+ wire Kraków + wire Southeast Asia

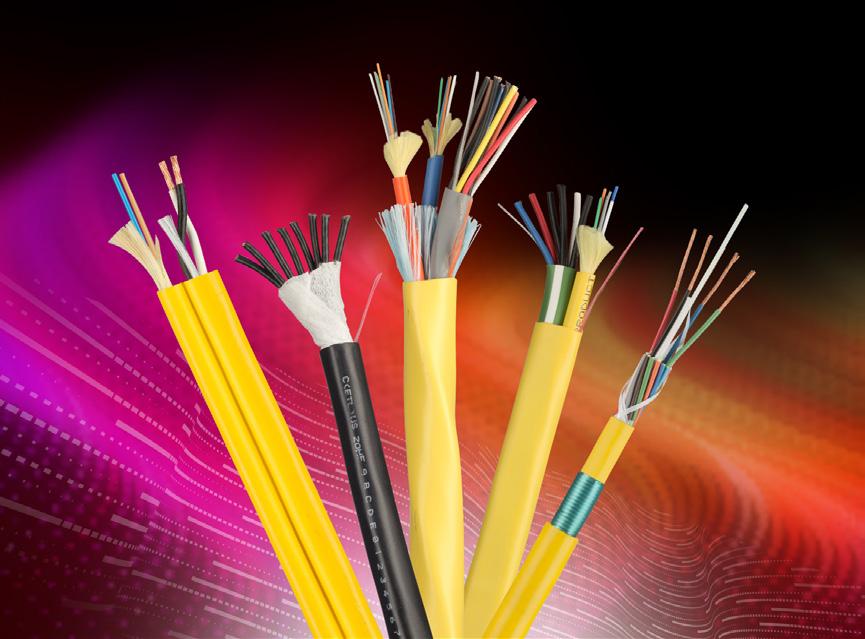

Sumitomo Electric shared with WJI how it redefined submarine power transmission with a DC XLPE cable that reliably carries HVDC across long undersea distances. The advance—rooted in decades of research—faced challenges that included one deemed impossible yet ultimately led to a solution. Pictured below is the company’s 400kV submarine power cable: its newest cable is on the next page.

Sumitomo Electric’s (Sumitomo) ambitious journey to produce a new DC XLPE submarine cable for intercon nector projects—technology essential for linking national grids and transmitting large volumes of renewable power over long distances underwater—was shaped by a series of pivotal R&D decisions made to overcome obstacles encountered during testing and deployment.

The specific goal was first set in the mid‑1980s, when Sumitomo engineers realized that a DC version of XLPE could transform long‑distance power transmission if the material barriers could be overcome. The decades‑long R&D effort, initiated in the mid‑1980s, reached maturity in the 2000s and was proven in full scale with projects such as Nemo Link, commissioned in 2019.

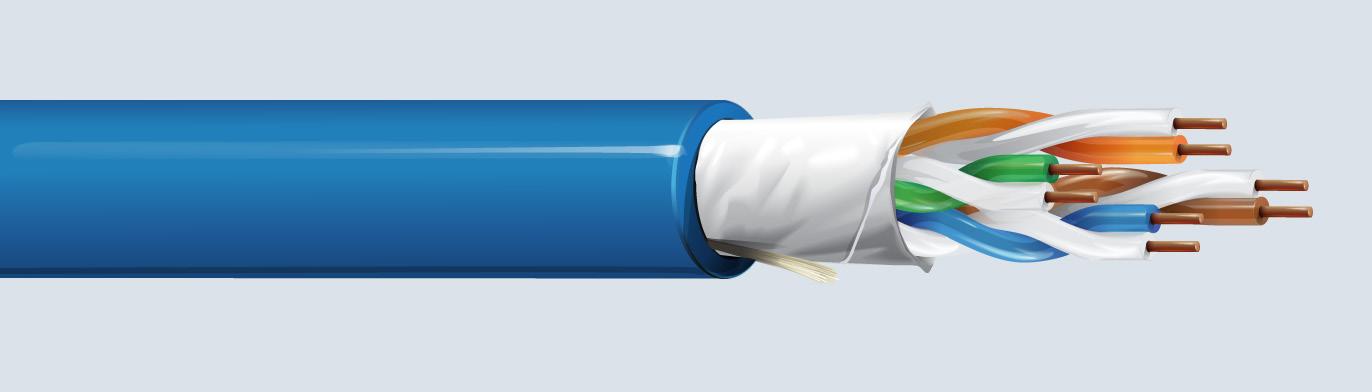

The aim was to create a cable that could operate at much higher voltages, tempera tures, and capacities than conventional submarine cables—a critical step for expanding cross‑border power links and renewable integration—while still main taining exceptional reliability and environ mental safety. What made this so difficult was that conventional XLPE insulation, well‑suited for AC service, repeatedly failed under DC conditions due to the accumulation of space charges in the insulation. In simple terms, space charges are stray electrical charges that slowly build up inside the insulation under DC voltage. Over time, the buildup distorts the electric field and weakens the mate rial from within. Eventually, the insulation breaks down without warning, making standard XLPE unusable for high‑voltage DC transmission across undersea distances. Addressing this meant rethinking the material science and the production process, pioneering not only a new additive to disperse space charges but also new manufacturing and installation techniques to ensure that every meter of cable, from the factory floor to the seabed joint, would perform flawlessly for decades.

tric breakdown and unlocked the possibility of true DC XLPE transmission at the voltages and lengths required for new interconnector projects.

Developing this insulation was only part of the answer. Because submarine cables may run for hundreds of km, Sumitomo had to guarantee that the precise balance achieved in the lab could be reproduced at manufacturing scale. That meant continuous monitoring at every stage— extrusion, curing, cross‑linking, and spooling—plus repeated mechanical, electrical and accelerated‑aging tests to catch flaws before installation. These stringent measures set a high bar but were critical for ensur ing no weak points would emerge once the cable was laid.

Installation brought its own set of challenges. The company had to refine how cables were handled, moved, and joined—especially at landfalls and underwater connec tions. When the Nemo Link between the U.K. and Belgium hit an unex pected snag just three km from shore during installation in 2018, Sumitomo quickly switched contractors and adapted its cable‑land ing methods. The project was completed on schedule despite logistical and marine obstacles. This ability to manage change in real time, supported by preparation and scenario planning, proved as vital as any laboratory breakthrough and demonstrated that R&D success also hinges on execution in the field.

Initial attempts to adapt AC XLPE cable as a DC solu tion exposed the problem: repeated breakdowns under direct current, even in controlled laboratory conditions. Rather than abandon XLPE’s environmental and oper ational advantages, Sumitomo’s R&D teams systemati cally investigated the underlying cause, conducting years of tests with polymer blends and evolving manufacturing techniques. The breakthrough decision was to challenge industry orthodoxy—the long‑held belief that “pure” insulation was always best. Engineers instead devel oped and optimized a filler additive for polyethylene that dispersed space charges within the cable insulation. This innovation shifted the industry’s understanding of dielec

The results are now visible in quantifiable, real‑world performance. The cables maintained target voltage and current ratings over long stretches and at temperatures up to 90°C, with no oil leaks or insulation failures. The addi tive‑based XLPE insulation set a new standard for DC reliability, and the company’s process controls allowed manufacturing at the scales required by major intercon nector projects. Facility operation rates such as the 99.8% achieved by Nemo Link stand as testaments to the sound ness of the R&D—not to abstract ambition.

Sumitomo Electric’s story is less about proclama tions and more about hard‑fought advancement: and maintaining the discipline needed to deliver consis tent, field‑ready performance. Each cable laid and grid connected stands as evidence that tough R&D deci sions—pursued over more than 20 years and carried through to manufacturing and installation—made a new generation of global submarine power interconnectors not just possible but proven.

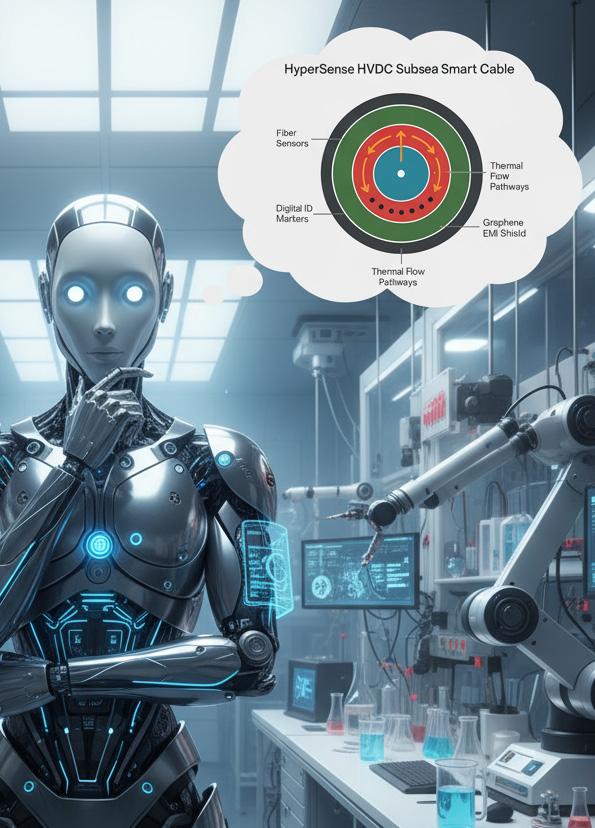

Sumitomo’s new 525 kV HVDC submarine cable stands out as a true breakthrough in power transmission tech

WJI asked Sumitomo Electric’s research and development department to discuss what makes its new 525 kV HVDC submarine power cable stand out. Below is their response.

nology, raising the bar for both volt age and capacity in a marketplace that is rapidly turning to renewables and interconnectors. With the highest volt age rating ever achieved using cross linked polyethylene (XLPE) insulation, this cable system can transfer more than 2 gigawatts per circuit—enough energy to power millions of homes or link national grids across continents. The use of proprietary DC XLPE compounds with advanced nano fill ers ensures the cable can handle high temperatures (up to 90°C), maximizing thermal stability and minimizing loss, while maintaining reliable performance even under demanding load and marine conditions.

Passing long term PQ test for 400kV system more than 10 years ago according to the international stan dard CIGRE TB496, Sumitomo’s cable proves itself with endurance and safety, backed by independent certifica tions. The engineering also includes seamless factory and offshore joints, transition technology for onshore integra

tion, and flexible splicing solutions—making it adaptable for complex large scale installation projects. These advances result in a cable that reduces losses, enhances operational efficiency, and cuts maintenance needs for operators, all of which are crucial for grid reliability and sustainability.

As countries expand offshore wind farms and invest in cross border energy transfer to meet climate targets, Sumitomo’s 525 kV cable becomes the backbone for high capacity, long range clean power delivery. Its efficient, high performance design directly supports the shift toward decarbonization and a resilient energy future. By combining advanced materi als, proven manufacturing, and system reli ability, this submarine cable system sets a new world standard and highlights the critical role of innovation in enabling the new era of renewable electricity transmission. Plus, it allows project developers to confi dently plan for even larger interconnections in years ahead, enabling flexible expansion and more robust global energy networks.

Shoshi Katakai, an ex fellow of Sumitomo Electric’s Electric Wire & Cable Energy Business Unit, has spent his career on one relentless challenge: making XLPE insula tion viable for high voltage direct current. Since joining the company in the 1980s, he set out to achieve that goal, which was considered promising but unattainable.

The difficulty wasn’t just theoretical. Conventional XLPE, which had revolutionized AC power cables, failed under DC. Long lab tests showed the same result again and again: space charges built up inside the supposedly “pure” polyethylene insu lation, weakening it until it broke down. From the standpoint of accepted industry knowledge, the outcome was unavoidable.

For years, develop ment stalled, but Katakai refused to accept it. Others clung to the dogma of purity, but he chose to experiment

with the opposite: adding something new. He began test ing fillers and additives, searching for a material that, if distributed uniformly inside the insulation, could suppress the space charges. It was not glamorous research. Each candidate had to be analyzed, blended, cured and tested. Progress was incremental, setbacks frequent.

Eventually, Katakai’s persistence paid off. He and his team developed a special filler material that dispersed evenly in XLPE and delivered superb DC insulation characteristics. The result was a stable, manufacturable compound capable of carrying HVDC reliably under the extreme stresses of submarine interconnectors.

“To solve space charge, we had to abandon purity and prove that an additive could make XLPE stronger. It was long, frustrating work, but that’s what made DC XLPE cables possible,” Katakai said.

That achievement—the world’s first DC XLPE— changed the industry. Today’s long‑distance intercon nectors, quietly transmitting thousands of megawatts across sea floors, rest on the foundation Katakai discov ered in the early 2000s by challenging orthodoxy with slow, stubborn, technical work until failure finally turned into proof.