inDesigning the AI era

Design projects of any size with Archicad’s powerful built-in tools and user-friendly interface that make it the most efficient and intuitive BIM software on the market.

editorial

MANAGING EDITOR

GREG CORKE greg@x3dmedia.com

CONSULTING EDITOR

MARTYN DAY martyn@x3dmedia.com

CONSULTING EDITOR

STEPHEN HOLMES stephen@x3dmedia.com

advertising

GROUP MEDIA DIRECTOR

TONY BAKSH tony@x3dmedia.com

ADVERTISING MANAGER

STEVE KING steve@x3dmedia.com

U.S. SALES & MARKETING DIRECTOR

DENISE GREAVES denise@x3dmedia.com

subscriptions MANAGER

ALAN CLEVELAND alan@x3dmedia.com

accounts

CHARLOTTE TAIBI charlotte@x3dmedia.com

FINANCIAL CONTROLLER

SAMANTHA TODESCATO-RUTLAND sam@chalfen.com

AEC Magazine is available FREE to qualifying individuals. To ensure you receive your regular copy please register online at www.aecmag.com about

AEC Magazine is published bi-monthly by X3DMedia Ltd 19 Leyden Street London, E1 7LE UK

T. +44 (0)20 3355 7310

F. +44 (0)20 3355 7319 © 2026 X3DMedia Ltd

Revizto targets infrastructure, D5 builds visualisation pipeline, Procore acquires Datagrid for agentic AI, plus lots more

SketchUp AI to simplify modelling and viz, AI MEP startup secures $20m, CMap intelligence launches, plus lots more

While generative AI can fabricate compelling but hollow design work, it risks eroding professional trust and the value of authentic architectural expertise

AI is transforming how design ideas emerge, but architects remain responsible for shaping, refining, and realising concepts in the real world

We asked Autodesk’s Amy Bunszel what she expects to see from AI in 2026

Fabrication-ready design system KREODx aims to rebuild the link between design, fabrication and commercial reality

With no-code workflows and streamlined data pipelines, Unity aims to simplify how firms build interactive 3D experiences

Transcend and STV are bringing new levels of automation to early-phase civil engineering design

AI-enabled technology could be the best chance for water management teams to rise to the monumental challenge of addressing water leaks head-on

With CAD files taking minutes to open and sync delays preventing real-time collaboration, Widseth needed storage infrastructure that could support distributed teams without compromise

Register your details to ensure you get

register.aecmag.com

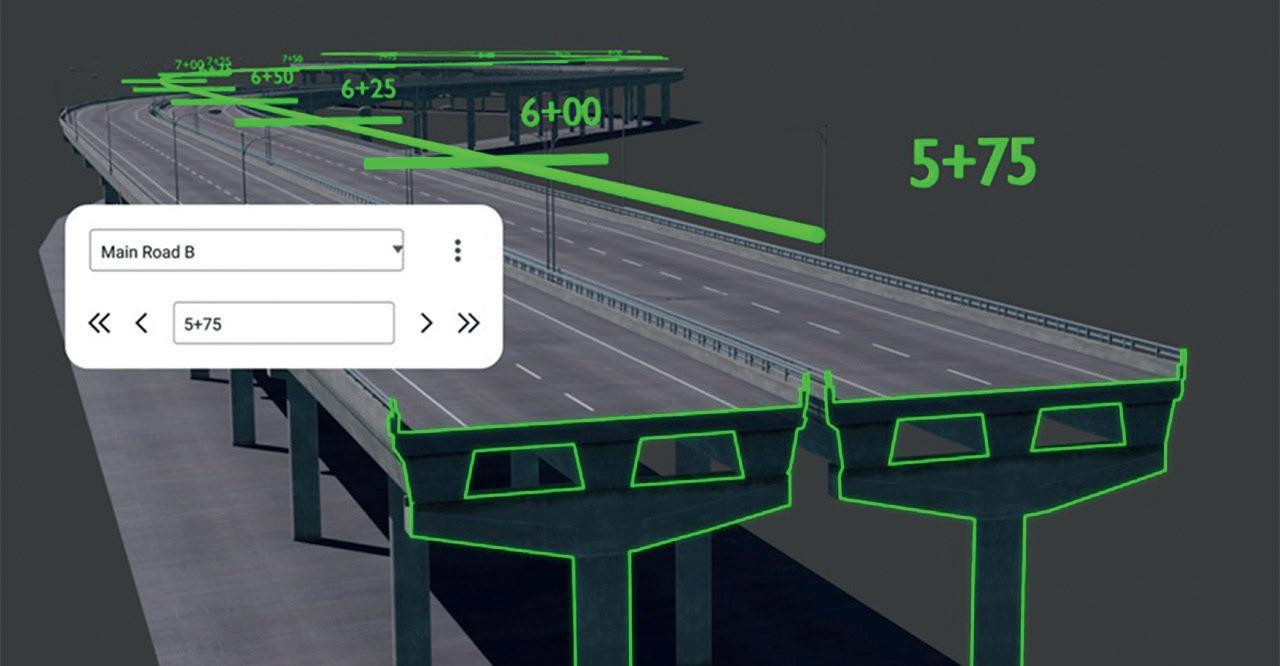

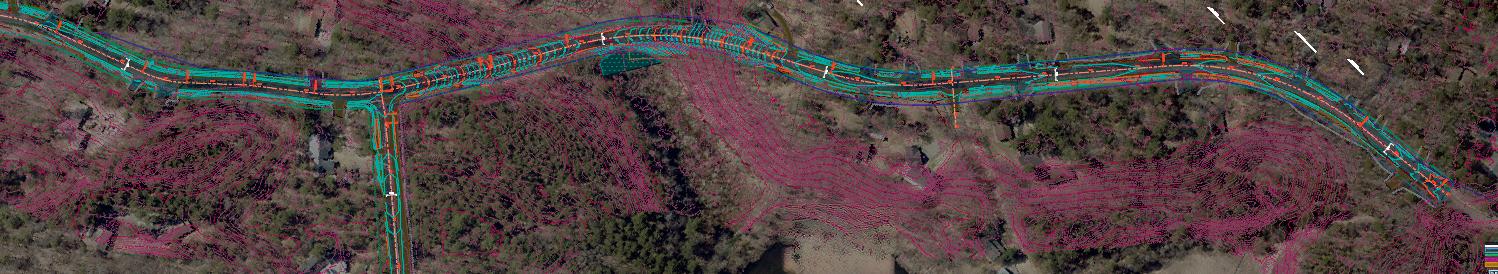

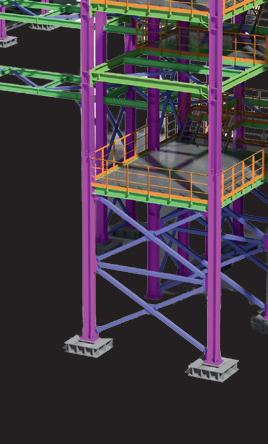

BIM collaboration software platform Revizto has introduced a new solution for the design, delivery, and ongoing maintenance of complex linear infrastructure projects such as highways, railways, tunnels, power lines, and energy networks.

Revizto for Infrastructure unites stakeholders in a single shared 2D/3D environment, giving teams a real-time, location-based view of progress from design to delivery and beyond.

It introduces a new capability called Linear Navigation, which is designed to

enable teams to coordinate across miles of terrain. It allows users to import alignments and chainage directly into Revizto, explore long corridors, and manage issues by precise location.

“Revizto for Infrastructure is the next step in our mission to simplify complexity across the AECO industry,” said Arman Gukasyan, founder and CEO of Revizto.

“By combining everything teams already trust in Revizto with new tools made specifically for large-scale, linear projects, we’re giving them the ability to plan, build, and maintain critical assets efficiently.”

■ www.revizto.com

Construction management software company

Procore has acquired Datagrid, a vertical AI platform focused on data connectivity and autonomous workflow execution. The deal positions Procore to move beyond embedded “assistive AI” features and toward something closer to an agentic, cross-platform intelligence layer for construction.

Datagrid is not a generative chatbot in the conventional sense. Its core value lies in connecting fragmented data sources, such as ERP systems, cloud storage, document repositories, project platforms and applying AI reasoning to orchestrate actions across them.

In practical terms, this means automating multi-step processes such as submittal reviews, RFI drafting, document

classification and cross-system search, rather than simply summarising text or answering questions.

Procore says the acquisition will accelerate its ability to “eliminate data silos” and automate complex workflows, a familiar ambition in an industry still dominated by point solutions and disconnected platforms.

More notably, Datagrid’s technology is designed to work across third-party systems, not just within a single vendor stack. That matters in construction, where most firms operate a patchwork of tools alongside their primary project platform. This could give Procore an edge in the industry, as there are not that many credible, vendor-agnostic data connectivity and reasoning layers.

■ www.procore.com

Hexagon has united its Voyansi, LocLab, Construction Analysis (formerly Avvir), and Multivista offerings under a single AECO-focused brand: Hexagon Multivista.

The company says the move brings together its capture, modelling and construction analysis capabilities, covering workflows from jobsite reality capture through to digital modelling and analysis.

According to Hexagon, the consolidation is intended to simplify vendor management and support better coordination between teams by reducing the number of separate tools and platforms used across a project, and provide data and insights across every stage of the project lifecycle.

Voyansi provides BIM solutions, Loclab is a digital twin specialist, Construction Analysis is a BIM-focused reality analysis platform, while Multivista focuses on construction photo and video documentation.

■ www.multivistaservices.hexagon.com

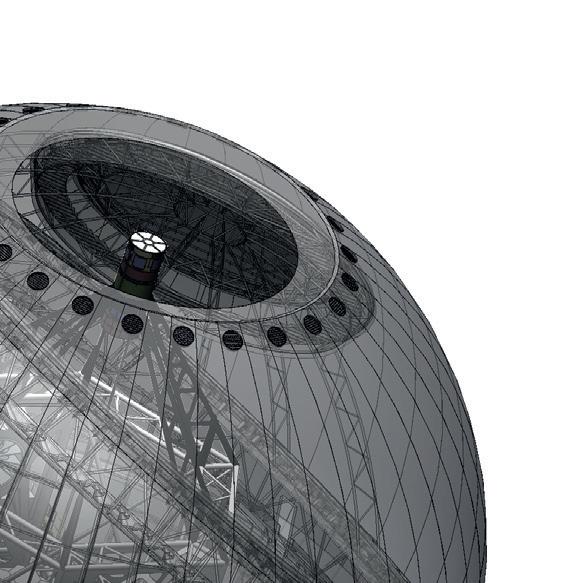

Autodesk has announced a new partnership with the Cleveland Browns, under which Autodesk Construction Cloud (ACC) will be used to support the build of the NFL team’s new 75,000 capacity Huntington Bank Field stadium, due to open in 2029.

ACC, now part of Autodesk Forma, will connect project teams through a unified model, to support informed decisionmaking, early issue detection, and streamlined coordination.

■ www.autodesk.com/construction

KREODx makes design executable. KREODx AI eliminates manual take-offs, specifications and cost estimation — by deriving them directly from design.

Construction doesn’t fail because of design. It fails because information is:

• Fragmented

• Manual

• Unverifiable

KREODx replaces drawings and disconnected BIM with executable, system-based DfMA:

• Geometry resolved once,

• Engineering logic embedded

• Manufacturing constraints validated

• Executable, system-based DfMA

• Manufacturing-ready assemblies

• Rule-driven engineering logic

• Digital material passports

• Design-derived BoMs & BoQs

• Live design-driven cost certainty

• Quotation-ready outputs

• Design-to-manufacture validation

A new study by researchers at Hosei University in Japan examines the long-standing separation of BIM models and maintenance information for bridges. The work reveals a novel integrated data model combining the international standards IFC and CityGML

■ www.hosei.ac.jp

Qonic, the cloud-based BIM platform, now allows users to import BCF files directly through the Issues panel. According to the company, this makes it easier to sync feedback from external checking tools and keeps all coordination notes in one place

■ www.qonic.com

Hexagon has launched GeoMonitoring, a web-based safety monitoring platform for geotechnical engineers. Its visualisation and analysis tools provide insights to support early intervention on landslides and ground deformation that can cause damage to urban areas and infrastructure

■ www.hexagon.com

Markup and collaboration specialist Bluebeam has introduced Task Link, a new feature designed to connect project tasks to drawings. The ‘unified field–office’ workflow is the result of bringing Bluebeam and GoCanvas together in 2024

■ www.bluebeam.com

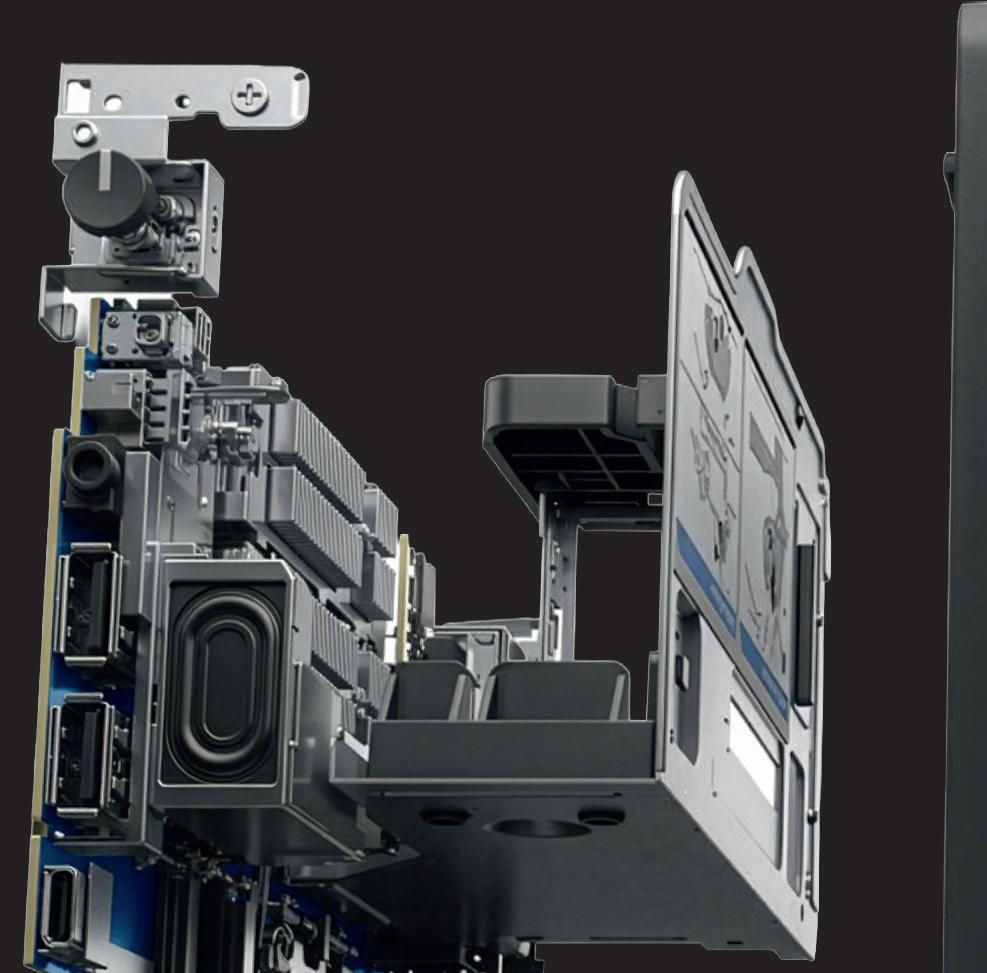

Following a backlash from partners and customers Dell is to revive its long-standing Precision workstation brand just 12 months after retiring it in favour of Dell Pro Max. We expect to see new Dell Pro Precision workstations launch later this year ■ www.dell.com

Bentley Systems has made moves to boost its capabilities in asset analytics. It has acquired Talon Aerolytics, a provider of solutions for site surveys, inspections, and asset digitisation for utilities, and technology from Pointivo, a company that spans drone data processing, AI-powered damage detection, and geolocation

■ www.bentley.com

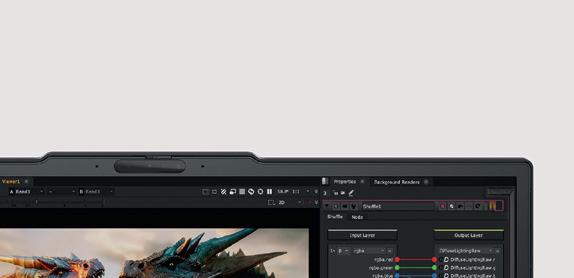

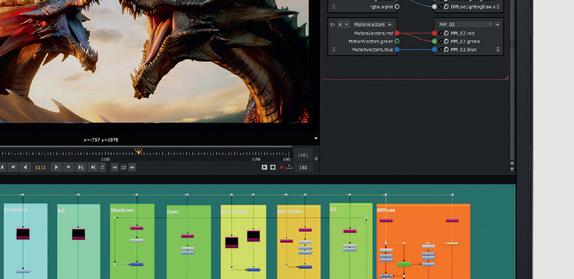

or its latest release, D5 Render has unveiled a new “AI-driven workflow” for its visualisation software built around three interconnected components.

Alongside D5 Render 3.0, the latest evolution of its real-time rendering engine, D5 has introduced D5 Lite, which brings AI-native real-time visualisation directly into early-stage design tools such as SketchUp, and D5 Works, a curated asset platform purpose-built for architecture, landscape, and interior design.

According to the company, these components are designed to bridge the gap between conceptualisation and design development and form a continuous loop rather than a linear sequence.

The workflow begins with D5 Lite, which is embedded within modelling tools such as SketchUp to allow users to visualise as they design.

D5 Lite is powered by the core D5 Engine but is described as the fusion of generative AI and real-time path tracing. It allows designers to quickly move from raw geometry to real-time visual feedback, by allowing AI to translate high-level intent, such as mood, lighting direction, or time of day. According to D5 this allows designers to iterate freely, test alternatives, and align internally without committing to production-grade detail. When visual accuracy and presentation quality become critical, the workflow transitions into D5 Render proper with a ‘seamless sync’ from D5 Lite. All earlier decisions — materials, lighting, assets, and atmosphere — are brought through. In this final phase, D5 explains that AI shifts into a supporting role, assisting with tedious tasks - refinement, material behaviour, lighting accuracy, and visual consistency. ■ www.d5render.com

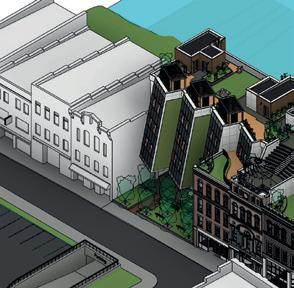

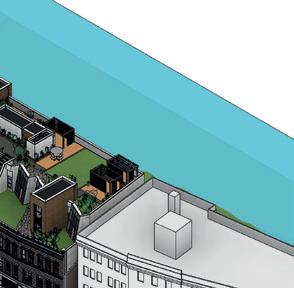

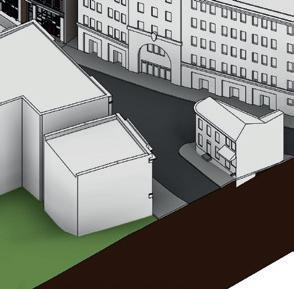

ityweft has integrated a new LiDAR-based building heights dataset for England into its web-based platform to help architects and planners bring spatial context into CAD/BIM software

The dataset is derived from highprecision LiDAR data collected by the Department for Environment, Food & Rural Affairs (DEFRA) from 2022 to 2025. Models can be exported via the Cityweft web platform, using the Rhino and other CAD plug-ins, or data can be

accessed through the Cityweft API. Models can be used for early-stage massing and feasibility studies, planning and presentations and competition visuals with realistic site context.

According to Cityweft, having accurate building heights enables more realistic city massing for planning and concept work, better environmental analysis for shadow, solar access, and visibility studies and enhanced building volume and form for data-driven workflows.

■ www.cityweft.com

Endra, a startup that uses AI to automate MEP design, has secured $20 million in funding. The Swedish firm claims its software can reduce the time needed to design a codecompliant electrical system for a 500,000-sq-ft commercial building from two months to less than a day ■ www.endra.ai

Acca Software has launched usBIM. codesign AI, a generative AI tool that lets designers upload a sketch, 3D model or photo, define style, lighting characteristics and finishes, and generate 3D architectural concepts and renderings in seconds ■ www.accasoftware.com

SketchPro is working on Revit, SketchUp, Vectorworks, and Rhino plug-ins for its generative AI tool that can create ‘instant’ renders from a sketch, elevation, 3D model, or image, visualise designs by uploading style references, and add objects to the scene with a click of a button ■ www.sketchpro.ai

CODiii is a new AI-backed tool that helps teams catch compliance issues throughout a building project lifecycle. The system connects all project requirements in one place (i.e. building codes, standards, specifications, client needs and more) and compares them against one another ■ www.codiii.com

Alice Technologies has launched Insights Agent, a new feature that adds conversational AI to its generative scheduling platform to make it easier for users to interrogate schedules, understand differences between plans, and uncover optimisation opportunities ■ www.alicetechnologies.com

our new AI hub

■ www.aecmag.com/ai

Trimble has introduced SketchUp AI, a suite of AI tools designed to help simplify modelling, visualisation and learning in SketchUp.

Features include AI rendering, 3D geometry creation, and a Help chat where users can ask specific questions about their workflow, modelling needs, or the SketchUp ecosystem.

SketchUp AI, initially available as a monthly subscription, includes AI Render and AI Assistant. AI Render, formerly SketchUp Diffusion, is Trimble SketchUp’s generative AI image creation tool designed to accelerate visualisation. Previously in the SketchUp Labs beta testing program, AI Render includes a redesigned interface and enhanced controls, such as Reference Images, Inpainting, and Negative Prompts.

With AI Render, designers can combine their SketchUp model with a text prompt and/or predefined styles to create images ‘in seconds’, from early concept iterations and inspiration to ‘realistic client deliverables’. Users can also refine generated images, such as altering colours and materials, or adding entourage.

Meanwhile, AI Assistant is an AI-powered SketchUp chatbot and 3D modelling partner. With Generate Object, an AI Assistant capability, users can turn an image or text prompt into 3D objects in seconds, directly within SketchUp.

Users simply upload an image or describe what they want to create, and AI Assistant generates the 3D object. It can be used as an alternative to 3D Warehouse, or to bypass the need to model from scratch.

■ www.sketchup.com

Map has introduced CMap intelligence, which includes a suite of ‘intelligence agents’ aligned to the core functions of professional services firms, including sales, delivery, operations, finance, and administration.

According to the company, CMap intelligence is not about adding another standalone AI tool, nor about forcing teams to work differently. Instead, as CMap explains, it embeds intelligence directly into established CMap processes that AEC and other firms already rely on, helping teams focus on where AI

genuinely supports better planning, delivery, and decision-making. CMap intelligence includes multiple agents. The Operations Agent, for example, is designed to surface real-time operational insight inside established workflows for managing capacity, resourcing, and delivery.

Meanwhile, for firms that have begun their AI journey, CMap is using Model Context Protocol (MCP) to allow CMap and other third-party systems, to be securely connected to an in-house LLM, enabling “rich, cross-platform” insights.

■ www.cmap.io/cmap-intelligence

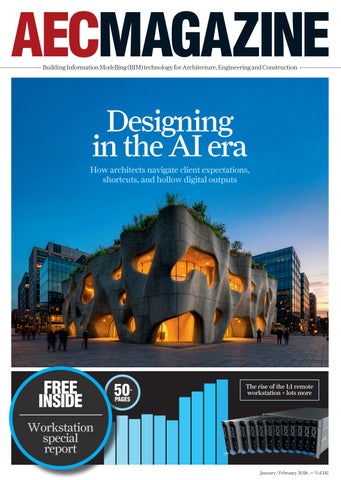

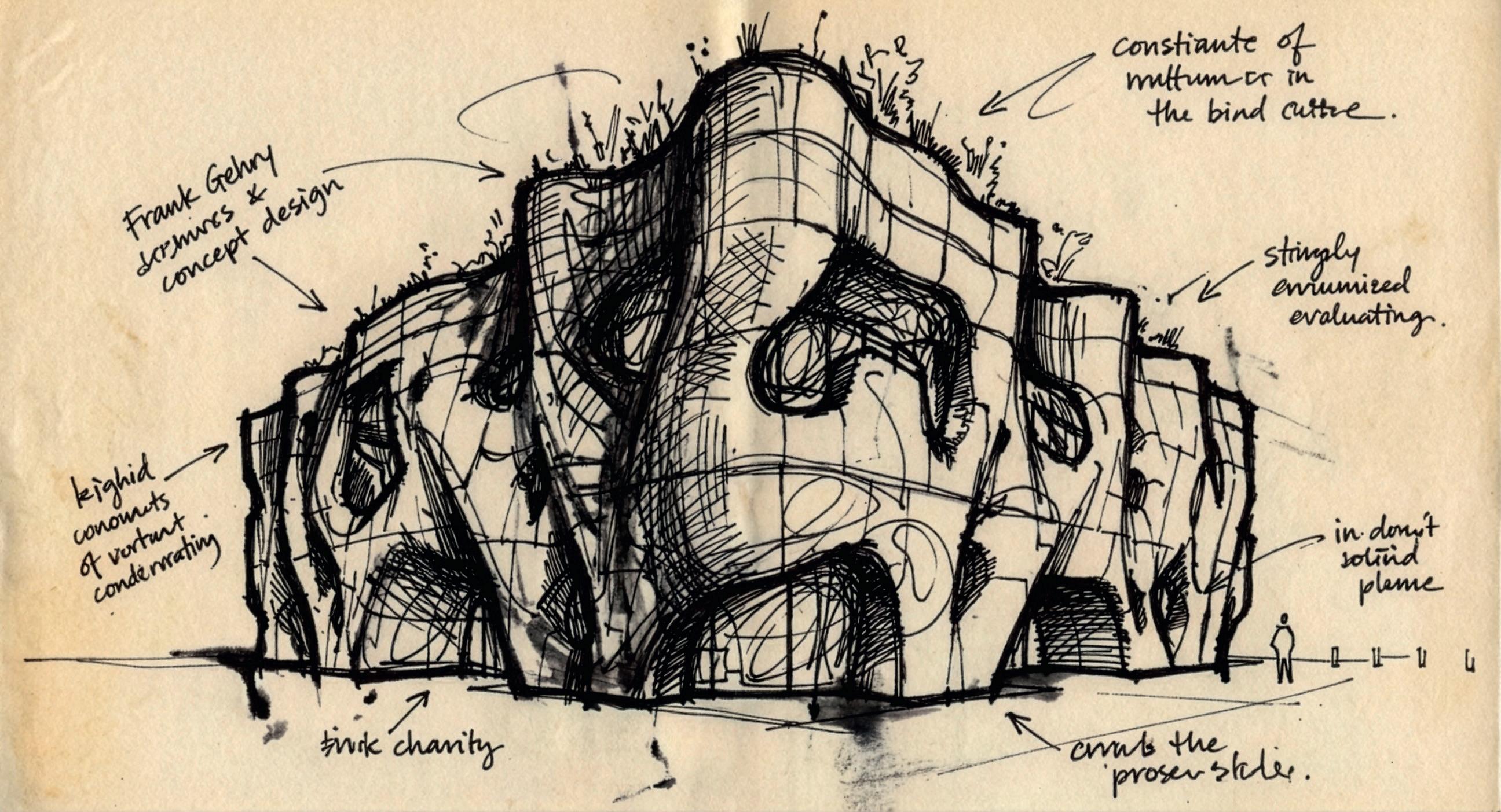

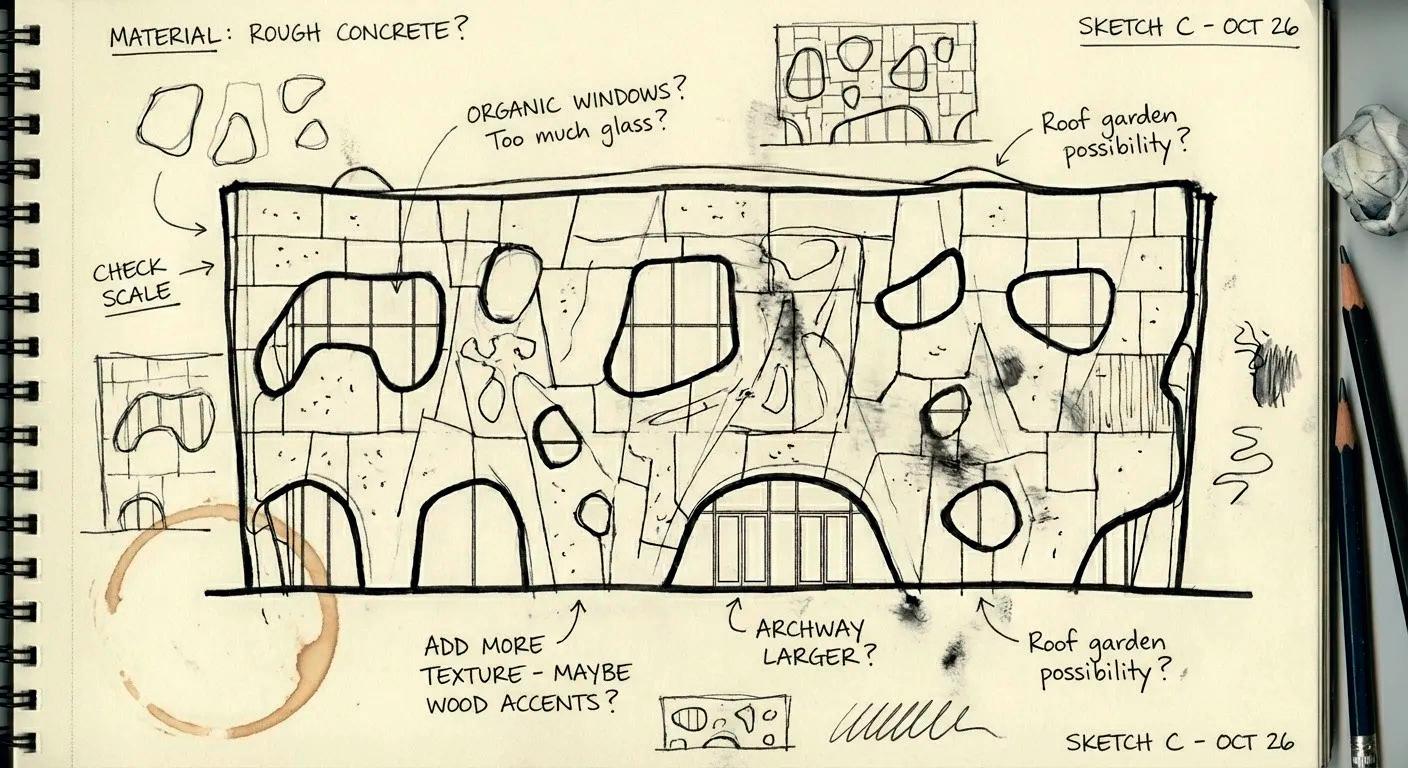

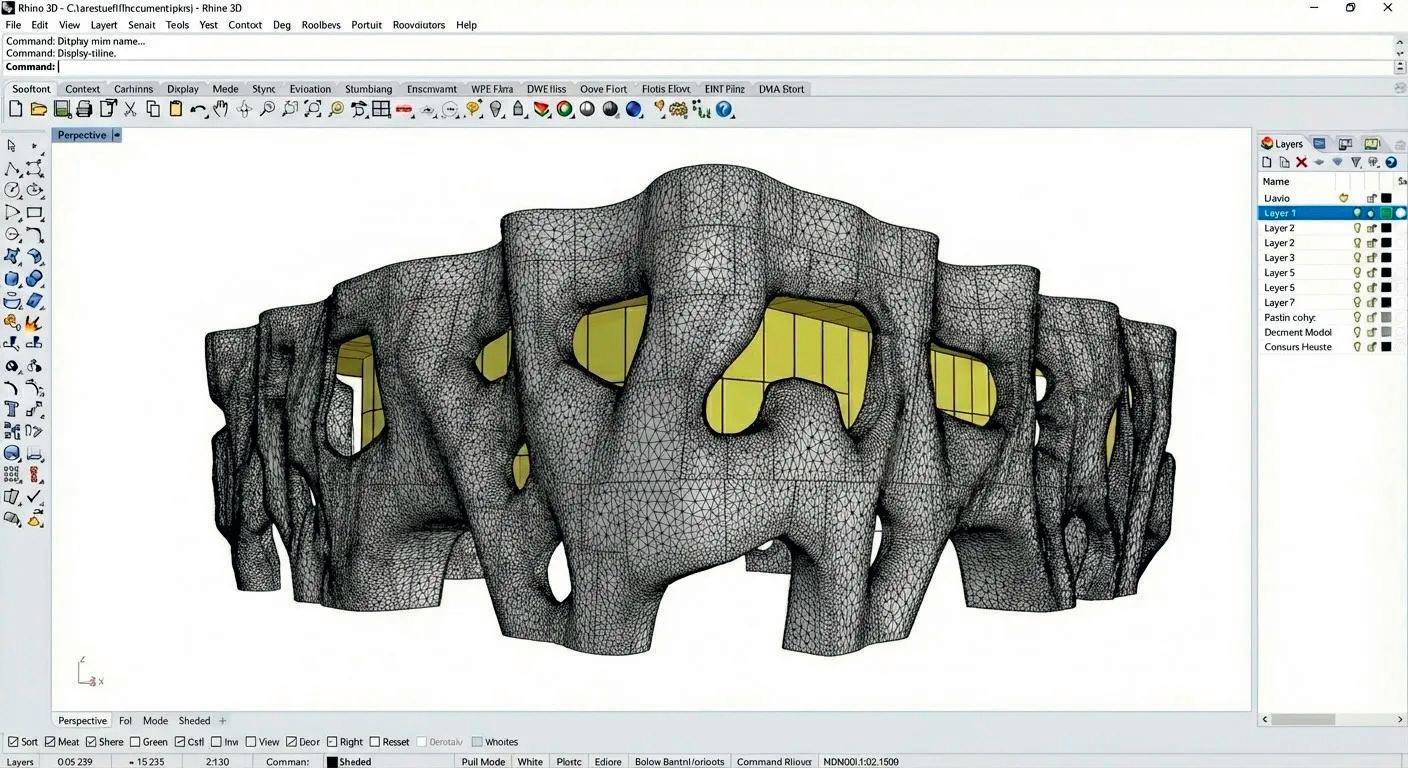

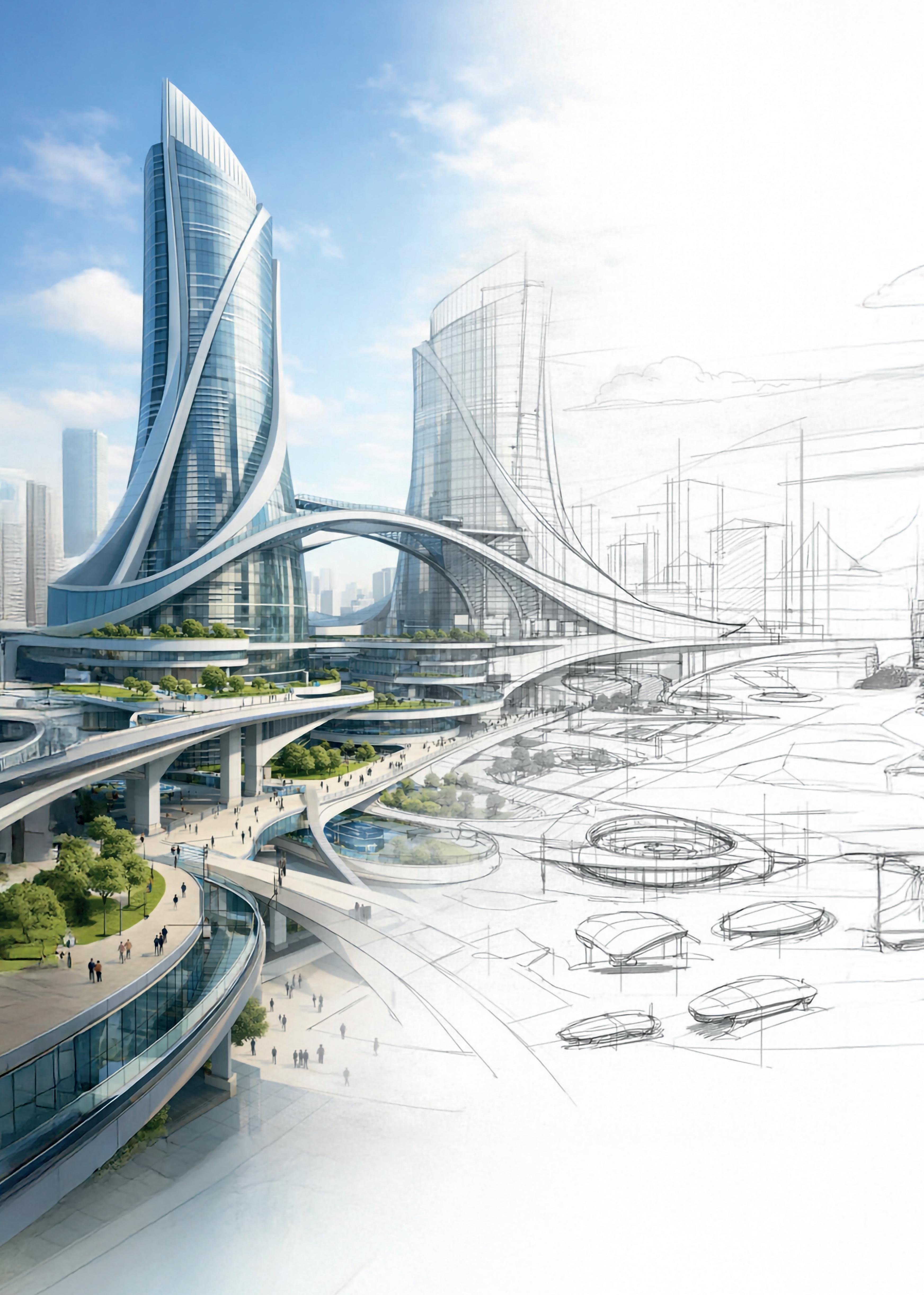

While generative AI can fabricate compelling but hollow design work, it comes with the risk of eroding professional trust and the value of authentic architectural expertise, writes Nathan Miller of Proving Ground

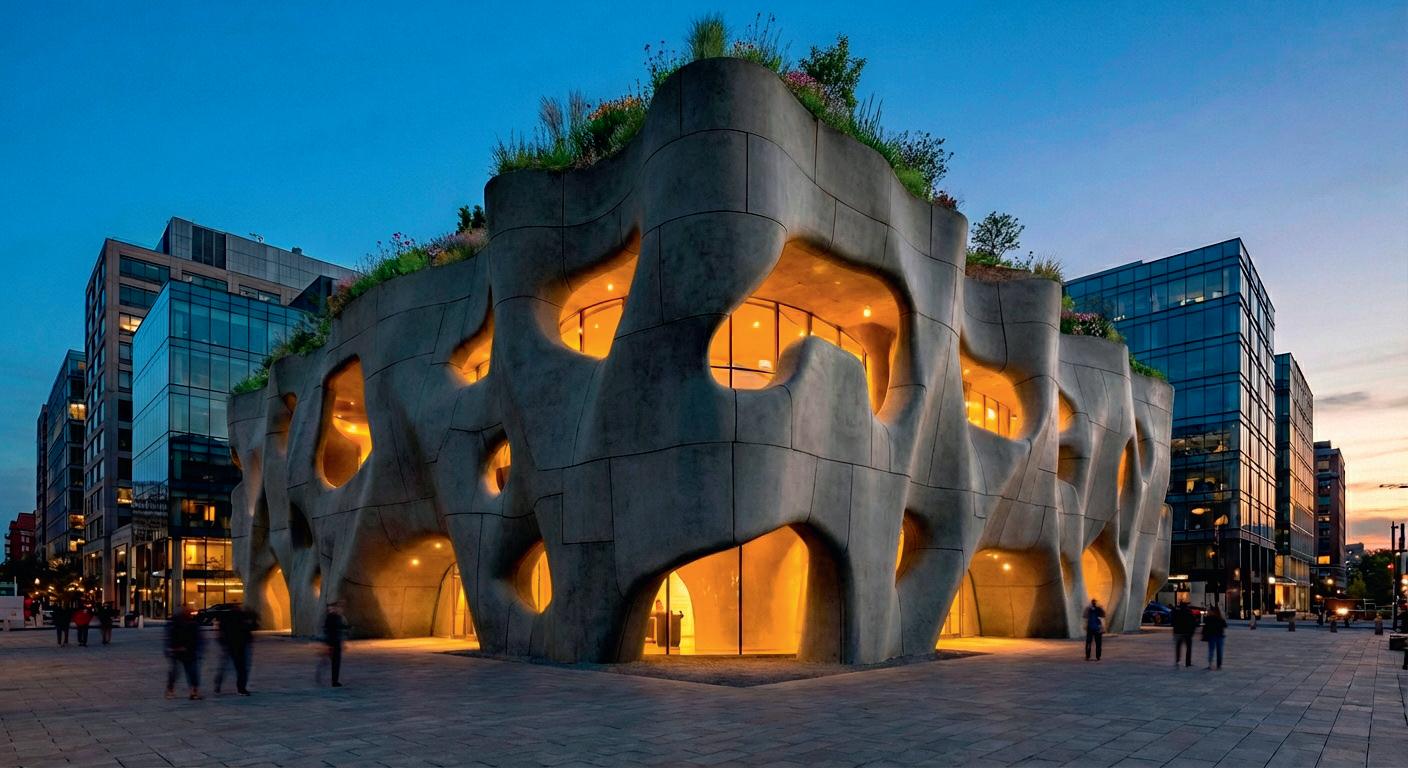

Anew museum foundation recently released a public request for proposals to a selected group of designers. The brief called for progressive, sustainable architecture and novel gallery experiences for their future visitors. The selected designer should not only demonstrate a unique aesthetic sensibility, but also a mastery of modern digital tools to help achieve efficient project delivery and sustainable design objectives.

consultations with some of the most creative teams in the industry.

Dusting off my design skills…

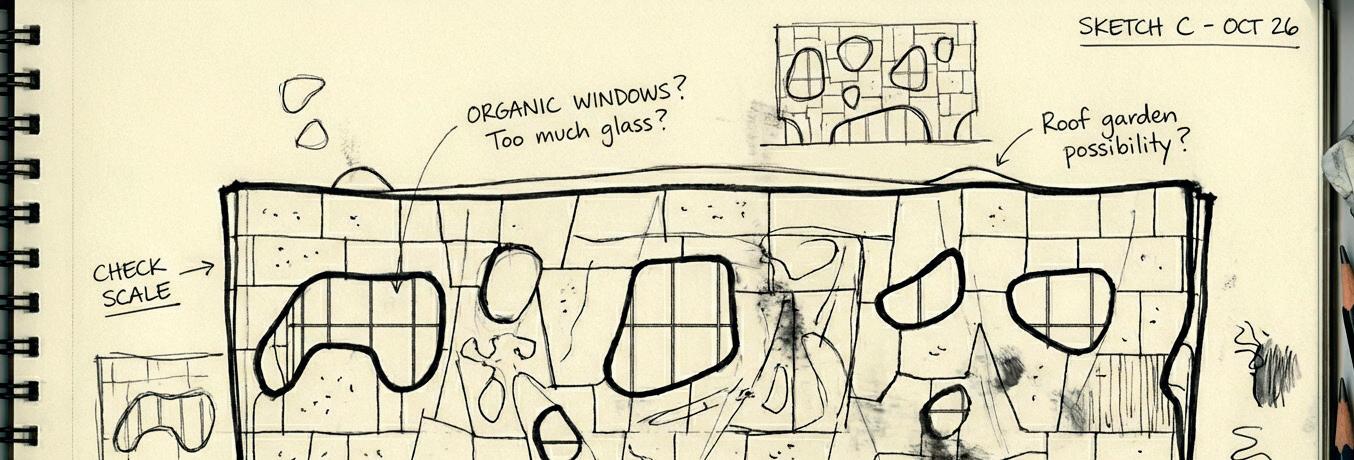

I began the design process the conventional way: I sketched! Drawing on my consulting experiences on museums like the Gilder Center and the Lucas Museum

‘‘

garden roof provides the city with a new amenity for gatherings and respite.

My ‘museum’ is not a design study: it is an attempt to see how far I could get by applying AI to fabricate something that looked like a design study ’’

As a consultant, I haven’t been in the design driver’s seat for over 13 years. As many of you may know, I took on a career path in technology consulting. Nevertheless, I have been feeling nostalgic for my time as a designer. With this new competition, I could apply the wealth of digital skills that I have acquired through years of project

(www.tinyurl.com/GilderLucas) I drew up an organic exterior geometry with large archway openings inviting the urban context into the main space. The facade creates a hard, porous shell so visitors can have access to daylight and framed views of the city as they tour the gallery spaces. To top it off – literally – a green

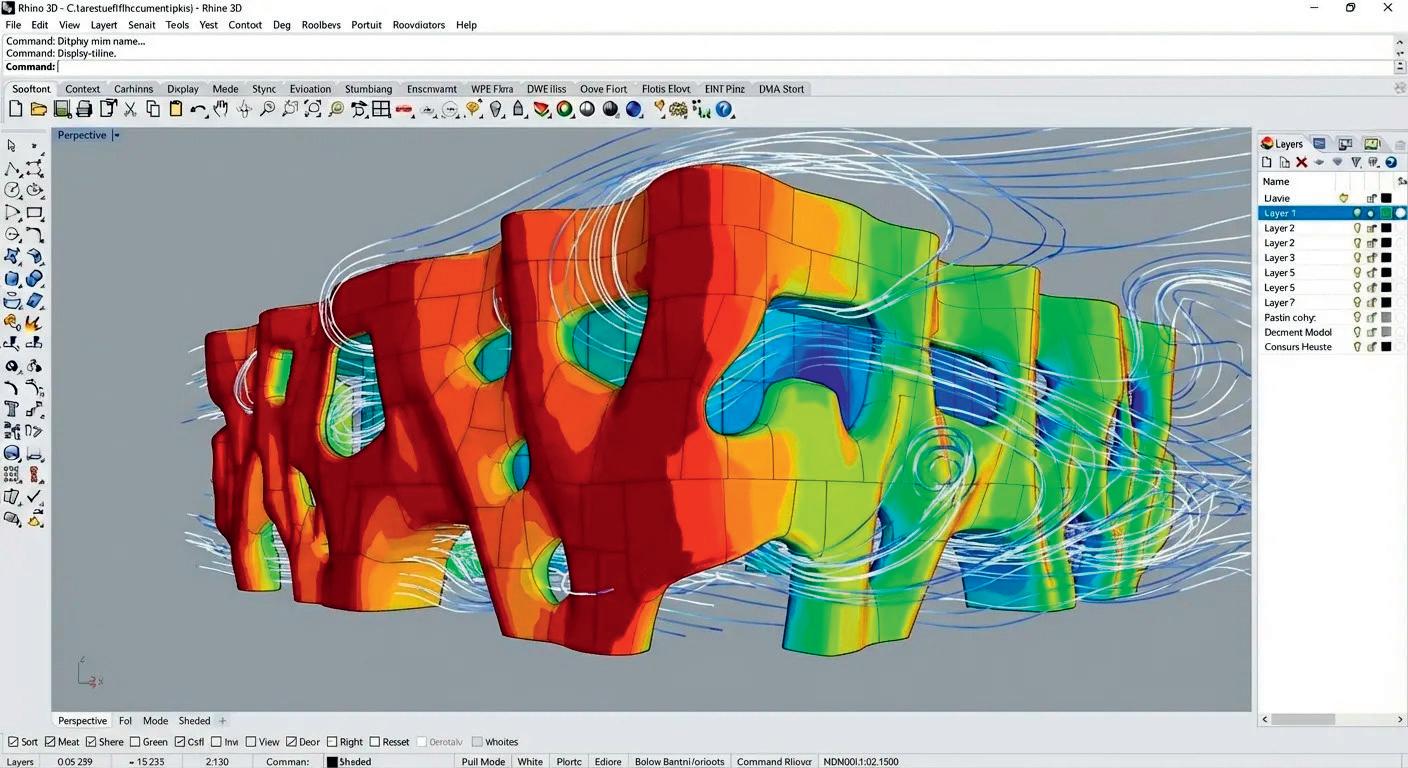

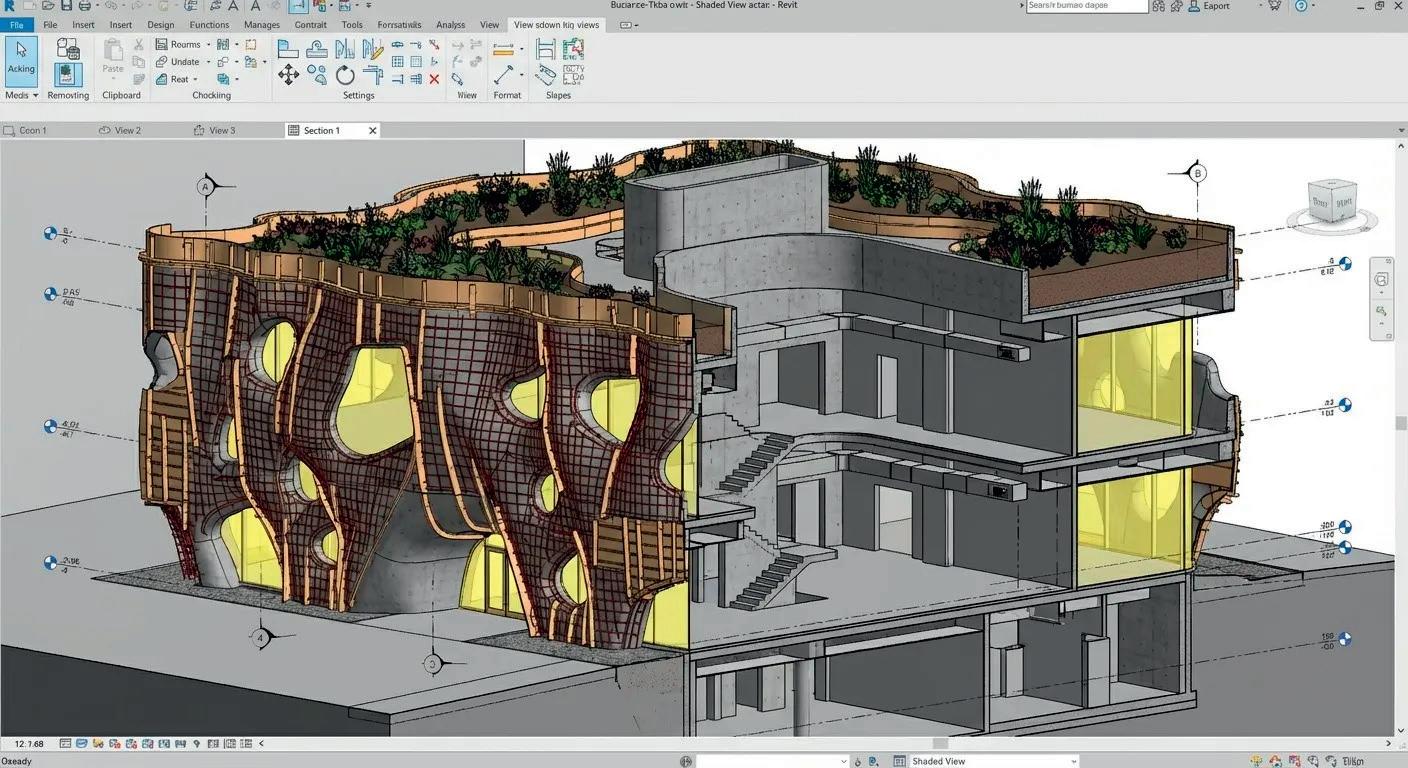

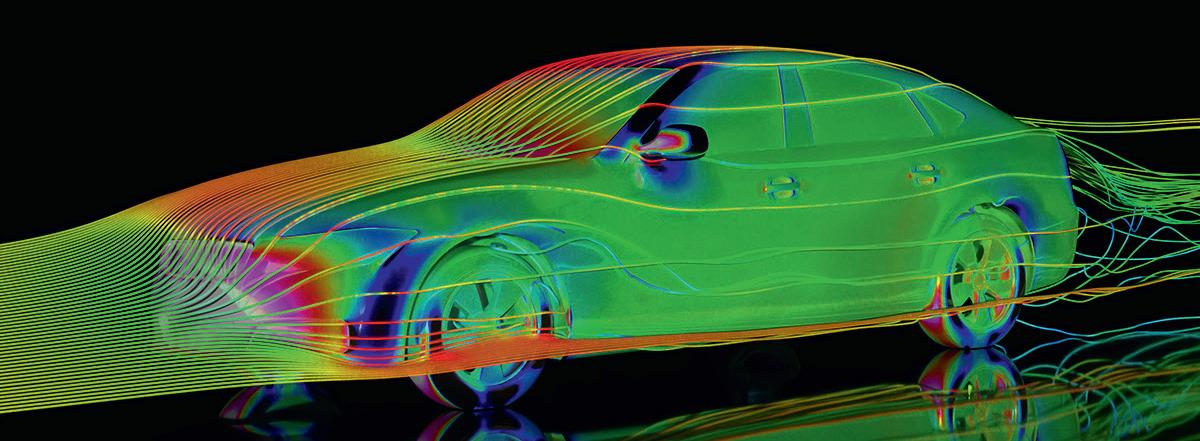

To develop the project, I used all of the technology skills I have mastered over my career: Rhino and computational skills helped me build a powerful control system for the exterior mesh geometry. Analysis tools like Ladybug and OpenFoam helped me use data to optimise the project concept for environmental conditions such as wind and solar conditions. And, of course, Revit was used to develop an integrated BIM with supporting documentation.

The AI facade

Sadly, none of this was true. The ‘visionary’ design sketches? The product of generative AI prompts. The ‘hero’ rendering showing the museum at dusk? AI. The screenshots of a coordinated Revit model

with BIM components? AI. The computational Rhino meshes? AI. Solar analysis? AI. Wind CFD study? AI. Elevations? Plans? AI all the way down.

Every 3D image, rendering, sketch, analysis, and documentation for this project is a fabrication: they do not correspond to any authentic digital asset or dataset expected from a professional architect.

On closer inspection, the images are rife with errors and are very uncoordinated. Zooming in and the images reveal dimensions that don’t add up, design features that are unaligned, and vast amounts of gibberish text. (Note: I’m sure these goal posts will continue to move…) Most importantly, they are certainly not representative of any earned professional knowledge or skill that would allow me to cultivate trust with a future client.

However, these AI bloopers are likely not readily apparent when scrolling past them on LinkedIn (www.tinyurl.com/ AI-bloopers) or when performing a review of a PDF portfolio submittal. Unassuming viewers might think they are looking at products of design work that took weeks of rigorous study and were created by a technically savvy expert. Instead they are the artifacts of an artificial process directed by simple prompts and vibes.

Don’t slip on a (nano) banana peel… In total, it took me less than 10 minutes to create all of my ‘project’ images using Nano Banana – a Gemini AI image generator. Thanks to advancements in their reasoning models, the latest releases of these tools by Google boast new capabilities to generate sequences of images that have a degree of continuity and consistency with each other.

Not only can Gemini generate a single image from a prompt, it can take instructions to “show me a 2D plan based on this 3D image” or “render corresponding aerial view.” If you want your image to look like it came from specific software, like Rhino or Revit, Nano Banana will produce images with a UI backdrop and viewport style consistent with that software. If you want to make it appear as if you performed rigorous simulation and analysis, AI also has you covered. My ‘museum’ is not a design study: it is an attempt to see how far I could get by applying AI to fabricate something that looked like a design study.

As we close out the year 2025, the needle continues to move with regards to AI’s influence over the architectural design process (and many other facets of the industry… and the world at large). A popular fear has been the outright replacement of humans in various sectors

‘‘

AI

has the potential to erode trust in professional capability through the proliferation of content that appears comparable but is ultimately hollow in authenticity,

void of exacting rigour, and empty of critical thought ’’

of the marketplace. This, however, seems a gross overestimation given what I have experienced to be serious limits in generative outputs. I remain convinced that AI will never be in a position to truly replace the creative ingenuity or technical prowess of a design professional.

However, I have become more concerned by a different kind of existential threat: the race for speed, efficiency, and ease promised by AI is in danger of giving way to a race to the bottom dominated by shortcuts, fakery, and a general devaluation of the discipline of design. AI has the potential to erode trust in professional capability through the proliferation of content that appears comparable but is ultimately hollow in authenticity, void of exacting rigour, and empty of critical thought.

In another recent article (www.tinyurl. com/ArchitectEthics), I outlined concepts and tactics where AI is confronting the ethics of architecture professionals. Standards of competence, trust-based relationships with clients, and environmental responsibility are all impacted by these new technologies. Even as AI tools become more widely used, the responsibility for their output falls on the user to ensure that professional obligations are being met. (The tech companies authoring these tools are certainly are not keen to take on liability in their licence agreements.)

All of this is to say: It is incumbent on professionals to educate themselves on these tools, not only for adoption, but as a way to reaffirm the value of human skills, thinking, discipline, ingenuity, and the earned knowledge of a designer.

You may not find yourself being replaced, but you might soon find your credibility being called into question.

Nate Miller is the founder and CEO of Proving Ground, a digital design agency that enables digital transformation with creative data-driven solutions to the building industry.

■ www.provingground.io

AI is transforming how design ideas emerge, but architects remain responsible for shaping, refining, and realising concepts in the real world, writes Roderick Bates, senior director product operations, Chaos

Like all trades, architecture is an industry that is shaped by its tools. The tools intrinsic to a given trade assert a strong push and pull relationship with craft and outcome, and architectural design is no different. From the drafting table to the rise of CAD and the adoption of powerful tools like BIM and real-time visualisation, each shift changes the process of generating, testing, and communicating design concepts, geometry, and ideas. AI is the latest tool asserting influence on the practice of architecture, and it’s already having an impact that exceeds many of the tools that came before it.

Today, thanks to the wide availability of image-generation tools powered by AI, clients can walk into a studio with a clear visual concept of their dream building. Gone are the days of tentative sketches and back and forth discussions about details they are envisioning. Instead, a client, absent of any expertise, can turn a loosely formed idea into a realistic picture almost instantly.

project. After all, the value of design, and of the architect who created it, has never been merely in the creation of images, but in the judgment required to define their meaning and assess their relevance to the project at hand, all in service of delivering a building.

A new beginning, not a finished idea

Where clients once relied on descriptions and rough sketches to convey an idea or ask, they can now present architects with AI-generated imagery that represents their

Where clients once relied on descriptions and rough sketches to convey an idea or ask, they can now present architects with AI-generated imagery that represents their vision, even when the images are entirely unbuildable

While this shift fundamentally changes the starting point for both the design and the architect client relationship, it doesn’t change the goal of an architecture

vision, even when the images are entirely unbuildable. What these client generated visual artifacts do is surface the client project goals and ambitions early, clarifying preferences, and serving as mediating artifacts for conversations about form, mood, and intent. While they serve many functions, what they clearly are not are designs that can actually be built.

Common AI models don’t understand the contextual nuances needed for functional design. They cannot weigh cost

against longevity, aesthetics against responsibility, or understand the nuanced physics of material weathering, water infiltration, and thermal performance. AI-generated imagery is a tool for exploring possibilities, but it fundamentally lacks the judgement necessary for determining the viability. Fortunately, the early design phase has always been about exploring options, but it is also about knowing which paths not to take, focusing the design enough to support the process of refinement in subsequent phases. That responsibility still sits firmly with the architect.

with the architect.

Authorship as responsibility AI makes the question of authorship inevitable. If a client arrives with an image at the start of the project, who is the intellectual and architectural author of the finished building?

lating the design into a documentation

Architectural authorship is more than just who came up with the idea, it’s fundamentally about accountability. The architect assumes accountability by deciding what design best meets the clients requirements, satisfies relevant compliance requirements, and by translating the design into a documentation set for construction. Any initial visuals

are fed into the larger design process, where they are evaluated against the architect’s knowledge of an area’s geography, regulations, and aesthetic specifications. This judgement is the professional responsibility of the architect and is what transforms a compelling and aesthetic picture into a structure that can function and endure.

erences, allowing for a deeper dialogue consequences. The value shifts the consultation pro-

With clients arriving with an AI image of their design vision, architects are given a pathway to expedite conversations with clients about aesthetic preferences, allowing for a deeper dialogue regarding trade-offs, constraints and consequences. The value shifts the consultation process away from producing visuals towards bringing the client’s vision to life.

the level of precise control necessary for ideas to be explored rigorously, supporting deeper conversations, clearer feedback and more informed decisions long before construction begins.

This is also where architects increasingly use their own visualisation and rendering workflows to test ideas, challenge assumptions and communicate intent with precision. Highquality 3D visualisation allows

Authorship in an evolving landscape Architecture has always been a careful dance, balancing imagination with reality, and whilst AI is changing how quickly ideas can appear, it falls short when it comes to understanding what is actually a good design.

As clients arrive with AI-generated concepts in hand, the role of the architect is not to compete with tools, but to apply judgement, to refine, contextualise and realise ideas in the physical world.

visualisa-

It’s at this stage that architects can also utilise AI as a copilot in their workflow, speeding up the feedback loop. It’s important to remember though that just because something is faster, this doesn’t mean the perfect image is created instantly. Oftentimes working with AI is about being able to generate and test a higher volume of options quickly which can then be narrowed down by the architect, saving countless steps and reducing the time it takes to complete a project.

Ultimately, AI is influencing where design begins but creative authorship lives and ends with the architect who decides what gets built and why.

■ www.chaos.com

We asked Amy Bunszel, EVP of architecture, engineering and construction solutions, Autodesk, what she expects to see from AI in 2026

Until recently, AI in AEC has largely focused on efficiencies like automating documentation, speeding coordination, and reducing repetitive tasks. Those gains remain essential, but on their own they are no longer enough to address the deeper challenges facing the industry.

AEC firms are expected to deliver more complex, higher-performing buildings and infrastructure with fewer people, tighter margins, and rising expectations around sustainability. Owners and communities expect projects that perform as intended and hold up over time, these outcomes result in tighter schedules, stricter budgets and less room for error.

Early decisions have always carried outsized weight in AEC, but in 2026, the tolerance for revisiting them later will continue to shrink. What were once treated as provisional choices, like site strategy, massing assumptions, or sequencing assumptions, are expected to hold up as

‘‘ Apply AI where decisions matter most, invest in connected data as foundational infrastructure, and intentionally build the transparency and continuity teams need to trust AI-driven outcomes

AI to project data such as site conditions, environmental factors, systems performance, and constructability, teams can explore tradeoffs before decisions are locked in. As the range of options expands, the advantage increasingly lies not in having more information, but in how teams evaluate tradeoffs and make decisions, especially where expertise, creativity, and judgement still matter most.

The value of AI in 2026 and beyond now lies not in making digital work faster, but in helping teams make better decisions and unlock higher levels of creativity and innovation across the project lifecycle.

projects move forward with far less room to course correct downstream.

Owners increasingly expect credible answers about feasibility, performance, and risk earlier, based on analyses teams can stand behind as projects evolve. AI’s role is becoming essential not because it replaces expertise, but because it helps teams understand consequences sooner, when change is still feasible. By applying

What we expect to see in 2026 is AI actively supporting continuity as projects move from early design into more detailed building definition. Instead of treating conceptual exploration and technical definition as requiring handoffs, teams will be able to carry intent forward as early ideas evolve into more detailed layouts, such as aligning spatial decisions, system logic, and performance expectations as designs mature. In practice, this means AI helping teams move from broad concepts into detailed build-

ing layouts and systems without losing the intent or assumptions established early on. This will shorten the path from early ideas to buildable solutions.

As this process unfolds, design intent will increasingly be evaluated alongside engineering assumptions and delivery constraints as part of the same decision-making process, rather than being handed off and reinterpreted later. Fewer issues will be pushed downstream, and fewer projects will require late-stage redesigns or course corrections. AI’s value here is not speed, but confidence that early design decisions that are grounded in shared data and tested assumptions will translate into solutions that are viable to build and operate.

A meaningful shift we expect to see in 2026 is how teams use shared analysis and simulation as part of everyday decision-making. Architects, engineers, and constructors have long worked from different views of the same project, often resolving differences late, when change is harder. AI-enabled analysis will close that gap by allowing teams to test performance, feasibility, and risk against shared project data early and continuously.

When teams can evaluate energy use, material impacts, sequencing, or climate exposure before decisions harden, constructability and scheduling considerations become part of the design conversation and performance expectations are carried forward into delivery.

This only works when data is connected and when teams have clear, trusted boundaries around how this data is used. AI does not compensate for fragmented workflows; it exposes them. Without transparency and continuity, AI-driven

analysis introduces uncertainty rather than confidence in the decisions it informs. Disconnected models, siloed information, and brittle handoffs limit what AI can deliver. Organisations that invest in continuity across planning, design, and construction are better positioned to commit with confidence. Those that don’t are left reacting when options are limited.

As AI becomes more embedded in connected workflows, its impact will be felt less in isolated features and more in how consistently teams can move from intent to execution without rework. That shift is becoming essential as capacity tightens across the industry; Autodesk’s 2025 State of Design & Make report highlights that capacity and skills constraints remain a key challenge for many AEC firms. Together, these pressures will push firms to rely more on data continuity and AI-supported workflows to deliver projects predictably at scale.

As this shift takes hold, performance becomes a design input, not a secondary check. Energy use, carbon impact, resilience, and lifecycle cost will guide scope, budget, and delivery decisions. AI will accelerate this change by making performance implications clearer earlier, when tradeoffs are still possible.

Sustainability and resilience are becoming part of what defines a successful project, not considerations deferred to the end.

At the same time, AI will play a growing role in addressing the industry’s most persistent constraint: capacity. By reducing rework, improving predictability, and allowing teams to focus on judgment instead of coordination, AI will enable firms to deliver more with the resources they have. But the benefits will not be evenly distributed. Firms that connect intent with execution will be better positioned to see measurable gains, while those that limit AI to isolated automation are likely to encounter diminishing returns.

The next phase of AI in AEC will not be defined by novelty or faster interfaces. It will be defined by fewer downstream surprises, better-performing assets, and teams that can meet rising demands without burning out.

For leaders, the priorities are becoming clear: apply AI where decisions matter most, invest in connected data as foundational infrastructure, and intentionally build the transparency and continuity teams need to trust AI-driven outcomes. It’s also critical to treat performance as a baseline expectation rather than a late-stage check.

That shift changes how different disciplines engage with the work. For architects, form and performance are increasingly inseparable. For engineers, assumptions are tested sooner. For contractors, means and methods are influenced before work begins.

In 2026, the firms that succeed will be the ones using AI to bridge digital insight to execution, enabling earlier confidence, smoother delivery, and more sustainable outcomes that hold up over time.

■ www.autodesk.com

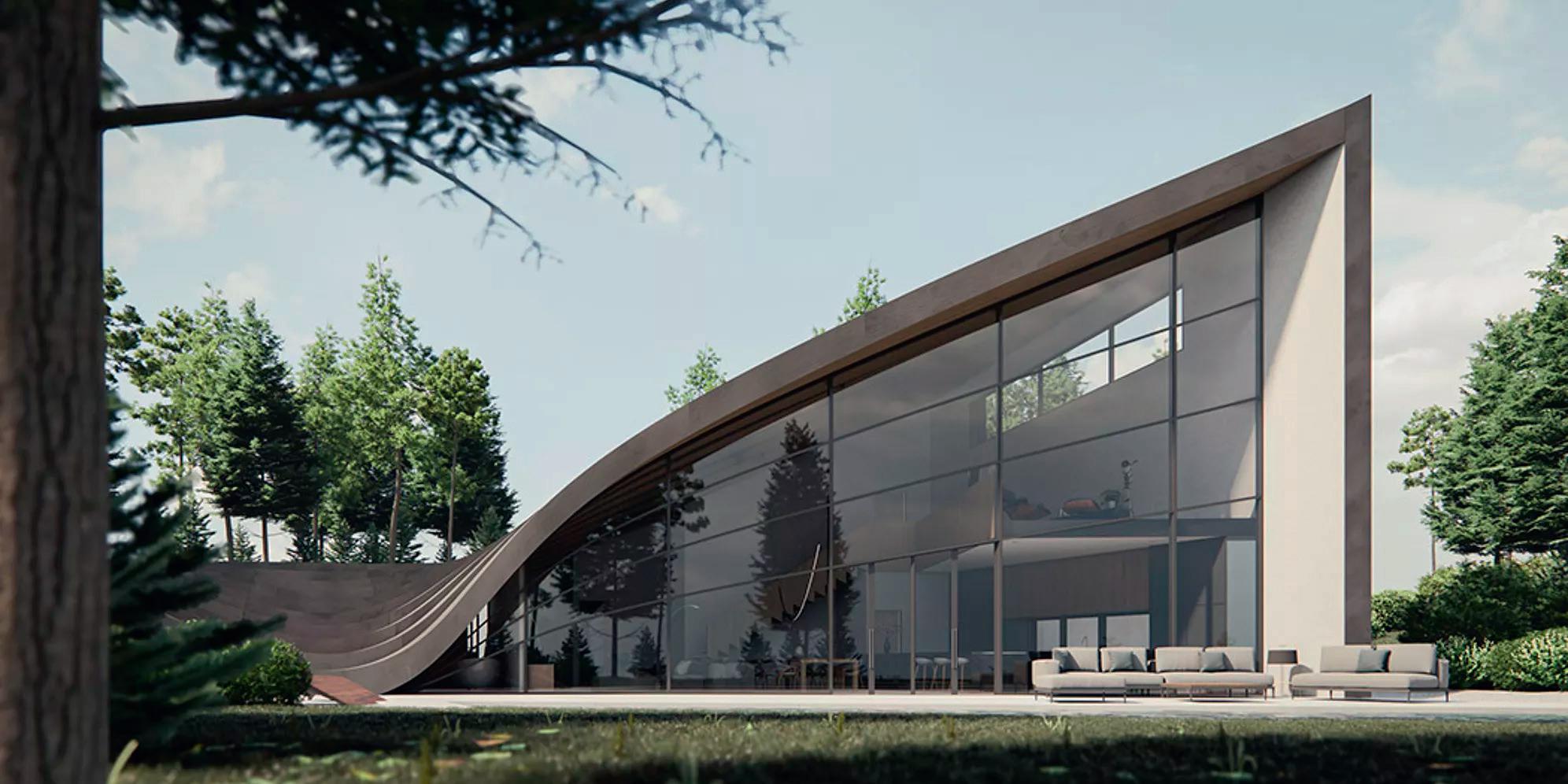

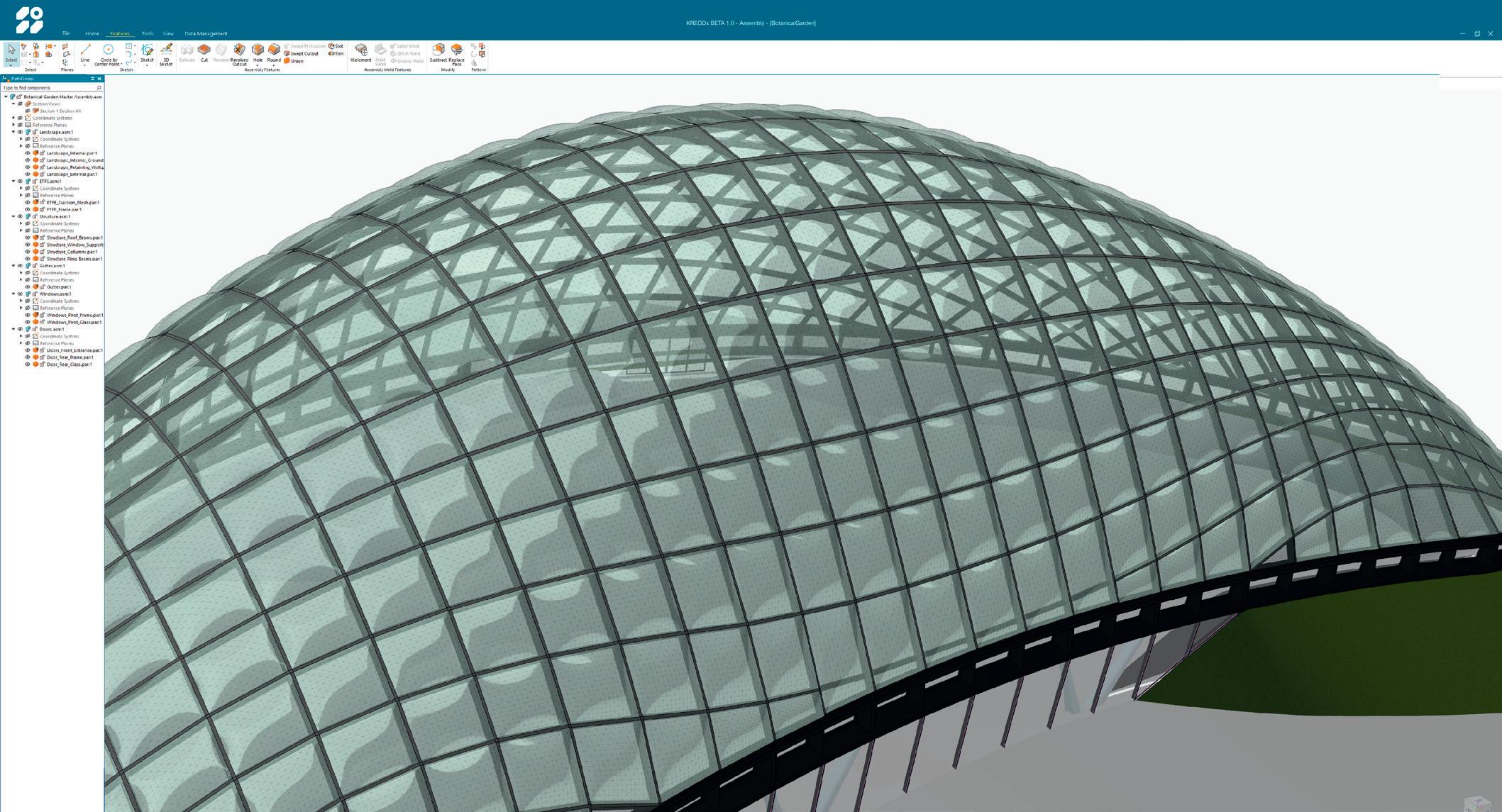

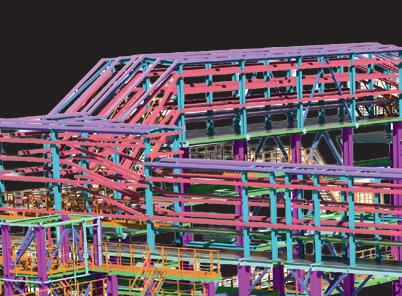

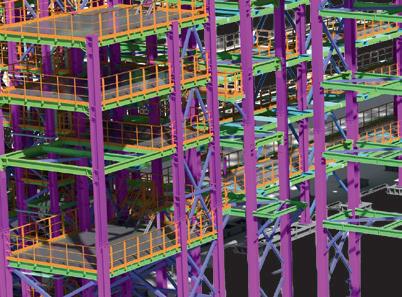

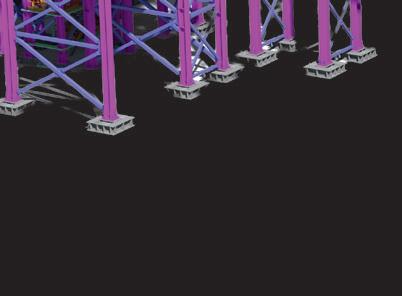

Chun Qing Li is one of the UK’s true innovators. As an architect, he is intent on rebuilding the link between design, fabrication and commercial reality, and that has meant writing his own fabrication-ready design system, writes Martyn Day

Early-phase engineering and architectural design is the least visible and least well rewarded part of a building project, yet it is often the phase that most strongly determines whether a scheme ever becomes affordable or buildable. In an industry that still absorbs extraordinary financial risk during concept and feasibility, decisions made before a single drawing is signed off routinely lock in cost, procurement behaviour and even long-term operational performance. It is into this uncomfortable gap between design intent and commercial reality that Chun Qing Li has stepped in with KREODx, a design system that is neither conventional BIM nor a parametric plug-in, but a fabricationaware solid modeller built from scratch.

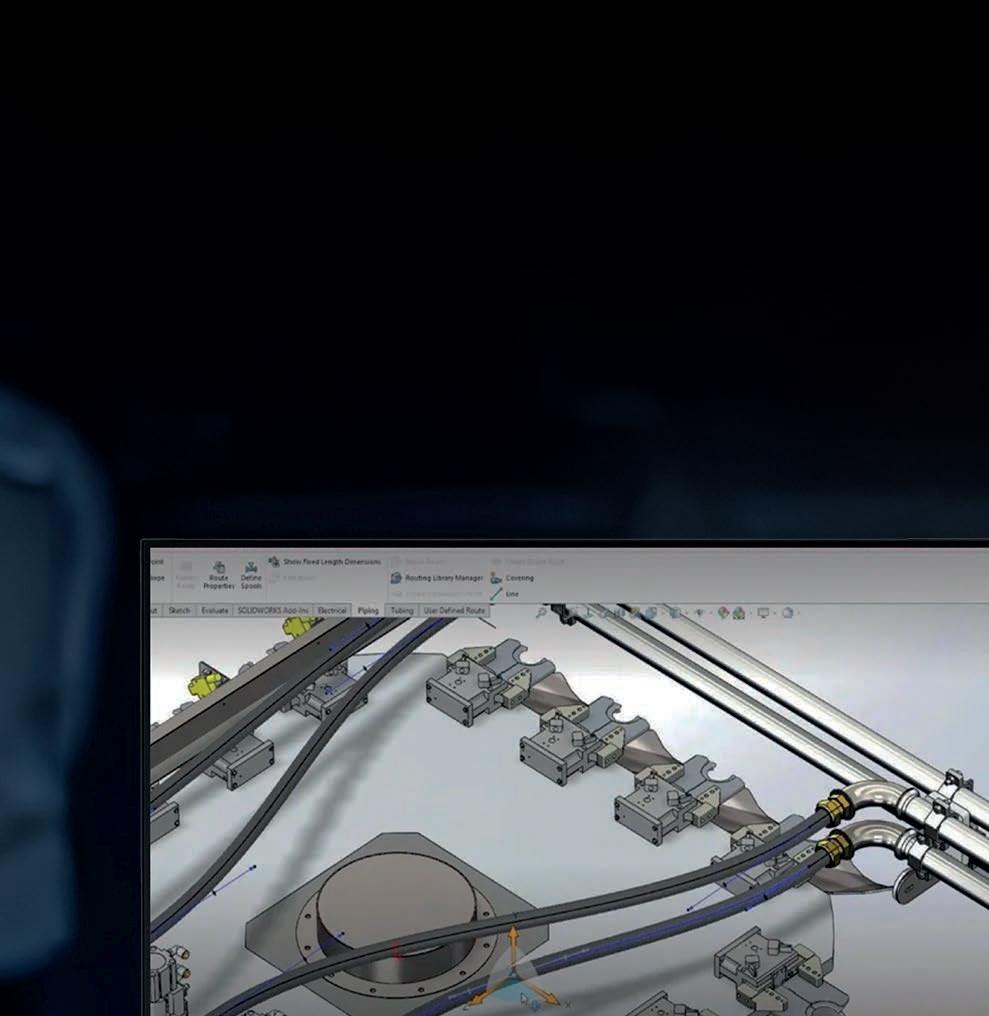

Li’s journey to this point is unconventional, even by AEC startup standards. Trained as an architect, he went on to run his own construction company, then decided that the only way to resolve the structural contradictions he kept encountering between drawings, procurement and site reality was to use a manufacturing-grade mechanical CAD system. He began by using Dassault Systèmes Catia, which is used extensively in the automotive and aerospace sectors. He customised the system to be more building-component aware and started to wonder whether the layer he was creating might become a commercial product that other architects could use. “I was using Catia. It can model anything,” he recalls. “But out of the box it doesn’t understand buildings, tolerances, procurement, or how things are actually fabricated.”

the long line of tools that attempt to civilise BIM from the outside.

This is the origin story of KREODx, a proprietary Parasolid-based solid modelling and automation platform, designed to treat buildings not as geometric compositions but as negotiated assemblies of manufacturable parts, constrained by tolerance, cost and supply chain reality from the outset.

What distinguishes KREODx from yet another attempt to refine BIM is that Li does not see design as the main problem domain at all. He sees it as merely the first compression point in a much longer chain of economic consequence. In his framing, most of the financial damage in construction is not caused by bad drawing, but by bad information continuity, where assumptions made during concept quietly metastasise into procurement decisions, site improvisation, maintenance burden and asset write-downs years later. “Design decisions shouldn’t just be about what looks right,” he argues. “They should be about what can actually be built, paid for, complied with and operated.”

‘‘ If you draw something that cannot be built, or that will bankrupt the client, you’re not an architect. You’re just an artist with liability ’’

This is why KREODx is conceived not as a frontend modeller, but as a lifecycle system that carries validated geometry, system logic, compliance data and cost truth from design through manufacture, construction, occupation and long-term operation. The ambition is not better drawings, but fewer financial surprises across the entire asset lifecycle.

munication or cost certainty.

“Would you hire a solicitor to perform heart surgery?” he asks. “If it’s no, why would you hire a software engineer to solve the AEC industry problems? He or she doesn’t even know the size of the brick.”

For Li, this disconnect is not just a tooling problem, it is a governance failure. He sees architecture as having abdicated its historical role as system integrator, retreating into representational geometry while contractors, quantity surveyors and manufacturers quietly absorb the commercial consequences of design ambiguity.

“If you draw something that cannot be built, or that will bankrupt the client, you’re not an architect,” he says. “You’re just an artist with liability.”

This is what he means by the architect as general. Not a nostalgic power grab, but a demand that the lead designer once again takes responsibility for the full technical and economic coherence of a building, including how parts are fabricated, how they are procured and how cost behaves under design change. In Li’s world view, design authority is not earned through aesthetic vision but through predictive accuracy. In a riskaverse industry, Li is running towards the gunfire, not from it.

That philosophy is why KREODx is not built on top of Revit, Rhino or Grasshopper. Those platforms, in his view, are optimised for geometric flexibility and visual coordination, not for manufacturing truth. They allow almost anything to be drawn and then rely on downstream consultants and contractors to reconcile fantasy with feasibility.

The implication he drew from that experience was radical and slightly mad in equal measure. “I realised, if I want the computer to understand construction logic, I have to build the geometry engine myself.” It is a decision not for the light-hearted, and one that immediately separates KREODx from

The architect as general Li’s technical eccentricity is rooted in a deeper professional and political critique of the AEC industry. He argues that most construction software is built by people who have never been financially or legally exposed to site failure, and that this explains why the industry keeps generating tools that accelerate drawing production without addressing risk, miscom-

KREODx, in contrast, is built as a parametric solid modeller. Its primary job is not to draw buildings but to instantiate real building systems. Geometry is subordinate to constraint. Every component carries embedded rules about maximum size, allowable spans, connection logic, tolerances and cost consequences. If a designer exceeds a manufacturing limit or creates a bespoke variant that breaks standard production economics, the system flags the consequence immediately.

What Li is really building here looks less like architectural software and more like a

form of building-scale systems engineering. The intellectual lineage is closer to aerospace or automotive product lifecycle management (PLM) than to BIM authoring. KREODx behaves as an expert system, embedding manufacturing constraints, assembly logic and interface rules directly into the geometry layer so that design choices become executable technical decisions rather than optimistic suggestions.

Li describes it bluntly as an AEC fintech play. “This is not a software startup. The product is financial certainty,” he says. In other words, geometry is just the user interface for a deeper economic machine that exists to make cost, compliance and constructability behave deterministically instead of probabilistically.

This kernel-level control is what allows KREODx to behave more like an expert system than a drafting tool. It is also what makes Li’s decision to abandon Catia comprehensible. Aerospace software can model almost anything, but it does not contain the glue logic of construction, the rules that determine whether a panel can be transported, whether a joint can be assembled on site or whether a dimension drift will cascade into rework.

Li’s ambition is to capture that logic once and reuse it everywhere, instead of forcing every project team to rediscover it through failure.

Internally, Li structures this worldview around what he calls DEMACOMB, shorthand for Design, Engineering, Manufacturing, Assembly, Construction, Occupation, Maintenance and Beyond. The acronym is less important than the provocation behind it. Buildings, in his view, are not projects with an endpoint at practical completion, but long-lived technical systems whose real costs and risks

emerge years after the ribbon is cut. Most digital tools stop caring the moment the keys are handed over. KREODx is explicitly designed to retain system logic, product provenance and spatial intelligence across those later phases, so that a decision made in concept does not become an untraceable liability during maintenance or retrofit.

That long view is unusual in an industry that still treats handover as a finish line rather than a liability transfer.

The intellectual coherence of this argument would be unconvincing if it had not been forged under real financial pressure. Li’s authority in this domain comes from having tested his ideas on his own live projects, most notably during the refurbishment of Browns Hotel in London.

The project carried huge penalties for delays. During the fit-out, Li discovered that the interior designer, the principal contractor and the on-site carpenter were not in sync. “I spoke to the interior designer. I spoke to the principal contractor. I spoke to the carpenter. Three different dimensions,” he says. “One was fiftynine millimetres out.”

On bespoke panels and joinery, that discrepancy would have triggered catastrophic rework. “Every day we were late, it was ten thousand pounds,” Li recalls.

Instead of issuing another drawing revision, he 3D scanned the rooms, modelled every component in his own software and sat down with the carpenters to negotiate tolerances digitally before anything was cut. Once the dimensions were agreed, the data was sent directly for CNC fabrication. The parts fitted perfectly.

“The carpenter said, ‘We should have had you much earlier!’,” Li said.

This episode functions as KREODx’s credibility crucible. It demonstrates what happens when errors are found in software rather than on site, and why Li believes fabrication-level modelling is not an indulgence but an economic necessity.

Browns Hotel was not a one-off. KREODx has been quietly exercised across a string of live projects, from the remastering of the London Olympic Pavilion, originally delivered in 2012, to residential schemes across London, Surrey and Kent, modular housing projects, golf driving ranges and other Modern Methods of Construction deployments. These are not laboratory pilots. They are commercial projects executed under real contractual risk, using KREODx as both a design environment and a fabrication coordination layer.

That matters, because it reframes the software not as a speculative product vision, but as a delivery system that has already survived contact with site reality multiple times.

KREODx emerged from similar repeated experiences as a full-stack attempt to rebuild the geometry layer of construction around manufacturing truth rather than low-tolerance representation. It is a parametric solid modeller whose primitives are not walls and slabs but real components sourced from real manufacturers.

Li describes the system as a form of digital DfMA, borrowing from aerospace and automotive practice. Designers work with intelligent component libraries rather than generic BIM families. Those libraries embed fabrication constraints, tolerance behaviour, cost curves and assembly logic. When components are combined, the system checks whether the resulting configu-

ration is manufacturable, transportable and economically coherent. “If it goes beyond that you get an alert,” Li explains. “So this is going to be a unique product.”

This is not optimisation in the academic sense. It promises bounded reality. It ensures that what is being designed exists within the feasible envelope of the supply chain.

The strategic implication is that early design stops being speculative. Instead of issuing abstract geometry and discovering its cost later, KREODx allows cost and constructability to co-evolve with the design of the form.

The practicality of this approach becomes clearer in the first commercial deployments of KREODx, particularly with manufacturers who live at the wrong end of architectural ambiguity. One such client is Uniblock, a UK supplier of an insulated, interlocking concrete formwork system.

be answered. “This is not the end product,” Li says. “It is a strategic beachhead.”

Reconnecting designers & fabricators

What makes the Uniblock deployment strategically interesting is not the AI trick itself but what it unlocks next. Once a manufacturer’s product logic exists in parametric form, it can be reused upstream in KREODx.

This is where Li’s longer-term ambition becomes visible. He is attempting to build a shared digital layer where designers work directly with fabricationready components sourced from manufacturers, and where those components carry live cost and procurement logic.

The commercial mechanics of this are deliberately opaque and business-sensitive at the moment, but the conceptual move is clear. Instead of design intent being handed off to contractors to reinterpret and value engineer, procurement becomes a direct extension of design.

makes this especially persuasive, at least to me, is not the software itself but the way Li keeps forcing every abstract idea back into site-level consequence.

Li’s decision to abandon Catia and build his own Parasolid-based solid modeller is objectively irrational if judged by conventional startup metrics. It only becomes rational when seen as a response to a structural market failure, the inability of existing tools to connect design intent with fabrication reality and commercial consequence.

His vision of the architect as general is not about professional dominance. It is about professional accountability. It demands that the lead designer once again becomes responsible for whether a building can be fabricated, afforded and delivered without deception.

Uniblock’s bottleneck was not manufacturing capacity but quotation throughput. The company received hundreds of 2D PDF drawings each month. To produce a quote, a team of five people manually rebuilt each scheme in Solidworks, generating a bill of quantities one house at a time. This allowed them to process roughly one project per day.

“I specify the super window and the contractor comes back and says we’re not going to use Kingspan because it’s too expensive,” Li says. “But when you give it to a contractor, they use something else. Obviously, they downgrade it.”

Li’s response was not to push KREODx directly into architectural practices. Instead, he built a narrow browser-based AI tool called Build X AI, designed to attack this specific pain point.

“The output of every BIM system is the same. A 2D PDF,” Li says. “That’s where everything goes wrong, because there is no data left.”

Build X AI reads the uploaded drawings, generates a 3D model using Uniblock’s components and produces a bill of quantities and quotation in under a minute. “If my AI can read the drawings, build the model and generate the quantities, all the manufacturer has to do is press send,” Li explains.

For Uniblock, the economics are brutal and obvious. Replacing even two staff members covers the annual cost of the tool. The turnaround time collapses from days to minutes. Every enquiry can now

It is also, implicitly, about re-pricing risk in an industry that has never learned how to model it properly. From an investor or developer’s perspective, KREODx is less interesting as software than as infrastructure, a way of turning design decisions into auditable financial commitments rather than educated guesses. Once systems are configured, quantities resolved and assemblies validated, procurement stops being a negotiation and becomes a data outcome. Estimation gives way to quotation. Fragmentation gives way to traceability.

KREODx is designed to prevent that substitution logic by collapsing specification and procurement into a single transaction layer. The architect specifies a real component. The client sees its real cost. The supply chain delivers exactly that component.

“You never change things by fighting the existing reality. To change something, build a new model that makes the existing model obsolete,” Li says, quoting Buckminster Fuller.

allowed them to and procurement into layer. The architect a ponent. The client sees its

Li describes this as building the Amazon of the AEC industry. Not a retail interface, but a digital marketplace that links design, manufacturing and payment into a single source of truth.

The deeper implication is that adversarial supply chains become unnecessary. If cost is known early and locked in, contractors stop needing to protect margins through substitution. Clients stop being lied to about where money goes. Risk becomes visible and therefore negotiable.

KREODx is not interesting because it is clever software. It is interesting because it is an attempt to realign responsibility, authority and financial truth inside a deeply dysfunctional industry. What

KREODx is not yet that model. It is still mainly an in-house, eccentric and unproven at scale. But it is one of the few attempts in the AEC technology landscape that actually targets the real problem, not drafting speed or visual coordination, but the financial lies embedded in the way buildings are currently designed and procured. The Uniblock case demonstrates that this world view can generate immediate commercial value without waiting for industry-wide adoption. It also reveals the deeper logic behind KREODx, where narrow automation tools generate parametric product data, which feeds intelligent libraries, which enable fabrication-aware design, which creates financial certainty, which attracts more manufacturers.

If Li succeeds, the consequence will not be prettier BIM. It will be fewer surprises on the journey between concept and fabrication, and a profession that reclaimed responsibility for the economic reality of the things it draws.

■ www.kreodx.com

Architects make decisions that stand the test of time at the very moment when uncertainty is greatest. Early-stage design is the phase where environmental considerations, zoning constraints, environmental, transportation, community priorities, and feasibility questions all converge.

Sweco, one of Europe’s largest architecture and engineering consultancies, has spent years studying how digital tools can influence improved/optimised project outcomes. The firm sees the most powerful industry trends today are open data, parametric design, and AI/automation. These trends are actively reshaping the way architects approach the design process and are guiding Sweco’s own digital strategy.

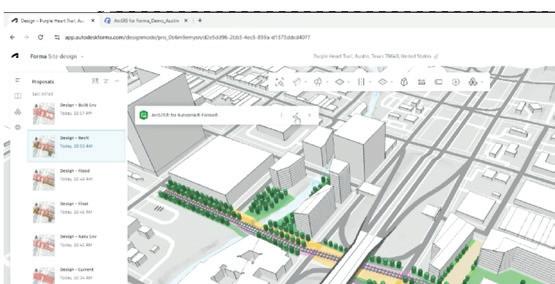

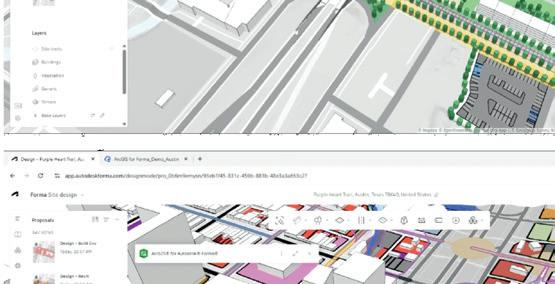

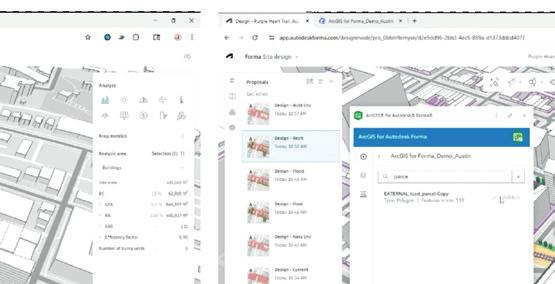

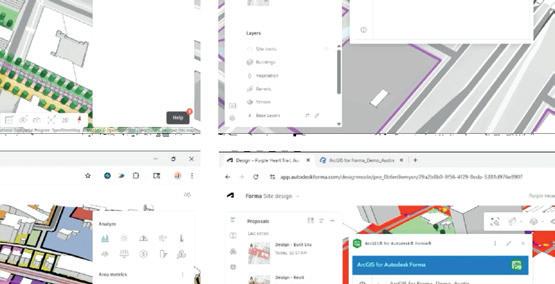

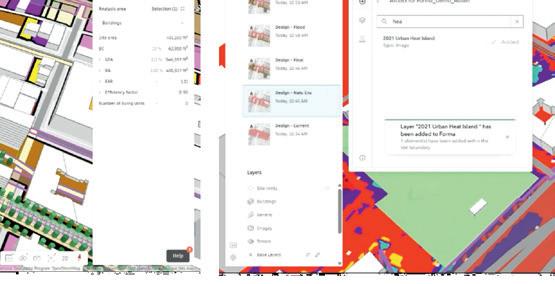

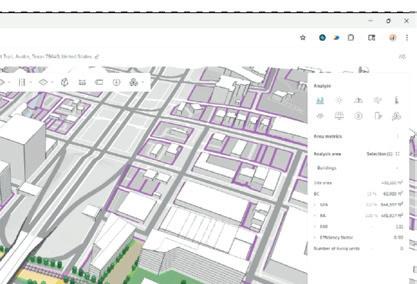

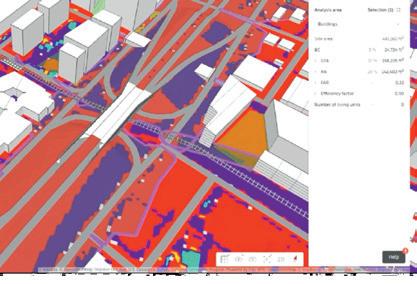

ArcGIS for Autodesk Forma was created to support these types of requests by delivering authoritative geographic intelligence into the conceptual built and natural environment. With this integration, architects can explore their ideas with clarity, confidence, and real-world context from the very beginning.

Sweco’s planners and designers know that the earliest moments in a project carry the highest uncertainty, yet also determine the greatest portion of environmental impact and long-term performance. This directly reinforces the value of integrating the power of ArcGIS into the Forma designs.

“Projects powered by geographic information system (GIS) technology will be almost as important a tool as BIM for architects.”

(Source: Sweco Digitalisation Trends)

ArcGIS for Autodesk Forma allows teams to bring zoning, risk, mobility, greenspace, natural, and demographic information directly into conceptual design. Layers can come from ArcGIS Living Atlas of the World, municipal open data, or an firm’s own data. This use of geographic and environmental information creates a conceptual design that is grounded in real-world site conditions. Instead of approximating, architects can quickly evaluate what is possible, what is risky, and what might offer the most opportunity.

To illustrate what this looks like in practice, imagine a designer working on a downtown mixed-use development. The project includes residential units, retail space, structured parking, community greenspace, and stormwater-resilient public areas. Using ArcGIS for Autodesk Forma, the team loads flood plains, canopy distribution, land use,

bike networks, pedestrian corridors, and the city’s ongoing planning initiatives.

These layers allow the team to explore massing and orientation while responding to planned city connections and public realm goals. It also mirrors the early site analysis process in Sweco’s DigiMAP methodology, where teams use geographic information to pinpoint a location, to analyse its potential, and build a data informed concept.

As the team explores their designs, Autodesk Forma uses GIS data from ArcGIS to reveal areas of excessive shading and potential wind tunnels. Because the design is grounded in geographic reality, the team easily reshapes the massing to produce a comfortable microclimate surrounding the development. A flood analysis reveals an opportunity to extend greenspace along the river creating a natural buffer. By addressing these issues early, the team avoids costly redesigns and strengthens the long-term resilience of the development’s design.

Sweco notes that project workflows are rarely linear. Designers move back and forth as information arrives, and the number of tools involved leads to unnecessary file conversions and repeated work. Their digitalisation team emphasises the need for an ecosystem that supports continuous movement between tools. ArcGIS for Autodesk Forma directly supports this pattern by ensuring that geographic information remains integral to informing the model from the first moment of creation.

When the project is ready for the next phase, the team exports their ArcGIS for Autodesk Forma model into Autodesk Revit for further development. Because geographic location and site context

are already embedded in the file, the downstream work in Revit becomes much more efficient. There is no need to reestablish geographic coordinates or rebuild context manually. This continuity aligns perfectly with Sweco’s approach that prioritises collaboration, automation, and consistency in project data.

ArcGIS for Autodesk Forma represents a shift in how informed, high-quality architectural decisions are made. Instead of relying on assumptions or manually collected datasets, architects can understand the true conditions of a site from the very beginning. This allows them to explore ideas widely, iterate quickly, and justify their design choices with credible data. It also strengthens collaboration between designers, planners, engineers, and community stakeholders by creating a shared understanding of the site and its constraints through location/geography.

Sweco’s digitalisation research, which highlights the increasing importance and adoption of open data and evidence-based design, echoes this direction strongly. The company positions GIS as a natural companion to BIM in a world where environmental and urban complexities require more than geometric modeling alone. ArcGIS for Autodesk Forma embraces this reality head on and better equips architects to meet the expectations of modern cities and digital-first practices.

For more information on how ArcGIS for Autodesk Forma can support informing your early-stage designs with the power of location/ geography, visit the product page today at https://link.esri.com/AAF

With

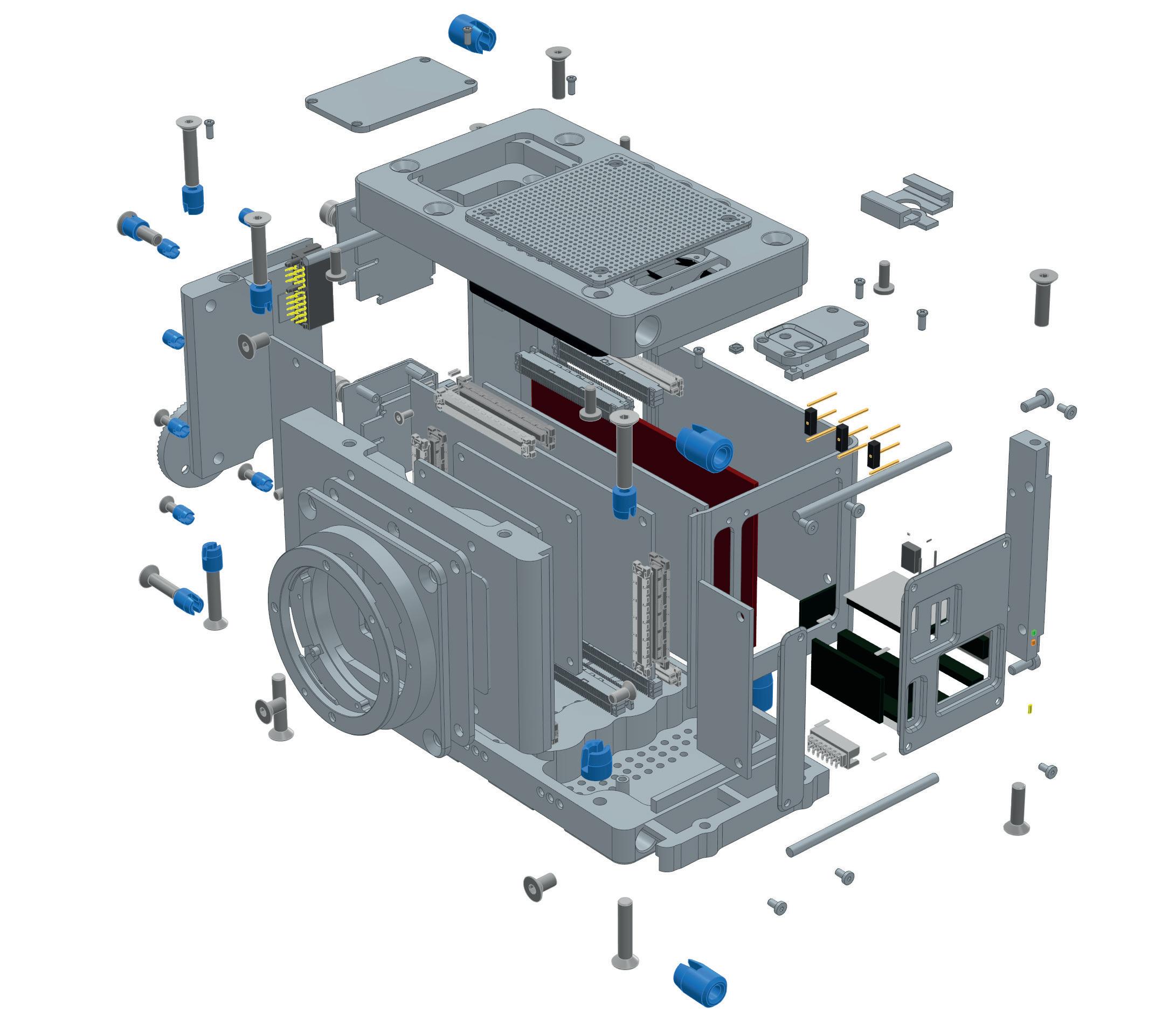

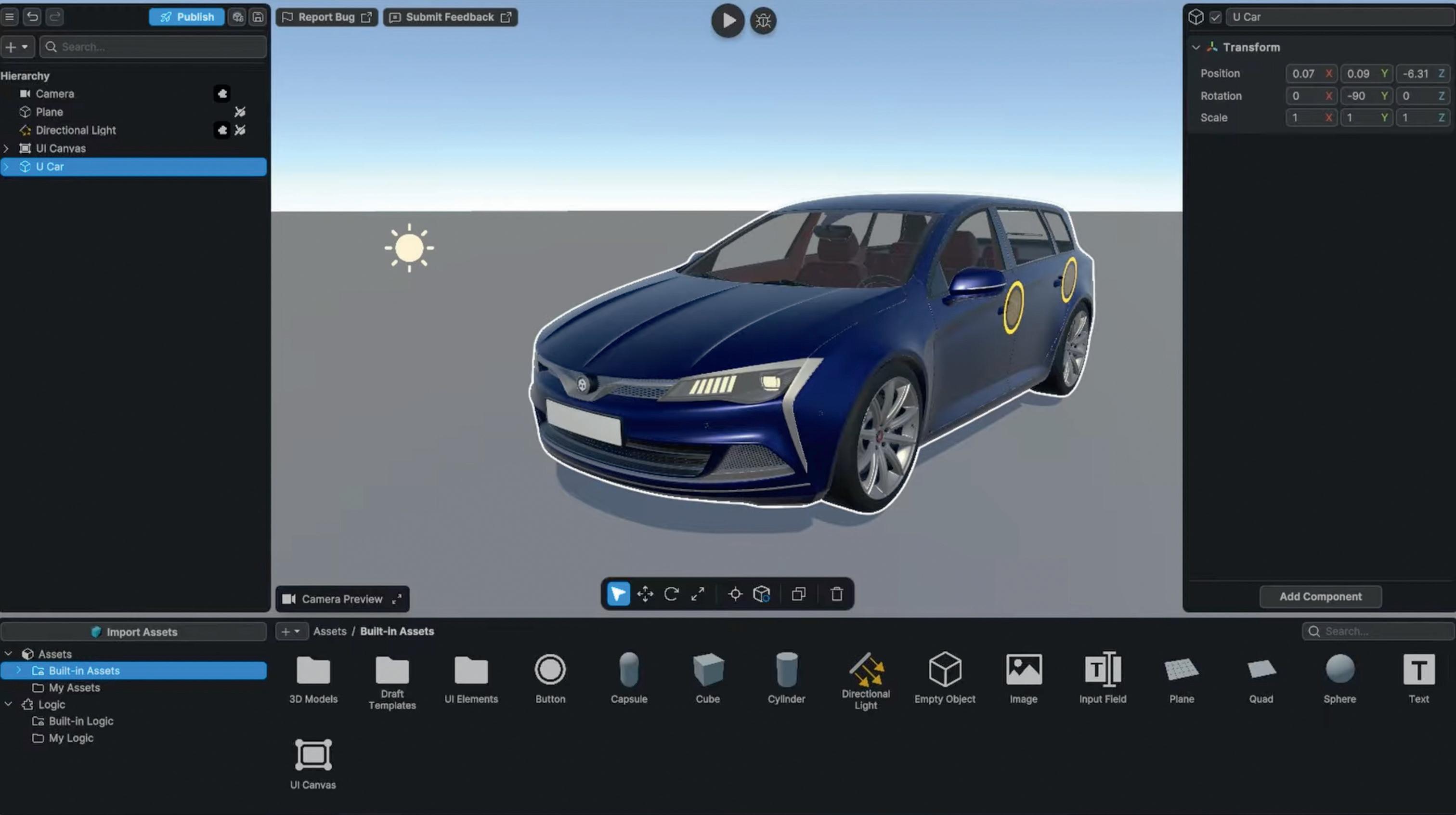

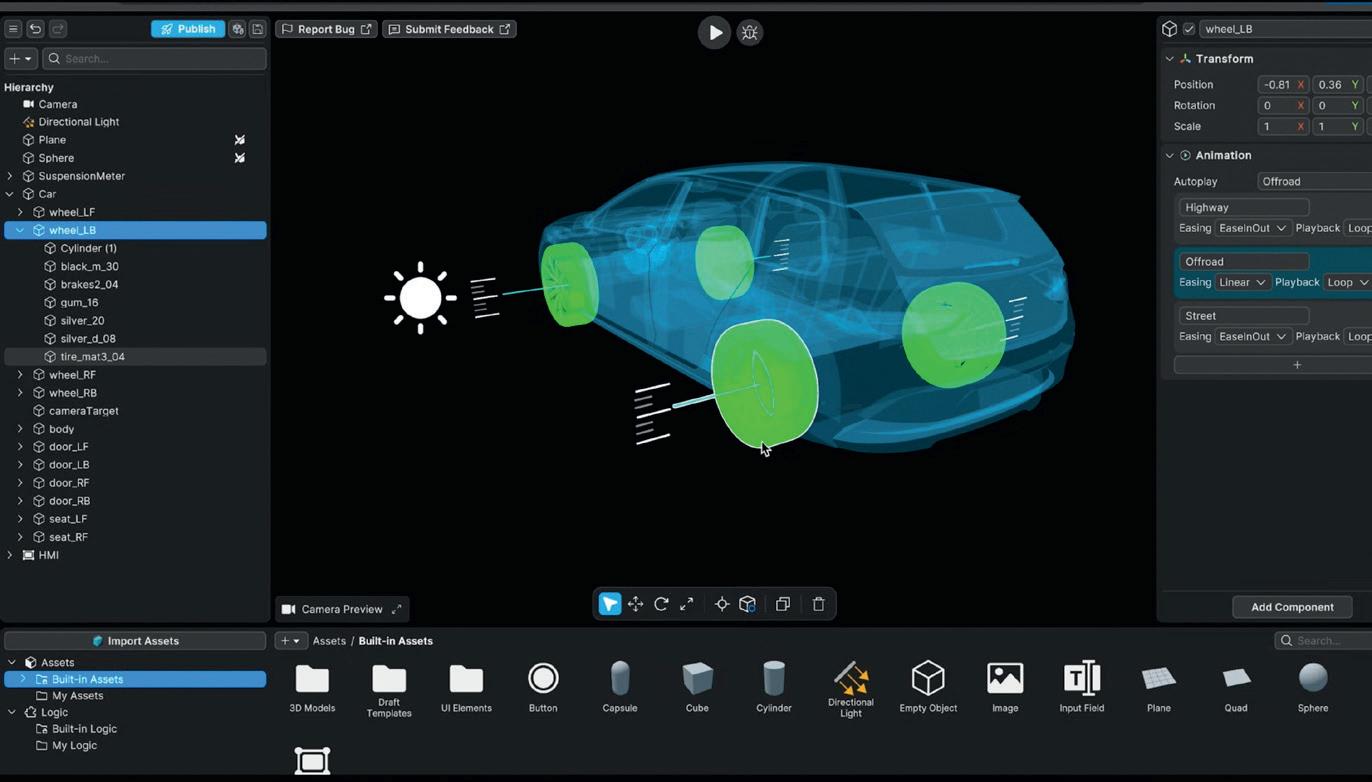

no-code workflows and streamlined data pipelines, Unity aims to simplify how firms build, share, and scale interactive 3D experiences, writes Greg Corke

Creating interactive 3D experiences has long been regarded as the domain of technical specialists — coders, game developers, and those skilled in customising realtime engines like Unreal and Unity. In product design, manufacturing, automotive and AEC, this technical barrier has stalled countless ideas before they could become usable tools. Sarah Lash, GM & SVP of Industry at Unity, calls this “POC purgatory” — the place where promising ideas never progress beyond the initial proof of concept.

“I’ve had conversations with people that go like, ‘Yeah, we’ve got 60 requests for projects in queue, and we have enough bandwidth to do five of them,” she says. But there’s an obstacle that affects many more firms, “If they don’t have a C# developer, how are they getting started?”

Unity Studio, now out in beta, aims to change that dynamic, offering an intuitive, webbased platform designed to let “anyone” create interactive 3D experiences without having to write a single line of code.

In its simplest form, this could be an interactive 3D viewer where users click elements in a CAD or BIM model to reveal more information, or a web-based product configurator where customers choose options, colours, and materials and see the 3D model update in real time.

Unity Studio can also be used to power training applications that animate 3D models to guide engineers through servicing procedures, collaborative design review tools, giving non-CAD users real-time access to large models, or construction-sequence simulations that help contractors visualise each stage of a build.

manage 3D applications, including games. However, unlike the full Editor, Unity Studio runs in a browser and is built around a simple, drag-and-drop visual interface. “It gives the ability to start something in a Unity-like environment, whether you’re a designer, a trainer, or project manager, and help bring some of those ideas to life,” says Lash.

Unity Studio features a visual scripting system called Logic that lets users add behaviours and interactivity to an experience, instead of having to write code. It can be used to trigger actions based on events (such as when a user clicks a button or selects an object), control animations, adjust scene lighting or combine multiple actions to create more complex behaviours.

Applications created in Unity Studio can either serve as a launchpad for further development in the full Unity Editor or be published straight away.

‘‘ By lowering the barrier to entry and streamlining access to data, Unity is opening the door for far more people to participate in building, or contributing to the development of, real-time 3D applications ’’

Unity Studio is essentially a cut down version of Unity Editor, the main workspace where users create, organise, and

Lash recalls an example where a training subjectmatter expert from a large printing company used Unity Studio to create an immersive 3D animated training environment to show users how to replace the industrial cartridges — a process that was previously explained using PowerPoint.

Another example includes an automotive company, where a designer with no prior Unity experience created a prototype of a HumanMachine Interface (HMI) for a car. The goal was to visualise the suspension travel of each tyre. Taking a sketch from collaborative design platform Figma and an optimised wireframe CAD model of the car, the designer added simple animations to demonstrate the movement.

Unity Studio seems like an obvious fit for smaller firms that may never have considered creating their own 3D experiences. But, as Lash points out, even the most forward-thinking organisations can

have thousands of architects yet only a handful with the necessary C# skills.

This is true at BMW, where Markus Herbig, XR IT specialist admits that Unity Studio has created significant interest within the company, from both CAD users and project managers. “There’s a lot of people that don’t know how to handle a game engine, they don’t know how to programme C# or even C++, so Unity Studio gives us a huge benefit on creating new concepts, especially on the HMI side.

“If you have an idea, you just go to Unity Studio, you create it, and you can share it directly with somebody who maybe has some more influence,” he says. In other words, it’s about communicating ideas clearly to help decide which are worth pursuing.

With Unity Studio it’s also very easy to publish content, as Daniel Reichert, director, Unity Studio explains, “You don’t have to worry anymore about build settings or where do I host this?” he says. “You just click one button, you get a URL, and you can send it via email, via Teams or via Slack, to anyone in your company to check out the project.”

Unity is already working on new features, and there are plans to add real time collaboration. “This will enable multiple people to work on the same problem at the same time,” says Reichert. “In combination with commenting, this brings workflows that you know from the web browser, from tools like Figma, directly to the 3D editing world.”

AI powered capabilities are also on the horizon. The software already allows users to take a basic scene and upscale to make it look like a high-end render. While this is standard fare in many 3D applications these days, Unity is also working on a feature to generate logic dynamically —a capability that could, in practice, deliver substantial productivity gains.

At present, Unity Studio only allows applications to be published to the web, whereas the full Unity Editor lets you publish for Mac, Windows, mobile and XR platforms. Expanded support isn’t on the roadmap yet, but as Lash told AEC Magazine, it is under discussion.

For more advanced users, there’s Unity Industry, a suite of tools for developing and managing industrial applications across sectors such as manufacturing and AEC.

One of the biggest challenges facing any firm wishing to develop 3D experiences is access to data. “A lot of times [assets] are locked in silos or in different departments, or you need access to that type of [software] product in order to open a BIM model,” says Lash.

“We can only scale on the creation side if everybody’s working from the same foundation. We can only bring that to life if we know where all of that data lives.”

In Unity Industry this is handled by two tools – Unity Asset Transformer (formerly known as Pixyz Plugin) and Unity Asset Manager.

Unity Asset Transformer can ingest over 70 different file types, turning complex heavy CAD, BIM, 3D, reality modelling and other file types into lightweight meshes. Users have full control over mesh size and quality, so data can be optimised to maintain performance in different real time experiences on different target devices, across mobile, desktop, and XR.

Meanwhile, Asset Manager is a cloud-based digital asset management (DAM) system that stores all of this data and makes it discoverable for anybody across the business so it can easily be brought into Unity Editor or Unity Studio.

“What could take weeks of converting these file types and having to email them back and forth and then check you’re working on the right version, is now happening in seconds and minutes,” says Lash. “Engineers, designers, internal partners, they can all work from the same live asset now. The more centralised they are, the more you can do with them, long term.”

Japan-based construction company Obayashi has built an entire 3D collaborative application, Connectia, around this workflow, transforming complex CAD, BIM, and point cloud datasets into ‘ready-to-use’ assets. Asset Manager automatically handles the data conversion and version control, eliminating the need for manual conversion.

BMW has also recently turned to Asset Manager and Asset Transformer to overcome the persistent challenges it faces

when managing and accessing the digital assets critical to developing virtual experiences. The Unity tools form the backbone to BMW’s 3DMine, a comprehensive 3D asset management platform designed to streamline access by centralised data in a private cloud environment.

As Markus Herbig describes, the process of building virtual experiences was like “chasing a ghost” with teams constantly asking “what assets do we have? Where do we get the car from?”

“You’re kind of lost in this huge maze, and you don’t know where they are. You don’t see the assets,” he says. This lack of visibility made it difficult for BMW’s creators to efficiently find and utilise the necessary resources, often repeating the same processes again and again.

“[With 3DMine] each use case gets the right data in the right format at the right time,” he says.

Data prep – push / pull

Unity has been working to bring more automation to file optimisation and delivery, helping ensure that users have access to the right data at the right time.

A new tool called Pipeline Automation allows users to connect the Asset Manager to Product Lifecycle Management (PLM) systems like Siemens TeamCenter, or PTC Windchill, and other data sources, and create automations based on events, schedules or API calls.

Unity’s roadmap for pipeline automation focuses on giving users the flexibility to build pipelines however they want — whether through custom scripts, rule-based tools in the editor, or in the future AI.

“You can retrieve your CAD data from a PLM system and Pipeline Automation automatically converts this CAD data into usable real time 3D data, so it can be used downstream in real time 3D applications,” says Simon Nagel, staff solution architect, Industry at Unity. “Pipeline Automation can make sure that changes in the PLM system are automatically brought through.”

At the recent Unity Industry Summit in Barcelona, Matthew Sutton, senior manager of EMEA solutions engineering at Unity, shared an example of a Skid Loader Assembly model built in Solidworks. Changing the number of teeth in the bucket assembly and syncing it with the PLM system automatically triggers a pipeline automation, allowing Unity to retrieve the updated files and prepare the data for the Unity runtime. Importantly, the system can be set up to manage complex assemblies and their dependent sub-assemblies and parts.

The big model challenge

For viewing huge datasets, such as those used in automotive or digital twin applications, Unity applies 3D Data Streaming - not to be confused with pixel streaming, where graphics are processed in the cloud and the pixels are then streamed to an end point.

With Unity’s 3D Data Streaming the client device intelligently fetches only the necessary portions of 3D assets, such as specific levels of detail, textures, or regions of a model required for the current view. Everything is handled automatically - no manual data prep is required.

Biopharmaceutical company AstraZeneca is using the technology to review a colossal factory model with 437 million polygons and 1.3 million parts in XR on an untethered Meta Quest 3 headset.

“It’s possible to zoom in, take a look at a specific detail, and data streaming will just load the high-quality version of this completely automatically,” says Nagel.

Back in 2019, Unity launched Unity Reflect, a commercial design-review tool for AEC built around Revit and other CAD/BIM applications such as Rhino and SketchUp. What made Unity Reflect stand out was its unusually deep integration with Revit — deeper than the standard Revit API allowed — enabled through a close partnership with Autodesk. This meant BIM models could be synced in real time, complete with both geometry and metadata. The product showed real promise, but development slowed, and Unity Reflect was eventually retired a few years later. Even so, many of the design / review workflows it championed still live on.

Today, they continue through the Unity Industry Viewer Template, which helps users of Unity Industry build custom, cloud-connected collaborative viewers for exploring and sharing 3D models in real time. The template provides development teams with an optimised foundation for streaming assets directly from Asset Manager and enabling multi-user collaboration across desktop, mobile, and XR.

At the Unity Unite conference, Unity demonstrated how Asset Manager can serve as a collaborative hub for large AEC models, including those from Revit and Navisworks. The key takeaways: massive BIM datasets can be instantly shared with multiple stakeholders, streamed into a web browser for viewing and annotation on modest hardware, all while preserving access to the rich metadata normally locked inside the original authoring tools.

Unity’s latest initiatives with Unity Studio, Asset Manager, and its expand-

ing automation pipeline signal a clear shift in how interactive 3D experiences can be conceived, created, and shared. By lowering the barrier to entry and streamlining access to data, Unity is opening the door for far more people to participate in building, or contributing to the development of, real-time 3D applications.

But accessibility alone won’t guarantee adoption. Unity still must overcome long-held perceptions. For many firms, game engines remain associated with complexity, specialist skills, and steep learning curves. In the AEC sector, Unity Reflect once provided an accessible on-ramp into deeper customisation; without it, Unity will need to work harder to show that its tools aren’t just for developers.

Pricing will also be a key factor. While final details have not been confirmed, Lash told AEC Magazine that Unity Studio will cost significantly less than Unity Industry, which starts just under $5,000. The package will likely include the full Asset Manager capabilities, but only selected features of Asset Transformer.

Looking ahead, AI-powered capabilities such as dynamically generated logic could play a crucial role in simplifying customisation even more and further reducing the skill threshold.

If Unity can pair these advances with clearer messaging and industry-specific guidance, it has a genuine opportunity to reshape how real-time 3D is adopted across manufacturing, automotive, and AEC — not just by experts, but by anyone with an idea worth exploring.

■ www.unity.com

By Nathaniel Rackham, Digital Design Lead, Hawkins\Brown & Jack Stewart, Co-founder, Remap

DoesafeelingofstrainintheAEC sector,duetolargeandoftencostly softwaresubscriptions thatcontinue torise,soundfamiliar?We don't believe we are the only ones suffering. The tools themselves often deliver partial fits, built with crowded interfaces and an abundance of features, designed for everyone but precisely tailored to no one. More practices are now recognising that the answer isn’t more generic software, but better fitting tools. We work with CustomSoftware Developers,Remap, who offer an alternative. Bespoke software shaped around the way that our organisation actually works.

BIM models, data structures, design processesand coordination workflows vary. Most off the shelf platforms can only respond to this diversity in broad strokes, forcing our teams to adapt their workflows to the software rather than the other way

around. Custom tools flip that relationship. They help us to eliminate repetitive manual tasks, embed organisation specific standards and automate full processes. In turn this supports richer iteration, improves model quality through tailored validation and createsa lasting competitive advantage Rather than fighting against limitations, Remap build our team toolsthatalignperfectlywith ourneeds and project requirements.

Don’treinventthewheeltunetheengine

Custom development doesn’t mean rebuilding BIM software from scratch. Instead, the real value lies when Remap help us to layerbespoke apps, scripts and plugins on top of the platforms that we use already This isn’t reinventing the wheel, it’s tuning the engine and an approach that transforms existing software into a high performing engine, tailored to our workflows and fully adaptable as technology and industry expectations evolve.

KeyBIMtoolsdevelopedbyRemapforHawkins\Brown

Model Exporter rapidly packages up BIM models for issue.

Sheet Duplicator turns GA’s into entire drawing packages instantly

BIMView Lite monitors model performance in application in real time

Plotter exports in multiple formats with sheet set management.

Intuitive Revision, Status and Purpose of issue Manager.

Quickly Align Legends across multiple drawing sheets

There is also a strong financial logic to this We pay once and own the solution outright, with no reliance on subscription pricing and/orlicense structures In addition, we can improve continuously and reuse across our portfolio. Our internal toolkits savehundredsofhours,per designer,eachyear and over time, become a unique digital asset embedding knowledge in software rather than dispersed across teams.

Theindustry’sdirectionof travel

As highlighted at NXTBLD 2025, AEC’s digital future is most likely not monolithic but hybrid, modular and highly customised. We believe that the practicesthatstandoutwillbe thosewillingtoshapetheirown tools. Those who see software as something they can make, not just something they consume.

Partneringtobuildtoolsthat workforus

We have beenworking with Remap for several years They design and develop precisely the tools we need, grounded in deepexperienceacross AEC,BIMandsoftwaredevelopment

If you're ready to go beyond generic tools and build a digital toolkit that reflects the way you really work, it might be time to Remap your engine.

Visit: www.remap.works

Reach out: hello@remap.works

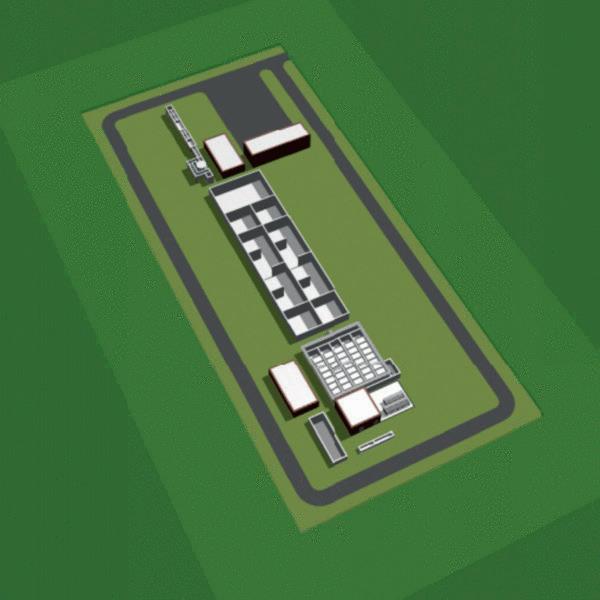

Early-phase engineering design is the least visible and least rewarded part of a civil engineering project, yet it can make or break a bid — and decide whether a concept ever advances to detailed design. AEC Magazine spoke to Adam Tank, co-founder of Transcend, and Chris Haney, STV’s Operating Group President for Water, about how automation changes that equation

Civil infrastructure design is entering a period of structural stress. Utilities, municipalities and public authorities are being asked to make long-horizon capital decisions under conditions of growing volatility: climate instability, regulatory churn, drought and flooding cycles, political scrutiny, energy price uncertainty, population growth and intensifying public accountability for ratepayer spending.

Yet the phase of a project that disproportionately determines its long-term cost, sustainability and political viability still begins in preliminary design, and it remains stubbornly manual, slow and under-resourced. For all the digital progress made downstream in BIM workflows, clash detection and construction coordination, early-stage infrastructure decision-making is still dominated by spreadsheets, siloed modelling tools, expert workshops and linear iteration.

In an environment where clients increasingly demand rapid answers to “what if” questions - what if demand doubles, what if discharge limits tighten, what if energy prices spike, what if potable reuse becomes mandatory - design teams are under pressure to explore multiple plausible futures quickly. For a growing number of firms,

this is no longer a technical nice-to-have. It is becoming a strategic necessity.