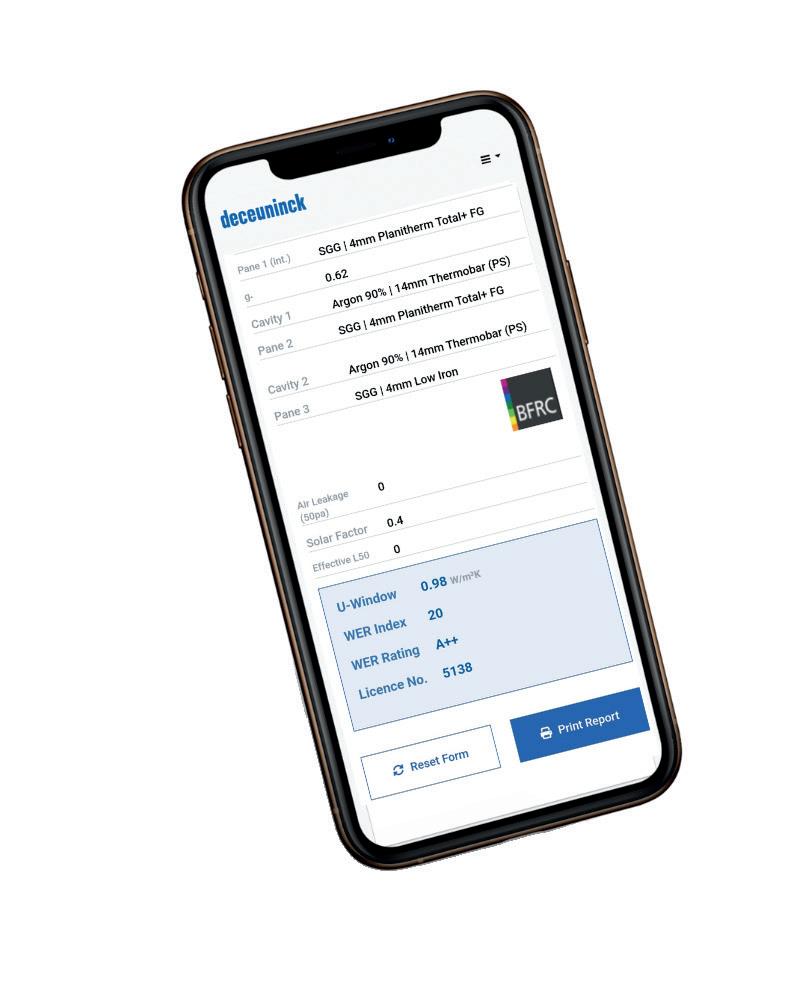

Powered by Deceuninck

Developed with Deceuninck fabricators & installers in

FREE Leads & Lead Dashboard

Dedicated Subsites on 3 Websites

Media Centre

Product Configurator

Energy Savings Calculator

Energy Ratings Calculator

Award Winning Marketing

Brochures, Images, Videos, VR Tours & more!

John Cowie

Editor - Head of Online Content

Tel: 07474 123287

E: john.cowie@windowsactive.co.uk

Jennie Shoglen - Graphic Designer

Emma McCormack - Sub-Editor

ADVERTISING SALES

Steve Gravestock

Sales Director

Tel: 07990 671901

E: steve.gravestock@windowsactive.co.uk

Donna Crockatt

Publishing & Sales Executive

Tel: 07919 448809

E: donna@windowsactive.co.uk

PRODUCTION AND CIRCULATION

Tel: 07919 448809

E: production@windowsactive.co.uk

WINDOWS ACTIVE is published by:

Active Magazines Limited PO Box 627

Rickmansworth Herts, WD3 0BQ

004 - NEWS Glaston receives order for ultrathin IG production from Regency Glass; Apeer hosts Blinds in Glass for UK expansion strategy discussions; Manufacturers urged to review certifications under revised BS 7412; Specifiers call for transparency as embodied carbon data remains elusive; Reynaers reports uplift in window sales amid refurb trend; Allan Brothers opens new showroom to expand reach in the south.

038 - DIRECTOR FOCUS

In this month’s director of the month feature, we talk to Emma Arrell, Group Finance Director of Garnalex.

042 - BUSINESS INTRVIEW

In his latest Podcast, Guy Hubble MD of RegaLead, sat down with the Managing Director of Entrance Composite Solutions Gregory Kelly.

044 - SPECIAL FEATURE

From graduate to strategy setting for the UK: Meet Amy Steven, Fenestration Sales Director at Veka. Aluminium.

046 - SUSTAINABILITY

Big promises, little data— sustainability stalls as specifiers demand green clarity manufacturers aren’t yet prepared to deliver.

056 - FABRICATION

Twenty years strong, still evolving — Unique Window Systems blends legacy with innovation to define the future of fenestration.

073 - MACHINERY

Designed to revolutionise production insight, Stuga’s new dashboard delivers precision control, sharper visibility, and operational finesse.

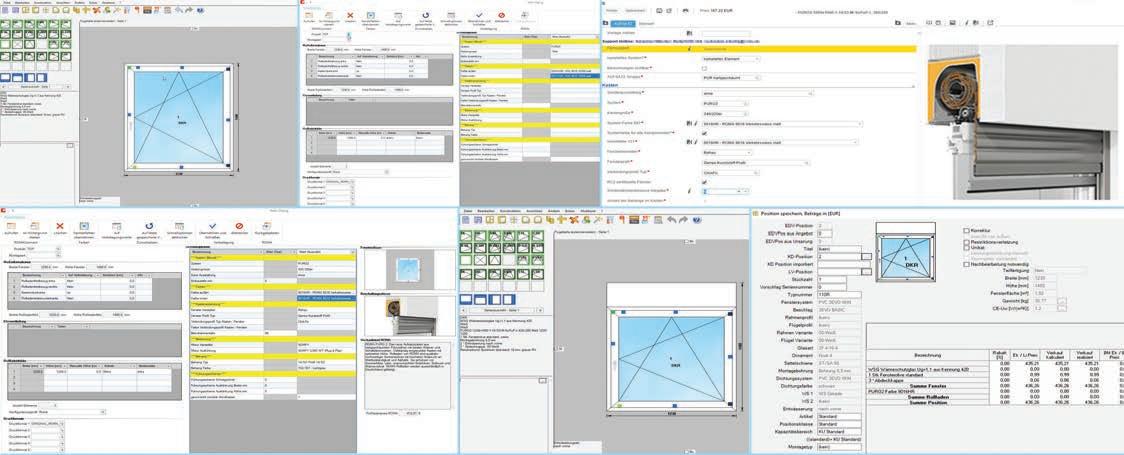

084 - ECOMS & IT

Smart, seamless, and futurefocused—3E’s 3E-LOOK redefines window production with elegant automation and flawless connectivity.

100 - PVC-U SYSTEMS

A comprehensive round-up from some of the leading names in the PVC-U systems sector. Includes features from Veka, Rehau, Eurocell and Vinyl Plus.

048 - GLASSTEC INSIGHTS

AI is no longer optional—it’s revolutionising glass, from mass producers to glaziers, elevating efficiency, precision, and possibility.

052 - GENERAL FEATURE

Ged Ryan, CEO, Hoppe (UK), explores the history of Hoppe and how the hardware manufacturer still holds on to its family values.

054 - MARKETING SPECIAL

Marketing expert Komaldeep Kaur Dhir sees AI and marketing as creative chemistry — one side brings the data, the other brings the soul.

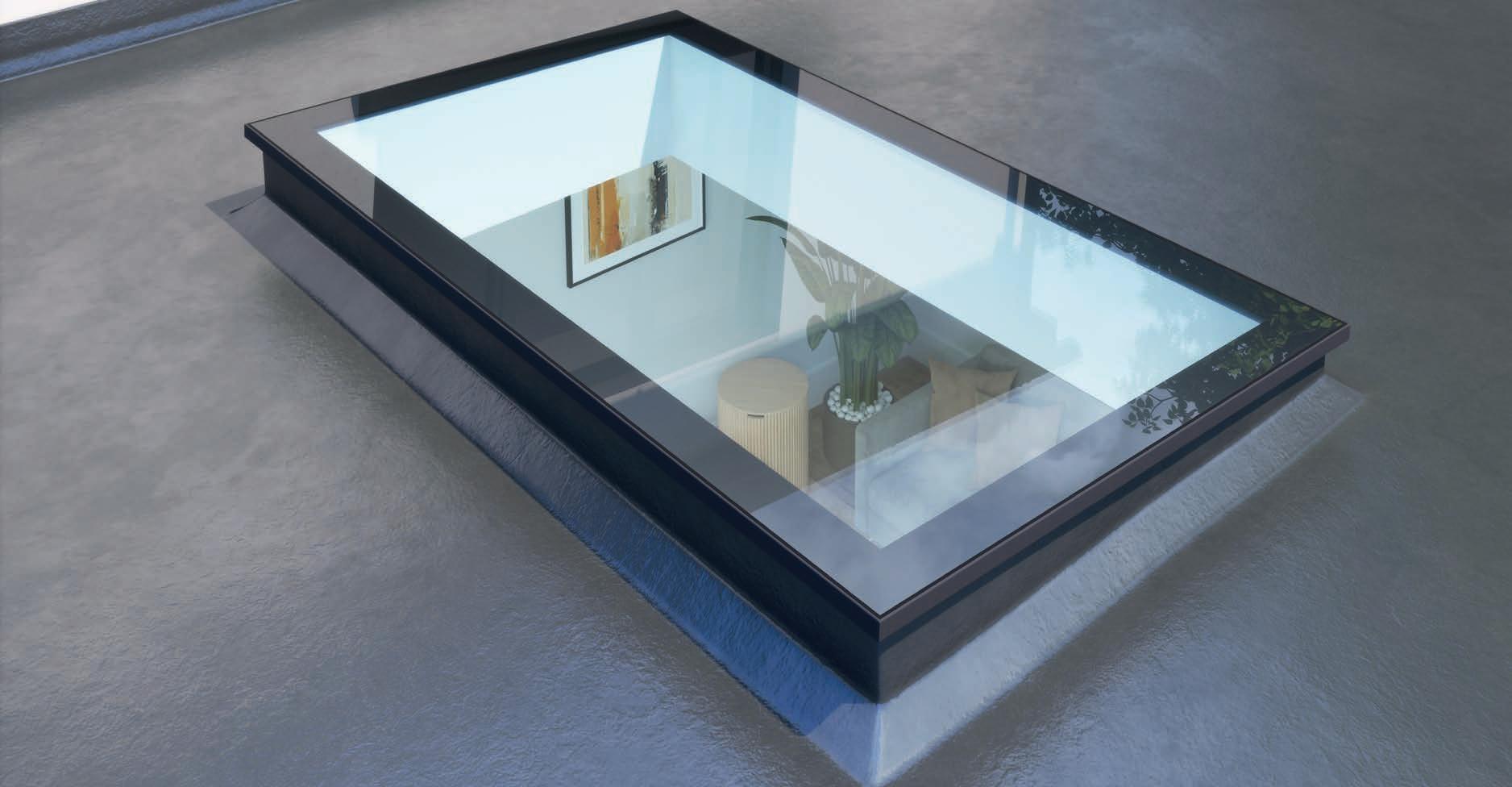

110 - PRODUCT INNOVATION

Boldly reimagined and effortlessly expansive, Eurocell’s roof lantern redefines flat roof elegance with unmatched scale and simplicity.

118 - MOVERS AND SHAKERS

The latest appointments and promotions from the human resources arena of some of the leading firms in the sector.

RegencyGlassand CorningIncorporated

LaunchingaNewTriple GlazingSolution, RevolutionisingtheUK Market...

•0.5mmglasscentrepane

•onlya5%increasein weightonconventional double-glazedunits

•uvalue=0.7to0.9 W/m²/K forastandard 28mmunit

•withstandthermalstressand reducebreakagewithoutthe needfortempering

Regency Glass and Corning Incorporated Will Launch a New Triple Glazing Solution, Revolutionising the UK Market

Regency Glass, in collaboration with Corning Incorporated, a world leader in glass and materials science, will soon launch a triple glazing solution that incorporates Corning’s ultra-thin architectural glass, thus defining the future of the UK glazing market.

Over the past two years, Regency Glass has made substantial investments in personnel, processes, and technology to enhance the quality of its glazing solutions. These investments include internal training programmes, expanded marketing resources, and a brand-new website with bespoke features designed to benefit end users—focusing on the theme: “Glass for Your Home.”

At Regency, the difference is clear. This guiding ethos is embedded in every aspect of the company’s operations, from recruitment and training to product innovation and service delivery. This commitment to excellence has positioned Regency at the forefront of industry advancements.

Today’s triple glazing performance hinges on several key factors: glass thickness, toughening processes, thermal efficiency, and overall durability. Through extensive research and development and a strategic collaboration with Corning, Regency achieved groundbreaking advancements across all these areas and will deliver a more cost-effective, energy-efficient, and advanced triple glazing solution for the UK market.

Manufactured on Corning’s fusion forming platform, Corning‘s architectural glass is a revolutionary 0.5 mm centre pane of glass designed to be a drop-in solution that can withstand thermal stress and reduce breakage without the need for tempering in triple-glazed units. This breakthrough not only maximises argon gas volume for superior thermal efficiency but also surpasses the reliability and cost-effectiveness of any current triple-glazed solution available in the UK.

Corning’s architectural glass is set to transform the UK windows industry, delivering an unparalleled triple glazing solution that is up to 9 kg lighter per square metre. This reduced weight equates to a 30% decrease from conventional triple-glazed units and only a 5% increase on conventional double-glazed units, making installation easier and safer while maintaining superior durability and performance.

Through ongoing testing and regulatory reviews, Regency Glass anticipates center-of-glass U-values for triple-glazed units incorporating Corning’s architectural glass in the range of 0.7 to 0.9 W/m²/K for a standard 28 mm unit, ensuring enhanced energy efficiency for consumers by up to 35% compared to current 28 mm offerings. Full testing results and compliance updates will be shared in due course.

So, when will Regency Performance Glazing with Corning’s thin glass be available? Regency Glass CEO, Darren Beazant, shares:

“Wearethrilledtoleadtheintroductionofthisproductto theUKmarketbyQ12026.Ourdevelopmentand planningareinadvancedstages,andouragreement withCorning,oneoftheworldleadersinthinglass development,marksamajormilestoneinourcompany’s historyandasignificantleapforwardfortheUKglazing industry.”

“CollaboratingwithcompanieslikeRegency,whichshare Corning’sstrongcommitmenttoinnovation,enables residentsandbusinessownersintheUKtoenjoya higherqualityoflifewithmorecomfortableandenergy efficientspacesathomeandwork,”

said Ron Verkleeren, Senior Vice President, Emerging Innovations Group, Corning Incorporated.

As Regency Glass prepares for the launch of products enabled by Corning’s architectural glass, the company will continue its expansion throughout 2025. For more information on this revolutionary technology and how you can be among the first to experience its benefits, get in touch today.

Contact: T: 01942 262162 E: stevemassey@regencyglass.co.uk

As the UK window installation industry reaches the midpoint of 2025, a stark divide is emerging. While the higher end of the market continues to report stable sales and resilient demand, a mounting crisis is unfolding further down the chain. For mid- and lower-tier installers, the market has become increasingly defined by aggressive pricing, unrealistic customer expectations, and an alarming erosion of standards. The result is a race to the bottom, in which price rather than quality has become the overriding concern—and the consequences are reverberating across the supply chain.

At the heart of the problem lies a growing mismatch between what consumers expect to pay and the actual cost of delivering a compliant, high-quality installation. On industry forums, installers share stories of customers hoping to secure full-house window replacements for as little as £3,000 to £5,000—price points that may have been achievable a decade ago but are now far below the cost of materials, insurance, labour, and regulatory compliance. “I can’t even price in proper trims and sealants at what they expect me to quote,” one installer noted, pointing to the increasingly difficult decisions facing tradespeople.

Fuelled by persistent inflation and supply chain disruption, input costs have climbed steadily. But consumers, often unaware of the true cost of quality, continue to anchor their expectations on outdated benchmarks. This problem is exacerbated by the pricing tactics of some national brands, where quotes can start at £20,000 before being slashed to £7,000 under pressure to close. While such strategies may drive short-term sales, they also reinforce the belief that initial quotes are artificially inflated and open to deep negotiation. In turn, this breeds mistrust—before the first frame is even measured.

For local and independent installers, the pressure to compete has pushed many to strip their offerings to the bare minimum. To win work, some are omitting features such as trickle vents, switching to cheaper hardware, or cutting the time allocated for installation—measures that ultimately compromise quality. The implications are all too familiar: botched finishes, increased callbacks, remedial work, and customer complaints. In the process, the reputation of the entire trade is undermined.

Doing the job properly now often means pricing oneself out of contention. Installers committed to regulatory compliance—such as FENSA registration and insurancebacked guarantees—are finding it harder to justify their quotes in an environment where undercutting is rife. For some, the

only viable route forward is to pivot away from domestic jobs altogether and seek more structured commercial contracts, where pricing expectations, though still competitive, are more grounded in reality. Others are leaving the sector entirely, deepening an already acute shortage of skilled labour.

That skills crisis is casting a long shadow over the industry’s future. An ageing workforce, limited apprenticeship uptake, and the reduction in overseas labour post-Brexit have combined to restrict the flow of new talent. Installers increasingly report struggling to find qualified fitters, and delays or substandard workmanship due to inexperience are becoming more common. Training provision remains uneven, and younger workers are often drawn to more lucrative or higher-profile trades. Without coordinated investment in workforce development, the sector faces a long-term decline in capacity and capability.

The pressure is also being felt in the retail environment. Sales staff—often working under commission models that reward volume over value—face constant pressure to close deals quickly. In this context, the temptation to discount heavily or promise more than can be delivered becomes hard to resist. But short-term wins can carry long-term costs: confused consumers, overburdened installers, and a slow erosion of trust in the sector’s integrity.

Still, some firms are charting a more optimistic course. Businesses investing in recruitment, skills training, and clear communication are reporting more stable outcomes. By focusing on professionalism and setting clear expectations from the outset, they are not only securing work but building long-term customer loyalty. These efforts suggest a path forward—but only if the industry is willing to follow suit.

If the sector is to escape this spiral, it will require a collective reset. Transparency around pricing is vital. Educating consumers about what their money buys—durability, compliance, skilled labour—can help shift the narrative away from bargain-basement quotes. But that effort must be matched by a commitment within the industry to hold the line on quality, even in the face of competitive pressure.

There is little doubt that saying no to unviable jobs during tough economic times is difficult. But the alternative—a sector characterised by mistrust, poor standards, and a shrinking talent pool—is far worse. Low prices may win work today. But only professionalism, trust and quality will sustain the industry tomorrow.

John Cowie - Editor

Missing items on orders?

Poor paint quality?

Elusive technical support?

Long lead-times?

Products that don’t conform?

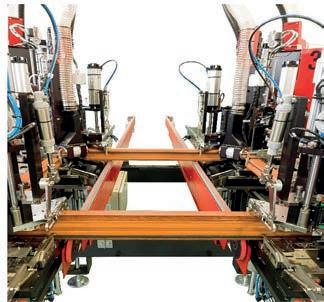

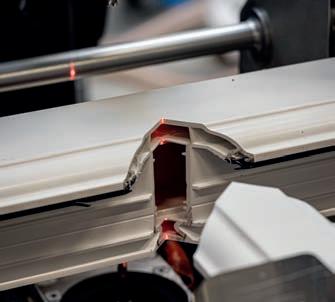

Glaston has received technology and equipment orders from Regency Glass, a well-known producer of high-quality insulating glass units (IGU) in the UK. The orders are booked in Glaston’s Q1 2025 order book. They include an ULTRA TPS® line for manufacturing insulating glass units with ultra-thin center glass, MULTI’ARRISSER machines for edge processing, and an FC Series X machine for glass tempering. The orders will be delivered in the second half of 2025.

Regency Glass has a long experience in providing insulated glass units for the replacement and new build market in the UK. Relying on Glaston’s technology, the company is now expanding its production capabilities, specifically designed to produce ultra-thin triple-glazed insulating glass units.

The triple IG unit with ultra-thin center glass down to 0.5 mm is significantly lighter than conventional triple IG units, and it offers high-performance glazing in a slimmer, more efficient package. These units offer up to 35% better U-values than conventional double glazing, while

also addressing the issues of thickness and weight. Regency Glass’s new triple glazed offering is only 5% heavier than a conventional double IG unit.

Regency Glass has a quality and efficiency-driven operating model. Glaston was the only vendor capable of providing the needed technology to meet their production

quality and efficiency requirements. The customer has already automated its glass tempering process with Glaston’s Autopilot and will continue utilizing those capabilities in the future, too.

“Building on top of the automation capabilities, Regency Glass had the opportunity to plan their new offering around the production process of new ultrathin IGUs. The production design makes the most of the proven TPS® technology and a patented processing method created specifically for ultra-thin glass,” says Sasu Koivumäki, Chief Sales Officer at Glaston.

“We focus on investments that will meet the future requirements of the glazing industry. To address the market’s growing need for energy efficiency, we see a potential for ultra-thin insulating glass units with a better U-value that fit the existing window frame width. With Glaston’s technology and process know-how support, we are confident we will maintain our established production quality and reliability when stepping into a new production field,” says Wayne Fitzmartin, Chief Operating Officer, Regency Glass.

Door manufacturer Apeer Doors recently welcomed Blinds in Glass Group to its Ballymena based factory site for in-depth product training and strategy talks concerning the growing distribution of Apeer doors across the UK. As part of the partnership deal between the two companies, BIGG will help drive sales through its own network of window companies and facilitate the delivery of the product to areas within England and Wales which are still undeveloped by Apeer.

Since establishing the partnership, BIGG managing director, Ian Woolley, along with son Ben, have worked closely with Apeer to ensure the positioning and marketing of the Apeer range of doors meets their mutual high standards in terms of performance and service. Their visit to Apeer’s factory highlighted how dedicated and committed the company and its workforce are, on a daily basis, to those very concepts.

“The market is tough at the moment, but that only gives companies such as BIGG, and Apeer, the opportunity to truly showcase a ‘best in class’ type approach,” commented BIGG’s Ian Woolley. “I was bowled over by what Apeer has achieved over the last 30 years, and as a relatively new kid on the block, we have set ourselves some BIGG targets. Apeer is the level of partnership we are constantly seeking to help us achieve

those targets.”

“The BIGG mindset and approach to doing business is what we are constantly seeking to instil across our trade installer network, and we are already seeing the energy levels increasing across the market,” added Apeer’s CEO Asa McGillian. “In tougher economic conditions it is the strength of the supply chain that will help any business overcome adversity. Working with BIGG gives us confidence that the

foundation we are building today will bear even more prosperous fruit in the future.”

Ian Woolley established BIGG during the height of covid in 2020, and has grown it into a solid £1.6m turnover business focusing primarily on integral blinds and composite doors. The company has created a solid operational framework for growth, and sees this partnership as a primary focus for growth, continuing high levels of service with minimal investment.

REDUCED THERMAL ABSORPTION

DOESN’T REQUIRE THERMAL BREAK

ENERGY EFFICIENT

HARD WEARING & ROBUST

MINIMAL CONDENSATION RISK

GENERALLY LOWER COST OVER ALUMINIUM

With VEKA’s systems and Feinstruktur foil finish, you get the premium look of aluminium with all the thermal advantages of PVCu – a clear winner for modern energy conscious homes.

Scan QR Code to find out more

In light of recent regulatory changes to BS 7412 and PAS 24 requirements,

Element Materials Technology is urging manufacturers to make sure their products meet the latest standards to maintain certification. Compliance with BS 7412 (general performance requirements) is a prerequisite of PAS 24 (enhanced security requirements) for PVC-U windows and doors.

The updates to BS 7412 enforce that each item of hardware on a window product complies with the EN 13126 series of standards. This means all window hardware must be tested and classified to demonstrate compliance with the relevant part of the test and classification standard as part of the requirement for certification to BS 7412:2024.

In addition to the hardware updates above, there have also been updates that relate to updated Factory Production Control (FPC) requirements such as the inclusion of partially welded corners, the removal of infill panel references and the use of thermal inserts.

The classification, requirements and test methods standard for PVC-U profiles has also been updated. Profiles that have no surface covering must be marked in accordance with EN 12608-1:2016+A1:2020 to declare that they meet the updated requirements for PVC-U extrusions. This marking indicates that the profiles have undergone the required testing to confirm

and classify their quality, consistency and durability e.g. impact testing and heat reversion tests.

Andrew Sumner Certification Schemes Manager at Element Materials Technology, said: “These new requirements are significant for manufacturers, as they must ensure that each individual piece of hardware for windows is tested and classified before they can achieve BS 7412:2024 certification.”

Manufacturers have until January 2027

to ensure their Q-Mark certified products comply with the latest requirements of BS 7412:2024. Element has testing capabilities for to the EN 13126 series of standards to help meet the updated requirement. Andrew added: “Every PVC-U window manufacturer should be contacting their hardware suppliers to ensure that the components they wish to use under their certification has the appropriate test and classification evidence in good time to meet the deadline of January 2027.”

Agrowing rift between specifiers and product manufacturers is threatening progress on the UK construction industry’s net-zero ambitions, according to the latest Sustainability Report from NBS, released on 27 May.

The report reveals that 92% of specifiers feel constrained by the lack of robust sustainability performance data— particularly embodied carbon metrics— when making early design decisions. This comes despite increasing pressure from regulations such as the Future Homes Standard and The London Plan, which are pushing developers to prioritise low-carbon building strategies.

Nearly half of specifiers (46%) and over half of architects (52%) now say they only consider manufacturers with above-average sustainability credentials. Environmental Product Declarations (EPDs)—which offer lifecycle carbon analysis—are becoming a key factor in this procurement shift.

Yet many manufacturers are still falling short. Despite environmental performance and embodied carbon ranking as the

top priorities for specifiers, the report shows these are absent from the five most commonly provided data types. Instead, basic information such as product origin dominates—undermining efforts to accurately measure environmental impact during the specification stage.

Lee Jones, Head of Sustainability at NBS, said: “There is a real appetite among specifiers for meaningful, actionable sustainability data. But if environmental data is vague or incomplete, it doesn’t

support decision-making at pace.”

He added that achieving low-carbon outcomes must start with consistent and transparent data sharing: “If we want sustainable choices to become the default, we have to make those choices easier to identify and compare.”

Fewer than half of projects are currently meeting rigorous sustainability standards, according to the report. Major barriers include inconsistent supply chain data, limited access to credible certification schemes, and a fragmented approach to carbon reporting.

NBS’s digital platforms, Chorus and Source, aim to bridge these gaps by integrating sustainability data into the specification process. By streamlining access to EPDs, carbon metrics, and compliance tools, the platform is helping specifiers make lower-carbon choices without sacrificing performance or speed.

As net-zero targets edge closer, manufacturers may find themselves sidelined unless they can deliver on data as well as design.

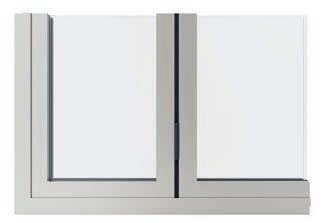

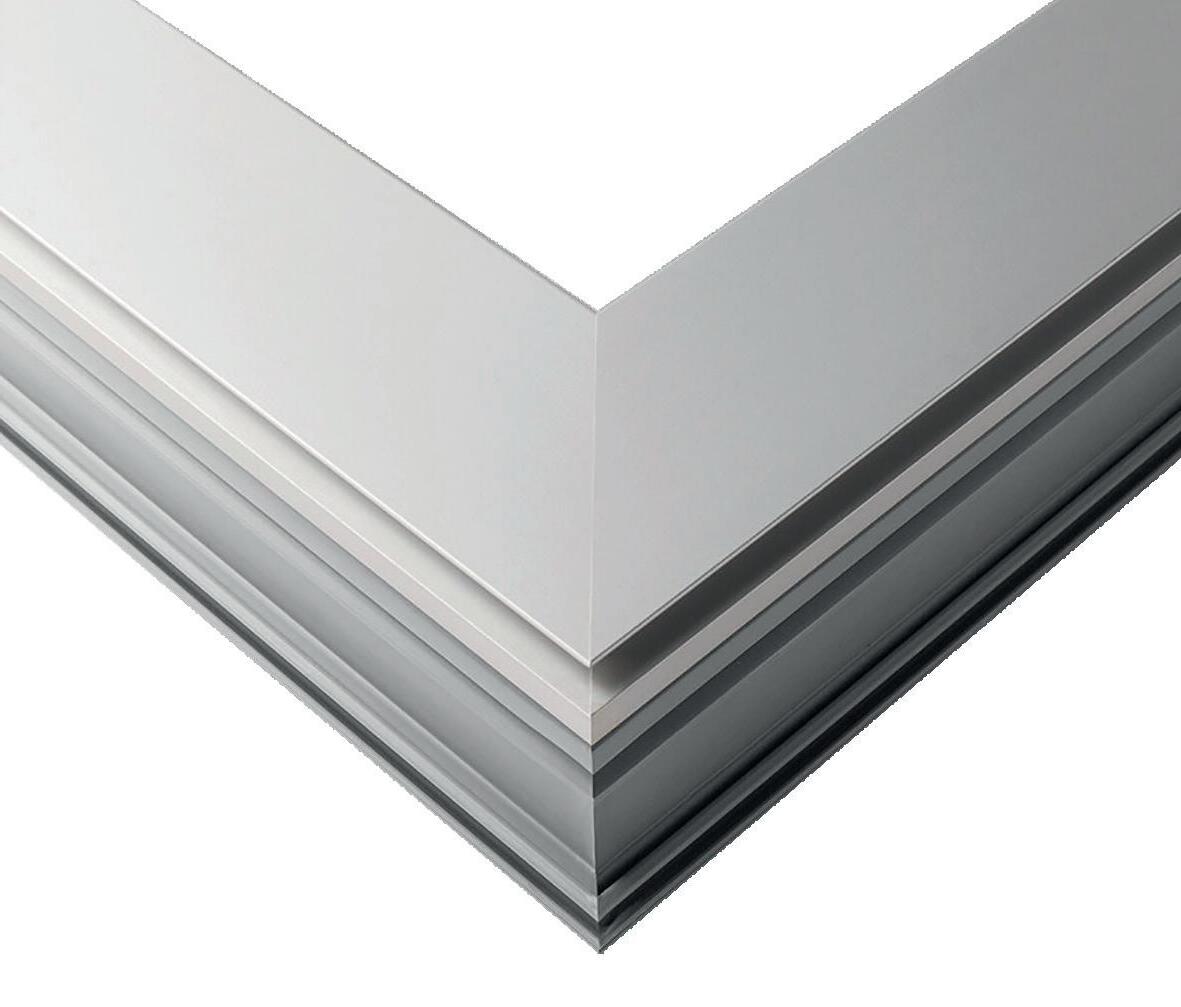

Reynaers Aluminium UK has reported a notable uplift in sales of its residential aluminium windows in the past 12 months as homeowners look to align windows with slimline aluminium doors in refurb projects.

The increase in sales has been led by a trend for homeowners to match external aesthetics by investing in upgrades to the exterior of their home.

With Reynaers’ high performance SlimLine 68 (SL 68) seeing a 12 per cent increase in sales and SlimLine 38 (SL 38) achieving almost a 40 per cent lift, the company believes this has been driven by a trend in homeowners looking to upgrade to a slimline architectural look, to replace previously pvc-window frames, that in most cases have a much heavier, bulkier sightline.

Available in a range of contemporary or heritage finishes, SL 68 and SL 38 window systems are ideal for a wide range of refurbishment projects and upgrades.

Terry Ledwith, Head of Sales – Trade and Retail at Reynaers Aluminium UK, said: “Our range of SL68 and SL38 aluminium windows has seen exceptionally strong growth,

particularly given tough market conditions.

“In the face of the cost-of-living crisis and rising inflationary pressures, homeowners are keen on improving the appearance of their homes. This is a continuation of a trend that started during Covid when we

saw a rise in homeowners opening up their homes to the outside using large scale, slim sightline doors.

“The quality of these windows – and the slimline aesthetic they deliver - make them an ideal choice to echo that stylish finish across the rest of the property. This is something we are seeing more and more frequently as people choose to make changes that they know will last the test of time and enhance the finish of their home.”

Designed to fit into a standard 68mm window frame, Reynaers’ SL 68 is a highperformance aluminium casement window that boasts industry-leading thermal insulation and can achieve a U-value as low as 1.1 W/m²K.

Both SL 38 and SL 68 are available in double and triple glazing options up to 43mm thick, which makes them future ready in terms of accommodating high standards in thermally-efficient triple glazing.

Awarded Secured by Design accreditation, both windows systems reach the PAS24 security standard, to demonstrate resilience to break-in attempts.

Allan Brothers, the UK’s oldest timber window and door manufacturer, has opened a new showroom to serve Oxfordshire, the Cotswolds and the Home Counties regions. Blenheim Palace Sawmills, a nineteenth-century barn conversion on the Blenheim Palace Estate near Woodstock, is now showcasing the company’s solid timber and Alu Clad windows and doors, including traditional sash windows, flush casement windows, entrance doors, and a variety of patio door solutions.

“The new showroom is the latest in a series of exciting developments at Allan Brothers, which started with a £2.6 million factory upgrade last year, including the installation of state-of-the-art CNC machinery, followed by the introduction of our new upgraded Crafted Range of timber windows,” said Managing Director Morten Bach Valsted. “At a time when the industry is experiencing a 20% downturn, and many companies are pulling back, we are continuing to push forward by investing in our products, our employees and our premises.”

As part of its expansion south, Allan Brothers has strengthened its sales and marketing team with three new appointments.

Heading up the southern operation is Commercial Director Charlotte Whelan, who is responsible for the company’s

business growth and brings a wealth of experience from her previous role as Managing Director of Oxfordshire window installer Jack Brunsdon. Working alongside Charlotte is newly appointed Hannah Wardle as Marketing Assistant and Account Manager, and Christopher Seymour, who will be identifying new opportunities and delivering tailored solutions to trade and residential customers in the south.

“With a new experienced team in place

and well-located new premises, I am confident that we will continue to build on our growing customer base in the south of England,” said Morten.

The new Allan Brothers showroom is open to homeowners, architects and trade professionals. Opening hours are Monday to Friday, 9 am to 4 pm and visits can be arranged by appointment by calling 01289 334600 or emailing enquiries@ allanbrothers.co.uk

THERMAL PERFORMANCES

glazing * Uw from 1.2 (W/m²K)

Triple glazing * Uw ≥ 0.8 (W/m²K)

* Double glazing Ug=1.0 / Triple glazing Ug=0.5

25% FASTER FABRICATION

Possibility of supplying pre-inserted gaskets

Up to 48 mm glazing capacity

Pre-inserted gaskets

45 mm thermal break

Double bearing system with a gimbal stabiliser

to order from 16th June

Quick & Easy Installation

PAS24: 2022 Security

Triple Weather Seals – Provides superior weather protection

Available in Set Sizes: From 400x700mm to 1000x2700mm

28mm double or 44mm triple glazed options

Engineered for Affordability

UK Manufactured & UK Warranty

Free site delivery*

The UK construction industry is showing encouraging signs of recovery, with the latest Glenigan Construction Index for June 2025 revealing a significant uptick in projects starting on site. The report, covering the three months to the end of May, paints an increasingly optimistic picture for a sector that has endured years of economic uncertainty. This renewed vigour is largely attributed to a robust performance in the residential market, which has defied broader challenges.

Overall, projects starting on site increased by a quarter (25%) over the preceding three months, also posting a 10% year-on-year increase compared to 2024 figures. This growth signals a potential turning point for the industry, which has been closely watched for indicators of broader economic health.

The standout performer remains the residential construction market, which “rocketed 39%” on the preceding three months, finishing an impressive 45% higher than last year. Within this sector, private housing construction starts surged by 55% against the preceding three months and experienced a substantial

56% increase year-on-year. Social housing also saw considerable growth, up 29% and 13% respectively over the same periods.

Geographically, the South West, North West, North East, and West Midlands all reported strong performances in residential starts, while the South East and London saw mixed but generally positive results.

While the non-residential sector experienced an 18% decline compared to 2024, it managed to break even against the preceding three months, holding its ground in challenging socioeconomic conditions. The long-troubled civils sector, despite a third (-33%) drop year-on-year, showed signs of softening decline, down by a modest 2% during the core measurement period.

Allan Wilen, Glenigan’s Economic Director, welcomed the results, stating, “The industry will welcome these results as, despite the downturn in major projects recently shown in the May Review, the underlying market, which represents the majority of work across the sector, appears to be on the up.” He suggested that a perceived increase in “relatively good news business stories coming from Downing Street” might be boosting investor confidence. With the residential vertical showing such strong figures, Wilen anticipates the upward trend will continue into the latter half of 2025, adding that the upcoming Spending Review and Glenigan’s own Spring/Summer Forecast will offer crucial insights into the future direction of UK construction activity.

Crittall Windows has announced a new strategic collaboration with Secco Sistemi, the renowned Italian manufacturer of high-performance steel windows and doors systems. The partnership represents a further commitment by Crittall to expand its product portfolio and maintain its leadership in the premium market segment. This new relationship will see Crittall working alongside Secco Sistemi and Barclay Mathieson Architectural (BMA), the sole importer of Secco systems into the United Kingdom. Through this collaboration, Crittall will fabricate Secco’s thermally broken steel systems for both the UK and North American markets. The partnership builds on shared values of quality, innovation and technical excellence.

Secco Sistemi, based near Venice, has been a driving force in steel window and door innovation since its founding in 1947 by Aldo Secco. Known for its use of architectural metals such as brass, corten steel, stainless steel and galvanised steel, the company has consistently produced awardwinning systems that combine technical performance with refined aesthetics. Its products have been specified in landmark projects across Europe and beyond, including the James Simon Galerie in Berlin by David Chipperfield Architects. With more than seven decades of

experience, Secco has evolved from its industrial origins to become a highly regarded partner to contemporary architects. Crittall will source Secco profiles and accessories through BMA, ensuring full control over specification and supply. The partnership enables Crittall to bring Secco systems to market with the same attention to detail and project-led service that has defined the Essex-based company for 175 years.

Crittall’s decision to invest in this new product line reflects the business’s long-term strategy of growth through

innovation. It complements its in-house range by offering new solutions for high-end residential and commercial projects where thermal performance, material quality and design integrity are essential.

Russell Ager, Crittall Windows’ MD, said: “This partnership allows us to offer a broader range of high-performance steel solutions while staying true to the principles that define Crittall: precision, quality and a clear understanding of architectural intent. It reflects our commitment to evolve with our clients’ needs and to bring new, design-led systems to market without compromise.”

Nationwide aluminium manufacturer, Glideline, has welcomed new findings from the latest Keystone Market Research report, which confirms that sliding doors have overtaken bifold doors as the UK’s most popular patio door style.

The Spring 2025 Consumer Fenestration Trends Report released by Keystone Market Research analysed the evolution of behaviours, demands, and frustrations of UK homeowners in the window and door market. Surveying more than 5,000 homeowners, it shows that as well as adjustments in priorities, the shift towards sliding doors across all 12 UK regions has reinforced Glideline’s dedication to sliding door fabrication.

Long-time advocates, the Great Yarmouth-based manufacturer has spent nearly a decade perfecting its ultra-slim aluminium sliding doors – delivering unmatched minimalism, performance and innovation.

From U-values as low as 1.2 W/m2K; slim sightlines – with its GS15 Sliding Door offering 15mm sightlines, the slimmest available on the market – to integrated flooring and noise reduction of up to 40dB, Glideline has future-proofed the demands for its trade partners, who now have a range of the highest performing sliding doors available.

“We’ve always recognised the real value and appeal sliding doors bring to

the market, so for us, this research only confirms what we already know. In an age where minimalism is a must-have, you need to have the products to deliver all of that and more, and bifold doors are a long way from hitting the mark,” says David Pickering, Glideline’s Managing Director.

David continues, saying: “The latest insight, coupled with the continuous demand we see from our customers, not only confirms our belief in sliding doors as a superior product, but re-affirms that they are no longer just a niche product, but an essential offering.

“Slim sightlines, uninterrupted views and natural light are some of the most consistent trends we’re seeing, alongside growing interest around security and energy efficiency.

“The GS20 is an example of that, and is among our most popular sliding doors,” David adds. “The integrated flooring option we introduced along with the door has proven to demonstrate further innovation from us too, creating a whole new level of functionality and seamlessness.”

www.glideline.com

Despite reports of fluctuating consumer confidence, the latest figures from Leads 2 Trade show that extensions are still high on the homeowner wish list.

Andy Royle, Director and co-founder of the UK’s leading provider of double-qualified sales leads in the home improvement sector, reveals a 10% increase in conservatory enquiries over April and May compared to the start of 2025 – and that, far from falling out of favour, the upward trend suggests that homeowner appetite for conservatories and home extensions remains robust.

“Consumer interest only seems to be gaining momentum in 2025,” explained Andy. “Not only are we seeing increased demand for new conservatories, but there’s been consistent interest in orangeries and extensions, despite wider market concerns.

“These are strong indicators that homeowners are still investing in ways to add space and value to their homes.”

Encouragingly for installers, the figures are holding steady year-on-year. “When we

compare this year’s numbers to 2024, they are virtually identical,” said Andy. “There’s no sign of a slowdown, which is welcome news for the industry.”

The upward trend isn’t limited to new builds either. Leads 2 Trade is also seeing continued demand from homeowners upgrading existing conservatories with new roofs, aiming to improve insulation and usability.

“We’ve recorded a steady 5% increase in

conservatory roof replacement enquiries since January,” Andy added. “That figure has grown with the warmer months, showing that homeowners are keen to make better use of their existing space.”

Leads 2 Trade is urging installers to capitalise on the demand by joining its Trusted Installer Network and receiving double-qualified leads in postcodes of their choice through the company’s appointment booking and hot key telephone transfer services to convert more enquiries into sales.

“Installers looking to grow their pipeline can tap into strong consumer demand by partnering with us,” added Andy. “It’s a golden opportunity to get in front of ready-to-buy homeowners and secure highquality conservatory, roof replacement and orangery leads.”

For more information on how the discount app, and to become an accredited installer, telephone 0800 124 4308 or visit

https://leads2trade.co.uk/discountoffer-supplier/

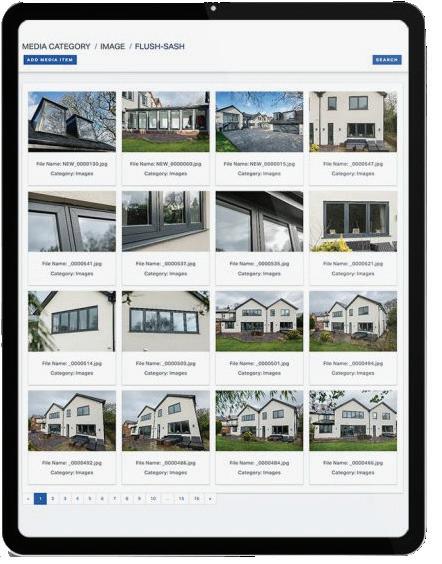

Don’t get left behind - homeowners nationwide are falling in love with the charm of heritage styles.

Our authentic flush sash window system captures the heart of traditional design, while cutting-edge uPVC construction delivers outstanding performance. Get in touch today to become a Timberlook installer!

• Heritage flush sash style

• Timberweld joints for heritage style

• Elegant woodgrain foils

• Heritage cill & hardware options

• U-Values as low as 1.2

• Concealed trickle vents

• Complementing flush French & single door

• Available on Tommy Trinder Framepoint®

• Free leads in your area

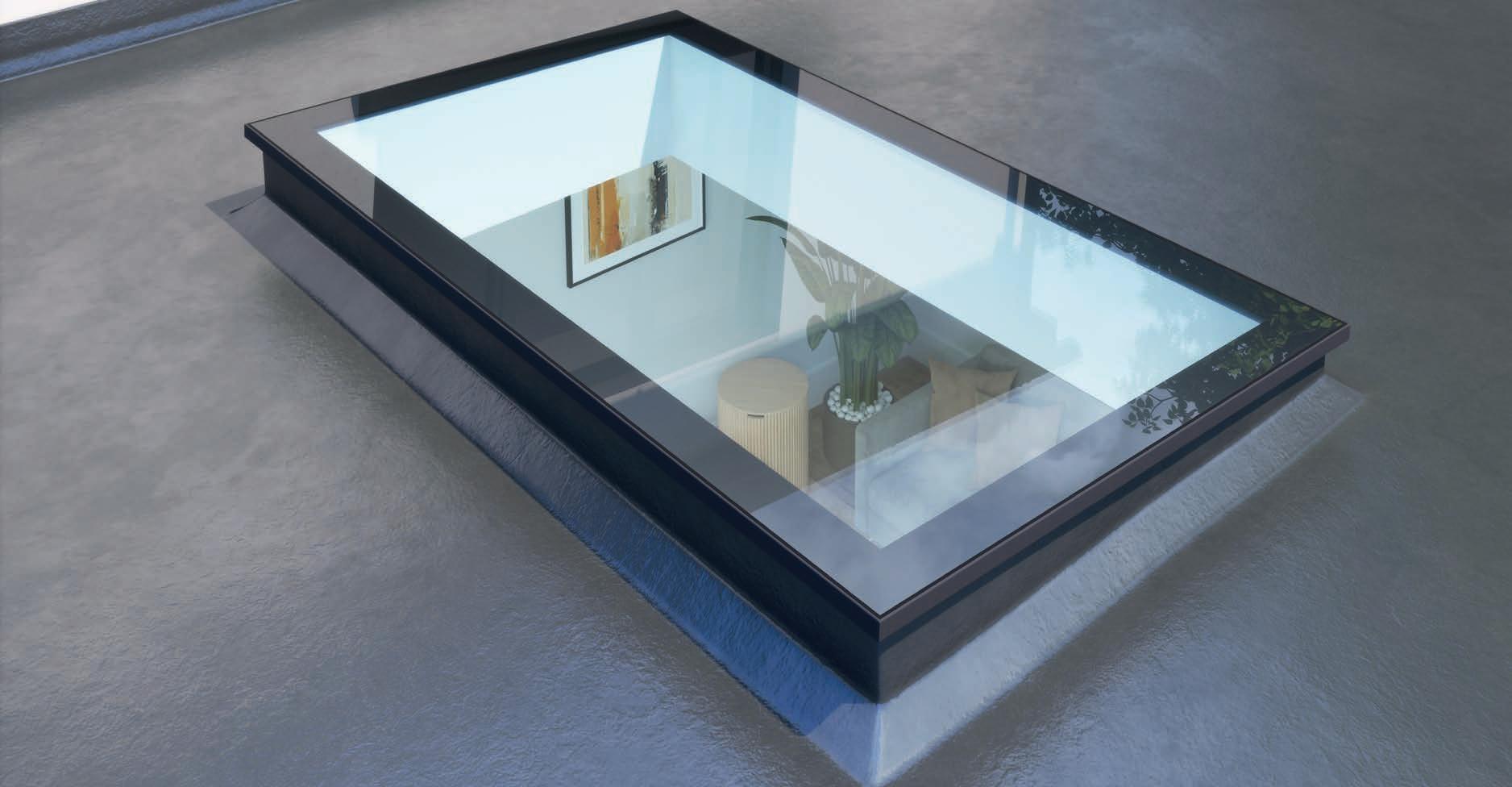

As supplier collapses increase across the UK fenestration sector, Made For Trade reaffirms its position as the reliable constant for aluminium glazed products, service, and supply.

The UK fenestration industry continues to navigate one of its most turbulent periods. With an alarming rise in pre-packs, liquidations, and supplier failures, many trade professionals are facing unexpected project delays, broken supply chains, and growing uncertainty.

At a time when trust in the market is being tested, Made For Trade (MFT) stands firm, offering an unshakable commitment to quality, stability, and long-term partnership. “The UK fenestration industry is currently facing significant challenges, with well-established and once household names collapsing at an alarming rate,” said Bradley Gaunt, Managing Director at Made For Trade.

“Economic pressures, rising material costs, shifting consumer demand, and post-pandemic operational strain have created a volatile environment where even the most recognisable brands are facing daily challenges to compete and perform. This instability has left many installers exposed to disruption, uncertainty, and

loss of supply chains they once relied upon. In contrast, Made For Trade stands as a beacon of reliability. With over 40 years of trading history and a flawless record, having never gone bust or restructured, we have weathered industry storms and emerged stronger each time. Our Korniche-branded products have become synonymous with innovation, quality, and service excellence, and are backed by a business model built

on resilience and long-term commitment to our customers. As the industry reshapes and consolidates, it has never been more important to align with a partner that offers not just market-leading products but stability, continuity, and trust. Made For Trade is that partner: - tried, tested, and here for the long term”

Backed by its flagship Korniche Roof Lantern and Bifold Door, MFT continues to lead the trade sector in both product design and customer service. Installers benefit from:

• Multi-award-winning products, engineered for performance and ease of installation

• Fair, consistent pricing

• Free direct-to-site delivery, streamlining logistics and reducing project disruption

• KwikQuote, a proprietary instant quoting platform for effortless onboarding and fast ordering

• Dedicated UK-based support from people who understand the trade

In line with its latest “lifebuoy” campaign, MFT is calling on installers, builders and fabricators affected by the ripples from supplier uncertainty to reach out and regain control with a partner that has the history, reputation, and strength to weather the storms.

Updates have been made to the PAS 24 enhanced security standard for windows and doors. Element Materials Technology is encouraging manufacturers to prepare for these changes sooner rather than later. PAS 24:2022+A1:2024 details methods to evaluate the security performance of doorsets and windows. This includes testing for updated attack methods to simulate typical burglary techniques. Adherence to PAS 24 is often necessary for obtaining insurance cover and may assist with Building Control compliance for both residential and commercial properties.

The updates to the standard require lock cylinders to pass a new test that simulates modern attack methods, which is beneficial to the property owner. The change also follows on from recently released Office for National Statistics metrics, which show that for the year ending December 2024 there were an estimated 422,000 domestic burglary offences across England and Wales. The attack methods often used by burglars target the cylinder functionality, specifically aiming to disable the security mechanism. Manufacturers must now demonstrate that their products can

withstand the latest attack methods to maintain compliance with the PAS 24:2022+A1:2024 standard. Andrew Sumner, Certification Schemes Manager at Element Materials Technology, said: “As opportunistic individuals continually devise new methods to breach doors and windows, it’s crucial that our certification and testing processes evolve accordingly. These updated requirements will ensure that windows and doorsets are able to meet the latest test methods, helping to safeguard the property

owner against break-ins.”

There will be a transitional period for the new requirements, during which the previous version will remain in effect until January 2027. After this date, all doorsets seeking PAS 24 certification must pass the newly developed cylinder test. Alternatively, cylinders can comply with the latest requirements of TS 007-1:2024 standard or alternative compliance such as being Sold Secure Diamond rated (SS312:2024). It should be highlighted that there are other options available to meet the enhanced security requirements, such as additional cylinder protection.

Element is encouraging manufacturers to update their products and processes to align with the updated standard before the deadline. Element Materials Technology has state of the art facilities that are equipped and able to test to the requirements of the recently updated standards. Element offers full PAS 24 testing alongside a host of other cylinder, lock and hardware testing services at its laboratory in Wednesbury. For more information, please visit: www.element. com/construction/building-products/ doors-and-windows-testing/physicalsecurity-testing

This major collaboration – which incorporates Saint-Gobain’s innovative glass recycling technology into Veka Recycling’s capabilities – is a significant step towards creating a circular economy in the UK fenestration industry.

In a step change for the fenestration industry, Veka Recycling, a pioneer in PVC-U recycling since 1993, has announced a groundbreaking partnership with global sustainable construction leader, SaintGobain. This will bring Veka Recycling closer to realising its mission of creating a closed-loop recycling system within the UK.

Due to the lack of infrastructure for effective collection and recycling, a huge amount of post-consumer glass cullet is currently lost to landfill. By developing cutting-edge solutions and combining their expertise, the two companies are setting a new benchmark for post-consumer recycling and resource recovery.

The collaboration allows Wellingborough-based Veka Recycling to take fully glazed frames, eliminating the need to deglaze on-site and offering a cost-effective, environmentally friendly solution for glass waste disposal. With regular, reliable collection schedules within 100 miles of Veka Recycling.

Central to this is the deployment of Saint-Gobain’s patented ICG Recycling Machine, which efficiently separates annealed and toughened glass from spacer bars. The glass can then be processed and reintroduced directly into float glass production, offering a higher recovery rate and improving the

sustainability of the supply chain.

This innovative process enhances resource recovery rates while reducing the need for raw material extraction, lowering energy consumption by 30% and cutting CO2 emissions across the supply chain.

Tim Taylor, Commercial Director at Veka plc, said: “This marks a monumental step on our journey towards creating a circular economy within the UK. For the fenestration industry, ensuring that materials can be collected, recycled and then manufactured into new products without needing to leave the country is instrumental in meeting sustainability goals.

“By combining our infrastructure with Saint-Gobain’s innovative glass recycling technology, we are confident that we can overcome current challenges to significantly increase the rate of post-consumer glass recovery in the UK.”

Michael Butterick, Marketing Director at Saint-Gobain Glass, said: “We are thrilled to

The organisers of the G-Awards are pleased to confirm that the G24 Awards will take place on Friday 28 November 2025, returning to the London Hilton Park Lane.

After a record-breaking number of entries last year, the glass and glazing industry will be invited to enter their innovative products, services and solutions as soon as possible. Entries for the G25 Awards are free of charge and will be judged by a selected group of industry experts.

Here is the full list of awards up for grabs.

• Best Business Initiative of the Year

• Commercial Project of the Year

• Component Supplier of the Year

• Customer Care Initiative of the Year

• Fabricator of the Year

• Glass Company of the Year

• Installer of the Year

• Machinery Innovation

• New Product of the Year

• Promotional Campaign of the Year

• Rising Star

• Sustainability Initiative of the Year

• Training & Development Initiative

• Unsung Hero

Entries are now open, and companies can enter online at www.g-awards.com – the entry deadline is Thursday 31 July 2025

The organisers are thrilled to welcome back some fantastic event sponsors including BM Data, Deceuninck, Emplas, Epwin Group, FENSA, FIT Show, Forel, GGF and Thermoseal.

The gala dinner is one of the biggest nights in the calendar and companies will be invited to join in with the event’s 21st anniversary of celebrating the best in the UK glass & glazing industry.

be partnering with Veka Recycling to offer a solution for post-consumer glass recycling. The potential of this initiative is vast — by addressing the current gap in infrastructure and leveraging key partnerships, we can achieve our sustainability goals.”

Post-consumer glass recycling is central to Saint-Gobain’s journey to Net Zero CO2 emissions by 2050. While Veka Recycling is pushing to create a closed-loop system and circular domestic supply chain for the UK fenestration industry.

To support Veka’s mission to ensure that sustainability is at the core of the industry, Veka’s Recycling’s facility in Wellingborough has had a £15m investment, enhancing its capacity and efficiency. In 2024, Veka Recycling and Veka plc were brought under one Board, aligning the two businesses under this shared goal.

Tim Taylor added: “This significant partnership marks another crucial step toward building a greener future — reducing the use of raw materials, lowering energy consumption, and significantly cutting CO2 emissions across the supply chain.”

Full details for entries, booking your table or being involved as a sponsor can be found on the event website www.g-awards.com

For over 20 years, Solidor has been the final touch that transforms houses into homes across the UK. Now, we’re taking things even further. Introducing our bold new look. The benchmark in composite doors is being redefined. And we’re just getting started. Solidor. Proudly made in Britain

Powered by Deceuninck

• FREE Leads & Lead Dashboard

• Dedicated Subsites on 3 Websites

• Media Centre

• Product Configurator

• Energy Savings Calculator

• NEW Energy Ratings Calculator

• Award Winning Marketing

• Brochures, Images, Videos, VR Tours & more!

Atlas Aluminium is one of the UK’s largest fabricators of aluminium windows, bifold and sliding doors and is the creator of the Atlas Roof product range. We were proud to welcome Dr Simon Opher, Member of Parliament for Stroud, to our manufacturing facility in Stonehouse, Gloucestershire last week.

The visit provided an opportunity to showcase our operations, meet our uniquely experienced and hardworking team, and discuss the importance of supporting local manufacturing and sustainable innovation in the aluminium fenestration sector.

During the visit, Dr Opher toured our production floor and met with team members across various departments, gaining first-hand insight into day-today operations and the realities facing manufacturers in the current economic climate.

A follow-up discussion with staff offered the chance to reflect on broader sector challenges and share perspectives from the shop floor. This included a discussion on the recent rise in Employers’ National Insurance contributions and its disproportionate impact on UK-based companies, which are likely to suffer more than multinationals that can shift profits offshore and are often quicker to reduce staff.

Dr Opher was very positive throughout

his visit and particularly praised the attitude and commitment of all the staff he met and noted the ‘happy’ atmosphere. The visit was a strong reminder of the importance of conversations between industry and government and that each sector, not least fenestration, has its unique issues.

“We were delighted to host Dr Simon Opher and share the work we’re doing to deliver high-quality aluminium window, door and glazed roof products to our customers across the UK,” said Jamie Newall,

CEO at Atlas Aluminium.

“We are very proud of our experienced workforce and the work we have done since December to give them the support they need to flourish. It’s encouraging to see local leaders take an active interest in our industry, workforce, and future growth.”

Atlas Aluminium remains committed to investing in people, technology, and environmentally responsible practices as we continue to serve our valued customers with pride and precision.

ODL Europe has completed a sixfigure investment in its in-house door prep facility, doubling its footprint and significantly increasing its prepping capacity. Suzanne Nicholl, Head of Sales and Marketing at ODL Europe, said: “The investment significantly increases our capacity and will allow us to meet growing demand for our door prep service.”

The expansion involved knocking through into an adjacent building to extend production space, alongside investing in new equipment including a state-of-theart CNC machining centre that will build on the quality and efficiency for which the company is known.

ODL Europe’s door prep service is a flexible offer that allows fabricators to outsource as much or as little as they need. The service includes everything from basic door sizing to full door prep, customised to specific configurations and hardware requirements.

Suzanne commented: “A composite door slab requires precise preparation and getting it right takes real expertise. Our skilled in-house team can prep for any lock, any

hinge, open in or open out, with or without edge banding. As demand for our door prep service has grown, we’ve continued to invest in the technology and expertise needed to support our customers with accuracy, flexibility and efficiency.”

ODL Europe is the exclusive UK partner of Capstone Engineering Ltd, one of the world’s leading suppliers of composite door slabs. This partnership means fabricators choosing ODL’s door prep service benefit from premium-quality composite doors that have been rigorously tested in the most

demanding environments and prepared to their exact specifications.

ODL’s high-performance composite doors are designed for long-term durability. They are manufactured to resist bowing or twisting over time, ensuring a consistently accurate fit and reliable performance from day one.

Over 750,000 Capstone doors are installed worldwide each year. ODL Europe offers over 30 door styles, both glazed and unglazed, including many that are unique to the company. There is also the Guardsman Fire Door, which offers impressive, consistent fire resistance and won New Product of the Year at the G Awards.

Alongside its door offer, ODL Europe also offers a comprehensive cassette range that includes the market-leading TriSYS® glazing cassette.

Suzanne concluded: “We continue to grow as a business because our aim is to secure long-term partnerships with our customers by delivering excellence at every interaction. This includes investing in our business to ensure we can continue to deliver exceptional quality to every customer.”

Low-carbon glass is expected to become a mainstream specification choice over the next five years, but concerns around its performance, cost and limited awareness are still preventing wider adoption today, according to new research from Pilkington UK.

The study, conducted with 100 UK-based architects and specifiers, found that only 54% expect to frequently specify low-carbon glass within the next five years. This reflects a growing ambition across the industry, but also highlights that current uptake remains lower than needed to meet broader decarbonisation targets.

The findings were unveiled during Pilkington UK’s recent webinar, ‘Specifying glass – circularity, performance and practicalities’, which explored the key benefits of low-carbon glass for architects and suppliers.

When asked about the main barriers, 42% of respondents cited concerns about performance or durability, while 41% pointed to cost compared with standard products. A third (33%) said that a lack of information or awareness about sustainable glass options was a barrier, while the same proportion reported resistance from clients. Limited availability was noted by 31%, and 28% said the lack of industry standards or guidance played a role.

Despite these challenges, there is optimism about the direction of travel. More than half (51%) of architects and specifiers said that the quality and aesthetics of low-carbon glass match standard alternatives, while 34% believe low-carbon options actually outperform them in this regard.

Only 14% thought they performed worse.

Respondents also recognised a range of benefits beyond reducing embodied carbon. A total of 44% said specifying low-carbon glass improves brand reputation and supports alignment with ESG goals. The same proportion said it helps them to meet corporate or project-specific sustainability commitments. In addition, 43% said it enhanced appeal to tenants, buyers or investors who prioritise sustainability, and 34% felt it helped future-proof projects against stricter regulations.

The research also explored the role of circular design in specification. Four in

five (80%) respondents said circularity is currently important when specifying glass, and 74% expect that influence to increase in the next five years. Arne De Ceapog, Specification Manager at Pilkington UK, said: “We’re seeing growing ambition in the industry to cut embodied carbon, but that’s not yet translating into widespread specification of low-carbon glass. To change that, we need to build trust in the performance of sustainable products and address common misconceptions. At Pilkington UK, we’re working closely with specifiers to support low-carbon choices with real-world insight and technical clarity.”

VBH, the hardware manufacturer, has advised that sales of one of its star products for aluminium window production is ‘on the up.’

The greenteQ Securitas Offset Security Espagnolette is a specialist product for users of slim aluminium casement windows from three of what VBH describe as the ‘most popular’ aluminium systems, including Sheerline.

These slim profiles have no Eurogroove to accept the locking system. Securitas Offset’s 16mm wide U-rail stainless steel faceplate is designed to be surface fit to account for this, and its offset gearbox ensures that the glazing area is not broached when fitted.

Up to four pairs of bi-directional adjustable mushroom headed cams provide compression and security when in the locked position. The cam pairs locate into both sides of a greenteQ night vent striker plate to firmly hold the sash secure even in

the face of a determined attempt at forced entry.

Nine lengths, starting at 320mm going all the way up to 1320mm, mean that even the smallest and largest casements can benefit from Securitas Offset

Gary Gleeson, marketing manager at VBH, says, “Securitas Offset is a major strand of our range of locking systems for outward opening single and double sash casements. We now offer thirteen different solutions across the greenteQ, Roto and Yale brands.

“We launched this product eighteen months ago and it proved so popular that the industry voted it Window Component of the Year last autumn. 2025 has seen sales continue to rise as we penetrate further into the aluminium sector. It really is one of our products that is “on the up.”

As well as being very quick to fit, VBH advise that Securitas Offset is approved for use on Q-secure PREMIUM installations, offering consumers the peace of mind that the popular hardware security guarantee brings.

.As with all greenteQ products, Securitas Offset is supplied with a long guarantee; ten years in this case.

The global market for antibacterial glass is set for substantial growth, projected to nearly double from $289.54m in 2024 to an impressive $588.34m by 2034, marking a compound annual growth rate (CAGR) of 7.36 per cent. This surge reflects a burgeoning demand for materials that actively inhibit the spread of harmful microorganisms.

Antibacterial glass, which integrates agents such as silver ions, copper compounds, or titanium dioxide coatings, is engineered to prevent the proliferation of bacteria, a stark contrast to conventional glass surfaces that can readily harbour germs. Crucially, it maintains the transparency, durability, and aesthetic appeal of standard glass, making it a versatile solution for a hygiene-focused world.A heightened global awareness of health and hygiene, amplified by recent health crises like the COVID-19 pandemic, is a primary driver. This is particularly evident in healthcare facilities, where antibacterial glass is being adopted to minimise bacterial transmission on frequently touched surfaces. Beyond clinical settings, businesses and consumers are increasingly prioritising environments that promote health safety.

Technological innovation is also a key propeller. Continuous advancements in antimicrobial coatings, including nanotechnology for ultrathin yet powerful effects, are rendering antibacterial glass

more effective and durable. Manufacturers are also exploring multifunctional glass, combining antibacterial properties with features like UV protection, scratch resistance, and self-cleaning capabilities. Regulatory support further bolsters market expansion, with governments worldwide encouraging the adoption of antimicrobial materials in public infrastructure. Looking ahead, emerging

trends include “smart” surfaces that visually signal contamination and a shift towards sustainable, eco-friendly coatings, exploring biodegradable or less toxic materials. Customised solutions tailored to specific industries, such as pharmaceutical manufacturing and hospitality, are also on the rise, cementing antibacterial glass as a critical material in safeguarding public health.

Leading trade fabricator Dekko Window Systems has announced the appointment of Steve Collett as its new Sales Director.

Bringing over 25 years of industry expertise to the role, Steve joins Dekko with an impressive track record, having previously held senior positions at several major names, including Sales Director at Cotswold Trade Aluminium, Commercial Director at Epwin Group Plc, National Sales Manager at Customade Group, and Sales and Marketing Director at Britdoors Group.

The appointment comes at an exciting time for Dekko, having recently expanded its product portfolio with new door offerings as it targets the commercial sector, with plans to introduce more innovative products including timber, garage doors,

and pergolas. Managing Director Kurt Greatrex said: “It’s great to welcome Steve on board and his vast experience and industry

knowledge make him the perfect fit.

“It’s an appointment that represents a significant investment in Dekko’s future and we’re looking to tap into Steve’s proven ability to drive sales and continue the strong customer relationships we already have.”

A delighted Steve Collett said: “I’m delighted to be joining Dekko at such a pivotal time. The Dekko name is synonymous with quality and sustained growth and I’m looking forward to helping that to continue.

“Dekko has built an excellent reputation, so my focus will be on strengthening our position within existing markets while driving growth in new sectors, and I’m looking forward to working with the team to deliver exceptional value to customers.”

Birmingham based PVC-U Window and Door Systems Company, Selecta Systems, are revelling in the achievement of being nominated finalists in seven categories at the 2025 National Fenestration Awards. Managing Director Maximilian Weihe opens up about being NFA finalists and the Selecta success story so far.

“We’re very proud of what we have and continue to achieve here at Selecta. Over the years, we have seen the demise of so many profile systems and systems companies’, whereas Selecta have remained consistently strong and well placed within the market. There have been many factors that have contributed to other systems companies’ downfall. However, Selecta’s ability to remain successful for over 43 years shows our resilience and ability to adapt to market conditions and our customer’s needs.”

“At Selecta, we believe that the two biggest assets in any company are its staff and customers. Without either, there is no company. For context, we have approximately 300 fabrication customers on our books and a number of those have been long-term Selecta partners. Just over 47% of our customers have been Selecta partners for 10 years or more, with just over 10% accounting for 20 plus years. We’re very proud of the loyal customer base that we have established at Selecta.”

“This loyalty and commitment also

extends to our staff. Our success has been built around a knowledgeable, dedicated and experienced team over the years. What this shows is the businesses’ ability to create stability, continuity and solidarity, not only amongst our customers but also our team.”

“This is why we are extremely proud to again be recognised by our industry peers at this years NFA’s. To receive seven category nominations is testament to the teams outstanding work here at Selecta. I also believe that the individual staff nominations demonstrates our ability to build a strong, talented and competent team here at Selecta.”

“To have individual recognition for your ongoing contributions to your customers, the business and the industry brings a sense of immense personal pride that should be celebrated. Therefore, I would like to extend my gratitude and congratulations to all that have been nominated and also to the team that has contributed to our continued success.”

“We have successfully and continuously consolidated our place in the market. Our objective

has and will always be to provide a range of quality window and door profile systems, backed up by a flexible and personal support package and service.”

“The aim is to build on the 43 years of success and ensure that Selecta and the ADVANCE 70 System are the go-to brands for fabricators, installers, specifiers and homeowners. The introduction of two new products, an improved flush sash window and a new flush sash door, reinforce that commitment. Whilst the upcoming lead generation, sales and fabrication management package on offer from our Connect Portal Mode further strengthens that promise to our fabricators and installers.”

“Taking all of the above into account and managing the business with transparency, trust and honesty, we believe will breed loyalty and success. You can then only hope that this philosophy is acknowledged by your industry peers and all who become ‘part of the family’. I consider being nominated finalists in seven categories at the National Fenestration Awards 2025 as part of that acknowledgement and recognition.”

Sheerline’s award-winning products can now be viewed on NBS Source.

The purpose of the specialist platform is two-fold; first, to enable specifiers to confidently select the best products for their projects based on specific requirements such as sustainability, or a particular building material such as aluminium.

Second, it provides a unique opportunity for manufacturers to showcase their products alongside the certifications and literature most important to them. One of the features available allows specifiers, architects, designers, and engineers to easily find and compare products side-by-side, ensuring they choose the best fit for their project requirements.

To showcase how broad its awardwinning product range is, Sheerline has added everything from the increasingly popular Prestige Tilt & Turn Windows to the Classic Heritage Door, and the S1 Roof Lantern. It has illustrated its versatility by including its arched frame service and Prestige Reverse Butt Joint, which won best Technical Innovation at the GGP Installer

Awards 2025.

For Sheerline, joining NBS Source was a natural progression after launching its Specification Guide at the end of 2024. These actions collectively further the organisation’s commitment to supporting fabricators to win more commercial work. It also reflects the increase in demand for support for commercial projects.

One example in close proximity to Sheerline’s HQ is the Pepper Pots building in Derby, which has undergone a significant renovation. Every apartment surrounding the building has been fitted with

Sheerline’s Prestige Tilt & Turn windows in collaboration with BSW Window Solutions. New build projects and renovations are all set to increase.

Particularly if the government is to meet – or even get close to – its self-imposed housing targets. The need for easy access to compliant products that offer a stylish, yet practical solution will grow exponentially over the coming years.

Dave Wigley, Sheerline’s Head of Marketing, said: “As a data-driven company, we understand the need for specifiers to be able to access reliable data quickly, so they can make informed decisions when looking for products.”

“Having a profile on NBS Source will make it easier than ever for specifiers to find everything they need to know about Sheerline – from our award-winning products to industry accreditations, and technical data. This aligns with our ethos of making life easier for our partners,” he added.

Sheerline’s NBS profile can be at: https:// tinyurl.com/4ps4dwm9

grooves to easily locate I Beam position

All components cut to size and provided with personalised assembly drawings

Pre-assembled insulated lantern upstand as standard

With exceptional looks and thermal performance, the Warmer Beam Flat Roof System combined with a S1 roof lantern will bring stylish ambience to any home. Now even stronger, the timber I-beam joist which consist of c24 timber with a 10mm particle board web can reach roof projection spans of up to 7m meters without the need of additional support. The I-Beams are lighter than conventional timber trusses and steel, ensuring less pressure on the supporting walls and frames.

We understand the process can seem daunting for any first-time Building Control users. For this reason, Warmer Roof have created a dedicated in-house specialist team to process your application and guide you every step of the way. This personal touch is designed to provide a stress-freebuilding control experience

ROOF SWAP : £355+VAT

ROOF & FRAMES : £395+VAT

NEW BUILD EXTENSION : £850+VAT

GGF training and technical manager John Mannell recently attended the UAP and FDM industry round table on behalf of the Glass and Glazing Federation group of companies. John’s attendance forms part of the GGF’s overall drive to represent proactively the interests of its members across the industry in all matters relating to compliancy and competency, particularly in the wake of Grenfell.

Dame Judith Hackitt, former Chair of the Health & Safety Executive and author of the Building a Safer Future report, was joined at the round table by representatives from fire door manufacturers, awarding bodies, trade associations, tier 1 contractors, JCI, government and training providers. Conversations focused on the current challenges facing the fire door industry and celebrated the efforts of FDM – Training & Development in driving forward with training for fire doors, not just for installers, but all the way from specifiers to maintenance.

Nicola John, Managing Director at FDM – Training & Development said: “The Grenfell Inquiry and Building Safety Act have triggered real change – but the conversations we’re having across the industry show there’s still a long way to go. At our recent roundtable, it was clear: people want clarity, accountability, and better training when it comes to fire door safety. These are critical safety systems that must be procured, installed, inspected and maintained with precision. We’ve got the legislation – now we need consistent action on the ground, and that’s exactly what FDM – Training & Development is providing.”

Dame Judith Hackitt, Author of the Building a Safer Future report, said: “FDM is a shining example of what this industry should aspire to. They’ve taken the principles of the Building a Safer Future report and embedded them into their day-

to-day operations—not because they were forced to, but because they recognised it was the right thing to do. That’s the kind of leadership we need more of. Too many organisations are still waiting for regulators to drive the agenda before they act. FDM proves that real cultural change is possible now if we stop making excuses and start taking responsibility. The rest of the sector should take note and follow their lead.”

“It is only by having so many interested parties sitting round a table and participating in open and transparent conversations that we can truly identify the discrepancies across the supply chain with regards to regulations and consistency in standards,” said John Mannell. “Our active participation in these talks is essential to not only offer our own knowledge and expertise, but to also implement ideas and expertise into our own services across the range of GGF companies.

“There was a lot of stress on the importance of maintaining practical,

face to face training as well as online” continued John. “Purpose and outcomes in training encourages companies to think beyond compliance, and beyond yet again competence, to truly understand what it means to create a safe environment for people to live in. Such conversations are crucial to the evolution of our GGF training platform as we move towards the post grandfather rights era, with the new generation of trades who recognise the impact of the work they do.”

With training centres like this run by Fire Door Maintenance – Training & Development, an integration of the GGF training platform was launched six months ago and is already proving to be a vital tool in ensuring companies have access to the very latest industry training. By creating the right mix of online training assessments and more practical face to face training courses, the GGF is dedicated to helping members lead the way in terms of driving regulatory compliance across the industry.

Yale is pleased to announce the successful release of Environmental Product Declarations (EPDs) for five of its leading domestic window hardware products, Vertex Decorative Furniture, Defender Hinge range, the Expede Window Bracket, Quartus Espag handle, and the Revolution Window Hinge.

Developed and independently verified, the EPDs provide comprehensive, third-party environmental data, representing a significant step forward in Yale’s ongoing sustainability journey. They expand upon Yale’s existing portfolio of EPDs for commercial window hardware, further underscoring the company’s commitment to transparency, responsible

manufacturing, and sustainable innovation. Each EPD delivers in-depth insights into key environmental impacts, including energy consumption, carbon footprint, emissions, resource use, and waste generation. This transparency empowers architects, specifiers, and procurement professionals to make more informed, sustainability-driven decisions. Increasing trust and comparability across markets to encourage informed decision-making, they testify that the products are compliant with ISO 14025 and EN 15804 for construction products, ideal for green building projects and sustainable development goals. Fully compliant with ISO 14025 and EN 15804 standards for construction

products, these declarations support green building initiatives and align seamlessly with sustainability frameworks such as LEED and BREEAM. By offering verifiable environmental data, Yale enables its customers to earn certification credits and meet the growing environmental expectations of the construction industry Grant Stratford, Yale’s Senior Fenestration Technical Director – ASSA ABLOY, Residential, comments: “With EPDs already in place for our commercial products, these new EPDs position Yale as a frontrunner in responsible manufacturing and transparent product reporting across the UK window hardware market. We’ll continue to roll out EPDs for all new product launches, helping customers meet modern sustainability expectations with confidence.”

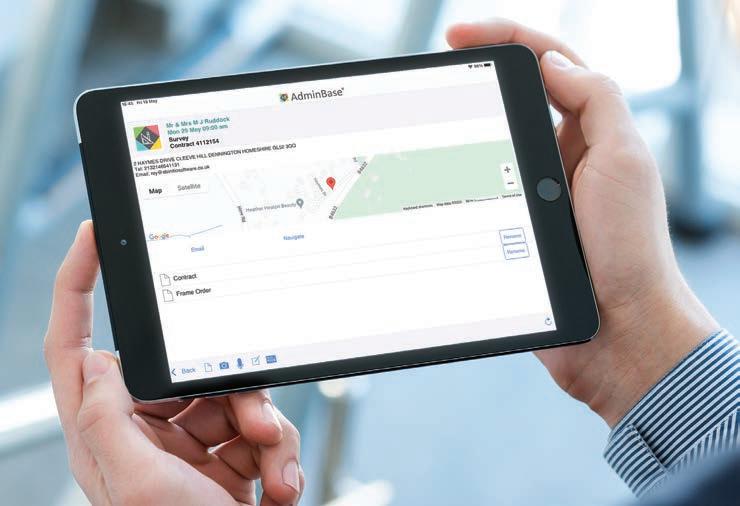

As part of its commitment to support its partner network, Schüco UK has launched a brand-new homeowner website schuecohome.co.uk. Designed to make it easier for homeowners to connect with Schüco partners, the site is set to drive more qualified leads and create valuable new business opportunities.

The new website serves as a user-friendly digital hub, providing homeowners with project inspiration, product overviews and practical guidance. Crucially, it also enables users to easily identify and contact their local Schüco partner, simplifying and accelerating the sales process. Homeowners can find their local Schüco partner and contact them through the website.

A newly developed bespoke system on the back end of the platform makes it easy for fabricators to connect with potential customers, respond to quote requests and track the progress of projects – creating a more efficient and transparent workflow from first contact to final delivery.

The website also lists all Schüco partner showrooms across the UK and Ireland, detailing which Schüco products are available at each site, along with contact details and directions, to encourage more, quality leads.

Dan Gleeson, Sales Director for Schüco UK and Ireland, commented: “At Schüco, our partners are at the heart of everything we do. The new website is a key tool to support them, not only by educating and inspiring homeowners, but by actively streamlining the connection between customer and fabricator. It’s designed to generate high-quality leads, simplify project

communication and ultimately help our partners win more business.”

The launch of the new website marks a significant step in the long-term strategy of Schüco UK to support its partner network. By creating a user-centric, content-rich platform, Schüco is helping to create more opportunities for successful, high-quality projects.

The Residence Collection enhances a stunning countryside cottage with new Residence 9windows in the special colour option, Golden Oak. Collaborating with fabricator HS Trade, Beta View Windows and Doors Limited completed their very first Residence Collection installation in the exclusive Golden Oak colourway, a special colour option that beautifully replicates traditional timber aesthetics. For a high quality, wood-look finish, the Timberweld joint® manufacturing method was used on the R9 windows.

The windows feature Regal Black pear drop handles, Cassini glass with 28mm double glazing, and The Residence Collection’s trickle vent cover. Due to the depth of the R9 system, the team skilfully cut back the linings and used expertly scribed trims to ensure seamless symmetry throughout the property. The cottage sits in close proximity to a conversation area, making the Residence 9 windows the ideal choice for preserving period charm, all whilst delivering modern performance, efficiency and security.

The selected windows exceed British Building Regulation standards with a

u-value of 1.2W/m²K with double glazing, and offer A++ energy ratings, as well as meeting Passivhaus standards with triple glazing. The R9 collection, available in 20 colours, provides optimal insulation and energy savings.

Daniel Sloan, Director of Beta View Windows & Doors, commented: “We

are proud to be officially recognised as a recommended installer for The Residence Collection. The onboarding process has been smooth and efficient, with the team visiting us several times to ensure we meet their high standards.

“Their support, from marketing materials to professional guidance, has been invaluable. We are thrilled to offer such high-quality products and are proud to represent The Residence Collection. Their products align perfectly with our commitment to delivering exceptional craftsmanship and customer satisfaction.”