INDUSTRY SPEAKS

Experts’

Experts’

Dear Readers,

The evolution of architecture reflects how we live, work, and interact with the spaces around us - and few materials embody this evolution quite like glass. Once used sparingly, today, glass dominates modern building exteriors, transforming skylines and redefining how buildings communicate with their surroundings.

Glass is no longer just a material - it is an experience. Its inherent transparency fosters openness and invites natural light, creating visually expansive interiors and a seamless connection between indoor and outdoor spaces. Whether in urban towers or serene homes, glass merges architecture with nature, making buildings feel lighter, brighter, and more welcoming.

But beyond aesthetics, the benefits of glass are multi-dimensional. It is hygienic, odourless, and incredibly easy to maintain. Technological advancements in glass manufacturing have made it more resilient, thermally efficient, acoustically insulating, and fire-resistant. These performance characteristics have made it the preferred material for façades, skylights, windows, and even roofs. Whether used in expansive curtain wall systems or sleek interior partitions, glass meets the demands of modern architecture with grace and versatility.

In this edition of our magazine, we put the spotlight on Glass and Glazing in Building Exteriors. Our cover story explores the critical role that glass plays in modern façades and fenestration. Industry experts share their insights on the evolving trends, performance benefits, and the future of glass in contemporary design. From double-skin façades to cutting-edge glazing systems, this issue unpacks the full spectrum of possibilities.

In an age where energy performance, sustainability, and aesthetics must go hand in hand, glass stands out as a material that offers a perfect balance. From smart glass that adapts to sunlight to laminated panels that ensure occupant safety, the potential for innovation remains vast. Architects and designers are continuously exploring how glass can do more - perform better, last longer, and elevate the built environment in new and inspiring ways.

As always, we believe this platform belongs to the entire industry. We warmly invite our readers, practitioners, and professionals to share their suggestions, opinions, and original articles related to façades, fenestration, and building envelopes. If you have ideas, projects, or expertise you would like to showcase, we would be delighted to feature your voice in our upcoming editions. Write us at editorial@wfmmedia.com.

10

Solving Facade Complexity with Parametric Design & Digital Tools

Jack Cruzado, Principal, FacadeOption, Philippines

Achieving Net Zero Carbon Emission through High Performance Glass

Rajkumar Karunakaran, Business Development Manager, Al Salla Glass & Aluminium Installation and Maintenace LLC

Paving the Path to Sustainability: The Vital Role of External Thermal Insulation Composite Systems

04

14

24

Dimitrios Bouraimis, Technical Manager, Marmoline BU 42

Magdy Eladl, Co-founder and Managing Director, Smart Window

16 The Comeback of Double-Skin Façades: A Century-Old Idea Reinvented for the Future

Advanced Façades and Glazing Failures

Eng. Dasun Siriwardena, Deputy General Manager - Design Engineering, Aparna-Craft Exteriors Pvt Ltd.

Light Properties of Glazed Elements in Buildings

Alessandro Massarotto, Founder, Frame Façades

Shaping the Future in Glass: Innovations, Insights, & the Façade Revolution

20

Experts’ opinion on the advancements in glass façade, the rise of smart and dynamic glazing systems

Industry Speaks

Interview with George Sergiou, Founder, Glass & Façades LLC

Face to Face

Interview with Sameer Kumar, Founder, Techne

Jack Cruzado Principal, FacadeOption, Philippines

About the Author

Jack Cruzado is a façade specialist with over 15 years of industry experience, specialising in façade design, engineering, and automation. Based in Manila, Philippines, he has extensive expertise in everything about façade, including performance analysis, QA/QC inspection (both on-site and factory), performance mock-up testing, and installation. With a strong background in software and plugin development, Jack is dedicated to revolutionising digital façade fabrication modeling. His work focuses on automating complex design processes, allowing façade contractors to reduce design time, improve efficiency, and enhance the accuracy of fabrication documents. As the founder of Façade Option, he is at the forefront of façade automation, developing innovative digital tools that bridge the gap between design and construction, ultimately transforming the façade industry.

Façade designs have evolved far beyond simple glass curtain walls. Today, they serve as dynamic architectural elements that regulate energy use, optimise daylight, and contribute to a building’s identity. However, this increasing complexity presents several challenges:

• Complexity in Design and Fabrication: Modern façades often feature intricate geometries, irregular patterns, and advanced materials that require high precision. Traditional workflows—such as 2D fabrication drawings and manual reporting—struggle to keep up with these demands. As a result, errors, inefficiencies, and design constraints frequently arise, leading to higher costs and longer production timelines.

• Shortage of Skilled Façade Engineers: The rapid increase in façade projects, combined with growing design complexity, has created a significant gap between demand and the number of qualified façade engineers. One of the main reasons for this shortage is that façade engineering is not commonly taught at universities. Instead, most professionals in the field have learned through industry experience. Unfortunately, many still rely on traditional, manual design methods rather than adopting parametric and automated design principles.

With traditional design approaches unable to keep pace, the industry must shift towards parametric and

computational design to improve efficiency, accuracy, and scalability in façade fabrication.

Rather than manually designing thousands of façade components, parametric design enables architects and engineers to establish rule-based relationships between elements. This means that when a single parameter is modified—such as panel size, spacing, or material constraints— the entire model updates dynamically, ensuring consistency and efficiency.

• Automated Design Iteration: Rapidly generate and test multiple façade variations, optimising for aesthetics, performance, and fabrication feasibility.

• Customisation Without Extra Effort: Easily create unique façade elements without manual adjustments, making complex geometries feasible at scale.

• Seamless Fabrication Integration: Design data can be directly exported to digital fabrication tools such as CNC machines, robotic arms, or 3D printers, minimising errors and reducing manual labour.

• Visual Modelling: Parametric design allows for real-time 3D visualisation, making it easier to assess design variations instantly. By linking datadriven inputs to geometric models, engineers can make informed design decisions early in the process, ensuring efficiency and accuracy before fabrication.

Implementing training programmes ensures that façade engineers and designers can effectively use parametric tools without needing specialised computational expertise. This includes:

Workshops and courses to introduce parametric workflows.

Industry-wide adoption programmes that integrate parametric design into traditional engineering practices.

Hands-on training with intuitive UIbased tools, reducing the learning curve and making automation accessible.

By training façade engineers and ensuring that parametric tools are intuitive and easy to use, firms can bridge the knowledge gap and make parametric workflows a standard approach in modern façade design and fabrication.

Computational design software plays a crucial role in streamlining façade workflows by enabling real-

time parametric adjustments and eliminating the inefficiencies of manual modifications. However, for widespread adoption, these tools must be accessible to engineers and designers, not just computational specialists. The focus should be on intuitive interfaces and simplified workflows that integrate seamlessly into existing façade engineering processes, ensuring ease of use and efficiency.

• Parametric Panelisation: Automates the generation of complex façade layouts, ensuring efficiency while maintaining design flexibility.

• Automated Data Export: Converts parametric models into fabrication-ready formats, directly

linking to CNC cutting, robotic assembly, and 3D printing.

• Intuitive User Interface (UI): Simplifies navigation and operation, enabling engineers to adapt parametric workflows without requiring specialised computational skills.

• Seamless Integration: Works alongside existing design software, ensuring a smooth transition from traditional CADbased workflows to parametric methodologies.

By prioritising user-friendly interfaces and automation, parametric tools can become a standard part of façade engineering, allowing professionals to design, iterate, and fabricate with greater speed, accuracy, and control—without requiring expertise in computational design.

BEYOND DESIGN: CUSTOM SOFTWARE AND ONLINE COLLABORATION

CUSTOM SOFTWARE AND CLOUD-BASED SOLUTIONS FOR FAÇADE FABRICATION

While digital modelling tools handle parametric façade generation, custom software solutions and cloudbased platforms are transforming how designs are shared, reviewed, and fabricated.

CUSTOM SOFTWARE FOR FAÇADE FABRICATION

Many companies are developing in-house solutions tailored to their specific needs, allowing them to:

• Automate panelisation & nesting for efficient material usage.

• Generate custom fabrication scripts for manufacturing processes.

• Seamlessly integrate with construction and fabrication workflows to minimise errors.

CLOUD-BASED DESIGN REVIEW

Online platforms enable architects, engineers, and manufacturers to view and manage façade models remotely without relying on large file transfers or specialised software.

• Real-Time Updates – Design modifications can be shared instantly across teams.

• Interoperability – Works across multiple design and fabrication tools.

• Remote Accessibility –Stakeholders can review façade models from any location.

By leveraging custom software and cloud-based collaboration, teams can streamline façade fabrication, reducing errors and improving efficiency at every stage.

Parametric and computational design have already transformed the way façades are conceived and built. As digital fabrication, automation, and cloud collaboration continue to advance, the process will become even more efficient, sustainable, and precise.

By integrating data-driven workflows and digital fabrication methods, architects and fabricators can navigate increasing façade complexity while reducing reliance on traditional labour-intensive methods.

Case Study: Innovative Façade Design with Parametric Façade Fabrication Modelling

The Rockefeller Hotel, located in Cape Town, South Africa, showcases a unitised curtain wall façade system that blends aesthetics, functionality, and sustainability. The façade was designed to create a dynamic and visually striking appearance, incorporating a combination of insulated glass units and insulated aluminium composite cladding panels in variable shades of colour.

By leveraging parametric façade fabrication modelling, the design allows for variable panel sizes and material configurations, ensuring seamless integration of glass and solid elements while maintaining efficiency in fabrication and installation. The building envelope was carefully planned to balance energy efficiency, daylight optimisation, and thermal insulation, meeting both environmental and performance standards.

• Insulated Glass Units for HighPerformance Glazing: The façade integrates IGU glass, a high-performance insulated glazing system designed to enhance thermal insulation and acoustic control. The

• glass panels vary in size and transparency, allowing for a fluid and dynamic composition. The doubleglazed units (IGU) with Low-E coatings improve energy efficiency by reducing heat transfer while maximising natural daylight.

• Aluminium Framing for Structural Efficiency: The entire façade system is supported by a custom-designed aluminium framing system, offering:

Lightweight yet durable construction, capable of handling large IGU panels.

Seamless integration with glass and cladding panels, allowing for variability in panel sizing and material use.

• Insulated Cladding Panels for Enhanced Energy Performance: Alongside the glazing, the façade features insulated cladding panels with a variable

colour pattern, offering thermal efficiency and design flexibility. These panels are used strategically to minimise heat gain and cooling demands.

The cladding consists of:

• High-density insulation cores, reducing thermal conductivity.

• Weather-resistant aluminium skins, ensuring durability against environmental factors.

• Parametrically optimised layouts, reducing material waste during fabrication.

To achieve precision and efficiency, the project utilised parametric façade fabrication modelling scripts. This approach streamlined:

• Automated Panel Fabrication

Modelling: The scripts adapt to different panel sizes and generate the required cutting list and bill of materials.

• Custom Panelisation & Size

Variability: Instead of using a repetitive grid, the modelling allowed for variable panel sizes and mixed-material placement, creating a unique yet constructible pattern.

• Direct-to-Fabrication Data

Export: The digital workflow seamlessly integrated with CNC cutting by outputting STP files for extrusions and DXF files for cladding CNC cutting. These

sizes were then optimised through cut list optimisation software to minimise material wastage.

This project is a testament to how parametric design, high-performance materials, and precision fabrication enhance façade engineering. By integrating variable panel materials, automated modelling, and sustainable materials, the façade improves aesthetics and performance and sets a new standard for energyefficient and adaptable building envelopes.

This innovative approach to façade design demonstrates how architecture can be technically advanced and environmentally responsible.

• Project: The Rockefeller Apartments and Hotel

• Location: Cape Town, South Africa

• Client: Ryan Joffe Properties

• Architect: MLB Architects

• Façade Consultant: Sutherland

• Façade Contractor: World of Windows

• Façade Engineer to the contractor: Façade Option

• Materials used for façade: Unitised curtain wall with performance glass and expressed ACP panels

• Commencement Date: 2019

• Completion Date: 2021

About the Author

Rajkumar Karunakaran

Business Development Manager, Al salla glass & Aluminium Installation and Maintenace LLC

Rajkumar Karunakaran is a Mechanical Engineer with over 19 years of industry experience, including leadership roles in glass processing and architectural aluminium fabrication in India & Middle East. I brings a strong background in production optimisation, project execution, and delivering sustainable Solutions in Glass & Aluminium field. Passionate about continuous learning, He is aims to integrate academic knowledge with practical industry application to contribute to support the future of sustainable Façade Engineering.

Achieving the Net Zero Carbon emission target by 2050 is essential for preventing the most severe impacts of climate change, helping environmental sustainability, and strengthening economic resilience, while also upholding global climate commitments such as the Paris Agreement. This article discusses the critical role of highperformance glass in achieving global Net Zero Carbon 2050 targets by enhancing building energy efficiency, reducing carbon emissions, and improving occupant comfort. It evaluates essential factors such as thermal performance, solar heat gain control, visible light transmittance, structural durability, acoustic insulation, cost-effectiveness, and climate adaptability.

• Thermal Performance: High-performance glass minimises heat transfer (U-value), optimising energy performance by reducing both heating and cooling demands.

Technologies like Low-E and triple glazing are key for improving insulation, which is essential for reducing the operational carbon footprint of buildings across all climates.

• Solar Heat Gain Control (SHGC): SHGC is critical for regulating indoor temperatures. Glass with low SHGC reduces

the need for cooling in warmer climates, while glass with higher SHGC minimises heating demands in colder regions, contributing to lower energy consumption and carbon emissions. It is important to find a balanced SHGC glazing.

• Visible Light Transmittance (VLT): Maximising natural

• light while maintaining energy efficiency is essential in reducing reliance on artificial lighting. Highperformance glass with optimal VLT enhances daylighting and lowers energy use, supporting overall carbon reduction goals.

• Acoustic Insulation: In densely populated urban environments, noise pollution can affect well-being. Acoustic glass, particularly doubleglazed and laminated options, significantly reduces noise transmission, improving indoor quality and aligning with sustainability goals by creating energy-efficient, comfortable spaces.

• Cost-Effectiveness: Though high-performance glass involves higher upfront costs, it offers substantial long-term energy savings, reducing operational energy use. This makes it an economically viable choice in the transition toward

carbon-neutral construction, with savings on energy costs contributing to the financial viability of sustainable building investments.

• Climate Adaptability: Highperformance glass adapts to both hot and cold climates, ensuring energy efficiency throughout the year. Technologies such as electrochromic glass can dynamically adjust to solar radiation, maintaining optimal thermal comfort and reducing energy use, which is crucial for reducing the overall carbon footprint of buildings globally.

• Structural Durability: Advanced glass technologies, such as tempered and laminated glass, provide strong resistance to environmental forces like wind and seismic activity. These materials ensure longevity and reduce the need for replacements, contributing to the sustainability of building

materials and their reduced lifecycle carbon impact.

• Sustainability & Regulatory Compliance: High-performance glass supports the global sustainability agenda by reducing operational energy use and greenhouse gas emissions, thus contributing to the Net Zero Carbon 2050 goal. It complies with evolving international regulations and certifications such as LEED and BREEAM, which promote the use of energy-efficient, low-carbon materials in building design.

Selecting high-performance glass based on these factors not only improves energy efficiency and occupant comfort but also contributes to global carbon reduction targets. By minimising energy consumption and ensuring sustainable building practices, highperformance glass plays a pivotal role in achieving the Net Zero Carbon 2050 goal across the global construction industry.

Dimitrios Bouraimis Technical Manager, Marmoline BU

About the Author

Dimitrios Bouramis is currently working as Technical Manager at Marmoline BU, Nordia. He got his Masters Degree in Water, Energy and Environment from Liverpool John Moores University and Bachelor Degree in Civil Engineering from University of Liverpool.

In the pursuit of a more sustainable future, the construction industry is at a pivotal crossroads. With buildings accounting for a significant portion of global energy consumption and carbon emissions, innovative solutions are imperative. External Thermal Insulation Composite Systems (ETICS) emerge as a cornerstone in this transformative journey, playing a crucial role in conserving energy and resources. Let’s explore how ETICS are driving us towards a greener, more sustainable future for our communities and the environment.

The primary function of ETICS is to improve the thermal performance of buildings. By creating an insulating layer on the exterior of structures, ETICS minimise heat loss in winter and reduce heat gain in summer. This results in significantly lower energy consumption for heating and cooling, translating into substantial cost savings for building owners and a marked reduction in greenhouse gas emissions. As energy efficiency becomes a central tenet of sustainable construction, ETICS stands out as a powerful solution.

The environmental benefits of ETICS extend beyond energy savings. By lowering the demand for heating and cooling, ETICS contributes to a decrease in the reliance on fossil fuels, thereby reducing the carbon footprint of buildings. This aligns perfectly with global efforts to combat climate change and achieve carbon neutrality. As communities worldwide adopt stricter environmental regulations, ETICS provides a practical and effective means of meeting these goals.

Sustainability is not solely about reducing energy consumption; it’s also about conserving resources. ETICS help extend the lifespan of buildings by protecting them from external elements such as rain, wind, and temperature fluctuations. This enhanced durability means fewer resources are required for maintenance, repairs, and replacements over time. By preserving the integrity of buildings, ETICS contributes to a more sustainable use of materials and resources.

ETICS are integral to the broader movement towards sustainable building practices. They enable the construction of high-performance buildings that meet stringent energy codes and sustainability standards. Moreover, the production and installation of ETICS can be aligned with green building certifications, further promoting eco-friendly

practices in the construction industry. This holistic approach ensures that sustainability is considered at every stage, from material selection to end-use performance.

Beyond their environmental impact, ETICS also play a role in enhancing community well-being. Improved thermal comfort and indoor air quality contribute to healthier living and working environments. Additionally, the energy savings achieved through ETICS can alleviate financial burdens on households and businesses, fostering economic resilience and stability within communities.

As we chart a course towards a more sustainable future, External Thermal Insulation Composite Systems (ETICS) are indispensable. Their ability to enhance energy efficiency, reduce carbon emissions, conserve resources, and promote sustainable building practices makes them a vital component of modern construction. By embracing ETICS, we not only build stronger, more resilient structures but also take significant strides towards safeguarding our planet for future generations. In the quest for sustainability, ETICS are not just a building solution - they are a beacon of hope for a greener, more sustainable world.

Magdy Eladl Co-founder and Managing Director, Smart Window

About the Author

Magdy Eladl is the Co-founder and Managing Director of Smart Window, a façade engineering company operating across the Middle East and Africa. He holds a Master’s degree in Façade Engineering and an MBA, and is currently pursuing a Doctorate in Business Administration (DBA). With extensive experience in delivering innovative and high-performance façade solutions, He is passionate about sustainability, technical excellence, and driving the industry forward.

At a time when energy efficiency, occupant comfort, and sustainability are reshaping the way we design buildings, an architectural concept from the early 20th century is making a confident return—the double-skin façade. Once considered experimental, this two-layered glass system is now being embraced globally as a smart, sustainable, and aesthetically appealing solution to modern design challenges.

But what exactly is a doubleskin façade? Why is it making a comeback? And how can architects and engineers effectively integrate it into projects today? Let’s take a deep dive.

The idea behind double-skin façades isn’t new. It dates back to the early 1900s, with one of the earliest implementations found in a building in Germany in 1903. Later, in the 1920s, Swiss-French architect Le Corbusier envisioned what he called a “neutralising wall,” an early concept of an air-buffered façade. Even William Lescaze’s 1937 design for the Loomis House in New York included a layered glass system designed to condition air and control humidity.

However, it wasn’t until the energy crises of the 1970s and advancements in glass technology that double-skin façades began attracting serious attention. The Occidental Chemical Building in New York (1980) is often cited as the first modern example, featuring a glass cube with a 1.2-metre cavity to preheat ventilation air during winter.

Fast forward to the early 2000s, and the world started seeing prominent

Cross-sectional detail of a double-skin façade showing the external façade, internal façade, and the intermediate cavity used for thermal and acoustic buffering Image Courtesy: Adapted from technical illustrations in double-skin façade system specifications

projects like The Gherkin in London and Manitoba Hydro Place in Canada utilising double-skin systems to reduce energy loads while enhancing indoor comfort.

Today, as building performance standards become more demanding, the double-skin façade is once again in the spotlight - only this time, it is backed by smart controls, AI, and deep environmental insights.

At its core, a double-skin façade is a building envelope system made of two glass layers, separated by an air cavity. This cavity can be either naturally or mechanically ventilated, depending on the climate and design intent.

• In winter, the cavity acts as an insulating buffer, trapping

warmer air and reducing heat loss.

In summer, vents allow the hot air to escape, often using the stack effect for natural cooling.

Dynamic shading devices such as blinds or louvres are typically placed within the cavity, protected from weather, extending their life and performance.

Advanced systems use smart sensors and actuators to open vents, adjust blinds, or redirect air automatically based on indoor and outdoor conditions.

One of the biggest drivers behind the resurgence of double-skin façades is their measurable performance impact.

• Energy Efficiency: Numerous case studies and simulations have shown that buildings with double-skin façades can achieve energy savings of up to 30–50%, especially in heating and cooling. For example, Manitoba Hydro Place reduced its energy use by over 60% compared to typical towers in Canada’s extreme climate.

• Thermal Comfort: By buffering indoor spaces from outdoor temperature swings, these façades create a more stable and comfortable environment for occupants. No more freezing next to the window on a cold day or baking under direct sunlight during summer.

• Noise Reduction: The extra glass layer and air gap act as a natural sound barrier, reducing external noise by up to 30–36 decibels—a vital benefit for buildings in noisy urban environments.

• Improved Air Quality & Daylighting: In naturally ventilated systems, filtered outside air enters the building without drafts or pollution.

Diagram showing vertical and horizontal sections of a double-skin façade system with natural ventilation. Blue arrows represent incoming air flow through the cavity, while purple arrows indicate exhaust airflow exiting the building envelope

Image Courtesy: Adapted from architectural technical drawings commonly used in climate-responsive façade design

Occupants also enjoy enhanced daylight access without the glare, thanks to adjustable blinds hidden within the cavity.

A side-by-side illustration showing a real-world double-skin façade cavity alongside a technical section diagram. The image highlights key components such as inner and outer glazing, the air cavity, and directional airflow from inlet to outlet—essential for understanding thermal and ventilation performance

Image Courtesy: ISA Projects – Contemporary Glass Facades and Double-Skin Façade

• Design Freedom: Architects can play with depth, transparency, and texture. The second skin adds a sculptural quality to the façade, offering opportunities for dramatic forms or soft transitions without compromising performance.

Some of the most recognised buildings in the world have successfully leveraged double-skin technology:

• The Gherkin (London): A 41-storey tower with automated vents and smart climate control, achieving 50% energy savings compared to traditional high-rises.

• One Angel Square (Manchester): Achieved a BREEAM “Outstanding” rating thanks to its double façade, which facilitates natural ventilation and controls solar gain.

A contemporary interpretation of a double-skin façade featuring an artistic, geometric screen as the outer skin. The design merges aesthetic expression with solar shading functionality, illustrating how double façades can enhance both performance and visual identity

Image Courtesy: BIMobject – Double Skin Geometric Façade by Pacific Pipe

Of course, implementing a double-skin façade isn’t without its complexities. Some common concerns include:

• Cost: The initial investment is higher due to the extra materials, structural considerations, and automation systems. However, the ROI often justifies the cost when energy savings, comfort, and property value are considered.

• Space: The cavity requires depth, which can reduce usable floor area if not planned properly.

• Maintenance: Cleaning the inner surfaces of the outer skin and maintaining moving parts (vents, louvres) requires forethought and access systems.

• Regulatory Gaps: Some building codes still don’t have clear provisions for double-skin systems, especially regarding fire safety and cavity compartmentalisation.

What’s truly revolutionising the application of double-skin façades today is smart technology.

Sensors embedded in the façade track:

• Temperature

• Humidity

• Light levels

• CO₂ concentrations

• Wind speeds

These inputs feed into automated control systems that adjust vents, blinds, and even airflow direction in real time. Advanced systems now integrate AI and machine learning to predict building needs based on occupancy patterns, weather forecasts, and energy pricing.

The next generation of double-skin façades is already on the horizon, promising:

• Integrated solar panels and energy-harvesting systems

• Biophilic elements like vertical gardens within the cavity

• Phase-change materials for thermal buffering

• Light-responsive smart glass that tints or clears on demand

• Prefabricated modules for easy retrofitting of existing buildings

CONCLUSION: A TIMELESS STRATEGY, REINVENTED

The comeback of double-skin façades isn’t just a nostalgic nod to the past – it is a timely response to the environmental, social, and aesthetic demands of the future.

What began as a radical experiment in climate control has matured into a versatile design tool, blending form, function, and technology. Whether designing a net-zero office tower, a high-performance retrofit, or an iconic cultural building, the double-skin façade offers a path to performance without compromise.

In a world where buildings must do more with less, this is one comeback we should all be cheering for.

Eng. Dasun Siriwardena Deputy General Manager - Design Engineering, Aparna-Craft Exteriors Pvt Ltd.

Eng. Dasun Siriwardena has been in the façade design and engineering sector for 12 years as of 1st April 2017. After completing his education at D.S. Senanayake College, Colombo 7, Sri Lanka, in 2005, he pursued design engineering draftsmanship at a polytechnic college. His career progressed through roles such as Design Engineering Technical Officer, Quantity Surveyor, Project Manager, and Construction Engineer in the façade industry. His expertise covers conceptual design, structural analysis, detailing, simulation, quantity surveying, and construction management. Having worked in Sri Lanka, the Maldives, the UAE, Oman, Iran, and Africa, he has gained extensive knowledge in façade engineering, recognising it as a highly specialised and rare discipline within structural engineering.

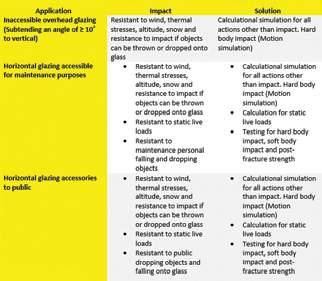

Overlooking building envelopes (façades), there are various types of façade systems and materials being innovated architecturally for buildings. The majority of the façade types below are illuminating in the sector.

As this article specifically focuses on façade safety and security, I will highlight the various types of glazed façade screen structures and the safety precautions that should be considered at the design and engineering stages by architects, façade consultants, and façade design engineers.

Framed systems are designed to support each glass panel on two or four sides. Various similar systems have been innovated as ‘Framed’ while adhering to the aforementioned support standards.

Stick-built glass façades are a method of curtain wall construction where much of the fabrication

and assembly takes place onsite. Mullions made of extruded aluminium may be prefabricated but are delivered as unassembled “sticks” to the construction site. These mullions are then installed onto the building’s façade to create a frame for the glass, which is subsequently installed.

Truss systems can be designed using various types of aluminium or steel profiles. Such systems provide continuous support to the simplest and most minimal off-the-shelf glazing systems, thereby combining relatively high transparency with excellent economy.

Panel systems are generally designed using framed glass units. The framed panel can be point-fixed to a structural supporting system while the glass remains continuously supported on two or four sides.

Frameless glazed systems are considered the most expensive

of all glazed systems. These glass panels require perforations to accommodate specialised bolting hardware. Cast stainless steel spider fittings are commonly used to tie the glass panels to the supporting structure. The glass must be designed to accommodate bending loads and deflections resulting from the fixing method.

Point-fixed clamped systems are designed to fix glass panels without any perforation for support. In the case of a spider-type fitting, the spider is rotated 45 degrees from the bolted position so that its arms align with the glass seams.

Mullion: Mullion systems include a steel or aluminium section positioned at every vertical joint in the glazing grid. These steel and aluminium mullions can be designed in either open or closed positions.

Truss: Truss systems employ a planar truss design, often in a hierarchical system that combines various element types and tension components. These truss systems are complex steel fabrications and are frequently manufactured to meet architecturally exposed structural steel (AESS) standards. Additionally, rods or cable elements may be incorporated into the truss design, and lateral tensile systems are often used to stabilise the façade structure.

Mast Truss: The mast truss utilises cable bracing as a strategy to reduce visual mass. This structural type is named after its nautical origins, where a central compression element (or mast) is stiffened by cable bracing incorporating spreaders to shape the tensile elements. Stiffening the mast helps reduce its length

between supports, minimising its buckling force. These bracings can be mounted in bilateral, trilateral, or quadrilateral symmetry around the central mast.

Cable Truss: The design and engineering of this system rely on the introduction of pre-stress forces into the tensile elements of the truss to provide stability. Depending on the span and load conditions, as determined by design calculations and structural statics, the required pre-stress forces can be quite high and must be resisted by adjacent building structures. Therefore, it is crucial to identify these forces and incorporate them into the static design of the façade and structural analysis.

Glass Fin: The glass fin system is quite simple in concept. It utilises a glass fin set perpendicular to the glass pane at each vertical line of the glass grid.

The strength of annealed glass depends on several factors. The surface condition and edge quality of the glass panel play a crucial role in determining its overall strength. Additionally,

the duration of the load applied to the glass panel influences its performance over time. Environmental conditions, such as humidity, can also impact the integrity of the glass. The distribution of stress on the surface affects how the glass withstands external forces. The size of the stressed area is another important consideration, as larger stressed areas may lead to greater vulnerability. Lastly, any damage on the glass surface, including flaws and cracks, can significantly reduce its strength.

The process increases the apparent tensile strength of glass by introducing compressive residual stresses on its surface. This method operates on a principle similar to “pre-stressing” techniques used in structural engineering. Additionally, it enhances breakage performance by ensuring that, upon fracture, the glass shatters into small, blunt fragments, making it a form of safety glass known as tempered glass. Furthermore, it maintains the improved tensile strength while preserving breakage performance in laminated glass after fracture, similar to the

behaviour of laminated annealed glass, a characteristic of heatstrengthened glass.

These allowable stress limits should be incorporated into the design calculation simulation of each façade at its design stage, following the protocol to maintain a façade safety factor of 2+.

• Instability failure – Compression member or flexural member

• Overstressing of the glass in tension – due to excessive uniform load, blast, impact, thermal stress, or uneven/ inappropriate supports

• Surface and edge effects

• Solid inclusions

Spontaneous breakage refers to the sudden failure of thermally tempered glass without any external action. This phenomenon has been known since the 1960s. In highrise buildings, a major concern in the media is the occurrence of flying glass debris caused by such breakage.

A common reason for spontaneous glass breakage is the presence of small nickel sulfide (NiS) inclusions, which range from 50µm to 500µm in diameter and undergo a volume change. The typical breakage pattern, often resembling a butterfly shape, can be an indication of NiS inclusions, but it is not a definitive sign.

To mitigate this issue, the heat soak test has recently been recognised as the most effective measure to detect and eliminate panes with inclusions before installation.

Façade specialists, engineers, and consultants have the responsibility to adhere to all necessary design and

engineering protocols to develop a well-designed façade, considering sustainability, weather tightness, interaction with the superstructure, thermal gains and losses, occupant comfort and energy efficiency, shading, ventilation, natural lighting, fire behaviour of the building envelope, acoustic performance, safety and survivability, security, maintenance, and durability.

Moreover, façade failures encompass a vast area of experience and knowledge, which can be analysed and demonstrated in various ways with precise solutions and studies.

Alessandro Massarotto Founder, Frame Facades

About the Author

Alessandro Massarotto is a chartered member of the Institution of Civil Engineers (ICE), a member of the Society of Façade Engineering (SFE), and a chartered engineer in Italy. His experience ranges from façade engineering, consultancy, and project management, working for both an international multidisciplinary engineering practice in London and Dubai and for a façade contractor in Italy. Its experience is focused on complex façades design and delivery with a strong background in UK and US. Alessandro has recently founded Frame, a turnkey façade solutions provider, delivering consultancy and project management services for façade packages from the early design stage to final delivery.

Light properties are fundamental to understanding the amount of daylight that passes through the glass, the reflection on the glass panel, and the colour of the glass. Some of them are directly related to comfort within the building, and others are more aesthetic.

The VLT is the percentage of daylight passing through the glass compared to the external environment. The higher the VLT, the light passes through the glass. This is especially important to consider when conducting daylight analysis on a building. What affects the VLT?

Glass substrate: Mid Iron glass allows for less light to get in Presence of coatings to reduce the amount of energy transmission through the glass, like Low-E or Solar control coatings Any freet in the glass, the higher the coverage percentage, the lower the final VLT to be achieved.

The light reflection, seen from the interior or exterior of the glass panel,

is the percentage of the reflected light incident on the glass.

The higher the value, the greater the specular effect on the glass. It is also important to consider these parameters in the design of the glazing panel:

• The internal light reflectance creates issues looking through the glass with higher percentages

• The external light reflectance can be limited in some countries to disregard the risk of birds’ impact into the glass. Typically, values less than 15% are sufficient. Regarding bird protection, there are also specific coatings on the market that are able to achieve such requirements.

The Colour rendering index, or CRI, is a measure of the ability of a light source to reproduce the colours of various objects being lit by the source. It is a method devised by the International Commission on Illumination (CIE). The best possible rendition of colours is specified by a CRI of one hundred, while the very poorest rendition is specified by a CRI of zero. Numbers from 80 to 100 are excellent CRIs.

To maximize VLT, usually, low-E coatings, compared to Solar control coatings, are preferable. Please note that external shading shall be provided in this case to reduce the amount of solar energy entering the building in the summer.

There are often local requirements related to the amount of daylight that shall be provided within the building, either as an average per year or daily.

Sometimes, maximising the VLT in some types of glass can be detrimental: skylights will need to be properly designed to avoid glare during the use of the building.

External and internal reflection can be reduced using anti-reflective coatings. These should be considered for high-end shopfronts.

In this cover story, we delve into the minds of several industry experts to uncover the advances that are not only shaping façades today but are also paving the way for the built environments of tomorrow. Our experts reflect on the leaps made in coated and laminated glass, the rise of smart and dynamic glazing systems, and the increasing performance demands driven by climate change, urbanisation, and evolving regulations.

One of the most vulnerable aspects of building design is the façade. Because the majority of the populace is unaware of the material’s performance, they frequently misunderstand the importance of façade design, particularly in limiting or spreading fire spread. Fire safety has traditionally been overlooked in favour of beauty, energy efficiency, cost, and other factors. However, in light of current market trends, this has progressed beyond only the aesthetic aspect and now plays a larger role in light conveyance, acoustical execution, and efficacy.

It is about the universal understanding of the reality that any possible fire threats can only be mitigated when façade systems, materials, and testing are given the attention they deserve. The emphasis should be on a comprehensive approach to examining the performance of façade materials, components of façade design for fire safety, fire testing of façade materials, compartmentalization, and much more.

Over the past decade, glass has emerged as one of the most transformative materials in modern architecture, transcending its traditional role as a transparent barrier to become an intelligent, high-performance component of contemporary façades. Once seen merely as a medium for daylighting and aesthetics, glass has evolved into a multifunctional solution addressing thermal insulation, acoustic comfort, safety, sustainability, and even energy generation. The façade, once a passive skin, is now an active, dynamic interface between the indoors and the outside world—with glass and glazing technologies playing a pivotal role in this transition.

From cutting-edge solar control and photovoltaic glass to the growing relevance of electrochromic and thermochromic technologies, the glazing industry is responding rapidly to the dual challenges of performance and sustainability. Whether it's through triple-glazing that drastically improves insulation or fire-resistant glass that adheres to stricter building codes, every innovation is a step towards façades that are not only smarter and more efficient but also safer and more resilient.

The opinions and ideas of subject-matter experts are featured in this cover story. We sought to collect their thoughts on things like façade fire safety, laws and regulations, appropriate materials, the best approach to build a fire-safe façade, and so on.

As cities become denser and buildings reach greater heights, acoustic and thermal comfort have become critical considerations. In this context, our experts explore how innovations in acoustic glazing and thermally enhanced units are enhancing liveability in urban spaces. They also discuss how eco-consciousness is driving the shift toward recyclable materials, lowembodied carbon products, and energy-generating façade systems.

The future of façades is one where the boundaries between design, engineering, and performance are continuously blurring. With the convergence of glass science and smart technologies, we’re witnessing the dawn of a new era in building envelopes—one where glazing is not just a material choice but a strategic design decision.

SAM A. MOHAMMAD Co-Founder, 5D Projects

• How has glass technology evolved in the last decade, and what are the key advancements shaping modern façades?

Over the past ten years, glass technology has undergone significant development, particularly in its role within contemporary façades. Innovations in manufacturing, engineering, and sustainability have led the way. One major milestone is the introduction of high-performance coatings during float glass production, which enhance energy efficiency

by managing solar gain and light transmission. Digital tools and parametric software now allow for custom-shaped panels, expanding both design and performance possibilities.

Meanwhile, structural glazing has advanced to support slimmer, stronger glass with minimal hardware, allowing for nearly invisible joints. Progress in lamination techniques has improved safety and durability through high-performance interlayers. Additionally, the rise of smart building systems is driving demand for glass that responds dynamically to light and heat—paving the way for façades that do more than simply enclose space.

• What are the most critical performance criteria for selecting glazing in contemporary building façades?

Choosing the right glazing involves balancing aesthetics, performance, and budget. Engineers typically focus on:

• Thermal efficiency (U-value, SHGC, VLT) to improve indoor comfort and reduce energy use.

• Structural strength to withstand wind loads and potential impacts, particularly in tall buildings or seismic zones.

• Acoustic insulation, essential in dense urban environments to ensure occupant comfort.

• Safety and security, using tempered and laminated options for added protection.

• Daylighting and glare control, which affect both visual comfort and energy consumption.

• Design flexibility to support specific visual effects or material pairings.

Together, these factors determine how well a glazed façade meets architectural intent and performance goals.

• How do innovations in glass coatings, double/ triple glazing, and dynamic glazing contribute to energy efficiency in buildings?

Glass coatings, especially low-emissivity (Low-E) and solar control types, allow visible light to enter while reflecting infrared heat, significantly reducing cooling loads.

Double and triple glazing improve insulation by using air or inert gases between panes. When combined with Low-E coatings, this setup becomes even more efficient.

Dynamic glazing, including electrochromic and thermochromic glass, adjusts transparency based on temperature or user control. These systems reduce heat gain and glare in real time, helping buildings manage energy use without compromising comfort or daylight.

• What advancements have been made in laminated and tempered glass to enhance

safety, durability, and resilience in extreme weather conditions?

Laminated glass has benefited from stronger interlayers such as ionoplast, which offer better tear resistance, UV protection, and post-breakage safety.

Tempered glass is now produced with greater precision, resulting in stronger panels with fewer visual distortions. Some manufacturers are also exploring chemical tempering, which enhances surface strength and allows for thinner, high-performance products.

These advancements make glass more reliable in areas prone to storms or seismic activity, ensuring both safety and continuity of building operations.

• With increasing urban noise pollution, how is acoustic glazing improving the comfort of highrise and commercial buildings?

Acoustic glazing addresses noise through several strategies:

• Laminated glass with special interlayers that absorb sound vibrations.

• Varying pane thickness, which disrupts different sound frequencies.

• Optimised gas gaps and heavy gases, which increase sound resistance.

These improvements make a noticeable difference in occupant comfort and mental well-being, particularly in busy urban or commercial areas.

• How is the glass industry addressing sustainability concerns, and what are the latest trends in eco-friendly glazing solutions?

Today’s sustainability efforts extend beyond recycling. Key trends include:

• Using recycled glass (cullet) to lower energy consumption during production.

• Low-carbon manufacturing, with research into electric or hydrogen-powered furnaces.

• Lighter glass designs, reducing transport emissions and embodied carbon.

• Building-integrated photovoltaics (BIPV) to transform façades into power-generating surfaces.

These innovations support green building certifications and help move the industry towards net-zero energy goals.

• What role do smart glasses (electrochromic, thermochromic, and photochromic) play in shaping future façade designs?

Smart glass technology is shifting façades from passive to responsive systems:

• Electrochromic glass tints via electrical signals, controlled by the building system or user input.

• Thermochromic and photochromic glass react to heat or light, adjusting automatically to conditions.

This adaptability improves comfort, reduces reliance on blinds or HVAC systems, and supports more energyefficient and visually dynamic façades.

• How effective is solar control glass in reducing heat gain, and what innovations in photovoltaic glass are making façades energy-generating surfaces?

Solar control glass selectively filters infrared rays while allowing visible light to enter, maintaining bright interiors without excessive heat gain. This significantly reduces cooling loads.

Photovoltaic (PV) glass, particularly BIPV systems, now comes in semi-transparent and decorative options that integrate seamlessly with architecture while generating electricity.

These solutions transform the building envelope into a source of energy, supporting sustainability goals without compromising design.

• With increasing fire safety regulations, how is the demand for fire-resistant glass shaping façade designs?

Stricter fire codes have led to increased use of fire-rated glazing, capable of withstanding high temperatures and preventing fire spread for extended periods.

Modern solutions include intumescent interlayers, which expand under heat to form protective barriers. These allow architects to design safer yet visually appealing façades, even in larger openings.

• What emerging technologies do you see revolutionising the glass and glazing industry for façades in the next five years?

Key innovations to watch include:

• Programmable smart glass with multi-sensory responses.

• AI-integrated façades that learn and adapt for better energy management.

• Nano-coatings for self-cleaning or scratch repair.

• Ultra-thin glass laminates with hybrid materials such as carbon fibre for enhanced strength.

• Advanced solar technologies, including transparent solar films and quantum dots.

These advancements aim to transform façades into intelligent systems that enhance sustainability, aesthetics, and user comfort.

KARAM HAMADEH Managing Director, TPSolutions ME

• How has glass technology evolved in the last decade, and what are the key advancements shaping modern façades?

Ten years ago, glass was just… glass. Today, it is doing a whole lot more. It is no longer just about letting light in or keeping the elements out - now, it is an active part of the building’s performance, identity, and even its energy strategy.

In the MENA region, we have seen a major shift toward high-performance glazing systems. With our intense sunlight and temperature swings, there is been a clear push for smarter glass - from coated, laminated units to full-on dynamic façades. Buildings in places like Dubai, Riyadh, and Doha aren’t just iconic for their shape – they are showcases of how far glass has come.

• What are the most critical performance criteria for selecting glazing in contemporary building façades?

It depends on the project’s priorities, but in this region? Solar control tops the list - no surprise there. Keeping interiors cool without going overboard on the AC is a constant balancing act.

Beyond that, you are looking at U-value (for insulation), visible light transmittance (how much daylight you’re letting in), and, increasingly, acoustic performance - especially in city centres. Safety, too, is huge. Whether it is wind loads on a tower or shatter resistance in public spaces, performance is non-negotiable now.

• How do innovations in glass coatings, double/ triple glazing, and dynamic glazing contribute to energy efficiency in buildings?

In one word: Significantly.

Low-E coatings, for instance, have become essential. They bounce heat back while letting daylight through, which means less need for blinds or artificial lighting. Add in double or triple glazing with gas fills, and you’ve got a pretty efficient envelope.

Dynamic glazing - especially electrochromic - is the next step. It is still premium, yes, but we’re starting to see it used in luxury villas, airport lounges, and even

government buildings. It adjusts tint automatically, based on sunlight or user control, so you don’t need external shading systems. It’s sleek and smartarchitects love it.

• What advancements have been made in laminated and tempered glass to enhance safety, durability, and resilience in extreme weather conditions?

This is a big one. Especially with climate extremes becoming more common, glass has to be tougher than ever.

Laminated glass often uses interlayers like SentryGlas, which are far stronger than traditional PVB. They don’t just hold the shards in place after breakage - they resist penetration and perform under serious stress.

Tempering, too, has become more precise. With better quality control, issues like spontaneous breakage from nickel sulphide inclusions are far less common. And in cyclone-prone or high-wind areas, impact-tested systems are being specified more, especially in coastal projects.

• With increasing urban noise pollution, how is acoustic glazing improving the comfort of highrise and commercial buildings?

It is a game-changer, honestly.

People used to think of glazing only in terms of heat and light. But now, in cities like Beirut, Dubai, or Jeddah, where construction noise or traffic is non-stop, acoustic comfort is becoming a major selling point - especially for high-end residential or hospitality projects.

Acoustic glazing works by using thicker panes, special laminates, or asymmetrical layers to reduce sound transmission. You walk into a hotel room facing a motorway, and it is dead silent. That is what acoustic glass is delivering now.

• How is the glass industry addressing sustainability concerns, and what are the latest trends in eco-friendly glazing solutions? It is slow, but it is happening.

We are seeing more recycled content in float glass, and manufacturers are investing in energy-efficient furnaces. Some are even pushing for low-carbon glass and cradleto-cradle certifications - a significant shift from the old days of “make it cheap and fast.”

Here in the MENA region, the momentum is building. Developers aiming for LEED, Estidama, or even WELL certifications are pushing suppliers to provide environmental data and proof of sustainability. It’s no longer just about greenwashing - the industry is being asked to show real figures.

What role do smart glasses (electrochromic, thermochromic, and photochromic) play in shaping future façade designs?

These glasses are essentially the Apple Watches of architecture - functional, sleek, and undeniably cool.

Electrochromic glass, in particular, is leading the way. It changes tint when voltage is applied, adapting to sunlight in real time. That means no blinds, no mechanical shading, and full control over glare and heat. It’s especially popular in offices, airports, and upscale homes that want full glass walls without turning the interior into an oven.

Thermochromic and photochromic options are less “techy” but still smart — reacting to heat or UV. They’re increasingly used in skylights, atriums, and specialist applications where automation isn’t needed, but performance is.

• How effective is solar control glass in reducing heat gain, and what innovations in photovoltaic glass are making façades energy-generating surfaces?

Solar control glass is one of those quiet heroes. With the right coating, you can reduce heat gain by more than 50% - which is crucial in a region where HVAC is often the biggest energy consumer.

As for photovoltaic glass, it is still a niche product, but interest is growing rapidly. Architects love the idea of a glass wall that doesn’t just look good but also generates power. We’re seeing thin-film PV glass used in shading fins, skylights, and even entire spandrel sections. Once prices drop and incentives catch up, expect a significant rise in BIPV adoption in the region.

• With increasing fire safety regulations, how is the demand for fire-resistant glass shaping façade designs?

It is pushing designs to be both smarter and safer.

New fire-rated glazing systems can now withstand fire for 45, 60, or even 120 minutes - and they look just as sleek as standard glass. This is critical in mixed-use towers and public buildings, where glass is often used to divide fire zones without compromising transparency.

The challenge lies in sourcing. Not all suppliers in the region provide certified fire-rated glass, so there is a growing demand for tested, listed products from Europe or North America. Expect this category to expand as regulations evolve.

• What emerging technologies do you see revolutionising the glass and glazing industry for façades in the next five years?

We are just getting started. Some exciting innovations to watch:

• Vacuum Insulated Glazing (VIG): It is like double glazing on steroids - super thin, ultra-efficient, and perfect for retrofits.

• Glass as a display surface: Think LED-embedded façades that showcase media or branding.

• AI-controlled smart glass systems that learn occupant habits and climate patterns.

• Nanocoatings that make glass self-cleaning or antismog - invaluable in dusty cities like Riyadh and Abu Dhabi.

• And perhaps most importantly: local innovation. With more MENA-based glass processors and system designers, the region is shifting from being a consumer to a contributor in global glass technology.

JINCY MARIAM RINU Facade Lead, GHD

• What are the most critical performance criteria for selecting glazing in contemporary building façades?

The most critical performance criteria for selecting glazing in contemporary building façades include thermal insulation, solar control, impact resistance, acoustic performance, and durability. Energy efficiency is of utmost importance, with low U-values and low solar heat gain coefficients (SHGC) essential for reducing cooling

loads. Laminated and tempered glass solutions enhance occupant protection by mitigating the risks of breakage due to blasts or high-wind events. Acoustic insulation is crucial in urban environments, requiring specialised interlayers or double-glazed units. Additionally, longevity, ease of maintenance, and aesthetics play vital roles, ensuring the façade remains functional, sustainable, and visually appealing over time.

• How do innovations in glass coatings, double/ triple glazing, and dynamic glazing contribute to energy efficiency in buildings?

Innovations in glass coatings significantly enhance energy efficiency in buildings by optimising thermal performance and solar control. Low-emissivity (Low-E) coatings minimise heat transfer, reducing cooling and heating demands. Double and triple glazing with insulated air or gas-filled cavities improve thermal insulation, lowering U-values and enhancing indoor comfort. Dynamic glazing, such as electrochromic or thermochromic glass, adjusts tint levels in response to external conditions, reducing glare and solar heat gain while maximising natural light. These advancements collectively lower energy consumption, enhance occupant comfort, and contribute to sustainable building design.

• What advancements have been made in laminated and tempered glass to enhance safety, durability, and resilience in extreme weather conditions?

With the region's emphasis on resilience and security, the demand for blast-resistant glass is rapidly increasing. This surge is particularly evident in critical infrastructure projects, including government buildings, transportation hubs, and high-risk commercial facilities, where stringent safety standards necessitate advanced impact-resistant glazing solutions. There is also a growing demand for highperformance laminated glass, ensuring enhanced structural integrity, occupant protection, and long-term durability in the region’s challenging environmental conditions.

• With increasing urban noise pollution, how is acoustic glazing improving the comfort of highrise and commercial buildings?

Acoustic glazing plays a pivotal role in enhancing comfort in high-rise and commercial buildings by reducing sound transmission and improving indoor environments. Laminated glass with specialised acoustic interlayers dampens vibrations and absorbs sound waves, significantly lowering external noise levels. Double and triple glazing further enhance insulation by creating air gaps that disrupt sound waves. These advancements contribute to quieter, more comfortable indoor spaces, boosting occupant wellbeing, productivity, and overall building performance. This is especially important in densely populated city centres and areas near transportation hubs and airports.

• How is the glass industry addressing sustainability concerns, and what are the latest trends in eco-friendly glazing solutions?

Advancements such as low-carbon glass, high-performance coatings, and vacuum-insulated glazing minimise energy consumption while improving thermal performance. Recycling initiatives and closed-loop manufacturing

processes are reducing waste and resource depletion. Smart glazing technologies, such as electrochromic and photovoltaic glass, are integrating energy generation and adaptive shading, further supporting sustainable building design. These trends help drive the industry towards more environmentally responsible solutions.

• What role do smart glasses (electrochromic, thermochromic, and photochromic) play in shaping future façade designs?

Smart glasses transform façade designs by enabling dynamic control over light, heat, and glare. These solutions adapt to environmental conditions, reducing reliance on artificial lighting and HVAC systems, thereby enhancing energy efficiency. Electrochromic glass allows users to adjust transparency electronically, offering on-demand shading and privacy. Thermochromic and photochromic glass automatically optimise indoor comfort by responding to temperature and sunlight intensity. These technologies enable façades to achieve greater sustainability, occupant well-being, and architectural flexibility.

• How effective is solar control glass in reducing heat gain, and what innovations in photovoltaic glass are making façades energy-generating surfaces?

Solar control glass is highly effective in reducing heat gain by incorporating advanced coatings that reflect or absorb solar radiation, minimising the need for cooling and heating loads. Innovations in photovoltaic (PV) glass are further enhancing the energy-generating potential of building façades. PV glass integrates solar cells directly into the glazing, allowing façades to harness sunlight for power generation while maintaining aesthetic appeal. Recent advancements in PV glass include increased efficiency, thinner profiles, and improved integration with building designs, turning windows and façades into active, energy-generating surfaces that contribute to a building’s overall sustainability and carbon-neutral potential.

DOUGLAS SUM

Technical Director - Façade, AESG

• How has glass technology evolved in the last decade, and what are the key advancements shaping modern façades?

It is been quite a transformation! Over the last decade, glass technology has really pushed the boundaries of what’s possible in façade design. We're seeing key advancements such as:

• High-performance coatings: These coatings are now incredibly sophisticated, offering precise control over solar heat gain and light transmission

while also achieving very low internal reflectance. This is crucial for energy efficiency and minimising disturbance to the view from the interior.

• Larger panels: With more glass suppliers investing in larger processing machines (instead of standard sizes), jumbo glass design and manufacturing have become more accessible. This allows for more dramatic, uninterrupted views and reduces the need for obtrusive support structures.

• Dynamic glazing: Smart glass technologies that can tint on demand are becoming more common, offering exciting possibilities for responsive façades.

• Transparent photovoltaic glass: Still relatively new to the market, but I believe that as it becomes more widespread, it will eventually become standard practice due to the urgent need for more sustainable façade solutions.

• What are the most critical performance criteria for selecting glazing in contemporary building façades?

When selecting glazing today, it is a balancing act of several critical factors:

• Energy efficiency: This is paramount, with U-values and solar heat gain coefficients (SHGC) being key metrics. We need to minimise energy consumption for heating and cooling. Considering climate change, we must assess the building's thermal requirements to accommodate climate behaviour over its lifespan (typically 50 years).

• Light transmission: Optimising natural light while controlling glare is essential for occupant comfort and well-being.

• Acoustic performance: Especially in urban environments, glazing needs to provide adequate sound insulation, ensuring that the fenestration system offers equivalent performance.

• Safety and structural integrity: Glass must meet safety standards and withstand wind loads and other stresses. It’s essential to collaborate with security consultants to understand the safety and security risks of the building. Security glazing should be provided in sensitive areas if required.

• Aesthetics: Naturally, the visual appearance of glazing is a major consideration for architects and building owners. In modern façade design, irregular shapes, jumbo sizes, curved glass, and free-form surfaces are becoming increasingly common.

• Embodied carbon: This will become one of the more critical criteria in selecting glass manufacturers and processors. We must ensure that the embodied carbon of the glass is minimised to meet the minimum requirements set by ESD (Environmental Sustainable Design) embodied carbon calculations.

• How do innovations in glass coatings, double/ triple glazing, and dynamic glazing contribute to energy efficiency in buildings?

These innovations are game-changers for energy efficiency:

• Glass coatings: Advanced coatings can selectively control the amount of solar radiation entering a building. For example, low-E coatings reduce heat transfer, while solar control coatings minimise solar heat gain. Thanks to glass suppliers, new coating technologies continually push the limits

of heat reduction and light transmission—which is excellent. I recommend staying in regular contact with glass suppliers to stay updated on the latest developments.

• Double/triple glazing: Adding more layers of glass with insulating gas fills significantly reduces heat loss or gain through the façade, improving thermal insulation. However, it’s also essential to calculate the embodied carbon of the build-up to ensure that the additional layer of glass does not negatively impact the overall embodied carbon footprint of the building.

• Dynamic glazing: Smart glass technologies, such as electrochromic or thermochromic glass, adjust their properties in response to changing sunlight conditions, optimising both natural light and heat gain. This reduces the need for artificial lighting and HVAC usage. Additionally, dynamic glazing can integrate with dynamic façade systems, creating façades that are not only visually dynamic and attractive but also energy efficient.

• What advancements have been made in laminated and tempered glass to enhance safety, durability, and resilience in extreme weather conditions?

Safety and durability are non-negotiable, and significant strides have been made in laminated and tempered glass:

• Laminated glass: This type of glass, consisting of two or more layers held together by an interlayer, now offers enhanced strength and impact resistance. It also improves acoustic performance and blocks UV radiation. In the event of breakage, the interlayer holds the glass fragments together, reducing the risk of injury. Today, interlayers are much improved—clearer, stronger, more stable at the edges, available in a range of colours, and even paintable. I expect the interlayer industry to continue advancing its technology and providing better products for the industry.

• Tempered glass: This glass undergoes a special treatment to make it much stronger than regular glass. It is designed to shatter into small, relatively harmless pieces if broken. Since tempered glass can experience spontaneous breakage due to nickel sulphide inclusion, glass suppliers are developing better solutions to minimise breakage rates. Additionally, they are addressing the issue of anisotropy, which was previously unavoidable.

• With increasing urban noise pollution, how is acoustic glazing improving the comfort of high-rise and commercial buildings?

Acoustic glazing is becoming increasingly important in our noisy cities. Here’s how it helps:

• Sound insulation: By using thicker glass, laminated glass with special acoustic interlayers, and double or triple glazing with wider air gaps, acoustic glazing systems can significantly reduce the transmission of external noise into buildings.

This creates a much more comfortable and productive indoor environment, particularly in high-rise offices and residential buildings located in busy areas. I recommend working with an acoustic consultant to consider the overall build-up, including interior finishes, curtains, and the interface between wall partitions and façades. A holistic approach to design will better address occupants' real needs.

• How is the glass industry addressing sustainability concerns, and what are the latest trends in eco-friendly glazing solutions?

Sustainability is a major driver of innovation in the glass industry:

• Energy-efficient manufacturing: Glass manufacturers are working to reduce energy consumption and emissions associated with glass production.

• Recycled content: There is a growing emphasis on using recycled glass in new products, helping to conserve resources.

• Durable and long-lasting products: High-quality, durable glazing reduces the need for replacements, minimising waste over a building’s lifecycle.

• Environmental certifications: Products with certifications such as LEED contribute to sustainable building practices.

The focus is on minimising the environmental footprint of glass from production to end-of-life.

• What role do smart glasses (electrochromic, thermochromic, and photochromic) play in shaping future façade designs?

Smart glasses are incredibly exciting for the future of façades:

• Electrochromic glass: This type of glass can change its tint electronically, allowing for precise control of light and heat gain.

• Thermochromic glass: This glass changes its properties in response to temperature variations.

• Photochromic glass: This glass darkens in response to sunlight.

These technologies offer the potential for:

• Dynamic façades: Buildings that can adapt to changing environmental conditions in real-time.

• Energy optimisation: Reducing the need for artificial lighting and HVAC.

• Enhanced occupant comfort: Creating more comfortable and visually stimulating indoor spaces.

• How effective is solar control glass in reducing heat gain, and what innovations in photovoltaic glass are making façades energy-generating surfaces?

• Solar control glass: This type of glass is highly effective in reducing heat gain. It uses special coatings to reflect or absorb a significant portion of the sun's infrared radiation, preventing excessive heat build-up inside buildings. This leads to lower cooling costs and improved occupant comfort.

• Photovoltaic (PV) glass: This cutting-edge innovation integrates solar cells into glass to generate electricity.

Innovations in PV glass are transforming façades into energy-generating surfaces, contributing to on-site renewable energy production. While this technology is still developing, I believe it will significantly reduce a building's reliance on the grid.

• With increasing fire safety regulations, how is the demand for fire-resistant glass shaping façade designs?

Fire safety is a critical consideration in façade design, and the demand for fire-resistant glass is shaping how we approach it:

• Compartmentalisation: Working closely with fire engineering consultants, fire-resistant glass helps create fire-resistant compartments within buildings or prevents the spread of flames and smoke in closely spaced structures.

• Egress: It can also be used in exit pathways to provide safe escape routes during a fire.

As fire safety regulations become more stringent, we are seeing an increased use of advanced fire-resistant glass solutions in façade design to protect occupants and property.

• What emerging technologies do you see revolutionising the glass and glazing industry for façades in the next five years?

Looking ahead, I think several emerging technologies will make a significant impact:

• Advanced smart glass: Further developments in electrochromic, thermochromic, and other dynamic glazing technologies, with improved performance, affordability, and integration capabilities.

• Building-integrated photovoltaics (BIPV): Wider adoption of PV glass and other BIPV solutions, turning façades into active energy-generating systems.

• Vacuum glazing: This technology offers exceptional thermal insulation by using a vacuum between glass panes, potentially outperforming traditional double or triple glazing.

• Self-cleaning glass: Coatings that minimise the need for cleaning and maintenance, reducing costs and improving long-term performance.

• 3D-printed glass: While still in its early stages, 3D-printed glass could offer new possibilities for complex and customised façade designs.

These innovations will drive the development of more sustainable, energy-efficient, and visually striking buildings.

TAMER NEZHA

Senior Project Manager, NR Group

• How has glass technology evolved in the last decade, and what are the key advancements shaping modern façades?

Over the past decade, glass technology has witnessed remarkable advancements. We have seen significant improvements in: