Cleaning solutions for every engine room challenge

Clean, compliant, and operational

Engine room cleanliness has consistently ranked among the most frequently identified deficiencies under SOLAS and MLC in recent years. This long-standing issue is highlighted in statistics and advisories from major Classification Societies and Flag States, with data showing that older vessels are often cited but notably, many older ships maintain high standards and remain inconspicuous. Deficiencies can stem from both overall engine room hygiene and specific machinery systems. A clean engine room directly signals a wellmaintained vessel and is a top five Port State Control (PSC) inspection deficiency. Between 2021 and 2024 alone, the Paris MoU recorded 198 detentions and 2,001 deficiencies relating to engine room conditions.

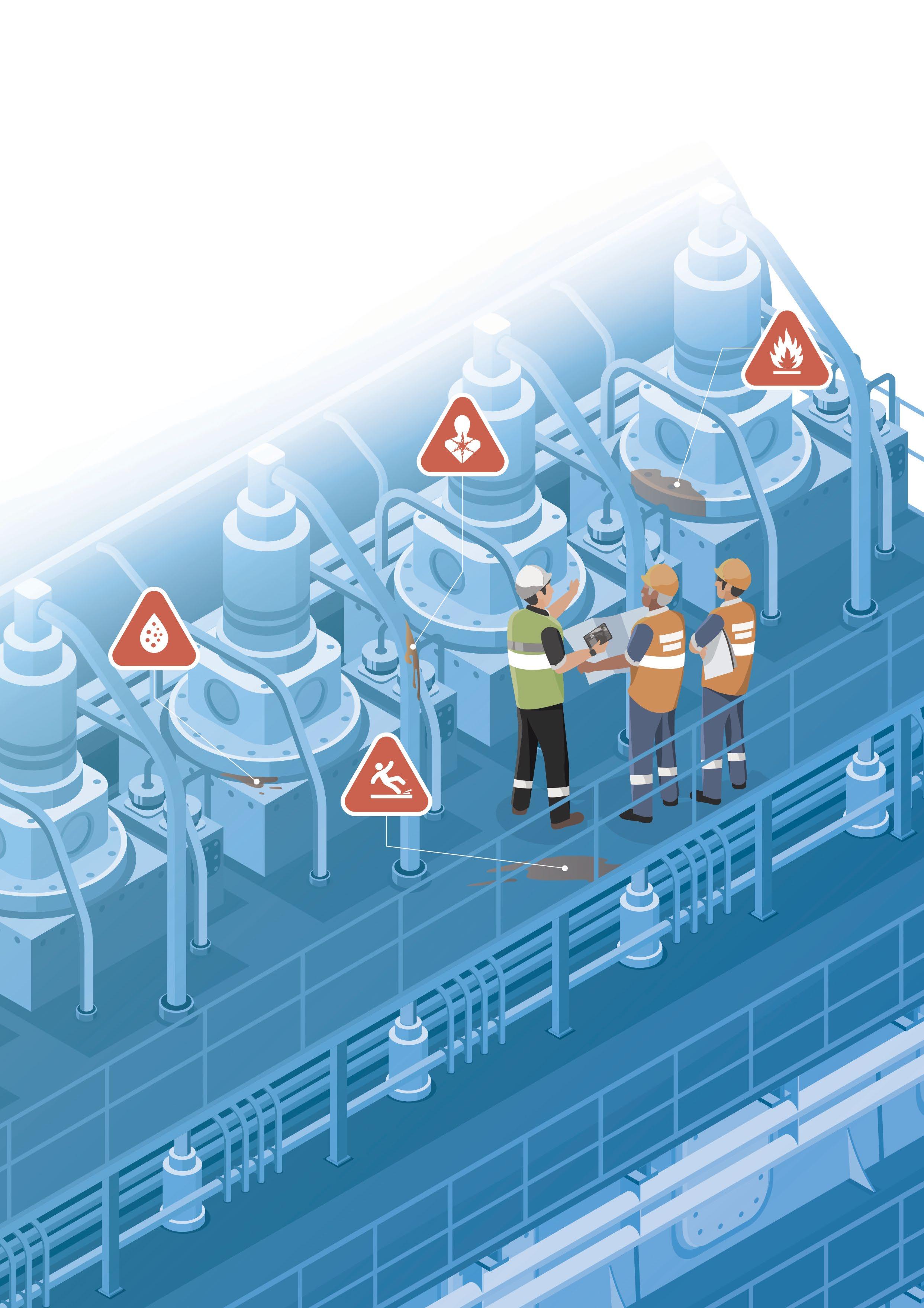

Reducing accident risks

“Fuel and lubricant leaks can easily lead to fire or explosion due to their highly flammable nature or result in pollution and hazardous situations. Leaks from fuel pumps, main engines, generators, and steering gears must be corrected immediately. A robust preventive maintenance system ensures repairs are carried out before small leaks escalate into major incidents.”

Guidance on Machinery Space Deficiencies, Marine Advisory 06/2023, Liberia Maritime Authority

Contaminants reduce the performance and reliability of essential equipment

Maintaining a clean engine room is essential to reducing operational risks. According to the European Maritime Safety Agency’s 2024 Annual Marine Casualties and Incidents Report, slips, stumbles, and falls are the leading causes of workplace injuries and fatalities at sea. From 2014–2023, 186 fatalities (50.3% of the total) and 1,958 injuries (30.1%) were attributed to such incidents.

Oily surfaces and residues increase fire and pollution risks

Hazardous substances endanger health

A dirty engine room poses significant dangers.

Safety-critical defects must be rectified without delay, and prevention should be prioritized. The Safety Management System (SMS) is a valuable tool to structure and document both proactive and corrective measures, ensuring risks are consistently managed and mitigated. Importantly, a tidy, well-lit engine room with active incident management minimizes PSC inspection disputes and is the foundation for effective hazard prevention.

Slippery areas lead to accidents

Minimizing downtime and cost

A clean engine room not only reduces the risk of accidents and fire; it underpins vessel efficiency. Comprehensive planned maintenance and cleaning routines limit the accumulation of dirt, oil, and grease across all surfaces, reveal early signs of leakage (such as water or oil from cylinder heads, blocked purifiers, or oil contamination in boilers and cooling systems), and reduce unnecessary wear. In turn, this enhances energy efficiency and controls costs systems fouled by dirt, corrosion, or contamination work harder, consume more energy, and are more likely to fail, leading to costly operational downtime.

“Limescale deposits thicker than 0.5 mm obstruct heat transfer and can cause thermal overload of cooling components.”

MAN Cooling Water System Cleaning

Proactive maintenance with UnitorTM

Managing the complexity of engine room maintenance does not have to be overwhelming. In fact, simplification is the key to efficiency. By standardizing onboard cleaning chemicals and focusing on essential, high-performance products, procurement and operational efficiency can be significantly enhanced:

• Reduced procurement complexity and lower inventory costs

• Crew become more proficient in correct usage, minimizing wastage and preventing overdosing

• Compliance with environmental regulations and safety standards

This approach not only streamlines operations but also empowers crew members to work more confidently and safely. Wilhelmsen offers a comprehensive portfolio of cleaning solutions tailored to the unique challenges of engine room environments, addressing the full spectrum of engine room cleaning needs, from daily maintenance to precision care for sensitive components. This holistic methodology ensures:

Maximized operational uptime

Specialized engine room chemical cleaners rapidly dissolve and remove oil, grease, carbon, scale and other tough contaminants from machinery, piping, and critical components. Their fast-acting formulas minimize labour and downtime, enabling ship operators to return vital systems to service swiftly and efficiently.

Extended asset lifespan

Regular chemical cleaning protects equipment and painted surfaces by preventing corrosive build-up, neutralizing acidic residues, and preserving metal integrity. By maintaining cleanliness, these products help prevent rust, pitting, and premature wear, keeping key assets performing longer.

How scale buildup impacts efficiency

Limescale and other scale deposits may appear minor, but drive-up energy consumption, restrict flow rates, and accelerate equipment wear, leading to unscheduled maintenance and increased operational costs. Regular and proper water treatment and cleaning are essential to prevent scale and maintain peak machinery efficiency:

Optimized fuel and energy efficiency

Specialized chemical treatments remove scale, soot, and baked-on deposits from heat exchangers, cooling systems, and exhaust pathways, ensuring maximum heat transfer and machinery effectiveness. Cleaner systems run cooler and smoother, directly supporting improved fuel economy and reduced maintenance costs.

Enhanced safety and compliance

Engine room cleaning chemicals keep floors, machinery, and bilge areas free from oil spills, cargo residues, and hazardous films that can cause slips, falls, and fire hazards. Our products are compliant with international maritime safety and environmental regulations, supporting a safer workspace and peace of mind during audits and inspections.

Unitor’s products are developed with advanced chemistry that outperforms conventional cleaners, offering effective cleaning, degreasing, descaling, and precision care, even under the demanding conditions found at sea. Our products are designed to meet and exceed international maritime regulations, including MARPOL Annex V and safe handling requirements.

Increased fuel use

A scale thickness of just 1 mm on the boiler waterside can increase fuel consumption by 5%–8%.

Reduced flow and overheating Scale within pipes, boilers, or heat exchangers narrows flow paths, increases friction, and forces systems to operate at higher and riskier temperatures.

Environmental impact Poor energy efficiency translates into higher carbon emissions affecting the annual operational carbon intensity indicator and CII rating

&

and usage

Engine room essentials

General engine room cleaner & degreaser

Enviroclean

Enviroclean is a heavy-duty, all-purpose micro emulsion water-based cleaner and degreaser suitable for general engine room and deck cleaning tasks. Enviroclean is highly concentrated, low toxic, biodegradable, and effective for removing grease, oil, sludge, polymer compounds, carbon deposits, dirt, and grime. It is compatible with oily water separators and supports a safe working environment.

Product number: 765018

General engine room cleaner

Aquabreak PX

Aquabreak PX is a highly effective, multipurpose general engine room cleaner widely used in marine applications for removing dirt, oil, and grease without harsh solvents or caustic agents. It is water-based, biodegradable, and safe on all materials, making it suitable for regular cleaning tasks throughout the engine room. It has excellent dispersant property.

Product number: 575613

General engine room degreaser

Cleanbreak

Cleanbreak is a highly effective, economical solvent-based cleaner and degreaser designed for engine rooms, machinery spaces, bulkheads, tank tops, and bilges. It features selfsplitting emulsifiers to allow separation of oil and water for oily water separator compatibility.

Product number: 571497

Coldwash HD is a heavy-duty degreaser based on petroleum solvents, emulsifying agents, and surfactants, designed for use on soiled surfaces, bilges, and machinery parts. It effectively removes oil contamination, is safe for most metal and painted surfaces, and allows soak cleaning of machinery parts. After cleaning, it splits to release the oil phase for easy recovery, leaving surfaces clean and oil-free with rapid rinsing.

Product number: 571430

Rust removal & surface brightener

Heavy duty hand cleaning

Natural Hand Cleaner

Metal Brite HD is a highly concentrated, non-flammable liquid detergent compound containing phosphoric acid and nonionic surfactants. It is designed for rust removal and surface brightening, including aluminum. It cleans and passivates ferrous metal surfaces to inhibit further corrosion and provides a base for paint adhesion. The product also removes light rust, rust stains, tarnish from non-ferrous metals, and rust stains from painted, ceramic, and wooden surfaces.

Product number: 571679

Natural Hand Cleaner is an effective, mild gel skin cleaner containing natural ingredients that removes severe industrial grime, oil, and grease from hands. It contains no petroleum solvent derivatives and uses naturally occurring mineral scrub agents for exfoliating cleaning. The formula is gentle enough for daily use, has mild antiseptic properties, and is easier to rinse off than many other gel cleaners. Supplied with a hand pump for optimal dosing, it leaves hands clean without drying out the skin and complies with cosmetic regulations.

Product number: 571800

Engine room speciality cleaning purpose

Carbon deposits removal

Carbonaceous deposits form on engine components during combustion and can become hard, adherent layers that are difficult to remove during maintenance. These stubborn residues reduce engine efficiency, hinder heat transfer, and accelerate wear, making effective carbon deposit removal essential for reliable performance and extended equipment life.

Carbonclean LT

Carbonclean LT is a non-corrosive, powerful microemulsionbased cleaner formulated for the removal of carbonaceous deposits. It contains no chlorinated solvents or phenolic compounds and is low in toxicity to both the environment and users. It is ideal for cleaning carbon deposits from engine parts such as pistons, piston rings, valves, and burner tips, as well as fuel injectors and oil coolers. The product can be used by soaking or circulation methods, is safe on all light metals including aluminum, and eliminates the need for hard scraping. It also has a low evaporation rate and contains no estrogenic compounds like nonylphenol ethoxylates.

Product number: 575696

Air cooler cleaning

Regular cleaning of turbocharger air coolers and scavenge spaces is essential to ensure a diesel engine operates at peak efficiency. Accumulated dirt, oil, and other contaminants can reduce cooling performance, increase fuel consumption, and lead to higher exhaust temperatures, potentially causing engine damage over time.

ACC Plus

ACC Plus is a powerful microemulsion-based cleaner designed for diesel engine air coolers, scavenging air systems, and the compressor side of turbochargers. It combines biodegradable surfactants with low toxicity solvents to replace harmful traditional solvents without compromising cleaning performance. ACC Plus meets the latest environmental standards, is non-toxic to people and the environment, and contains no chlorinated or aromatic hydrocarbon solvents or nonylphenol ethoxylates. It effectively removes oil, grease, and carbon deposits while maintaining and maximizing air cooler efficiency. The product can be used for hand spray cleaning or soaking methods and leaves no residue or harmful effects on engines.

Product number: 698704

Coldwash HD

Metal Brite HD

Descaling of boilers, cooling water system, condensers, evaporators & heat exchangers

Scale and corrosion gradually weaken boiler tubes and cooling system surfaces, reducing heat transfer efficiency and increasing the risk of damage. Accumulated scale can cause hot spots and tube rupture, while rust undermines structural integrity and cooling performance. In marine systems, these issues arise from water quality, temperature, and material interaction—making regular cleaning essential to prevent costly and dangerous failures.

Descaling Liquid

Descalex is a powerful dry acid cleaner formulated to remove rust and scale deposits from boilers, diesel engine cooling water systems, condensers, evaporators, calorifiers, and heat exchangers. It contains inhibitors to protect metals, a color indicator to show the strength of the cleaning solution, and an anti-foaming agent. Descalex is efficient, economical, safe to use, and approved by the Norwegian National Institute of Public Health for cleaning evaporators. It should be used with caution due to strong acids and requires proper personal protection. After descaling, neutralization with an alkalinity control solution is recommended, and it is not compatible with aluminum, zinc, tin, their alloys, or galvanized surfaces. Safe on plate’s material, rubber gaskets and seals.

Product number: 571646

Descaling Liquid is a powerful hydrochloric acid-based cleaner formulated to efficiently remove scale and rust from boilers, heat exchangers, evaporators and condensers. It contains corrosion inhibitors to protect ferrous metals and wetting agents for deeper penetration into deposits. The product is highly concentrated, fast-acting, easy to rinse off, and suitable for various marine and industrial descaling applications. It should not be used on aluminum, zinc, tin, stainless steel, titanium, or galvanized surfaces. Proper safety precautions, including personal protective equipment and ventilation, are essential during use.

Product number: 571653

Degreasing of boiler & cooling water system

Oil contamination in marine boilers and cooling systems can cause overheating, tube damage, and reduce heat transfer efficiency. Common sources include leaking fuel oil tank heating coils, faulty machinery seals, and cargo tank heating systems. In engine cooling water system oil ingress often arises from leaking oil coolers, failed head gaskets, or cross-contamination in shared heat exchangers. Effective cleaning is essential to restore system performance and prevent costly damage.

Seaclean Plus

Seaclean Plus is a modern, low-toxic, biodegradable solvent-based product primarily used as an excellent tank cleaner and degreaser. It is IMO approved and meets safety and pollution hazard requirements for cleaning double bottom, deep, and fuel oil tanks at sea, as well as crude and refined mineral oil cargo tanks. The product is versatile and can also be used for degreasing and cleaning bilge spaces and engine rooms. It features biodegradable emulsifying agents, contains no nonylphenol ethoxylates or estrogenic compounds, and offers quick penetration with powerful emulsifying properties. Seaclean Plus is economical with very low dosage rates, easy to use by conventional means, and safe on most metal surfaces, painted surfaces, and tank coatings. It is easy to rinse off, leaving clean and oil-free surfaces.

Mild multifunctional scale, rust, oil & grease removal from system

Pre-commission cleaning is vital to ensure new systems perform efficiently and last longer. It removes mill scale, grease, and construction residues that can impair heat transfer and trigger corrosion. Skipping this step can lead to costly inefficiencies and premature system wear.

Commissioning Cleaner

Commissioning Cleaner is an innovative, multifunctional, water-based cleaner designed for the cleaning of new boilers and cooling systems, especially on-board new buildings. It removes scale, rust, oil, and grease in a single step through recirculation using an external pump. The product is low foaming, biodegradable, and free from nonylphenol ethoxylates and estrogenic compounds. It provides temporary corrosion protection by passivation, is safe on aluminum, zinc, tin, and their alloys, and achieves quick oil separation after cleaning without needing neutralization chemicals afterward.

Product number: 624932

Ballast UV, filter & pre-filter cleaner

Clean-In-Place (CIP) systems provide an automated and efficient method for cleaning the internal surfaces of tanks, pipelines, and equipment on board without the need for disassembly. They are essential for maintaining system hygiene, preventing contamination, and ensuring optimal operational efficiency. In Ballast Water Treatment Systems, CIP effectively removes scale, sediment, and biofouling that can reduce the performance of UV lamps and electro chlorination units.

BallastGuard CIP Cleaner

BallastGuard CIP Cleaner is an environmentally friendly, biodegradable liquid cleaner based on citric acid and specialized dispersants. It is designed for cleaning-in-place (CIP) applications in ballast water systems, including UV and electro-chlorination types, and for prefilter/filter cleaning. The product effectively removes scale, metal oxides, and iron rust with superior dispersing performance while being low in toxicity, phosphate-free, and non-marine pollutant. It features a low-foaming formulation for ease of use, safer handling compared to stronger acids like sulfuric and hydrochloric acid. It can also be used for manual cleaning and is formulated to reduce precipitation and redeposition of removed deposits.

Descalex

Product number: 654715

Fuel system cleaning

Proper maintenance of the fuel system ensures reliable engine performance and protects against contamination from poor fuel quality. Over time, separator discs and filter elements can accumulate varnish and deposits that restrict flow and reduce efficiency. Regular cleaning helps prevent blockages, maintains fuel purity, and safeguards engine components from costly damage.

Fuel oil separators

Disclean

Disclean is a water-based blend of inhibited acids, surfactants, and emulsifying agents formulated for cleaning heavy, tenacious deposits from fuel and lube oil centrifugal separator discs. It effectively removes these deposits without requiring dismantling of the disc stacks. The product is acid-based, nonflammable, free from nonylphenol ethoxylates or estrogenic compounds, and approved for use in engine rooms by Marinfloc AB. Disclean leaves no film or residue, reduces system downtime, and cleans down to metal surfaces. It is not recommended for use on zinc, tin, galvanized surfaces, or anodized aluminum, and the Chemical Cleaning Unit can be used to enhance cleaning of disc stacks by forced circulation.

Product number: 571687

Lube/Fuel oil filters (soaking method)

Filtercare

Filtercare is a heavy-duty cleaner and degreaser based on powerful petroleum solvents and self-splitting emulsifiers, specially designed for cleaning fuel filters, pre-heaters, burner tips, and other machinery parts. It provides quick penetration and solvency, allowing the slop water to break into separate oil and water phases after use. This enables oil residues to be reclaimed and incinerated on board, reducing disposal costs and environmental impact. Filtercare contains no chlorinated solvents and is not compatible with rubber or synthetic rubber, and it should not be used in ultrasonic cleaning units. It has a flash point above 61°C.

Product number: 769915

Filter & other machinery parts cleaning (inside ultrasonic unit)

Ultraclean GO

Ultraclean GO is a water-based, high alkaline cleaner designed for ultrasonic cleaning applications. It is highly effective at removing grease, fuel oil, lube oil, soot, and combustion residues from filters, filter parts, machinery parts, pump components, and valves. The product is readily biodegradable, low toxic, non-flammable, and free of hydrocarbon solvents and phosphates. Ultraclean GO keeps loosened deposits suspended to prevent re-deposition, is economical in use, easy to handle, and safe for use on aluminum materials.

Product number: 571321

Electrical equipment & parts

Cleaning electrical components and motors is vital for maintaining reliable operation and extending the service life of onboard electrical systems. Regular removal of dust, oil, and oxidation prevents short circuits, overheating, and efficiency loss, helping ensure stable performance and longterm equipment protection.

Electrosolv-E

Electrosolv-E is a powerful, non-chlorinated solvent specifically formulated for cleaning and degreasing electrical equipment and components. It features a controlled evaporation rate for rapid penetration and efficient removal of grease, dirt, and contaminants without leaving moisture or film residues. It is non-corrosive, safe for use on most electrical insulation and components, and tested to DIN-57370 standards with a high breakthrough voltage of 209 KV/cm. The product is suitable for cleaning electrical motors, generators, switchgear, control panels, and electronic devices and can be applied by brush, swab, or fine spray. Caution is advised to avoid use on running motors or generators and to prevent use near open flames during spraying.

Product number: 604389

Soot & wax deposits

Soot deposits typically result from inefficient combustion in engines or heating systems, often caused by poor fuel quality or incorrect air-to-fuel ratios. When expelled, soot can settle on deck surfaces, sometimes mixed with oil residues. Environmental factors such as humidity and temperature can intensify adhesion, making removal more difficult. Regular cleaning and prompt spill response are essential to prevent staining, surface buildup, and maintain deck appearance and safety.

Aquatuff

Aquatuff is a heavy-duty, highly concentrated water-based alkaline cleaner suitable for multiple cleaning applications such as removal of greases, waxes, vegetable and animal oils, sludge, soot, carbon deposits, dirt, and grime. It is biodegradable, free from hydrocarbon solvents and nonylphenol ethoxylates or other estrogenic compounds, and safe for epoxy coatings. Aquatuff is particularly effective for removing wax deposits and soot from inert gas systems. It can be applied by brush, hand spray, or high- and lowpressure washing.

Product number: 607826

Cleaning equipment essentials

Keeping your engine room safe, efficient, and reliable means having the right cleaning equipment to do your job effectively. With Unitor cleaning equipment, you can reduce downtime by keeping machinery clean and operational, work more safely by avoiding exposure to oil, grease, and harmful residues, and save time with efficient solutions that make maintenance easier and less labourintensive—allowing you to focus on running the vessel smoothly.

Ultrasonic cleaning machines

Ultrasonic cleaning machines make maintenance faster, safer, and more effective. They reach even the smallest crevices, removing oil, rust, scale, bio-fouling, and other contaminants from filters, valves, pumps, nozzles, and precision components, ensuring your engine room stays in top condition.

Aeroflow double diaphragm pumps

The Aeroflow double diaphragm pump is a reliable and robust solution for transferring a wide range of liquids on board, including chemicals, water, and cleaning solutions. Its airoperated design ensures safe operation without electricity, while the durable construction handles continuous use in demanding marine environments. With high flow capacity, chemical resistance, and low maintenance requirements, it allows you to move liquids efficiently, safely, and precisely, supporting cleaning, circulation, and maintenance tasks throughout the vessel. Comparison table

1. All pumps are being supplied with Fluid & Air barbs, and Collar Clamps. 2. Atex Z1 ALU pumps are supplied with Fluid & Air barbs, Collar Clamps, and Bonding Ground Set. 3. 1/2” SS Pump is supplied as a stand-alone pump.

Chemicals Dilution Station

The 4 Chemicals Dilution Station is a robust and efficient dosing unit designed for heavy-duty use. This advanced system features a durable stainless-steel housing, making it ideal for handling both acid and caustic-based chemicals. With its user-friendly push-button operation, it’s simple to use yet highly effective for nearly any dilution control requirement. Capable of mixing up four different chemicals.

Chemical Pump Lever Type

The lever chemical pump provides a simple, cost-effective way to transfer small to medium quantities of liquids from barrels, drums, or pails. With its easy-to-use design and compatibility with solvents and chemicals, you can quickly move cleaning agents or other liquids wherever needed on board. This helps you save time, reduce spills, and handle chemicals safely, making daily maintenance and cleaning operations more efficient.

Product number: 637447

Chemical Cleaning Unit

The Chemical Cleaning Unit provides thorough cleaning of onboard systems such as heat exchangers, boilers, pipelines, and tanks without dismantling equipment. With its mobile circulation design, built-in stainless steel pump, heater, and chemical-resistant hoses, you can perform CIP (CleaningIn-Place) operations using acidic, alkaline, or solvent-based chemicals. This helps you maintain optimal performance, prevent fouling and corrosion, and protect your critical equipment on board.

Product number: 572060

Jet Spray Unit

The Jet Spray Unit allows you to safely and efficiently apply cleaning chemicals, degreasers, and electro-solvents on board. Its robust stainless-steel design, 10-liter tank, and ergonomic pump make it easy to carry and operate, even in tight spaces. You can quickly pressurize and spray pre-mixed solutions over surfaces, decks, and machinery, ensuring effective cleaning while minimizing chemical.

Product number: 572085

Spray Gun

The Spray Gun allows you to efficiently apply Electrosolv-E and solvent degreasers with precision. Its adjustable nozzle lets you control the spray from a fine mist to a solid jet, making it ideal for cleaning machinery, components, and hard-to-reach areas. By enabling safe, controlled chemical application, it helps you save time, and reduce waste.

Product number: 592568

Safe Chemical Handling Protection PPE Kit

The Safe Chemical Handling Protection PPE Kit ensures you can handle and apply cleaning chemicals safely on board. It includes chemical-resistant gloves, splash-proof apron, face shield, and goggles. By providing full protection against splashes, fumes, and accidental exposure, it helps you carry out cleaning and maintenance tasks confidently while reducing the risk of injury and chemical hazards.

Product number: 734781

Product number: 778862