ANDRITZ: Automatic tail threading: keeping skilled personnel safe

ANDRITZ: Automatic tail threading: keeping skilled personnel safe

Raw material and energy efficiency, combined with circularity, play an important role in pulp production. Our shared target is optimized performance with maximized reliability and low operating costs.

Together, we can create more high-quality pulp and other value-adding products with less raw material, less chemicals and produce renewable energy.

Valmet offers a unique combination of innovative process technologies, automation, flow control solutions and services to move your pulp production forward.

Explore valmet.com/pulp

Welcome to the May-June issue of Pulp Paper & Logistics, which incorporates our regular section covering the latest developments in green packaging.

Fibre-based green packaging enables products as diverse as food, drinks, and fast-moving consumer goods and industrial products to be transported safely while offering the best possible recyclability and sustainability. It is one of the drivers for our industry’s expansion, replacing materials that contribute to unnecessary or unrecyclable waste.

Consumers are increasingly aware of the benefits of recycling, but some still need help in their choices. That’s why those who are tasking packaging designers continually push the boundaries of what’s needed to deliver a sustainable and effective packaging strategy.

In food packaging, designers are having to now select a packaging base material that will enable a barrier to be easily removed by the consumer to enhance recyclability.

These demands will hopefully feed back to both the pulp mills and their in-house production teams to evaluate the specification and achievability within the mills’ own systems.

For our next issue, July-August, we invite contributions on the following subjects – machine clothing developments, recycling processes and recovery, and paper recovery systems – which should be emailed to me no later than 18 July at pulppaperlogistics@ virginmedia.com.

Vince Maynard, Publisher and Editorial Director

Hydrogen powers ships with electricity in pilot test at the Port of Gothenburg

Staying ahead in tissue line operations

Automatic tail threading: keeping skilled personnel safe

Real progress in decarbonisation: pulp and paper’s journey to net zero GREEN PACKAGING

Paper-based packaging for barbecue starters

Vol. 15 Issue No. 90, May/June 2025

ISSN 2045-8622 (PRINT)

PUBLISHER & EDITORIAL DIRECTOR

Vince Maynard

Tralee, Hillcrest Road, Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724

http://www.knockoutprint.co.uk Front cover: See page 12

Mobile: +44 (0) 7747 002286

Email: pulppaperlogistics@virginmedia.com

Email: pulppaperlogistics@outlook.com

EDITOR

John Nutting

Tel: +44 (0) 1732 868071

Mobile: +44 (0) 7860 221486

Email: johnnutting47@gmail.com

CONSULTANT EDITOR

David Young

Tel: +44 (0) 1737 551687

Mobile: +44 (0) 7785 796826

PRODUCTION

Anthony Wiffen

Tel: +44 (0) 1460 261011

Mobile: +44 (0) 7851 612799

Email: anton_print_1@mac.com

PRINTER

KNOCK OUT PRINT

+44 (0) 1892 823540

Unit 2 The Coppice, Petteridge Lane, Matfield, Kent TN12 7LP

info@knockoutprint.co.uk

Following International Paper’s (IP) completion of the acquisition of DS Smith at the end of January, the US-based world-leading pulp and paper giant has started rationalising and consolidating its operations on both sides of the Atlantic.

In April, Germany’s Palm Group offered to buy five corrugated box plants from IP, a move that would satisfy the requirements of the European Commission following the DS Smith acquisition.

The five plants comprise three in Normandy: two box plants in Saint-Amand and Mortagne, and a sheet plant in Cabourg; a box plant at Ovar in Portugal and another at Bilbao in Spain. The closing of the sale is expected by the end of the second quarter of 2025.

“Finding the right buyer for these five facilities has been a top priority for our team since the completion of the acquisition of DS Smith, and I’m pleased that we have found one in PALM,” said IP’s chief executive Andy Silvernail. “We are grateful for the many contributions the team members at these five plants have made to the company and know they will continue to be successful and deliver value with their new owners.”

In the UK, IP is planning to improve operational efficiency by closing five sites, about a fifth of DS Smith’s operations in the country, by the end of 2025. The move would also “address changing customer needs in difficult market conditions”. The five sites were not identified.

In addition to the closures, IP has proposed relocating one site, reducing operations seven

days a week operation to five at another location, and job cuts at two other sites.

“Although the proposals result from a strategic review by the UK business,” IP said in a statement. “They constitute an update to the intentions with respect to DS Smith set out in the Offer Documentation.”

In the US, IP has started construction of a ‘state-of-the-art’ packaging box plant at Waterloo in Iowa. The new facility will primarily focus on packaging for the protein segment.

“We are thrilled to break ground and invest in our company and the city of Waterloo,” said John Berry, group vice president at IP. “This facility represents our dedication to growing in markets where we want to compete, advancing our capabilities and ensuring our customers receive quality and reliable products.”

The facility is scheduled to start up in the fourth quarter of 2026.

On the border with Mexico, IP is realigning its operations in the Rio Grande valley so that it can “better serve its customers”.

IP will convert its sheet plant at Edinburg, Texas, to a warehouse and invest in its facility in McAllen, Texas to increase capabilities and transfer its operations at Reynosa in Mexico to a new, more modern facility that is currently under construction in Reynosa. The company will close its box plant and sheet plant at Edinburg in Texas.

“The decision to cease operations at our two Edinburg facilities while investing in McAllen

and Reynosa allows us to focus our efforts, provide excellent customer experiences and maintain a competitive cost structure that we believe positions us for profitable growth,” said Tom Hamic, president of Packaging Solutions for North America at IP.

In IP’s first quarter 2025 results it reported global sales of US$5.9 billion, up from $4.6bn on the same period a year earlier, before the acquisition of DS Smith.

But it made a net loss of $105 million, partly due to a pre-tax charge of $271 million relating to restructuring charges associated with closure of IP’s Red River containerboard mill at Campti, in Louisiana.

“This year’s first quarter results reflect higher sales and earnings, primarily driven by the DS Smith acquisition, sales price increases, and cost out,” said chief executive Andy Silvernail. “We also made good progress on growing our market position in our North American packaging business.

“Overall market demand, however, was softer than anticipated in both of our regions. In this uncertain macroeconomic environment, we are focusing on actions within our control as we accelerate our 80/20 execution to drive commercial excellence and cost out across the company.”

With headquarters in Memphis, Tennessee, USA and in London, UK, IP employs more than 65,000 staff worldwide with operations in more than 30 countries. Net sales in 2024 were $18.6bn.

Initiatives that showcase paper’s enduring relevance in today’s increasingly digital world are being supported by Sappi. By partnering with industry organisations and educational institutions, the European arm of South Africa-based global paper maker Sappi is actively working to address misconceptions about paper, highlight its environmental credentials, and ensure its place in modern communication strategies.

For the first time in France, Sappi and a collective of graphic industry players have joined forces with the GMI (Groupement des métiers de l’Impression et de la Communication) to launch a national campaign to promote paper and print.

The aim of this campaign, targeting the general public, is to highlight the value of paper. Four campaign visuals tackling misconceptions head-on have been developed, covering the four most common stereotypes about paper, deforestation, recyclability, and understanding. The campaign uses a paper superhero to spread the word through a 360 degree campaign. These visuals have also been relayed on social media, targeting especially young people, who are non-paper native audiences, demonstrating paper's vital role in a sustainable future.

The ‘OrigAMA la carta’ campaign in Italy represents another key educational initiative, reaching more than 1,000 students across 15 schools and universities. Led by a coalition of paper industry, printing, and graphic arts associations, this project challenges students to develop creative campaigns promoting paper's

Flavio Froehli, sales and marketing chief at Sappi Europe – “initiatives demonstrate how our sector has evolved beyond simply producing paper to driving genuine environmental change”

environmental credentials.

Sappi contributes through both manpower and expertise, helping to guide the project's direction and development. The initiative has produced impressive results, with more than 400 students participating in the design competitions and a winning campaign that was implemented across several channels including metro posters, newsstand displays, and social media. The campaign creatively uses origami animals to convey how the paper industry protects forests, with the Italian message ‘Chi vive del bosco, lo protegge! Così fa anche la carta’, or Those who depend on the forest protect it.

Meanwhile, in the German market, Sappi supports the WE.LOVE.PRINT initiative, a movement dedicated to strengthening the print industry and positioning it within omnichannel communication frameworks. The initiative educates society about the values of print and sustainability while providing training

In Germany Sappi supports the WE.LOVE. PRINT initiative, dedicated to strengthening the print industry

opportunities in the graphic arts industry.

“In a world facing urgent environmental challenges, the paper industry stands as a model of transformation,” says Flavio Froehli, vice president of sales and marketing at Sappi Europe. “These initiatives demonstrate how our sector has evolved beyond simply producing paper to driving genuine environmental change.

“We’re achieving measurable reductions in carbon emissions, leading in circular economy practices, and educating future generations about sustainable communication choices. It’s about showcasing how an industry can adapt and thrive while meeting crucial sustainability goals.”

Through these combined initiatives, Sappi says it is strengthening the foundation for paper’s future as a renewable and sustainable medium. As the industry continues to innovate in production methods and circular economy practices, it sets new standards for environmental responsibility in manufacturing.

A long-running dispute over control of Brazilian pulp producer Eldorado Brasil looks close to being resolved.

For more than seven years, J&F Investimentos and Paper Excellence have been launching lawsuits against each other in the ownership tussle.

But at the end of May, Brazil’s Supreme Federal Court approved a joint request from

both former partners in the pulp producer to withdraw all ongoing lawsuits before the court, according to a report by Valor International.

Under the agreement, reached outside the courts, J&F has acquired Paper Excellence’s indirect 49.41% stake in Eldorado for US$2.64 billion (R$15bn) in cash.

“This transaction fully meets the interests of both parties and definitively ends all ongoing

court and arbitration proceedings,” the companies said in a joint statement. Sales at Eldorado Brasil Cellulose in 2024 were R$6.37 billion (US$1.12bn), 11 percent up on the year earlier, on the back of pulp prices that were on average 9 per cent higher than in 2023. This was despite the company’s pulp volumes for the year dropping 6 percent to 1.76 million tons.

The European pulp and paper manufacturing sector, the fourth largest industrial user of energy in Europe, has achieved a 46 percent reduction in carbon dioxide (CO2) emissions since 2005, successfully decoupling growth from potential climate impacts.

However, the EU Emissions Trading System (EU ETS) mandates further reductions, targeting a 62 percent decrease by 2030, with even steeper cuts required in the future. To meet these ambitious goals, the pulp and paper industry has for the past five years enlisted the expertise of professionals across renewable energy engineering, finance, and regulation, through its ‘Energy Efficiency Solutions Forum’ (EESF). Currently, the pulp and paper industry invests more than €5 billion a year, primarily in clean

energy systems. The EU Clean Industrial Deal, announced in February, aims to support such initiatives, which in the pulp and paper industry can yield several hundred million euros in investments and result in hundreds of thousands of tonnes of annual CO2 emissions reductions per project.

The Clean Industrial Deal, proposed by the EU Commission earlier this year, spans initiatives including green public procurement, €100 billion in funding for the deployment of decarbonisation technologies, and a ‘Bioeconomy Strategy’, to create favourable regulatory conditions for investments in Europe’s manufacturing sector. If successful, it is estimated that by 2030, the pulp and paper industry could increase its renewable on-site electricity and heat production by nearly 31 TWh, in

addition to the 50 TWh already generated today.

Looking beyond 2030, EU energyintensive industries, including paper producers, will need to ramp up investments in clean energy even more significantly. According to the EU Commission’s own projections, industry investments must increase by a factor of seven to meet gradually rising emission thresholds.

The REINVEST 2050 report, unveiled in April, highlights 28 real-world investment cases, already effectively phasing out fossil energies in the pulp and paper industry.

Commenting on the case studies, Jori Ringman, director general of Cepi, said: “While the urgency to act is only getting higher, we are not starting from scratch.

The REINVEST 2030 case studies serve as inspiration and proof that industrial decarbonisation

is achievable through strategic investments, innovative technologies, and a regulatory environment that reflects Europe’s commitment to a more sustainable future.

“Most importantly, it shows that collaboration and partnerships are a key factor in the success of these projects. For the paper industry, collaboration within and across value chains comes naturally and presents an example of how this could be done in other energyintensive industries.”

Smurfit Westrock, which last July was created with the merger of Smurfit Kappa and WestRock, reported first quarter 2025 sales of US$7.66 billion. Net profit was however $382 million, with a profit margin of 5 percent, slightly down on the equivalent quarter a year ago.

Commenting on the results, chief executive Tony Smurfit, said: “I am especially pleased with how well the combination has come together, with strong operational and cultural integration taking place across all three regions. Coupled with our geographic footprint and our unrivalled portfolio of innovative and sustainable packaging solutions,

Tony Smurfit, chief executive of Smurfit WestRock – actively optimising its asset base

we have a customer-focused and performance-driven team that is delivering for all stakeholders.

“Our synergy programme is on

track to deliver $400 million, with approximately $350 million in the current year. We believe there is substantial opportunity to continue to structurally improve the business through a sharper commercial and operational focus, at least equal to our synergy target.

“We continue to actively optimise our asset base. We have recently announced the closure of over 500,000 tons of paper capacity in North America. We are also closing two converting facilities in our North American region and have initiated consultations to close two of our converting facilities in EMEA & APAC.

“To consolidate our leadership position and better support our customers, we have constructed two state-of-the-art converting plants in Washington and Wisconsin and are completing a new Bag-in-Box facility in South Carolina in our North American region.

“Comparable investments in EMEA & APAC, in high-performing converting equipment, will reduce our cost base and strengthen our overall footprint in the region while in Latin America, we continue to invest in cost take-out and growth projects, for example, the biomass boiler in Colombia which is nearing completion.”

The A-ConApex continuous cooking technology by ANDRITZ is the ultimate solution for processing fines, rejects, textile waste, and non-wood materials. Achieve maximum raw material utilization, minimal waste, and the possibility to produce pulp

from almost any cellulose-containing fibrous material with this versatile and efficient system. Experience unparalleled efficiency and boost your pulp production by as much as 350 t/d with A-ConApex cooking technology, all while keeping your costs in check. For more information, visit our website.

The US paper making industry increased its average utilisation rate to 87.5 percent in 2024, a rise of almost four percentage points year-on-year, reports the American Forest & Paper Association (AF&PA).

The key figure is part of the 65th Paper Industry Annual Capacity and Fiber Consumption Survey, which provides detailed data on US paper industry capacity and production compiled by the AF&PA statistics team.

Paper and paperboard production increased 3.2 percent last year, with improvements in all categories, led by strong growth in containerboard. US paper and paperboard capacity declined by 2.0 percent in 2024, to 78.1 million tons. For comparison, the average

annual rate of decline since 2015 was 0.9 percent.

The industry continues to invest in new machines and machine conversions, particularly in the packaging and tissue sectors. Four containerboard machines came online in 2023, one boxboard machine came online in 2025, and another will start up later this year. One new tissue machine is planned for startup in the second half. However, more capacity has been removed across all sectors resulting from investments in mill system modernisation and streamlining of businesses for efficiency and competitiveness.

Containerboard capacity declined 0.9 percent in 2024. Despite three consecutive yearly declines in up to 2024, containerboard capacity continues to account for more than

50 percent of total US capacity to produce paper and paperboard.

Packaging paper capacity increased 4.6 percent in 2024 following a strong 4.8 percent rise a year earlier. For the second year, all the growth came in unbleached packaging papers while bleached packaging papers has now declined for six consecutive years.

Meanwhile, boxboard capacity declined 3.3 percent in 2024. One bleached boxboard machine came online in May 2025 following conversion from printing-writing and a recycled boxboard machine is scheduled to come online in the fourth quarter of this year as part of a new mill.

Printing-writing paper capacity fell 6.9 percent in 2024, the steepest decline since the pandemicinduced drop of 14.9 percent

Through knowledge and awareness, Visy’s corrugated board mill at Hamilton on New Zealand’s North Island has developed a positive safety culture, says its corrugator supervisor, Sandeep Ralm.

Safety on site is crucial, according to Ralm, who sees it as a matter of returning home safely. “Site safety is important, as this can often dictate whether we return home in the same shape we came in,” he explains. “The culture is a big part around safety, and by being proactive, instead of reactive, I hope this feeds a positive culture.”

Creating a strong safety culture has been a challenge, but Ralm is proud of the progress made. “The

culture we currently have is much improved from the past,” he says.

Working in different roles at the site has given Ralm an understanding of safety from multiple perspectives.

“As a leader, I need to be the one to follow safe operating

procedures and ensure PPE is used correctly,” he says. “By leading by example, I can expect the same from my operators.”

Ralm has been directly involved in several key safety projects, including the creation of standard operating procedures (SOPs) for

in 2021. After printing-writing capacity dropped below 10 million tons for the first time in 2023, the level is now less than 9 million tons. Printing-writing accounted for just 12 percent of total US paper and paperboard capacity in 2024, the same as in 2023.

Tissue capacity declined 1.7 percent in 2024. Despite the three recent consecutive year-over-year declines, the tissue share of total US paper and paperboard capacity has grown steadily compared to other grades over time, from 7.2 to 11.3 percent since the year 2000. The Survey is available for purchase online. Go to afandpa. org/statistics-resources/reports or contact statistics_publications@ afandpa.org or telephone +1 202 463 4716 for this and other industry reports.

the corrugator and competency assessments. Clear SOPs eliminate confusion and reduce the risk of errors that could lead to injury or machine damage.

“By creating these standardised procedures, not only do we increase skill levels, but we also build awareness around health and safety,” Ralm explains.

“A big focus this year is improving the SOP process, ensuring this system actively flows.”

Looking ahead for the rest of the year, Ralm’s focus is fostering a culture where everyone feels comfortable speaking up. “I want to create a culture that is based around looking after one another and doing the right thing, instead of the fastest thing,” he says.

The Confederation of Paper Industries (CPI) has published its 20242025 Annual Review: Blueprint for the Future – Charting Industry’s Drive to Sustainability.

The Review is said to capture the critical role CPI continues to play in representing and supporting the UK’s paper-based industries through a period of what it calls “profound political, economic, and environmental change”.

“2024 was a year defined by major global elections and ongoing geopolitical instability,” CPI said in a statement. “The election of a new Labour government in the UK, a second Trump Presidency in the United States, and a rightward shift across Europe’s political landscape all contribute to an increasingly

complex backdrop for industry. With continued conflicts in Ukraine and the Middle East, pressures from energy costs, disrupted trade, and subdued economic growth remain key challenges for the year ahead.

“Despite this uncertainty, CPI’s strong track record of advocacy and leadership is clear. The Annual Review highlights significant progress in key areas including environmental policy, energy policy, packaging issues, forestry, recycling, health and safety, industrial strategy, and employment. We have also redoubled our efforts on issues such as trade and skills to help build a more resilient industry for the future.

“CPI’s leadership in health and safety remains central to its mission.

As chair of the Paper and Board Industry Advisory Committee (PABIAC), CPI is driving the 2023–2027 strategy forward with a renewed focus on psychosocial risks, human factors, and accident investigation. Member engagement with the PABIAC Pledge continues to grow, and CPI remains committed to achieving full sector participation.

“Progress has also been made in shaping the business environment. Notably, CPI’s engagement with Defra on Simpler Recycling has helped to reprioritise the separate collection of paper and board — a vital move to support quality and efficiency across the recycling stream.”

Director general of the CPI Andrew Large commented: “This year’s Review underlines

Andrew Large, director general of the CPI “The challenges ahead are real”

the importance of a strong and united voice for the sector. The challenges ahead are real, but so is our capacity to respond. I am especially proud of our work on health and safety, recycling, and industrial strategy – areas where CPI has shown clear leadership and delivered tangible progress. 2025 will be a testing year, but it will also be a year in which CPI again proves its value to members, helping to secure the sustainable, competitive future our industry deserves.”

Apilot project using a hydrogen generator to supply electricity to ships docked at the Port of Gothenburg is now in its final phase. The method may pave the way for reduced emissions in other ports where conventional shore power connections are not feasible.

Powering ships with electricity instead of using their conventional engines while docked saves large amounts of carbon dioxide emissions. The first facilities for connecting ships to shore-side electricity – known as on-shore power supply (OPS) – were installed at the Port of Gothenburg in the early 2000s.

At that time, the OPS-facilities at Stena Line’s terminals for Germany and Denmark traffic

were among the first of their kind in the world.

However, many other ports in the EU and across the globe have not come as far and often lack necessary prerequisites.

Nine pioneering ro-pax ships have been ordered by the Grimaldi Group, of which Finnlines is a part.

Six vessels will be used in the Mediterranean, while three will be operated in the Baltic. Key features include reduced environmental impact and enhanced onboard comfort.

The news comes a year after Finnlines launched a ro-pax service between Malmö, Sweden and Świnoujście, Poland in April 2024. “Expectations have been well met,” Antonio Raimo, line manager at Finnlines, said.

“The new connection between these two ports complements our service and route network exceptionally well. At the same time, we have also improved our

services at the ports.”

The Grimaldi Group has commissioned the construction of the nine ro-pax vessels from China Merchants Jinling Shipyard (Weihai). The value of the new build vessels is worth a total of US$1.3 billion.

The new ships have been designed to raise the quality of maritime transport for both rolling cargo and passengers in the Mediterranean and the Baltic Sea. All nine will be equipped with engines capable of running on methanol, making them ready to achieve the ‘Net Zero Emission’ goal.

Four of the new vessels will sail under the Italian flag and be operated under the Grimaldi Lines brand, while two, under

Finnlines will be receiving low-emission vessels for its Baltic services

the Greek flag, will be deployed by the Greek subsidiary Minoan Lines. These six sister ships belong to the ‘Next Generation Med’ class and will serve routes in the Mediterranean. The other three will be delivered to Finnlines, sail under the Finnish flag and inaugurate the ‘Hansa Superstar’ class intended for

OPS systems require significant investment as well as a robust underlying electrical infrastructure in the ports.

In these ports, alternative methods are needed. Mobile hydrogen generators, like the one currently being tested at Stena Line’s Germany terminal, may offer a promising way forward.

As part of a two-week pilot project, a hydrogen-powered generator was connected to Stena Line’s existing shore power facility at the Port of Gothenburg. Using ‘green’ hydrogen as fuel, the generator supplied electricity to the vessels Stena Germanica and Stena Scandinavica while docked.

“At Stena Line, we are eager to collaborate to test new technologies aimed at reducing emissions from our industry. This project shows that there are alternative solutions for

routes in the Baltic Sea.

All nine ships will be delivered between 2028 and 2030 and will feature ground-breaking, green technology. Optimised hull and propeller designs, energy-efficient onboard power management systems (both at sea and in port), shore power readiness and the application of silicon-based hull coatings will reduce energy consumption and thereby carbon dioxide emissions per cargo unit by more than 50 percent compared to vessels currently operating on the same routes.

With length of 229 metres, the new Mediterranean ropax vessels will have a cargo capacity of 3,300 lane metres for rolling freight and more than 300 cars.

The three new builds designated for the Baltic Sea, they will be 240 metres

ports that lack the infrastructure for shore power,” says Anders Peterson, group head of port development & engineering at Stena Line.

In 2030, a new EU regulation will come into effect requiring container and passenger vessels to use OPS while at berth.

According to a study by ICCT, this is expected to reduce carbon dioxide emissions by just over one million tonnes per year.

Hydrogen as a fuel has a range of potential applications in a port context. Today, the Port of Gothenburg has a hydrogen refueling station for trucks, hydrogen-powered work vehicles are currently being tested, and the technology used in the current OPS trial has also recently been used in the port by Skanska to power heavy machinery in a major terminal expansion project.

long, with a cargo capacity of 5,100 lane metres for rolling freight plus 90 cars, and accommodation in 320 cabins for up to 1,100 passengers.

“With the order of these nine extraordinary ro-pax vessels, we continue and strengthen our long, successful alliance with China Merchants Group, an outstanding partner for the building of cutting-edge ships,” said Emanuele Grimaldi, managing director of the Grimaldi Group.

“The exceptional performance in carbon dioxide emission reduction and the use of methanol as an alternative fuel brings our group even closer to the global goal of net-zero emissions, further solidifying our position as a leading player in short-sea transport in the Mediterranean and Baltic regions.”

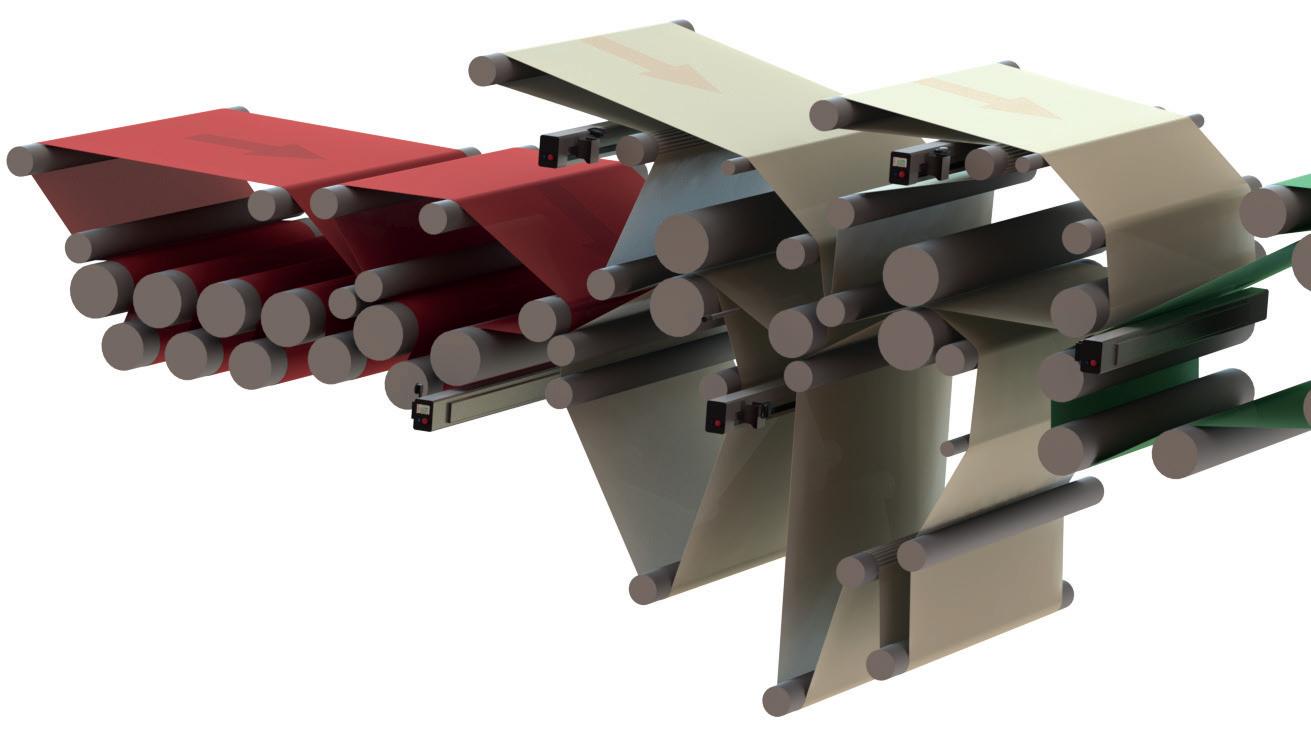

Kris De Leener (KDL), one of Belgium’s leading logistics service providers, is equipping its new 18,000 sqm warehouse in the Lokeren logistics corridor near Antwerp with a highperformance automated storage and retrieval system (ASRS) from Movu Robotics.

At the centre of this new facility will be Movu’s Atlas shuttle system, engineered to manage more than 22,000 pallet locations in high-density racking, alongside over 10,000 conventional positions. The system is fully compatible with both Europe and Industrial pallets — including those with significant overhang — and designed for heavy-duty handling of up to 1200 kg per unit.

The facility’s architecture supports both efficiency and flexibility: with a free internal height of 15 metres, 20

loading docks, and a dedicated temperature-controlled cell, the building is suited for crossdocking, diverse product handling, and multi-client operations.

The new development builds on the success of KDL’s current automated high bay warehouse which continues to play a central role in the company’s daily operations. By integrating both sites within the same logistics ecosystem, KDL ensures maximum synergies in flow, labour, and IT.

“The decision to again collaborate with Movu was a natural one,” said Kris De Leeneer, chief executive of KDL. “We’ve experienced first-hand how their automation enables smarter, more responsive logistics. This next phase will strengthen our capacity to serve customers with speed, precision, and sustainability.”

Movu’s Atlas shuttle system will manage more than 22,000 pallet locations in high-density racking at Kris De Leener’s new warehouse in Belgium

Maintaining excellence in the operation of tissue lines is key to high productivity. What should mills expect to achieve from a full-service supplier like Valmet?

In today’s industrial landscape, where maximum efficiency and competitiveness are paramount, a crucial question arises for tissue manufacturers: how can machine performance be maintained over time at the same levels achieved during the startup phase?

It is precisely in the postcommissioning phase that the most critical challenges emerge. The main hurdle is maximising the effectiveness of the current equipment in operation, ensuring operational continuity which translates into measurable operational excellence based on OEE indicators – productive performance, quality and availability.

In the management of continuously operating assets, a reactive approach is no longer viable: it is crucial to stay ahead by adopting a proactive vision, capable of preventing critical issues with a maintenance strategy tailored to the actual risks of unplanned machine downtime. In this scenario, client expectations towards machine manufacturers are also evolving:

technology is now merely the starting point and what truly makes the difference is the ability to offer services that generate value throughout the entire lifecycle of the equipment.

Valmet’s tailored approach

In an industrial context, where operational costs, efficiency and sustainability represent strategic levers for competitiveness, relying on a structured Performance Service Programme nowadays holds the value of an actual fourth production factor, alongside capital, labour and raw materials.

Franco Franceschi, performance services & digital sales manager, explains: “The results speak for themselves: companies that have chosen Valmet’s Performance Service Programme have achieved tangible improvements in terms of productivity, quality and overall profitability, with a direct impact on return on investment.

“Three concrete examples prove this: in Algeria, the adoption of the programme led to a 45 percent increase in log production; in a plant located in El Salvador, performance was improved by 27 percent over two years; and in the UK, in one of the most recent interventions, we achieved 100 percent efficiency, fully meeting the performance target set by the client.”

At the core of this approach lies a structured and continuous collaboration between Valmet and the customer. The programme originates, in fact, from discussions with each player in the tissue sector to define expectations, share goals and

build tailored paths aimed at maximising the overall equipment efficiency (OEE) of converting and packaging lines. In this regard, the Performance Service Programme brings together all essential services, consolidated best practices and Valmet’s technical know-how into a single suite.

The Performance Service Programme goes the extra mile: Four phases, one commitment

Valmet’s Performance Service Programme is structured into four closely interconnected phases, designed to ensure continuous and personalised support throughout the entire performance optimisation process.

First phase – Initial analysis and definition of priorities

The first phase is dedicated to an in-depth analysis of the initial situation, where the Valmet team examines the history of technical interventions already carried out

and collects updated information on any upgrades or modifications made to the production lines.

Subsequently, through a preliminary remote consultation, an initial list of critical issues identified internally by the customer is shared, clarifying their expectations to establish a mutually agreed list of priorities and objectives on which to base the programme’s action plan.

and definition of targeted actions

The second phase involves an onsite visit to the client’s production facility, to gain a complete and direct understanding of the operational conditions of the running line. By observing the system in action, the Valmet team identifies any inefficiencies and intervenes in a targeted manner. Firstly, they optimise the system mechanically, electrically and in terms of software updates.

Secondly, they address any potential skill gaps, and, if necessary, replace critical components or update the system. The intervention goes beyond problem resolution but also aims to enhance in-house competencies, fostering a more efficient, informed and proactive work environment.

“Truly understanding a client’s needs means being there, closely observing the operational reality and establishing an open and continuous dialogue. During field activities, what makes the difference is attention to detail: each line has its specific characteristics, and only through interaction with operators can we grasp what truly impacts performance,” emphasises performance center trainer Iacopo Giannecchini.

His fellow trainer Gabriele Salotti adds: “But the real change occurs when we transfer knowledge and tools that enable the client’s personnel to work better, with greater awareness and autonomy, ultimately maximising the peak performance of the equipment.”

The third phase is dedicated to measuring and monitoring the results achieved. All activities are documented in detailed visit reports available on the Valmet portal, serving as a tool for continuous dialogue with the client and planning the next steps.

Any pending activities, technical recommendations regarding spare parts or obsolete components, are meticulously recorded to keep performance under control and ensure full traceability of interventions.

The fourth and final phase is focused on continuous support between interventions. During this period, the client is never alone and can rely on the excellence of the Expert Online Service, a 24/7 service designed to provide timely assistance.

A dedicated team responds

quickly to every request, ensuring constant support even in the most critical situations. In addition to remote support, periodic calls are organised to build a roadmap aimed at continuous improvement, based on experience and targeted interventions scheduled for upcoming visits.

From on-site collaboration to 24/7 support, Valmet goes the extra mile for its customers. Efficiency, quality, and availability are the three key words for those operating in the tissue sector, to which Valmet, with the Performance Service Programme, adds a fourth: trust, turning commitment into action every day.

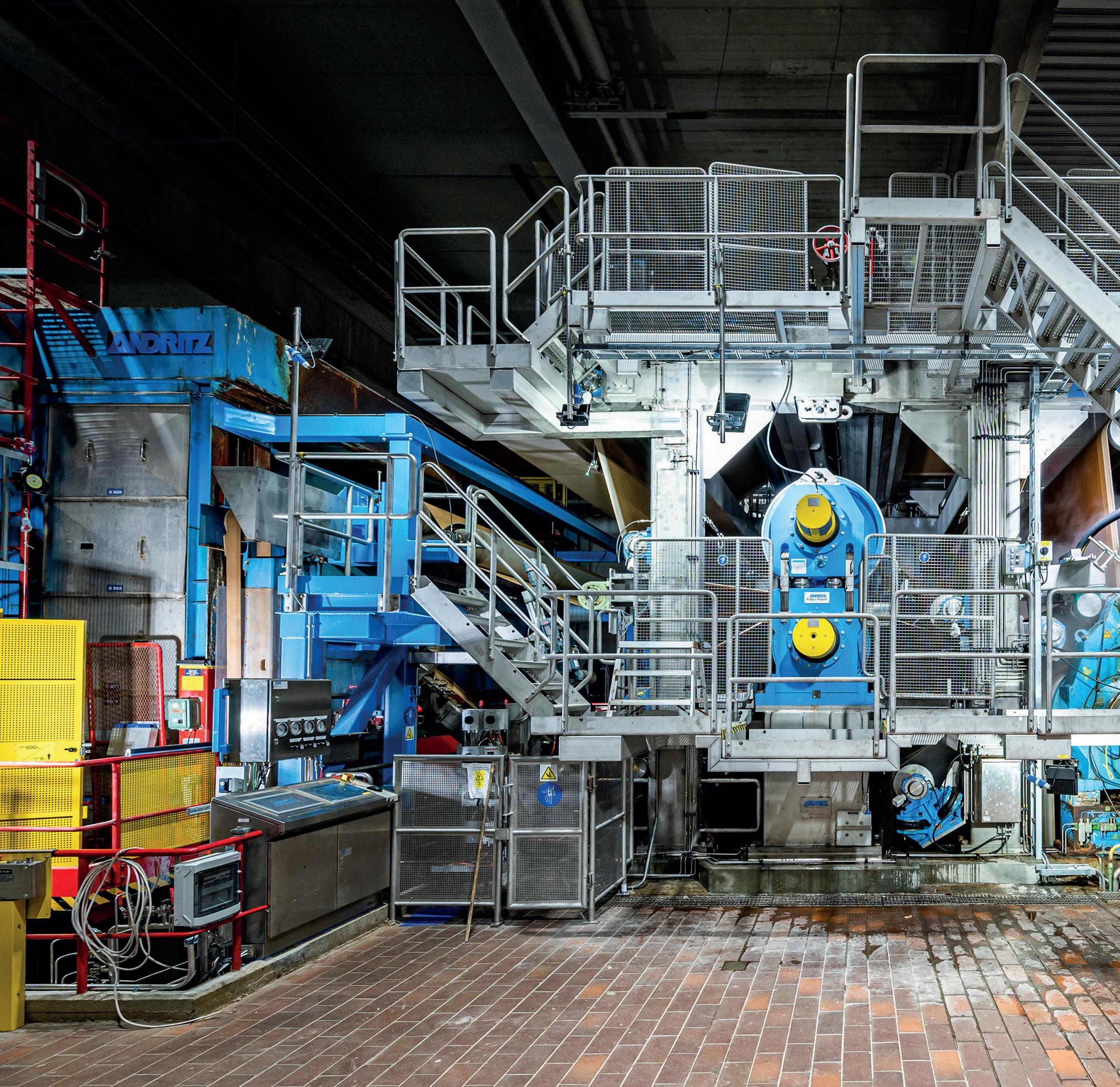

It is a credit to the skills of pulp makers across the globe that there are not more accidents reported when carrying out tail threading in the drying process. Andritz has created a full range of solutions for automated tail threading from the wet end to the cutter to avoid exposure to moving parts.

Manual tail threading in the drying process of a pulp mill exposes operators to dangerous moving systems. To improve safety and remove the risks, Andritz has developed automatic systems

“We have already been supplying Andritz automatic tail threading for dryers and cutters for decades,” says Fredrik Fors, product manager for dryers in pulp drying at Andritz. “This means that we have built up a lot of experience

in design and operation – we can even guarantee the success rate of the systems.”

To an outside observer, tail threading could look like a particularly dangerous task, especially in the wet end due to

the threading of a tail between press nips, over rolls, and other moving parts.

“The majority of all tail threading at the wet end is still done by hand,” says Michael Bloder, product and technology manager

for wet end in pulp drying at Andritz. “This is a very skilled task; the operator takes the tail and feeds it between presses and rolls.

“But this is also a dangerous task; just a slip or a trip could mean a fatality or at the least a serious injury. As the focus on safety has increased, Andritz has already

These can all be combined with centre tails as well as edge tails.”

Moreover, pulp producers are aiming to increase the safety of their employees. Personnel will no longer be exposed to running equipment and machines that, of course, directly affect tail threading procedures.

The automatic tail threaders have different designs for different stations along the line, and all are tailored individually to the particular stations. The automatic threading technology includes various solutions to ensure that tail threading takes place accurately, for example, threading tape, conveyors, a mixture of vacuums, and cushions of air.

“There are different principles needed at each threading area according to where the sheet is on the line,” says Bloder. “The wet end, for instance, demands a different format of threader sequence and technology as the sheet is much weaker, and it carries a lot more water.”

on board. All our systems have now been developed to be handsfree, which means safe feeding throughout the whole machine.”

Automatic transfer systems are supplied by Andritz for the complete pulping line that completely eliminate operational risks, providing the process with reliability and safety. Importantly, the systems also comply with all the latest safety regulations.

Added to the basic wet end transfer systems, ANDRITZ has also developed the Advanced Web Transfer for tail threading that dramatically reduces the risk of sheet breaks due to the removal of the open draw between the combi press and shoe press. In this case, the system is fully supported throughout the press section, thus leading to increased reliability.

Installations of the systems generally take just a few days, with the systems being adaptable and robust, and able to be tailored to be installed into tight spaces.

been hard at work on developing automatic tail threading for the wet end, which means the system now covers the whole line.”

Fors adds: “After a lot of development work, we now have automatic tail threading applicable to machines and equipment of any design and production processes and at a wide range of speeds.

Wet end automatic threaders are not as common in the industry, simply because demand and regulation have not yet existed for the wet end. However new regulations set to be introduced into the industry means that pulp producers will need to install automatic threaders onto the wet end in the near future. “There are relatively few installations of the tail feeders in the wet end area globally,” says Bloder, “however, we are expecting a ramp up of installations as the regulations come in.”

Fors comments: “We now have cases where pulp producing companies are not even getting permits to operate new lines without automatic tail threaders

“Installation is quite straightforward,” says Bloder. “We can basically find a unique solution for every customer as we are well aware that there is lot of variation when it comes to size and area available.

“Once running, the automatic tail feeders can be adjusted and optimised according to the process needs by simply touching a screen or pressing the start and stop button.”

Examples of tail threading system installations

Cenibra, Belo Oriente, Minas Gerais, Brazil

Andritz recently supplied an automatic tail threading system to Cenibra’s Belo Oriente pulp mill

in Brazil. The system, from dryer to cutter, was installed on the tending side of an existing Lamb cutter that was first installed in the 1970s. There were no major modifications needed during installation.

Weldon de Paula Nascimento,

Cenibra’s baling coordinator, says: “The work required to return the machine to operating status naturally demands greater attention from the operator as there are numerous actions to be carried out very close to the equipment. The system provides

Sweden. The delivery included an automatic tail threading system that operates throughout the whole pulp drying line.

Andreas Jonsson, operation specialist from SCA Östrand says: “We are really pleased with the installation of the automatic tail threading system from Andritz. The system is effective and reliable and, above all, improves safety for our operators.”

In 2021, Andritz supplied an automatic tail threading system for the wet end and drying area to Stora Enso’s Oulu pulp mill in Finland.

Pekka Kylliäinen, drying machine area manager at the OCO-project, says: “Safety of our personnel is a top priority at Stora Enso. The automatic tail threading system fulfills our needs perfectly by eliminating risk of injuries during tail threading. We are satisfied with the easy operation of the system.”

Suzano, Jacarei, São Paulo, Brazil

Andritz recently supplied an automatic tail threading system throughout the forming machine and the cutter to Suzano’s Jacarei pulp mill in Brazil.

Tertuliano Rodrigues de Lima

an increase in operator safety and has become more autonomous.”

SCA’s Östrand pulp mill, Sweden

In 2018, Andritz supplied a complete new pulp drying line to SCA’s Östrand’s pulp mill in

Neto, production manager from Suzano says: “The system has provided more security in tail threading activity as everything is now carried out automatically. The operator simply requests the process on the machine and the equipment promptly initiates the action in a continuous and safe way.“

Fabio Antero Afonso, project coordinator at Suzano adds: “The additional benefit is that the tail threading process is now more reliable in terms of process quality and standardisation.”

Stop collecting paper samples!

Improve your press section efficiency! SmartScan™ contactless sensor accurately measures paper web dryness after the press section 24 hours a day, 7 days a week. Using a proprietary microwave technology, it is developed to overcome the typical limits of the NIR (near-infrared) sensors. SmartScan™ is available both for fixed point positions or traversing web scan. To save hundred of thousands of Euros in energy costs, stop collecting samples, choose the safe accuracy of SmartScan™ technology.

Giuseppe Cristini S.p.A. Diagnostic Systems Via Bombardieri, 5 – 24020 Fiorano al Serio (BG) Italy Tel +39 035 715 111 Fax + 39 035 711 451 email diagnostic.systems@cristini.it website www.cristini.com

In the mosaic of global industry decarbonisation efforts, the pulp and paper industry holds a distinctive position. Operating at the intersection of natural resource management and energy-intensive manufacturing, the industry has both unique advantages and considerable challenges in its journey toward carbon neutrality.

While the industry relies heavily on energy and water resources to function, it possesses a sustainability advantage that few other industries can claim: its primary raw material can be sustainably grown, repeatedly recycled, and forms part of a

Although the pulp and paper industry holds strong cards as it progresses towards removing fossil fuels from its processes, the journey isn’t straightforward. Stefano Cinquina* explains why in this review of a recent ABB white paper on the subject

natural carbon cycle.

This circularity provides a foundation upon which the industry can build its decarbonisation strategy. However, the road to net zero isn’t straightforward. Energy consumption remains substantial, water usage is significant, and the transition away from fossil fuels requires coordinated action across multiple fronts.

This article presents key highlights from our latest

industry paper ‘Real Progress in Decarbonisation: Pulp and Paper’s Journey to Net Zero’. In developing this research, ABB conducted extensive interviews with numerous industry stakeholders across the global pulp and paper ecosystem. This article features insights from conversations with industry leaders including Smurfit Westrock, UPM, and Modellfabrik Papier. Through these discussions and additional research, we’ve distilled essential perspectives

on the drivers, challenges, and solutions shaping this critical industrial evolution.

Turning the page on fossil fuels

Decarbonisation represents the most significant challenge the pulp and paper industry faces today. The pulp and paper industry currently accounts for approximately 6 percent of global industrial energy use and 0.6 percent of global greenhouse

emissions – a carbon footprint exceeding the total of Denmark, Finland, Norway, and Sweden combined. Meanwhile, global production volumes are projected to surpass 460 million tonnes by 2030, up from 414 million in 2022, driven by population growth, e-commerce expansion, increased tissue adoption, and growing demand for sustainable packaging. According to the International Energy Agency (IEA), while the industry has achieved steady emissions reductions over the past two decades, further improvements in energy efficiency and accelerated fuel switching will be necessary to align with net zero by 2050 scenarios.

Drawing upon decades of environmental innovation and leveraging established expertise, the industry could accelerate its progress toward collective carbon neutrality goals by implementing practical tools and solutions that deliver immediate impact, while simultaneously maintaining sight of longer-term sustainability objectives.

The industry has developed mature sustainability strategies and implemented emissions reporting systems predating the turn of the millennium. Once considered among the most significant industrial polluters of the twentieth century, the pulp and paper industry has evolved into a leader in sustainability practices and bio-based economy principles.

Sweden’s pulp and paper industry provides a compelling example, having reduced emissions by 80 percent between 1973 and 1990. In Finland, the industry’s use of biomass as on-site fuel for manufacturing processes has meant that despite an increase of 23 percent in paper and cardboard production, there has only been a 1 percent increase in energy use in the past two decades. These Nordic region examples establish benchmark models for environmental performance and circular economy implementation.

More recent data from the Confederation of European Pulp and Paper Industries (CEPI) demonstrates that the industry has reduced fossil carbon emissions by 34 percent since 2005, with total emissions per tonne of product declining 55 percent between 1990 and 2023. Notably, the industry has established itself as the largest industrial generator and user of renewable energy, with biomass constituting 62 percent of its energy consumption.

Across the Atlantic, the US Environmental Protection Agency reports that greenhouse gas emissions from pulp and paper operations decreased from 42.2 million tonnes of CO2 in 2011 to 34.9 million tonnes in 2021 – a 21 percent reduction over a decade.

Despite this progress, the IEA reports that the pulp and paper industry is not currently on track to meet the net zero emissions by 2050 scenario. So while there is still work to be done, these achievements provide valuable precedents and lessons for companies at earlier stages in their decarbonisation journeys.

Compliance and sciencebased targets

Target validation has become increasingly important as regulatory frameworks evolve.

The Science-Based Target initiative (SBTi) provides independent validation of corporate decarbonisation pathways, offering assurance that targets align with current climate science.

This principle of external validation informs material solutions leader UPM’s Sustainable Supply Chain Strategy, published in 2023. The strategy integrates both regulatory requirements and internal standards that support UPM’s environmental, social, and governance goals. Yuanliang Hu, supplier quality and sustainability manager at UPM Specialty Papers, notes that the strategy organises sustainability efforts around ESG pillars with specific ambitions for each supply category.

“All of these aspects combine together to achieve UPM’s vision: we create a future beyond fossils,” says Yuanliang.

“The decarbonisation targets are recognised by the SBTi and also written into UPM's official agreement with its downstream

partners and stakeholders.”

For UPM, formalising sustainability expectations represents a significant milestone in the company’s environmental evolution. Says Yuanliang, “From a higher-level perspective, the strategy aims to establish common goals with strategic partners. Our development is not just driven by product price or costs. Within this scope, we hope that our cooperation can be expanded to a wider range of improvements in sustainability and circularity of products. That's our expectation. Meanwhile, the strategy also covers critical sustainability topics including human rights, occupational health and wellbeing, and zero deforestation.”

Two primary strategies dominate pulp and paper decarbonisation efforts: deploying energy-efficient technologies and transitioning to fossil-free energy sources.

Achieving net zero will require implementing both approaches in parallel.

While the industry is actively adopting renewable energy sources where feasible – including hydroelectric, solar, and wind power – regional variations in clean energy availability mean that most businesses are implementing phased transition plans.

This approach is showcased by UPM’s Changshu paper mill, where decarbonisation efforts have focused on equipment upgrades and power plant optimisation. “Since our new paper machine was launched in 2016, we have continuously carried out energy conservation and transformation projects, such as the transformation of the vacuum system in our paper machine and

upgrading of the power plant. And we have implemented an ISO 50001 energy management system to make the energy management of the whole plant more systematised,” says Wang Jue, sustainability manager at UPM. “We have also been purchasing green power to reduce our carbon emission through external means.”

For Smurfit Westrock, a globally-integrated company operating 63 paper mills and 560 converting plants worldwide, the strategy includes experimenting with diverse technological pathways and disseminating successful approaches across the organisation.

“Smurfit Westrock has a very ‘think global, act local’ mindset,” explains Jurgita Girzadiene, director of sustainability and

Better Planet Packaging at Smurfit Westrock. “As a company with a clear sustainability focus for more than two decades, we’re able to harness the benefits that come with collaboration and sharing experiences and knowledge.

“We’re actively experimenting on various technological pathways – electrification, geothermal, green hydrogen, biomethane. Having the scope and opportunity to experiment and innovate at the local level means there is great potential for solutions with global impact, while also acknowledging that every mill is unique and will operate differently to another.”

Digitalisation as a key enabler

Digitalisation represents a foundation element in

modern operations and provides essential support for sustainability initiatives. By enabling connectivity, visibility, and process optimisation, digital systems deliver both operational improvements and environmental benefits.

Importantly, digitalisation offers numerous cost advantages through the implementation of advanced solutions. Advanced process control and quality management systems enhance productivity and product quality while simultaneously supporting sustainability goals by improving efficiency and reducing energy consumption. For global operations, optimisation can significantly improve the overall sustainability footprint when implemented across

multiple facilities.

Moreover, digital technologies play a crucial role in verifying sustainability progress and ensuring product traceability. These capabilities can enhance corporate reputation and potentially enable premium pricing for products with verified sustainability credentials.

Smurfit Westrock demonstrates this approach with its digital toolkit for calculating packaging carbon footprints, including Paper to Box and Pack Expert software solutions. “We have tools that utilise the data we have captured from our global experience in the supply chain and help work out the carbon footprint of the packaging solutions we provide to customers,” notes Girzadiene. “This means when we’re

developing solutions together, we can factor in this knowledge as to how our customers might reduce emissions or realise other sustainability benefits.”

Digital simulation also supports workforce development by providing realistic training environments for operators. This capability ensures personnel are prepared to handle complex scenarios from their first day, contributing to safe and efficient operations that support broader sustainability objectives.

Control system technologies have evolved substantially in recent years, providing papermakers with comprehensive visibility and control across their value chains. Modern systems go beyond simply reducing variability to offer mills automatic process and energy consumption optimisation, while minimising waste, costs and ensuring product quality standards are met.

Sweden’s SCA Östrand pulp mill provides an instructive example. When installing a new

recovery boiler designed to generate ‘green’ electricity, the company invested in the ABB System 800xA Simulator to ensure comprehensive operator training. By creating a virtual environment mirroring the actual control system, the training ensured all operators were fully prepared to manage operations without issues.

Elsewhere, Mondi Swiecie, a leading pulp producer in Poland, partnered with ABB to implement an advanced process control (APC) solution optimising chemical and energy use while improving product quality and reducing production costs. This implementation reduced variability in the Kappa number by 56 percent, significantly enhancing pulp quality. Additionally, the company optimised chemical usage in the cooking process, achieving a 30 percent reduction in alkali losses during brown stock washing. The system also stabilised chip levels in the digester, contributing to more consistent production rates and reduced steam consumption. These case studies highlight an

essential truth: while individual mills can achieve remarkable efficiency improvements through digital systems, the magnitude of the decarbonisation challenge facing the entire sector demands a more expansive approach. The most ambitious sustainability goals will require not just technological solutions within single facilities but coordinated efforts that transcend organisational boundaries and leverage the collective expertise of the entire industry ecosystem.

As we look toward 2050 and beyond, the industry possesses significant potential to contribute to reductions in global carbon dioxide emissions while decarbonising its own operations. Realising this potential requires extensive collaboration – between supply chain partners, with government and regulatory agencies, and within industry associations worldwide. What began decades ago as incremental improvements in

emissions control has matured into a comprehensive reimagining of how this vital industry could operate within planetary boundaries while continuing to deliver essential products for society. The examples highlighted throughout this article – from Nordic mills achieving dramatic emissions reductions to innovative consortia rethinking papermaking fundamentals –demonstrate that meaningful progress is not merely aspirational but attainable. These pioneers are writing a new industrial narrative that challenges the false separation between environmental stewardship and economic viability.

Learn more about how industry leaders are driving a low-carbon future and innovative pathways to decarbonise, by downloading ABB’s industry paper, Real Progress in Decarbonisation: Pulp and paper’s journey to Net Zero, here: https://new.abb.com/pulppaper/campaigns

* Stefano Cinquina is Global Business Line Manager, Pulp and Paper, ABB Process Industries

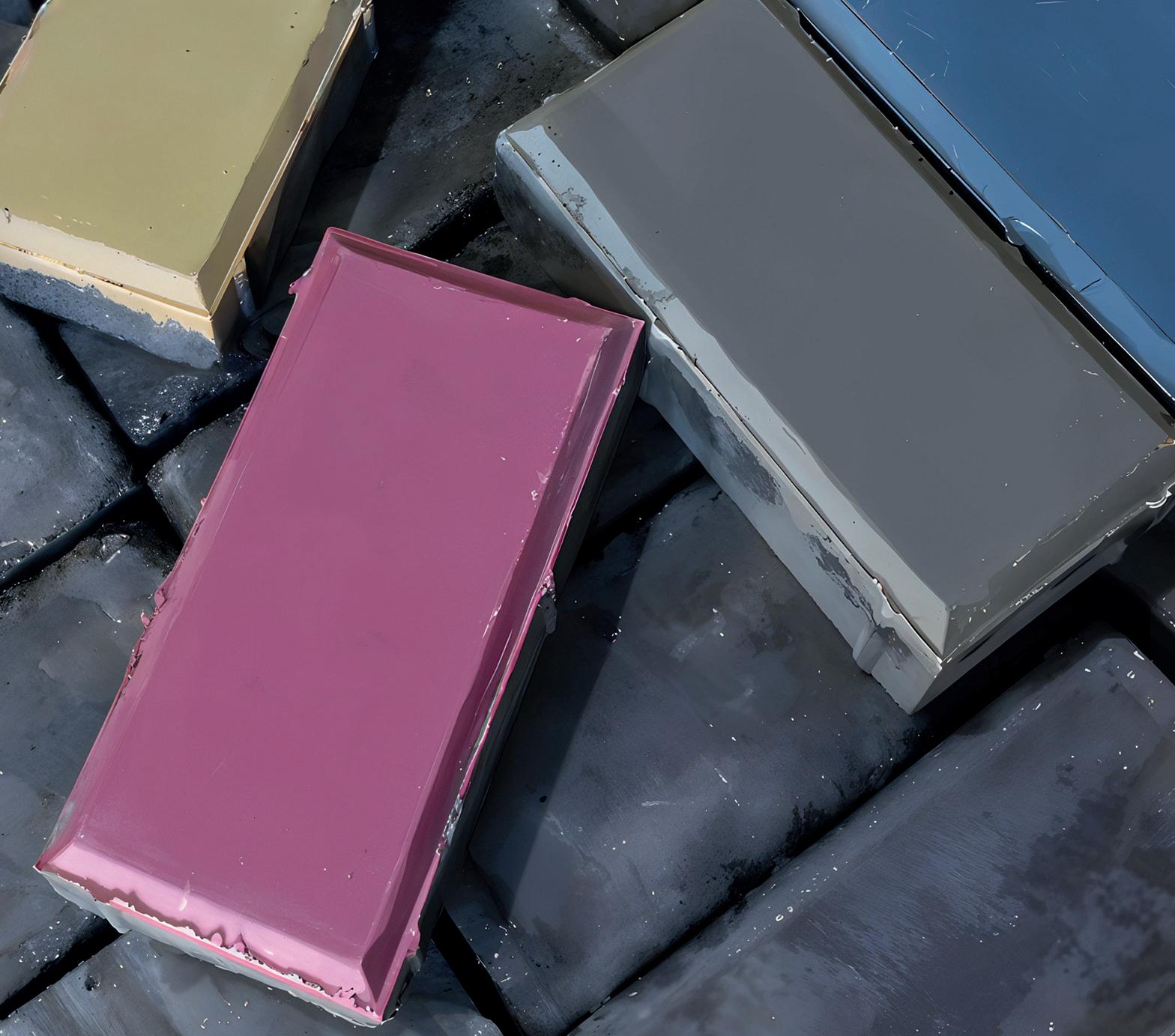

Apartnership between Mondi and Zarelo has enabled the launch of recyclable paperbased packaging for fire starters used in fireplaces and barbecues.

Made from Mondi’s re/cycle FunctionalBarrier Paper 95/5, the new packaging provides strength and durability while protecting the fire starters from moisture during storage and transport.

Mondi’s re/cycle FunctionalBarrier Paper 95/5 is produced in-house, made from FSCTM and PEFC certified paper. As part of Mondi’s re/ cycle portfolio it is recyclable in existing European paper recycling streams.

Arzberg, Germany-based Zarelo’s fire starter range includes coiled wood fibres and newlyintroduced compact cubes, packed in three sizes: 32 items, 1 kg, and 2 kg. The packaging ensures puncture resistance and

durability, protecting the products during transport and handling. Its high-quality printability enhances Zarelo’s brand visibility at the point-of-sale, strengthening its presence in retail chains.

The transition to re/cycle FunctionalBarrier Paper 95/5 enabled Zarelo to switch from

manual to an automated filling process, improving production efficiency and optimising resources. The coated paper runs smoothly on Zarelo’s vertical filling line that is converting, filling and securely sealing the paper bag without the need for additional materials such as glue.

SpA has been one of the leading distributors of print media for the graphic design, publishing,

luxury packaging, advertisement and visual communication sectors in the Italian market since 1974.

“Fire starters require packaging that keeps them dry and intact while ensuring ease of handling and storage,” said Francesco Fardella, business solution manager for Functional Paper & Films at Mondi. “This solution combines strong barrier properties with excellent printability, offering both product protection and a premium retail presence – all while supporting circularity.”

Christoph Raithel, plant manager at Zarelo, added: “Switching from cardboard to flexible paper-based packaging was a key step in improving efficiency for our filling process. Our collaboration with Mondi enabled us to scale production and expand our presence beyond Germany into international retail markets, including the UK, Italy and Poland.”

More information from www. mondigroup.com

Today, the company runs several branches in the country, including a 5,000 sqm warehouse at its headquarters in Pomezia and a specialised cutting centre for packaging. Brizzi has now added the top product in Koehler’s Greenium portfolio, Eco paper, into its offerings for customers in Italy.

“We’re tremendously proud of the fact that we’re now the official sales partner for Koehler Eco paper products in Italy, with the goal of offering luxury packaging manufacturers, high-end print shops and paper project developers a wide range of colours and grammages of premium recycled paper,” said

Messouk, Brizzi Italia’s marketing manager.

Koehler’s premium Eco paper products, made from 100 percent secondary fibre materials, open new possibilities for creative designers, print producers, premium print shops, publishers and processors of luxury packaging in Italy. Greenium is made by Koehler Paper at its Thuringian site in Greiz and is available from Brizzi in a range of colours: clay, dust, winter sky, mud, nautical blue and black in a size of 72 x 102 mm with grammages of either 270 or 350 gsm.

More information from www. koehler.com

Together with organic ready-to-eat meal manufacturer Pack&satt, Koehler Paper has developed packaging for convenience products, with its NexPlus Advanced flexible paper.

It provides protection for Einpott ready-to-eat meals due to what are described as its extraordinary oxygen, mineral oil and grease barrier properties. The meals are available in three flavours: Tomate Linse (lentils and tomato), Curry Linse (lentil curry), and Rote Bete Kartoffel (red beet and potato).

The Pack&satt ready-to-eat meals were originally bottled in returnable jars. Following customer feedback, coupled with a general overhaul of the

product, the company looked for alternative packaging options.

Founder of Cologne, Germanybased Pack&satt Sophie Gnest explains: “Our customers frequently told us that if they had an electric kettle, that meant that they also had bowls or cups available, making the jars redundant.

“In addition, we found out that using paper instead of glass to hold dry product would improve our environmental footprint. Given all that, we were tremendously happy when we found Koehler and saw that they offered the right packaging material for our needs.”

Alexander Rauer, head of business development for flexible packaging paper products at

Pack&satt is “incredibly happy” with Koehler’s NexPlus Advanced flexible paper packaging for its dry products

Koehler Paper, added: “When developing NexPlus Advanced flexible packaging paper, the focus was on making it recyclable and ensuring it would provide outstanding product protection. As a result, the paper can be recycled conventionally and reused frequently.”

This recyclability has been confirmed by the Papiertechnische Stiftung (PTS) institute with CEPI testing, as well as by environmental service provider Interzero with its ‘Made for Recycling’ seal. More information from www. koehlerpaper.com

This year the SUN Automation Group celebrates its 40th anniversary of providing innovation and industry leadership in corrugated packaging technology.

Since its founding in 1985, SUN says it has been a driving force in the industry, dedicated to providing cutting-edge technologies and unmatched customer support.

Founded by industry pioneers Lou Sardella and Pat O’Connor, what began as a small startup in Baltimore County, in Maryland, USA, has since grown into a global organisation with a reputation for pioneering advancements in corrugated production. Over the past four decades, SUN’s services and product have been installed in more than 20,000 facilities in 70 countries or more

At SUN Automation, “employees are more than just team members –they are owners” says company president Chris Kyger

“While the industry has evolved significantly over the decades, our mission remains the same: to provide the most advanced, reliable, and value-driven solutions for corrugated manufacturers,” says

Chris Kyger, president of SUN Automation Group. “Our team’s dedication to innovation and customer success has allowed us to grow and adapt alongside our customers.”

Over four decades, SUN

has advanced corrugated technology, state-of-the-art equipment engineering, and digital solutions, including Helios, the first IIoT predictive analytics platform for the corrugated industry, and the SUN625 HD, an advanced Rotary Die Cutter designed to enhance productivity and profitability.

“The legacy of innovation that began with our founders still drives us today, inspiring us to look even further ahead,” says Greg Jones, executive vice president of SUN Automation Group. “We remain committed to developing solutions that meet evolving industry challenges, ensuring our customers remain competitive in a rapidly changing market.”

More information from www. sunautomation.com

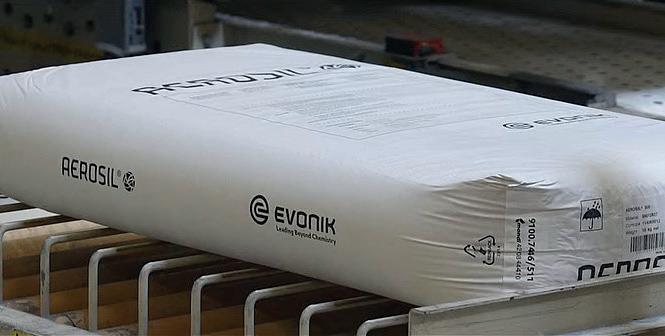

Recyclable pre-made paper bags for chemical powders have been developed by Mondi, working in partnership with chemical company Evonik.

The lightweight bag has been developed to reduce the carbon footprint of packaging for fumed silica, which is used as a performance additive in various industrial and consumer applications.

Evonik started investigating more sustainable packaging in 2022 and worked closely with Mondi to find an innovative pack. The collaboration resulted in a two-ply pre-made paper-based bag, removing a plastic-coated paper layer from the previous packaging. This means that less paper and plastic is used, resulting in an overall weight reduction of the packaging by 30 percent, compared to the previous example.

The new paper bag also has a lower carbon footprint which was assessed in Mondi’s in-house life cycle-based PIA (Product Impact Assessment) tool. Following intensive tests conducted by

Evonik, the suitability and product protection of the new bags were proven, and the bags are now launched to the market.

The new bag was created using Mondi’s high-porosity kraft paper, which is said to offer superior strength, durability and stretch. Mondi applies a small amount of spot coating to the bag, enabling Evonik to securely seal it after filling. The new bag is recyclable according to the CEPI v.3 test method and 4evergreen’s fibrebased packaging recyclability evaluation protocol.

High-quality packaging that protects the products while reducing waste is one of Evonik’s

goals. The fine powders with tailor-made properties must not only be easy and efficient to fill but also withstand the demanding conditions of vacuum chamber filling.

Mondi’s high-porosity kraft paper used for the new bags is not coated, which allows swift air release, reduces vacuum filling time, and the closing mechanism ensures tight and secure packaging, tested to meet the highest quality standards. After the filling process, Evonik palletises the bags and shrinkwraps the pallets for storage and transport.

Susanne Pellengahr, head of

sustainability transformation at Evonik’s Smart Effects business line, says: “At Evonik, we are committed to enabling transformation and going beyond the familiar. In the Smart Effects business line, we collaborate closely with our partners on projects focused on carbon dioxide reduction, portfolio transformation, and the circular economy. Our partnership with Mondi on packaging transformation exemplifies how every part of our business is aligned on the same sustainable path.”

Florian Ullrich, sales director for paper bags in Germany at Mondi says: “Valve bags are designed for high-speed filling and with sensitive contents such as these speciality chemical powders, high quality material and secure closing options are also paramount. Being able to deliver and indeed improve on these elements, while reducing the carbon footprint of the packaging, was a challenge we were delighted to answer alongside Evonik.”

More information from www. mondigroup.com/

Forestry industry company

Metsä Group and Amcor, a global leader in packaging, are collaborating in the development of threedimensional moulded fibre packaging for a variety of food applications, including modified atmosphere packaging.

Combining Metsä Group’s Muoto wood-based moulded fibre product, developed by Metsä Spring, with Amcor’s

Made from renewable wood pulp, Muoto is fully recyclable and biodegradable

advanced high-barrier film liner and lidding technology,

the partnership seeks to deliver packaging that protects perishable food products and extends shelf life.

Made from renewable wood pulp, Muoto is recyclable and biodegradable. It can be used in various applications, from take-away meals to industrial packing. By integrating Amcor’s laminated film, Muoto gains enhanced functionality, including high-performance

sealability.

The finished product will be recyclable in the paper stream in most markets, with a CEPI recyclability score of more than 80 percent. In the longer term, the ambition is to develop a fully compostable version. The first products from this partnership are expected to be commercially available in Europe later in 2025. More information from www. amcor.com

According to a recent life cycle assessment conducted by Metsä Board, switching from white-lined chipboard (WLC) to Metsä Board’s folding boxboard reduces the carbon footprint of food packaging by more than 60 percent.

The LCA study, which compared MetsäBoard Classic FBB to corresponding grades available in European markets, was verified by the IVL Swedish Environmental Research Institute.

The reduction in carbon footprint is possible due to the high share of fossil-free energy used in Metsä Board’s manufacturing process

similar products made of recycled fibres, they retain the durability and functional properties of traditional heavier grades thanks to

assessments across three key packaging segments, which include beauty care, health care, and now food packaging,” said Anne Uusitalo, director of product safety and sustainability at Metsä Board.

“These comprehensive studies offer brand owners fact-based data

and insights into the potential of our paperboards, helping them make informed decisions on how they can reduce the carbon footprint of their packaging, as well as their Scope 3 emissions.”

More information from www. metsagroup.com/metsaboard

Leibinger, which manufactures industrial coding and marking systems, is strengthening its presence in the UK through a new partnership with locally-based Rotech Machines Ltd, which provides coding systems.

This strategic collaboration enables Germany-based Leibinger to serve more effectively the UK market which is known for its high expectations for flexibility, reliability and expert consultation. In a mature industrial landscape where products and packaging must be reliably marked with batch numbers, expiry dates or other information – often at high speeds and under challenging conditions – success depends on robust, low-maintenance and user-friendly high-end technology.

At the same time, compliance with UKspecific regulations, such as UKCA marking, remains essential for long-term market access. Leibinger systems are equipped to meet these evolving demands, delivering both technical performance and regulatory compliance.

Rotech contributes in-depth application knowledge, close customer relationships and decades of experience, with a wide range of printing technologies.

“Our mission has always been to provide reliable, easy-to-use systems that meet our customers’ needs and solve their challenges,” said Richard Pether, general manager at Rotech. “Over the years, we’ve offered various technologies, from hot foil to thermal transfer and thermal inkjet, each with unique features and benefits. The Leibinger range of continuous inkjet printers is a welcome addition to our range and has been wellreceived by our customers, across many applications.”

While Rotech’s range of Thermal Inkjet (TIJ) printers remains a trusted technology for many applications, it isn’t without its limitations, particularly on high-speed production lines or in harsh or changing environments. Continuous inkjet (CIJ) systems excel in these conditions, offering the perfect complement to Rotech’s portfolio and enabling a more versatile offering that meets every customer requirement.

“We are very excited about our collaboration. I’d say this is a perfect match. Rotech and Leibinger share the same commitment: Innovative technology that delivers real value to customers, empowering them to achieve their goals – maximum productivity and efficiency. For over 75 years, this has been the foundation of Leibinger, ensuring smooth production and packaging processes,” commented Tim Richards, Leibinger’s international area sales manager. More information from www.leibingergroup.com and www.rotechmachines.com

Mondi says that its ProVantage containerboard paper grades range, available in both brown and white, will ensure that businesses are able to meet growing demand for sustainable packaging without compromising on performance.

Made from fully recycled to 100 percent fresh fibre, the containerboard papers provide a strong foundation for corrugated packaging and are also well-suited for applications like honeycomb structures and fibre drums.

Meeting packaging needs of customers in eCommerce, fresh fruit & vegetable and heavy-duty applications, the ProVantage range offers a variety of paper grades that balance strength, sustainability, and printability. The portfolio includes: appearance grades for premium printability and standout branding; kraft grades for

superior strength and protection; recycled grades that deliver a sustainable edge; and Semi-Chem grades for moisture resistance and durability, ideal for long-distance transportation

“As sustainability expectations rise, businesses need packaging that protects their products while reducing environmental impact,” explained Remy Eecke, senior value chain and sustainability manager at

Mondi Containerboard. “Our containerboard papers are 100 percent recyclable and made from 100 percent sustainably-sourced raw materials, giving brands the edge they need in a competitive, eco-conscious marketplace.”

Recent advancements by Mondi include the paper machine at the Ružomberok mill in Slovakia, which launched the ProVantage SmartKraft White paper grade in 2021. This Kraft Top White grade combines fresh and recycled fibres, offering both strength and printability for brands looking to make an impact.

Once fully ramped up, the newly-acquired machine at Mondi Duino, near Trieste in Italy, will produce 420,000 tonnes of highquality recycled containerboard a year, increasing security of supply for customers. More information from www.mondigroup. com

Anew white grade of packaging paper in James Cropper’s Rydal range has been launched. Eco White is a fibre-based material is comprised of 100 percent recycled fibre, and features a crisp, clean, and brighter shade of white compared to other recycled whites in the Rydal range.

Launched at PCD Milan, Rydal Eco White is said to use FibreBlend Upcycled Technology

Made from recycled fibre, Rydal Eco White uses FibreBlend Upcycled Technology, combining the tactile luxury of uncoated board with the precision and performance associated with coated products

and is made from recycled fibre, combining the tactile luxury of uncoated board with the precision and performance typically associated with coated options.