ONE POWERFUL PARTNER. ENDLESS POSSIBILITIES.

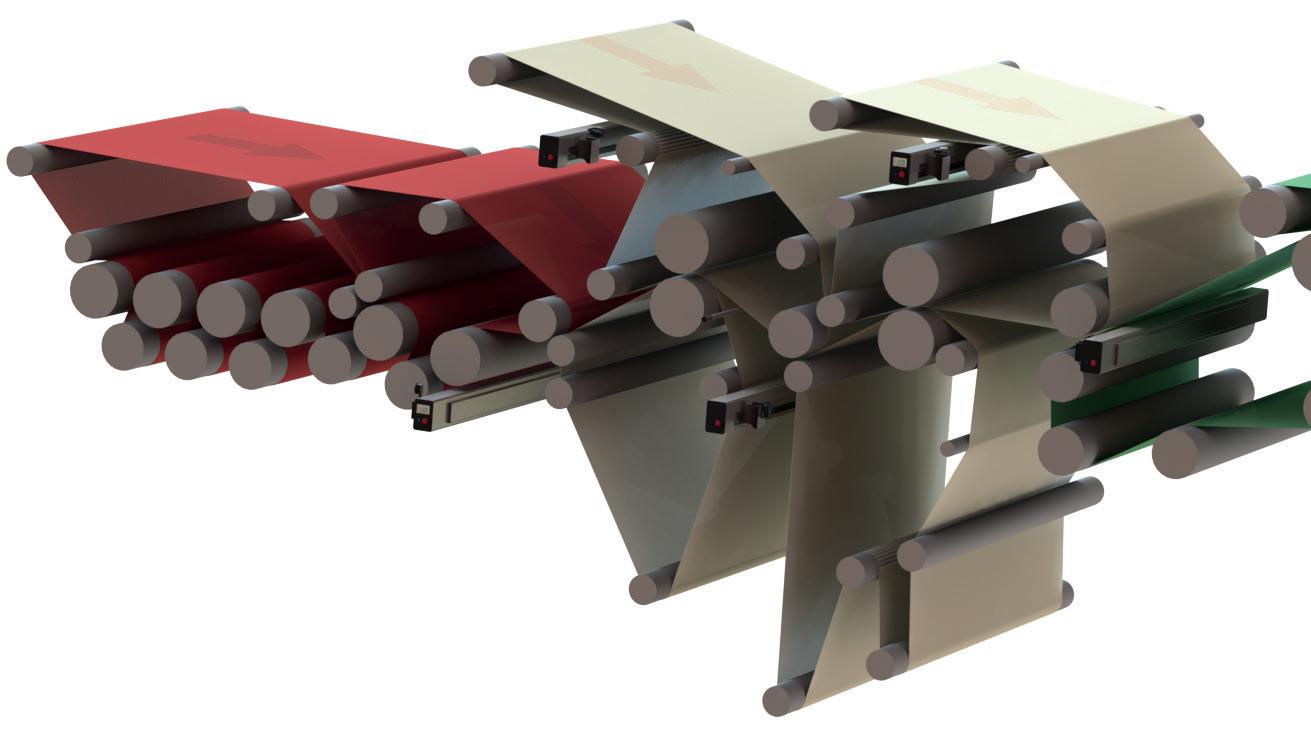

With the acquisition of A.Celli Paper, ANDRITZ is set to deliver even more to the global tissue, paper and board industry. This powerful combination brings together cutting-edge technologies, deep industry expertise, and a shared

commitment to innovation. To our customers this means a broader portfolio, smarter solutions, and faster service – wherever they are in the world. From entire tissue machines to key components like winders for the paper industry, including roll handling, packaging systems, and beyond – everything

needed for efficient, high-performance production is now available from one single, trusted source.

Stronger together. Smarter for you.

For more information, visit our website.

elcome to the September issue of Pulp Paper & Logistics, which includes our MIAC show preview and exhibitor plan.

With the completion of this issue we will have also wrapped up our annual re-registration of readers and taken note of the areas of interest for editorial coverage for 2026.

I’ll be attending the MIAC trade show in Lucca, Italy, from 8-10 October, and still have some slots in my diary available to arrange meetings and discuss any aspect of the magazine.

However, before we release the schedule for next year, we still have the forthcoming November issue which will include a Logistics and handling update; Board production machinery and processing (including packaging grades) and Energy saving systems for the modern pulp and paper mill. Deadline for editorial submissions is 17 November. They should be emailed to me, Vince Maynard, at pulppaperlogistics@ virginmedia.com.

Hope to see you all in Lucca: in addition to the show venue, you could always find me at Fuori di Piazza pizzeria. Cheers!

Vince Maynard, Publisher and Editorial Director

Vince Maynard

Tralee, Hillcrest Road, Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

Email: pulppaperlogistics@virginmedia.com Email: pulppaperlogistics@outlook.com

John Nutting Tel: +44 (0) 1732 868071

+44 (0) 7860 221486

johnnutting47@gmail.com

+44 (0) 1737 551687

+44 (0) 7785 796826

Wiffen

+44 (0) 1460 261011

+44 (0) 7851 612799 Email: anton_print_1@mac.com

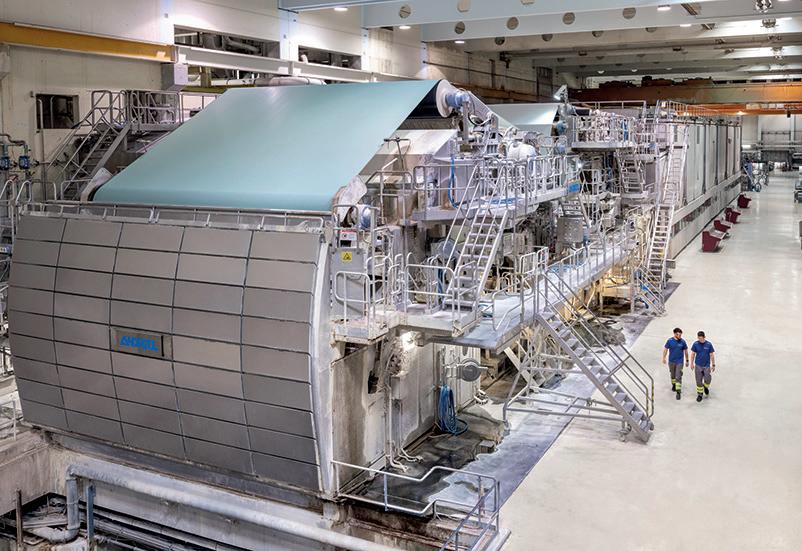

The acquisition of Italian tissue equipment manufacturer A.Celli Paper by engineering group Andritz was completed at the beginning of August.

The terms of the deal, the agreement for which was signed in April, were not revealed.

The acquisition enables Andritz to be a full-line supplier to the tissue paper and board industries, from stock preparation to finished reel.

In a statement, A.Celli Paper said it was proud to be part of the Andritz Group. “This marks an exciting new chapter in the journey of both organisations as they strengthen, innovate further, and expand their presence in the tissue, paper, and board sector,” it said.

A.Celli Group and A.Celli Nonwovens remain independent, owned by the Celli family, and continue to be a key player in the nonwovens industry.

Operating in more than 60 countries, A.Celli Paper has around 1,000 installations. Its installed base includes more than 100 tissue machines, 400 rewinders for tissue and paper and 100 roll handling systems.

Austria-based Andritz said that the acquisition strengthens each company’s positions in the tissue and paper business, aligning product and service portfolio and capabilities –particularly in the European and Asian market. It combines A.Celli Paper’s specialised knowledge in tissue and paper production with Andritz ’s global reach and technology leadership.

“Both of us benefit from a

“With this acquisition we are extending our scope quite a lot,” said Alexander Wassermann, executive vice president of Andritz Paper & Tissue

significant network of suppliers and partners near our facilities, enabling to adapt efficiently to market demands and opportunities,” said Andritz

Alexander Wassermann, executive vice president of Andritz Paper & Tissue, explained in a podcast how A.Celli Paper fits in the future strategy of Andritz:

“A.Celli Paper has been on our radar for a while. I would say we are competitors in some areas, and they have been suppliers. But certainly [we were] competitors in tissue. But if you look carefully

we are only partly overlapping in our deliveries. A.Celli Paper has a strong presence in singlewidth machines all across the globe. Andritz has concentrated especially outside of China on the faster and double-width machines. Bringing those two together under one roof seems like a natural fit even though we have been competitors in the past.

“Where we haven’t been competitors is with the winders. Andritz didn’t have any winders in its portfolio, but in many cases A.Celli Paper has delivered winders to us when we had to package them into our deals. So to become a full line supplier and supply full plants from stock preparation to the fibre treatment up to the final packaging of the goods, this acquisition is a perfect fit because we have the winder for tissue and for paper and board and can be a full line competitor in the market.

“Also, the acquisition of PMT by A.Celli Paper has given the

possibility to be active in paper and board rebuilds. This is an area where Andritz is also active with certain overlaps in competences. We believe the field of comprehensive rebuilds will actually grow quite a lot in the future as the investment in large machines will be reduced and many customers with older assets are thinking about rebuilds. So this is part of our strategy to be a comprehensive and well-accepted provider of rebuilds of paper and board machines. With this acquisition we are extending our scope quite a lot.”

Customers will, it’s said, benefit from a broader portfolio of products and services, These combine A.Celli Paper’s expertise in winding, rewinding, and packaging with Andritz ’s full-line capabilities, an expanded global service network offering faster, more localised support, and continued innovation through joint development in automation and digitalisation.

Europe’s largest and most up-to-date packaging board line has been inaugurated at Stora Enso’s Oluo mill in Finland.

The event in August was attended by Finland’s premier Petteri Orpo, Stora Enso’s chairman Kari Jordan, Stora Enso’s chief executive Hans Sohlström and the mill’s chief shop steward Olli-Pekka Kaikkonen.

Stora Enso said that the Oulu mill serves growing demand for renewable packaging and contributes to the transition to a circular bioeconomy. At the same time, the production site supports

Finland’s competitiveness and increases exports with products of higher added value.

The line represents an investment of €1.1 billion, which is part of a total of €1.7 bn spent at the site since 2019.

This involved the conversion of former paper machines into board lines utilising the latest technology, while the environmental impact has been reduced by cutting fossil carbon dioxide emissions by 90 percent. The mill produces folding boxboard, kraftliners, paper bag material, and unbleached softwood pulp. Board materials are suitable for direct contact with food. Almost all of the Oulu mill’s production is exported.

Commenting on the project, chief executive Hans Sohlström said: “The Oulu production site is a strategically significant investment as it strengthens our leading position in high added value renewable packaging materials and increases Finland’s export revenue significantly.

“Consumer packaging made from wood fibres has great potential to replace plastic packaging and our materials are designed for existing recycling streams. The nearly carbonneutral production site in Oulu is a prime example of an investment in bioeconomy, and it concretely

contributes to the transition from fossil materials to renewable and recyclable packaging.”

The Oulu mill’s new production line utilises Stora Enso’s patented FibreLight fibre processing technology. This enables the production of lighter, yet robust and durable boards. End products include a range of cardboard packaging for frozen, cold and dry food products, medicines, and beverage multipacks.

“Our folding box board can be up to a third lighter than traditional boards, the material is efficient and durable and helps our customers to reduce the consumption of packaging material and at the same time reduce their transport emissions. This means also that they have very high added value.

Our mill’s location next to the deep port enables efficient logistics worldwide throughout the year. It is important for us to be involved in mitigating climate change,” says Matti Lielahti, head of Stora Enso’s Oulu business unit.

“We mainly use pulpwood purchased from private forest owners in Finland, small-diameter wood, and wood chips from our sawmills for board production. We also utilise bark and sawdust for energy production. The bioenergy produced in the mill is used for district heating in Oulu.”

Stora Enso’s consumer packaging board line is expected to reach its full capacity of 750,000 tonnes by 2027, when its annual sales are anticipated to be around €800 million.

German paper maker Feldmuehle has implemented its restructuring measures, including adjustments to production capacities, changes to management and the shift system.

The decisions follow discussions

with the company’s works council and aim to ensure better planning, greater reliability and punctuality for customers and suppliers, without compromising product quality.

As part of the reorganisation

at the Uetersen mill, the sales department is also being restructured.

Martin Mönke is leaving the company at the end of September at his own request and by mutual agreement. Helmut Teuschler

has been appointed as global sales chief supported by Stania Sabatkova. Feldmuehle has been exhibiting at events such as Labelexpo in Barcelona, Drinktec in Munich, and Fachpack in Nuremberg.

Packaging Corporation of America (PCA) has completed the acquisition of Greif Inc’s containerboard business.

PCA earlier agreed to purchase Greif’s containerboard business for US$1.8 billion in an all-cash transaction. The deal includes Greif’s containerboard mills, sheet feeders, and corrugated plants in the US and is expected to increase PCA’s sales and capacity.

Ole Rosgaard, chief executive of Greif, commented: “The closing of this sale marks an important step forward for Greif. This transaction unlocks immediate value for our shareholders and allows Greif to deliver stronger and more consistent earnings power, enhances our capital efficiency, and accelerates debt reduction.”

At the time of the agreement earlier this year PCA’s chief executive Mark Kowlzan said: “This

International Paper (IP) is making a number of changes in its North American operations to better serve its customers.

The changes include mill closures and conversions. IP is pulling out of the moulded fibre business and is converting its facility in Reno, Nevada, to produce packaging materials.

Closures affect a packaging facility at Marion, Ohio, and at its recycling facility at Wichita in Kansas.

In Mexico, IP is selling its containerboard mill at Xalapa and its recycling plants in Xalapa and Apodaca to Acabados de Papeles Santinados y Absorbentes (APSA).

In the US, the changes will impact about 110 hourly and 24 salaried employees. In Mexico, APSA intends to retain current onsite staff at each location.

“These decisions are never easy because of the impact on our employees, their families and the communities in which we

Tom Hamic, president of IP’s Packaging Solutions North America business: “These decisions are never easy”

operate. We will assist employees and customers as much as possible through this transition,” said Tom Hamic, president of IP’s Packaging Solutions North America business.

“While difficult, these decisions will help enable IP to prioritise the right geographies, customers and products and make investments in resources to support our growth in sustainable packaging.”

acquisition furthers PCA’s profitable growth strategy. The mills nicely complement PCA’s system and will provide containerboard to support PCA’s continued corrugated products growth. We expect to achieve significant synergies with minimal capital investment through our operational expertise and will identify even more opportunities within the combined system for future high return investments to grow with our corrugated and

Chief executive of Packaging Corporation of America Mark Kowlzan: “We expect to achieve significant synergies with minimal capital investment”

sheet feeder customers. We will continue to generate significant cash flows and value for our shareholders.”

Mondi’s Merebank paper mill at Durban in South Africa is now capable of generating 60 percent of its electricity demand internally following the installation of a new steam turbine.

The project, which significantly reduces the mill’s reliance on grid-supplied power and improves operational efficiency, also includes cooling towers, piping and control systems, using excess steam from the mill’s boiler.

“This project is a game-changer for the mill,” says Donovan Naidoo, operations director at Mondi Merebank. “By generating power on-site, we reduce our dependency on external electricity supply, reduce costs and take a step towards energy independence, climate resilience and long-term operational stability. Once the cooling tower upgrade is completed, the new turbine will produce more electricity than the mill consumes – a significant milestone in our journey towards self-sufficiency.”

In addition to increasing energy self-sufficiency, the new turbine project will also reduce the mill’s carbon footprint.

Alongside the energy investment, the mill has completed two flood-proofing projects to mitigate risks from natural disasters. The projects include the installation of flood gates and the deployment of inflatable flood barriers, allowing for the rapid creation of water-catchment dams. Together, these measures help protect the mill’s operations and nearby communities from extreme weather events, helping ensure business continuity.

Paper maker Mondi welcomed international customers and partners to celebrate the start-up of its Duino mill in Italy following the successful conversion of its existing paper machine to produce containerboard.

The event in September showcased the production capabilities of the machine which produces premium containerboard products from recycled materials.

When fully operational, the machine will produce 420,000 tonnes of high-quality recycled containerboard a year, increasing Mondi’s integration and improving security of supply for customers.

The mill’s product portfolio includes waste-based fluting, starting with 80 gsm, testliner from 90 gsm upwards, and paper reels from 950mm to 3,350mm on Mondi’s

widest recycled paper machine. Mondi Duino offers short delivery distances to local and neighbouring markets while also serving

international customers through nearby ports.

“Launching this mill on time shows the strength and commitment of our team and is illustrative of our long-term promise to our containerboard customers. With this paper machine, we are investing in their future too –ensuring resilient supply, sustainable packaging products, great service and the opportunity to grow together,” said Klaus Peller, operational chief at Mondi Containerboard.

Mondi’s comprehensive containerboard portfolio offers a wide range of paper grades, from fully recycled to 100 percent virgin fibre, providing sustainable, high-performance packaging for various applications. With Mondi Duino now part of Mondi’s integrated value chain, customers benefit from a broad choice of containerboard solutions and an expanded network of six containerboard mills worldwide.

Forest industry player Metsä Group has started operating a carbon-capture pilot plant at its Rauma mill in Finland, in cooperation with technology company Andritz, which supplied the plant.

The pilot will test the capture of carbon dioxide from pulp mill flue gases, an application not previously trialled in the industry, says Metsä.

During the autumn of 2025, various operating models will be tested concerning aspects such as energy consumption and the amount of carbon captured. The pilot period will also provide information about the need for flue gas treatment and the quality of the end product.

“So far, the technology appears

to be working well with the pulp mill’s flue gases,” says Kaija Pehu-Lehtonen, Metsä Group’s business development chief and the director of its carbon capture project.

As part of the Rauma pilot, Metsä Group will also explore the possibility of a larger-scale demo plant for carbon capture at a second location with a potential capacity for capturing between 30,000 and 100,000 tonnes of carbon dioxide. No decision has been made regarding the project or the location of the demo plant. Implementing the project would require resolving all technical and financial issues.

Bio-based carbon dioxide is a virtually untapped pulp mill side stream, says Metsä. Carbon dioxide can be used as a raw

material – for example, in the chemical and fuel industries – and it can serve as a replacement for fossil-based raw materials. Carbon capture does not increase wood use at the pulp mill, nor does it undermine production efficiency.

“The investments related to capture are large, and the market is underdeveloped, so we’re proceeding gradually. In addition, the value chains from raw material to finished products are often new and complex, requiring close cooperation between the participants and insight into industrial operations,” says PehuLehtonen.

Metsä Group’s sites annually generate around 12 million tonnes of wood-based carbon dioxide, and the company

Kaija Pehu-Lehtonen, Metsä Group’s business development chief and director of its carbon capture project

is increasingly focusing on promoting its large-scale capture.

“Bio-based carbon dioxide is an important but still untapped side stream that could be harnessed more effectively as the technology and markets develop,” says Pehu-Lehtonen.

Tissue maker Sofidel, known particularly in Italy and Europe for its Regina brand, has completed the acquisition of Royal Interco, for which it had entered into an asset purchase agreement based on a ‘stalking horse’ bid.

The agreement between Sofidel and Royal Paper – a recognised player in the US in both the At-Home and Away-from-Home tissue segments – was originally announced in April.

Three facilities in Arizona – the paper mill in Gila Bend (with an annual production capacity of 61,000 tonnes) and two converting facilities in Phoenix – plus a converting facility in Duncan, South Carolina, are now part of Sofidel’s production operations.

in our growth”

Commenting on the deal, Luigi Lazzareschi, chief executive of Sofidel, which is based at Lucca in Italy, said: “This is another important milestone in our growth journey in North America. The location of these production assets – particularly the three facilities in Arizona – allows us to significantly strengthen our

presence in the western United States. This enhances our ability to serve customers and improves our efficiency by reducing delivery times and optimising logistics.”

Steve Schoembs, chief executive of Royal Paper, added: “The Royal Paper team and its 35 years of paper manufacturing experience in the US market are excited to join the Sofidel family to serve its customers and consumers more completely.

“Importantly, Sofidel also plans to offer employment to a significant portion of Royal Paper’s workforce, helping ensure continuity and laying the foundation for future growth together.”

With the acquisition, Sofidel now operates 15 facilities in

the United States, a market that represents 50 percent of its global sales, which total €3.23 billion. Meanwhile, two production expansion projects are progressing in the US: one at the Duluth paper mill in Minnesota, where buildings are under construction to house new converting lines and an automated warehouse; and one in Circleville, Ohio, where a new paper machine – the third at the facility – with a capacity of 70,000 tonnes, will be started up.

Established in 1966, the Sofidel group is active in 13 countries, 12 in Europe and the US (13 states following the Royal Paper’s assets acquisition), with more than 9,000 employees and a production capacity of 1.9 million tonnes per year.

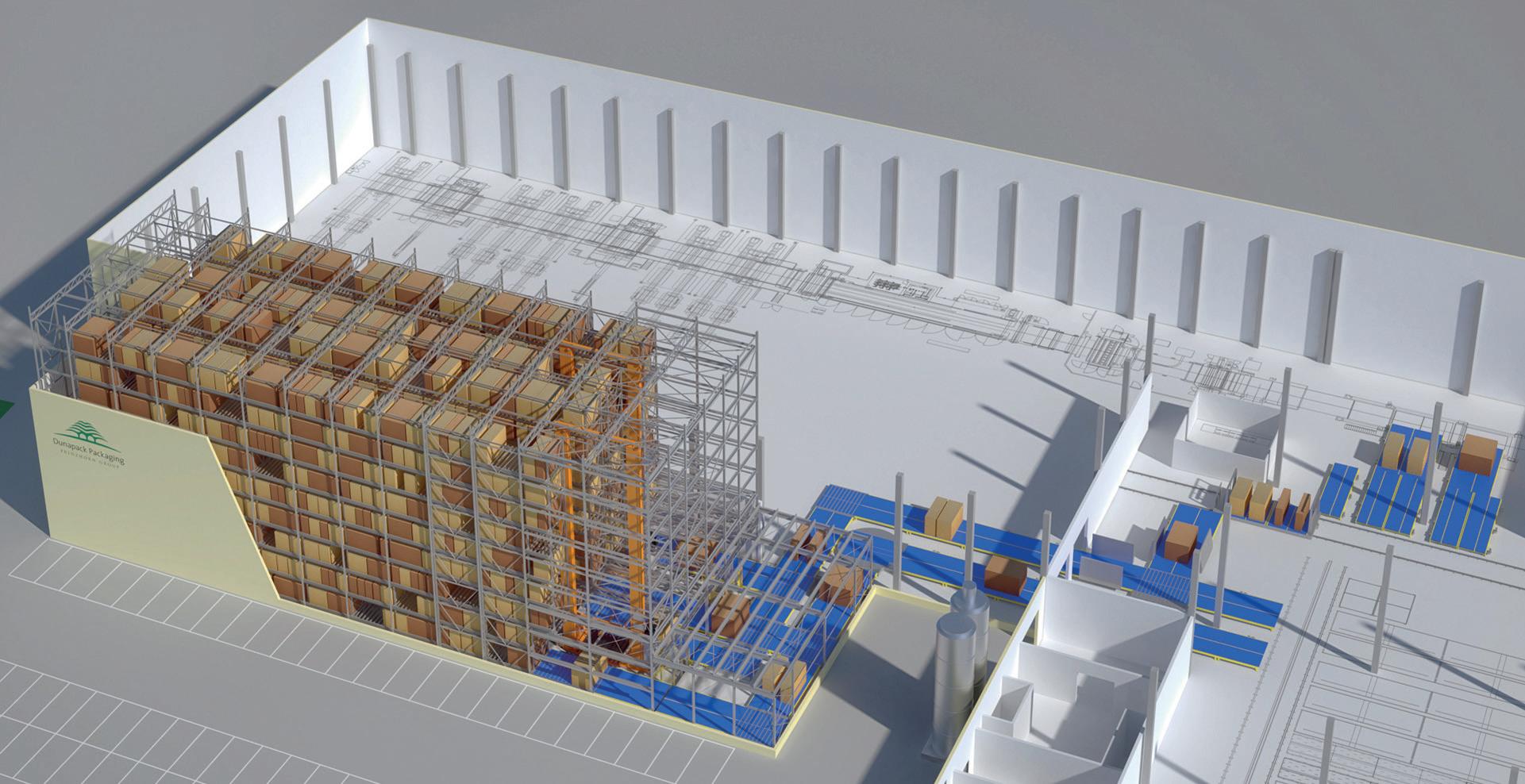

Apartnership has been created between Germany-based Hörmann Intralogistics and Van den Bos Corrugated Machinery to deliver complete turnkey logistics services for corrugated board manufacturers.

The ‘first-of-its-kind’ partnership is said to address a persistent challenge facing corrugated board manufacturers: integrating systems from multiple suppliers whilst managing complex API interfaces.

“Until now, corrugated manufacturers have had to coordinate several suppliers and manage intricate system integrations,” says Michael Hoffmann, sales director at Hörmann Intralogistics. “Our turnkey solution delivers everything from a single source – high-bay warehouse technology, gentle conveyor systems, and intelligent software control.”

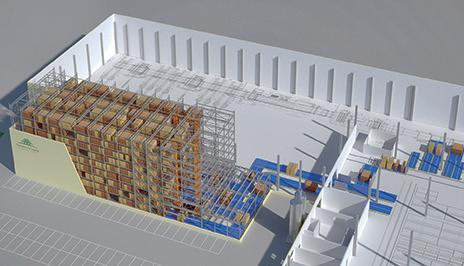

The comprehensive service has three core elements: modern automated storage and retrieval systems with integrated dispatch areas, conveyor technology specifically engineered for corrugated board formats, and a modular HiLIS warehouse management system providing centralised process control.

The partnership builds on projects currently being delivered to established industry players. At Dunapack Mosburger Packaging

at Straßwalchen in Austria, a two-aisle high-bay warehouse with 40 LU/h incoming goods capacity and 65 LU/h outgoing goods throughput is currently under construction. The Palm Wellpappe project at Alzenau in Germany demonstrates the system’s scalability: featuring two million square metres of format sheet storage capacity and 41,800 net storage positions for finished goods.

Hörmann’s HiLIS Warehouse Management System forms the technological foundation of the concept. “Our WMS provides full vertical integration – from ERP interface down to PLC

level,” says Hoffmann. “For specific requirements of the corrugated board industry, we will also offer a particularly high-performance ‘off-theshelf’ edition.”

Van den Bos CM contributes complementary expertise in corrugated board processing. “As a family-owned company with genuine passion for our craft, we develop bespoke, transport-friendly plastic belt conveyor technology for paper products,” explains managing director Paul van den Bos. “Integrated within Hörmann’s intralogistics concept, we guarantee seamless material flow for corrugated board and packaging manufacturers.”

A heavy-duty electric truck being evaluated by Södra in Sweden is expected to reduce the environmental footprint of wood chip transport and represents an important step on the forest product manufacturer’s path towards climate neutrality.

The Scania truck will be charged with self-

generated renewable electricity and operate in Blekinge and eastern Småland, covering about 400km per day. The evaluation, extending to 2027, will analyse the vehicle’s performance, identify areas for improvement, and facilitate planning for a more large-scale electrification of Södra’s vehicle fleet.

Says Henrik Brodin, project owner for large-scale electrification at Södra: “With the electric wood chip truck, we are taking an important step towards fossil-free transport in the forestry industry. We have already invested in expanding the charging infrastructure to meet the needs of heavier transport. By now testing the technology in our daily operations, we are gathering valuable experiences that can contribute to a more sustainable future, both for Södra and for society at large.”

The electric truck is a Scania 45R with a load capacity of 64 tons and a range of 250300 km per charge. It is powered by three integrated electric motors generating 610 hp. Battery capacity is 624 kWh, making the truck well-suited for regional transport. Charging is carried out with a power of up to 375 kW, enabling a charging time of about one hour in normal operation.

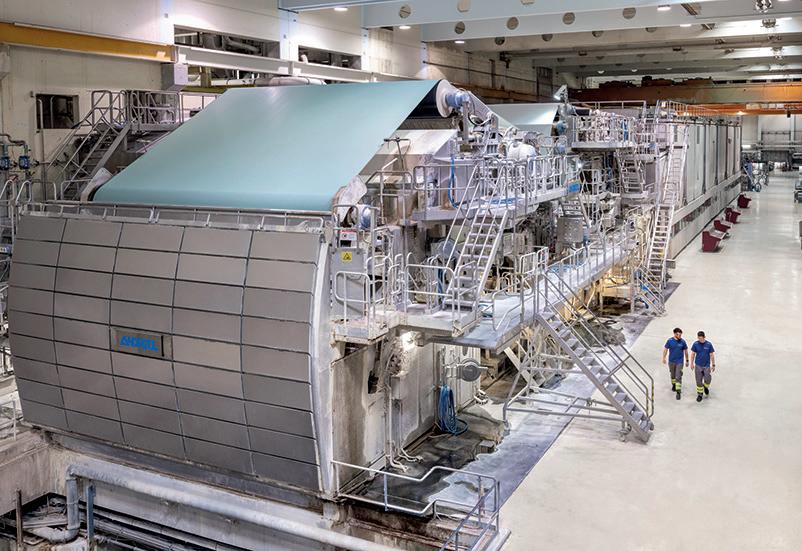

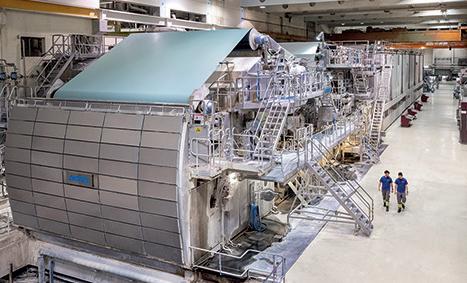

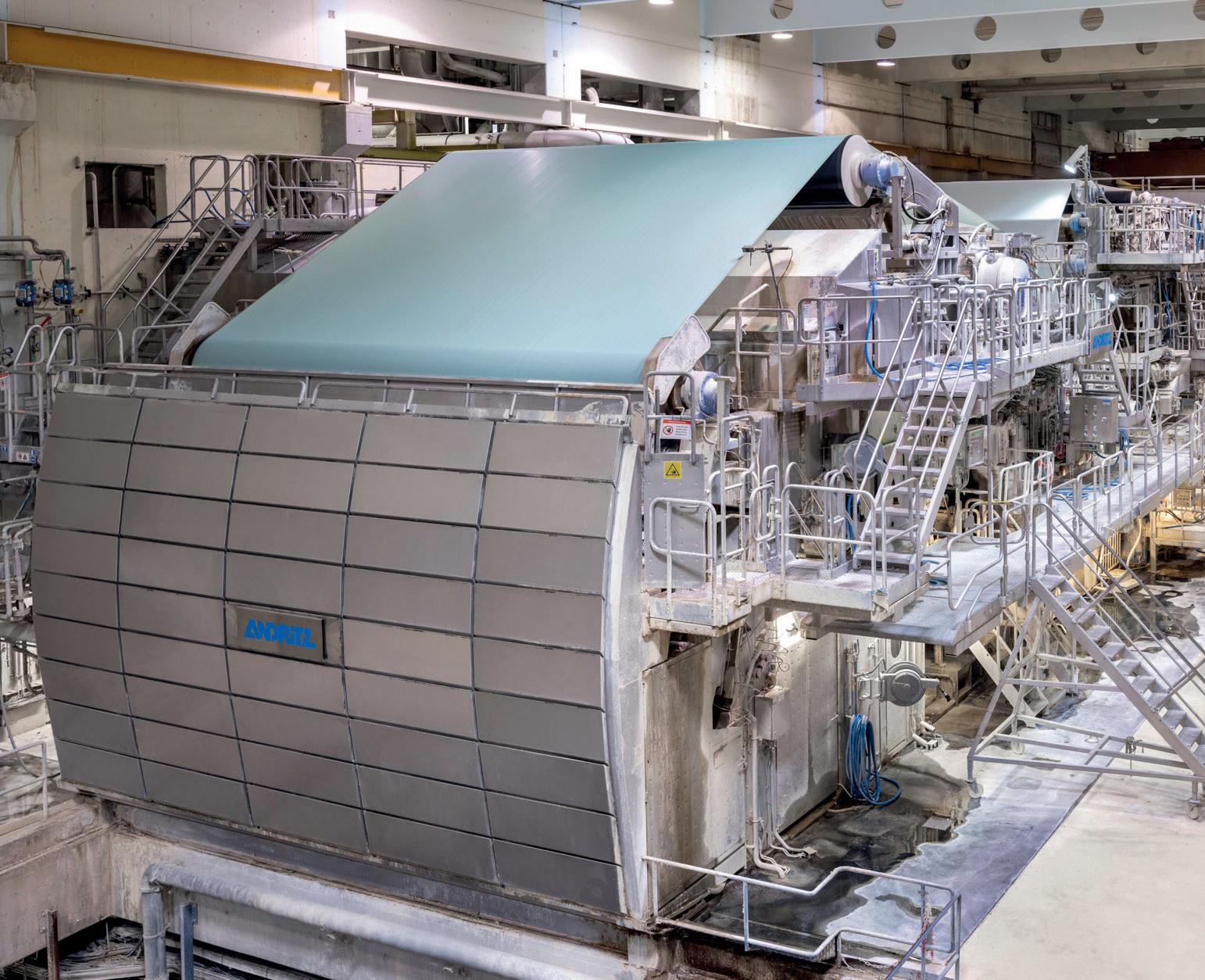

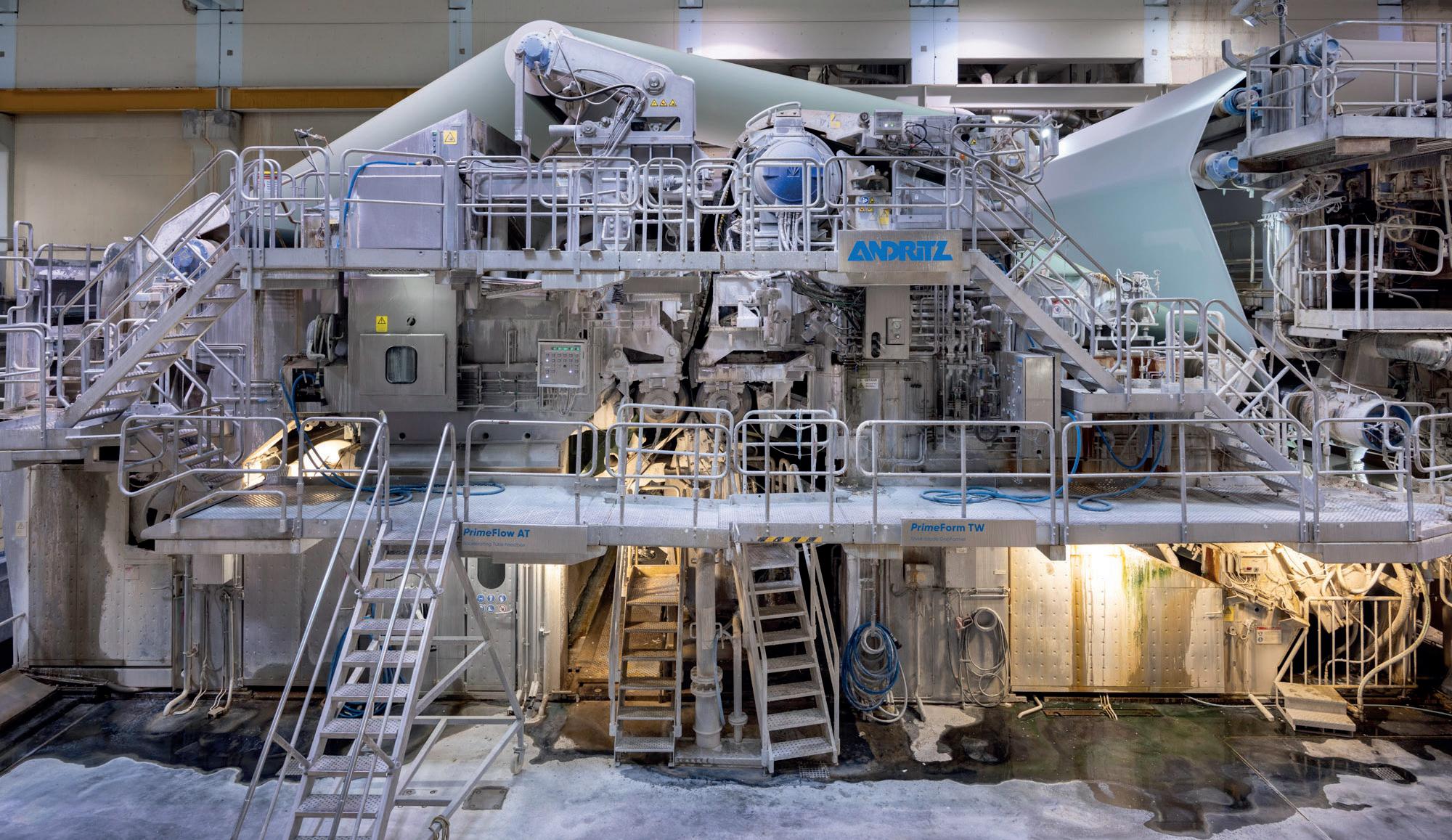

At the Starkraft mill in Austria, an idled supercalendered paper machine has been converted by Andritz to produce kraft papers for packaging in what is regarded as a revolutionary project. PPL reports

Conversion of the PM6 paper machine at the Steyrermühl mill, part of Starkraft, a business unit of Heinzel Pöls, has significantly expanded the company’s kraft paper production capabilities and positioning it as a major player in the global market, thanks to a ground-breaking partnership with Austrian engineering group Andritz. The ambitious project involved converting the idled

supercalendered (SC) PM3 at the Steyrermühl mill in Austria into PM6, producing kraft papers for sustainable, flexible packaging.

The family-owned Heinzel Group, based in Austria, is one of the most important pulp and paper producers in Central and Eastern Europe, trading in pulp, paper, waste paper and packaging worldwide.

Starkraft produces paper on three machines at two sites in Austria. Its diverse product range

includes both white and natural variations, catering to the needs of its customers with versatility and flexibility.

The timeline for this project was tight, and the startup curve correspondingly steep. PM6 reached, and indeed exceeded, its target speed of 1,200 metres per minute within a few months of startup early in 2024.

The ambitious timeline reflected

the desire to seize market opportunities, which wait for nobody, explained Heinz Schnedl, chief technical officer at Heinzel Pöls.

“This was a strategic decision within the group, based on the reality of an increasing market for brown and white kraft paper, the decline in graphic grades, and having identified an available asset at Steyrermühl that could meet the future requirements of this market.

The idled PM3 at Starkraft’s Steyrermühl mill was converted by Andritz into PM6 to produce kraft papers for sustainable, flexible packaging

“We had to get ahead with production volumes and quality so as not to miss the round of budget discussions with our customers for 2025, and to ensure we were a first mover with this innovative technology.”

The project was not without its challenges, including the integration of new and existing equipment and the need to ensure the stock preparation was flexible enough to produce a wide range of end products.

There was also the factor of personnel, as Siegfried Gruber, head of technical planning at

Heinzel Pöls points out: “Our team had to switch from one running paper machine to another idled one – newsprint PM4 to the new PM6 – coping with enforced downtime, different technology on a narrower machine, and also dealing with a far broader range of product specifications – having previously been operating within the narrower specification confines of graphic grades. In the end, we were fortunate to have retained so much expertise inhouse alongside the work of the dedicated Andritz team.”

PM6 now has a design speed of 1,200 metres per minute, a paper width at the reel of 6,300 mm and 150,000 tonsper-year capacity. This strategic investment allows Starkraft to produce up to 350,000 tons of kraft paper per year at its mills in Pöls and Steyrermühl, and offer a full range of 20 gsm to 120 gsm bleached and unbleached kraft papers.

In addition to the gamechanging paper machine conversion, the Andritz scope of delivery included upgrades of the stock preparation, approach flow, and broke handling systems as well as extensive upgrades of the automation systems (DCS, QCS, MMD), detailed engineering packages, mechanical erection, and an upgraded steam and condensate system.

At its heart, a ‘first’ in forming technology

One of the standout features of the project is the use of the first gapformer designed specifically for kraft paper production. The production of kraft paper usually requires a fourdrinier former, but PM6’s gapformer rebuild features a new, unique concept, proven in pilot trials,

which is based on a pulsationfree impingement shoe of the PrimeForm TW.

This fully-adjustable shoe-blade gapformer retains high flexibility in basis weights and grades, ensuring robust, yet forgiving operation. On the PM6 in Steyrermühl, it enables crucial, grade-specific paper properties with the lowest possible MD/CD ratios for both bleached and unbleached paper grades. This is combined with a PrimeFlow AT headbox with dilution control for excellent cross-direction profiles and overall dimensional stability. Andritz applied patented technology to give a truly pulsation-free impingement zone and adjustable geometry in the forming zone with variable wrap technology to allow grade-specific optimisation and a very wide operating window. At the same time, use of a gapformer offers a step increase in energy efficiency, forgiving operation, and much higher speed potential than Fourdrinier technology.

The combination of the Andritz PrimePress X shoe press and the upgraded steam and condensate system has resulted in significant energy savings, while maintaining High-quality production. The new Andritz VIB SteamTech profiling system and the PrimeCal soft calender technology, which replaces a multinip calender, further enhance the paper’s surface quality, making it ideal for flexible packaging applications.

The project team identified the DCS, based on the Damatic Classic control system, for a substantial upgrade. This covered stock preparation, part of the wet end, drying groups, and the steam & condensate system, as mentioned above.

In particular, it included the DNA Operator Station, which includes a DNA Backup and AlarmServer, a

The Steyrermühl project at a glance

Heinzel took over the Steyrermühl site from the Finnish paper group UPM at the beginning of 2024. The Steyrermühl paper mill had a long tradition of producing high-quality graphic paper products, but Andritz converted the former PM3 SC paper machine to produce sustainable kraft papers for the growing flexible packaging market.

The rebuilt machine, now called PM6, will produce up to 150,000 tons per year of brown and white kraft paper in a range of basis weights, marketed under the established Starkraft brand. The new kraft paper grades will be used to manufacture carrier bags and pouches, among other flexible packaging products.

20-client DNA Display Server, the GDCAD to DNA software upgrade, and the OPC UA Server. The network was upgraded, while the existing IO cards and application software from the XDi System were reused. Andritz modified 50 percent of the existing application software, while upgrading the process station hardware and system software to the latest versions.

Last but not least are the pumps – the beating heart of any process industry.

Andritz installed 10 new pumps and upgraded around 50 existing process pumps up to optimised energy performance with modified impellers, base frames and various additional components to meet the new operating specifications. In addition, Andritz developed a conversion kit for the existing coupling guard to meet the latest compliance requirements. Using

an adapter disc, the integration of the current coupling guard of the outstanding ACP pump series will be facilitated.

A long-standing partnership “This has been a highlychallenging project,” says Mario Wiltsche, corporate director for paper technology at Heinzel Holding GmbH. “It was complex and very intensive, with a short schedule to meet, a very steep startup curve, and a lot of discussion about what to retain from the old machine and where new equipment was required. And all this within an existing environment rather than a greenfield scenario. But thanks to skilled, experienced, and dedicated teams from Steyrermühl and Andritz, we had a great startup despite the time pressure and technical challenges.”

The successful completion of the project is testament to the longstanding and fruitful partnership between Heinzel Group and Andritz. Previous collaborations include the conversion of the PM10 line at Laakirchen and the delivery of two new MG paper

machines for the Pöls mill.

“It’s always a more fluid situation when dealing with a rebuild,” says Andritz project manager Andreas Pfennich. “No matter the level of detail you might include in the project proposal, when the time comes to execute the rebuild or replace existing parts, there will be unforeseen technical aspects to handle. PM6 was no exception, but we were pleased we managed to adhere to the agreed schedule despite this.”

Christoph Draxler, sales

manager for Paper & Board at Andritz, adds: “This project not only enhances Heinzel Group’s production capabilities, but also underscores its commitment to sustainability, through energy savings and material optimisation, and thanks to technological advancement in general.

“Andritz has proved itself to be a dependable, innovative partner through its ability to rise to the challenge of tailor-made solutions, while confirming its leading position in kraft and speciality

grades. Despite necessary changes to the scope as the project progressed, Andritz managed to keep to the original schedule. It was a project which required Andritz ’s highly-flexible team of experts to think out of the box, particularly when recommending which parts of the old machine to retain and rebuild, and which to replace entirely.”

Steyrermühl’s future

With the Steyrermühl mill now producing high-quality kraft papers for packaging under the established Starkraft brand, Heinzel Group is poised for continued growth. This project not only enhances its production capabilities, but also underscores its commitment to sustainability and technological advancement.

“It has been a privilege to accompany Starkraft on this important journey,” concludes Andritz ’s Christoph Draxler. “At Andritz, we further strengthened our leading position in flexible packaging paper technology development, having introduced a world-first technology, and successfully completed a project characterized by daily challenges and rewards.

Stop collecting paper samples!

Improve your press section efficiency! SmartScan™ contactless sensor accurately measures paper web dryness after the press section 24 hours a day, 7 days a week. Using a proprietary microwave technology, it is developed to overcome the typical limits of the NIR (near-infrared) sensors. SmartScan™ is available both for fixed point positions or traversing web scan. To save hundred of thousands of Euros in energy costs, stop collecting samples, choose the safe accuracy of SmartScan™ technology.

Cristini S.p.A. Diagnostic Systems Via Bombardieri, 5 – 24020 Fiorano al Serio (BG) Italy Tel +39 035 715 111 Fax + 39 035 711 451 email diagnostic.systems@cristini.it website www.cristini.com

At the Voith Paper Technology Center in Germany, experts work with Qualiflex press sleeves to identify innovative opportunities for continuous improvement

Real-world trials and precise tools are enabling the continuous improvement of Voith’s latest range of press sleeves. PPL reports on the processes that lead to longer sleeve life, energy consumption reductions and productivity improvement in paper mills

How does the fully customisable QualiFlex press sleeve portfolio achieve higher dewatering performance and dry content after press? At the Voith Paper Technology Center, a team of multi-disciplinary experts are hard at work identifying innovative opportunities for continuous improvement.

This article explains how cuttingedge MicroCT analysis, laboratory tests and test rigs, as well as realworld field trials, secure the best results for every type of paper mill – even under the most challenging of conditions.

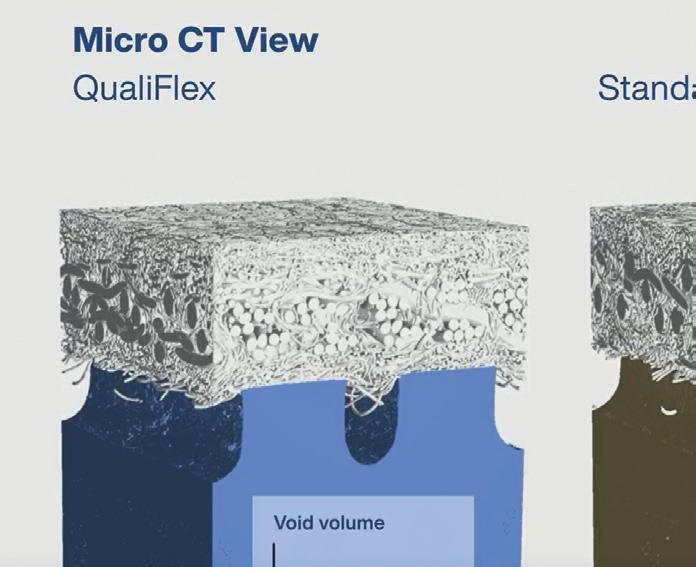

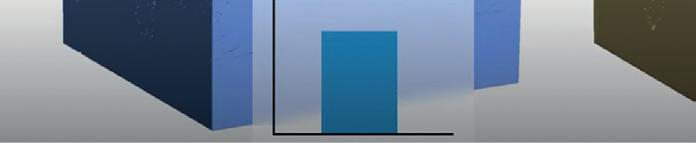

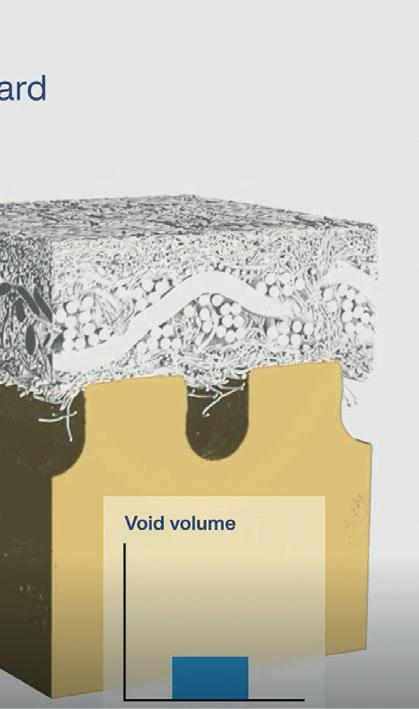

Slice by slice, the remarkable benefits of the QualiFlex press sleeve portfolio are revealed for all to see.

“What we are doing is unique in

the industry,” explains Dr Christina Bauer, global product manager for press roll covers at Voith Paper. “With our cutting-edge MicroCT analysis tool, we can see inside new and used press sleeves. This gives us a better understanding of the groove design, void volume and material properties that maximise dewatering performance and ensure a long, stable and reliable lifetime of our QualiFlex family.”

Long-term studies using the MicroCT tool confirm that the QualiFlex reputation for reliable and superior dewatering properties is rightfully earned, notes Bauer.

“Time and time again, the MicroCT analysis confirms that the combination of our patented material and customised designs ensures that the void volume of

our grooves remains consistent over a longer service life. Such superior and stable void volume is key to efficient water flow, which leads to effective and efficient dewatering in the press section.”

superior dewatering properties

This assessment is echoed by Peter Weichenberger, manager of the QualiFlex business unit at Voith Paper. “Our MicroCT technology allows us to scientifically investigate the performance of press sleeves in real-world conditions. Our customers increasingly value our science-backed R&D methodology, which clearly visualise the benefits of our press sleeves for their production lines.”

What’s more, such in-depth analysis means that Voith is able to accurately and individually customise the design of each QualiFlex press sleeve to achieve a higher dry content after the press for every type of paper grade and paper mill.

“A higher dry content is the goal of any papermaker, as it ultimately leads to reduced steam and energy consumption and/or higher production capacity,” adds Weichenberger. “The MicroCT analysis helps us secure excellent dewatering properties over a longer, stable service life for every kind of paper mill.”

Unique MicroCT analysis on dewatering performance

One recent field study in particularly demanding conditions

compared the performance of a customised QualiFlex press sleeve to an alternative from another manufacturer. Both were used in the only shoe press on a paper machine to produce the same quality of paper. While the QualiFlex showed excellent dewatering performance for 145 days, the alternative had to be replaced after only 64 days due to poor dewatering results.

Back in the lab at the Voith Paper Technology Center, the R&D innovation hub in Heidenheim, Germany, the QualiFlex specialists got to work to identify the root causes for the marked differences in performance. The MicroCT analysis looked at the void volume of the grooves in the press sleeves before and after hydrolysis treatment under various pressures up to 7 MPa.

Essentially, Voith’s MicroCT analysis uses advanced X-ray technology and computer algorithms to see inside the press sleeves slice by slice to create high-resolution, threedimensional images of the small grooves in the sleeves. This enabled detailed structural analysis and precise measurement of material properties.

The QualiFlex press sleeve stands out for stability and resilience

Among the key findings of the MicroCT analysis, two are especially interesting for papermakers. First, it showed that the initial void volume of the grooves in the new QualiFlex press sleeve was much higher than the grooves in the unused alternative. Second, at the end of the service life of 145 days, the QualiFlex press sleeve still had a remaining void volume of 348cc per cubic metre.

Most notably, the MicroCT

analysis showed that this end capacity for the QualiFlex press sleeve was close to the initial void volume of the alternative, which was 358cc per cubic metre at the outset. At the end of its short service life of 64 days, the alternative ended with a far lower capacity of 288cc per cubic metre.

This explains the poorer dewatering effect. An overview of several MicroCT studies is available upon request from Dr Bauer (christina.bauer@voith. com).

“These types of comprehensive comparative studies confirm not only that QualiFlex has better initial pressure resistance, but that our patented material and groove designs are significantly superior when it comes to withstanding the harsh conditions and pressure

of the paper machine over time,” notes Bauer. “This is essential to ensure stable and consistent, high dewatering performance over a longer period, whatever the conditions at the mill.”

For one European paper mill with an annual production capacity of around 200,000 tons of fluting and testliner between 110g/sqm and 215g/sqm, the higher dewatering performance of QualiFlex press sleeves was evident after a temporary switch to a press sleeve from another manufacturer. The QualiFlex press sleeve had recorded a stable and efficient dewatering performance more than 451 days. In contrast, within 140 days with a third-party alternative, the press section already showed increased misting around the press sleeve.

Initial investigation of the issue suggested that the misting was likely caused by the heavy wear and swelling of the surface of the third-party press sleeve, which was unable to withstand the harsh conditions of this particular paper mill.

The MicroCT analysis tool is not just about measurement, however. It’s also a powerful R&D tool for customer-centric innovation. Crucially, this one-of-a-kind research in the industry ensures that the Voith QualiFlex specialists can identify key opportunities for continuous improvement. Continuous improvement is a key topic of interest at the Voith Paper Technology Center. It’s also where the custom-made QualiFlex press sleeves are designed and manufactured using innovative, patented materials.

This clear focus on continuous improvement at the production site has led to further developments in the design, material use and manufacturing methods for the portfolio of QualiFlex press sleeves. Each improvement is aimed at ensuring a higher dry content after press with stable and reliable production.

“We invest considerable sums in R&D and quality control for our press sleeves, which sets us apart from other suppliers,” explains Bauer. “It’s a luxury that gives us time to focus on continuous improvement and customercentric innovations at our stateof-the-art research hub. We can them try our ideas out on test rigs that replicate conditions in paper

mills before moving to real-world trials in close collaboration with our customers.”

This approach takes time, but there’s a good reason for this. “Our way is specifically aimed at protecting our customers and giving them a competitive edge,” explains Bauer. “We never increase the risk for our customers.”

This tried-and-tested process has led to proven popular innovations with patented materials in the QualiFlex portfolio. These include the blind-drilled surface in the QualiFlex press sleeves that optimises the dewatering process. It’s also why QualiFlex press sleeves are breaking world records in service life, measured both in terms of nip cycles and operating days.

In addition, the QualiFlex specialists have another key advantage on top of the cuttingedge research facilities, highlights Weichenberger. “We are members of a multi-disciplinary team at a full-line supplier, which means we have access to every kind of insight, expertise and knowledge of process engineering that is necessary to ensure our

innovations have a positive impact on the paper production process.”

Greater impact resistance and mechanical strength

Another type of impact can be a considerable cause of concern for paper makers who produce board and packaging with higher grammage. When a paper wad of testliner makes its way through to the press nip in these production lines, for instance, it can suddenly increase the pressure on the press sleeve. The impact of such a paper wad can lead to damage on a press sleeve if it is not tough enough to withstand the shock. These wad impacts are relatively rare even in the harshest conditions on board and packaging production lines. However, when they occur, they can lead to costly unscheduled maintenance shutdowns. This is why the QualiFlex team has also been making use of the high-tech R&D facilities to research ways to ensure superior impact resistance of the press sleeves.

At the research hub, the QualiFlex specialists have replicated testliner wad impacts on a NipcoFlex test rig running

the results, numerous field trials followed in close collaboration with customers around the world.

Currently, hundreds of QualiFlex press sleeves with the new reinforced structure are running successfully. The switch to the new reinforced structure has been smooth and viewed positively by customers involved in the trials.

The improved toughness and impact resistance of the new reinforced structure ensures that the QualiFlex press sleeves retain mechanical strength throughout the service life and have high wad and shoe crack resistance.

at 800 m/min with a line load of 1,100 kN/m. Lab tests followed using various weights to simulate impacts under mill conditions. One key finding of the series of tests was that impact failure always starts with damage to the yarn structure.

“Our research shows that when the reinforced structure has higher impact resistance, the press sleeve itself is more durable in the long run,” explains Bauer. “This insight subsequently led to the development of a new type of reinforced structure with higher mechanical strength and flexibility in direction of the cross section for the QualiFlex portfolio.”

Following the initial results of the research into the impact failures, the Voith specialists identified a way to improve the reinforced structure of the QualiFlex press sleeves to secure higher impact strength.

The first QualiFlex press sleeves with the new reinforced structure underwent extensive lab testing. Once the team was satisfied with

Solving the shoe edge cracking challenge

Increased shoe crack resistance is not a benefit that many papermakers will immediately notice, simply because shoe edge cracking of the QualiFlex press sleeve is not an issue for most papermakers. It generally occurs only under the most challenging conditions, and even then, only in the most demanding applications. Nevertheless, shoe edge cracking was an occurrence that caught the attention of the QualiFlex specialists who saw it as another opportunity for continuous improvement.

Long-term rigorous trials and analysis at the research hub in Heidenheim led to an innovative optimisation of the production process to further reduce the rare occurrences of shoe edge cracking. Repeated trials on test rigs confirmed that the press sleeves produced using the new process showed no signs of cracking.

“Although this particular improvement is not something that every paper maker will notice, it is something that benefits everyone,” says Peter Weichenberger. “Our

manufacturing process ensures that our QualiFlex portfolio is designed to withstand the most challenging conditions – which leads to a longer stable service life for all applications.”

Superior performance through tailored service and support

As the QualiFlex press sleeves have such a long life, Voith ensures that its customers are provided with long-term service over the entire life cycle. QualiFlex specialists and Voith engineers team up to offer a wide range of comprehensive support that is designed to improve not only the performance of the press sleeves but also the press section as a whole.

As a full-line supplier, Voith provides tailored service packages that include audits, maintenance, and troubleshooting across the entire paper machine, not just the press section. Teams of experienced application engineers work closely with customers to optimise press sleeve designs for specific paper grades, machine layouts and production processes.

As an international organisation, the teams can leverage a global network of experts to solve issues. It’s possible to draw on the collective knowledge of Voith

engineers and resources across regions to quickly address any type of challenge that a customer might be experiencing in the press section – or elsewhere in the mill.

“By offering this level of comprehensive support and expertise, we are a true longterm partner to our customers,” explains Weichenberger. “We help them maximise the efficiency and reliability of their paper production operations and make them fit for the future.”

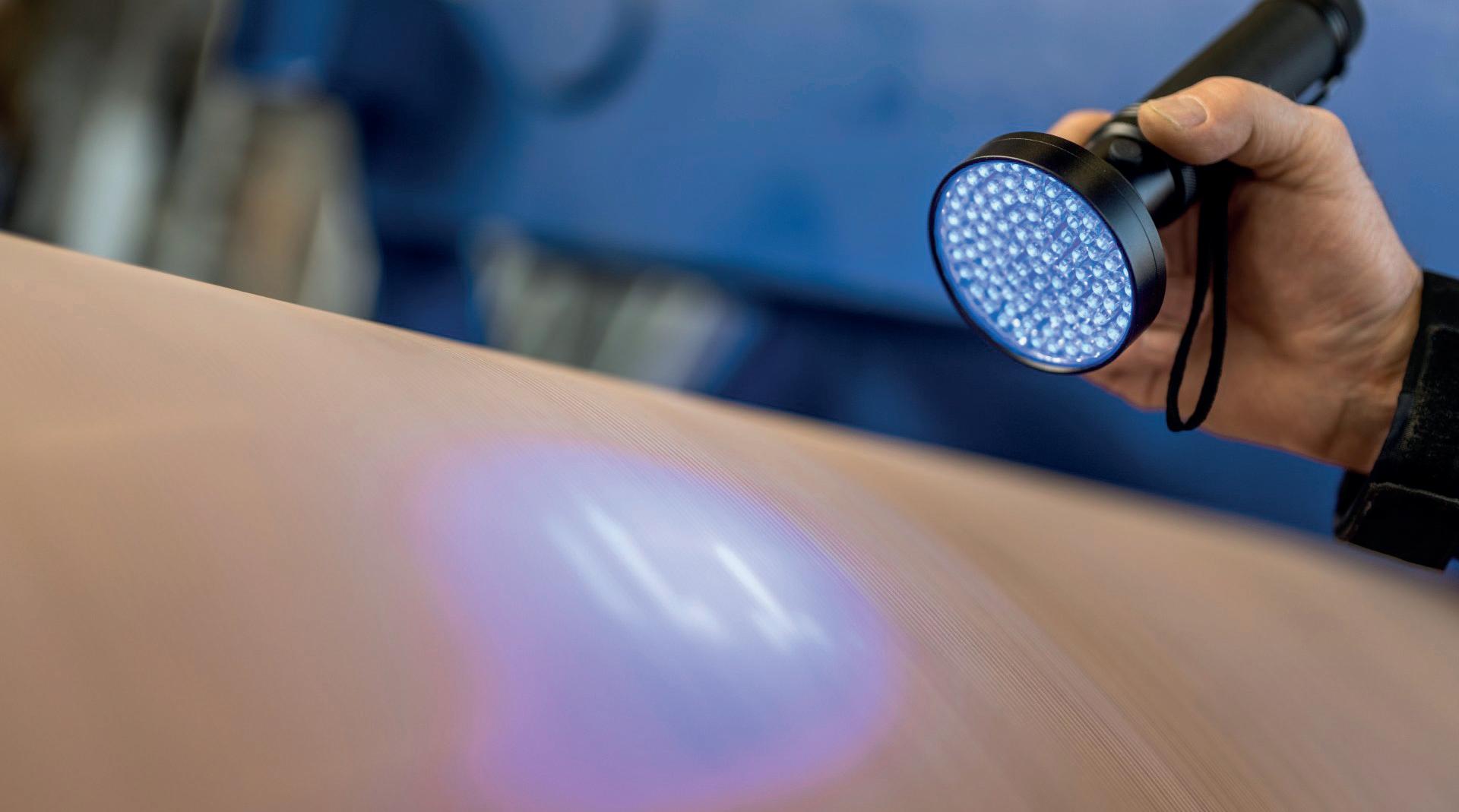

One such innovative service is performed with the Voith Surface Scanner. “With this tool, Voith service engineers can perform essential inspections of the QualiFlex press sleeve during a planned maintenance shutdown anywhere in the world,” explains Mario Neumann, senior global application manager at Voith Paper.

Unlike conventional inspections that generally use manual imprints and are known to overlook critical wear points, the self-driven Voith Surface Scanner automatically carries out a seamless full-width profile and delivers high-resolution images over the length of the press sleeve surface. Following detailed

analysis of the void volume, the remaining lifetime of the press sleeve can be reliably calculated, and maintenance procedures can be efficiently planned.

All the research, innovative improvements and service options are geared at ensuring papermakers have fewer unplanned shutdowns and can better plan maintenance, which results in higher overall equipment efficiency (OEE) and lower operational costs.

In addition, as the superior dewatering performance of the QualiFlex sleeve press leads to a higher dry content, papermakers ultimately save steam and energy consumption in the dryer section. Generally, a 1 percent increase in dry content saves 4 percent in energy consumption. Papermakers can also choose to use that 1 percent increase in dry content to increase production by 4 percent.

One example of what a difference this all-round expertise and service can make is exemplified by another recent innovation: the HighPerformance Press. This consists of Voith’s NipcoPress Shoe Press technology, a new press concept, a tailored combination of press felts and QualiFlex press sleeves. Together, they contribute to an even higher dry content.

Simulations show that, depending on the initial conditions, up to a 3 percent increase in dry content can be achieved, which reduces the steam consumption by up to 12 percent.

“After installing the HighPerformance Press, we have seen a higher dry content after the press section and lower steam consumption, which helps us reduce our carbon emissions,”

explains Wouter Lap, managing director at Smurfit Kappa’s Roermond Papier mill. But the advantages don’t end there for the PM1, which has an operating speed of 1,250 m/min, a sheet width of 5,000mm and an annual production capacity of 275,000 tons of high-performance lightweight packaging paper with basis weights between 80 and 135 g/sqm. “This solution also has a cost-price benefit,” Lap adds. “And it has increased our machine capacity.”

Customised press sleeves and services for greater efficiency

The specific requirements and conditions differ greatly from one paper grade and mill to another. As a result, the ability to design, manufacture and service customised QualiFlex press sleeves is crucial for achieving the highest possible dry content after press on every type of machine and a higher runnability.

Each QualiFlex press sleeve is therefore custom-made in the Voith Paper production site at Heidenheim. The portfolio covers all paper grades, and each press sleeve is tailored to the requirements of individual machines and mill conditions. During the production process, the surface of the

The press sleeves are treated to create the grooves, blind-drilled surface and distinct profiles that give the sleeve press some of its unique qualities.

“Finding the perfect QualiFlex press sleeve for every type of paper machine is a fascinating process,” adds Bauer. “Figuring out the best possible solution and seeing how our innovations maximise the optimisation potential of a paper mill is incredibly rewarding.”

Tissue paper is an essential product in households, businesses and industries worldwide. For most people it’s difficult to imagine life without it, especially toilet tissue. From humble beginnings to today’s highly sophisticated production processes, the tissue paper industry has undergone remarkable technological advancements aimed at meeting the ever-evolving demands of consumers and companies.

The early days

Fifty years ago, tissue paper manufacturing was a relatively simple process. Mills primarily relied on virgin wood pulp, and the production was energyintensive, and used large amounts of water and chemicals. Paper machines were slow, and quality control depended largely on manual inspection. The range of products was limited, with basic

toilet paper and facial tissues dominating the market.

Initially, the industry was dominated by two primary technologies: Through-Air Drying (TAD) for ultra-premium products with very high bulk, softness and absorption properties while the conventional dry crepe tissue technology has been, and continues to be, the most

common process to produce economy-premium tissue for the Consumer and Away-from-Home market. These two methods have set the standard for tissue products for decades.

Valmet calculates that since the 1990s it has reduced energy consumption in the tissue making process by almost 50 percent while water usage is 80 percent lower. At the same time efficiency has increased significantly, both in productivity and capacity. A modern Advantage DCT machine enables a mill to produce 65,00070,000 tons of tissue per year at a speed of more than 2,000 metres per minute, meeting growing consumer demand while keeping costs competitive.

Over the past two decades, innovations in advanced technologies, hybrid processes,

different fibre blending and embossing, have enhanced tissue paper quality. Modern manufacturing techniques enable the production of soft, strong, and highly absorbent tissues, catering to a more discerning consumer base.

In recent years energy efficiency and product quality significantly improved in conventional machines after the introduction of Valmet’s flexible Advantage ViscoNip press, which has become a benchmark in the tissue industry. Today it’s not only limited to the Advantage DCT concept but can also be used in Valmet’s small and mid-size IntelliTissue machine.

The Yankee dryer was invented more than 150 years ago and still plays a significant role in tissue making. Even if it looks almost the same on the outside, significant developments have happened inside. Also the manufacturing process has been modernised to meet the requirements of safety, energy efficiency, and the addition of third-party certification. Today most Yankee dryers are made of steel and Valmet recently delivered its 700th Yankee dryer to the Metsä tissue mill at Mariestad in Sweden.

One solution doesn’t fit all The Through Air Drying technology is still the best method for producing ultra-premium quality tissue with the highest softness and absorbency. It comes with a higher energy cost which is

balanced by the fibre savings, very high output and the price premium per case on the shelf. However, in recent years, flexible hybrid technologies like Valmet’s Advantage NTT, eTAD and QRT concepts have emerged as significant alternatives, offering premium tissue close to TAD level, enhancing product quality while maintaining cost efficiency. The benefits include high softness and bulk, energy and fibre efficiency, as well as increased flexibility in product differentiation.

In addition, the production efficiency driven by automation and digitalisation have taken a big leap. Computerised control systems and Industrial Internet

solutions have simplified the machine operator’s life and enabled the possibility to predict, maintain and troubleshoot operations both at the mill and remotely from Valmet’s Performance Centers.

Since 2024 Valmet has enhanced manufacturing performance through a joint venture with Körber, fully integrated in Valmet. FactoryPal empowers shop floor teams to achieve seamless operations and optimised production by digital and AI aided solutions.

The evolution of tissue paper manufacturing over the past half century demonstrates significant progress in innovation, efficiency, and sustainability. As technology

continues to evolve, we can expect even more innovations in the tissue paper industry. Alternative fibre sources like bamboo and agricultural waste to process improvements such as AI-powered production optimisation, electricpowered mills and carbon-neutral power sources are already a reality.

In the light of the growing demand for sustainable solutions it will be crucial to adopt a holistic approach considering the complete lifecycle and utilise the full potential of what modern Valmet tissue technologies are capable of providing. Maintaining the production equipment at its optimum performance and thereby prolonging the lifetime will save natural resources, reduce waste and emissions.

Valmet’s capability to develop the tissue making process, from fibre-in to finished-tissue product out, including stock-preparation, tissue-making, converting and packaging, will have a significant impact on the development of production performance and endproduct quality.

The challenge of attracting a skilled workforce will remain and is putting pressure on tissue machine suppliers to continue innovating with AI driven tools and autonomous operations.

The outlook for the tissue industry is promising and producers who remain informed of emerging trends will have an opportunity to capitalise on these advancements to meet consumer expectations and drive business success.

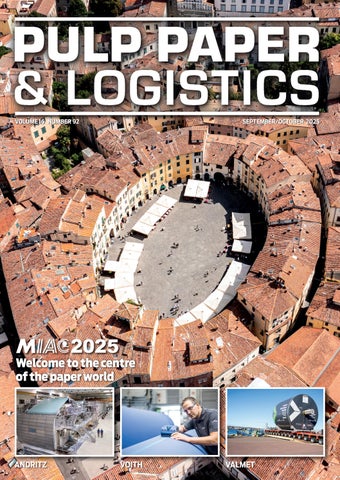

The MIAC 2025 trade show in Italy brings professionals from the pulp, paper and tissue industries from all over the world. PPL outlines what’s in store

For more than 30 years, the MIAC exhibition has been providing the paper and tissue making industries with three days of top-level meetings and conferences.

Held at the centre of Italy’s ‘paper district’ in Lucca, this year from 8 to 10 October, the Polo Fiere has attracted more than 250 exhibitors who expect to meet upwards of 6,000 attendees from the paper, cardboard and tissue sectors.

The show and conferences are free to participants provided that they register. They will find that there will be networking opportunities for discussing the challenges in the global paper industry.

Following a number of significant mergers and acquisitions in the global paper industry and its equipment suppliers, the drive has been to further reduce production costs, but mills also continue to meet the needs of customers looking for more sustainable products.

These needs and the industry’s responses will be addressed in the two MIAC Tissue Conference mornings where new technology and innovation that supports the industry will be showcased.

The move away from using fossilbased to renewable energy has accelerated in the past year with the use of forest by-products as fuels, with biomass increasingly becoming the source of choice. In the MIAC Energy conference these new technological approaches will be explored.

Visiting MIAC 2025 provides

a complete overview of the technology and equipment available to the paper industry sector, from the production of paper and cardboard to the converting of tissue.

With 165 paper and tissue mills, Italy is fourth largest of the key producer countries in Europe with 20,000 workers contributing to an annual output of nine million tons a year worth €6.8 million. Italy is also a leader in the corrugated cardboard sector.

The region around Lucca is the officially acknowledged ‘paper district’ in Europe with around 140 mills and converters employing 6,500 workers and producing two million tonnes of paper and corrugated cardboard with turnover of €3.5 billion.

Lucca is also home to major companies that supply technologies, machinery and services to the global paper industry sector, with a turnover of more than €2.6 billion and around 8,000 workers.

In Europe, Lucca is the number one spot for tissue production (with a 24 percent share); Italy is also one of the leading countries in the corrugated cardboard sector.

The city of Lucca, which is considered one of the major tourist destinations in Italy, is well known also abroad for the walls that surrounds the historical centre. The Walls of Lucca are unique in the world.

Another famous symbol of the city of Lucca is the charming

Anfiteatro Square built on the ruins of the ancient Roman amphitheatre.

Within walking distance from this beautiful corner of the city you can find the medieval Fillungo street, which is the main street of the town centre and heart of shopping in Lucca. Other architectural and cultural attractions of the city of Lucca is the Church of San Michele and the famous San Martino Cathedral. Lucca was also nicknamed “The city of 100 churches”.

Of the more 250 towers and bell towers that decorated the city in medieval times just a few are still visible today: the most important ones include the Guinigi Tower and the Tower of the Hours. Like an open-air museum, Lucca conserves many works of art.

As a media sponsor Pulp Paper & Logistics will be at MIAC. Publisher Vince Maynard will be pleased to meet exhibitors and industry professionals alike. Email Vince at pulppaperlogistics@virginmedia. com to make an appointment.

MIAC 2025 is located at the Lucca

Exhibition Centre, Via della Chiesa XXXII 237, 55100 Lucca, Italy.

To reach the free parking of MIAC Exhibition it is advisable to look on your satnav for ‘Vitricaia street –Lucca’.

Activities covered at MIAC 2025

● Machines and equipment for the production of paper, board and tissue

● Machines, complete lines and equipment for tissue paper converting

● Components, equipment and sections of paper machines

● Drying, suction and ventilation machines and systems

● Measuring, testing, control and data management instruments and systems

● Electrical controls, motors and panels

● Machines and plants for water and waste treatment

● Chemicals, additives and fibrous raw materials

● Energy: technologies, systems and solutions

● Material handling, end-of-line and internal logistics

● Technical services, engineering, maintenance and logistics

● Process digitalisation and automation

Session 1, 9 October 2025, MIAC Conference Room, 10:00

Efficiency, innovation and sustainability in tissue paper production: technologies compared.

10:10 – Francesco Pasquini, Lucart

Business, environment, and society: the value of the tissue industry’s presence in Italy.

10:30 – Gerda KröswangAdanic & Peter Bräuer, Andritz High consistency refining of hardwood kraft pulps for tissue application. Use of traditional ideas for new applications.

10:50 – Maurizio Tomei, Oradoc

Drilled suction covers: performance improvement and case studies.

11:10 – Leonardo Cavirani & Mario Battiston, Runtech Systems

Best available vacuum technology for paper machine vacuum systems.

11:30 – Luigino Furlan, Valmet Innovating the approach to moisture profiling for an enhanced tissue production and energy consumption reduction

11:50 – Ludovic Veyre, Kadant

How to achieve real water and energy savings in tissue paper production using M-clean

12:10 – Anne Klaschka, Voith Paper

Circularity for press felts, a key element of Voith Paper’s sustainability strategy.

MIAC Tissue Conference

Session 2, 9 October 2025, MIAC Conference Room, 14:00 Technologies, automation and sustainability for the evolution of tissue converting

The second session of the MIAC Tissue Conference addresses the most current challenges and opportunities in tissue paper converting, with particular attention to energy efficiency, process innovation, advanced automation, and environmental sustainability.

14:10 – Hampus Mörner, Afry How pulp integration affects cost pressure in tissue converting

14:30 – Dario Giannini & KarlJohan Tolfsson, Valmet

Unified pilot trials. Empowering tissue innovation

14:50 – Guido Finocckì, Giotto Technologies

Innovation in the right direction: enhancing process sustainability and meeting market demands

15:10 – Pablo Andres Peraffan Eraso & Veljko Zlatanović, BW Converting

The Ventus-TI platform: A new wind in folded tissue innovation

15:30 – Alberto Colombo, Omet

Integrated solutions in tissue: Efficiency, continuity, and innovation

15:50 – Martina Nannizzi, Futura

Tailor made as a standard, where the customer needs meet innovation excellence

16:10 – Francesco Furzi, Smartlogistix

Cost of not automating today: benefits of a fully automated factory

16:30 – Stefano Pasquali & Leonardo Palma, E80 Group Technology and innovation: safety serving people and scalability for industrial flows

MIAC Energy Conference, 8 October 2025

Energy efficiency, lowemission technologies and decarbonisation in the paper industry

14:00 – Allessandro Beoglio, Assocarta

Opening remarks

14:10 – Speaker to be confirmed, GSE

Tools managed by GSE to support decarbonisation.

14:30 – Marco Pezzaglia CIB Biomethane: use in hard-to-abate sectors.

14:50 – Paolo Masiero, Solar Turbines

Flexibility and energy integration in tissue and paper production. Solutions for efficiency, resilience, and low carbon intensity.

15:10 – Mehdi Aminyavari, Cannon Bono

Integrating heat upgrade technologies in paper mill.

15:30 – Federico Baroni, Garioni Naval

Thermal innovation in paper: combined water tube boilers.

15:50 – Daniele Coppola, Magaldi Power

Decarbonising industrial heat with fluidised sand bed-based electro Thermal Energy Storage technology.

16:10 – Francesco Ureni, Toscotec

Leading the change. The first fully-electric tissue machine in the world.

16:30 – Christian Birnstingl, Andritz

How to achieve significant energy savings in paper production process with optimised pump systems

9.September – Tissue Converting stand B57

ACE Tissue Technologies stand B5

Acquaflex stand B76

Aermec stand A5

Aerothermic stand B61

AFT Aikawa Fiber Technologies stand B75

Officine Airaghi stand C23

Air Project stand A9

Albany International stand B98

Amotek stand B37

Andritz stand B28

A. Piovan stand B80

Archroma stand C34

AstenJohnson stand C8

Atlas Copco stand B93

Axchem Group stand B84

Azmec stand B82

Baosuo Enterprise stand B4

Baroncini Nello stand A6

Bellmer stand B22

B.F.G. Rapp.ze Ind.li stand B76

BHM Ingenieure – Engineering & Consulting stand C24

BIM Kemi Sweden stand C25

August Blecher stand A18

Böttcher Systems stand B78

Bolzoni stand A1

Bretting Manufacturing stand B3

BTG stand B65

Buckman stand B77

BW Converting stand B101

Camozzi stand B93

Cannon Artes stand A20

Cannon Bono stand A20

Carta&Cartiere stand MP

Cascade stand A8

Cellwood Machinery stand B9

Centrax Gas Turbines stand C30

Centro Aria Compressa stand B93

CHT Germany stand C27

Coincart stand A14

CPS Company stand B38

S.A. Giuseppe Cristini stand B76

CTP stand B79

DALIAN JORI stand C14

De Iuliis Carlo & Alfonso stand B33

Debem stand A22

Dechangyu Paper Machinery Manufacture stand C43

Deublin stand B66

Devasol stand B18

Di Marco stand B59

D.M. Progetti stand C4

Durlast stand B78

Dystar stand B76

E80 Group stand B52

Ecol Studio – Lifeanalytics stand B60

Ecoverde stand B22

Effebi stand A5

Eigenmann & Veronelli stand C7

EIL stand B23

Elettromar stand B13

Elio Cavagna stand B43

Emtec Electronic stand B41

Enfasi stand C21

Enrico Toniolo stand B15

EOC Group stand A2

Euroimpianti stand B26

Euroincis stand B20

Eurotronix stand B31

Everllence stand A26

Evonik stand C48

Fan Separator stand B32

La Fenice Global Service stand A16

Fercam stand C10

Fife-Tidland stand B24

Filtereco stand C47

Firefly stand B91

Fis Impianti stand B100

FlexLink stand C29

FMW Förderanlagen stand B75

Food Contact Center stand A24

For-Tech stand C9

F.lli Frediani stand B32

Fujian Light Industry Machinery & Equipment stand C41

Futura stand B42

Gambini stand B67

Garioni Naval stand C1

GEL stand A5

Ghetti 3 stand A10

Giancol stand C33

Giotto Technologies stand B4

Giuliani stand B80

GTK Timek Group stand C22

Guangdong Zhidesheng Technology stand C13

Hannecard Tissue & Paper stand B102

Henkel stand A19

Hergen – Máquinas e Equipamentos stand C18

Hoerbiger Italiana stand B66

IBS Austria stand B32

ICM Makina Ve Muh. stand B48

Idrotherm 2000 – COREX Division stand C35

IFP Packaging stand B26

IM Converting stand B21

Indexa Italia 2 stand B51

Infinity Machine & Engineering stand B14

Ingersoll Rand stand B8

Inox BF stand A15

Intecom stand C36

Italmatic stand B63

Italprogetti stand B45

I-Valve stand A5

Jaeger stand B32

Julia Utensili stand B92

Jungheinrich stand A13

Kadant Group stand B105

Kairos stand B40

Kapp-Chemie stand B22

Kappa stand C16

Kawasaki Gas Turbine Europe stand B32

Kemira stand B72

Lario Energy stand B27

L.B.Z. Lavorazioni Meccaniche stand C23

Zhengzhou Leizhan Technology Paper Machinery stand C38

Linde Material Handling Italia stand A3

L&M Pumps stand C26

Lotus stand C5

Liuzhou ZODE Machinery Sci-Tech stand C42

MacDue stand B106

Maflex stand B11

Magaldi Green Energy stand C28

Mamec

Mare

Mario

Gruppo Martinelli Industriale stand A5

Mevas

Microline

Mink Bürsten

NCR Biochemical stand B54

Northern Engraving stand B101

Noviprofibre stand B80

O.B.L. stand C12

OCME stand B68

OK Science and Technology stand C39

OMC Collareda stand B55

Omet stand B87

O.M.T. stand A23

Zhejiang Onepaper Smart Equipment stand C15

Oradoc stand B109

Overmade stand B1

Papnews stand MP

Parason Machinery stand B80

Paul Wegner stand B75

PCHEM stand C11

PCMC – Paper Converting Machine Co. stand B101

Petrofer stand B76

Plastylenia stand B69

PL di Lazzari stand A22

Plusline stand B42

Pneumax stand C3

PNR Italia stand A25

Polimek stand B80

Powermade stand B1

Proxitalia stand C17

PTE – Pulp Test Equipment stand B15

Pulsar Engineering stand B39

R.A. Jones stand C29

Renova stand B95

Replus Tissue stand B23

RIF stand B53

Righi Elettroservizi stand B36

Robopac stand B68

Robuschi stand B8

Röchling Industrial Oepping stand B29

Rolco Europe stand B44

Rotocalco Mediterranea stand B90

Runtech Systems stand B8

SABA Automation stand B88

Sadas stand B111

Sael stand B73

Safem stand C19

Sauer stand B30

Saueressig stand B12

S.B.R. Solutions stand C16

Schäfer Rolls stand B71

SDF stand B46

Senning stand B2

Service AMS stand C31

Serv-o-tec stand C45

Sicem Saga stand B35

Sicma stand B74

Sinergy-SL stand B73

Smartlogistix stand B81

Solar Turbines stand B19

Solenis stand B22

Songlin Doctor Blade & Saw Manufacture stand C40

Shanghai Soontrue Machinery Equipment stand C44

Sorgato stand C37

Sotemapack stand B68

Spares Service & Machinery stand B83

ST Macchine stand B97

Stiavelli Irio stand A4

STILL stand A6

Sulzer stand B32

Svecom-P.E. stand C2

Tamburini stand C6

Tau Machines stand B107

TC Rolls & Covers stand B94

Techno Paper stand B75

Technowrapp stand B47

Techpap stand C46

Tec.Mec. stand B16

Tecnofer Ecoimpianti stand C49

Tecnomec 3 stand C20

Tecno Paper stand B49

Tip95 stand B108

Tissue Tec Sales & Service stand B25

TissueMAG stand MP

Tissuenet stand B34

TKM stand B10

IMA TMC stand B62

Toscana Spazzole Industriali stand A12

Toscotec stand B85

Toyota Material Handling Italia stand A11

Trimble stand C50

Tubicom stand B56

Unimatec stand B110

Vakuo

Paper-based container products from Tokan Kogyo and Nippon Tokan Package, both subsidiaries of Japan’s Toyo Seikan Group, received the Packaging Category Award1 (two products) and the Packaging Technology Award2 (one product) at the ‘2025 Japan Packaging Contest’ organised by the Japan Packaging Institute.

Awards were given to packaging that has made a significant contribution to the rationalisation and improvement of packaging and to products that are technically excellent in packaging technology, such as enhanced protective functions or appropriate use of materials to improve packaging functionality by utilising superior expertise. Toyo Seikan Group is

Toyo Seikan’s award-winning packaging (from left): before improvement, with partition supports; after improvement, without partition supports; triangular prism shapes at the four corners

characterised by two specific areas of operation: developing and offering products and services that support a range of lifestyles; and developing and

offering products and services that are environmentally sound. Moving ahead, it will continue to contribute to environmental conservation and the realisation of a sustainable society with the development and provision of these products and services. More information from www.tskg-hd. com

Packaging for Lumen’s Beauty Advent Calendar has been awarded the ‘Carton of the Year’ title at the European Carton Excellence Award gala held in Istanbul, Turkey.

The calendar was designed by Metsä Board’s packaging design team and manufactured by VG Kvadra Pak, part of the Van Genechten Packaging Group. The outer packaging is made of MetsäBoard Prime FBB Bright 380 gsm and the inner packaging is made of MetsäBoard Pro FBB Bright 220 gsm.

“The Carton of the Year award celebrates true excellence in packaging design, sustainability and user experience. It’s a tangible result of customercentric collaboration with our valued partners, Van Genechten

Packaging and Lumene,” said Maarten Florizoone, sales chief for FBB Europe at Metsä Board.

“On behalf of Metsä Board, I warmly congratulate all the ECEA 2025 winners.”

Metsä Board’s paperboard was also featured in several other award-winning entries at the European Carton Excellence Awards. Biobalance Mineral Sense Sun Fluid by Alpaya

Dermaceuticals received a Platinum Award in the Beauty & Cosmetics category. Its packaging, made of MetsäBoard Pro FBB Bright 245 gsm, was converted by Omaks Packaging. In the same category, the promotional packaging for Germaine de Capuccini, made of MetsäBoard Prime FBB Bright 305 gsm and converted by Alzamora Group, earned a Gold Award.

The packaging for Ringana CAPS was recognised with a Platinum Award in the Pharma & Healthcare category. It was converted by Cardbox Packaging Wolfsberg GmbH using MetsäBoard Natural FBB 325 gsm.

More information from www. metsagroup.com

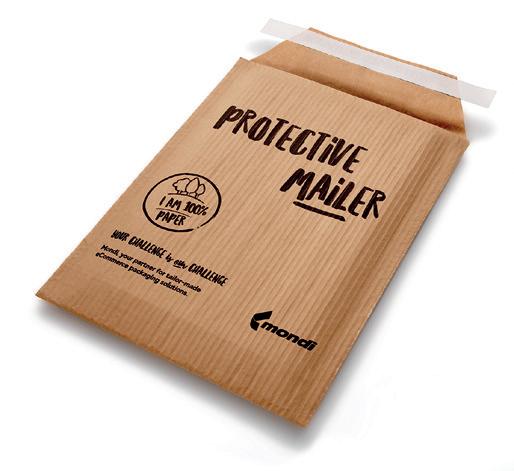

For the first time in the UK, Mondi showcased its complete eCommerce packaging portfolio –from paper to boxes to bags – at eCommerce EXPO in London during September. Designed to meet the growing demand from online retailers and brands for innovative and sustainable packaging, Mondi has expanded its product range to include solid boards and fanfold to provide a greater choice of tailored options for eCommerce retailers in the UK.

Visitors to Mondi’s stand were able to explore a variety of innovative, consumer-centric packaging, including the awardwinning Protective Mailer. Crafted entirely from paper, it is recyclable and eliminates the need for plastic packaging, offering a sustainable alternative to padded bubble mailers. In addition to the eCommerce MailerBAG range, Mondi presented a number of

corrugated options, some of which featured state-of-the-art printing, highlighting the power of digital printing to create exciting unboxing moments.

Mondi’s paper-based eCommerce portfolio supports the company’s MAP2030 sustainability commitments, which include making 100 percent of its products reusable, recyclable or compostable by 2025. Mondi is also actively investing in research and development to ensure its packaging performs in real-life logistics settings (ISTA lab certification available on request) while meeting the highest environmental standards. More information from www. mondigroup.com

Latest packaging design from Koehler Paper is its newlydeveloped NexPlus Seal Coat paper, which has excellent flexcrack resistance, glossy surfaces and vibrant printing results.

This is said to close a gap in the market by enabling brands to showcase their products in paper packaging, with a “look and feel that leave nothing to be desired in comparison to plastic”, while also being recyclable.

A specially-developed technology means the paper product has a uniform highgloss without any cracking. In addition, the paper is also said to feature extraordinary suitability for subsequent processing, and

Examples of Koehler’s NexPlus Seal Coat paper

can be processed with the same speed as plastic on packaging machines. It is also heat-sealable at lower temperatures.

“The development of this packaging paper represents an incredible breakthrough,” explained Christoph Wachter,

director of flexible packaging paper at Koehler Paper.