+ wire Kraków + wire Southeast Asia

In May 2025, Belden introduced its TIA‑compliant 10GXM13 Cat 6A U/UTP cable, highlighting a filler‑free design with a 0.230 in (5.84 mm) outside diameter that supports 100‑meter channels meeting Cat. 6A per ANSI/TIA‑568.2‑D. Below, Jim Valentine, Belden’s product manager for smart infrastructure solutions, discusses how the cable came to be.

WJI: The 10GXM13 cable sets a new benchmark for small-diameter Cat. 6A performance. What was the original spark or customer feedback that prompted Belden to pursue such a compact, filler-free design?

Valentine: The development of our 10GXM13 cable was driven by clear market evolution and direct customer feedback. We’ve observed a consistent 15% annual growth in the adoption of Cat. 6A cabling in the Americas. This trend is fueled by several factors: the need to support 10Gb/s data rates for future-proofing networks, the deployment of modern multi-gigabit Wi-Fi access points, the increasing power demands of PoE (Power over Ethernet) devices, and the specification of Cat. 6A as a baseline standard in many government, healthcare, and enterprise tenders.

Within this context, the demand for a reduced-diameter Cat. 6A cable has become a significant focus in the

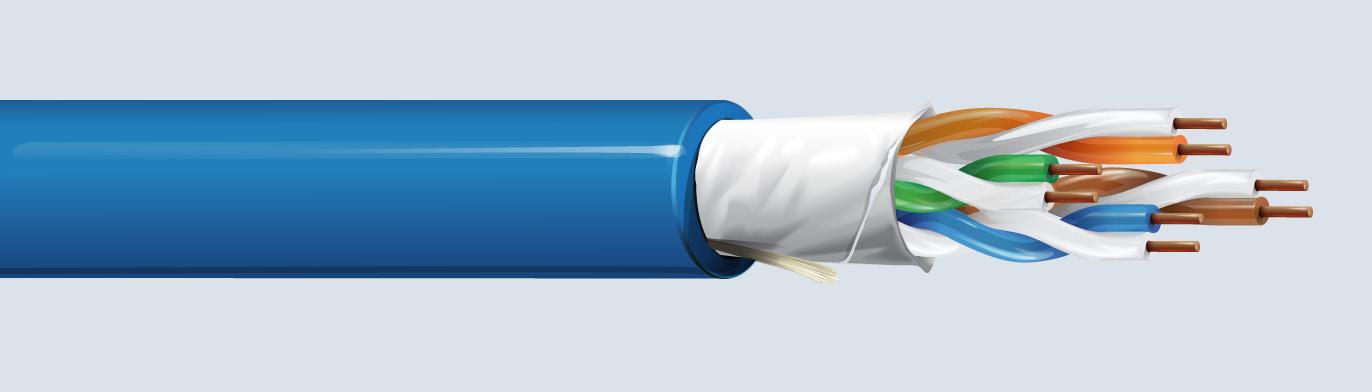

Belden’s 10GXM13 Cat 6A U/UTP cable.

structured cabling industry. Our customers consistently requested a smaller, more manageable cable to address key challenges in high-density environments. Specifically, a smaller diameter allows for:

• Improved pathway management: Increased capacity in conduits, cable trays, and J-hooks, which is critical in both new installations and legacy infrastructure with limited space.

• Higher-density racks: A more flexible cable with a tighter bend radius simplifies routing in crowded racks and patch panels.

• Enhanced thermal performance: Large, thick cable bundles can trap heat, potentially degrading network performance. A smaller cable profile improves airflow and cooling efficiency.

• Material and cost efficiency: A more compact design inherently uses less material, contributing to overall project cost-effectiveness.

WJI: When did this R&D journey begin, and was it a story of tweaking an existing cable, or was it far more complicated than that?

Valentine: This project began several years ago, and while our initial approach was to modify an existing design, it quickly became apparent that a complete re-engineering effort was required. The undertaking was far more complex than a simple tweak. Achieving the stringent electrical performance parameters of TIA Cat. 6A—particularly alien crosstalk performance—without the use of a traditional central filler, or spline, presented a significant engineering challenge that necessitated a ground-up redesign.

WJI: One of your challenges was to achieve both TIA compliance and the 0.230 in. diameter. Did any unexpected technical obstacles emerge along the way? Were there any design detours, surprises, or pivotal moments during development?

Valentine: Yes, there were numerous technical challenges. Unlike designing a component in a CAD environment, high-frequency cable design is an intricate blend of product engineering and iterative manufacturing trials. It combines known technological principles with empirical testing—essentially, “let’s try this and see if it works.” The primary obstacle was the removal of the spline, whose function is to maintain the geometric stability of the twisted pairs and minimize crosstalk. To compensate, we had to achieve a flawless core design, manufactured with exceptional precision. This required a deep dive into material science, insulation characteristics, and the physics of signal propagation at high frequencies.

WJI: Looking back, was there one “Eureka!” moment that you will long remember?

Valentine: Rather than a single “Eureka!” moment, the success of this project was the result of sheer persistence and a methodical, iterative development process. Our team’s dedication to continuous refinement and problem-solving was the true breakthrough.

WJI: Eliminating fillers might seem simple: just don’t use them. Why wasn’t it that simple, and what made it possible?

Valentine: While fillers are often omitted in less complex cables like Cat. 5e and some Cat. 6 designs, they are a standard feature in Cat. 6A for a critical reason. Cat. 6A must support double the frequency (500 MHz) and ten times the

data rate (10 Gb/s) of Cat 6 over 100 meters. This demands exceptionally crisp and stable electrical performance. The filler plays a key role in maintaining the precise pair separation and geometry needed to meet these demanding requirements.

Eliminating it required a holistic approach. We leveraged advanced insulation materials with superior dielectric properties and developed a proprietary manufacturing process that ensures unparalleled precision in the twisting and arrangement of the pairs. It was this combination of material science and manufacturing excellence that made the filler-free design possible.

WJI: What do customers gain with this new cable? Can you estimate the reduction in conduit costs, installation time, or material waste compared to conventional Cat. 6A options?

Valentine: The primary benefits for customers are enhanced installation efficiency and optimized infrastructure performance. This includes easier pathway management, higher rack density, improved thermal management, and simpler handling during installation. For a tangible example, we had a project where a customer needed to run two cables through a ½-inch pathway. A standard-diameter Cat. 6A cable would not fit, but the compact design of the 10GXM13 made it possible, saving significant time and cost on conduit modifications. While specific savings vary by project, the ability to use smaller conduits and increase fill capacity can lead to substantial reductions in both material and labor costs.

Richmond, Indiana, and our world-class manufacturing facility in Nogales, Arizona, highlighting our integrated approach to innovation and production.

WJI: Were there lessons learned in this research that will help you in future R&D?

Valentine: Absolutely. The insights we gained into advanced material science and high-precision manufacturing techniques are invaluable. This project has deepened our understanding of the complex interplay between a cable’s physical construction and its electrical performance at high frequencies. These lessons will undoubtedly inform and accelerate the development of our next generation of high-performance cabling solutions.

WJI: Does cable design still have an element of “art” to the process?

Valentine: Yes, very much so. While grounded in rigorous scientific principles, advanced cable design involves an element of artistry. It is the blend of theoretical modeling with empirical testing, guided by the deep experience and intuition of our engineers. This “art” is what allows us to push the boundaries of what’s possible and translate complex requirements into a reliable, high-performing product.

WJI: Was AI used for this research?

WJI: How many different staffers/departments were part of this effort?

Valentine: This was a significant collaborative effort that drew on the expertise of multiple teams across our organization. It involved a close partnership between our product engineering team at the Belden Engineering Center in

Valentine: No, Artificial Intelligence wasn’t utilized in the development of this specific product. What truly defined this effort was the expertise and collaboration of our teams on the ground, with engineers and manufacturing teams working side by side across our U.S. and Mexico operations. While AI can assist with modeling and data analysis, innovations like the 10GXM13 come from the hands-on experience and expertise of people who understand the materials, the process, and the needs of our customers. It reflects what we call being Rooted in America, combining local ingenuity, craftsmanship, and manufacturing excellence to deliver reliable solutions for our customers.