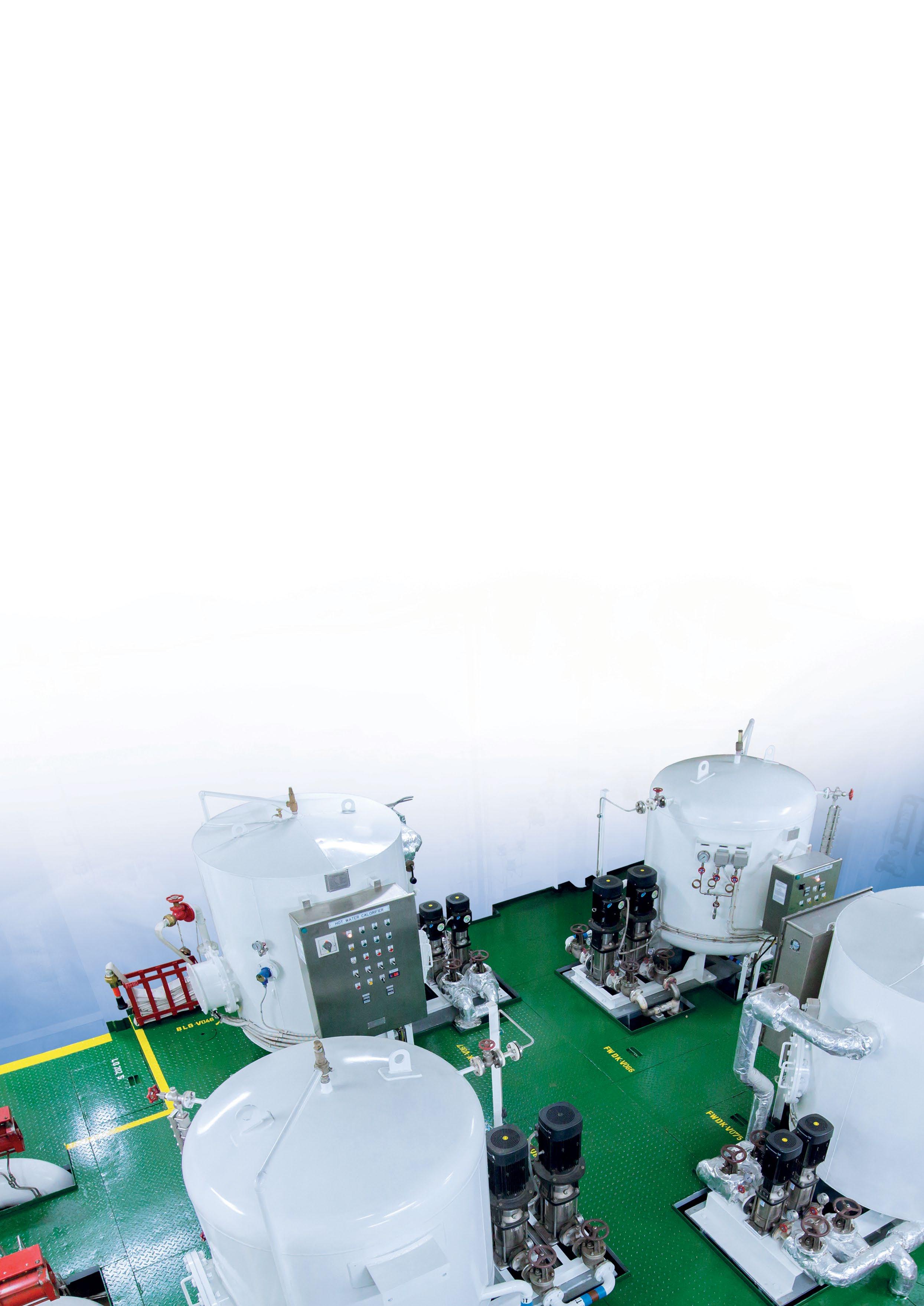

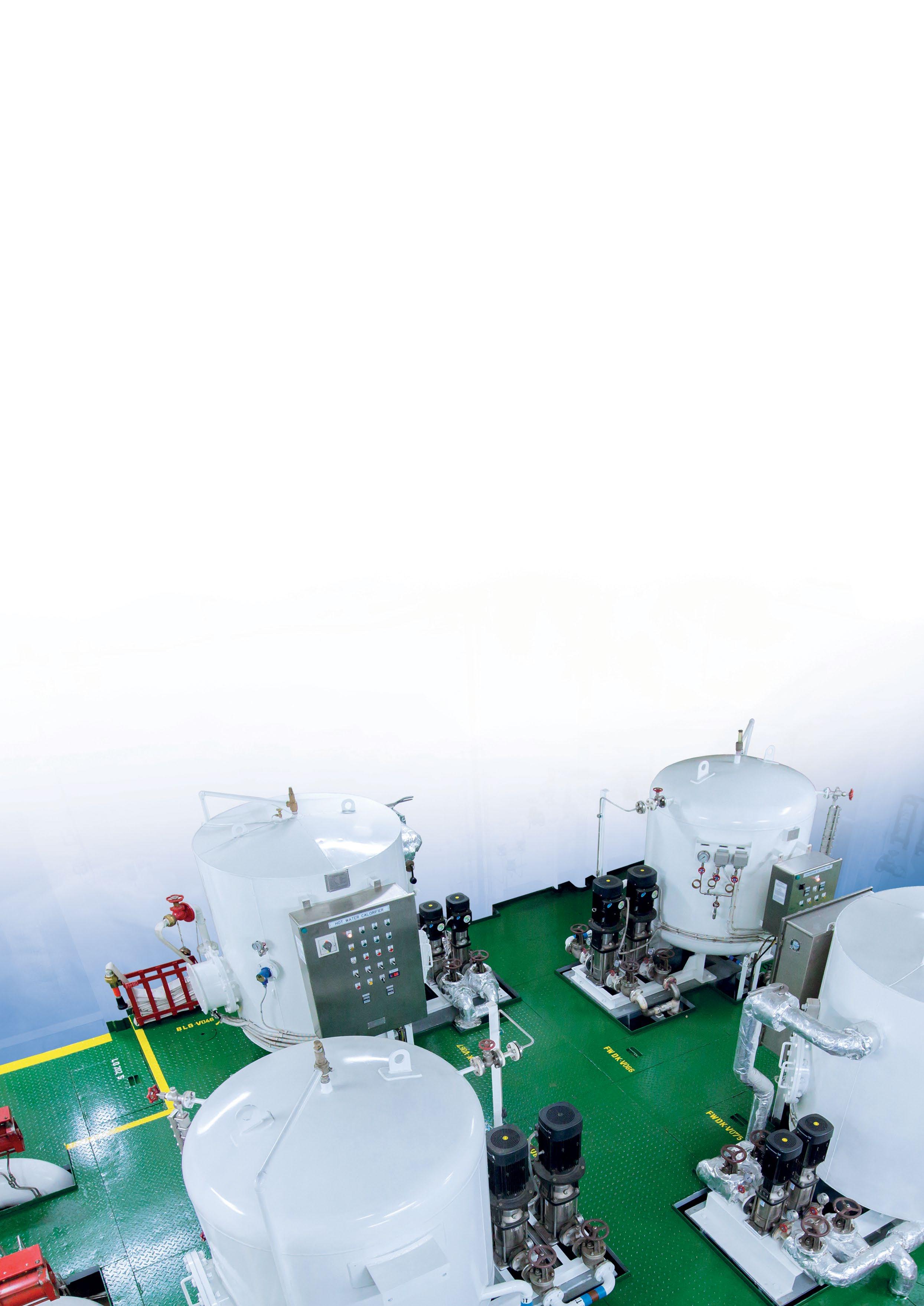

Reliable fluid handling for demanding marine environments

Fleet managers and superintendents face tough choices every day balancing performance, compliance, and crew safety. Whether you’re pumping corrosive chemicals, oily water, sludge, or fuel, the equipment must be reliable, easy to maintain, and safe for operation in zones where sparks and electrical failure are not an option.

The marine environments present unique and demanding challenges for fluid transfer systems. One of the most pressing challenges is the limited access to electricity in remote parts of the vessel. Whether deep within the engine room or on an isolated deck, power may not be readily available or even permitted, making traditional electric pumps less practical in many critical areas.

On top of that, vessels handle an incredibly diverse range of fluids, each with its own viscosity, abrasiveness, or corrosive properties. A one-size-fits-all approach simply does not work. Operators require pumping systems that can adapt to these varying fluid types without compromising performance or safety.

Hazardous or flammable environments, such as fuel-handling zones or chemical storage areas, often come with strict restrictions that prohibit the use of electrical equipment due to the risk of sparks and ignition. In these contexts, pump solutions must be inherently safe and compliant with explosion-proof standards.

Environmental compliance adds yet another layer of complexity. Regulations like MARPOL demand careful handling of waste, chemicals, and bilge water, with stringent rules around containment, discharge, and cleaning. Pumps used on board must support this compliance without adding extra burden to the crew.

Lastly, marine equipment is expected to deliver high uptime with minimal maintenance. Downtime is not just inconvenient, it can be costly and dangerous.

Crews need pumping systems that are reliable, easy to service, and capable of withstanding the rigours of continuous use at sea.

Unitor™ Aeroflow Air-Operated Double Diaphragm (AODD) pumps are designed for general fluid transfer and are powered by compressed air from the ship’s system or from portable compressors.

Double diaphragm pneumatic pumps are designed to handle a wide range of fluids, whether acidic or alkaline, viscous, or containing solid particles in suspension. They are ideal for various applications, including:

• Ideal for spill response (Part of SOPEP)

• Cleaning in place (CIP)

• Drum transfer for fluids up to 1,000 centipoise

• Circulation of low viscosity chemicals and detergents

• Fluid evacuation from bilges

• Waste water removal

• Low viscosity adhesive supply

• Sludge out of cargo areas

• Emptying cargo holds after cleaning

• Deck and Cargo Hold cleaning

They can also run dry without issues and handle suction lift without damage, preventing costly repairs. Their compact size and simple design make them easy to install and service.

AODD pumps utilize compressed air to drive two diaphragms, creating alternating suction and discharge strokes. This simple yet effective mechanism offers several advantages for marine applications.

Safe for hazardous zones

Powered by air, these pumps do not generate sparks, making them suitable for handling flammable liquids

No complex motors or seals to fail

From light fuels to viscous sludge and slurries, the flow rate and pressure can be easily adjusted by regulating the air supply

Portable & versatile

Quick to move between compartments or decks, offering flexibility in diverse operational scenarios

Each AODD pump uses two flexible diaphragms that move back and forth, creating a vacuum to draw and push fluids. Compressed air alternates chambers, allowing continuous, self-priming operation.

Unitor™ Aeroflow pumps come with metal or plastic pump casings that can easily handle corrosive and abrasive fluids. All Unitor™ Aeroflow diaphragm pumps are ATEX approved, with aluminium being ATEX Z1.

Compressed air fills right inner chamber, causing the opposing diaphragm to create suction, lifting the lower valve ball, pulling in fluid at inlet. Simultaneously, the right chamber is in “Discharge” cycle.

Wide range of sizes and materials suits to a variety of conditions and chemical fluids

Self-priming up to 5m (dry) and up to 9.8m (wet), works in suction lift applications

Compressed air fills left inner chamber, causing upper valve ball to open and discharge fluid. Simultaneously, the right chamber is in “Suction” cycle.

Handles liquids with solid particles making it ideal for abrasive and viscous media

Seal-less design to allow dry-run without damaging pump or system

Easy and quick to maintain without special tools to ease servicability

Safely “dead head” function, against closed discharge, without pump damage

Allows high flow rates through optimal casing design to ensure efficient performance

Fully submersible according to the fluid compatibility

Long-lasting diaphragm construction ensures a consistent performance and a longer operating life.

Special exhaust chamber with double silencer to expand diffusion passages, reduce the icing and assure low noise level.

Efficient air distribution design: low air consumption. Un-balanced pilot spool, precisely controls positioning of the main power spool to eliminate stalling and increase efficiency.

Solid polypropylene air chambers and plastic air valve for maximum chemical resistance in highly corrosive environments.

All bolted design for an effective sealing to extended leak-proof service.

Special pinch clamping, design to minimize wear and increase life of the diaphragm, and provides a uniform seal to avoid leak.

Pneumatic exchanger is easily externally accessible for a quick inspection.

Special Air system: lubefree, non-stall, non-freeze.

Acetalic shuttle ensures long valve life, autolubricated material.

To select the right Aeroflow pump for your application, the following factors should be considered to achieve economy of operation, long pump life, and minimal maintenance costs:

• The nature of the medium to be pumped, its viscosity, and the solids content

• Pumping capacity in relation to the desired output

• Suction and pressure conditions

Considering these parameters, an optimal pump size is selected when the intersection of the intended installation “pressure vs. flow rate” is near the middle section of the curves.

To determine compressed air requirements and proper size for a Aeroflow AODD pump, two elements of information are required:

1. Required Flow Rate

2. Total Delivery Head

As an example, consider a Unitor TM Aeroflow 1 Inch Pump performance curve, pumping about 135 l/min at 25m. Point A on the performance curve is where the desired Flow Rate and Total Delivery Head points intersect. This point determines compressed air requirements for the particular pump. At performance point A, the pump will require approximately 7 bar air inlet pressure. To arrive at this figure, follow the solid blue curve to the left to read the air pressure rating in BAR. By looking at the nearest green curve, it is determined the pump will require approximately 900 nl/min (Normal litre per minute) of air consumption.

72

Sampling, fluid transfer, chemical circulation, waste removal, dosing, and adhesive transfer (low viscosity)

Collar clamps Bilge stripping, wastewater and fuel transfer, chemical dosing, tank cleaning, drum emptying, and fluid sampling

Cargo

Typical applications: Sampling, fluid transfer, chemical circulation, waste removal, dosing, and adhesive transfer (low viscosity).

Technical data

Fluid connection 3/8” BSPP Air connection 1/4” BSPP

Max flow rate 20 l/min

Max air pressure 7 bar

Max delivery head 70 m

Max suction lift dry 5 m

Max suction lift wet 9.8 m

Max solid passing 2.5 mm Noise level 65 dB

Max viscosity 10,000 cps

Displacement per stroke 30 cc

Supplied with: Fluid barbs, Air barbs and Collar Clamps

Spare parts: Complete Service Kit (Air & Fluid Side)

(2 pcs) 635646

Accesories:

Fluid Inlet and Outlet & Air Hose Kit:

Consists of 3/8” rubber fluid inlet and outlet hoses (50-meter coil / 25m each side) and a 1/4” PVC air hose (50-meter coil).

Typical applications: Bilge stripping, wastewater and fuel transfer, chemical dosing, tank cleaning, drum emptying, and fluid sampling.

Technical data

Fluid connection 1/2” BSPP Air connection 1/4” BSPP

Max flow rate 65 l/min

Max air pressure

Max delivery head 80 m

Max suction lift dry 5 m Max suction lift wet 9.8 m

Max solid passing 3.5 mm Noise level

cps

Displacement per stroke 140 cc

Supplied with: Fluid barbs, Air barbs and Collar Clamps

Description

Spare parts: Complete Service Kit (Air & Fluid Side)

Barbs + Collar Clamps (2 pcs each)

Barbs (2 pcs)

Accesories:

Fluid Inlet and Outlet & Air Hose Kit:

Consists of 1/2” rubber fluid inlet and outlet hoses (50-meter coil / 25m each side) and a 1/4” PVC air hose (50-meter coil).

Suction Rigid Tube PP (1,000 mm)

Typical applications: Ballast and wastewater sampling for treatment monitoring and compliance.

Technical data Fluid connection

Pump is supplied without Accessories.

Spare parts:

Fluid Inlet and Outlet & Air Hose Kit: Consists of 1/2” rubber

Typical applications: Cargo hold, tank, and bilge cleaning; deck and hull maintenance; wastewater/sludge removal; fuel/oil transfer; general maintenance.

Technical data

Fluid connection 1” BSPP – DN25

Air connection 1/2” BSPP

Max flow rate

Max delivery head

Max suction lift dry

cps

Displacement per stroke

Supplied with: Fluid barbs, Air barbs and Collar Clamps

Spare parts: Complete Service Kit (Air & Fluid Side)

(2 pcs) 635657

Accesories:

Fluid Inlet and Outlet & Air Hose Kit: Consists of a 1” spiral fluid suction hose (5 meters), a 1” rubber fluid outlet hose (50-meter coil), and a 1/2”

air hose (50-meter coil).

Casing

Diaphragm

Typical applications: Aggressive chemical transfer, circulation cleaning, cargo hold and tank cleaning, bilge water transfer.

Technical data

Fluid connection 1” BSPP – DN25

Air connection 1/2” BSPP

Displacement per stroke

Supplied with: Fluid barbs, Air barbs and Collar Clamps

Description

Spare parts:

Complete Service Kit (Air & Fluid Side) 635660

Fluid Barbs + Collar Clamps (2 pcs each)

Air Barbs (2 pcs) 635657

Accesories:

Fluid Inlet and Outlet & Air Hose Kit:

Consists of a 1” spiral fluid suction hose (5 meters), a 1” rubber fluid outlet hose (50-meter coil), and a 1/2”

Typical applications: SOPEP spill response, fuel/oil transfer, bilge/sludge transfer, dewatering, cleaning support, chemical handling in hazardous areas.

Technical data

Fluid connection 1” BSPP – DN25

Air connection 1/2” BSPP

Max flow rate 170 l/min

Max air pressure 8 bar

Max delivery head 80 m

Max suction lift dry 5 m

Max suction lift wet 9.8 m

Max solid passing 7.5 mm Noise level

dB Max viscosity 35,000 cps

Displacement per stroke

cc Description

Supplied with: Fluid barbs, Air barbs, Collar Clamps and Ground bonding set

Spare parts: Complete Service Kit (Air & Fluid Side)

+

Accesories:

Fluid Inlet and Outlet & Air Hose Kit: Consists of a 1” spiral fluid suction hose (5 meters), a 1” rubber fluid outlet hose (50-meter coil), and a 1/2” PVC air hose (50-meter coil).

Diaphragm

Typical applications: Aggressive chemical transfer, circulation cleaning, cargo hold/tank cleaning, bilge water removal.

Technical data

Fluid connection 2” BSPP – DN25

Supplied with: Fluid barbs, Air barbs and Collar Clamps

Spare

Accesories:

Fluid Inlet and Outlet & Air Hose Kit:

Consists of a 2” spiral fluid suction hose (5 meters), a 2” spiral fluid

hose (5 meters), and a 3/4”

Typical applications: SOPEP, fuel/oil transfer, bilge/ sludge removal, dewatering, cleaning, chemical handling in ATEX zones.

Technical data

Fluid connection 2” BSPP – DN50 Air connection 3/4” BSPP Max flow rate

viscosity

cps

Displacement per stroke 3,050 cc Description

Supplied with: Fluid barbs, Air barbs, Collar Clamps and Ground bonding set

Spare parts: Complete Service Kit (Air & Fluid Side)

Accesories:

Fluid Inlet and Outlet & Air Hose Kit: Consists of a 2” spiral fluid suction hose (5 meters), a 2” spiral fluid outlet hose (5 meters), and a 3/4” PVC air hose (50-meter coil).