Measurement and control of wall thickness, diameter, eccentricity and ovality

Up to 3 layers of different materials

“One Button Operation” – no calibration, no parameters

Clear visualization of product parameters and data logging

Individual solutions for specific applications, e.g., THHN wires or foamed cables

COPPERWORKS BY THE NUMBERS

COPPERWORKS manufactures enough finished copper product each year to wire approximately:

2.22 MILLION AVERAGE-SIZED HOMES

2.36 MILLION BATTERY ELECTRIC VEHICLES

3.46 MILLION AVERAGE-SIZED APARTMENTS

87,000

Every day, COPPERWORKS is trusted to make copper rod that supplies the needs of the automotive, construction, energy, electronics, and other industries. Annually, we manufacture more than 430 million pounds of high-conductivity copper rod that becomes the wire vital for a wide range of products. By offering more choices with Advantage, Elemental, and our proven lowest-carbon-footprint Infinity Copper Rod and Wire, we meet the growing demands of copper wire manufacturing and lead the way in sustainability.

Call us to learn more about the infinite possibilities COPPERWORKS can offer you. THIS IS WHERE COPPER WORKS, SUSTAINABLY, FOR EVERYONE.

3-MEGAWATT ON-SHORE WIND TURBINES 260.748.6565 | COPPERWORKS.COM 1640 South Ryan Road, New Haven, IN 46774

An economical way to remove copper dust, excessive oil lubricant, dirt, and dust from primary wire or strand

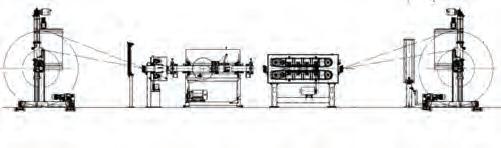

•Stranding & Cabling Lines

•Take-Ups / Pay-Offs / Coilers

•Fully Automatic Re-Wind Lines

•Complete Extrusion Lines

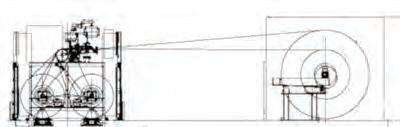

WIRE RANGE: Up to 0.098 in. (2.5 mm.) diameter

MAX. F/M: Approx. 8000 ft./m.

MATERIALS: Ferrous or nonferrous material / tinned, bare, or plated

FLOOR SPACE: 18” x 27”

•Reduce Spark Faults

•Improve Insulation Bond

•Easy to Install

•Improve Insulation Concentricity

•Increase Pre-Heater Sheave Life

•Environmentally Friendly

•Ultrasonic, Wet Blast, and Various Mechanical Cleaning Systems

•Drum Packers, Air Wipes, and Taping Lines

TYPICAL WIRE SIZE:

15 mm. (0.6 in.)

inlet down to .5 mm. (0.02 in.)

outlet

NUMBER OF BLOCKS:

Up to 15 blocks

LINE SPEED: 30 m./s. (6000 f/min.)

CAPSTAN COATING:

Tungsten Carbide or ceramic coating

•Forming / Welding / Sizing Lines

•Wire Drawing and Shaving

•Semi and Auto Re-Spooling

Tel: 914-834-8865 | Fax: 914-834-8903 info@cableconsultantscorp.com

914-240-6033 mmcclaugherty@cableconsultantscorp.com

A new site, strong educational program and effective Supplier Exhibition™ made for a very good event.

Organizers report that the Nov. 4-6 staging at the Pragati Maidan in New Delhi was its best ever.

If just about every new employee can become an owner ... is that really a good thing? This report offers the perspective of three ESOP companies, and more.

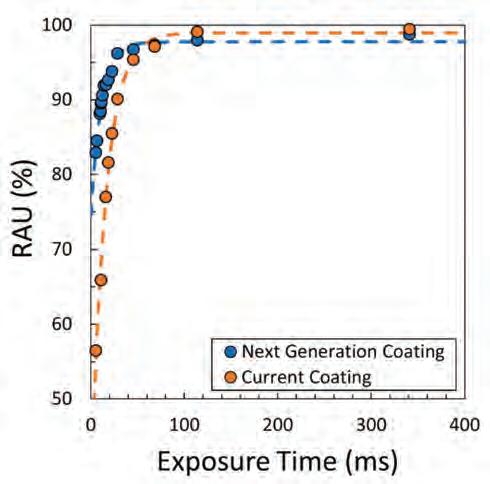

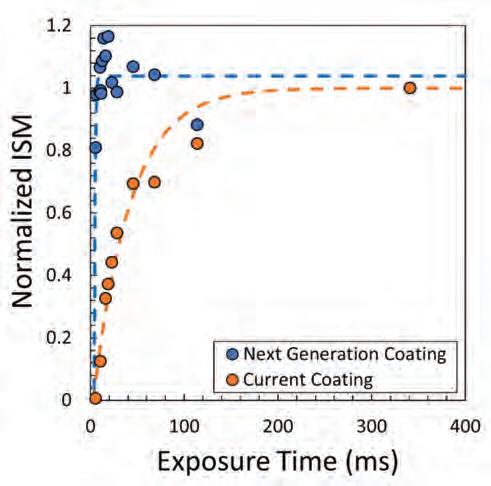

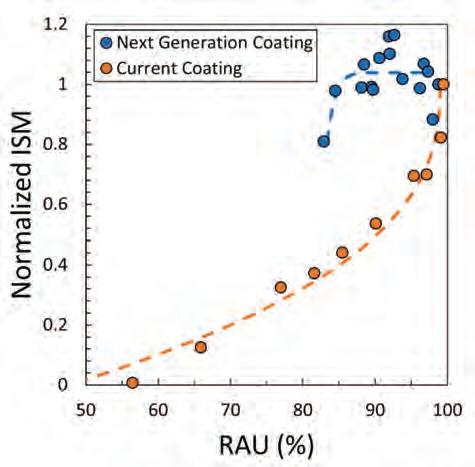

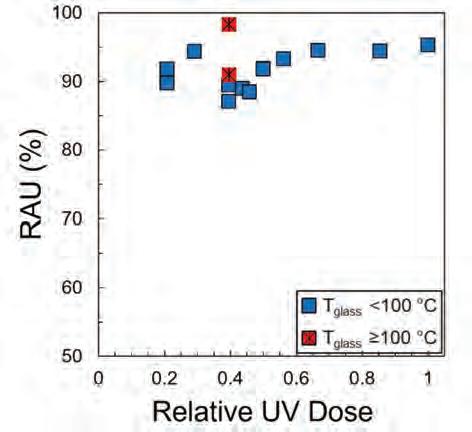

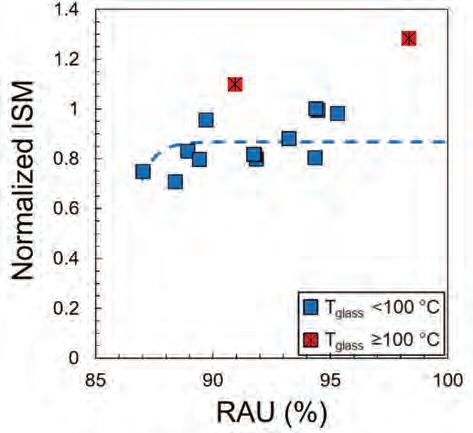

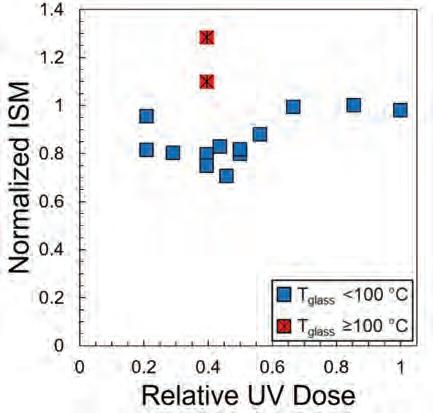

Fast curing next generation primary coating technology providing improved consistency in optical fiber performance and draw tower process

Grant Sheridan, Todd Anderson, Katherine Roberts, Meng He, Brett Register and Eric Urruti

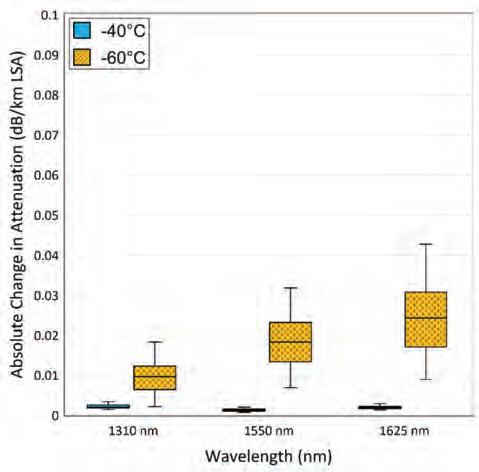

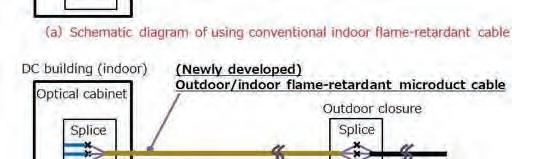

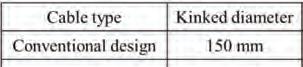

Ultra high-density microduct cables with Freeform Ribbons and applications

Shuhei Nakayama, Fumiaki Sato, Yohei Suzuki, Takao Hirama and Hitoshi Tsubakiyama

• Feature: The Year to Come

• Sector Update: Tapes, yarns and strength members

IWCS 2025 was bolstered by dependable program elements and a new location

The 2025 staging of the IWCS Cable & Connectivity Industry Forum at the David L. Lawrence Convention Center in Pittsburgh, Pennsylvania, once again presented a memorable education program. The event included its comprehensive education program and speakers, the Supplier Exhibition™ and a continued focus on theme sessions of demanding industry growth sectors.

ESOPs: the shop floor dynamic changes when the staffers are also the owners

Though few in numbers, Employee Stock Ownerships Plan (ESOP) businesses in the wire and cable industry have largely fared well. Three companies—Carris Reels, Pelican Wire and Web Industries—provide their perspective on what the experience has meant. Being an ESOP does not guarantee success, but when everyone on the shop floor is also an owner, the data look good.

EXPL521

¾” Am Kuhne Lab Ext Line

EXPL514

65mm SAMP Quick Color Change Ext Line (3)

EXPL523 – Davis Std 3”, 24:1 Ext Line, Nextrom EKP-50 TU

EXPL520 – Davis Std 3.5”, 24:1, Ext Line, Co Ext, Endex Drop Coiler

EXPL519 – 80mm Nokia Maillefer Ext Line w/Vert Ext, MP Capstan

EXPL517 – 65mm Maillefer Ext Line, Endex 630mm Dual Spooler (2)

EXPL513 – 4½” Entwistle Ext Line, Coext, 30” BWC, Syncro Barrel Packer

EXPL505 – 1½” Davis Std. Hi Temp Extrusion Line

EXPL504 – 2½” Davis Std. Hi Temp Extrusion Line

EXPL503 – 2” Sterling Primary Line, 24” PO, 18” Auto Dual TU

EXPL500 – 3½” D-S Jacket Line, 72” MGS POs, 2m Skaltek TUs

EXPL499 – 2½” TEC Optical Fiber Sheathing Line, 84” PO/TU

EXPL498 – 3½” Davis Std Optical Fiber Sheathing Line, 84” TEC PO/TU

RWD723 – Clipper SP-16 Respool Line, S/L PO

RWD718 – 48”-20” TEC Rewind Line, S/L PO, Dual Shaft TU

PAY2615 – 800mm SAMP S/L Driven Payoffs, Dancer (9)

CBR1506

Northampton/Setic Cat BT Twinner (4)

WRD1174

SAMP MT50.2 Dual Rod Line

WRD1188 – SAMP MT105.2X14.18, 28W Drawing Line, Annealer, Spoolers

WRD1187 – Niehoff 16 Wire Drawing Line, Annealer, (2) 800mm Spoolers

WRD1183 – Niehoff 8W Drawing Lines w/Annealer, 800m S/L Spooler (7)

WRD1179 – Niehoff 14W Drawing Line w/Annealer, (2) 800mm S/L Spoolers

WRD1178 – Syncro FX–13 Rod Breakdown Lines w/30” Deadblock Coiler (3)

WRD1176 – Syncro 18T10 Rod Breakdown Line w/30” Deadblock Coiler

CBR1502 – 24” TEC DTCA-24, Double Twist Twinners, Dual Shaft PO (2)

CBR1500 – 30” TEC DTC-30, Double Twist Cabler, Dual Shaft PO

CBR1496 – 1250mm Northampton Double Twist Buncher

CBR1495 – 1.00m Northampton DT Buncher, (3) 800mm Bekaert S/L PO

CBR1494.1 – Niehoff DT631, DT Bunchers, 800mm Bekaert S/L PO (2)

CBR1493.14 – Niehoff 630DT, Double Twist Bunchers, w/Payoffs (10)

CBR1492.14 – Kinrei HK630, Double Twist Bunchers, Year 1999, w/PO (15)

MSC3721 – RDI Model CCP100, Electron Beam, (3) Drop Coilers, DCFPO

The feature this issue, a first-ever for Wire Journal International, is about Employee Stock Ownership Plan (ESOP) companies, of which there are relatively few in the wire and cable industry. One is a wire manufacturer (Pelican Wire) and two are industry suppliers (Carris Reels and Web Industries). There are some others, but still, not very many, especially when you consider that thousands of companies nationwide likely could qualify to be ESOP operations.

Per the National Center for Employee Ownership (NCEO) and The ESOP Association, at one point in early 2025, there were 6,358 ESOP companies in the U.S. Of those, at least 25% were listed as manufacturers. Per NCEO, there are some 250,000 manufacturing companies in the U.S., and of those, between 30,000 and 50,000 could qualify as ESOPs. There’s no simple way to estimate how many companies (both manufacturers and suppliers) in the wire and cable industry could become an ESOP if they wanted to. Yet when one reads the experiences shared by the leaders of the three companies, it raises a big-picture question. What should a company want to be remembered for?

Co-location of Wire Expo 2026 is a plus for everyone

Wire Expo will once again co-locate with the Electrical Wire Processing Technology Expo (EWPTE) on May 6-7, 2026, at the Baird Center in Milwaukee, Wisconsin, USA.

The two events previously co-located in 2010. It’s not easy to co-locate, as events tend to be planned years in advance. This one is a very good fit as the EWPTE trade show covers the electrical wire harness, wire and cable processing industries. Its show floor will field some 200 exhibitors, and it will draw more than 3,000 attendees from 40-plus states and 25 countries.

Next May, attendees of Wire Expo and EWPTE will be able to experience both events. Per a 2024 study cited in Meetings and Conventions, co-locating is on the rise. The study, the Exhibition and Convention Executives Forum Pulse, reported that 44% of surveyed C-level event producers are either very or somewhat likely to begin co-locating a show with another within the next three years. They also found that nearly half of respondents (48%) were very or somewhat likely to continue their current co-location arrangements.

It may call for a bit more discipline in time management, but the idea of being able to visit two events with just one set of travel arrangements and expenses is most appealing.

Mark Marselli Editor-in-Chief, editor@wirenet.org

PUBLISHER Steven J. Fetteroll

EDITOR-IN-CHIEF Mark Marselli

GRAPHIC DESIGNER Charlotte Ashley

DIRECTOR OF SALES Shannon Timme

DIRECTOR OF INTERNATIONAL SALES & BUSINESS DEVELOPMENT

Anna Bzowski

DIRECTOR OF MARKETING & CORPORATE COMMUNICATIONS

Janice E. Swindells

WAI PUBLICATIONS COMMITTEE

Dane Armendariz, consultant

Ferruccio Bellina, TKT Group/President ACIMAF

Michael Crowle, QED Wire Lines Inc.

Tom Moran, consultant

Giulio Properzi, Continuus Properzi

Willem Sundblad, Oden Technologies Inc.

John N. Tomaz, Stolberger

Robert Wild, Niehoff Endex North America

W.T. Bigbee, Encore Wire Corp.

TECHNICAL ADVISORS

John Drummond, Scotia Group

R. M. Shemenski, RMS Consulting, Inc.

Images: Adobe Stock.

Wire Journal International (ISSN-0277-4275) published monthly by The Wire Journal, Inc., is a wholly owned subsidiary of The Wire Association International, Inc., which is located at 71 Bradley Road, Suite 9, Madison, CT 06443-2662, USA, and can be contacted at tel. 203-453-2777; fax 203-453-8384; Internet wirenet.org; e-mail editor@wirenet.org. Address all correspondence concerning advertising production, editorial and circulation to the above address. WJI is printed in the USA.

Subscription rates: $110 per year, USA; $120 per year, Canada and Mexico; other countries, $140 per year (includes air mail). Back copies: $10 WAI members, $15 non-members. Periodicals postage paid at Madison, CT 06443, USA, and at additional offices.

Wire Journal International grants photocopy permission to libraries and others registered with Copyright Clearance Center (CCC), 21 Congress St., Salem, MA 01970, USA, for a fee of $0.50 per article. Payments should be sent directly to the CCC. Requests for bulk orders or reprints should be sent to the Wire Journal International, 71 Bradley Road, Suite 9, Madison, CT 06443-2662, USA.

© 2025 by Wire Journal, Inc. All rights reserved. The Publisher of WJI assumes no responsibility for the validity of manufacturers’ claims made herein. Back issues of WJI are on microfilm and available from University Microfilm, 300 North Zeeb Road, Ann Arbor, MI 48106, USA. Phone: 313-761-4700.

POSTMASTER: Send address changes to Wire Journal International, 71 Bradley Rd., Suite 9, Madison, CT 06443, USA.

“Breaking down the subject matter into short, distinct videos focusing on each subtopic made the information much easier to understand.”

Start learning wire industry essentials at your own pace with WAI’s on-demand videos and see how quickly your achievements add up.

Led by industry experts, and built for individuals and teams, each course includes interactive content, a quiz, and a certificate of completion to track your progress.

New content is added regularly. Courses are offered separately or bundled; and WAI members get discounts.

Learn more with WAI https://wirenet.org/education/online-courses/ or contact: education@wirenet.org

Check out:

• Introduction to Ferrous Metallurgy

• Single-Layer Extrusion Overview

• Extrusion Applications

• Extrusion Materials

• Extrusion Special Process Considerations

• Manufacturing Safety EDUCATION

JAN. 13-15, 2026: Wire Tech Poland Nadarzyn, Poland. This event—the International Trade Fair of Cable and Wire Technology—will be held for the second time at the PTAK Warsaw Expo. Contact: PTAK Warsaw Expo Co. Ltd., tel. +48-518-739-124, rodo@warsawexpo.eu, www.warsawexpo.eu.

MARCH 3-5, 2026: Cables Düsseldorf, Germany. This event, organized by AMI, will be held at the Hilton Düsseldorf. Contact: AMI, tel. +44 (0) 117 924 9442, annabel.kerr@amiplastics.com, www.amiplastics.com.

APRIL 7-9, 2026: World Copper Summit Santiago, Chile. This event is organized by the CRU Group. More information and registration will be available at a later time at www.events.crugroup.com/copper/homes, and conferences@crugroup.com.

APRIL 13-17, 2026: wire Düsseldorf Düsseldorf, Germany. To be held at the Messe Fairgrounds. Contact: Messe Düsseldorf North America, tel. 312-781-5180, info@mdna.com, www.mdna.com.

MAY 6-7, 2026: Wire Expo & 96th Annual Convention Milwaukee, Wisconsin, USA To be held at the Baird Center, colocated with the Electrical Wire Processing Technology Expo (EWPTE). The WAI’s Fundamentals of Wire Manufacturing Course will be held May 5.

SEPT. 21-24, 2026: wire China Shanghai, China. This event will be held at the Shanghai New International Expo Centre (SNIEC). Contact: Messe Düsseldorf/Messe Düsseldorf (Shanghai) Co., Ltd., www.wirechina.net, www.mdna.com.

OCT. 7-9, 2026: SpringWorld Expo and Symposium Rosemont, Illinois, USA. This event, presented by the Chicago Association of Spring Manufacturers, Inc. (CASMI), and the Symposium, presented by the Spring Manufacturers Institute (SMI), will be held at Donald E. Stephens Convention Center. Contact: CASMI, tel. 414-908-4963, info@casmi-springworld.org, www.springworld.org.

OCT. 14-17, 2026: 75th IWCS Cable & Connectivity Industry Forum

Providence, Rhode Island, USA. To be held at the Rhode Island Convention Center. Contact: IWCS, tel. 717-993-9500, www.iwcs.org. WAI will be exhibiting at this event, so look for us there.

NOV. 30-DEC. 2, 2026: Wire India

Mumbai, India. This event, organized by Messe Düsseldorf India Pvt. Ltd, will be held at the Bombay Convention & Exhibition Center (NESCO). Contact: Messe Düsseldorf North America, tel. 312-781-5180, info@mdna.com, www.mdna.com.

MAY 4-6, 2027: Interwire & WAI’s 97th Annual Convention

Atlanta, Georgia, USA To be held at the Georgia World Congress Center, this event includes the trade show, technical programs and WAI’s 97th Annual Convention.

JAN 29, 2026: New England Chapter Annual Dinner

Uncasville, Connecticut, USA. The New England Chapter will hold its annual meeting at the Mohegan Sun Casino. See p. 32.

MAY 6-7, 2026: Wire Expo & 96th Annual Convention

Milwaukee, Wisconsin, USA. To be held at the Baird Center, co-located with the Electrical Wire Processing Technology Expo (EWPTE). The WAI’s Fundamentals of Wire Manufacturing Course will be held May 5.

MAY 4-6, 2027: Interwire & WAI’s 97th Annual Convention

Atlanta, Georgia, USA To be held at the Georgia World Congress Center, this event includes the trade show, technical programs and WAI’s 97th Annual Convention.

For more details on WAI/WAI Chapter events, go to www.wirenet.org then “events” and/or “chapter events.

“Every expert was once a beginner”

— R.B. Hayes

WAI’s on-demand video training courses are designed in manageable segments that are ready to go when you are. You set the pace.

Led by industry experts each course includes engaging interactive content, a quiz, and a certificate of completion to track your progress.

See how quickly you can achieve more career milestones.

New content is added regularly. Courses are offered separately or bundled; and WAI members get discounts.

Learn more with WAI https://wirenet.org/education/online-courses/ or contact: education@wirenet.org

Check out:

• Introduction to Ferrous Metallurgy

• Single-Layer Extrusion Overview

• Extrusion Applications

• Extrusion Materials

• Extrusion Special Process Considerations

• Manufacturing Safety

U.S.-based TriMas Corp. has entered into a definitive agreement to sell its aerospace segment to an affiliate of Tinicum L.P. for $1.45 billion.

A press release said that the sale marks a significant shift for TriMas, which has been actively evaluating strategic options to streamline its business portfolio. The Aerospace segment generated approximately $374 million in revenue over the past 12 months and includes nine manufacturing facilities and roughly 1,250 employees.

Fasteners are estimated to account for 60 to 70% of the segment’s revenue, underscoring their central role in the business. Per Precedence Research, the global aerospace fasteners market is expected to expand from $7.85 billion in 2025 to approximately $15 billion by 2034.

TriMas Aerospace supplies highly engineered fasteners and precision-machined components for mission-critical applications across commercial and defense aviation markets. Its brands include Monogram Aerospace Fasteners, Allfast Fastening Systems, Mac Fasteners, TFI Aerospace, RSA Engineered Products and Weldmac Manufacturing Co., among others. The company’s products have supported programs such as the U.S. Air Force’s T-7A Red Hawk training jet.

The deal will allow TriMas to focus its resources on higher-growth and more profitable operations, including its packaging and specialty products platforms. Posttransaction, TriMas plans to invest further in its remaining

segments, aiming to expand market share and enhance operational efficiency. TriMas executives said that the transaction is expected to close in early 2026.

“This agreement represents a compelling valuation and validates the high-quality nature of the business,” said Herbert Parker, TriMas board chair. TriMas will focus on its high-margin packaging platform and specialty products group that serves consumer and industrial markets.

Southwire announced that it is expanding operations at its plant in Heflin, Alabama, adding approximately 340,000 sq ft to the location’s footprint in a project that is expected to also result in more than 85 new jobs.

A press release said that Southwire’s Heflin Plant, which opened in 1996 as Forte Power Systems, was built to support medium- and high-voltage cable production. This will be the fourth expansion at the plant, highlighting the company’s ongoing commitment to reinvesting in core wire and cable operations.

Beyond the capacity and production expansion, the facility design includes comfort cooling and other efforts to provide a modernized team member experience as well as sustainability enhancements, like a rainwater collection tank for designated facility operations. Construction is expected to begin in late 2025 with equipment and capacity coming online in late 2027.

“Southwire has committed more than $1.8 billion into modernization efforts across our footprint thus far, and we continue to grow,” said Southwire President and COO Norman Adkins. “This expansion in Heflin reaffirms our

A WJI story in November said that Kinderhook Industries had sold SDI LaFarga COPPERWORKS to the Rhone Group. The company sold was Copperweld. Southwire’s Heflin plant will undergo a major expansion.

commitment toward creating an extraordinary place to work – today and for generations to come.”

“We continue to purposely invest in modernizationacross our facilities, equipment, systems, technologies and more, allowing us to best serve our customers and help power a more sustainable future,” said Southwire President & CEO Rich Stinson.

Prysmian recently marked the completion of a $63.8 million expansion of its Du Quoin, Illinois plant with a ribbon cutting ceremony attended by local leaders, state officials and company executives.

A press release said that the event, which also celebrated the facility’s 60th anniversary, highlighted the company’s ongoing investment. The project, which saw the addition of 100,000 sq ft of manufacturing space, is creating 80 new jobs. Prysmian’s investment is designed to ramp up production of renewable energy and electric vehicle (EV)

cables to keep pace with the growing demand, while also modernizing the plant and implementing an advanced Energy Management System.

A central element of the expansion is a new solar farm that now generates about half of the energy needed for the plant’s operations, reducing the carbon footprint and the energy required to make cables critical for U.S. grid improvements. Supported by the state’s Reimagining Energy and Vehicles in Illinois (REV Illinois) initiative, the project received praise from community and utility leaders

China Railway Major Bridge Engineering Group (part of CREC) used advanced steel wire technology for the main cables of what is claimed to be the world’s highest bridge.

Per CREC, the Huajiang Canyon bridge is a 1,420-meter-span steel truss stiffened suspension bridge with a 625-meter vertical distance between the deck and the water surface, making it the tallest bridge in the world. The bridge features 93 segments of steel truss girders weighing about 22,000 tons in total, equivalent to three Eiffel Towers. On January 17, the final steel truss girder weighing approximately 215 tons was precisely installed using China’s independently developed fourth-generation intelligent cable crane system.

Per CREC, the bridge employs two main cables made of steel wires each 5.7 mm in diameter, with a smart cable system where two strands in the cable have been replaced with

optical fibers to monitor temperature, humidity and stress to prevent rust and ensure durability. The steel wires are part of a forged saddle and cable system designed for high strength and resilience, with innovations in welding technology to ensure the microstructure density and integrity of the steel plates used.

Upon completion, the bridge surpassed the Beipanjiang Bridge on the Hangzhou-Ruili Expressway to become both the tallest bridge in the world and the longest-spanning mountain bridge globally. The steel truss girder structure, manufactured by China Railway

Hi-Tech Industry, consists of main trusses, main cross trusses, lower chords, and deck panels.

Per its website, CREC has a staff of about 290,000, including 85,000 skilled technicians, and carries out projects in more than 90 countries and regions around the world. It holds 18,568 valid patents, including 3,969 invention patents.

including ComEd and Ameren Illinois, who highlighted the facility’s importance to the regional clean energy economy and electric grid reliability.

Prysmian’s Du Quoin plant, established in 1965, produces specialized cables for wind, solar, EV charging and grid-hardening projects, further solidifying its position as a pillar of local manufacturing and a driver of innovation for both Illinois and the national clean energy transition.

South Korea’s LS Marine Solution announced that its subsidiary, LS Buildwin, will undertake a significant ultrahigh voltage (UHV) underground power grid project in Singapore valued at approximately $60 million

Per an MoU, Saudi-based Riyadh Cables Company may help Syria’s SMCC further its wire and cable manufacturing scope.

A press release said that the contract represents the final stage of a broader effort led by the LS Group to expand Singapore’s 230 kV underground power network to meet growing electricity demands from AI and data centers. The project highlights the integrated scope of the LS companies, with LS Cable & System securing the main contract and supplying the high-voltage cables, LS Buildwin managing the entire underground cable installation and LS Marine Solution overseeing the subsea cable construction. Per the parent company, LS Buildwin, established as a subsidiary of LS Marine Solution, specializes in underground cable installation and has a long track record with projects across Singapore, Qatar, Denmark, Britain, Saudi Arabia and France. LS Marine Solution’s broader construction expertise covers both marine and underground installations, and its recent order backlog totals approximately $525 million, reflecting rapid growth.

Earlier phases of the Singapore project involved LS Cable & System’s supply of high-voltage cables under contracts worth $147 million awarded in April 2025, followed by an additional contract in July valued at about $108 million.

Riyadh Cables Company, a subsidiary of Saudilisted Riyadh Cables Group, has signed a non-binding memorandum of understanding (MoU) with the Syrian Sovereign Fund to support the development of Syria’s cable manufacturing sector.

A press release said that the agreement, announced in early November, outlines plans to manage, operate, and develop the facilities of Syrian Modern Cable Company, one of the country’s few established cable producers.

Per a filing with the Saudi stock exchange (Tadawul), the MoU is valid for six months and aims to localize technical expertise and enhance Syria’s capacity to produce power and electrical cables. While the deal does not involve an acquisition, it marks a rare instance of foreign industrial engagement in Syria’s post-conflict economy.

Syrian Modern Cable Company, founded in 1996 and based in Adra Industrial City, has historically exported to Europe and the Middle East, but its scale remains modest. With annual production capacity of 10,000 metric tons, it is a prominent Syrian cable manufacturer. The company produces an array of electrical cables, including enameled wire and PVC granules. It maintains international quality certifications such as ISO 9001-2015 and BASEC.

The Syrian Sovereign Fund has been actively courting foreign partners to revitalize key sectors, particularly those tied to infrastructure and energy. Per Reuters and Zawya, Gulf states and Turkey have pledged over $40 billion in reconstruction investments since 2024.

Syria’s cable industry includes a handful of domestic players such as Union Electrical Group and Universal Electric, which already export to Iraq, Lebanon and Jordan. However, international sanctions, banking restrictions, and logistical hurdles have limited foreign competition.

China’s ZTT Group announced that it plans to invest approximately $100 million to establish a submarine and terrestrial cables manufacturing facility at Saudi Arabia’s Ras Al-Khair Port.

According to the Saudi Press Agency, the company signed a land lease agreement with the Saudi Ports Authority (Mawani) to set up the 80,000 sq m facility. The planned facility will have capacity to annually produce 500 km of submarine cables, 500 km of terrestrial cables and 12,500 km of fiber-optic cables. GCC Business News reported the cable will support large-scale renewable energy installations, bolster digital connectivity networks

and advance offshore infrastructure projects throughout the country and beyond, reported.

The partnership was described as essential for building Saudi Arabia’s submarine and terrestrial cable sector, directly advancing the National Transport and Logistics Strategy’s aim of making the kingdom a global logistics hub. Al-Mazrou described the project as a strategic move that would reinforce Ras Al-Khair Port’s role as an industrial center in the country. The collaboration would ioth help localize cable manufacturing and attract technologies that support Saudi Arabia’s growing telecommunications industry.

Per the ZTT Group website, the business—officially known as Jiangsu Zhongtian Technology Co., Ltd.—ZTT employs over 16,000 people and operates 80 subsidiary companies. It has more than 54 offices and 12 marketing centers overseas, with plants in India, Brazil, Indonesia, Morocco, Turkey and Germany. ZTT exports products to over 160 countries and regions worldwide.

Nexans has announced a strategic minority investment in Sensewaves, a French artificial intelligence start-up, alongside American Electric Power (AEP), a major U.S. utility.

A press release said that Sensewaves, founded in 2015, specializes in AI-powered analytics for power grids. Its flagship Adaptix.Grid platform is designed to unify data from disparate utility sources and deliver granular, real-time grid insights. The platform offers utilities advanced visibility and situational awareness for both low voltage and medium voltage networks, regardless of the level of digitization or data completeness. It can support optimization across the entire grid lifecycle, from planning to real-time operations and maintenance.

The goal is to drive Sensewaves’ growth, expedite the deployment of Adaptix.Grid, and support market expansion. The funds will bolster Sensewaves’ R&D, product teams, and business development, enabling accelerated innovation and strategic geographic expansion. The result

is a full-service offering for utilities seeking to modernize networks and meet the demands of the energy transition, including the integration of renewable generation and electric vehicle infrastructure.

Sensewaves’ CEO, Fivos Maniatakos, welcomed the partnership, stressing the complementary strengths of Nexans as a cable and turnkey systems company and AEP as an experienced grid operator. “The collaboration positions Sensewaves as a serious contender in delivering smart, scalable grid management solutions for the utilities sector.”

Italtrecce Srl, a business of U.S.-based International Wire Group (IWG,) has acquired Special Corde Srl, an Italian supplier of specialty conductors based in Gioia Sannitica, Italy.

A press release said that Special Corde Srl, founded in 2001, supplies wire and cable for power and distribution transformers, electric motors and associated electrical systems. The deal was made through IWG’s Italtrecce Srl.

“This acquisition is yet another opportunity to increase our presence in critical electrical infrastructure applications,” said IWG CEO Gregory Smith. “As the electrification buildout broadens, transformers represent a critical component of grid modernization. Special Corde will play an important role in supplying products used in these applications. In addition, Special Corde, with other recent IWG acquisitions, deepens existing customer relationships, playing a vital role in the burgeoning, global electrification needs.

“It is a great opportunity to partner with a global brand such as IWG,” said Dino Grandi, general manager of Special Corde. “It is an exciting time to be part of the electrification movement, and we look forward to playing our part in this journey.”

France’s Orange Marine has ordered two new cable laying and repair vessels designed for subsea telecommunications operations from Sri Lanka shipbuilder Colombo Dockyard PLC (CDPLC).

A press release said that the vessels to be made by CDPLC will be designed by Norway’s Vard Design AS. The vessels will have optimized hull forms and bow shapes to enable high speeds and reduce fuel consumption, meeting Bureau Veritas classification society standards and French Flag Authority regulatory requirements. Delivery of these new vessels is anticipated for 2028 and 2029.

“These new vessels will allow (us) to operate the most modern cable ship fleet in the world, serving all our customers across the globe with an optimized environmental footprint,” said Didier Dillard, president of Orange Marine and Elettra Tlc.

The vessels will focus on cable laying, repair, and remotely operated vehicle (ROV) inspection duties. Each vessel will have an Orange Marine–designed ROV for cutting, inspecting, and burying subsea cables. The design prioritizes strong sea-keeping and excellent station-keeping performance while minimizing environmental impact, aligning with BV CLEANSHIP low fuel consumption standards.

Orange Marine, a global leader in submarine telecommunications, specializes in engineering, installation and maintenance of intercontinental and regional cable links. The company notes that its fleet represents 12% of the world’s cable maintenance ships.

Epsilon Composite has taken a major step in expanding its presence in the power transmission sector with the opening of the French company’s subsidiary, HindEpsilon Composite, headquartered in Chennai, India, and incorporated in October 2025.

A press release said that HindEpsilon Composite will focus on manufacturing high-temperature, low-sag composite core conductors (HVCRC®) designed to increase the capacity, efficiency, and reliability of overhead power lines. The subsidiary is the first step in Epsilon’s plan to establish a local factory in India that will produce composite cores and other high-performance parts, supporting the Indian government’s “Make in India” initiative.

Epsilon Cable, through HindEpsilon and collaborations with local partners, has already secured significant reconductoring projects in Indian states such as Uttar Pradesh, Uttarakhand, and Assam. The subsidiary has engaged with key Indian power sector stakeholders, including the Ministry of Power, Central Electricity Authority (CEA), and Power Grid Corporation of India Ltd. Epsilon has also

formed strategic partnerships with Indian stranders such as Transrail Lighting Ltd., Lumino Industries and Shashi Cables Ltd. to help supply and deploy HVCRC technology across the country.

Epsilon Composite’s headquarters and primary manufacturing facility remain in Gaillan-en-Médoc, France, where the company produces pultruded carbon fiber composite cores used in high-voltage conductors worldwide. It has regional offices in Japan, Central Europe, Mexico, and Italy, and HindEpsilon Composite will be the key subsidiary involved directly in wire and cable manufacturing and local production in India.

Epsilon has strategic partnerships with Indian stranders, including Transrail Lighting Ltd, Lumino Industries, and Shashi Cables Ltd, to help supply and deploy the HVCRC technology across the country.

South Korea’s LS Cable & Wire (LS C&W) announced that it will supply busducts to a large U.S. tech company that marks its full-scale entry into the global AI data center (AIDC) power market.

A press release said that the deal could be worth more than $340 million over three years. The order, from an unnamed U.S. customer, is for data centers “in North America and other regions.” To meet demand, LS C&W has strengthened its global busduct production in South Korea, North America and Vietnam.

Last May, LS C&W announced it would build two new factories to make busducts and electric vehicle (EV) battery components on a 126,000-sq-m site in an industrial park. At that time, it also had busduct production plants in in Gumi, Wuxi, and Ho Chi Minh City. “The completion of the new plant currently under construction in Mexico is expected to further enhance supply efficiency and delivery competitiveness for North American customers.”

LS Eco Energy will cover the Southeast Asian market centered in Vietnam. In October, it supplied busducts to a 50 MW class hyperscale data center in Indonesia. The LS Cable & System Mexico plant will cover the North American market.

The company stated that its busduct activity could be even greater as LS C&W is in negotiations with another large global tech company. “We will secure the leading position in the power infrastructure competition in the era of AI,” said Kim Woo-tae, head of LS Cable & System’s Power Distribution Solution Division.

U.S.-based Primetals Technologies reports that it has received a Final Acceptance Certificate (FAC) from Celsa France for a major upgrade to the finishing end of the company’s wire rod mill in Bayonne, France.

A Primetals posting said that the company replaced a problematic finishing block and reform station “that had been supplied by a third party and had repeatedly caused unplanned downtime.” With the new equipment in place, Celsa France has significantly increased mill availability and production levels while improving product quality and reducing operational costs.

The upgrade included a new 10-stand Morgan Vee No-Twist Mill designed to operate at speeds up to 105 meters per second across low-, medium-, and high-carbon steel grades. The installation also included a 3-Hi speed increaser gearbox that links the new mill to Celsa France’s existing motor position, demonstrating the design flexibility and compatibility of the technology. The upgrade has already led to quicker, more efficient rolling, reduced maintenance costs, and shorter roll change times.

The project also saw the replacement of the 1,200 mm reform tub. Equipped with a patented ring distributor, the new tub minimizes coil height, eliminates stray rings, and ensures tangle-free payoff. These improvements have

dramatically reduced delays in downstream processing, further enhancing overall productivity.

Celsa France was described as Europe’s first circular, low-emission steel producer, recycling ferrous scrap in electric arc furnaces to produce steel for construction, automotive, energy, and oil and gas sectors. The Bayonne upgrade strengthens this position by ensuring that the company’s wire rod production is both efficient and environmentally responsible.

According to Celsa France, the Bayonne facility produces about 550,000 tons of rolled products annually, primarily wire rod. The recent upgrade adds to an earlier €65-million investment that created around 140 direct and 420 indirect jobs across France and Spain.

Earlier this year. Italy’s Danieli reported that it has been chosen by Alter Steel to supply technology and equipment for a landmark electric steelmaking facility in Pinkenba, Queensland, Australia, that was estimated to cost $750 million.

Per Danieli, it will build the first greenfield steel mill built in Australia in more than 40 years. The project will use its MIDA QLP – Quality Long Product – technology and incorporate its Digimelter and Q-One power feeder for sustainable electric steelmaking. The plant will produce 500,000 metric tons (mt) per year of reinforcing bar, wire rod, hot-rolled mesh, spooled coil and bar, all from steel scrap. The endless casting-rolling process eliminates billet reheating, cutting energy use by up to 75%.

Per an article in greensteelworld.com, the facility is scheduled to be completed by late 2027. The project has secured Conditional Development Approval. The facility is designed for 100% renewable energy compatibility and will emit just 0.37 mt of CO2 per tonne of steel, an 80% reduction compared to traditional blast furnaces.

The International Wire Group (IWG) announced that it has acquired EMS Elektro Metall Schwanenmühle GmbH (EMS), a German supplier for engineering and manufacturing of customized busbars used in electrical power generation, transmission, distribution and storage.

A press release said that EMS provides products and services to meet the market needs of electrical infrastructure, data centers, battery storage, electrolysis, industrial applications, electric vehicles, and renewables.

“This acquisition leverages many existing customer relationships while expanding our geographic presence in the electrical infrastructure ecosystem,” said IWG CEP Gregory Smith. He noted that EMS expands IWG’s product portfolio in electrical infrastructure, energy storage, and power distribution markets.

New England Wire celebrated a sizeable expansion to its existing manufacturing plant in Lisbon, New Hampshire, on Sept. 22, 2025.

New England Wire Technologies President Tom White wields the scissors for the ribbon-cutting.

The company held an official ribbon cutting for the nearly 38,000-sq-ft expansion to the eastern side of the plant. The 78 ft by 487 ft addition houses machining and fabrication shops, specialty braiding and expanded silicone

•Roteq's rewind lines efficiently transfer cable between reels of varying size, or from large reels to smaller coils or spools. Ideal for packaging custom lengths with speed and precision.

•Roteq's taping lines feature high-performance concentric or eccentric tape heads, integrated between pay-off and take-up units, typically of matching size. Designed for versatility, they handle plastic, mylar, and copper tapes with ease.

•Taping and rewind lines may integrate third party (customer supplied) components such as spark testers, printers, etc.

rubber extrusion, as well as having room for significant additional space for future capacity growth.

Moving the machine and fabrication shops together under one roof freed up almost 6,000 sq ft of space for future expansion and growth for the company’s tubing division, New England Tubing Technologies. Strategies are being formulated as to how best to use this additional space with both added capacity and new capabilities.

The Lisbon facility has seen multiple investment rounds over the past decade, reflecting continued demand for the company’s custom cable and tubing solutions in advanced medical, industrial, and telecommunications markets.

Madem-Moorecraft Reels USA, a subsidiary of the Madem Reels Group Brazil, announces a significant expansion of its wooden reel production capacity at its Tarboro, North Carolina facility.

A press release said that $7 million was invested in the project. It includes new production lines that use fully robotized machinery, enabling a 50% increase in the plant’s installed capacity.

Madem-Moorecraft already operates a solid logistics network with distribution centers in Texas, Georgia,

Arizona, West Virginia, Ohio and North Carolina. As part of its expansion plan, the company is considering opening new distribution centers in Colorado, Connecticut, Indiana, Louisianna, Missouri, Maryland and Pennsylvania, further enhancing its coverage and proximity to key customers. In addition to its Tarboro plant, Madem-Moorecraft also operates another industrial facility in Denton, Texas.

Madem Reels Group has manufacturing plants in Brazil, Colombia, Mexico, Spain and Bahrain. It supplies some 200 cable producers in 45 countries.

Denmark’s NKT has joined the First Movers Coalition (FMC), reinforcing its commitment to the advancement of low-carbon aluminum across global supply chains.

A press release said that FMC, led by the World Economic Forum, brings together industry leaders to accelerate decarbonization in sectors that are traditionally challenging to abate. By participating in the FMC’s aluminium sector, NKT pledges that by 2030, at least 10% of its annual primary aluminum purchases will be low-carbon, in accordance with the coalition’s stringent emissions criteria. This move marks a notable strategic step in NKT’s broader objective to reduce the carbon intensity of its power cables—a priority that supports both the company’s sustainability targets and the decarbonization goals of its clients.

This strategic move supports NKT’s broader goal to reduce the carbon intensity of its power cables, aiding both its sustainability targets and those of its clients. The company’s pursuit of lower-carbon materials is already underway, highlighted by its April 2025 agreement with Norwegian group Hydro for REDUXA 4.0 aluminum— produced using renewable energy and featuring a carbon footprint 75% lower than the global average.

NKT also secured first rights to Hydro’s upcoming REDUXA 3.0, furthering its role in Europe’s energy transition and grid modernization. The collaboration also sends a strong market signal, encouraging early adoption of climate technologies and reinforcing NKT’s position as a proactive force in the shift to greener infrastructure.

Nexans reports that its Halden plant in Norway marked a historic milestone as its cable-laying vessel, Nexans Aurora, departed with a record 9,731 tons of subsea cable.

A press release said that cargo represents the highest load ever in the company’s history, exceeding the previous record, set in 2023 for the Oseberg Project, by 256 tons. “This feat represents not only a record for Nexans Aurora but also for the Halden plant itself, which has been supplying large-scale cable solutions since its first delivery to Nexans Skagerrak in 1976.”

The Halden’s newly expanded high-voltage subsea cable facility, completed in early 2024, enabled this scale of operations, more than doubling its capacity for state-ofthe-art HVDC and HVAC cable production. The plant now employs around 1,000 people and houses the tallest building in Norway—its second extrusion tower—allowing simultaneous cable insulation across four production lines.

This latest record highlights Halden’s role as a cornerstone in Nexans’ global supply chain, supporting key offshore wind farm, interconnector, and electrification projects worldwide.

Suzhou-based Hengtong has won a contract for the Liaoning Huadian Dandong Donggang Phase I Offshore Wind project (Donggang) that calls for it to provide not just the cable but also the engineering, procurement, construction, and installation (EPCI).

A press release said that the Donggang contract site is located about 50 km offshore from Donggang City in China’s Liaoning Province. The project, owned by Huadian (Dandong) Offshore Wind Power Co., Ltd., a subsidiary of China Huadian Corporation, represents “a significant achievement” in offshore wind power transmission.

Hengtong will supply and lay more than 120 km of 500 kV high-voltage direct current (HVDC) XLPE submarine cables. The Donggang Phase I project will include 84 offshore wind turbines, each with a capacity of 12 megawatts, resulting in a total installed capacity of 1 GW for the first phase.

The full project aims for a total capacity of 2 GW over two phases. This transmission capacity was described as representing one of the largest and most advanced HVDC offshore power evacuation systems globally, enabling long-distance, high-capacity delivery of renewable energy.

Hengtong’s responsibilities include offshore installation and integration of the wind turbines themselves. The project demonstrates China’s accelerated commitment to decarbonization and sustainable development, showcasing HVDC technology’s pivotal role in expanding offshore wind grid integration.

Of note, Hengtong recently announced that it has completed a new type test for a 525kV HVDC high-temperature, large cross-section aluminium conductor land cable system, which is now fully compliant with European TSO specifications. “This achievement not only marks a technological first in China but also showcases Hengtong’s continuous leadership in advanced cable design, testing and manufacturing.”

Egypt-based Kemet Industries Group has signed a memorandum of understanding with Emirati-Chinese firm Al Qalaa Red Flag to invest up to $3.5 billion in three mega industrial projects, one of which is for manufacturing optical fiber cables.

A press release from the principals said that the projects will be located in the Ain Sokhna Industrial Zone, part of the Suez Canal Economic Zone (SCZONE).

The fiber optic plant will bolster Egypt’s expanding digital infrastructure sector, contributing to faster, more efficient highspeed networks.

Egypt has at least one major Egyptianowned and operated fiber optic cable manufacturing plant: Elsewedy Communications Cables Factory, which opened earlier this year in 10th of Ramadan City. That plant was described as the largest telecom cables manufacturing facility in Egypt and the Middle East,

producing both fiber optic and copper communications cables. Another fiber optic plant is run by Benya Cables, which operates in partnership with the Arab Organization for Industrialization and international technology partners. Benya, which is partly Egyptian-owned, is based in Egypt. Al Qalaa Red Flag is a consortium with Emirati and Chinese ownership focused on industrial investments in Egypt. The other two “mega” projects are for manufacturing steel pipe factory and tires.

(Industry News continued, see p. 20)

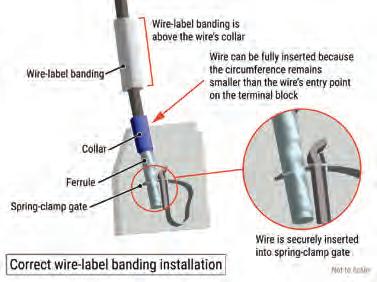

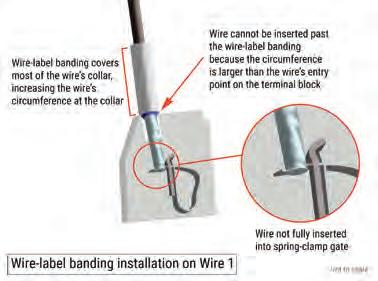

The National Traffic Safety Board (NTSB) reports that a single loose wire on the 984-foot-long containership Dali caused an electrical blackout on March 26, 2024, that led to the giant vessel veering and contacting the nearby Francis Scott Key Bridge in Baltimore, which then collapsed, killing six highway workers.

The report from NTSB said that a loose wire in the ship’s electrical system caused a breaker to unexpectedly open. That caused a sequence of events that led to two vessel blackouts and a loss of both propulsion and steering near the 2.37-mile-long Key Bridge. Investigators found that wire-label banding prevented the wire from being fully inserted into a terminal block spring-clamp gate, causing an inadequate connection.

After the initial blackout, the Dali’s began swinging to starboard

toward Pier 17 of the Key Bridge. Investigators found that the pilots and the bridge team attempted to change the vessel’s trajectory, but the loss of propulsion so close to the bridge rendered their actions ineffective. A substantial portion of the bridge subsequently collapsed into the river, and portions of the pier, deck and truss spans collapsed onto the vessel’s bow and forwardmost container bays.

A seven-person road maintenance crew and one inspector were on the bridge when the vessel struck, leading to the deaths of the highway workers. The NTSB found that the quick actions of the Dali pilots, shoreside dispatchers and the Maryland Transportation Authority to stop bridge traffic prevented greater loss of life.

JDR, which is based in the U.K. and is part of the TFKable Group, announced that it has an MoU with the Emdad Group to establish a Middle East service base.

A press release said that agreement with the Emdad Group— a Saudi-based industrial services company — reflects the importance of the partnership and shared commitment to providing localized support to the energy industry. It also noted that there are plans to expand operations to Saudi Arabia in the near future, further strengthening our regional capabilities.

Above: how the wire label should have been placed and what the NTSB reported was done.

“Our investigators routinely accomplish the impossible, and this investigation is no different,” said NTSB Chairwoman Jennifer Homendy.

“The Dali, at almost 1,000 feet, is as

long as the Eiffel Tower is high, with miles of wiring and thousands of electrical connections. Finding this single wire was like hunting for a loose rivet on the Eiffel Tower. “But like all of the accidents we investigate,this was preventable,” she said. “Implementing NTSB recommendations in this investigation will prevent similar tragedies in the future.”

To be located within Emdad’s facility in Abu Dhabi (UAE), the new service base will provide access to skilled technicians, advanced equipment and faster mobilization, enabling immediate and efficient support for customers, the release said. The facility will serve as a regional hub for installation and termination services, equipment storage and rapid mobilisation of spares to support both existing and forthcoming projects.

“This new service base represents another step forward in JDR’s mission to deliver reliable, responsive, and innovative subsea cable and umbilical solutions, ensuring greater efficiency and customer focus in every project.”

and replacement of high voltage cables and joints

U.S. Patent No.: 12,407,152

Patent date: Sept. 2, 2025 Filed: April 30, 2025

Assignee: Brugg Kabel AG, China

Inventors: Ronny Steinhaus, Michael Junghans, Willibald Nägele, Simon Eberhart, Omar Abbara

A method of repairing or replacing a joint for high voltage polymer cables or a high voltage polymer cable (1c), comprises the steps of: a) removing a section to be replaced of the joint or the high voltage polymer cable (1c) such that two cable ends (1a, 1b) result, whereby the two cable ends (1a, 1b) are oriented toward each other and whereby the two cable ends (1a, 1b) are positioned in a separation distance (20) from each other and whereby each cable end (1a, 1b) comprises a cable conductor (10a, 10b), b) preparing the two cable ends (1a, 1b) by exposing the cable conductors (10a, 10b) of both cable ends (1a, 1b) over a first length c) connecting the two cable conductors (10a, 10b) with a connection piece (3) which comprises two receiving sections (31a, 31b) and a centre section (30) and which is electrically conducting, whereby a length of the centre section (30d) corresponds to the separation distance (20) and whereby the cable conductors (10a, 10b) are mounted in such a way to the receiving sections (31a, 31b) that a mechanical and an electrically conducting connection is established.

U.S. Patent No.: 12,407,130

Patent date: Sept. 2, 2025 Filed: Jan. 17, 2023

Assignee: TE Connectivity Solutions GmbH, China

Inventor: Raghunandan Shrikanth Shanbhag

A flat flexible cable (FFC) seal comprises an elastomeric body defining a generally hollow interior space. The body includes a first seal portion surrounding the interior space and comprising an outwardly extending first sealing rib. A cavity is formed into the first seal portion in an axial direction and is sized to receive a portion of a connector component. The body further includes a second seal portion surrounding the interior space and comprising an outwardly extending second sealing rib. The second seal portion extends in the axial direction of the body from an end of the first seal portion. The second seal portion is

foldable into the interior space of, and generally under, the first seal portion such that that second sealing rib extends inward into the interior space.

Connector for shielded electric wire, and wire harness

U.S. Patent No.: 12,407,117

Patent date: Sept. 2, 2025 Filed: Aug. 9, 2023

Assignee: Yazaki Corporation, Japan

Inventors: Daisuke Sugiyama, M. Higashitani, T. Hayakawa; Y. Chikamatsu

A connector for a shielded electric wire includes: a shield terminal connected to a braid on one end side thereof and grounding the braid by contact at a leaf spring on the other end side thereof; a first packing (sealing member) that seals between a housing and an object inserted into a through hole from an inner surface of the housing to an inner surface of the through hole; and a support member that is a resin ring exteriorly mounted on the shield terminal to be adjacent to the leaf spring and disposed inside the through hole in such a manner that an outer circumferential edge thereof is in contact with the inner surface of the through hole, thereby suppressing an offset of a central axis of the shield terminal with respect to a central axis of the through hole.

Insulated wire and preparation method thereof, coil and electronic/electrical device

U.S. Patent No.: 12,406,780

Patent date: Sept. 2, 2025 Filed: Dec. 30, 2024

Assignee: Well Ascent Electronic (Ganzhou) Co., Ltd., China

Inventors: Huimin Ye, Yuejia Zhu, Zuomao Zhu

An insulated wire and a preparation method thereof, a coil and an electronic/electrical device are provided. The insulated wire includes a conductor and an insulating layer at the periphery of the conductor. The cross section of the conductor is rectangular, a sunken part is formed in the insulating layer on at least one surface of the conductor, the sunken part extends in the whole length direction of the insulating layer, a convex part is formed in the left and right sides of the sunken part, the distance between the bottommost part of the sunken part and the surface of the conductor is L1, L1 is 50 μm-300 μm, the distance between

The most dangerous scam involves accusations of copyright infringement. A client contacted me last week and asked if the email she received accusing her of infringement was legitimate. Thankfully, she didn’t click the link. If she had, a Trojan virus could have been installed. These scams also appear in website comments. Other types include phishing attempts and payment requests. Other scammers impersonate YouTube or Shopify and send fake “copyright strike” emails. You click their login link, and they steal your account. My advice: don’t click on any links. Either ignore them or ask them to send the documents via snail mail.

Three trademark scams are circulating: two via email and one by phone. Both aim to scare you and steal your money. Don’t fall for them.

The first scam is an email that begins with URGENT: LOSS OF TRADEMARK RIGHTS. I receive several emails each month from clients who got this email. It appears to originate from a law firm representing a “client” attempting to register your trademark. It claims that if you don’t act quickly, you will lose your trademark. They state that their email is being sent “as a courtesy.” It employs one of the Seven Weapons of Influence from Robert Cialdini’s well-known book Influence: Scarcity: “Hurry, call us, or you will lose your trademark,” it declares.

They go on to state that “It’s important to note that, as stipulated in the Lanham Act of 1946, specifically §§ 1051 et seq, federal registration of

your mark is essential to establish and protect your ownership rights.”

The clearest red flag is a blatant ethical violation. (Yes, lawyers follow a code of ethics.) This lawyer is disclosing confidential client information. They are supposed to keep a client’s intention to register a trademark private. There is no client; it’s a trick.

The second issue is a clear misunderstanding of the law. Federal registration of your mark is not mandatory. In the U.S., common law rights protect your trademark even without federal registration. While federal registration has value, it is not required.

Then there’s the second email scam that claims to list your trademark in an international directory. I’ve lost count of how many times clients have shown me this one. This email offers (for a fee) to include your trademark in some international directory. There is no such thing as an international directory for trademark registration. It’s a scam. International trademark registration isn’t that simple. You need to apply for registration through the relevant authorities in the countries where you plan to do business.

The third type is the phone call that “Spoofs” the USPTO. A client told me he received a call from a “USPTO examiner” claiming his trademark was about to expire. He was just one credit card number away from “renewing” his registration for $2,400. However, there were two issues: his renewal wasn’t due for three years, and USPTO examiners will never call you to request money. Scammers use software to spoof

caller IDs, making the call look legitimate. It seems legit, and it feels legit. It hits business owners where they’re most vulnerable because your brand is personal. Threaten it, and your heart rate spikes instantly.

Patent scams involve fake “patent maintenance fee” invoices that closely resemble USPTO notices. These scammers exploit patent owners’ fear of missing a payment. Maintenance fees are only due at 3.5, 7.5, and 11.5 years, and only the USPTO collects them—never by mail or phone. If you receive a paper invoice, it is 100% fake.

Scammers can access your intellectual property details because they are publicly available. Your patent, trademark and copyright information are all online, along with your contact details. It’s easy for them to find out what IP you own, when fees are due, and who to contact. As you probably know, AI is making scams easier. I did a quick AI search for a client’s intellectual property, and it listed everything in seconds. With a little programming, I could easily create emails just like the scammers. If someone contacts you urgently, out of fear, or under legal pressure, stop. Scammers thrive on panic. If unsure, call your IP lawyer or the USPTO Assistance Center at 800-786-9199 or the Copyright Office at 877-476-0778. Don’t call the number in the email. That’s like calling the wolf to ask if he’s a sheep. Your IP is valuable, so scammers try to target it. Just don’t let them scare you into doing something you’ll regret.

-Bill Honaker

Bill Honaker has been an intellectual property attorney for more than 30 years, helping businesses—from Fortune 100 firms to individual entrepreneurs—protect their patents, trademarks and copyrights. A former Patent Office Examiner, he is a partner with Dickinson Wright, PLLC. He notes that he is especially good at keeping clients out of court. He can be contacted at whonaker@dickinson-wright.com, tel. 248-433-7381.

the bottom of the sunken part and the highest point of the convex part is L2, and the value that L1 is divided by the sum of L2 and L1 is greater than 1.3 and smaller than or equal to 10.

Telecom cable tension screening technique based on wave propagation and distributed acoustic sensing

U.S. Patent No.: 12,405,135

Patent date: Sept. 2, 2025 Filed: May 17, 2023

Assignee: NEC Corporation, Japan

Inventors: Yangmin Ding, Yue Tian, Sarper Ozharar, Ting Wang

A radio-controlled, two-way acoustic modem for operating with a distributed fiber optic sensing (DFOS) system including circuitry that receives radio signals including configuration information, configures the modem to operate according to the configuration information, and generate acoustic signals that are detected by the DFOS system. The acoustic modem includes one or more sensors that detect environmental information that is encoded in the acoustic signals for further reception by the DFOS system. The received configuration information may change the operating times, sensors or other operating aspects of the modem as desired an such information may be transmitted from a fixed location or a mobile vehicle.

luminescent cable

U.S. Patent No.: 12,404,979

Patent date: Sept. 2, 2025 Filed: Sept. 27, 2024

Assignee: Shanghai Lanhao Electric Co., Ltd., China

Inventors: Lei Zong, et al.

Provided is a passive luminescent cable. The passive luminescent cable includes a cable core and an outer sheath. The outer sheath is wrapped outside the cable core, and the cable core includes at least a power wire core, a ground wire core, an electromagnetic field energy

collection wire core and a light strip. The electromagnetic field energy collection wire core includes a magnetic conducting wire core and multiple first conductor wires. Each first conductor wire is wound outside the magnetic conducting wire core to form a coil, and two ends of the first conductor wire are respectively connected to two electrodes of the light strip to form a loop. The outer sheath and a protective sleeve of the light strip are made of a light-transmitting material.

U.S. Patent No.: 12,404,632

Patent date: Sept. 2, 2025 Filed: Aug. 3, 2021

Assignee: Fort Wayne Metals Research Products, LLC, USA

Inventors: Jeremy Schaffer, Robet Mitchell, Andrew Kritsch

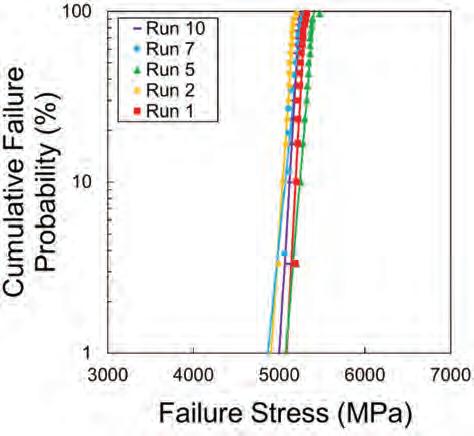

Ultra-High-Strength (UHS) wires are suited to high strength wire, strands, cables and rope applications including robotics force transmission and other high-performance mono- and multifilament wire applications. The wires exhibit high strength, low stretch and fatigue durability. Exemplary UHS materials include binary molybdenum-rhenium or tungsten-rhenium alloys with between 20 and 50 wt. % rhenium. These alloys are processed from a moderate strength (<2 GPa) warm-drawn rod to drawn monofilament wire with extreme nanocrystalline grain refinement, high apparent fatigue durability, and ultimate strength levels exceeding 5 GPa in all cases, and up to 6.8 GPa at monofilament diameters ranging from 7 to 100 μm.

U.S. Patent No.: 12,404,392

Patent date: Sept. 2, 2025 Filed: Feb. 5, 2021

Assignee: Heraeus Electronics GmbHh & Co. KG Heraeus Materials Singapore Pte. Ltd.

(Patent Report continued, see p. 66)

A major step forward for Asia’s cable industry unfolded at the recent staging of wire and Tube Southeast Asia 2025 in Bangkok. The Association of Thai Cable Manufacturers (ATCM), newly formed by the nation’s five largest wire and cable producers, made its exhibition debut by signing a memorandum of understanding with the Malaysian Cable Manufacturers Association (MCMA) and joining the Asia Wire & Cable Industry Cooperation Alliance (AWCCA). Per media reports, industry leadership described the milestone as a unified effort to raise technical standards, boost safety and quality, and secure greater competitiveness for the region’s manufacturers.

At its 2025 Annual General Meeting, ATCM unanimously elected its first President: Pongsapak Nakornsri, Chief Commercial Officer of Bangkok Cable BCC, to lead the association for the 2025–2027 term.

The ATCM—whose membership includes Bangkok Cable, Thai Yazaki Electric Wire, Charoong Thai Wire & Cable, Phelps Dodge Thailand and Prysmian Thailand— brings together firms responsible for a substantial portion of Thailand’s cable market. The association’s founding reflects a sharpening focus on upgrading product quality and representing collective interests. President Nakornsri stressed the importance of collaboration, describing cables as essential not just for energy infrastructure but for the steady growth of entire economies.

MCMA, representing Malaysia’s chief cable manufacturers since 1980, partnered actively in the announcement. Vice President Tee Kok Hwa emphasized the reciprocal benefits of cooperation, with both countries standing to gain from joint technical programs, harmonized standards and shared market knowledge.

ATCM’s entry into AWCCA marks a coordinated push across Asia’s cable sector. AWCCA, now comprising more than 50 member companies and organizations from China, Taiwan, Vietnam, Indonesia, Malaysia and now Thailand, aims to support both regional innovation and global representation. The alliance is viewed as an important vehicle for sharing expertise, responding to regulatory challenges, and shaping infrastructure development.

Industry observers point to the growing importance of such alliances. Bringing competing firms together helps address market access issues, coordinate on new technology rollouts—such as green manufacturing or digitization—and build a more unified regional presence. With the energy transition and continued development of communications infrastructure across ASEAN, collaboration is set to play a defining role in the sector’s future direction. The joint announcement at wire and Tube Southeast Asia 2025 signals a promising shift for the Asian cable industry.

Essex Solutions has upgraded its facility in Suzhou—a major city located in Jiangsu Province in eastern China—a project that included a major office renovation, the relocation of key departments and the creation of additional production space to support future growth in the region.

Per the company, it transformed an existing office building into a fully functional production support facility. The quality department, engineering department, R&D center, EHS and production office were relocated from their previous locations in the workshop to the newly renovated space. This move was designed to bring together critical production support teams in one location to improve efficiencies while freeing up valuable square footage in the manufacturing facility itself.

The relocation of the laboratory to the new site resulted in production line employees spending significantly more time delivering samples, which reduced overall work efficiency. The facility introduced robots to handle the sample delivery. This was not a substitution for the incremental task, but a strategic upgrade that significantly enhanced efficiency. The robots not only eliminated the added time burden but also created additional capacity for employees to focus on higher-value tasks.

That extra capacity is already earmarked for new production equipment. With more space available, Essex Solutions is preparing to expand its production capabilities in Suzhou—an essential step in meeting the increasing demand for the company’s products across the region.

“The relocation project represents more than just a change of space,” said Zack Kim, president of Essex Solutions Asia. “It is a commitment to efficiency, collaboration, and growth. By optimizing how we use our facilities, we can better serve our customers in the region and strengthen our global network.”

The Suzhou expansion is closely aligned with Essex Solutions’ global strategy to enhance production capacity, strengthen operational excellence, and support long-term business growth. By creating space for new equipment and centralizing support departments, the company is building a stronger foundation for innovation and customer service in one of its most important markets.

As demand in China and the region continues to grow, Essex Solutions’ ability to adapt and expand will play a critical role in sustaining customer partnerships and delivering high-quality products. The recent office renovation and department relocation are key steps forward in ensuring the company remains agile, competitive, and prepared for the future.

Indonesia’s state-owned utility Perusahaan Listrik Negara (PLN) has completed the reconductoring of its 500 kV Suralaya Lama to Cilegon transmission line.

Per the utility, the 10.9-km double-circuit line was upgraded with Amsterdam size ACCC® Conductors manufactured by PT. Karya Mega Sarana (KAMESA) under license from CTC Global. In total, 288 km of conductor were supplied, supporting increased transmission capacity and more secure electricity flow to the region’s consumers. The locally manufactured conductors also reflect PLN’s broader efforts to support sustainability goals.

The quad-bundled 500 kV line was supported by steel lattice towers with spans up to 703 m. The project, engineered by PT. PLN PUSMANPRO and installed by PT. Centra Multi Elektrindo, was efficiently completed

in about five weeks per circuit using two coordinated stringing teams.

Per ACCC, what makes the project especially significant is the use of its conductor technology on a 500 kV line, one of the highest transmission voltage levels in operation anywhere in the world.

Linkers Industries Limited (LII) , a Malaysian manufacturer of wire and cable harnesses, announced that its subsidiary—Linkers Asia Pacific Limited—has signed a Share Sale and Purchase Agreement to acquire 20% of LPW Electronics Co., Ltd.

A press release said that LPW, incorporated in Thailand in March 2023, specializes in wire harness manufacturing and has developed a production facility in Pathum Thani. LPW’s established customer portfolio including multinational corporations in the automotive and industrial sectors.

The acquisition is expected to enhance LII’s customer base in the automotive and industrial sectors in Thailand, supporting its expansion in the region. LII’s core structure already includes wholly-owned companies like TEM SP Limited and TEM Electronics (M) Sdn Bhd, which are central to their manufacturing and operational reach. n

SDI La Farga COPPERWORKS has named Jerry Evans as its president. He joined the company in 2017 as operations manager. He has more than 20 years of industry experience, including roles in copper processing and manufacturing. Prior to joining SDI La Farga COPPERWORKS, he managed operations in metal recycling and plant technology. He replaces Kurt Breischaft, the former president. Based in New Haven, Indiana, SDI La Farga COPPERWORKS is a joint venture of Steel Dynamics and La Farga Group of Spain, producing copper rod, wire, and welding wire for varied industrial sectors.

Hubbell Incorporated announced the promotion of Richard Conner to vice president & general manager of the wiring business unit. He joined the company as vice president, product marketing, in 2024. Prior to that he had worked for eight years for Medtronic and before that 13 years for Honeywell. He holds a B.S. degree in electronic engineering and an MBA from the University of New Haven. Based in Shelton, Connecticut, Hubbell Incorporated provides cable assemblies and connectivity solutions for multiple sectors.

Paul Lorigan has been promoted to chief innovation officer at Benvic USA. He joined the company in 2024 as sales and technical director. He has more than 30 years of industry experience, having previously served as manager of technology and laboratory services at M. Holland Company, technical director of T&T Marketing Inc, and other positions at AT Plastics and BP America Chemicals Company. His career started as a product development engineer at Anaconda Wire & Cable Co. Based in Princeton, New Jersey, Benvic USA makes custom thermoplastic compounds to sectors that include wire and cable.

Priority Wire & Cable has named Jeff Smith as regional sales manager - utility. He has 15 years of industry experience, including 12 years with General Cable in positions that included regional sales manager - utility division, territory sales manager and inside sales - utility division. Based in Little Rock, Arkansas, Priority Wire & Cable manufactures a wide range of aluminum, copper, specialty, utility and low-voltage cables.

Aran Harper has been named project manager at Ridgway Machines Limited, tasked with managing customer projects. He previously worked in roles in other fields delivering custom engineering solutions. He holds a degree in mechanical engineering from Nottingham Trent University. Based in Long Eaton, United Kingdom. Ridgway Machines Limited supplies wire and cable machinery.

Southwire announced that Denise Voss has joined the company as senior vice president of services and high voltage, a new position that integrates its high voltage business into the Southwire Services team. She most recently was head of commercial operations of the Americas with Danish Wind Power Academy. Prior to that she worked in energy-related positions for RNWBL Training, about two years; Artera Services, for three years and GE Power for 16 years. She holds a B.S. degree in mechanical engineering from the University of Wisconsin-Madison. Based in Carrollton, Georgia, USA, Southwire is one of North America’s largest wire and cable manufacturers.

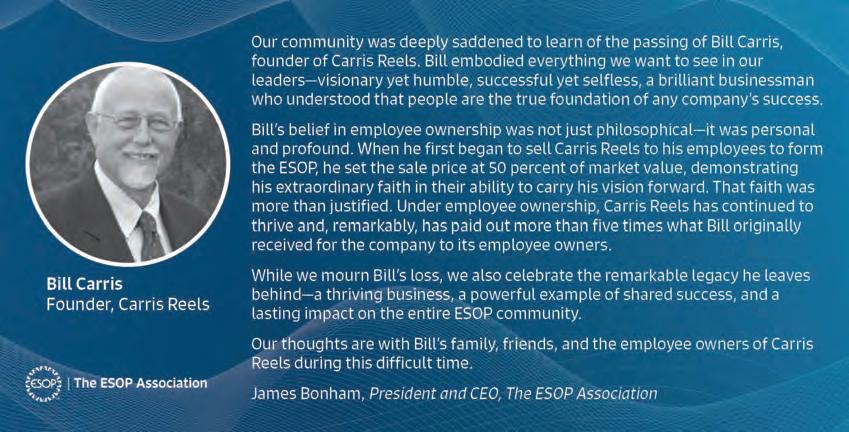

The owner who furthered the family success of Carris Reels and turned it into an ESOP

William Huntington Carris, the former president of Carris Reels— better known as just “Bill”—died Oct. 22 at age 81, leaving a lasting legacy as a visionary business leader, advocate and philanthropist.

In 1980, Bill Carris succeeded his father Henry as president and CEO of Carris Reels, guiding the Vermont company from a modest family business to a major international supplier of reels and wire products. In 1995, he implemented an employee owner-

Marinela Cirstea was named the global president of the Automotive Business Unit at Leggett & Platt. She has a background in finance and has been in the automotive industry for over a decade, including leadership roles at FORVIA (formerly Faurecia) and as group vice president for the Stellantis account. She worked for seven years at Schneider Electric, where she was in charge of financial performance for 10 European plants, plant finance director/CFO and cost-controlling manager. She holds a degree from ESCP Business School in France. Based in Carthage, Missouri, Leggett & Platt is a diversified manufacturer whose product lines include steel wire.

Kyle Koenig has been named chief commercial officer for Champlain Cable Corporation. He joined the company as a customer service/inside sales representative in 2007 and served over the years as inside sales manager, regional sales manager, director of sales and marketing in 2018, vice president of sales and marketing in 2020 and vice president of sales

ship model (ESOP), which remains central to the company’s success and culture today. See p. 44. He and his wife Barbara launched charitable programs that continue to benefit communities nationwide, with over $6 million donated under their guidance.

After retiring as CEO, Bill Carris remained on the board for two decades, serving the company for more than 50 years. A former junior Olympic long ski jumper, he was a three-term Vermont state senator, known for supporting small businesses, the arts and recovery programs, for crossing party lines with his warmth and humor and his boundless energy.

Per his posted obit, “Throughout his adventurous life (Bill) took on many roles: son, sibling, husband, father, business leader, politician, philanthropist, and all around badass.” He is survived by Barbara, his four children— Emily, Jesse, Jenne and Tracy—eight grandchildren, and an extended network of family and friends.

& marketing and Vermont operations in 2023. He holds a B.S. degree in business, management, marketing and related support service from Northern Vermont University. In July, the company also hired Jon Makhlouf as strategic account sales manager. He most recently was a project manager for Ecoclean North America, and has worked in management and/or engineering positions at Test Products, Inc., Pektron, Shiloh Industries, General Motors, Magnas Electronics and Mueller Industries. Based in Colchester, Vermont, Champlain Cable Corporation manufactures high-performance wire and cable products for sectors such as automotive, defense, marine and telecom.

Zumbach Electronics Corp. has promoted Mike Hullstrung to regional sales manager. He joined the company as a field service engineer in 2022. He previously worked for W.L. Gore & Associates. He holds a B.S. degree in mechanical engineering from the University of Delaware. Based in Mount Kisco, New York, Zumbach Electronics Corp. supplies testing and measuring equipment.

In October, the Fiber Optic Association (FOA) introduced a new standard titled “FOA Standard For Installing Fiber Optic Cable Plants” that fundamentally reshapes how best practices are documented and shared for every phase of fiber optic deployment.

This change marks the formal withdrawal of the ANSI/ NECA/FOA 301 standard, which had guided the fiber optics sector since 2000, most recently revised in 2016. FOA decided a more modern, open-source, and fielddriven approach was needed, as the old five-year ANSI revision cycle no longer fit the complexities and rapid changes the industry faces. Feedback from FOA advisors and instructors, along with global industry input, showed it was impossible to cover such a diverse sector with a single document. The growing range of installations—including data centers, rural broadband, FTTx, and LAN—made the need for flexibility clear. Because of this, the FOA completely rebooted its standards approach.