tompkins prowrap

tompkins prowrap

starting at $33.00 (1120120050XP)

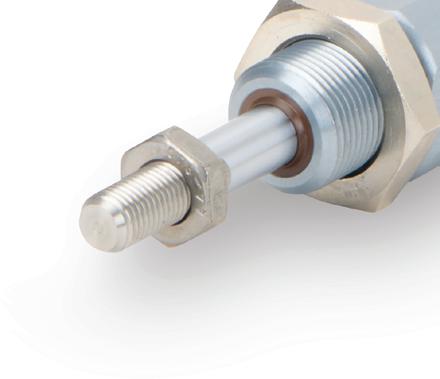

Metal Work ISO 6432 pneumatic air cylinders offer an ideal solution for metric applications where an inexpensive actuator is desired. They feature a magnetic piston for position sensor compatibility.

• Double-acting models are interchangeable with other common brands of ISO 6432 cylinders

• Bore sizes from 12mm to 25mm

• Stroke lengths from 50mm to 300mm

• Universal mount dependent on accessories selected to include: foot mount, rod clevis, rod eye, rear clevis, pivot mount, and flange mount

• Chamfered 304 stainless steel barrel

• 145 psi maximum operating pressure

starting at $135.00 (W143016A010N)

Metal Work heavy-duty metric dual guide rod cylinders are ideal for applications requiring precision mounting and tolerance to a sideload. These cylinders feature magnetic pistons, bronze bushings, anodized extruded aluminum alloy housing, and switch mounting tracks.

• Interchangeable with other common brands of metric guide rod cylinders

• Bore sizes from 16mm to 63mm

• Stroke lengths from 10mm to 400mm

• Double-acting

• Maximum operating pressure of 145 psi

• Maximum sideload of 10N to 250N

AutomationDirect's pneumatic offering includes a wide selection of air cylinders, air prep components, valves, tubing, fittings, and supporting accessories.

Paul J. Heney • VP, Editorial Director

“WE’RE CRAWLING AND WALKING into the recovery phase right now,” said Connor Lokar of ITR Economics at the National Fluid Power Association’s annual International Economic Outlook Conference in August. Lokar noted that 2023 and 2024 were poor years for the fluid power industry, but ITR is expecting the overall economy to grow in 2025 and 2026 and for the fluid power sector to see modest gains. Additionally, he said that pneumatics has rounded the corner and is on the way to recovery, although hydraulics is going to take somewhat longer.

Lokar noted that manufacturing volumes are rising/accelerating and they’re cautiously optimistic for the rest of 2025 and 2026.

“We are seeing that the core economy is growing today, and it wasn’t last year ... we are seeing growth in the parts of the economy that you care about,” he told the audience largely comprised of fluid power component manufacturers and distributors. “Most

of the growth over the last two to three years from your markets have been down again.

[The economic heat] was data centers, it was EV grid fortification, it was green energy, that high tech chip side of the economy — that's what's been on fire, not necessarily of our core legacy fluid power environment.”

But Lokar said ITR sees that manufacturing capacity utilization is recovering, and people are starting to get busier.

“ They’re starting to refortify and use existing machines. We are seeing that wholesale channels are starting to clear.”

Lokar feels that “recovery is close. Cap ex is rising. We’re seeing acceleration. With capital expenditures, we caught some bad numbers in the spring because of the tariff uncertainty, but that’s starting to fade away, and people are going to start holding cash a little less tightly and start getting on with their lives. And we're seeing that again, generally capex is up. That's going to bode well for the industry.”

Lokar did caution that inflation isn’t going away anytime soon — and anything you don’t buy today is going to cost you more tomorrow, next week, next month, next quarter, or next year.

“You can’t pre buy two years’ worth of groceries, unfortunately, but if you need durable goods, you are not doing yourselves any favors by waiting. And again, tariffs are compounding that. This is a direct byproduct of reckless government spending. The inflation cake for 2025 and 2026 was fully formed and baked prior to tariffs,” Lokar said. “View tariffs as additive sprinkles on top of what was already going to be an upside inflation environment over the next two years. Now, unfortunately for the administration, the entirety of any and all inflation outcomes going forward will be blamed on tariffs, which is not going to be totally fair, but somewhat self-inflicted.”

Lokar also noted that there are structural concerns here in the U.S., from interest expense on the debt to healthcare and Social Security spending, which aren’t going away anytime soon.

“If we think that somehow our bills are going to look like they did five years ago, you’re going to turn to dust while you wait,” he said. “If your kid has been waiting to buy a house and they think, ‘I missed it in 2020 but someday, surely soon, somehow, I’m going to get mortgage rates back to 3% — but also home prices aren’t going to go up and I’m going to be able to get in again,’ they’re going to turn to dust slowly, as well.” FPW

Paul J. Heney • VP, Editorial Director pheney@wtwhmedia.com linkedin.com/in/paulheney

Smart technologies for industrial hydraulics

Smart sensors, edge computing and AI are practical tools that boost uptime and cut costs for the future.

Smart technologies driving modern mobile machinery

At this year’s iVT Expo, hydraulic technology suppliers showcased how intelligence and connectivity are reshaping pumps, valves, and system architectures. 34 PNEUMATICS

Ensuring growth through energy savings

Reducing energy use through compressed air monitoring and management allows you to speed up production and fine-tune efficiency.

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com

Editor-in-Chief Mary Gannon mgannon@wtwhmedia.com

Technology Editor Ken Korane kkorane@wtwhmedia.com

Senior Editor Rachael Pasini rpasini@wtwhmedia.com

Contributing Editor Josh Cosford

Contributing Editor Carl Dyke

Contributing Writer Robert Sheaf rjsheaf@cfc-solar.com

MARKETING

VP, Operations Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

www.nfpa.com

VP, Creative Services

Matthew Claney mclaney@wtwhmedia.com

Art Director, FPW Erica Naftolowitz enaftolowitz@wtwhmedia.com

Art Director, FPW Digital Eric Summers esummers@wtwhmedia.com

Director, Audience Growth Rick Ellis rellis@wtwhmedia.com

Audience Growth Manager Angela Tanner atanner@wtwhmedia.com

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

FLUID POWER WORLD does not pass judgment on subjects of controversy nor enter into dispute with or between any individuals or organizations. FLUID POWER WORLD is also an independent forum for the expression of opinions relevant to industry issues. Letters to the editor and by-lined articles express the views of the author and not necessarily of the publisher or the publication. Every effort is made to provide accurate information; however, publisher assumes no responsibility for accuracy of submitted advertising and editorial information. Non-commissioned articles and news releases cannot be acknowledged. Unsolicited materials cannot be returned nor will this organization assume responsibility for their care.

FLUID POWER WORLD does not endorse any products, programs or services of advertisers or editorial contributors. Copyright© 2025 by WTWH Media, LLC. No part of this publication may be reproduced in any form or by any means, electronic or mechanical, or by recording, or by any information storage or retrieval system, without written permission from the publisher.

SALES

Ryan Ashdown 216-316-6691 rashdown@wtwhmedia.com

Jami Brownlee 224.760.1055 jbrownlee@wtwhmedia.com

Mary Ann Cooke 781.710.4659 mcooke@wtwhmedia.com

Jim Powers

312.925.7793 jpowers@wtwhmedia.com

Courtney Nagle 440.523.1685 cseel@wtwhmedia.com

LEADERSHIP

CEO Matt Logan mlogan@wtwhmedia.com

Scott

Mike

SUBSCRIPTION RATES: Free and controlled circulation to qualified subscribers. Nonqualified persons may subscribe at the following rates: U.S. and possessions: 1 year: $125; 2 years: $200; 3 years: $275; Canadian and foreign, 1 year: $195; only US funds are accepted. Single copies $15 each. Subscriptions are prepaid, and check or money orders only.

SUBSCRIBER SERVICES: To order a subscription please visit our web site at www.fluidpowerworld.com

FLUID POWER WORLD (ISSN 2375-3641), USPS PUBLICATION #18060 is published six times a year: in February, April, June, August, October, and December by WTWH Media, LLC; 1111 Superior Ave., Suite 1120, Cleveland, Ohio 44114. Periodicals postage paid at Cleveland, OH & additional mailing offices.

POSTMASTER: Send address changes to: Fluid Power World, 1111 Superior Ave., Suite 1120, Cleveland, OH 44114

I’M NOT GOING TO LIE, I’m pretty good at troubleshooting hydraulics. It wasn’t always that way, of course. When I was with my previous employer, I recall my first customer visit in 2008, where I was expected to resolve their cylinder issue. It was a drill rig. They couldn't get the auger to push itself into the ground, and I was immediately stumped.

Luckily, the president of my previous employer was just a phone call away, and I was able to leverage his quarter-century of expertise in fluid power and troubleshooting. You fluid power specialists probably already knew what he asked me to do — remove the rodside work line and then actuate the valve to extend the crowd cylinder. When fluid began pissing out of the open work port, I relayed this to my boss, and he matter-of-factly replied that the piston seals were pooched, which I passed along to the customer.

The kicker was that despite that three-hour visit, the customer didn’t buy even so much as an O-ring for my efforts, and I’m sure many of you outside sales readers can relate. Troubleshooting can be the most thankless job, especially when the culprit is simply incorrect operation or a poorly adjusted valve. Figuring out that a customer installed their internet-purchased D03 valve backwards on the manifold may offer a meager reward of “oh geez, thanks” in lieu of future business, apparently.

And therein lies one of the rarely discussed downsides to being an effective troubleshooter: customers love someone who can fix their problems for free. Meanwhile, the peddler salesman solves the same problem by throwing new parts at the problem until something sticks. “Oh, it wasn’t the $4,000 pump I sold you? Hmm, maybe buy the $500 D03 from me because the one you bought online is defective." And then, when the D03 valve arrives, the maintenance manager randomly installs the new valve in the correct orientation, and everything magically works. Mr. Peddler now

enjoys the $4,500 padding to his sales target while wasting half the time it would have taken to troubleshoot “for free.”

My sales approach was always to follow the Golden Rule, with the hope that the laws of reciprocity would eventually lead to increased commissions. In reality, I was probably beaten out by the "Always Be Closing" guy, but I have no regrets. Helping customers is always the right thing to do. Regardless, whether you should pursue your ability to troubleshoot proficiently is up to you, because this article is more about whether you can do so even if you try.

I'm going to be frank here, and I mean no offense, but not everyone is on the problemsolving end of the intellectual bell curve. Don't get me wrong; it's commonly known that C-students make up their fair share of millionaires. However, those individuals would pay someone else to do their troubleshooting so they can shake hands and make deals instead. Being book smart is also not enough. You need to possess the traditional intelligence that enables you to assemble Ikea furniture without instructions, and you must have both attention to detail and high-level critical thinking.

You must be an analytical thinker to troubleshoot well. When a customer describes an overheating system, a newbie will first think, "Let's see if the cooler is working." However, coolers don't fail catastrophically without clear signs, such as leakage, burnt motors, or water contamination. Something is generating excess heat,

so it's essential to understand what can cause heat in a hydraulic system. You need to understand how any hydraulic component, from pressure valves to pumps, can generate heat and also grasp how heat can affect the entire circuit.

With the right mind and mindset, you have the potential to be an expert troubleshooter, but that doesn't guarantee success. You just need to be a giant nerd. The innate desire and patience to perform tedious tasks such as making ten printed copies of the schematic and using colored highlighters to mimic the pressure, work and tank lines under various operational conditions to help understand all possible circumstances. Such a task is not necessary for a log splitter, but is likely required for a 1,000ton injection molding machine.

You must be willing to study hydraulics, learn to interpret even the most complex circuits and then get out into the field and put it all into practice. You need to be patient and methodical, which means most of Gen Z are disqualified (no hate … it is what it is). I’m sorry, but I just can’t picture any of my five children spending time reading schematics for hours, especially considering that my eldest son absolutely loves cars but can't bring himself to read the driver's handbook, despite being 16 for the past 16 months.

I apologize, as I know my take is controversial, but I feel like it's suddenly okay to have controversial opinions again. If you feel left out or underestimated, then by all means, prove me wrong. I know I won't get any takers because you're probably only reading this if you fit the criteria. Either you're a pro troubleshooter already or well on your way. FPW

Josh Cosford • Contributing Editor jcosford@higginson.ca linkedin.com/in/joshcosford

Rachael Pasini • Senior Editor

THOUGH HYDROGEN HAS PROVEN its value as a sustainable fuel, it remains cost-prohibitive due to the lagging infrastructure necessary for widespread adoption. Common culprits are not the fuel cells or vehicles, but the transportation and operational equipment — especially the critical technologies for hydrogen compression and decompression.

“Operational expenses are really bad, and that changes what options are available,” said Dave Hull, regional VP at Bosch Rexroth. “There are two ways to look at this currently: a gaseous compressor or a liquid hydrogen compressor. Liquid is the future for high volume and scaling because liquid makes the density of hydrogen much smaller, so you can get more hydro-

“Almost 40% of the fuel that shows up at your station never actually makes it into the vehicle. Imagine if 40% of the gasoline just spilled on the ground and evaporated and never got in the car. That’s a huge cost that needs to be addressed and fixed.”

gen in less space, transport it, and store energy like a battery.”

Bosch Rexroth partnered with FirstElement Fuel, the largest distributor of hydrogen at scale. The company operates approximately 40 hydrogen refueling stations in California and dispenses more than two million kilograms of hydrogen per year. FirstElement Fuel informed Hull and his team that 90% of the problems at filling stations lie in compressing hydrogen.

“Almost 40% of the fuel that shows up at your station never actually makes it into the vehicle,” said Hull. “Imagine if 40% of the gasoline just spilled on the ground and evaporated and never got in the car. That’s a huge cost that needs to be addressed and fixed.”

The problem Hull described is called boil-off, when liquid hydrogen evaporates into a gas as unwanted heat inevitably enters the cryogenic storage tank. Traditional hydrogen filling stations use a small pump to compress hydrogen

into storage cylinders for dispensing, where pump inefficiencies and hydrogen losses have been accepted due to technology limitations. Additional losses occur during transfill, when transported hydrogen is transferred to the fill-

STAGE 1 KEEPS LIQUID HYDROGEN AT 16 BAR AND INCLUDES TWO SERVO-HYDRAULIC PUMPS. LIQUID HYDROGEN CAN BE DISPENSED TO A VEHICLE OR FED INTO STAGE 2.

ing station storage tanks before compression.

Hull and his team, in collaboration with FirstElement Fuel, started from scratch and designed a new cryogenic pump and CryoPump Station that eliminates the storage cylinder system and related valving and equipment. This simplifies the filling station and improves installation, operation, and maintenance costs. It also eliminates losses during transfill.

“Liquid hydrogen is at 23 Kelvin. There’s some really weird stuff that happens at those temperatures. It’s almost absolute zero. It’s very cold to make it a liquid. To pump that efficiently, if you put any energy into it, it wants to become a gas,” said Hull. “Simply put, compressing a gas is five times more energy-intensive than compressing a liquid. So if you can put liquid hydrogen into your compressor and then compress it in one shot, we can do that with the power

WE ARE PASSION, BUILT LIKE FAMILY, DRIVEN BY EXCELLENCE

of this hydraulic system extremely efficiently.”

The CryoPump Station consists of two hydraulic stages. In stage 1, liquid hydrogen is kept extremely cold at 16 bar, ready for dispensing or to feed stage 2. In stage 2, cold liquid hydrogen from stage 1 enters, and another set of hydraulic cylinders compresses it from 16 to 900 bar in one stroke. The cylinders are powered by electric motors, and the station’s power electronics and digital controls drive the system.

“A Rexroth servo is a variable-speed motor, and we can vary the speed of the input to the hydraulic pump,” said Hull. “The hydraulic pump is variable stroke, so we rotate the motor always in the same direction so that it keeps the same speed, and then we’re able to change the direction of the hydraulic fluid by adjusting the pump. And there’s no valve in between, no valve at all. So the system perfectly matches the required load to the power input.”

Hull noted that most hydraulic systems are

“A Rexroth servo is a variable-speed motor, and we can vary the speed of the input to the hydraulic pump.”

designed to modulate power with valves. He compared it to driving a car with one foot on the gas to ensure there is enough power, and one foot continuously modulating the brake to control the system. This method is inefficient and wastes energy as heat.

“We’ve eliminated all of that by simply only driving with the gas pedal. And we modulate the gas pedal so that it exactly matches how much load is required from our system,” he said.

When a vehicle arrives at the filling station, no matter the pressure in its tank, whether it is

300 bar, 400 bar, or otherwise, when the cryogenic pump plugs into the vehicle, the pump will match the vehicle’s tank pressure. This loadmatching provides tremendous energy efficiency gains and can fill vehicles in record time.

“It has a high enough flow rate that it can fill a Class A truck in less than 10 minutes,” said Hull. “It’s exactly the same as if you were filling it up with diesel.”

The CryoPump Station can supply one liquid and two gaseous hydrogen dispensers, providing a flow rate of 600 kg/h. With a footprint of less than 11 m² and a noise level of less than 65 dB(a), they can even be used in residential areas.

To view an interactive demonstration of the CryoPump Station and its major components, visit: virtual-world.boschrexroth.com/ cryopump-station. FPW

Bosch Rexroth boschrexroth.com

Check

Flow

Needle

Flanges & Adapters

Bar & Custom Manifolds

Pressure Gauges & Snubbers

SSW Power Unit Systems

Transfer Pumps

Industries Served:

• Oil & Gas

• Industrial Hydraulics

• Mining

• Forestry

• Chemical & General Processing Plants

• Medical

• Aerospace

• Factories

• Mobile Equipment

• Defense

• Machine Tool

• Testing Equipment

• Ocean Depth Technology

• Automotive

• Food Processing

• Agriculture

• Industrial

• Aviation

• Petrochemical

•

Edited by Mary C. Gannon • Editor-in-Chief

KUHN NORTH AMERICA, a manufacturer of agricultural and industrial equipment, is leveraging the benefits of Webtec CTA series hydraulic system flow monitors to expedite the development journey and time-to-market of its latest three-head Merger. Thanks to the adoption of three IoT-enabled CTA units on each prototype, Kuhn is able to identify potential issues remotely. Several prototype Mergers are currently undergoing real-world tests at pilot customers across the USA ahead of production.

Kuhn, headquartered in Brodhead, Wisconsin, specializes in machinery that enhances the efficiency and productivity of farming operations. The company has come a long way since Joseph Kuhn founded a village forge in 1828, evolving to become one of the world’s largest manufacturers of equipment for the agriculture market. Popular solutions include a broad range of hay and forage, livestock, and crop production tools, as well as landscape and road maintenance equipment. Today, the company markets thousands of machines every year in North America and worldwide under the Kuhn, Kuhn Knight, and Kuhn Krause brands.

The latest development project at the 500-employee Midwest Distribution Center and Manufacturing Facility of Kuhn in Brodhead is a new three-head Merger that aims to maximize hay harvesting efficiency. With user-friendly controls and robust construction, the Merger will present the perfect solution for farmers seeking to enhance productivity and achieve consistent, high-quality results.

The need to continue innovating, even in a sector that extends back to dawn of civilization, is paramount. Kuhn faces a range of strategic and operational challenges driven by shifts in technology, global markets, sustainability demands, and workforce dynamics. These challenges are both sector-specific and company-specific.

For example, the current trend of farm expansion is leading to higher capacity demands, meaning Kuhn must design equipment with greater efficiency and durability. Farmers also increasingly expect smart, connected technologies without compromising ease-of-use. Skilled labor shortages, meanwhile, ensure Kuhn must offer more manpower-saving automation. And of course, sustainability and compliance with environmental regulations hold further influence over newly developed solutions.

To remain cost-competitive, it is essential that Kuhn maintains its strong investment in innovation without inflating costs, an ethos applied effectively to its new Merger.

A carefully managed prototype phase is essential in any new product development process, which is why the company turned to Webtec for assistance in its latest project. A customer of Webtec since 2010, Kuhn invested in multiple sets of Webtec CTA heavy-duty hydraulic flow monitors in December 2024. The units were acquired in two sizes (16 and 40 gpm) to suit different machines from Webtec’s authorized regional distributor Fluid System Components (FSC in Wisconsin). By February 2025, three CTA flow monitors were fitted to each prototype of the 42 ft wide Merger, which is driven by a triple 12-gpm hydraulic gear pump running at up to 3,500 psi.

The Webtec CTA units, which have a very high protection against dust, moisture and vibration (to IP6K9K and SAE J1455 standards), monitor hydraulic pressure line flows as the prototypes undertake real harvesting processes for a whole season at pilot customers across the USA. With the CTA compact turbine flow monitors in place, Kuhn engineers are able to identify any potential issues and make design adjustments prior to production.

Key here is the CTA’s SAE J1939 CAN-bus interface for monitoring and transmitting oil flow and temperature data (a 4-20 mA analog output is also now available for flow reporting). The industry standardized J1939 communication protocol for heavy-duty vehicles provides a common language for electronic control units (ecus) to communicate with one another.

Webtec is always available to help customers meet application-specific requirements, so for this project the company provided assistance in reprogramming PGN’s (Parameter Group Numbers) where multiple monitors were installed on the same BUS. J1939 messages are identified by 18-bit Parameter Group Numbers (pgns), so reprogramming was necessary to assign a different PGN to each of the three CTAs used in a set. If required, customers can also reprogram CTA units in the field using an off-the-shelf tool.

With Webtec’s CTA units now connected to the CAN-BUS, the Kuhn team can monitor its Merger prototypes wherever they are located using an IoT condition monitoring solution. Data for flow and temperature is fed via J1939 to telematics (with over 45 channels of data), helping the engineers monitor and analyze the entire system’s performance remotely. Alongside high levels of insight, further benefits include major savings in travel time and costs, with company personnel no longer required to board flights at short notice.

Webtec’s CTA units provide considerable value to Kuhn. The pur-

pose of any prototype phase is to reveal issues that the manufacturer needs to resolve prior to production. In the case of the three-head Merger, Kuhn noticed a potential problem that initially pointed to the hydraulic pump. How ever, thanks to true flow rate data provided by Webtec’s CTA compact turbine flow moni tors, Kuhn engineers could discount any pump issues. The CTA provided flow and temperature data directly to the CAN BUS. From here it was possible to compare actual flow to theoretical flow (speed x displacement) and calculate vol umetric efficiency, confirming correct pump performance.

Engineers subsequently traced different signals through the system to evaluate the operation of each component. The issue was soon isolated to a highly unusual fault with a mechanical adaptor. Kuhn simply shipped a replacement to the customer’s nearest located dealer for fitting.

Eliminating any issues with the pumps is

Ron Marshall • Contributing Editor

YOU’VE SEALED LEAKS, upgraded nozzles, optimized piping, and trained your team on compressed air efficiency — yet all your compressors are still running. Sound familiar? You’re not alone. Many facilities invest heavily in improving the demand side of their compressed air sys tem, only to see little or no reduction in compressor usage.

The problem? The side hasn’t been re-tuned According to experts, no amount of demand-side efficiency will

As a leader in the US Wind Industry, we’ve made sure our pitch control valves are built to last many years under the toughest conditions. With over 5000 valves installed since 2014, and most still in operation, we are committed to provide you with trouble-free operations over longer periods than anyone else.

Josh Cosford • Contributing Editor

HYDRAULIC BRAKES ARE a specific fluid power application so well-suited to their purpose that I find it difficult to imagine them being replaced by any other force transfer method. Hydraulic brake technology has been used in its current form for decades, and small changes in only the control method have changed over the years.

Let's be clear that hydraulic brakes provide the preferred arresting method for machinery above and beyond that of vehicles, although it makes a great starting point for this discussion to cover how hydraulics are the number one choice for cars, trucks and self-powered machinery.

Compared to mechanical braking methods, the force multiplication effect of hydraulic brakes enables powerful braking capacity with less user input force. A mechanical braking method using cables or levers is only really possible with lightweight vehicles, such as go-karts. With added mass comes added inertia, and any combination of vehicle and human mass above a few hundred pounds can take advantage of hydraulic brakes. In simple terms, hydraulic pumps and actu-

ators act as force multiplication systems similar to gears or levers, as you trade distance for force. On a vehicle, this means a 2-in. pedal travel, for example, can increase pedal force 16 times when the brake pad only moves 1/8 of an inch. Twenty pounds of leg effort will translate into 320 lb of braking force. Modern vehicles are equipped with brake boosters that utilize vacuum to amplify output pressure further, working much like an air-over-hydraulic pump. Such systems take advantage of the smooth and progressive nature of hydraulics, which provides progressive physical resistance for the operator based on braking effort. This “feel” is also why hydraulic braking systems are used exclusively in race cars. In fact, hydraulic brakes will pair with bias valves that allow racing drivers to direct braking effort fore and aft, thereby changing the overall balance for different tracks or even different corners.

Although rarely considered during your daily commute, hydraulic brakes also ensure even pressure at all four corners, which makes a vehicle reliable and controllable. Valves can

“pump” the brake pedal in emergencies to prevent wheel lockup, and any brake pad wear is automatically compensated for, requiring no physical adjustments.

For industrial applications, hydraulic brakes remain the number one choice, especially where reliability and safety are the top priorities. Mine hoists, for example, are critical for moving persons and equipment down to extreme depths below the surface, some of which can be well over a mile deep, and hauling hundreds of thousands of pounds.

When so much is at stake, the braking systems must be both powerful and reliable. It may require over a hundred tons of clamping force to ensure a mine hoist decelerates quickly and remains in position. Like many braking systems, mine hoist brakes are spring-applied and hydraulic release, which ensures the default condition is also the safest condition.

Compared to pneumatic brakes, hydraulic brakes are much more compact. The compact actuator sizes allow for more versatile installation options, as well as reduced power consumption when comparing a hydraulic power unit to an air compressor of equal braking capacity. Hydraulic brakes also offer precise and instantaneous pressure adjustments. Frequent partial application and feathering is accurate and in real-time using measurements of back pressure, hoist velocity and deceleration rate, ensuring target deceleration is precise regardless of load, direction of travel and even partial system failures.

With so many benefits and so few downsides, it's unlikely that hydraulic brakes will be replaced by any emerging technology soon, including electric actuation. A technology's life cycle can be judged by how quickly it's replaced with modern technology in everyday items. Consider that hydraulic brakes have only recently permeated the bicycle industry, and you'll quickly understand that this technology is nowhere near its peak. FPW

Contributed

by

Sidney Mondin

• Regional Manager, Filter Resources – an MCE Company

OIL & GAS OPERATIONS RELY HEAVILY ON FILTRATION FOR A VARIETY OF MISSION-CRITICAL SYSTEMS.

the integrity and performance of equipment are closely tied to the cleanliness of the fluids and gases that flow through them. Contaminants can silently compromise components, shorten equipment lifespans, and lead to costly unplanned shutdowns. This is where filtration steps in as an operational essential.

Oil and gas operations span some of the most challenging environments. High pressures, harsh chemicals, sand, saltwater, extreme temperatures, and vibrations all take a toll on systems. Add in the threat of particulate contamination — rust, dirt, metal shavings, water aerosols, hydrocarbons — and the risk to both mechanical performance and safety becomes significant.

Contaminated fluids can:

• erode seals and valves,

• cause blockages and flow restrictions,

• lead to overheating and corrosion,

• accelerate wear of gears and bearings,

• trigger sensor errors and component failure,

• and introduce hazardous substances into the process stream.

In hydraulic systems alone, contamination is responsible for up to 75% of all failures. That

level of impact makes filtration not just a maintenance tool, but a proactive investment in uptime, efficiency and employee security.

Selecting the right filter depends on the fluid, expected contaminants, pressure levels, and system requirements. Here's a look at of some of the most widely used filters across upstream, midstream, and downstream operations.

Coalescing filters: Remove fine liquid aerosols and submicron particles from gas streams. Common in natural gas dehydration, compressor protection, and gas turbine intake systems. The benefits: High-efficiency separation of moisture and oil aerosols that could cause corrosion or performance loss.

Activated carbon filters: Adsorb volatile organic compounds (vocs), hydrogen sulfide (h₂s), and hydrocarbon vapors. Used in gas scrubbing and air purification in refineries and petrochemical plants. Benefits: Remove trace impurities and odors, contributing to safety, compliance, and product purity.

Particulate filters: Trap solid contaminants such as rust, sand, and debris. Installed on pipelines, hydraulic systems, and as pre-filters in multi-stage assemblies. Benefits: Prevent abrasive wear and clogs, reducing failure rates.

Multi-stage systems: Combine multiple filtration mechanisms (particulate, coalescing, carbon) for broader contaminant removal. Tailored for high-contamination settings like offshore platforms, fracking systems, and refinery process lines. Benefits: Modular and configurable to match exact operational conditions.

H₂S removal filters: Chemically adsorb hydrogen sulfide and sulfur compounds from gas and liquid streams. Used for sour gas treat-

ment, pipeline protection, refinery desulfurization units. Benefits: Minimize corrosion, protect downstream components, and support emissions control.

Hydraulic systems are the backbone of oil and gas field operations, powering everything from drilling rigs to subsea controls. Maintaining fluid cleanliness is vital for avoiding seizure, scoring, and overheating. Key filter types here include: High-pressure hydraulic filters: Built to withstand pressures exceeding 6,000 psi, these filters are crucial for protecting pumps and actuators from abrasive contaminants.

Return-line and off-line filters: Clean hydraulic fluid as it cycles through or independently circulates through a system to maintain ISO cleanliness levels.

For pneumatic systems, compressed air filters remove moisture, particulates, and oil aerosols that could rust components or lead to system failure. Clean air also supports safety in confined spaces and improves tool reliability.

Oil-lubricated equipment like compressors, gearboxes, and turbines depends on clean lubricant to minimize friction and dissipate heat. Contaminants such as soot, dust, or metal particles can degrade oil quality and lead to catastrophic failure. Lubrication filters help extend oil life, lower wear rates, and keep high-value equipment in service longer.

For general-purpose filtration in systems like cooling loops, fuel lines, and low-pressure process fluid circuits, cartridge filters offer an economical, easy-to-replace option. With options in pleated or depth media, they offer reliability without excessive cost. FPW

Filter Resources, an MCE Co. mceautomation.com

Smart sensors, edge computing and AI are practical tools that boost uptime and cut costs for the future.

BY JOSH COSFORD, CONTRIBUTING EDITOR

is an interesting industry. On the one hand, enormous mills are using fifty-year-old hydraulics while producing hundreds of thousands of tons of steel per year. On the other hand, new factories are popping up with connected technology providing real-time data and analytics on every parameter from filter health to millisecond-accurate pressure curves.

Smart technologies revolve around information and its decentralization. Despite the proven hydraulic technology that may still allow an old steel mill to turn a profit, smart technologies are simply becoming too good to ignore. So, if you’re a stakeholder within any industrial environment operating hydraulics, keep reading to see how Industry 4.0 is changing our Fluid Power World (pun intended).

The Industrial Internet of Things (iiot) describes the interconnected nature of machinery and components used within the industrial space. Machines now may connect to the internet, much like your TV, thermostat and, for some of you, the fridge. I get it; the whole smart fridge thing didn't pan out as we all hoped. We expected everyone's food supply to automatically replenish when Maytag sent orders to Karen through Uber Eats so she could leave organic Kefir or Flamin' Hot Cheetos at your doorstep.

Keep in mind that a typical family home with 3.7 persons can run more dynamically than an automotive assembly plant producing 1.3 cars per minute. Let's be honest — your home won't shut down because you ran out of oat milk. However, in the highstakes, high-pace world of automotive, an hour of downtime equates to millions in potential lost revenue. An unexpected failure of a material handling robot is simply unacceptable, so the increasing use of integrated and connected equipment not only provides insight into predictive main-

tenance but also enhances efficiency and safety while reducing energy consumption.

IIoT moves past "network-enabled" components that provide insight into only a few machines relaying data to the maintenance or production manager's desktop computer. Using sensors, edge computing, cloud connectivity, and sophisticated analytics, we can monitor and optimize every aspect of machine performance in real time.

All these buzzwords sound great, but we need to dig deep into actual examples to elucidate the power of modern, smart technology for industrial hydraulics. Specifically for hydraulics, we can monitor performance variables like pressure, flow, temperature, vibration and contamination to predict failures, analyze productivity, and plan maintenance.

Smart sensors and controllers are the backbone of every hydraulic machine leveraging Industry 4.0 technology. Unlike traditional analog sensors, smart sensors can perform self-diagnostics, detect anomalies,

and communicate rich data via digital protocols such as IO-Link, CANopen, or Ethernet. Smart sensors help hydraulic systems become more autonomous and efficient by providing actionable information, not just raw signals, to controllers or cloud-based systems.

I understand the apparent contradiction between a more autonomous machine and one that is part of the Industrial Internet of Things, so let me explain the difference. An old injection molding machine was certainly autonomous but used no smart technology, providing no capacity to monitor, predict or adapt. Using some of the previously mentioned sensors, modern machines can identify and adjust in real time and use advanced, integrated multi-core computers with AI capability to improve efficiency and reliability.

Edge computing has risen to prevalence with the above in mind while still communicating with other machines or the cloud. This hybrid model provides your operation with advanced technologies that your smartphone has been providing for

years, alongside automated performance improvements on the fly. Again, I feel like it's all too easy to throw around Industry 4.0 jargon to sound cool, but without specific examples, it's all very arbitrary.

Let's use the injection molding machine to illustrate how smart technologies apply to real-world applications, especially since these machines are hydraulic-heavy. Any good IMM starts with a mold clamping system to keep the dies closed during the injection molding process. Most molds use a hydraulic cylinder and a toggle to exert hundreds or thousands of tons of force against the platen and dies. In some large machines, you may even see four hydraulic cylinders, one each at every corner. Using a pressure sensor on the piston side of the clamping cylinder(s) or load cells in each tie bar, the machine ensures even clamping force on each corner. The smart controller can detect misalignment,

general wear or hydraulic imbalance to make pressure corrections to maintain quality. For example, if even a slight reduction in clamping force is detected, compensating with higher pump pressure or flow to prevent even a single short-short or flash non-conformance provides 100% first-pass yield. An egg tray in your smart fridge is of no use if it only holds eleven eggs.

A standard deviation within the above example may be processed automatically without operator or maintenance interaction, but should internal adjustments fall outside of a predetermined range, other connected sensors can provide data to tell a broader story. A thermal imaging camera now detects the clamping cylinder exhibiting localized heat across the tube, especially during clamping. Artificial intelligence now diagnoses the original clamping force issue as leaking piston seals, which reduced clamping force. The small increase in pressure compensated for the original minor leak, but as the seals further degraded, bypassing fluid resulted in more heat.

Any good IMM starts with a mold clamping system to keep the dies closed during the injection molding process.

Until now, the machine ran "at the edge," and no warnings or human interaction were required. The machine subsequently signals the maintenance team via their mobile app that they should replace the cylinder within the next week using the spare cylinder the connected ERP software knows is in stock. The maintenance concern is pressing but not critical, as the machine controller is still providing extra pressure and flow to stabilize the clamping force in the interim.

When taking full advantage of today's advanced ERP platforms, the maintenance can be scheduled, and the software can automatically make adjustments for the production downtime. The work order for the cylinder replacement is created, and jobs are assigned to the maintenance team, who scan their barcode at the beginning and end of the repair. The seal kit used for the repair is then automatically removed from inventory while an RFQ or PO is auto-generated and emailed to the supplier for fulfillment.

Of course, such technologies are available for any and every machine. Even if you wish to take advantage of smart technology without breaking the bank or retrofitting an entire machine, individual sensors can provide insight into critical parameters for the purpose of improving efficiency, reducing unexpected and costly downtime or saving costs on redundant maintenance.

Smart pressure sensors, for example, are so much more than a way to monitor pressure remotely; they can solve problems. A Bluetooth pressure sensor provides monitoring through mobile and desktop apps while providing real-time measurements and trends, compiles data in various formats, uses configurable notifications and alerts, all the while offering a cloud-based app for any number of team members to view and analyze.

Imagine installing such a smart sensor on the nitrogen side of an accumulator. It's rare to see pressure gauges monitor accumulator precharge to begin with, so such an upgrade is already an obvious choice. Precharge inevitably drops as nitrogen leaks through the permeable rubber blad-

This energy-saving, inverter-driven hydraulic power unit is designed for top-tier performance. Enjoy precise temperature control, low noise, and easy operation all with competitive pricing. Perfect for demanding applications, these units outperform traditional systems with up to 60% energy savings.

TO SELL BELOW $3,000

Compare our costs to all other equivalents including the top-of-the-line Daikin inverter units

At this year’s iVT Expo, hydraulic technology suppliers showcased how intelligence and connectivity are reshaping pumps, valves, and system architectures.

By Mary C. Gannon, Editor-in-Chief

As mobile machine technology moves towards more electrified, intelligent designs, hydraulic systems are keeping pace. Data-driven controls and connected components are reshaping the way hydraulic systems are designed, monitored, and maintained. At the iVT Expo in Chicago in August, experts showed how sensors, smart electronics, and predictive algorithms are being embedded into pumps, valves, and systems. From the show floor to several presentations at the NFPA Advanced Hydraulics Conference, fluid power manufacturers introduced and highlighted advances in their tech that will deliver smarter, more efficient, and more connected hydraulic systems.

In his presentation, Mark Preissig, General Manager - North America, discussed how the Casappa Power Systems – CSP and CSD onboard digitalization solutions for pumps integrate smart sensors, on-board electronics, and advanced algorithms to deliver insights and control for OEMs. It is an evolution of the Load Sensing flow sharing system and allows for management of the machine's hydraulic system.

“All the characteristics of pump pressure you normally want to see — load-sense, inlet, outlet, case drain — are all there naturally, combined with active monitoring and swashplate angle,” Preissig said. “The housing on the right contains our OBE processor as well as a Bluetooth transmitter. The enclosure on the top is essentially Casappa’s proprietary lab-on-a chip environment which contains temperature and fluid condition monitoring in a micro scale.”

This powers two main offerings: smart power and smart data.

• Smart power creates “real-time closed-loop displacement control for the pump,” Preissig noted, using both internal signals and CAN bus inputs from the OEM. The system enables power management solutions that “perfectly match the expectation for the machine, the OEM, and the operator.” OEMs can configure profiles such as anti-stall torque control, economy fuel modes, or extreme breakout modes — flexibly adapting machine behavior through integrated pump intelligence.

• Smart data leverages Casappa’s sensor suite to support cycle monitoring, anomaly detection, performance analysis, and predictive analysis. “What we want to resolve is … an array of sensor data that's out there, flow, pressure, temperature, rotation, speed, fluid conditioning, all coming from different sources today, giving OEMs an obstacle for just configuration, specification, maintenance, acquisition, all those things ongoing forever in the life of that design,” Preissig said. “We're trying to get away from that with one simple solution, incorporating all of these into one pump environment, communicating in the same way with those devices that a dispersed solution would.”

Plugging this into the Casappa app allows users to conduct pump condition monitoring, cycle acquisition and identify a particular machine function, whether it is digging, driving, lifting, etc., and monitor it and look for definitive characteristics that may create conditions which are adverse to either safety or the well-being of the machine. “We learned to establish operating condition alarms, parameterization of all of those sensor inputs that says

WHILE AT IVT EXPO IN AUGUST, SEVERAL FLUID POWER EXHIBITORS there said that event was a teaser to their CONEXPO-CON/AGG presence, as they gear up for what most agree is the biggest showing of fluid power technologies in North America.

Although the IFPE show was discontinued after the 2023 iteration, most fluid power exhibitors are planning to return to the event, which is slated to take place March 3–7, 2026 at the Las Vegas Convention Center. Fluid power exhibitors will no longer be in a dedicated space but will still primarily be located on the second floor of the South Hall. However, fluid power exhibitors are joined on the second floor by OEMs like Caterpillar and Briggs & Stratton and power transmission and engine manufacturers like Kubota and Cummins, among others. There are currently more than 2100 exhibitors registered with several hundred of those being fluid power exhibitors.

The National Fluid Power Association will continue its education initiatives, and will host a two-day Advanced Hydraulics Conference for off-highway vehicle and fluid power engineers in conjunction with CONEXPO-CON/AGG. The conference will be held March 4-5 from 9 to 11 a m. and 1 to 4 p m. each day. Sessions will be led by industry experts who will offer insights into the latest hydraulic technologies, applications, and innovations shaping the future of off-highway equipment.

Topics will include:

• Increased Runtime for BatteryElectric Excavators

• Unlocking Digital Transformation: Why Strategic Ecosystem Partnerships are Essential to Delivering Risk-Reduced, High-Value Digital Services

• Smart Hybrid Architectures for OffHighway Machines: Standard Components, Smarter Controls

• Optimization and Validation of eHydraulic System Performance on a Battery-Electric Backhoe Loader

• Using 3D Finite Element Analysis to Increase Performance in Shaft Seals

for Hydraulic Pump Applications

• Hydraulic Data from the Heart of the Circuit: Pump Output Digitization

• Unlocking the Power of Practical AI in Mid-Market Manufacturing and Distribution

• Variable Flow with Fixed Displacement Pump

• Lowering Total Cost of Ownership

• eHydraulic Building Blocks: Inverters, Components, and ApplicationSpecific Systems

• How Mechatronics Integration Eases the Adoption of Electrification

Additional sessions will be added in the near future. Stay tuned for Fluid Power World’s complete coverage of the event, and a full conference schedule in our February show preview edition.

Registration for the NFPA Conference is separate from the CONEXPO education sessions. One day conference passes will be $100 and two-day passes will be $150. Registration for the conference will open soon. Visit nfpa.com for more details.

Registration for the trade show area is already open at:

something is out of spec, something's going in the wrong direction,” Preissig said.

“We’re talking about knowing when static parts, rotating parts, and the regulation function of the pump will fail,” said Preissig, noting that Casappa’s predictive algorithms draw on decades of endurance testing, warranty data, and correlation studies of pumps operating under varied oil types, contaminant levels, pressures, and temperatures.

The result is not just raw sensor readings but contextual intelligence. Casappa’s algorithms calculate hydro-mechanical efficiency, duty cycle severity, and mean time to replacement, giving OEMs a deeper understanding of system performance and component life. “It’s identifying not only what’s going wrong in that surface fatigue mode, but translating back to failure modes within the pump,” he said.

To deliver this intelligence in the field, Casappa developed the Smart Data Service Tool, a mobile app and diagnostic interface. Through Bluetooth or CAN bus, users can visualize pump condition, resolve alarms, log data, and perform firmware updates. While not a full replacement for high-speed diagnostic tools, the app provides “a centralization of conditions critical to system operation from just one source.”

Instead of OEMs sourcing multiple discrete sensors for flow, pressure, temperature, and fluid health, Casappa integrates them into a single pump environment. “From one component — which you’d be buying anyway — we can offer so much more value at a collaborative level that’s not found in dispersed technology,” he said. This reduces wiring complexity, improves diagnostic accuracy, and streamlines system integration.

During his presentation, Cory Fisher, Director of Strategic Sales, Sun Hydraulics, highlighted Sun’s various electrohydraulic valves designed to merge proven cartridge valve technology with integrated electronics and digital configurability. Fisher explained that the goal is to add value to the operator experience, and gives OEMs greater flexibil-

ity, easier system integration, and a foundation for connected hydraulics.

“What we’re focused on is making valves that are smarter, more adaptable, and easier to integrate — so OEMs can spend less time on the plumbing and more time on the machine,” Fisher said.

Sun integrates electronics directly into their valve bodies. This allows OEMs to configure ramp times, flow profiles, and operating modes via CAN bus or mobile tools, reducing hardware variations across platforms.

The intelligence also extends to diagnostics. Valves can monitor coil health, detect wiring faults, and provide performance feedback in real time. “Say the operator is having a problem. They request on their app support, and they get connected to that tech support individual, and when they get connected that tech support person can see the entire CAN network. They can see data logging. They can even ask the operator to turn their camera on,” Fisher said.

Having this camera connection allows users and tech support to find and diagnose a problem. Users can draw on their screen to pinpoint where a problem might be, allowing tech support to help find problems. This also saves time if an in-person visit is required of tech support, as they can better prepare for the work they will have to do on the machine.

ABOVE: CYGNUS FROM SUN HYDRAULICS ALLOWS OPERATORS AND TECH SUPPORT TO COMMUNICATE AND SEE SYSTEMS IN REAL TIME.

RIGHT: CASAPPA'S CSD SOLUTIONS FOR PUMPS INTEGRATE SENSORS, ELECTRONICS, AND ADVANCED ALGORITHMS TO DELIVER MACHINE INSIGHTS TO OEMS.

your cell phone or the operator's cell phone, into your connection device,” he said.

Adam Livesay, co-founder of Elevāt, shared how IoT and AI technologies are transforming the mobile machinery industry through ecosystem collaboration, smarter components, and data-driven services.

Livesay began by highlighting the shift from fragmented, “wild west” telematics projects to scalable, business-driven IoT solutions. “IoT has really revolutionized fluid power,” he said. “We’re seeing a lot more smarter components, a lot more options for telematics, gateways and devices … now it’s very pointed business value solutions.”

Sun emphasized that this approach simplifies assembly and reduces wiring complexity while enabling new levels of machine customization. OEMs can use one valve type across multiple applications, then tailor software settings for specific machines. From an operator standpoint, the same valve can deliver economy, precision, or high-power modes — all defined digitally rather than through circuit redesigns.

The Cygnus platform also aligns with broader industry shifts toward dataenabled hydraulics. By streaming performance information to machine controllers or cloud systems, the valves support condition monitoring, service efficiency, and predictive maintenance strategies.

Fisher positioned Cygnus as both a continuation of Sun’s cartridge valve expertise and a forward-looking platform. “Cygnus, at its heart, is a tech support tool that turns

Falling sensor costs, better connectivity, and tighter regulations have helped move IoT from experiment to enterprise-ready systems. Related to this, hardware deployment has grown dramatically. This has accelerated adoption across OEMs and suppliers. Livesay said that most companies are now on their “second, third, or fourth revision of telematics or IoT,” with many OEMs integrating machine data directly into cloud platforms and ERP systems.

The rapid rise of AI is also reshaping operations. Elevāt is preparing to launch its first AI service with several OEMs and expects to see more AI offerings at CONEXPO in March. “One of our engineers told me that on his trip from Oregon to Seattle, he did 500 lines of code with the help of Copilot — work that normally would have taken two weeks,” Livesay noted, emphasizing the dramatic efficiency gains. Unlike

IoT, which required years of education and adoption, AI has entered the industry swiftly because it’s already embedded in daily life.

Livesay detailed partnerships with Cummins, Hydraforce, and IDEX Fire & Safety. With Cummins, Elevāt has progressed from simple telematics to edge AI and predictive analytics, aiming to reduce costly downtime. With Hydraforce, Elevāt has worked on smart valves and sensors, ensuring OEMs have multiple connectivity options.

IDEX needed a connected solution for fire and safety equipment like the Jaws of Life. Elevāt built a customized platform, enabling live system monitoring, preventive maintenance, and automated service workflows. “This is about shaving off seconds to save lives,” Livesay explained. Firefighters can now track pump pressure, flow, and tool usage in real time, improving readiness while easing administrative burdens.

Elevāt’s mission, he concluded, is to help OEMs and their partners harness IoT and AI to build smarter services, reduce

downtime, and generate new digital revenue streams. “We’re trying to take this next generation of service, these very complex machines, and work together with our partners’ knowledge to provide better value to OEMs and end customers,” Livesay said.

At Bailey International, load-sensing, variable displacement pumps for work trucks are one of their newest lines, said Daniel

• P rovides safe operation

Strati, North American Sales Manager.

Here, a load-sense control device is integrated into the pump and works with a machine controller, which delivers information to the hydraulic system. The valve regulates the pump flow according to its functions and needs. The load-sensing pump with intelligence inside allows the pump to communicate with the system, to better deliver what the system needs in terms of horsepower, for example, Strati said.

“We can offer a sensor that actually can tell the machine controller how fast it’s going,” Strati said. This allows the pump to regulate its flow while heat, noise and pressure loss are also reduced, Strati said. The truck engine power output is optimized, allowing for longer life for components, saved energy, and a better environmental compliance. FPW

Casappa S.p.A. casappa.com

Sun Hydraulics sunhydraulics.com

• E fficient hose routing

• R educes set up time

Over 450 configurations possible

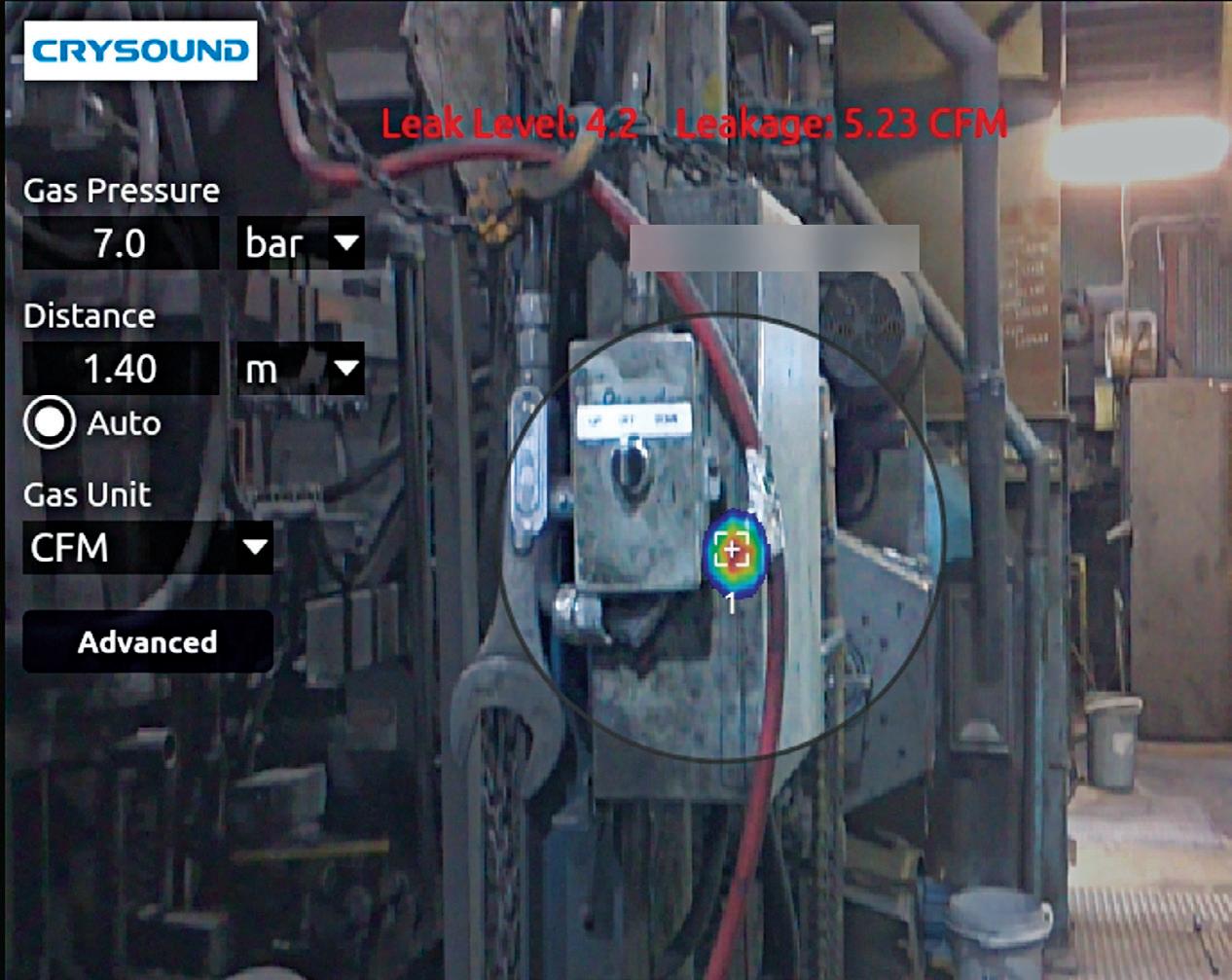

Reducing energy use through compressed air monitoring and management allows you to speed up production and fine-tune efficiency.

Edited by Mary C. Gannon, Editor-in-Chief

especially compressed air which can be eight times more expensive than electricity, with up to 50% of it being wasted through leaks. Pneumatic machines wear. Systems are often oversized, taking more energy than required.

Research has shown that successful energy management programs start with measurement. Discover large consumers, leakages, incompetent use, and overdue maintenance. Use actual data to justify improvement investments and maintenance management.

One of the best ways to grow as an industrial manufacturing company is to save energy. Reducing consumption is best done through through compressed air and industrial gases monitoring.

“If you do this now, you will soon get it back as extra capacity,” said Pascal van Putten, director/founder of Delft-based VPInstruments. Measuring is knowing is admittedly a cliché, van Putten acknowledges, but in terms of content it is still extremely topical. “Nowadays there is no more room on the electricity grid for many manufacturing companies. It is therefore important to work collectively on energy savings,” he said. “We must do everything we can to ensure that companies can continue to grow in the future. I know examples of production companies that have hit a wall in this regard.” VPInstruments offers flow measurement systems for compressed air and industrial gases. The company develops and assembles in Delft and exports to approximately 70 countries worldwide.

VPInstruments’ customers can be found in various sectors, such as the food, glass, steel, automotive, high-tech, electronics, and chemical sectors. “Every manufacturing company has a compressed air component. Think of controlling valves on the assembly line, machines that make packaging, or blowing granules in light chemicals,” van Putten said. For example, at a chocolate factory, targeted energy management could achieve annual savings of 125,000 euros. Van Putten noted that assembly and packing machines producing the chocolate had a great deal of leakage. A partner of VPInstruments used one insertion type flow meter and measured in several places in the factory, both supply and demand side. “During breaks the machines were on standby, but the consumption was still 50% compared to nominal,” he said. “We were able to trace where it leaked. You can walk through the factory with a leak gun — that's nice but expensive equipment — but it takes a lot of time if you must do this in several buildings.”

The ultrasonic leak gun revealed leakages throughout the entire factory. However, the biggest find was the leaks in the cacao presses. Once they fixed those, the pneumatic press opened and closed faster. Machine cycles also had slowed down in this chocolate factory. After VPInstruments’ technology was installed, the pneumatic press opens and closes faster again, resulting in significantly higher production and fewer malfunctions. The latter has a positive effect on the atmosphere in the workplace.

Companies can also fine-tune the efficiency of compressed air systems by combining the right types of compressors. This can make a difference of tens of percent, Van Putten continued. The payback period for the investment in one or more flow sensors is generally less than a year, he said. “'Less is more' is the trick with sensors. We use the art of omission and are not in favor of filling a factory with sensors. We work topdown: first we do the main line and then we roll it out like a pyramid. That is by far the smartest and most effective approach.”

For industrial gasses, the payback time of a flow sensor is even shorter. While compressed air costs a few cents per cubic meter, gases such as argon, nitrogen or oxygen cost a few euros per cubic meter. “For example, welding uses argon and CO2. Hoses connected to the welding torch often leak,” he said. “You can't smell that, and I know a factory in the United States where the leaks were in the barrels. We are helping more and more companies with managing these industrial gasses.”

Flow meters are essential tools for quantifying and managing compressed air leaks in industrial facilities. One common method is to measure air consumption during nonproduction periods. Many factories are idle over weekends yet still observe compressor activity and air usage, clear indicators of leakage. By monitoring flow during these

VP INSTRUMENTS’ VPFLOWSCOPE M HAS A BUILT-IN ETHERNET (MODBUS/ TCP) INTERFACE, MAKING IT EASY TO CONNECT DIRECTLY TO ANY NETWORK. IT CAN BE INSTALLED UNDER PRESSURE AND MEASURES (BI-DIRECTIONAL) THERMAL MASS FLOW, PRESSURE, TEMPERATURE AND TOTAL FLOW SIMULTANEOUSLY.

HOLDING COMPRESSED AIR IN A TANK FOR PEAK USAGE TIMES HELPS PREVENT SLOW OPERATIONS OR PRIORITIZE CERTAIN FUNCTIONS OVER OTHERS.

downtimes, the volume of leaks can be effectively estimated.

In facilities operating 24/7, establishing a baseline consumption is key. Install a flow meter to monitor overall air usage, then conduct an ultrasonic leak audit to identify and repair leaks. After repairs, the reduced air consumption becomes your new baseline. Any future increase in consumption may signal new leaks.

To localize issues more precisely, place flow meters in different production zones. This allows you to compare air usage by area, identify anomalies, and focus your ultrasonic inspections where they are most needed. This zonebased approach turns leak detection into a continuous

COMPRESSED AIR SYSTEM KPIS HELP TO TRACK AND IMPROVE THE PERFORMANCE OF YOUR SYSTEM.

and data-driven process.

Monitoring the right set of KPIs, such as efficiency, pressure loss, and leakage, is a must-have for any energy manager or plant owner. VPInstruments’ uses its VPFlowScope M flow meter, which provides a window into your overall system. If consumption is significantly higher than normal or you see a pressure event, you need to look at your production lines or talk to operators in the plant. If dew point is off, fix/service the dryer or check if it is properly sized.

Van Putten has an interesting idea for factories with high peak consumption. “If such companies invest in compressed air storage, you could run the same production with smaller compressors. This relieves the burden on the local electricity grid, and you do a service not only to yourself but also to your neighbor. There are parties — including a start-up in the Netherlands that is active in this field — that store compressed air in salt domes underground. That is a relatively cheap battery. But it can also be smaller with local storage tanks in your own compressed air system.”

For example, suppose that as a producer in Rotterdam, you do not need compressed air all the time or you want to purchase the electricity for your compressed air cheaply. Then you run the compressor when the electricity price is low. With the help of your storage tank, you can manage the peak load better. Investment in storage tanks is not expensive, he said. FPW VPInstruments vpinstruments.com

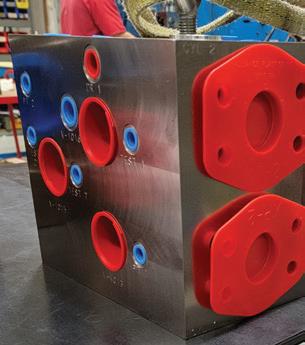

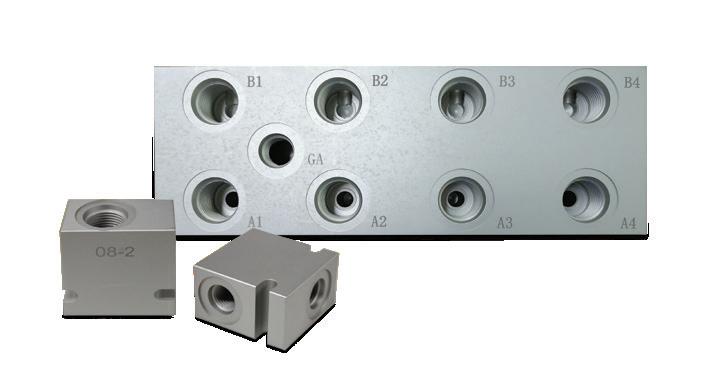

Advanced multi-port air manifold will transform service trucks and vans into highly efficient and organized pneumatic workstations. This precision-machined manifold block is constructed from robust, corrosion-resistant material. It supports seamless connectivity, accommodating multiple hose sizes with 3/8 and 1/2 in. quick-connect fittings, and a 1. in. Chicago fitting, ensuring compatibility with diverse air tools from impact wrenches to jackhammers. With a maximum airflow capacity of 185 cfm and operating pressures up to 200 psi, it significantly reduces pressure drops and shortens airflow paths, resulting in increased energy efficiency and lower operational costs. An additional safety feature includes a manual ball valve paired with a sintered exhaust muffler, allowing operators to rapidly and safely depressurize tools.

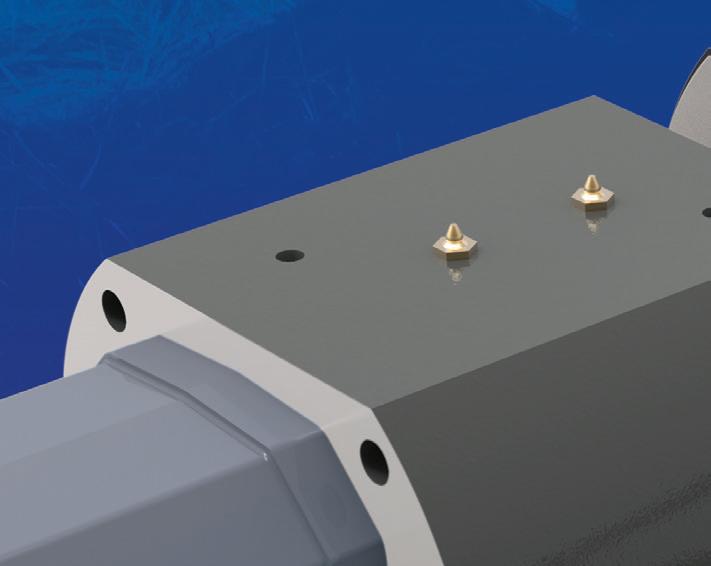

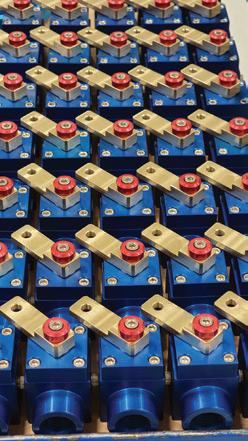

For hydraulic or pneumatic units to function properly, they must be closed systems with no pressure loss. During production, auxiliary bores may be drilled for all channels. For these systems to function properly and to prevent pressure losses, these bores must be sealed tightly. Steel and stainless steel sealing plugs work on the principle of pressure and expansion, in which a ball integrated in the expansion sleeve serves as the expansion element. The sealing plugs are equipped with a serrated sleeve, which expands when the ball is pressed in. This causes the sleeve to expand until the bore is sealed, and the sleeve is anchored in the base material. They can withstand continuous pressure up to 448 bar without the need for additional sealants. The sealing plugs can be removed later if necessary.

Rod locks are crucial safety devices for hydraulic and pneumatic cylinders — they are designed to automatically clamp a cylinder to hold a load safely in case of power loss. They are designed to hold loads of hundreds up to millions of pounds. RCHX Exclusion series is a hydraulically actuated solution engineered to perform in the most demanding conditions, including submersible applications. It builds upon the company's AMLOK RCH Rod Lock platform but enhances that design with a heavy-duty steel housing for severe operating conditions. Its through-hole design is compatible with standard NFPA cylinder mounts and stand-alone configurations. It also maintains equal clamping force in both directions for consistent performance and eliminates rod displacement upon activation, ensuring accurate positioning.

Norstat Inc. norstat.com

Inline pressure sensor is available with analog output for applications that require continuous data and reliable integration. There are no connection threads — you just cut the hose and install Inline in between. Its ultra-compact design and light weight requires no additional fastening or bracketing making it suitable for applications in vacuum lifting, industrial automation, and robotics. It features a durable PBT/PC housing and IP68 protection rating. Pressure ranges from -14.5 to 174 psi are available. The user-friendly installation has push-in connections for 4-, 6-, 8-, or 10-mm fluid ports and has a MTTF of up to 2,528 years. Operating medium is filtered, dry or oiled air and non-corrosive gases.

Robert Sheaf • Founder of CFC Industrial Training

THE ATTACHED SCHEMATIC indicated that the pump controls included a torque limiter control, as well as load sense and maximum pressure setting. The torque limiter control was set too low. Either someone adjusted it improperly or possibly a weak spring affected the pressure. This control allows for using an electric motor that is smaller than what normally would be used. With an AMP meter on the electric motor, the torque limiter pressure is increased until the meter reads what the motor name plate states. At this setting, the maximum system horsepower will be reached and if additional pressure is required, the flow will start to drop proportionally so the horsepower required will remain the same, allowing for more pressure with less flow at the same horsepower input. FPW

Editor’s Note: We do not have a new edition of Troubleshooting Challenge this month, as Bob Sheaf is stepping back from writing currently. JR (Jon) Rhodes, CFPECS, CFPS, CFPAI, President of CFC Industrial Training, will be taking over this column in the near future.

Designing efficient systems involves much more than simply understanding a few basic principles. There is a true art to balancing the specific requirements of an application in order to achieve the desired goals in the best possible way. Help us understand the unique needs of your application and together, we’ll develop something that surpasses what any of us could have done alone.

Contact your distributor to learn more, or visit clippard.com to request a free catalog and capabilities brochure.