Enhancing Indoor Air Quality Onboard Marine Vessels

Addressing air quality challenges at sea

In recent years, the maritime sector has made notable strides in reducing greenhouse-gas emissions and advancing decarbonization efforts. However, another critical aspect of Environmental, Social, and Governance (ESG) compliance has received less attention – ensuring safe and healthy onboard environments for seafarers.

While achieving emissions targets is essential, safeguarding IAQ is equally vital for protecting human health. The importance of this cannot be overstated for seafarers who often spend months at sea, making their onboard environment their primary living space.

Recent research conducted by the School of Engineering and Built Environment at Griffith University, Brisbane, Australia, underscores the effectiveness of Tea Tree Oil (TTO) in significantly reducing airborne bacterial and fungal aerosols. Controlled experiments featuring the Unitor™ Duct Air Treatment (DAT) and A/C Unit Air Treatment (AAT) demonstrated remarkable antimicrobial results, achieving over 73.5% inactivation of microbial aerosols within the first 24 hours, and up to 98% within 7 days.

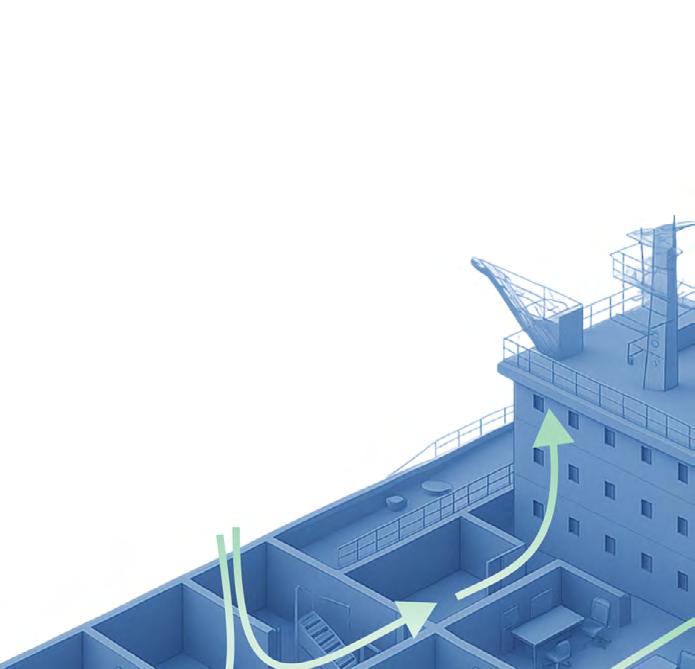

In accordance with MLC 2006 Guideline B3.1.2; Ventilation, air-conditioning systems, whether centralised or individual, must be designed to facilitate easy cleaning and disinfection to prevent or control the spread of disease.

Marine Heating, Ventilation and Air Conditioning (HVAC) systems, when poorly maintained, can become breeding grounds for harmful microbes. This is particularly challenging in humid and warm climates, where allergens such as mould, bacteria and viruses can multiply rapidly, posing both immediate and long-term health risks.

73.5% – 90.3% within the first 24 hours Over

Using advanced monitoring techniques, researchers meticulously tracked bioaerosol concentrations in sealed environments, including small rooms and large laboratory spaces. The study reveals:

High effectiveness against airborne bacteria and fungi.

Additionally, the experiments highlighted its ability to neutralize odour-causing compounds and inhibit microbial growth, contributing to improved air quality. inactivation of microbial aerosols

The gradual release of TTO vapours ensured prolonged antimicrobial action, making the solution suitable for diverse indoor environments requiring stringent bioaerosol control.

These findings are particularly relevant for improving Indoor Air Quality (IAQ) in the maritime industry, where confined spaces and limited ventilation can exacerbate health risks for crew members and passengers.

Why IAQ matters

IAQ is frequently overshadowed by more tangible aspects of ship operations, but maintaining good air quality is essential for crew health and comfort, as well as operational efficiency. Poor air quality, caused by factors such as inadequate ventilation, pollution from engine emissions and bacteria/mould in HVAC duct systems, can lead to a range of health issues. These include respiratory conditions, headaches, fatigue and other conditions that can potentially compromise daily performance.

The American Thoracic Society and other health organizations confirm that exposure to particulate matter and Volatile Organic Compounds (VOCs) can significantly affect respiratory health, particularly in confined environments like ships. Studies indicate that pollutant levels onboard vessels can be two to five times higher than outdoor air, making proactive IAQ management essential.

In the maritime context, prolonged exposure to subpar air quality can impair crew alertness and decisionmaking, increasing the likelihood of accidents. Recent findings by the International Maritime Organization (IMO) also link poor IAQ to reduced productivity and increased absenteeism.

Combatting bacteria and infection risks

Mould and bacteria present serious health risks, requiring proactive measures to protect crew and passengers from exposure to airborne spores. Left untreated, mould growth in HVAC ducts can worsen air quality and trigger respiratory issues and allergic reactions.

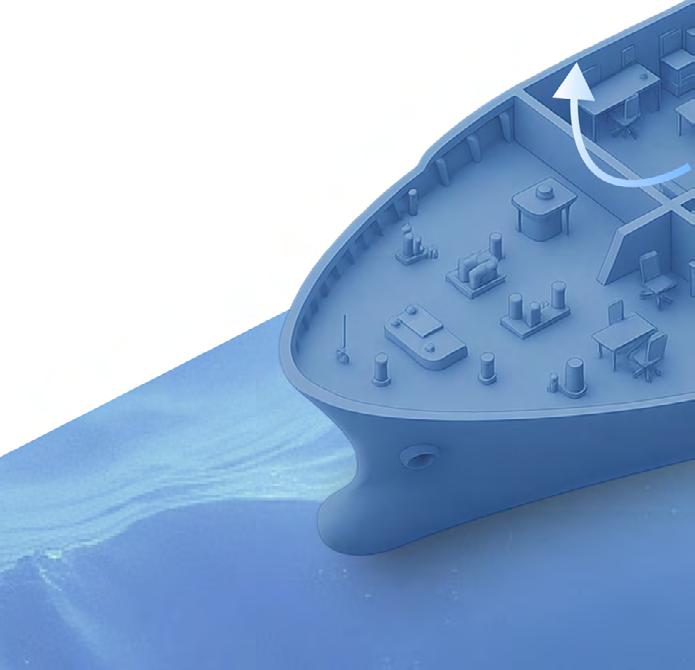

The integration of Duct Air Treatment (DAT) units and A/C Unit Air Treatment (AAT) into onboard HVAC systems is a powerful solution for addressing these challenges. These systems prevent mould growth, neutralize bacteria and reduce viral activity. Additionally, DATs eliminate unpleasant odours at the source rather than merely masking them, maintaining a fresher and healthier onboard environment.

Headaches

Respiratory Conditions

Fatigue

Other conditions that can potentially compromise daily performance.

Tea Tree Oil: nature’s powerful remedy

The Unitor Duct Air Treatment and A/C Air Treatment is made of a natural complex polysaccharides surfactants, purified water and pure Australian Tea Tree Oil. The natural antimicrobial qualities in Tea Tree Oil make it highly effective in controlling bacteria, mould, and odour-causing compounds within HVAC systems of ships.

Unlike harsh chemical biocides, Tea Tree Oil is non-toxic, biodegradable, and sustainable, ensuring prolonged microbial control without leaving harmful residues. Its gradual vapour release technology, as applied in Unitor™ air treatment products, delivers continuous protection by neutralizing microbes at the source and maintaining fresher, healthier air, ensuring seafarers with quality air management in compliance with Maritime Labour Convention (MLC, 2006), Regulation 3.1 requirements.

Tree Industry Association (ATTIA), ensures the highest product standards by sourcing pure, organically grown, ATTIA COPcertified essential oil from the Tweed Valley in New South Wales. Rigorous testing is performed in compliance with international chemical composition standards.

Scientifically proven efficacy

The experiments conducted at Griffith University demonstrated that TTO vapours delivered through Unitor™ DAT and AAT achieved 73.5% to 90.3% microbial inactivastion for bacteria and mould within 24 hours, with near-total eradication by day seven. The tests were performed in controlled environments designed to closely simulate real-world application conditions.

The findings revealed that TTO vapours effectively inhibit microbial growth while neutralizing odours and maintaining a fresher atmosphere. This not only contributes to compliance with health and safety standards but also supports crew well-being and operational efficiency. The controlled, gradual release of TTO ensures prolonged antimicrobial action, positioning it as a scalable solution for maintaining IAQ.

Biodegradable

Up to 98%

Inactivation for bacteria and mould within 24 hours, with neartotal eradication by day seven

Unitor™ DAT and AAT is compatible with all HVAC systems, including ducted systems, air handling units, and packaged air conditioners, making it adaptable for a wide range of marine environments.

Conclusion

The maritime industry has made remarkable progress in addressing environmental concerns, but IAQ improvement remains a crucial frontier. Ensuring safe and healthy onboard air quality is essential for safeguarding seafarer and passenger health, improving operational efficiency and supporting ESG compliance.

WSS, through its innovative use of Australian TTO in Unitor™ DAT and AAT, is setting new standards for IAQ control, offering both a natural solution and scientifically proven results for a healthier maritime environment.