IN INNOVATION IS SILENT THE

As your behind-the-scenes partner, our mission is to ensure your greatest MedTech ambitions become a reality. That’s why Resonetics is laser-focused on the details—ensuring every aspect of your critical components is engineered, prototyped, and manufactured to the highest specifications. And with our unmatched dedication, we’re able to move rapidly from design to full-scale production so you can bring exciting developments to market. Speak to an engineer by visiting resonetics.com.

EDITORIAL

VP, Editorial Director Paul J. Heney pheney@wtwhmedia.com

Editor-in-Chief Rachael Pasini rpasini@wtwhmedia.com

Managing Editor Mike Santora msantora@wtwhmedia.com

Executive Editor Lisa Eitel leitel@wtwhmedia.com

Senior Editor Miles Budimir mbudimir@wtwhmedia.com

Senior Editor Mary Gannon mgannon@wtwhmedia.com

DIGITAL

VP, Operations Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Rep Tracy Powers tpowers@wtwhmedia.com

Customer Service Rep JoAnn Martin jmartin@wtwhmedia.com

Customer Service Rep Renee Massey-Linston renee@wtwhmedia.com

DIGITAL PRODUCTION

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

WEB DEVELOPMENT

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com

Six tips for using customer visits to better understand device user

Baxter Chief Operating Officer

Knight looks back at the crisis after Hurricane Helene and shares lessons about leadership, emergency management and supply chain resiliency.

Leaders from Medtronic, Insulet and more taking action in the face of policy and economic challenges offer tools for others to do the same.

analysis of Medtech Big 100 companies shows more women in C-suites and nearly double the number of CEOs compared to last year, yet women remain considerably underrepresented in medtech leadership.

Precision Control Solutions

Designing efficient systems involves much more than simply understanding a few basic principles. There is a true art to balancing the specific requirements of an application in order to achieve the desired goals in the best possible way. Help us understand the unique needs of your application and together, we’ll develop something that surpasses what any of us could have done alone.

Contact your distributor to learn more, or visit clippard.com to request a free catalog and capabilities brochure.

Beware of the invisibility cloak

A couple months ago, I took my youngest son Matthew to Tucson to start his freshman year at the University of Arizona. The empty nest descended upon us.

Like Matthew, I attended college many states away from home. At freshman orientation, my father had a program of his own to attend. Georgia Tech gave parents a rundown of what to expect, including the fact that their straight-A high school students might bring home Cs, Ds, or Fs. After all, college is a different animal than high school, and Tech has always been a “weed-out” school for engineering students, especially the first year.

My experience in Tucson was quite different. There was no program for me to attend. Instead, I was relegated to being the driver, credit-card holder, and luggage carrier … which might be expected, I suppose. But during dorm check-in, I felt truly invisible. After years of check-ins for library storytimes, elementary-school homerooms, and lacrosse camps at which I was given instructions or asked to sign forms, now I was entirely unimportant to the process. No one interacted with me, looked at me, introduced themselves, or paid me any attention. It was a profoundly alienating experience.

Members of minority communities often speak of being unheard or unseen. My elderly family members often talk about feeling invisible in our youth-focused society. While I’ve empathized with the concept, it seems we must experience irrelevancy firsthand to truly understand what it’s like.

The same imbalances can arise in work settings requiring group collaboration. Sometimes certain voices (often the loudest though not necessarily the smartest or most thoughtful) dominate conversations. What’s more, on engineering teams, the oldest and most experienced engineers are often perceived as most valuable. So, the input of the youngest engineers can go ignored … even to the detriment of important projects.

In fact, diversity goes beyond race, gender, and orientation heterogeneity. Teams ideally consist of qualified people with a diversity of backgrounds, cultures, ages, and physical abilities.

Especially in engineering, diversity can also include divergent personalities. That’s why the leaders among us would be wise to keep an eye on that cloak of invisibility. Ensure each member on your team feels welcome. Ask the quiet ones for their opinions. Seek feedback from any colleagues who may feel afraid or awkward to speak up. Do this because at one point or another, we’ll all be that invisible one who could benefit from a champion. DW

STATISTICS ON DIVERSITY ENGINEERING in

INFORMATION ABOUNDS ON RECENT DEI EXPENDITURES, PROGRAM

SIZES, AND IMPACT BUT FIGURES ARE OFTEN CONFLICTING. HERE, DESIGN WORLD PRESENTS THE QUANTITATIVE DATA THAT CAN BE GLEANED (BOTH RELIABLY AND QUESTIONABLY) FROM VARIOUS SOURCES.

Recent years have seen public and private debates about the role of diversity, equity, and inclusion (DEI) programs aimed at promoting the fair treatment and full participation in organizations and industries by people of all backgrounds.

In the U.S., widespread horror at the public asphyxiation of George Perry Floyd Jr. on May 25, 2020 along with anti-Asian violence amid the COVID pandemic spurred a rapid uptick in DEI program introductions and expansions. Cooling these efforts were a spate of 2023 and 2024 state bills prohibiting certain race and gender studies, the Supreme Court decision in Students for Fair Admissions v. Harvard (SFFA) on June 29, 2023 (ruling race-based admissions policies unconstitutional), and a series of presidential orders starting January 20, 2025.

interruptions, staff and funding cuts, and in some cases the elimination of granular breakdowns of engineering-field information related to race, ethnicity, and gender identity.

So, filling some of the informational gap is DEI-related grey literature in the form of unpublished research, policy documents, theses, conference proceedings, and reports from organizations and researchers not formally funded or distributed via traditional channels.

LISA EITEL EXECUTIVE EDITOR

U.S. statistics from sources such as the Bureau of Labor Statistics, National Center for Science and Engineering Statistics, and Census Bureau have been subject to dataset-update

In addition, surveys by professional associations such as the Society of Women Engineers, Society of Hispanic Professional Engineers, and National Society of Black Engineers (along with independent research from Deloitte, McKinsey, RAEng, and others) often yield valuable particulars about groups’ perceptions of STEM-career challenges and benefits.

In Canada, a leading data source remains Statistics Canada or StatCan — the country’s federal statistical agency tasked with regularly publishing in-

PureSolution| Adobe Stock

Better than you thought is easier than you think.

Mitsubishi Electric Automation delivers quality, performance, and compatibility that exceeds your expectations, making your job, and your life, easier. When products are built better, last longer, and work seamlessly with current and future applications, you not only reduce downtime and expenses… you also reduce energy usage, electronic waste in landfills, and scrap. That helps you achieve your productivity and sustainability goals. Servos and Drives

Learn more about efficient production

depth data on ethnocultural diversity, Indigenous peoples, immigration, and other statistics related to demographics.

Compared to those in the U.S., Canadian DEI programs are older (especially as evidenced by the 1982 Multiculturalism Act), more developed, and entrenched into cultural, legal, and governmental bodies to ensure representation of women, Indigenous peoples, persons with disabilities, and members of visible minorities.

Though subject to setbacks and challenges, DEI spending as well as Federal Employment Equity Act and diversity disclosure rules are less controversial than similar programs in the U.S. Perhaps it’s no wonder with Canada’s population of 23% immigrant, 26.5% minority, and 5% Indigenous peoples as of 2021.

Following are statistics on DEI programs, minority involvement, and other demographic trends in the field of engineering and manufacturing for both Canada and the U.S. Sources are linked at engineering.com. DW

Percent of U.S. engineers 55 or older: 25

Percent of U.S. manufacturing workforce 55 or older: 25

U.S. manufacturing jobs to go unfilled in the U.S. by 2030: 2.1M

Minimum cost of unfilled manufacturing positions to the U.S. economy over 10 years: $2.5T

Potential cost for each instance a federal contractor billed the U.S. federal government and violated Executive Order 14173 outlawing programs for women and underrepresented minorities: Treble damages plus $14,000 to $28,000

Cost to train a CNC machine operator: $3,000 to $13,000

Percent of U.S. tool and die makers, CNC operators, and machinists aged 50 to 64: 38.8

Percent of machinists who are men: 92.6

Suicide rate of U.S. working males: 32.0 per 100,000

Overall suicide rate of U.S. females: 8.0 per 100,000

Hours of sworn testimony Boeing whistleblower and quality-control manager John Barnett gave in the days before his 2024 suicide: 11 to 14

Suicide rate of U.S. males working in aerospace products and parts manufacturing: 147.5 per 100,000

2023 compensation of Boeing’s CEO (2020 to 2024) and board of directors member (2009 to 2020) David L. Calhoun: $32.8M

Calhoun’s minimum 2022 compensation counting stock positions: $22.5M

Percent by which real wages (adjusted for inflation) of U.S. working men stagnated or declined since 1979: -4 to +8

2024 net worth of all 1,135 U.S. billionaires: $5.7T

1970 percent of U.S. aggregate household income going to middle class families: 62

2022 percent: 43

Minimum years that the disparity between working-class and middle to upper-class employees’ financial satisfaction and work exhaustion increasingly diverged: 52

Percent increase of white male leaders’ trust and integrity ratings by direct reports after participating in diversity and inclusion labs: 6 to 10

Percent of manufacturers that say they will have ongoing difficulties in attracting and retaining workers in 2021 and beyond: 77

Percent of U.S. architecture and engineering professionals who are Black: 5.9

Minimum percentage of U.S. population that is Black: 14.4

Minimum percent by which U.S. primary and secondary-school budgets in White neighborhoods exceed those in neighborhoods serving students of color: 16

Return on investment for every $1 spent on early childhood programs: $4 to $9

Number of children losing access to afterschool STEM programs due to recent cuts affecting semiconductorfocused CHIPS Act budgeting: 1.4M

Percent by which students in private-school voucher programs rose 2020 to 2025: 100

Percent of voucher dollars spent at religious schools (Catholic or evangelical Christian-affiliated): 88.9

Difference between private and public-school students’ mathematics scores when accounting for socioeconomic background: 0

Percent increased likelihood a student will stay in an engineering track if supported by an intervention to impart feelings of belonging: 15 to 20

Percent by which DEI mentions in S&P 100 firms’ 2025 filings dropped from 2024 mention counts: 68

Percent of S&P 100 firms that shrunk or removed DEI-related targets: 21

2020 peak of U.S. corporate spending on DEI programs: $7.5B

Percent of science and engineering workforce who are women: 28

Percentage of engineers in the U.S. who are women (2024): 17.4

Percentage of mechanical engineers who are women: 11

Percent of U.S. population that is Hispanic: 19

Percentage of mechanical engineers who are Hispanic: 7.1

2025 federal earmarks for DEI according to Christian nationalist thinktank Center for Renewing America: $1.1T

Authoritative federal budgets or department audits that track total dollars for DEI: 0

Maximum number of employees at the Institute of Education Sciences (IES) after recent reductions: 20

Percent by which LGBQ students are less likely than straight students to complete STEM programs: 10

Percent by which LGBTQ STEM professionals are more likely to experience workplace harassment compared to peers: 30

Percent of Canada’s population that is female: 50.34

Percent of licensed engineers, engineers-in-training, and student members of Engineers Canada who are women: 15.4

Surveyed Canadian manufacturer losses in one year due to projects unfulfilled resulting from labor and skill shortages: CAD $12.6B

Canadian companies participating in the 50-30 Challenge promoting gender parity and 30% representation of equity-deserving groups in leadership: 2,853

Canada’s 1.5M workers in the science and technology sector 55 or older: 320,000

Percent of surveyed Canadian employers reporting 2023 DEI budgets had stayed the same or increased over the previous year: 81

Percent of surveyed Canadian employers reporting 2024 DEI budgets had stalled or rolled back as compared to the previous year: 38

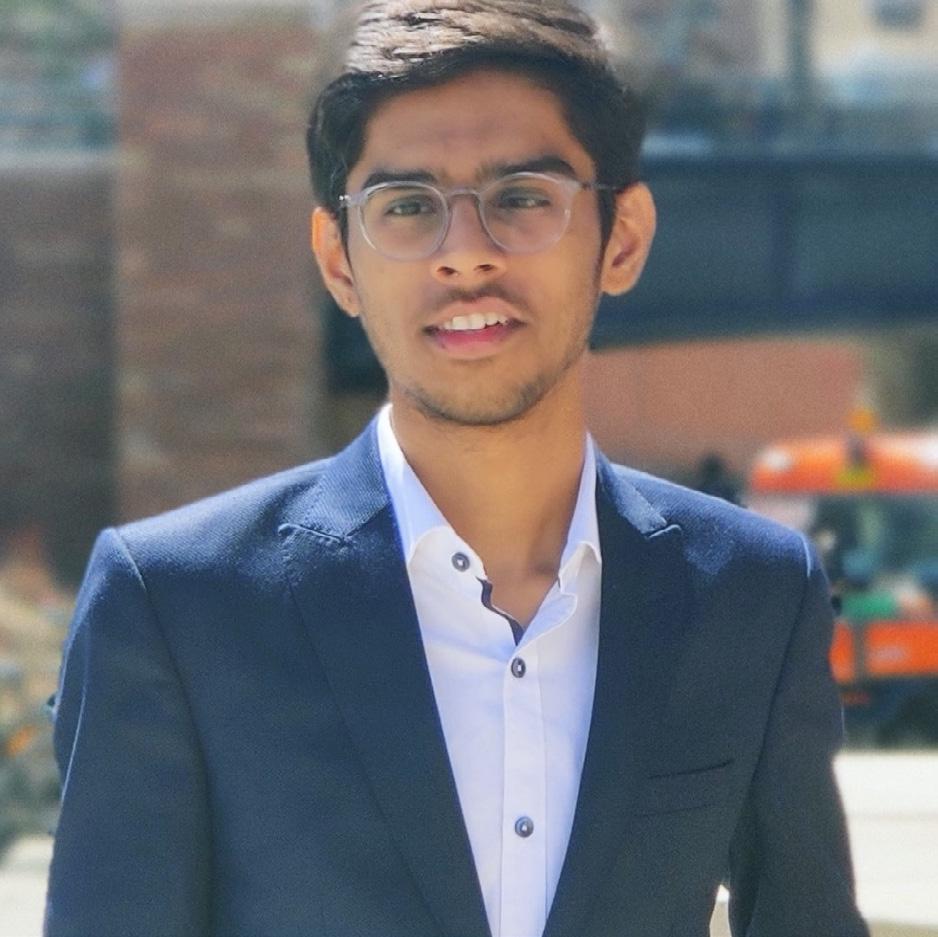

A manufacturing engineer describes his journey from watching airplanes fly overhead to helping build them.

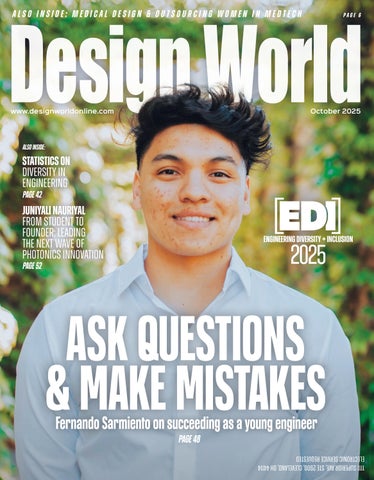

Fernando Sarmiento

ALBA

SENIOR EDITOR

MICHAEL

Fernando Sarmiento

Fernando Sarmiento grew up watching airplanes. Now, as a manufacturing engineer at Swift Engineering, he’s helping them fly.

The first of his family to become an engineer, Sarmiento forged his own path into the profession. Driven by a passion for planes and a ceaseless curiosity, in 2022 he graduated from UC Irvine with a B.S. in Materials Science and Engineering. He worked as a chemical engineer at Axiom Materials after graduating and moved on to Swift Engineering in April 2025.

Now, with a few years of experience on his back, Sarmiento wants to help other young engineers find their footing. Engineering.com spoke with Sarmiento to learn about his engineering journey, his advice for engineers starting their careers, and his thoughts on getting more people involved in engineering.

The following transcript has been edited for brevity and clarity.

Engineering.com: What first drew you to engineering?

Fernando Sarmiento: I grew up really close to LAX, so as a kid I would always watch the airplanes fly over. I was always super fascinated by them. Like, how are these things even flying right now?

As I grew older I learned that engineers play a really big part in making these aircraft. So I saw that that was a career path that could potentially lead to working on one of these things. That was always a dream of mine, being able to work on something that was able to fly in the sky.

So I’ve been working away at that dream of mine since I was a kid. I was also super curious and always asking questions. And built a lot of Legos too.

Were there any influential engineers who helped shape your decision to become an engineer?

Growing up, in my family there were basically no engineers. I’m a first generation Latino, so not much of my family went to college here in the States, and the ones that did are not

engineers. So I didn’t really have anyone from my family that was an engineer to look up to. I kind of had to do my own research and figure it out on my own, or in school they would mention that career path from time to time. So I wouldn’t say I had anyone who helped shape my decision, in terms of an engineer.

I HAVE MY MOM AND DAD TO THANK FOR WHO I AM TODAY AND THE POSITION I’M IN TODAY.

I would just say I had a really, really solid family backing me to whatever decision I wanted to make. I have my mom and dad to thank for who I am today and the position I’m in today. When I mentioned to them that I wanted to be an engineer, they gave me their full support. And I’m just happy to say that they’re proud of their son, proud he was able to become an engineer.

Where are your parents from?

My dad is from El Salvador and my mom is from Guatemala. Both immigrants. And they met over here and they raised me here in LA.

How did you find your way into materials science?

That was in college. I went in undeclared to college, but I knew I wanted to do some type of engineering. I really liked the mix of chemistry and physics that materials science gave at the time. I felt like mechanical engineering was more physics heavy, and then chemical was just full on chemistry. So I really liked having a mix of a little bit of everything. I love materials science.

Could you describe your involvement in an engineering project that went well?

At my previous company we were trying to launch a new material, and we had a machine that no one had used. So we were trying to figure it out on the fly. I was involved by running small lab-scale samples in the lab, and from there, getting data to try at a full production scale to see what could potentially work, what wouldn’t work, what we shouldn’t bother using our time on.

So I was collaborating with a few of the other engineers and technicians to help standardize a new product line of material. And I believe I was able to improve the team by training technicians on how to run the machine. I definitely gained a lot of experience there. I wrote basically all the procedures, all the paperwork for how to properly operate that equipment. I also learned a lot about working with technicians. It was kind of just learning through trial and error. I definitely made a lot of mistakes, but an important thing is it’s okay to make mistakes. Just try to not repeat them, and you can learn from them.

I think I was able to help the team by taking my knowledge from an engineering standpoint and being able to translate it down to the technician standpoint, putting all the paperwork in line. And I believe even to this day they’re still using that to train new hires to work on that machine.

At the end of the day, it was a pretty successful project. We were able to ship good material to our customers and got good feedback. It’s probably still a work in progress, but that’s just the nature of R&D.

What do you do in your current role at Swift Engineering?

I’m a manufacturing engineer now. Before, I was making the materials to make the parts, and now I’m actually making parts that could potentially go onto aircraft. And that’s the path I was looking to take in my career. So when I saw the opportunity I jumped at it.

I’m working a lot with the production floor on day-to-day tasks of making composite parts and troubleshooting. There’s always issues with any part that

you’re going to make. So I’m working with them, trying to iron out any issues, again working on documentation, on procedures to make their life easier, giving them the right steps to follow for making good parts. That’s my role now.

What was the biggest engineering challenge you’ve faced so far, and how did you solve it?

Around December last year I needed to do some mechanical testing at my previous job. It was pretty critical testing, and I had very, very short notice and a short time frame to complete it. And on top of that, this was going to be my first

time being the lead on running these tests, because the previous engineer had left. And whenever you do something for the first time, it adds a little bit of stress thinking that you could potentially mess something up. It was also the end of the year, so we wanted to push out as many purchase orders as possible to get the end-of-year financials to look good. So my back was really against the wall.

The big challenge I was facing for that mechanical testing is that we needed to complete it at elevated temperature. And the problem was that our test setup wasn’t great with insulating heat. You would heat up your test specimen and

then it wouldn’t stay in the stable range where you could test it, or it would just not reach the test temperature at all. So that was a challenge. I definitely leaned on my team and asked a bunch of questions of everyone to try to figure out the solution.

I realized I needed to minimize the distance between my test specimen and the furnace. There’s two heating coils on the furnace, so I just needed to get those as close as possible without affecting any of the mechanical tests, without getting anything in the way of the extensometers or anything. So to do that, I had to custom make some insulation blocks. But at the end of the day, luckily, it ended up working. The ramp rate for the heat ended up going up quite significantly, and it was able to stay stable at that temperature.

I’m glad I was able to lean on my coworkers and fellow engineers to find that solution. I’m also happy that people in the future won’t run into the same issue. If you’re not documenting your changes, the people after you aren’t going to benefit. That was a pretty stressful time, but it really forced me to learn to improvise, and I felt like I came out a better engineer at the end of it. So even though it was stressful, I’m glad I had that challenge.

In your opinion, what more can be done to increase the participation of young people in underrepresented communities in engineering today?

I believe exposure is a really, really big thing. I think if we’re able to expose our younger generation to the career path of being an engineer from a younger age, they’ll be inspired to actually pursue it. I think showing them some of the fascinating things that we work on can be really inspiring for a lot of students.

There’s a program called MESA — Mathematics, Engineering, Science Achievement. They work with underrepresented communities as outreach for engineering in different middle schools and high schools. So I think by supporting programs like that,

“I really, really love to snowboard. And the snowboard that I have is made with biobased resin.” Fernando Sarmiento

if we’re able to get them at a younger age and show what you can do by becoming an engineer, I feel like a lot of people would be inspired and a lot of parents would be proud to call their child an engineer.

Were you involved with MESA?

Yeah, I was in that program in high school, and it was really cool. They did a bunch of different contests, like who could build the strongest bridges out of straws, or an egg drop test where you had to make an enclosure for the egg. It was different projects exposing you to thinking outside the box, which engineers have to do every day. I think the younger you can expose people to that, the better.

What unique perspective do you think diverse teams bring to engineering or design projects?

In a diverse team people come from different backgrounds, and everyone will have a different way of dealing with and solving problems. I think that’s the really important thing. Having a diverse team can lead to more thinking outside the box. And you can learn about how people from different cultures and backgrounds approach problem solving, and you might learn something that you didn’t know before, learn about an approach that you had never taken before.

career can be a little bit intimidating at times. You see everyone in the office running around, we all have meetings, there’s deadlines, everyone’s working on multiple projects. So it could seem that everyone’s super busy and doesn’t have time, but I think a really important thing to try to minimize making mistakes is asking questions.

It’s okay to ask questions. No one’s going to look at you funny for asking questions. It’s expected. Even if everyone seems super busy, we spend a lot of time writing procedures for how to do things. So if your superior is busy at the time, they could at least point you

enjoy showing interns and entry level engineers the ropes. I don’t have a problem with it at all. If I’m busy at the time, I’ll just try to point them in a direction that they can review some paperwork in the meantime. And after that we can get on to the hands-on stuff.

If you had unlimited time to apply your engineering background, what global challenges would you be interested in tackling?

My background is mostly in composites, so I love working on composites and making parts. A really big thing around those is sustainability. The materials that they’re made out of are not very sustainable, and there’s a lot of waste generated when you make composites. Anyone that works in composites will know that.

MY KEY TAKEAWAY FOR YOUNGER PEOPLE, OR LATINOS LIKE MYSELF LOOKING TO GET INTO THIS: DON’T BE AFRAID.

in the direction of some documentation, some specs or some procedures to review while they make some time to show you the ropes. Ask a bunch of questions.

So I think that really leads to more creativity in a group setting. And I think a lot of projects could really benefit from having a diverse team, having several inputs from different backgrounds, to try to achieve the same goal.

What advice to you have for junior engineers looking to develop confidence in the workplace?

As a young engineer, starting your

Also, it’s okay to make mistakes. I’ve definitely made a lot of mistakes in my career so far. I’m probably going to make some more. The big thing is to not repeat them, and learn from them. While I’m working on a project, I try to document any mistakes that I’ve made so I can remember: Hey, I tried this. I’m not going to try this again. Or: This is the solution to what I tried from before.

I know the full-time world can be intimidating for new grads, but please just ask questions. I really

There are a lot of companies that are starting to make environmentally friendly resins, bio-based resins, and use natural fibers as a reinforcement for composites. Applying my background in composites and working on stuff like that would be a dream of mine. I would love to put my skills to use there.

Any final thoughts you’d like to share about your experience as an engineer?

My key takeaway for younger people, or Latinos like myself looking to get into this: Don’t be afraid.

I was definitely intimidated at first getting into this industry. At moments you kind of feel out of place, you don’t see too many people that look like you, but that’s okay. Just ask questions. No one’s going to look at you any type of way. You’re trying to improve yourself, and we all recognize that. At the end of the day, it’ll make you smarter, it’ll make you a better engineer. DW

FROM STUDENT TO FOUNDER:

EMMA LUTJEN • ASSOCIATE EDITOR • EE WORLD

parents were here who could guide me as I was building, I had to develop my own support system of a network of mentors and advisors who could help me.”

This was made even harder by the fact that Juniyali is a petite woman who has been mistaken for much younger than she is more than once. She admits, “[People] always think I'm a kid.” But she wasn’t a kid. She, through her research into connecting fibers to chips with low loss, had identified a need and was looking to build a company to fulfill it. Unfortunately, this task was made more difficult by an astounding lack of role models within the industry.

“Being a female, when you don't look old and you're starting a company, it's hard, but it was also very difficult to find similar-looking people in the positions where I wanted to be. This industry is very male-dominated. And yes, there are a lot of Indians in the field who are male at higher positions, but I could not see a female startup entrepreneur in the field whom I could look up to and actually see that that is possible.” There was no example for Juniyali, so she had to become the example herself.

Through perseverance and the support of the network she crafted in her years at the University of Rochester, Juniyali was able to create Photonect Interconnect Solutions; a company focused on sustainability, diversity, and the future of photonics.

Prioritizing diversity in the workplace

Although it’s not part of the official tagline, diversity has been an integral part of her company from its inception. Rochester’s resources and help from people with a shared interest in her work is how she was able to hire herself full-time after graduating. Now, she carries that energy forward in her company with how she hires and conducts her team. The small team varies in age, race, and background.

I THINK IT'S SUPER IMPORTANT TO HAVE A DIVERSE TEAM IN ENGINEERING AND RESEARCH PROJECTS, BECAUSE THE BACKGROUND OR HOW PEOPLE GREW UP IMPACTS AND INFLUENCES HOW THEY MAKE DECISIONS…THERE ARE IDEAS THAT YOU ONLY GET ONCE YOU HAVE REALLY CONTRASTED AND DIVERSE INDIVIDUALS IN A TEAM.

When asked about her interviewing process, Juniyali said, “Diversity is definitely a consideration…we've always paid attention to how we can be more proactive in reaching out to different types of all the sectors and being as diverse as possible… having no bias while we interview, and just purely based on skills and their outlook, making a decision.”

To her, diversity changes a team for the better: “I think it's super important to have a diverse team in engineering and research projects, because the background or how people grew up impacts and influences how they make decisions…there are ideas that you only get once you have really contrasted and diverse individuals in a team. Then you can listen to everybody's feedback, because everybody brings great ideas and new thoughts into the company.”

Juniyali values her team and does her best to support them like she was supported in Rochester. They have weekly lunches with a focus on collaboration, and annual reviews that pinpoint what success means to them beyond their role at the company. She believes, “My priority as their CEO is to help them develop, not just at Photonect but wherever they are in their career. I want to make sure that every day they learn something new, and they keep growing.”

The future of Photonect

The Photonect team’s overall goal is to see photonics everywhere. Openly cautious about its repercussions for the next generation, Juniyali leads her

company with sustainability in mind, but with the main goal of “photonics” being a household term.

She hopes to see photonics-based cell phones and photonics-based laptops. “I want to make consumer photonics a thing as compared to consumer electronics, and that is what I think is the future of photonics. Not just somewhere in a data center, but we want it more widespread and approachable to everybody.”

With Photonect’s technology of packaging the fibers to chip, the cost of their devices is almost on par with the packaging cost of an electronic circuit. So, while photonics does raise sustainability questions — like energyhungry fabrication, scarce materials, and tough recycling — the company has set out to tackle these head-on.

“It'll be a long process, but in a few years, I can see the industry working together. It would not be that you completely get rid of electronics. No, it would be a co-existing partnership between electronics and photonics, and you would see it in consumer devices as well.”

With her eye on success, driven by dedication and the desire to echo the impacts of greats like Einstein and Newton, Juniyali became a role model for a whole new generation. Maybe one day she’ll be a household name herself. DW

If you want to stay updated on her or Photonect’s journey, you can follow her on Linkedin or visit the Photonect site: www.photonectcorp.com

Danna Jensen, PE, LEED AP, is one of the founding principals of Certus Consulting Engineers. With more than 25 years of experience in the consulting engineering field, she has extensive experience in the design of reliable and efficient electrical systems for complex health care projects. She brings large-scale technical expertise and innovative concepts to her role at Certus where she focuses on advancements in engineering and technology.

Jensen loves that the technical nature of electrical engineering design means no project is ever the same. Her favorite Certus core value is “We work with integrity,” which embodies her everyday approach to life and business

and she’s honored to use her problemsolving skills to indirectly impact the important work healthcare professionals do every day. Jensen was a 2009 Consulting-Specifying Engineer 40 Under 40 winner.

Describe your involvement in a building design project that went well. How did you work with/ mentor others on your team through the projects?

One of the first large-scale projects we were awarded after launching Certus was part of a major expansion for a large hospital campus that included a new five-story patient tower housing inpatient beds as well as full emergency and radiology departments. The project was

delivered through a strategic designassist/integrated approach, which was critical due to the aggressive schedule and the ongoing supply chain issues and lead time delays we faced in the wake of COVID.

As one of the principals in charge and senior electrical engineer, I was responsible not only for planning the electrical infrastructure to support the new facility, but also for leading the integration and coordination with trade partners and driving communication between teams.

Throughout the project, I worked closely with both junior and mid-level engineers on our team to guide them through the technical challenges and client coordination efforts. I made a point

AMARA ROZGUS • EDITOR-IN-CHIEF • CONSULTING-SPECIFYING ENGINEER & PLANT ENGINEERING

to involve them in meetings so they could observe the collaborative process firsthand and begin developing their own leadership skills. I provided regular check-ins and coaching moments, and encouraged them to take ownership of specific aspects of the project with the understanding that I was there to support them if questions came up. This approach helped them grow technically and professionally, while also ensuring the project had consistent, high-quality execution across all phases.

What made this project especially successful was the close collaboration between the owner, design and construction teams. This allowed for real-time problem solving, close coordination across disciplines and efficient, informed decision-making. The success of this project has opened the door to additional work on the campus, including a master planning effort to guide the hospital’s growth over the next 20 years.

What inspired you to launch your own engineering firm and how did diversity and inclusion factor into that decision from the beginning? Were there specific challenges or gaps you saw in the industry that you wanted to address?

I was working for a leading engineering firm where I had built a strong reputation through relationships and quality work. As I advanced further into leadership, I found myself pulled away from what I loved most — engineering and connecting with clients. I enjoyed the business side, but I started to feel like my true strengths were being underutilized. I didn’t want to become disconnected from the work that inspired me in the first place.

Starting my own firm was a chance to reclaim that passion and to help shape a company culture that values people, not just process. From the beginning, diversity and inclusion

were natural priorities. As a woman in a male-dominated field, I had seen firsthand how important representation and opportunity are. I wanted to create a space where different voices were heard, respected and empowered to lead, not just included, but truly supported.

When you were building your team, what intentional steps did you take to ensure diversity — in background, thought and experience? How do you measure the impact of those decisions today?

One of my go-to lines when interviewing prospective team members is: “We’re engineers, we like to use our brains.” Our value lies in solving problems, not just drawing lines. That mindset is at the heart of our hiring process. We look for people who think critically, collaborate naturally and bring diverse perspectives to the table. Different backgrounds

lead to different ways of approaching challenges and that’s where the best solutions are envisioned. We’re not focused on being like-minded; we’re focused on a shared goal.

At Certus, we emphasize to our team that as engineers, we can make a real difference. Our work in health care impacts the communities we live in. That shared sense of purpose helps unify diverse voices across our team and extends into how we collaborate with clients, clinical staff and contractor trade partners. Our projects are highly technical and demand innovative thinking, so we intentionally foster an environment where that innovation can thrive. The results show the strength of our culture, the creativity of our solutions and the pride our team takes in knowing that our work serves real people and real families.

Describe your biggest engineering challenge or business to date. How did you conquer or resolve it — or what was the outcome?

It’s hard to pick a single biggest challenge. Many of the projects I lead involve complex infrastructure upgrades within active hospitals that are incredibly challenging, but also incredibly rewarding.

One project stands out that was recently completed. We began designing nearly four years ago to upgrade the emergency power supply system for a 1.2 million square-foot hospital campus. The goal was to increase resiliency and redundancy by planning for a generator plant that supported the campus needs and was expandable up to 10 megawatts. The scope included new paralleling switchgear, automatic transfer switch upgrades, increased onsite fuel storage and the addition of the cooling plant to the emergency power system. At the same time, we had to decommission some of the hospital’s oldest infrastructure including the aged generators and paralleling switchgear, without disrupting power to a 24/7/365 facility.

I WANTED TO CREATE A SPACE WHERE DIFFERENT VOICES WERE HEARD, RESPECTED AND EMPOWERED TO LEAD, NOT JUST INCLUDED, BUT TRULY SUPPORTED.

The greatest challenge was logistics — how to phase the replacement of the entire emergency power system while maintaining service and minimizing disruptions. Through detailed system studies and outstanding team collaboration, we planned a new location for the upgraded equipment and developed a carefully sequenced two-year phasing strategy to switch over services safely and effectively.

These are the engineering feats I love: solving complex problems with smart planning and great teamwork. While the hospital experienced some short-duration shutdowns, the project went incredibly smoothly. I’ll admit, I lost a few nights of sleep worrying about every possible failure mode, but in the end, everything worked as planned. The

hospital now has a much more robust and reliable emergency power system that will serve them well for decades to come.

In your opinion, what more can be done to increase participation of young people in underrepresented communities in engineering today?

We need to be intentional about outreach at a younger age such as getting into schools and connecting with students in a way that feels personal and meaningful. Not necessarily through formal seminars, but more like a “big brother/big sister” approach — informal, one-on-one and relationship-based. The goal isn’t just to explain what engineering is, but to show why it

matters. It’s about making it real and relevant by showing how engineers impact their communities such as improving hospitals, designing safer infrastructure and solving real-world problems.

Exposure and access are key. Many young people, especially those in underrepresented communities, don’t pursue engineering simply because they don’t see it as a viable or relatable option. There are small but powerful ways we can change that, starting with early, personal exposure that helps them imagine themselves in these roles.

What unique perspective do you think diverse teams bring to engineering or design projects?

When designing electrical systems for hospitals, there’s rarely one “right” answer. Complex projects benefit from diverse perspectives and each team member may see a different solution. Encouraging multiple approaches leads to more creative, thoughtful and effective outcomes that ultimately serve the facility, its staff and the patients they support.

How can those new to engineering develop confidence in the workplace? What safeguards would you recommend to minorities who are aiming to minimize mistakes?

Any comments on learning from mistakes yourself?

I once told a junior engineer — after we’d talked through a mistake and I saw the crushed look on his face — “I get it. It was a tough day for me too when I realized I wasn’t perfect.” Of course, I said it in jest and followed up with a few real examples of mistakes I’ve made throughout my career.

The truth is that confidence comes from experience and experience includes mistakes. What matters most is how you respond. I make a point to bring team members into the field with

me when something goes wrong. Not to point fingers, but to give them firsthand experience in solving problems under pressure, working through solutions and seeing how we overcome challenges together. Mistakes are part of the process. If you show up to fix the issue and support the team, it’s not the error that people remember at the end of a project, it’s the success that came from working through it.

If you had unlimited time to apply your engineering background, what global challenges would you be interested in tackling?

As an electrical engineer, the obvious answer is clean, renewable power. I live in Texas and if you ever drive through West Texas, you see the landscape dotted with wind turbines, often as far as the eye can see.

However, I don’t think the general public understands the amount of energy required to manufacture, transport and construct them or the amount of energy production required to charge all these “clean” electric vehicles. I would love to help find truly sustainable energy solutions that not only reduce

the strain on limited natural resources, but also expands global access to reliable, affordable power.

What advice would you give to other women or underrepresented engineers considering launching their own firms or stepping into leadership roles in commercial building design? What do you wish you had known at the beginning of your journey?

Lead with integrity, say what you mean and do what’s right — no matter what. Care about the people around you because relationships are key in building your business and will take you further than you imagined, it did with me. So don’t try to be someone you are not. Be a leader who inspires others and focus on leaving a legacy one person at a time. Mentor, train and share your journey because success includes preparing the next generation. Finding and growing the right talent will be one of the hardest, yet most important, parts of building a business. And most of all, keep doing meaningful work that makes a difference so you always enjoy what you do. Life is too short to live it any other way. DW

LEAD WITH INTEGRITY, SAY WHAT YOU MEAN AND DO WHAT’S RIGHT — NO MATTER WHAT....KEEP DOING MEANINGFUL

THAT MAKES A DIFFERENCE SO YOU ALWAYS ENJOY WHAT YOU DO. LIFE IS TOO SHORT TO LIVE IT ANY OTHER WAY.

Candis Polite

Sparking curiosity and discovery

From welding to engineering, Candis Polite’s career has always been fueled by curiosity. Here, we learn how tenacity and an inquiring mind are crucial to developing the engineers of tomorrow.

By

Nikki Maginn

Helping engineers rewire their responses

Nikki Maginn started as a nuclear engineer and today teaches emotional intelligence to help engineers lead impactful careers.

By Rachael Pasini • Editor-in-Chief Design World and Engineering.com

Harsh Zala

An engineer on a mission to eliminate active landmines

Equipped with mostly self-directed education and a strong sense of purpose, Harsh Zala dedicates his intelligence and skills to saving lives.

By

Roy Steinberg

Engineering focus with ADHD

Roy Steinberg explains how his quest to improve his concentration in college led to the invention of the Pinchy quiet fidget toy.

By Ian Wright • Senior Editor Engineering.com

From a family of engineers

Maryam Rofugaran co-founded Movandi with her brother. The two come from a long line of family engineers.

Handling political differences in the workplace

Much has been written describing, analyzing, and decrying the seemingly ever-increasing divisions in our society. People express the belief that we are becoming more intolerant, less civil, and less accepting of differences. In fact, some may describe it as the defining element of our times. Recent studies provide insights into the state of the workplace today and practical recommendations on what we can do.

By Miles Budimir • Senior Editor Design World

Maryam Rofugaran

By Martin Rowe • Senior Technical Editor EE World

Mike Santora • Managing Editor Design World

Rachael Pasini • Editor-in-Chief Design World and Engineering.com

2025 engineering diversity + inclusion

NW MN Chapter of WE United

In 2018, DigiKey founded the NW MN chapter of WE United, a community of women in the electronics industry committed to working collaboratively with their male counterparts to advance opportunities for women in electronics and related industries. Since then, membership and participation have continued to grow within DigiKey, bringing increased networking and learning opportunities.

Team members at DigiKey’s headquarters face the unique hurdle of being tucked away in the northwest corner of Minnesota. Being far removed from other tech hubs makes it harder for the team to attend industry networking events and speaker sessions and participate in cross-business mentorship programs, which is why the WE United chapter has been such an important initiative.

The Thief River Falls chapter of WE United is a dynamic group that supports its members in various ways. The chapter offers monthly training, which has helped many feel more confident in their communications and empowered to express their ideas.

The mentorship program has also been an invaluable resource for many. It connects women in different roles and stages in their careers and promotes collaboration, support, and career development opportunities. It’s become a place for many to feel safe and discuss challenges with someone with an outside perspective. Furthermore, it has opened doors previously unavailable to many. Some employees, once mentees, are now looking to become mentors and help encourage the next generation of women in tech.

Talk about the culture at your company. What makes it inclusive or supportive of diversity in engineering and automation? What efforts does your company (or individuals at your company) make to recruit or support people from backgrounds currently underrepresented in engineering and automation?

The responsibility of being a major local employer is not lost on leadership, and this WE United investment is an initiative paying dividends for the broader community. WE United provides access to learning and development resources that we can utilize onsite and share with anyone in our local community who desires access to experts, tools and support to empower and develop women leaders in the workplace.

The DigiKey culture wholeheartedly believes that diverse teams are critical to a business’s success because they broaden perspectives on any initiative or idea. There are many research-proven reasons why diverse teams lead to better business results.

Beyond stronger financial returns, diverse teams increase access to better talent, more effective problem-solving, superior innovation, stronger retention and more relevant solutions for end customers.

Our industry is very forward-looking and thinking, but it’s also a very mature industry, especially at the leadership level. In the next decade, there will be a high turnover rate in the industry due to aging leadership. We need to build that bench for the future of the industry so that we can continue to grow and transform.

With the ongoing competition for talent, addressing this talent reservoir is critical for our ongoing sustainability. Our partnership with WE United provides a platform to talk about those challenges and promote the need for change within the industry.

2025 engineering diversity + inclusion

Deana Fu

Sr. Director, Strategic Marketing Mitsubishi Electric Automation

Deana Fu began her career as a support engineer at Mitsubishi Electric in Japan, where she tackled customer challenges by uncovering overlooked insights in manuals or collaborating directly with product developers. Her ability to simplify complex issues naturally extended into supporting marketing teams with product demonstrations, sparking a passion for storytelling and customer engagement. She realized her strength lay not in debugging, but in helping customers envision how new products could transform their work.

Today, as Senior Director of Strategic Marketing, Deana brings a holistic lens to growth, one that transcends individual product lines to shape company-wide impact. She leads with a blend of technical fluency and market insight, aligning cross-functional teams around shared goals and customer value. Her work is rooted in inclusive strategy development, ensuring that diverse perspectives inform the company’s direction and innovation roadmap.

Talk about the culture at your company. What makes it inclusive or supportive of diversity in engineering and automation?

At Mitsubishi Electric Automation, our culture is built on our core values: commitment to excellence, respectful relationships, and passion for the customer.

We are deeply committed to creating an inclusive workplace that actively minimizes bias, encourages collaborative decision-making, and upholds equity and fairness. Our culture promotes understanding of cultural differences and unconscious bias, and values empathy and emotional intelligence as essential leadership traits. We are also committed to building a workplace where everyone can thrive, including minorities, women, individuals with disabilities, veterans, or early grads. While our backgrounds and experiences may differ, we are united by a shared vision: to be the most customer-centric organization in industrial automation.

What first drew you to engineering?

Sending their children to college was everything my parents had hoped for. I felt the weight of living up to their expectations while falling short for not knowing what I wanted to study. But I was raised to seek new experiences, embrace discomfort, and take calculated risks; so I did exactly that. I enrolled at Cornell University to pursue a degree in Electrical and Computer Engineering. I stumbled into engineering not knowing what to expect, but I quickly found myself immersed in a diverse and welcoming community.

Describe your biggest career challenge. How did you solve it?

A few years ago, I was asked to lead the implementation of a business operating system based on the 80/20 principle. We also had just set a bold vision: to become the most customer-centric manufacturer in industrial automation. With rapid growth underway, we needed a strategic approach to scale effectively.

Several cross-functional initiatives were launched, and I was tasked with coaching each business group to define impactful strategies, make data-driven decisions, and establish clear performance indicators. Initially, I had doubts, but after seeking advice from mentors, I realized it was an opportunity. Taking on this challenge pushed me outside my comfort zone and helped me grow professionally.

What career advice would you give to your younger self?

Build authentic relationships any chance you get. A genuine desire to support those around us is one of the most powerful ways to shape not just a rewarding career, but a fulfilling life. Over the years, I’ve grown close to many brilliant colleagues who became friends, advisors, and mentors. Some check in to remind me to pause and enjoy life, offer encouragement, or simply share a good laugh. I consider it an accomplishment when I can reciprocate, offer support, and celebrate their successes.

While it’s exciting to chase the next career milestone, it’s the kindness, compassion, and connection shared among peers that truly make the journey worthwhile. Relationships built on trust and mutual respect are what sustain us through challenges and amplify our successes.

Want your North American and international hospital-grade cord sets to arrive in the customized lengths, colors, packaging and labeling you need to keep your testing equipment, servers, and surgical robots up and running? Besides providing the correct amperages and voltages for medical equipment such as portable CT scanners, X-ray machines, medical-grade treadmills, all Interpower® hospital-grade conductors inside the plug are secured by a stainless steel ring ensuring electrical continuity when power is paramount.

North American and Japanese hospital-grade plugs and receptacles bear the green dot, signifying the plugs have passed the rigorous UL 817 Abrupt Removal Test (UL 817, 18.2.4.1) and C22.2 No. 21-14 requirements for hospital-grade cords. Interpower cords and components are manufactured in accordance with its product quality plan: hipot testing, continuity testing, and ground testing with multiple inspections. Interpower offers value-added options such as lengths, colors, packaging and labeling!

• Same-day on in-stock products

• Blanket and Scheduled orders available

• 1-week manufacturing lead times