March 2023

MOTION CONTROL: Part one: Scalar and vector VFD control methods

p. 50

ELECTRONICS: Sustainability challenge: Lithium-ion versus sodium-ion batteries

p. 56

Precision

CONNECTORS: Rotary slip ring connectors — what are they used for?

motion stage

has the right stu

www.designworldonline.com inside:

p. 66 page 42

LINEAR

LOCAL MANUFACTURING

THK is committed to meeting the worldwide demand for linear motion products. We manufacture, assemble, and ship across North America from our location in Hebron, Ohio. We’ve also ramped up our automating processes at existing facilities, including our U.S. manufacturing plant, where over 70% of THK Robotics Components are manufactured. Automated processes at this state-of-the-art facility enable increased production while maintaining the high standard of precision associated with THK products.

To learn more, call us at 1-800-763-5459 or visit www.thk.com.

See us at ATX West, Anaheim CA, Feb. 7 - 9, Booth #4254

The Assembly Show South, Nashville TN, April 4-6, Booth #557

THK Manufacturing in Hebron, Ohio

1–2 Week Delivery of Select LM Guides and Actuators

Quality Linear Motion Solutions from THK WORLD-CLASS

MOTION

QUICK SHIP COMPONENTS

See us at: Promat, Chicago IL, March 20-23, Booth #N9810

As with most industrial control projects, cost is king, but you don’t have to sacrifice quality to keep your budget intact. For over 15 years, the C-more line has served tens of thousands of installations without missing a beat.

C-more HMIs are built to last and provide many advanced capabilities, including object animations, logic and math operations, web server/mobile app access, and data logging, all for a surprisingly low price.

Now with FREE software!

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2022 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405 Research, price, buy at: www.automationdirect.com/cmore Time-tested, industry-approved HMIs C-more HMIs

the go-to

for low-cost system visualization

are

choice

C-more Touch Panel HMIs starting at: $668.00 (EA9-T7CL-R)

C-more HMI design software can now be downloaded free of charge. Get started on your project today or take it for a test drive.

as often as

need. No

Get your copy now at: www.go2adc.com/cmoresw

Download

you

license or key needed.

World’s first wear-resistant DLP resin

Rapidly print high resolution components

iglide® i3000: Purchase resin directly or print parts with our online 3D print service

• Withstands long-term temperatures of up to 80°C

• Lasts 30-60x longer than conventional DLP resins

• Dry-running, low-maintenance performance

• Resolution of up to 35µm

• Inner channels possible

• Extremely wear-resistant

A new way of thinking

One of the most valuable pieces of “real estate” in any magazine is the page facing the inside back cover. Over the years, I’ve known many publications — both trade and consumer — with must-read departments or columns in that sacred space. Many times, they’re on the lighthearted or even humorous side. I’ve even subscribed to some publications where the column was such a draw that I’d open the magazine “backwards” to digest that content first. While Design World has never had a dedicated column on that page, it’s something our editorial team has long discussed.

You may have noticed that we’ve finally made a change there; starting with last month’s issue, a new column called Technical Thinking appears facing the inside back cover. We’re so excited about this change, thanks to the always thought-provoking writing of our new columnist, Mark Jones.

Mark is the Creative Director at MJPhD, LLC, an independent consulting firm. He retired after an industrial career of more than 30 years with a Fortune 100 company. During his career, he investigated a wide range of technologies, developed goals for sustainability related to innovation, implemented strategies related to renewable resources, and more. Responsibilities for communications and strategy around R&D filled the last decade of Mark’s career. Technology and e orts to improve sustainability remain fascinations to him. Mark has written for our sister publication, R&D World, and his occasional contributions there have consistently been some of that magazine’s most widely read content.

The main thrust of Design World will, of course, remain the highly engineered componentry and system design news, applications, and technical how-to features that you’ve counted on over the past 17 years. But Mark has a gift for taking real world interactions — reading a restaurant menu, hunting for morels in a forest, observing roads being salted — and delving into the technical steps that led humanity to that moment or wondering what that activity means for the future. I believe that his writing will add something positive to your reading experience each month.

I hope you enjoy Mark’s writing as much as our sta has, and that you soon find yourself opening Design World in a “backwards” fashion first. DW

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

On

Insights 4 March 2023 www.designworldonline.com DESIGN WORLD - brushed or bldc motors - 5 amps per axis - 16 analog inputs - 16 on/off drivers - home and limit in - live tech support - made in the USA WWW.ALLMOTION.COM (510) 471-4000 30097 Ahern Avenue Union City, CA 94587 Technical Support (408) 460-1345 See the EZQUAD SERVO in action! 2.25”

SERVO from NEW!

4 AXIS

Twitter @wtwh_paulheney

Companies get by with a little help from their friends in 2023

It’s March. If you’re like me, by now, your New Year’s resolutions are either collecting dust or just starting to pay dividends. Which scenario we find ourselves in often depends on realizing early that we need to work with others to achieve our goals — those that find the best team tend to find the best results. Going into 2023, PT/MC companies seemed to agree with this logic.

At the beginning of the new year, the Power Transmission Distributor’s Association posted an article about recent mergers and acquisitions on its website. According to the PTDA, companies across the PT/MC marketplace were choosing to work together. Despite 2022’s economic witches brew of interest rate spikes, bond market instability, a pullback in leveraged finance, and more, several companies chose to unite.

“Mergers and acquisitions are on the rise across all industries, and the PT/MC marketplace is no exception. Not even a global pandemic could sideline M&A activity. Economies of scale and scope, increased market share, tapping into new markets and fresh talent — all can bring great rewards.”

The PTDA specifically cited Motion’s blockbuster acquisition of Kaman Distribution Group (KDG) and FICODIS’ acquisition of independent distributors, to name a few. A recent Wall Street Journal piece also explained that we can expect even more companies to follow suit in 2023. If not necessarily in the same ways we’ve seen in the past.

“…many companies adapted, structuring deals to sidestep market volatility and minimize financing costs. In doing so, they provided a glimpse of what’s likely ahead for

deal-making this year, bankers and advisers said. ‘The M&A market is not going to stop. It just doesn’t work that way. What it does is it evolves,” said Christopher Auld, head of leveraged finance at investment firm Stifel Financial Corp.’”

While 2023 is expected to see an uptick in M&A activity, exactly when is not clear. Mergers and acquisitions are still heavily influenced by the kind of stability and predictability that’s been in particularly short supply in the last few years. How does the Federal Reserve plan to pace future rate increases? Are regulatory demands going to increase as they did in 2022? And, of course, there’s a blue ribbon for anyone that can tell you what will happen with inflation. For now, it looks like companies will continue to band together to reach their goals before the next new year and its new resolutions. DW

Mike Santora

On Twitter @dw_mikesantora Technology Forward 6 March 2023 www.designworldonline.com DESIGN WORLD

msantora@wtwhmedia.com

AdobeStock.com

The PROmax power supplies from Weidmüller are extremely durable and offer high levels of scalability. Their robust construction allow them to withstand brief and continuous overload conditions, ensuring reliable power to critical loads. Additionally, the integrated mounting system allows for easy installation into a preexisting control panel.

automation 24 .com – Your online supplier for automation technology 2 YEAR SUPPOR BACK 1 0 0 % NTEE 90 DAYS EXC FREEAPPLICA ODUC RODUCTS 2 YEAR S ONEY BACK 1 0 0 % GUARANTEE 90 DAYS EXCEPTIONAL PRICING $ FREE HIGH QUALITY IN STOCK PRODUCTS PRICING $ YEAR 01 0 % MONEY BAC GUARANTEE 90 DAYS EXCEPTIONAL PRICING $ FREEAPPLICATION HIGH QUALITY IN STOCK PRODUCTS UPPORT 2 YEAR SUPPORT 01 0 % MON GUA DAYS EXCEPTIONAL PRICING $ FREEAPPLICATION HIGH QUALITY IN STOCK PRODUCTS 2 YEAR SUPPORT 01 0 % MONEY BACK 1 0 0 % GUARANTEE 90 DAYS EXCEPTIONAL PRICING $ FREEAPPLICATION HIGH QUALITY IN STOCK PRODUCTS 01 % GUARANTEE DAYS 2 YEAR SUPPORT 01 0 % MONEY BACK 1 0 0 % GUARANTEE 90 DAYS EXCEPTIONAL PRICING $ FREEAPPLICATION HIGH QUALITY IN STOCK PRODUCTS IN STOCK F N YEAR 0 % 1 0 0 90 Y HIGH QUALI EXCEPTIONAL REEAPPLICATIO 2 MONEY BACK

800-250-6772 (free) or 610-981-2900 mail@automation24.com automation24.com High-performance power for demanding requirements!

Reliably operate in continuous overload conditions

Small footprint for easy mounting in tight spaces

Wide operating temperature range of -13°F to 158°F automation24.com/promax-power-supplies

products

All

Paul J. Heney • VP, Editorial Director

Wiegand energy harvester enables new IoT technologies

UBITO, part of the FRABA family, has announced a development of Wiegand technology as an energy source for smart sensors. After more than two years of e ort at FRABA’s R&D center in Aachen, Germany, a research team has demonstrated a prototype of a wireless sensor powered by Wiegand technology that could support Internet of Things networks. The project involved the development of a new Wiegand Harvester capable of capturing enough energy to power the sensor’s electronics package, including a highe ciency ultra-wide-band radio transmitter. This achievement (a world first) helps to position Wiegand technology (which collects energy from movements of an external magnetic field) beside established energy harvesting techniques such as solar, piezo, or thermo-electrics as an energy source for sensor nodes in the emerging industrial IoT.

8 March 2023 www.designworldonline.com DESIGN WORLD

Sustainable Engineering

“Wiegand sensors have been a core component of our encoder products for over 15 years,” said Tobias Best, global head of the UBITO startup. “While this technology has provided a highly reliable way of detecting and recording rotations in flow meters and multiturn encoders, we have always been looking forward to its wider potential, especially for energy harvesting.”

With this goal in mind, FRABA undertook a development project aimed at improving the energy output from Wiegand devices and demonstrating the possibility of selfpowered sensors that could detect events and transmit data wirelessly to an IoT network. The R&D project was conducted with Aachen’s University for Applied Science, with financial support from the German Ministry of Education and Technology. The project team succeeded in producing a new Wiegand Harvester — a device that could generate more than 50 times the energy of commercial Wiegand sensors.

“This level of output makes it possible to dream of energy selfsu cient sensors that can communicate data wirelessly over a significant distance,” said Best.

The team chose a window sensor system for a practical demonstration of an IoT sensor node powered by Wiegand-harvested energy.

Two Wiegand harvesters and their associated electronics were mounted on the window, with bar magnets mounted on the frame. The harvesters, made up of a 21 mm long pieces of Wiegand wire surrounded by a copper coil, are the size of an AAA battery. Whenever the window is opened or closed, the harvesters pass the magnets, triggering abrupt magnetic polarity changes in the Wiegand wires.

The amount of energy delivered is largely independent of how quickly or slowly the window is moved — a key benefit of Wiegand technology.

The current pulses induced by these polarity reversals generate about 10 microjoules of energy. A key goal had been achieved: the amount of energy captured was su cient to activate a microcontroller and collect a reading from a temperature sensor built into the system. The team added an ultra-wide-band transmitter module that could transmit 134 bytes of data to a receiving station 60 meters away.

“This is a lab demonstration, not a commercial product,” said Best. “However, by showing the capabilities of a system made up of Wiegand devices and o -the-shelf electronic components , we hope to spark interest in the wonderful potential for this technology. With the Industrial IoT projected to grow by a factor of three over the next decade, the future is very exciting.” DW

UBITO www.ubito.com

WHAT DO YOU THINK?

Connect and discuss this and other engineering design issues with thousands of professionals online

DESIGN WORLD www.designworldonline.com March 2023 9

42 LINEAR MOTION

High-precision motion stage has the right stu

In-house designed and built motion control components are used to design and build a high-precision motion stage.

50 MOTION CONTROL

Part one: Scalar and vector VFD control methods

AC motors pair with variable frequency drives to satisfy process as well as motion-control applications. Here we compare how the operation of these drives diverge.

56 ELECTRONICS

Sustainability challenge: lithium-ion versus sodium-ion batteries

As electrification increases, rechargeable batteries will contribute significantly to sustainability goals. But determining which battery type is best remains a challenge.

62 TEST & MEASUREMENT

What is a Smith chart and why do I need one?

A Smith chart provides insight into RF/microwave designs. Even if you work primarily with lowspeed analog and mixed-signal designs, you could benefit from familiarity with the Smith chart as wireless products proliferate and as high-speedserial data signals exhibit microwave-like e ects.

66 CONNECTORS

Rotary slip ring connectors — what are they used for?

Rotary slip ring connectors are important components in various applications like multi-axis robots in industry 4.0, wind turbines for sustainable green energy, machine tools, medical systems, and more.

Contents 3 • 2023 • vol 18 no 3 • designworldonline.com asbpe.org SILVER REGIONAL AWARD 2022 asbpe.org GOLD REGIONAL AWARD 2022 asbpe.org BRONZE REGIONAL AWARD 2022 10 March 2023 www.designworldonline.com DESIGN WORLD asbpe rg BRONZE NATIONAL AWARD 2022 asbpe.org GOLD NATIONAL AWARD 2022 ON THE COVER The Proton Motion Stage is built entirely from in-house off-the-shelf components, ensuring maximal integration and compatibility. | courtesy of Prodrive Technologies © Hrishchenko Oleksandr | Dreamstime.com

50

3.23 • contents 12 March 2023 www.designworldonline.com DESIGN WORLD departments 04 Insights 06 Technology Forward 08 Sustainable Engineering 14 Design For Industry 24 Design Notes 34 Coupling Notes 36 Internet of Things 72 Product World 79 Ad Index 80 Technical Thinking THIN ENOUGH? BXR Brakes · Up to 480 in-lbs static · Up to a 1.125'' bore · 19 watts or less · Produced for over 10 years Our Innovative design features a very thin profile, reducing weight and space. For more information: Call: 800.533.1731 www.mikipulley-us.com

Follow the whole team on twitter @DesignWorld

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor

Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Senior Editor Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor

Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael

Associate Editor Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

CREATIVE SERVICES

VP, Creative Services Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Senior Graphic Designer Allison Washko awashko@wtwhmedia.com @wtwh_allison

Graphic Designer Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director,

Bruce

bsprague@wtwhmedia.com

WEB DEV / DIGITAL OPERATIONS

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager

Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Webinar Coordinator Halle Sibly hkirsh@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com

EVENTS

Events Manager Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

VIDEO SERVICES

Videographer

Garrett McCafferty gmccafferty@wtwhmedia.com

Videographer

Kara Singleton ksingleton@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager

Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative

Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative

JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative

Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative

Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager

Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist

Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer

Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist

Elise Ondak eondak@wtwhmedia.com

FINANCE

Controller

Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist

Jamila Milton jmilton@wtwhmedia.com

TOP WORK PLACES 2022 DESIGN WORLD www.designworldonline.com March 2023 13

WORLD Medical Design & OUTSOURCING

DESIGN

WTWH Media, LLC 1111 Superior Ave. 26th Floor Cleveland, OH 44114 Ph: 888.543.2447 2011 - 2020 2013 - 2017, 2021 2014 - 2016

Audience

Development

Sprague

Design for Industry

Flexible gaging for inspection

When an aerospace or medical application calls for high-speed comparative gaging for inspection, the Renishaw Equator system may fit the bill. It’s a lightweight, fast, and highly repeatable gage that operates with “push-button” simplicity. It can also be used by firearms manufacturers for production of handgun barrels, frames, and slides, and some lower and upper AR (Armalite Rifle) components.

The Equator system takes a simple concept of using a master (known) part and couples it with a highly repeatable and versatile structure for fast, flexible gaging on the factory floor. Along with IPC (Intelligent Process Control) feedback, the Equator system allows the gaging to update the machining process for immediate feedback without a need for manual o set adjustments.

Based on an easily scalable and adaptable “parallel kinematic” structure, the Equator system allows high speed scanning and rapid moves between features, while retaining sti ness that delivers point-to-point repeatability, critical for accurate gaging. The Equator system o ers the flexibility to scale appropriately without too much in the way of dedicated fixturing.

Installation of an Equator system takes minutes, and an operator can switch between gaging of di erent parts in seconds. Re-configuration of the gaging system to accommodate part design changes, or to measure new parts, is possible in a fraction of the time needed for conventional custom gaging, using industry standard DMIS programming.

Equator systems are available with two levels of software; a programmable version for production engineers to create DMIS programs and, at a lower price, a shop floor system which allows those programs to be executed but prevents operators from making modifications. Both software levels include easy-to-use MODUS Organizer operator front-end software. In the programmable version, MODUS Equator programming software allows engineers to rapidly create gaging routines for any part – simple or complex, prismatic or free-form. DW

Aerospace/military

14 March 2023 www.designworldonline.com DESIGN WORLD

Renishaw | www.Renishaw.com

Triaxial variable

capacitance accelerometer handles

harsh environments

When you need to take precise measurements in harsh environments, the Model 3743F provides accurate readings over a wide operating temperature range. It is for testing aircraft flight/flutter, in-flight vibration, low frequency aircraft/ airframe vibration measurements, space launch vehicle vibration, automotive ride quality, road load data acquisition (RLDA), and structural dynamics.

As part of the “F” series of MEMS DC response sensors, which also includes 3711F, 3713F, and 3741F, the Model 3743F uses variable capacitance MEMS technology for stable and accurate measurement in a wide input voltage range from 5 to 32 Vdc. It simultaneously measures acceleration and lowfrequency vibration in three mutually-orthogonal axes (X, Y, Z).

The triaxial di erential output accelerometer features:

• Stable and accurate measurements using MEMS technology

• Ability to measure low frequencies and long duration events

• Excellent linearity (0.3%) and low noise

• Exceptional Thermal Performance (+/- 1% from -54 to 121 C)

• Available in six measurement ranges: ± 2, ± 10, ± 30, ± 50, ± 100 and ± 200 g’s

The titanium package is stud mounted and has an integral hermetic 9-pin receptacle that mates with our 037Gxx / 037ENxxxNU detachable shielded cable assembly, sold separately. The 3743F is currently shipping in 6-8 weeks. DW PCB

DESIGN WORLD March 2023 15

Piezotronics

www.pcb.com

|

Magnetics handle the harsh environments of space

Fiber optics collect the light om the celestial bodies. The extremely precise alignment of each of the fibers is performed by 500 small robots, which are driven by FAULHABER motors.

The CCM (Chameleon Concept Magnetics) family of products withstand the harsh environments of aerospace and particularly of space applications. CCM technology is a response to the growing interest of electronic engineers for inductors and transformers with multiple outputs, high power density, and reduced footprints. These ‘chameleon-like’ products can be either an inductor or a transformer depending on the inductor ranges and complement the existing SESI and TT product families.

The CCM product family currently consists of five sizes, CCM4/5/6 and CCM20/25, allowing optimized component design in a pick-and-place surface mount (SMD) package. Through-hole (TH) packages are also available upon request. The maximum transferable power in the CCM25 is about 200 W, depending on the operating conditions of the transformer. The CCM30 is currently under development and this model would approach 350 W. The CCM series is flexible with a number of pin options available, from 2×6 pins for the smallest package, up to 2×10. Qualified for aeronautic and space applications, the CCM product line is robust. The monolithic design provides high mechanical performance, proven by the successfully testing in accordance with MIL-STD-202 (methods 213 and 204).

CCM transformers and inductors can operate over a wide temperature range with a minimal operating temperature of -55°C. The standard thermal grade of the technology is 140°C. Thanks to the technology design, the thermal resistance is 30% lower than standard industrial components. The epoxy molding that protects the winding ensures a lower temperature gradient and a better heat dissipation.

Design for Industry 16 March 2023 www.designworldonline.com DESIGN WORLD Aerospace

Each unit is thoroughly tested with a dielectric withstanding strength of 1,500 VAC. Component materials meet UL 94-V0 rating. Thermal resistance data is available for each package size. The CMM products are manufactured to MIL-STD-981.

Features and benefits:

• Designed to withstand severe environment as space, avionics

• Bobbin winding Technology using standard profiles (RM, EQ, etc.)

• Epoxy Transfer molding technology

• SMD package

• Multiple pins

• Ferrite withstand high shocks and vibration (MIL STD 202 Method 213 & 204)

• Good repeatability of electrical characteristics, allows good regulation of multiple outputs power supply

• Higher power density up to + 30% compared to standard package

• Easy to pick and place

• Flexibility of use

• No stress on the Ferritecore External assembly

Applications:

• Aeronautics & Space

• Common mode chokes

• PFC chokes

• Gate Drive transformers

• SMD filtering chokes

• Current transformers

• Flyback transformers

• Forward transformers

• Push-Pull transformers

DW

Exxelia Magnetics

Exxelia.com

DESIGN WORLD March 2023 17

Connect and discuss this and other engineering design issues with thousands of professionals online

WHAT DO YOU THINK?

CNC for smart production processes

Machine controls continue to o er a greater range of features. One example is the SINUMERIK ONE CNC, which o ers new technological functions and a redesigned user interface. It o ers 95% operational compatibility with Sinumerik 840 D sl, as well as optimized machining speed, contouring accuracy, and machining quality.

A universal and flexible CNC system, it is compliant with the applicable IT security standards. The extended option package, included as standard with SINUMERIK ONE, includes the following options:

• Execution from external storage (EES)

• Shopturn/Mill upgrade package

• CAD reader for the Sinumerik

• Sinumerik & EMCONNECT, your digital process assistant

EMCONNECT is included in the standard machine. All it takes to switch between the EMCONNECT apps and the control is one click. What is more, all production-relevant data can be displayed in full screen or in sidebar view.

The SINUMERIK ONE was developed for smart production processes.

• The digital twin for production planning is an integral part of the CNC. The virtual and physical controls merge and complete each other

• Run MyVirtual Machine replaces Sinutrain

• Significant reduction of the product development and launch times thanks to the ‘digital first’ strategy

• Improved networking and data communication capabilities

• The virtual preparation of the start-up reduces the actual commissioning time

• Significantly increased CNC performance

• Significantly reduced non-productive times and full integration into the TIA portal thanks to the integrated SIMATIC S7-1500F PLC

18 March 2023 www.designworldonline.com DESIGN WORLD

Design for Industry

Machine tool

DW EMCO | www.emco-world.com

Positioning stage offers four motor choices

Flexibility in machining components enhances the design process. For example, the XYZR Series of Four-axes Stages are the integration of a: 15 mm, 30 mm, 50 mm, 75 mm, or 100 mm linear stages (in any combination) for the X, Y, and Z axes, and a 60 mm or 100 mm diameter rotary stage capable of 360° of continuous rotation. These stages suit applications such as: Laser scanning, drilling, and machining, reverse engineering, inspection, assembly, measurements, tracking, and positioning.

This series of four axes stages feature four motor options. The -01 option is Stepper Motor driven, the -02 option is Three PhaseServo Motor driven with a Quadrature Optical Encoder, the -03 is DC Servo Motor Driven with a Quadrature Optical Encoder, and the -04 option is Stepper Motor Driven with Quadrature Optical Encoders for position verification.

Each axis of these black anodized aluminum alloy stages features high precision crossed roller bearings. The 15 mm, 30 mm, 50 mm, 75 mm linear axes feature high precision 1 mm per turn lead screws and the 100 mm linear travel stage has a 4 mm per turn lead screw. Typical repeatability and positional accuracy of a stepper motor driven stage is 10 microns. For higher resolutions and greater travel speeds select one of the closed loop servo motor options.

The rotary axis is equipped with a HOME switch to signal the motion controller the ZERO position. Each rotary axis has a pattern of precision mounting holes for mounting tooling and the 100 mm diameter stage has a thru hole. The linear axes are equipped with limit switches to signal the motion controller that end of travel is reached.

Each of these stages can be ordered with a fully plug-andplay compatible multi-axis motion controller for any motor combination. DW

DESIGN WORLD March 2023 19 WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly. Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor. 33 Higginson Avenue, Central Falls, Rhode Island 02863 Telephone: (401) 728-0700 • FAX: (401) 728-0703 E-mail: info@whittet-higgins.com Web: www.whittet-higgins.com POWER TRANSMISSION

WHITTET-HIGGINS USA BEARLOK SHOELOK BEARLOK Shrink Disc BEARHUG CLAMPNUT TANGENTLOK PRECISION NUTS & WASHERS ADAPTER SLEEVE ASSEMBLIES NUTS & WASHERS HARDENED TONGUE WASHERS SPLIT COLLAR RETHREADING DIES ADJUSTABLE SPANNER WRENCH BEARING ASSEMBLY SOCKET INCH and METRIC THREADS LEFT HANDED as well as RIGHT -HANDED Materials of: CARBON, ALLOY and HARDENED ALLOY STEELS Materials of: ALLUMINUM and CORROSION RESISTANT STEEL

RETAINING DEVICES & maintenance & assembly tools

Optimal Engineering Systems, Inc. (OES) www.oesincorp.com

Compact linear motion system for small spaces

When you need to implement complex applications in small spaces, this family of compact linear systems can make design easier. Designers needing thrust and bearing support in a single, compact unit now have the flexibility to build such applications with these versatile components.

As demand for smaller-scale applications grows, so does the challenge of packing high functionality into a smaller footprint. In building a compact linear system, a designer can configure a unit or combination of units from a variety of components based on their specific application details. Components include, but are not limited to:

• Integrated stepper motors

• Lead screws

• Profile rail linear guides

• 60 Case LinearRace shafting

• Linear Ball Bushing bearings

• End blocks

Many features can be customized, including screw diameters and leads, mounting holes and mounting configurations.

To take maximum advantage of such flexibility, engineers can refer to an innovative 3D modeling tool that optimizes their solution by revealing design tradeo s in real time. The tool guides the designer in tailoring motor size, stroke length, and other variables to function most e ectively within given load and space parameters.

The resulting design information is used to produce a prototype, which is sent back to the engineer for testing. Because of such close user involvement during the design process, the number of design iterations is reduced, which, in turn, decreases the likelihood of mistakes being made.

These compact linear systems are appropriate for applications requiring high-accuracy linear axes in confined spaces, such as 3D printers, microscope stage managers, medical pipetting systems, and semiconductor manufacturing. They are available with NEMA motor sizes between 14 and 23; stroke lengths of up to 40-in. (1000 mm); and load capacities up to 2091 ls (9300 N). DW Thomson

20 March 2023 www.designworldonline.com DESIGN WORLD

Machine tool Design for Industry

Industries, Inc.

products/compact-linear-systems

www.thomsonlinear.com/en/

CLEAN EATING

UNCOMPROMISING PURITY IN FOOD PRODUCTION THANKS TO EFFICIENT SEALS

Seals used in the food industry have to meet very high requirements. That‘s because hygiene and the appropriate certifications are critical for the safety of processes and end products. Yet extreme temperature fluctuations, aggressive media such as cleaning agents and grease, and abrasive additives like nuts or pieces of fruit

present a huge challenge. Freudenberg Sealing Technologies has developed special seals made of innovative materials that can withstand these extreme conditions permanently and uncompromisingly – for the clean production of all kinds of food. foodandbeverage.fst.com

Register for our NEWSLETTER and stay informed!

for Industry

Stepper drive for fixed-load, lowspeed, point-to-point applications

The P80630-SDN stepper drive o ers features such as smoothness, precision and torque across the full speed range in a more compact package that enables smaller, lighter, more versatile machines.

The stepper drive powers and controls stepper motors operating on 24 to 75 VDC with up to 5.5 Arms current per phase (7.8 Arms peak). It suits labelers, indexing tables, CNC machines, packaging systems, pumps and other single-or multi-axis systems requiring low-speed, point-to-point motion control for fixed loads.

The drive delivers improved positional accuracy as demonstrated in laboratory tests using PMX series stepper motors. This compact, powerful new drive achieves 10% greater output current in a 60% smaller package that is up to 34 mm shorter in height than the 6410, depending on the model. Moreover, it reduces setup time by delivering smooth, precise performance at all speeds without the need for electronic damping control switches.

The P80630-SDN stepper drive supports conventional single-ended or di erential step and direction interfaces (user-provided pulse train required) or CW/CCW command inputs. Dip-switch selectable settings include motor phase current, idle current reduction and step resolution up to 1/128 microstep, all with no programming required. Dedicated enable input and fault output provide control of the drive’s power stage and error monitoring. Additional models with new features are scheduled for release in the coming months. Selected drives will also include widely used fieldbus protocols for integration with industry-standard motion controllers. All drives in the series are CE, RoHS, and REACH certified. DW

Kollmorgen

www.kollmorgen.com/en-us/products/drives/ stepper/p8000

22 March 2023 www.designworldonline.com DESIGN WORLD Packaging

Design

Hollow sha gears offer high

torque outputs

HPF series of hollow shaft gear units provide exceptional torque density and positional accuracy, making them suitable for a range of industrial applications including robotics, packaging, and material handling. They feature a high torque output, with maximum continuous torque ratings up to 1000 Nm and maximum peak torque ratings up to 1500 Nm.

The hollow shaft design allows for easy integration and installation in tight spaces, while also allowing for the passage of cables, hoses and other mechanical parts through the gear unit. Additionally, the hollow shaft design provides a high torsional rigidity, making it suitable for high-speed applications.

Built with state-of-the-art manufacturing processes and materials, the HPF series gear units are durable and reliable even in the most demanding environments. They also feature low backlash and low noise operation for applications where precision and quiet operation are a must. DW

Features include:

• Hollow Shaft: 25 to 32 mm

• Available in 2 Frame Sizes

• Peak Torque: 100 to 200 Nm

• Ratio: 11:1

• Backlash <3 arc-min

• Extra-large Cross Roller Output Bearing

Harmonic Drive

electromate.harmonicdrivegearhead.com/products/harmonic-planetary-gear-units/hpf

DESIGN WORLD www.designworldonline.com March 2023 23 TRIMS AND SEALS CELE B R ATING YEARS CELE B R WWW.TRIMLOK.COM • INFO@TRIMLOK.COM NEW LOCATION NEW LOCATION NOW OPEN! NOW OPEN! Trim-Lok Corporate 6855 Hermosa Circle Buena Park, CA 90620 Trim-Lok Midwest 5540 Beck Drive Elkhart, IN 46516 Packaging

Manufacturing an all-new Italian SUV

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

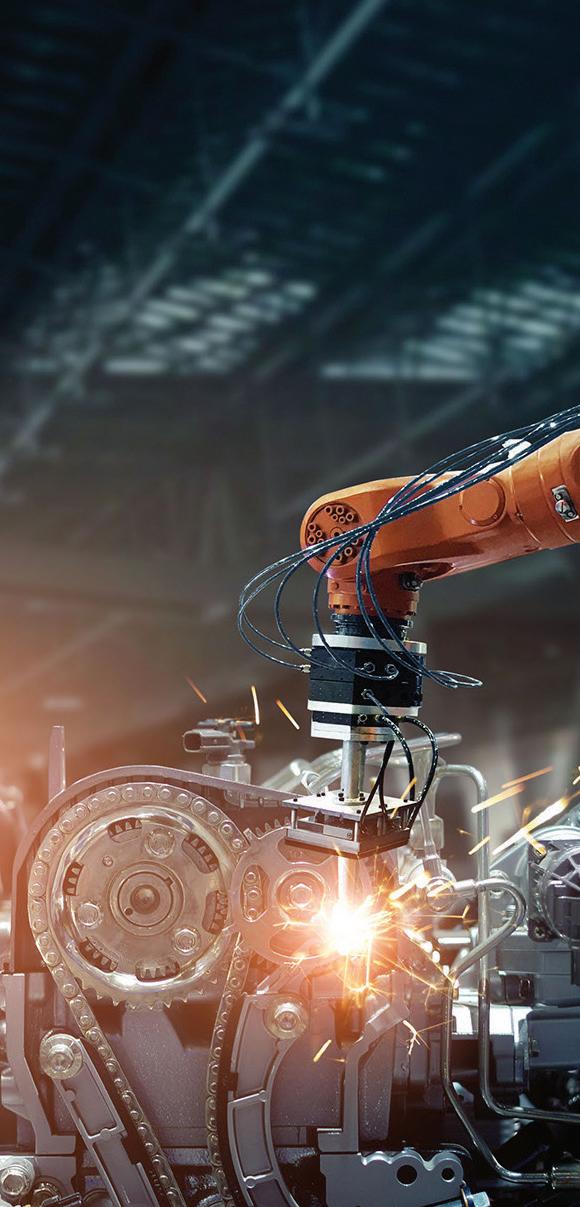

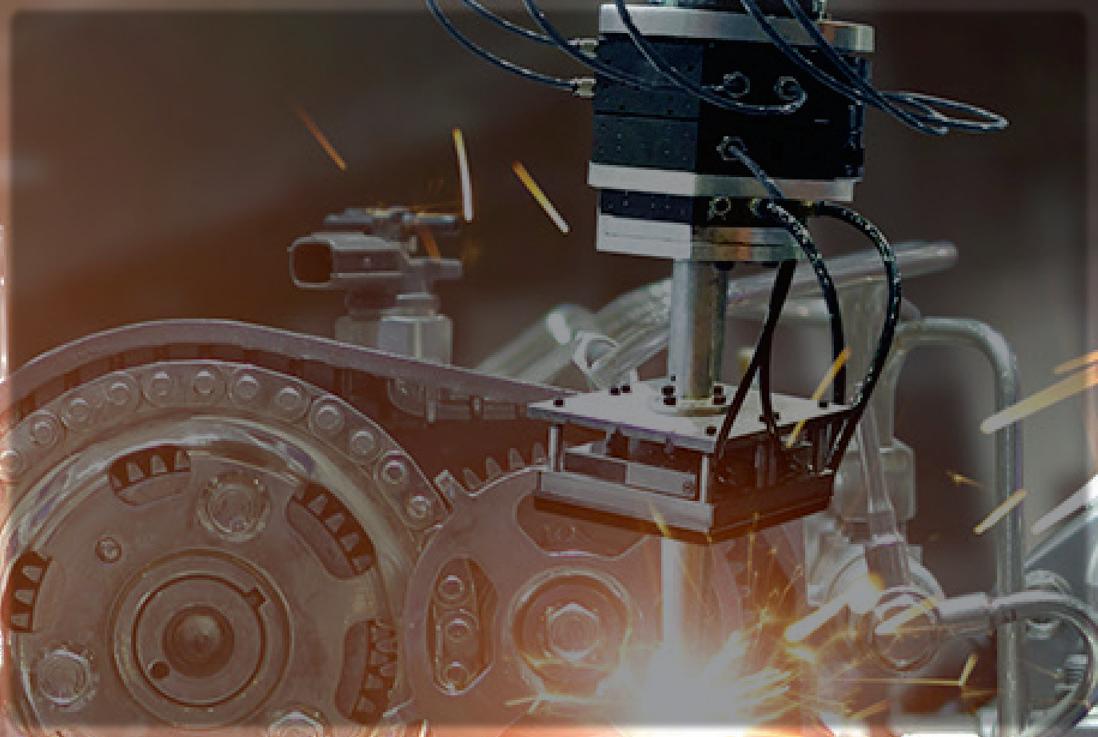

Comau has designed and deployed a flexible Body-In-White (BIW) manufacturing solution for Alfa Romeo’s all-new Tonale, the first Alfa SUV of the new generation, meeting customer production targets, quality goals, and time-to-market objectives.

The new and enhanced 20 lines are designed to allow the automaker to assemble its mid-size Tonale in a random mix of up to 4 di erent versions while maintaining the desired throughput. Fully scalable, the solution lets the automaker produce multiple brands on the same line while allowing them to further expand production in the future.

Tasked with building five completely new lines and retooling 15 existing lines to accommodate the new vehicle, the Comau team deployed the production lines in record time despite multiple challenges. The SUV chassis is significantly larger than the compact car for which the line was originally designed, and the team was asked to make the necessary changes without sacrificing the production of either vehicle. Through simultaneous engineering, the team designed a transformation strategy that allowed the retooling operation to be executed in parallel with the existing activities, according to its “Zero Loss Launch” philosophy. Comau also worked on the lines during the plant’s natural downtime, thus minimizing any impact on production.

24 March 2023 www.designworldonline.com DESIGN WORLD

As part of the engineering team’s lean manufacturing approach, the automated and semi-automated production solution is based on the proprietary ComauFlex technology, nicknamed Butterfly, due to its agility and use of suspended robots. This setup allows Alfa Romeo to change or modify a specific vehicle model by adjusting the robot tooling, not the arrangement of the robots themselves. In addition to protecting the scalability of the customer’s initial investment, the solution is designed to enable the introduction of new models in the future for a fraction of the initial expenditure.

Indeed, the entire system features 468 welding robots, 148 of which are entirely new and 320 taken from existing lines. The engineering team used advanced simulation tools during the development period, guaranteeing the best quality product and throughput.

In addition to allowing Alfa Romeo to perform the complex body shop processes with precision, the solution fully assembles the entire BIW from start to finish. With the aid of three di erent vision systems to aid the automated picking and positioning of pieces, the robots weld, fasten and perform other activities, including spreading the semi-structural adhesive on the parts and plasma cutting during the end-of-line activities. All said, the process involves the insertion of roughly 2,800 welding spots for each model.

With significant net output, Alfa Romeo can bank on substantial savings in terms of time, long-term costs, and production e ciencies. Moreover, because the solution is a fully modular system built around standard products combined within an expandable design framework, the automaker can quickly expand its manufacturing environment with limited impact on existing production.

“To join forces with a prestigious brand such as Alfa Romeo is an

The entire system features 468 welding robots, 148 of which are entirely new and 320 taken from existing lines. The engineering team used advanced simulation tools during the development period, guaranteeing the best quality product and throughput. In addition to allowing Alfa Romeo to perform the complex body shop processes with precision, the solution fully assembles the entire BIW from start to finish.

incredible opportunity to develop cuttingedge technologies. We are proud to see the tangible results of Comau’s field-proven expertise within the collaboration between two Italian examples of excellence,” explained Pietro Gorlier, Comau CEO. “Our commitment to unwavering quality is seen within the processes and products used to make the Tonale and allow us to ensure maximum value for the customer.”

“In supporting the Alfa Romeo brand in their product expansion, Comau has fully leveraged its longstanding experience in automation and smart manufacturing to deliver an unprecedented level of flexibility,” added Andrew Lloyd, Comau’s Chief of Engineering. “This innovative approach to implementing new technologies and retooling existing lines and equipment is a direct result of our commitment to o ering increasingly scalable and sustainable solutions, helping our customers better meet their objectives today and tomorrow.” DW Comau | comau.com

DESIGN WORLD www.designworldonline.com March 2023 25

Plate heat exchangers vs. shell and tube designs

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

For simple non-viscous fluids, the choice of heat exchanger typically comes down to a choice between plate heat exchangers (PHEs) and shell and tube designs. The proponents and manufacturers of both types of heat exchangers make strong cases for the use of each technology and the suitability of each type of heat exchanger, but ultimately the heat transfer situation will determine the best heat exchanger for the role.

There are also several considerations less frequently addressed when evaluating the advantages of shell and tube and plate heat exchangers. It is first important to understand the di erence between the two designs, as this will make it easier to understand the di erences in costs, operational e ciency, and maintenance.

Design Notes 26 March 2023 www.designworldonline.com DESIGN WORLD

One aspect of plate heat exchanges often not considered is the cost of gasket replacement.

As the name suggests, a plate heat exchanger consists of a series of pressed metal plates separated by gaskets. The service fluid (which provides the heating or cooling e ect) and the product (the material to be heated or cooled) flow through the gaps between alternate plates. In contrast, a shell and tube design features a tube (or series of tubes) running through a shell. The product flows through the tube, and the service fluid through the gap between the tube and the shell.

The advantages of plate heat exchangers include their simplicity and high-heat exchange performance (when used with simple fluids). However, the

DESIGN WORLD www.designworldonline.com March 2023 27 +1 678.880.6910 info@indusolamerica.com www.indusolamerica.com/switches Diagnostic Industrial Managed Switches PROmesh IN STOCK BEST PRICE Cable Diagnostics Performance Monitoring EMC IssueAlarms The latest generation of switches ...with automated condition monitoring German Automation

In a plate heat exchanger, the service fluid and product flow through the gaps between alternate plates.

Design Notes

Shell and Tube heat exchangers contain fewer gaskets, normally simple O-rings.

capital costs of the two technologies are not always clear-cut. Neither are the di erences in pressure drop created by the two designs, but tubular heat exchangers are generally capable of operating at higher temperatures.

While PHEs often require less space than tubular units, the exact size di erence depends on the design of the tubular unit being compared. Heat exchangers which use corrugated tube technology (like HRS tubular heat exchangers) to increase thermal e ciency can provide equivalent heat exchanger performance in a smaller package than traditional smooth-tube designs.

Many PHE manufacturers claim their designs will operate for years without the need for maintenance but will also admit that cleaning (which often involves similar levels of disassembly to servicing) depends on the viscosity, fouling, and scaling potential of the product. In other words, admitting that real-world performance is much less impressive than the theory. In contrast, corrugated shell and tube heat exchangers are specifically designed to reduce fouling, meaning that their performance parameters are based on real-world operational situations.

Total cost of ownership (a combination of the capital cost and operational costs over the working life of the unit) is a major factor when considering which type of heat exchanger to invest in. Cost of ownership depends heavily on maintenance. And one of the biggest maintenance costs is gasket replacement.

The gaskets between each plate are an inherent design feature of PHEs but are prone to failure, particularly when operating at high temperatures. This is particularly true where operation involves many repeated heating and cooling cycles, which stress the gasket material, and the metal plates, which are often just 0.5-0.6 mm thick.

Even when they do not fail, regular gasket replacement is often part of the standard service requirement. This means that the price of gaskets must be considered in the overall cost of ownership, along with the downtime and direct servicing costs. Because most shell and tube designs are of welded construction, there are no internal gaskets to fail or replace. Where removable tubes are used, O-ring gaskets are the norm, making them much easier and less expensive to replace than the bespoke gasket designs required for plate heat exchangers. DW

HRS | hrs-heatexchangers.com

In a shell and tube heat exchanger, the product flows through the tube/s, while the service fluid flows through the gap between the tube and the shell.

28 March 2023 www.designworldonline.com DESIGN WORLD

OVER 25 YEARS’ EXPERIENCE WITH MANUFACTURING AND SOURCING OF MATERIAL, SUB-ASSEMBLIES AND FULL TURNKEY PRODUCTS.

• PRODUCTS: We offer component manufacturing, engineering, sourcing, custom component manufacturing. Kingway offers components and subassemblies all the way to full box builds.

• LOGISTICS: Kingway can help develop a custom Logistics plan to meet your needs including Expedited Air Freight, Sea Freight and Domestic Warehousing.

• VISION STATEMENT: Kingway Electronics offers Direct Sourcing and Customized Logistics Management by utilizing our 25 plus years of relationships and experience to deliver better Pricing, Shorter Lead Times with the Goal of Maximizing our customers profitability.

kingway-usa.com (330) 205-4904

STANDARD TO FULLY CUSTOM OEM SOLUTIONS

Where the rubber meets the road for component design and manufacturing

Edited by Mike Santora • Managing Editor

Optimizing the development of a custom rubber seal can be challenging. Relying on industry specialists and considering potential manufacturing methods and production volumes will enable you to navigate the innovation process. Custom rubber seal manufacturing experts o er a great understanding of how production volumes, methods, materials, and design, interrelate and impact costs and a ect performance and time to market. They also contribute diverse skillsets.

One powerful skill is prototyping production-intent custom elastomer components. Prototyping is advantageous, as it allows testing on the live part before committing significant budget and resources to any aspect of component design, giving design engineers the opportunity to adjust and consider the potential production outcomes. By bringing the prototype

design, materials, and methods as close to the production equivalent as possible, you will yield accurate component performance results and the highest quality production.

The earlier you involve your custom rubber manufacturer in your product development process, the better. Relying on elastomer manufacturing specialists can help you prevent design and performance issues while achieving budgetary constraints.

Your rubber component is the final piece of the product design puzzle, and it must fit your

Design Notes

30 March 2023 www.designworldonline.com DESIGN WORLD

product — there is no room for deviation. Failure to recognize the importance of the rubber component design can negatively impact your costs and product performance.

In short, the earlier you talk to your rubber component manufacturing specialist about your project and objectives, the easier you will arrive at the best process and material solution.

When it comes to manufacturing custom elastomer components, there are three common molding techniques:

Injection molding

Injection molding injects heated elastomer material into the mold under high pressure. The compound flows from the heating chamber to a series of runners and sprues, which direct the rubber into the tool at multiple points. Some materials are better suited for injection molding than others. Elastomers with better flow rates will move through the machine more favorably than highly viscous materials. Injection molding is suitable for highvolume production and can yield better results for components with generally lower geometric complexities. Injection molding is typically an automated process, making operator costs null.

Transfer molding

Transfer molding is most like injection molding. A sheet of rubber material is placed into a pot, located above the top plate, that features gates through which the compound flows into the mold below. Above the pot, a plunger lowers and compresses the material and, while also applying heat and pressure, forces the compound to flow through the top plate gates and fill the entire mold cavity.

During this process, the compound fills the contours of the pot and forms a pad of elastomer that doesn’t fill the mold. This pad is disposed of as waste, making transfer molding ideal for lower-cost materials.

Compression molding

Compression molding is suitable for low-volume production. A pre-form of rubber compound is placed into one side of the tool cavity. One half of the tool is closed against the other, and heat and pressure are applied to enable the material to flow and fill the cavity.

Compression molding is suitable for more malleable materials, with medium-hard elastomers working best. This method is often better suited for simple designs, as the pre-form compound is initially very flexible and di cult to insert into complex molds. Additionally, compression molding can have a very high cavity count, which helps to o set labor costs.

Unlike injection molding, compression molding machines require an operator, making the process subject to labor availability and more human error. Applications for compression molded components range from simple O-rings to complex diaphragms with diameters exceeding 10-in.

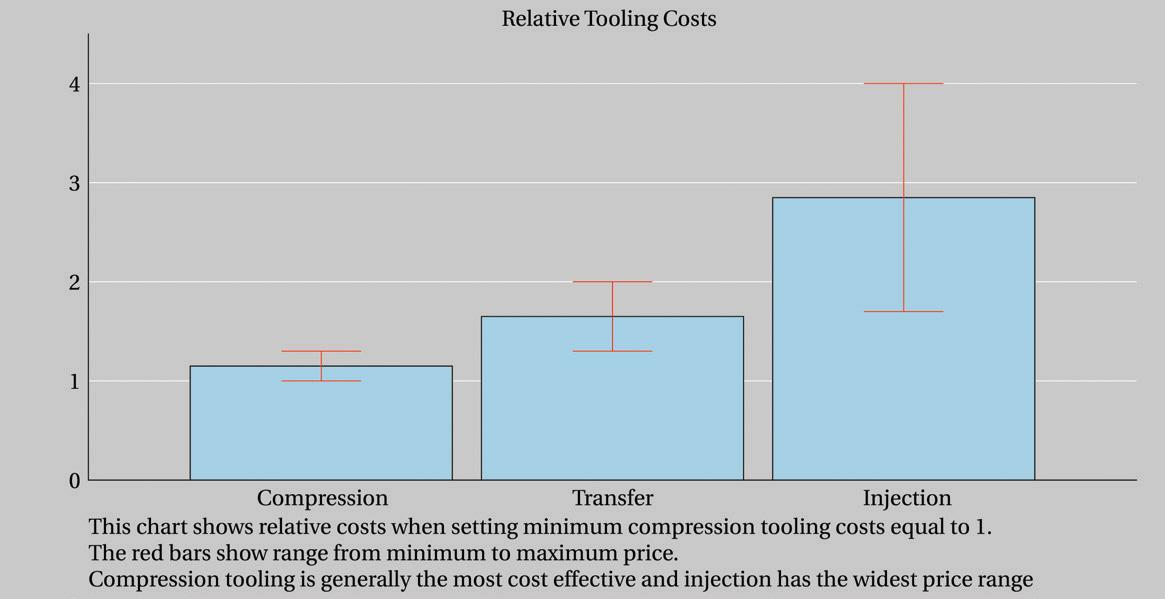

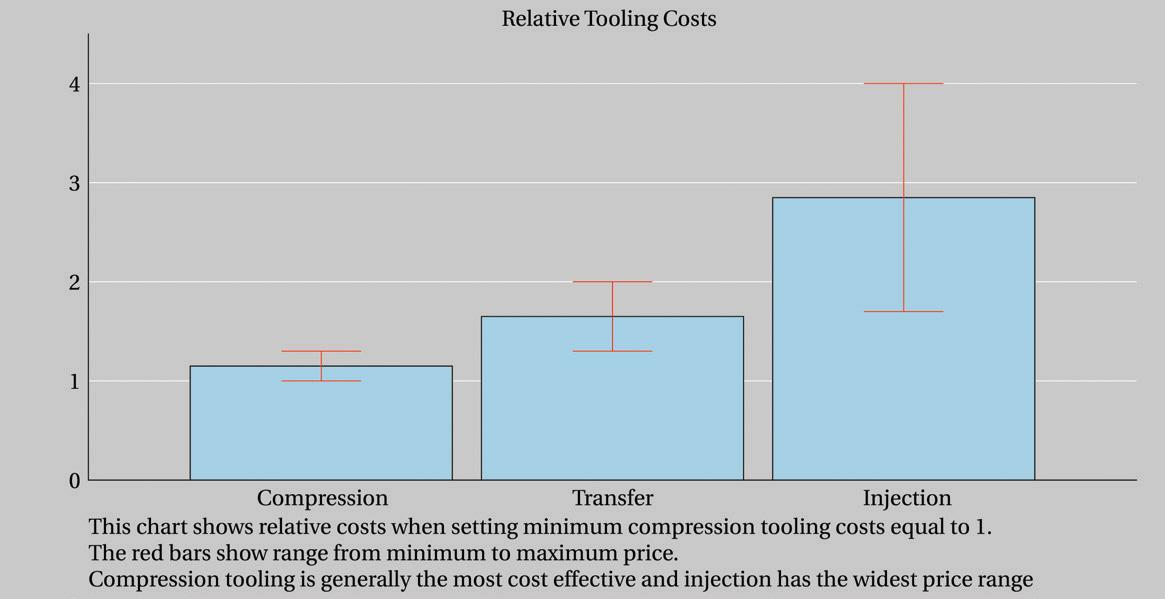

Relative Tooling Costs

How to choose the right tool for the job Tooling, or the mold that forms the elastomer, typically consists of two or more custom-machined cavities and steel plates. In most elastomer molding processes, the tooling plates undergo heat and pressure to force the rubber compound

This chart shows relative costs when setting minimum compression tooling costs equal to 1. The bars show the range from minimum to maximum price. Compression tooling is generally the most coste ective, and injection has the widest price range.

DESIGN WORLD www.designworldonline.com March 2023 31

Design Notes

into the tool. It’s important for all parts of the mold to have consistent dimensions, close tolerances, and proper surface finishes to ensure high-quality finished components.

Tool construction begins with CNC machines hollowing out a solid steel block that is divided into multiple plates according to the component’s design. If a design requires interior contours, a steel core pin is inserted into the tool to shape the internal features of the finished component.

Consider your production volumes

Production volume impacts molding machine selection and cost-e ectiveness and is typically the first factor to consider when deciding which molding process to use. For example, at high production volumes, some manufacturing methods cannot keep up with the cycle times necessary, ultimately a ecting the end-product’s time to market.

The industry rule of thumb is to use injection molding when producing a million components or more per year, while low-to-medium volume production is the sweet spot for compression and transfer molding.

Finding the right material

To decide which rubber compounds to use, it’s critical to understand the function of the finished component. For example, if the objective is to seal a fluid, you should know whether it needs to seal against many di erent fluids or one specific fluid.

Some common factors to consider include

• Providing structural support.

• Energy transmission or absorption.

• Pressure and temperature conditions.

Whether you need a variable-speed AC, a high starting-torque PMDC, or a zero-maintenance brushless DC gearmotor, we’ll help you find the right solution for your application.

EXPERIENCE.

If you’ve got questions, we’ve got you covered.

• Wet or dry environments.

Failure to consider the critical requirements and functions may result in failures. Trelleborg

Sealing Solutions has an extensive compound portfolio, and it commonly formulates new materials to meet application-specific requirements for custom-tailored components.

Design features that influence product development

Molded rubber components vary in design complexity and can range from simple ring seals

32 March 2023 DESIGN WORLD bodine-electric.com | info@bodine-electric.com | 773.478.3515 (USA)

to complex subcomponents that must be overmolded together. The design will naturally push engineers toward di erent materials or processes. Here are some of the most common design features that will have an impact on your choice:

Corners. Sharp corners are generally di cult to manufacture and increase the likelihood of component defects. Although costly, high-quality tooling can mitigate potential defects and impact the success of the end-product.

Undercuts. An undercut is a feature that projects back into the main body of a component. The closer an undercut comes to the axial center, the deeper the undercut. Deep undercuts provide their own set of challenges, as they make the component di cult to remove from the mold. Orientation also contributes to removal di culties. For example, if a deep cut is perpendicular to the mold opening, it can be impossible to remove the component from the mold.

Sharp edges. Components with thin edges, often referred to as “knife edges” or “feather edges,” usually tear as they are removed from the mold. Post-cure deflashing steps can further chip the edge, creating additional imperfections. If possible, it’s best to avoid incorporating knife edges in designs unless absolutely necessary. If your component does require a thin edge, squaring o the edge with a flat minimum of 0.010-in. will significantly reduce the likelihood of damage.

bonding to occur, special adhesives must be applied to the insert before molding. This bond will keep an overmolded component as one object without relying on the component or insert shape.

Incorporating inserts into component designs usually requires secondary preand post-mold tasks, such as insert surface etching, masking, unmasking, applying adhesive, and deflashing.

Flash. The excess rubber that escapes in small amounts from the mold while undergoing heating and pressure is called flash. Usually, this small amount of rubber is forced through the parting lines, or seams, between the tooling plates. It is common to remove flash as part of the post-molding process via manual tear trimming, cryogenic processing, tumbling, or precision grinding.

Overmolding. Sometimes elastomer components must be paired with subcomponents of other materials like steel, brass, aluminum, or plastic. Typically, the rubber compound is overmolded over the non-rubber subcomponent. When designing rubber overmolded components, there are a few design principles to keep in mind to maximize the strength of the bond between the elastomer and insert.

Gates. Transfer and injection molded components usually employ gates to ensure the compound uniformly flows into the tool. You can place gates at various locations on the cavity. Gate marks, the small, raised spots or depressions where the gate interacts with the cavity, are left behind after the molding process is complete and can sometimes impact seal functionality and appearance.

Holes. If your rubber component requires holes, a pin must be placed inside the mold cavity. This core pin is responsible for forming the internal contours of the finished component. The molding process uses high pressures with the potential to deflect the core pin and produce a hole with inconsistent dimensions. Designing core pins with diameters as large as possible, particularly at the pin base, will minimize the risk that the pin will bend or break during the molding procedure. Other guidelines to keep in mind:

• The hole height should not be more than twice the diameter.

• The minimum hole diameter should be 0.050-in.

• Cover as much of the insert’s surface as possible with rubber, maintaining a minimum thickness of 0.020-in.

• Avoid shutting o the flow while the compound travels along a vertical surface.

• Provide proper lands (steps).

Building the prototype

There are two types of bonding methods used when overmolding rubber to a subcomponent material:

• Mechanical bonds require the insert to feature holes, projections, or depressions on its surface. For chemical

When operations are running at maximum capacity, unforeseen issues can impact uptime significantly, leading to missed deadlines. Prototyping provides opportunities to refine designs and manufacturing processes before production and is essential to ensure full-scale production goes o without a hitch. During the prototyping phase, especially with complicated designs, it’s best to manufacture and test under conditions as close to the operational manufacturing environment as possible. DW

DESIGN WORLD www.designworldonline.com March 2023 33

Trelleborg Sealing Solutions trelleborg.com/en/seals

In 1980, Great Britain’s National Trust recommissioned Gondola, an 1859 steam-powered vessel for 86 passengers styled after a Venetian gondola, on Coniston Water in Cumbria, England.

How to bring a 164-year-old gondola back to life

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

In 1980, Great Britain’s National Trust recommissioned Gondola, an 1859 steam-powered vessel for 86 passengers styled after a Venetian gondola, on Coniston Water in Cumbria, England. The 86-ft. long vessel is powered by a twin-cylinder, “V-90” configured double-acting steam engine that generates a maximum torque of 8,000 Nm (5,900 lb.ft.) with a service speed of approx. 8 knots.

To bring the boat back to life, a Bibby Resilient Series grid coupling was installed between the steam engine crankshaft and the propeller shaft. The coupling was a smart choice for the propulsion drivetrain since torsional flexibility and alignment damping were primary concerns for steam engines, which have high torque and significant expansion/ contraction characteristics.

34 March 2023 www.designworldonline.com DESIGN WORLD

Coupling Notes

Bibby Turboflex grid coupling.

Over four decades later, in 2022, operators noticed a knocking noise at higher RPMs and shortly after a change of speed. The grid coupling was suspected to be a possible source of the noise. The boat’s manager sent photos of the coupling to Bibby for help in determining whether he needed to replace the coupling.

Upon viewing the photos, a Bibby engineer identified the coupling as a Type C and Size 212. While the coupling’s hubs and cover remained in good condition, the gridmember was corroded and worn. It has since been found that the coupling was not the source of the knock, but the gridmember was replaced as a precaution regardless.

Fortunately for Gondola, Bibby still manufactures a standard issue RC212 coupling and was able to quickly ship a replacement gridmember. Bibby was also able to confirm the availability of parts and support for the future. DW

DESIGN WORLD www.designworldonline.com March 2023 35 Torsional flexibility and alignment damping are primary concerns for steam engines, which have high torque, and significant expansion/contraction characteristics. Simplified hose configuration, less hose and adapters combine to reduce repairs and downtime, cutting the overall cost of hydraulics. 1-763-784-5531 www.SuperSwivels.com No Kinks No Hose Twisting Full Flow Quality Products Made In The U.S.A. Patent No. 5547233 Fax: 1-763-784-7423 Email: sales@superswivels.com Available In BSPP Hydraulic Live Swivels Inline & 90° Heavy Duty Ball Bearing Design • Also In 304 & 440 Stainless Steel • Rated To 10,000 P.S.I. • Heat Treated • Custom Design & Sizes Available • Rebuildable Ball Bearing Design • Full Flow —Low Pressure Drop • Superior Quality Alloy Steel • Side Load Resistant Sw i tc h Y o u r S w i v ®le S w i t c h Y o u r S w i v ®le

Bibby Turboflex bibbyturboflex.com

eSIM makes it easier to change carriers

eSIM frees up space in IoT devices and can be programmed remotely, making connecting devices and changing carriers easier.

By Steve Taranovich Subscriber Identity Module (SIM) cards

By Steve Taranovich Subscriber Identity Module (SIM) cards

add cost, take up valuable space inside devices, and can be troublesome to handle. eSIM devices eliminate such cards. For IoT devices, users can switch carriers without sending a person to a remote site to swap a card. How did eSIM evolve from SIM cards, and why? Let’s explore.

What is a SIM card?

A removable SIM card is a small chip contained in nearly all cell phones and cellular-connected IoT devices. The SIM card’s function is to store information that enables a cell phone to communicate with its carrier’s cell towers. If the SIM card is removed from a phone, the ability to text, call, or access information on the internet would not be possible.

36 March 2023 www.designworldonline.com DESIGN WORLD

Internet of Things

| Pixabay

Enter eSIM

An eSIM takes the chip out of its card. It’s usually soldered directly to a device’s PC board. That saves precious space, enabling such things as increasing battery sizes. The eSIM can be programmed and re-programmed remotely through software when a user wants to change carriers for phone numbers.

One example of SIM use is an Apple eSIM on the iPhone 14, which lets users activate any cellular plan, provided the eSIM isn’t locked on a single network. Users can program eight or more eSIMs on an iPhone and switch between two phone numbers at the same time.

GSMA and eSIM

eSIM is a global specification issued by the Groupe Speciale Mobile Association (GSMA) that enables remote SIM provisioning of any mobile device. The GSMA announced the first eSIM Security Certification on July 19, 2022. Moving from removable SIM to eSIM provides many benefits:

• eSIM has the same level of security as the removable SIM.

• Device end users benefit from easy management of subscriptions and connections. There is no longer a need to manage multiple SIM cards.

• eSIM allows remote management of subscriptions for organizations.

• Distributors now have simplified logistics and reduced customization for regional areas and specific operators.

• Operators can now simplify the expansion of their businesses in emerging markets, such as consumer electronics, wearables, and automotive.

• Manufacturers of devices can benefit from the reduced space in their product designs, leading to smaller devices. Devices can also now be made airtight to resist dampness, vibration, and temperature.

The IoT was one of the reasons that the eSIM card was ushered into existence. The eSIM was small and did not need a slot in devices because it is an embedded chip, hence the name “eSIM.” Thales, an eSIM solution provider, reports that by 2025, approximately 4 to 5 billion smartphone connections will be using eSIM cards from the M2M/B2B IoT and consumer markets.

eSIM applications Mobile phones

The newest iPhone, iPad, Samsung, Oppo, and Pixel smartphones are just a few examples of devices with eSIM capability. eSIMs have many benefits, including highly e cient subscription management and seamless remote connectivity over a product’s lifecycle. This greatly benefits fastgrowing product sectors in large IoT deployments, such as smart meters. eSIM benefits include easier changing of service providers without swapping phones or SIM cards because they can be reprogrammed through the phone. International travel with a smartphone with an eSIM no longer requires replacing the eSIM as the original SIM devices did.

IoT

The IoT is continuing a digital transformation that is enabling more device connectivity. This is leading to the job of interfacing with many Connectivity Service Providers (CSPs) who need roaming agreements to connect their devices in a multitude of countries. Such businesses need

SIM card sizes have shrunk, and that trend continues with eSIM.

DESIGN WORLD www.designworldonline.com March 2023 37

LOW VISCOSITY COATING features SUPERIOR ACID

Tested

Part

an easy, secure method to connect devices, especially with the benefits of using only one SKU, which can eliminate extra supply chain costs.

Transportation and mobility

A dynamic eSIM environment provides the necessary flexibility to automatically and dynamically enable devices that can connect virtually to any cellular network without that device having to travel across a city, country, or border.

Service providers

eSIM technology service providers can now simplify device activation while saving time and cost. Here is how.

• Remote management: Technicians will no longer need to travel to sites to update SIM cards and devices when the Mobile Network Operator (MNO) contracts expire.

• Simplification of the manufacturing process and logistics: eSIM enables devices installed via a service provider to connect to any MNO. This eliminates the need to manufacture multiple product variations that can support various networks.

• Streamlining installations: Devices with an eSIM will automatically choose the best MNO for each deployment site. This eliminates technicians traveling many travel hours to various sites to test devices for their connectivity needs.

Moving eSIM forward eSIM and its successor, integrated SIM (iSIM), have positioned themselves as part of the range of capabilities that designers need to consider when planning a cellular-based IoT product. Moving away from a plastic removable SIM has led to a requirement for Remote SIM Provisioning (RSP) that manages the profiles on the device.

Benefits to the consumer will be a much easier device setup because there is no longer a need to insert or replace a SIM card. Plus, there is a range of new mobile-connected devices from which the consumer can choose, and devices will be able to operate independently of a smartphone. DW

References

Using eSIM and iSIM will save money for IoT deployments, Quectel

IoT Connectivity – Understanding the role of SIM and eSIM in IoT, Thales

How eSIM can help you with your connectivity needs, Thales Thales adaptive connect, Thales

Solving permanent roaming challenges through eSIM and localization, Kaleido Intelligence

What is an eSIM card? How will it impact you?, US Mobile

38 March 2023 DESIGN WORLD 154 Hobart St., Hackensack, NJ 07601 USA ∙ +1.201.343.8983 ∙ main@masterbond.com www.masterbond.com

RESISTANCE

ACID RESISTANCE PROFILE

EXCELLENT

Sulfuric Acid 70% ∙ Hydrochloric Acid 10% Nitric Acid 10% ∙ Phosphoric Acid 10% FREE FLOWING SYSTEM

in the following acids for over 14 months at 75°F with no reported failures TWO COMPONENT EPOXY EP21ARLV

A:

cps

75°F

B: 4,000-6,000 cps

ELECTRICAL INSULATION

resistivity >10 14 ohm-cm at 75°F LINE SHAFT CONVEYOR BELTS Original Equipment and Connectable CUSTOM MADE IN INCH, METRIC & O-RING SIZES • Round, Flat and Connectable Polyurethane Belts • Very Clean Operation • Eliminates Tensioning Devices • Exceptional Abrasion Resistancexxxxxxxxxxxxxx pyramidbelts.com POWER TRANSMISSION-PART CONVEYING PYRATHANE® BELTS Lifetime Warranty Against Manufacturing Defects AN ISO 9001 CERTIFIED COMPANY 641.792.2405 sales@pyramidbelts.com 19Pyramid_4x475_PC.indd 1 12/4/2018 4:56:13 PM Internet of Things

3,000-6,000

at

Part

at 75°F RELIABLE

Volume

STANDARD PRODUCTS Advanced Products for Robotics and Automation

CGI Motion standard products are designed with customization in mind. Our team of experts will work with you on selecting the optimal base product and craft a unique solution to help di erentiate your product or application. So when you think customization, think standard CGI assemblies.

Connect with us today to explore what CGI Motion can do for you.

copyright©2021 cgi inc. all rights reserved.

CUSTOM SOLUTIONS

800.568.GEAR (4327) • www.cgimotion.com

YOUR

ARE CGI

On-device learning AI chip targets edge IoT apps

Rohm Semiconductor has developed an on-device learning AI chip (SoC with on-device learning AI accelerator) for edge computer endpoints in the IoT field. The new AI chip uses artificial intelligence to predict failures (predictive failure detection) in electronic devices equipped with motors and sensors in real time with ultra-low power consumption.

Generally, AI chips perform learning and inferences to achieve artificial intelligence functions, as learning requires a large amount of data to be captured, compiled into a database, and updated as needed. So, the AI chip that performs learning requires substantial computing power and consumes a large amount of power. Until now, it has been di cult to develop AI chips for edge computers and endpoints that can learn in the field and consume low power to build an e cient IoT ecosystem.

Based on an “on-device learning algorithm” developed by Professor Matsutani of Keio University, Rohm’s newly developed AI chip mainly consists of an AI accelerator (AI-dedicated hardware circuit) and Rohm’s high-e ciency 8-bit CPU “tinyMicon MatisseCORE.” Combining the 20,000-gate ultra-compact AI accelerator with a high-performance CPU enables learning and inference with an ultra-low

power consumption of just a few tens of milliwatts (1000 times smaller than conventional AI chips capable of learning). This allows real-time failure prediction in a wide range of applications since “anomaly detection results” (anomaly score) can be output numerically for unknown input data at the site where equipment is installed without involving a cloud server.

Going forward, Rohm plans to incorporate the AI accelerator used in this AI chip into various IC products for motors and sensors. Commercialization is scheduled to start in 2023, with mass production planned for 2024. DW

Rohm | rohm.com

Internet of Things 40 March 2023 www.designworldonline.com DESIGN WORLD

The new AI chips for edge devices and endpoints consume low power to support an efficient IoT ecosystem.

| courtesy of Rohm

motion stage

High-precision has the right stu

In-house designed and built motion control components are used to fabricate a new high-precision motion stage.

Edited by Miles Budimir

Edited by Miles Budimir

Linear Motion

42 March 2023 www.designworldonline.com DESIGN WORLD

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

The Proton Motion Stage from Prodrive Technologies is built entirely from in-house off-the-shelf components, ensuring maximal integration and compatibility.

In many specialized manufacturing operations, precision is non-negotiable. Yet, at the same time, many system designers and integrators are also being challenged to increase performance and reduce costs.

To meet the dual demands to increase performance and lower costs, Prodrive Technologies has developed a portfolio of high-precision motion components that are othe-shelf. This new line of products is specifically designed with advanced technologies to help meet the demands of high-performance motion applications. It’s also designed to keep costs under control and make it possible to easily select and combine the right products for the specific application’s requirements.

As an example, the company recently developed a high-precision stage known as the Proton Motion Stage. The stage combines a range of o -the-shelf components, designed and manufactured in-house, to meet the requirements of high-precision and reliable measurement inspection applications, such as those involving scanning electron microscopes or wafer inspection.

One thing that makes the new stage stand out compared to other motion stages is the modular and scalable approach to the design, which also simplifies the process of bringing solutions to market. “In the past, businesses would create a motion stage by sourcing the di erent elements from various suppliers and attempting to combine them for their requirements,” explains Milan van den Muyzenberg, Technical Director for Prodrive Technologies Motion & Mechatronics program. “Our solution has been designed to provide a ‘one-stop shop’ instead, helping to speed up the time to market.”

Because all of the components are manufactured by one source, they are designed to be easily integrated and work seamlessly together. For example, every drive is optimally designed to work with the actuators and every part of the stage can communicate accurately with the master controller. What’s more, these components can also be e ectively combined with products from other manufacturers, if and where required.

DESIGN WORLD www.designworldonline .com March 2023 43

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Tried and true building blocks

Each application has di erent system requirements, from velocity, stroke, and accuracy, to throughput. A fully configurable system, where one can develop a motion solution by picking and choosing the specific products required, has clear benefi ts.

The Proton Motion Stage is scaled to specific requirements using othe-shelf components as its building blocks. It can even provide a highaccuracy option for those specifying systems for vacuum compatibility, where in the past there has been far less choice compared to stages suitable for atmospheric operation. With conventional motion stages that apply cross roller bearings and appropriate pre-loading, interference can be an issue as a result of temperature changes which can cause variations and negative e ects on friction. The new stage is uniquely built with statically determined preloaded mechanisms to ensure that interference has a limited e ect on motion performance. A number of othe-shelf components were used in its construction, including linear actuators, servo drives, motion controllers and more, including a motion software platform with real-time performance and tooling. Below is a look at how each of these components contributes to the overall design of the motion stage.

The Gryphon family of ironless motors are suitable for applications requiring long stroke motion and a high peak force without force ripple and attraction forces in vacuum conditions. The motors also use flat wire technology to maximize the heat transfer from the coil to the housing.

Highly efficient motion without contamination

A bad actuator in a motion stage has the potential to result in bad yield, poor accuracy, low performance, and reduced throughput. In vacuum stages, it’s also critical that particles from the actuator do not ‘leak’ or cause out-gassing into the environment. In other words, clean operation is vital. Another challenge is that there is no air to dissipate heat within the vacuum environment, meaning that heat must therefore be transferred di erently.

The company’s Gryphon linear actuator series features ironless linear motors that were designed to manage thermal challenges by transferring heat via the metal part of the coil unit. This increases reliability, preventing system failures. In precision applications, such as semiconductor inspection, failure of a part such as a linear motor can have a big impact on operations.