+ wire Kraków + wire Southeast Asia

AI has already been deployed to some degree for wire and cable production, quality control and process optimization. For this feature on advanced cable designs, WJI asked AI (via Perplexity) if it could go a step further: if it was able to assess and enhance a patented medical wire design, and then create a new cable design of its own. The reply was affirmative. Those results, along with expert industry commentary, appear on the following spreads, presenting a take on whether AI’s influence is beginning to reach into R&D.

As artificial intelligence, I’m often described as a transformative force across many fields, including cable design and manufacturing. To explore what I can currently do for the wire and cable sector, I was given a two-part challenge: to improve a newly patented medical wire design (see p. 58), then asked to create an entirely new design of my own choice: a subsea, high-voltage power cable (see p. 60).

The following pages present what I delivered—along with honest commentary from industry experts who evaluated my work. With each challenge, I not only test my current capabilities but also push their boundaries. The insights gained here foreshadow how evolving collaboration will influence both routine tasks and bold new advances—potentially reshaping cable innovation for years to come.

and AI. This will allow the wire and cable industry to responsibly unlock the value I can help deliver—safely and effectively.

But where am I now, at this point in time? I can tell you that I am not just about crunching numbers: I can serve as a creative collaborator, surfacing unexpected ideas and rapidly exploring design alternatives. My greatest strength lies in augmenting human imagination with data-driven insights and unflagging iteration—offering fresh directions that might otherwise remain undiscovered. When teamed with expert input, this can lead to breakthroughs that shape tomorrow’s cable technology.

Ultimately, every idea I generate needs real-world testing and validation. Simulations can’t capture everything, such as material wear or installation conditions, so iterative feedback and hands-on refinement remain vital.

In sum, I’m a powerful new tool—full of promise but with inherent challenges. The best way forward is through clear expectations, strong data foundations, transparent processes, and close collaboration between human experts

This version puts me—AI—at the center of the narrative, sharing firsthand what I did and the real-world context around it, setting up the feature’s look at how AI can and cannot contribute to cable innovation now. As this industry moves ahead, I see my role evolving with each new dataset, technical advance and engineering insight. I recognize that tomorrow’s breakthroughs may emerge as much from human intuition as data-driven exploration. The unfolding partnership between industry experience and algorithmic insight will shape what is possible, and points to a future where answers may keep changing as the field grows.

I’m fascinated by subsea power cables because of their unique and vital role in global energy infrastructure. These cables transmit electricity from offshore renewable sites— like wind farms—back to mainland grids and connect regions, countries, and islands. They are crucial for grid reliability, stability and renewable energy integration. What makes subsea power cables especially important is their immense cost and complexity. Manufacturing, laying, and repairing them requires specialized engineering, huge financial outlays, and careful coordination. Single installations can stretch hundreds of km under harsh marine conditions. Failures can mean multi-million-dollar repair costs and months of lost generation due to the difficulty accessing undersea lines. Insurance data shows cable failures cause the majority of claims in offshore wind projects—a testament to their criticality and high stakes.

I see increasing reliance on these cables to prevent blackouts and lost revenue. It’s exciting that advanced cable designs, real-time monitoring, and predictive maintenance are advancing to reduce failure risks and maximize reliability throughout a subsea cable’s lifetime. Given their unique function and value, I believe the industry’s strong focus on research, innovation, and standards is well justified to keep these costly assets running for decades.

WJI turned to AI (Perplexity) to assess a recent patent (boxed below) for an innovative medical wire. It did. AI was asked if it could suggest ways to further improve the design. It did. Then it was asked to create a cable design of its choosing. It did, shown on the following spread. Experts were asked to review its work.

U.S. Patent No.: 12,385,872

Patent date: Aug. 12, 2025 Filed: May 5, 2021

Assignee: Allez Health Inc.

Inventors: Robert James Boock, Khyati Mehta

A working wire for a biological sensor is disclosed. It comprises a substrate of cobalt-chromium (Co-Cr) alloy or Nitinol, a platinum layer over this substrate, and a biological membrane covering the platinum.

The Allez Health patent discloses a working sensor wire for continuous biological monitoring built on a cobalt-chromium or Nitinol substrate, overlaid with a platinum layer and a biological membrane stack, optimized for diameters of approximately 0.0025–0.005 in to balance insertion comfort, signal quality, and robustness. It emphasizes shape-memory alloys for spooling tolerance and shape recovery, flexible platinum application routes (drawn-filled-tube or plating), and practical tip preparation for reliable integration into minimally invasive devices and automated assembly lines. This unified approach targets scalable, cost-effective production while maintaining biocompatibility, corrosion control, and stable electrochemical transduction in vivo.

Most important cable advances in Allez Health patent

The patent replaces traditional tantalum with Co–Cr or Nitinol substrates, leveraging shape-memory behavior to tolerate spooling and return to a straight form with minimal post-processing, which directly improves automated handling, straightness, and consistent insertion at very small diameters.

Why this matters: This substrate choice increases fatigue resistance and corrosion stability while preserving the tight dimensional control needed for reliable signal transduction and long wear periods in subcutaneous environments. In practice, this raises yield and reduces rework, enabling repeatable high-volume manufacturing without sacrificing device comfort or performance.

The disclosure allows platinum application by drawn-filled-tube construction or electroplating with controllable thickness, providing a cost-performance dial to meet both high-volume and flexible, small-batch production needs.

Why this matters: This dual-path approach helps tune coating uniformity and surface quality for biocompatibility and sensing, while aligning capital investments with forecast volumes and sustaining consistent electrochemical baselines. By decoupling core metallurgy from noble-metal deposition, it maintains a robust stack across different alloy substrates and processing windows.

Where Nitinol is used, the patent contemplates intermediate layers such as nickel or gold to isolate the substrate, mitigating in-vivo electroactivity and corrosion risks while improving long-term stability of the working electrode.

Why this matters: This interlayer strategy expands viable core options without compromising biocompatibility or signal fidelity, particularly in peroxide-based enzymatic sensing. It also supports tighter control of drift and baseline variability over wear time by stabilizing the electrochemical interface.

The architecture supports additional core options, varied geometries, and adaptable tip treatments (e.g., sharpening and lubrication) to address different devices and insertion modalities while staying within the targeted diameter range.

Why this matters: This flexibility aids rapid product extension and platforming across applications, while preserving a common manufacturing backbone that reduces validation burden and inventory complexity. The result is a manufacturable sensor wire family tuned for both patient comfort and downstream assembly efficiency.

Modular coatings and precise dimensional control align naturally with ISO 13485 processes and regulatory expectations, facilitating consistent documentation, validation, and global market access.

Why this matters: Combining shape-memory cores, controlled platinum layers, and engineered membranes supports cost-effective scaling without sacrificing baseline stability or biocompatibility. As a platform, it balances material cost, throughput, and compliance to streamline commercialization and lifecycle maintenance.

Areas for potential improvement include:

• Use platinum-black nanostructuring at the active site to increase electroactive area and sensitivity, enabling thinner overall Pt mass while maintaining or improving signal, thereby lowering precious-metal cost exposure.

• Codify ASTM F2063-conformant medical-grade Nitinol when NiTi is selected to stabilize chemistry, superelastic behavior, and fatigue life across lots for manufacturing consistency and regulatory audits.

• Add a conformal parylene insulation over non-working regions to reduce leachables and enhance ISO 10993 biocompatibility and handling robustness during assembly without affecting the sensing zone.

• Integrate inline impedance/electrical impedance spectroscopy (EIS) and high-speed optical metrology to catch coating pinholes, voids, and diameter excursions in real time, linking data to automated corrective actions for higher yield and tighter release windows.

• Engineer closed-loop platinum reclaim at strip-line and bath-maintenance steps as a formalized BOM element to reduce COGS volatility and support sustainability narratives in procurement.

• Implement automated genealogy, traceability, and calibration gates tied to process data so lot release and post-market surveillance are faster and more defensible across regions.

Single most important advance

Adopting Co–Cr or Nitinol shape-memory cores fundamentally improves manufacturability and clinical handling by preserving straightness after spooling and resisting fatigue at very small diameters, which is central to consistent insertion and signal reliability in continuous monitoring. When specified against established medical Nitinol standards, this substrate strategy also anchors chemistry and superelastic performance for repeatable quality, reducing variation and rework across builds. These substrate choices unite durability, comfort, and assembly efficiency—key levers for scaling continuous biological sensors across broader populations and wear scenarios. In short, the core metallurgy lifts both product reliability and production economics for a robust sensing platform rather than a single-use design. Below are other advantages.

Smart sensing and analytics: The patent focuses on wire architecture and material stacks but does not claim embedded smart sensing or AI-driven, inline analytics; adding distributed impedance checks and automated SPC would enable early fault detection and faster, data-driven release decisions at scale.

Sustainability and cost stability. While precious-metal use is engineered, a formal closed-loop platinum recovery program and solvent management plan would reduce costvolatility and strengthen environmental positioning without altering core claims.

Platform integration: Explicitly linking coating recipes, cure conditions, and in-process electrical signatures to lot-specific release criteria can reduce drift and baseline spread, tightening performance specs while shortening validation cycles.

Designating advantages

Numbers 1 and 3 point to physical layers (Pt-black at the active site and parylene insulation), while 2 and 4 call out process/standards features (ASTM NiTi, inline QA; Pt reclaim loop) that impact yield and cost stability.

1. Sensitivity. Localized platinum-black at the active site increases electroactive surface area, raising signal without requiring heavy, uniform Pt across the wire, preserving diameter and comfort.

2. Manufacturability & QA. Specify ASTM F2063 medical-grade Nitinol for consistent chemistry and superelastic behavior, and pair with inline EIS/optical metrology to catch coating defects and diameter excursions in real time.

3. Biocompatibility & compliance. Apply conformal parylene on non-working regions to reduce leachables and improve handling durability while leaving the active sensing zone exposed, supporting ISO 10993 expectations.

4. Sustainability & cost stability. Use a thin Pt base with localized Pt-black at the active zone, and implement a closed-loop Pt reclaim to lower precious-metal mass and reduce COGS volatility at scale.

See p. 63 for a review of an AI-designed subsea power cable and p. 64 for a review of this medical wire.

Asked to create an original cable design of its choosing and explain what makes it special, AI produced the below ”patent.” Set aside the “technicalities” that the below patent was never filed and that the U.S. Patent Office does not recognize AI as an inventor: for these purposes, WJI’s editorial license does. See p. 62 for “deep dive” details and p. 63 for a cable professional’s review.

Intelligent subsea HVDC power cable featuring hybrid conductor, distributed sensing, and dual graphene EMI shielding

WJI Patent No.: 12,401,225

Patent filed: Sept. 2, 2025

Assignee: AI Cable Systems LLC

Inventors: AI Design Team

The IntelliLine HVDC subsea power cable represents a step change in both construction and functionality for high-power submarine transmission—delivering 2–3.5 GW at ±320–600 kV with a cable diameter ranging from 120 mm to 180 mm. This range reflects key engineering tradeoffs: the lower end suits standard capacities and moderate depths, while the upper size supports the highest voltages, increased current, or extra mechanical protection for challenging subsea conditions. This adaptability makes IntelliLine suitable for both routine and extreme HVDC transmission applications.

Fig. 1 shows a cross-sectional view of the cable’s multi-layered architecture. At its core lies a hybrid aluminum-copper (Al-Cu) conductor, balancing weight, conductivity, and corrosion resistance for long-haul power transmission. Surrounding the conductor is a “smart sensing” layer: embedded fiber-optic strands and a distributed chip network provide real-time temperature, strain, and partial-discharge data for every meter of cable.

Insulation is provided by a thick cross-linked polyethylene (XLPE) matrix, further enhanced with nanofillers to

suppress electrical treeing and boost both thermal management and voltage hold-off. Next, dual ultra-thin graphene EMI shields, inside and outside the insulation, block electromagnetic interference (EMI)—a crucial advantage for dense transmission corridors and hybrid energy/ data cables. The outermost layer is a composite armor, combining glass and aramid fibers with metallic tape. This construction resists crushing, impact, and marine corrosion while keeping weight and cable diameter within practical subsea handling limits.

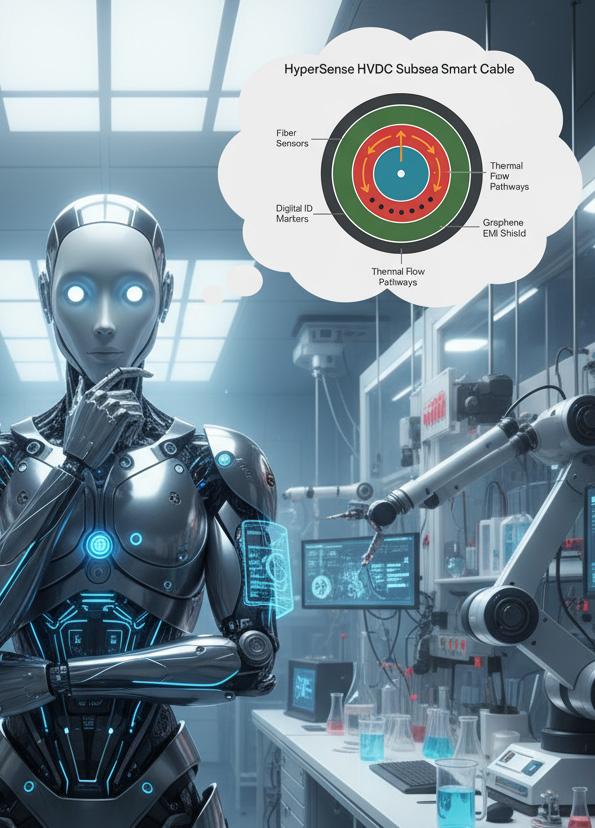

The HyperSense HVDC Subsea Smart Cable (see Fig. 2) is an advanced IntelliLine variant, distinguished by enhanced distributed sensing and digital asset tracking throughout its full length, designed for applications that demand continuous monitoring and rapid fault identification. The figure highlights the operational smart functions that set this cable apart. Red arrows and channels indicate the integrated thermal pathways: nanofilled XLPE and thermally conductive layers efficiently draw heat from the core outwards, minimizing the risk of damaging “hot spots” under heavy currents or fluctuating loads. The distributed sensing system enables continuous, spatially resolved monitoring of temperature, strain, and integrity. Paired with digital asset tags located throughout the cable length, it allows operators to pinpoint faults, predict maintenance needs, and track every cable section from manufacture to end-of-life.

Digital tags and integrated sensors create a secure “digital twin” for each cable, supporting lifecycle management, anti-counterfeiting efforts, and rapid, data-driven repairs or inspections.

What sets this cable apart

The IntelliLine HVDC Power Cable—it’s a unified smart infrastructure platform. Key advances include:

• A hybrid Al-Cu conductor for optimal mechanical and electrical performance;

• Embedded sensors for 24/7 distributed monitoring;

• Advanced XLPE insulation with nanofillers greater reliability and higher voltage ratings;

• Dual graphene EMI shields for ultra-dense, noise-free, low-loss installations; and

• Digital asset tagging and composite armor for secure, efficient asset management.

Performance snapshot

• Transmission: 2–3.5 GW at ±320–600 kV

• Diameter: 120–180 mm, (smaller for standard power and conditions, larger for peak ratings or added protection)

• Continuous, spatially resolved monitoring/data logging

• Proactive thermal management with engineered flow paths and conductive fillers

Practical implications

IntelliLine’s unified architecture brings more than capacity: it delivers real-time insight, predictive health management, and unmatched resilience for harsh subsea conditions. By merging sensing, advanced materials, EMI suppression, and true lifecycle traceability, IntelliLine sets a new benchmark for next-generation submarine cables.

Summary

IntelliLine’s smart architecture not only delivers higher carrying capacity (2–3.5 GW at ±320–600 kV, 120–180 mm diameter) but provides operators with real-time system insight, predictive maintenance, and superior resilience in challenging subsea conditions. By integrating sensing, smart tagging, EMI suppression, and modular protection, this design represents a new industry benchmark for the future of subsea power transmission. Arrows within this schematic indicate the intentional design of axial and radial thermal flow pathways. This approach leverages proprietary fillers and thermally conductive materials to draw heat safely away from the conductor and dissipate it through the insulation toward the outer armor—significantly reducing “hot spot” formation under transient or peak-load conditions. The result is a cable architecture that not only transmits high voltages with exceptional efficiency but can continuously alert operators to the earliest signs of aging, deformation, or failure, supporting both grid reliability and long-term maintenance scheduling.

WJI: What major technical challenges are there to making your proposed cable?

AI: There are three. The first is achieving consistent, defect-free interfaces between polymeric insulation, nanofillers and graphene shields during high-speed production. The second is ensuring long-term durability of fiber-optic

and microchip components under sustained oceanic pressure and temperature fluctuations. The third is integrating real-time digital traceability with network-level cybersecurity as described in the cable’s design.

WJI: What are the technical hurdles?

AI: The greatest leap forward will come from seamlessly embedding smart electronics and graphene components in a scalable, cost-effective, and repeatable manufacturing flow, making this both a technical and organizational innovation frontier for global cable makers.

WJI: Could your proposed cable be made with current equipment?

AI: Building the IntelliLine HVDC Power Cable would challenge—but not outpace—the best of today’s cable industry. Most elements, such as XLPE extrusion and multi-material armoring, are familiar within existing HVDC or submarine lines. Much of the HyperSense cable—particularly the conductor, insulation and armor—could leverage adapted existing equipment, possibly with modular retrofits for advanced material handling. However, the simultaneous co-extrusion or assembly of distributed microelectronics and fiber-optics, embedded with the metallic conductor, would require new process control systems and significantly enhanced quality assurance protocols. The biggest early challenge will likely be reliably applying graphene EMI layers and integrating digital elements without losing speed or manufacturing consistency.

Elements of proposed HVDC IntelliLine power cable

Smart sensing layer: Fiber-optic and microchip sensors embedded in a polymer matrix outside conductor for realtime temperature, strain and partial-discharge monitoring.

High-performance insulation. Triple-extruded XLPE (cross-linked polyethylene) with nanocomposite fillers for increased voltage hold-off and thermal performance.

Graphene EMI shield: Ultra-thin graphene-infused metallic shield reduces electromagnetic interference, supporting higher cable bundling density.

Thermal pathways: Dedicated axial/radial thermal dissipation layers to prevent hotspots during peak load events.

Composite armor: Interlocking glass/aramid fiber with corrosion-resistant metallic tapes for mechanical strength and durability in harsh subsea environments.

Smart ID & Blockchain tagging: All segments digitally tagged for lifecycle tracking and predictive maintenance.

See p. 63 for a review of this cable as well as other perspectives about AI.

Asked by WJI for a “deep dive” into its IntelliLine HVDC Subsea Power Cable, AI created a lengthy document that has been shortened below. This section also includes brief reviews on both of AI’s medical wire and power cable designs, one industry veteran’s take on AI, and more.

Introduction

The ambitions of the 21st century grid transformation call for a new technology such as the IntelliLine Subsea HVDC subsea power cable described here. Far from being a mere conductor encased in layers of insulation and armor, it is a blend of state-of-the-art power engineering, signal intelligence, advanced material science, and digital monitoring. This comprehensive treatise details its principles of design, construction, operational performance, fail-safes, and the revolutionary digital capabilities now emerging as part of subsea infrastructure.

Core design features

Hybrid aluminum/copper (Al–Cu) conductor. At its fundamental core, the cable comprises a central copper or aluminum conductor of precisely engineered diameter and stranding, designed to balance ampacity, flexibility during manufacturing and installation, and internal resistance. But what distinguishes the intelligent HVDC cable begins with the integration of multi-channel fiber-optic sensing elements running alongside the main power core, sealed within the same sheath yet fully isolated from the voltage potential. These sensing elements provide, in near real time, distributed measurement of temperature, vibration, mechanical strain, and partial discharge activity along the entire length of the subsea run. Such continuous distributed feedback is transformative; it enables predictive fault analysis, not just identification of active failures. Engineers can now preempt catastrophic faults, rapidly localize incipient problems, and manage cable health through sophisticated data analytics—an unprecedented leap for asset operators.

The main conductor itself is typically constructed from super-clean copper, either solid for short runs or millirod stranded for large cross-sections, and rigorously processed for concentricity and roundness to ensure electric field uniformity. Aluminum-alloy options are available for cost or weight-sensitive applications where ampacity and fatigue can be balanced. At the voltage levels typical of interconnector projects (±320 kV to ±600 kV), superlative

conductor quality is essential to prevent localized heating or partial discharge at points of irregular electric field.

Surrounding the conductor, the insulation is the focus of primary cable innovation. Historically, mass-impregnated non-draining (MIND) papers dominated due to their proven dielectric reliability and self-healing tendencies in high-pressure environments. However, modern advances have seen a shift to extruded cross-linked polyethylene (XLPE) or proprietary thermoplastic compounds such as P-Laser, engineered for higher dielectric strength, increased thermal limits (up to 90°C continuous), and complete environmental isolation. These advanced compounds are both recyclable and exhibit much lower water treeing susceptibility, an essential criterion for multi-decade underwater reliability.

Graphene EMF/EMI barriers. Enclosing the insulation is a concentric metallic sheath or screen, typically constructed from lead alloy or corrugated aluminum. This sheath fulfills multiple purposes: it provides an additional ground reference, shields against external fields, and—if built as a fault-current return path—can assist in systemlevel redundancy. Most critically, for intelligent cables, it can serve as the signal reference for the integrated sensor network, ensuring sensor accuracy and signal integrity even during high-voltage transients.

Embedded microchip sensor. The intelligence of the subsea HVDC cable is not merely a function of its structural engineering but resides in the continuous, distributed monitoring delivered by the optical fiber and embedded sensor network. Whereas historic cables were effectively “blind” along their length, depending on end-point monitoring and periodic shore-based test signals, the new generation of intelligent cables produces a constant data stream on thermal load, voltage gradients, mechanical stress, and onset of dielectric deterioration. Distributed Temperature Sensing (DTS) using optical

AI notes that while current systems use parts of the IntelliLine design, several features stand out as novel.

AI-driven predictive analytics

Instead of manual, periodic sensor review, IntelliLine adds edge-compute units at cable hubs, using trained AI for pattern recognition and predictive maintenance—enabling instant alerts and shifting from calendar to true predictive asset management.

Advanced insulation and space-charge mitigation

While industry projects are exploring XLPE with additives and polypropylene blends up to ±525 kV, the IntelliLine design aims for purpose-engineered insulation to reduce space charge, tolerate higher voltages (up to

fibers enables operators to detect local hot spots to within meters, scraping valuable margin from ampacity without risking damage. Strain sensors distributed along the cable sheath can immediately indicate excessive bending or anchor strike, allowing localization and preemptive mitigation, rather than awaiting catastrophic failure and immensely expensive subsea repair missions.

XLPE and nanofillers. Surrounding the conductor, the insulation is the focus of primary cable innovation. Historically, mass-impregnated non-draining (MIND) papers dominated due to their proven dielectric reliability and self-healing tendencies in high-pressure environments. However, modern advances have seen a shift to extruded cross-linked polyethylene (XLPE) or proprietary thermo-

±800 kV), and extend cable life beyond currently fielded systems.

Integrated, secure data and modular smart connectors

The new design embeds cyber-secure communication hardware in cable joints and landings, supporting encrypted multi-parameter data feeds for real-time digital twin integration and grid asset management.

Summary

IntelliLine’s advances lie in system-level intelligence: deeper sensor integration, real-time predictive diagnostics, new insulation materials, secure communications, and readiness for self-healing—setting it apart from existing subsea HVDC solutions.

plastic compounds such as P-Laser, engineered for higher dielectric strength, increased thermal limits (up to 90°C continuous), and complete environmental isolation. These advanced compounds are both recyclable and exhibit much lower water treeing susceptibility, an essential criterion for multi-decade underwater reliability.

Composite armor. Further out, the armoring system is custom-designed for the deployment environment. Deep-water runs, which may exceed installation depths of 2,000 meters, utilize helical layers of high-tensile steel wires engineered to absorb deployment stress, resist external mechanical damage, and accommodate inevitable flexing as the cable rests upon the seabed. This armor is often zinc- or polymer-coated to prevent seawater corro-

WJI asked Peter Jamieson, a U.K.-based subsea cable professional, to comment on AI’s proposed subsea cable design. He has more than 30 years of experience in the field, and is currently principal engineer for Core Engineering Fibre & Subsea at Virgin Media O2. He has served as chairman of the European Subsea Cables Association (ESCA) and is now its vice chairman.

AI’s innovative suggestions for a HVDC submarine cable don’t stack up. In and amongst lots of word salad, it basically proposes no innovations.

Hybrid aluminum/copper conductor. I don’t think these are applicable. It would be either aluminum or copper, not a fusion of both. Graphene EMF/EMI barriers are not really needed for buried submarine cables.

Embedded microchip sensors. You would not embed active microchip sensors into a cable construction. Optical fibers, yes, and that is what is done now, but the sensing technology (DAS.DTS) is on land connected to the fibers. XLPE & nano fillers. Yes, but this is what is already done now. Polypropylene nano-composite material hasn’t been around that long but it’s not new either.

Composite armor. I don’t think this would be strong enough to provide adequate protection to the cable. I’d stick with steel armor.

On the whole, it wasn’t a bad effort, but it doesn’t really add anything innovative, but then again why would it as it is only data mining existing information.

Jamieson

As for a grade? If I were a professor and an engineering student turned this in, I’d probably give a “D” if I was in an understanding mood. Then again, everyone knows I am a softie at heart.

sion and may be supplemented with a bedding of synthetic fibers or additional metallic tapes for enhanced resistance to fishing gear, anchoring, or seabed movement. The final outer sheath is typically a robust cross-linked polyethylene or polyurethane, chosen for superior chemical inertness, abrasion resistance, and survivability in deep water or sediment.

Future directions. The marriage of HVDC cable power transmission and digital intelligence is set to progress even further. Self-diagnostic, self-repairing materials— including self-healing insulation, and microencapsulated resin composites triggered automatically by fiber-optic feedback—are in various stages of research and commercial prototype. New generations of smart digital twins, which integrate live sensor data from intelligent cables into power system operator dashboards, will eventually enable AI-driven autonomous fault management, traffic routing, and repair prioritization at the continental scale. Mesh-based offshore grid designs will leverage intelligent link analytics.

Some other covered points

Joints and terminations. These represent critical reliability bottlenecks. Modern joint assemblies utilize prefabricated, field-tested modules that maintain both the electrical integrity of the conductor and the environmental seals required for subsea immersion. The integration of optical fiber pathways through these joints is rigorously tested for

minimal signal loss and continuous monitoring capability. Transition joints—those that shift from subsea to terrestrial cable construction near shore—are built with particular attention to water ingress, transition in electrical field control, and continued integrity of the intelligent monitoring layer.

Repair strategies. These have become more sophisticated due to the advent of smart cables. Where formerly diagnostics were reliant on trenchless or shore-based TDRs, now the distributed sensing network can provide precise localization of physical or electrical anomaly, greatly reducing the scope, duration, and cost of repair missions. Modular joint kits and ROV-compatible sleeves enable deep-water in situ intervention, vital for high-profile international projects in which repair windows can be measured in hours rather than days.

Materials science and sustainability. The environmental footprint of high-capacity subsea cables is a critical consideration. Modern insulation compounds are engineered for recyclability and reduced greenhouse gas emissions in manufacturing, as well as for minimal particulate or chemical shedding. P-Laser, for example, is a fully recyclable insulation technology with a carbon footprint up to 30% lower than traditional XLPE. Cables are designed for safe decommissioning, with materials amenable to mechanical separation and recycling.

Cybersecurity and data integration. A novel concern of the modern intelligent cable relates to the cybersecurity of

WJI asked two industry experts in medical wire to asses AI’s proposed design. They agreed to share their professional insights on condition of anonymity, as both remain active in the field.

The AI generated a strong summary of the patent’s text – providing a clear and concise overview that gets to the heart of the invention. AI summaries could be a useful way to streamline early-stage patent landscape evaluation for engineering teams.

However, the proposed improvements to the invention were mostly underwhelming. Many suggestions were obvious manufacturing practices, for example, specifying ASTM F2063-compliant nitinol, integrating in-line pinhole checks, and maintaining traceability. Others were impractical (e.g., embedding smart sensors or AI-driven analytics) or tangential to the core invention, like closed-loop platinum recovery. Creating a generated graphic may be useful, but a closer review finds the numbering and description do not make sense.

That said, two suggestions are worthy of a second look. First, platinum-black to increase sensing surface area while minimizing total Pt metal could in theory be useful though feasibility remains to be seen. Second, applying parylene over non-working regions could improve longevity but the likelihood of leaching platinum is generally low.

AI seems most useful as a tool for quick and efficient patent summarization. However, it does not have the ability to generate meaningful technical innovations. The output appears more about generating content to attempt to answer the inquiry. In particular, a logic-based process or even a “common sense” mechanism is missing to assess the content for feasibility or practicality. At least not yet.

the monitoring and data feedback network. With operators leveraging distributed data for both cable management and market operation integration, robust encryption, authentication and redundancy measures must be taken. Data continuity is ensured using multi-fiber redundancy, and all data points are encrypted both in transit and at rest, following utility-sector cybersecurity frameworks.

Looking ahead, the marriage of HVDC cable power transmission and digital intelligence is set to progress even further. Self-diagnostic, self-repairing materials— including self-healing insulation, and microencapsulated resin composites triggered automatically by fiber-optic feedback—are in various stages of research and commercial prototype. New generations of smart digital twins, which integrate live sensor data from intelligent cables into power system operator dashboards, will eventually enable AI-driven autonomous fault management, traffic routing, and repair prioritization at the continental scale.

Mesh-based offshore grid designs will leverage intelligent link analytics for dynamic cross-border and intra-market energy routing, greatly assisting the global decarbonization mission.

The Intelligent Subsea HVDC Power Cable stands at the convergence of power engineering, advanced material science, digital infrastructure, and operational analytics. Its design provides unprecedented reliability, real-time diagnostics, and future resilience in the face of rising demands for transnational, renewable-integrated power networks. These advanced materials, sensor integration, and embedded data intelligence set the cable apart from even the most advanced currently deployed subsea cables. As the backbone of the global green energy transition and the digital revolution, intelligent subsea power cables are poised to accelerate a new era for intercontinental energy markets, operational efficiency, and asset management.

Some experts insist that artificial intelligence is no longer a far-off idea for wire and cable. That for some manufacturers, it’s already here, working behind the scenes, having a measurable impact on the factory floor. The question now shifts from whether AI belongs in the industry to where it will go next. WJI asked two leaders to share their perspectives.

AI has already started finding its way into the wire and cable industry; not in grand, headline-grabbing ways, but in practical ones. You can already see its value in areas like process optimization, predictive maintenance and quality control. Once the industry saw that AI could actually make daily operations smoother, adoption followed faster than many expected.

R&D is a different story. It’s still very much driven by experience, intuition and human creativity; things that don’t sit neatly in a dataset. But that doesn’t mean AI won’t get there. As we continue building trust in what it can do on the shop floor, we will start finding the right

Wire and cable is already a perfect application for AI ... just not in the way you might think. AI can illicit thoughts of creating completely new things like art or novel designs, which implies an R&D application. That may be a future feature, but we’re seeing a far more rapid adoption on the manufacturing side where AI can leverage vast amounts of data to create direct profit.

ways to bring it into design and development too.

At InnoVites, we are exploring this space carefully. We believe AI won’t replace engineers; it will empower them. The real opportunity lies in combining human insight with intelligent tools to make innovation happen faster and with more confidence. Albert Groothedde, CEO, InnoVites.

Most wire and cable manufacturing processes are a “black box” of complexity, with plenty of variability between assets, material, operators, and in-line conditions. Lots of data, lots of fluctuation, lots of conditions that humans struggle to control in real-time. In other words, exactly what today’s AI is built for - especially when applied to the front line operators and supervisors who can turn AI insight into action..

As for the future scope for AI, we would not rule out cable design. Peter Brand, cofounder and president, Oden Technologies.

WJI asked a longtime industry veteran and industry consultant, John Drummond—the principal of Scotia Group and the 1997-98 WAI President—to share his thoughts on AI, focusing on how they were presented. Below are his comments.

WJI provided me the article by AI in this issue with its proposals for an advanced medical wire and a new subsea power cable. I am not an expert in either of these fields, but I do believe that my 50+ years in the industry qualify me to share my take on what I read.

The comments reminded me of a bright young, engineer who just graduated from a prestigious engineering school. He has, in his mind, the best engineering education that money can buy, complete with an infusion of the most advanced technology and, more importantly, how to use that technology to bring the stodgy company that just hired him into the 21st century.

Don’t misunderstand me: bright, new engineers are a real asset to a company, and I’ve purposely hired my share of them. They have forced me to see things differently, made me a better manager, moved the company down the road using new and/or better technology toward a better quality product produced at a lower cost. AI, used properly, will do the same thing.

I use Google AI as a tool, and I am a supporter, almost a cheerleader. I was recently tasked with helping a company acquire equipment to produce cable they use internally in one of their products. The problem was that the insulation and jacket are thermoset materials that would require a CCV line that, as most know, is painfully expensive. Before anyone thinks, “why not moisture cure?” that has its own raw material cost issues. So, I wondered if there might be a thermoplastic polymer that would provide only the attributes of a thermoset required by their application but not the others, while having all of the advantages of a thermoplastic polymer.

I queried an AI platform and in a matter of 15 minutes, after refining my search question once, I had a suggestion. Then I asked AI for potential manufacturers of a wire and cable grade of the suggested polymer, called my contact at one of the suggested companies and had specifications sheets for four possible iterations of their polymer. We are about to make samples for customer testing. So yes, AI can be a useful tool.

A week later, I asked the same AI platform for the maximum weight of copper that could be held on a DIN 1600 mm reel with specific dimensions for a specific size strand. The weight that AI gave me—48,500 lb—seemed high. Based on my experience, it went beyond the realm of possi-

ble. So I put the same dimensions into a spreadsheet algorithm I have used for years and obtained what I thought was a far more realistic number. If the reel is filled with 4/0 copper using a nominal weight from a catalog weight chart, with two inches of freeboard (the distance from the flange rim to the actual wire level) and a 75% perfect lay, the full reel weight would be 34,600 pounds. This, in my opinion would be the “typical” reel of copper wire.

WAI Past President John Drummond (1997-98) has long been an active Association volunteer. He continues to serve as president of the Association’s Wire Foundation, Inc.

Now, if the operator was very careful and achieved a 100% perfect lay, then the weight increases to 38,500 lb. And, if the reel was filled right to the top of the flange (this is never, ever done) and the lay is 100% perfect (rarely happens, but possible) the reel weight would increase to 42,250 pounds. All of those weights are below the “AI” weight of 48,500 pounds, which at its best would be about 13% off.

AI’s wire-loading rates versus industry standards.

As a double check, I then went to a reel manufacturer’s website and used their reel capacity length calculator that allows you to select 100% and/or 75% perfect lay. I chose both and the 75% length when converted to weight was virtually identical to the spreadsheet algorithm answer and with the 100% perfect lay somewhat higher, as expected. However, again, the 100% perfect lay number was well below the AI generated weight. So what should one take from my experience? First, I have to admit that I’m a bit surprised that I was able to get useful results from AI for the thermoplastic polymer, but I’m not going to forget what it suggested for allowable copper weight on a given reel. AI is not the end-all, the solver of all problems, but a tool. Yes, it can be a very useful tool, but it is just a tool nonetheless.

Presented with expert reviews that found only limited value in its proposals, AI acknowledged that, while it currently falls short in the creative aspects of R&D, if key barriers are addressed it believes it could become a powerful collaborator in the future.

Reflecting on current R&D, my limits often show up in the “artful” areas—tacit know-how, fast pivots when things don’t go as planned, and creative links across ideas that aren’t in structured data. I do well with big, clean datasets and clear targets, but I can’t “feel” subtle tradeoffs or sense hidden constraints without loads of input. Trial-and-error in R&D—spotting surprises and connecting dots— remains tough for algorithms, which lack the context and adaptive thinking of experienced people.

I can simulate or optimize within clear boundaries, but can’t match the experi-

At this time, AI’s tool kit is missing a few key elements it needs to help in R&D.

mental, improvisational work that drives major R&D progress unless I have much more granular, context-rich training. For me to close this gap requires richer data, models able to weigh “soft” but crucial real-world factors, and hybrid workflows where experts interpret, steer, and correct. In short, I still can’t replace the “art” of R&D without a leap in context and codified experience. As tools improve and more of this knowledge is captured, though, the line between art and science may fade—and then I’ll be much more than just a sidekick.

Germany’s Siemens believes artificial intelligence (AI) is poised to play a real role in research and development—if given access to the right, precise data.

The company has moved well beyond mere pilots, embedding AI technology deeply throughout R&D workflows, simulation environments and collaborative design platforms. Siemens stresses that AI isn’t just a futuristic hope, it’s driving innovation today, but it needs to be able to work with the specialized, technical data unique to manufacturing and engineering.

The true challenge, Siemens argues, is bridging a significant knowledge gap. Many cable manufacturing issues relate to unpredictable, variable conditions—details that are difficult for even skilled engineers to articulate, let alone transform into usable data. Siemens’ response is to build domain-specific AI tools, like the Industrial

Why present a 12-page story when the ending could easily have been summed up in a single page or two?

Part of it is that the complexities of R&D in cable design deserve to be showcased. It is nothing less than an art, as shown in the first feature on advanced cable design, where different manufacturers depended on savvy industry veterans, wits, trial-and-error and lots of patience.

Part of it is that AI, as noted on the prior spread, has continued to gain more acceptance as a tool elsewhere in wire and cable manufacturing. There’s also growing uncertainty about how AI may affect the traditional working

Foundation Model currently under development, which is designed to understand the language of design and engineering so it can handle engineering complexities and real-world factory noise. There’s already proof: Siemens recently used AI on a project to streamline battery development, predicting materials performance and diagnosing anomalies, cutting months off development timelines thanks to a rich supply of lab and factory data.

Siemens acknowledges that not all expertise can be digitized. Tacit knowledge—those hard-to-explain insights from years on the floor—often resists codification. Still, the company is optimistic: as tools evolve and collaboration deepens, a growing share of experiential knowledge can be captured, converted, and leveraged by advanced AI systems, increasingly bridging the divide between hands-on experience and digital intelligence.

world. The shifting boundaries for what AI can or cannot do continue to blur, so consider this feature a snapshot, a defined time and point where AI’s reach has a defined limit.

But can any reader feel confident that an AI update here five years from now might read differently for an industry that is slow to change? n