CONTENTS JULY/AUG 2025

GETTING IN CONTACT

EDITORIAL

John Cowie

Editor - Head of Online Content

Tel: 07474 123287

E: john.cowie@windowsactive.co.uk

Jennie Shoglen - Graphic Designer

Emma McCormack - Sub-Editor

ADVERTISING SALES

Steve Gravestock

Sales Director

Tel: 07990 671901

E: steve.gravestock@windowsactive.co.uk

Donna Crockatt

Publishing & Sales Executive

Tel: 07919 448809

E: donna@windowsactive.co.uk

PRODUCTION AND CIRCULATION

Tel: 07919 448809

E: production@windowsactive.co.uk

WINDOWS ACTIVE is published by:

Active Magazines Limited PO Box 627 Rickmansworth Herts, WD3 0BQ

GENERAL ITEMS

004 - NEWS

Headlines this month include:

Unique Window Systems acquires AluFold Direct’s business and assets; Ultraframe’s Hup! system surpasses significant milestone with 1000th order; Scientists unveil hydrogel smart window offering cooling and heat recovery; Deceuninck clinches 14th consecutive award for health and safety excellence; Urging resilience over desperation amid tough market conditions.

036 - DIRECTOR FOCUS

In this month’s director of the month feature, we talk to Robert Hartill, Commercial Director at Safeware.

040 - ACTIVE VOICES

Increased competition and panic is pushing some fabricators into an unsustainable pricing model. says Ryan Johnson of Emplas.

048 - SPECIAL FEATURE

Vacuum Insulated Glazing is a solution emerging as a gamechanger for installers and manufacturers alike, reports Windows Active.

FEATURES REGULARS

044 - VACUUM GLAZING

John Cowie looks at how a Birkenhead gem is rewriting the rulebook for sustainable heritage with vacuum glazing.

058 - SMART HARDWARE

Ingenious Technical Director Stuart Carpenter says innovation focuses on reducing complexity for fabricators and distributors.

074 - HERITAGE

Heritage prestige meets modern innovation as Veka Omnia helps Glazerite installers to elevate projects with confident distinction.

081 - GLAZED EXTENSIONS

Expertly engineered and relentlessly refined, Warmer Roof delivers the timber roof solution redefining excellence in modern conservatory design.

097 - ALUMINIUM ACTIVE

The exclusive feature kicks-off with Ben Brocklesby, Director at Origin, the UK manufacturer of aluminium doors and windows, discusses the brand’s latest product innovation.

050 - SOFTWARE FOCUS

PST Software sharpens its edge — unleashing a smart, integrated digital suite transforming how fenestration businesses scale, serve, succeed.

054 - MARKET UPDATE

Neil Evans, MD at Veka plc, gives his thoughts on the current market and explains what Veka is doing to help its customers steady the waves.

056 - FABRICATOR FOCUS

Full circle and future-bound, TWR Group triumphantly returns to Sunderland roots, unveiling a bold new headquarters vision.

122 - PRODUCT INNOVATION

Six new colours boost the versatility and appeal of slimline integral blinds; Composite door with smart security and bespoke style from TWC; Stellar launches inline sliding door handle.

126 - MOVERS AND SHAKERS

Recent appointments and promotions within the human resources departments of some of the sector’s leading firms.

YOUR ONE-STOP-SHOP

FOR ALL TIMBER SYSTEMS

Warmer Roof has quickly grown to establish itself as the number one timber manufacturer of conservatory solid roofs in the country. Widening the portfolio of products on offer with the inclusion of Garden Room and Extension Systems, it’s easy to see why, with an emphasis on price, service and quality, Warmer Roof has implemented and improved all areas, not only for the fitter, but business owners too. The only timber system to be LABC approved, featured in The Times and always looking to innovate. We don’t just have customers, we have partners.

WarmerRoom

Extensions and Conservatory Replacement

ONTO NEW OR EXISTING BASE FOUNDATION

TIMBER PRE-FABRICATED

HOME IMPROVEMENT SYSTEM

A Warmer Room can take all the worry and much of the effort out of any new extension project. What’s more, our competitive pricing, rapid manufacturing and delivery turnaround mean that you can provide your customers with a brighter, more spacious home quicker and cheaper than any traditional extension.

Highly insulated, modular timber structure

Quicker fabrication and installation, saving costs

Kit form - less mess, less waste

Tested and approved - building control approval

Our technical support team are available to guide you every step of the way. On-site assistance available to help familiarise with fitting procedures.

vehicles provide a quality service across all of England and

EDITOR’S COMMENT

THE HEAT IS ON A CHANGING LANDSCAPE

Britain’s run of extreme heatwaves is forcing the fenestration sector to confront a dual challenge: how to help design homes fit for a hotter climate, and how to secure the workforce needed to deliver those solutions in an era of rapid technological disruption.

For many, soaring temperatures have been a welcome opportunity to enjoy outdoor life. But expert climatologists are warning that the current heatwave is neither a freak event nor a fleeting phenomenon. Instead, it stands as a visible marker of global warming — and a preview of summers that could soon see UK temperatures regularly pushing past 40 degrees Celsius.

That prospect has cast a sharp light on modern British house design. New research from the Centre for Cities suggests that the UK’s newer housing stock faces growing risks of overheating. Flats featuring large windows, a staple of contemporary architecture, are particularly vulnerable. At the same time, newer homes are increasingly built with thinner walls and synthetic woven insulation — methods aimed at improving winter energy efficiency but offering less protection from summer heat.

Policymakers are scrambling to respond. The government is reportedly considering grants to help homeowners install air conditioning, mirroring earlier subsidies for heat pumps. Yet such proposals are drawing sharp criticism for tackling symptoms rather than causes. Providing financial incentives to heat homes in winter and cool them in summer risks creating an energy-intensive loop that does little to address the underlying climate challenge.

More radical measures have also been floated. Government research and proposals have raised the possibility of reducing window sizes as a way to limit solar gain and combat overheating. However, such solutions bring significant downsides. Smaller windows mean darker interiors, potentially harming occupants’ wellbeing by limiting natural daylight and views outside. Mental health experts and designers alike warn that dark, enclosed living spaces can have damaging impacts on both mood and health.

Within the fenestration industry, there is frustration at suggestions to simply “shrink windows” as a blanket fix. Industry leaders argue that the sector already possesses the tools to address overheating without sacrificing daylight or aesthetic appeal. Solar control glazing — advanced glass that blocks heat while letting in light — combined with external shutters, awnings, and blinds, offers a highly effective solution. Yet there is a persistent lack of awareness outside the industry

about these modern products, fuelling calls for stronger communication and collaboration between manufacturers, designers, and policymakers.

While the environmental pressures mount, the sector faces another crucial issue: ensuring it has a workforce capable of delivering the solutions required for a changing climate. The world of work is undergoing a seismic transformation, driven in part by advances in artificial intelligence (AI). Geoffrey Hinton, widely recognised as the “Godfather of AI,” has issued stark warnings about the technology’s potential to eliminate jobs involving routine intellectual tasks, from law and accountancy to communications. “I’d say it’s going to be a long time before it [AI] is as good at physical manipulation,” Hinton recently observed. “So, a good bet would be to be a plumber.”

That assessment resonates deeply with emerging trends in the UK labour market. A recent discussion on BBC Radio 5 explored how schools are struggling to find work experience placements for pupils, particularly in traditional office environments. The rise of remote working has made officebased opportunities less accessible, leaving young people without crucial exposure to workplace culture and hands-on experience. One headteacher highlighted manufacturing firms as vital partners in filling this gap, offering varied roles that allow students to learn practical skills and develop interpersonal abilities.

As AI threatens to erode entry-level white-collar jobs, skilled trades are increasingly viewed as stable and attractive career paths. For the fenestration sector — which is already wrestling with a shortage of skilled workers — this shift presents both a challenge and a significant opportunity. Engaging young people, showcasing the technological innovation involved in modern fenestration, and offering clear career pathways could help secure the workforce required to deliver sustainable, climate-resilient homes.

The convergence of climate change and technological disruption places the fenestration industry at a pivotal crossroads. With hotter summers becoming the norm and AI reshaping the employment landscape, the sector has the potential to play a defining role in the UK’s economic and environmental future. The question now is whether it can communicate its capabilities, attract new talent, and help ensure that the homes of tomorrow are fit for both the climate and the workforce of the 21st century.

John Cowie - Editor E: john.cowie@windowsactive.co.uk

WORLDCLASS EXTRUDED SOLUTIONS

Liniar helps you meet any customer demand - with a full suite of PVCu window, door, and outdoor enhancement solutions, and an aluminium range featuring French, bi-fold and residential doors.

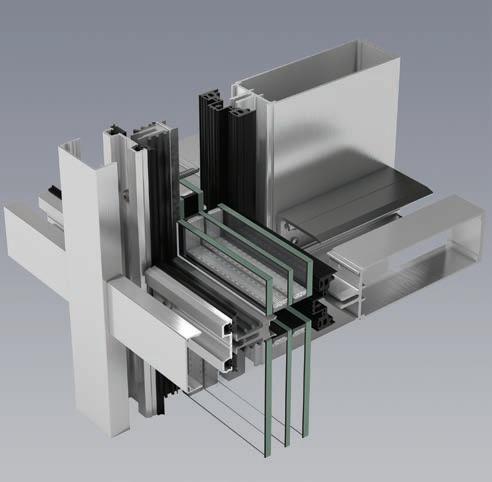

Unique Window Systems acquires AluFold Direct’s business and assets

Unique Window Systems, a multi-award-winning fabricator of PVC-U and aluminium windows, doors, and curtain walling has acquired the business and assets of AluFold Direct. Sunil Patel, Joint Managing Director at Unique, explained: “Having recently increased our turnover to £45 million and growing, we are in a strong position to invest in the business, and the acquisition of AluFold’s assets gives us the opportunity to further boost our aluminium capabilities. With more companies being forced to close their doors in ongoing difficult market conditions, we are particularly pleased that the acquisition will help us grow further and retain capacity in the industry.

“We have already celebrated 20 years in business this year, but we are not resting on our laurels. Our longevity makes us even more ambitious. We want to continue to give our installers, and their homeowner customers, and the wider commercial market everything they need now and in the future, and as the demand for aluminium window and doors continues to grow, it’s a great time for us to strengthen our geographical footprint.”

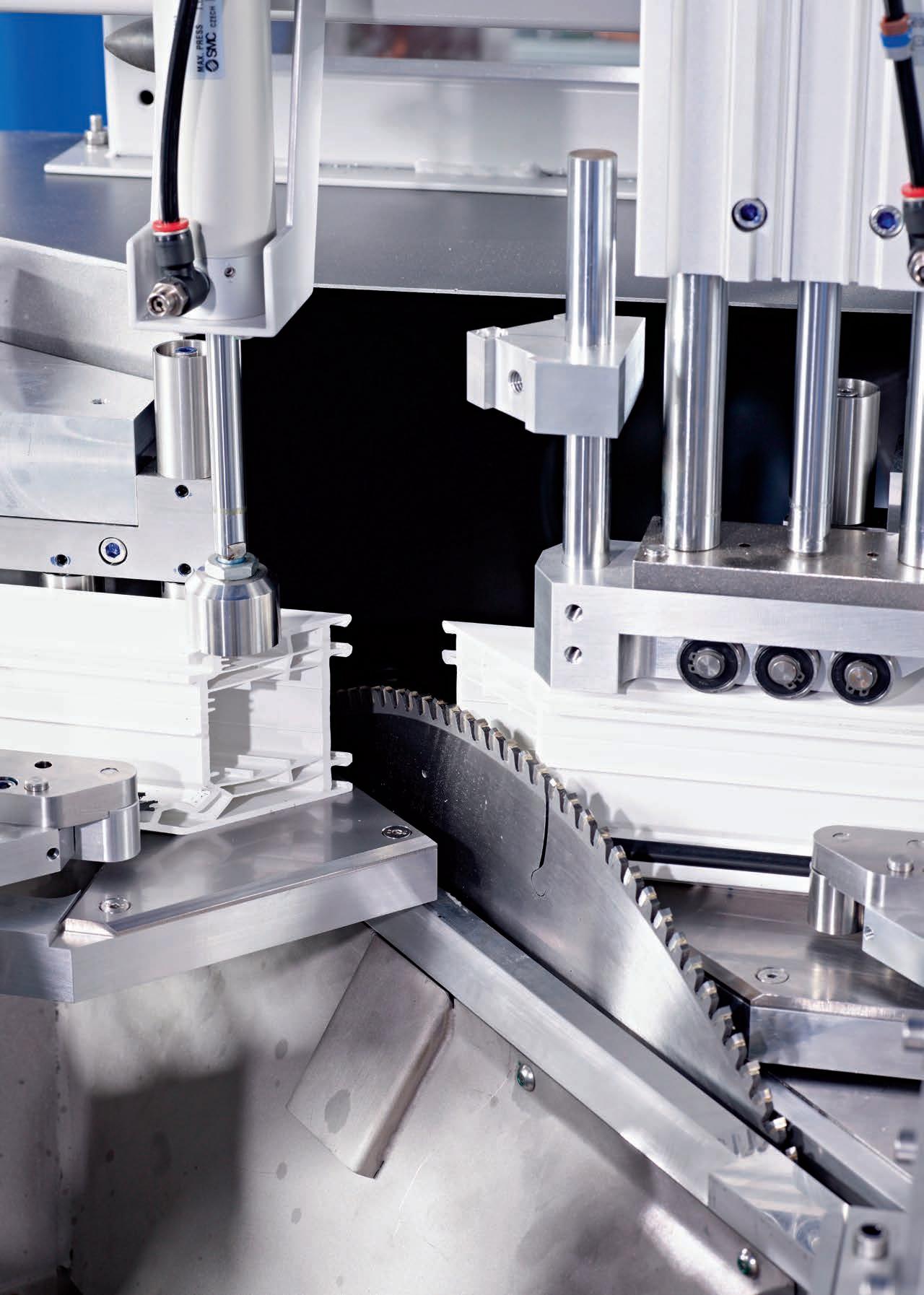

AluFold’s factory in Blackburn is home to cutting-edge machinery including CNC machining centres, CNC 4-headed crimpers and dedicated assembly lines,

and so provides Unique Window Systems with an opportunity to increase its presence in the North. The deal was supported by Gunner Cooke LLP and Freeths LLP from a legal perspective and Torr Waterfield as accountants and business advisors.

Sunil continued: “We know that homeowner expectations are rising and to help our customers deliver on these expectations we need next generation capabilities and superior environmental

performance across our entire PVC-U and aluminium range. Coupling the impressive assets from a well-respected brand such as AluFold Direct, with Unique’s considerable resources and expertise, builds on an already solid foundation of quality and performance.

“We are excited about this next stage of growth,” concluded Sunil, “and the headstart the acquisition gives us and our customers for 20 more successful years.”

Ultraframe’s Hup! system surpasses significant milestone with 1000th order

The hup! building system from Ultraframe has reached a grand milestone with the 1000th order placed at the beginning of July. Launched in 2022, the system eliminates the need for traditional brickwork – and the many problems that are often associated with it – bringing speed and simplicity to extension builds. The momentous 1000th order was placed by County Windows, a Conservatory Outlet Premier Retailer, using the simple-to-use hup! online ordering system, and is a lean-to design with a tiled Ultraroof.

Ultraframe Marketing Director, Alex Hewitt, said: “We have seen hup! really gaining momentum with installers across the UK since its launch and we are delighted to have received our 1000th order. Sales are rapidly building now, and our sales growth is exponential as this innovative method of construction gathers pace within the market and installers learn about the huge benefits that hup! brings to a build. Those customers who decided to try it out initially are now changing the way they build across their business, preferring hup! to traditional methods. We are seeing bigger players

coming on board, as well as a network of smaller independent installers, all of whom are enjoying the speed and simplicity that hup! brings to a site.”

“From day one, our mission has been to bring more certainty to builds, making them faster, simpler and less stressful. Hitting 1000 orders proves that hup! is a system that’s actively reshaping the way that our industry builds. With 1,000 orders and counting, the future is building up fast for hup!”

Over the last 12 months, a network of hup! Trade Centres has opened in locations across the UK, providing a one-stop shop for installers wanting to build a business around hup! and help them fully embed the revolutionary system into their business. Visitors to the hup! Trade Centres can design, specify, quote, and place hup! orders, as well as benefitting from technical support and on-site training. To find out more about hup! and its network of Trade Centres, visit www.hup-home.co.uk .

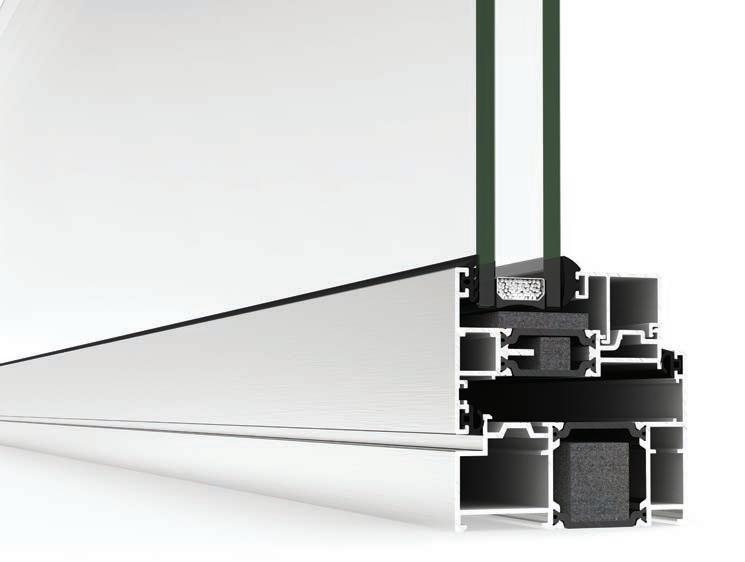

The Complete Flush Suite.

OMNIA: A complete double flush suite of award winning PVCu windows and doors. Casement and Tilt & Turn alongside residential and French doors gives you a full range for stock minimisation and seamless performance. Scan the QR code to find out more

Scientists unveil hydrogel smart window offering cooling and heat recovery

Ateam of researchers from Fudan University and collaborating institutes has unveiled a bionic hydrogel-based smart window system capable of sustaining sub-ambient temperatures for a record 168 hours while simultaneously harvesting waste heat for reuse. The transparent composite hydrogel, dubbed CPPB, achieves an average visible-light transmittance of 92%, blocks more than 75% of ultraviolet radiation and suppresses near-infrared transmission by roughly 30%, all without sacrificing clarity.

At the heart of the innovation lies a multilayer assembly: a thin film of CPPB hydrogel bonded to conventional glazing and a concealed water-circulation layer. During the day, the hydrogel’s thermochromic and evaporative-cooling properties enable a sustained temperature drop of approximately 22 °C below ambient temperatures, outperforming previous smart-window prototypes by a wide margin. Excess thermal energy absorbed by the system is collected via the integrated water loop, offering the potential to pre-heat domestic water or feed low-grade heat back into building systems.

Lead author Qianwang Ye explained that achieving both high transparency and prolonged cooling performance required careful optimization of the hydrogel’s polymer matrix and crosslink density.

“Our composite balances water retention for evaporative cooling with mechanical robustness,” he said. “It can withstand UV irradiation and thermal cycling without significant degradation, which is essential for real-world façade applications.”

Independent durability tests revealed no measurable decline in cooling efficiency after 100 cycles of simulated solar exposure. The implications for building energy management are considerable. Windows

account for up to 30% of a building’s heat gain in summer months, placing heavy demand on mechanical cooling systems. By passively maintaining lower interior surface temperatures, CPPB windows could reduce reliance on air-conditioning and trim peak electricity loads. Meanwhile, the harvested waste heat—collected at temperatures up to 60 °C—could supply domestic hot water or support underfloor heating during cooler periods, enhancing overall energy efficiency.

Despite its promise, CPPB faces hurdles before commercial deployment. Largeformat coating of hydrogel layers must be scaled up cost-effectively, and longterm field trials are needed to validate performance across diverse climates. Moreover, integration with existing window frames and compliance with façade fire and safety standards will require collaboration between material scientists, glazing manufacturers and building regulators.

Industry observers note that the CPPB system’s combination of cooling and heatrecovery functions distinguishes it from other smart-window technologies focused solely on light modulation. “This represents a significant step forward,” said Dr. Helen Carter, an independent façade engineer. “The dual functionality addresses both peakload reduction and utilisation of what would otherwise be wasted thermal energy.”

As global building sectors seek to meet stringent energy and carbon targets, the CPPB hydrogel window could play a key role in decarbonising the built environment.

The research team is now engaging with glazing fabricators to pilot prototypes in commercial offices in Shanghai and Europe later this year. If successful, the technology may herald a new generation of smart façades—ones that not only regulate light and heat but also actively harness energy for on-site reuse.

Deceuninck clinches 14th consecutive award for health and safety excellence

Deceuninck has been awarded its 14th consecutive RoSPA award in recognition of its commitment to maintaining high standards of health and safety across its operations.

After receiving the goldstandard for nine consecutive years between 2010-2019, Deceuninck can now add another President’s Award to its trophy shelf, after achieving the accolade for the past five years. The RoSPA Health and Safety Awards are among the most respected industry schemes worldwide, recognising

organisations that demonstrate excellence in the management of occupational health, safety, and wellbeing. Deceuninck’s continued success reflects its strategic focus on embedding robust safety processes into its daily operations.

“Health and safety is integrated into every one our processes”, said Darren Woodcock, General Manager at Deceuninck. “The consistency demonstrated by our teams in achieving this award ensures that we maintain safe and reliable manufacturing standards,

minimising any potential disruption for our customers.”

Deceuninck also holds ISO 45001 for health and safety, ISO 9001 for quality management, and ISO 14001 for environmental management. And according to Darren, aligning day-to-day operations with these recognised standards, alongside the frameworks set out by RoSPA, has helped streamline processes and improve collaboration across teams.

“Running our business to these standards isn’t just about ticking a box - it’s made a real difference in how we work together, making our operations smoother and more efficient, which ultimately benefits our customers.”

ULTRA-SLIM SIGHTLINES OF JUST 29MM

OPTIONAL FLUSH STACKING EXCLUSIVE SIGNATURE KNURLED HANDLE

Urging resilience over desperation amid tough market conditions

After more than three decades in the glazing and fenestration sector, Mark Powell, Sales Director at Direct Trade (Yorkshire), has seen his fair share of industry highs and lows. But, speaking candidly on Linkedin, Powell admits that today’s climate feels particularly fraught with uncertainty.

“This industry has put food on my table for over 30 years and I love it,” he says. “But I’ve rarely seen the market quite like this. Consumer confidence is low, and the general mood feels anxious. While the country might be crying out for a shake-up, I’ll leave the politics to those who claim to understand it better than I do.”

What Powell does understand, and speaks passionately about, is the danger of the short-term reactions he sees emerging

once again as market conditions tighten—chief among them, the industry’s perennial fallback: aggressive price-cutting.

“I read a recent piece from one of our competitors, and it really hit home. The race to the bottom on price helps no one. Yet here we go again. When things get tough, too many businesses default to slashing prices.”

Powell believes this is often a sign of poor preparation. “Maybe it’s panic. Maybe it’s that some didn’t prepare for leaner times— no rainy-day fund, no investment strategy, no grip on their finances. Often, they don’t realise they’re operating at a loss until the bills start piling up.”

But for Powell, the solution lies not in radical change, but in steadfastness. “Business moves in cycles. A well-run company should be able to ride out the

downturns. That doesn’t mean changing who you are. It means doubling down on what you do best—maintain quality, protect your margins, and know your worth.”

He is especially emphatic on the subject of gross margins. “Without a gross margin, there is no net margin—and without that, you can’t invest in your team, look after your customers, or deliver a product that stands out. Margins matter.”

And if the phones are quiet, Powell sees it as a time to invest in evolution, not desperation. “Use the space to get better. Improve systems, sharpen your offer, become more efficient. Don’t join the race to the bottom. Stand tall and trust in the quality that built your business in the first place.”

For Powell, the responsibility goes beyond profit and loss. “Our businesses feed more than just ourselves. And that’s something worth protecting.”

Hurst reinforces compliance pledge with upgraded FD30s performance

As we approach eight years since the Grenfell Tower fire tragedy, Hurst is reiterating its commitment to regulatory compliance and high performance across its composite FD30s fire door offering. Triple certified for fire, smoke and security, Hurst’s fds fire door range achieves an average fire resistance time of 44 minutes, 14 minutes over the FD30 standard requirement.

With Building Safety Act compliance central to its specification, the FD30s is UKCA-accredited and tested to BS EN1634-1 and PAS24:2022. Furthermore, all fanlight and sidelight options for our FD30s fire doors carry UKCA marking - offering specifiers and contractors compliant external as well as internal fire door solutions, with added reassurance.

“Accountability is essential at every stage of the supply chain,” said Mark Atkinson, Sales Director, Hurst.

“Through third-party certification and test evidence, we’re supporting our partners to confidently demonstrate compliance and fulfil their obligations under current safety legislation,” he added.

“Critically, this also helps to uphold the ‘golden thread’ of information relating to the safe design, construction, occupation and refurbishment of buildings, an integral part of the Building Safety Act and the Building Safety Regulator in the UK.”

With significant opportunities for compliant fire doors in both new-build, social refurbishment and maintenance markets, specialists are also on hand to help

Hurst installers navigate every stage of their fire door project.

Through Hurst’s dedicated customer portal, Hurst Live, customers can quote, place and track orders for compliant fire doors, with access to a comprehensive order history for easy management of both past and current projects.

From smaller projects to large-scale schemes, Hurst Live is designed to streamline and simplify the ordering process, allowing customers to specify their exact fire door requirements efficiently.

Available in a variety of colours, Hurst’s fire doors also meet BS6375 for weather performance, provide a U-value as low as 1.6

W/m²K and reduce noise by 33db. Each door also comes with comprehensive installation instructions, enabling installers to meet the high standards required for compliance and performance with confidence.

“Fire doors play a vital role in the safety of buildings and their occupants, but we don’t want our customers to be daunted by the weight of this responsibility,” Mark added.

“Our FD30s fire door is one of the most extensively tested in the UK, undergoing rigorous bi-directional testing to meet and exceed the EN1634 standard, while Q-Mark certification from BM Trada reinforces our commitment to high standards and affirms our position as a trusted supplier.

“As the industry continues to navigate tightening regulations and greater safety expectations, the FD30s offers not only compliance, but peace of mind for specifiers, developers, installers and building owners alike,” Mark concludes.

Cortizo Inf inity

100% RECYCLED POST-CONSUMER ALUMINIUM, MANUFACTURED IN OUR OWN FOUNDRIES

BUREAU VERITAS certification

OVER 30 YEARS RECYCLING ALUMINIUM

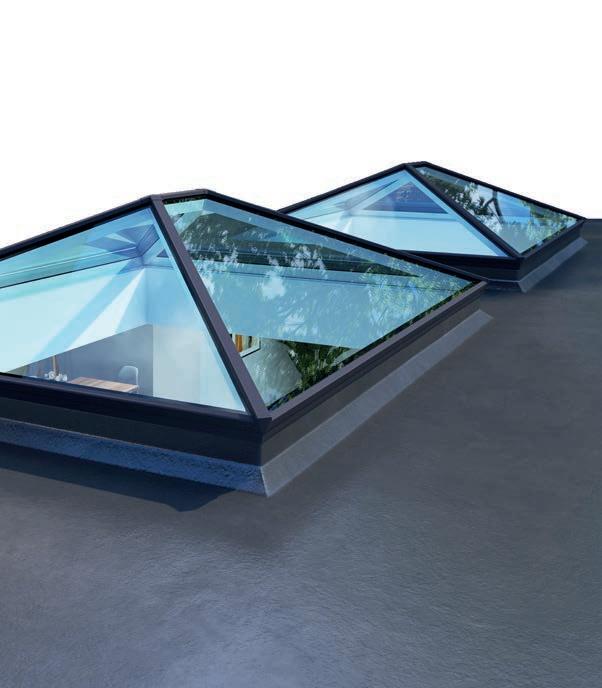

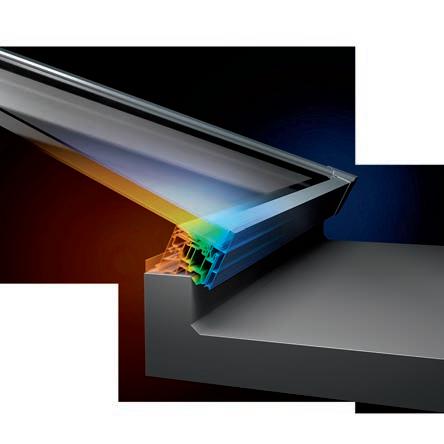

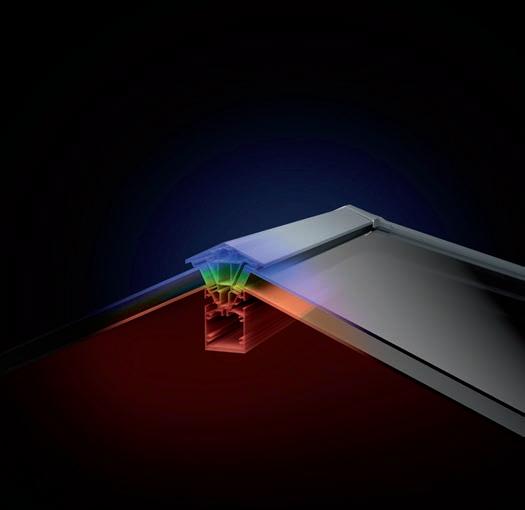

Fitted in minutes, glazed in seconds

Strongest lantern in class

Available up to 3x2.5m in four glass panels and a maximum size of 6x4m Black, White and Anthracite Grey. Single and dual colours with no extra cost

DERW Glass future-proofs operations with new Forel HT IGU line

DERW Glass, a leading independent glass processor in West Wales, has bolstered its manufacturing capacity with the installation of a new Forel High Tech Insulating Glass Unit (IGU) line, underlining its ambition to remain at the forefront of high-performance glazing production.

The family-run firm, established in 1991 by Julian and Noela Palmer, has acquired the latest generation of Forel’s IGU line, which features a twin bobbin flexible spacer bar applicator. The technology enables seamless switching between different spacer widths, enhancing efficiency and reducing changeover times on the production floor.

The new line, equipped with Industry 4.0 software, offers capabilities tailored for evolving market demands, including the manufacture of thin triple-glazed sealed units incorporating centre panes

as slim as 1mm. Such products are increasingly specified in energy-efficient building projects and stringent regulatory environments, giving DERW Glass a competitive edge as the market shifts towards higher-performance solutions.

“The investment allows us to futureproof our business and respond to new specifications in the commercial and residential sectors,” said Julian Palmer. “As sustainability targets tighten, particularly around building energy use, our customers are looking for advanced glazing products that deliver on performance without compromise.”

This is DERW Glass’s second significant investment in Forel equipment, following the installation of a vertical arris line in 2023. The latest acquisition underscores a trend among UK glass processors to adopt automation and flexible manufacturing

systems to manage labour constraints and rising demand for complex glass products.

This investment by DERW Glass is part of a broader pattern of capital investment in the glass and glazing sector, where firms are seeking technological upgrades to maintain market share and improve production efficiencies.

Industry analysts note that as legislation around building insulation and carbon reduction continues to tighten across the UK, fabricators and processors with modern, adaptable machinery are better positioned to serve architects, contractors and homeowners demanding higherspecification glass solutions.

DERW Glass’s latest purchase signals confidence not only in its own growth but in the resilience of the UK glazing market amid shifting economic pressures and sustainability goals.

ODL Europe drives door fitness

ODL Europe has reported a growing number of fabricators and installers choosing its Capstone-engineered GRP door slabs for their proven resistance against bowing, twisting and distorting, especially in high temperatures.

Suzanne Nicholl, Head of Sales and Marketing at ODL Europe, explains: “As soon as the summer heat hits, we hear the same thing from installers - frustration with alternative composite doors that become ‘bent like a banana’. The callbacks and reputational damage that follows is costly. With ODL Europe’s door slabs, those concerns are eliminated thanks to our product’s inherent structural stability.”

She continues: “Some assume LVL thickness alone determines whether a door will stay flat, but that’s only part of the equation. The real difference likes in the door skin. Doors that warp often have a similar internal construction, but inferior GRP skin composition. Ours are manufactured using high-glass-content GRP SMC skins, pressed to exacting standards for superior performance.”

ODL Europe’s composite door slabs

feature 2mm thick impact-resistant GRP skins available in both TrueGrain woodgrain and smooth finishes. These skins are bonded to a high specification subframe made from water-resistant pure PVC polymer and reinforced with highdensity LVL (minimum 570 kg/m³). The entire structure is assembled with advanced urethane resin adhesives to ensure complete stability and product longevity.

Each slab is manufactured by Capstone Engineering , one of the world’s largest GRP

door producers and exclusively supplied in the UK through ODL Europe. With over 750,000 doors installed annually worldwide, Capstone sets the standard for GRP durability and performance.

The range includes over 30 door styles, both glazed and unglazed, with several designs unique to ODL Europe. Whether fabricators and installers need traditional, contemporary or modern door aesthetics, the collection is developed to reflect current design trends and give customers a clear point of differentiation.

Every slab meets PAS24 security standards, is manufactured under BM Trada Q-Mark certification and benefits from ISO 9001 and ISO 14001 certified processes. Capstone timbers are FSC-certified, ensuring full chain-of-custody sustainability.

Sue concludes: “At ODL Europe, we’re committed to delivering a product that not only looks great but performs consistently whatever the weather. Installers choose our doors because they trust them not to bow or twist, which avoids callbacks and protects their reputation. It’s a powerful advantage for our customers.”

Don’t get left behind - homeowners nationwide are falling in love with the charm of heritage styles.

Our authentic flush sash window system captures the heart of traditional design, while cutting-edge uPVC construction delivers outstanding performance. Get in touch today to become a Timberlook installer!

• Heritage flush sash style

• Timberweld joints for heritage style

• Elegant woodgrain foils

• Heritage cill & hardware options

• U-Values as low as 1.2

• Concealed trickle vents

• Complementing flush French & single door

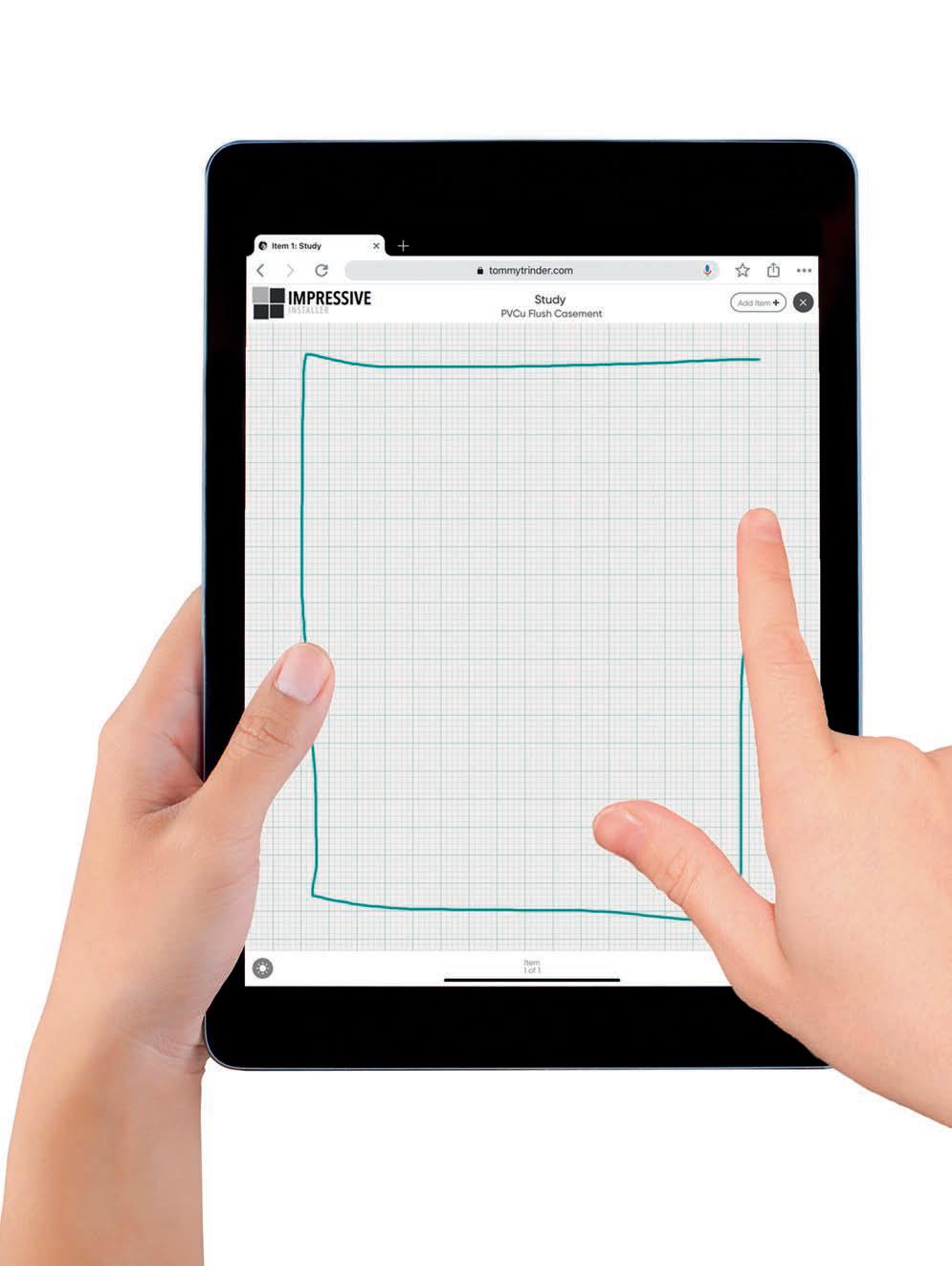

• Available on Tommy Trinder Framepoint®

• Free leads in your area

Expanded UKAS accreditation and bespoke testing support from Winkhaus

Winkhaus Laboratories has once again demonstrated its leadership in the fenestration testing sector with the renewal and expansion of its UKAS accreditation. The updated scope now includes the 2024 addendum for PAS24:2022, solidifying them as a premier destination for customers with their comprehensive, accredited testing services.

As one of the first laboratories to be audited and approved by UKAS for testing to PAS24:2022, they now offer assessments to the new 2024 addendum PAS24:2022 +A1:2024, which introduces new tools to the attack testing for both PAS24 and TS0071. A two year transition period to adopt testing to the new standard has been set for January 2027, with the laboratory team there to support customers in their compliance journey, helping them adapt efficiently and effectively.

This falls as part of a wider update of security testing, with changes to the security part of building regulations (Approved Document Q or ADQ) expected in the near future, that will no longer reference earlier versions of PAS24, from 2016 or earlier, and that will widen the scope of ADQ from new build projects to include refurbishment projects for the first time. Manufacturers and fabricators will therefore need to plan a review of their existing test evidence, or plan to create fresh evidence in line with these standards changing.

“Transitioning to the updated standards and new addendum doesn’t mean starting from scratch,” explains Ade Collins, Laboratory Manager at Winkhaus UK. “Our approach involves reviewing existing test data, identifying gaps, and creating bespoke testing programmes that build on what our customers already have. This saves both time and money while ensuring compliance.”

This consultative approach is a hallmark of Winkhaus Laboratories. With almost 50

years of experience in testing, development, and product innovation, the team offers more than just pass/fail results. Their Technical Development Days are a standout service, designed to help customers refine products before formal testing begins. These sessions allow for early identification of any potential vulnerabilities, enabling iterative design improvements without the cost and delays of full-scale testing.

“Traditional testing can be a bottleneck in product development,” advises Ade Collins. “Our development days provide a low-risk environment to explore design tweaks and validate concepts, giving our partners confidence before committing to full accreditation testing.”

Winkhaus’ bespoke development process is further supported by in-house Computer Aided Design (CAD), 3D prototyping, and close collaboration between the product, technical, and laboratory teams. This integrated approach accelerates time-to-market and enhances product competitiveness, particularly valuable

when working with new profile concepts or custom hardware solutions.

The laboratory’s capabilities span a wide range of testing services, including PAS24:2022 & +A1 2024 addendum for enhanced security performance, BS6375 parts 1–3 for doors and windows, BS EN1634-3 for smoke control, and TS007-1 for security hardware. With the latest UKAS accreditation updates, Winkhaus remains uniquely positioned to offer its customers a full-spectrum of testing aligned with the latest industry standards.

Established for over 25 years and a proud member of United Kingdom Accreditation Service (UKAS), the British Measurement and Testing Association (BMTA), and the Test House Studies Group chaired by Secured by Design, Winkhaus Laboratories continues to set the benchmark for quality, innovation, and customer support in the fenestration industry. For more information or to discuss your testing requirements, contact the team at test.lab@winkhaus co.uk or visit winkhaus.co.uk

Long standing partnership celebrated

Droylsden Glass, a well-established name in the North West’s glazing and home improvement sector, is celebrating 28 years of continuous partnership with premium composite door manufacturer Rockdoor. The milestone marks one of the industry’s longest-standing collaborations between a fabricator and supplier — and reflects a broader trend of firms leaning into trusted partnerships to drive long-term performance.

MD Kevin Thackeray praised Rockdoor’s consistent quality and service, describing the relationship as a cornerstone of Droylsden Glass’s growth: “As we approach our 29th year of working with Rockdoor, we’re proud to celebrate a partnership that

has stood the test of time.”

Rockdoor, headquartered in Lancashire, is widely regarded as a market leader in secure, thermally efficient composite doors — a product segment that has become increasingly important amid growing consumer demand for energy-efficient home upgrades. Thackeray credited Rockdoor’s product innovation and support

team, singling out individuals including Birdy, Simmy, Pete and Damo, for their role in helping Droylsden Glass consistently meet customer expectations. “Their commitment to quality, innovation, and service has played a key role in helping us deliver exceptional results to our customers year after year,” he said.

The announcement comes at a time when supply chain resilience and reliable sourcing remain top priorities for firms in the fenestration sector. Amid volatile material costs and shifting customer expectations, longstanding partnerships like this offer competitive advantage, ensuring consistency in both delivery and product performance.

Vacuum Glazing UK launches 25-year vacuum glazing warranty

Vacuum Glazing UK has announced a new 25-year manufacturer warranty for LandVac vacuuminsulated glazing (VIG), setting a new benchmark for longevity and performance in the glazing industry. This is the longest vacuum glazing warranty ever offered in the UK.

LandVac VIG combines ultra-slim dimensions with exceptional thermal performance. Its centre-pane U-value is just 0.34 W/m²K, independently certified by ift Rosenheim, making it one of the highestperforming glazing products on the market.

Unlike standard guarantees, LandVac’s 25-year warranty is a contractual commitment that is fully transferable and provided at no extra cost. It remains valid even if the glass changes ownership, offering long-term peace of mind for homeowners, architects and developers.

LandVac’s durability is backed by over a decade of laboratory and field testing. This includes:

• Xenon arc accelerated ageing: 22,500 hours under simulated sunlight exposure, equal to 25 years of weathering

• 10,000 temperature cycles: performance remained stable between 25 °C and 75 °C

• Outdoor field testing: over 100 units installed in natural conditions since 2012 have shown no drop in vacuum pressure

With a total thickness of just 8.3 mm, LandVac preserves the sightlines of heritage windows while dramatically improving energy efficiency. This has made it a popular solution for conservation areas, listed

buildings and low-carbon retrofits.

“We’ve seen too many projects compromised by glass that fails within a few years,” said Andrew Madge, Director at Vacuum Glazing UK. “This 25-year warranty reinforces what our testing has proven for years: LandVac delivers performance that lasts.”

Anglo returns under Sullivan with cost savings for fabricators

Paul Sullivan has returned to the helm of window and door steel reinforcement specialist, Anglo with a mission to support fabricators in driving down costs and maximising margins.

Now part of the Amari Metals Engineering Group (AMEG), Paul headed the business from 2006 to 2022, following a three-year leave of absence he picked up the reigns at the steel roll-forming specialist in June.

With rising employment and energy costs putting even more pressure on fabricators, he argues new operational efficiencies, combined with the steel buying power of a multi-billion-dollar specialist metals group, put Anglo in a stronger position than ever before, to support fabricators in lowering their overheads.

“I’m passionate about the window and door industry. This is very much a personal project for me. I want to give fabricators the biggest savings backed by the best service”, Paul said.

“We’re in a better position to do that now than ever before. Amari have invested in new lines, quality control and accreditation – plus we have immense buying power.

“We’ve guaranteed our supply and our prices well into 2026. We’re more

competitive than we’ve ever been, and we are committed to holding those prices.

“At a time when fabricators face massively increasing costs, buying in steel from us either as full bar length or cut-tosize, is one of the few ways that you can take back control, and deliver big savings.”

National Insurance jumped from 13.8% to 15% in April. Combined with the increase to the National Living Wage, employing staff over the age of 21, even in an entry level position, now costs employers close to £30K per employee, significantly impacting their bottom line.

Available for all leading PVC-U systems, in addition to the supply of full bar

length, Anglo European offers cut-to-size reinforcement supply - delivered in only three-days from point of order.

Supporting fabricators reducing overheads by removing significant costs, such as labour, inventory, and wastage it delivers average savings of 30-40% on system company steel prices.

This equating to savings from £1,000 to £15,000 a month depending on the size of your operation.

Anglo achieved ISO 9001 in 2024, launching AngloGalv, Anglo’s own-brand of BS EN 10346-accredited galvanized steel.

Recent investments include the addition of a multi-million-pound double-sided CNC line – the most advanced roll-forming line in the UK.

Paul continued: “Our scale and as part of AMEG, means that we’re not looking to make big margins. We can buy steel at the right price, and as we’ve always done, we are committed to passing those savings on to our customers.

“At the same time, we’re also driving up service, bringing the flexibility and support to fabricators that they want and need.

“It’s not complicated. We’re here to disrupt the market because that’s what we are. The winners in that are fabricators.”

Leamore Windows announced as new Veka fabricator partner

Veka plc has announced Leamore Windows as the latest fabricator to switch to its systems, marking the start of a new and exciting partnership. The Walsall-based business will also join the Independent Network as a retail fabricator, strengthening its long-term commitment to quality and customer satisfaction. The move sees Leamore Windows making a full switch-over to Veka systems, including Omnia - the award-winning double flush system – alongside the Veka M70 system, recognised for its exceptional thermal performance, the traditional sculptured Rustique system and the Imagine Patio Door range.

Gary Hackett, Managing Director at Leamore Windows, explained the decision behind the switch: “Veka has always stood out to us as a premium brand, and becoming part of the Independent Network reinforces that sense of quality and long-term value. The level of investment going into the Veka Installer Programme clearly demonstrates a strong commitment to supporting growth at every level, and we see real potential to strengthen our trade customer relationships as a result. There’s a visible drive for product innovation, and we’re excited to be adding the full Omnia suite to our range, offering a double rebate flush window, door, and tilt and turn option. Alongside this, we’re also introducing the M70 system for its outstanding thermal performance, the Imagine Patio Door range and the traditional sculptured profile in the Rustique range, ensuring we’re delivering excellence across every product category.”

Gary praised the process of working with Veka during the transition, highlighting the professionalism and support from the team:

“Through every meeting, we’ve felt confident we’re in good hands. Veka has impressed us with their responsiveness and collaborative spirit – they truly operate as one team. The onboarding support has been exceptional.”

Leamore’s changeover to Veka has been overseen by Veka’s Technical Service Engineer, Stefan Sorah, who has worked closely with the business and its suppliers to ensure a smooth transition. Gary acknowledged the impact of Stefan’s commitment: “Stefan has been brilliant. He’s put time into every part of our manufacturing, working with third parties to make sure everything is in place. We’ve also had fantastic support from our Business Development Manager, Andy Costall, and Veka’s Customer Marketing Manager, Loredana Emmerson. Their visits to site and hands-on support have made it easy to come on board.”

The marketing transition has also been a key focus, with Veka providing Leamore Windows with a range of materials and strategic support to communicate the change to its customer base.

“We’ve spoken to our trade customers

about the move to Veka, and the response has been universally positive,” said Gary. “It’s encouraging to see how highly Veka is regarded across the industry.”

Tim Taylor, Commercial Director at Veka, welcomed the new partnership: “We’re absolutely delighted to welcome Leamore Windows into the Veka family. Their decision to switch fully to Veka and join Independent Network is a strong vote of confidence in the value we provide - from product quality to technical support and marketing. We’re incredibly grateful for the trust they’ve placed in us and proud of the collaborative work that’s gone into this transition. We look forward to many successful years of working together.”

The new partnership reflects Veka’s continued focus on providing fabricators and installers with premium, highperformance systems backed by marketleading service and support.

Glass production line investment

Pilkington UK, part of the NSG Group, has launched a new glass production line at its Greengate Works site in St Helens as part of a multi-million-pound investment to safeguard the future of rolled texture glass manufacturing in the UK. The new rolled glass production line manufactures Pilkington UK’s Texture by Pilkington glass range, featuring 21 original designs and textures used for privacy and style in interior design.

Production of the range has moved to Greengate Works from nearby Watson Street Works, which stopped production last year after two centuries of pioneering glassmaking.

Moving the production of Texture by

Pilkington will enable the company to save 15,000 tonnes of CO2e annually, with Pilkington UK now manufacturing all glass from one furnace in the town, instead of the two between Greengate Works and Watson Street Works. Pilkington UK are supporting the council with plans to transform the Watson Street site.

Investing in the new line supports Pilkington UK’s wider sustainability goals, which include a 30% reduction in greenhouse gas emissions by 2030 compared to 2018 levels and achieving net zero by 2050. The upgrade received £3.7 million in funding through the UK government’s Industrial Energy Transformation Fund (IETF), which supports

industrial decarbonisation efforts.

Pilkington UK’s Greengate Works in St Helens continues to pioneer the future of glassmaking globally. In recent years, it’s hosted a number of global firsts in hydrogen-fired glass production, achieving key milestones in reducing emissions across the sector following the move to Greengate Works. Neil Syder, MD of Pilkington UK, said: “Texture by Pilkington has been manufactured by our team in St Helens since 1852 and we’re proud to continue that legacy with this new rolled glass line. It represents a meaningful step forward, not just in securing the future of texture glass manufacturing, but in significantly lowering the carbon footprint of the range.”

NorDan acquires majority shareholding in Performance Doorset Solutions

NorDan, one of the UK’s leading manufacturers of high-performance timber and aluminium clad timber windows and doors, has acquired a majority shareholding in Performance Doorset Solutions (PDS), a door manufacturer based in Littleborough, Greater Manchester. The strategic deal is aimed at strengthening NorDan’s position in the UK entrance door market, where demand for certified, high-quality products has continued to grow.

Founded in 2003, PDS has built a reputation for producing fully certified fire door sets, including FD30, FD60, and Secure by Design entrance doors. Its focus on quality and compliance is seen as a strong complement to NorDan’s existing product range, which includes its NTech windows and doors and the StormGuard window, designed for extreme weather conditions.

NorDan’s operations span residential, commercial, social housing, and large-scale construction projects across the UK and Northern Europe. The company said the acquisition would enhance its ability to offer a more comprehensive and tailored range of entrance door solutions to customers.

Craig Greenwood, Managing Director of NorDan UK, described the move as a significant step for the business. “We are

proud and excited to take a controlling interest in PDS and look forward to working closely with the management team. This joint venture significantly strengthens NorDan’s position in the UK market,” he said.

The current directors of PDS will retain a significant shareholding in the business and will continue to have representation at board level, ensuring continuity of leadership and vision.

Tim Fairley, Managing Director at PDS,

welcomed the acquisition, highlighting shared values between the two businesses. “We are very excited to build a significant business together with NorDan. As a family-owned business approaching its 100th anniversary in 2026, we share a strong commitment to our people, innovation, sustainability and long-term growth,” he said.

Dag Kroslid, Group CEO of the NorDan Group, said the acquisition would expand the company’s capabilities in the entrance door sector, describing NorDan as “one of Northern Europe’s leading door and window manufacturers.” He added that the combined business would focus on delivering sustainable products to customers of both companies.

Johannes Rasmussen, CMO of the NorDan Group, said the partnership would also enhance NorDan’s brand value. “With PDS’s reputation for excellence and NorDan’s legacy of innovation, we see exciting opportunities to deliver even more value to our customers than ever before,” he said.

Both companies said they would prioritise seamless integration, knowledge sharing and continued customer satisfaction as they begin this new chapter together.

Rehau celebrates the evolution of its

Total70 window and door system

Rehau is celebrating the evolution of its leading Total70 polymer window and door system as the innovative product continues to cement the company’s status as an all-in-one partner for the fenestration sector.

Launched in 2012, the 70mm Total70 solution offers a range of styles crafted using PVC-U, including the Rehau Total70c chamfered system, the Rehau Total70s sculpted system, and the Rehau Total70R fully reversible window system. It can achieve an A+ rating, the highest possible Window Energy Rating (WER) for thermal efficiency, while meeting or exceeding all relevant Building Regulations and security standards.

This includes Part L governing energy efficiency, and Part F formalising ventilation requirements, and noise control regulations set out in Part E. Most popular for retrofitting and replacements projects, Total70c’s sales have continued to go from strength to strength, with widespread and growing use in commercial projects.

“The adaptability and versatility of Total70 has proved its key strength,” says Clare Higgins, Senior Product Manager at Rehau. “As much as Rehau continues to

evolve, so does Total70. For instance, the system has been adapted for our similarly successful Rio Flush Fit frames and can be integrated with security hardware, further affirming its longevity as a leading product within the Rehau portfolio. Total70 hasn’t stood still since its launch, and neither have we.”

Key to Total70’s success has been Rehau’s long-established relationships with customers and hardware providers, with many employees involved in its development still working for the company. This has further enhanced Rehau’s already leading service levels and cemented the company’s status as an all-in-one partner

for customers’ fenestration needs, providing vital components and hardware beyond the profile alone.

“Total70 really is the backbone of Rehau’s Windows Solutions division,” Clare concludes. “Its popularity reflects its quality, but Total70’s success also relies on Rehau’s excellent service and trusted supplier relationships.

“As a private, family-owned company, Rehau can more easily adapt to industry challenges including decarbonisation and the push for energy-efficient homes, as well as more specific concerns such as reducing product lead times. It is for this reason we’re confident Total70 will continue to be wellreceived by fenestration professionals.”

NEW DOOR STYLES

Discover the latest styles today.

As the UK’s leading PVC-U door panel manufacturer, we offer a high-quality collection with diverse styles, colours, and glazing options. Now featuring seven new contemporary designs, our range is available with Securicore™ reinforcement - a proven PAS 24 compliant option which delivers enhanced security without compromising on style.

return to the market

OWS Fire Rated, the specialist designer, fabricator and installer of re resisting glazed systems have recently been acquired by the Haerens Group. Eribel, a specialist in technical joinery and also a member of the Haerens Group, has now secured the Lunax re door technology, previously held by Vetrotech, a subsidiary of the Saint-Gobain Group. Thanks to this strategic operation, the Lunax product is being integrated into the OWS Fire Rated product portfolio.

Lunax is recognised as a pioneer in fully glazed interior re resisting doors, combining excellent aesthetics with high technical performance. The product can provide up to EI 60-minute re resistance and can be installed as a stand-alone door system or combined with glazed sidelights and over-panels. The group will continue to develop and innovate the Lunax range, thus o ering clients and developers rst class products that will meet both the visual and functional requirements within both new and existing buildings. “With Lunax, we are rea rming our commitment to high-level technical and aesthetic solutions,” says Steven De Tollenaere, CEO of the Haerens Group. “The technology integrates perfectly with our existing range of reproof, burglar-proof, bullet-proof and acoustic joinery in wood, aluminium and steel.” E: Kevin.hulin@ows rerated.

Butterick is new GGF president

The Glass & Glazing Federation has announced that Michael Butterick, marketing director for Saint-Gobain Glass, is taking on the role of President. He is taking over from Natalie Little, whose tenure has come to an end after two years. Natalie’s dedication to the GGF has helped to amplify the association’s voice through clearer messaging, better visibility, and making sure that people felt heard. “We all extend a huge thank you to Natalie for everything she has brought to the role during her tenure,” said GGF managing director Ben Wallace. “Her improvements will have a lasting impact. Going forward, Mike’s insight, direction and expertise will continue to add massive value.”

Mike Butterick added: “Considering the changes that our industry is experiencing within our operating environment, the need for all sectors to understand each other is more important than ever. Hopefully I will have a role to play in that. Above all, I very much look forward to supporting the GGF team to promote the value of our industry and deliver benets for all GGF members.”

For the past 15 years, Mike has worked in the at-glass sector where he is Marketing Director for Saint-Gobain Glass. Before this, Mike spent 18 years working in the window systems sector of our industry. “I feel that this experience has given me a useful perspective. I have seen our industry from di erent viewpoints, through working with window fabricators and installers, and also with glass processors and a wide range of glazing professionals.”

Mike has been involved with the GGF for several years, including serving as a Board Director. Mike has supported a variety of GGF forums, including recently Chairing the Consultation Response Group, which has been focussing on providing feedback to Government on proposed standards and regulations, including the forthcoming Future Homes Standard.

TO

FROM EMMEGI (UK) - Emmegi (UK) has bid a very fond farewell to Sales Manager Andrew Jones, who is moving on to a new chapter outside of the industry.

Andrew, known for his charm, humour, and occasional love of a cravat, is a wellknown gure in the industry, having worked in machinery sales for more than 20 years. He joined Emmegi (UK) when the business was rst established in the UK in 2010, and since then has been an integral part of the tight-knit team behind its ongoing success.

Managing Director Ian Latimer, paid tribute to his friend and colleague: “Andrew has made a huge contribution here and he will be very much missed. His knowledge, experience and commitment have been immensely valuable over the past 15 years, and he has played a huge role in helping us shape Emmegi (UK) into the respected and responsive business it is today.

“While he might have made it look easy along the way, I know he has worked immensely hard to build great relationships with customers and colleagues, and has always been willing to go above and beyond to make sure customers get a great experience whenever they deal with Emmegi.

“It’s no surprise to any of us that Andrew has so many friends amongst his customers and even competitors, and I’m sure everyone will share our best wishes for Andrew in the future and for the new opportunities which I’m sure will come his way.”

A FOND FAREWELL

ANDREW JONES

Emplas installer partnership powers

£60 million in new build tenders

The Commercial Window Group, Emplas’ new build and social specification installer partnership, has delivered in excess of 250 tenders to its members in less than 12-months.

Launched in September 2024, the exclusive installer network combines national specifications and supply, with installation by regional new build and social specification specialists.

Members get access to commercial tenders and new business support which has

so far generated more than 250 tenders and £60 million of business opportunities.

Jody Vincent, Sales Director, Emplas, said: “The new build housing sector has been more challenging for the past two or three years, but despite tough trading conditions and lower new build outputs, we’ve achieved an exceptional level of tenders and high conversion rates.

“With the commitments that the Government has made to deliver more homes and to reform the planning process, the sector is expected to deliver a significant increase in demand from housebuilders, housing associations and registered social landlords, in the second half of this year.”

The Government unveiled its strategy to deliver 1.5million new homes earlier this year, including a major shake-up of the planning system and release of new funding.

A new report released by construction specialist Glennigan, suggests that on the back of these changes, after a contraction of 8% last year, the private new build sector will see a strong rebound of 8% in 2025.

The Construction Industry Forecast for the UK and Republic of Ireland, published in June this year, forecasts that this will be followed by a further 10% growth in 2026, and 18% in 2025.This reflects a renewed appetite for new build housing development as inflation falls, and consumer confidence and household budgets increase.

The social and affordable housing sector is predicted to see growth - 3% this year, 8% in 2026 and 11% in 2027 as government

spending on affordable and social housing translates into more social starts in the second half of this year. This compares to a contraction of 11% last year.

To support network members in winning new business, the Commercial Window Group offers 12-months fixed pricing on window and door supply and product guarantees underwritten by Emplas as the manufacturer.

“The Commercial Window Group launched with founder partner members”, Jody said. “The demand that we’re seeing, has however, exceeded our expectations and while memberships are limited, we are open to exploring new opportunities with qualifying potential partners in areas not already covered by members.”

The Window Company (Contracts) supports local youngsters

The Window Company (Contracts) hosted a recent visit for three students from the nearby Thriftwood School for children with additional needs, so they could experience a real workplace in action and see the kinds of opportunities that might exist for them in the future.

The aim was to show the young people that work can be an exciting, supportive and rewarding place, and the response from everyone involved was universally positive.

Equipped with high-vis jackets, mini toolkits and even specially prepared lunch boxes, the students really enjoyed seeing the process of ordering, surveying and delivering new windows, and especially liked seeing the pictures of when The Window Company (Contracts) fitted new windows and doors in their own school.

For the team at the commercial window installer, the experience proved equally rewarding as they got to see their work

from a completely different perspective and experienced the company’s commitment to social value first hand.

Katie Thornton, Director of Compliance and Administration at The Window Company (Contracts), said after the visit: “We really enjoyed hosting the visit. It was obviously an opportunity for us to give back to our local community, but in an industry faced with an ongoing skills shortage, it was also a useful reminder that we could all maybe look beyond traditional qualifications and experience to find talent and potential.”

The visit was organised in conjunction with Ductu, which is a social value organisation helping students from disadvantaged backgrounds or with disabilities to interact with socially responsible employers via work experience, workplace visits and in-school activities.

More info at: https://thewinco.co.uk/ and https://www.ductu.co.uk/

AluK forms strategic partnership with IGU specialist Clayton Glass

AluK has just announced a first-of-akind partnership with IGU specialists Clayton Glass. The partnership, full details of which were revealed at AluK’s Exploration Day, will bring a whole raft of benefits to AluK customers, designed to make buying and fitting glass easier and more cost effective.

This includes preferential glass pricing deals for AluK fabricators and installers, free onsite training and technical support via Clayton Glass’s dedicated SASSY Sales and service support vehicle and access to Clayton Glass’ innovative EcoCycle glass recycling scheme.

Russell Yates, AluK’s Managing Director, commented: “It’s significant that this is the first time that Clayton Glass has joined forces with any aluminium systems company and shows just how determined AluK is to add real value to our customer offering. This partnership on IGUs sits alongside all the other elements of our customer support package – from specialist marketing and technical support to inhouse testing facilities and free training at the AluK Academy, and gives fabricators yet another reason to upgrade their system to AluK.”

Clayton Glass Director Ryan Green added: “We’re really excited to be joining forces with AluK and further strengthening our position in the ali sector alongside such a dynamic player in the marketplace. We already supply lots of AluK customers, but this brings another dimension to that and lets them access special pricing deals and some of the aspects of our service that we define as The Clayton Difference.”

The SASSY vehicle, which was a big

attraction at the Exploration Day, can now be booked for free training and technical support at any AluK fabricator’s premises. The Clayton Glass team will arrive on site and showcase everything from solar and acoustic options to vacuum sealed units and 28mm triple glazing. They can deliver dedicated 30-45 minute training sessions to help AluK customers make the optimum glass choice for every application and use glass most effectively to reach U-Value targets.

AluK customers also now have access to Clayton Glass’ EcoCycle scheme alongside the CAB’s Closed Look Recycling Scheme that AluK has signed up to. EcoCycle is a recycling service dedicated to postconsumer glass waste and takes advantage

of the fact that glass, like aluminium, is one of the most recyclable materials on the planet. It is part of Clayton’s response to the UK target of using 50% recycled glass in all new production by 2030.

AluK customers can book in a free EcoCycle collection of glazed frames and loose glass to coincide with their delivery from Clayton Glass and save on waste management and skip costs. They can improve the sustainability of their operations and, at the same time, be part of the EcoCycle mission which channels the profits from the initiative into grants for local good causes. Ryan Green added: “We’ll be inviting AluK customers to nominate projects in their local areas so we can share the benefits directly with them.”

Hörmann Truedor to open its doors

Hörmann Truedor is opening its doors once again this Autumn, inviting the industry to an exclusive behind-the-scenes look at one of the most advanced composite door manufacturing facilities in the UK.

Taking place in September and November – Tuesday 16th September and Tuesday 11th November - the Open Days will be hosted at the IG Doors manufacturing plant in South Wales. Attendees can choose from either a morning or afternoon session, offering flexibility to suit busy schedules.

The Open Days will provide an opportunity to experience first-hand the 200,000 ft² automation and production technology that underpins Hörmann Truedor’s composite door offering. Guided tours will allow visitors to follow the entire production process highlighting why Hörmann Truedor stands out in the market as the only volume GRP composite door manufacturer to produce its own door slab in the UK.

The event provides the chance to meet with the Hörmann Truedor team and discuss the company’s latest innovations, service offerings, and support available to its trade partners. All attending companies will also gain exclusive access to discounts worth up to a total of £1000 which will be redeemable against the Hörmann Truedor

composite door range and the company’s online Door Designer.

David O’Mara, Marketing Manager at Hörmann, commented: “We’re excited to once again offer the industry the chance to come along to our manufacturing base in South Wales. These Open Days offer a unique opportunity to see our cutting-edge production facility in action and understand what makes Hörmann Truedor different. The feedback from previous events has been extremely positive, particularly regarding the scale of our operation and the qualitydriven investment we’ve made.”

“With limited spaces available, we encourage early booking to secure your place - whether you’re a new customer or looking to strengthen your existing partnership with us.”

To find out more and reserve a place at one of the Open Days https:// hormannevents.co.uk/hormanntruedor-open-day-1, scan the QR code or call 01530 516868.

UK workers increasingly confident as AI transforms roles and responsibilities

Workers in the UK feel ‘optimistic but overwhelmed’ by the advancement of AI in their workplaces according to a recent report by the World of Work Institute at Henley Business School. The organisation surveyed more than 4,000 full-time workers across a number of sectors and found that 56% of them were feeling optimistic about AI, but 61% were also feeling overwhelmed.

63% of those surveyed said they were already using AI at work, yet 49% said that their workplace had no AI guidelines in place. 60% agreed that they would embrace AI more with better training.

“This new research falls in-line with the conversations we’re having with people in the glazing sector about embracing AI,” said Elton Boocock, founder of thinkivity AI. “Many people are starting to use AI tools to help them with their day-to-day tasks, but businesses are struggling to support their teams with AI adoption and training.

“The world of AI moves at such a rapid pace, it can be difficult to keep up with the latest tools and have time to research what the best options are for your own way of working. That’s where GlazePro AI comes in.”

GlazePro AI membership offers expert AI training, support and insights and as well as access to a community of like-minded

people in the glazing industry who are already embracing AI. Membership works through a low-cost monthly subscription which gives users access to free online AI training courses and weekly online discussions, where members talk about the latest tools and share their own AI experiences. This is all backed by direct contact with the thinkivity team for expert AI advice and support. Elton adds: “The

weekly online sessions are invaluable for our members and it’s great to see glazing businesses collaborating and sharing how they have used new AI tools successfully to save time, resource or money.”

GlazePro AI offers individual membership or company membership specifically for the glazing sector. For more information go to: https://thinkivity.co.uk/ glazepro-ai/

Sternfenster transport division achieves

99.5% COTIF in performance report

Sternfenster’s transport division has reported an impressive Complete & On Time In Full (COTIF) score of 99.5%, demonstrating the reliability of its industry-leading delivery service. “Our extremely strong COTIF metric shows that over 99% of our customers are receiving their deliveries both on the agreed date, and in the complete, correct quantity,” said Nathan Court, Sternfenster’s Sales and Marketing Director.

“We continually strive to deliver the best possible service to our installer partners, and these figures reflect that. However, we always strive for 100%, so we’ve recently implemented some changes within our transport division, that have already delivered further positive results for our customers.”

Having identified the main barriers to progress in the department, amendments to working patterns and additional training for operators were key in helping the fabricator to drive improvement. “All our operators are now fully trained to use a forklift truck, and shunt vehicles, which has significantly improved the capability of our transport division,” added Nathan. “We’re constantly

assessing, reviewing and refining our processes across each department to ensure we’re operating at the highest level. It’s a win, win, approach, for us as a business, and our customers.”

Having invested close to £500k in its delivery fleet in recent years, other standout features of Sternfenster’s top-notch transport service include live vehicle tracking, providing real-time visibility of the

progress of deliveries. Relaying information on the driver’s whereabouts and how many drops need to be made prior to delivery, a two-hour delivery window allows customers to plan and utilise their time more effectively for improved productivity, and in turn, profitability.

“Efficiencies in delivery are enormously beneficial for window companies,” added Nathan.

ODL Europe’s in-house

Door Prep Service delivers precision-prepared composite doors with a 7-day turnaround on standard colours and 10 days on any RAL colour.

• Fast turnaround.

• Consistent reliability.

• Precision prepped to your requirements.

Certass announces official support for Building Our Skills initiative

Certass has announced its support for Building Our Skills – Making Fenestration a Career of Choice (BOS) – an established and respected industry initiative committed to creating a workforce for tomorrow in the fenestration sector.

As the glazing industry faces increasing demand for competent tradespeople, it has never been more important to invest in structured skills development. BOS has a proven track record of engaging young people and guiding them into rewarding careers in fenestration and its related disciplines. Through partnerships with employers, training providers, and industry bodies, BOS helps remove barriers and simplifies the process of taking on apprentices.

Certass has long championed the value of professional development and competency across the industry, and our alignment with BOS reinforces this commitment.

Jon Vanstone, Chair of Certass and the National Home Improvement Council, said: “Building Our Skills is exactly the kind of

initiative our industry needs right now. It’s practical, it’s well-established, and it opens real pathways into our sector. At Certass, we

see competency not as a one-time box-tick, but as a continuous journey. Supporting BOS is part of that bigger picture, one where the industry gets stronger by investing in people.”

Mark Handley, Partnerships Manager, Building Our Skills, added: “We are delighted to be a part of this collaboration and the opportunity to help create apprenticeship opportunities for the SME business community which is very much the lifeblood of our industry. Working alongside Certass will help us to support the industry further as we all strive to grow a workforce for tomorrow”.

Through this partnership, Certass members will have the opportunity to access apprenticeship pathways for their businesses, including guidance documents and support facilitated by BOS and their national partners. Certass are looking forward to working closely with Building Our Skills to create more opportunities for SMEs to access emerging talent and build the next generation of competent installers.

Thermoseal urges IGU firms to meet compliance amid regulatory pressure

Thermoseal Group is urging IGU manufacturers to ensure that their products comply with regulations, as the Office for Product Safety and Standards (OPSS) ramps up its inspections in the glass and glazing sector.

Part of the Department for Business and Trade, the OPSS is the UK’s national product regulator. Designed to ‘protect people and places from product-related harm by ensuring the safety and integrity of goods’, it enforces a wide range of regulations across the lifecycle of products, including those related to the construction and energy efficiency sectors.

With heat soaked thermally toughened glass currently under particular scrutiny, the Glass and Glazing Federation (GGF) reports that the OPSS is conducting detailed inspections into manufacturers’ entire production processes. This includes Factory Production Controls (FPC), Declarations of Performance (DoP) and compliance with CE and UKCA markings.

“The focus is on heat soaking at the moment, but that could change at any point – and if your components are faulty, your units could be caught out,” said Thermoseal Group’s Sales Director, Mark Hickox.

“Our customers have nothing to worry about, because we have full traceability and test data for all of our products, and indeed, the vast majority of our products are manufactured right here, in-house in the

UK.

“That means that we have full control over our products, ensuring that they fully comply with all relevant regulations. If you source your components elsewhere, and your current supplier can’t say the same, you might want to give us a call,” he added.

The specialist IG component maker and distributor extensively tests all its products in-house at its EN1279 test facility, strengthening its credibility as a trusted product provider.

According to the most recent test results from IFT Rosenheim, the European notified and internationally accredited certification body, Thermoseal Group’s Thermoflex is currently the best performing flexible

silicone rubber spacer bar in the world. This is also approved by the British Fenestration Rating Council (BFRC) in the UK, further evidencing the high quality of Thermoseal Group’s warm edge products.

“During the R&D phase, we test our products thoroughly to ensure that they perform as intended, in full compatibility with other products in a complete unit,” added Mark.

“This helps to raise the bar for quality assurance in the wider industry and gives our customers total confidence in the components we provide. Customers can also download full certification for every product on our website, for added peace of mind,” added Mark.

OPSS threatens product withdrawals amid doorset compliance crackdown

Doorset manufacturers are being reminded about their responsibilities regarding third-party certification for emergency exit and external panic doorsets, as the Office for Product Safety and Standards (OPSS) clamps down on non-compliance. The callout comes from Warringtonfire, a leading provider of testing, inspection, and certification services. It warns that many doorset manufacturers are not adhering to the correct procedures for third-party certification of their external doorsets, resulting in non-compliance. This follows recent scrutiny from industry bodies such as the Door & Hardware Federation (DHF) and the Guild of Architectural Ironmongers (GAI), who have been informed of the situation by the Office for Product Safety and Standards (OPSS).

It is the responsibility of manufacturers to ensure their products are correctly certified and have a Certificate of Constancy of Performance (CoCoP), which then allows the product to then obtain a conformity marking (CE or UKCA). Without this, doors cannot be legally sold on the market, posing significant financial and reputational risks

to manufacturers, as well as putting people at risk.