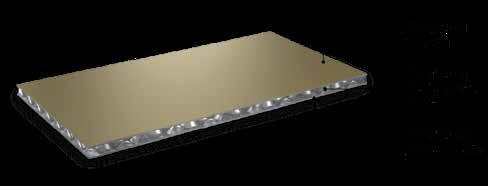

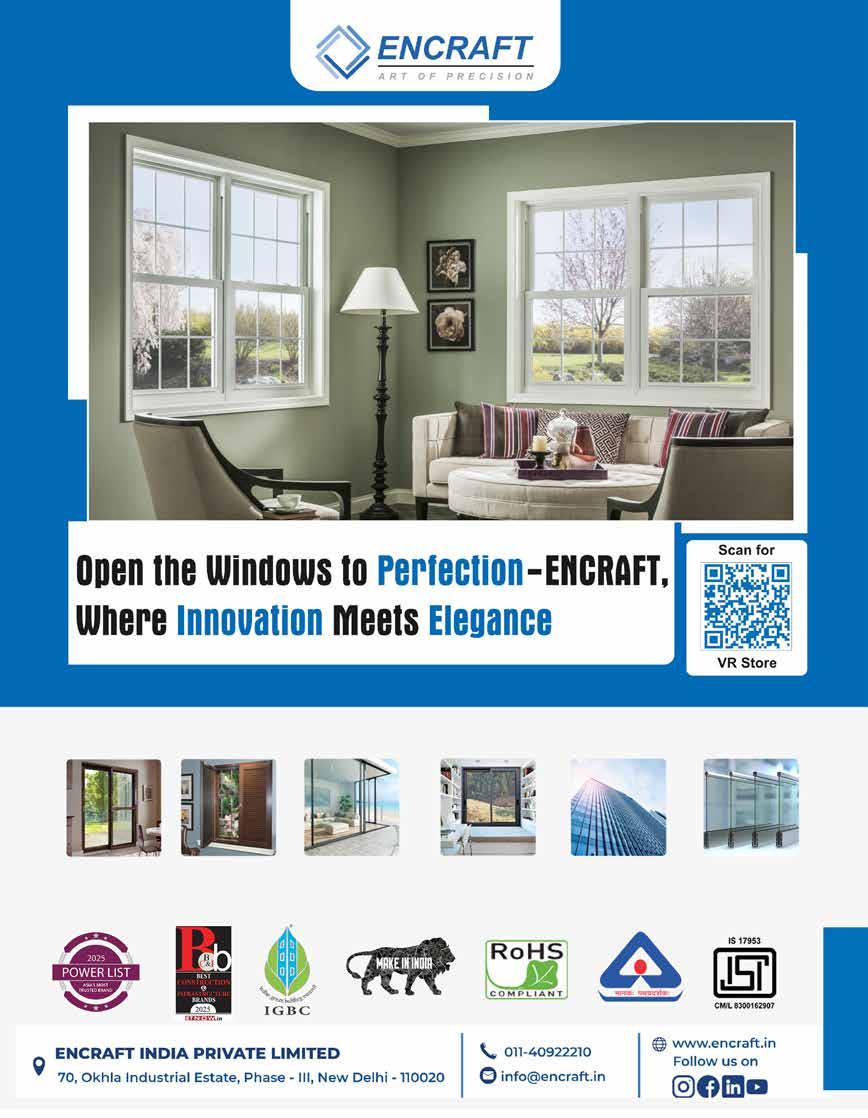

Combining cutting-edge design with superior performance.

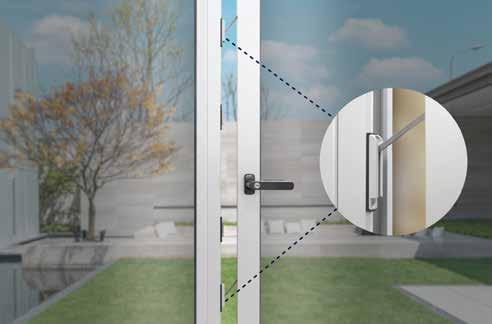

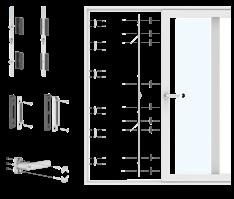

– Aligned sashes for a perfectly symmetrical view

– Minimal aesthetic (7 cm central post with NP Ultra handle)

– Load capacity up to 400 kg

– Concealable frame with low threshold

– New generation rollers

– Fully anodized diverters with stainless steel guide

– High performance with central gasket and perimeter closure

– Micro-ventilation available

– Anti-burglar hardware compatible

More than 60 years of innovation, development & production of premium hardware for aluminum windows and doors.

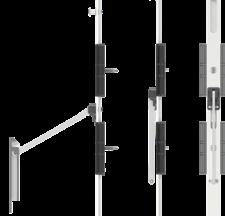

Open up to effortless elegance with B-Slide, the multipoint lock for sliding windows. Designed for style, strength, and simplicity, the B-Slide combines premium materials with seamless motion for a flawless experience every time. Whether used with aluminium or PVC profiles, B-Slide delivers uncompromising security, effortless operation, and lasting durability, all in a sleek, modular design that adapts to your needs.

B-Slide. Strong. Smart. Smooth. The perfect sliding window solution for modern living.

Sobinco, your reliable partner for high-end, architectural hardware. Get in touch: abhishek.kale@sobinco.com - 3rd Floor, Shivana building, Right Bhusari Colony, Chandani Chowk, Pune 411038

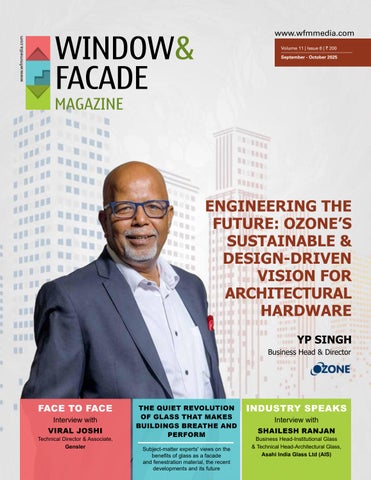

Volume 11 | Issue 6

September–October 2025

18

21

Designing for Performance: How Intelligent Façades are Shaping India’s Sustainable Future

Dr. S.P. ANCHURI, CEO, Anchuri & Anchuri

GRC Façades: A Modern Solution for Architecture

AMAN UPADHYAY, Site Incharge, KK Holding

24 The Façade Consultant’s Role in Early Design Stages: Saving Time and Cost

28

32

HumaShahnaz media@wfmmedia.com

+91 98701 44425

RNI: DELENG/2014/57870

RAJ SINGH, Director and Principal Consultant, Nexivaa Fenestrations Pvt Ltd

The Façade and the Face: A Philosophical Reflection on Architecture and Personality

VIJAYA BHARGAV, Partner, Ostraca

Breaking the Coordination Bottleneck: How Systemic Delays Are Undermining India’s Façade Engineering Excellence

SENTHILKUMAR BALASUBRAMANI, Design Manager & Façade Engineering

Expert, ISE - Integrated Smart Engineers

36 Designing Efficient Glass Façades and Fenestrations: The Role of AI, Automation, and Material Innovation

ER. ABINASH MISHRA, Managing Director & CEO, Repairtech India Pvt Ltd

39 Unitised vs. Semi-Unitised Glazing Systems: Choosing the Right Solution for Your Project

CHETAN K SHARMA, Managing Director, ADI Façades

42 Design with Glass: Efficient Use of Glass on Façade and Fenestration

AR. RAJKUMAR KUMAWAT, Founder, Rajkumar Architects

46 Glass & Glazing – Innovations in Materials and Technologies

VIJAY DAHIYA, Partner, team3

51 Merging Aesthetics with Sustainability by Integrating Photovoltaics with Façades

Dr. NEHA GUPTA, Head of Department, Netaji Subhas University of Technology

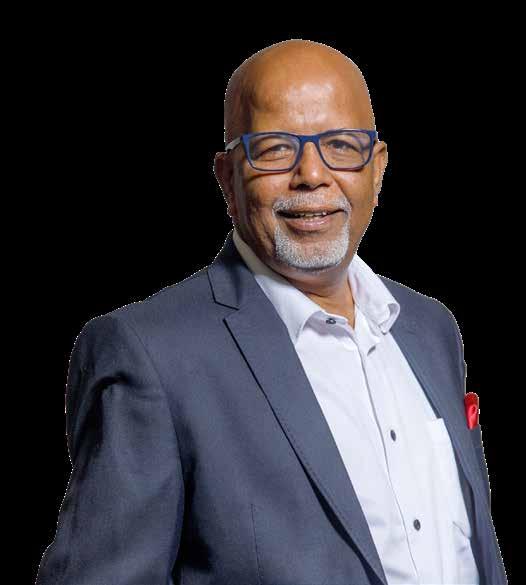

60 The Expert’s Edge

Interview with Y.P. Singh, Business Head & Director, Ozone Group

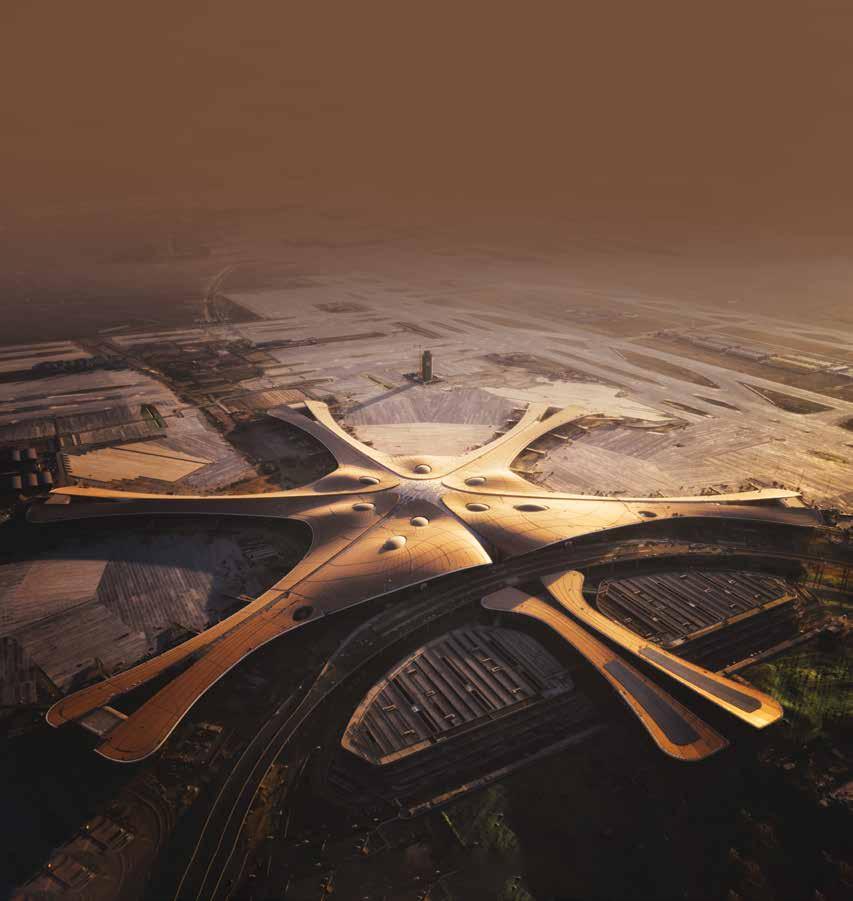

66 Cover Story

The Quiet Revolution of Glass that Makes Buildings Breathe and Perform

92 Industry Speaks

Interview with SHAILESH RANJAN, Business Head-Institutional Glass & Technical Head-Architectural Glass, Asahi India Glass Ltd (AIS)

98 Face to Face

Interview with VIRAL JOSHI, Technical Director & Associate, Gensler

108 Case Study

Use of Timber as Building Façade Material

HEENA BHARGAVA, Associate, Architecture Discipline

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www.wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

“Printed and Published by Amit Malhotra on behalf of M/s F & F Media and Publications. Printed at Thomson Press India Limited, 18/35, Delhi-Mathura Road, Faridabad - 121007, Haryana, Name of the Editor-Ms. Renu Rajaram”

Glass has quietly led one of the most transformative revolutions in contemporary architecture. Once seen merely as a fragile surface for windows, it has evolved into a defining material that shapes how buildings breathe, perform, and connect with their surroundings. The cover story, “The Quiet Revolution of Glass that Makes Buildings Breathe and Perform,” celebrates this evolution—exploring how glass has become both a medium of artistic expression and a tool of environmental performance.

From drawing daylight deep into interiors to enhancing comfort and energy efficiency, glass now performs far beyond its aesthetic value. It has become the intelligent skin of modern buildings—balancing transparency with insulation, elegance with resilience, and beauty with responsibility. With advances in glazing technologies, automation, and material science, glass façades today respond dynamically to light, heat, and sound—creating spaces that are both efficient and uplifting.

In this issue, Dr. S.P. Anchuri explores how intelligent façades are driving India’s sustainable future, while Dr. Neha Gupta examines the integration of photovoltaics with façades, merging aesthetics with renewable energy. Aman Upadhyay highlights the innovation and endurance of GRC façades as modern architectural solutions, while Ar. Rajkumar Kumawat, Ar. Vijay Dahiya, and Chetan K. Sharma share insights on optimizing performance through design precision and early collaboration. Senthilkumar Balasubramani discusses the systemic challenges impacting façade engineering, and Ar. Viral Joshi of Gensler eloquently defines façades as a building’s dialogue with its surroundings—a reflection of its function, intent, and identity.

As we approach another year, this edition stands as both a celebration and a reminder. The future of façades lies not only in creative vision or technological advancement but equally in accountability—in selecting the right materials, adhering to codes, and mindfully applying building regulations and safety norms. Every design decision we make shapes environments that influence human wellbeing, energy consumption, and urban sustainability.

To all members of the AEC community—architects, engineers, consultants, and manufacturers—your continued collaboration and commitment fuel this ongoing journey. Let us move forward together, designing façades that perform beautifully, endure responsibly, and stand as testaments to innovation, integrity, and imagination.

As India’s cities grow and climate challenges intensify, building envelopes must do more than enclose space — they must conserve energy, harness daylight, regulate thermal comfort, and reflect identity. The building façade today is a critical design interface where architecture meets engineering, and aesthetics merge with performance.

Across typologies, from commercial towers to healthcare facilities, façade design has emerged as a primary driver of operational energy efficiency. With evolving codes like ECBC 2017 and an increasing focus on net-zero targets, projects that respond to their

environmental context using passive and integrated envelope strategies are setting the benchmark for responsible design.

One such example is the upcoming project, SAHI Healthcare Building in Vizag — a modern institutional facility designed — which not only redefines façade expression through vertical fins and glazing strategies but also records measurable energy performance, achieving a 36.78% energy saving and securing Super ECBC (6-Star) compliance.

SAHI is a ground-plus-threefloor hospital located in a warm-

humid climatic zone. The building’s design champions an integrated architectural-engineering approach with a layered envelope system that is both visually compelling and functionally optimised.

Vertical Fins: Reinforced AAC fins provide continuous solar shading, reducing glare and heat gain while creating visual rhythm.

High-Performance Glazing: 13 mm double-glazed units with an SHGC of 0.27 and a U-value of 2.2 W/m²K allow ample daylight while minimising thermal ingress.

Layered Wall Assembly: AAC block layers with 120 mm of glass wool insulation achieve a wall U-value of 0.18 W/m²K.

Cool Roof Design: Roof sections feature high-reflectivity finishes and 150 mm insulation, resulting in a U-value of 0.20 W/m²K.

Optimised WWR (Window-to-Wall Ratio): Though the design embraces a bold WWR of 75.7%, passive controls and performance glazing maintain compliance.

Together, these strategies ensure the building envelope is airtight, thermally efficient, and visually transparent where needed — all while significantly reducing the building’s energy demand.

The following charts and data, drawn from the official ECBC compliance report for the SAHI project, reveal compelling insights into its superior façade and energy performance:

The project followed the Whole Building Performance method under ECBC 2017,

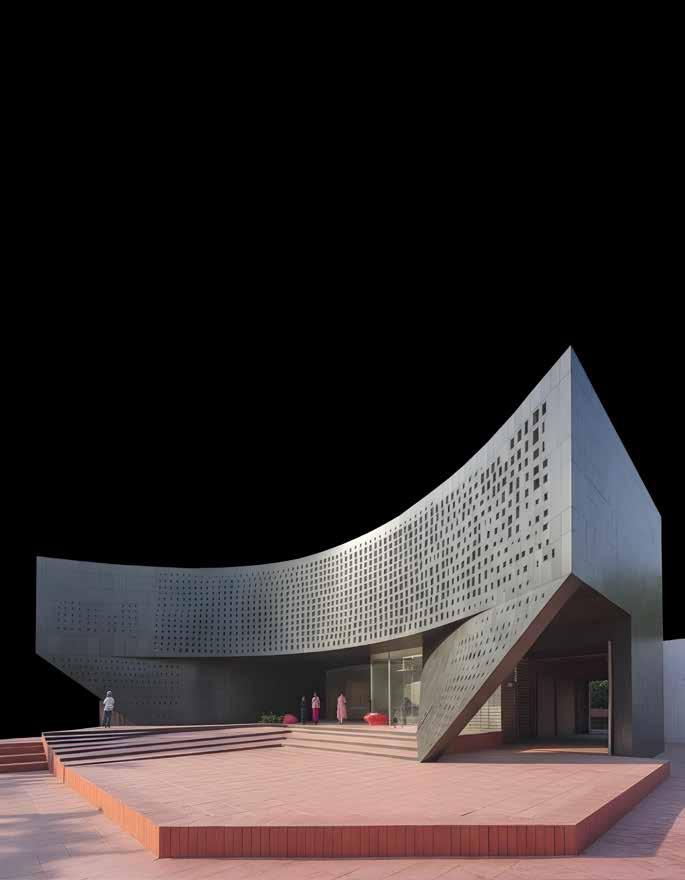

Brick and Glass, Koromangala , Bangalore Façade Efficiency: This façade demonstrates thermal and environmental efficiency through its solid-to-void ratio, recessed windows, and external shading elements. The brick cladding offers natural insulation, while deep-set windows reduce direct solar gain—minimising cooling loads. The regular window spacing ensures uniform daylight penetration, reducing the need for artificial lighting. Overall, the design blends classical aesthetics with energy-conscious planning for a durable, low-maintenance, and climate-responsive façade

using Design Builder simulation software to compare the proposed design against a baseline ECBC-compliant model.

These figures not only confirm performance compliance but also reflect

deep integration of passive design, efficient HVAC (COP ≥ 4.7), smart lighting, and renewables.

Lighting Power Density (LPD): Reduced from the ECBC baseline of 9.7 W/m² to just 2.2 W/m² using energy-efficient LED fixtures.

Daylight Compliance: Achieved 61.4% Useful Daylight Illuminance (UDI) across the building — doubling the ECBC requirement (30%).

Controls Installed:

• Occupancy sensors and daylight dimmers

• Automated shut-off based on schedules

• Manual overrides in individual spaces

• These measures ensure maximum use of natural light while keeping artificial lighting loads to a minimum.

Beyond compliance, the SAHI façade expresses the mission of a progressive healthcare institution. The verticality of the fins suggests upward growth

Bansal Complex at Komapally, Hyderabad. Combination of glass, HPL and Walls: The façade’s deep recesses, vertical fins, and shaded balconies make it ideal for Hyderabad’s hot climate. It minimizes heat gain, maximizes natural light, and enhances thermal comfort through passive design suited for intense sun and high temperatures

and care. The transparent glazing invites openness and community. The integration of form and performance demonstrates leadership in climatesensitive architecture.

This façade breathes and responds not just to the sun and wind, but to the social context it serves. It becomes a symbol of architecture that heals — in both form and function.

Building for a Resilient Tomorrow, this article explores the critical role of intelligent façade design in enhancing building performance, energy efficiency, and sustainability in India’s evolving urban landscape. Using the SAHI Healthcare Building in Vizag as a case study, it demonstrates how passive strategies — such as vertical fins, high-performance glazing, and thermal insulation — combined with ECBC compliance

and simulation-based design, can deliver measurable energy savings and architectural impact.

The future lies not just in how buildings look but in how they perform, adapt, and endure.

Quick Facts:

• Project Name: SAHI-ENT Centre

• Location: Vizag

• Client: SAHI

• Lighting designer: EcoConCS

• Architect: Anchuri and Anchuri

• Other Consultants: Weavers Pvt Ltd for Post-tension design

• Materials used for façade: AAC and DG glass

• Commencement Date: March 2024

• Completion Date: March 2026

DR AR. ER. S. P. ANCHURI

CEO, Anchuri & Anchuri

Dr Ar. Er. S. P. Anchuri is a renowned architect, structural engineer, and ECBC expert with over 30 years of experience. As Chief Consultant at Hyderabad-based Anchuri & Anchuri, he has led the design of 3,000+ projects with integrated architecture–structure synergy. A pioneer in energy-efficient buildings, he played a key role in achieving Super ECBC compliance for the SAHI Hospital in Vizag, recording 36.78% energy savings. A professor, advisor, and speaker, he has guided national ECBC implementation and mentored future professionals. He blends traditional wisdom with modern technology to create resilient, performance-driven, and contextually responsive built environments.

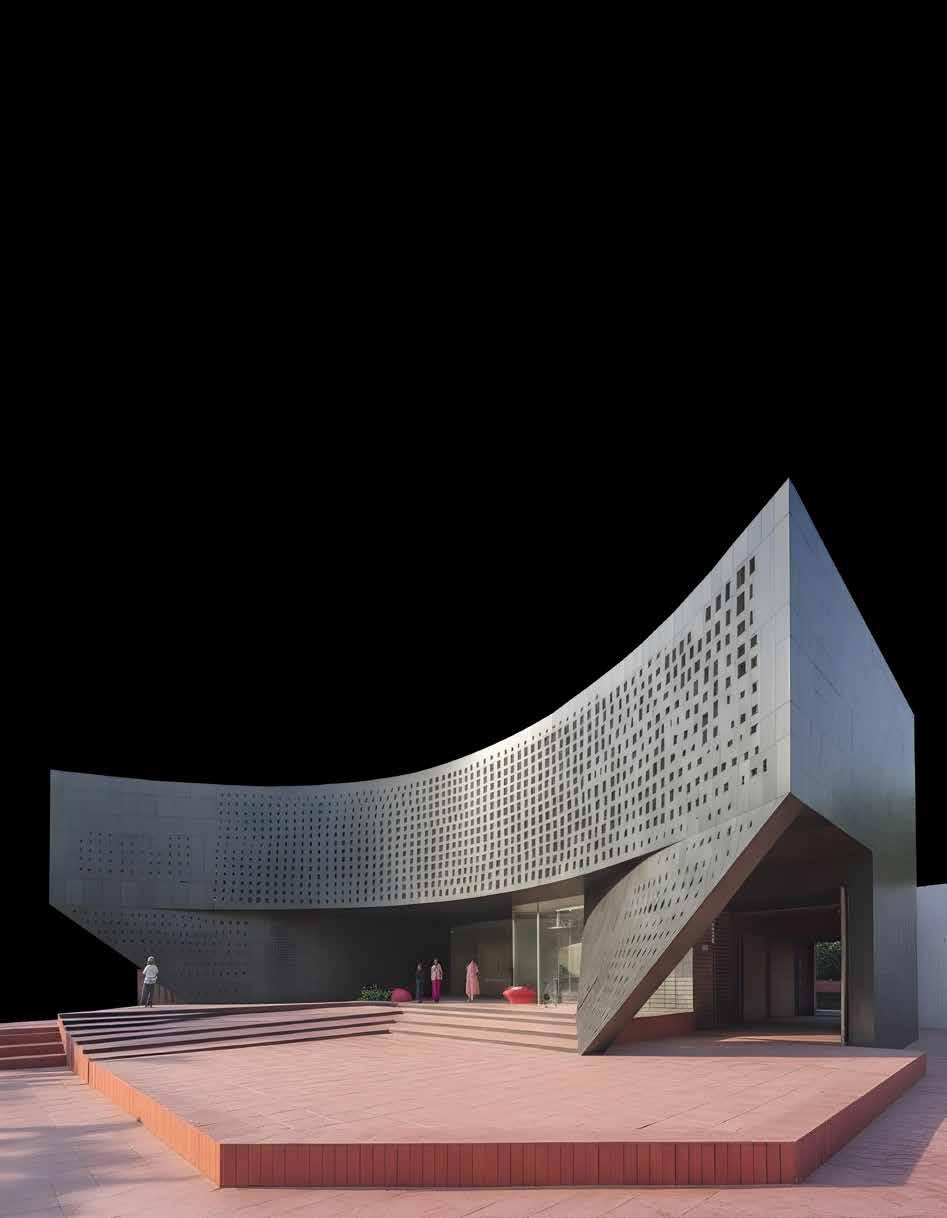

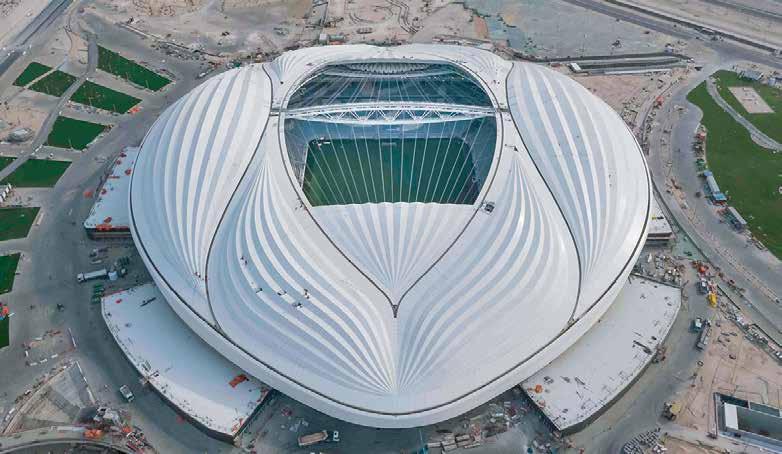

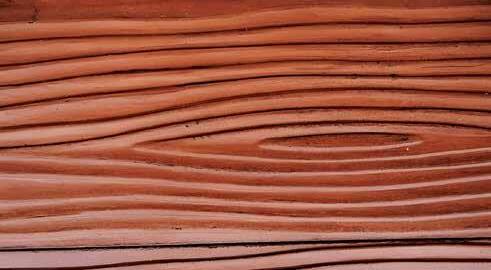

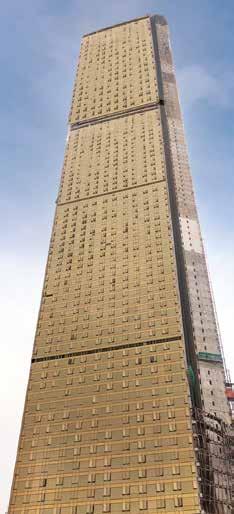

Glass Fibre Reinforced Concrete (GRC), also referred to as Glass Fibre Reinforced Cement (GFRC), is an exceptionally versatile and durable material that has become increasingly popular in contemporary façade design. Celebrated for its remarkable strength, lightweight composition, and design flexibility, GRC allows architects and engineers to bring their most creative and ambitious concepts to life. It enables the creation of intricate, elegant, and visually striking façades without compromising on structural stability or longevity. With its blend of aesthetic appeal and robust performance, GRC continues to redefine the possibilities of modern architectural expression.

GRC is a composite material made from a mixture of cement, fine aggregates, water, polymer, and alkali-resistant (AR) glass fibers. These glass fibers provide tensile strength and flexibility, making GRC much lighter and stronger than traditional concrete. Its ability to be molded into various shapes and textures makes it ideal for architectural façades.

Lightweight: GRC is considerably lighter than traditional concrete, which helps to reduce the overall load on a building’s structure. This lightweight nature not only enhances construction efficiency but

also makes GRC an ideal choice for highrise buildings and intricate architectural designs that demand both strength and flexibility.

Durability: GRC is exceptionally resistant to weathering, UV radiation, and corrosion, allowing it to retain its appearance and performance even after years of exposure. Its low permeability further enhances durability, enabling it to withstand harsh environmental conditions such as heavy rainfall, humidity, and temperature fluctuations. This remarkable resilience makes GRC a long-lasting and dependable material for modern façades, combining strength with enduring aesthetic appeal.

Flexibility in Design: GRC can be moulded into an extensive variety of shapes, sizes, and textures, giving architects the freedom to bring their creative visions to life. Whether used to achieve sleek, modern finishes or intricate, handcrafted details, GRC offers remarkable versatility. Its adaptability allows for both subtle elegance and bold architectural statements, making it a preferred material for designers seeking to balance aesthetics with functionality.

Fire Resistance: Being a non-combustible material, GRC offers outstanding fire resistance, making it a highly reliable choice for enhancing building safety. Its ability to withstand high temperatures without compromising structural integrity ensures greater protection for both residential and commercial developments, giving architects and occupants added peace of mind.

Eco-Friendly: GRC is considered a highly sustainable material as it requires significantly less cement than traditional concrete, thereby conserving natural resources. Its lightweight composition not only simplifies handling and installation but also helps reduce transportationrelated emissions. This combination of efficiency and environmental responsibility makes GRC an ideal choice for modern construction projects that prioritise both performance and sustainability.

Cost-Effective Installation: GRC panels are much easier and quicker to install compared to traditional materials. This not only helps streamline the construction process but also significantly reduces labour requirements, transportation costs, and on-site installation time, making it a highly efficient choice for modern building projects.

Low Maintenance: GRC requires very little maintenance throughout its lifespan. Its excellent resistance to cracking, chipping, and fading ensures that façades

continue to look fresh and well-preserved for years. This durability not only reduces upkeep costs but also helps maintain the building’s aesthetic appeal and structural integrity over time.

Adaptability: GRC can be seamlessly incorporated into both modern and traditional architectural styles, offering designers and builders remarkable flexibility. Its adaptability makes it an ideal choice for a wide range of projects — from contemporary urban façades to heritage restorations — while maintaining aesthetic appeal and structural integrity.

Customisable Finishes: GRC panels can be crafted and finished to beautifully replicate the look and texture of natural materials such as stone, wood, or even terracotta. This versatility allows architects to achieve high-end, visually appealing designs while keeping costs significantly lower compared to traditional materials.

Cladding Panels: GRC is widely used for cladding panels, adding depth and character to a building’s exterior. Its adaptability enables designers to create elegant, durable, and visually striking façades that enhance a structure’s overall architectural appeal.

Decorative Elements: From elegant cornices and classical columns to intricate geometric patterns and modern sculptural forms, GRC is an ideal material for crafting detailed decorative elements. Its versatility allows architects and designers to achieve both traditional and contemporary aesthetics with remarkable precision and durability.

Restoration Projects: GRC is widely used in the restoration of historical and heritage buildings because of its remarkable ability to replicate traditional architectural details, intricate mouldings, and authentic textures. Its versatility allows designers to preserve the original charm and character of old structures while enhancing their strength, durability, and longevity for future generations.

In conclusion, Glass Fibre Reinforced Concrete (GRC) has truly transformed the landscape of modern façade design by uniting strength, versatility, and sustainability in one remarkable material. Its lightweight yet robust composition allows for greater design freedom, enabling architects and designers to push creative boundaries without

compromising on structural performance. From sleek, futuristic high-rises to carefully restored heritage buildings, GRC offers unparalleled adaptability, effortlessly blending functionality with aesthetic sophistication.

Moreover, its eco-friendly attributes— such as reduced material consumption, energy-efficient manufacturing, and recyclability—support the growing demand for greener and more responsible construction practices. The ability of GRC to mimic natural stone, metal, or intricate sculptural forms also enhances its appeal in both contemporary and traditional architectural expressions.

As urban environments continue to evolve towards smarter, more sustainable and visually engaging spaces, GRC stands at the forefront as a material that embodies innovation and resilience. It not only enriches the visual identity of buildings but also contributes meaningfully to the longevity and environmental responsibility of modern architecture. In essence, GRC represents the perfect harmony between art, technology, and sustainability—shaping façades that are as enduring, expressive, and inspiring as the vision behind them.

Site Incharge, KK Holding

Aman Upadhyay has four years of experience in the façade industry, specialising in doors and windows, ACP and aluminium cladding, tensile fabric façades, canopies, structural glazing (unitised and semi-unitised), HPL cladding, perforated sheet cladding, mesh façades, coping, railings, louvres, and stone cladding. He has completed 11 projects for esteemed clients such as DLF, TATA, NBCC, NPCIL, Nestlé, L&T, Kalpataru, among others.

In contemporary architecture, façades are no longer mere enclosures; they define how a building performs, sustains itself, and endures over time. Yet, one of the most overlooked aspects of the building envelope remains the timing of façade consultant engagement. Too often, façade specialists are brought on board postdesign phase, or worse, when the façade contractor is appointed. By then, opportunities for cost optimisation, material rationalisation, and performance alignment are already lost.

As someone who has worked across complex façade projects for over a decade, I’ve seen firsthand how involving façade consultants from the earliest design stages transforms outcomes. The façade can account for up to 25% of a building’s total construction cost, but its influence extends far beyond budget. It affects daylighting, thermal comfort, acoustics, energy consumption, and longterm maintenance.

Early collaboration with stakeholders not only refines design outcomes but also

significantly saves time and cost, often improving project efficiency.

“Engage early, and the façade works for you. Engage late, and you work for the façade.”

Bringing the façade consultant to the table early helps to validate concepts for constructability, performance, and compliance.

Early design stages—concept, schematic, and design development—

define a project’s direction. Choices related to glazing type, frame systems, shading devices, and structural support are made here. A façade consultant’s role is to translate the architectural vision into technical feasibility, ensuring design intent aligns with performance, minimum compliance requirements, and constructability.

When consultants join the team early, they can:

• Evaluate design concepts for thermal and structural performance before finalisation.

• Guide the selection of system types— unitised, stick-built, or hybrid—based on building typology and installation constraints.

• Identify risk factors such as complex geometry, inaccessible maintenance zones, or high windload areas.

• Recommend façade strategies that reduce material waste, rework, and delays later in the project.

In façade design, timing is everything. Engaging consultants early can be the difference between visionary architecture and costly compromise.

Value engineering in façade design is often misunderstood as a process of cutting costs. In reality, it’s about enhancing performance and constructability while ensuring longterm reliability. The key lies in defining accurate façade specifications early in the design process.

A well-prepared façade specification governs everything, from selecting the right system type (stick, semi-unitised, or unitised) to identifying suitable materials, coatings, and performance parameters. These choices should always be driven by the project’s architectural intent, building height, local climate, and installation constraints, rather than budget considerations alone.

When façade consultants are involved early, they help architects and developers

arrive at specifications that are fit for purpose.

Architectural creativity and engineering accuracy must work in tandem. Early façade consultancy bridges this gap by translating design intent into technically viable systems.

When complex geometries or curved envelopes are proposed, façade consultants use parametric tools to assess feasibility, structural behaviour, and fabrication methods. Even subtle refinements, like optimising mullion spacing or adjusting panel dimensions, can preserve design integrity while streamlining production and installation.

The earlier this collaboration occurs, the smoother the transition from concept to construction becomes. Early façade design reviews prevent rework and ensure the creative vision remains both achievable and efficient.

The building envelope interfaces with multiple building elements, making collaboration essential.

Façade collaboration fosters a multidisciplinary approach in which façade consultants work alongside architects, structural engineers, and sustainability experts to create solutions that are integrated, not isolated.

When façade consultants participate in early coordination meetings, they define clear interface details, tolerance zones, and load paths that integrate seamlessly with the building envelope. This early clarity minimises site conflicts and change orders, ensuring faster progress through tendering, fabrication, and installation.

“True façade collaboration is multidisciplinary, uniting architecture, structure, and building physics into one coherent system.”

In modern architecture, façades act as environmental regulators. Early engagement helps the project to analyse solar orientation, daylighting, and heat gain/loss to determine the optimal mix of glazing ratios, shading devices, and ventilation systems.

Energy modelling and daylight simulations enable data-driven decisions that reduce HVAC loads and improve occupant comfort. Such proactive analysis is vital for meeting sustainability standards, such as LEED, IGBC, and GRIHA, ensuring façades perform as well as they look.

Façade systems involve multiple materials, sealants, anchors, and movement joints, each with potential points of failure. Early façade consultancy enables technical vetting of design concepts through structural analysis, thermal modelling, and system mockups.

Compliance with codes such as EN, ASTM, and IS can be validated before tendering, avoiding costly redesigns and on-site corrections. This foresight not only saves time but also significantly reduces the likelihood of post-construction defects.

The façade consultant serves as a bridge between the architect’s vision and the fabricator’s capability. This collaboration doesn’t limit creativity; it empowers it through informed technical decisionmaking.

During the concept and design phase, Nexivaa’s involvement often includes developing conceptual façade strategies and providing input on wind-load calculations, structural loads, façade performance, building physics, build-up material thermal breaks, drainage, and movement joints, key aspects integral to both design integrity and safety.

In projects with complex geometries or high-performance façades, such as double-skin or ventilated systems, early involvement becomes indispensable. Consultants can digitally model, test, and coordinate fabrication methods well before physical prototypes are produced.

Engaging façade consultants early is not an added expense; it is a strategic investment. It empowers design teams to make informed decisions, avoid pitfalls, and deliver buildings that are beautiful, functional, and cost-effective.

Today’s façade consultants bring cross-disciplinary expertise spanning building physics, materials science, and computational modelling. They ensure compliance with ECBC, ASHRAE, and EN standards, and guide projects toward LEED or IGBC certification through façade performance analysis.

RAJ SINGH

Director and Principal Consultant, Nexivaa Fenestrations Pvt Ltd

This integration of art, engineering, and regulation defines the modern façade design process.

The future of façade design lies in datadriven, performance-led engineering. With advances in parametric modelling, BIM, and digital fabrication, façade consultants now shape not just design outcomes but the entire project workflow, from ideation to delivery.

Early-stage façade engineering isn’t a cost; it’s an investment in predictability, performance, and precision. As the Indian façade and fenestration industry matures, the shift towards early consultant involvement will define project success. This collaborative approach could save millions in rework and accelerate the adoption of sustainable building envelopes.

Raj Singh represents the embodiment of Nexivaa’s mission and values. A mechanical engineer by qualification and façade engineer by practice, Raj brings over a decade of specialised experience in complex façade system design, value engineering, and project management across all RIBA stages. A mentor and practitioner, he bridges the gap between architecture and engineering through precision-led solutions that optimise performance, cost, and constructability. Under his leadership, Nexivaa Fenestrations continues to champion innovation, integrity, and excellence in façade engineering across India and beyond.

Architecture has always been more than the act of constructing buildings; it is the material expression of human thought, culture, and aspiration. Among its many elements, the façade occupies a unique place. Literally, it is the outer skin of a building - the interface between interior and exterior, between private and public. Metaphorically, it echoes the human condition itself, for we, too, construct façades: the ways we present ourselves to the world, the choices we make about what to reveal and what to conceal.

In philosophy and psychology, the “persona” is the mask we wear to navigate social life. It is not inherently false, but rather a necessary mediation between inner reality and outer expectation. Likewise, a building’s façade is not merely a decorative front; it is a negotiator between the structure’s function and the environment in which it exists. A glass curtain wall in a dense city is as much about openness and dialogue with its surroundings as it is about enclosure. A modest

a quiet neighbourhood tells a different story - one of rootedness, humility, and endurance.

wall in

When façades become excessively ornamental, however, they risk becoming disingenuous - like individuals who hide behind elaborate pretences. In both architecture and life, there is a moral dimension to this: honesty matters. Just as we value authenticity in people, we value buildings that are truthful to their structure, material, and purpose.

An honest façade does not conceal but reveals. It reflects the logic of the building rather than disguising it. The exposed concrete of Brutalism, the skeletal steel of Modernism, or the untreated timber of vernacular houses - each asserts a kind of architectural candour. These buildings communicate not with ostentation but with clarity: This is who I am, and this is how I stand.

Such honesty aligns with the principle that “less is more,” a dictum famously championed by Ludwig Mies van der Rohe. To strip away the unnecessary, to avoid the temptation of excessive ornament, is not to diminish beauty but to refine it. This restraint is not only an aesthetic philosophy but also a sustainable one: fewer materials wasted, fewer resources consumed, more integrity preserved.

Minimalism in design parallels integrity in personality. Just as an individual who lives simply and truthfully is more resilient to the pressures of pretence, so too a building designed with restraint is more enduring and sustainable. A façade that arises from functional necessity - shading devices responding to climate, openings aligned with natural ventilation, materials sourced locally - becomes beautiful precisely because it is authentic.

In a time when sustainability is not just a choice but a necessity, façades that are performative rather than purely decorative embody ethical responsibility. They provide insulation,

filter light, harvest energy, and connect inside and outside without unnecessary excess. Here, function becomes form, and form becomes beauty.

When we stand before a building, we are, in a sense, standing before a personality. We read its façade as we read a face - looking for honesty, coherence, and depth. A façade that is truthful to its materials and function resonates with us, just as an authentic person does.

Perhaps the ultimate lesson is this: architecture, like human character,

flourishes in sincerity. The façade should not be a mask, but a mirror - revealing rather than concealing, speaking rather than posturing. And in embracing the principle of “less is more,” both architecture and humanity move towards sustainability, clarity, and truth.

The façade, in whichever language, should allow communication between its inside and the world outside. And when this communication creates a rhythm, it forms a soulful rendition by itself. Through fenestration rhythms, one can visualise how spaces are organised, where people gather, and how daylight enters. Shading devices, perforated screens, and louvres are not merely technical solutions but expressions, telling us how the building breathes in response to sun, wind, and climate. Just as in human communication, the words spoken by the façade - if minimal and crisp - would convey the design and the function in the best possible way.

VIJAYA BHARGAV Partner, Ostraca

Vijaya Bhargav is an experienced Partner with a demonstrated history of working in the information services industry. She is skilled in AutoCAD, mixed-use developments, renovation, construction, and sustainable design. A strong entrepreneurial professional, she holds a Bachelor of Architecture (B.Arch.) with a focus on Interior Design and Architecture from JNTU.

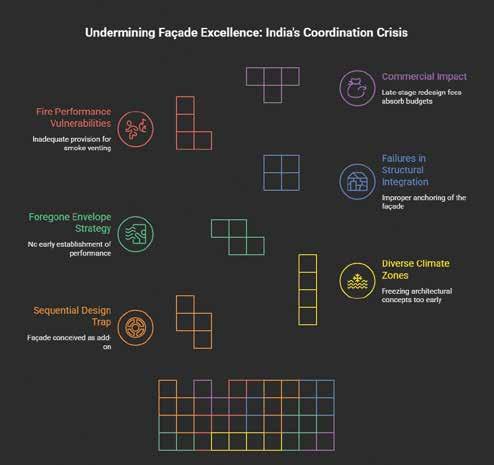

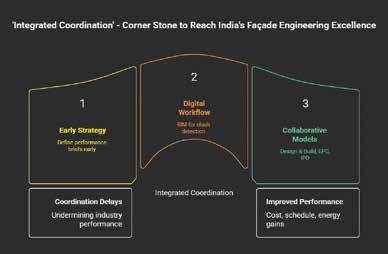

India’s entire construction landscape is undergoing an unprecedented transformation. Mirrored within the glowing towers of Gurgaon to smart cities across the subcontinent, façade systems have transcended their boundaries as building envelopes in the modern age, coalescing into a complex, performancecritical assembly defining thermal comfort, energy efficiency, fire safety credentials, and long-term propositions defining a building’s attractiveness or value.

However, lurking ominously under this architectural renaissance is a latent

issue that could undermine industry performance: delays in coordinating key stakeholders that are essential for successful project execution. The delays between architects, façade consultants, MEP engineers, structural designers, and project managers are more than mere inconveniences regarding schedule. They can be seen as institutional barriers through which technical excellence is compromised, costs are inflated, and innovation is stifled throughout the industry.

Recent industry analysis reports that over 70 percent of major façade projects face

delays due to coordination issues in tierone cities in India. They suffer, on average, scheduling overruns of about 12–16 weeks as a direct consequence of stakeholder misalignment. Dislodged from the lifecycle of the project, however, these delays cause irrevocable loss of technical integrity in the building envelopes that, in fact, determine occupant comfort and energy performance across decades.

It is at this juncture that the project delivery methodology adopted by the Indian construction industry in façade integration falls short when compared with international project delivery methodologies. Most Indian projects follow a sequential, compartmentalised design process, conceived as an add-on to the building rather than an integral component of it.

Consider a typical workflow: architects finalise schematic and design development drawings in isolation. Structural and MEP systems are subsequently designed around these parameters—before, and oftentimes at tender or GFC stage, the façade consultant enters the project. Cascading technical compromises throughout the entire project lifecycle create a situation of life-and-death importance to the whole project.

In fact, this leads to severe consequences: structural embed provisions do not deliver façade load requirements, and this necessity involves tedious retrofits, adding costs of anywhere between 15 and 20 percent of structural budgets. Based solely on aesthetics, window-to-wall ratios are fixed in such a way that there are buildings requiring about 40 percent additional cooling energy compared

with optimally designed alternatives. MEP interfaces also become inaccessible afterthoughts, compromising practicality and maintenance protocols.

However, India’s diverse climate zones present their greatest challenges. Conditions ranging from humid coastal areas to arid inland regions represent very different types of façades in terms of performance requirements. The freezing of architectural concepts before façade consultants are hired puts an end to possibilities for responsive design optimisation and project success.

Perhaps of greater concern is the industrywide practice of foregoing early-stage envelope strategy development. Typically, developers progress through feasibility phases without any establishment of key façade performance parameters — target U-values, Solar Heat Gain Coefficients, air infiltration rates, fire resistance requirements, and maintenance strategies. Industry studies report that early-stage envelope strategies save 25–30 percent in façade costs, with approvals taking 40 percent longer to obtain through building-permit systems.

The technical implications of poor coordination go far beyond scheduling delays to basic performance compromises that would eventually affect the operation of the building for decades into the future.

The most critical of its failure modes is improper anchoring of the façade. When structural teams design away from façade load data, the result is misaligned cast-in channels or inadequate bracket provisions, which further compromise slab edge coordination. These cause very expensive structural retrofits — often core drilling and epoxy anchoring — that could cost three times more than what would have been spent on properly planned cast-in systems.

It is not about the cost. It compromises joint integrity regarding seismic action,

raises questions of proper tolerance in movement accommodation, and creates potential for poor wind load resistance — all of which fundamentally affect the safety of the building, all the more critical in seismically active areas of India.

Fire safety compliance has specific vulnerabilities caused by coordination breaches, increasing concerns that have arisen following recent NBC updates regarding fire safety in India. The lack of an efficient fire stop or inadequate provision for smoke venting in façades crossing compartmentation lines could delay occupancy approvals for 6–12 months and could lead to retrofitting costs between 15 and 20 percent of original budgets.

On the thermal performance and energy fronts, the stakes are equally high, particularly in light of the ambitious Energy Conservation Building Code targets set by India. Improperly specified glares or poorly detailed visual barriers with no coordinated shading systems may increase HVAC loading by up to 30 percent. Such deterioration in performance, even worse, has been experienced in India’s extreme climates, where a building could consume up to 40–50 percent more energy than optimally designed alternatives due to façade miscoordination.

Commercial implications continue to stretch far beyond direct cost overruns.

Late-stage redesign fees for façade alterations tend to absorb 3–5 percent of façade budgets, which is significant when façades cost about 15–20 percent of total construction costs in buildings. Emergency procurement requirements for custom profiles inflate material costs by 20–30 percent and extend delivery schedules by 8–12 weeks.

Schedule impacts tend to be equally expensive, especially during monsoonaffected construction periods in India. Façades generally require lead times of about 10–16 weeks, in addition to a few buffer weeks owing to monsoon logistics. Delays in releasing “For Construction” drawings create cascading delays in shop drawing development and mock-up construction before final fabrication.

Ultimately, the delays affect weather seal completion, thus impacting the scheduled times for interior works, HVAC commissioning, and occupancy permits. In Mumbai’s commercial market, every month of delayed occupancy could cost property developers about 2–4 percent of total rental income potential, hence making coordination efficiency a very important competitive advantage.

Changes are required in the approach to project delivery, stakeholder engagement methods, and technology adoption strategies to truly address delays in coordination.

This means, among other aspects, the clear definition of envelope performance briefs early in the conceptual stage in terms of environmental performance metrics, budget parameters, fire safety requisites, and maintenance protocols.

Façade consultants should also be engaged during Stage 1 and Stage 2 design discussions so that the requirements of the façade inform rather than react to architectural and structural decisions. The leading developers in India are displaying the benefits of this approach. Some projects in Gurgaon achieved a 15–20 percent reduction in façade costs and improved schedules by almost 30 percent through façade consultants being brought on board during the schematic design stage.

Early in the project, leading property developers in Mumbai achieved a 25–30 percent reduction in energy consumption from early façade–HVAC coordination protocols.

Integration of a digital workflow means that technology adoption does not stop at BIM but goes further to require Level of Detail 350+ modelling across all trades. All elements at the interface of a façade — such as anchors, louvres, and fire collars — must also be included in digital clash detection protocols.

A new building completed in Pune claimed to have installed 95 percent of its façade free of clashes through systematic BIM coordination protocols, which cut down installation time by 25 percent and eliminated costly field modifications. Introducing collaborative procurement and delivery models reflects a shift in project delivery methodology from traditional design–bid–build to Design & Build, EPC, or even Integrated Project Delivery. These collaborative approaches enable early vendor feedback on system feasibility and cost implications.

Consider, for instance, some notable developers based in Chennai who established early contractor engagement through integrated design–build delivery methods, resulting in 20 percent reduced façade costs and 35 percent improved schedules.

Cultural transformation is the necessity on the road ahead, as it positions façade integration at the very heart of design development. This demands better collaboration protocols, systematic technology adoption, and performancebased decision-making.

Projects that embrace integrated façade coordination achieve 15–25 percent cost reductions, 30–40 percent schedule improvements, and 25–35 percent enhancements over traditionally coordinated projects in energy performance. Without improvements at the fundamental level, India certainly cannot achieve those lofty sustainability targets under the National Solar Mission and Energy Conservation Building Code. The technical sophistication of today’s façade systems demands coordination that matches the excellence their performance potential can achieve.

Coordination delays in façade engineering form the basic blocks to achieving technical excellence, commercial success, and environmentally friendly performance in this rapidly transforming industry in India. For project teams, developers, and industry stakeholders, façade coordination is not a luxury — it is a fundamental requirement for project success in an increasingly performancedriven market.

The question is not whether or not industry stakeholders will move toward integrated coordination practices. It is a matter of propelling the systematic changes necessary — and doing so swiftly — to unlock the full potential of façades. The future belongs to those who embrace proactive, integrated methodologies to deliver façades.

SENTHILKUMAR BALASUBRAMANI Design Manager & Façade Engineering Expert, ISE - Integrated Smart Engineers

Senthilkumar Balasubramani brings over a decade of rich experience in façade engineering, having worked with top industry names such as British Aluminium, Qatar Design Consortium, Saint-Gobain, Inventure, and Al-Barary. His exposure spans the full spectrum of façade consultancy and contracting — from concept development and detailing to performance testing and execution. He has contributed to large-scale commercial and institutional projects across the Middle East, South-East Asia, and Australia. His strength lies in understanding complex façade systems and ensuring compliance with diverse international codes. With a reputation for technical clarity, detailing precision, and collaborative leadership, Senthilkumar is recognised as a notable façade expert committed to delivering robust, sustainable, and globally compliant façade solutions.

Façades and fenestrations have moved far beyond their traditional role as the “skin of the building.” Today, they are performance systems that influence energy efficiency, occupant comfort, aesthetics, and sustainability. The efficient use of glass in combination with other materials, coupled with the integration of AIdriven tools and façade automation, is reshaping how we design and build in India and globally.

This article explores three interlinked aspects: efficient use of glass, emerging technologies in façade design, and the long-term outlook for the door and window industry in India.

Glass remains the most defining material in modern façades. Yet, its efficiency lies

not in isolation but in how it combines with complementary materials.

• Low-E and Solar-Control Glass: Advances in coatings reduce solar heat gain while maintaining daylight

penetration, cutting down HVAC loads significantly.

• Hybrid Material Combinations: Pairing glass with shading devices, aluminium frames, or composite panels ensures optimised thermal performance.

• Dynamic Glass Solutions: Electrochromic or thermochromic glasses adjust transparency in real time, responding to external temperature and sunlight.

• Acoustic Glass Applications: In urban environments, multi-layered glass with acoustic laminates improves indoor comfort by cutting noise pollution.

The principle is clear that glass performs best when it becomes part of a material ecosystem, balancing transparency, insulation, and structural needs.

Artificial Intelligence and computational design tools are emerging as gamechangers in façade engineering.

• Parametric Design Software: Tools such as Rhino and Grasshopper allow architects to simulate hundreds of façade patterns, optimising daylight, airflow, and aesthetics simultaneously.

• AI for Performance Prediction: Machine learning algorithms can predict how different façade designs perform under varying climate conditions, offering databacked decisions early in the design stage.

• Generative Design: AI can create multiple façade options based on inputs like solar orientation, wind loads, material efficiency, and cost. This speeds up design cycles and ensures optimised outcomes.

• Energy Simulation Platforms: Integration with BIM models enables real-time assessment of U-values, SHGC (Solar Heat Gain Coefficient), and energy savings.

The future belongs to data-driven façades where design choices are validated against performance analytics rather than just aesthetics.

Automation in façades is no longer futuristic — it is here.

• Automated Shading Systems: Motorised louvres, blinds, or kinetic façades respond to sunlight intensity and building occupancy.

• Ventilation Control: Smart fenestration integrates sensors to adjust natural ventilation, improving indoor air quality while reducing mechanical cooling loads.

• IoT-Enabled Glass: Glass surfaces embedded with sensors track energy usage, temperature variation, and

even occupant movement for adaptive control.

• AI-Based Building Management Systems (BMS): Façade performance data feeds into centralised systems, enabling predictive maintenance and efficiency optimisation.

For high-performance buildings, façade automation ensures comfort, energy efficiency, and operational reliability in real time.

India’s doors and windows industry has transformed rapidly in the past decade, driven by urbanisation, rising disposable incomes, and global design influences.

• Current Trends: uPVC Windows: Fastest-growing category due to durability, low maintenance, and insulation properties.

• Aluminium Systems: Preferred for commercial buildings due to strength, slim sightlines, and design flexibility.

• Wood & Engineered Timber: Gaining traction in premium residential projects for aesthetics and natural appeal.

• Steel & Composite Systems: Used in high-security and specialised applications.

• Expected CAGR of 8−10%, reaching an estimated value of ₹45,000–50,000 crore by 2035.

• Growth is driven by government initiatives like Smart Cities Mission, Green Building Code, and the rising demand for energy-efficient housing.

• Increasing integration of prefabricated, modular, and automated fenestration systems in large-scale projects.

• Growing emphasis on sustainability and recyclability, pushing the adoption of recycled aluminium, low-carbon glass, and bio-based materials.

While growth is promising, challenges remain:

• Lack of skilled labour for the installation of high-performance façade systems.

• Price sensitivity in mass housing is limiting the adoption of advanced glass technologies.

• Gaps in awareness among mid-tier developers about the lifecycle cost savings of energy-efficient façades.

• Industry-wide collaboration, training, and policy support will be essential to overcome these barriers.

The façade and fenestration industry is at a turning point. The efficient use of glass with hybrid materials, AIpowered design tools, and automation technologies is no longer optional— they are becoming industry norms.

For India, the next decade offers unprecedented opportunities. As the doors and windows industry grows at double digits, stakeholders must embrace innovation not as a luxury but as a necessity for sustainability, performance, and long-term competitiveness.

In the words of one façade engineer: “We don’t just design façades anymore; we design ecosystems that breathe, adapt, and perform.”

Managing Director & CEO, Repairtech India Private Limited

Er. Abinash Mishra is the Managing Director and Chief Executive Officer of Repairtech India Private Limited, and a recognised subject matter expert in the building materials industry, with over 28 years of experience. His career spans leadership roles across cement, concrete, steel, boards, roofing, and innovative construction technologies, where he has consistently driven growth, market expansion, and sustainable practices. He is widely respected for his ability to blend deep technical knowledge with strategic business acumen, building scalable distribution networks and pioneering the adoption of next-generation products. A strong advocate of digital transformation and innovation in construction, he continues to mentor teams and shape the industry’s shift towards smarter, greener, and more durable solutions.

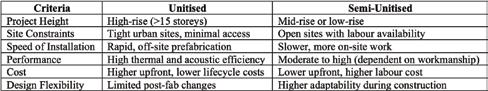

In modern architecture, the façade is far more than a surface - it is a high-performance envelope where engineering, efficiency, and elegance converge. Nowhere is this truer than in the choice of glazing systems. For commercial towers, institutional campuses, and high-rise residential buildings alike, developers are often faced with a pivotal decision: unitised or semi-unitised glazing?

It impacts everything from construction timelines to thermal performance, from design flexibility to lifecycle costs. In this article, we explore the differences, advantages, and ideal applications of both systems, so your next project doesn’t just look good, but performs even better.

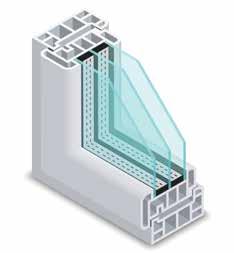

At its core, a glazing system is how glass and supporting elements (like mullions and transoms) are assembled, transported, and installed on a building’s façade.

Unitised systems arrive at the site as fully prefabricated panels - glass and frame already assembled - ready to be hoisted and anchored.

Semi-unitised systems involve partial factory fabrication; glass and vertical mullions are pre-assembled, but horizontal components and final fixing are done on-site.

The difference may seem slight, but it cascades across the project lifecycle.

Unitised systems are built for speed. Because 80–90% of the work is done off-site, installation is swift, sometimes reducing on-site activity by up to 50% (W&W Glass, 2015). This makes them ideal for tight urban sites, highrise towers, and phased construction projects. It’s not uncommon for experienced teams to install 30–40 panels per day with minimal scaffolding.

By contrast, semi-unitised systems offer greater flexibility during installation. They suit projects where site adjustments, late-stage changes, or access constraints are more likely. However, they typically require more labour, time, and supervision on-site, which can extend timelines.

Weatherproofing and thermal performance are key in façade systems. Here, unitised systems tend to outperform (Cordero, García, & Overend, 2015). Factorycontrolled fabrication allows for precision sealing, reduced tolerance errors, and better curtain wall integrity—critical for high-rise projects exposed to wind and rain.

Semi-unitised systems rely more on-site workmanship. While high-quality results are achievable, they demand rigorous quality control during installation to match the airtightness of unitised panels.

Modern buildings are dynamic structures - they move, settle, and expand. Unitised systems, with their interlocking gaskets and built-in movement joints, are engineered to accommodate this behaviour (Memari et al., 2011; O’Brien et al., 2012). They’re particularly effective in seismic zones or towers over 15 storeys, where thermal expansion and structural sway are pronounced.

Semi-unitised façades, though structurally sound, may not offer the same ease of movement accommodation and often require additional design detailing to handle these stresses.

Cost comparisons between unitised and semi-unitised systems can be misleading if judged solely on material prices. Unitised systems often carry a higher upfront fabrication cost. But when one factors in faster construction, lower on-site labour, fewer errors, and reduced rework, they may offer better long-term value (Life Cycle Assessment

Unitised systems arrive at the site as fully prefabricated panels - glass and frame already assembled - ready to be hoisted and anchored

of Curtain Wall Façades, 2024), especially for large-scale projects.

Semi-unitised systems can be costeffective for mid-rise buildings or where budget constraints favour a higher share of on-site work. They also allow developers to phase costs more evenly across the construction timeline.

As buildings get smarter, glazing systems are evolving too. Some projects now blend the best of both worldscombining unitised panels for tower cores with semi-unitised systems for podiums and retail fronts. With technologies like BIM and digital twins, façade engineering is becoming more integrated, enabling mixed systems to coexist seamlessly.

Moreover, sustainability imperatives are reshaping choices. Systems are being evaluated not just for installation speed or aesthetics, but for embodied carbon, reusability, and disassembly.

Therefore, in a sector where façades are increasingly the face of innovation, making the right glazing choice can mean the difference between a building that merely exists and one that endures.

CHETAN K SHARMA Managing Director, ADI Façades

Chetan K Sharma has worked for over 27 years at the intersection of architecture and engineering, with a particular focus on façade systems - complex, high-performance, and precise. He has led projects that have shaped skylines and pushed the boundaries of design. Some are iconic; all are technically exacting. He has founded and grown ventures that consistently deliver beyond expectations. His strength lies in the clarity of his vision, methodology, and outcomes. He collaborates closely with architects, developers, and engineers around the world. Together, they build with longevity in mind. His ambition extends beyond construction; it is to contribute meaningfully to cities, to the practice of building, and to its future.

Improving building performance requires careful consideration of façade and fenestration material selection. By enhancing insulation and limiting heat gain or loss, efficient façades serve as a barrier against the weather and lower energy usage. Within this, glass is one of the most preferred materials in contemporary construction. Highperformance glass, composite panels, and cladding systems offer thermal efficiency, durability, and aesthetic appeal. To improve comfort and energy efficiency in fenestrations, glass is usually treated with low-emissivity coatings and double or triple glazing. Combining these cuttingedge materials can improve a building’s acoustics and environmental impact.

One should never lose sight of the fact that the main purposes of glass are to

let in light and to allow visibility via its transparency. The most crucial aspect of glass is visible light transmission (VLT); a higher VLT will increase daylighting but also energy transfer and glare. Strength, safety, acoustics, and other considerations should be taken into account, in addition to light and energy, to assess the processing requirements of the primary or basic glass that was previously chosen. It will be beneficial to introduce a method to the selection process that all parties involved can understand and that guides them towards a shared strategy.

For human health and well-being, natural light is essential. The penetration of daylight into the building’s interior space and the management of internal and external heat loads must be taken

into account when designing glass and glazing. While internal loads include heat released by electric lighting systems, equipment, and people working in the building area, external loads include heat gains from the sun through fenestration, heat losses across glass surfaces, and undesired air infiltration into the building. The benefit of daylighting can be obtained through proper building orientation and careful consideration of window size and placement during the design phase.

One of the most important aspects of glass is to consider that glare will almost certainly occur, even with glazing that transmits only 10% of the light. Mechanical shading, such as a canopy, an overhanging floor, a balcony, or a louvre system, can help decrease glare. Reorienting the windows to prevent

direct sunlight from entering could also be an option. As an alternative, glare can be removed by appropriately designing the interior arrangement. It can be reduced with glazing products that have a light transmission of less than 50%. These devices permanently limit the amount of sunlight that is admitted while decreasing the sky brightness component.

Efficient use of glass is a careful balancing act: maximising benefits while minimising drawbacks such as heat gain and energy dependency. Double-skin façades with two layers of glazing offer a ventilated cavity that can significantly improve insulation and create stack ventilation. Often used in office towers, they also allow integrated shading devices. External louvres or

overhangs reduce solar exposure while maintaining transparency. Internal blinds, when combined with highperformance glass, enhance occupant comfort. In hot climates like Rajasthan, solar-control glass with shading devices minimises cooling loads. In colder regions, high-performance IGUs retain heat while capturing low-angle winter sun.

Coated glasses have superior thermal performance; they can be utilised as a solution to reduce heat transmission through the glass. Special coatings on solar-control windows lower the amount of heat gain through the glass by limiting the quantity of solar radiation that passes through it. These coatings also reduce the amount of light that can pass through the glass. When selecting these glasses, it is essential to strike the optimal balance between heat and light transmittance.

In essence, the efficient use of glass requires a multidisciplinary approach: architects envisioning aesthetics and craftspeople embedding meaning. It frames the city while filtering climate and the project’s identity, while enhancing performance.

Case Study - 1

Glass Haven perfectly combines the ease of the city with the peace and quiet of the countryside. The idea seeks to reinvent a person’s way of life by offering a sanctuary of calm amid the bustle of the city. This outhouse, envisioned by Ar. Rajkumar Kumawat was used for entertaining and as a place to unwind.

The structure deviates from usual volumetric zoning to opt for an L-shaped form that provides expansive vistas from all angles. In order to ensure that not every room needs to be opened during gatherings, this also made it possible to create distinct areas for entertaining. The main element used here was glass for façade design. Although located in a city like Jaipur, where heat prevails in the region, glass is strategically used to reduce glare and heat transmission. Low-E glass and Insulated Glass Units (IGUs) are used to complete the façade. Low-E glass is coated with microscopically thin layers that reflect infrared energy, balancing heat gain and loss. Further, at certain places, IGUs are incorporated where two or more panes are separated by air or inert gas, dramatically improving thermal performance.

The outhouse is transformed into a mystical haven by the soft glow of well-placed lighting. Focus lights

and wall sconces are incorporated into the exteriors with a minimalistic style, taking the design to new levels of sophistication. Desired focal areas are highlighted by warm yellow lighting incorporated throughout the landscaping and pool.

Thus, the outhouse is a sanctuary that offers respite from the city’s chaos and an opportunity to reconnect with nature.

• Project Name: Glass Haven

• Location: Vatika, Jaipur

• Architect: Ar. Rajkumar Kumawat

• Other Consultants: Rajkumar Architects

• Completion Date: 1 June 2023

AR. RAJKUMAR KUMAWAT Founder, Rajkumar Architects

Architect Rajkumar Kumawat commands admiration in the architectural arena for his exceptional prowess in shaping spaces that epitomise design brilliance. His architectural journey echoes his steadfast dedication to bringing exceptional visions to reality that surpass passing trends, solidifying his place as an influential figure in the world of architecture. Armed with a B.Arch from I.I.A., Navi Mumbai, his illustrious career spans a trajectory marked by a relentless commitment to creating built structures that transcend the limitations of passing trends. His design philosophy centres around an immense focus on forms and masses, seamlessly blending contemporary architectural trends while designing environments that withstand the test of time. Having previously served as Partner and Principal Architect at Design Square Architects, he leveraged this rich experience to establish Rajkumar Architects — a venture poised to extend his creative vision into new frontiers. His design approach is characterised by an exacting attention to detail, encompassing volume, scale, and materiality.

Over the past two decades, India has witnessed an unprecedented boom in construction, driven by rapid urbanisation, rising aspirations, and the growth of high-rise developments across its cities. This transformation has brought façades to the forefront of design, as markers of identity and as critical components of performance and sustainability.

Among façade materials, glass has emerged as a defining element of contemporary architecture. With high solar exposure, long cooling seasons,

and increasing urban density, the choice of glazing directly impacts energy use, occupant comfort, and long-term resilience. What is evolving today is not the importance of glass but the technologies that allow it to perform more intelligently, offering adaptability, safety, and durability for Indian cities.

For decades, glazing was static: once installed, its performance remained fixed, regardless of changing weather or orientation. In India, this often meant high solar heat gain and significant energy

spent on cooling. Studies show that in composite climates like Delhi’s, poorly specified glazing can increase cooling loads by up to 25–30%, directly adding to electricity demand.

Dynamic glazing has begun to shift this balance. Electrochromic and thermochromic glass technologies allow façades to respond to sunlight and heat, modulating tint levels to cut glare and reduce cooling demand. These solutions improve energy efficiency and enhance comfort, creating interiors that remain bright without overheating or excessive

artificial lighting. As costs reduce, smart glass is finding a stronger foothold in India. For high-performance office spaces and institutional buildings, it offers a way to meet both design aspirations and sustainability goals.

As India’s cities densify, façades are also evolving as communication surfaces. Media façades through LED-integrated glazing or transparent display systems are becoming visible in retail destinations, corporate campuses, and cultural venues. Beyond commercial branding, these systems hold potential for public information, civic messaging, and even cultural storytelling in public infrastructure like airports or convention centres.

However, Indian conditions present unique challenges. Long summers, heavy monsoons, and high dust levels demand robust integration. Any media façade must perform as an efficient envelope first, ensuring insulation and daylighting while carrying the load of visual display. Energy efficiency and maintenance are critical factors, especially since high operating costs can quickly erode viability in this market. As LED and glazing technologies advance, thinner, more durable solutions will allow wider adoption without compromising façade performance.

In a country where high-rise construction is expanding rapidly, the conversation on safety is more urgent than ever. Glass façades in India must contend with a combination of risks: heavy wind loads in coastal zones, seismic activity in the north and northeast, extreme rainfall during the monsoons, and densely occupied urban cores.

Laminated glass with advanced interlayers has become central to ensuring occupant

safety. It prevents shattering, enhances resistance to impact, and improves security against forced entry. Fire-rated glazing systems are increasingly enabling transparent yet safe evacuation routes in airports, shopping malls, and workplaces. In Indian cities where fire incidents remain a recurring risk, these solutions are becoming an essential part of design.

Equally important is ensuring that framing and anchoring systems work in tandem with glazing. In seismic regions, façades must be flexible enough to absorb movement without failure. As the skyline of Indian cities grows taller, glazing must be seen as integral to building safety rather than a decorative surface.

Maintenance is one of the biggest challenges for glass in India. With high dust levels and urban pollution, façades require regular upkeep. For high-rise buildings, this often means costly and water-intensive cleaning regimes. Selfcleaning glass is a particularly relevant innovation for our cities. Using coatings that break down organic dirt under UV exposure, and then allowing rainwater to wash it away, such glazing reduces maintenance cycles. This saves water and cuts long-term operational costs. On the

VIJAY DAHIYA Partner, team3

horizon, self-healing glass technologies are able to repair minor scratches or micro-cracks, which could extend lifecycle performance further. While these are still in early stages of adoption, they point to a future where façades will demand far less from owners and operators while retaining their quality over time.

Adopting these innovations is about aligning them with India’s climate realities. From the humid coasts of Chennai to the dry heat of Ahmedabad and the composite conditions of Delhi, glazing solutions need to be responsive and

regional. High-performance glass works best when paired with architectural strategies: appropriate orientation, external shading, insulated walls, and natural ventilation.

India’s Energy Conservation Building Code (ECBC) has already set benchmarks for glazing performance, prescribing limits for U-values, Solar Heat Gain Coefficients (SHGC), and Visible Light Transmission (VLT). These standards are pushing the industry towards better practices, ensuring glass is used with climate sensitivity rather than as a default aesthetic choice. At the same time, green building frameworks such as GRIHA and IGBC are encouraging projects to adopt glazing that supports daylight access while minimising thermal penalties.

Glass façades in India are evolving and becoming smarter. The glass box towers of the early 2000s are giving way to façades that are more nuanced: selective in placement, high-performing in specification, and often combined with shading devices or complementary materials. This evolution reflects a broader shift in Indian architecture, where climate responsiveness, energy efficiency, and occupant comfort are as important as aesthetics, ensuring that glass façades remain functional, resilient, and future-ready.

Vijay Dahiya, a Partner at team3, is with an award-winning, multi-disciplinary architectural practice that aspires to create human-centric and contextual expressions. The practice’s work draws on contemporary influences while responding to local climatic, historical, and social settings. Founded in 2012 in New Delhi by the three partners Sanjay Bhardwaj, Shubhra Dahiya, and Vijay Dahiya, team3 specialises in creating holistic projects across diverse scales. Dahiya brings over 20 years of prior experience, working on projects from large mixed-use developments to architectural and interior projects. His extensive portfolio includes the revamp of the iconic Soaltee Hotel and Lobby in Kathmandu, the renovation of the SMR Jaipuria School in Lucknow, and multiple residential projects, including the Mehra Residence and B10 in New Delhi. He believes that design needs to be built for longevity beyond styles and trends. Having completed his education at DY Patil College of Engineering and Technology, Kolhapur, Dahiya was responsible for the design and execution of numerous projects as Director at Morphogenesis, New Delhi, before founding team3. He is also a certified GRIHA trainer.

Studies show that buildings use almost 40% of the world’s energy. This has led to a shift in thinking — buildings are no longer just places to live or work; they can also generate energy. One way to do this is by adding solar panels directly to the building’s walls and windows.

Using solar panels/photovoltaics as part of the building’s design isn’t just about looking good; it’s a key part of sustainable construction. These photovoltaic modules integrated with the building envelope (façade, sunshade, roof, windows, etc.), called Building Integrated Photovoltaics (BIPV), help reduce dependence on fossil fuels, lower electricity bills, and make buildings more self-sufficient by generating heat, electricity, and natural light, depending on how they’re installed.

Therefore, it can be clearly stated that these integrated façades not only serve as an envelope that fulfils a building’s functional and aesthetic purposes but also generate clean energy. BIPV, therefore, combines smart design with renewable energy, making it a game-changer for

architecture. It also helps in earning green certifications such as IGBC, GRIHA, and LEED, while supporting global goals for net-zero energy buildings.

Traditionally, building façades serve as protective skins that control heat transfer, light, and sound while giving a building its unique appearance. However, when a façade is integrated with solar panels, it can do much more than this — it can generate electrical energy, provide thermal benefits, and contribute to daylight savings, depending on the type of module selected for integration.

Different types of panels (transparent, semi-transparent, and opaque) can be integrated with various building elements such as sunshades, windows, walls, cladding, roofs, canopies, louvres, and skylights without compromising the building’s design — in fact, they can enhance it if planned from the conceptual stage. Using transparent or semi-transparent panels can replace conventional glazing, allowing natural

daylight to filter through while generating electricity, reducing the need for artificial lighting, and saving energy. Architects can control the level of transparency and absorptivity, enabling a dynamic interaction between indoor comfort and energy efficiency.

One of the most exciting things about integrating panels into buildings is their design flexibility. Unlike traditional rooftop panels, BIPV can be customised in colour, texture, and transparency according to the building’s needs, theme, and purpose. This allows architects to make bold design statements while still generating energy, turning the building into a producer of energy rather than just a consumer.

They are available in a wide range of colours, from earthy tones to vibrant shades, and can be arranged in various patterns (geometric or organic) to create visually striking façades. Semi-transparent panels allow natural light, maintain views, reduce glare, and control heat transfer, improving thermal comfort for occupants. This means façades are no longer just functional; they become a creative canvas that combines beauty with sustainability.

The most important factor in achieving this is to plan the integration during the conceptualisation of the building, considering its purpose and spatial design.

Globally, several iconic projects showcase the success of PV-integrated façades:

• The SwissTech Convention Center, Lausanne, incorporates coloured PV glass panels that produce energy while creating a striking visual impression (Fig. 1).

• The Edge, Amsterdam, Netherlands, integrates semi-transparent PV glazing into its façades. The panels generate renewable energy while allowing

The Edge, Amsterdam, Netherlands Source:https://upload.wikimedia.org/wikipedia/commons/c/c1/Zuidas_20210512_%286%29_uitsnede.jpg

• daylight to filter through, reducing artificial lighting needs and creating a sleek, modern appearance (Fig. 2).

• In India, emerging projects are experimenting with BIPV skylights and curtain walls, paving the way for wider adoption in tropical climates where solar potential is immense.

Like all new technologies and adaptations, PV-integrated façades also present significant potential along with challenges. Integrating PV with buildings means replacing conventional building materials, which involves a higher initial investment and requires more skilled technical personnel. However, the longterm energy savings often compensate for these costs. The life-cycle conversion efficiency depends on energy metrics such as embodied energy, energy production factor, and energy payback time.

The efficiency of solar cells is influenced by several factors, including building orientation, shading, and local climate. Maintenance is another important consideration, as panels must be easy to clean and service — dust accumulation can otherwise reduce efficiency. While PV-integrated façades tend to perform particularly well in cold climates due to the thermal gains they provide, smart design

strategies such as shading, ventilation, and selective transparency can also enable them to function effectively in hot climates.

Looking ahead, PV-integrated façades in the form of skylights, windows, canopies, solar shading devices, louvres, and other elements are set to become a key feature of sustainable architecture. As technology advances, PV panels will become thinner, more efficient, and easier to integrate seamlessly into building designs. With increased government subsidies and mass-scale production, the cost of investment is expected to decrease further. Future “smart” façades may even combine solar power with adjustable shading and ventilation, creating buildings that are not only visually striking but also highly energy-efficient and intelligent.

PV integration with façades and windows characterises the essence of modern architecture, where form meets function. It allows buildings to be expressive, energypositive, and environmentally responsive. For architects and designers, it presents a unique opportunity: to craft façades that are not only aesthetically compelling but also instrumental in shaping a sustainable future.

DR. NEHA GUPTA

Head of Department, Netaji Subhas University of Technology