+ wire Kraków + wire Southeast Asia

On Sept. 4, India’s Sterlite Technologies Ltd. (STL) introduced its 864F Intermittent Bonded Ribbon (IBR) cable. The company—which also has a 168,000-sq-ft operation in Lugoff, South Carolina—describes it as the world’s slimmest such product. Below, Badri Gomatam, chief technology officer, shared with WJI how STL is able to pack a record 864 fibers into a cable diameter of just 11.7 mm.

WJI: When did the idea for this cable design first surface, and what sparked it?

Gomatam: This was a customer requirement to make the most of the duct space available for their network. This requirement pushed our R&D team to go beyond conventional cable designs and explore new pathways for achieving maximum fiber density in minimal space. It wasn’t just a response to a customer request. This was an opportunity for us to redefine the limits of compact cable engineering.

WJI: Did you start with an existing cable design that was “tweaked”?

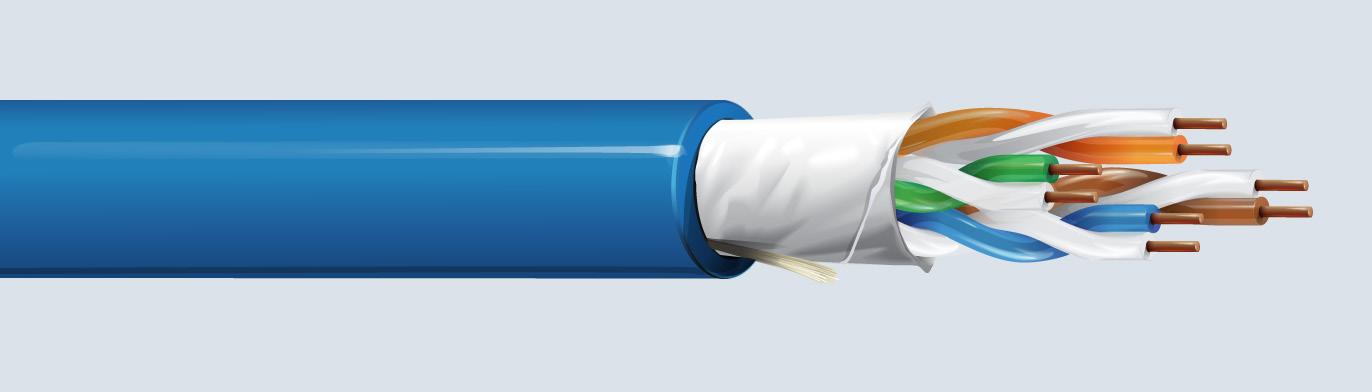

Gomatam: No, this was a ground-up innovation. STL did not previously have an 864F IBR cable using 200 μm fiber in its portfolio. To achieve such high density within a sub-12 mm diameter, we had to explore new fiber geometries and optimize material performance. While we had earlier developed an 864F IBR cable using 250 μm fiber, which served as a useful reference, this new design demanded an entirely different level of precision. Our engineers applied learnings from past developments but ultimately engineered a new design framework that combined advanced fiber technology, microstructure optimization and material science innovation.

WJI: What were the most difficult technical elements you faced and how did you overcome them?

Gomatam: There were two very demanding technical challenges. The first was the requirement to make a cable with a diameter less than 12 mm that could fit 864 fibers. This required precise optimization through numerous DoEs involving fiber selection, core design and compound rheology. The second was to meet the minimum blow distance of 2,700 feet in a stringent blow track with multiple bends. These achievements reflect the depth of STL’s R&D expertise and its ability to translate complex engineering challenges into reliable, scalable solutions.

WJI: If you started at Point A and your goal was Point B, was the design path from A to B a straight line, or were there some/considerable zigs and zags along the way?

Gomatam: The journey from concept to completion was far from linear. Multiple Design of Experiments (DoEs) were run to meet the customer’s requirements. This involved multiple design iterations and several DoEs to fine-tune every variable, from fiber packing to sheath material composition. Each phase presented unique challenges, from maintaining mechanical robustness to ensuring smooth air-blowing performance at high fiber densities. The process truly tested our R&D agility and our ability to balance mechanical strength, performance reliability and installation efficiency. The results prove it as the cable meets ICEA S-122-744 standards, is GR-20 compliant and can be installed in a 14/18 mm micro subduct.

WJI: How many staff people were involved in this?

Gomatam: We had a team of about 10 expert staffers from areas that include new product development, application engineering, QA, program management, material science, and manufacturing and supply (excluding sales and regional AE’s). This project was a collaborative success. Insights from sales and regional teams into customer requirements guided the early design framework. This integrated team structure exemplifies STL’s culture of collaborative innovation and multi-disciplinary problem-solving.

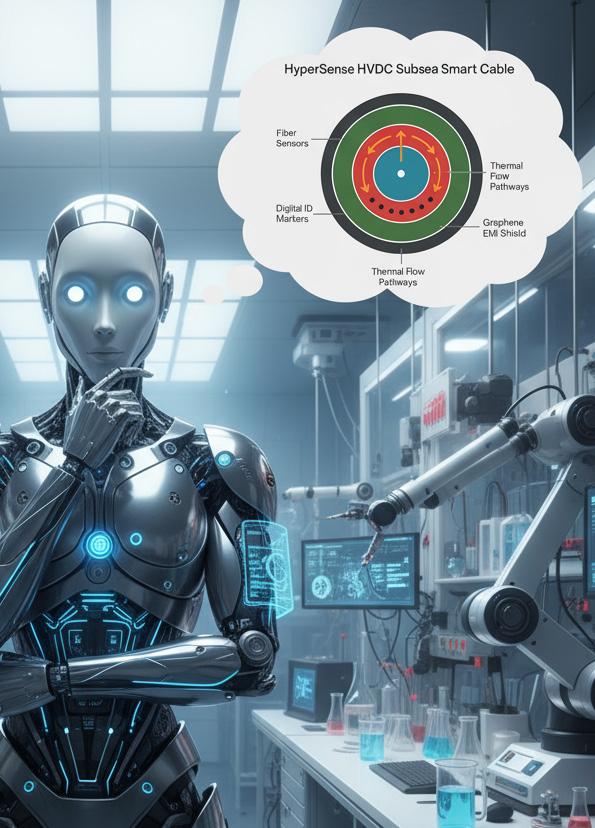

WJI: Is AI part of your R&D toolbox? Can it be more than that, especially in the years to come?

Gomatam: We extensively leverage advanced modelling and simulation tools to predict real-world cable performance, especially in critical areas like STL’s R&D unlocked record high-fiber density in new IBR cable air-blowing efficiency, mechanical integrity and environmental resilience. As our innovation roadmap evolves, we foresee AI playing a much bigger role in predictive design optimization, digital twin simulations and accelerated

(Feature continued, see p. 54)

material discovery, making the cable development process faster, smarter and even more precise.

WJI: What does this accomplishment mean to your company?

Gomatam: I am proud to note that our IBR cable portfolio now spans from 12 fibers to an industry-leading 6,912 fibers, with the company having produced and delivered multi-million fiber-km to customers across Europe and the U.S. over the past five years. With 10 manufacturing facilities strategically located in North America, Europe and Asia, STL is well-positioned to meet diverse global connectivity needs swiftly and at scale.

WJI: Any other points to share?

STL’s 864F Intermittent Bonded Ribbon (IBR) cable.

Gomatam: I want to stress the depth of research, experimentation and teamwork that goes into creating a product like the 864F IBR. Developing this wasn’t just a product milestone, it was about pushing the limits of what’s possible in high-density cable design. It represented the culmination of years of investment in material science, advanced fiber technology, and precision extrusion capa-

bilities and our people. It took close coordination between material scientists, design engineers, and application specialists to get it right. Behind every milestone like this sits a larger purpose: building smarter, faster and more sustainable networks. Our R&D teams operate out of world-class facilities that allow us to model, simulate, and test every parameter before real-world deployment. That gives us the confidence to innovate boldly while ensuring our customers get reliable, long-lasting performance. Another noteworthy point is how we approach sustainability in cable design. Whether it’s optimizing materials, reducing waste, or improving energy efficiency in manufacturing, we want every new design to contribute toward STL’s net-zero goals. The 864F IBR project exemplifies how innovation and sustainability can coexist — delivering superior performance while minimizing environmental impact. This project brought together a passionate, cross-functional team that truly thrives on solving complex challenges. We worked closely with our customers, listened to their evolving needs and co-created something that sets a new benchmark for optical cable design.