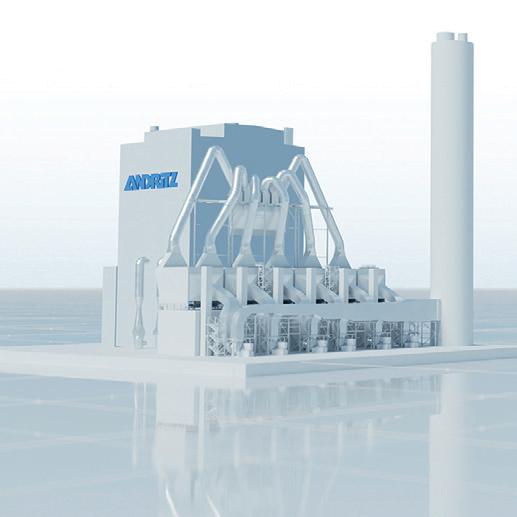

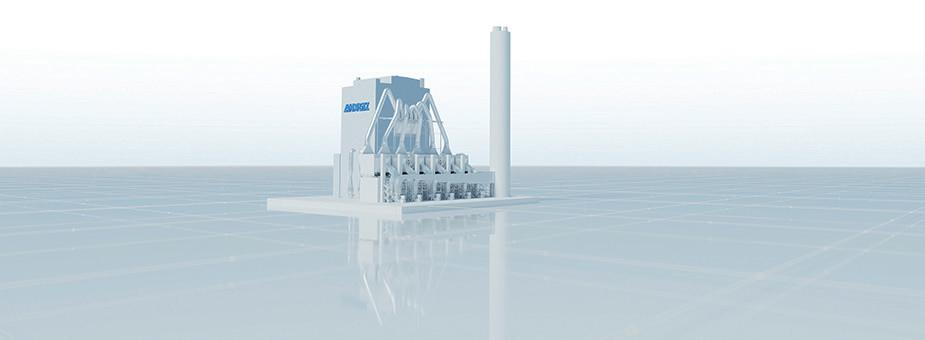

ANDRITZ is a global leader in delivering advanced technologies and services for the pulp and paper industry and the power generation sector. For energy producers, ANDRITZ offers a comprehensive range of power boiler solutions, including circulating and fluidized bed boilers (CFB, BFB) and grate boilers, designed to handle a

For more information, visit our website.

ANDRITZ AG ⁄ andritz.com

wide variety of fuels – from biomass and sludge to waste-derived and challenging low-grade fuels. These boilers deliver high efficiency, fuel flexibility, low emissions, and long-term reliability, making them ideal for both industrial and utility-scale applications. ANDRITZ also provides automation and digitalization tools, such as

Smart BOA, to support performance optimization. A worldwide network of ANDRITZ engineers and service experts will guide and support you throughout the lifecycle of your plant.

Contact us today to learn more: powergeneration.ne@andritz.com

Welcome to the Autumn issue of Forest Bioenergy Review incorporating PIM renewable energy. As we continue to see innovations lead the way in renewable energy, some sectors such as biomethane and biogas, which offer a sustainable, low-carbon alternative to fossil fuels, continue to expand the sources that can now be utilised for feedstock.

Agricultural residues, for example, can be utilised in the production of biomethane/gas, making better use of both livestock waste and the by-products of sewage treatment plants, whilst helping to reduce carbon emissions. Biomass is also a growing sector of importance and how to maximise waste from forestry, furniture and joinery production, will be a topic for examination in our Winter issue.

We will also be looking at wind energy production, automation for energy production, green hydrogen and renewable fuel production plus woodyard handling and processing systems in the next issue.

Submissions should be sent via e-mail to: pulppaperlogistics@ virginmedia.com to be with us no later than 19th November.

Vince Maynard, Publisher

Volume 13, Number 66 – Autumn 2025 Contact information

PUBLISHER &

EDITORIAL DIRECTOR

Vince Maynard

KVJ Enterprises, Tralee, Hillcrest Road,

Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

E: pulppaperlogistics@virginmedia.com

CONSULTANT EDITOR

David Young

Tel: +44 (0) 1737 551687

Mobile: +44 (0) 7785 796826

E: youngeditorial1@btinternet.com

ISSN 2045-8514

PRODUCTION

Anthony Wiffen

ASTAC Business Publishing

Tel: +44 (0) 1460 261011

Mobile: +44 (0) 7851 612799

E: anton_print_1@mac.com

PRINTING

KNOCK OUT PRINT

+44 (0) 1892 823540

Unit 2 The Coppice, Petteridge Lane, Matfield, Kent TN12 7LP info@knockoutprint.co.uk www.knockoutprint.co.uk

Hydrogen-from-waste facility for Thames Freeport

Augwind to build world’s first commercial AirBattery in Germany

technology. The AMRC's capability to manage machining, welding and inspection in a single location allowed for the fabrication of a complete vessel rather than individual parts, proactively addressing potential future issues.

Ben Morgan, interim CEO at the University of Sheffield AMRC, said: “Large demonstrators like the ETU 3.0 reactor vessel are vital for effectively bringing advanced manufacturing methods into industry, offering a holistic solution for fabricating complex, large-scale components.

“The collaborative efforts of CVE, Kairos Power and the AMRC in addressing the complexities of welding, fixturing, machining and inspection for ETU 3.0 will undoubtedly accelerate the deployment of advanced nuclear technologies for clean, affordable and secure power.”

The ETU 3.0 reactor vessel was built using a cutting-edge electron beam welding technology from CVE, which produces high-quality welds at least an order of magnitude faster than conventional arc welding. For example, welds that previously took one week during the fabrication of the ETU 2.0 vessel were completed in approximately ten minutes for ETU 3.0.

Atest unit small modular reactor (SMR) vessel, built in partnership with the University of Sheffield Advanced Manufacturing Research Centre (AMRC) and Cambridge Vacuum Engineering (CVE), has been successfully installed by the US-based nuclear energy company, Kairos Power, at its campus in Tennessee.

The 14 ft high reactor vessel is the central component in Kairos Power’s non-nuclear reactor mock-up and

its installation marks a significant milestone for the company in the construction of its third Engineering Test Unit (ETU 3.0).

Supported by the US Department of Energy, Kairos Power is using its Engineering Test Unit programme to validate a safe, cost-effective pathway for the future deployment of advanced nuclear reactors in the United States.

Leveraging industry and academic partnerships, Kairos is piloting the use

of innovative engineering techniques and construction processes that can help lower costs and accelerate production timelines for a future commercial fleet of SMRs that will support the transition to clean energy in the US.

The University of Sheffield AMRC brought its unique expertise and capability to the ETU project, integrating various advanced manufacturing technologies under one roof, including CVE’s advanced welding

Bob Nicolson, Managing Director of CVE, said: “Our collaboration with Kairos Power and the team at AMRC underscores the transformative potential of electron beam welding in advanced manufacturing. The technology scales well to the precise and demanding requirements of nuclear construction and this partnership represents a significant step forward in SMR commercialisation”.

The ETU 3.0 building will also house a Modular Systems Facility where plant equipment modules for ETU 3.0 and the Hermes reactor will be staged, assembled and tested prior to installation. The modular reactor construction methods being piloted with the ETU series and Hermes will be fundamental in reducing construction costs and timelines for future plant deployments.

More information:

www.kairospower.com

Fives, a global leader in industrial combustion, held the first edition of its ‘Combustion Talks’ at the Fives European Combustion Centre, the largest R&D centre dedicated to industrial combustion in Europe, which is located in Piacenza, Italy. This inaugural event brought together 40 key players from industry, academia and technology to explore the theme ‘The transition to sustainable combustion: balancing research, regulations and collaboration’.

The roundtable discussion, moderated by Tracey Biller, an Independent Technical Writer

and Editor, featured: Hans-Jürgen Altendorf, Managing Director, LAMTEC; Christopher Molloy, Director Business Field Process Heat, EMEA, Karl Dungs; Stefano Consonni, Professor of Energy Systems, Politecnico di Milano; Davide Zorzenon, Application Manager and Process Engineer, Valmet; and Louis Ricci, Director R&D, BU Energy.

Together, they addressed the challenges and opportunities of industrial combustion in a context of increasing environmental regulations, rising energy costs and the need for operational performance.

Francesco Giudici, CEO of Fives ITAS, opened the event by stating:

“This first edition of ‘Combustion Talks’ marks a significant milestone for Fives. It reflects our ambition to work hand-in-hand with our customers, suppliers and the next generation of engineers to co-create pragmatic solutions that meet the evolving needs of industry”.

Beyond the technical discussions, ‘Combustion Talks’ also served as a valuable networking platform, encouraging exchanges and new connections between participants throughout the day to foster collaboration.

The event concluded with

Participants visited the Fives European Combustion Centre.

a visit to the 3,000 sq m Fives European Combustion Centre where participants discovered Fives’ latest innovations in combustion technologies, including ultra-low NOx, hydrogen, and oxycombustion solutions. A highlight of the tour was the ITAS Remixflame™ air-gas controlled premix induct burner, a cutting-edge solution designed to advance performance and limit emissions in industrial drying applications.

More information: www.fivesgroup.com

One of the UK’s first airside solar farms has officially been opened at Edinburgh Airport by Deputy First Minister, Kate Forbes. The 11 acre farm is located adjacent to the airport’s runway and provides approximately 27% of its energy needs. On several occasions this year, the airport has operated solely on solar power between 0830-1900, demonstrating the potential of

renewable energy within the airport environment.

The project is the first of its kind in Scotland and has been supported by £2.1 million of Scottish Government funding aimed at helping businesses decarbonise as part of the route to net zero.

The airport has worked in partnership with solar experts AMPYR Solar Europe to develop, fund and operate the project, which

has been generating power since 2024, with 2025 marking its first full year of operation as the technology becomes an integral part of the airport’s energy mix.

Edinburgh Airport is working hard to reduce its emissions, in line with its net zero aspiration of 2030 for its own emissions. It has achieved a 90% reduction in emissions since 2019 and the solar farm is contributing towards the Zero

On 9 July, Global Energy Storage Group (GES) announced the completion of the sale of its terminal located in the Port of Rotterdam. The facility, which includes 212,000 cu m of tank storage and approximately 18 hectares of development land in the Europoort area, was sold to

Tepsa, a European bulk liquid and gas storage operator.

The transaction represents a key milestone for GES as it continues to focus its resources on expanding its presence in the fast-growing Asian market, with particular emphasis on its strategic terminal at Port Klang, Malaysia.

It also ensures that the Rotterdam terminal is passed into the hands of a high-quality follow-on owner, which is well placed to take the asset forward. The transaction also delivers a strong return for GES’s shareholders.

With the sale of the Rotterdam terminal, GES no longer holds

Carbon pillar of the Greater Good sustainability strategy. The airport is the only one in Scotland to reach Level 4+ in the global Airport Carbon Accreditation scheme – one of just 50 worldwide and six in the UK, and as part of the VINCI Airports network, Edinburgh supports the wider goal of net zero emissions across European and UK airports by 2030.

More information: www.ampyrsolareurope.com

assets in The Netherlands. The company’s growth strategy remains firmly anchored in Asia, where demand for bulk liquid storage, including chemicals, biofuels and new energy products, continues to rise.

More information: www.gesgroup.global

used to generate electricity and heat – a decisive contribution to a climate-friendly energy supply for the region.

The DHE replaces the former Walsum 9 coal-fired power plant and is firmly committed to renewable energies.

The combustion of waste wood saves around 125,000 tonnes of CO 2 annually. The two-line plant offers redundancy and high flexibility to reliably cover district heating demand and carry out scheduled maintenance work without interrupting supply. A modern flue gas cleaning system ensures that all emission limits are reliably complied with.

The efficient use of waste wood, state-of-the-art technology and the highest environmental standards ensure a sustainable and reliable heat supply in the Lower Rhine region of Germany.

The Dinslaken Wood Energy Centre (Dinslakener HolzEnergiezentrum – DHE) is

considered a milestone in the sustainability strategy of Stadtwerke Dinslaken. Using stateof-the-art technology from Doosan Lentjes, waste wood is efficiently

As part of the turnkey contract, Doosan Lentjes was responsible for the delivery, installation and commissioning of the two incineration process lines. The technology used was specially adapted to the requirements of the project and the use of waste wood. More information: www.doosanlentjes.com

In collaboration with its French partner, AGRIPOWER France, German manufacturer Weltec Biopower is currently building a biomethane plant for the Elivia Group. France‘s second-largest beef producer has its headquarters in Le Lion-d‘Angers in the Pays de la Loire region, Western France. At this location, the plant will begin operating in November near the company‘s own slaughterhouse and feed biomethane into the public gas grid.

One of Elivia‘s goals is to significantly reduce its carbon

emissions. With this investment of approximately €6 million, the French industrial and commercial company, which has a workforce of 2,700 and an annual sales volume of 152,000 tons of meat, highlights the importance of green energy sources.

In Lion-d‘Angers, biogas is produced from a mixture of slaughterhouse waste, fats and sludge from the sewage treatment plant and animal by-products. The processing capacity of the slaughterhouse substrates thus totals 85 tons of raw material a day. This corresponds to an annual volume

of approximately 26,000 tons. The raw materials are first hygienised using waste heat from the slaughterhouse. In total, about 2,500,000 standard cu m of biogas are converted into 1,700,000 standard cu m of processed biomethane, which Elivia feeds into the grid every year. This is enough for the yearly heat supply of about 1,600 households.

Prior to the digestion, the materials are kept in a storage tank, which is supplied by Weltec Biopower along with two pump stations in the container and the stainless steel digesters. In

the two stainless steel tanks – each 26.87 m in diameter, 8.80 m high and with a capacity of 4,991 cu m – the agitators then ensure a homogeneous substrate mix for the biogas process. The digestate is used as high-quality agricultural fertiliser. The biogas produced is refined into biomethane using membrane gas processing.

The German manufacturer uses its web-based control software Weltec Control to ensure smooth synchronisation of the plant. More information: www.weltec-biopower.de

The PowerCell Group is deepening its long-term collaboration with Robert Bosch GmbH (Bosch), through a series of initiatives aimed at accelerating the deployment of hydrogen fuel cell systems in mobility applications. Furthermore, both companies are jointly evaluating further possibilities for market entries in stationary applications. The partnership reflects a shared ambition to scale the technology and make it accessible to a broader set of customers, particularly in emerging,

high-growth markets such as China and in the global power generation sector.

To meet the rapidly growing demand for high-performance fuel cell stacks in China, Bosch has acquired extended use rights for its China-based stack development for the automotive market. Valued at approximately €6 million, the agreement will enable Bosch to further stack adaption not only to local requirements, but also to a global perspective.

Under the new framework,

PowerCell will open access to Bosch for selected non-automotive customers in China, including those in the back-up power, construction and industrial mobility sectors. These segments are rapidly electrifying and require robust, high-efficiency solutions. Bosch’s footprint and capacity to industrialise, paired with PowerCell’s advanced technology, can accelerate the market penetration of fuel cell systems in these adjacent sectors.

“We are happy to continue to

build on this very strong industrial collaboration,” said Richard Berkling, CEO of PowerCell Group. “This agreement reinforces the collaboration and with our combined expertise, we excel at bridging the gap between technological platforms and customer reality, making fuel cells work in sectors where performance and reliability are non-negotiable. Together with Bosch, we scale faster, smarter and more sustainably.”

More information: www.powercellgroup.com

A£200 million privatesector commitment to build a next-generation hydrogen-from-waste facility on the Tilbury Tax Site at Thames Freeport has been confirmed by London Thames Hydrogen. The project advances the Government’s Industrial Strategy and marks an important step toward net-zero, clean industrial growth.

The investment represents the first stage of a £1 billion national hydrogen corridor, comprising multiple green hydrogen production sites across the UK road network for decarbonisation of road transport. This initiative will also include a

5 tonne-per-day hydrogen-fromwaste development in Doncaster comprising hydrogen vehicle refuelling and off-grid hydrogenfuelled EV ultra-fast superchargers for cars, LGVs and HGVs.

Delivered by Chinook Hydrogen, a pioneer in advanced wasteto-hydrogen technology that produces carbon negative hydrogen and backed by Middle Eastern investment, the Tilbury plant will: produce up to 12 tonnes per day of hydrogen that meets the UK Low-Carbon Hydrogen Standard, using residual waste otherwise destined for landfill, for vehicle decarbonisation; remove more than 50,000 tonnes

of CO 2 per year; create more than 150 skilled jobs in engineering, operations, logistics and cleantech; and eliminate landfill methane and cut supply-chain emissions through Chinook’s patented modular gasification process.

Baroness Gustafsson, CBE, Minister for Investment, announced:

“The UK is a world leader in clean energy, and it’s great to see this investment will not only deliver cutting-edge low carbon hydrogen technology, but create 150 new skilled jobs, putting more money in people’s pockets as part of our Plan for Change.

“We’re serious about fostering the benefits of net zero, which is

why our modern Industrial Strategy is driving growth into our clean energies sector to attract even more investment and create jobs. Thames Freeport, one of our Industrial Strategy Zones, provides the perfect environment for this initiative to get started.”

Engineered with minimal on-site hydrogen storage, the facility is designed to remain outside COMAH regulations, enabling a streamlined approval process. It is expected to be operational by 2028, forming the first node of a national hydrogen network for HGV refuelling and other industrial uses.

More information:

www.chinookhydrogen.com

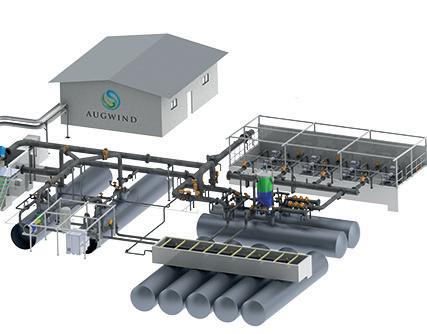

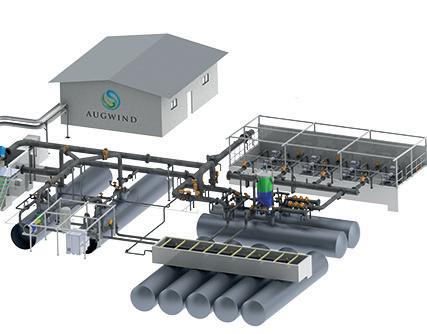

On 30 June, Augwind Energy, a publicly-listed pioneer in air-based energy technologies, announced it intends to build its first commercial AirBattery project in Germany. The facility will be the world’s first industrialscale operational installation of Augwind’s AirBattery Hydraulic Compressed Air Energy Storage (CAES) technology designed specifically for grid-scale storage for up to months at a time - a game-changer for the global energy transition.

In regions such as Germany and elsewhere in central Europe, long periods of low solar and wind output known as ‘Dunkelflautes’ severely challenge grid stability. Augwind’s AirBattery offers a resilient buffer, providing back-up for up to months, helping utilities, grid operators and traders to deal with renewables intermittency and stabilise electricity markets.

Augwind’s revolutionary AirBattery system combines two well-established technologies in an innovative way: it merges pumped hydroelectric principles with compressed air storage, circulating water between underground chambers to compress and decompress air at vast scales.

Excess energy is used to compress air to pressures from 50 bar all the way to above 200 bar, depending on the demand and geomorphic structure of the cavern, and feed the pressurised air into vast underground caverns, larger than the Empire State building. The excess renewable energy is effectively stored for times that the sun doesn’t shine and the wind doesn't blow with a typical cavern having the potential to store enough compressed air to generate 3-8 GWh of electricity.

The energy is recovered from the system by simply returning the high-pressure air back through the

water-filled chambers, streaming the water to spin a turbine and generate electricity. Augwind has already reached a 47% AC-toAC round-trip efficiency at its AirBattery demonstration facility in Israel, validating that commercial installations will exceed 60%.

Augwind’s first commercial AirBattery facility will be built in Germany and will utilise a mined salt cavern suited for such longduration energy storage. The cavern will serve as a low-cost, highcapacity compressed-air reservoir, enabling scalable and costeffective energy storage for up to several months, a vital capability as Europe races to increase renewable energy penetration beyond 50%.

Or Yogev, Founder and CEO of Augwind, said: “This is more than a project; it’s a milestone for achieving net zero. With the AirBattery, we’re introducing a storage solution that finally matches the scale and rhythm

of renewable energy. Germany’s redundant salt caverns, industrial leadership and climate ambition make it the perfect launchpad for our first commercial deployment. Our goal is to become Europe’s preferred partner for multi-week storage solutions. With this German launch, we are proving that longterm energy storage to balance the grid is not only technically feasible, but it’s economically sound”. With an initial target commissioning window of 2027-28, Augwind is now working closely with local cavern-owners, utilities, energy traders and industrial off-takers to secure permitting and finalise the system design. The project will not only showcase the techno-economic viability of Augwind’s Hydraulic CAES, but also lay the groundwork for broader deployment across Europe by 2030.

More information: www.aug-wind.com

ANDRITZ is the leading supplier of recovery boilers to the worldwide pulp and paper industry, with hundreds of units delivered since the 1950s. Each boiler has been individually designed for specific customer needs with a capacity range from the

“In particular, our customers are very pleased with the reliability and uptime of our recovery boilers - when we guarantee a performance value, we deliver what we promise.”

Elina Suomalainen, Sales Director, Recovery Boilers at ANDRITZ

smallest, up to 20,000 tds/day in the future.

“Our recovery boilers are always engineered to meet exactly what our customers require,” said Elina Suomalainen, Sales Director, Recovery Boilers at ANDRITZ. “With our numerous references and satisfied customers worldwide, we have gained a reputation for delivering the very best solutions when it comes to safety, smart operation and sustainability.

“In particular, our customers are very pleased with the reliability and uptime of our recovery boilers - when we guarantee a performance value, we deliver what we promise.”

The recovery boiler is one of the most hazardous areas in a pulp mill. To enhance safety and reduce operator involvement, ANDRITZ has introduced advanced monitoring systems and automated controls. These innovations minimise manual intervention, ensuring safer, more efficient and reliable recovery boiler operation through increased automation and process oversight.

ANDRITZ has developed robot-based technologies especially designed to ease the daily work of recovery boiler operators and increase safety in hazardous and timeconsuming tasks. One example is the Smart Smelt Spout Robot, an ingenious solution that automates the cleaning of the smelt spout.

Again, with the safety of the operator in mind, ANDRITZ supplies solutions that increase safety around black liquor burners. A new modular liquor burner rack, Modirack, enhances safety when working with the liquor burners. Modirack,

with a safety gate, quick burner ejection and automatic burner cleaner, results in less exposure to the risks arising from black liquor burner openings.

ANDRITZ also supplies smart measurements for smelt flow and char bed measurement to ensure safe operation of the furnace. Leakage detection is enabled by ANDRITZ Smart Water Leakage Advisor, where operators can be assured that the very smallest leakage can be detected.

As the world’s leading supplier of large recovery boilers with capacities over 8,000 tds/d, ANDRITZ has introduced an increased tube size diameter for furnace walls to improve circulation and avoid leakages. The larger diameter of the tubes creates less pressure drop and allows the water to circulate better, thus cooling down the tubes more effectively.

“Due to the greater size of the boiler furnaces, ANDRITZ considers larger diameter tubes as the only safe solution to avoid leakages and possible explosions,” stated Rodrigo Tavares, Technology Director, Recovery Boilers at ANDRITZ.

Furthermore, for added safety, a smelt spout cooling system has been designed with a vacuum to ensure good water circulation so there is no

contact with the smelt. The system also requires less manual interaction from operators.

Smart operation of recovery boilers is not only limited to digital solutions; it starts with the basic design of the recovery boiler, as well as the materials used for reliable operation.

Modern mills now target continuous operation for up to 24 months, making boiler cleanability critical. The boiler bank is particularly susceptible to plugging. A key design priority is controlling flue gas temperature before it reaches the generating bank. To address this, ANDRITZ has developed an innovative solution: the pre-boiler bank.

“ANDRITZ pays extra attention to the optimised location of the soot blowers in the boiler bank, which ensures the boiler is kept clean for maximum uptime,” explained Tavares. “For larger recovery boilers, a boiler bank with two soot blower cavities is supplied to ensure the range covers all areas.”

Effective combustion air systems have an impact on reduction rate, carry-over and emissions, and ANDRITZ incorporates more room for optimising and adjusting air flows according to different capacities or black liquor characteristics. As an example, primary and secondary air openings can now be controlled one by one.

Material selection of the superheater requires special attention. According to Tavares, “It is essential to select exactly the right superheater materials as they have a big impact on capital and operational costs. To serve this purpose, ANDRITZ has developed a tool to calculate the material temperatures in each part of the superheater and thus make the precise material selection”.

Demand for shorter shutdown times

is increasing as maximising the pulp mill availability and production is essential. With ANDRITZ's lower furnace design that has a refractory-free floor, customers are able to shorten the shutdown time by 24-48 hours.

While design features are vital, operator easeof-use and effective training are equally critical. ANDRITZ supports this with e-learning modules that complement classroom sessions. Advanced simulators, ranging from theoretical scenarios to full-scale recovery boiler models, accelerate operator learning and enhance preparedness for abnormal situations, thus benefiting both operators and supporting personnel.

ANDRITZ recovery boilers cover the full range of sustainability demands for the 21st century customer.

Energy production is maximised from the recovery process and achieves a high steam-toliquor ratio, which not only enhances the overall efficiency of the boiler, but also contributes to the production of green energy and often eliminates the need for fossil fuels.

With ANDRITZ recovery boilers, atmospheric emissions of harmful pollutants such as sulphur oxides (SOx) and nitrogen oxides (NOx) can be reduced to below regulatory demands according to customer requirements. Combustion air systems serve as a primary method for NOx emission reduction.

Tavares added, “Further reduction of emissions is made possible by secondary flue gas treatment methods such as selective catalytic reduction (SCR). ANDRITZ experts have configured a set-up where an SCR is used in combination with an Electrostatic Precipitator (ESP) and fabric filter. This system also contributes to SOx and dust reduction to a minimum. One of the added benefits of the technology is that no water is used, so it reduces

“Due to the greater size of the boiler furnaces, ANDRITZ considers larger diameter tubes as the only safe solution to avoid leakages and possible explosions.”

Rodrigo Tavares, Technology Director, Recovery Boilers at ANDRITZ

costs and environmental impact”. Suomalainen concluded, “We are able to design and tailor-make our recovery boilers specifically for individual circumstances and are able to reach even the highest of stringent environmental permits and regulations. Our customers are assured of receiving safe, smart and sustainable solutions for all their needs”.

More information: www.andritz.com

By Elin Boström and Årencrantz

Denmark’s Meliora Bio

AsP has restarted the former Inbicon plant in Kalundborg, which had been idle since 2014. The completely modernised facility is now making advanced second-generation bioethanol, innovative food ingredients and lignin products.

Meliora Bio ApS has recently bought the bioengineering company

COMET, and together they upcycle crop residues from wheat straw that is collected from local farmers to produce second-generation bioethanol, prebiotic dietary fibres and lignin. The newly modernised biorefinery aims to have the lowest possible CO 2 footprint, with minimum energy and water use, while reducing its production waste to zero. This circular approach

also benefits local farmers by fully utilising their entire harvest, while generating a valuable new revenue stream and improving the circularity of the food chain.

Valmet’s BioTrac pretreatment process is a core technology in the biorefinery that transforms wheat straw residues to second-generation bioethanol. As a by-product, the process also produces C5 sugar to

make ARRABINA, a prebiotic fibre that is added to different foods to promote better gastrointestinal health.

The start of an innovative journey

“Our goal is to produce several thousand tonnes of ARRABINA and 4.5 million litres of ethanol at full capacity. We are also exploring

the potential to use lignin as a substitute for bitumen in asphalt. Lignin’s future applications are a significant topic in the biomass sector,” said Henrik Maimann, CEO at Meliora Bio.

When the pandemic started in 2020, the Danish government asked Meliora to produce sanitary ethanol for hospital institutions. “Over that Summer, we produced 2.5 million

litres of ethanol for hospitals and institutions that needed sanitisers. During this time, we encountered COMET, which had patented and developed prebiotic food ingredients derived from straw and hemicellulose. After several months’ consideration, we decided to join this innovative project, marking the beginning of our current journey,” stated Maimann.

Valmet has been involved with Meliora since 2020 and the collaboration has been positive.

“We’ve enjoyed extensive cooperation, particularly in recent months, focusing on service and maintenance. Valmet’s experienced team has been invaluable, providing excellent support and

Valmet’s BioTrac pretreatment process is a core technology in the state-of-the-art biorefinery.

maintaining open communication about necessary adjustments,” said Maimann.

“The operational dialogue is excellent, and we appreciate being able to bring customers to showcase the Valmet BioTrac technology at the Meliora site. It’s fantastic and we’re very happy that our great collaboration with Meliora enables us to do this,” agreed Tomas Jonsson, Sales Manager Biomass Conversion, Valmet.

Valmet BioTrac technology plays a crucial role in production and in simplifying operations. “We’re very satisfied with the Valmet BioTrac technology. It’s robust yet straightforward and once our teams mastered it, significantly eased their workload. The Valmet BioTrac design has been instrumental in overcoming previous challenges, leading to stable production and improved steam explosion and cooking efficiency,” said Henrik Maimann.

Despite the successes, there have been some challenges. One has been optimising the feeding system. Another is the volatility of ethanol prices, influenced by political decisions. “We avoid experimenting with the feeding system on our own due to its cost and because it is extremely valuable equipment. However, we have experienced people from

Valmet helping us when we need them,” added Maimann.

COMET’s ARRABINA product is now a key business component for Meliora. “Our interdependence made merging a natural step. Prebiotic fibre is our most profitable product and we will grow even stronger as one company. We now have 65 employees working on the site,” said Maimann.

Meliora was the world’s first bioethanol plant to use straw. It was built in 2008 and commissioned in 2009. The Polish company Orlen is now starting up a second-generation bioethanol plant as well, which will be the first significant European competitor. “We don’t view them as a threat due to their vast market size. It’s beneficial to have someone demonstrating the feasibility of such projects. As for the future, our strategy is to progress incrementally, validating prebiotic fibre sales before scaling up production. We’re confident in the plant’s capabilities, as results have been promising,” explained Maimann.

The market for prebiotic fibre is currently substantial in the US, where Meliora exports its products. “We hope that by the end of this year or early next year, the EU market will open as well. We plan to keep our production in Denmark, but

The Valmet BioTrac design

has led to stable production and improved steam explosion and cooking effi ciency.

it may be possible to build a larger plant in the US,” he added.

“We recognise that several investments are necessary for our future production, but timing is critical. Establishing a new plant takes at least two years from the decision point. So, we must align our timing with market demands. We aim to have a fully operational plant by next year. While this doesn’t guarantee immediate operation, the plant will be ready, allowing us to decide on scaling up production based on prebiotic sales,” Maimann concluded.

More information: www.valmet.com