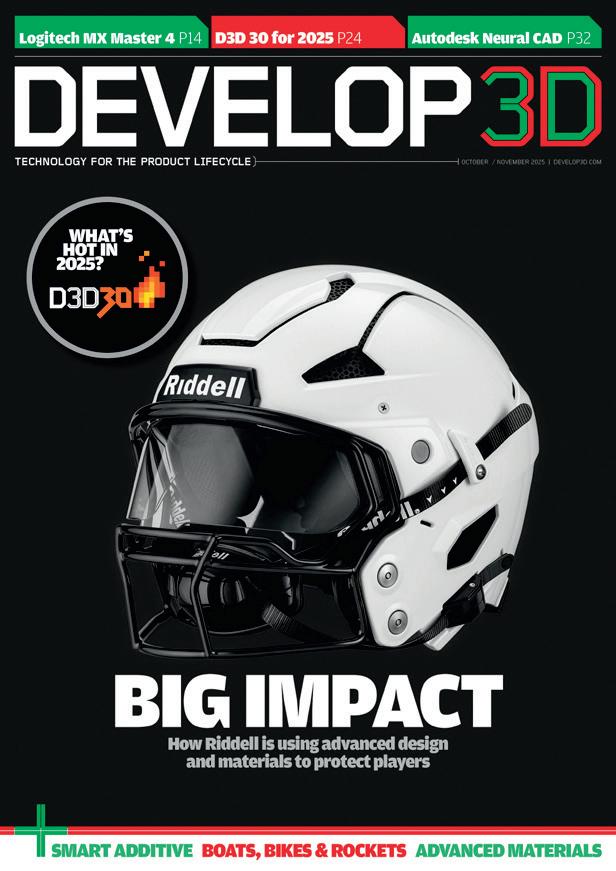

How Riddell is using advanced design and materials to protect players WHAT’S HOT IN 2025?

How Riddell is using advanced design and materials to protect players WHAT’S HOT IN 2025?

EDITORIAL

Editor

Stephen Holmes

stephen@x3dmedia.com

+44 (0)20 3384 5297

Managing Editor

Greg Corke

greg@x3dmedia.com

+44 (0)20 3355 7312

Consulting Editor Jessica Twentyman jtwentyman@gmail.com

Consulting Editor

Martyn Day martyn@x3dmedia.com

+44 (0)7525 701 542

DESIGN/PRODUCTION

Design/Production

Greg Corke greg@x3dmedia.com

+44 (0)20 3355 7312

ADVERTISING

Group Media Director Tony Baksh tony@x3dmedia.com

+44 (0)20 3355 7313

Deputy Advertising Manager

Steve King steve@x3dmedia.com

+44 (0)20 3355 7314

US Sales Director Denise Greaves denise@x3dmedia.com

+1 857 400 7713

SUBSCRIPTIONS

Circulation Manager Alan Cleveland alan@x3dmedia.com

+44 (0)20 3355 7311

ACCOUNTS

Accounts Manager Charlotte Taibi charlotte@x3dmedia.com

Financial Controller Samantha Todescato-Rutland sam@chalfen.com

ABOUT

During the course of 2025, the DEVELOP3D team has covered many, many miles across trade-show floors around the world in order to see the latest technologies, and we’ve plenty more miles to travel before the New Year.

You’ll see the results of our e orts in this issue, particularly in the D3D 30 listings, which include some truly incredible new finds that we think you’ll want to know about (see page 24).

On our travels, we’ve heard plenty of chatter about the burgeoning movement to reindustrialise production and reshore critical manufacturing. So far, this hasn’t gone much further than the industries you’d expect – mostly defence and space, sectors associated with low volumes, high customisation and deep pockets. But in order to shift even some production around the tari s and back on to home soil, the movement has to start somewhere.

Whatever the eventual outcome, there’s a renewed sense of optimism around producing parts at volume in the US, UK and Europe, and that’s also reflected in the latest technologies.

Our cover story for this issue takes a look at how 3D printing continues to creep ever closer to the mainstream, in the form of Riddell’s Axiom 3D helmet. Riddell’s means of manufacture allows for a better product overall, one that requires less testing and offers greater customisation, comfort and user experience. It can also be produced in the US for the domestic market. And most importantly, it helps protect its wearer better than any other helmet that has ever existed – an achievement only possible thanks to Carbon’s 3D printing and materials science technology.

There’s also a look at Aston Martin’s partnership with J. Laverack to produce a very special road bike, as well as the equally high-end Donkervoort and its eyecatching new supercar. In both cases, these are products for connoisseurs with big budgets and the results are still impressive. The .1R bike is not only bespoke and driven by purpose, but also is aesthetically beautiful. The air cooler design for the upcoming Donkervoort P24 RS is so e cient and compact, it’s a marvel of engineering.

DEVELOP3D is published by X3DMedia 19 Leyden Street London E1 7LE, UK

T. +44 (0)20 3355 7310

F. +44 (0)20 3355 7319

© 2025 X3DMedia Ltd

All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors in

In conclusion, the most advanced manufacturing methods are allowing the most exciting products to be made. Hopefully, bringing more of that technology closer to home is going to drive even greater design, and allow more of us to access it.

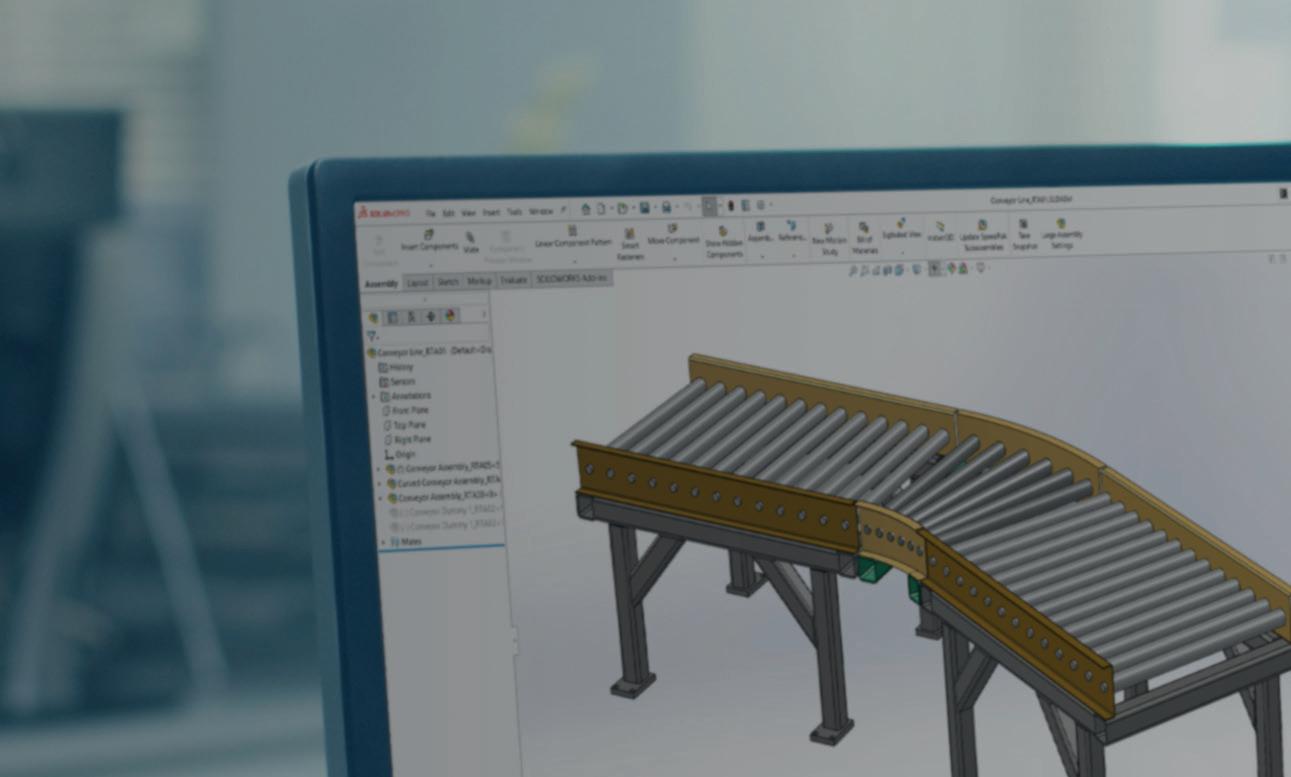

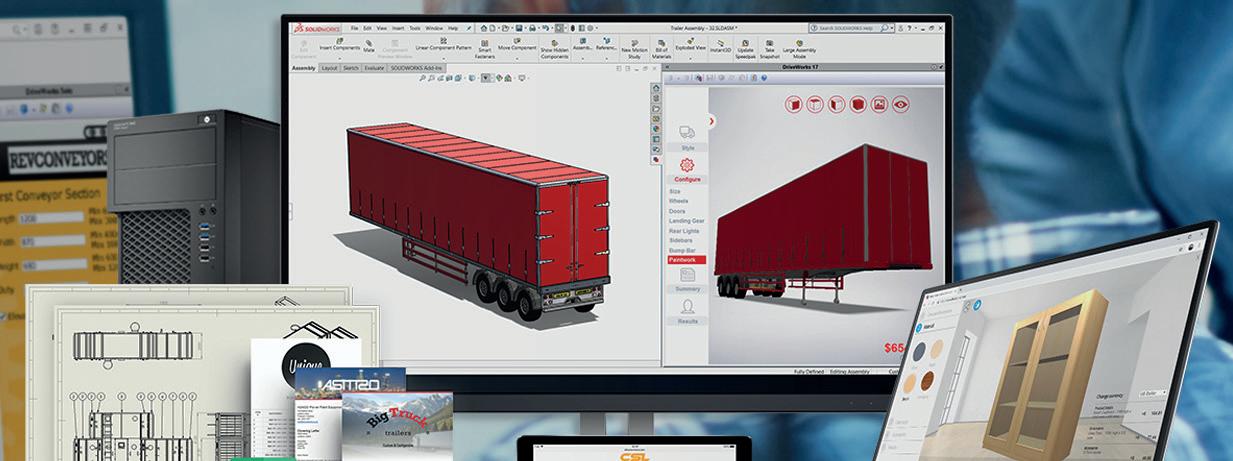

DriveWorks is flexible and scalable. Start for free, upgrade anytime. DriveWorksXpress is included free inside SOLIDWORKS or start your free 30 day trial of DriveWorks Solo.

Entry level design automation software included free inside SOLIDWORKS®

Entry level SOLIDWORKS part and assembly automation

Create a drawing for each part and assembly

Find under the SOLIDWORKS tools menu

Modular SOLIDWORKS® automation & online product configurator software

One time setup

SOLIDWORKS® part, assembly and drawing automation add-in

Automate SOLIDWORKS parts, assemblies and drawings

Generate production ready drawings, BOMs & quote documents automatically Enter product specifications and preview designs inside SOLIDWORKS

Free online technical learning resources, sample projects and help file

Sold and supported by your local SOLIDWORKS reseller

Complete SOLIDWORKS part, assembly and drawing automation

Automatically generate manufacturing and sales documents

Configure order specific designs in a browser on desktop, mobile or tablet

Show configurable design details with interactive 3D previews

Integrate with SOLIDWORKS PDM, CRM, ERP, CAM and other company systems

Scalable and flexible licensing options

Sold and supported by your local SOLIDWORKS reseller

Set up once and run again and again. No need for complex SOLIDWORKS macros, design tables or configurations.

Save time & innovate more

Automate repetitive SOLIDWORKS tasks and free up engineers to focus on product innovation and development.

Eliminate errors

DriveWorks rules based SOLIDWORKS automation eliminates errors and expensive, time-consuming design changes.

Integrate with other systems

Connect sales & manufacturing

Validation ensures you only offer products that can be manufactured, eliminating errors and boosting quality.

DriveWorks Pro can integrate with other company systems, helping you work more efficiently and effectively.

Intelligent guided selling

Ensure your sales teams / dealers configure the ideal solution every time with intelligent rules-based guided selling.

Autodesk unleashes Neural CAD AI foundation models, CAM Assist 2.0 unveiled, ExOne and VoxelJet come together for large format AI casting and more

Comment: Adrian Wright on the rise of the machines

Comment: Rich Wetzel on the AM training imperative

Visual Design Guide: Logitech MX Master 4 mouse

COVER STORY TOUCHDOWN AT RIDDELL

The D3D 30: This year’s hottest tech for product design

Event report: Autodesk University 2025

Boltless beauty: J.Laverack & Aston Martin’s bike design

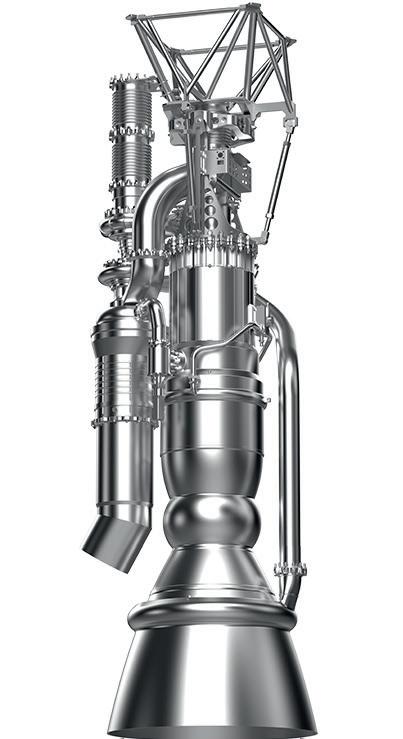

Final frontier: Metals 3D printing and the QL-1 rocket

Material world: Goodfellow’s guide to advanced materials

Donkervoort’s water-charge air coolers from Conflux

Crest of a wave: Arc’s new all-electric leisure craft

Ship shape: NMIS weighs up maritime lightweighting

New ways to manufacture products offer designers huge advantages, so why do so many stick to tried-andtest approaches, asks Stephen Holmes? The answer, he writes, lies in modernising industry education for all

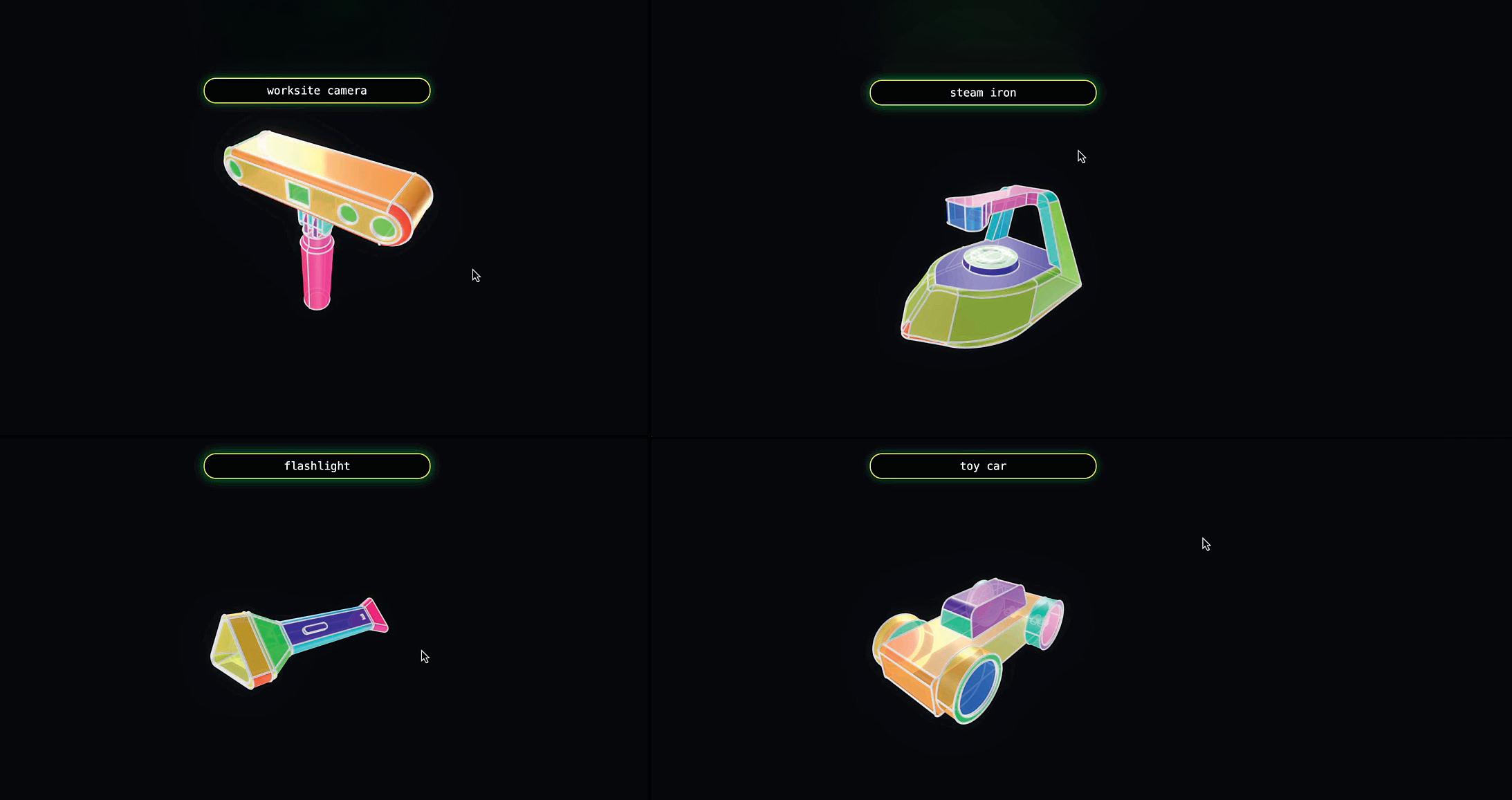

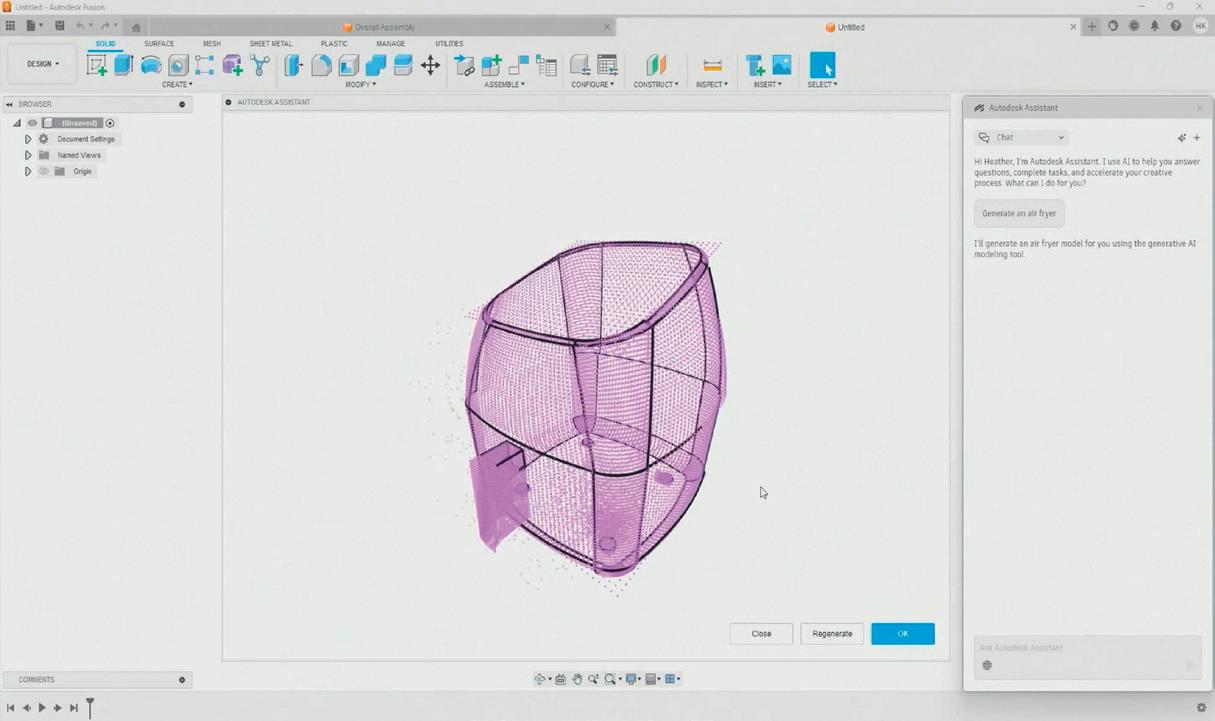

Autodesk has introduced Neural CAD, a new category of 3D generative AI foundation models coming to its Fusion and Forma products, which company executives claim will completely reimagine the traditional software engines that create CAD geometry and automate “80% to 90% of what you [designers] typically do” model."

Unlike general purpose large language models (LLMs) such as ChatGPT, Gemini and Claude, Autodesk's Neural CAD models are trained on professional design data, enabling them to reason at both a detailed geometry level and at a systems and industrial process level, exploring ideas like identifying the most efficient machine toolpaths or the optimal building floorplan layouts.

Autodesk says that, in the future, customers will be able to customise the neural CAD foundation models, by tuning them to their organisation’s proprietary data and processes.

So far, the company has presented two types of Neural CAD models, one for product geometry and another for buildings.

With Neural CAD for geometry, designers using Autodesk Fusion will be able to use language, sketching or imagery to produce first-class CAD geometry that can then be used directly in the product development and manufacturing processes.

With Neural CAD for buildings, meanwhile, architects using Autodesk Forma will be able to transition between early design concepts and more detailed building layouts and systems. www.autodesk.com

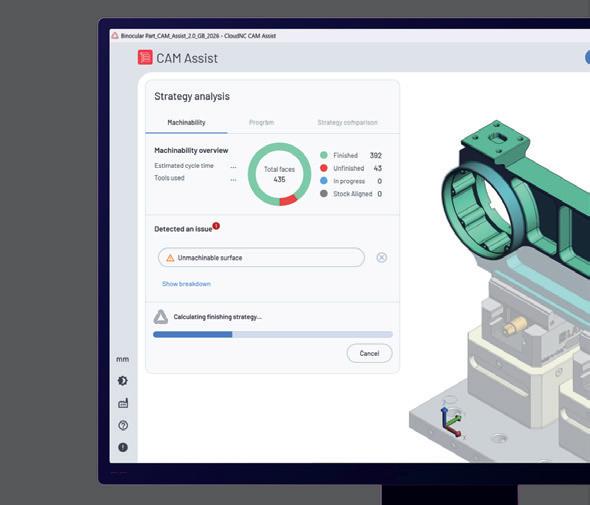

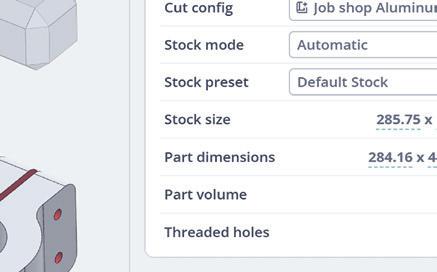

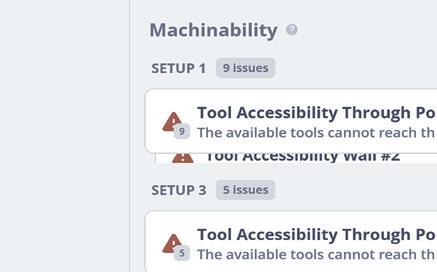

With the launch of CAM Assist 2.0, CloudNC is promising users the speed of AI-powered toolpath generation with new step-by-step oversight, giving programmers even greater control.

Improved workflows within CAM Assist 2.0 let users configure machines, materials and tool assemblies in minutes, review AI suggestions as they are made and export approved machining strategies directly into their CAM platform.

The web-based CAM automation application, which initiates from the user’s CAM package supporting 3-axis and 3+2 operations, features a new web user interface, from which the user still generates a working toolpath by pressing the CAM Assist button. CAM Assist 2.0 breaks out the AI stages so that parts can

be assessed prior to running. Moreover, as files are being computed, control over strategy editing is passed to the user.

The launch of CAM Assist 2.0 comes as CloudNC celebrates CAM Assist being used by over 1,000 machine shops globally to accelerate CNC programming with AI. www.cloudnc.com

xOne and Voxeljet are being united under ExOne Global Holdings, combining the expertise of the two rival large-format binder jetting 3D printing companies.

The move concludes a period of business uncertainty for both companies, with the two businesses looking to integrate their operations to provide a broader product line, better aftermarket support and global printing services. For users, it presents a catalogue of 7 Voxeljet and three ExOne printing systems able to produce parts in sand, ceramics and polymers, as well as a range of application-focused binders. www.exone.com

ModuleWorks’ new GPU Simulation technology will launch first in new releases of Cimatron and Mastercam, as part of ModuleWorks’ strategic partnership with Sandvik.

ModuleWorks GPU Simulation uses GPU-accelerated processing to increase simulation speed. The combination of this technology with the multi-axis capabilities of Cimatron and Mastercam is designed to enable more efficient verification and programming workflows and increase job throughput. www.moduleworks.com

CAM Assist enables users to configure machines, materials and tools in minutes

Siemens and leading machine tools and laser manufacturer Trumpf have partnered to join Siemens’ Xcelerator portfolio with Trumpf’s machinebuilding and software expertise.

The partnership aims to address the disconnect between information technology (IT) and operational technology (OT) systems that can hinder production efficiency and innovation.

Users are set to benefit from increased operational efficiency, reduced engineering costs and future-proof scalability by using open, modular automation solutions to advance AI-readiness and reduce time-tomarket, according to spokespeople from the two companies. www.siemens.com

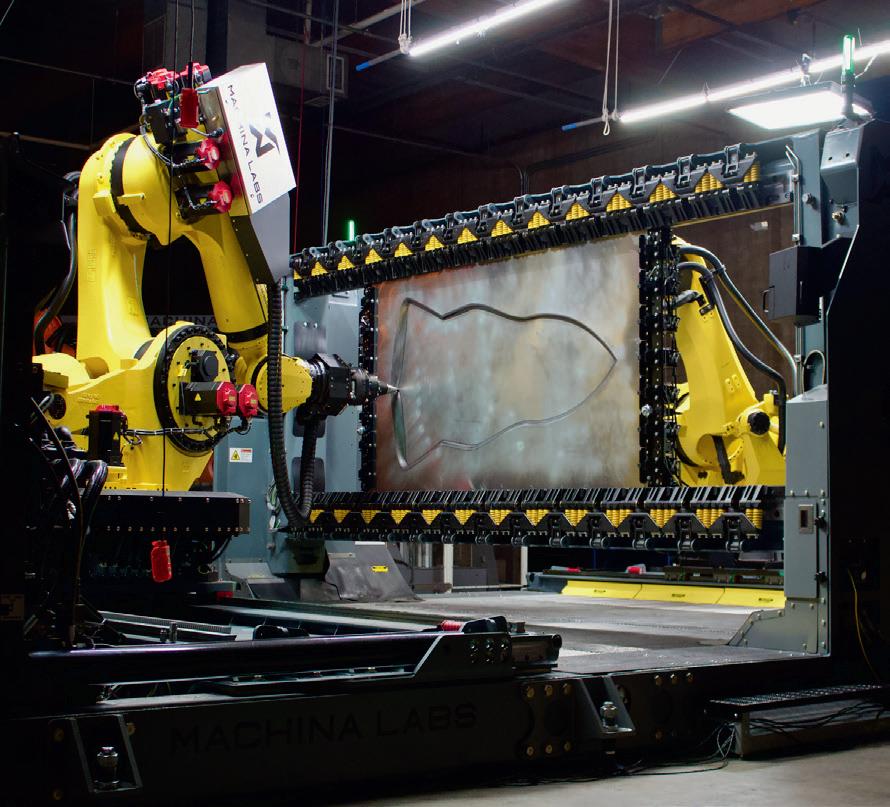

Machina Labs has announced its latest technology advancements for the customisation of automotive body panels and accessories without the need for extra tooling or dies away from existing production lines.

Machina’s RoboForming technology uses a proprietary form of incremental pressure forming – a robot positioned either side of the panel, shaping the design – to customise production body panels, eliminating the need for dedicated tooling per model variation. The use of robotic forming enables on-demand part production in low volumes from cells that can be placed near the existing assembly line, allowing for dynamic batching or broadcast-driven manufacturing – all without disrupting existing flow.

“Traditional production tools are often massive, comparable in size to a small car and weighing over 20 tons,” said Machina Labs CEO Ed Mehr. “With our solution, the need for dedicated tooling per model variation is eliminated. That means lower project capital, less storage both in-plant and for past models, which today can last up to 15 years, and faster production changeovers.”

The launch included a pilot of the technology with Toyota Motor North America and announcement of investment from Woven Capital, Toyota’s growth-stage venture investment arm.

“We envision a future where customisation is available for every Toyota driver,” said Zach Choate, general manager of production engineering and

core engineering manufacturing at Toyota Motor North America. “The ability to deliver a bespoke product into the hands of our customers is the type of innovation we are excited about.”

The automotive customisation and accessories industry was valued at $2.4 billion in 2024 for trucks alone. George Kellerman, founding managing director at Woven Capital, expects demand will continue to grow, while design teams and engineers need faster, more costeffective paths to create them without the constraints of traditional supply chains.

“We’re excited to team up with Machina Labs, supercharge their development roadmap in automotive, and support their journey in accelerating innovations that advance the future of manufacturing,” added Kellerman. www.machinalabs.ai

Engineers need faster ways to customise vehicles without supply chain constraints

Arburg is withdrawing from additive manufacturing and will shelve products including the Freeformer and innovatiQ technologies for polymer 3D printing, but no mention has been made of ArburgAdditive being sold off or spun out at this stage www.arburg.com

DyeMansion has acquired fellow German 3D printing post processing company ASM, expanding its vapour smoothing portfolio with the addition of ASM’s VX1, an entry-level production solution that boasts an all-in-one, plug-and-play design and a small footprint www.dyemansion.com

Materialise has unveiled the 2025 Magics release with nTop implicit geometries integration, with a view to helping users overcome traditional 3D printing design challenges by reducing build preparation time from days to seconds, while maintaining design precision www.materialise.com

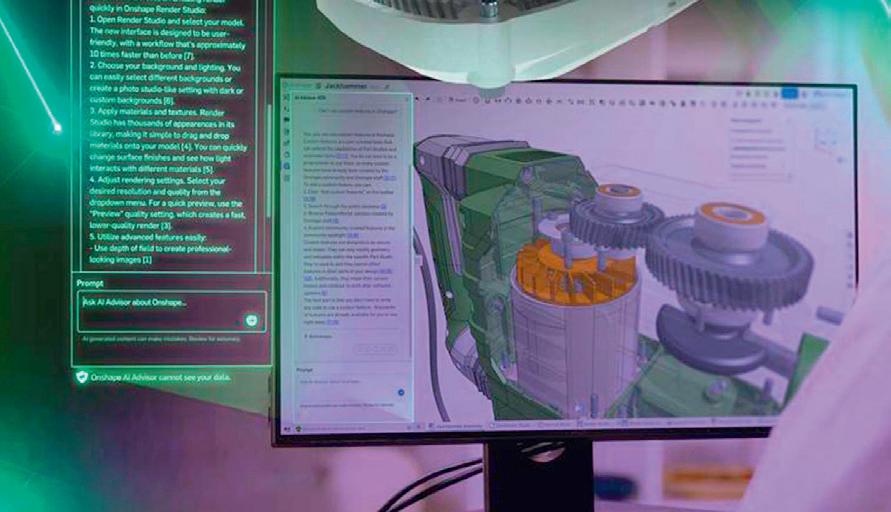

PTC has announced that Onshape AI Advisor is now embedded directly in the CAD software’s design environment, providing realtime guidance as users create.

The latest Onshape update gives every user of the product immediate access to its new AI capabilities, which PTC notes as being powered by Amazon Bedrock.

With a redesigned interface, AI Advisor sits within the main Onshape workspace, providing users with step-by-step recommendations, troubleshooting features and best practices as they work.

The announcement also gave insight into PTC’s plans for AI within Onshape and potentially other software such as Creo, Windchill and Arena.

PTC says it is advancing agent workflows in Onshape to enable productivity, to

help collaboration via intelligent design agents and to support interaction with model metadata. They will also be capable of assisting with model troubleshooting tasks, generating FeatureScript code and streamlining repetitive operations that sap designers’ time. www.onshape.com

now offers a helping hand from AI in tasks that can eat up design time

LK Metrology has announced point cloud inspection package Focus 2025 R1 as part of its software suite to drive its H120 handheld laser scanners and Freedom scanning arms, as well as modernisation of its file menu, giving users clearer visibility of recent files www.lkmetrology.com

CAD Rooms has launched a cloud-based product data management (PDM) solution called CAD Rooms, which aims to eliminate technical silos and equip teams with tools to work regardless of location. It supports over 30 file formats and open standards like STEP and STL www.cadrooms.com

Amulet Hotkey has updated its CoreStation HX2000 datacentre remote workstation with a new Intel Core Ultra 9 285H processor option, delivering higher clock speeds and built-in NPU AI acceleration.

The CoreStation HX2000 is built around a 5U rack-mounted enclosure that can accommodate up to 12 single-width workstation nodes, which can be removed, replaced or upgraded.

Each workstation node is accessed by a single user over a 1:1 connection and can be configured with a choice of discrete MXM laptop GPUs – the Nvidia RTX A1000 (4 GB) or Nvidia RTX 2000 Ada (8 GB) –

making it well-suited to mainstream CAD and BIM workflows.

Features include redundant power and cooling, hot-swappable components and ‘full remote system management’, including core management capabilities such as secure remote access, power control, BIOS-level KVM access and system-wide firmware updates.

The Intel Core Ultra 9 285H features six performance (P) cores and eight efficient (E) cores and delivers clock speeds of up to 5.4 GHz. Although the processor is typically used in laptops, Amulet Hotkey says its datacentre integration provides greater power and cooling headroom than a mobile platform. www.amulethotkey.com

Lenovo has redesigned its flagship mobile workstation, the ThinkPad P16, with a new Gen 3 edition that is thinner, lighter and draws less power than its Gen 2 predecessor.

The 16-inch pro laptop features the latest ‘Arrow Lake’ Intel Core Ultra 200HX series processors (up to 24 cores and 5.5 GHz) and a choice of Nvidia graphics up to the RTX Pro 5000 Blackwell Generation (24 GB) Laptop GPU.

This workstation may come with a topend mobile CPU and GPU, but its smaller 180W power supply — down from 230W in the previous generation — suggests to DEVELOP3D that some performance may be left on the table. This would particularly true when configured with the RTX Pro 5000 Blackwell, which alone has a max power consumption of up to 175W.

Lowering power improves portability and energy efficiency, but could put Lenovo at a performance disadvantage against

rivals. However, the move could be seen as paving the way for a beefier 16-inch or 18inch model that might ultimately surpass the ThinkPad P16 Gen 3 as the company’s most powerful mobile workstation. www.lenovo.com

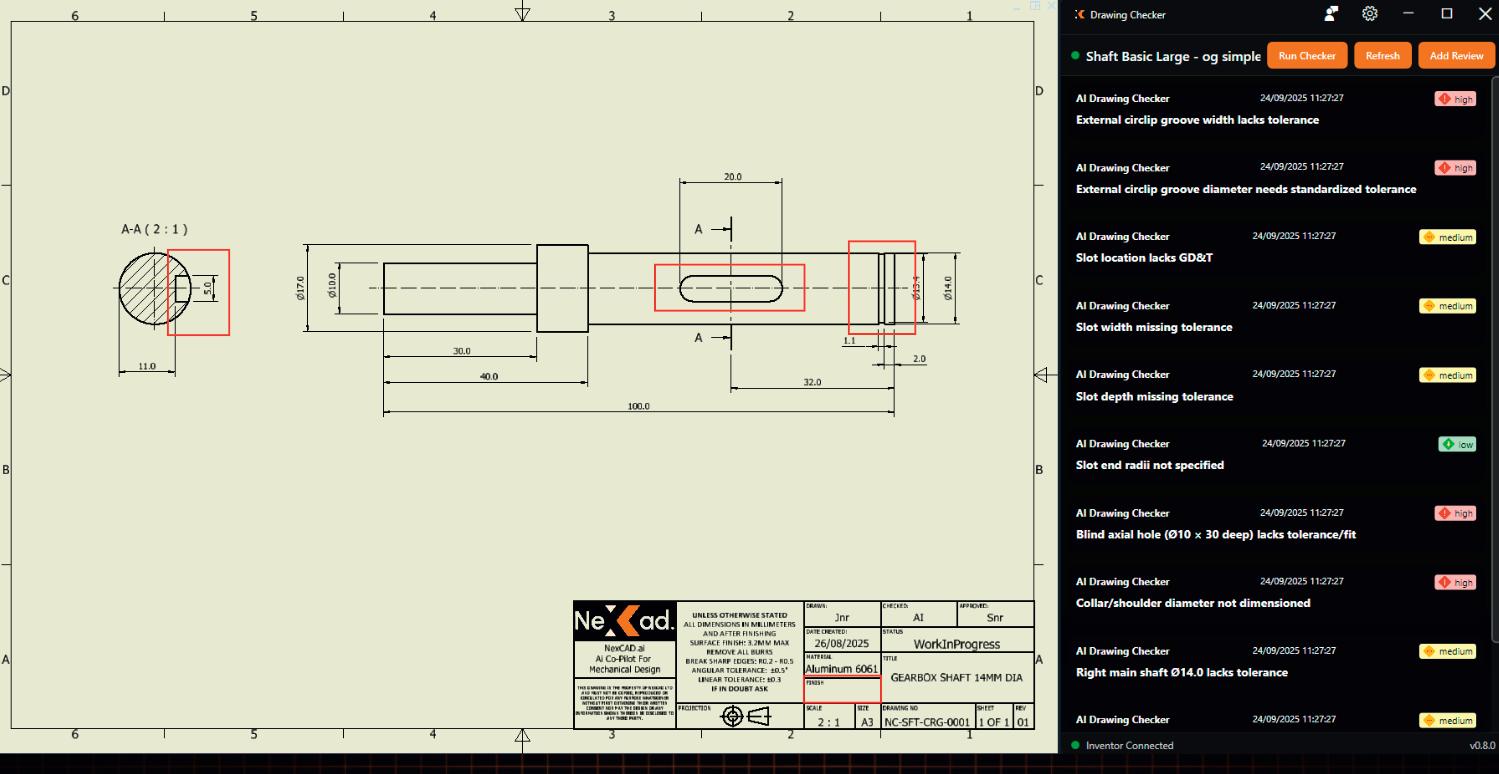

NexCAD has launched AI Checker, an intelligent assistant to automate engineering drawing reviews, cut review times and prevent manufacturing errors.

At launch, AI Checker supports Autodesk Inventor and Solidworks, while the company plans to integrate further CAD softwares in the future.

AI Checker has been trained on engineering standards and best practices and has proven to be highly accurate. It also learns from user feedback to continuously improve its performance according to specific user requirements. www.nexcad.ai

OpenBOM has announced the private beta release of its AI BOM Agent with Model Context Protocol (MCP) support.

It's a vital ingredient in OpenBOM's vision of AI agents playing a vital role in BOM quality and validation, helping companies to ensure accuracy, consistency and readiness of data before that data flows into their procurement and production systems. www.openbom.com

Lenovo's ThinkPad P16 is thinner, lighter and draws less power than its predecessor

Chaos V-Ray will soon support AMD GPUs, so that users of the photorealistic rendering software can choose from a wider range of graphics hardware, including the AMD Radeon Pro W7000 series and the AMD Ryzen AI Max Pro processor that has an integrated Radeon GPU.

Until now, V-Ray’s GPU renderer has been limited to Nvidia RTX GPUs via the CUDA platform, while its CPU renderer has long worked with processors from both Intel and AMD.

Chaos plans to roll out the changes publicly in every edition of V-Ray, including 3ds Max, SketchUp, Revit and Rhino, Maya and Blender.

At Autodesk University in September 2025, both Dell and HP showcased V-Ray running on AMD GPUs. www.chaos.com

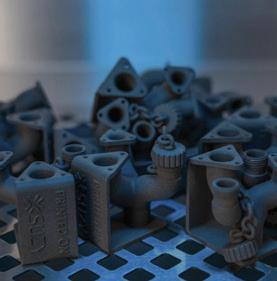

A lack of adequate staff training is a common weak link in the adoption of additive manufacturing, but with smart thinking and investment, it can be one of the simplest issues to solve, writes

Additive manufacturing (AM) is no longer a new technology – and we need to stop treating it as if it is. If we don’t, it will keep catching us by surprise. As with any production-grade technology, it only makes sense to invest in AM when investing in the entire workflow. Otherwise, it’s a recipe for failure.

Organisations investing in AM systems often underinvest in the skills and procedures that make them productive. As an industry, we must build up AM capabilities by building up the people responsible for them. In production, ‘good enough’ is never adequate.

We see this all the time, as AM moves from 3D printing for prototyping purposes to building molds, tooling, fixtures, final parts and other mission-critical structures. Rising rates of standardisation mean organisations expect better of parts, whatever the technology used to produce them.

If AM-made parts aren’t good enough, end users and others in the supply chain will reach the false conclusion that AM itself isn’t good enough. It’s time to face that gap and to work out best practices designed to bridge it.

Manufacturing, at its best, is always boring. Boring is predictable, repeatable and reliable – all the things, in short, that manufactured parts must also be.

A good AM work cell looks boring. Builds begin on time, the standard test part sits nearby, and hand-offs between workers happen seamlessly.

When an error occurs, they know how to recognise it and what to do next. This is the result of a structured approach to people and process, which starts with investment in training.

The more AM falls under this umbrella, the more realisable the technology and its goals will be.

Training is often treated as a single event, and typically comes in the form of a vendor demonstration, with the assumption that proficiency in the process will follow. From there, daily practice is overshadowed and reliance on a few expert individuals becomes daily practice. This is an unfortunate reality experienced by many firms that didn’t invest in structured, skillsbased training.

This lack in training is one of the single biggest weak links in the AM chain – and one of the simplest to address to turn performance around.

Developing skills is one thing, but repeatable success in AM depends on different people making the right decisions at the right time. Specific roles require different types of training content and in different formats. For example, a designer would certainly benefit from instructor-led training when learning a new software, but a manager may receive more value from asynchronous online training. Organisations should build pathways to meet each role where the work actually happens.

To create scalable, repeatable successes, they should approach team training the same way. That means documenting successes and failures throughout and integrating these situations into refreshers for the team. Let training continue building upon a foundation, wrapping lessons learned into ongoing education.

At The Lanterman Group, we have seen measurable success among teams that approach their training with the same care that they devote to every other aspect of their end-to-end workflow. We’ve developed real-world tested training plans that target measurable goals, using blended learning that focuses on skills development for specific roles.

Interactive online modules, digestible content, asynchronous offerings and virtual reality are just some of the remote, yet hands-on, approaches that we’ve found effective.

Manufacturing, at its best, is boring – predictable, repeatable and reliable. All the things, in short, that manufactured parts must also be

People don’t become proficient in AM by attending a single training day. They get good by doing the work and putting in the practice in a way that’s enabled by the leaders of their organisation.

Take Ohio-based Humtown Additive, for example: the company built a capability around 3D-printed sand cores and moulds, scaling binder jet production and earning global recognition as an industry leader. Its success can be attributed to its investment in talent development and culture initiatives that treat learning as an operating system and not a one-off programme.

Your entire AM production flow remains dependent on a few individuals. Avoidable failures will occur, safety is compromised and quality varies by shift. This isn’t inevitable, but it shouldn’t come as a surprise, if training is treated as an afterthought.

Why invest in AM without investing in the expertise needed to use and manage expensive equipment and materials? That’s tripping at the (very costly) finish line, when what you should have done is more training before the race. Let’s approach the AM race like we mean to win it.

ABOUT THE AUTHOR: Rich Wetzel is president of The Lanterman Group, a Chagrin Falls, Ohio-based consulting company that focuses on building the AM workforce through expert-led training. Wetzel has worked with organisations including America Makes, the US Department of Defense and Youngstown State University www.thelantermangroup.com

In an era where manufacturing efficiency is more crucial than ever, businesses across the industry are looking for ways to reduce costs, minimise waste and enhance productivity.

Automation and Industry 4.0 have become buzzwords as well as dominant trends, with manufacturers increasingly integrating robotics, data-driven decision-making and smarter machinery into their processes.

It was previously predicted that by 2025, some 50% of manufacturers globally would adopt IoT technologies as part of their Industry 4.0 strategies. Adoption is driven by the potential for productivity increases of 20% to 35% and reductions in downtime of up to 50%.

However, one aspect that often gets overlooked in these discussions is energy efficiency — an area where modern CNC routers and fibre lasers are redefining what’s possible.

Waste reduction is an ongoing challenge in manufacturing. While many businesses recognise the importance of optimising efficiency, few fully quantify the financial and environmental cost of material waste. Take, for example, a manufacturer that we at Daltons Wadkin recently spoke to about improving accuracy and driving efficiency gains. The company was discarding 20% of parts for every 1,000 parts produced, meaning that 200 parts per batch were going straight to waste. At another company, only three out of 16 precision blades met its required tolerances, resulting in a staggering 75% to 80% scrap rate. These inefficiencies aren’t just costly in terms of raw materials. They also have a direct impact on operational costs, including machine running times, energy consumption and additional labour. Data shows that companies can spend between 4% and 10% of their annual turnover on waste if they lack proper waste management strategies.

Industry reports suggest that manufacturing waste accounts for billions in losses annually. According to some reports, the manufacturing industry generates around 17% of global waste, further exacerbating supply chain constraints and environmental impact.

Traditional manufacturing processes often rely on outdated machinery with high energy consumption and inconsistent performance. In contrast, modern CNC routers have been engineered to optimise material usage, improve accuracy and significantly lower power consumption.

One of the primary advantages of CNC routers in multi-material manufacturing is their precision. By reducing deviation in cuts and machining, modern CNC routers minimise scrap, leading to both cost savings and sustainability benefits.

Furthermore, CNC routers integrate seamlessly with smart factory systems, offering real-time data insights on energy use, maintenance needs and material efficiency.

Beyond material savings, modern CNC routers also offer substantial energy efficiency benefits. The shift towards leaner, greener machines is evident in the latest developments across the industry.

During a recent trip to visit Italian press brake supplier Schaivi, I saw first-hand the importance of energy efficiency. The point driven home to press brake users is how fully electric small- and mediumsized machines are more efficient than full hydraulic machines and are offered in higher tonnage by comparison.

Smart automation is now also allowing press brakes to achieve job changeovers with zero operational setup time – a remarkable leap in efficiency.

For manufacturers, the financial case for energy-efficient machinery is clear. The cost of running high-energy, inefficient equipment quickly adds up, especially when

While many businesses recognise the importance of optimising efficiency, few fully quantify the financial and environmental cost of material waste

factoring in rising electricity prices and sustainability targets.

As manufacturers face growing pressure to cut costs while improving sustainability, those who invest in smarter solutions today are more likely to secure a long-term competitive edge.

Automation technologies have been shown to be capable of reducing energy consumption by up to 20% in manufacturing processes, yet despite such easy wins, many manufacturers still operate in a reactive mode, dealing with inefficiencies only when they become too costly to ignore. However, the businesses that will thrive in the future are those that proactively seek smarter solutions now.

The energy efficiency revolution in manufacturing is here, but only those who take action will reap its benefits.

As automation, robotics and data utilisation continue to define the industry, businesses must look beyond simply acquiring new machinery and instead invest in solutions that drive real, measurable efficiency and productivity gains.

The future of sustainable, costeffective manufacturing is within every manufacturer’s reach. For those looking to stay ahead of the curve, now is the time to rethink their approach to efficiency.

ABOUT THE AUTHOR: Adrian Wright is a fibre laser and sheet metal specialist at Daltons Wadkin, a Nottingham, UK leader in implementing precision-driven CNC and laser solutions with the aim of helping manufacturers to cut down on waste and improve efficiency www.daltonsmachines.com

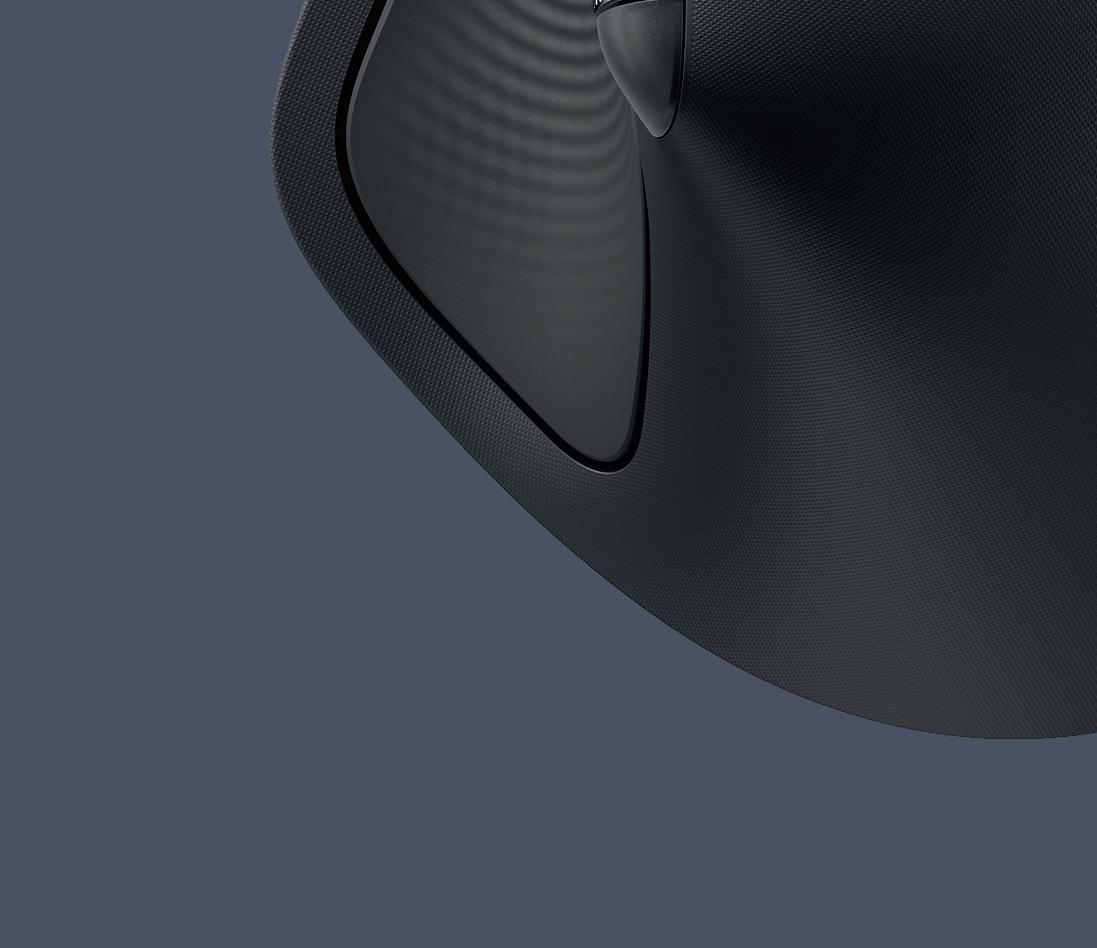

» Logitech’s new high-performance mouse reimagines user control with customisable haptic feedback that delivers subtle vibrations for scrolling, navigation and selection

An 8,000 DPI sensor provides smooth, accurate tracking on virtually any surface, including glass

In terms of its environmental credentials, the Master 4 boasts 48% post-consumer recycled plastics shell panels, a low-carbon aluminium thumb wheel and a battery based on 100% recycled cobalt. The mouse has also been designed for easy disassembly in preparation for recycling at the end of its useful life

Customisable haptic feedback delivers subtle vibrations that bring a tactile precision to design work, as well as tasks such as video editing and data analysis

Action Plan, a digital overlay enabled by Logi Options+, o ers app-specific shortcuts and customisable controls, saving users 33% of their time and reducing repetitive mouse movements by 63%, according to Logitech executives

The Haptic Sense Panel features a 3D design inspired by ripples on water developed using computational design tools and producing a pattern that the company says embodies “the craftsmanship of the digital era”

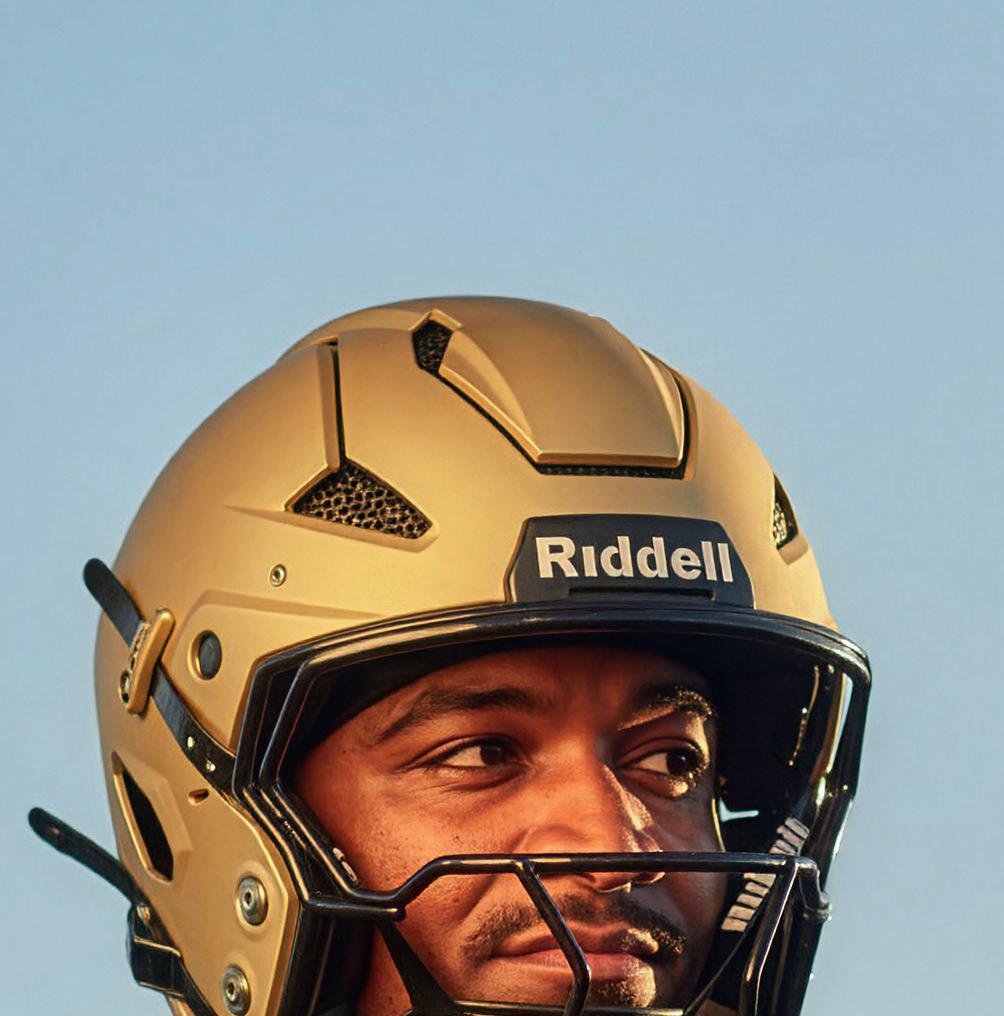

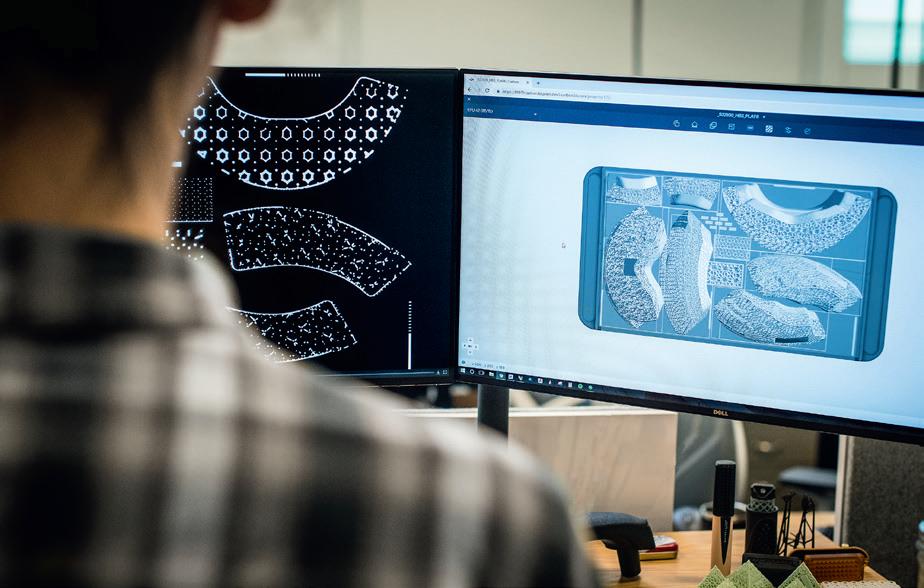

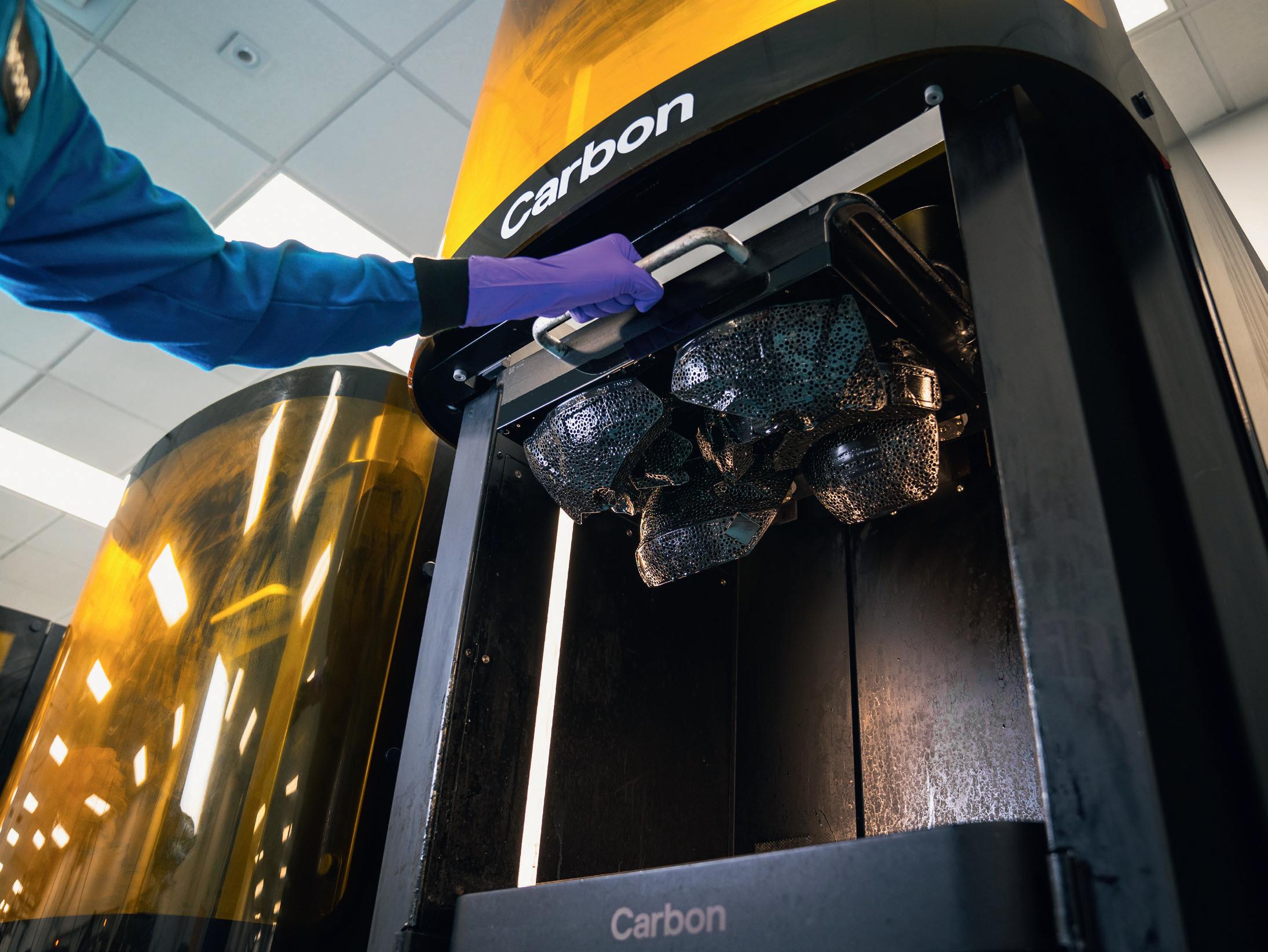

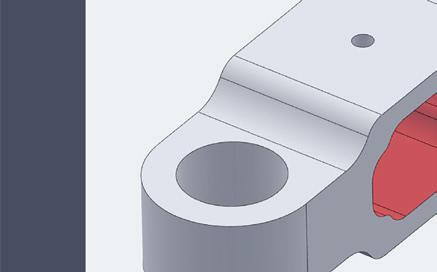

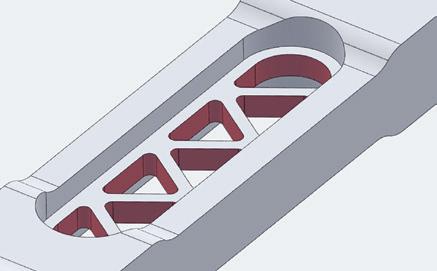

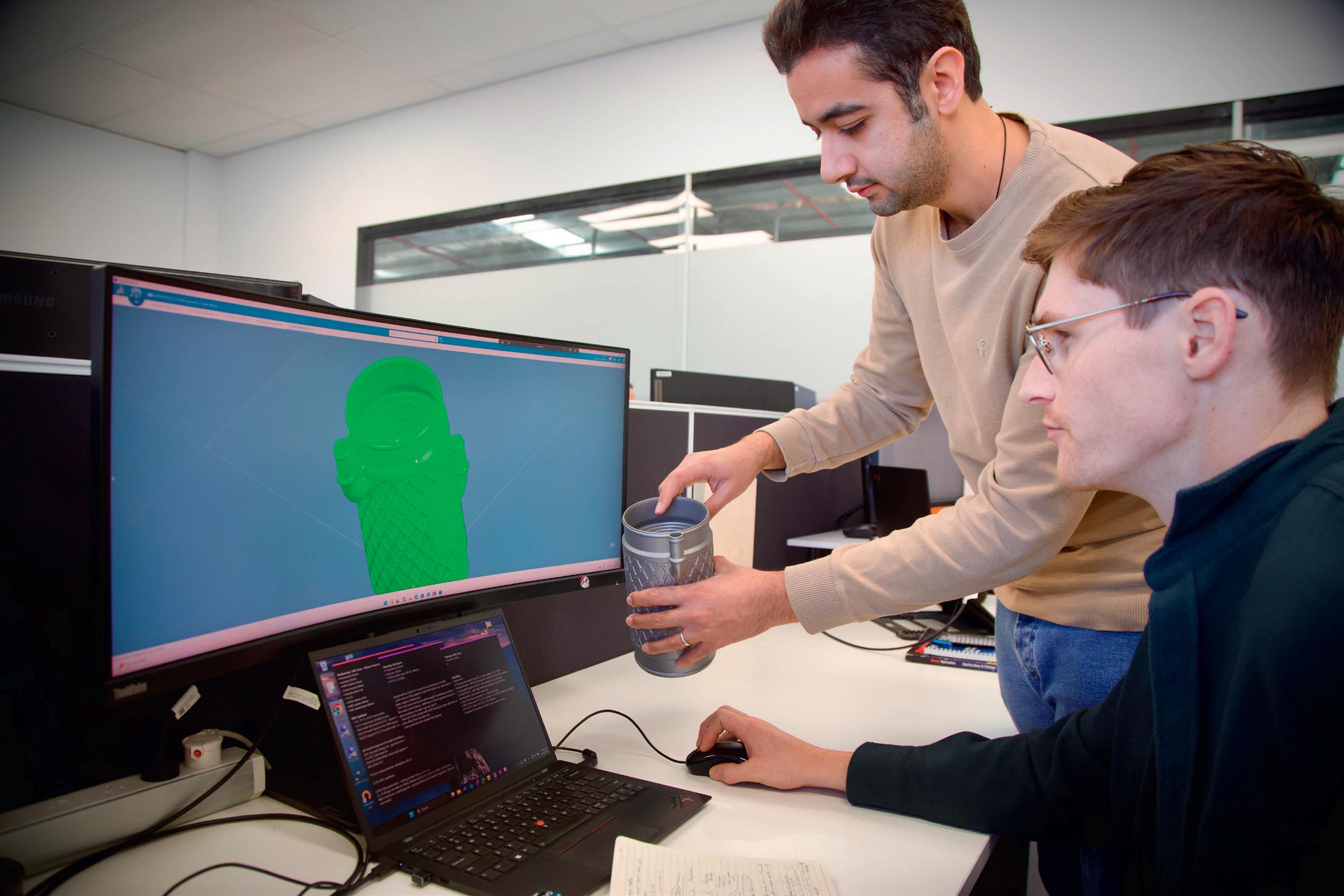

For its Axiom 3D helmet, Riddell uses additive manufacturing to build the liner components that deliver improved impact response

» In a sport where powerful collisions are all part of the action, protecting players is a priority. Stephen Holmes speaks to helmet manufacturer Riddell about Axiom 3D, its latest product that brings computational design and 3D-printed polymer lattices onto the field

The thump of protective pads connecting. The crack of helmets colliding. The gasps as breath is forcibly expelled at speed from lungs. The thud of hefty bodies hitting the ground.

American football is a tough game.

Contact between players in the NFL (National Football League) can be perilous, thanks to the sheer forces that come into play when athletes in peak physical condition and minds focused on victory meet on the field. Even at lower and amateur levels, this sport can be extremely punishing for competitors.

With the aim of protecting players at all levels, Riddell Sports Group has been at the forefront of helmet design ever since founder John Tate Riddell launched the first plastic shell helmet in 1939. Over the decades, Riddell has added innovations including chin straps, face masks and air-filled padding.

Its research in the area of materials has seen thermoplastics and polycarbonate polymers contribute to increased protection and enabled colour to be baked into helmets since the 1940s, enhancing the spectator experience with recognisable colours and team identities.

In the 2000s, helmet manufacturers began to focus more specifically on addressing the risk of concussion. Helmet forms and materials were updated thanks to new testing methods. Electronics like Riddell’s Head Impact Telemetry Systems introduced sensors that have since collected well over two million data points relating to onfield impacts.

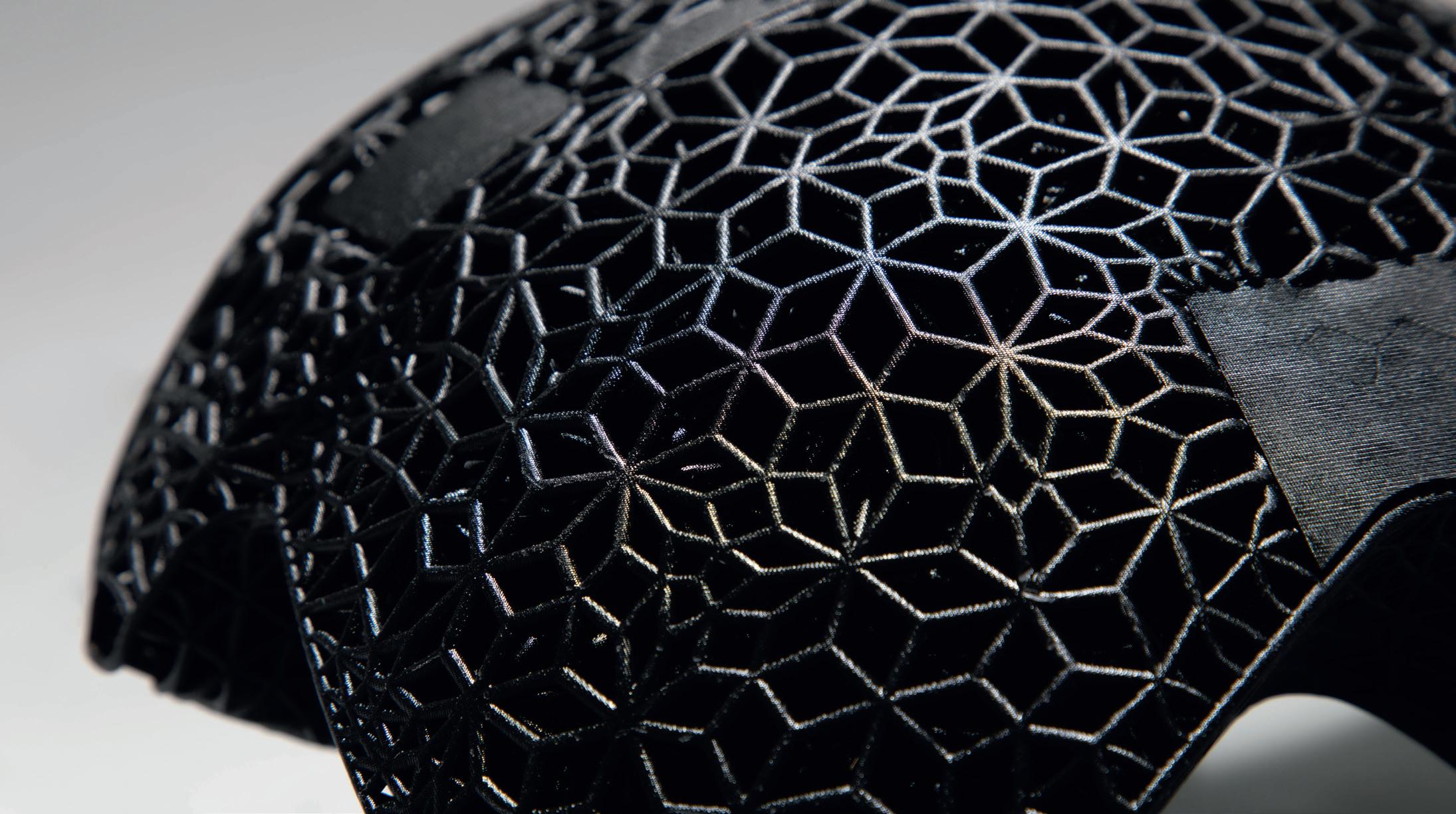

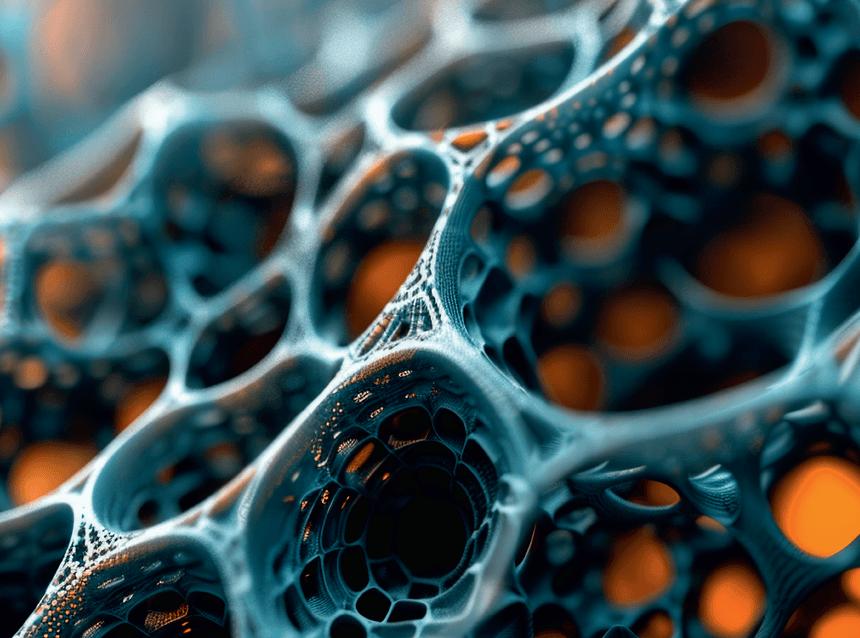

One of the greatest modern evolutions to the helmet arrived in 2019, with the arrival of individually tailored polymer lattice structures, which replaced massproduced foams. This success – and its subsequent enhancement – is reflected in one of Riddell’s latest products, the Axiom 3D, which today is rated the number one helmet available to NFL players.

Throughout his career, Thad Ide has kept on top of all these developments. In his current role as Riddell’s chief product officer, he oversees the incorporation of cuttingedge design approaches and carefully monitors players’ changing attitudes to the equipment that keeps them safe.

“Twenty-five years ago, I think players were a lot more resistant to change and to new technology than they are

today,” he says, speaking from Riddell’s headquarters in Chicago, Illinois. “I think that now, they’re far more receptive to legitimate new technologies that can help them perform better, stay healthy and stay on the field.”

A big part of this mindshift comes down to customisation. Today’s helmets are designed not just for the part played by each position out on the field, from quarterbacks to wide receivers, but also for the exact dimensions of each individual player.

Ensuring an exact fit used to involve a Riddell representative travelling cross-country and lugging a large Pelican case to each team’s equipment room, to set up a 3D scanning station there. Today, the data capture process far simpler and more seamless, according to Ide, and is used not just for a team’s brightest stars, but also its up-andcoming hopefuls.

It’s so much simpler, in fact, that a team’s own equipment staff can be trained to perform full head scans themselves, with the process taking only minutes.

That said, Riddell representatives continue to visit toplevel teams regularly, says Ide. “It gives us the opportunity to have some interaction with the players, to learn about what they want from the product, how they want it to fit and about different aspects of the product that make it unique to them.”

It’s vitally important that members of the Riddell design team keep up to date with how the science around head protection and injury prevention is evolving and that they constantly monitor the latest research and studies from around the world.

They must also understand the needs of players at different levels of the sport. “Somebody who’s buying helmets for 12-year olds is maybe not thinking about it the same way as people buying helmets for elite university athletes or professional athletes,” says Ide.

“That’s kind of our job: to understand what goes on at every level of play, and what features and attributes in the helmet can best serve the athletes at that level of play.”

At youth level, for example, teams are particularly focused on protecting young athletes and will naturally gravitate towards the best protection available – yet at the same time, such purchases also need to take into account budgetary and aesthetic considerations.

“You shouldn’t underestimate the influence a teenager asking for something can have on his coaches or athletic directors,” Ide says.

This ‘mirror test’ is an important consideration, because Riddell’s designers are aware they can build the very best protective product in the world – but if players don’t want to wear it, it’s not protecting anyone.

‘‘ I want to give the design team the software package that allows them to their job the way they want to do their job and create the best product

Thad Ide, Riddell Sports Group

Riddell’s design team is hardly short on feedback, given that almost 80% of NFL players wear the company’s helmets, a proportion that jumps to around 89% of players at college level.

Aside from some early sketch concepts, Riddell’s workflow quickly jumps into digital mode, says Ide. “We put a design right into either Creo or Solidworks very early on in the process, because that allows us to then create 3D-printed prototypes that we can evaluate – the look, the aesthetic, sometimes even physical prototypes that are testable.”

Known in the industry as ‘the Helmet Guru’, Ide has worked in team sports helmet design for over 30 years.

He is keen to point out that Riddell gives members of its design and engineering team the freedom to choose any software that they think can make a difference when it comes to adding safety to the design. For CAD, this means PTC Creo and Dassault Systèmes Solidworks, but also McNeel Rhino, among others.

“I want to give them the software package that allows them to do their job the way they want to do their job and create the best product,” he says.

This approach also applies to simulation. The team uses Ansys LS Dyna and its FEA toolset for simulating drop tests and impacts, for example. However, simulating the whole protective system of each helmet configuration

can prove overly complex when compared to physically building a helmet and putting it through its paces.

Ide says that the design and testing laboratory at its Riddell’s headquarters is second to none, allowing the team to produce full-scale prototypes and put them through a variety of impact tests. They then take those results back to the design, in order to develop the next iteration – something that can often tell the engineers more about a design in the long run.

“Ultimately, it’s going to have to perform in the physical world. That’ll be the ultimate grade of the product,” he says.

Riddell has a number of 3D printing and machining capabilities for prototyping, but the ability to prototype faster and with greater accuracy has been significantly boosted by the company’s adoption of digital light synthesis 3D printing from Carbon.

Having first adopted the technology in 2019 for its SpeedFlex helmet platform, this is how Riddell incorporates 3D printed lattice pad structures inside the helmet liner in a custom fit for each individual player.

The use of additive manufacturing has removed the need for tooling, and the same polymer, EPU 45, is used in production as well in testing. As a result, the designers can tune the impact performance of a helmet rapidly to get the responses they want, knowing that the end product will pass all necessary tests. By not having to commit to hard-tooling to produce parts, they are also free to continue developing and upgrading a product after its launch.

The Riddell team works very closely with the Carbon team based in Redwood City, California, particularly its application specialists, with their advice on using Carbon Design Engine to generate lattices, identify appropriate materials and custom-tune products.

“The same lattice doesn’t work the same everywhere in the helmet,” explains Ide, “so you have to have custom lattices that work all around the player’s head.”

With constant design iterations and test feedback, Riddell is now able to customise helmets to tune the compliance and dampening provided by sections of the lattice for the specific needs of different player positions.

“There’s a way to tune them for the types of impacts that a quarterback would be expected to see, or a lineman would be expected to see, or an all-purpose player. So, the latticing structure that the Carbon technology supports lets us tune the liners.”

Using 3D scan data – now provided by Riddell’s own Verifyt app, which uses a mobile phone’s camera –Axiom helmets fit to the surface of each player’s head exactly. The whole internal system of the helmet, in fact, is lined with protective material.

Regardless of the lattice form they take, 3D-printed materials have to perform in every environment in

● 3 Carbon Design Engine is used to develop the intricate lattices for each section of a helmet

● 4 3D-printed lattice liners are fitted to Axiom 3D helmet shells

● 5 Riddell’s testing lab is one of the best-equipped for testing head impacts

which the sport is played. It could be freezing nights in Detroit, scorching afternoons in Arizona or damp, foggy mornings in Seattle. Materials must remain stable and perform well regardless of climatic conditions, and this is a key selling point of Carbon’s EPU 45 polymer.

The Axiom helmet design also features engineered flex points in its outer shell. These were first debuted in the 2014 SpeedFlex helmet, along with a hinged cantilever panel at the front of the shell. The Axiom design takes this concept and runs with it, adding fl ex panels to the sides and the rear of the shell as well. These are selectively tuned to deliver the best impact response.

“You might ask, ‘Why didn’t you do that right off the bat in the SpeedFlex in 2014?’ And the short answer to that is because it was a scary prospect – taking

away from the shell!” says Ide. “We needed to see how it performed on the field before we expanded the concept.”

With the wellbeing of players on the line and every moment of a game scrutinised in high definition, the stakes are high. “Nobody wants to see anything fail on the field. We spend a lot of time engineering our products so they perform as people expect them to perform.”

Ide hopes that Riddell can now drive its 3D-printed lattice helmet technology down to high school players and younger. “I can see the protective advantages and the fi t advantages. We’re working to do that,” he says.

Regardless of the high-stakes action on the field, nothing is more important than player safety – and Riddell’s got that covered.

www.riddell.com

Build volume: 130 x 180 x

Build speed: up to 20 mm/h

Layer height: 75 microns

Max part size: 398mm

Laser: 30W IR fibre

Materials:

By: Emily Suzuki

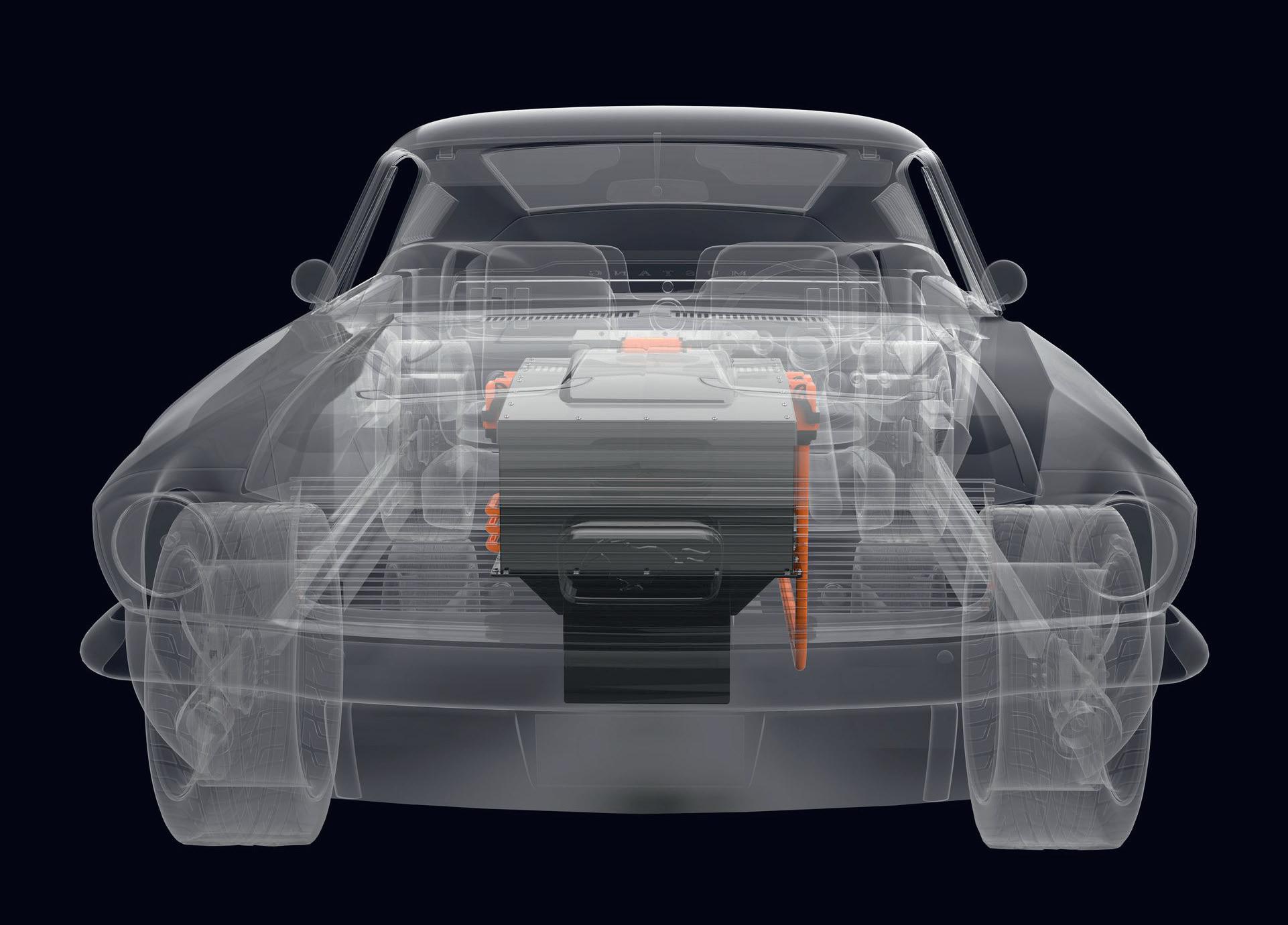

With the numerous innovative electric vehicles on the road today, it may seem surprising to consider that a classic, gas-powered car could be more sustainable than its modern counterparts. Picture this: under the hood, the engine is removed and replaced with a smooth, reliable battery. No new materials or manufacturing are required. It’s a bold move for the circular economy and the ultimate reuse of existing vehicles. Less noise, less pollution, and the undeniably cool, retro style remains.

This isn’t just hypothetical. Based in the UK, Fellten is making the transformation and retrofits of old MINI Coopers, Porsches, and Land Rovers into clean electric vehicles a reality.

“The goal is to basically give all of these classic cars a new life by creating a solution that you can bolt in without changing the bones,” says Lucy Dicken, design engineer, Fellten.

“With our projects, we’re basically taking an item that was not designed to be electric, which involves a humongous amount of design and development,” adds Chris Hazell, co-founder and CEO, Fellten. “We’re fundamentally taking a battery that’s

normally underneath a car and making it engineshaped to put under the hood. At the same time, we’re doing this without making any modifications to the original chassis or vehicle at all.”

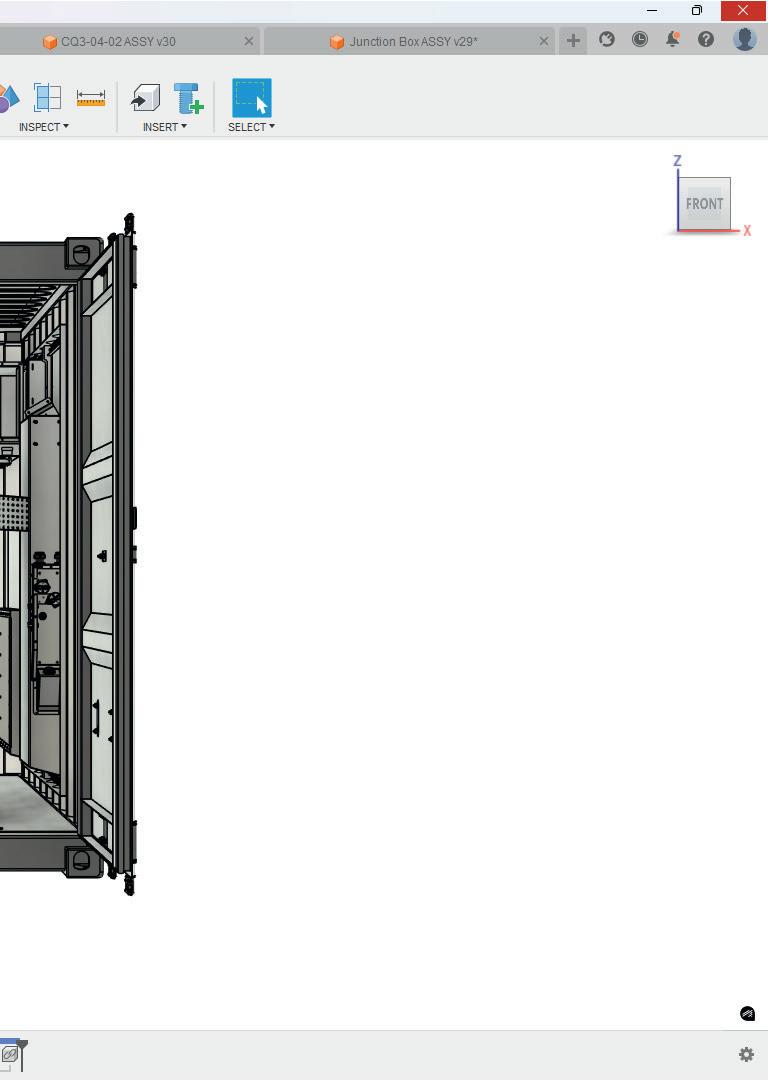

And, from the very beginning, they’ve used Autodesk Fusion to bring their electric battery systems and products to life.

Inside look at the design process

Of course, it isn’t as simple as taking a battery and swapping out the combustible engine in a classic car. Each vehicle is different and requires its own specific design to ensure all the electronics and battery will fit—whether it’s a MINI Cooper, Porsche, or Land Rover.

“We get a lot of scan data that we import into Fusion just to make sure our designs will fit before we go on to prototype and then manufacture to install in real life,” Dicken says. “We also keep the weight as close to the original car as possible, so it handles and performs the same way.”

Their design workflow typically starts with a brainstorming session to collect the team’s input and agreement on an idea to move forward. It then goes into Fusion, where a rough CAD design is started to include critical dimensions,

electronics, and features where the entire team can collaborate seamlessly in the cloud. After a design review, a new, clean CAD model is completed with all the finishing touches. Then it’s on to physical prototyping for testing to final design for manufacturing. The entire process typically clocks in at around three months.

“Batteries are extremely heavy, and lifting one in and out of a vehicle to do measurements and the like is just not an option,” Hazell says. “With Fusion, we can basically take every single component, visualize it in a 3D space, and test multiple iterations quickly.

“If you did this physically, it would take months and months, and you’d spend a huge amount of money on materials and trying things out,” he adds.

“In the CAD world with Fusion, you can very quickly design, develop, and test. We can also do stress analysis and even look at things like flow rates with our liquid cooling plates to make sure we’re getting the right cooling systems for the batteries.”

Cars and boats are only the beginning Fellten isn’t limiting itself to only car retrofits and has continued to evolve with the design of electric battery packs for a variety of applications, including brand new boats. They have also strategically identified the need for better charging infrastructure for fleet customers to adopt electric vans.

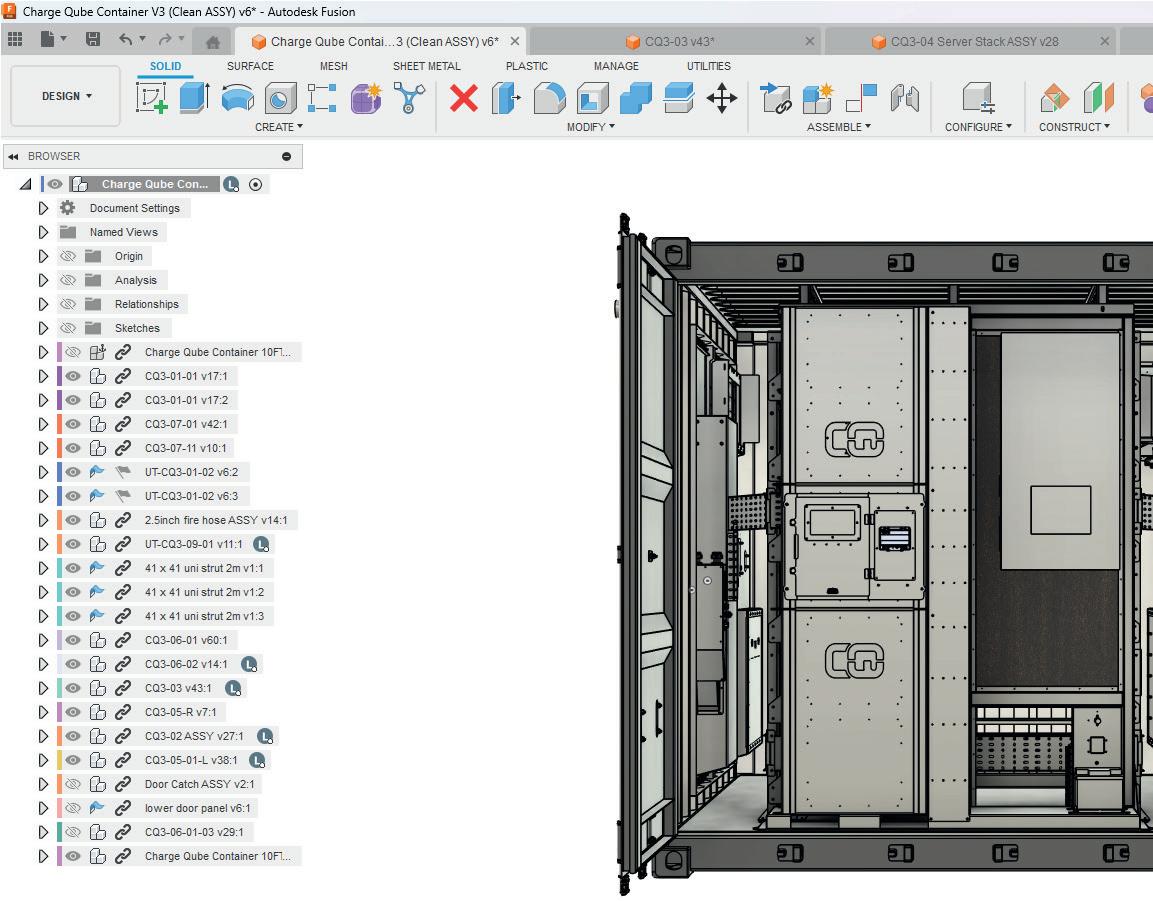

With that opportunity in mind, Fellten is now expanding with the new Charge Qube, an innovative mobile solution that brings scalable energy storage and EV charging anywhere. It repurposes EV batteries, enabling them to live on another 15-20 years to charge new electric fleets. Charge Qube can either be used with 3-phase grid supply or renewable energies such as solar or wind, and it’s highly transportable to remote and even semipermanent locations.

“The main goal for Fellten is to provide a more

sustainable future, looking at end-of-life battery packs, especially with the Charge Qube,” Dicken says. “We want to provide a circular economy for end-of-life battery packs, giving them another use and providing a charging solution that can be deployed basically anywhere in the world.”

“What excites me most about Fellten is the fact that we’re actually going to start making a massive environmental difference,” Hazell adds. “Yes, we’ve been saving beautiful classics and retraining people into a new industry. But with our energy storage products, we’re actually going to be able to get highemission van fleets transitioning to electric faster. We’re going to help that transition to a net-zero world as fast as possible, and we can use Fusion to design these products to help make it happen.”

Inpreviousrolesatcompaniesusing othersoftware,I’dhavetowaituntilthe mechanicalteamwouldactuallyfinish theirdesignbeforeIcouldstartonmy ownelectricaldesign.WithFusion,Ican startbeforethey’redone,anditsaves days,ifnotweeks,oftime

LouisMalster,HeadofElectronics Development,Fellten

» Welcome to The D3D 30, our round-up of 30 new technologies from around the world that we firmly believe could deliver a major boost to your product development work

It’s that time of year again, when the DEVELOP3D team presents its list of 30 new and exciting technologies that look likely to impact the workflows of product designers, engineers and marketers. Welcome to the D3D 30 for 2025.

As you might expect, artificial intelligence (AI) pops up frequently, with many of the best new tools and updates leaning on AI in some way or another. From CAM assistants to 3D scanning software, the addition of AI can speed up mundane tasks and provide users with helpful advice and guidance.

AI is also showing up in established 3D CAD packages, most often as an intelligent assistant, but clearly poised to play a bigger role in the near future. The likely repercussions of that are still up for debate –but readers can expect AI in CAD to do far more than simply point them towards the correct button to click.

Lots of new AI technology brings lots of new names to the table. These are often start-ups, but in many cases, they’re helmed by executives with many years of industry experience and a deep understanding of what product designers and engineers need from their software tools.

The D3D 30 isn’t just about AI, however. There’s also some exciting hardware to explore here, as well as updates to existing tools that make tried-and-tested workflows much smoother or faster.

As ever, we want to remind you that, unlike many other awards and rankings, the companies and technologies on our list are chosen entirely on merit. There’s no entry fee to pay and no flashy blacktie ceremony. There’s certainly no pay-to-play fee demanded of the companies on this list. Our aim is simply to help readers identify the tools that will help them design and build the products of the future.

FIGURE 4 135

Automation-ready

The 3D Systems Figure 4 has established itself as a workhorse 3D printer since the ‘Standalone’ version launched in 2018. Its latest incarnation, the 135, builds on the platform’s broad materials catalogue and high-definition output with out-of-the-box accuracy and repeatability.

The Figure 4 135 is designed for high-mix, low-volume manufacturing, typically replacing or supplementing injection moulding. When combined with a material such as 3D Systems’ own flame-retardant Touch 75C FR Black, the move from prototype to production is only a click away for parts like electrical connectors. New automation features come as standard, giving the 135 the power to evolve in line with your demands. www.3dsystems.com

Cooler

An alternative to 3D printing metal, Alloy Enterprises’ trademarked Stack Forging process supports single-piece construction while eliminating the leak points common in traditional liquid cooling systems. With a build volume of 300 x 250 x 200mm, the Stack Forging process can now be used to create copper parts as well as aluminium parts, bringing new opportunities to its target market of liquid cooling equipment for data centre hardware. Compared to traditional cooling methods, Alloy’s topology optimised designs can use targeted liquid cooling where heat loads are highest, while a massive reduction in pressure required means smaller pumps and greater energy savings. www.alloyenterprises.co

Max headroom

With up to 16 high-performance CPU cores and a remarkably powerful integrated GPU, the AMD Ryzen AI Max Pro delivers serious performance in a small, energy-efficient package and sets a new benchmark for compact workstations.

Its memory architecture is where the AMD Ryzen AI Max Pro really shines. The integrated GPU can access up to 96 GB of system memory, handling large datasets smoothly, with none of the VRAM bottlenecks or out-ofmemory crashes you see with some discrete GPUs. That makes it ideal for memory-intensive AI and viz workflows, especially since support was recently added for tools such as KeyShot and (later this year) Chaos V-Ray. www.amd.com

Neural CAD is Autodesk’s 3D generative AI foundation model and executives at the company claim it’s set to transform geometry creation in Fusion and potentially automate up to 90% of routine tasks.

It’s still early days for Neural CAD, but initial demonstrations show promise. For example, users might use it to add a handle to a power drill that is not only aligned correctly but also adheres to the existing design intent.

Neural CAD models are trained on professional design data, so that the technology can reason at both a detailed geometry level and at a systems and industrial process level. Autodesk has big plans for this technology (for more details, see page 32).

www.autodesk.com

Stellar results

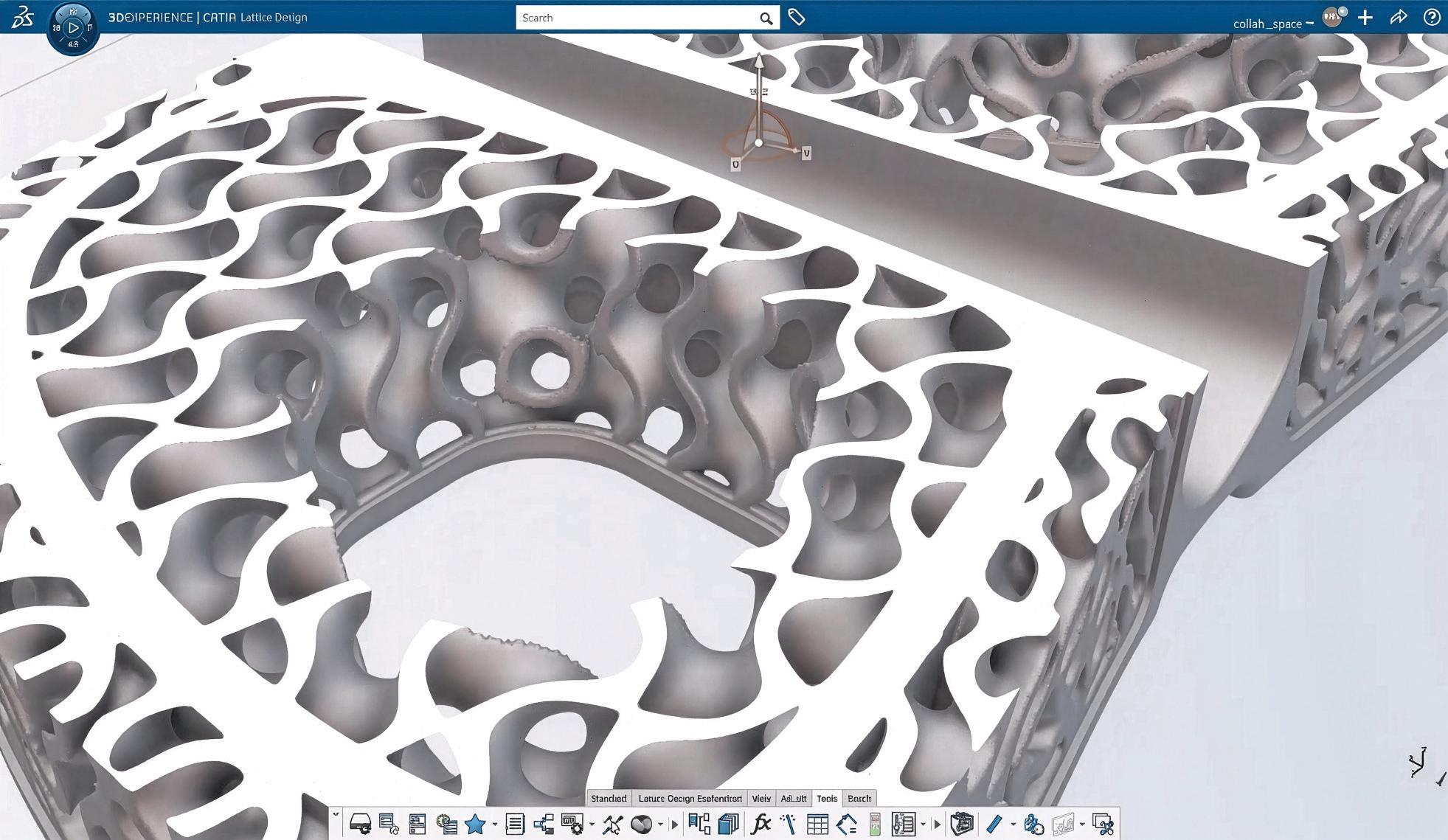

Catia’s styling and visualisation tools have undergone a glow-up in the

company’s 2025x release, with its dated renderer now supplanted by the faster, sharper and more realistic Stellar Interactive Rendering Engine. The update is ideal for appraising the aesthetics of Catia’s Class-A surfacing while

keeping the workflow in the same software. Stellar Interactive Render Mode offers optimised global illumination, bridging the gap between real-time and maximum-quality rendering, while laying on physical-based lighting,

materials and human perspective. This makes it a great option for surface designers who must continuously check a model’s surface appeal and need fast feedback on how they’re doing. www.3ds.com

Scanning made good

Backflip’s AI model can transform 3D scan data into parametric CAD in a matter of seconds, with plug-ins available for Solidworks, Onshape and a standalone web app. Automatically converting surface data into clean geometries designed for existing 3D CAD is a huge timesaving and doing it with intelligence is key – a factor strengthened by the Backflip team’s background in manufacturing. The company’s plug-ins show each step of the process used to build a part’s geometry, generating a native feature history that users can modify, enabling them to fine-tune a generated 3D model in the CAD environment to which they’re most accustomed.

www.backflip.ai

The H2D Pro has firmly established consumer favourite Bambu Lab in the professional space. This enterprise-focused desktop 3D printer comes with dual tungsten carbide extruders that can reach 350C and a 120C build plate, enabling it to handle tougher carbon-filled materials. Yet it’s the speed and accuracy of the 3D printer that are its main strengths, offering output that is genuinely impressive for such a fast-working machine.

Available through local resellers, technical support is now an option, but with a fully loaded version costing around £3,000, it’s a lowrisk way to add more in-house production capabilities to your organisation’s armoury. www.bambulab.com

Picking up where the CFD-focussed Millennium M1 leaves off, the M2000 supercomputer has been built by Cadence in partnership with Nvidia, in order to tackle broader AIaccelerated, multiphysics simulations for engineering applications.

To call it a luxury would be an understatement, but this turnkey combination of powerful hardware (Nvidia HGX B200 systems, RTX PRO 6000 Blackwell GPUs and CUDA-X libraries and solver software) and Cadence’s simulation software promises deeper insights from AI to tackle the most complex multiphysics simulations.

Available as either a cloud-service or on-premise supercomputer, it’s a blazing hot option when speed and scale are needed. www.cadence.com

Immersive insights

Campfire’s XR Design Review spatial collaboration platform comes with broad hardware support for headsets, iPads and other devices, allowing anyone to join a design review in the most immersive way possible, be they in the boardroom or on the factory floor.

Capable of displaying interactive 3D scenes, users can examine, pull apart and edit designs. They can also draw measurement lines on their designs and on real-life elements around them for speedy measuring. Above all, this is a smooth and slick visual experience that’s quick to start and allows the users to see others in the ‘room’, bringing reviews to life wherever you are. www.campfire3d.com

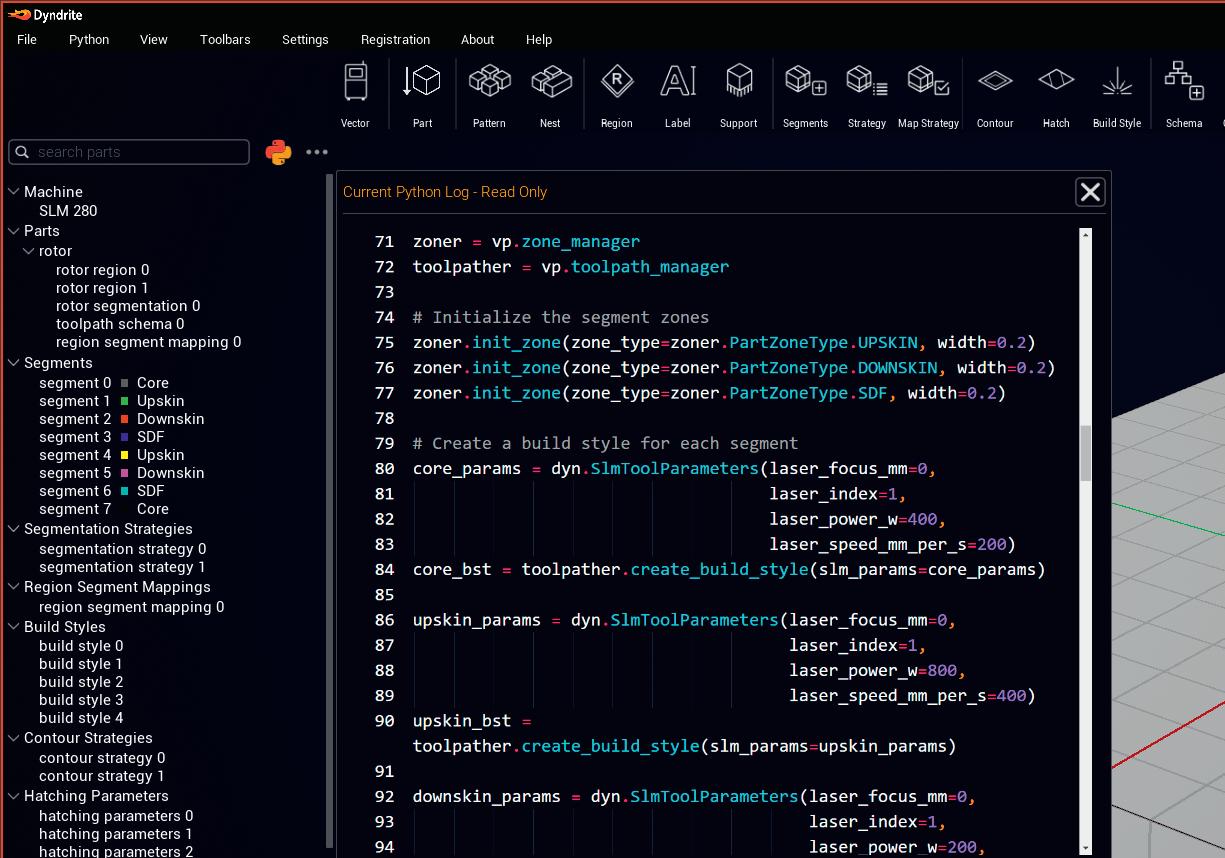

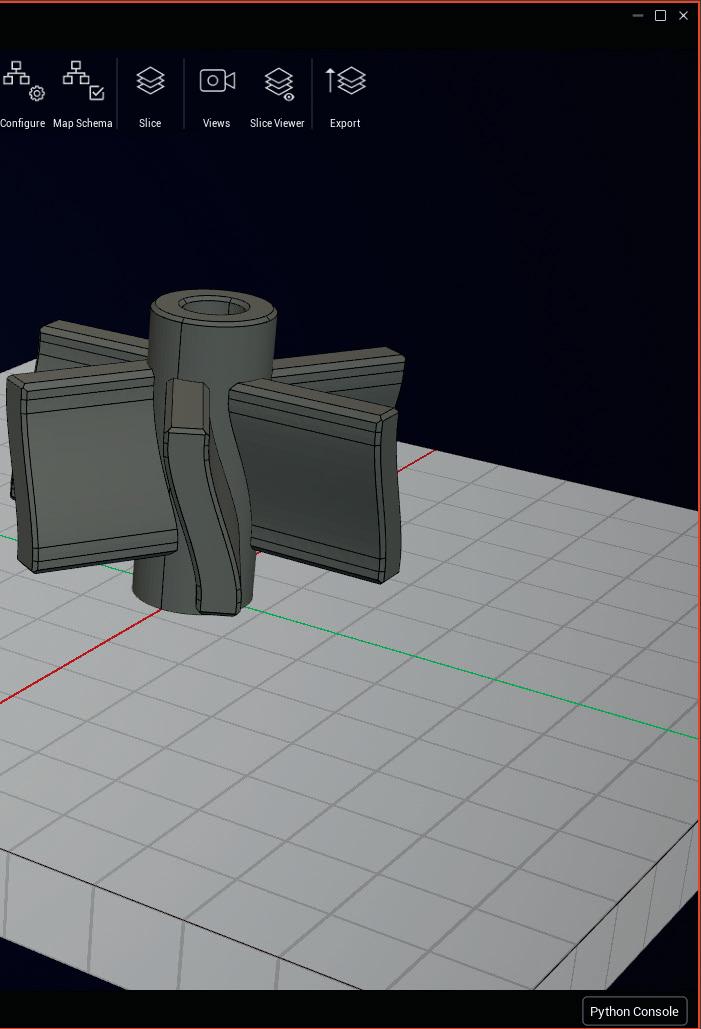

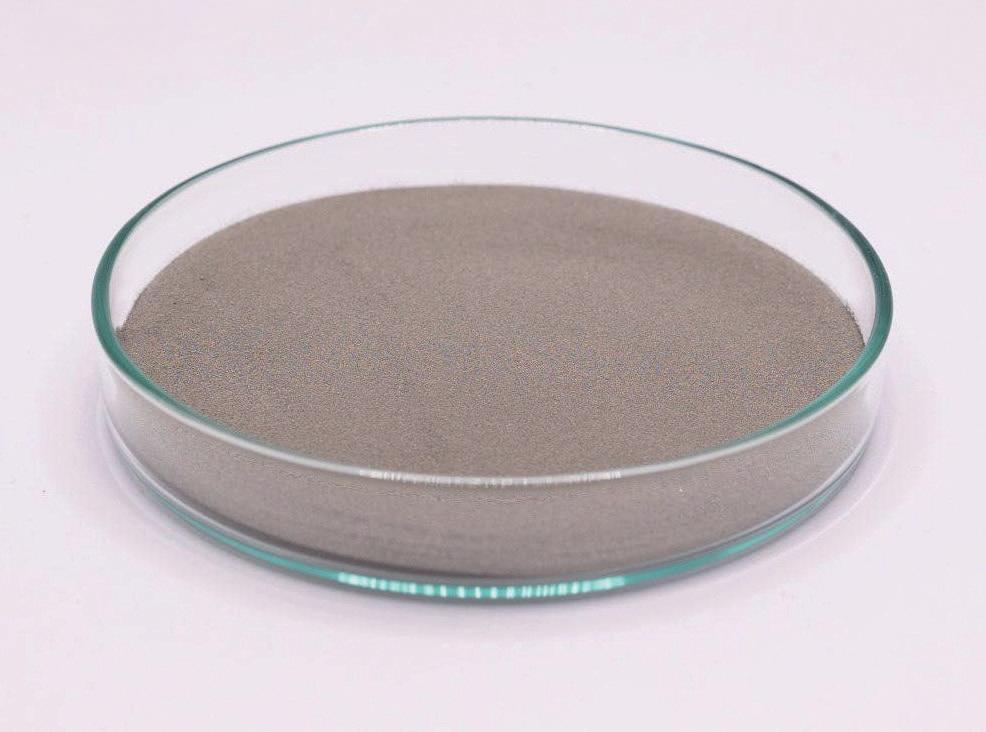

Laser accuracy

For users of laser powder bed fusion (LPBF) metal 3D printers, the level of control provided by Dyndrite’s software, along with its speed of preparing files and generating toolpaths, is eyecatching stuff.

Built on Dyndrite’s GPUaccelerated engine, LBPF Pro can handle huge complex geometry files and large data sets including native CAD with ease, hooking up directly to your EOS, Nikon SLM, Renishaw, Additive Industries or Aconity3D printer. More machines are to be added in the future at no extra cost.

It’s smart and intuitive, while the ability to add part marking and labelling at the earliest stages reduces the risk of process errors. www.dyndrite.com

Extra eye

According to executives at CoLab, designers spend nearly a quarter of their time on time-sapping administrative tasks. The company’s AI-powered Auto Review is designed to help users avoid repetitive design checks and get back to doing what they do best – designing. Auto Review is capable of observing common standards and practices, as well as any company-specific design rules, and can validate 2D and 3D models in PTC Creo, Siemens NX, Dassault Systèmes Solidworks and Catia. The technology is also able to flag any design features that have previously led to manufacturing issues, product failures or warranty claims, putting such problems firmly in the past.

www.colabsoftware.com

Solidworks boasts the largest installed base of all CAD software, so the addition of AI to this workhorse package was always going to act as a litmus test for AI acceptance among designers. With that in mind, it was a surprise to see Aura announced so early on in AI’s development. At present, Aura acts as an automate and assist tool, eliminating repetitive tasks and predicting user intent through features like Smart Mates, Fastener Recognition, Command Predictor and Generative Drawings. Where it heads next – and when – remains to be seen, but Solidworks execs plan for Aura to act as an orchestrator, coordinating agents across design, simulation and manufacturing. www.solidworks.com

Picture this

Depix has evolved from offering AIgenerated backgrounds for renders to promising some of the most jaw-dropping sketch-to-photoreal visuals. Its ImageStudio product does the same for CAD models. Users simply snap a screenshot and drag and drop it onto the canvas, with options to generate mood variants and seasonal looks in seconds. Control comes via a veritable chocolate box of presets, giving them fast options for tweaking image and video content. Once the early concepting stage is over and done with, ImageLab takes on a new role, generating brand stories and marketing content with photorealistic humans observing, modelling or even riding in the product displayed www.depix.ai

Between the lines

Any software that eliminates some of the time associated with producing usable 2D drawings is a bonus in our book. With a range of AI-enabled options now available, Drafter is one of the tools most worthy of your attention.

Drafter’s Solidworks integration places the tool at the heart of the action. The plug-in allows users bi-directional sync between Drafter’s automated 2D drawing creation and the 3D SolidWorks model, generating an accurate standardised ASME Y14.5-2018 compliant GD&T drawing. Built on AWS GovCloud, Drafter’s security is tight, leaving users ready to put it to work with confidence.

www.drafterinc.com

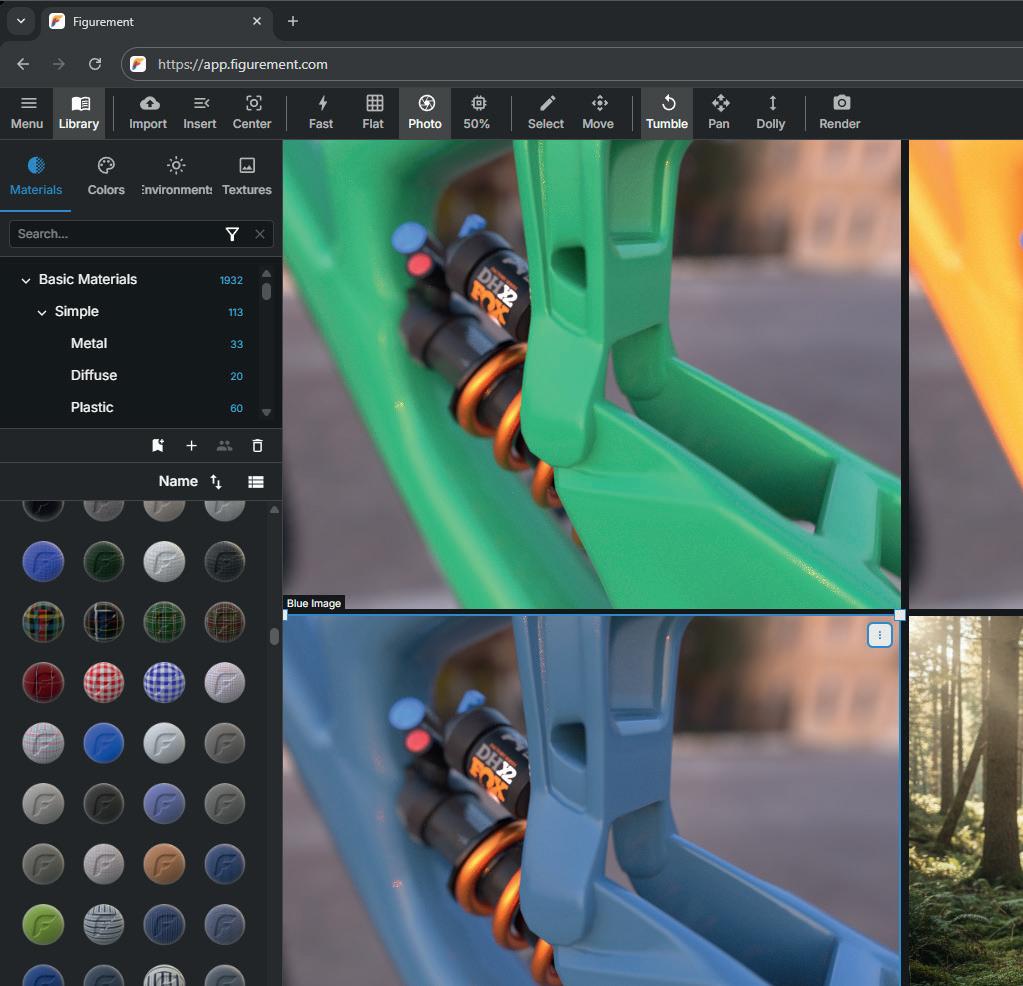

CMF cloud collaboration

A browser-based rendering platform that is accessible anywhere, Figurement allows for greater project collaboration and less visualisation gatekeeping, helping users move beyond static hand-offs and into a world of real-time iteration. The centralised cloud environment replaces local files, meaning assets and CMF libraries can be shared faster while fresh angles and changes can be viewed almost instantly. Text prompts generate AI backgrounds, surroundings and even users while still in Figurement’s UI, while users maintain control over the hero model, its CMF, as well as sceneviewing angles and composition. The quality of results is excellent, although Figurement’s real strength lies in its accessibility. www.figurement.com

On-target IP

A smart contract tool, Final Design is designed to protect intellectual property (IP) and creative designs from unauthorised use or outright theft – something that all designers need to consider in an age when generative AI can produce hundreds of variations of their creations in a matter of minutes.

AI aside, there are many other IP-related issues that Final Design can tackle, too, all via a commendably simple user experience. Every time the user uploads their data to the platform, a smart contract is triggered to securely log it on the blockchain.

Final Design has been reviewed internationally by various law firms to ensure it holds water in worst-case scenarios. www.final-aim.com

First impressions

In the age of AI, Hypersketch comes closest to providing a whole new approach to the offthe-cuff napkin sketch. Free to download and intuitive to use on the Apple iPad, the tool is capable of transforming a child’s simple doodle into 50 product concepts in a matter of minutes. Imagine what it might be able to achieve in the hands of a professional designer. A nice range of sketch and paint tools can be selected and a remarkable amount of detail and finesse can be achieved by the user. However, the main aim is to support lightning-fast sketch ideation anywhere, anytime, with results that get progressively more fully-formed with a hit of the Brainstorm button.

www.hypersketch.com

14-inch powerhouse

We don’t often use ‘14-inch’ and ‘powerhouse’ in the same sentence, but the HP ZBook Ultra G1a changes all that. Powered by the AMD Ryzen AI Max Pro processor with integrated Radeon GPU, this machine packs the kind of punch you’d normally expect from a larger 15- or 17-inch laptop. For product designers, that’s a big deal — it’s the first 14-inch mobile workstation that can genuinely handle GPU-accelerated 3D visualisation workflows in tools such as KeyShot, and not just 2D or 3D CAD. Despite its power, it’s slim, light and impressively efficient, running cool and quiet even during long CPU or GPU renders. This may be a milestone moment for 14-inch mobile workstations. www.hp.com

KEYSHOT

KEYSHOT STUDIO AI

Triple threat

New generative AI rendering tools launch almost each week, so we were eager to see how KeyShot would approach the opportunity. With KeyShot Studio 2025.2, the visualisation expert doesn’t disappoint, debuting its first foray into AI in the form of KeyShot Studio AI, which includes three apps. They are Restyle (promptbased style direction), Imagine (unlimited fast concept generation) and Background (generates new settings and backdrops). All three produce excellent output, but it’s their ability to work locally on the user’s computer that stands out. This makes the technology applicable to far more projects than other tools, so users can take advantage of generative AI even on top-secret projects.

www.keyshot.com

Remote muscle

Lenovo Access is a new remote workstation solution that delivers full desktop power wherever you’re working. It combines highperformance workstation hardware with easy-to-deploy Blueprints — pre-configured reference architectures that make rollout simple for IT teams and resellers.

Users get the same turbo-charged CPU and GPU performance as a dedicated workstation, but accessed remotely, with no compromise in performance, even for demanding 3D applications. The first Blueprint features seven rack-mounted Lenovo ThinkStation P3 Ultra SFF workstations in a 5U shelf, running Mechdyne’s TGX remote graphics protocol. Robust remote management and security tools keep everything secure and running smoothly. www.lenovo.com

Poly good stuff

Matoha has developed a portable scanner, the PlasTell, which identifies plastics, making it a good fit with reverse engineering projects, competitor product breakdowns, or even just sorting through all your workshop waste bins and old 3D printed models for recycling.

Each scan takes less than one second to perform and no training is required. The device has a simple physical interface where materials are identified to the user and the technology recognises common plastics straight out of the box (PET, PVC, PE, PP, PS, PC, PMMA, PLA, ABS). On request, Matoha’s team is able to add further specialist plastics to the PlasTell’s repertoire. www.matoha.com

Control the narrative

Jester3D might be part of a service offering from digital creative agency Mediaman, but its ability as a visualisation software for building and controlling scenes generated by AI has left us mightily impressed.

Developed in-house to meet the huge demand among Mediaman’s own clients for digital marketing content, Jester3D’s output is perfect for internal ideation or for building social media campaigns.

A library of high-quality 3D assets built by the Mediaman team enables clients to experiment with building scenes around their products. It’s just a question of guiding the AI by adding simple block shapes, positioning cameras, writing prompts and hitting go. www.mediaman.com.cn

Checked off

AI Checker from NexCAD offers intelligent automation for engineering drawing reviews. Initially launched for Autodesk Inventor, readers can expect it to roll out for other CAD packages, too, cutting review times and highlighting costly manufacturing errors so they can be nipped in the bud long before they become major issues.

The platform automatically scans engineering drawings for missing dimensions, tolerance inconsistencies and standards violations, giving engineers instant feedback. Each review builds an internal knowledge base, ensuring consistency and smarter checks. And by allowing AI to handle the repetitive tasks, designers can focus their minds and talents on creativity and problem-solving. www.nexcad.ai

Making magic

Designing high-complexity, computationally enhanced parts is one thing, but building them is quite another. That’s why nTop’s link-up with 3D printing expert Materialise is a big step forward for users. Making the most of Materialise’s next-gen Build Processors for metals and polymers, nTop implicit geometries can be processed without the need for mesh conversion, drastically reducing prep times. With Materialise’s slicing capabilities, the design and production of parts previously impossible due to huge data and memory requirements are now on the table. Advanced functions such as measurements, wall thickness analysis, nesting and STEP file export make this applicable to CNC machining workflows, too. www.ntop.com

Small but mighty

The Nvidia RTX Pro 2000 Blackwell GPU offers workstation performance in a compact package. Built for tiny machines like the HP Z2 Mini G1i and Lenovo ThinkStation P3 Ultra SFF, this GPU packs a terrific punch without hogging space, and with a full-height bracket, it also fits inside standard towers.

Optimised for 3D CAD, viz and AI workflows, Nvidia claims this GPU is up to 1.6 times faster for 3D modelling, 1.4 times faster for CAD, and 1.6 times faster for rendering compared to the previous Ada generation.

With 20 GB of GPU memory – 25% more than before – it can load larger datasets entirely on-board, keeping demanding viz and AI workflows running fast and efficiently. www.pny.com

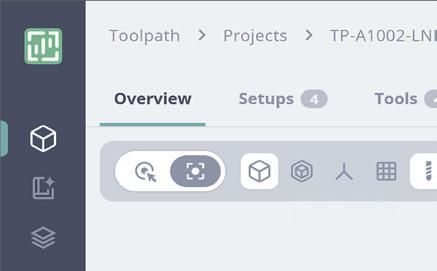

Magical milling

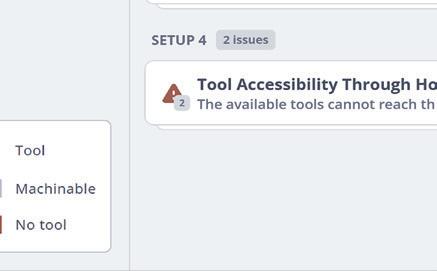

A seamless integration with Autodesk Fusion’s manufacturing workspace sees Toolpath use AI to help automate timeconsuming tasks such as design-formachinability analysis, quoting and CAM programming.

When a user runs a part through Toolpath, out comes a complete machining plan complete with cost estimates, the optimal number of set-ups and the most effi cient series of toolpath operations, all based on the tools the user has at their disposal. It’s AI-powered productivity done right, allowing businesses to free up the time and talents of machinists for more complex, hands-on work. Autodesk has recently joined other investors in the company, further guaranteeing Toolpath’s development for Fusion in the future. www.toolpath.com

Stronger stuff

Across the board, Creo 12 does a great job of addressing usability – but it’s in composites design where we see the most impressive advances, with PTC going from zero to potentially best-in-class in little over three releases.

The use of composites is rising in multiple industries, which is why PTC is enthusiastically embracing the trend, but that’s not to say it’s lacking in any of the tools needed in key industries such as aerospace. With geometric processing algorithms specific to composite parts, users can now use Creo to design parts, develop full-fidelity composite lay-ups, and transition them all the way through to manufacturing.

www.ptc.com

Designer details

New cloud-native model-based definition (MBD) capabilities in Onshape are yet another example of the company’s determination to bulk up its toolset for serious designers. These capabilities enable teams to embed all common product manufacturing information directly into a 3D CAD model, including dimensions, tolerances, annotations, surface finishes and material specifications, and remove the chore of interpreting 2D drawings. The result is that users can work faster, with greater clarity and fewer errors. Since the Onshape toolset is cloud-native, information can be shared around teams using URLs that open directly in browsers, preserving model display settings, section views and annotations. www.onshape.com

Testing transformed

AI-assisted workflows promise big things, but Siemens is pushing what can be achieved with AI in terms of accuracy and efficiency in analysis software like its Simcenter Testlab.

AI is credited with making the modal analysis processes in Testlab up to seven times faster, reducing the resources and skills needed to perform accurate physical testing. Automated data capture and processing via the new analysis dashboard streamlines testing workflows, allowing users to test faster, smarter and earlier than before. Testlab works with Simcenter SCADAS hardware to acquire the data. So confident is Siemens that its own software will prove first choice for analysis, it has opened up the platform to export data in universal or third-party formats. www.siemens.com

Best foot forward

Footwear is possibly one of the most exciting sectors in product design right now, and Toolkit3D’s suite of industry-focused apps is a slick package that manages to cover three core elements of footwear design.

There are apps for Insoles, Midsoles, and Design-toMold, with each addressing a critical step in the footwear development process, from scanto-print insoles to profile-driven midsoles and tooling-ready moulds.

For a simple route into custom manufacturing orthotics, or for building out consumer applications for running shoes, Design Apps allow users to turn scans and profiles into ready-toproduce designs at scale. www.toolkit3d.com

» Autodesk’s AI story has matured. While past Autodesk University events focused on promises and prototypes, this year Autodesk showcased live tools, giving customers a clear view of how AI could soon reshape workflows across design and engineering, writes Greg Corke

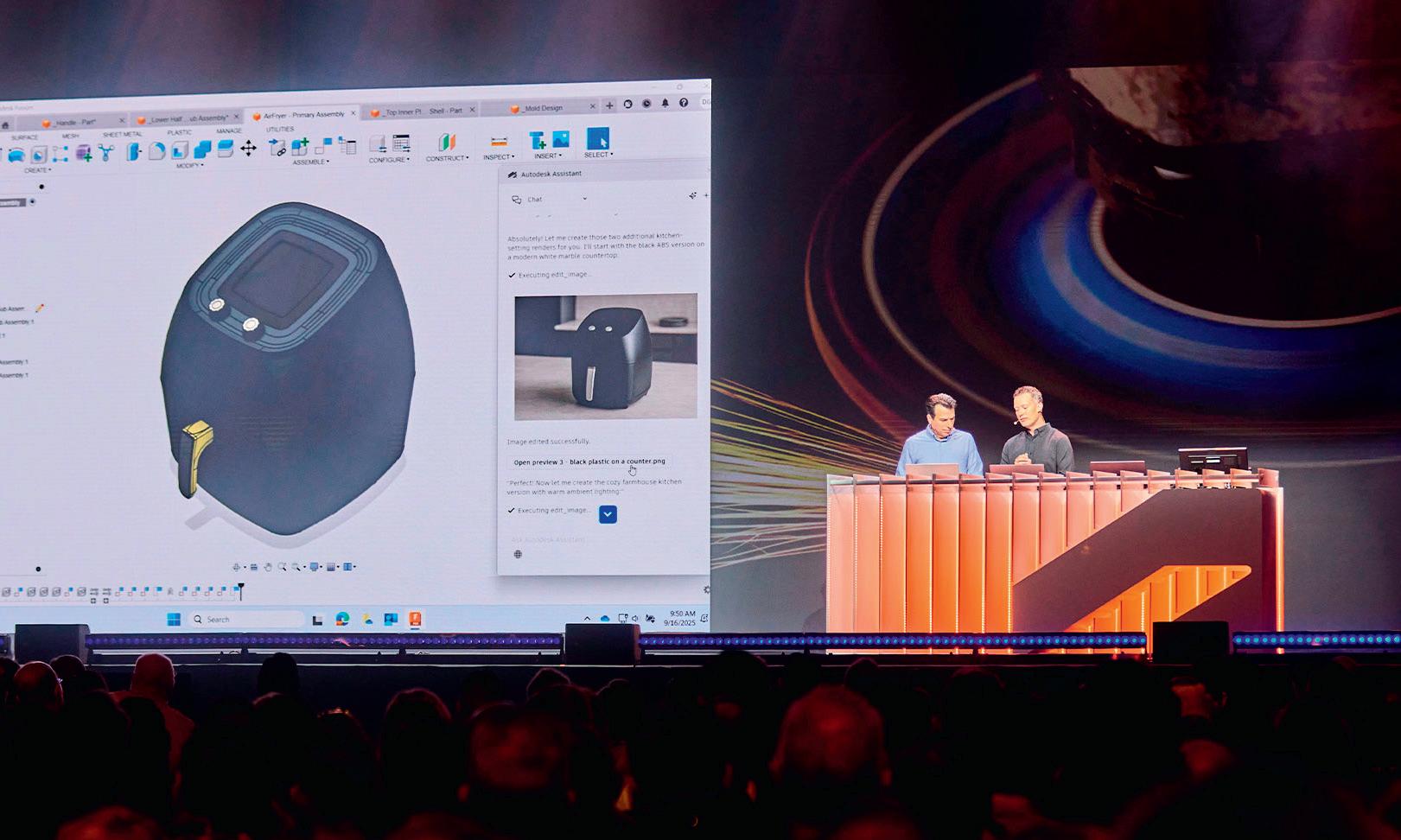

At AU 2025, Autodesk took a significant step forward in its AI journey, extending far beyond the slide-deck ambitions of previous years. During CEO Andrew Anagnost’s keynote, the company unveiled brand-new AI tools in live demonstrations using pre-beta software. It was a calculated risk – particularly in light of recent highprofile hiccups from Meta – but the reasoning was clear: Autodesk wanted to show that it has tangible, functional AI technology that will be available for customers to try soon.

The headline development is Neural CAD, a completely new category of 3D generative AI foundation models that Autodesk says could automate up to 80–90% of routine design tasks, allowing professionals to focus on creative decisions rather than repetitive work. The naming is deliberate, as Autodesk tries to differentiate itself from the raft of generic design-focused AI tools in development.

detailed geometry level and a systems and industrial process level.

Neural CAD marks a big leap forward from Project Bernini, demonstrated at AU 2024. Bernini turned a text, sketch or point cloud ‘prompt’ into a simple mesh not well-suited for further development in CAD. In contrast, neural CAD delivers “high quality, editable” 3D CAD geometry directly inside product development software Fusion or building design software Forma, just like ChatGPT generates text and Midjourney generates pixels.

Autodesk has so far presented two types of neural CAD models: “neural CAD for geometry”, used in Fusion; and “neural CAD for buildings”, used in Forma.

Neural CAD AI models will be deeply integrated into product design workflows through Autodesk Fusion and into BIM workflows through Autodesk Forma and according to company execs will “completely reimagine the traditional software engines that create CAD geometry.”

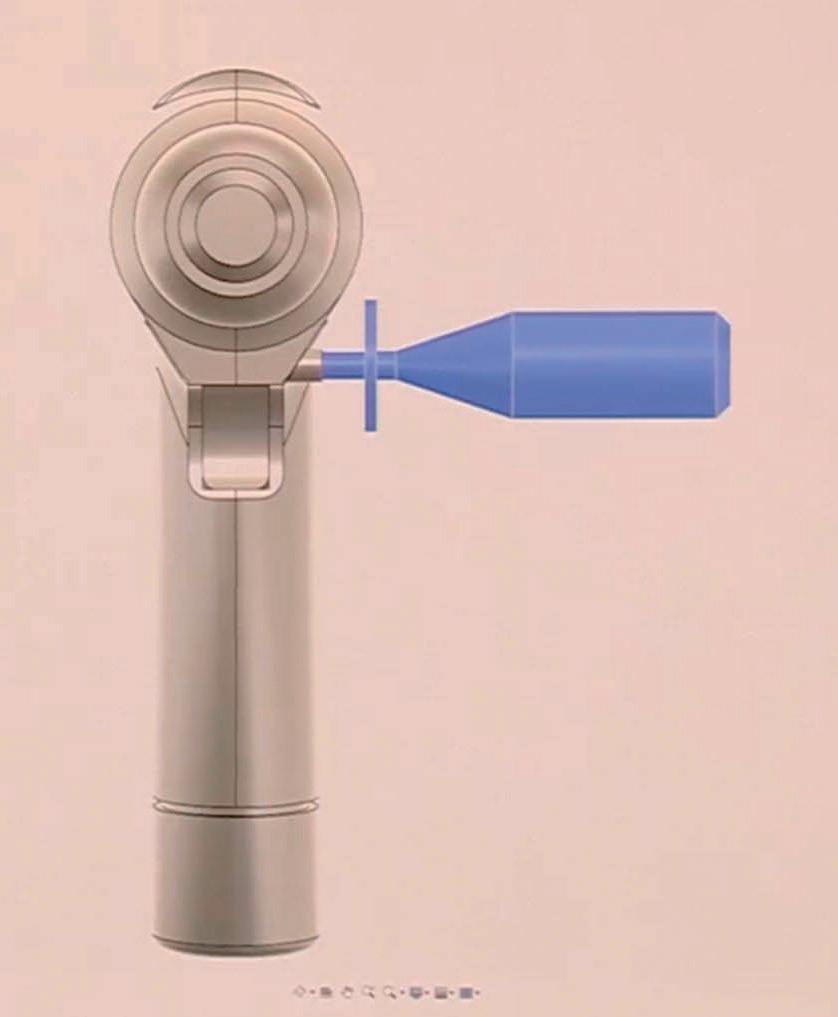

Autodesk is also making big AI strides in other areas. Autodesk Assistant is evolving beyond its chatbot product support origins into a fully agentic AI assistant capable of automating tasks and delivering insights based on natural language prompts.

Neural CAD marks a fundamental shift in Autodesk’s core CAD and BIM technology. As Anagnost told the press, “The various brains that we’re building will change the way people interact with design systems.”

Unlike general-purpose large language models (LLMs) such as ChatGPT and Claude, or AI image generation models like Stable Diffusion and Nano Banana, Neural CAD models are specifically designed for 3D CAD. They are trained on professional design data, enabling them to reason at both a

For Fusion, there are two AI model variants. The first is what Tonya Custis, Autodesk’s senior director of AI research, described as an “auto regressive transformer model”, designed to generate fully editable 3D CAD models from text input. She explained how the model is well-suited to generating organic curved surfaces found commonly within consumer goods and can also be guided by other input types, such as sketches, point clouds and images.

On stage, Mike Haley, senior VP of research, demonstrated how the AI model could be used in Fusion to automatically generate multiple iterations of a new product – in this case, a power drill.

“Just enter the prompts or even a drawing and let the CAD engines start to produce options for you instantly,” he said. “You can literally watch the Neural CAD engine produce the desired geometry as it reasons through the request. Because these are first-class CAD models, you now have a head start in the creation of any new product.”

The AI model can also be used to augment existing designs, Custis explained: “When provided with a set of assembly interfaces in the form of face selections, it can generate multiple parts that precisely preserve the given assembly interface.”

But how does the technology work? Custis explained that the AI model generates 3D CAD by learning to break apart and then synthesise faces, edges and the topology of CAD representations. “We represent faces and edges as point grids, and then we uniformly sample points over those grids,” she said.

The second Neural CAD for geometry model is better suited to creating prismatic objects with flat surfaces and clearly defined edges for designs more commonly found in mechanical systems. Custis described this as more of an autocomplete for Fusion – for modifying existing designs and generating editable CAD objects.

Starting with a sketch prompt and geometry constraints, the AI model can recreate the sequence of commands within Fusion, generating objects step by step so the user can inspect the history of commands used to generate the 3D model. “This means you can make edits as if you modelled it yourself,” said Haley.

On stage, he showed how the AI could be used to generate a new handle for a power drill. “We can select the precise attachment geometry which Neural CAD will honour,” he said. “We provide a conceptual sketch, which the AI interprets to produce a matching detailed 3D handle aligned correctly.”

Meanwhile, in the world of Building Information Modelling (BIM), Autodesk is using Neural CAD to extend the capabilities of Forma Building Design to generate BIM elements.

The current aim is to enable architects to “quickly transition” between early design concepts and more detailed building layouts and systems with the software ‘autocompleting’ repetitive aspects of the design.

Instead of geometry, neural CAD for buildings focuses more on the spatial and physical relationships inherent in buildings, as Haley explained.

“This foundation model rapidly discovers alignments and common patterns between the different representations and aspects of building systems. If I was to change the shape of a building, it can instantly recompute all the internal walls,” he said.

“It can instantly recompute all of the columns, the platforms, the cores, the grid lines, everything that makes up the structure of the building. It can help recompute structural drawings.”

Neural CAD models are trained on the typical patterns of how people design. “They’re learning from 3D design, they’re learning from geometry, they’re learning from shapes that people typically create, components that people typically use, patterns that typically occur in buildings,” said Haley.

In developing these AI models, one of the biggest challenges for Autodesk has been the availability of training data. “We don’t have a whole internet source of data like any text or image models, so we have to sort of