THAT’S WHERE ONSHAPE, POWERED BY AWS, CHANGES THE GAME.

Supplier BERLIN, DE

How cloud-native CAD removes infrastructure drag

Why real-time collaboration leads to faster decisions

How global teams stay in sync—without VPNs or file checkouts

What it really means to design at the speed of innovation

Manager LONDON, UK

60% of product teams miss deadlines due to breakdowns in design and communication

This eBook shows how to break the cycle

Concurrent Engineering helps innovative companies streamline processes, accelerate change and scale with confidence.

Companies like IGS are reshaping their industries by combining advanced engineering with sustainable growth. These organisations rely on Creo and Windchill to overcome complexity and deliver results faster.

Discover how your business can benefit from smarter data management.

Read the IGS case study here bit.ly/igs-case-study or scan the QR code to learn more.

A

AI, but the race is far from over and there are still plenty of opportunities for other firms to catch up,

In engineering circles, there are growing rumours of a handful of companies quietly pulling ahead in competitive terms, thanks to their use of AI – but is the fear of missing out (FOMO) justified among those still on the starting blocks?

In SimScale’s State of Engineering AI 2025 survey of 300 senior leaders, 93% of respondents said they expect big productivity gains from AI and 30% are betting on AI having a “very high” impact on their engineering workflows.

However, it’s a far smaller proportion –around 3% – that report actually seeing those gains today.

After countless conversations with teams from organisations ranging from start-ups to global manufacturers, I can confidently say the success stories are real and that their wins come down to practical steps that any firm can take.

The first hurdle is fractured data. Finding the right simulation file can feel for some like a treasure hunt where the map is missing. When results live on separate desktops, shared drives or old CAE platforms, building reliable AI models is almost impossible.

Then there’s the enthusiasm gap: 42% of CTOs assume deep resistance to AI within their teams, yet only 29% of engineers recognise this in their peers. In my experience, engineers are supereager to experiment with AI, but what is holding them back is the thought of needing senior management’s blessing.

Culture makes a huge difference. AI frontrunners have leaders who celebrate small wins and treat setbacks as lessons

More than half of those surveyed point to siloed data as their biggest blocker. I’ve seen teams spend weeks just pulling together a single data pipeline before they attempt a proof of concept.

Another pain point are legacy tools. I spoke with a major automaker where engineers still use five different applications to get a full system simulation. They know AI could cut their set-up time significantly, but outdated software won’t cooperate.

Focusing only on the barriers leaves out the other half of the story. I’ve sat down with the teams already in that small but growing first wave of AI adopters, and here are the lessons they’ve shared. They treat data as critical infrastructure. One aerospace group I met stores every simulation it runs in a cloud repository where it is tracked, tagged and accessed through simple calls. This organisation’s data scientists can launch training runs in minutes, rather than days. Successful companies weave AI into the heart of their workflows. A medtech firm showed me how its system suggests optimal boundary conditions the moment that an engineer starts a new model. Tweaks happen on the fly and set-up times shrink dramatically. Speed is a common theme. These teams start with small, focused experiments and prove value in a matter of weeks. Once an AI model pays off, they push it straight into day-to-day work without waiting for endless approvals. Version control matters just as much for models as it does for code. A heavyequipment manufacturer explained how it logs every result, every AI model update and every metric in open formats. Engineers can see exactly where a recommendation

came from and roll back if needed. Culture makes a huge difference. The frontrunners have leaders who celebrate small wins and treat setbacks as lessons. Frontrunners also focus on the use cases that matter most. Instead of chasing every AI trend, they pick one or two routines where shaving off days transforms outcomes, whether automating batch simulations or speeding up thermal analysis. Clear goals keep stakeholders engaged and prove ROI fast.

If you’re feeling the FOMO too, here’s my challenge: gather your core group, pick one painful bottleneck, and sketch a lean prototype with clear measures of success. Treat your data as the foundation, weave agentic AI and automation into the workflow, and don’t wait for everything to be perfect. Move fast, learn fast. Keep communication open, celebrate every win, and you’ll find yourself joining The 3% Club before long.

ABOUT THE AUTHOR: David Heiny is CEO of SimScale. He holds a Bachelors of Science in Mathematics and a Diploma in Mechanical Engineering from the Technical University of Munich, as well as a Master’s degree in Computational Science and Engineering from the Georgia Institute of Technology www.simscale.com

The way hardware is developed often finds itself in conflict with sustainability goals. Electronic consumer goods are frequently built to optimise functionality, cost and aesthetics – but the longer term is not necessarily taken into account. Reuse, repairability and safe disposal in the form of recycling have been secondary concerns for too long.

Now, growing pressure from consumers, boardroom members and lawmakers is prompting a rethink. Minds are focused on sustainability, not just as a ‘nice to have’, but also as a valuable source of competitive advantage and an imperative for the wellbeing of the planet.

That leaves product designers asking, ‘How can we ensure that our products work better for longer, and without damaging the environment, across the entire ‘cradle to grave’ lifecycle?’

But more than that, they’re asking this question right at the start of the design process. That’s important because, according to the EU Science Hub, over 80% of a product’s overall environmental impact is determined during its design phase.

Systems thinking is an approach that aims to future-proof product design by considering the sustainability of a product’s entire lifecycle from its conception and through its manufacturing, active use and eventual disposal.

It has not just led to incremental gains, but also to the creation of new types of electronic interfaces, ones that use lighter and better materials, fewer components, and are far less complex to update, recycle and dispose of safely.

Take, for example, TG0’s own smart surfaces: these integrate electronics with surfaces in a new, simplified fashion. As a company, we’ve long recognised that e-waste is one of the fastest-growing waste streams. An estimated 62 million tonnes

of e-waste were produced globally in 2022, and only 22% was documented as having been formally collected and recycled.

Incorporating new smart surfaces into their products, designers can reduce energy waste and e-waste at every stage of the lifecycle, by:

• Developing surfaces with fewer parts and reconfigurable interfaces, so that a single physical platform can support multiple product variants, resulting in shorter production runs, reduced bills of materials and less tooling waste.

• Decoupling functionality from physical form, so smart interfaces can support the evolution of physical products over time. User interface updates and feature rollouts refresh the user experience without altering the hardware itself. In turn, that creates added digital value without added costs in materials.

• Creating products that can learn user behaviour. Using embedded AI models that operate locally on-device can help reduce power consumption, via support for smart standby modes, adaptive lighting or load balancing, for example.

• Reducing parts and materials through the integration of sensors. This cuts manufacturing waste and energy consumption during production and assembly, as well as reducing material usage and lightweighting the end result.

At TG0, we’ve also considered incorporating more post-consumer resin (PCR) materials, replacing plastics with biological components, such as those derived from sugar cane.

In order to get the best results from new ways of thinking, businesses must fully

As sustainability becomes a competitive differentiator for all kinds of products, designers need to apply systems thinking to the task of reducing their lifetime environmental impact from design to disposal, writes Dr Liucheng Guo of TG0 of

Systems thinking is leading to the creation of new types of electronic interfaces, ones that use lighter and better materials, fewer components and are far less complex to update, recycle and dispose of safely

embrace cross-disciplinary and crosscompany collaboration. They should involve UX designers early, integrate software teams into hardware sprints, and measure success, not just by unit sales or launch velocity, but by lifecycle impact, too. Collaborating with academic partners or external designers may also accelerate sustainable innovation.

Integrating sustainable practices into product development is often seen as cost-prohibitive, yet many experts argue that initial expenses are outweighed by the long-term advantages.

As new technologies and materials become more accessible and scalable, sustainable development can drive significant cost efficiencies over time.

At TG0, we believe sustainable hardware starts with smarter thinking, using fewer materials, embedded intelligence and digital flexibility to future-proof design. As sustainability becomes a competitive differentiator, the opportunity is clear. The tools are here. Demand is growing. What’s needed now is a market-wide shift in mindset.

ABOUT THE AUTHOR: Dr Liucheng Guo is co-founder and CTO at London/Hong Kong-based AI hardware company, TG0. His research has led to seven groups of patents and over 20 publications. At TG0, he works on the creation of touch and pressure-sensing technology that offers design flexibility while reducing environmental impact. www.tg0.co.uk

• Validation in hours, not weeks – from three weeks to same-day.

• Real-world testing ready – durable enough to be sewn directly onto shoes.

• Better predictability – prototypes that closely match production performance.

3D Systems delivers proven, productionready additive solutions – backed by unmatched expertise and a trusted portfolio – so teams can qualify parts faster and with confidence that lasts.

Accelerate your design validation – from concept to test, faster than ever.

» Nuance Audio is aiming to remove the stigma associated with hearing aids, with sharp designs for ‘hearing glasses’ targeted at customers with mild to moderate hearing loss

Microphones strategically placed around the lenses enhance sound clarity, so that wearers can follow conversations with ease, even in noisy environments

Nuance Audio’s hearing glasses are available in two designs and two colours. There’s the Wayfarer-style Square frame and a rounder Pathos design, both available in black and burgundy. Nuance’s audio technology benefits from piggybacking on the styling skills of parent company, eyewear giant EssilorLuxottica

Lightweight, open-ear ‘air conduction’ speakers avoid irritation and offer all-day wearability, amplifying sounds from up to three metres away

The battery supports a full day of normal use, while the convenient wireless charging pad fully charges the hearing glasses when not being worn in just three hours

No audiologist visit is required. Users go through a set-up process via the Nuance Audio App, which also controls the level of background noise and can focus sounds for face-to-face conversations

An optional remote control has been developed for users who require a discreet way to adjust their hearing glasses without needing a smartphone

Despite the frames having somewhat thicker arms than is typical, in order to house batteries, microphones and electronics, they remain similar in weight to regular eyeglasses, ensuring maximum comfort for extended use

» BOA Technology’s innovative ratcheting mechanism gives footwear a precise, secure and comfortable fit, and this tough technology relies on a design process that is as agile and demanding as its end customers, as Stephen Holmes discovers

From its origins on the ski slopes of Colorado, the popularity of BOA Technology’s microadjustable fastener system has flourished over the past two-plus decades. Today, it frees athletes of many kinds from the struggles associated with shoelaces. They include track stars and trail runners, road bike racers and mountain climbers, fishing fans and golf enthusiasts.

When speed is of the essence, or gloves get in the way of manual dexterity, the BOA Fit System replaces traditional shoelaces with a system of dials and cables that give footwear a more precise, secure and easily adjustable fit. The innovative system been used in work boots, too, as well as in medical bracing.

The system’s core design, meanwhile, has gone through several phases since its debut as a fastener for snowboard boots back in 2001. It has been pared back for lower power applications, such as low-cut athletic footwear, and beefed up for use in more extreme environments. It has also been reconfigured for use in different apparel categories, including bike helmets and fishing gloves.

For the BOA Technology design team, there’s huge value in understanding different end uses and in bringing specific needs into the iteration loop, according to director of engineering Clay Corbett.

“It’s not just making a little ratcheting mechanism,” he explains. “It’s also [figuring out] how you make it perform when it’s packed with dirt and sand, or when it’s working at really high tensions, like in an alpine ski boot.”

The team is now in a phase in which it’s primarily focused on introducing further innovation in categories where the BOA Fit System is already well-established, he continues.

“We’re doing that by asking, ‘How do we make things more integrated? How do we improve the user experience with the product? How do we make it more sustainable and use less plastic along the way?’”

This requires intensive design and engineering activity. Take, for example, BOA Technology’s most recent design for an alpine ski boot fastener; its development forced the team to consider punishing levels of forces and tensions, while simultaneously maintaining the familiarity and simplicity of its user interface. In response, the company developed a compact new planetary gear system within the ruggedised device housing and designed new wire guides to better fasten the boot.

Much of this work, says Corbett, depends on members of the team taking their current experience with the system and applying it in entirely new ways, leaning on the latest technologies to help them build and test their ideas as quickly as possible.

BOA Technology designs and engineers the whole Fit System in-house: the iconic dial and its internal gearing; the textile or stainless-steel cables that provide the lacing; and

the low-friction guides that replace traditional shoe eyelets.

But developing each individual product is far more than simply attaching a standardised system to a shoe, Corbett emphasises. When you see a BOA product on a piece of footwear, he points out, it’s been designed to work specifically with that piece of footwear.

As a supplier to some of the world’s largest sports and outdoors brands – including Adidas, Fizik, Timberland, Salomon and Fox Racing – the choice and placement of BOA Fit System components is critical to performance and often leads to entirely new designs.

At present, BOA has developed ratchet and lacing systems for four power levels: low, mid, high, and a more extreme level such as is seen in alpine ski boots. These levels enable the company not only to deliver the necessary degree of lace tension but also vary the size of components and how the system looks when fitted to a particular product.

A lot of work goes into creating a configuration that is super-low friction and creates an even pressure that comfortably closes the fastening, Corbett explains, pointing out that running a cable system through the tight bends of existing shoe eyelets simply wouldn’t achieve this goal.

Much of the guidance on where best to position the system comes from BOA’s in-house biomechanics lab,

‘‘ It’s

not just making a little ratcheting mechanism. It’s also how you make it perform when it’s packed with dirt and sand or operating at really high tensions

Clay Corbett, director of engineering, BOA Technology ’’

where designers and engineers validate configurations and different fits. This brings a great deal of practical insight to the process as well as highlighting potential benefits of different approaches.

At the same time, the company works closely with its partner brands from the outset. In fact, while the product development team focuses on developing new products, an application team works directly with these footwear companies and their designers and factories in order to ensure that everything is installed correctly.

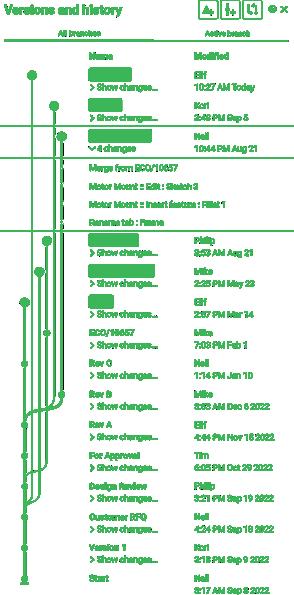

the branching and merging stuff within the data management, just so that our team could really experiment a bit more along the way,” says Corbett.

“It made it a lot easier for people to just try out ideas, get things down, merge things back in if they made sense, or just leave them if they didn’t. I think the overhead in the traditional PDM system of doing that kind of stuff prevented a lot of it from ever really happening.”

partner brands from the outset. In fact, while the product and 3

For much of its history, employees at BOA Technology have relied on 3D CAD as the place where design work starts. In the past, they used Dassault Systèmes’ Solidworks to model and test CAD models. More recently, they have switched to PTC Onshape.

The shift didn’t happen before some thorough evaluations were carried out to determine whether the Onshape feature set was a good fit for BOA’s demanding design process. Having seen that it was, the team began to explore some of the benefits they might experience from a cloud-native CAD system like Onshape.

“One thing that was really great was just some of

reseller, Corbett knew that system and start working, and we don’t have to

Having previously worked as an applications engineer at a Solidworks reseller, Corbett knew that system inside-out, but says he was impressed by what Onshape was able to offer.

“I think the big benefits we saw when looking at Onshape were, first of all, just the stability. Everyone can fire it up and start working, and we don’t have to worry about so many of the hardware issues or software crashing,” he says.

“Working with Solidworks all those years, I had to learn a lot about how Windows works under the hood and stuff like that. That’s not really doing CAD work! That was a really big issue for us, and we were at a spot where it was getting difficult.”

The ability to more easily collaborate on CAD models and across PDM is another benefit. Previously, BOA stored everything in a PDM vault that all the design and engineering team needed to access. But accessing this via a VPN proved troublesome for off-site staff and there were further challenges around checking files in and out. “If someone goes on vacation and forgets to check something back in, that kind of thing [can be problematic],” says Corbett, grimacing at the recollection. For the most part, the product development team is based in the same office. “They can just yell back and forth with each other and walk across the room,” laughs Corbett. But with a growing group, and members of the brand-facing applications team scattered around the globe, BOA Technology is starting to see more collaboration using the CAD software’s features, like sending Onshape links back and forth.

Including the knowledge of the applications team - many of them experts in pattern cutting and shoe construction - increases the potential for the product team to design better products. Already, a set of rules has been developed to help designers understand the shoe manufacturing process: what processes a shoe will need to go through, the dimensions it will need to fit, the type of sewing used to apply the BOA Fit System to a shoe. While BOA products are designed to be tough in the great outdoors, says Corbett, the manufacturing process “is another demanding environment that our products need to be able to survive.”

● 3 BOA’s fasteners for alpine ski boots must withstand high tensions

● 4 Prototypes must be able to survive footwear manufacturing processes

● 5 BOA’s in-house testing lab puts the Fit System through its paces

● 6 BOA Technology uses a 3D Systems Figure 4 printer for prototyping

Heavy testing of BOA’s products has been critical from the very early days of the company. In fact, methods have evolved only slightly from the early ‘make it to break it’ trips performed on the ski slopes of the Rocky Mountains.

While the team runs CAD models through a handful of FEA simulations, these typically act as a ‘gut check’ to make sure a design makes sense before heading to physical prototyping. All results from physical testing are looped back into the FEA model to check it correlates as a design progresses.

But it’s physical testing that plays a more critical role, with BOA’s well-stocked workshop offering a range of 3D printers and CNC machines to build prototypes.

As Corbett explains: “We use the right prototyping process for the stage of the prototype that we’re in. We’ve got some 3D printers that are fast and easy to use, that’ll just give us a good gut feel on size, whether something looks about right integration-wise, and on basic function.”

From there, the process becomes more specific, edging closer to identifying what the ideal production material and product performance should look like, and narrowing these down with each iteration.

The goal, Corbett explains, is to establish a test loop that is as specific as possible for a particular product. To do this, BOA builds tests to mimic the environments where the product will have to perform under the toughest conditions.

supports wider material options, including Figure 4 PRO-BLK 10 – a tough, rigid plastic. This makes the technology perfect for more functional prototypes that give an accurate idea of how a part will sit on a garment. This aspect of testing requires dials to be sewn directly into fabric without moulded holes. Finding conventional plastics that can be stitched is hard enough, let alone finding a UV-cured 3D-printed material that will perform without cracking.

Getting prototypes onto the shoe for early testing and interaction is a big plus point for BOA’s design team, even for concepts that don’t make it to production. Putting iterations through real-world use and abuse helps designers gather more design and performance data that provides firm indications of what works and what doesn’t. For final test models, BOA uses CNC-machined prototypes to get as close as possible to the materials used in the end part, giving team members a chance to send products out to the test lab where they’re subjected to load and tensile tests, and into the hands of almost 350 field testers out in the real world.

“We have a pretty robust field-testing program with the real diehards who are out every day on this gear – people who are putting in over 100 days a year on skis or similar,” says Corbett.

“And then, honestly, for the catch-all, sometimes we just take things out to the parking lot and kick it against the brick, really hard,” he laughs.

Many prototypes are built using 3D printers from 3D Systems, including its Figure Four and MultiJet Printing (MJP) technologies, which use resins to create high-resolution, plastic parts.

The MJP technology is used heavily for fast iteration, says Corbett. While parts produced in this way are not quite as durable for testing, this technology is fast and easy to use when members of the design team want to move fast and print a few rounds of prototypes within a day.

The Figure 4 technology, meanwhile,

“That helps us fi nd really unexpected stuff !”

used to fasten critical gear, with significant implications for sporting results or even the health and safety of the wearer. Conquering

Always firmly in mind is the fact that BOA Technology’s products are used to fasten critical gear, with significant implications for sporting results or even the health and safety of the wearer. Conquering the unexpected is part and parcel of what the product development team does. By combining cutting edge technology with good old-fashioned brute force, BOA Technology ensures that its products remain dialled-in, regardless of punishing usage and harsh external conditions. www.boafit.com

good old-fashioned brute force, BOA Technology ensures that its products remain dialled-in, regardless

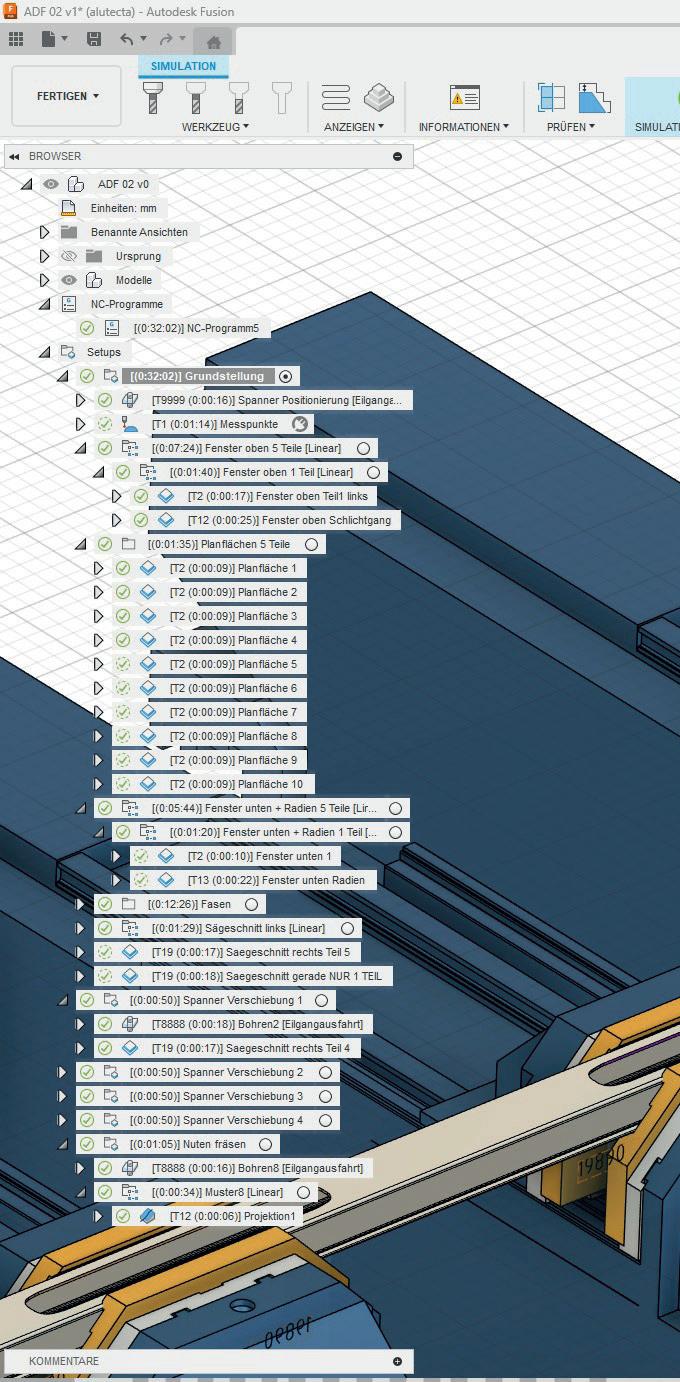

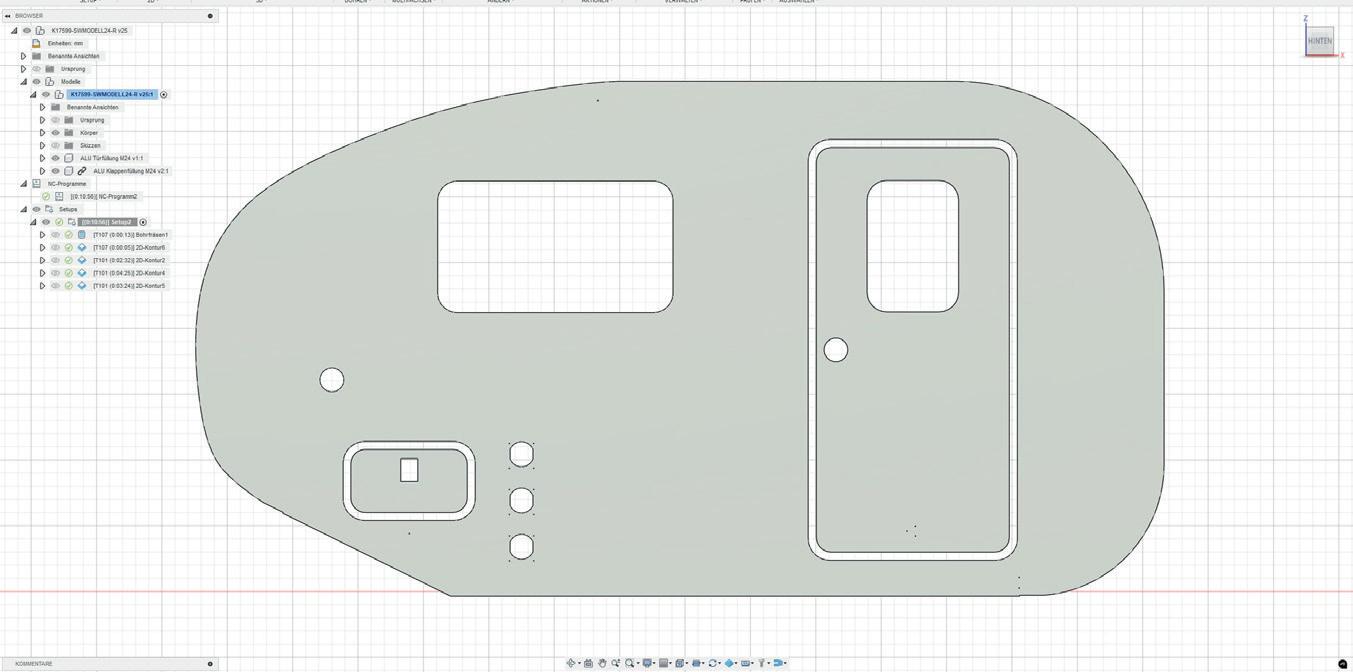

When Managing Director Michael Oswald’s father founded ALUTECTA in 1970, he was a mechanical engineer from a modest background setting out to build something of his own in rural Germany. Five decades later, ALUTECTA— with a motto of “aluminium in form, colour, and function”—has grown into a modern, family-run company with more than 130 employees.

As an expert in both processing and machining aluminium sheets and profiles in addition to surface treatments, the company delivers high precision, customised aluminium products for many industries, from construction to automotive, healthcare, and more. “If you name it and it’s aluminium, we can do it,” Oswald says.

Over the years, ALUTECTA expanded to more services and types of projects. But they also collected many different pieces of software along the way. Up until November 2023, there were up to 5 programs, including two different CAD systems, plus three CAM solutions for the different machines. Then ALUTECTA was introduced to Autodesk Fusion, and many inefficiencies were revealed. By adopting Fusion, the company replaced all the software with one platform and gained incredible new capabilities for optimisation and time savings.

“Since we handle multiple projects every day

from a single piece to the creation of complete sheet metal facades, Fusion constantly helps us solve our challenges,” says Tom Stasek, production manager, ALUTECTA. “This is especially true for the combination of multiple functions and controlling the entire machining fleet within a single software package.”

“The support from the Autodesk team is incredible and a major contributor to our successful use of Fusion today,” Oswald adds.

Since ALUTECTA serves many different markets, their customers also run the gamut of digitalisation and varying file types. Previously, they had to run customer files through a complex chain of different software programs, each tailored to specific machines, making the process time-consuming and rigid. Now, with Fusion, they can handle all tasks— from file import to milling setup—in one workflow.

“Now, we’re quite free with Fusion,” Oswald says. “We put in the file from the customer and do all the tasks right inside Fusion. Then at the end we can decide which machine to use. The work preparation and machine setup time has been cut nearly in half.”

Milling operations is easier—and faster—than ever before with an estimated 30% in time savings.

“Flexibility in machine utilisation and time savings is huge,” Stasek says. “Previously, a separate

milling program for the same component had to be created for each machine. With Fusion, we can define the milling operations on a component once and then easily create an NC program for all machines with a simple mouse click, without having to repeat the same task multiple times.

“Another major advantage of Fusion is the ability to animate, simulate, and manufacture these components,” he adds. “Especially in the manufacturing area, I see the advantage of having many manufacturing methods available: milling, turning, laser cutting, and even slicing for 3D-printed components.”

By using Fusion for their entire workflow, ALUTECTA can respond to customer needs faster, whether it’s tweaking a component design or scaling to a full production run. With CAM in Fusion, the company is taking advantage of more of their own machines and capabilities. For example, the company’s use of a 5-axis milling machine with 10 independently moving clamping blocks is now fully utilised, thanks to Fusion. Nesting is also used to place multiple components as efficiently as possible on the sheet metal, reducing waste. ALUTECTA takes full advantage of the Manufacturing Extension for measuring and probing on the 5-axis milling machine as well as performing 5-axis simultaneous machining if required.

“You don’t even need statistics or numbers to relay the improvements we have with Fusion and the Manufacturing Extension,” Oswald says. “You just see it and experience it.”

OneofmyfavouriteFusionfeatures istheabilitytomodelandintegrate componentsthree-dimensionally anddefinethemachiningoperations. Combinedwiththeabilityto simulateprogrammedmachining operationsandevendesigningsheet metaledgeelementsdirectlyand creatingaflatpatternandassociated millingprogram,wecanworkmore efficientlyandprecisely TomStasek,ProductionManager, ALUTECTA

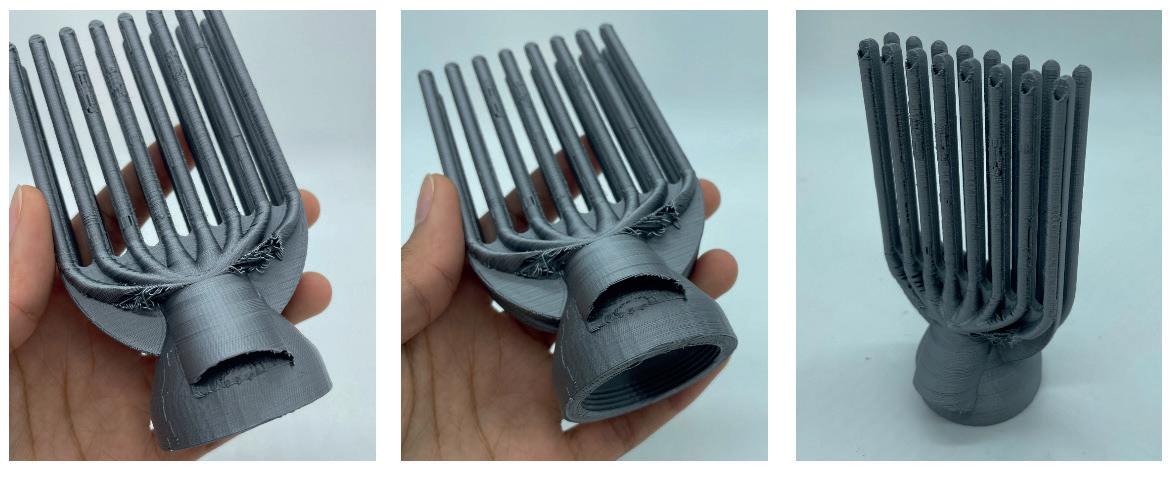

» New Designers is an annual London showcase of some of the UK’s most innovative emerging design talent. DEVELOP3D scoured the exhibition floor of Islington’s Business Design Centre in order to bring you our pick of the five most promising up-and-coming names and their visionary ideas

1

SIERRA KEBBIE UNIVERSITY OF SUSSEX

In the global haircare market, the managing of curly hair is often an afterthought. CurlFlow is a hairdryer attachment designed to streamline at-home or in-salon styling processes and evenly distribute styling products through 3a-4c hair types, to achieve voluminous, natural looks.

Following a survey of nearly 100 people with those hair types, Sierra Kebbie began to visualise via sketches her idea to combine heat fl ow from the hairdryer with styling product distribution. Cardboard prototypes assessed size, ergonomics and attachment of the product to existing hairdryer models, so that CurlFlow remains usable when hairdryers are replaced or upgraded.

Once in Solidworks, a flexible yet heatresistant 3D-printed Nylon 66 prototype further developed the tool. Renders in Adobe Dimension allowed different hairdryers to be imported into scenes, demonstrating how the attachment fits a wide range of hairdryers.

imported into scenes, demonstrating how the

“The highlight of this project was speaking to people to help solve a problem within their lives that had been overlooked,” says Kebbie. “Their input was crucial in ensuring the product worked efficiently and effectively.” www.linkedin.com/in/sierra-kebbie-610897219

The New Designers show represents the pinnacle of UK graduate work in product design, and in recognition of its importance, DEVELOP3D was the proud sponsor of the DEVELOP3D Top 5 award at this year’s event.

Focusing on projects that address real-world needs in verticals covered by the magazine, our judges were on the lookout for designs that demonstrate both real ingenuity and a strong foothold in commercial reality.

The finalists on this year’s list were able to clearly articulate the passion behind their projects, provide us with a deep-dive into the processes that brought them to life and field our questions about the manufacturability of their designs.

With so much exciting work on display, selecting our finalists was no easy task, but here are the five who most impressed us.

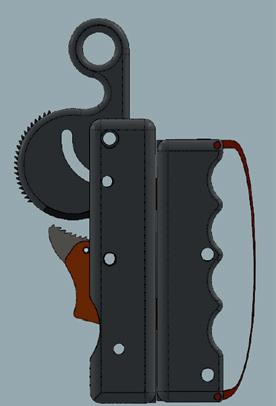

SCARLETT HARRIS BOURNEMOUTH UNIVERSITY

Aloft is an independent anchoring option for sailors working at height on yachts, securing to the existing main sail track and standing rigging, removing reliance on others and minimising human error.

An experienced sailor, Harris conducted interviews to understand user behaviours and safety concerns, before sketching potential solutions. Extensive physical ideation was used early on and AI was deployed to explore aesthetic forms.

(Below)

Precise mechanical design and integration of functional components was carried out in Solidworks, while KeyShot was used for rendering. Early models used MDF for quick validation, moving on to more accurate lasercut timber and acrylic to validate geometry. Eight weeks of high-fidelity prototype manufacturing saw Harris machine and anodise aluminium components to provide an exact model of the design.

“One of the most rewarding aspects of this project was how closely it balanced technical problem-solving with user-led empathy,” says Harris. “The product wasn’t just about performance. It needed to feel intuitive, trustworthy and effortless in unpredictable, high-stress environments.”

www.linkedin.com/in/scarlett-harris-294a33252 2

Auri is designed to act as an early warning system for hearing loss among workers exposed to dangerous noise levels, in environments where up to 50% of hearing loss cases might be prevented with earlier detection.

The handheld device identifies issues before they become permanent using two standard industry tests: pure tone audiometry and bone conduction.

Having first consulted professional audiologists, Luke Fone identified a routine pain point in existing processes – taking time away from the workplace for testing – and set to work on initial concepts for a device that could be used quickly and safely on job sites.

Modelling the project in Solidworks allowed him to build a working prototype with a 3D-printed casing, electronics, software and flip-over ear cups that enable Auri to test both ears comfortably. KeyShot renders helped him explore form and aesthetics, culminating in a final physical CMF model and a cutaway display demonstrating the internal layout and DFM considerations.

“Seeing a product come to life and actually work is an incredibly rewarding experience,” said Fone. “Receiving positive feedback from professionals and the target user group made the experience even more rewarding, and it reinforced how meaningful and impactful a career in product design can be.” www.linkedin.com/in/luke-fone

‘‘ Seeing a physical product come to life and actually work is an incredibly rewarding experience ’’

4

LOUIS PILKINGTON UNIVERSITY OF SUSSEX

Ibex is a response to both the growing popularity of grip-intensive sports such as bouldering and jujitsu and the boom in recovery products. One-quarter of all sports injuries affect the hands and forearms, but existing tools designed to aid in their recovery are often unsatisfactory.

After wading through science papers, Pilkington settled on a tool that incorporating temperature change with rotating steel balls to safely massage tissues. From early on in the project, Pilkington dived into 3D-printed and CNC-machined physical prototypes that could test ball positioning and sizes, fitted in a matrix calculated using measurements of muscle sizes, distance between tendons and the depth of reach required for effective muscle stimulation.

Thermal expansion made material choices important. Aluminium 6082 was chosen, which can also be anodised like climbing hardware, while the handle is cast in the same polyurethane as most climbing holds, adding a sense of continuity to the CMF.

bag, its portability and effectiveness making

A round of funding from the University of Sussex helped the prototype to be destructively tested, with the results leading to an overhaul of certain components. The resulting product fits easily into a climbers’ bag, its portability and effectiveness making it a pleasure to use.

www.linkedin.com/in/louis-pilkington-a10882348

SCOTT RUTHERFORD EDINBURGH NAPIER UNIVERSITY

Blood loss in road traffic collisions is a leading cause of preventable death.

Scotseal aims to give the general public a tool to tackle ‘bleeding out’, which can claim a life in as little as three minutes, after Rutherford’s research with paramedics and fire service personnel showed that existing methods can be effective, but only in the hands of people with both training and experience.

Multiple concept models and sketches formed the early stages of the process, developing a fast eff ective way to ‘pack’ wounds that can vary greatly in size and depth. Having narrowed his ideas down to three concept mechanisms, Rutherford used Autodesk Fusion to create the housing and then 3D-printed the forms. Blender was then used to help visualise the fi nal outcomes in chosen materials.

The end product attaches a ‘pod’ over a wound that expands with equal pressure in every direction, mimicking the exact shape of the wound to compress ruptured vessels and stop blood escaping.

“I am most proud of how simple the final outcome of operation is for the user,” says Rutherford. “Once the device is in your hand, it can be applied in four simple steps, in only two to four seconds.” www.linkedin.com/in/scottmakesdesigns 5

‘‘ What I am most proud of is how simple the final outcome of operation is for the user ’’

Bringing transparent pricing to the SOLIDWORKS market

Achieving Platinum support status and delivering exceptional customer experience

Flexible training at a fair price

Get in touch to learn why 300 customers have chosen to partner with us so far

» At Siemens Realize Live in Amsterdam, attendees got to hear how the company is focusing on integration and innovation to deliver a single digital thread for manufacturing and product development, as Martyn Day reports

You know you’re at a Siemens event when the speaker roster includes some of the global manufacturing sector’s biggest names.

At the company’s recent Realize Live event, which ran for three days in Amsterdam between 30 June and 2 July, over 1,800 attendees had the opportunity to watch presentations by representatives of Airbus, Unilever, GE Aerospace, Rolls-Royce and Scania, among others.

These are challenging times for such companies. Global trade turbulence triggered by the Trump administration’s sweeping programme of tariffs is focusing manufacturing-sector minds on where raw materials are sourced, how products are made, and where they are sold. Software from Siemens, in areas such as CAD, PLM and smart factory automation, plays an increasingly important role in how companies make such decisions – but the times are challenging for Siemens, too, as the volatile trading environment leads to extended sales cycles and delayed technology investment decisions among customers.

Still, Siemens Digital Industries Software has a strategy for weathering the storm, based on three pillars, and these were outlined at the event by chief revenue officer Robert Jones.

The first pillar, said Jones, focuses on providing “the world’s most comprehensive digital twin”, which delivers a complete virtual representation of products and processes.

The second pillar is one that Jones referred to as ‘Adaptive Operations’, and which aims to integrate the physical and digital in manufacturing, using softwaredefined automation and, in Jones’s words, “bringing the industrial edge into the software world.”

Finally, the third pillar is ‘Lifecycle Intelligence’, which involves leveraging data and AI within Teamcenter to create an “adaptable AI backbone” that delivers deeper insights throughout a product’s lifecycle. According to Jones, this vision is driving the company’s investment strategy, and ultimately, Siemens’ portfolio must deliver this breadth of functionality, with best-in-class applications delivered as an integrated solution on a ‘digital thread’ backbone. The company’s commitment here is evidenced by its acquisitions of Altair (simulation), Dotmatics (life sciences), Downstream Technologies (PCB verification) and Wevolver (supply chain resilience).

At Siemens Realize Live in Amsterdam, I got the distinct impression that the company’s decades-long programme of internal development, acquisitions and planning is starting to pay off for the company, giving it several advantages over competitors. In terms of digital thread technology, for example, Siemens now has a product suite in which constituent parts all speak the same design language. NX, which is managed through Teamcenter PLM from initial concept to analysis and fabrication, not only covers mechanical components but also software, electrical and even chip design. In other words, it spans the desktop and the cloud, individual work and team collaboration, and all areas up and down the supply chain.

That stands in contrast to Dassault Systèmes, which still has a disconnect between Solidworks Parasolid and Catia CGM. At Autodesk, it’s between Fusion and Inventor. At PTC, it’s between Onshape and Creo.

By contrast, Siemens executives were heavily selling the company’s new product engineering suite –Designcenter – which was launched earlier this year (www.tinyurl.com/designcenter-D3D) . This acts as a strategic umbrella for all the company’s product engineering solutions. NX, It has already consolidated NX and NX X under Designcenter, and will continue to add solutions under that brand, including a new cloudbased tool called NX X Essentials.

Siemens executives explained that Solid Edge is a key product within Designcenter, a lot of work has been dedicated to enabling the combination of NX and Solid Edge in design teams to work together as one.

The Solid Edge and NX product names will continue to be used, and the products won’t be rebranded or replaced. Instead, they will be integrated under the new Designcenter umbrella. As part of this there will be 4 NX X tiers: Essentials, Standard, Advanced, and Premium versions.

Solid Edge and NX previously functioned as technically different product stacks, but they both use the same Siemens tool components, including Parasolid, DQ and JT. It looks like Solid Edge in Designcenter will see changes over time to increase the interoperability and alignment with NX, in terms of data, user personas and the digital thread flow across the entire product stack. Minor changes have already been made to the Solid Edge UI, to align colours, look and feel. Parts and

‘‘ Long term, Solid Edge and NX will move to become a single tech stack that makes movement of data between the two toolsets seamless ’’

assemblies can be exchanged between NX and Solid Edge with no issues and, for Solid Edge customers, drawings can be moved from Solid Edge to NX using an interoperability manager.

The AI-enabled co-pilot technology, available in NX, is released as the same co-pilot in Solid Edge, sharing code and leveraging capabilities between the historical teams. In many ways, this is the same amazing engineering feat that Siemens pulled off developing both SDRC Ideas and Unigraphics to eventually become NX over many years. Unifying NX and Solid Edge is an easier prospect, as the products already share so many core software components.

Siemens’ Zel X product, a cloud-based 3D model viewing tool that supports 2D drawings, sketching, history-part based modelling and project sharing, has been rebranded NX X Essentials.

When it comes to the interplay between desktop and cloud environments, product updates are now applied to both NX and NX X. Siemens positions NX and NX X, which features cloud-based integrated product lifecycle management, as part of its broader Siemens Xcelerator portfolio. This indicates that while the core functionalities reside within the NX software, the strategic direction embraces and supports integrated cloud workflows through NX X. The 2025 release of Solid Edge last year also included the launch of Solid Edge X, which also provides cloud-workflows for that product.

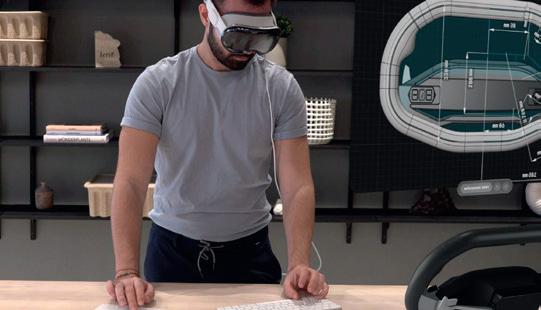

Recent updates to NX and NX X, which encompass advancements such as the AI-driven Design Copilot NX, immersive engineering capabilities including NX Immersive Designer and NX Immersive Collaborator, and enhanced Design for Manufacturing (DFM) tools like NX Inspector and DFM Advisor, are all delivered as part of this broader Designcenter suite.

Additionally, integrated designer-focused simulation tools, such as NX CFD Designer software, are also aligned with this consolidation. This framework signifies Siemens’ ongoing commitment to integrating and evolving its product engineering toolset.

For design for manufacturing (DFM), Siemens has introduced several enhancements such as NX Inspector, which is a new capability that extends model-based design (MBD) by adding model-based characteristics to a digital twin. This aims to streamline downstream quality and manufacturing processes based on industry standards.

The DFM Advisor automates early manufacturability assessments by analysing part geometry and identifying potential challenges across various manufacturing processes like drilling and milling, and providing actionable feedback. Furthermore, the NX Mold wizard has been enhanced with intelligent standard parts and improved cooling channel simulation tools.

Integrated designer-focused simulation tools are now available directly within the CAD workspace. NX CFD Designer software, powered by Simcenter FLOEFD technology, provides fluid flow and thermal simulation

‘‘ In uncertain times, investments in flexible engineering management tools have the potential to pay for themselves many times over ’’

capabilities. It is designed for ease of use, automating complex tasks like fluid volume detection.

The capabilities of Performance Predictor have also been extended to enable mechanical stress analyses across entire assemblies.

In uncertain times, investments in flexible engineering management tools have the potential to pay for themselves many times over. At Siemens Realize Live, there was lots of great tech on display.

NX goes from strength to strength. Siemens is succeeding in both acquiring and integrating a vast portfolio of products, getting them to work together and introducing to the mix advanced technologies such as AI, XR and simulation. So far, we are only just scratching the surface when it comes to understanding where all this is going.

Another product that caught my eye at Realize Live was Mendix, a low-code environment for developing new applications, acquired by Siemens in 2018. This enables users to quickly develop and deploy enterprisescale solutions via drag-and-drop components and the guidance of an AI co-pilot, meaning users don’t need

extensive software development skills and experience to build apps that solve internal workflow issues.

The digital thread strategy, meanwhile, is resulting in Siemens winning some big deals, according to company executives, as well as enabling it to become more deeply entrenched within existing customers. Bob Jones highlighted as examples recent successes at BYD, Volvo and Bombardier. For a company that has never really focused on marketing, Siemens is exceptionally confident of its products and its vision.

If I have one complaint, it’s that branding and naming conventions are too complicated. It’s just hard to keep up. But my overall impression is of a company that is evolving and reorganising itself – and doing so publicly and in front of a global audience. Clarity is still a little lacking. I’ve been told that there is significant consolidation still to come when it comes to groups and branding. We shall see.

View on-demand content from Siemens Realize Live here: https://events.sw.siemens.com/realizelive/europe/

Next year’s European event will run from 29 June to 1 July 2026. The US event will run earlier, between 1 and 4 June 2026.

Siemens Designcenter delivers CAD, CAE, and CAM capabilities to users looking to design, simulate and manufacture products via a single platform

Wandering around the Siemens Realize Live exhibition, I bumped into Ian Briggs of BAC (Briggs Automotive Company). He told me that a significant shift at BAC has seen the company move from Autodesk Fusion/ Inventor digital design tools set to software from Siemens Digital Industries Software, which it will use to develop its nextgeneration, single-seater, roadlegal supercar. More specifically, it has selected NX X CAD from Siemens’ Designcenter suite.

“The reason we chose Siemens’ Designcenter software to develop the next generation

of Mono is because it’s the best – and it gives us the tools we need to take our vision to the next level,” Briggs told me. Adopting Designcenter, he continued, will ensure compliance with global regulatory and safety standards: “Understanding the specific positional requirements for everything from headlights to driver sight lines is a complex minefield. Designcenter’s advantage lies in its ability to build that entire regulatory framework directly into our 3D CAD model, giving us new levels of confidence and a greater

speed of development.” Briggs added that BAC is also exploring how Siemens’ immersive XR engineering technology might be used to enhance the customer buying and customisation experience. This technology enables them to visualise and interact with bespoke vehicles, utilising real-world 3D CAD data in high-fidelity realism. In this way, customers can sit in a seat fitting jig and see all of the customisations they want around them, as if they were already implemented in their custom car. www.bac-mono.com

In the fast-moving world of modern work, time is precious, and every second lost is an opportunity missed. Whether it’s waiting for large project files to load, struggling with multiple applications slowing your system down, or dealing with clunky collaboration tools, these bottlenecks add up quickly. They disrupt the flow of ideas, delay important decisions, and make everyday tasks feel like a constant battle with technology.

But this doesn’t have to be the case. Lenovo mobile workstations are designed to break free from the constraints of traditional laptops. These latest devices, such as Lenovo’s newly launched ThinkPad P14s / P16s powered by AMD Ryzen™ processors, are built for professionals who need more than just a basic device. They’re tailored to handle the complex workflows that define modern work, where data, collaboration, and creative tasks often collide.

Let’s consider a common scenario: project managers juggling multiple applications— everything from Primavera P6 and SAP to Teams, emails, and spreadsheets. Each application demands memory, processing power, and attention. But what happens when your laptop can’t handle the load? It starts freezing, stalling, and you’re left waiting. ThinkPad P series are built to eliminate this problem. Equipped with high-speed memory, these workstations allow you to run multiple heavy applications at once, without the system crashing

or slowing down. Whether it’s tracking a project or responding to urgent emails, you’ll experience smooth multitasking with no interruptions. With Unified Memory Architecture, your machine intuitively allocates system resources to handle demanding tasks, so you don’t have to worry about your computer holding you back.

The Unified Memory Architecture also benefits professionals in with 3D rendering and visualization needs, where slow model edits or long render times can halt creativity. You need great graphics memory to tackle the demanding graphical tasks. The latest Lenovo mobile workstations ensure there is no more waiting for renders to finish or materials to load— just a continuous, uninterrupted workflow that lets you focus on the creative process.

In today’s remote-first world, collaboration is at the heart of almost every workflow. Yet, the challenges of managing team members across different locations, software tools, and time zones are significant. Whether you’re handling data analysis, designing 3D models, or simply working on a multimedia project, it’s easy to feel overwhelmed when your system struggles to keep up with multiple apps running simultaneously. The latest AI-powered mobile workstations from Lenovo, like ThinkPad P14s and P16s powered by AMD Ryzen™ processors, solve this by ensuring smooth multitasking and collaboration. Equipped with 50+ TOPS NPU for AI-driven performance, these workstations accelerate real-time

on-device AI tasks, from data processing to virtual meetings. This ensures smooth collaboration even when working with large, complex files. Whether it’s editing 4K video, reviewing models, or sharing your screen during a client presentation, these machines can handle the load without delays. You’ll experience better, faster teamwork, all while benefiting from real-time security and adaptive power management, keeping you productive on the go.

These workstations don’t just eliminate lag and delays; they transform your workflow into something fluid, something that feels natural. Collaboration tools are more intuitive, creative processes are less interrupted, and even data analysis is faster. It’s like having a team that anticipates your next move—empowering you to do more, faster, and with less frustration.

In the past, workstations were specialized tools used only by engineers, designers, or 3D professionals. But as the demands of work have shifted, the definition of what a power user needs have expanded. Today, professionals in data analysis, project management, and even content creation are faced with AI assisted workflows that require more than a typical laptop can provide. AI-powered workstations offer solutions to these challenges, delivering productivity and realtime processing that can handle even the most complex tasks.

Whether you’re tracking resources, analyzing data, or rendering designs, these workstations provide the power and flexibility you need to stay productive and efficient. No longer is it about whether you can get by with a laptop—it’s about whether your device can keep up with your growing workflow demands. As AI continues to reshape industries, those who are equipped with the right tools will stay ahead of the curve.

Is your current machine holding you back? Evaluate your device with the self-assessment tool to see if it meets today’s demands, or if an upgrade is needed for future workflows.

» We spoke with Brian Thompson, Division Vice President and General Manager for the CAD segment at PTC, about the company’s new Creo 12 release, its highlights, why its composites tools could lead the segment, and where AI fits into the equation

Q: Productivity is at the heart of this Creo 12 release, with greater integration between design, simulation and manufacturing. Are you seeing user roles expanding to cover more bases – designers doing more simulation, for example – or is it more a case of enabling entire teams to work in the same environment?

A: It’s an intersection of both points. What’s happening in industry right now is customers are looking at the flow of digital information from the very beginning of their development programmes, all the way out into manufacturing. And what they’re realising is that there are places along the way where manual steps or thirdparty technologies are not particularly well integrated with their digital thread.

What’s happening is those things are coming back into Creo. That’s the key trend. It’s different users: it’s manufacturing engineers; it’s people who do just the design work; it’s people who do design work and simulation; it’s people who do mould design. It’s different personas, but they’re all coming back into Creo for tasks related to product development.

I’ve had three customer visits just this week where we were talking about this. We’re seeing customers re-entrench into the product because they love how the product development dynamic changes when all of that is deeply integrated in Creo, and everything just stays up to date.

Q: Updates and new features for composites design and production are key aspects of the new release. Is this trend being driven by wider use of these materials across your users, or is it to fi t with PTC targeting specifi c sector growth?

We have some truly excellent relationships with some customers that do composite design, who have let us peek behind the curtain competitively to see what’s out there in the market. We felt like there were some serious gaps and when we got started with Creo 10, we weren’t 100% sure exactly how to solve those gaps, but we have kept at it to the point that we believe Creo 12 is now the most capable composite system in the world.

Users are now able to build structures in Creo with full fidelity composite layups – all the detail of how all the plies drop off – to that level of detail. You might be able to build it in other systems, but it would take you three, four, five times longer. It is that good and the underlying technology is unique to PTC.

We built unique geometric processing algorithms specific for composite parts that we have not seen anywhere. It creates a tremendous amount of leverage for us, from an associativity point of view and the way we connect the whole design from the lay up all the way out into the manufacturing domain. It’s a remarkable technological achievement!

● 3

● 4

Q: The partnership between PTC and Ansys for simulation continues in this release. Can you tell us more about how this collaboration benefits Creo 12 users?

Our initial foray into you