July 2024

6 / Liner Notes

Keep Moving Forward

James “Ruggs” Kochevar celebrates America and our Wrap Family in this month’s editorial.

8 / The Wrap Business

Who’s Your #1 Client

Matt Richart has realization has had a huge impact on Digital EFX.

12 / Tips N Tricks (TNT)

Navigating Material Warranties

Shawn Warden tackles the sticky topic of material warranties and who is ultimately responsible.

14 / The Shop

Print Shop to Custom Shop

Adam Sumner, helps you better understand what it means to offer and schedule color-change wraps.

18 / Opinion

The Ethical Problems Facing

Subcontracted Installers

Jonathan Belkus-Blair explores the dilemmas facing contracted wrappers.

21/ Featured Podcast Series WrapOn Podcast

Scott Decker sits down with Mike & Haley Sinclair of Sinner Creations. Click to watch this fantastic episode.

July 2024

22/ Feature

Creating an Angel

Dallas Fowler, takes us behind the scenes to give us an in-depth look at creating an Angel wrap.

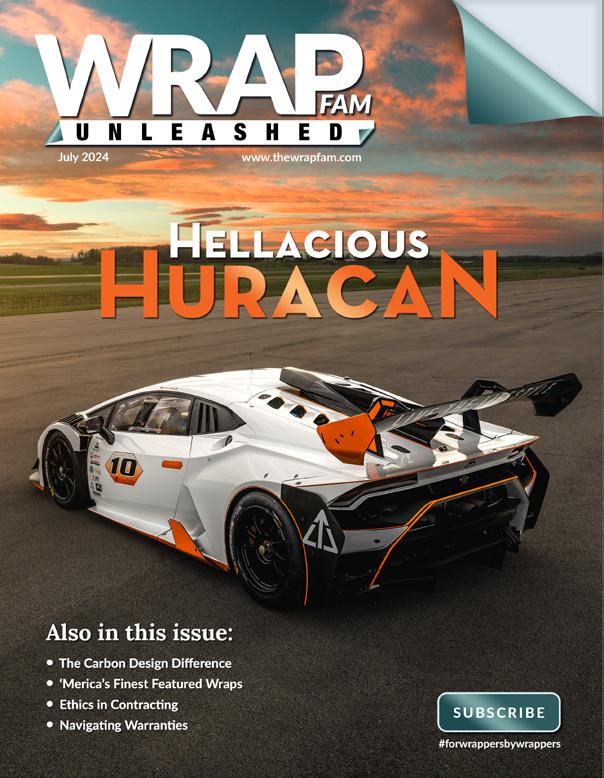

30 / The Centerfold Racecar Flashiness with Artistic Precision

A&M Graphics brings us a jawdropping Lamborghini Huracan wrap.

39 / Featured Video Series Branded NOT Blanded

Dan Antonelli gives us a lesson in memorable branding techniques.

40 / Design Studio

Driven by Design

Steve Carney shares what inspires his incredible creations.

44 / Pro Tip

The Do’s and Don’ts of Boat Wraps

The foremost expert in boat wraps, Albert Hatfield, shares his secrets to wrapping watercraft.

48 / Featured Wraps

Celebrating the Red, White & Blue

A visual tribute.

54 / Pro Tip

Find Your Lane

Chad Munroe shares advice on finding your niche rather than competing for every crumb.

56 / New Products

Product Showcase

Bringing you the industry’s latest innovations.

57 / Video Minute

Wrapping a Quarter Panel

Industry vet and Tallest Wrapper Alive, shares wrap-tip gold.

58/ Feature

Celebrating 20 Years of Innovation

YelloTools marketing sensation, Ernie Macias, shares his experience from this benchmark celebration.

60 / In The News

A Look at What’s Happening in the Market.

Bringing you the latest news.

61/ Trainers Spotlight

Trainer Profiles

A look at who’s ready to train you for success!

63 / WrapToons

The Wrap’s Markets Dedicated Toon!

Dallas Fowler’s unique perspective and artistic gift to the wrap world.

- On the Cover -

A&M Graphics smashes this custom wrap for their friend Dennis Kelly. Check out their process and final results in this month’s Centerfold on page 30.

W R A P I T L I K E A P R O J o i n T o d a y !

“Welcome

Somethingtells me The Offspring would appreciate this issue. Their punk style and the avant-garde mastery that went into this issue’s Tribute to the Red, White & Blue feel like a match made in heaven. We asked for your salutes to the flag, your camo, your ‘Merica - and you didn’t disappoint! We have boats, cars, trucks, ATVs and more. We’ve got the Stars & Strips just about every way you can imagine them. Dallas Fowler is also going to take us behind the scenes and show us the making of his 9/11 Tribute Angel.

We’ll also take a look at some taboo topics involving the ethical treatment of subcontracted installers, the finger-pointing game of who’s responsible when failures happen, and how you separate your company when everyone in town claims to be the best at everything you’re already claiming.

As we hit the halfway point in the year we’re going to take time to celebrate, not just our country’s independence, but our success thus far and the success of our friends in the industry. It is amazing to see the growth in this niche market and truly awe-inspiring to witness the personal growth and shop success of so many good friends. It’s time to grab a hotdog, a cold beer (or 6), and maybe even some apple pie. Let’s hoist one to our friends and loved ones.

That said, I’d be remiss without offering a word of caution - In true drunken WrapFam fashion, I know some folks out there who love to blow shit up… John, Kyle, Daren, y’all know what I’m talking about. “Oh God, the safety’s on!?!” With that, I want to wish you all a fantastic 4th and offer this reminder, it’s a lot tougher creating tension on film if you’re missing some fingers, so be careful out there!

Cheers!

Publisher, Editor-in-Chief

James “Ruggs” Kochevar ruggs@thewrapfam.com

Art Director, Graphic Design

Leslie Kochevar leslie@northstargraphicspromo.com

Contributors

Adam Sumner adam@wrapixacademy.com

Matt Richart matt@digitalefx.com

Dallas Fowler dallas@digitalefx.com

Matthew Wolynski tallestwrapperalive@gmail.com

Guest Contributors

Dan Antonelli

Scott Decker

Steve Carney

Matthew Ferguson

Johnathan Belkus-Blair

Shawn Warden

Albert Hatfield

Chad Munroe

Ernie Macias July 2024 www.thewrapfam.com

By Matt Richart

start off with this question as my header to give you something to think about. Ask yourself who is your number one client that brings you the most business. I was asked this same question by our business coach about three years ago. We were having lunch discussing business plans, strategies, growth rates, and other topics, and our coach asked this question to Dallas and myself. I started to comb through my mind on what client had been with us the longest. I then started to think of who was generating more revenue than other customers that we had built over the past twenty years in business. The more I thought about it the more difficult it became. After a minute of pondering who that number one client was, I reeled off a few customers while Dallas shook his head in agreement. Our business coach responded to both company names with a no. After naming the third client on my top three list he replied with a no again. I was now a little confused and, to be honest, a little frustrated because I thought this guy really didn’t know our business at all. He paused for a second and said I know who your number one client is. Dallas and I both responded, “Well then, who is our number one client”? He calmly said your number one client is your TEAM. After hearing this statement, it started to sink in and finally hit me hard. Your team is your number

one client because that is who your clients deal with daily even if you are also involved in every aspect of your business. Your team provides the services, installation, design, production, and communication, and allows your clients to have that experience with your company. If this is all done correctly and consistently it will make you more profitable, which in the end is the main goal. The day I truly realized how important our team was to our business and growth really changed the way I looked at our roster of talented individuals. I don’t think I ever took for granted what our past team members contributed to our business or what our current team members continue to do on a daily basis. Dallas and I believe that we have always treated our team members with respect and created an atmosphere that allowed people to be creative along with producing amazing wraps. With that said my biggest mistake was focusing on our client base more than our team. This is where I missed the mark in not realizing that our team was our number one client. I think it’s difficult to think about these matters when you are solo or only have a small team around you. Keep in mind that everything is relative regardless of the number of team members you have in your organization. When we first started out in business, we were limited to the number of installers that were available to work along with being able to afford to pay someone a

respectable wage for the type of work we require to be produced here at Digital EFX Wraps. Once we were able to find wonderful team members who could contribute to our success, we really started to focus more on our team just as much as our clients. We are very lucky and fortunate to have most of our original team still employed here. Over 80% of our staff has been with us for over ten years or more. A few of our first hires are hitting the sixteenyear mark. To be in business for twenty years your clients have had a lot of interaction with your team over that time frame. Our business just like others reading this article have a sales department, design team, installation team, and other administration tasks that require

communication and transparency with your clients. The is what brings you more business, more leads, and most importantly more revenue. Your sales team should also be harvesting more business from your existing client base which in turn allows your company to grow by taping into more customers. I like to call this new blood or new lifelines of customers that you can have for decades to come if your team is treating your clients the way they should be treated. We finally started to invest in our team or as we now say our number 1 client. The first step was to create a vision and mission for our team that they could believe in and work by. The second step was creating a culture that I discussed in my last article. When your team

feels your culture and lives by it that’s when your clients experience your culture as well. The third step is investing in your team through education and training. I have said many times before that you must slow down to speed back up. This held true when we went back and re-trained our installation team on what our procedures were and why we executed them in that manner. We also realigned our team so that each member knew what was expected of them, what their strengths, and weaknesses were, and what they excelled in. By taking the time to focus on our team and how we can be more proficient, skilled, and confident allowed us to gain more business. Every time we dedicate effort to our team it

reminds me who our number one client is. It reminds me why we are doing things differently than twenty years ago. When I walk into our facility each morning I try to greet and interact with each team member, when possible, to get each day started out the proper way. If our team is energized and dialed in that will carry over to your clients. I truly believe business has a lot to do with feelings and the vibe you get when you walk into another business. Our clients hopefully feel this when they step into our building each day. Try to take some action on how to get more training and education injected into your team. When I find small videos or blogs about life lessons, business ideas, or just something

motivational I will share these with our team. This is another great way to keep your team motivated and engaged so that your clients will feed off that great energy. It really becomes a great working relationship between your team and your clients.

Treating your team members as your number one client is the best way to drive loyalty and retain top-level talent in your industry. This also will attract better talent when that time comes for you and your company. We also instill in our team how important they are to this company along with being Digital EFX Wraps’ number one client. When you can humanize the employment experience it creates an environment that your

team members want to be a part of. If your team feels that way you can only imagine how your clients feel! Make your team your number one client today if you haven’t already started that process. If you are a solo entrepreneur make yourself your number one client from the beginning. I wish I had but we all live and learn.

Matt Richart Matt@digitalefxwraps.com

Co-Owner/CFO, Digital EFX Wraps LLC.

Instructor, Inside The Wrap Shop

By Shawn Warden

ou know we have all asked the question about material warranties, but it’s usually too late when the client has brought it to our attention. Today, I am writing this article as a small business owner who primarily installs Other Peoples Graphics (OPG)!

As an installer with over 10+ years of experience with installing a variety of materials from multiple manufacturers, I have been lucky and only had a few issues (knock on wood) from my clients in regards to coverage. That being said, I am not responsible for any purchase or production of materials. I am usually 3-4 tiers down from the logistics and responsible for the installation only.

When I was asked at the last trade show in regards to how I warranty my installations. I have a default that I use which is 1 year crack, fade, peel that I have on all my invoices to my clients. Most failures that are caused by the installer are present within the first year. Anything after that is most likely the material or production. One of the first steps you should do when receiving graphics is to have valuable information on the material from the manufacturer—the type of material, ID or part numbers, production dates, etc. Also, the important information that I

feel is necessary is the production date, which is when it was printed. This is very important because all materials have a shelf life for production and also after they are printed. Most manufacturers of materials spend millions of dollars on product development and lawyers to produce warranty information that reads like a mortgage contract with fine print for days!

Regardless of the shop size, having the label information will help during the warranty process is essential. If we look at the entire pipeline and not just the purchase we can get a picture of how just simply adding the information in your invoicing could help with replacement and even labor in some cases. The material we mainly use for our wraps is a petroleum base and spends most of its time decomposing and/or shrinking back to its original state. Once you store it for a few months, then print on it in a high-heat situation it only speeds up the process. So, knowing when it was produced and started its life is the primary information to start any warranty process.

One of my personal experiences was for a fleet container wrap job a few years ago. I requested all the information before I accepted the project which had a date of manufacture including lot numbers because it was multiple rolls. I also requested the date of production of when it was printed/laminated and shipped to the client. The red flag for me was the amount

of time the client had these prints at the location awaiting the final container locations. I inspected the shipping date which was 18 months previous and then the material was shipped in different manufacturer boxes. This is very common for contract installers and asking for verified information is important on any size job. Once I requested this information it started a shitstorm. This was a large contract and the client had mentioned that the other locations had numerous issues with the vinyl not sticking which I qualified with the information provided. These prints were on a material produced 5 years previous and printed 18 months before shipped to locations. They were experiencing over 80% failures and submitting chargebacks to the installers of which most of them were walking away.

My point is having the necessary material information on ALL your jobs and maintaining a standard to basically “cover your ass” should be practiced regardless of the size of the job. I'm sure anyone reading this has more than a few experiences at many levels, more than once.

I’m calling out to everyone to start gathering this information to hold everyone who touches your materials before they end up in your hand or your client's equipment and/or surface to be put on notice. If you are a shop like mine that installs other people's graphics only, then put on your invoices, “guaranteed installation only 1-year crack, fade, peel”. As long as the hiring

client can produce the information needed from the manufacturer and/or distribution company for any warranty claims you should be covered. Any failure that is the installer's fault will normally happen in the first year, even in the next few months and that is on you to cover. If you're confident that it is a material failure then the best quality of service is that you requested this information before the installation. This helps everyone involved and your client will thank you many times over.

Test this out anytime and ask your hiring company for the material information, 90% of the time it would take weeks to even find the correct information. If you're doing the production of the material, start putting this information and tracking it on all your jobs. It will make sense in the long term and address an issue that most never even thought about or just stopped doing it. Believe me, it will not happen on the small job!

I hope this information reaches at least 1 installer or shop somewhere and makes a difference in your daily operations.

Shawn Warden Owner/ Installer City Sign Co, LLC Contract Installer New England, USA gowrapdaddy@gmail.com

By Adam Sumner

olor change wraps are quite possibly the one thing I love to hate. Let me clarify: while they may not be my personal favorite, there's no denying their appeal. A high-end car in the shop looks far better than Jimmy’s plumbing van, and they dominate on social media. Yet, despite our substantial investments in printers, laminators, routers, and other equipment, something about altering a car's color doesn't quite hit the mark for me.

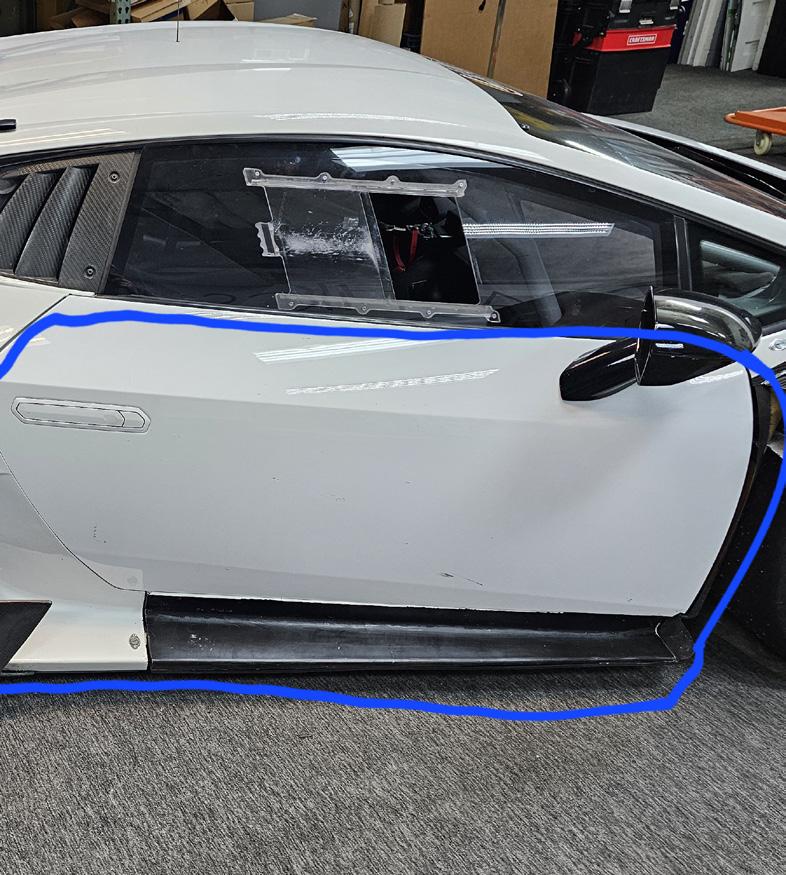

Now, don’t get me wrong we do a ton of color change wraps and the one thing no one talks about is the different versions of color changes they offer. Our bread and butter color changes we refer to as commercial color changes. What this means is we leave as much on the vehicle as possible and when you walk up to the car what you see is what we wrap. These by far make up the majority of color changes we sell and complete. Starting around the 3500-4000 price range. This style of color change has its appeal for price and is usually the best option for anyone with a dark-colored vehicle. The darker the car the less coverage and parts we need to remove saving us time on labor and the customer on cost.

Then there are high contrast color changes, like turning a white car to satin black. These

require more time, film, and parts removal. We even inlay into door jambs a few inches to ensure seamless transitions and eliminate visible paint between door seams. costing an additional $600 to $1,200 depending on the vehicle type, sedan or SUV, and original color of the vehicle, and what material color choice they have made.

At the top tier are complete color changes, ranging from $8,000 to $12,000 depending on the size of the vehicle and amount of parts needing to be removed. Those that have wrapped a G wagon know exactly what I mean. Complete color changes include the removal of just about every trim bumper light and accessory piece you have. Typically labor for these vehicles includes 2-4 days of disassembly and reassembly of the vehicle on top of the time to wrap the car. We try our best to sell options 1-2 as much as possible because the time of the vehicle in the shop for us is not worth it in the long run, but shit complete color changes look good on the gram.

The trick to adding color changes into your workflow as a print shop is one build in the time if you think it’s going to be a 3-day install tell the customer 5. Nothing has pissed me off more was to have a color change in the shop and my number 1 customer calls and needs 3 vans done that week and I have to tell them no or burn the guys out on installs to make it all happen. We always build in extra time for color changes to fill in gaps between our bread and butter commercial wraps.

The key to a successful color change is to set the expectations for the customer before you even begin. (Below: before, Right: color change wrap)

helping hand. Well, with today’s inflation who knows what they would charge now, but it’s always worth looking into it. Color changes to me are no different than installing a commercial wrap in some aspects I think they are easier and in others, they are way more difficult.

We teach 3M’s vehicle color change and have seen a ton of small print shops coming into the class to start offering color changes to supplement their day-to-day. The most common thing asked is how we take apart the cars. My opinion - DON’T. If you’re not comfortable wrenching on vehicles partner up with a local body shop. Back in the day when I was a solo operation I would grab a 30-pack and an envelope with 300 cash walk to the local body shop and ask the owner if I could borrow one of his guys to take apart a car for me. He told me to go in the back and offer it up and let me tell you I never had an issue finding someone to lend a

The key to a successful color change is to set the expectations for the customer before you even begin. We will walk the customer through the vehicle point out issues in paint and also discuss how we will install the wrap and all the parts that will be removed, where we will have to have seams in the wrap. YES, SEAMS. There are a few cars we install that don’t have a seam or multiple on the vehicle. And I will tell you 98% of mirrors and antennas leave our shop with a seam. Can we do them in one piece sure most of the time they last forever but I’m not in the business of most of the time I want vehicles to leave and never return unless they would like a new wrap. We outline to our customers

exactly where the seams will be and if they are unsure of what it's going to look like or have reservations we show them with some scrap film exactly what we are going to do and almost every time they say “Wow, that disappears”. My goal for each wrap color change or commercial is to set the expectation upfront so that when they come in they are not looking for problems they are looking at the transformation.

Over the years especially with social media, our customers are coming in with what they think is knowledge and sometimes they are correct and others they just think they know what they are talking about. It is my goal with each interaction to school them on wraps and in the nicest way possible (tell them they don’t know shit and that is why they are standing in my shop) to get the wrap done and not doing it themselves. I actually never sell them a wrap. I educate them on the process the materials the good and the bad what the wrap will be like in a month in a year in 5.

What they need to do to prolong the life of the wrap how to maintain what to look out for, so if there is an issue with the film or my installation we can catch a problem and fix it immediately so that it won’t be a costly repair either for us and time fixing out a mistake. Or to them for leaving the wrap on too long causing damage to the vehicle or putting a dent in the pocketbook because the removals will be a nightmare.

Offering color changes or expanding your current offerings to include them is vital to the success of your business. The key is setting expectations knowing your limits getting help when you need it and don’t be afraid to make a mistake. Just own up fix it and move on.

Adam Sumner Adam@wrapixacademy.com Owner, Wrapix Academy Owner,

By Jonathan Belkus-Blair, My Wrap Game

’ve made a point of introducing new ideas to the industry through provocative discussion, not because we always benefit from them, but because we tend to listen more when we’re a bit offended.

Now, being three days overdue on my latest polemic submission and in quite a mood, I thought I’d share my unfiltered thoughts on the ethical problems subcontractors face. Subcontractors are crucial to this industry and are expected to adhere to strict ethical standards—non-solicitation agreements, confidentiality clauses, and conduct guidelines ensure we don’t poach clients, leak information, or compromise quality.

But here’s a provocative thought: have you — the shop owner — been so focused on protecting and growing your business that you’ve inadvertently crossed ethical boundaries with your contractors?

In this article, I’ll delve into some of the minor ethical dilemmas I’ve encountered, highlighting the often overlooked need for protections that respect subcontractors as valued partners in the industry.

Have you ever noticed a customer photographing you and your unfinished

work? It’s always bothered me, and I’ve finally figured out why. As installers, we use unique proprietary methods and techniques that give us a competitive edge. It can be very distressing when these are shared online without permission. While the end result undoubtedly belongs to the shop, the process and the methods should be considered part of our intellectual property. To address this, it’s essential for shops to respect the intellectual property of their subcontractors. Before taking photos or videos, ask for permission and clarify how the content will be used. Implementing a clear agreement that protects the contractor’s proprietary methods can prevent misunderstandings and ensure that both parties feel respected and valued.

Here’s another one. Have you ever asked your contractor to wear your shirt or, at the very least, asked them to hide their branding while onsite? Seems harmless, right? The idea is to avoid uncomfortable questions from the end customer about middlemanning, which can lead to concerns about transparency and value for money.

But here’s the crucial dilemma: if I’m asked about it, should I lie? This would mislead the customer and put unnecessary pressure on contractors to conceal their true position, distracting them from focusing on their work.

Instead of concealing branding, consider a more transparent approach. Allow subcontractors to retain their branding while making it clear to clients that they are trusted partners. This builds trust and maintains transparency. Your contractors will feel a lot happier if they don’t have to lie for you.

Do you think it's fair to leverage a subcontractor's skills to win an account and then exclude them from future work?

Many times, companies use my expertise to secure lucrative contracts, only to replace me with less experienced in-house staff afterward. This feels unfair, especially when my skills were crucial in winning the job.

Perhaps I'm overreacting, but I've always believed you hire a skilled specialist for specific tasks that require their unique abilities or to handle overflow work. Using a contractor to win an account without acknowledging their contribution doesn’t necessarily feel wrong, but it certainly doesn’t feel right either.

To foster fairness, ensure that subcontractors are included in future work if their skills were instrumental in securing an account. This not only makes subcontractors feel valued but also builds long-term, trusting relationships.

I’ve worked with over 150 companies as a subcontractor, and most have, at some point, asked about my other clients. The most egregious requests have involved soliciting staff from competitors. These sorts of questions, even if seemingly harmless, put me in an extremely uncomfortable position — not only because they presume to involve me in an unethical conspiracy, but also make me question how they would treat me if I was no longer useful to them. This one is simple: avoid asking subcontractors for information about their other clients or competitors. If they were to reveal your competitor's secrets, how could you trust them to keep your secrets safe? Instead, focus on building a relationship based on mutual respect. Clear agreements about confidentiality, whether written or verbal, should be in place, ensuring that both parties are protected and that ethical boundaries are maintained.

And while we’re at it, do you give proper credit to your subcontractors for their contributions? Let me be clear, I’m happy for my customers to take the spotlight, but this comes at a cost and I’ll be less inclined to partner with you long-term. When subcontractors aren’t given credit, we’re rendered invisible, and it

affects our future business opportunities.

Take my experience, for example. There are some companies that have never acknowledged my contribution, despite leveraging my skills to win work, publishing my face on their social media, and dragging their feet on payment. This approach is unsustainable and detrimental to building long-term relationships.

To ensure your subcontractor is loyal and willing to support you at short notice, try to regularly acknowledge and credit them for their work. Recognizing their contributions builds an atmosphere of respect and trust, opening doors to new opportunities. Otherwise, you risk losing their commitment as they seek more appreciative partners.

Have you made it this far? No, seriously, this isn’t the most thrilling topic, but it’s crucial. Subcontractors exist because shops need flexibility and the ability to focus on their core strengths without overextending. We need each other to thrive.

When shops and contractors respect each other's ethical boundaries, everyone benefits. But when that respect is missing, we have a breakdown in industry cooperation that leads to uncertainty, distrust, and delays. Isn’t our job hard enough?

Jonathan Belkus-Blair Owner, My Wrap Game

Watch this episode of the WrapOn Podcast, as Scott Decker sits down with Mike and Haley Sinclair of Sinner Creations, a self-made, family and veteran-owned business. Discover how they treat each customer's vehicle like a unique project with its own story, working closely with clients to create custom artwork that brings dreams to life. With a passion for the automotive industry, Mike and Haley are redefining vinyl wrap as a new form of art, guaranteeing their work and ensuring every vehicle stands out as if it just received a new paint job. Don't miss this inspiring conversation about creativity, dedication, and the love of cars.

Wrapped with Respect: The 9/11 Angel Cars Collaboration

By Dallas Fowler

Let me start by expressing how honored I feel to be included in a project that I know has a much greater impact than I can ever imagine. The interesting part was when I was asked to be a part of this. I knew it was going to be cool, but how it intertwined with so many other events in my life ended up making it one of the greatest things I've been a part of. I remember Ruggs approaching me after "Meet the Masters" and telling me he thought he had a cool project lined up for us. It was something for 9/11, and we were going to do a collaboration of five different artists. Without him even being able to finish, I said, "I'm in."

First, let me say that I felt stoked to be asked to be one of the five artists, some of whom I look up to and now will be able to share a platform with. The interesting part is that I knew I would have to bring my A-game, and that already excited me. By the nature of the project, I knew we would push each other to level up and give our best. A few weeks after the show was over and I was back to the normal grind, I remember Ruggs reaching out to me and saying, "Okay, are you ready? I've got all the details, and here's what they are." He explained that he had five artists for this project: Dallas Fowler - Digital EFX Wraps, Casey Folk - PDX Wraps, Ryan "Glarb” Sandoval

- Glarb Designs, Jamie "Mully” Mullican - The Wrap Artist, and Kevin Kempf - PG Nola. We were going to be designing five Camaros for an organization called Fueled by the Fallen.

Fueled by the Fallen is a non-profit that pays tribute to military members, first responders

and their families. This basically means that five different Camaros represent the five angels of 9/11. At the time, we had no idea what each car represented, and each artist had not been assigned to a car just yet. After several Zoom meetings and coming together as a group, we were able to each pick a car that we felt we could do the best job on in terms of artistic vision and what car subject matter excited us the most.

I want to talk about two other important parts of my life that really impacted my art and what I would create for this project. The ironic part about this project was that earlier that year, in February to be exact, I got to go to New York because my stepdaughter, Addyson, had been asked to participate in Fashion Week. It made for an awesome family trip to see Addy on the billboard in Times Square and watch her go on the runway, but the best part was that we got to visit the 9/11 tribute at Ground Zero. Little did I know how much impact this would have on the artwork I created for Angel #3.

So, you can guess how hard I pushed to work on Angel #3. The special part about this project, outside of being able to give back and touch somebody's heart, was doing something great and showing my love for America. I wanted to express how patriotic I am and give back to all the people who make it possible for us to walk around safely every day—from policemen and firefighters to our military. Another super important influence lingering in the back of my mind was how I could make my brother proud of being part of such an amazing

project that shows my respect for America and everybody who has helped us. I couldn't wait until this project was done so I could present it to my brother. My brother, Ricky Fowler, Chief Warrant Officer 3, retired U.S. Army Special Forces out of Colorado Springs, CO, 10th Special Forces Group Airborne, served for 28 and a half years. I hope that one day he gets to see the cars live in person—not just my car, but all the cars.

After our first or second Zoom meeting, I remember quickly realizing how this was a large order in a short time frame. It was funny to think that we had time, and one might say, "Welcome to the Wrap Game." When I say tight, I mean super tight—like one week for the first draft, the second week to have it done, and the third week we’re printing and shipping to Vegas. Meanwhile, the cars were going to be shipped to Vegas, stripped, ready for print, and then ready to ship for an event in California for a homecoming event for our troops.

Like any good design or logo, I began to research and compile my recent trip to New York with tons of videos and facts about Tower Two. As my ideas began to come together and my visions of what I wanted to create started to become clearer, I want to share with you some of the facts that helped me create this awesome piece.

I was going to base my hood piece on the pools located in the 9/11 memorial. The focal point of the memorial is two pools, nearly an acre in size, that sit exactly where the North and South Towers were located. The pools contain the largest man-made waterfalls in North

America. Each has a waterfall that flows thirty feet into a square basin, and then each pool drops another twenty feet until it disappears into a void. The architect, Michael Arad, says the pools represent absence made visible. Although the water flows, it can never be filled, but the sound makes the pools a calm place of contemplation right in the middle of all the noise of the city.

Some other interesting facts I learned through my research of videos and articles: there are more than 400 swamp white oak trees filling the plaza around the pools. This species is native to the areas of all three 9/11 crash sites—New York City, Arlington, Virginia, and Somerset County, Pennsylvania. I thought that was a pretty cool and amazing fact.

Although I didn't include it in my art, another amazing fact is that recovery workers at the site found a damaged tree at Ground Zero. Members of the New York City Parks and Recreation Department removed it from the site and nursed it back to health. Having survived the events of 9/11, the tree became known as the Survivor Tree. It was returned to the plaza site in 2010 and now stands in the plaza as a symbol of resilience and perseverance.

So, my hood piece would be of the 9/11 Memorial Plaza, featuring firefighters raising the flag and an angel wing encompassing them. You probably have seen the picture of the flag raising at Ground Zero this is a photo by Thomas E. Franklin. These were Brooklyn-based firefighters George Johnson, Dan McWilliams (both from Ladder 157), and Billy Eisengrein

of Rescue 2... The importance or symbolism of the angel wing is special as it represents purity, courage, love, harmony, and protection. Angels provide us with happiness, hope, and faith.

With only two weeks to complete this project, it was time to draw. Good thing wrap designers are built for this and we're used to tight deadlines. With time being one of the main challenges, the second challenge I quickly realized was how to organize over 1,400 names on this Camaro and do it with class, taste, and respect for the names that were going to be placed on this car.

When I was designing, I realized that it would be too difficult to have 1,400 names on one side of the car. So, I began to divide the names evenly throughout the car's sides and trunk. Not only was I dividing the names evenly across three different sides of the car, but I also wanted them to flow along the body line. I knew this was going to be special, and along the way throughout my process, I took small videos of sketching, coloring, and designing the hood piece.

The tools that I used were my Wacom Cintiq 27" using the program Clip Studio Paint, and I finalized the final art in Photoshop. I think I clocked somewhere around 40-plus hours of design time. I know we were all under the gun, trying to create some badass artwork. Ryan was trying to finish his art and was also tasked with the beautiful curse of templating the Camaro for all of us. How cool is that to get to throw down and design and see the mastermind thinking and execution

behind Ryan's awesome templating skills

After everyone finished their designs we sent them off for client approval to Fueled By The Fallen’s founder and head-advocate, Kevyn Major Howard “Rafterman”, from the Stanley Kubrick classic Full Metal Jacket. He

sent back an amazing review of how unique each Camaro design was and how excited he was to share these designs across America.

Now, let's get to the other important ingredients of this project. We were super thankful that 3M stepped up and was able to provide us with printable silver wrap film, which gave each one of our prints an amazing candylike look. Each designer chose a different finish, and for me, I was able to pull off amazing print quality with my Roland VG2 and Kala laminator.

In the meantime, while all of us were designing, the cars were being shipped to none other than Elliott Nail at 5150 Wraps, who was tasked with the difficult obstacle of removing

not only ten-year-old vinyl but also ten-year-old vinyl cut names that were baked into the car's paint. Each designer printed and shipped their kits to Las Vegas. Let me just say how difficult it must have been for Elliott and his team to not only do his everyday work but now also slide

in five Camaros with a super tight deadline. I would imagine he had to put some of his other jobs aside to be able to pull it off. I do think he was kind of like a kid in a candy store. As each kit from each designer showed up at his shop, he was excited to open it up and see what awesome prints and designs were presented by each of us.

I’m sure the excitement wore out quickly as I believe some of our designs were super complicated and very difficult to install, with such precision points needing to match. Thanks again 5150 Wraps! Thanks to Ryan's great templating, I believe 5150 Wraps was able to pull this off with an A+ rating.

After each kit arrived at 5150 Wraps in Las Vegas, we waited patiently, anticipating pictures from Elliot as he finished each car one by one. If you've ever installed wraps then you can imagine that these wraps are more like super complicated, intricate puzzles of life-sized artwork. In the words of my business partner Matt Richart, we created “custom-fitted suits for Camaros.” I'm sure after many late nights, Elliot and his team at 5150 were happy to see the hard work they endured during the wrap come to fruition and the victory of seeing a cool piece leave their shop.

In a matter of a month or so, we were able to see them revealed at the WWWRAP party at SEMA. And while it seemed cool for everybody, all I could think about was seeing all the cars lined up and being able to enjoy the wrap designs that I had only seen on a computer screen. Now, we get to see them in real life. It was super cool, and I was honored to be a part of something so amazing.

As the event drew closer, I was super pumped about reuniting with my wrap family and being able to showcase our cool car wrap designs. It had been hush-hush the entire time working on the project. Each one of us received a special limited-edition coin and badge from Kevyn Major Howard. We got to hear heartfelt stories about how the car names and the impact they've had on families and friends over the past ten years. Now, with a brand-new facelift for each one of the Angels, it was inspiring to think about how the unique artwork would impact young kids to adults with these cool new wrap designs on the Camaros.

The second cool part about being presented with the medal was that I spent most of my childhood watching Full Metal Jacket with my brothers, and now getting to meet one of the actors in person was so cool. Like a great team leader who knew what this vision and project was going turn out to be, I want to say thanks again to Ruggs for not only believing in me but including me in this project and knowing how great of a team all of us would make.

In closing, if somebody were to ask me if I'd do it again, without hesitation, I would say yes. This project was not just about designing car wraps; it was about honoring the memory of those we lost and creating something that touched the hearts of many. The camaraderie, the stories, the late nights, and the immense pride I felt in contributing to such a meaningful tribute made it all worthwhile. If I'm ever asked what was one of the coolest projects, I've ever been a part of, I would say the Fueled by the Fallen 9/11 Camaro Angel Cars. It wasn't just cool; it was deeply moving and profoundly impactful, a reminder of the power of art to bring people together and keep memories alive.

Dallas Fowler

Dallas@digitalefxwraps.com

Co-Owner, Digital EFX Wraps LLC Creator, WrapToons

By Matthew Ferguson

Graphics, renowned for its exceptional Premium Graphic Environments, has built a solid reputation in the B2B sector. Known for delivering high-quality, professional graphic solutions, the company typically steers clear of more flashy projects like color change wraps and racecar liveries. However, when a great friend and loyal client, Dennis Kelly, approached them with a special request, A&M Graphics decided to bend the rules a little.

Dennis Kelly, a passionate car enthusiast, was adding a second Lamborghini Huracan to his stable. This new addition was destined for the racetrack, a purpose-built track car demanding a unique and eye-catching design. Understanding the significance of this project, company President and Creative Director Matthew Ferguson saw an opportunity to step outside their usual business-to-business boundaries and create something extraordinary.

The transformation began with the exotic track car’s carbon fiber body. Using 3M 2080 Gloss White Gold Sparkle, A&M Graphics wrapped the Lamborghini, giving it a stunning, luminous finish. To add contrast and depth, they accented the design with 3M 2080 Gloss

Deep Orange. These vibrant colors provided the perfect canvas for the final custom touches.

Custom-printed logos and intricate livery details were added using IJ180mC-114 clear cast film. This special film allowed the underlying Gloss White Gold Sparkle to shine through, creating a harmonious effect in the overlays. The result was a striking balance of racecar flashiness without tipping into gaudiness, exactly as Dennis had envisioned.

The finished product was a testament to A&M Graphics' ability to adapt and excel, even outside their typical scope of work.

The gleaming Lamborghini Huracan, now a head-turner on the track, showcases A&M’s commitment to delivering perfection for their clients, no matter the challenge.

The project not only highlighted A&M Graphics' versatility but also reinforced their commitment to client satisfaction. By stepping out of their comfort zone and embracing this unique challenge, A&M Graphics demonstrated their capability to push creative boundaries and deliver exceptional results, further solidifying their reputation as a top-tier provider of graphic solutions in the industry.

Looking ahead, A&M Graphics aims to leverage the success of this project to explore more dynamic and diverse opportunities.

This venture into the world of high-end racecar aesthetics has opened new avenues for creative expression, inspiring the team to continue innovating and setting new standards in the graphic solutions market.

In this episode of “Branded or ‘Blanded,’” Dan discusses Ponderosa Garage Doors' successful rebranding. Featuring a new look and impactful vehicle wrap, their unique color scheme and logo redesign led to a $3.3M (275%) revenue increase within a year. See how Ponderosa became a standout in the garage door industry.

By Steve Carney, Carbon Wraps

Back in high school, I discovered my love for art and design using Photoshop 5. It all started with doodles and drawings as a kid, which eventually evolved into creating graphics in Microsoft Paint. As my skills grew, I went deeper into graphic design and the world of car wraps.

Movies like Fast and Furious were a huge inspiration for me. They sparked my interest in designing decals and graphics for cars, starting with personal customization projects.

My high school graphic arts teacher, Mr. Lovett, really pushed me to think creatively. He challenged my entry-level design skills to think

outside the box and collect business cards. He then had me redesign the cards and supply them to the business owner. I was able to make several contacts this way. It also fueled my passion for helping business owners and clients stand out creatively. I'm proud to say we are still in contact.

After graduation, I landed a job at a local resort's sign production department. There, I learned everything from sign fabrication to large-format printing and vehicle wrapping. It wasn't long before I decided to start my own business, Carbon Wraps.

I mainly use Adobe Photoshop and Illustrator on my trusty HP laptop because I like being able to work wherever creativity strikes. Each project starts with what the client wants.

My design process starts off with the client's ideas/interests as a foundation. For example, one of our clients wanted a 90's arcade-themed wrap, so we narrowed it down to Street Fighter II. With that as a launching point, I took a deep dive into the classic arcade game world focusing on Street Fighter II. My process is to learn as much about the subject in the hopes of achieving the same

excitement as the creators of the game had.

I tend to think best at night, I will cast my design on the big screen at home aka the Dojo/ retro game room. Submersed in music and research I start with bringing in the elements that communicate the client's ideas best. Then get input from Jen and we work together to finalize.

The philosophy I have found that works best for me is to work on projects I am excited about.

I love the creativity and challenge of bringing a client's ideas to life. When I can match their energy about the project, I know we are going to have a super blast through the process. @carbonwraps

Communication is key. I keep clients updated throughout the process and make sure I'm fully prepared for each project. Before diving in, I create 3-5 quick mock-ups to get a feel for the client's expectations. Adding our logo watermark to designs helps protect our work and keeps things professional. I make sure to keep in contact with the client throughout the process in a timely fashion. I never accept a design job if I’m not ready for it.

One lesson very quickly learned is to require a nonrefundable deposit before any design work is done. I charge for design time, not for artwork. Our designs/ artwork belongs to Carbon Wraps. The client pays for the end result but does not own the artwork. Selling the artwork is a separate price and is an available option. We also provide one-time designs. We let all of our clients know that their wrap will be the only one of its kind from us.

You are a designer so think outside the box. It's fine to have inspiration, however, be sure to have your own style. Don't be afraid to lead the client. Often times they are not able

to picture or verbalize what they truly need. Some clients need a little pushing and some need a little reigning in, either way, be sure you are proud of the art that is out there.

By Albert Hatfield

The marine industry is absolutely enormous and we can be a true asset to the more than 17 million boats and Yachts in the United States alone. One thing they all have in common is that they take a lot of constant maintenance just to stay afloat, let alone look good…. That's where we come to the rescue. Through the proper application of the right product, we can solve a fuckton of problems for customers.

It’s not a hard sale. Boat wrapping offers a host of benefits, from cost savings ( on average is 1/3 the price of paint or gel coat) and customization to enhanced protection and ease of maintenance. Whether you’re looking to refresh your boat’s appearance,

protect its surface, or boost its resale value, a vinyl wrap provides a practical and stylish solution. As more boat owners recognize these advantages, the popularity of boat wrapping continues to rise, creating a need for wellinformed and talented marine wrap specialists.

In 2014 we opened OceanWraps a division of our company dedicated to the marine industry. Over the last 20-plus years, I have personally wrapped more than 1000 marine craft-related items, like boat hulls, interiors, walls, countertops/ bar tops, handrails, transoms, and a bunch of other stuff. One time even an anchor. My goal is to be an asset to the owner, crew or broker and make their life better through vinyl and PPF.

Size - it does in fact matter. When it comes to size, it’s about management being able to handle 30 to 150 feet of material hanging freely is daunting at first, but depending on the film and temperature you may need to pull a few feet at a time and apply or bridge the material between the rubber rail and the bottom of the hall. This gives you time to come back and work with the material in sections without making contact with the surface.

Environment - I’m not talking about hippy shit, I mean the conditions of your installation area. Will you be in a boat barn, or in the sun,

on the water or on dry land. All these things you must know ahead of time, so you can price the job accordingly. They all have their own issues. In South Florida, heat is something that we deal with almost year-round and something that you have to take into consideration when taking on these projects. Stay hydrated stay covered up from the sun, sunscreen, and protect yourself and your crew. Don’t forget these little expenses add up and need to be factored into your pricing as well. Trash - This is super important and depending on installation location it can be challenging it keep track of it all. Make sure you or your crew roll up your backing paper. This stops you from taking up all the

space in the dumpster and pissing off the marina or shop that you’re working at.

Design - You must get a good designer with knowledge of the shape of a hull. In my experience, it’s important to make sure that all the text and graphics are not near the edges and are straight. Do not try to curve them in the print to the shape of the hull. Leave it in one large rectangle and manually manipulate the film as needed Keep the important stuff away from the edges. Give yourself room to manage the print. Boat shapes vary and are always a funky odd shape so the film takes some manhandling to get it right.

Decorum - If you ever want repeat business, you must learn proper boat/ yacht etiquette. It’s important not to piss off customers before getting on the boat. It is also important to learn, nautical terms that describe different portions of the boat due to the fact that that’s what people will be telling you when you discuss their project with them.

• Bow: The front of the boat.

• Stern: The rear of the boat.

• Port: The left side of the boat when facing forward.

• Starboard: The right side of the boat when facing forward.

• Helm: The area from which the boat is steered.

• Deck: The flat surface covering the hull of the boat.

• Cabin: The enclosed space inside the boat, used for living and sleeping quarters.

• Galley: The kitchen area on a boat.

• Head: The bathroom on a boat.

• Hatch: An opening in the deck or cabin roof for access or ventilation.

• Cleat: A fitting on which a rope can be fastened.

• Beam: The width of the boat at its widest point.

• Draft: The depth of water a boat needs to float.

• Fender: A cushion placed between the boat and a dock or another boat to prevent damage.

• Transom: The flat surface forming the stern of a boat.

I hope this helps take away some of the fear of boat wrapping. It’s a great gig and boat people spend money, so that next job is probably on the boat sitting right next to the one you’re wrapping.

Albert Hatfield CEO, Fifty Nine Fifty Wraps / OceanWraps

Starting with the April issue, we now offer on-demand print copies of WrapFam Unleashed.

@glarb.design

By Chad Munroe, Get Graphic

Whenever I find myself discussing business with colleagues or industry peers—whether at events, trade shows, social media chat rooms, or on the job—the topic of "competition" inevitably comes up. People often talk about how a competitor is "killing the market" with low prices or "owning the market" with superior success. This chatter has always intrigued me, but it's not something I've allowed myself to be consumed by.

As a lifelong entrepreneur, I've experienced both success and failure in various industries, not just in wrap and graphics. What I've learned is that my successes haven't come from "stealing customers" from my competition, and my failures haven't been due to someone else undercutting prices or offering a superior product. In fact, the success and failure I've experienced over 30 years in business have been determined by quite the opposite.

I've always made an effort to be aware of what others in my industry are doing, regardless of their company size. It’s beneficial to observe local, national, and global trends. There's a wealth of knowledge available if you know where to look. However, many business owners get bogged down in trying to gain market share from their competition,

which I see as a slow, tedious, expensive, and exhausting process—a "race to the bottom."

Our approach to gaining market share at Get Graphic, as well as in other endeavors I’ve been involved in over the years, has been to identify a niche that our competition wasn’t catering to and to focus our efforts on attracting a new and untapped clientele by filling that void.

When we entered the graphics industry, there were about 15 shops offering graphic services within a couple of miles of us. They were largely successful, but it was in the early days of certifications, and no one in the entire state of Arkansas was a certified installer. As a result, we pursued and were the first in the state to attain certifications from 3M, Avery, Orafol, Arlon, and others. To this day, no one in the state matches our level of certification, setting us apart and attracting different customers. Instead of competing for local sign or vehicle wrap jobs, we carved out a niche in contract installations for nationally recognized brands like Culligan, Applebee's, Buffalo Wild Wings, and CertaPro Painters, while also having the ability to print. Using this as a marketing tool also brought in significant local business and helped establish us as a leader in our field, which we then used to catapult ourselves onto a national stage, further separating ourselves from anyone locally who we could have potentially viewed as competition. Undoubtedly, as a result of our success,

we've inadvertently "stolen" customers from other companies over the years, and I'm sure we've lost customers to other companies who consider themselves competitors. But we’re busier than ever, and I sleep well at night without worrying about undercutting or undermining colleagues. We found a void, filled it, and built upon that foundation. Because of this, we’ve always existed in a lane unique enough to the industry that I’ve never felt like we were a threat to or threatened by other companies at any level as competition.

In my observation, the most successful companies in any industry typically follow a similar strategy. Companies like Sears and Montgomery Ward began as catalog stores when travel was inconvenient for their consumers. As the world evolved, they adapted to retail. Companies like Kmart then improved customer catering methods. Walmart revolutionized the retail industry in the 1970s by mastering distribution, keeping costs low and shelves stocked more reliably than competitors. They further isolated potential competition by combining dry goods and groceries. When the aforementioned companies didn’t keep up, they ultimately met their own demise.

In the late 90s, Amazon didn't build stores to compete directly with Walmart. Instead, they changed the customer experience by offering the convenience of online shopping, filling another market void. In turn, Walmart has invested

billions to ensure they don’t meet the same fate as the companies they impacted during their rise to retail supremacy. There are countless other examples of exactly this: Blockbuster’s rise and fall, Netflix’s growth, the success of Apple, Nike, Crocs, and even leading companies in the graphics industry like Miller Decals, The Wrap Institute, and WrapFam Unleashed, the very publication you’re currently reading. These entities thrive by innovating and offering something unique that others don’t efficiently offer or scale while maintaining the same quality and value.

If you’re aiming to grow your business, be aware of what others are doing, but don't waste time trying to compete by simply copying their model, undercutting prices, or marginally improving products. Instead of focusing on beating your competition, eliminate them—not by attempting to run them out of business, but by finding a lane that no one else occupies, being the best in that lane, and staying ahead of changes in market trends that might affect the trajectory of that lane. If you do that, no one will ever be able to catch you.

Chad Munroe Owner, Get Graphic

Discover the latest in wrap industry innovations. Here, we feature cutting-edge tools, materials, and solutions designed to enhance your wrap projects. These new offerings come from leading manufacturers, boasting advanced features and improved efficiencies. Explore these novel products to stay at the forefront of wrap technology and elevate your craft. Visit their websites for detailed information and availability. Revolutionize Your Printing with

Roland DGA introduces the VersaOBJECT™ CO-i Series UV flatbed printers, capable of printing directly on substrates and objects up to 9.5 inches in height and 640 pounds in weight. Available in two models, these printers offer unparalleled versatility, precision, and ease of use for various applications.

Matthew Wolynski (World’s Tallest Wrapper) offers advice on wrapping a quarter panel.

By Ernie Macias

Irecently took a little trip to this hidden gem called Windeck in the beautiful countryside of Germany. I've taken this trip quite a few times now in the 8 years I have been working with Yellotools and I have fond memories of the first time this trip was presented to me at a trade show in Long Beach. I was visiting my girlfriend at the time who told me I just had to meet these crazy people she met that morning while she was checking exhibitors in and handing out badges.

I sit here now with that girlfriend as my wife and me being one of those crazy people! If you've ever met anyone from Yellotools at a trade show, you would have to admit we're a bit crazy right? Who asks you "What do you hate about your job?" or "Would you like to smell my

squeegee?" but as all of us Yellotoolers know, it's in the asking of a question that really helps to open your mind to a new possibility, and new possibility is really where we are coming from. To some, that's crazy, but doing the same thing over and over again and being miserable is Insanity!

A little over 20 years ago, Michael Althoff, in his admitted laziness, wanted to make his life a little easier and change the way he stores his vinyl rolls for his little sign shop. He was tired of using tape and rubber bands..."What do you hate about your job?" was born with his first innovation called The SpeedClip! It was never meant to be a mass product. Just a little improvement to make his day a little better. It turned out to change an entire industry around the world! Millions of these clips were sold in the

last 20 years and dozens of competitors jumped on the train and copied them countless times!

Over 500 game-changing products such as the world's first rubber-coated magnet, the legendary bodyguard, knife, and the Wrap-U-ezee wrapping tool for car mirrors. He also changed the way of handling self-adhesive vinyl. Over 100,000 running meters of safety rulers protect sign guys and gal's fingers all over the planet. A wooden squeegee that's 65 inches wide is crazy, right? Putting up a sign the size of a small building with a 4" piece of plastic is insanity! Our TimberMaxx squeegee changed the way we install big graphics simply by asking why.

My little trip to the hidden gem called Windeck in the beautiful countryside of Germany was to visit the Headquarters of Yellotools

and to celebrate 20 years. The celebration was not for 20 years of a successful and profitable business, but 20 years of passion for helping people to make their job easier. The success comes naturally as a result of this focus and I am happy to say that Yellotools has changed my life by teaching me by example that helping those around you and building people up only adds to your own life's happiness. Thank you

Yellotools for being the industry leader in not only tools but innovation and passion for making everyone in our industry proud to say "Signmaking is the best job in the World".

Happy 20th Anniversary, to the entire Yellotools family!

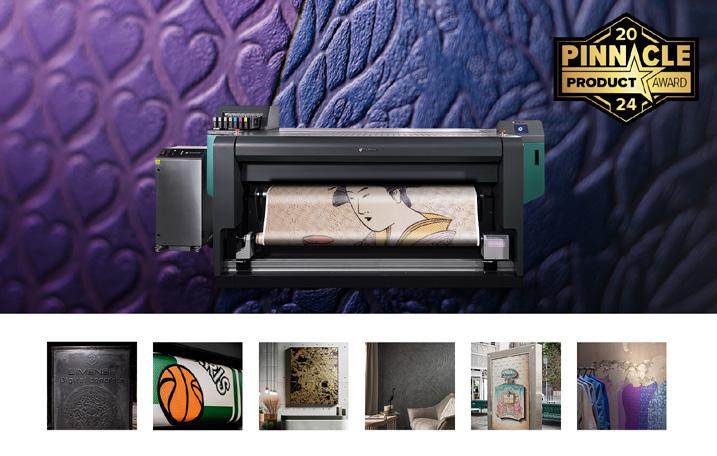

Three Roland DG Products

Win PRINTING United Alliance 2024 Pinnacle Product Awards

Irvine, Calif., June 27, 2024 – Roland DG Corporation, a leading manufacturer of wide-format inkjet printers, announces that three of its products received the PRINTING United Alliance 2024 Pinnacle Awards: the Dimensor S large-format textural printer in the “Technology” category, DIMENSE™ media for the Dimensor S in the “Media - Textile - Traditional Wallcovering” category, and the VersaOBJECT™ MO-240 benchtop UV flatbed printer in the “Tabletop Flatbed (Industrial/Small Item Decoration)” category. The winning products will be showcased at

PRINTING United Expo 2024, September 10-12, in Las Vegas. The Pinnacle Product Award competition evaluates products available for sale in 2024, judged by a panel of industry experts. Brian Brooks, Roland DGA’s manager of product management, expressed pride in the recognition of their innovative products that enhance digital decorative printing, offer new market opportunities, and maximize profitability. For more information and a full list of 2024 Pinnacle Product Award winners, visit: pinnacleawards.printing. org. Learn more about Roland DGA and their products at www.rolanddga.com

Roland DG Americas serves as the marketing, sales, distribution, and service arm for Roland DG Corporation in North and South America, specializing in wide-format inkjet printers and other advanced digital devices.

MUTOH Wins EDP Award for XpertJet 1462UF

Phoenix, AZ, June 25, 2024 – MUTOH INDUSTRIES LTD. announces that its XpertJet 1462UF flatbed UV-LED printer has won the European “EDP Award 2024” for its high image quality and productivity. The EDP Award, given by the European Digital Press Association, honors top digital printing products. This year, MUTOH received awards in the following output categories:

• XpertJet-1641SR Pro

64” Eco Solvent Printer – Roll-to-Roll Solvent/ Latex (under 80 in.)

• ValueJet-2638X 104”

Eco Solvent Printer –Roll-to-Roll Solvent/ Latex (over 80 in.)

Welcome to the Trainer Spotlight, where we highlight individual trainers. The spotlighted trainers are industry leaders with a wealth of knowledge to share, offering valuable tips, techniques, and hands-on experiences that will empower you to excel in your wrap craft. Be sure to visit their websites for more info and training dates .

Adam Sumner

WRAPIX Academy

Burbank, CA 91502

818-433-7548

Adam@wrapixacademy.com

Wrapix Academy is the only west coast 3M Authorized training and testing facility. With over 6000 square feet our training facility is dedicated only to graphic installations. We offer 11 different hands on stations to build and refine skills. Whether you be new to the industry or a seasoned professional, our training classes can be adapted to fit any need.

Jamie Mullican School Of Wrap Nashville, TN 37210 (615) 646-3277

mully@schoolofwrap.com

Located in the heart of the music city, School of Wrap is a 3M Authorized Training Facility offering 3 different certifications and training. As 3M Preferred Installer you will be recognized as among the best in the industry. Promote yourself and your business as a leader in installations and 3M will list and promote you as well. Our training will teach you the latest techniques and standards used in the industry.

What sets Budget Inks apart? Its commitment to excellence! Manufactured to the highest standards, Budget Inks UV ink is meticulously formulated for HP's Scitex FB500 and FB700 UV printers. This ultra-premium UV-based ink not only delivers exceptional durability but also ensures seamless media compatibility, empowering users to push the boundaries of their creativity with every print.

...continued from page 60

Moreover, the compatibility of the HP250 ink with the original is unparalleled. With a virtual one-to-one match, there's no need to adjust color profiles or flush the lines. Budget Inks takes pride in its USA-made ultra-premium ink, delivering outstanding quality and performance that users can rely on. Join us in embracing the future of printing. Elevate your printing endeavors with Budget Inks' compatible boxes for HP FB250 Scitex Ink and experience excellence like never before.

• ValueJet-1638UH Mark II

Visit www budget-inks com for more information

64” UV-LED Hybrid

The Quality you Trust Better Printability, Durability, and Reliability 100% Guaranteed

Printer – UV/Latex Hybrid (under $100K)

HP Scitex FB250 UV ink 3.2 L List: $284.95 Web: $274.95 � CMYK, LC, LM, includes: 3 2 L of ink

� W includes 2 L of ink

Supported Models

� HP Scitex FB500 and FB700 Printers

To provide further insights into MUTOH America’s award-winning products, Tony Simmering, MUTOH Product Manager, reflects on the success of the XpertJet-1641SR Pro and ValueJet 2638X, stating, "MUTOH eco-solvent printers have always been the superior choice for Print Service Providers seeking excellence in speed, quality and reliability," he adds, "Winning the Pinnacle Product Award for the XPJ-1641SR-P and VJ-2638X recognizes our commitment to unmatched color accuracy and print consistency on workhorse printing systems."

45 S. Public Square, Angola, IN 43615 www.budget-inks.com or

duction and superior print longevity.

• Seamless compatibility with media.

• USA-made with meticulous formulation and precision engineering.

Scitex FB250 UV ink (3.2 L)

HP 500/700 Scitex

FB250 UV Ink (3.2 L)

For more details on MUTOH’s XpertJet 1462UF, visit: www.mutoh.com. For information on the EDP Awards, visit: www.edpawards.com

Phoenix, AZ – June 26, 2024 – Budget Inks is proud to launch its new compatible boxes for HP FB250 Scitex Ink, designed to enhance printing experiences to unprecedented levels. Crafted with precision and engineered for excellence, these OEM-compatible inks promise superior performance, exceptional image quality, and unmatched durability.

Designed to elevate printing experiences to unprecedented heights, boxes promise unparalleled performance, exquisite image quality durability Crafted with precision and engineered to perfection, for HP FB250 Scitex Ink guarantee an exceptional printing journey color reproduction and superior print longevity, they redefine industry print stands out with vibrant hues and unmatched clarity.

What sets Budget Inks apart? Its commitment to excellence! Manufactured standards, Budget Inks UV ink is meticulously formulated for HP's UV printers. This ultra-premium UV-based ink not only delivers ensures seamless media compatibility, empowering users to push creativity with every print.

Supported Models:

For more information, visit www.budget-inks.com RELEASE

• Virtual one-to-one match with the original ink, no need for color profile adjustments or line flushing. "Our new HP FB250 Scitex Ink sets a new standard in print quality and reliability," said Emma Kioski, Marketing at Budget Inks. "It delivers vibrant colors, durability, and ease of use, empowering users to achieve outstanding results with every print."

Moreover, the compatibility of the HP250 ink with the original one-to-one match, there's no need to adjust color profiles or flush pride in its USA-made ultra-premium ink, delivering outstanding users can rely on. Join us in embracing the future of printing. Elevate with Budget Inks' compatible boxes for HP FB250 Scitex Ink and never before.

Compatible with HP Scitex FB500 and FB700 Printers

Visit www budget-inks com for more information.

Key Features and Benefits:

• Ultra-premium UV-based ink for HP Scitex FB500 and FB700 printers.

• Accurate color repro-

• The New Joker Wrap • Cast vs Calendared • Inside CW Wraps • The Man Behind Digital Precision