CONTENTS

GETTING IN CONTACT

EDITORIAL

John Cowie

Editor - Head of Online Content

E: john.cowie@windowsactive.co.uk

Jennie Shoglen - Graphic Designer

Emma McCormack - Sub-Editor

ADVERTISING SALES

Steve Gravestock Sales Director

Tel: 07990 671901

E: steve.gravestock@windowsactive.co.uk

Donna Crockatt

Publishing & Sales Executive

Tel: 07919 448809

E: donna@windowsactive.co.uk

PRODUCTION AND CIRCULATION

Tel: 07919 448809

E: production@windowsactive.co.uk

WINDOWS ACTIVE is published by: Active Magazines Limited PO Box 627

Rickmansworth Herts, WD3 0BQ

UAP ACQUIRED BY GLOBAL SECURITY PRODUCTS AND SOLUTIONS PROVIDER ALLEGION

UAP Group (UAP), the door hardware specialist, has been acquired by Allegion plc, a leading global security products and solutions provider, through one of its subsidiaries for an undisclosed sum. UAP designs solutions around its customers’ needs, equipping them to navigate the ever-changing fire and security landscape. Driving progress since 1996, its fire and security solutions, combined with its continual innovation, ensure customers are always one step ahead.

FACE-TO-FACE SELLING STILL OPENS DOORS

Andrew Scott says face-to-face selling still opens doors and how traditional sales tactics remain essential in a digital world.

IDSYSTEMS MARKS 25 YEARS STRONG

Innovative glazing supplier and manufacturer IDSystems is celebrating its 25th year in business this year. The company was started in 2000 when founder Richard Hunter secured the exclusive UK rights to supply and install Sunflex door systems from Germany.

DIRECTOR OF THE MONTH

“On returning to the glass Machinery market after 14 years in fenestration, many things had changed, most notably the advancement in technology and the justification to purchase new machinery. Starting with technology. Today’s machinery manufacturers have embraced advances in software & the components used to construct the machines.”

Brian McDonald CEO Forel UK & Ireland

DOORS ACTIVE SPECIAL

The bumper 28 page special kicks off with: Unapologetically vocal and persistent, Asa McGillian is challenging the silence surrounding questionable composite door U-values.

DECEUNINCK SWITCH POWERS RAPID GROWTH

Dean Pitcher, General Manager at PVC-U window and door manufacturer Rapid Windows, says he sees the business as a massive opportunity and believes they can take it to the next level very quickly

“It’s got the customer service, the quality products, the ‘can do’ attitude, all combined with that family-feel that makes the customers feel welcome. With a bit of hard work, we can totally refine the business. It just needs that finishing touch...”

With more than 50 years’ experience serving the trade with high-quality products made in-house, we know what you need from a manufacturing partner.

For five decades, Arkay has built more than windows and doors, we’ve built trust.

Fifty years of hands-on experience means we understand what you need: precisionengineered systems, swift lead times, and support that actually supports.

Install with confidence. Our products are tried, tested, and tailored for modern design — from sleek minimal sightlines to robust performance. We know the specs, we hit the deadlines, and we stand by every frame.

Choose Arkay, and you’re not just getting aluminium. You’re getting insight honed over generations, service that delivers, and a partner who’s grown with the trade — and shaped it. Get

EDITOR’S COMMENT DISCRETIONARY SPENDING BOOST

As Britain returns to work following a summer break that increasingly mirrors continental habits, early signs point to a notable shift in consumer behaviour. New research commissioned by Travel Counsellors and conducted by Censuswide has revealed that 32% of respondents now intend to prioritise home improvements in their discretionary spending, ranking just behind holidays and clothing.

For the fenestration industry, this development is a rare bright spot in a year defined by economic and political uncertainty. The sector at large has faced a raft of challenges beyond its control, from weak GDP growth and tightening fiscal policy to rising operating costs and cautious consumer sentiment. As pressures on businesses mount and confidence remains fragile, companies are being forced to create their own momentum in a sluggish market.

The domestic replacement market, long a cornerstone of the sector, is showing renewed promise. The reported uptick in consumer intent is translating into increased retail sales leads, offering a welcome shift in sentiment. A product portfolio that meets consumer demands for kerb appeal, added security, energy efficiency, and more liveable space places the industry in a strong position to capitalise. Marketing tools and support services are now more sophisticated and accessible, giving

businesses a wider range of options to convert interest into tangible sales.

Yet wider macroeconomic and structural headwinds persist. Hopes that a new political cycle might trigger a resurgence in housebuilding appear premature. The recent change in housing minister, with Steve Reed assuming the role of Secretary of State, has done little to inspire confidence. His call to “build, baby, build” was met with scepticism by many in the construction industry, weary of rhetoric and calling instead for tangible action to address deep-rooted issues such as labour shortages and surging input costs.

The question of workforce availability remains central. Professor James Hampshire has highlighted the UK’s structural dependence on migrant labour, noting that many of the 948,000 individuals who entered the country legally in 2024 filled essential roles within construction. While some see this as a short-term fix, the issue is undeniably compounded by decades of under-investment in domestic training and education pipelines.

This disconnect is reflected in recent findings from Fix Radio’s National Construction Audit, which reported that 65% of Britons were never encouraged to pursue a trade career, while a fifth were actively dissuaded. The conclusion is stark: a cultural and educational bias toward academic pathways is failing both young people and the wider economy. Reinforcing this point, a Microsoft report on jobs most resilient to AI disruption identified trades as among the safest, while roles such as accountancy, law, and editing ranked most at risk. For fenestration firms, the challenge now lies in translating this renewed consumer appetite into sustained sales growth. With a growing ecosystem of marketing tools and support services, companies have more channels than ever through which to reach potential customers. But execution remains key. Social media in particular offers a wealth of connection opportunities, though success depends on working with experienced partners who can deliver tailored campaigns with measurable outcomes. In an environment where attention is fragmented and competition is fierce, generic messaging is no longer enough.

As the post-holiday period brings consumers back to routine, the time is ripe to reinvigorate marketing efforts. In a competitive landscape, strategic investment in promotion will be crucial to capturing demand and building long-term resilience. To borrow from a recent industry adage: stopping marketing to save money is akin to stopping the clock to save time.

John Cowie - Editor

ULTRA-SLIM SIGHTLINES OF JUST 29MM

OPTIONAL FLUSH STACKING EXCLUSIVE SIGNATURE KNURLED HANDLE

UAP acquired by global security products and solutions provider Allegion

UAP Group (UAP), the Manchester-based door hardware specialist, has been acquired by Allegion plc, a leading global security products and solutions provider, through one of its subsidiaries for an undisclosed sum.

UAP designs solutions around its customers’ needs, equipping them to navigate the ever-changing fire and security landscape. Driving progress since 1996, its fire and security solutions, combined with its continual innovation, ensure customers are always one step ahead.

Headquartered in Manchester — a region synonymous with innovation — UAP proudly serves customers in all corners of the UK. Through its comprehensive portfolio of door hardware, it is creating a safer, more resilient built environment, which is highly aligned with Allegion’s vision for creating a safer and more accessible world.

UAP holds nearly 200 patents, trademarks, and registered designs, including for its pioneering Armasmart range, the industry’s first door hardware range to eliminate 99.98% of viruses, including COVID-19. Its strong reputation for innovation is also closely aligned with Allegion’s values and strategic goals.

Another testament to its innovation, UAP has won several industry awards recently, including winning “Hardware Company of the Year” in 2023 and 2024 at the National Fenestration Awards and the 2024 Guild of Architectural Ironmongers’ Community Award for Company Innovation. Following the acquisition, UAP will report into the Allegion International segment. This will strengthen Allegion’s presence in the region and complement its UK’s non-residential portfolio, while expanding its breadth of solutions to the companies’ combined customers. David Jennings, CEO of UAP, will join Allegion to facilitate a smooth transition and support

accelerated growth for the combined organisations.

David Jennings, UAP’s CEO, said: “Bringing together UAP and Allegion adds great value for our joint distribution and customer base. We’re broadening our highquality portfolios and creating meaningful opportunities toinnovate together.”

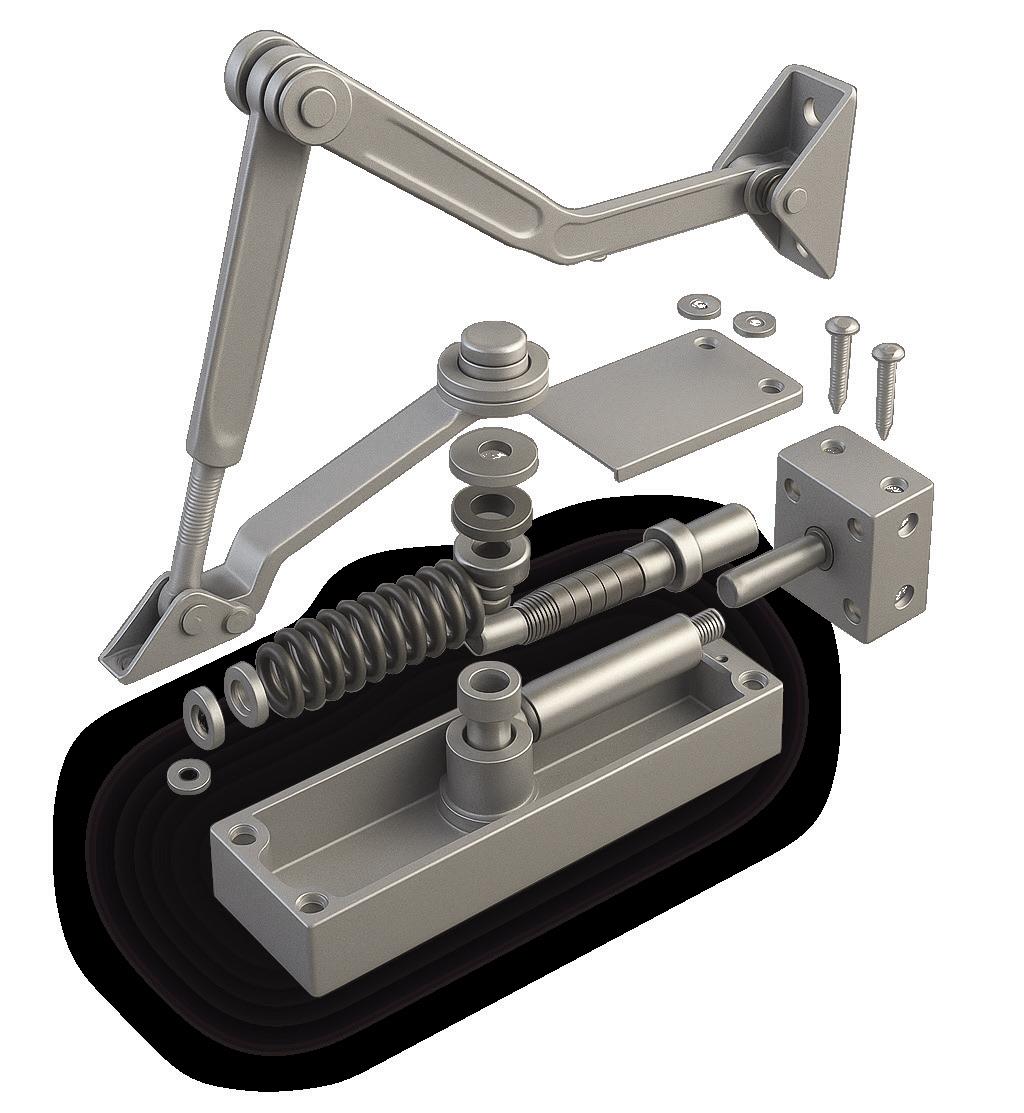

For more than a century, Allegion, through its leading brands like Briton, have kept people safe and secure by designing and manufacturing category-leading products. Allegion produces mechanical hardware solutions, offering everything from door closers and exit devices to door furniture and residential and commercial locks, as well as software and services that support them.

“This is a natural extension of Allegion’s core mechanical portfolio with highly specifiable products that will leverage our existing solutions offerings and capabilities,” said Tim Eckersley, Allegion senior vice president and president of Allegion International. “Through our go-to-market alignment, complementary channels and sales expertise, we’ll fuel additional growth for both UAP and Allegion.”

Profine acquires Profilink in strategic aluminium systems expansion drive

Profine GmbH, a leading global provider of window and door systems, today announced the acquisition of Profilink, a company based in Plovdiv, Bulgaria. As part of the transaction, profine is taking over the aluminium and PVC operations of the company, including all system brands as well as employees from the marketing, sales, and engineering departments.

Profilink’s operations will be continued under the umbrella of profine GmbH and the internationally recognised Kömmerling brand.

With this acquisition, profine is consistently pursuing its strategy to significantly expand its product segment of aluminium window, door, and sliding systems. The Profilink portfolio is a strong addition – complementing both the aluminium systems developed in-house and the expertise and solutions gained through the acquisition of EFP Facades in October 2024.

Dr. Peter A. Mrosik, Owner and CEO of profine GmbH, commented: “The acquisition of Profilink is a further strong signal of our commitment to expand our aluminium business across Europe. We are broadening our product range and strengthening our development expertise – both in aluminium and PVC. This enables

us to offer our customers an even more comprehensive and powerful systems portfolio from a single source.”

Profilink has many years of market presence and expertise in developing and marketing aluminium and PVC window, door, and sliding systems. Existing customer relationships and market shares – particularly in Southeast-ern Europe – will now become part of the profine network. The integration of the company marks

another milestone in profine’s growth strategy in the European market for aluminium solutions.

The goal is to significantly accelerate the development of the aluminium segment while further strengthening Kömmerling as a leading brand for high-quality window and door systems.

www.profine-group.com www.profilink.eu

Reynaers marks 60th anniversary with focus on sustainable growth

With 60 years at the forefront of innovation and sustainable design, Reynaers Aluminium has been working with fabricators, architects and construction professionals to transform buildings and help to shape the future of the fenestration industry.

Since its inception in 1965 in a small workshop in Belgium, Reynaers has grown into one of the world’s leading systems’ houses, specialising in aluminium windows, doors and façade solutions. With six decades of expertise, Reynaers has contributed to impactful projects in over 70 countries, from sustainable skyscrapers to energy-efficient, low carbon private homes, demonstrating its commitment to quality and innovation.

Bert Geerinckx, CEO of Reynaers Group, said: “The building industry has experienced many changes throughout the years. However, Reynaers Aluminium, as an entrepreneurial family-owned business, has always turned challenges into opportunities. Bold yet considerate, our company dares to invest today to ensure a more prosperous tomorrow. After all, innovation and entrepreneurship are at the core of our DNA.”

Reynaers’ global presence is bolstered by its local knowledge, supporting its extensive national partner networks with technical expertise, bespoke testing, digital tools and expert after-sales support. Its digital eco-system has been evolving over the company’s history, with landmark developments such as Avalon, a state-ofthe-art Virtual reality room designed to visualise and evaluate projects before they are built. Additionally, DigiTrace digital

product passports have been designed to allow partners instant access and complete transparency for performance, material and sustainability information. Such tools are designed for convenience, and as means of enhancing competency and best practice in the face of increasingly stringent regulations such as those evolving with changes to Document L, as well as those brought about by changes associated with The Building Safety Act.

The Reynaers brand is aligned with high performance systems and sustainable innovations for both commercial and residential sectors. Testing has been vital to the development of Reynaers systems, with the company having one of the most advanced façade test centres in the industry at its global HQ in Belgium. All Reynaers systems are rigorously tested to ensure compliance. Recent certifications include the Performance Assessment Specification (PAS 24:2022) of its Vision 7 Thermal Commercial Door with Concealed Panic Hardware, which has also achieved 1m open-close test cycles proving the highest level of durability.

Ian Clayton, Interim MD at Reynaers Aluminium UK said: “Over the past 60 years Reynaers has become synonymous with award-winning product innovations, sustainability leadership and forging meaningful partnerships that have made transformative contributions to the global building industry. At the heart of our successes are the partnerships we have built with our customers, employees, and communities. In the UK, our business has supported partners in the design, performance and sustainability of projects such as Kings Cross Central and the Croydon Towers, as well as playing a vital role in regeneration projects, with Reynaers’ technical expertise enabling the realisation of complex project briefs.

“Reynaers Aluminium UK has been in operation for almost 40 years and we are proud to represent the expertise and innovative heritage developed by Reynaers over the past six decades. We look forward to continuing to be the partner of choice for many building professionals across the country, as together, we pave our sustainable road ahead.”

Simon Monks appointed to lead sales and marketing at UAP Group

UAP, the Manchester-based door hardware specialist, is welcoming industry expert Simon Monks as its new Group Sales & Marketing Director. Monks joins UAP with almost two decades’ experience in the door and fenestration industry, including spearheading sales and marketing strategies. He has previously risen through the ranks at different hardware companies, moving from sales to the C-suite. He has spent ten years in directorship positions — seven as Managing Director — with experience in fenestration markets both in the UK and overseas.

On his appointment, Simon Monks, Group Sales & Marketing Director at UAP, said: “I was drawn to UAP because of its ambition, growth plans, and reputation for innovation, with products like the Armasmart and Kinetica ranges driving progress in the industry. In such an exciting

time for the business group, I can’t wait to get stuck into shaping its future alongside the stellar team.”

UAP Limited, established in 1996, has become a leading UK door hardware supplier. Its products range from fire-rated

hardware to locking systems and door and window security that drives progress in the hardware industry. The company designs door hardware solutions around customer needs, equipping them to navigate the ever-changing fire and security landscape. Monks’ appointment comes amid UAP’s recent acquisition by Allegion plc, a leading global security products and solutions provider, through one of its subsidiaries.

Steve Cox, Managing Director of UAP, said: “Simon has joined us at an integral stage of our growth journey. His market knowledge and industry standing are exceptional, and his leadership and customer skills are key additions to our team.

“Simon’s insights will be fundamental as we consolidate our UK plans, including targeting repair markets, and expand into international markets that are new to us.”

Noise pollution trends highlight demand for superior acoustic windows

Following the European Environment Agency’s latest noise pollution report, Rehau has called attention to the importance of windows that offer strong acoustic performance when specifying for retrofit and new-build residential projects.

The report, Environmental noise in Europe 2025, reveals that over 20% of Europeans are exposed to harmful levels of transport noise, with road traffic identified as the primary source. As the document states, long-term exposure is linked to cardiovascular disease, sleep disturbance, and reduced cognitive performance in children, making noise pollution a public health issue as well as a planning concern.

Here, Rehau UK CEO Martin Hitchin has highlighted the role that high-performance windows can play in reducing external noise in homes.

He said: “In many regards, windows are the make-or-break component when it comes to keeping out noise. Factors such as the type of glazing specified, the quality of the frame, and how well it has been fitted can be the difference between a good night’s sleep and a restless one.

“This can be a particular challenge for social housing developments, which are often situated in urban areas where there

is more noise, and many vulnerable people occupying them. Here, windows have a key role to play in ensuring that transport noise levels do not impact tenants’ long-term health.”

Progress towards this goal can already be seen in the Social Housing Decarbonisation Fund, which has allocated £1.29bn to modernise properties in line with the nation’s net zero targets. This includes upgrades such as high-performance windows, insulation, and heat pumps.

Recent projects across the UK have demonstrated what is possible when noise mitigation is built into the design process

alongside these decarbonisation aims.

For example, in County Durham, homes near a main road and industrial estate were fitted with acoustic glazing and soundattenuated trickle vents, reducing internal noise levels by up to 40dB. In a separate commercial-to-residential conversion near Heathrow Airport, developers met a strict 41dB acoustic rating through careful collaboration with suppliers and fabricators.

Martin concludes: “Windows are obviously vital to all residential properties but they can be significant sources of heat loss and a major way that external noise enters a home. However, with informed specification practices, fenestration professionals can identify cost-effective solutions that can significantly impact both a building’s overall energy efficiency and acoustic performance.

“Whether upgrading social housing or building new residential properties, thirdparty expertise is key to noise reduction for current and future homes. Retrofitting also offers great potential for future public and private housing, and fenestration professionals that leverage supply chain knowledge will stay ahead of the curve as building work intensifies in line with elevated residential construction targets.”

Star Safety Glazing signs 3 year supply agreement with Stellar Aluminium

Reading-based Star Safety Glazing has signed a three-year supply agreement with Stellar Aluminium Systems, marking a significant shift in its aluminium window and door offering.

The family-run business, owned by Bobby and Shila Sekhon, has made a strategic move away from its previous supplier to exclusively manufacture Stellar’s awardwinning aluminium window and door system, demonstrating the strong market appeal and growing demand for the Stellar brand.

Impressed by the system’s slim sightlines, fabricator-friendly design and pre-gasketed profiles, Star Safety Glazing quickly recognised the potential for Stellar to elevate its offering across trade, domestic and commercial sectors. Bobby said: “From the start, it was clear that Stellar aligned with our ambition to offer a premium product that doesn’t compromise on performance or appearance. The fact that it’s so straightforward to fabricate and comes pre-gasketed makes a huge difference on the shop floor. And because the gaskets don’t shrink or overstretch, we can be confident that every unit goes out with a perfect, consistent finish.”

Support has also been a major factor in the success of the switchover. Bobby added: “The team at Stellar have been proactive and incredibly supportive. Their training during the transition period has been excellent and the level of service and ongoing communication we’ve received throughout has been second to none.”

A further advantage for Star Safety Glazing has been access to Connect, Stellar’s award-winning digital portal. The platform gives fabricators instant access to technical documentation, specification support, marketing assets, imagery, brochures and

point-of-sale materials, empowering them to grow their business with ease. Bobby said: “Connect is a brilliant resource and it gives us everything we need in one place, whether we’re quoting a job, looking for technical data, or pulling together marketing materials. It will make our day-to-day operations much smoother and far more efficient.”

In addition, Stellar’s market-leading five-day turnaround on stocked colours has allowed Star Safety Glazing to deliver at speeds comparable to the PVC-U sector, keeping projects on track and customers happy.

The company now manufactures the complete Stellar Aluminium range including Flush Casement Windows, Flush Residential Doors, Bifold Doors, the Inline Sliding Door and the Stellar Lift & Slide Door.

Jon Foulds, Key Account Manager at Stellar Aluminium, added: “We’re delighted to welcome Bobby, Shila and the team at Star Safety Glazing. They’re a quality-driven, customer-focused business and exactly the kind of partner we want representing the Stellar brand. We look forward to supporting their continued growth.”

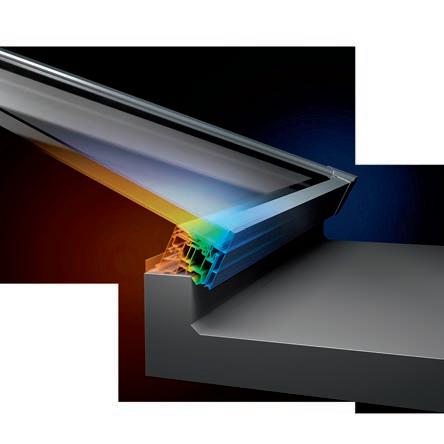

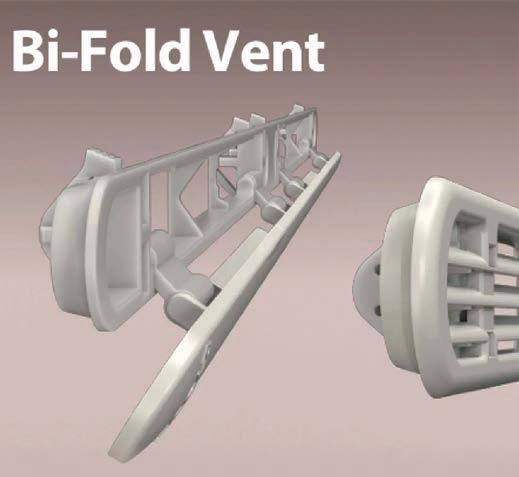

BI-FOLD PLUS

THERMAL PERFORMANCES

glazing * Uw from 1.2 (W/m²K)

Triple glazing * Uw ≥ 0.8 (W/m²K)

* Double glazing Ug=1.0 / Triple glazing Ug=0.5

25% FASTER FABRICATION

Possibility of supplying pre-inserted gaskets

Up to 48 mm glazing capacity

Pre-inserted gaskets

45 mm thermal break

Double bearing system with a gimbal stabiliser

110 mm

Double

Door

Removable SPEEDBEAD allows adjustment and remedial work without damage

Pre-hung doors, no site assembly required

Integral Uni-Blind glass options*

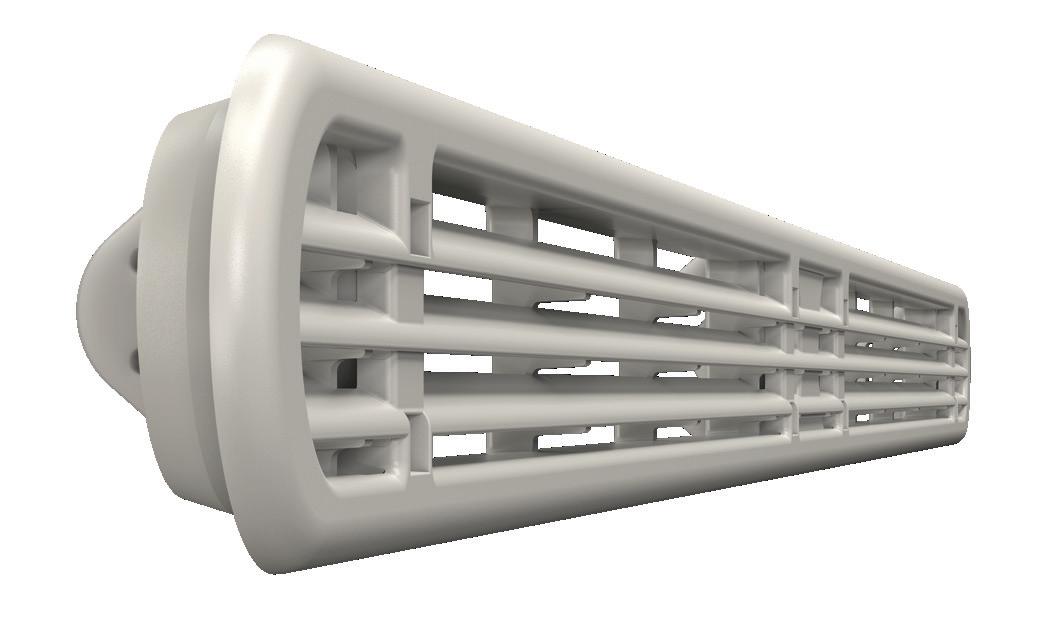

Trickle vent fitted to frame head, no add on required

PAS24 security*

Standard single & dual colours at no extra cost

Premium hardware to match including Brushed Stainless steel

Duration Windows marks 40 years with new showroom launch

Duration Windows has celebrated four decades in business with an open day that combined entertainment with the unveiling of its latest product ranges and a new showroom.

The Essex-based manufacturer, which specialises in bespoke aluminium windows, doors and roofs welcomed customers old and new to the anniversary event, held at its headquarters. The day featured live music from singers and a DJ, alongside a magician who performed for guests.

A highlight of the celebrations was a guided tour of the company’s facilities, giving visitors a behind-the-scenes view of how its products are made. The programme also included a ribbon-cutting ceremony to mark the official opening of the new showroom, which showcases the firm’s expanding collection of designs.

As part of the anniversary launch, Duration Windows presented a number of new products. These included its Curve on Plan and Flush Casement window, as well as an internal sliding door and a double door with side lights, both of which have been added to the company’s Heritage Range.

Founded in 1985, the business has built a reputation as one of the UK’s leading independent manufacturers of aluminium glazing systems. Over the years it has developed a broad portfolio of doors, windows, and roofs designed for both residential and commercial use.

Grant Chelton, Managing Director described the open day as a chance to strengthen ties with long-standing clients while introducing the brand to new customers. The event was positioned as both a celebration of the company’s history and a statement of intent for its future.

The showroom is designed to give visitors a hands-on experience of the firm’s products, allowing them to see first-hand

the finishes, fittings and technical details that differentiate its ranges. The launch also underlined Duration Windows’ focus on design innovation, with new products aimed at expanding customer choice and meeting changing tastes in home design.

The event closed with thanks to attendees and staff, who were credited with helping the company reach its 40-year milestone.

While the anniversary marked a moment of reflection, the emphasis of the day was firmly on what lies ahead. With its latest showroom and product launches, Duration Windows signaled its intention to continue growing in a competitive market while building on the foundations established since 1985.

Installers target high-end contracts with aïr 400SS sliding doors

Everglade Windows is helping installers close high-end jobs with its next-generation aïr 400SS Minimal Frame Sliding Door. Everglade is continuing to help put its installers ahead of competition with its ultra-slim sliding door. Launched to meet homeowner demand for slimmer frames, expansive glass, and high performance, Everglade Windows’ aïr 400SS Minimal Frame Sliding Door has quickly become a favourite with installers. Its beaded and site-bonded design makes transportation, installation, and aftercare far quicker and easier – allowing installers to fit its premium product more efficiently, without compromising on finish or performance. “We designed our aïr 400SS to make high-end installations simpler for our customers, so it’s fantastic to see it delivering both practical and commercial benefits”, says Mike Wilson, Regional Sales

Manager at Everglade Windows. “As demand grows for light-filled, architecturally styled spaces, our installers are saving time on site while offering homeowners a door that performs brilliantly and complements modern interior design.”

After having recently completed several residential projects that featured the aïr 400SS, Sussex Glazing, one of Everglade’s long-standing partners, knows firsthand the

value Everglade’s sliding door has delivered to its business. Patrick McInerney, Director at Sussex Glazing, says: “The bonding process for the aïr 400SS Minimal Frame Sliding Door is really straightforward – it’s just like installing a standard patio door, with the simple added step of applying the bonding agent. For our team of installers, it means quicker fitting times and a much sleeker result, especially with the slim 34mm and 20mm interlocks. It’s been a real win for us, and we’re still seeing a similar demand for the product now.”

As well as its 34mm and 20mm ultra-slim sightlines, the aïr 400SS Minimal Frame Sliding Door comes with PAS24:2022 certification; U-values from 1.2 W/m²k; a weight limit of 250Kg per panel; configurations up to 6 panels wide; maximum sizes of 2 by 2.5 metres per panel, as well as a triple track option.

Aluminium range expanded as Glazerite partners with ALuK and Cortizo

The Glazerite UK Group’s decision to launch the in-house fabrication of aluminium has been welcomed by installers who can now access high-quality, leading brand aluminium and PVC-U products from a single, trusted fabricator.

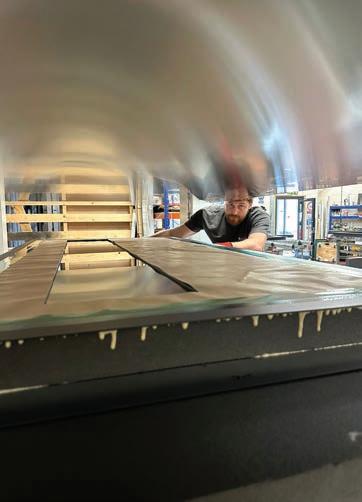

Fabrication of AluK’s aesthetic and highperformance products, including slimline casement, flush casement, tilt and turn and commercial casement windows, and its stunning heritage door, will follow later this summer. Meanwhile, production of the Cortizo Bifold Plus Door and Cortizo 4900 Sliding HI is underway at Glazerite’s North West Division in Bolton, where a previously underutilised area of the site has been transformed into an aluminium fabrication hub. The unit is staffed by skilled fabricators and led by recently appointed Aluminium Manager, Louis Nuttall, who, like his team of specialists, has been recruited because of his expertise in aluminium products and manufacture.

Rob Brearley, Group Managing Director, Glazerite says: “Thanks to its slim sightlines, contemporary aesthetics and durability, commercial clients and homeowners alike are increasingly choosing aluminium, and we want to ensure our installers can tap into this market from their usual, trusted supplier while continuing to benefit from

our quick quotation turnaround, short lead times, UK wide delivery, technical expertise and dedicated marketing support.”

Rob adds: “The addition of AluK and Cortizo has further enhanced our highquality suite of solutions and marks a significant step for both Glazerite and our installers. Our commercial base in particular have welcomed the expansion, though it will also open up new opportunities for those in the residential sector, with homeowners

drawn to the contemporary look and feel of aluminium.”

Russell Yates, Managing Director, AluK adds: “We’re delighted to be working with Glazerite on the fabrication of our leading range, which combines cutting-edge design with exceptional performance. Our team has recently been onsite to assist with set up and training and there has been a real buzz about its introduction. It is an exciting time for Glazerite and its installers, and a journey AluK is thrilled to be a part of.”

Alejandro, Sales Director of Cortizo, says: “We’re proud to see our high-performance aluminium systems being fabricated by a partner like Glazerite, whose manufacturing expertise and commitment to quality mirror our own. With full in-house control over the production process – from extrusion and powder coating to thermal break assembly – and systems tested in Europe and the UK’s most advanced laboratories, Cortizo delivers reliability, innovation, and market-leading performance.”

The creation of a dedicated aluminium facility at the Bolton site forms part of Glazerite’s broader strategic plan to expand its offering for its extensive installer base. It follows a recent £1 million+ investment across the Group to transform its IT infrastructure, online ordering system, and operations across the UK.

InvisiHinge design offers minimalist solution for Sheerline Prestige door

In partnership with Ingenious Locks & Hardware (Ingenious), Sheerline has announced the launch of the patent-pending InvisiHinge for the Prestige Door. This clever concealed hinge is a game-changer, allowing for a totally flush finish and enhancing the overall aesthetics of any entrance.

But that isn’t the only benefit. The development and launch of the InvisiHinge is significant for a number of reasons. A concealed hinge has arguably been on the wish list of systems houses for years, but no other hardware company has been able to deliver a practical cost-effective solution.

As the new hinge is not visible, it is supplied in just one colour (black). The benefits of this are two-fold; the colour complements all doors, which in turn means fabricators have less inventory – reducing stockholding and lowering costs, freeing up cash, and improving efficiency.

It’s easy to install and fully adjustable once in place. Plus, due to the clever design, installers can lift the door off and leave the fixings in place, simply by removing two screws. This isn’t just useful during installation, but also if maintenance is

required.

The lift-off design means the sash and outer frame can be assembled as separate components and then lifted together easily. This works the other way too and means the door can be removed with the hinge intact.

In the past, when fabricators have fitted hinges, there has been an emphasis on positioning to create a balanced look. But with InvisiHinge, there is the option to add a fourth hinge at stress points to add longevity to the installation without impacting the look of the door.

From a performance perspective, InvisiHinge is precision engineered for a flawless user experience. It features a builtin restrictor, so the movement of the door can be controlled for added safety.

For aluminium, the bespoke design of the InvisiHinge means it works exclusively with the Sheerline system, and a PVCu option is available exclusively through Whiteline Manufacturing – another of Sheerline’s trusted partners. Nigel Hutchinson, MD at Ingenious, said: We’re delighted that we’re able to launch the InvisiHinge and offer a concealed hinge to the market. It’s been our belief that there’s been a gap in the market for a product like this and it’s taken years of design and development to get it ready for launch. We’re excited to be partnering with Sheerline as we get to benefit from their expertise in the aluminium market to offer the best product possible. We have a great working relationship with them, and this will only go from strength to strength”.

Dave Watts, Sheerline’s Technical Sales Director, said: ““This has been a real ‘wish list’ project for us, and we look forward to continuing to work with Ingenious in the future.”

Don’t get left behind - homeowners nationwide are falling in love with the charm of heritage styles.

Our authentic flush sash window system captures the heart of traditional design, while cutting-edge uPVC construction delivers outstanding performance. Get in touch today to become a Timberlook installer!

• Heritage flush sash style

• Timberweld joints for heritage style

• Elegant woodgrain foils

• Heritage cill & hardware options

• U-Values as low as 1.2

• Concealed trickle vents

• Complementing flush French & single door

• Available on Tommy Trinder Framepoint®

• Free leads in your area

Frameline now fabricates complete Omnia window and door range

Liverpool-based PVC-U systems fabricator, Frameline, is excited to announce that they are now fully equipped to manufacture the complete OMNIA range of windows and doors, including residential and French doors. This marks a significant milestone in the company’s ongoing commitment to innovation and quality.

Since partnering with Veka in August 2023, Frameline has embraced Veka’s cutting-edge technology and systems, quickly becoming a key player in the market for high-performance, energy-efficient windows and doors. In just a few short months, the team at Frameline made great strides in adopting Veka’s state-of-the-art systems, and they haven’t looked back since.

The partnership with Veka and the integration of the Omnia range is already proving to be a game-changer for Frameline. With Omnia’s stunning double flush aesthetics, improved thermal performance, and a comprehensive system offering, the demand is rising rapidly. Installers now have access to a single system that caters to all their needs, making it easier and more efficient than ever before.

Gerry O’Brien, Operations Manager at Frameline, commented: “At Frameline, we have always sought innovation and continuous improvements, and Veka has truly delivered on this front. Their

commitment to excellence is visible in everything they do, and the introduction of Omnia has been welcomed with open arms. Our team has fully embraced Omnia as the new go-to flush system for the market, and we are already seeing orders coming in for this fantastic range. The sleek double flush aesthetics, enhanced thermal performance and the fact that we can offer installers everything they need with just one system, is creating a strong pull in the market. We’re excited to be fabricating this system and look forward to its continued success.”

Frameline’s rapid adoption of Omnia further solidifies their position as a fabricator that prioritises quality, performance, and customer satisfaction. The company is committed to delivering the best solutions to installers and homeowners alike, ensuring that they remain at the forefront of industry trends.

Amy Steven, Sales Director at Veka, also expressed her gratitude: “We are incredibly proud to have Frameline as a valued partner. Since they came on board with Veka, they’ve demonstrated professionalism, dedication, and a strong desire to bring the best products to market. The market for Flush windows and doors continues to grow and we are excited to see the success Frameline will achieve with Omnia and across the Veka product range”

With the full range of Omnia windows

and doors now available, Frameline is set to offer installers a quality product with the performance, aesthetics, and reliability that the market demands. This collaboration with Veka is poised to drive growth and elevate the fabricator’s offerings to the trade market.

UKO Group expands transport fleet to boost service and capacity

UKO Group, the umbrella company of UK Doors Online, Trade Window Centre, UKO Glass and UK Rooflights, has committed to further investment across the businesses following a period of huge growth and innovation.

Beginning with an expanded transportation fleet, they are strengthening their delivery network, meeting rising customer demand across the UK, and investing in upgraded machinery at all sites to boost output and enhance quality and service

This strategic investment will see the addition of new vehicles to the group’s logistics infrastructure, enhancing delivery capacity and service reliability across all five of its specialist brands. The expansion reflects UKO Group’s commitment to meeting rising customer demand and maintaining industry-leading turnaround times.

“As our brands continue to grow and diversify, it’s essential that our logistics capabilities evolve in tandem,” said Andrew Glover, Managing Director at

UKO Group. “This fleet expansion ensures we can continue to deliver exceptional service, reduce lead times, and support our customers and partners with even greater flexibility.”

The enhanced transport capacity will benefit customers across the UK,

particularly in high-demand regions such as Yorkshire. It also positions UKO Group to scale operations further as it continues to invest in innovation and customer service across its brands.

https://www.ukogroup.co.uk/

High-profile retail lead-generation initiative introduced by Emplas

Emplas has launched a high-profile retail lead-generation initiative designed to deliver high quality and qualified retail leads to participating Emplas customers.

Have gone live in August, Snug is a new national retail brand designed to make the window and door buying process simple for homeowners - and as part of that process, generate quality leads for Emplas customers.

In addition to the launch of a dedicated new website, Emplas will market Snug through social media ad campaigns, consumer case studies and influencer collaborations. The new brand will also focus on monthly giveaways and competitions, while Emplas will also create point of sale literature and local branding tools.

Jody Vincent, Sales Director, Emplas, said: “Retail lead generation is expensive and not always effective. We’re taking the strain for our customers by creating a distinct consumer facing brand. Snug will tap into consumer home improvement channels online and across social platforms. Creating high value marketing assets, and building collaborations with leading home improvement influencers, Snug is designed to connect homeowners with our approved Snug installers.”

With leads exclusively available to Snug approved installers only, , the fabricator is also setting up a consumer contact line and

email channels, with customer services resources in place to answer enquiries and qualify leads.

As part of the initiative, Emplas has grown its internal marketing team to include the appointment of a dedicated brand manager, social media executive and graphic designer. Leads will be automatically distributed by Emplas on a postcode area basis, with a push notification to Snug installers as an enquiry is made. These will be managed via a dedicated lead generation portal. Approved Snug installers

have the option to either accept the lead or decline it, in which case it’s passed to the next nearest Snug partner.

Jody continued: “We spend a lot of time talking about energy efficiency but just as important is that sense of coziness and comfort. We’re shifting the conversation a little, so that the language of the Snug is geared around the consumer. Homeowners can ‘get snug’ by visiting getsnug.co.uk and connecting with an Emplas installer, who can support them in improving the energy efficiency and the security of their home.”

ECDS invests in apprenticeships to secure skills and support trade growth

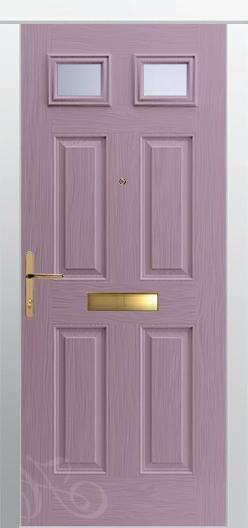

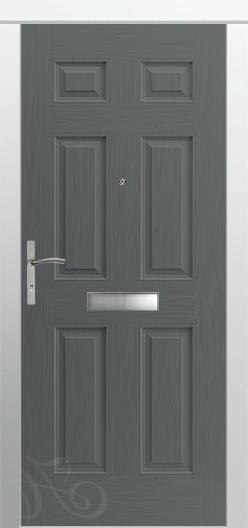

Entrance Composite Door Solutions (ECDS) has launched a new apprenticeship initiative aimed at securing long-term skills development within its team, while continuing to deliver the high levels of quality and service trusted by trade installers across the UK.

As part of the programme, Scott Ellward, head of the paintshop at ECDS’ Nottingham premises, has successfully completed his Level 3 Team Leader and Supervisor apprenticeship. The training has helped sharpen Scott’s leadership and operational skills, contributing to smoother workflows and consistent production standards in the paint and finishing department.

The business has also welcomed two new apprentices, Oliver Roberts and Konrad Taraszkiewicz, through Glass and Fenestration Training Solutions Ltd (GFTS), as part of its continued commitment to building a skilled, dependable workforce that can meet the growing demands of the composite door market.

Gregory Kelly, Managing Director at ECDS, commented: “We are continuously evaluating our current situation to ensure our customers’ quality and service is exceeding expectations, along with bringing them new and innovative products and designs to suit the changing market. This apprenticeship programme is another

step in making sure we’re always moving forward.

“For our trade partners, this means continued peace of mind – knowing the people behind the products are developing their expertise and contributing to reliable, top-quality manufacturing processes.

“Apprenticeships remain one of the most effective ways to tackle the industry’s skills shortage, providing real-world experience and formal training that benefit both businesses and their customers.

“With a clear focus on craftsmanship, consistency and long-term growth, ECDS’ investment in apprenticeships underlines our role as a supplier committed to supporting installers with products they can depend on – now and in the future.

“It’s incredibly rewarding to see team members like Scott progressing through formal training and making a real impact on the business. We’re also excited to welcome Oliver and Konrad as the next generation of talent – their enthusiasm and fresh perspectives are already proving valuable.”

AluK reshapes trade and residential team to bolster customer support

There is a new look to the AluK team supporting customers in the trade and residential markets, with a well-deserved promotion for Paul Greenaway, a new face in the form of Paul Roberts and the welcome return of Wayne Richards.

Between them, the three have almost a century of experience in fenestration. That encompasses everything from fabrication, installation, technical development and testing, to hardware, thermal break and profile sales, so they know all the headaches and frustrations that fabricators and installers face, as well as how to make the most of opportunities in almost every market condition.

Paul Greenaway has been promoted from Key Account Manager to Head of Trade and Residential Sales, reporting directly to AluK’s Managing Director Russell Yates. Paul is managing the dedicated UK trade sales team, focused on both existing and new customers, and making sure they get access to all of AluK’s extensive training, marketing and technical support services.

Paul explained: “We know conditions are challenging for many in the trade and residential market at the moment, but the AluK support offering really can make a difference in terms of bringing in new products, generating new sales enquiries and even optimising fabrication efficiency.

We’ve got the resources and the people in place to help AluK customers not just survive but actively thrive.”

Paul Roberts is a newcomer to AluK, but already very familiar with the business and the products, having worked for AluK’s thermal break supplier previously and before that for one of its hardware partners.

He commented: “I worked extensively with the technical team at AluK on the

development of their innovative range of HI profiles and have been really impressed with the range of products and the whole approach to customer service.

“Over my 38-year career in fenestration, I’ve also had plenty of aluminium systems sales experience as well, so I have lots to share with customers and lots of ideas about how they can develop new opportunities with new products.”

Wayne Richards has been tempted back to AluK after a four-year break into a new role as Business Development Manager, alongside looking after existing AluK customers in the Southwest and Wales.

While he has been away, Wayne has worked elsewhere in the industry as a Technical Manager and will be sharing all his knowledge and experience with both fabricators and installers.

He added: “It’s really nice to back with the AluK team, and I’m really looking forward to catching up with existing customers and making the most of all the new enquiries generated at FIT Show, at our Exploration Day and from our Upgrade Your System to AluK campaign.”

AluK now has two separate teams of specialists looking after customers operating in the trade and commercial spaces – each with specific expertise and experience and offering tailored packages of support.

Fail-safe or fail-secure, firms urged to prioritise correct protocols

With over 165 years of German engineering expertise, Fuhr is a leading manufacturer of multipoint locking systems, supplying fabricators and system houses across the UK and Europe with solutions that blend performance, flexibility and compliance. As smart locking and powered access control grow in popularity, one topic is becoming increasingly important - understanding the difference between fail-safe and fail-secure locking, and when to use each.

In simple terms, a fail-safe lock will automatically unlock in the event of a power failure, ensuring safe exit for occupants. This is critical for life safety applications such as escape routes in public buildings, where building regulations or EN 1125 and EN 179 standards may require it. A fail-secure lock, by contrast, will stay locked without power, protecting against unauthorised entry. This is often the preferred choice for securing high-value areas or residential doors.

Paul Balfe, Fuhr UK’s Business Development Manager, explains: “The key to getting this decision right is understanding

how the door will be used - both in day-today operation and in an emergency. The wrong choice can lead to costly retrofits, delays, or worse, non-compliance with building regulations.”

Real-world scenarios vary widely. A staff entrance to a secure facility might require fail-secure operation, while an adjacent fire

escape door could need fail-safe release. In multi-door projects, both may be neededwhich is why Fuhr’s motorised locks can be configured for either mode, sometimes even within the same installation.

Paul continues: “The conversation needs to happen at the start of the project, ideally when access control, automation and integration with building management systems are first being considered. It’s far easier and more cost-effective to choose the right lock early than to redesign later.”

Fuhr’s product range is designed to make this process simpler for specifiers and fabricators. Whether the requirement is for a fully motorised multipoint lock, automatic locking, or a panic exit system. Fuhr’s modular designs mean the same basic routing can be adapted for different modes and standards without redesigning the door.

From helping to interpret building regulations, to advising on access control compatibility or providing guidance on installation, Fuhr offers technical support at every stage. The aim is simple: ensure the right locking solution is specified first time, every time for projects of any size.

Veka hosts fabricator summit focused on collaboration, innovation and growth

Veka recently welcomed its fabricator partners for its annual Partner Day. Set against the elegant backdrop of Burnley’s Crow Wood Hotel, the day was filled with collaboration, celebration and entertainment.

Following the success of last year’s event that saw the introduction of the trailblazing OMNIA suite, this year’s gathering once again brought partners together in fivestar surroundings situated in the heart of Lancashire to reflect on a year marked by successful product launches and industry challenges. The event sparked valuable dialogue between Veka and leading fabricators, reinforcing their ongoing partnership and shared commitment to innovation.

The day opened with energy and insight as Neil Evans, Managing Director at Veka, delivered realistic but encouraging words confirming that as an industry, pulling together, supporting each other and driving the right change will create opportunity.

Josef Beckhoff, Veka Group’s Sales and Marketing Director flew in from Germany to offer a global perspective on how Veka’s innovations are resonating across markets. UK board members followed, sharing product performance, forecasts and technical developments that underlined Veka’s place at the forefront of fenestration and the strength of interaction with industry partners.

World-renowned economist Professor Joe Nellis offered a sharp look at the economic landscape ahead, prompting

thoughtful conversations about where opportunity lies in a changing world.

After a networking lunch, the room transformed into an immersive walkthrough experience, showcasing Veka’s latest innovations including a live demonstration of the Natural Smoke and Heat Exhaust Vents (NSHEVs). Every station was interactive, every concept tangible, providing partners with the opportunity to explore and give valuable feedback.

In one corner, a ‘Veka Difference’ area played video and audio case studies, real stories from real installers, sharing how Veka’s systems help them win business, delight customers and deliver confidently.

Throughout the day, Veka Partners engaged in meaningful conversations with Veka’s product experts who were prepared to dive into technical queries and discuss future concepts.

As evening approached, guests retired to prepare for an evening of dining, networking

and celebration. Veka also arranged a dose of inspiration courtesy of keynote speaker Sir Clive Woodward, whose insights into leadership and teamwork were welcomed by rapturous applause and nods of agreement throughout the room of business leaders.

As Managing Director Neil Evans put it, “You are the beating heart of our company, and we all succeed together. Events like this are vital to our collaboration and understanding of each other.”

Jessica Cooper, Marketing Director, echoed the sentiment: “It’s always a fantastic occasion when we get the opportunity to be in the same room as Veka partners. The discussions, feedback and conversations we can have together are invaluable.”

The Partner Day is a unique event that celebrates industry collaboration which underpins how Veka is committed to being more than a systems house to its partners.

Fabframes signs with Stellar Aluminium

Devon-based Fabframes has signed a three-year supply agreement with Stellar Aluminium Systems, marking a significant investment in its aluminium window and door offering. Previously buying in Stellar products, the family-run business has responded to strong customer demand by bringing production in-house. This strategic step is backed by a major expansion, with the addition of two new dedicated Stellar manufacturing units and a showroom showcasing the complete Stellar Aluminium range. After reviewing the market, Fabframes chose Stellar Aluminium for its ease of fabrication and the popularity of its knock-in, pre-gasketed beads.

Mike Taylor, MD at Fabframes, said: “We pride ourselves on delivering quality and efficiency for our customers, and Stellar ticks every box. The system is simple to fabricate, the pre-gasketed beads save time in production and installation and our installers value them because they don’t shrink or overstretch, ensuring a neat, consistent finish every time.”

Fabframes was also impressed by

Stellar’s competitive colour lead times, offering a five-day turnaround on stocked colours, a service comparable to the PVC-U sector that enables the South-West business to maintain its own fast delivery commitments. Mike added: “Our customers know us for fast turnarounds, competitive pricing and exceptional service. Stellar’s five-day colour lead time means we can keep our aluminium projects moving and deliver on those promises.”

As part of the transition, Stellar

delivered comprehensive on-site training to the Fabframes team, ensuring a smooth switchover to in-house fabrication. From September, the company will manufacture the complete Stellar Aluminium range, including Flush Casement Windows, Heritage Windows, Casement Windows, Flush Residential Doors, Slimline Bifold Doors and the popular Stellar Inline Sliding Door.

Jon Foulds, Key Account Manager at Stellar Aluminium, said: “Fabframes is exactly the type of quality-focused, customer-driven partner we want representing the Stellar brand. Their expansion shows real ambition and we’re delighted Stellar is at the heart of their growth.”

Founded in 1998, trade fabricator Fabframes remains committed to providing high quality products, a 7-day turnaround and free to-site deliveries across the South-West, supported by responsive customer service and technical expertise. The company is BS EN ISO 9001 registered and upholds numerous other industry standards.

Financing investment as construction confidence grows

The latest gures from the Institute of Chartered Accountants (ICEAW) Business Con dence Index con rm what most of us already know, writes Ian Latimer, Managing Director of Emmegi (UK). General business con dence is pretty low. The Index fell to -4.2 in the second quarter of 2025 compared to -3 in the rst, largely because of ongoing concern about the tax burden, global uncertainty and persistently low consumer demand.

However, if you dig a little bit deeper into those gures, there are some positives to be found for this industry. Annual domestic sales growth did fall to 3% in Q2 from 3.4 in Q1, but it is only marginally below the historical norm of 3.1%.

And business sentiment in the construction sector might have dropped marginally to +4.7 in Q2, but that is still substantially above the historical norm of +3.8. In comparison with other sectors, construction is second only to IT and communications in terms of con dence – boosted, of course, by the government’s commitments on housing and new infrastructure projects, which are expected to drive up demand and sales over the next twelve months.

In the light of that, we’re seeing a steady ow of new machine enquiries into Emmegi (UK) from businesses who want to ensure they are in the best possible shape to take advantage of that demand – either because they need to replace ageing machines or just want to increase their capacity.

Understandably, many are thinking long and hard before investing in cap ex and, alongside those enquiries, we’re seeing renewed interest in our nancing o er as a way of preserving cash.

We work with a nance partner who is massively experienced in machine nancing and who, in turn, has access to a wide range of funders who see the value and security of the asset. He says that the predicted growth in construction is actually making it easier to obtain nance at the moment and there is plenty of exibility in terms of structuring deals.

As always, the key for any fabricator is payback and if there is any uncertainty in the short term, then our partner can o er exible deposit amounts, VAT deferrals and front loaded payments and provide weekly, daily and even hourly cost analyses to show how payback could be generated.

And of course, we have the ongoing incentive of the 100% capital allowance which allows the full cost to be set against taxable pro ts – and funding facilities available even on machines costing as little as £10K.

There is no discernible trend in terms of the types of machines being nanced. It is all about value and payback and identifying where investment will deliver the biggest bene ts.

The key strength of Emmegi (UK) is the depth and breadth of our range. We have a vast choice of saws, machining centres, routers and ancillaries under the Emmegi brand, and as part of the Voilap group, we also have access to machines from other group companies including Tekna and Keraglass.

Our team can help fabricators choose the exact model to suit their requirements and their budget – and support with nding nance if needed.

NEWLY DESIGNED WEBSITE FOR GLASSCRAFT

- Glasscraft, one of the UK’s leading manufacturers of sealed glass units, has o cially launched its newly redesigned website — an upgrade that brings practical innovation to the forefront for trade professionals across the UK.

Now live at www.glasscraftglass.com, the site re ects Glasscraft’s commitment to quality, clarity, and customer- rst service. Designed with usability in mind, the clean, modern interface showcases real photography of the Glasscraft team at work while providing a suite of everyday tools to help customers with speci cations, quotes and also assist them in managing their orders faster. “At its core, this website is built for the people who use it,” said Bob Norris, Managing Director at Glasscraft. “We’ve created something that works as hard as our customers do, and that means delivering practical, time saving tools that make the day-to-day easier.”

Among the new features is QuickQuote, an online quoting tool that allows builders and installers to get a guide price of our Hytherm product range in just a few clicks. Hytherm itself is a major addition. The new range includes eight pre-speci ed sealed unit options designed to simplify glass selection across common performance requirements — including thermal insulation, solar control, acoustic comfort, and added security. Each unit is supported by clear product documentation, downloadable guides, and an easy-to-understand comparison matrix, helping users choose the right glass for each application.

Bob adds: “Whether you’re an installer on-site or part of a sales team guiding homeowners through their options, Hytherm simpli es the process for everyone.”

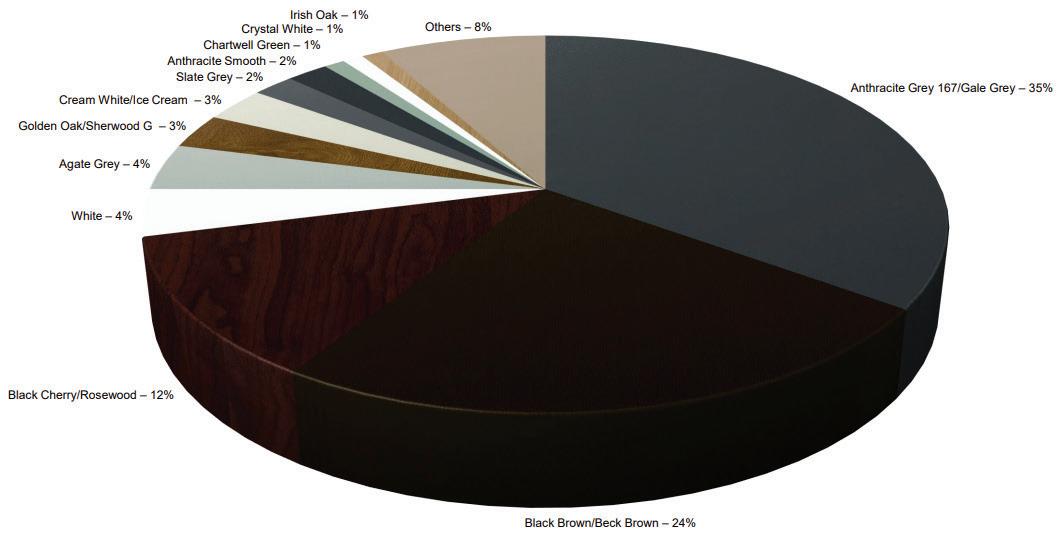

Agate Grey is the standout colour story in 2025 reveals Renolit

The latest industry data in the UK and Ireland has shown some interesting insights into the colour landscape for 2025. Renolit have supplied 93 different colours into the market year-todate 2025, marking a slight increase from the 90 colours sold at this stage last year. While this variety in colours would typically indicate a highly segmented market, it is in fact the opposite. The top 10 colours now account for 90% of total market demand, underscoring the continued dominance of a select group of foils.

Within the top 10 finishes only two woodgrains appear, highlighting a continuing shift toward clean, uniform finishes. Overall, solid colours now account for over 80% of the market demand.

Agate Grey is a standout story in 2025. Once a mid-tier contender, it has increased in popularity to become the sixth most popular colour, surpassing long-time favourites such as Golden Oak. Its rise aligns with broader industry preferences toward neutral, contemporary aesthetics.

But there are signs of changes in demand for colour and surface texture to indicate shifts are beginning to occur, when typically demand has been dominated by the same colour palette for extended periods of time.

Renolit Exofol PX Ulti-Matt has seen a 39% year-on-year increase with Black and Sage particularly strong performers.

Meanwhile Renolit Exofol PFX Super-Matt woodgrains has recorded a remarkable +234% growth. This rise of next-generation finishes suggests consumer appetite for improved aesthetics is stronger than ever.

Should demand continue to become increasingly design-driven, industry stakeholders will need to keep a close eye on emerging favourites and invest in flexibility and speed-to-market to stay competitive.

Renolit’s ability to respond to changing demands positions the company, and the industry, well for continued success in the second half of 2025 and beyond.

This trend suggests growing consumer appetite for contemporary, modern tones with minimalist appeal.

The subtle shifts in colour preferences and variations in surface finish suggest emerging trends within the exterior market, which has traditionally been dominated by a consistent colour palette for prolonged periods. Renolit’s capability to adapt promptly to evolving demands with precision and diversity strategically positions the company, and the industry, for sustained success in the latter half of 2025 and beyond.

TFM invests £100k with Kombimatec

Narberth based fabricator TradeFrame Manufacturers has invested the best part of £100,000 in a Kombimatec DGS450E electronic double mitre saw, and an AMC328 automatic sawing centre. The purchase has enabled TFM to effectively double production in its existing fabrication unit, enabling it to guarantee continued high levels of service to its customer base while it searches for new premises as part of its long term growth strategy.

An important element of the purchasing decision was the fact that Kombimatec has always given that personal touch when it came to providing service excellence. Having worked with the machinery supplier in the past, TFM MD Russ Evans always experienced high levels of after sales care – something that is not always a guarantee with other suppliers.

“When you have an issue impacting production the last thing you want is to be waiting weeks for it to be resolved, which has happened to us in the past. Kombimatec’s managing director David Parsons can often solve a technical problem for us, straight away, over the phone,” said Russ. “Equally, when sourcing a machinery supplier, we recommend that you check if they have any universal shut downs. When

this happened to us, we were unable to get any solution for the best part of a month, which significantly affected our own production schedules.”

Prior to buying both machines, Russ had done his due diligence in looking for alternatives and comparing and contrasting on the basis of cost alongside

performance and service. And while many imported machines matched Kombimatec’s offerings in terms of alleged production improvements and efficiencies, there was no guarantee in terms of providing convenient and accessible aftersales.

“The more I did my research, the stronger I believed buying Kombimatec made not just overall production sense, but sound commercial sense too,” continued Russ. “We have a strong trajectory for growth over the next few years, and the decision to invest in machinery had to fit in with our long term strategic plans. It came as no surprise then that we returned to Kombimatec – and it is important to us that we share this due diligence with other window companies across the UK, in view of the current turmoil within the economic climate.”

David Parsons continued: “Our full range of machinery products includes both British and overseas manufactured products, but ultimately Kombimatec is founded on its customer support, rapid response and comprehensive training, no matter what the provenance of the product itself. Any disruption to manufacturing cycles is money down the drain, so our focus is always to minimise downtime and ensure our machines keep running – we are perfectly positioned to achieve that aim.”

John Agnew retires as CEO of GGF Group after eight-year tenure

John Agnew has stepped down as CEO of the GGF Group, drawing a line under more than four decades of service to the glass and glazing industry. His departure marks the end of a leadership era that has seen the organisation navigate considerable structural and strategic change.

Agnew first joined the Glass and Glazing Federation (GGF) as President in 2017, before taking on the role of Managing Director in early 2020. He was appointed CEO in July 2023, leading the group through a period of renewed strategic focus and operational realignment.

His extensive career includes senior roles at both Toughglass and Independent Glass, where he developed a reputation for financial rigour and steady leadership. Colleagues credit him with bringing clarity and cohesion to the GGF Group’s direction at a time of evolving regulatory pressures and shifting market dynamics.

“It has been an honour and a privilege to lead the GGF Group over the past six

years,” Agnew said in a statement. “I am very proud of what we have achieved together and the role the Group continues to play in supporting and advancing the glazing industry.”

Agnew offered his full support to the GGF Group board and the Executive Management Group (EMG) as they undertake the recruitment process for his successor. An appointment is expected in the near future.

Corey Smalley, Group Chair of the GGF, praised Agnew’s tenure. “John has served the GGF Group with great dedication and commitment for over eight years, leading us through significant phases of change and growth,” he said. “His contribution cannot be understated, and he will be greatly missed.”

Agnew’s retirement comes as the GGF prepares for its next phase of strategic delivery, with increasing emphasis on sustainability, skills development and technical innovation within the sector.

The incoming CEO will face the challenge of building on Agnew’s legacy while adapting to a complex regulatory landscape and uncertain economic conditions affecting the wider construction industry.

Moisture risk from trickle vents raises industry-wide building concerns

CAB has reported a growing number of window installation problems since trickle vents were made compulsory in new build applications under Part F in June 2022, creating a potential ticking time bomb for installers.

Also, a requirement in some replacement applications, CAB has been approached by a growing number of installation specialists, who have been repeatedly called back to site to address moisture- related remedial works.

This includes damage to cill boards, internal plasterboard and oxidisation of internal window profiles.

Dale Pegler, Technical Director, explained: “We have a number of members who have reported a significant increase in the number of times that they have been called back to site since the since trickle vents were made compulsory, because of ‘moisture-related’ problems.

“The theory is - and I want to emphasise that at this point it remains a theory – is the trickle vent cut-outs, allow air to circulate around the external permitter of the window frame between the frame profile and the structure.

“The external air then acts as a cold bridge to the internal aluminium profiles increasing the risk of condensation on the internal face of the profile.”

Approved Document F in June, introduced a new requirement for replacement and new build windows to either put back the same level of ventilation

in new windows as was there before, where trickle vents were previously present; or to make sure that windows achieved a 8,000mm2 equivalent area (EA) background ventilation in kitchens and habitable rooms.

The requirement for replacement windows in bathrooms is 4,000mm2 EA, while in utility rooms and WCs, there’s no minimum requirement.

“Part F was controversial in that it was introduced a requirement to cut through a window at the same time as introducing new standards for energy efficiency”, Dale continued.

“But this is an unforeseen impact. In every window that we’re currently fitting, we

could be creating a future problem.

“The challenge is that moisture damage often takes a long time to be visible. The reports of moisture-related callbacks from our members are increasing, and there are patterns, with more complaints in winter when homes have more moisture build up and the outside is cold.”

CAB is collating information from members and appealing to the industry more widely to establish the cause of the problem.

“On some occasions it could clearly be about the quality of the installation but my hunch is that we’re seeing far too many complaints and that there is more of an underlying issue. The only way for us to establish causality is to track and develop a data set which proves things one way or another. If you have encountered problems, we’d encourage you to get in touch as your input will be vital in developing a full picture”, Dale said.

He added that CAB was already in discussion with trickle vent manufacturers for their input and dependant on findings, the development of a solution.

“The positive here, is that the solution doesn’t need to be expensive or complex. It may be simply about sealing the trickle vent so that cold air can’t escape down the profile channels or an adaptation of drainage.

“We can, however, only get to that solution, if we get to the root cause, and we need input from installers to do that.”

C & SV SYSTEM

A BETTER VS FOR LESS

Wide range of single and dual colours available on a 10-day lead time. Six different hardware finishes.

Achieves a U-value of 1.2 (W/m2K)

Quick release tilt arms for speedy removal of sashes as standard. Deep bottom rail, run-through sash horn option and SBD complaint security are other key features.

The new Kömmerling vertical sliding sash window is packed with technical and practical features. These include: Contact

FUSION WELD OPTION

TILT OPTION FOR CLEANING

RUN THROUGH SASH HORNS

DEEP BOTTOM RAIL

PREMIUM HARDWARE OPTIONS

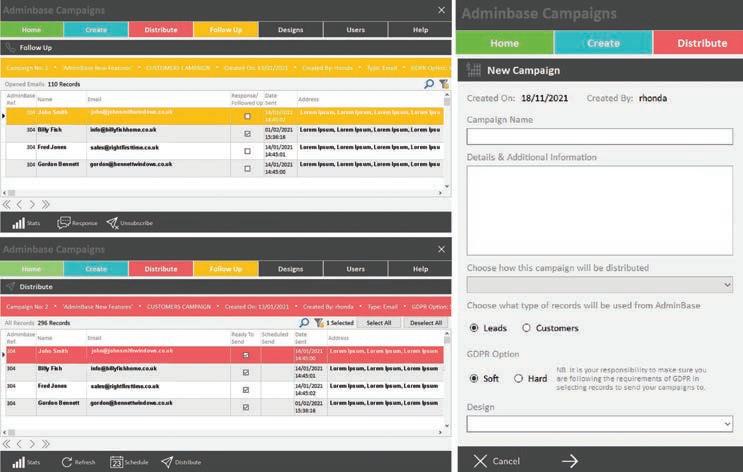

AdminBase Campaigns drive new business with 98.2% delivery success

The AdminBase Campaigns feature within the AdminBase CRM system from Ab Initio has been designed speci cally to help its window company customers maximise highly targeted, low cost email marketing campaigns without the need to import and export data from a third party software. With delivery rates at 98.2 per cent, and open rates averaging at nearly 24 per cent, AdminBase users are experiencing much higher returns from a much lower cost.

The accuracy of AdminBase Campaigns is due to it being part of a fully integrated management system designed speci cally for the fenestration industry, rather than a third party platform. It can handle bulk emails without the need to import or export any data – an action that can lead to loss of data detail, and eliminate mistakes made during that process. Data can be segmented down, and the results are readily available across all departments, eliminating the need for any time-heavy and costly manual interventions.

“Emails remain a powerful source of marketing, particularly to existing customers who will already recognise your company name and are more likely to respond positively,” commented Ab Initio’s managing director Rhonda Ridge. “Whether it is upselling a residential door to an existing window client, or o ering a voucher

for a recommendation, you can create a promotion and email sequence crafted for a speci c niche for maximum e ect”.

While there are many third party software platforms available, delivery and open rates can be temperamental. A good open rate is generally considered to be anything above 17 percent – though many prove to be signi cantly less than this.

“Our customers already have a wealth of potential new business sitting in their databases. We help them unlock that potential quickly, cost-e ectively, and in such a simple way,” said Rhonda. “As the economy tightens, systems like AdminBase come into their own, working on behalf of window companies to maximise e ciencies across every area of their business”

UKO Group celebrates team growth and operational expansion

UKO Group is pleased to share exciting updates across the business, re ecting the continued investment in people, innovation, and operational capacity.

They are proud to celebrate the graduation of one of their talented apprentices, Celia Brook, who has successfully completed her apprenticeship in Business Administration and joined the team in a permanent role. This milestone highlights the group’s commitment to nurturing emerging talent and creating long-term career pathways within the organisation.

In addition to this achievement, the Marketing Department has welcomed several new team members, strengthening their creative and strategic capabilities. These additions mark a signi cant step forward in their mission to elevate brand presence, enhance customer engagement, and drive growth across all UKO Group divisions.

Operationally, both UKO Glass and UK Doors Online have scaled up to meet

increasing demand. UKO Glass has seen the addition of new production team members to meet growing demand. UKD, again to meet increasing demand and improve e ciency, have transitioned to a double-shift system, operating both day and night shifts. This change has brought in a wave of new team members and unlocked substantial extra capacity, allowing them to better serve customers with faster turnaround times and greater exibility.

Natasha Erskine, Co-Founder and Marketing Director at UKO Group said:

“These updates re ect the momentum we’re building across the group. From welcoming new talent to expanding our production capabilities, we’re focused on sustainable growth and delivering excellence at every level. We’re proud to see our apprenticeship programme supporting real career progression, and equally proud of the teams who are helping us scale to meet growing demand. It’s an exciting time for UKO Group, and we remain committed to empowering our people, evolving our services, and exceeding expectations.”

what lies ahead

team, evolving

UKO Group are excited about what lies ahead and remain committed to empowering their team, evolving their services, and exceeding expectations.

The competition cuts corners Graf is V-Perfect

With Graf machinery from Haffner, cutting corners is a thing of the past. The patented V-Perfect technology delivers precision accuracy, ensuring a flawless, seamless finish – every time.

• Superior transom welding quality

• V-Perfect ® transom welding technology

• Weld seam elimination

• Suitable for both V Joints and Butt Joints

• Precision accuracy - delivering a perfect weld every time

• Faster, automated fabrication

Discover more of the benefits of Graf Synergy machines from Haffner

WINNER

NorDan UK expands in Scotland with majority stake in Esk Glazing

NorDan UK, part of the NorDan Group, and a leading manufacturer of high-performance windows and doors, has acquired a majority shareholding in Esk Glazing, expanding its operations in Northeast Scotland.

The acquisition expands NorDan UK’s reach across the north-east of Scotland, where the company has operated since 1981 and is headquartered in Livingston, with additional offices in Aberdeen and Inverness. NorDan UK reported a turnover of £96.9m in 2024 and has 6 showrooms across the UK.

This increased capacity enables faster project turnaround, broader service coverage, and stronger local responsiveness, further strengthening NorDan’s presence across public, residential, and commercial sectors.

Founded in 1974 by Eric Irons and now led by his son Craig Irons, Esk Glazing has built a strong reputation in Northeast Scotland for supplying quality windows, doors, conservatories, and bespoke stainedglass design. Esk, which recently marked its 50th anniversary, joins NorDan, nearing its 100th, bringing together more than 150 years of combined industry experience.

Guided them for decades