THE NEW HOME OF FLOWTITE

Reece and Viadux are the new and exclusive home of Flowtite GRP Pipe, making selecting, ordering, and delivering your next project more convenient.

Visit your local branch or reece.com.au/civil/brands/flowtite to find out more.

Our dedicated, experienced teams will help you with Flowtite product queries, specs and more.

With over 40 branches across the country, you’ll get Australian-made Flowtite products whenever and wherever you need. 40+

With the complete and exclusive Flowtite range, we’ll help find the product to suit your needs.

From the CEO Desk

Welcome to the May Edition of Operator. It has been an exciting and busy start to 2024 at WIOA. The Board have approved the Strategic Plan, after a comprehensive consultation process with our membership. We have also merged WIOA Incorporated into WIOA Limited, delivering on the One WIOA project, which provides business efficiencies that will be re-focused on member outcomes. Further, we have revised our internal structure for the optimal delivery of our Strategic Plan, and member offerings.

I would like to introduce you to Team WIOA:

• Glenn Alford, Manager - Membership, Sponsor & Exhibitor Support, who will focus on supporting our WIOA membership.

• Katy O’Sullivan, Manager of Operations who’s focus will be optimising and digitising our internal business process and outward events and publications.

• Ann Austin, Business Administration Coordinator (part time) who’s focus is on our business administration functions, and our newest team member;

• Fiona Monge Simmonds, Executive Assistant who will support the team at all levels within the organisation

• Kate Russell, Event Co-ordinator who will be supporting all of our conferences and Interest Days.

Did you know the team is now based in Queensland, New South Wales, and Victoria, as we strive to enhance our member service and engagement nationally?

NEW WIOA Social Channels

Our new Instagram page

We’ve recently launched our new Instagram account @wioa_aus. Follow us on Insta for fun Operator stories and reels, event stories and updates and anything else that takes our fancy!

If you would like us to come out and record a ‘Day in the life Reel’, please reach out to us at info@wioa.org.au. We’ll also be following and reposting content from our Utility and Corporate Members so be sure to give us a follow and a like so we can find you!

We have also held our first WIOA Interest Day in Darwin at NT Power and Water in April and will hold our first Interest Day in Western Australia in June at the Water Corporation!

This year we also changed our name to the Water Industry Operations Association (WIOA) and while we continue to focus on frontline operations, we also include the Executive/General Manager of Operations and everybody in between.

We have also started this year with a fresh focus on member engagement, input, and opportunity by opening up nominations for all State / Territory Advisory Committee members, two Board Director positions and in June our National Advisory Committee and Diversity and Inclusion Group, empowering our membership to help decide and deliver this next evolution of WIOA. If you are an active, passionate water industry person that wants to make a positive difference within this amazing industry that we work in, then now is your chance.

In closing, I hope you enjoy this edition of Operator, and catch up on the latest news at WIOA!

All the best,

Dean Barnett Dean Barnett Chief Executive Officer

WIOA Watercooler on Facebook

To further enhance our members network, we’ve also launched our Closed Members Facebook Group. Our NEW WIOA Watercooler is available to connect with fellow operators for discussions, troubleshooting and networking.

UPDATE FROM GLENN, MANAGER –

MEMBERSHIP, SPONSORS & EXHIBITOR SUPPORT

Greetings to all in WIOA World

I just wanted to take the opportunity to give a quick update on all things happening and planned for our Members.

We recently held our Victorian Conference & Exhibition at the end of February. Despite the searing heat outside, the event was extremely well attended with almost back to pre-covid numbers. It was a great few days with a full paper schedule and new innovations and technologies everywhere in the Exhibition Hall.

We trialled quite a few new ideas and changes to layout, format and booth style at this conference. We didn’t nail everything, but we will continue to listen to our members and make changes to refresh and make sure we are staging the best possible events for our Delegates, Visitors and Exhibitors.

WIOA is excited to announce that we have locked in dates for our first ever Interest Days in Western Australia and

UPDATE FROM KATY, MANAGER OF OPERATIONS

also the Northern Territory. We look forward to enagaging with members in these states. Keep an eye out for our communications regarding these days.

We have been quite active over the past few weeks in getting out to meet with our members. We want to get out and about to meet with our Utility, Corporate and Individual Members right across the country. If you would like to meet with us, please reach out and we will happily facilitate.

Thanks again for your loyal support of WIOA and hope to meet with you during the next few months.

Glenn Alford

Manager- Membership, Sponsor & Exhibitor Support

Welcome to our first edition of Operator for 2024

For those keen-eyed WIOA enthusiasts, you may be wondering why you’re seeing this in April and not February as you may be used to? Our team have been working hard behind the scenes to rejuvenate our publications and our member offerings overall. We’ve engaged closely with members through surveys, 1:1 conversations and open forums to best understand what members want and need from WIOA.

Through our 2023 Members Survey, our WIOA Digital Publications survey released in November 2023 and various conversations with YOU, we’ve learnt the following:

• An overwhelming majority of members preferred digital publications over print publications.

• A majority of surveyed members either were happy with the current WIOA frequency of publications or would like WIOA to reduce publication frequency but improve quality of articles.

• Members enjoy both Operator Magazine and Waterworks Journal for different reasons.

With that in mind, and in alignment with the WIOA 2024-25 strategic plan – we hope that you enjoy our minor updates to our publications this year.

We will continue providing hard copies to those who opt in through the new Members Portal and at our major events however using Issuu.com, we can send out immediate digital copies to our membership through an easy and accessible interface and with interactive links available. A reduction in printing and postage costs is a shift allows us to invest more in events, the website, and other initiatives.

We’ve updated our media kits for advertising and will keep fine-tuning our publications to ensure member satisfaction.

Happy reading!

Katy O’Sullivan Editor

For a glimpse into the event, visit our photo gallery.

EVENT WRAP UP

2024 WIOA Victorian Water Operations Industry Conference and Exhibition

The 2024 WIOA Victorian Water Operations Industry Conference and Exhibition, held in Bendigo Victoria on February 28th and 29th, was a resounding success, showcasing the dynamic innovation within the water operations sector.

The exhibition floor was alive with activity, spotlighting the latest technological advancements and fostering vibrant exchanges among industry professionals.

With 18 Operations-focused presentations and 5 Poster presentations, the conference offered valuable insights into industry trends and challenges. Attendees delved into discussions covering a wide array of topics, from diversity and inclusion in the water sector to water and wastewater treatment processes, operational monitoring software, and training, thereby enhancing collaboration and knowledge sharing within the industry.

Despite challenging weather conditions, the unwavering support of our Sponsors and Exhibitors was instrumental in creating an exceptional event.

We extend our heartfelt gratitude to all attendees, presenters, and volunteers for their indispensable contributions. Your dedication and support drive progress within the water operations sector, making events like the WIOA Conference and Exhibition both possible and impactful.

211 Exhibitors

243 Delegates

1,900+ Overall attendees A wonderfully run conference. Thank you for a great experience. - Laura from GWMWater, Delegate Great event, definitely a must attend for us!

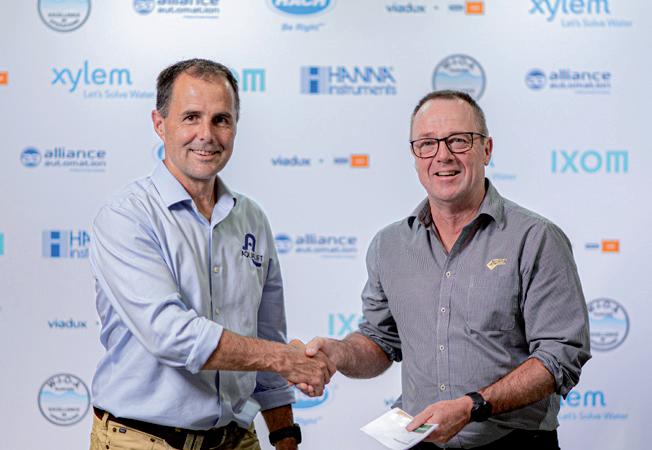

Victorian 2024 Operator of the Year

Dylan Hetherington, North East Water

Ron Bergmeier Best Exhibition Stand Grundfos

Best Operator Paper

Shaun Ratten – Westernport Water

Mains Tapping Competition

Rapid Tappers – Barwon Asset Solutions

Victorian Network Operator of the Year

Shaun Ratten – Westernport Water

Best Paper Overall

Steven Nash – Goulburn Valley Water

Best Poster

Chris Reus – Central Highlands Water

OOTY Highly Commended Brock Mulroyan - Barwon Water

OOTY Highly Commended Wesley Wilkie - Gippsland Water

Victorian Young Operator of the Year

Isabelle Beale – Barwon Water

Ixom Best Tasting Tap Water Yarra Valley Water

EMBRACING DIGITAL

SUSTAINABILITY

WIOA moves to digital publications in 2024

In 2024, WIOA is making the pivotal shift from printed hard copies to digital issues for our publications, WaterWorks and Operator. This change is fuelled by our commitment to reducing our environmental impact. By going digital, we significantly decrease paper usage, cut down on carbon emissions from printing and postage, and minimise overall waste.

When we first started sending out Operator and WaterWorks, it was with the understanding that our Operators may pick up one of these editions in the tearoom on their break and flick through the pages to read articles of interest, interviews with other Operators and check out upcoming events. Today, it’s more common for us all to scroll through our phones and digital devices during breaks and while we might not be as entertaining as a Tiktok dance or as funny as that Instagram short you tag your mate in – our operationally focussed articles and technical information is still as interesting and relevant to the sector as it has always been!

Beyond its ecological benefits, this transition enhances the accessibility and convenience of our publications. Members can now access content from anywhere, at any time, and on various devices, fostering a more connected and informed community. We can link to more information on services and products, as well as look at our readership analytics which informs our future editions.

Our decision to embrace digital publishing not only reflects our dedication to industry trends but also underscores our responsibility to contribute to a more sustainable future.

WIOA RESOURCES

We value your opinion!

We remain dedicated to providing the same high-quality content, now in a more eco-friendly and easily accessible format. Join us in this digital journey as we collectively work towards a greener and more interconnected WIOA.

If you would still like to receive a hard copy of our publications for your home or office, log in to our New Member portal – members.wioa.org.au, and opt-in to print publications.

Once you’ve registered, we’ll continue sending you hard copies of our Triannual Operator Magazine and our Annual WaterWorks Journal!

For more information or if you require any assistance, please email us at info@wioa.org.au

Our website offers a wide array of resources at wioa.org.au/resources, including technical papers, case studies, and industry reports. We’re keen to know if you currently use these resources and if you’d prefer to access them through our members’ portal. Your feedback will guide our efforts to enhance resource accessibility and usability.

Please take a moment to complete a brief survey here to share your thoughts. Your input is instrumental in shaping our resource delivery strategy, ensuring that we continue to meet your needs effectively.

Thank you for your ongoing support and participation in the WIOA community.

2023 Women of Water Breakfast

On Wednesday the 1st of November 2023, fifteen women from across the water industry of NSW got together for the inaugural Women in Water breakfast. Ladies came from across the state to gather at a beautiful, quaint café in Weston, Canberra.

Amongst the group were operators, administrators, sales reps, engineers and coordinators, speaking about their profession and networking whilst getting to know one another. It was an exciting opportunity for those experienced and new to the industry to liaise with each other about culture, knowledge, skills, and experiences.

An appreciative thankyou to WIOA for creating this opportunity and special thanks to the sponsors ProDetec for helping to create such a meaningful morning for women in water.

Contributed by Amy Hondema – Technician Wastewater (Jindabyne)

KELAIR - BLIVET Package Sewage Treatment Plant

The Kelair-Blivet is a stand-alone packaged sewage treatment plant, designed to accept raw (unsettled) sewage and produce a high quality final effluent without the need for ancillary tankage or equipment.

Compact, flexible, modular system suitable for:

- Environmentally sensitive sites

- Townships and villages

- Construction and remote sites

- Areas not connected to mains

We know the importance of choosing the right equipment to match your process. With our extensive range of pumps, first class customer service and ongoing comprehensive support, Kelair Pumps are second to none when it comes to your pumping requirements.

Find out more today 1300 789 466 www.kelairpumps.com.au

EVENT WRAP UP

2023 NSW/ACT Conference and Exhibition

The 15th NSW/ACT Water Industry Operations Conference and Exhibition welcomed over 700 industry professionals to EPIC in Canberra on November 1st and 2nd, 2023. Hosted by Icon Water, the event underscored the vital role of such gatherings in fostering professional growth and personal connections within the water sector.

Gerard Brierley of Icon Water delivered a warm welcome to delegates, setting the tone for an enriching experience. Mark Trembath from WaterAid captivated attendees with insights into WASH initiatives in developing regions. Kate McBride shared her journey as a river ambassador, advocating for better water management in the Murray-Darling.

Narromine Shire Council claimed the National Team of the Year Award, celebrated during the Meet the Exhibitors Dinner, where tributes were paid to industry stalwarts like George Wall, Ron Bergmeier, and Tony Hourigan.

109 Exhibitors

The week’s highlights included the NSW/ACT Water Taste Test and the Mains Tapping Competition, showcasing both skill and camaraderie. Icon Water’s victory in the latter resulted in a generous donation to Mens Link, supporting mental health initiatives in Canberra.

Our NSW/ACT Water Industry Conference and Exhibition for 2024 will be held in Tamworth NSW, on the 6th and 7th November. We hope to see you there!

168 Delegates 760+ Overall attendees

NSW Award Winners

Main Tapping Competition Winners

Tap-in-Yaki from Icon Water

Best Paper Overall

PLENTY, TASMANIA BRYN ESTYN WATER TREATMENT PLANT

In mid-November, a cohort of over 30 Operators joined TasWater at the newly refurbished Bryn Estyn Water Treatment Plant for the last Tasmanian Interest Day of the Year. Sponsored by Trojan Technologies and coordinated by the WIOA Tasmanian Advisory Committee, in conjunction with TasWater, the group were provided presentations on Ozone and UV in Water Treatment, as well as a guided plant tour of the new facilities.

Bryn Estyn Water Treatment Plant

Ozone contactors Ozone contactors

The Bryn Estyn Water Treatment Plant (WTP) is Greater Hobart’s primary source of drinking water, providing around 60 per cent of the water supplied to customers in the Hobart, Glenorchy, Clarence, Brighton, Derwent Valley, Kingborough, Sorell and the Southern Midlands municipalities.

Located at Plenty in the Derwent Valley, the Bryn Estyn WTP was originally constructed in 1962, with capacity augmentations completed in 1972 and 1992. Over the last two years, TasWater has completed upgrades and expansions of the plant to ensure it can continue to provide high-quality drinking water and meet projected demand in Greater Hobart for years to come.

TOWARDS CLEAN WATER FOR EVERYONE, EVERYWHERE:

WaterAid Initiatives

In the pursuit of universal access to clean water and sanitation, WaterAid Australia continues to make strides with two of its annual initiatives – the Walk for Water campaign and the Winnovators program, drawing participants from across the water sector.

Taking place in October, the event saw the active participation of 128 teams from 50 organisations, over 1,000 enthusiastic participants, and an impressive total of $206,000 raised for WaterAid Australia’s projects. This achievement was a testament to the growing commitment of individuals and corporations to WaterAid’s mission. Walk for Water 2024 will return 14th-18th October.

WaterAid’s Winnovators program is a distinctive blend of employee development and engagement, providing

staff with the opportunity to apply their expertise to solve real-life challenges faced by communities that WaterAid supports. In 2023, 14 teams from Australia and New Zealand participated.

Enrolment for the 2024 program is now open for WaterAid’s corporate members, and teams will be contributing to finding a solution for Papua New Guinea. Seize the opportunity to be part of this unique experience by reaching out to WaterAid’s Partnerships Manager, Mark Trembath at mark.trembath@wateraid.org.au.

Industry professionals delivering industry-based training services

E: training@trility.com.au W: trility.axcelerate.com.au

Far North Queensland Interest Day 2023

It was great to participate in the annual FNQ – TRILITY Interest Day followed by the optional Charity Bowls afternoon in Cairns on Friday 13 October 2023.

All up, over 65 water and wastewater staff from FNQ Councils and Corporate members attended the technical information presentations in the morning. Around 40 stayed on for the optional charity bowls afternoon which was a great opportunity to meet and network with each other. The opportunity for the Far North Community to get together again face-to-face was really appreciated.

The Keynote address was delivered by Troy Leyden (Fitzroy River Water/Department of Resources) winner of the best operator paper form the 2023 WIOA Vic Conference delivered his paper on Pumping down emissions by reducing life cycle costs.

There were several presentations by the local councils and organisations. John Sedasio a very passionate water operator and also is the Qld Operator of the Year Civil/All Rounder presented an overview of the Bamaga water plant and their water infrastructure and the importance of a secure reliable water supply for the first nations community of the Northern Peninsula Area Regional Council (NPARC).

Gary Dinse’s presentation on Electro chlorination systems verse gas verse sodium hypochlorite were very informative and given the need to mitigate chlorates and THM’s in potable water supply was of keen interest to the audience.

Following on the heels of these presentations were the hot topics of the ongoing skill shortages in the industry with Neil Holmes skills snapshot report and the interactions with DYJSBT. Skill shortages in the industry is a major concern for all councils and this led onto Jess Dean from the Qld Water Directorate and her presentation of the Regional Alliance Program. Jess strategically used her time slot to seek out one of the best bowlers in attendance Loui Macri to partner up for the afternoons bowls session.

The technical side of the day was sponsored by Cairns Regional Council, Water Treatment Services and Reece Civil. After a very tasty lunch and “networking” with fellow colleagues and suppliers, we headed out for the running of the 5th FNQ Water Main Tapping competition.

Thanks to all the sponsors for their involvement and everyone at WIOA for the effort in putting this great event together. Thanks to Cairns Regional for the Water Main Tapping competition a one of the high lights of the day, would also like to thank Josh Smith Cairns Regional, Simon Page Cassowary Coast Regional, the presenters and to all who participated without you all there wouldn’t be a FNQ Interest Day.

Contributed by Morris Hamill and Shane Bandiera, Mareeba Shire Council and Cassowary Coast Regional Council

Meet Ben Haddock, Water Quality and Compliance Officer at Southern Downs Regional Council

You’ve grown from a Waste Water Treatment Trainee, to Treatment Plant Operator and now to Water Quality and Compliance Officer in your career. Tell us a bit about your career journey?

I acquired a traineeship with the Tenterfield Shire Council. During this traineeship I worked at numerous water and waste water treatment plants throughout the region gaining experience and broad knowledge. This was fundamental in completing my certificate 3 in water industry operations.

After completing my certificate 3, I was highly motivated to see what other treatment plant opportunities were available out there within the water industry. I submitted my application to the Southern Downs Regional Council for an assistant treatment plant operator position and I was successful in gaining the position. It was fantastic to work at multiple water and waste water treatment plants, learning from more experienced senior operators and supervisors.

After 2 years as a trainee, I had been provided with the tools to become an independent treatment plant operator if any opportunities arose and fortunately one did. I applied for the treatment plant operator position at the Stanthorpe wastewater treatment plant and again I was successful. I then decided to further my knowledge within the water industry by undertaking a certificate 4 in water industry operations. This

was a good career path as I learnt how to use more complex thinking in the treatment plant and important supervisory skills. During this time I was humbled to be announced as the 2020 WIOA QLD young operator of the year. This award in itself was a huge accomplishment for not only myself but the whole water and wastewater team.

After completing my certificate 4, I was later promoted to senior treatment plant operator. This role involved floating between all water and wastewater treatment plants throughout the region, assisting the operators with any treatment plant operational performance issues and the supervisor with any tasks.

I have always has a passion for treatment plants but also the regulatory side. I thoroughly enjoy reviewing water and wastewater quality data and comparing those results to the ADWG, DWQMP and RWMP to ensure compliance objectives are being achieved. So I was offered a position within the regulatory team as water quality and compliance officer. I have really immersed myself within the regulatory space as there is so much to learn and find it extremely interesting. I have a fantastic supervisor who takes the time to teach and mentor me which has been beneficial from a performance and output perspective.

In your experience, what are some of the most pressing water quality challenges or issues facing the region or industry you work in, and how have you addressed them in your role?

In my experience some of the most pressing water quality challenges and issues are dealing with the drought and trying to attract operators. When I started in SDRC we were in the middle of a 10 year drought which presented major issues. The Stanthorpe raw water supply ran dry. With no alternative water sources, Southern Downs Regional Council embarked on one of the most significant water carting projects ever undertaken in Australia. Carting 1.5ML/day of water roughly 60km from Connolly Dam near Warwick to be treated in Stanthorpe was a logistical, technical and operational challenge that stretched staff in all areas. Water quality from Connolly was poor and notoriously difficult to treat, containing extremely high levels of Manganese (Mn Total >4.5mg/L, Soluble >3.8mg/L) as well as algae and taste and odour which the Stanthorpe WTP was not equipped to treat. Process investigations were undertaken to specify requirements for new chemical dosing systems, while significant investments were made in new infrastructure

for loading-unloading of trucks and providing a storage and connection pipeline to the Stanthorpe WTPs supply main. The operations team sourced and where necessary built new dosing systems for Potassium Permanganate and Powder Activated Carbon integrating these with the WTP’s control system. (This paragraph is the abstract from my paper I presented at the 2021 WIOA conference placing 3rd).

With the current aging population, a lot of the experienced senior operators are now retiring and the positions cannot be backfilled. The biggest challenge is awareness of this hidden industry and the endless opportunities that are out there within the water space. This is why I take part in WIOA opportunities to spread awareness, passion and otherwise missed chances.

Any advice for young operators in the industry facing similar challenges?

Look for opportunities and get after it, gain as much knowledge as possible from senior operators, mentors and training providers (I say, be a sponge). Spread this great career path to friends and family. Lastly don’t be afraid to have a go.

How do you stay up-to-date with the latest regulations and guidelines related to water quality reporting and compliance?

I stay up to date with the latest regulations and guidelines but attending regulatory workshops with relevant government bodies and reviewing any updates and changes online.

In 2020, you won the QLD WIOA Young Operator of the Year, what did this award mean to you?

Winning this award was a huge accolade for not only myself but the whole water and wastewater team. It shows that hard work, passion and determination doesn’t go unnoticed and is vastly appreciated. It fuelled the fire to get out there, make change in a positive way and inspire other operators.

If you have an operator experience to share in our next edition please email info@wioa.org.au, we’d love to feature your story!

Wastewater-borne environmental pollution from textile microfibres

One of the rapidly growing environmental concerns is a pollutant that is barely visible to the naked eye but has adverse effects on humans and nature. Microfibres are rapidly becoming a significant source of pollution as they often enter marine systems and waterways and are subsequently consumed by aquatic and other wildlife.

The textile manufacturing supply chain consists of thousands of manufacturing facilities in dozens of countries. Although the products and processes may vary greatly from one facility to the next, they all have one thing in common: the ability to shed fibres from textiles into the wastewater discharged from each facility. Shedding also occurs after manufacture with approximately 35 percent of microplastics released to oceans globally, originating from washing synthetic textiles.

Clothing fibres are the most abundant form of polymer currently found in the ecosystem and these have increased by over 450 percent in 60 years. These contaminants have been detected in seafood, tap and bottled water, fruits, vegetables, and even in table salt.

“Microplastics found in waste treatment plants are microfibres predominantly composed of manufactured synthetic fibres. Primary microfibres are produced during the manufacturing

and processing of garments and allied products,” says Australasian and Asia-Pacific wastewater authority Michael Bambridge, Managing Director, CST Wastewater Solutions (CST).

An organisation addressing this issue is The Microfibre Consortium (TMC) which is working with the textile industry to reduce the amount of microfibres released into the environment. The UK-based organisation has members all across the world and translates academic research into actionable solutions for textile production.

TMC’s Preliminary Manufacturing Guidelines identify strategies to remove microfibres from textile wastewater and capture them, for example, in the sludge of wastewater treatment systems. The report analyses screens and strainers, clarification, membrane bioreactors and ultrafiltration to remove microfibres.

CST Wastewater solutions has already developed drum screen technology that can help minimise environmental damage with fine screening capabilities down to 200 microns. “Our horizontal drum screens will screen out just about every microplastic you can see, which is a step towards addressing this significant environmental threat,” says Bambridge, who has more than 40 yeas wastewater treatment experience in Australasia and Asia.

The TMC report also advocates for the proper handling of sludge from wastewater treatment plants. Once the microfibres are captured in the sludge, the sludge must be handled and disposed of in a manner that does not release those microfibres back into the environment. TMC recommends the sludge handling guidelines laid out by multi-stakeholder organisation ZDHC (Zero Discharge of Hazardous Chemicals). Headquartered in Amsterdam, ZDHC works with the fashion industry to eliminate harmful chemicals from its global supply chain by promoting more sustainable manufacturing to protect workers, consumers, and ecosystems.

When dealing with textile related waste, the closer a mitigation step is to the point of generation, the larger the size of microfibres that will be present in the wastewater. However not all textile facilities have on-site effluent treatment, and it is common for effluent to be discharged to municipal plants for treatment alongside the discharges of multiple facilities.

Almost all manufacturing facilities are required to meet regulatory discharge standards for total suspended solids and failure to adhere to these will almost certainly result in discharges of large quantities of textile fibres. It is possible that more stringent standards for discharge of microfibres will be developed in the near future. Facilities will need to ensure existing processes for removal of solids are optimised and possibly invest in more advanced, zero discharge filtration technologies.

For its part, TMC expects that wastewater treatment facilities will adopt mitigation technologies to stop the discharge of microfibres. It is possible to divert microfibres from the discharge by using a dead-end ultrafiltration unit. Unlike a crossflow ultrafilter which flows a reject stream out of the filter, the upstream surface of a dead-end ultrafilter is cleared of microfibres and particles with a pulsed backwash where the pulsed backwash must be collected and treated.

Washing synthetic textiles in industrial laundries and households also create primary microplastics through abrasion and shedding of fibres. Fibres are then discharged in sewage water and potentially end up in the ocean.

Significant amounts of these textile fibres have been observed in many sampling studies both in open water and marine sediments. These fibres are typically made of polyester, polyethylene, acrylic or elastane.

While some manufacturers are considering biodegradable textiles as a solution to dealing with microfibres, TMC do not endorse biodegradability as a ‘solution’ to fibre fragmentation from textiles, although they would be open to getting to a position of support once adequate testing and toxicological work has been done.

TMC’s Microfibre Data Portal now houses over 5000 data points collated from 391 tested fabrics representing 115 manufacturers and 16 countries. The current dataset constitutes one of, if not the, largest databases on fibre fragmentation globally, with a significant number of fabric test results and data points collected. As a society, we are significant consumers of plastic and have a responsibility to educate ourselves and adapt our behaviour to protect human life and our planet.

For further information, please contact: Michael Bambridge, Managing Director CST Wastewater Solutions info@cstwastewater.com www.cstwastewater.com

Screening out microplastics with fine screening technologies is a step towards addressing this significant environmental threat. Such screening (top) complements coarser screening (bottom) to prevent pollution entering wastewater systems and damaging them.

AIS Water receives world-first accreditation

Brisbane-based water disinfection company AIS Water, has been named the first Accredited Intrapreneurial Organisation by the Global Intrapreneurs Institute (GII), as it continues to seek ways for its staff and business to excel.

AIS Water CEO Elena Gosse said that being the first company to complete the program was yet another example of AIS’ commitment to innovation and excellence.

“Most people are familiar with the term entrepreneur, however the benefits of encouraging intrapreneurship within an organisation are many, including increased employee engagement, improved problem-solving skills, and a greater capacity for innovation, Ms Gosse said.

“For years we have implemented various strategies and invested heavily in fostering intrapreneurial behaviour with our staff. Innovation is part of our company’s DNA and we actively encourage entrepreneurial and innovative thinking with every employee, every day, and in every department.”

In the context of the GII program, an intrepreneur means someone who is working inside the organisation and who actively embraces innovative thinking and a leadership mindset, irrespective of their role in the company. This empowers the individual to leave behind limiting beliefs and make positive contributions to the company as a whole.

Membership Growth

The WIOA membership is growing steadily as more people find the value in building their professional network and connection to others in the industry.

We have over 5,000 active members as of April 2024 which includes over 2,800 Utility Corporate and Individual Members! With engagement growing rapidly in WA and NT, we predict these numbers to continue growing in 2025.

4,391

5,105 Oct 2023

May 2024

Founder and CEO of the GII, Dr Irena Yashin-Shaw, describes intrapreneurs as “the enterprising employees who think and act like entrepreneurs while working INSIDE an organisation” and who are the “opportunity finders”.

Lead detection on the MOOve

We arrived onsite to inspect a leaking tank and found that Council had already sent one of their more experienced personnel to solve the issue.

- Submitted by David Barry from AquaSafeSkills

Underground network listening for leaks beneath your feet in Perth CBD

Hidden technology beneath your feet is listening for water leaks in the Perth CBD, in a new, Australia-first project by Water Corporation.

The cutting-edge distributed acoustic sensing technology by Perth-based Terra15 Technologies turns existing fibre-optic cable in the city into a giant acoustic leak detection network to detect water leaks before a pipe bursts.

Laser light is pulsed through a thin strand of fibre-optic cable, no thicker than a human hair, which detects any minute interruptions in the signal due to vibration or sound.

Programmed to listen for the distinctive sound of a leak in nearby water mains, the technology enables Water Corporation to fix the pipe long before it bursts, saving valuable water, money and more significant disruption.

The equipment is so sensitive it can detect regional earthquakes, as well as the background noise of footsteps, traffic and construction work. It can also detect tampering or theft on a pipeline.

Water Corporation General Manager Assets Planning and Delivery Evan Hambleton says the technology will help

improve the reliability of the CBD water supply and reduce reactive repair work, costing $12.5 million within the metro area in the last financial year (FY22-23) alone.

“While we are progressively upgrading the Perth CBD water network, some leakage is unavoidable with sections of our old cast iron pipes dating back more than 100 years.

“This clever technology, which uses spare capacity in existing telecommunications fibre-optic cable, causes the fibre to behave like thousands of vibration sensors, or acoustic loggers, spread out over many tens of kilometres.

“Sensitive enough to detect a tiny leak quickly and track it over time, it will enable us to fix the pipe long before any water would be visible at the surface, preventing a much more damaging and disruptive burst.”

The project is on top of Water Corporation’s planned $184.7 million investment (FY23-24) in the metro water network and supply projects, including its current $10 million project to replace ageing water mains around the Kaarta Gar-up (Mount Eliza) reservoir in Kings Park under its Pipes for Perth program.

Kiwi Deep Tech Company Secures Venture Capital To Take Innovative UV Technology Global

NovoLabs™, the New Zealand-based water tech innovator, has announced the successful closure of an oversubscribed Series A funding round, to assist in their mission to take their patented new UV disinfection technology global. With the backing of the Climate Venture Capital Fund, NovoLabs is set to accelerate the deployment of its patented Supercritical UV™ technology. This new technology enables the cost-effective treatment of liquids with UV light in a range of applications that legacy UV systems are unable to reach.

UV Is A Widely Established Disinfection Technology

UV disinfection is well-established as an effective disinfection technique for water, process liquids, wastewater, etc with an estimated total global market worth over $ 5 billion pa. The mechanics of the treatment are simple - specialised lamps emitting a specific range of UV light (termed UV-C or “germicidal range UV”) are used to irradiate liquids. This is highly effective in disrupting the RNA and DNA structures of bacteria, viruses and protozoa causing rapid deactivation and disinfection. Unfortunately, UV light intensity and its ability to disinfect drops off at a rapid exponential rate when it is radiated through water, especially when water clarity decreases.

NovoLabs Revolutionary Approach

Pioneered by Professor Andy Shilton, NovoLabs’ founder and CTO, Supercritical UV technology incorporates a revolutionary ‘top-down’ UV-C delivery system. This new system works by using UV-C lamps positioned above a fast-flowing ‘supercritical’ film of water only a few millimetres thick. This enables a markedly higher intensity of UV light to be maintained even in more opaque liquids and in liquids with higher levels of fine solids, for example in algae waste stabilisation pond effluents. This patented new approach not only can offer a lowercost treatment solution, but also expands the boundaries of where UV disinfection can be applied with research trials as diverse as for the treatment of calf milk to reduce microbe contamination underway.

Climate VC Fund Partner, Dr Jez Weston said “NovoLabs’ technology has the potential to replace a large and mature installed base of traditional treatment facilities. It can improve water quality and reduce emissions by avoiding the use of large amounts of chemicals for disinfection and clarification,” said Weston. “This technology allows water treatment plants to save on their operating costs, reduce their greenhouse emissions, and protect communities and ecosystems by killing pathogens. It’s a pretty compelling technology and company for a sector that’s looking for new and affordable solutions.”

Rapid Adoption Of Supercritical UV In NZ Market

Dr Matt Sells NovoLabs CEO, notes that despite the technology only recently becoming commercially available, its unparalleled performance in a range of otherwise difficultto-treat applications have led to organisations in industries ranging from meat processing to domestic wastewater choosing to deploy the NovoLabs technology. “We have had excellent feedback from industries, councils, engineering consultants and local iwi. This is great recognition for this Kiwi invention given that we are competing against legacy technology from global companies who have sold hundreds of thousands of UV systems”.

The Climate Venture Capital Fund will be represented on NovoLabs board of directors by Lance Wiggs who has a Yale MBA and brings decades of business and investing experience. Lance joins the existing Novolabs board of Rob Baan (DDL), Russel Wilson (MVL), and Andrew Shilton.

For more information, contact:

Dr. Matthew Sells, CEO, NovoLabs 0427 354 0321

Matt@novolabs.co.nz

Advertise in Operator

Operator is WIOA’s quarterly publication which includes individual and corporate member news, general interest stories, water industry news and more.

Produced three times a year it is an effective way of keeping the WIOA community in touch.

Advertising will be limited to the equivalent of 7 full pages for each edition. There are 10 ad opportunities in each edition of Operator. Three editions will be published in 2024.

To provide our corporate members with more opportunities to reach the operational employees, Operator includes a limited number of advertising opportunities in each edition.

To advertise

Contact WIOA on 03 5821 6744 or email info@wioa.org.au

POWER THROUGH 400 HOURS OF INTENSIVE FORMAL LEARNING AND PRACTICE IN JUST 3 MONTHS!

Learn faster, learn better, in a real plant.

Simmonds & Bristow has been providing exceptional learner outcomes and qualified operators as an RTO since 1998.

We know first hand that training using real equipment in a real network and/or treatment plant environment gets the most engagement from learners, and yields the best results and retention. Now, we’ve crafted a training program that will deliver that, faster! Learners will arrive to training daily over a 3 month period just as they would to a real job, working on real equipment, in a real plant. It’s hands-on, it’s practical and it’s POWERFUL!

To secure a limited place or find out more, email us at

COURSES OFFERED IN THIS PROGRAM꞉ NWP30219‑NWP30222 Certificate III in Water Industry Operations (Treatment) NWP30219‑NWP30222 Certificate III in Water Industry Operations (Network) sales@simmondsbristow.com.au or call us on 1800 620 690 (Only 8 places are available per quarter.)

Upcoming Events

12 June, 2024 | Free for Members

QLD Interest Day

Hosted by Central Highlands Regional Council, this interest day will showcase presentations and topics related to the QLD Water Operations Sector. More information coming soon to our website.

Discover upcoming events for Operators. If you have an upcoming event to share in our next edition email info@wioa.org.au

24 & 25 July, 2024

2024 Queensland Conference

12 June, 2024 | Free for Members

WA Interest Day

With presentations from Busselton Water, Rio Tinto, AqWest and Water Corporation, as well as a site tour of the Subiaco Wastewater Treatment Plant, this Interest Day is jampacked with interesting and thought provoking material. Free for members to attend. Register now!

14 -18 October, 2024 Walk for Water

Water Aid’s Walk for Water campaign raises awareness and crucial funds for water, sanitation and hygiene projects in countries supported by WaterAid Australia. You can register your interst for this event by scanning the QR code.

Advertisers

These advertisers are in this edition of Operator:

Join your peers at our QLD Water Industry event fostering information exchange among operational roles in water, wastewater, and recycled water sectors. Our Conference and Exhibition offers a platform for water professionals to update skills, network with peers, and explore cutting-edge technical advancements.

Event Includes

• An Operation focussed event program spanning two days including 18+ Paper & Poster Presentations, a Keynote speaker and Members forum

• QLD Women of Water Breakfast

• IXOM Water of Origin Competition

• 2024 QLD Awards Dinner

• QLD Main Tapping Competition

• Free Visitor Admission to the Expo Hall with over 119 exhibitors showcasing their latest innovations, services and products

6 & 7 November, 2024

2024 NSW Conference

Join your peers at our NSW Water Industry event coming to Tamworth this November. More details will come in the next issue of Operator!