LIGNA 2023 EUROPEAN EDITION woodmizer.com Cutting edge news and stories from the sawmilling industry

© Wood-Mizer, 2023 European Headquarters WOOD-MIZER INDUSTRIES Nagórna 114, 62-600 Koło, Poland +48 63 26 26 000 shop@woodmizer.eu woodmizer.com 2 Sawmilling in the French Alps 10 Learning Woodworking with Wood-Mizer in Sweden 16 Introducing Versatile Table and Panel Circular Saws 24 Expanding Product Range with Introduction of CNC Machines 28 Sustainable Public Forest Management in Catalonia 32 Wood Furniture Making in Lower Saxony, Germany 36 Polish Entrepreneur Creates Unique Furniture from Old Wood and Artifacts of the Past 44

CONTENT

What Are Sawmill Blades Made Of?

Celebrating 40 Years of Wood-Mizer

Part of the Wood-Mizer 40th Year video documentary series, “Our Beginnings” is the 25minute short film featuring the inspiring story of Wood-Mizer - the product, company, and philosophy. Learn about the early products that led the way to the first portable sawmill, what it was like

to work for the company during the early years, and how the products and company grew globally while staying true to the founders’ original philosophy. From our beginnings to our future, thank you for beingpartoftheworldwideWood-Mizerfamily.

WATCHTHEVIDEO!

WATCHTHEVIDEO!

In 1982 two entrepreneurs, Don Laskowski and Dan Tekulve, designed and manufactured a new kind of sawmill that was a true innovation for the sawmilling industry. The first Wood-Mizer portable sawmill was engineered to be efficient, cost-effective, and simple to operate, so that anyone, anywhere could safely turn logs into lumber. Using thin-kerf sawmill blades, more boards were recovered from every log, less energy was used to operate, and fallen trees in the forest or city were able to be salvaged by individuals on-site. From Sawmill #1 to 100,000+ worldwide, thank you for Celebrating 40+ Years of Wood-Mizer.

1

Sawmilling in the French Alps Sawmilling in the French Alps

2 WOOD-MIZER NEWS 2023 SAWMILLING

3

What is the best sawmill for working in mountainous areas? Sawmilling in the Alps requires much character and determination from the local sawmillers. Towing sawmills up the mountainous roads can be a challenge, even for the most experienced sawmillers. Apart from the skills and practical knowledge about wood, they also need the proper sawmilling equipment to do their job well.

4 WOOD-MIZER NEWS 2023

Xavier Poulat from the Trièves mountain region claims the best sawmill he has ever had is the Wood-Mizer LT70 mobile sawmill with full hydraulics and a wireless control unit. He knows from experience, as his LT70 sawmill is the fifth Wood-Mizer machine he has used in his sawmilling career.

There is much need for contract sawmilling services in Monestier-de-Clermont, a small village in the Trièves mountains, a range of the French Alps. The people here need good quality timber to build houses, maintain farms, or make original furniture. They are blessed with abundant forests and prefer that the wood be sourced locally and stayinthelocaleconomy

“I have often seen beautiful hardwoods cut down and sold as firewood. It could have been used in joinery, cabinetmaking, or carpentry. As soon as I found the right sawmill for my business, I knew it was my mission to salvage the local wood and allow people around to benefit from it. Today I try to work with locally-grown trees and process them for the local community,” explains Xavier Poulat, a sawmiller with more than 26 years of experience workingwiththeWood-MizerLT70sawmill.

Xavier was born into a family of farmers with a solid connectiontothelandandforest.Hisfather’sdream was to see him work on a farm, although Xavier decided to become a sawmiller “Before I started my business, I had worked for 15 years in forestry,

5

learning from my two lumberjack brothers. In 1994 during a forestry show, I saw a mobile sawmill for the first time, and I was completely amazed at that idea. I immediately contacted the Wood-Mizer representative and signed the purchase order later thatday,”recallsXavier.

Xavier’s beginnings in the sawmilling business were full of passion and involvement, as he had no

difficulty finding customers for his services. Learning to operate a sawmill was relatively easy, although he needed to develop the proper blade maintenance technique. “Back in the day, it was challenging to sharpen and set the sawmill blade. Today, sawmill blades are more efficient, as I maintain them on my own with the Wood-Mizer sharpening equipment. Sawmillers can easily operate and adjust a Wood-Mizer sawmill, even if

6 WOOD-MIZER NEWS 2023

they know little about general mechanics,” affirms Xavier.

Xavier currently uses a Wood-Mizer LT70 and admits that of the five Wood-Mizer sawmills he has owned, the LT70 is the best. “I’ve been following the development of Wood-Mizer machines ever sincethecompanyappearedontheFrenchmarket. I try to upgrade my sawmills every 4-5 years as new

improvements appear in the machines. I started with a gasoline LT40 sawmill, then I changed to a diesel LT40 sawmill, and for the past few years, it has been only the LT70 sawmill. This is my third LT70sawmillinarow,”saysXavier.

The LT70 mobile sawmill is a perfect choice for sawmillers who deal with a high capacity of wood and need a quick production time. Xavier’s LT70

A Mobile Contract Sawmilling in Mountains

A Mobile Contract Sawmilling in Mountains

7

WatchtheSawmiller’s Interview

sawmill is a mobile machine, allowing him to travel around for contract sawmilling services. Now he can’t imagine work without the hydraulic functions of the sawmill bed, which include vertical side supports, a dual-rod central log clamp, and chain log turners. To extend the sawmill blade’s lifetime, he also uses a debarker. Above all, Xavier appreciates the wireless controller for the convenient operation of the machine, regardless of the weather conditions. “Compared to my previous LT40 sawmill, the LT70 works faster and offers a higher sawing capacity. I can now rotate large or crooked logs with the fully hydraulic bed functions. In addition, I have all the controls linked to the wireless operator unit, with which I can walk around the sawmill and find the best position for myself.All these LT70 functions have improved my workstyle," Xavier points out.

Xavier enjoys working for local customers within a 100 km radius, supplying them with locally sourced timber products. He is recognized for his flexibility,

as he can tow his LT70 mobile sawmill and do all sorts of sawmilling wonders. “People appreciate that I can come to their site with the machine and do all the work for them. I can supply them with boards, cants, and roof beams. In my career, I have sawn all possible kinds of wood, including softwood, hardwood, poplar, chestnut, etc. I have never complained about lack of work – I process around 1000cubicmetersofwoodayear,” heshares.

“I work with self-builders who know how to organize the work to make it efficient. My customers often ask me for 6,5 m wide timber frames used in house construction, but I would also make even larger frames for them. With my first LT70 sawmill on an 8,5-m-longbed,Iusedtogotovariousskiresortsfor sawmilling contracts, facing the challenge of towing a nearly 3-ton machine with low clearance on muddy, mountainous trails. These days I work only on a 6,5-m-long sawmill bed which is a good compromisebetweencapacityandportability.”

8 WOOD-MIZER NEWS 2023

9

WOODWORKING HowaFamily Woodworking BusinessOperates inSweden WatchtheSawmiller’s Interview 10 WOOD-MIZER NEWS 2023

Learning Woodworking with Wood-Mizer in Sweden

11

"The best thing about working with wood is that you never get fully trained. You always have some issues even if you have worked for a long time. Let's say you're making a special profile for your customer, but you never know if it's going to come out good. When you get what you wanted, it's awonderfulfeeling," saysDavid.

Located in Torsåker, a small village in the central Sweden province of Gästrikland, is David’s company, “Woodab”. It is a small family run business with only two workers, a father and a son, who are open to exploring more about woodworking. "My dad operates the LT70 sawmill, and I work with the HR115 horizontal resaw and the four-sided MP360 planer/moulder," says David. "With the LT70, we mill logs and prepare the material for further processing on the HR115 and MP360. We produce stock of lumber to make customers'everywoodenwishcometrue."

David owes his passion for wood to his father, Lars, who used to operate a Wood-Mizer LT40 sawmill. Lars is an experienced sawmiller who has been working in the wood industry for more than 25 years. Now he enjoys working with his LT70 sawmill,appreciatingnature.

Lars upgraded his old LT40 sawmill to the larger LT70 sawmill only a few years ago. He shared that with the new LT70 sawmill, his work gathered more speed and efficiency, with operator comfort and cutting precision. The previous LT40 was a reliable sawmill that allowed Lars to run a sawmilling business for a long time. "My father bought the LT40 for use in our forest. However, he was getting somanyrequeststhateventually,hedecidedtouse it commercially and sell lumber to local customers. With the LT40, he had a full-time job," remembers David. "My dad decided to change to the LT70

because of the growing demand for lumber. The LT70 sawmill has hydraulic bed functions, an automatic board thickness control and offers more power and speed to produce more lumber for customers.Thisupgradewasnecessary."

For David, the adventure with wood began in 1998 when he got his first job as an operator of a large planing machine. In 2019 he decided to open up his own woodworking company to line up with his father's sawmilling business. "I wanted to complete mydad'sproductionwiththeproductsIcanmakeon my HR115 and MP360 machines," says David.

12 WOOD-MIZER NEWS 2023

However, the first months of his own business didn't come easy for David . "The biggest thing in starting my company was to leap from my old life with a steady paycheck into the busy world of running my own company. The transition was hard for me," says David. "Today, it's much easier to handle the business as I have learned how to use the potential ofWood-Mizermachines."

When asked which machine plays the crucial role in the business, David answers undoubtedly"Definitely the most important is the LT70! Speed, strength, precision, the comfort of use with the

computerized measurement system, easy to handle - this matches our business needs." Once the lumber is ready, David uses the HR115 resaw to cut boards . "I chose that machine to save time for myfathersothathedoesn'thavetofocusonmaking cants and boards with the sawmill. He can focus only on milling large logs and making larger-size lumber for further resawing with the HR115. It increases the production efficiency in a great way," explains David. In the last stage of production, David uses the MP360 planer/moulder to produce productsforthecustomers.

13

In Sweden, the wood-processing industry has a leading position in the economy. Forests cover two-thirds of the area, and it's been a long tradition for the Swedes to work with wood. A foreigner traveling across the country can easily observe houses and buildings made of wood housed beautifully in the forest or on the lake shores.These buildings need construction materials that are sustainable, easily accessible, and simple to work with."Apartfromordersforconstructionlumber,our customers ask me to prepare lumber for the restoration of their houses and buildings. They need customized boards and panels, with specific profilessothattheycangetthesamestyleto repair their original houses," explains David. "The restoration business is big. People don't want to waste or throw out old wood; they want to have their houses intact. With the MP360, I can offer every possible profile for my customers. I'm glad that the demand for such custom works is growing all the

time."Davidandhisfatherrealize howimportantitis to develop good relationships in business, as they cooperate with their customers. They also rely on the service from their local Wood-Mizer dealer. "It's excellent service and support. It's good we have Kjell Larsson (a local dealer) just a phone call away because when you operate a sawmill, there's always something that you could use - spare parts, oil, blades, or technical advice. Fast service and communication are essential," explainsDavid.

David enjoys working and learning about wood every day, and keeps thinking about the future of his workshop. "I'd like to upgrade my planer/moulder to the MP365, the one with five cutting heads, to be able to make even more complex profiles with only one pass through the machine. I'm figuring that with the MP365, we'd be able to make more complex ordersforourcustomers!"hesays.

14 WOOD-MIZER NEWS 2023

15

Wood-Mizer Sawmills Drive Circular Economy in Catalonian Villages WatchtheSawmillers’Interview SUSTAINABLE FORESTRY 16 WOOD-MIZER NEWS 2023

Sustainable Public Forest Management in Catalonia

By Juan Manuel Miranda, MADERA-SOSTENIBLE

The MMBB project that joined several urban communities in Catalonia is successfully developing a circular economy for the efficient and wastefree use of wood from public forests.

17

MMBB (Mancomunidad de Municipis Bergedans per le Biomassa) is a project of eight town councils and the MinistryofAgricultureoftheCatalonianGovernmentthat work together with the purpose of creating "sustainable managementofourpublicforests,"saysMoisésMasanas López,mayorofSaldes.Theprojectisastrikingexample of cooperation between different size towns (for example, Berga has 17,000 inhabitants, while Gisclareni hasonly30).

18 WOOD-MIZER NEWS 2023

SustainableforestmanagementinCatalonia

The project was born in 2012 when seven town councils signed the first agreement. By the end of 2019 the Ministry of Agriculture and another town councilinSolsonèshadenteredtheMMBB.

"We have several projects," says Moisés Masanas. "First, we decided to create a woodchip market for fourteen boilers that feed 32 objects in our area. This project allows us to use wood waste that would otherwisehavezerovalue."

The first step was the construction of boiler plants, includingaboilertoprovidethermalkilowattsforthe industrialzoneinBerga.

"Later, we started a project to increase the added value of wood. We believe that if we have a product to manage, but the product has a low market value, it hurts us.Therefore, we need to make sure that the product's value is increasing. Plus, we have quality wood that we don't want to use to produce cheap products. With the Wood-Mizer sawmill, we are solving this problem and bringing a new, highervalueproducttothemarket."

Increasingthevalueofwood

"We installed the Wood-Mizer sawmill in Saldes," says Luis Lluis Campmajò Puig, Mayor of Gósol. "We cut logs, and for those who need it, we have timber, boards, planks… good wood for everything

19

from the table to the roof, from a beam to whole houserenovations."

"The sawmill works great," says Lluis Campmajò. "We need to use this to add value to our timber. I am thinking about making wooden houses in our region. We will use the wood from our forests, cut it, dryitandbuildhouses."

"We source the highest quality logs from the forest and produce boards for carpentry," says Anna Jordà,Wood-MizersawmilloperatoratMMBB.

"With the help of the Wood-Mizer LT40 sawmill, we make boards with the required thickness. Then another machine, Wood-Mizer EG300 edger, cuts to the width and a third one cuts to the length. This way,wegetproductswiththeproperdimensions."

The Wood-Mizer LT40 sawmill is operated remotely from the control station, where the operator controls all parameters. Here the operator sets the required board thickness, and then the saw head is automaticallypositionedintheproperplace.

MMBB produces boards in standard sizes: 27 x 155 millimeters wide; length depends on the log length. Theycurrentlymillsixorsevenlogsaday.

"The LT40 machine is quite easy to operate," says Anna Jordà. "After you train and make a few cuts, you see how it works, you understand everything, and it becomes easy for you. It does not require much effort because it does almost everything itself. The LT40 sawmill lifts log from the ground, loads it onto the bed, cuts it, returns the boards, and you havetostackthem."

20 WOOD-MIZER NEWS 2023

"The LT40 machine is safe. The saw head moves, but the operator does not walk beside it. You control it from a remote panel; there is no danger. And changing the band blade is also easy. The machine does not require hard maintenance."

Developingacirculareconomy

MMBB aims to develop a circular economy and create jobs in their villages. Many people from this region work for MMBB. There are currently 36 people on staff. "We are not worried about depopulation because we are already depopulated. But we can do something important to repopulate these mountain villages. We need real jobs with fulltime, not seasonal employment." They also came up with another idea on how to improve the management of the power plant. "We are now selling thermal kilowatts, but we have fluctuations in consumption. If we produce electric kilowatts, first of all for our villages, and then sell to the network, this will make us more flexible in management," says

Lluis Campmajò

They wouldn't achieve these results if each town council worked alone, only putting their own timber for auction. The number of workers would be less because there would be seasonality.

Now they can achieve bigger profit based on economy of scale, adding value to the product, andbeingmoreefficient.

Moisés Masanas López, Mayor of Saldes

Lluis Campmajò Puig, Mayor of Gósol

Anna Jordà, Wood-Mizer sawmill operator

21

"We must continue to improve where we are not yet sufficiently effective and continue to createjobsthatweneedalot."

"I value the LT40 sawmill mostly for the ease and comfort of operation. For a woman working daily on this machine, it’s important to use the hydraulics for convenient log-loading, turning, leveling, and clamping it securely on the bed. My LT40 sawmill’s control panel is equipped with automatic thickness control. I no longer have to count and remember board thickness. The Setworks recalculates these values automatically, and each time the sawhead returns to its initial position, the device sets it to the desired thickness,” says Sandra Eule, a selfsufficient sawmillerfromThuringia,Germany.

22 WOOD-MIZER NEWS 2023

"The LT40 is a fantastic and useful machine. It works well in every weather. It does a great job contract sawmilling in the mountains. It is simple and easy to operate. I can transport it to the sawmilling site . I don’t have to carry heavy logs to the stationary sawmill anymore. I enjoy working on my LT40 sawmill,” says David Jones, Wood-Mizer LT40sawmillownerfromScotland.

"We fell in love with that machine the moment we saw it at the trade show presentation. With the mobile LT40 sawmill, we can get to the place appointed by the customer and work on site. Once we arrive, we warm up the engine, and after a few minutes,we’rereadytostartmakingtheboards.We managed to eliminate the transportation problem and save money. We don’t need a farm tractor or a truck to carry logs from the forest and deliver boards to the customer”, explains the Geronazzo brothers from Italy, who run contract sawmilling in hard-to-accessregionsoftheAlps.

23

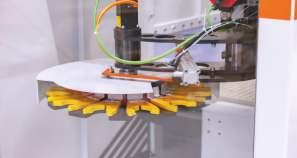

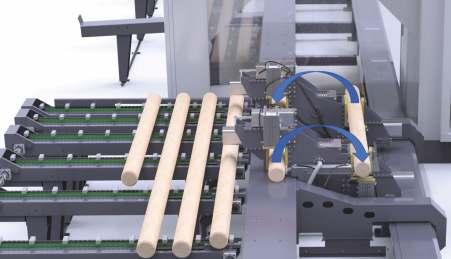

Wood-Mizer Expands Product Range with Introduction of CNC Machines

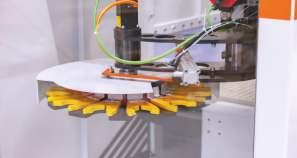

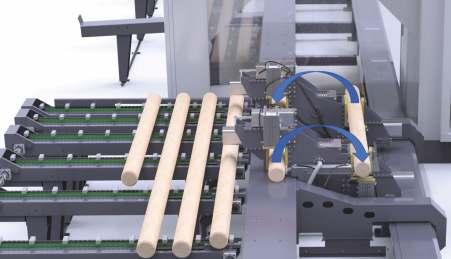

Wood-Mizer has developed an advanced line of CNC (computer numerically controlled) machines to provide maximum performance, precision, and fully automatic processing of wood, plastic, composites, and light alloys.

The Wood-Mizer CNC machines are designed as highly flexible machining centers that can be equipped with optional add-ons and functionalities, including a range of CNC aggregates, CAM software compatibility, an oscillating knife head, extra vacuum pads and plates, protective gates/light curtains around the machine, lasers for better materialpositioning,andmore.

The machining centers are manufactured from the highest-grade componentscombinedwithindustry-leadingnumericalcontrollers. "Throughoutourhistory,Wood-Mizerhasbeencommittedtoproviding

CNC MACHINES 24 WOOD-MIZER NEWS 2023

the best quality equipment to process logs into finished wood products,” said Magnus Fransson, Wood-Mizer CNC Machines Product Manager. “The design of the Wood-Mizer CNC Machine product line has been proven by customers worldwide for more than a decade, and are now backed by the high-quality service and support networkcustomersexpectfromWood-Mizer.”

The CNC5003 CNC Machine is the first product in the series, designed for the automated processing of wood, plastic, composites, and light alloys in arts and crafts workshops, as well as in medium-tolarge size companies producing sophisticated components for buildingkitchens,furniture,houses,andmore.

The CNC5003 is based on a gantry design with a dual drive for stability and precision, a carousel 12-position automatic tool changer mounted to the gantry for fast tool changes, and a multi-zone vacuum nestingtableforsecureandflexiblematerialpositioning.

The machining center has a powerful electro spindle assisted by digital servos with a high resolution that increases accuracy and minimizesvibrations.

The Wood-Mizer CNC machine range includes:

• CNC5003, 3 and 4 axis machine center with vacuum table

• CNC5005, 5 axis machine center with vacuum table

• CNC6003, large and heavyduty 3 and 4 axis machine center with vacuum table

• CNC6005, large and heavyduty 5 axis machine center with vacuum table

• CNC7000, beam and log machine center, 8 axis with automated material handling

• CNC8000, heavy-duty beam and log machine center, 6 axis with automated material handling

25

26 WOOD-MIZER NEWS 2023

All operations are supervised from a movable operator panel with the renowned Fanuc controller for advanced functionality and lifetime parts availability. In addition, the operator panel offers an interface for PC and CAMsoftwareandabuilt-inservercontroller.

The fast and precise 3-axis moving head operates across a sizeable multizone vacuum table, which allows for processing flat material with maximumdimensionsof3000x1500mm.

The table is built in six zones with 216 individual vacuum points to provide a wide variety of configurations.The spindle is equipped with a reliable and highly efficient dust extraction system to maintain a clean work environment.

“It is possible to increase the productivity of the CNC5003 with integrated material handling equipment. The machine can be expanded with a modular system for loading and unloading material, transforming it into a machining cell capable of processing complete batches of material without employing the operator’s supervision,” explains Magnus Fransson.

The CNC5003 and other upcoming CNC machines from this line complement the Wood-Mizer equipment range by adding more precision and automation to the finishing process of wood products. Please contact Magnus Fransson, Wood-Mizer CNC Machines Product Manager, for moreinformationandquotesatmfransson@woodmizer.eu

Specifications:

• Operating area –3080 x 1540 x 200 mm

• Material dimensions: 3000 x 1500 mm

• Speed (x/y/z) –60 x 30 x 15 m/min

• Spindle motor with tool change –11 kW at 24,000 rpm

• Tool change – 12-tool rotating carousel

• Vacuum pump –4 kW (or 5.5 kW)

• Vacuum pump capacity –3 126 m/h at 0.9 bar

CNC5003 CNC Machine

27

Wood-Mizer

IntroducesVersatileTable PanelCircularSaws and

In response to a growing demand in the industry for advanced carpentry tools, Wood-Mizer is expanding its Woodworkinglinewithahighlyfunctionaltablesaw,the Wood-Mizer MS500, and a robust advanced panel saw, the MS750. These professional tools are the product of cooperation between European engineers and experienced carpenters. They have been developed to match the everyday needs of small and medium woodworkingshops.

TABLE & PANEL SAWS

28 WOOD-MIZER NEWS 2023

29

The Wood-Mizer MS500 table saw features an efficient cutting unit shielded in a cast iron body, a scoring blade, and a sliding table built on guide rollers, as an alternative for larger panel saws with full-size sliding aluminum tables. The MS500 is a compact machine with an easy adjustment of cutting parameters, in which the main blade’s height and angle are adjusted by hand wheels featuring gauges for precise reading. The exact cutting width and length are read through the analog indicators with a magnifying glass along the parallel and perpendicular guide rollers. Replacing them with electronic readers for ultra-precise measurementsupto0,1mmispossible.

The MS500 table saw has been fitted with a quality sliding mechanism working in parallel and perpendicular directions for easy positioning of the material on the worktable and efficient cutting. The assistance table increases stability while working with demanding material. The undercut blade, also known as a "scorer", is a solution borrowed

from full-size panel saws to allow for neat and precisematerialcutting.

To replace the main circular blade or remove the scorer, unscrew the top cover and open the small magnet plate to access the quick installation system of the main blade.The scoring blade’s height can be adjusted and the blade can be conveniently lowered underneathifitisnotneeded.

In the heart of the MS500, there is a circular blade with a maximum 400 mm diameter working at either 3500 or 4500 rpm, which can be adjusted manually by switching the driving belt between the pulleys at the spindle. For cutting an MDF board, it is recommended to work at 3500 rpm and to use the scoring blade. It is recommended to work at 4500 rpm and without undercutting when using solid wood.

The MS500 is ideal for cutting medium-size fragments of a furniture board; however, for cutting full-size boards, it is recommended to use a panel saw,suchastheWood-MizerMS750.

30 WOOD-MIZER NEWS 2023

Wood-MizerMS500TableSaw

Wood-MizerMS750PanelSaw

The MS750 panel saw is built around an integrated cast-iron cutting unit with a 6kW main motor and aseparate0,75kWmotorforundercutting.

Aconvenient aluminum sliding table with a length of 3010 mm and a maximum width of longitudinal cutting of 1300 mm allows for all standard operations in cutting full-size panels. The cutting unit is installed on two cast-iron slides in the machine’s steel body, allowing for accurate cutting height and angle adjustment. The construction of the cutting unit is based on a short main spindle and a belt transmission. Replacing the circular saw blade with a maximum diameter of 400 mm is quick and convenient due to the toolless mounting system"Rapid".

The MS750 panel saw with a solid steel body is highly rigid and resistant to vibration and deformation. The sliding table system is fixed permanently to the machine’s body with four nabs allowing for stable operation and geometrical cutting. The cast-iron worktable is mounted on four supports for easy adjustment against the aluminum

sliding table. At the bottom of the steel body is a mechanism for leveling the machine and installing theanchors.

CastironforgedinEuropeisusedformanufacturing the Wood-Mizer MS500 and MS750. It is an ideal material for building worktables, cutting units, and woodworking machinery. It increases the construction's stability and rigidity, and resistance to vibrationsduringoperation.

The efficient removal of sawdust and woodchips is possible with the main 125 mm-wide outlet located directly at the cutting unit and the additional 80 mmwide outlet on the blade cover arm. For the best performance of the MS500 and MS750 machines, it is recommended to couple it with one of the WoodMizerMESdustremovalsystems.

To effectively and efficiently cut all sorts of furniture boards, wood boards, or solid wood, we recommend choosing a proper cutting blade from the Wood-Mizer TOOLS catalog. A wide range of circular saws and scoring blades perfectly supplement the Woodworking Machines developed formakingreadyproductsfromwood.

31

Wood Furniture Making in Lower Saxony, Germany

By Friedrich Hallweg

By Friedrich Hallweg

WIDE SAWMILLING 32 WOOD-MIZER NEWS 2023

Large logs are often inexpensive but more difficult to handle; only some woodworkers can process them. However, these difficulties did not stop Jan Narten, a young woodworker from Germany who cuts large-diameter logs and makes unique wooden furniture.

33

Right at the entrance to Jan Narten's carpentry shop in the small, well-maintained village of Stemmen in the district of Rotenburg an der Wümme, there is an imposing stack of sturdy oak boards. Jan Narten, welcomes his customers with a friendly smile and his customers receive something more than just wood products from his company

Jan realized that only a few people were interested in large logs Their transportation is too complicated, and further sawing is too laborious. However, the idea of processing logs up to 140 cm in diameter weighing several tons has two main advantages: such logs are relatively cheap to obtain and can be made into exceptional valueaddedproducts.

Butlet'sstartfromthebeginning.

Afterhisstudies,atage20,Janstartedworkingasa subcontractor for various companies, mainly in assembly work. He learned a lot during this time. But over the years, the idea of starting his own businessledhimtowoodworkinginitsfinestform. Aschool friend now working as a forester once told Jan, "You know, if I build a house for myself, you will make me a kitchen out of alder." It was an ordinary conversation between two friends over a beer. Still, as the topic kept coming up, one day, the friends decided it's time! They decided to make a kitchen from alder wood, which they would harvest themselves.

The first step was to find a good sawmill. The solution came from a YouTube video of a WoodMizerLT20bandsawmill.

enthusiasm, began to produce lumber for furniture making in his company. A robust loader now moves heavy logs. The freshly cut wood is first air-dried, placed on four large low-lying cargo trailers, then connected to a biogas wood kiln for final drying. In his company, Jan manufactures any piece of custom-made furniture, from a TV cabinet to living room furniture or kitchen cabinets. His clients are fully involved in the design Every detail is discussed. The customer determines the style, wood species and the boards from which the cabinet, table, or bed will be made. They can even use wood from their own property. Jan’s enthusiasm is infectious, and the relationship between the customer, carpenter, and product develops accordingly

Until recently, large, durable tabletops with natural bark-covered edges were still painstakingly carved from mighty trunks of trees.After drying for 26 hours and several days of processing, they were sanded to perfect smoothness by touch using a chainsaw and a parquet sander. But since 2021, this work has been carried out at Jan’s new sawmill. This is the Wood-Mizer LX250, which can cut thick boards up to 140 cm wide. Another machine, the Wood-Mizer MB200 SlabMizer, flattens and smooths large wood surfaces up to 142 cm wide. Now the old loader stacks large logs on the low bed of the LX250 sawmill with a wide-throat sawhead moving along tworails.TheLX250sawsbiglogsintocleanboards easily. The operator practically uses four fingers to control the joystick and potentiometer The surface is then finished in one operation using the SlabMizer

In2015,JaninstalledastationaryLT20sawmillwith an electric engine in his shop and, with growing

The final touches take quite a bit of time. On company premises, Jan knows the origin of every plank.At the customer's request, the corresponding information can be burned with a laser on furniture

34 WOOD-MIZER NEWS 2023

35

36 WOOD-MIZER NEWS 2023

made from this wood. With a smartphone, customers can see where their bed, table, or kitchen was once a tree.Customerslovethisextraservice.

Another essential raw material is reclaimed “wood waste” from demolishing half-timbered houses, ancient wooden bridges, and other old buildings. The LT20 sawmill, with its inexpensive, thin-kerf narrow band blades, produces more boards and less sawdust than conventional chainsaws or wide circular blades, has also proved its worth. Jan can be compared to a good cook in handling valuable wood waste. Everything goes to use!Almost all scraps and sawdust are recycled. They can be found in a unique rustic mirror frame or an epoxy resin countertop. It is a complex job that does not forgive many mistakes and only receives a high purchase price if executed perfectly At the same time, Jan carefully ensures that the wood does not entirely drown in resin but remains tangible in its structure providing an exceptional and pleasanteffect.

ForJan,atableisnotjustatablebutapieceoffurniture that brings people to eat, play, and spend time together This philosophy runs through all his work. The bedrooms he crafts are an oasis of well-being made from oak, alder, and cedar The beds are entirely made of wood and do not contain metal, right down to the frame inserts - no screws, rails, or clamps Therefore, aesthetics and quality are always the focus of his attention The company's showrooms are located in the courtyard and sometimes even in Jan’s house.

Previously,thisseemedlikeadis-advantage;however, it has become a hallmark of his success today. This openness, creative versatility, and love for his projects generate the trust distinguishing Jan’s carpentry workshop from other companies. And that also explainshiscompany'sslogan:"Morethanwood."

37

WOODWORKING 38 WOOD-MIZER NEWS 2023

Polish Entrepreneur Creates Unique Furniture from Old Wood and Artifacts of the Past

39

"Nature Makes Us Happy" – is a guiding thought for Kamil Broda, an entrepreneur from SkarżyskoKamienna, Poland. Kamil has worked in financial institutions for 20 years until he decided to make his woodworking dreams finally come true. His company OLD Mountains was founded to create furniture and everyday items from wood waste, joining it with steel, concrete, glass, and more –allowing Kamil to share his philosophy with his customers.

OLD Mountains is a small family company located in the suburbs, bordered with forests and fields, where it's fairly easy to get access to wood. Kamil's workshop is filled with professional equipment for wood processing, mainly Wood-Mizer machines, and the stock of unique products awaiting customers.

"Our woodworking company deals with the design and production of state-of-the-art furniture and everyday objects, in which we combine old wood with concrete, steel, and glass. By joining such materials, we provide our customers with goodlooking and original products. The wood that we source for production is waste material, and it comes from the demolition of farm buildings or the clearing of old fruit orchards. The steel is recycled

from wrecked machines," explains Kamil. "We'd like our products to remind us about past times, but on the other hand, we want to make them pleasant to lookatandaspracticalaspossible."

Acommon feature of all OLD Mountains’ products is promotingtheartof"lifecomposure,"meaninglifein agreement with nature, the joy of experiencing the order and tidiness found in the minimalism of the surrounding everyday objects. Such a life approach can help us achieve internal composure, safety, and happiness The message promoted by OLD Mountains is directly connected with philosophical streams such as wabi-sabi, hygge, and lagom, which oppose chasing materialism while favoring moderation, functionality, and appreciation of what we have around us These are precisely the products that Kamil makes in his workshop. "Our products help people find the way to real happiness. They strengthen the relations among people, and with our products, people feel easy and natural. Customers appreciate that our products are ‘just fine’ - which means they are simple, comfortable, and manufactured concerning nature," Kamil shares.

Kamil Broda's company has only three workers, so the division of roles is clear. Using his professional

40 WOOD-MIZER NEWS 2023

41

experience, Kamil deals with new product designs, marketing activities, and searches for new paths of expansion for his business. Two other team members, Kamil’s older brother and Kamil's son, areoperationalworkersdealingwiththeproduction. "Working with wood has been my dream for a long time. I have always admired my brother Darek's talent for making birds feeders, wooden gift cases, or garden gazebos, and now the time has come when we can join our efforts working together with wood," saysKamil.

The first months of the business activity were not easy for the family because they treated their work too much like a hobby "We wanted to become independent, and we wanted to raise productivity in our workshop. That's why we decided to invest in professional machines for wood processing from Wood-Mizer," said Kamil. The first machine which OLD Mountains ordered was a Wood-Mizer MP260 four-sided planer/moulder, which allowed the operator to significantly speed up the process of wood preparation. "For us, it's important to be able to prepare the material quickly, precisely, and consistently. Otherwise, it won't be possible for us to offer our clients attractive products in a large quantity, and with a short lead-time," explains Kamil.

The MP260 planer/moulder combines several woodworking operations in one unit, resulting in saving workshop space, lower maintenance costs, and increased efficiency. "It's a reliable machine, easy to operate and adjust, with which you can maintainhighconsistencyofproduction.

“Before ordering my MP260 planer/moulder, I did research online. I found out that it had been offered to the Swedish market for years, so its construction had already been tested by Scandinavian

customers. Currently, it's offered by Wood-Mizer, located in Koło, Poland, so for a customer like me, it's easy to get in touch with them, I can visit the factory and see the machines myself, or I can make an appointment with the technicians. Today, seamless cooperation is vital in building business relations,"Kamilpointsout.

OLD Mountains also purchased the LT15CLASSIC mobile sawmill and the MP100 planer. These machines allow for the preparation of material at the initial stage of production. “With the LT15 Mobile, we can mill the logs right at the spot and shape our products the way we want. For example, while

42 WOOD-MIZER NEWS 2023

clearing the old orchard from unwanted trees, we can decide the shape of our future products," Kamil says. "My LT15 features a layout of bed crosssections and side supports capable of holding short logs on the bed. This is a perfect solution for cutting the smaller, everyday sized items. The sawmill has a robust, strengthened bed frame that remains stiff during operation and during transportation. The MP100 planer is an ideal solution for the primary planing of wet wood on the sawmill bed. It can also be equipped with profile knives and used for the preparation of beams for house construction. In our case, we use the MP100 for building the original partitionwalls."

The cooperation with Wood-Mizer helped this family company expand in two significant ways. First, using the MP260 helped increase the efficiency of material preparation while retaining precision and consistency. Secondly, the LT15CLASSIC sawmill with the MP100 planer allowed them to take control of the material preparation right at the stage of milling the log. Kamil Broda admits that maintaining good business relations with Wood-Mizer is easy because the company cares a lot about good customer service. Anyone purchasing from OLD Mountains not only notices the esthetic, functional products but the philosophy that the company lives by,“howtolivesmartlyandreasonable”.

43

Polish Entrepreneur Creates Furniture from Wood Waste, Joining it with Steel, Concrete, and Glass.

WatchtheSawmiller’s Interview

What Are Sawmill Blades Made Of?

Carbon steel and high-alloy steel are the most common materials used to make sawmill blades for portable sawmills, industrial sawmills, and resaws. The type of material is important to consider when selecting sawmill blades. In addition to carbon and high-alloy steel sawmill blades, Wood-Mizer offers additional sawmill blade materials based on alloy,hardness,andmore.

DoubleHARDHigh-AlloyBandSawmillBlade ALLPURPOSE

Manufactured from tough, non-chip high-alloy steel material with induction hardened teeth, DoubleHARD is recommended for all-purpose sawing of softwoods, hardwoods, knotty woods, and frozen woods. Compared to standard carbon steel sawmill blades, DoubleHARD features double thebladelifeforincreaseddurability.

MaxFLEXPremiumBandSawmillBlade LONGERSAWINGLIFE

MaxFLEX is a premium quality all-purpose blade for sawing and resawing environments where ultimate flex life is necessary. With “premium highalloy” steel for maximum flexibility and sawing life, MaxFLEX blades are primarily used in portable and industrial sawmill operations. Still, you can also use theminresawingapplications.

SilverTIPCarbonBandSawmillBlade BESTFORRESAW

Manufactured from the most common and affordable carbon steel material, SilverTIP is recommended for economical sawing on portable and industrial sawmills or for high-volume sawmills and resaws. Compared to most standard carbon steel sawmill blades, SilverTIP is made with a higher carbon content with high durability steel for betterperformance.

BiMETALIndustrialBandSawmillBlade SPECIALTY

Manufactured from a two-piece, high-alloy steel body with high-speed steel (HSS) tooth tip, BiMETAL is recommended for specialty sawing of reclaimed beams or kiln dried lumber and in industrial sawmilling environments. Compared to standard carbon steel sawmill blades, BiMETAL features up to double the sharp life for increased runtime.

StartCUTCarbonBandSawmillBlade MOSTAFFORDABLE

Wood-Mizer introduced the StartCUT series as their most affordable sawmill blades for sawmills and resaws in the industry. StartCUT blades are made from carbon steel with induction hardened teeth that are set and sharpened. For those sawmillers who prioritize price, the StartCUT is the right choice as an inexpensive blade from the world-knownmanufacturer.

BLADE CORNER

1 1

1

44 WOOD-MIZER NEWS 2023

By Friedrich Hallweg

By Friedrich Hallweg