2024 Capstone Projects

Through a mix of in-person and virtual pathways, thousands across the globe experience engineering and computer science education at the University of Idaho through our annual Engineering Design EXPO.

EXPO is the longest-running student engineering and technological innovation showcase in the Pacific Northwest. The event welcomes K-12 and community college students, industry partners and community members to explore industry-sponsored projects designed by current U of I students in the college’s Interdisciplinary Capstone Design Program, ranked top seven in the nation for infusing real-world experiences into engineering education.

Biological Engineering

SHOCK CIRCUIT FOR VIRTUAL FENCE SYSTEM

Ranchers spend valuable resources constructing and maintaining fences to control the grazing boundaries of their cattle operations. As these fences are time consuming and difficult to build, the flexibility of the grazing area is lacking. This harms the landscape and decreases livestock production. There is a need for an adaptable system that can control the grazing area borders. A virtual fence system can be remotely operated, allowing ranchers to easily implement rotational grazing systems.

Team Members

Zachary DeLuca - Electrical Engineering

Abby Fellows - Biological Engineering

Jaycee Johnson - Biological Engineering

Sydney Schoth - Biological Engineering

Client/Sponsor

Dev Shrestha - Department of Chemical and Biological Engineering Faculty Advisor

Russell Qualls - Department of Chemical and Biological Engineering

BIOREACTOR SYSTEM TO EXPLORE CELL RESPONSE

Modern medicine has greatly improved our lives, and one hot topic is cell-based treatments. By understanding and using our own cells, we can treat once-untreatable injuries with amazing results. We designed and built a bioreactor that uses fluid flow to apply physical forces to cells to help advance this field.

Team Members

Benjamin Morenas - Biological Engineering

Ishmael Staples - Biological Engineering

Carson Sloan - Computer Science

Carson Rueber - Computer Science

Chris Bui - Computer Science

Zhonghao Guo - Electrical Engineering

Client/Sponsor

Joe Stanley - Stanley Solutions

Nathan Schiele - Department of Chemical and Biological Engineering

Faculty Advisor

Russell Qualls - Department of Chemical and Biological Engineering

Civil Engineering

LIBERTY PARK TERRACE APARTMENTS PHASE II

Our project is an expansion to an existing apartment complex in Spokane, Washington. We are providing all the necessary civil engineering design for this project including utility connections, earthwork calculations, stormwater management, site layout, and accessibility requirements. These new buildings will provide more housing for the growing need of the area.

Team Members

Tommy Dittman - Civil Engineering

Gabe Brandt - Civil Engineering

Archie Clark - Civil Engineering

Noah Hattrup - Civil Engineering

Client/Sponsor

Christie Johnson - Coffman Engineers

Avram Sin - Coffman Engineers

Faculty Advisor

Richard Nielsen - Department of Civil and Environmental Engineering

THE SUMMIT AT 11TH

Our project was to design and analyze a 9-story mixed-use building in downtown Boise, Idaho. The building contains space for residential, retail, office, and restaurant amenities for the local community. The design involved geotechnical and structural engineering elements as well as project management.

Team Members

Mark Slisenko - Civil Engineering

Julian Collins - Civil Engineering

Destiny Hillyard - Civil Engineering

Zhiyuan Xue - Civil Engineering

Client/Sponsor

Lucas Coutinho – KPFF Consulting Engineers

Chaney Wood – KPFF Consulting Engineers

Faculty Advisor

Richard Nielsen - Department of Civil and Environmental Engineering

ARCADIA LAKE PUMP STATION (CE)

We are helping a city reach the growing water demand by increasing the capacity that the city can provide from a nearby reservoir, Arcadia Lake. This project entails the design of a pump station as well as the pipeline connecting the intake to the water treatment facility.

Team Members

Talia Duke - Civil Engineering

Logan Jeanselme - Civil Engineering

Matthew Troxel - Civil Engineering

Client/Sponsor

Kelby Sommer - Schnabel Engineering

Faculty Advisor

Richard Nielsen - Department of Civil and Environmental Engineering

REDESIGNING THAIN AND 10TH INTERSECTION IN LEWISTON, IDAHO

The Thain/10th/Warner intersection is located in the middle of Lewiston Orchards. Escalating traffic volumes have led to a rise in vehicle and pedestrian collisions. Using the City of Lewiston’s standards, the students comprising STEW Engineering will analyze and redesign the Thain and 10th intersection with the goal of minimizing crashes and delay, improving overall traffic efficiency and safety.

Team Members

Wolfgang Beier - Civil Engineering

Sandra Faulkner - Civil Engineering

Tim Reed - Civil Engineering

Ethan Von Bargen - Civil Engineering

Client/Sponsor

Fred Wismer - Kittelson & Associates, Inc.

Faculty Advisor

Richard Nielsen - Department of Civil and Environmental Engineering

SNAKE RIVER ROAD IMPROVEMENTS

This project is intended to bring safety improvements, compliance, and accessibility enhancements to Snake River Road in Asotin county, Washington. The existing road is a relatively narrow two-lane paved county road, lacking adequate shoulders or protective guardrails. This project will address suboptimal horizontal and vertical curves, introduce guardrails, and increase the width of the road. The increased width will also increase accessibility for larger vehicles such as RV’s and trailers.

Team Members

Julian Blythe - Civil Engineering

Hunter DePriest - Civil Engineering

Olivia Haener - Civil Engineering

Aser Mpoyi - Civil Engineering

Client/Sponsor

Taylor Schwers - CONSOR Engineers

Hannah Long - CONSOR Engineers

Faculty Advisor

Richard Nielsen - Department of Civil and Environmental Engineering

CROW PUMP DIVERSION

This project focuses on the redesign of a diversion structure and canal to provide fish passage and irrigation water to the Charlo irrigation area near Flathead Lake, Montana. The primary goal of this design is to increase the flexibility, redundancy, and capacity of the pumping station.

Team Members

Kyle Schulz - Civil Engineering

Sadie Sundahl - Civil Engineering

Blaec Dettner - Civil Engineering

Addison Hoffman - Civil Engineering

Andrew Henrikson - Civil Engineering

Client/Sponsor

Jack Krusemark - DOWL

Faculty Advisor

Richard Nielsen - Department of Civil and Environmental Engineering

Chemical Engineering

THE SUSTAINABLE APPLICATION OF A PACIFIC NORTHWEST BIOCHAR OFF-GAS STREAM

Sponsored by C6 Forest to Farm (F2F) in Winthrop WA, the project contributes to their mission of reducing forest fire severity and enhancing forest soil health. The UIdaho-F2F Collaborative engineered a comprehensive application of the off-gas stream from a community-scale biochar production pilot plant. This includes the evaluation of feedstock compositions, identification of marketable components, and a design that separates and purifies additional products from an unused waste stream.

Team Members

Kendall Reeder - Chemical Engineering

Travis Kerr - Chemical Engineering

Ashley Keeley - Chemical Engineering

Kristian Jacobson - Chemical Engineering

Luke Zrodlo - Chemical Engineering

Client/Sponsor

Bret Richmond - C6 Forest to Farm

Faculty Advisor

Matthew Bernards - Department of Chemical and Biological Engineering

ELECTROLYSIS FOR SUSTAINABLE GENERATION

Sodium sulfate is produced as a by-product in several chemical processes, including the water recovery plant at Freeport-McMoRan Inc. (FMI).

Sodium sulfate has many applications, but an economically viable product cannot currently be produced by FMI, resulting in their sodium sulfate being transported as waste to a landfill. The WERC team aims to utilize electrolysis to produce and recycle sulfuric acid back to the FMI plant and, in turn, reduce waste production and transportation fees.

Team Members

Destinee Ditton - Chemical Engineering

Aaron Goeckner - Chemical Engineering

Grace James - Chemical Engineering

Nick Knowles - Chemical Engineering

Donald Macdonald - Chemical Engineering

Client/Sponsor

Matthew Bernards - Department of Chemical and Biological Engineering

Faculty Advisor

Matthew Bernards - Department of Chemical and Biological Engineering

GREEN GAS: CONVERTING RENEWABLE ENERGY TO SYNTHETIC NATURAL GAS

Renewable energy sources like wind and solar are an important step toward a sustainable future. Electricity generated from these processes can split water into oxygen and hydrogen. Our project focuses on reacting the hydrogen with carbon dioxide emissions to make methane, which can be used as fuel. This process is known as Power to Gas, and it helps remove greenhouse gases from the atmosphere while creating energy to store and use in the natural gas grid.

Team Members

Chelsea Barrera - Chemical Engineering

Kaylee Janett - Chemical Engineering

Paetra Morgan - Chemical Engineering

Client/Sponsor

American Institute of Chemical Engineers

Faculty Advisor

Matthew Bernards - Department of Chemical and Biological Engineering

Computer Science

MODELING CYBERSECURITY THREATS WITH A FERRIS WHEEL

Cyberattacks on industrial control systems are an increasing threat that can completely shut down access to vital resources like water and gas. The cost and complexity of industrial control systems make it difficult to analyze and research these critical systems. Our goal is to create a small-scale model of an industrial control system that is low-cost, modular, and can be run in a virtual environment to perform cybersecurity-related research.

Team Members

Hunter Squires - Computer Science

Sean Devine - Computer Science

Karina Permann - Computer Science

Matthew Neel - Computer Science

Zherong Qian - Computer Science

Client/Sponsor

Daniel Conte de Leon - Department of Computer Science

Faculty Advisor

Bruce Bolden - Department of Computer Science

SMART PLANK INSPECTION AND NAVIGATION FOR TIMBER EVALUATION AND RECOGNITION

We are developing a system to inspect planks for defects and knots using AI vision. The current problem is the human inspectors cannot keep up with the amount of product coming through the line. The job is tedious and awful. This system should replace the need for so many inspectors which will allow them to be utilized in better positions in the factory saving the company thousands of dollars a year. We are replacing a painful mundane job.

Team Members

James Lasso - Computer Science

Jordan Reed - Computer Science

Dan Blanchette - Computer Science

Brian Healy - Mechanical Engineering

Client/Sponsor

Katie Bradish - Wildwood Grilling

Jason Eddy - Wildwood Grilling

Faculty Advisor

John Shovic - Department of Computer Science

A COMPUTER NETWORK-RELATED GAME FOR EDUCATIONAL PURPOSES

The goal of our project is to create a computer network-related game for educational purposes through Unreal Engine. Our project aims to help more computer networking beginners gain a better understanding of what computer networking is. They can acquire some fundamental knowledge of computer networking while enjoying our project.

Team Members

Jonna Waage - Computer Science

Benqi Zhang - Computer Science

Zheyang Wei - Computer Science

Hongxi Zhu - Computer Science

Client/Sponsor

Daniel Conte de Leon - Department of Computer Science

Faculty Advisor

Bruce Bolden - Department of Computer Science

USING DEEP LEARNING TO PROVIDE FEEDBACK FOR REMOTE PHYSICAL REHABILITATION

When patients incorrectly perform physical therapy exercises their doctor suggests following an injury, their recovery time is extended, leading to financial and physical strain. By adjusting a deep learning model that analyzes videos of clients exercising remotely, we can provide real time feedback potentially resulting in improved rehabilitation outcomes.

Team Members

Molly Meadows - Computer Science

Noah Rieth - Computer Science

Xian Gao - Computer Science

Client/Sponsor

Alex Vakanski - Department of Computer Science

Min Xian - Department of Computer Science

Faculty Advisor

Bruce Bolden - Department of Computer Science

EMPOWERING HEALTH THROUGH DESIGN: ML SOLUTIONS FOR BREAST CANCER EARLY DETECTION

Early detection of breast cancer can reduce mortality rates and expand treatment options. With the growing use of artificial intelligence in the medical field, machine learning approaches for breast cancer detection have met or exceeded human expert performance standards. By designing a machine learning model and integrating it with application programming interfaces, a user-friendly application can detect if images are cancerous or not.

Team Members

Jackson Baldwin - Computer Science

Nyah Nelson - Computer Science

Sihan Wu - Computer Science

Bryan Frahm - Computer Science

Client/Sponsor

Min Xian - Department of Computer Science

Faculty Advisor

Bruce Bolden - Department of Computer Science

GAMIFIED COMPUTERS AND NETWORKS: DEVICES

Our project will be the creation of a gamified cyber security environment tailored for K-12 and university students. The main goal is to facilitate the learning process and solve the problem of the digital gap between a digital twin application and education. In doing so this project will help all by providing a user-friendly and intuitive interface, making learning accessible for all ages. Our project ultimately aims to educate students by enhancing their understanding of cyber security.

Team Members

Oscar Michua-Zarate - Cybersecurity

Cheng Zhao - Computer Science

Fei Teng - Computer Science

Yiqun Wang - Computer Science

Client/Sponsor

Daniel Conte de Leon - Department of Computer Science

Faculty Advisor

Bruce Bolden - Department of Computer Science

INTENSITY-BASED ALIGNMENT OF LASER DEVICES

Our project aims to design, implement, and test embedded software to drive a robotic arm for optical beam alignment. The objective is to have the devices communicate with each other about their location using optical intensity (light based). The devices will then use that to focus a laser signal to each other and align to achieve maximum strength.

Team Members

Dawson Burgess - Computer Science

Marissa Samayoa - Computer Science

Spencer Butler - Computer Science

Client/Sponsor

John Paul Hansen – Hansen Photonics

Faculty Advisor

Bruce Bolden - Department of Computer Science

Electrical and Computer Engineering

THE UNIVERSITY’S FIRST FORAY INTO CUBESAT PAYLOAD DEVELOPMENT

In the past there has been a lot of time between the idea for a space experiment, and the time it takes to go from development to implementation. With the Cube Satellite platform, there is no longer a need to wait so long to go from the idea phase to the delivery phase. Our team will be constructing a payload to attach to a CubeSat that will gather information on radiation in low Earth orbit.

Team Members

Nathan LaVoie - Biological Engineering

Lyna Tran - Mechanical Engineering

Sydney Munson - Mechanical Engineering

Conner Wiench - Computer Science

Dre Mata - Electrical Engineering

Lucien Lee - Computer Science

Client/Sponsor

Avery Brock - NASA Ames Research Center

Malachi Mooney-Rivkin - NASA Ames Research Center

Faculty Advisor

Feng Li - Department of Electrical and Computer Engineering

MAKE HOUSEHOLD POWER MORE EFFICIENT THAN USUAL!

Our project is focused on household electrical system. The main part is the AC to DC transfer system. The benefit of the project is to save more power and improve efficiency in our home.

Team Members

Christopher Pierson - Electrical Engineering

Shihao Bian - Electrical Engineering

Yuncong Zhou - Electrical Engineering

Client/Sponsor

Paul Ortmann - Idaho Power

Faculty Advisor

Kip Sikes - Department of Electrical and Computer Engineering

ARCADIA LAKE PUMP STATION (EE)

Our project is to design a 60 mgd Intake and Pump Station and build the backup generators including full 72-hour capacity, and sub-base fuel storage to handle electrical outages caused by a tornado. This project is to extract water from a lake to satisfy daily requirements.

Team Members

Lingyu Wang - Electrical Engineering

Yujie Xia - Electrical Engineering

Client/Sponsor

John Barrutia - DC Engineering

Faculty Advisor

Kip Sikes - Department of Electrical and Computer Engineering

PORTABLE LED ATHLETICS SCOREBOARD

Our product provides an affordable and enjoyable sports experience for children, fostering life skills like teamwork and perseverance. It eliminates financial barriers by offering fundraising opportunities through in-game advertising.

Team Members

Jenna-Luz Pura - Computer Science

Logan Finley - Computer Science

Paul Martin - Mechanical Engineering

Yuhan Jing - Electrical Engineering

Tingxuan Du - Electrical Engineering

Zoe Stefani - Mechanical Engineering

Client/Sponsor

Reese Shurtliff - Friday Night Flag

Faculty Advisor

Kip Sikes - Department of Electrical and Computer Engineering

Mechanical Engineering

AUTOMATIC END OF ARM TOOL CHANGER

The team is developing a scalable prototype of an automatic tool changer for Bastian Solutions’ material handling industrial robotic system. Bastian’s inability to switch between every end of arm tool forces them to accept either a small percentage of customer’s products or have multiple robotic arms and conveyor lines. Our design of a common interface will allow Bastian to automatically changeover between all tooling, including those previously incompatible.

Team Members

Devin Tanak - Mechanical Engineering

Mohammad Al-Qutub - Mechanical Engineering

Kadin Coddington - Mechanical Engineering

Jason Franklin - Mechanical Engineering

Client/Sponsor

Gabe Riggs - Bastian Solutions

Faculty Advisor

Matthew Swenson - Department of Mechanical Engineering

INL URANIUM, GLASS & DUST SEPARATION

Project creates a way to separate useful uranium fuel from glass and zirconium waste. This improves the efficiency of the fuel cycle for certain new nuclear reactor designs, and creates a way to process existing waste from older reactor designs. End product aids in increasing the viability of nuclear energy as a large scale energy source in the country’s near future.

Team Members

Isaac Corgatelli - Mechanical Engineering

Emily Mack - Mechanical Engineering

Joseph Norman - Mechanical Engineering

Ying Yang - Electrical Engineering

Client/Sponsor

Randall Fielding - Idaho National Laboratory

Faculty Advisor

Michael Maughan - Department of Mechanical Engineering

A BURNING PROBLEM - WILDFIRE SMOKE GENERATOR

Across the United States, forest fires are affecting cow’s dairy production. Our product will ensure the viability of the 2-billion-dollar dairy industry by allowing the University of Idaho College of Natural Resources and the Idaho Center for Agriculture, Food and the Environment (CAFE) to do groundbreaking research on dairy calves. The project enables them to utilize test chambers to manipulate smoke exposure to run biological tests on calves- determining how smoke inhalation impacts animal performance and health.

Team Members

Kathy Ruiz - Mechanical Engineering

Carter Donnelly - Mechanical Engineering

Derek Walker - Mechanical Engineering

Matthew Etherton - Mechanical Engineering

Client/Sponsor

Amy Skibiel - Department of Animal, Veterinary and Food Sciences

Pedram Rezamand - Department of Animal, Veterinary and Food Sciences

Faculty Advisor

Mark Roll - Department of Mechanical Engineering

SKIN FRICTION RIVET ANALYSIS USING OIL FILM INTERFEROMETRY

We are using the indirect form of measurement called “oil film interferometry” to measure drag presented on the surface of a plane’s

MAINTENANCE BUSHING

An essential part of all mechanical maintenance is regular lubrication. Lubrication, such as grease, can contaminate sensitive workplaces harming food or medical equipment. Additionally, a lack of lubrication can lead to catastrophic failure causing unexpected downtime and costs. Our project will test and validate new alternative bushing materials that aim to eliminate the need for lubrication. This could save an estimated 80,000 gallons of grease yearly.

Team Members

Carlson Wurster - Mechanical Engineering

Jason Jerke - Mechanical Engineering

Casey Lemon - Mechanical Engineering

Ethan Overstreet - Mechanical Engineering

Ben Al Douhani - Mechanical Engineering

Client/Sponsor

Oskar Peterson - Hyster-Yale Group

Faculty Advisor

Matthew Swenson - Department of Mechanical Engineering

SNOWMOBILE TOW-BEHIND ANALYSIS TRAILER

The emphasis on sustainability prompts scrutiny of emissions in recreational transportation like snowmobiles, ATVs, and side-by-sides. Existing tests lack accuracy in field conditions. A tow-behind analyzer is proposed to address this, offering precise emissions measurements. The objective is a device, used by the U of I CSC team, to aid snowmobile emissions research.

COME SOLVE WITH US

EMBER GENERATOR FOR FOREST FIRE SIMULATION

Wildfires in the US cost as much as $893 billion per year and buildings at the wild-urban interface are particularly susceptible to wind-carried embers. To better combat forest fires and defend infrastructure, the role these embers play must be better characterized. We designed an ember generator to simulate wildfire conditions and allow for the study of ember propagated fires.

Team Members

Jackson Coleman - Mechanical Engineering

Caleb Hanson - Mechanical Engineering

Aleczander Smart - Mechanical Engineering

Cassidi Shindler - Mechanical Engineering

Peter Wieber - Biological Engineering

Client/Sponsor

Alistair Smith - Department of Earth and Spatial Sciences

Doug Hardman - Department of Earth and Spatial Sciences

Faculty Advisor

Mark Roll - Department of Mechanical Engineering

CONTROLLED VELOCITY PROJECTILE ACCELERATION USING COMPRESSED AIR

Vista Outdoors manufactures defensive ammunition for law enforcement and civilians. Our client faces a challenge with controlling the consistency of their bullet velocity when testing with standard powder cartridges, as velocity is the main factor in how a bullet penetrates and expands upon entry. To reduce the extent of testing currently required to isolate the results from the velocity changes, our design will use a different propulsion system for better consistency in the bullet’s velocity.

Team Members

Reed Ofsthun - Mechanical Engineering

Jacob Liedle - Mechanical Engineering

Trenton Gardella - Mechanical Engineering

Aidan Whooley - Mechanical Engineering

Client/Sponsor

Jeff Williams - Vista Outdoor

Faculty Advisor

Mike Maughan - Department of Mechanical Engineering

STEAM PLANT/FISHERIES WASTEWATER RECAPTURE

Our goal is to redirect wastewater from campus Fisheries to the Steam Plant for use in the heating and cooling systems. This conserves water that otherwise needs to be sent for treatment, saving the University money and making better use of our natural resources.

Team Members

Jakayla Wight - Mechanical Engineering

Caden Hall - Mechanical Engineering

Client/Sponsor

Scott Smith - McKinstry

Marc Compton - McKinstry

Faculty Advisor

Paulo Yu - Department of Mechanical Engineering

RELOCATION GUIDANCE SYSTEM FOR C-ARM MEDICAL IMAGING

Most C-Arm X-Ray technology lacks a guidance system that remembers where an image is taken, resulting in surgical inefficiency and excessive radiation doses. This project implements image detection as an affordable guidance system with high accuracy and precision to reduce surgery time and radiation exposure.

Team Members

Hailey Faith - Biological Engineering

Hunter Holbrook - Biological Engineering

Turner Zischka - Mechanical Engineering

Kyle Fiske - Mechanical Engineering

Toby Mclenon - Computer Science

Alphonse Crittenden - Computer Science

Client/Sponsor

Dr. Doug Hiller - Whitman Hospital & Medical Clinics

Faculty Advisor

Paulo Yu - Department of Mechanical Engineering

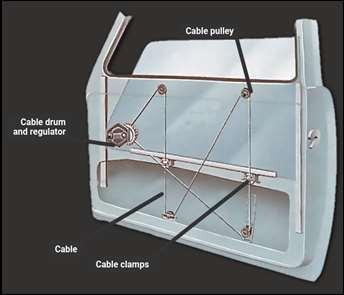

VERTICALLY OPENING FORKLIFT CAB DOOR WINDOW

Hyster-Yale has tasked us with providing a fully mechanical, vertically opening window for their customers. This consists of redesigning the current cab doors that have horizontally opening windows to improved air flow and visibility. We built and tested a proof-of-concept design for their 3-ton pneumatic lift trucks, which can be scaled to higher and lower capacity models.

Team Members

Cameron Kaminski - Mechanical Engineering

Alex Bailey - Mechanical Engineering

Hunter Higginbotham - Mechanical Engineering

Khaled Alamoudi - Mechanical Engineering

Client/Sponsor

Claire Linneman – Hyster-Yale Group

Faculty Advisor

Mathew Swenson - Department of Mechanical Engineering

DEVELOPMENT OF LOW-COST PROCESS TO CREATE EMI SHIELD

Our goal is to find and create a low cost and low volume process for making a metallic cage to protect an electrical current measuring device from foreign interference. The cage must be within 0.005” of the wall and have at most 1 Ohm of resistance between any two points.

Team Members

Paul Sanchirico - Mechanical Engineering

Khristian Ceballos - Mechanical Engineering

Stephen Wright - Mechanical Engineering

Keaton Hewitt - Mechanical Engineering

Kyle Richmond - Mechanical Engineering

Client/Sponsor

Jonathan Richards - Schweitzer Engineering Laboratories

Alex Olson – Schweitzer Engineering Laboratories

Faculty Advisor

Mark Roll - Department of Mechanical Engineering

AUTOMATED RING ASSEMBLY MACHINE

Our project aims to address the staggering $80 billion annual loss incurred by companies due to workplace injuries, with over 50% of injuries resulting from cumulative trauma. We are developing a prototype to automate repetitive tasks in Nightforce’s riflescope ring and mount assembly, enhancing operator comfort, reducing injuries, and boosting manufacturing efficiency for increased daily production.

Team Members

Bryce Hendrickson - Computer Science

Josiah Widmayer - Mechanical Engineering

Lane Pierce - Mechanical Engineering

Luke Presta - Mechanical Engineering

Client/Sponsor

Grant Minor - Nightforce Optics

Jake Elliott - Nightforce Optics

Faculty Advisor

Matthew Swenson - Department of Mechanical Engineering

ROBOTIC ASSEMBLY OF PHOTOVOLTAIC ARRAYS

On the Moon and Mars, there aren’t any solar panel factories, but any long-term missions will need a reliable source of solar panels to replace and expand infrastructure. Our project, based on a NASA patent, demonstrates a modular, scalable, accurate, and fully autonomous method of manufacturing solar panels, utilizing robotics.

Team Members

James Adams - Mechanical Engineering

Spenser Scruggs - Mechanical Engineering

Triston Hardcastle Peck - Computer Science

Conner Mullins - Computer Science

Haozhou Su - Electrical Engineering

Client/Sponsor

NASA Idaho Space Grant Consortium

Faculty Advisor

Matthew Swenson - Department of Mechanical Engineering

That’s why Idaho National Laboratory’s K-12 Education program is working to change the science, technology, engineering and math landscape. By working with students, teachers and communities across the state, INL seeks to grow STEM opportunities for all. INL offers a variety of outreach events and other learning opportunities to inspire innovation and show students of all ages that their futures could hold potential careers in STEM.

PRANDTL-D: ADVANCING AUTONOMOUS UAVS FOR WILDFIRE PREVENTION

Over the past year, wildfires surged across our country costing billions of dollars. Our mission is to develop an Unmanned Aerial Vehicle (UAV) equipped with technology to identify potential wildfire ‘hot spots.’ By utilizing heat sensors, our autonomous UAV locates emerging fires while they are still manageable.

Team Members

Ian Cluff - Mechanical Engineering

Virginia Herbord - Mechanical Engineering

Matthew Weber - Mechanical Engineering

Kyle Hash - Computer Science

Akhil Karri - Computer Science

Yibo Wang - Electrical Engineering

Client/Sponsor

NASA Idaho Space Grant Consortium

Faculty Advisor

Paulo Yu - Department of Mechanical Engineering

HOT CELL WINDOW CLEANING

A viewing window in the Idaho National Laboratory (INL) hot cell has become clouded over on the inside. This is obstructing the view into the cell, making the window nonfunctional. Our team is developing a solution to clean the window using a remote-controlled dry ice blaster to blast the window clean. This project has some unique challenges such as the room being radioactive, and the window having bars in front of it. By making a working remote-controlled window cleaner, INL will be able to use the window again.

Team Members

Levi Bailey - Mechanical Engineering

Owen McDonald - Mechanical Engineering

Andrew Johansen - Mechanical Engineering

Eli Franklin - Mechanical Engineering

Tyler Reighard - Mechanical Engineering

Client/Sponsor

Jesse Kappmeyer - Idaho National Laboratory

Faculty Advisor

Matthew Swenson - Department of Mechanical Engineering

THANK YOU, EXPO SPONSORS!

The University of Idaho College of Engineering thanks all of our corporate and academic sponsors for their generous support of the annual Engineering Design EXPO. We value and appreciate your participation and continued commitment to engineering education.

Corporate Presenting Sponsor:

Become a Sponsor

Planning the University of Idaho’s Engineering Design EXPO is a yearlong activity.

To explore future opportunities to support EXPO, contact: College of Engineering Development Team 208-885-5888 expo@uidaho.edu

We look forward to talking with you about how you can help support this event and current and future students.

Innovation Sponsors

Dynamic Sponsors

MEET OUR JUDGES

Judges are a critical part of the Engineering Design EXPO experience for University of Idaho College of Engineering students. Interaction between students and judges creates opportunities for students to gain new insight and learn about engineering career paths and the profession in general.

Carmen Achabal, Micron

Jon Adams, Engineered Solar Systems

Deepa Ajish, Mufg Bank, Ltd.

Richard Allen, Retired

Balvinder Singh Banjardar, Walmart Global Tech

John Barrutia, DC Engineering

Laura Bartenhagen, ESM Consulting Engineers, LLC.

Kenneth Bartenhagen, Potelco

Amanda Battles, Clearwater Paper

Owen Blair, Schweitzer Engineering Laboratories, Inc.

Pat Blount, Moscow School District

Bruce Bouton, Retired

Jim Brennan, MWH/Slayden Constructors

David Buehler, Schweitzer Engineering Laboratories, Inc.

Blake Bull, Schweitzer Engineering Laboratories, Inc.

Cretia Bunney, University of Idaho

Dave Christiansen, Retired

Jeff Coffin, Kleinschmidt Associates (Retired)

Patricia Colberg, Retired

Jordan Collins, Syntier Engineering

Shawna Conery, J-U-B Engineers, Inc.

Christopher Cook, University of Idaho

Nick Crabbs, Vynyl

Jocie Cracroft, Novelis

Randi Croyle, University of Idaho

Mattie Cupps, Micron

Jason Dearien, Schweitzer Engineering Laboratories, Inc.

Grant Dearing, Schweitzer Engineering Laboratories, Inc.

Raymond Dixon, University of Idaho

Vibhav Durgesh, University Of Idaho

Chris Dux, Avista Utilities

Chris Dyer, Power Engineers, Inc.

Shane Elmose, Wagstaff Inc.

Sharon Eroschenko, U.S.

Bureau Of Reclamation

John Fisher, Google

Byron Flynn, GE Renewables (Retired)

Charlie Ford, Idaho Contractors

Luke Fuess, University of Idaho

Lavanya Galla, Schweitzer Engineering Laboratories, Inc.

Matthew Gregg, Brown And Caldwell

John Grimes, University of Idaho

Alexander Hanson, Roguetally Llc

Daniel Hein, Diversified Fluid Solutions

Gary Hermann, Retired; Ch2m

Hill And Velsicol Chem Corp.

Connor Hill, Element 1 Corp

David Hollenback, Hdt Global

Paul Huber, The Boeing Company

Christopher Hyde, University of Idaho

Michael Jasberg

Nathaniel Jones, Schweitzer Engineering Laboratories, Inc.

Tory Kampfer, PSNS-IMF

Hatim Kapadia, American Express

Jesse Kappmeyer, Battelle Energy Alliance

Joseph Keegan , The Boeing Company

Braxton Klas, J-U-B Engineers, Inc.

Constantinos Kolias, University of Idaho

Tina Kosmicki, Novelis

John Kumm, Power Engineers

Tarun Joseph Kurian, Intel

Narendra Lakshmana Gowda, Walmart Global Tech

Bud Leber, Self

Alexandra Lehman-Chong, University of Idaho

Dale Lientz, Puget Sound Naval Shipyard

Nadine Lilley, Astronics AES

Philip Lohman, MWH Constructors

Justin Malsam, St. Luke’s Health System

Tyler Marines, Schweitzer Engineering Laboratories, Inc. Timothy Marston, The Applied Physics Laboratory, University Of Washington

Ken Mays, The Boeing Company

Gary Mecham, BEA

Manan Hitendra Mehta, Schweitzer Engineering Laboratories, Inc.

Sally Mei, Schweitzer Engineering Laboratories, Inc.

Jarrod Milligan, US Army Corps of Engineers

Emmett Minner, MWH

Steve Miranda, Retired

Thomas Moore, Self-Employed

Lester Morfin, Retired

Isaias Munoz Venegas, Avista

Shane Needham, Veloxity Labs, LLC.

Reilly Neel, Schweitzer Engineering Laboratories, Inc. Christian O’Bryan, Schweitzer Engineering Laboratories, Inc.

Alex Olson, Schweitzer Engineering Laboratories, Inc. Tyler O’Toole, Pbs Engineering And Environmental

Douglas Overholtzer, Wagstaff, Inc.

Hatim Palitanawala, Marsh And Mclennan

Joel Perry, University of Idaho

Tom Pfeiffer, Idaho National Laboratory

Carol Pochardt, University of Idaho

Carson Potere, Idaho National Laboratory

Shawn Pratt, HP, Inc.

Billy Reeves II, University of Idaho

Jonathan Richards, Schweitzer

Engineering Laboratories, Inc.

Gabe Riggs, Bastian Solutions

Kierra Ryssell, Clearwater Paper

Kim Salisbury, University of Idaho

Bennett Schlect, Clearwater Paper

Daniel Schneider, Fortune Brands Innovations

Eric Silk, University Of Illinois

At Urbana-Champaign

Jennifer Simler, Schweitzer

Engineering Laboratories, Inc.

Alex Simon, Boeing

Jacob Skaug, Schweitzer

Engineering Laboratories, Inc.

Howard Skidmore, Power Engineers, Inc.

Luis Skinner, Schweitzer

Engineering Laboratories, Inc.

Jamison Slippy, Kodiak Aircraft Company

Randy Smith, University of Idaho

Matt Soden, Blue Origin

Ron Stanley, Schweitzer

Engineering Laboratories, Inc.

Cynthia Stanley, Schweitzer

Engineering Laboratories, Inc.

Larry Stauffer, University of Idaho

Reid Stephan, St. Luke’s Health System

Tammy Stjohn-Tesky, University of Idaho

Ron Stubbers, Signal Advance, Inc.

Nathan Suhr, Forsgren Associates

Scott Sumner, Syntier Engineering, Inc.

Hussain Suttarwala, American Express

Todd Swanstrom, Western Trailer Co.

Jennie Tafoya, University of Idaho

Brandi Terwilliger, University of Idaho

Elli Tindall, Novelis

Kaleb Trotter, Lightcast

Edgar Vidal, Nobelclad /

Colorado School Of Mines

Bob Wagstaff, Oculatus

Melissa Warner, Idaho National Laboratory

David Wildman, Anderson Perry & Associates

Jeff Williams, Vista Outdoor

Michael Williams, Verdis

Micah Wilson, Wagstaff, Inc.

Zac Woodall, Amazon

Sarah Wu, University of Idaho

Min Xian, University of Idaho *includes

SHOCK CIRCUIT FOR VIRTUAL FENCE SYSTEM

BACKGROUND

• Multiple team project

o Engineering

o Animal

o Stakeholders

• Current Design is too heavy and consumes too much power

• Current design is based on shock collars and electric fence systems

VALUE PROPOSITION

Ranchers spend valuable resources constructing and maintaining fences to control the grazing boundaries of their cattle operations. As these fences are time consuming and difficult to build, the flexibility of the grazing area is lacking. This harms the landscape and decreases livestock production. There is a need for an adaptable system that can control the grazing area borders. A virtual fence system can be remotely operated, allowing ranchers to easily implement rotational grazing systems.

KEY REQUIREMENTS

• To construct a variable shock circuit

• Circuit shall provide feedback after shock is delivered

• Circuit should weigh no more than 15 grams

• System shall fit within a 250 x 100 x 300 mm enclosure

• Circuit is compatible with existing PCB design

CONCEPT DEVELOPMENT

THE FINAL DESIGN GHOST COWBOYS

VALIDATION

• Use cow ear to determine impedance and optimal frequency

• Test variability of shock using oscilloscope and ammeter Instructor: Dr. Russell Qualls Sponsor: Dr. Dev Shrestha

• Weigh finished circuit to ensure it’s less than 15 grams

• Test for feedback on successful shock delivery through current sensor feedback

CONCLUSIONS & RECOMMENDATIONS

• Use an ideal frequency of 1000 Hz

• Transformer – Increase voltage to target range

• Current sensor – Provide feedback on shock delivery

• Gate Driver – Arduino to MOSFET current amplifier

• MOSFET – DC to AC switching

• Diode – Protect components from high voltages

• Use in vivo probes to allow minimal resistance

• Integrate shock circuit into current design

• Test on live cows to find ideal shock values

ACKNOWLEDGEMENTS

We would like to thank Yuan Yuan, Hope De Avila, Karen Launchbaugh, and Matt Shyrock for their guidance on our project.

OBJECTIVE

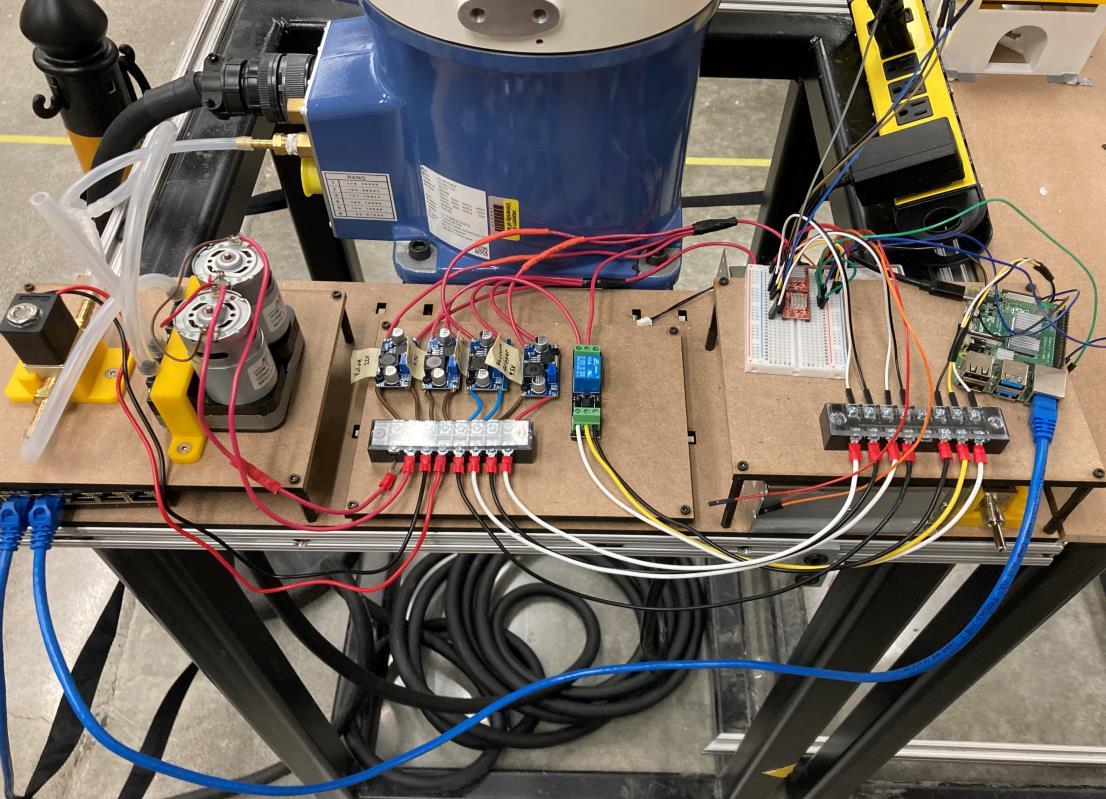

Tendon is a tissue in our body that attaches muscle to bone, playing a key role in force transfer and movement. Tendon has poor healing capabilities, making it a vital area to research for health.

Our goal is to create a low-cost, easily built bioreactor capable of mimicking human body conditions to aid in tendon cell study.

VALIDATION

BIOREACTOR SYSTEM TO EXPLORE

CELL RESPONSE

Team Members: Benjamin Morenas, Ishmael Staples, Carson Sloan, Carson Rueber, Chris Bui, Guo Zhonghao

Team Sponsors: Joe Stanley, Nathan Schiele Lead Instructor: Russell Qualls Team Mentor: Yuan Yuan

SYSTEM

The flow rate through the bioreactor is primarily controlled by varying the pump speed. Peristaltic pumps cause oscillations in the flow, which is mitigated by a pulsation damper device at low flow rates. At high flow rates, needle valves are used to precisely control the main and bypass lines based on measurements from two high-precision flow sensors.

Oscillations are mainly caused by the pump rollers squeezing the tubing and are proportional to the flow rate.

The program calculates the shear stress experienced by the cells based on the flow rate and bioreactor channel dimensions.

The

SOFTWARE INTEGRATION

The interface, powered by an ESP32, provides advanced control of the bioreactor and connection to Wi-Fi networks to enable real-time data transmission for visualization.

The bioreactor is controlled by connecting directly to the ESP32, while data can be visualized at thingspeak.com, from anywhere, any time.

REQUIREMENTS

• Long-term experiments with 0-150 mPa shear stress

• Short-term experiments with 1-2 Pa shear stress

• Flow applied to cells must be laminar

• Parts must be easy to clean

• Less than $1500 worth of easy-to-get parts

• Easy to use interface for creating experiment protocols

• Remotely visualize system status

CONCLUSIONS

The bioreactor meets most of the requirements listed above in short test cases, including meeting the target flow rates, applying laminar flow to cells, and being able to control and visualize data, all while remaining within our budget.

Future work would include upgrading the peristaltic pump and performing more multi-week testing with cells in the system to make sure it can run for long periods with highly accurate flow and shear rates. Since every part is replaceable, future users can customize the design with different parts if they want. Doing this is recommended, as there may be better options not utilized here that could provide an advantage in precision or ease-of-use.

ACKNOWLEDGEMENTS

We would like to give a special thank you to:

• Nathan Schiele & Russell Qualls for their support and mentorship

• Joe Stanley for his funding and mentorship

• Charles Cornwall for providing 3D printer access

BACKGROUND

Spokane, Washington near intersection of Perry Street and Hartson Avenue

Zoned residential multi-family (RMF)

3 parcels consolidated into 1

30 total units – 11 and 19 for each building

Site is ±1.42 acres

Grading

LIBERTY PARK TERRACE APARTMENTS PHASE II COST ESTIMATE

SITE DEVELOPMENT

SITE DESIGN OBJECTIVES

Minimize grades across site by 10-15% to allow for development

Connect to existing Phase I apartment complex

Stormwater

Gabe Brandt, Archie Clark, Tommy Dittman, Noah Hattrup Special

Provide management for 10-year storm event

Address 100-year storm overflow path

Accessibility

Provide ADA parking and routes

Install community commodities: sports court, lighting, open space

Utilities

Provide sewer and water connections to buildings

Provide fire connections and fire hydrant

OVERVIEW

To address the growing demand for housing, retail, entertainment, and business services in downtown Boise, a new 9-story mixed-use development project was designed.

Design Summary

Fire Rating

2 hour

Beams Steel Wide Flange

Girders Steel Wide Flange

Columns Steel Wide Flange

Braces Steel HSS Foundations

SUMMIT AT 11TH

DESIGN PROCESS

1 - Preliminary Phase

▪ Assign Roles and Billable Wages

▪ Review Project Documents

▪ Familiarization with Design Software

2 - Schematic Design Phase

▪ Develop Design Criteria

▪ Research Codes and Regulations

▪ Draft Preliminary Design

3 - Development Design Phase

Seismic Risk Category II ESTIMATED DESIGN COST = $47,040 PROJECT MANAGER

Special Thanks to:

▪ Design structural elements with Design Software and Hand Calculations

▪ Size Beams, Girders, Columns, Foundations, and Braced Frames

4 - Construction Design Phase

▪ Create Construction Drawing Package (Deliverable)

▪ Generate Financial Estimate for the Design (Deliverable)

5 - Design Presentation Phase

▪ Develop EXPO Presentation, Poster, and Report (Deliverable)

CURRENT INTERSECTION

COST ESTIMATES

SIGNAL ALTERNATIVE

TOTAL COST $1,254,029

ROUNDABOUT ALTERNATIVE

TOTAL COST $4,861,382

ACKNOWLEDGEMENTS

Instructor: Dr. Richard Nielsen

Sponsor: Fred Wismer

Mentor: Dr. Kevin Chang

Mentor: Dr. Ahmed Abdel-Rahim

WOLFGANG BEIER, SANDRA FAULKNER, TIM REED, ETHAN VON BARGEN

REDESIGNING THAIN AND 10TH INTERSECTION IN LEWISTON, IDAHO PROJECT BACKGROUND SIGNAL DESIGN

Escalating traffic volumes have led to a surge in congestion and traffic accidents at both the Thain/10th and 10th/Warner intersections. In hopes of minimizing injury, damage, and overall cost, the City of Lewiston is looking to incrementally reconstruct the Thain Road corridor over the next twenty years as funding becomes available.

Using the city’s standards, STEW Engineering has analyzed and conceptually redesigned the Thain and 10th intersection, improving overall traffic efficiency and safety.

ROUNDABOUT DESIGN

CROW PUMP DIVERSION

BACKGROUND

The Crow Pump Diversion, located in Lake County, MT is used to divert water from Crow Creek into a pumping plant that lifts the water to the Crow Feeder Canal. Once in the canal, water is used for irrigation and either delivered for storage or supplemental flow.

Improve operations of pump station

Reset service life of facility

Improve system hydraulics

Provide fish accommodations

COST ESTIMATE

$5,631,000 with 30% Contingency

Project Sponsored By: DOWL Contact: Jack Krusemark, EI

FISH PASSAGE AND GATES

Replace radial gate with sluice gate

Install partial-width rock ramp for fish passage

PUMPS AND STRUCTURE

Install three pumps & rotary drum screen

Replace structure to accommodate 40 cfs

CONVEYANCE SYSTEM

Replace 6,100 feet of earthen canal

Install 4,660 feet of 48-inch pipeline

Replace several irrigation structures

OBJECTIVES

Design a Power-to-Gas plant using hydrogen from renewable energy

Select a CO2 source for methanation reaction

Produce methane at 90-95% overall purity with 1-8% CO2

Utilize inherently safe design principles to minimize risk

DESIGN CONCEPT

GREEN GAS: CONVERTING RENEWABLE ENERGY TO SYNTHETIC NATURAL GAS

CHELSEA BARRERA, PAETRA MORGAN, KAYLEE JANETT

PROCESS OVERVIEW

Feed purification membranes: UBE

SELECTION OF CO2 SOURCE

Analyzed power, industrial, agricultural, biological sources

Steel industry emits 1.89 tons of CO2 per 1 ton of steel

Assumed composition of 72% N2 and 28% CO2

Free of contaminants

Product purification: 6FDA-TMDA, 6FDA-DAP

Fluidized bed reactor

Flash vessel to remove water

ENVIRONMENTAL IMPACT

Use of atmospheric CO2 for process feed

Environmentally friendly separation methods

SAFETY

Controls scheme, cooling jacket, and pressure relief

valve implemented on reactor

Failure rate of 0.0056 faults per year

Minimization of flammable and toxic chemicals used

HAZOP of reactor conducted

ECONOMICS

Process is sensitive to market prices of methane and hydrogen

Annual replacement of catalyst

CONCLUSION

Final product of 17.5 kg/hr of 92% methane

Not currently feasible

Design scale up for increased flow rates

Incorporate recycle stream

Advancements in membrane technology

OBJECTIVE

MODELING CYBERSECURITY THREATS WITH A FERRIS WHEEL

HUNTER SQUIRES, SEAN DEVINE, MATTHEW NEEL, KARINA PERMANN, ZHERONG QIAN ADVISOR : BRUCE BOLDEN | SPONSOR : DR . DANIEL CONTE DE LEON

Create a physical and virtual model of an Industrial Control System to demonstrate the effects of cyberattacks in a controlled environment

VALUE PROPOSITION

§ Facilitate cybersecurity development and education of the critical systems that provide resources such as water and gas

§ Create an accessible and affordable small-scale model of an industrial control system to perform cybersecurity -related research

BACKGROUND

§ Industrial Control System (ICS): Complex system employed to control a specific process using specialized components

§ Human Machine Interface (HMI): User interface for an ICS

§ Programmable Logic Controller (PLC): Devices commonly leveraged by ICS to control the state of the system

REQUIREMENTS

§ Physical model of an ICS including an HMI that can simulate a real-world process

§ Ability to run cyberattacks to disrupt the regular operation of the ICS via an attacker machine

§ Ability to observe all network traffic and logs from an observer machine that cannot be affected by the cyberattacks

§ Recreation of the model in a virtual environment

CONCEPTUAL DEVELOPMENT

Implement physical process as a Ferris wheel a process with clear visual indications of normal versus attacker manipulated behaviour

FINAL DESIGN

§ Libre PC Le Potato mini-pc running OpenPLC Runtime gathers sensor data and controls the Ferris wheel motor

§ Virtual machine (VM) running SCADA -LTS acts as the HMI, displaying valuable statuses about the physical process

§ Network of VMs hosting various aspects of Security Onion monitor and log the activity of the testbed

§ VM running Kali Linux employs Python scripts incorporating libraries such as scapy and Ettercap to attack the testbed with Denial-of-Service (DoS) and Man-in-the-Middle (MitM) attacks

§ Instance of Unreal Engine hosts the digital model of the physical testbed elements

VALIDATION

§ Ferris wheel successfully simulates a physical process (e g , rotation) controllable via an HMI

§ DoS and MitM attacks successfully interrupt the normal functioning of the system by preventing or hijacking rotation control

§ Security Onion successfully logs all network traffic events, enabling the observation of cyberattacks

§ Virtual model mirror the motion of the physical wheel, responding to commands from the PLC

CONTINUATIONS

§ Model status modifications to virtual model as physical modifications (bidirectional modelling)

§ Expend cyberattacks to include additional techniques

§ Implement rotation speed control

OBJECTIVE

Train machine learning models to produce feedback for videos of physical therapy exercises taken with a smart phone.

BACKGROUND

• A Deep Learning Framework for Assessing Physical Rehabilitation Exercises (Vakanski et al.)

• OpenPose (Body_25 Model)

o Skeletal extraction convolutional network model

• Python, Matlab, Jupyter Notebook

VALUE PROPOSITION

• Recovery time after injury can be extended when:

• Exercises are performed ineffectively

• Patients are discouraged from performing exercises due to lack of clear instruction

• Physical therapy sessions can be expensive

• Provide feedback for the quality of an exercise, given a smart phone recorded video

KEY REQUIREMENTS

• Analyze a video taken by a smart phone

• Model must be trained on at least one exercise

• Produce a numerical accuracy rating

• Provide feedback in a reasonable amount of time

• Extract movement data from joint positions

USING DEEP LEARNING TO PROVIDE FEEDBACK FOR REMOTE PHYSICAL REHABILITATION

TEAM: XIAN GAO, MOLLY MEADOWS, NOAH RIETH

CONCEPT DEVELOPMENT

VALIDATION CONCLUSION ACKNOWLEDGEMENTS

Sponsor: University of Idaho Computer Science Department (MIDA Lab)

Clients: Dr. Aleksandar Vakanski, Dr. Min Xian Instructor: Bruce Bolden

FINAL DESIGN

Validation of the spatio-temporal model using OpenPose

Validation of the spatio-temporal model using Vicon data.

• Use a larger database of self-recorded videos for extensive model training and better generalization

• Explore alternative methods of extracting skeletal data

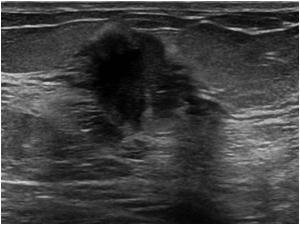

OBJECTIVE

MedAI has worked to advance early breast cancer detection by pretraining AI foundation models on large healthcare datasets that will be easily accessible on the official Machine Intelligence and Data Analytics (MIDA) website using APIs.

PROJECT BACKGROUND

Breast cancer ranks first for incidence in females in 159 countries and accounted for approximately 30% of new female cancers in the U.S.

MedAI introduces a solution to detect cancerous tumors in medical images with performance comparable (or superior) to human experts

The creation of a free, open-source website gives greater availability and more accurate tools for cancer detection, improving patient outcomes and saving lives

KEY REQUIREMENTS

Achieve a specificity of at least 85% and a sensitivity of at least 80% when tested on a large medical dataset

EMPOWERING HEALTH THROUGH DESIGN:

ML SOLUTIONS FOR BREAST CANCER DETECTION

JACKSON BALDWIN, BRYAN FRAHM, NYAH NELSON, SIHAN WUAI MODEL DESIGN

Curate large, labeled medical image datasets: breast ultrasound (BUS) and mammogram

o BUS – 8161 images

o Mammogram – 7605 images

Fine-tune a foundation AI model: Masked Autoencoder (MAE)

Evaluate the performance: accuracy, sensitivity, and specificity

Breast Ultrasound

Mammogram

Save model checkpoints to be used in the API

MASKED AUTOENCODER (MAE) ARCHITECTURE

▪ The encoder masks pixels and the decoder reconstructs the input data

▪ A classifier neural network is then added for the binary classification

EXAMPLE OF MAE MASKING AND RECONSTRUCTION

AI MODEL TEST VALIDATION

The website shall allow users to upload their ultrasound images for analysis

Users can easily upload files and view the results intuitively

The current website framework should be maintained with minor changes

CONCLUSION AND RECOMMENDATIONS

API DESIGN

Create Application Programming Interfaces (APIs) to allow for open use of the AI models without prior knowledge

The "Get Results" API allows selection of a dataset and a model and sends the result back to the user. The modular design allows for additional models to be added in the future

UI DESIGN

Enhanced image annotation tools

o Added zoom functionality

o Added touch functionality

Efficient user data management

o Communicate with models

o Provide user diagnosis

Improved visual design

o Focus on usability and consistency

ACKNOWLEDGEMENTS

After fine-tuning the MAE using a train and validation dataset, a test dataset consisting of 20% of the data was used to evaluate the model performance

The project exceeded requirements, acquiring strong evaluation scores and an improved UI. The API works as intended with the ML model and gives accurate reports to the user. Initially, two ML models were intended to be fine-tuned, but time only allowed for one. This project can be expanded by continuing work on additional API functions, as well as adding support for new ML models.

MedAI would like to thank Bruce Bolden, Min Xian, Shoukun Sun, MIDA Lab, Meta AI Research, and the UI CS Department for the help and support during the project.

GAMIFIED COMPUTERS AND NETWORKS: DEVICES

BY: OSCAR MICHUA-ZARATE, CHENG ZHAO, FEI TENG, YIQUN WANGCLIENT: DANIEL CONTE DE LEON.

GOAL

Our goal is to create a virtual-lab learning environment to educate about Cybersecurity. Within this environment, you will be able to change the difficulty of setting up and working with a virtual machine.

BACKGROUND

Currently, most of the digital network simulators platforms are lack comprehensive features for interacting with virtual structures and devices. Introducing such an immersive, game-like environment could revolutionize research and educational approaches in computing and networking.

KEY REQUIREMENTS

Our project demands a robust, scalable virtual infrastructure capable of simulating complex network environments and supporting varied cybersecurity educational needs. Key requirements includes reliable virtualization technology via Proxmox, a user-friendly interface and virtual environment designed in the UE5.

CONCEPT DEVELOPMENT

Create a virtual-lab learning environment to educate anyone with various knowledge of Cybersecurity.

o Be able to change difficulty for setting up a virtual machine

FINAL DESIGN VALIDATION CONCLUSION

Create a virtual Cybersecurity lab

Create an API to establish a connection between game client and hypervisor. Unreal

Simulate a 3D PC setup with a connection to a VM

This project represents a pioneering step towards integrating cybersecurity education with immersive, gamified technology. By leveraging cutting-edge virtualization and simulation tools, it aims to offer a dynamic learning platform that adapts to the cybersecurity training education.

ACKNOWLEDGEMENTS

Dr. Conte de Leon

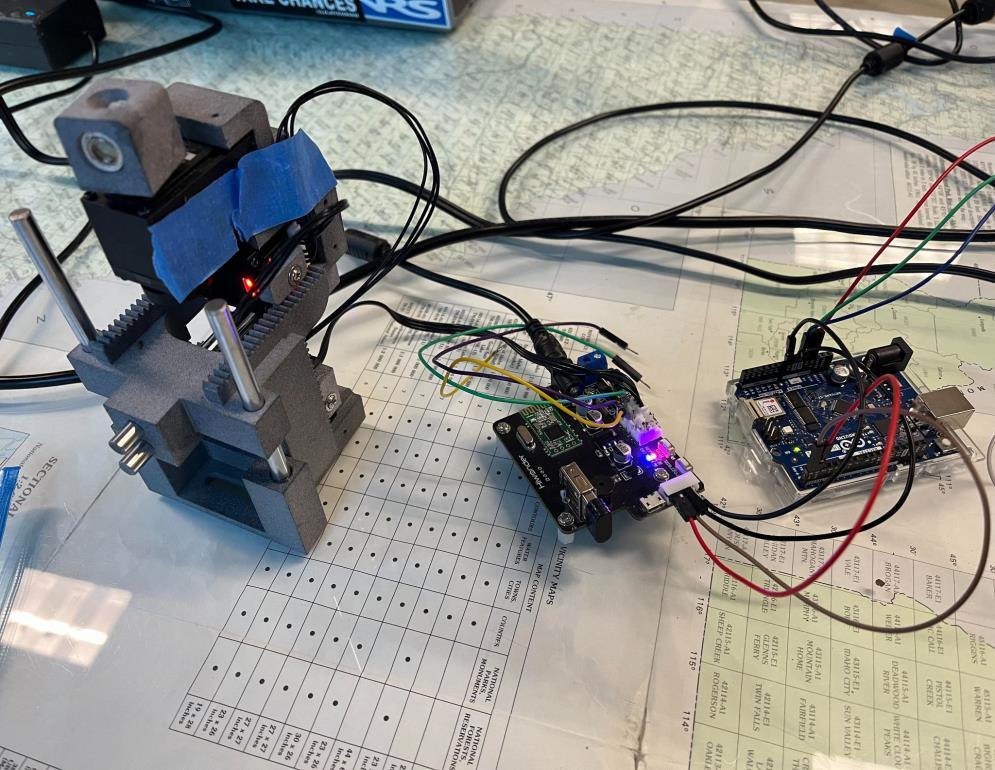

OBJECTIVE

Automate alignment of an optical receiver to a laser source, based on the measured light intensity at different positions. Reach optimal alignment by achieving maximum intensity.

BACKGROUND

Hansen Photonics Inc. is a small, family company located in Burien, Washington. They contribute to the computer networking industry with patents that cover modular networking hardware devices and systems. HPI works with universities, environmental science centers, and small businesses to help provide new, cutting-edge hardware solutions for everyone.

VALUE PROPOSITION

Optical transfer allows for greater data transfer capacity than electrically. It can be implemented in a cost effective and environmentally friendly way via lasers. This requires very precise alignment between two devices, potentially taking hours of labor to establish a connection. Automating the alignment with software provides significant convenience.

KEY REQUIREMENTS

1. This alignment process shall work at a minimum distance of 6 feet.

2. After program is started, the alignment process is fully automatic.

3. The finished device weighs less than 10 lbs.

4. The program is written in a modular, scalable style.

INTENSITY-BASED ALIGNMENT OF LASER DEVICES

Developed By: Track Tech

Dawson Burgess, Spencer Butler, Marissa Samayoa

Lead Instructor: Bruce Bolden

Client: JP Hansen – Hansen Photonics

CONCEPTUAL DEVELOPMENT

Design software for alignment of laser devices via optical intensity.

Language: Arduino C++

Environments: VS Code Platform IO

FINAL DESIGN

Final Process:

1. Find the brightest position along the R-axis, corresponding to the angle towards the broad light source.

2. Switch the light sensor to lowest gain, to support measuring the laser, which is very bright.

3. Alternate between optimizing along the X, Y, and R axes, searching for the brightest point upon each.

4. Continue until reaching a point where the measured value is sufficiently large.

CONCLUSION VALIDATION

1. Alignment worked at 6 feet.

2. Alignment worked at minor offset angles, as well as at 45 and 90 degrees.

3. Transmitter weighs 1.25lbs and receiver weighs 1.06lbs.

4. Alignment does not require user input after beginning the process.

The alignment process created meets the desired requirements, aligning the laser to the receiver. However, it may take several minutes, and the receiver may stop when reaching the side of the laser rather than the center. Further development could optimize the speed of the alignment or ensure that the receiver always reaches the exact center of the laser.

ACKNOWLEDGEMENTS

Dr. Conte de Leon

JP Hansen and Hansen Photonics

Objectives

• Develop a Cube-Sat payload for TES-22

• Measure Radiation in Low Earth Orbit (LEO)

• Communicate with the Primary Satellite Controller.

Value Proposition

In designing space experiments there is typically a significant delay between experiment readiness and actual launch date. The Cube Satellite platform provides the means to go from research inception to collecting data in an accelerated time frame. Our team will be constructing a payload which will attach to a CubeSat that will gather radiation data in Low Earth Orbit (LEO). Additionally, this payload will be ready for deployment in the third quarter of 2024, thereby going from inception to deployment in one academic year.

THE UNIVERSITY'S FIRST FORAY INTO CUBESAT PAYLOAD DEVELOPMENT

Team Members: Conner Wiench (CS), Dre Mata (EE), Lucien Lee (CS), Lyna Tran (ME), Nathan LaVoie (BE), & Sydney Munson (ME)

Advisors: Kip Sikes and Feng Li

Hardware Design

Renders of Tuna-Can Payload

• Interface with standard 1U (100mm cubed) CubeSat.

• All hardware confined to a 64mm x 35mm cylinder.

• Window allowing sensor direct contact with radiation activity.

• Use of automotive electronics that can withstand extreme temperatures.

• Avoided the use of heat dissipating electronic components

Software Design

Validation

Summary

• TES – 22 is set to launch onboard a SpaceX Transporter mission in August 2024.

• In harmony with the main CubeSat body, TES – 22 will orbit the Earth for up to 5 years gathering radiation data.

Acknowledgements

Requirements

• Fit in Dimensional & Weight Constraints.

• Measure Radiation Data.

• Interface with Primary Cube-Sat's Controller.

• Integrate Components onto a Printed Circuit Board.

• Payload driven off a Teensy 4.0 Microcontroller

• Communication through physical RS422 UART connection and the onboard LoRa Module

• Nanopb Proto-buffers to store and encode gathered data

TechEdSat Team

Avery Brock

Malachi Mooney-Rivkin

NASA Ames Research Center Model of Payload PCB

DC POWER BUS VALUE PROPOSITION

Addressing the need for a portable, reliable, rechargeable energy source that can be used to power a 100 Watt laptop up to 30 hours without a charge.

Low cost application that can be built without extensive technical expertise.

Can be used to power LED lighting, cell phone chargers, computers with the same plug as standard AC.

Programmable charging schedule during off-peak hours to take advantage of rate scheduling.

Scalable project that can be upgraded to power an entire house.

Integrates well with solar, system can be charged without inverter.

UNESCO GOALS

Affordable, Clean energy

▪ Provide affordable energy

Industry, Innovation and Infrastructure

▪ Provide energy in areas with infrequent or intermittent access to electricity

Sustainable Cities and Communities

▪ Portable energy always available during disasters and developing areas

RECOMMENDATIONS

Improve charging circuit to increase efficiency

Increase battery capacity

Provide detailed parts lists, schematics and build instructions to underdeveloped areas with need of dependable electrical power Rectifier and charging circuit diagram

FEATURES

Portability, easily moved and carried

Rechargeable with standard 120 VAC plug

Powers laptops, LED lights, cell phone chargers with standard AC plug.

3 kW energy storage that can power a standard laptop, three lights with LED bulbs and a cell phone charger for over 20 hours.

Programmable charge schedule

LEAD INSTRUCTOR

IDAHO POWER CLIENT

Kip Sikes

Paul Ortmann

PROBLEM STATEMENT

Arcadia Lake, a critical reservoir facility, faces challenges in meeting the rising water needs of Edmond, Oklahoma. The existing 30mgd pump station has been unable to meet the growing urban water demand, so the expansion of the pump station is imperative.

OBJECTIVE

To design a 60 mgd intake and pump station and the backup generator which should include full 72-hour capacity supported by subfuse fuel storage

BACKGROUND

The Arcadia Lake Pump Station project is located in Edmond, Oklahoma. The project is a 30 mgd (million gallons per day) raw water pump station that can be readily expanded to meet an ultimate capacity of 60 mgd.

ACKNOWLEDGEMENTS

Sponsor : John Barrutia

ARCADIA LAKE PUMP STATION

LINGYU WANG YUJIE XIA

VALUE PROPOSITION

To address this issue, a new raw water intake and pump station with a capacity of 60 mgd is required. It needs to be stable, reliable and secure.

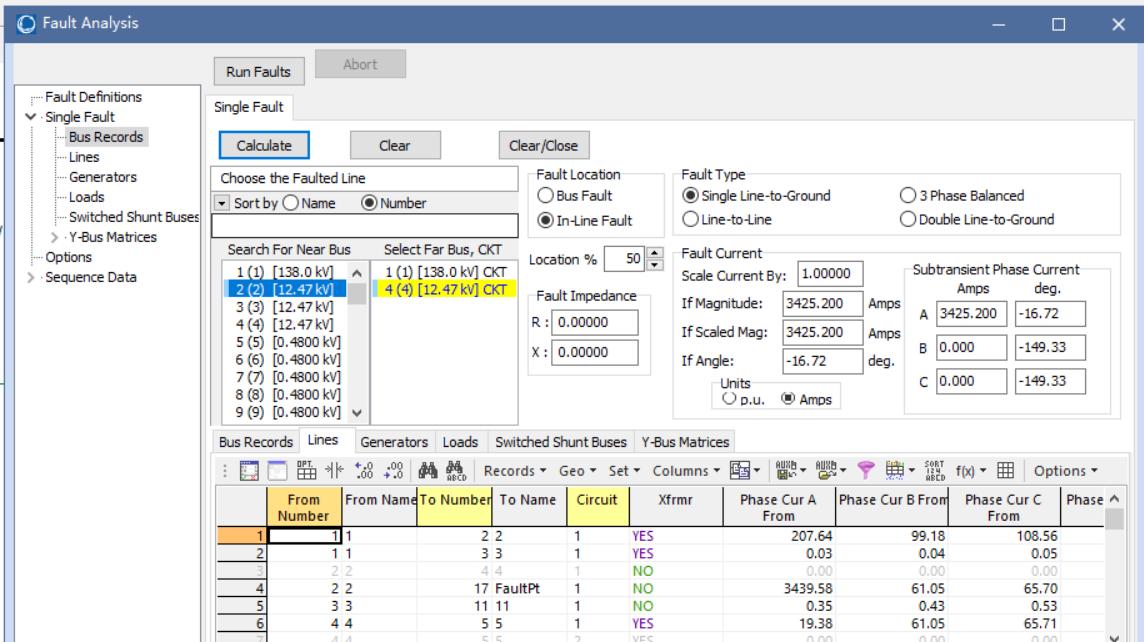

VALIDATION AND RESULTS

FAULT ANALYSIS RESULTS

CONTINGENCY ANALYSIS WITH CE

Pipelines are buried at a minimum of 4 feet

Adequate compaction of the pipe bed materials

Setting elevations of the reservoir to a return period of greater than 100 years

Pipe material is a structural steel pipe that provides more than enough strength to be able to withstand both internal and external pressures

The sloped pipeline will also have blowoff valves

PROJECT COST

OBJECTIVE + BACKGROUND

Complete a feasibility study by developing a prototype of an automatic tool changer to be used on Bastian Solutions robotic arms.

AUTOMATIC END OF ARM TOOL CHANGER

Mohammad Al-Qutub, Kadin Coddington, Jason Franklin, Devin Tanak

CONCEPT DEVELOPMENT

VALUE PROPOSITION

▪ Increase utility and capability of each robotic arm

▪ Reduce cost and increase profit by maximizing value

▪

22+ unique, potential solutions were explored and assessed before settling on current design.

A piston internal to the arm side has spring plungers attached facing outward. Internal profiles on the arm and tool side cause the plungers to compress then extend into the tool side as the piston actuates down. The force from the spring plungers lock the two sides together requiring the retraction of the piston to free them.

LOCKING MECHANISM

THE FINAL DESIGN ACKNOWLEDGEMENTS

KEY REQUIREMENTES

Lead Instructor: Dr. Swenson

Capstone Mentor: Keenan Bryan

Client Rep: Gabe Riggs

OBJECTIVE

To design, manufacture, and validate a system to separate metallic uranium from glass and zirconium oxide waste

BACKGROUND

The EBR-II and certain modern advanced nuclear reactor designs produce low level mixed quartz and metallic uranium waste through the production of their fuel. High assay low enriched uranium (HALEU) is extremely expensive and is subject to stringent tracking requirements, necessitating a system to efficiently separate residual uranium for recycle from the quartz waste

VALUE PROPOSITION

Magnetic separation is widely used in industry to separate metallic materials from non-metallics. Using powerful permanent magnets, the weak paramagnetism of uranium could be utilized to separate it from diamagnetic glass and zirconium oxide This would create a way to efficiently process waste from past and future reactor designs.

KEY REQUIREMENTS

95% Uranium Recovery by Weight

15 Minute Maximum Cycle Time

Dry Process

GLASS AND METALLIC URANIUM DUST SEPARATION SYSTEM

CONCEPT DEVELOPMENT VALIDATION AND RESULTS ISAAC CORGATELLI, EMILY MACK, JOSEPH NORMAN, YING YANG

Final SolidWorks Design

North-South Alternating Magnet Array

Design revolves around magnetic roller constructed from 264 ½ inch cube magnets

Vibration platform feeds material evenly over roller

Mixed material stream is separated slightly as it goes over the roller

Diverter plate directs uranium to collection box and other materials to the recycling ring

Recycling ring carries mixed material back up to beginning of cycle, allowing for continuous operation and recycling until required recovery is reached

Radial Alternating Magnet Array

used for magnetic field modelling

~2 Tesla max field strength at magnet array edges

Titanium granules used as uranium material surrogate due to its chemical stability and similar magnetic properties

Material Comparison

Final Testing Results

THE FINAL PRODUCT FUTURE WORK

N52 Magnets

Magnet roller constructed with ½ inch N52 neodymium magnets used to separate mixed material stream

Structure constructed with polycarbonate for easy viewing and high durability

Ring, magnet roller frame, mounting brackets, diverter, and ring rollers 3D printed using PLA

Powered with individually controllable DC motors linked with chains and sprockets

ACKNOWLEDGEMENTS

Reduce loss of material through open spaces in current design

Inclusion of industrial plate magnet roller

Implementation of cascading conveyor design

Smart controls for speed, material recovery, and cycle completion

Manufacture of more robust design with stronger materials for long term use in industry The

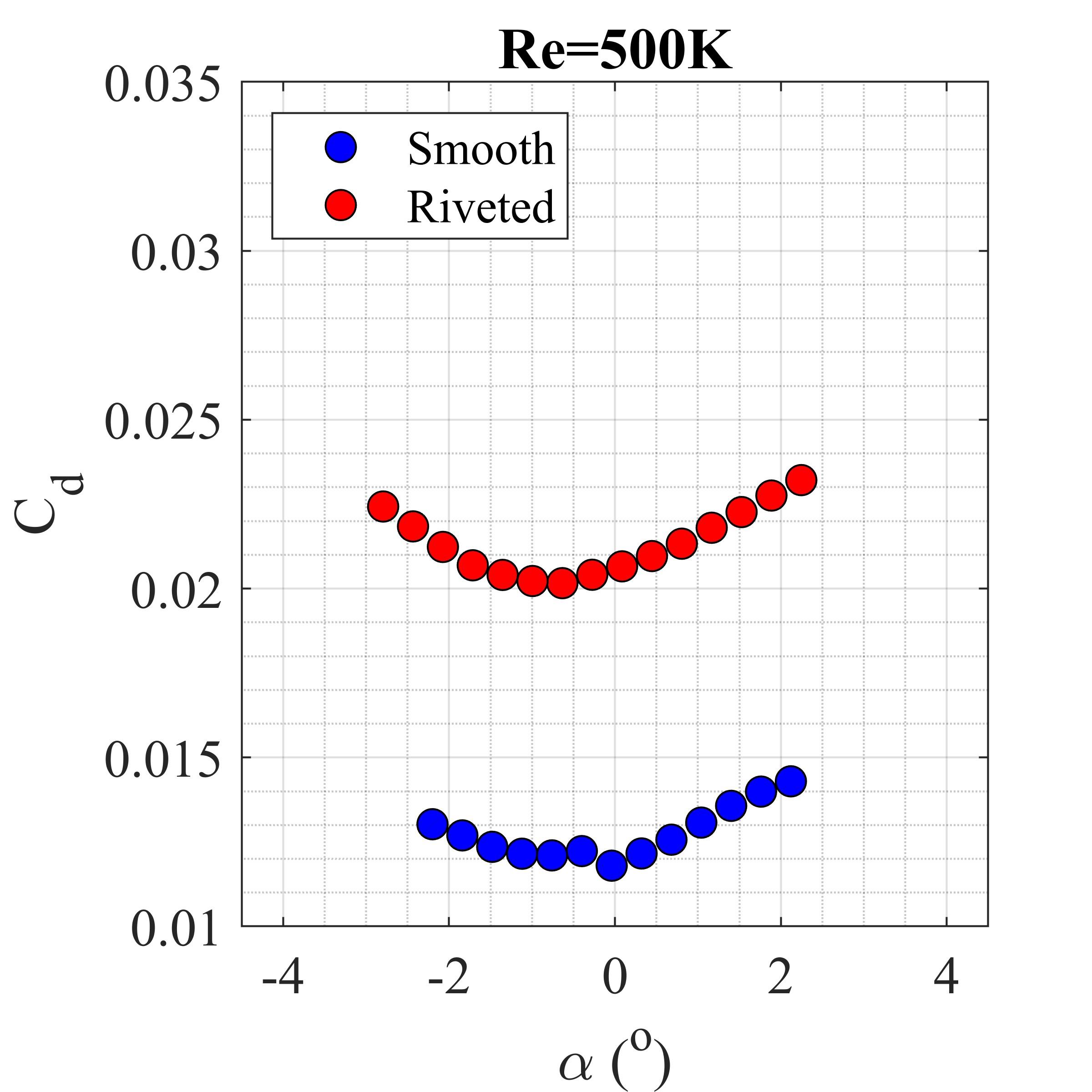

Skin Friction Rivet Analysis Using Oil Film Interferometry

Brad Hille, Garrett Green, Hayden Jacobson, Jared NelsonAcknowledgements: Dr. Vibhav Durgesh, Dr. Paulo Yu, Rodrigo Padilla, Wind Tunnel Lab

Value Proposition

Thisprojectaimedtoinvestigatethedrageffectsofriveted versus smooth aircraft surfaces using oil film interferometry (OFI). Through comprehensive testing, we aimed to provide Kodiak with insightful quantitative data to inform a major manufacturing decision.

OFI Theory

Oil film interferometry (OFI) is a technique used to visualize and quantify thin oil film distribution on surfaces. OFI relies on interference patterns formed by coherent light passing through the oil film, revealing details about film thickness, flow patterns, and surface conditions with exceptional sensitivity. OFI offers advantages such as non-intrusiveness

Airfoil Validation

Results

80% Increase in Coefficient of Drag when Rivets are Introduced OFI Testing

Oil Applicator Design

The oil applicator is 3d printed using a resin-based process that allows high resolution parts to be manufactured. This was designed to make application of the oil more consistent than previous methods.

Wind Tunnel Setup

1: Manometer

2: Airfoil

3: Wind Tunnel Control Panel

4: Servo Load-Cell Assembly Summary

This project successfully assessed the drag effects of riveted versus smooth aircraft surfaces using oil film interferometry (OFI). The coefficient of drag increased by 80 percent with rivets. Additionally, the oil applicator was developed to enhance the OFI process. This data provides valuable insights for Kodiak's manufacturing decisions, contributing to aerodynamic research and aircraft design optimization.

Flat Plate

Before performing OFI on curved surfaces, a flat plate testing fixture was made tovalidate our testing and post-processing procedures. The flat plate was designed in SolidWorks and then printed in three parts. It houses a polished square of stainless steel which acts as the testing surface.

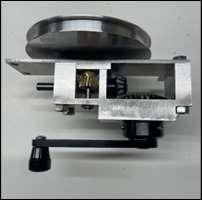

Objective:

Testmaterialstofindpotentialcandidatesforano maintenancebushingtobeusedinHyster-YaleGroup3.5 tonForklifts.

ValueProposition:

HYGproduces~140,000forkliftsannually,each equippedwithamastbushingrequiringregular lubrication.Thecurrentgreasingprocesscauses downtimeandmesses,particularlyproblematicinfood ormedicalsupplyenvironments.Redesigningthe bushingwithanewmaterialwouldreducemaintenance, preventunscheduleddowntimeandcontaminationin sensitiveenvironments.

MaterialsTested:

UHMWPolyethylene:

NOMAINTENANCEBUSHING

BENAL-DOUHANI,JASONJERKE,CASEYLEMON,ETHANOVERSTREET,CARLSONWURSTER

TheTestingDevice:

RequirementsandValidation:

TestPiece

LeverArm

Rotating Cam

Benefits–NoOil,Solidlubricant

Cost-providedbymanufacturer($20)

Source-InterstatePlastics

Result-Failureduetoplasticdeformation

Hydraulic Jacks

Motor Oscillating Shaft

•Materialmustbeabletowithstandafullloadforasimulated 15,000hoursofuse(85,000cycles)

•Fullloadconsistsof9150lbsofforceperbushing

•Simulatedmastrotationof12degrees(6degreesforward,6 degreesback)

•Materialmustretainathicknessofatleast0.1inchesafter testingiscompleted

OilImpregnatedBronze:

Benefits–Strong,OilImpregnated

Cost-$80/sample

Source-McMaster-Carr

Result-Testedto~50,000cycles,extrapolated topassingresult

Acknowledgements:

MainInstructor:MathewSwenson

StudentAdvisor:DanielRevard

ClientContact:OskarPeterson

GraphitePluggedBronze:

Benefits–Inexpensive,LowFriction

Cost-$50

Source-Ebay

Result-Testedto~20,000cycles,extrapolated topassingresult

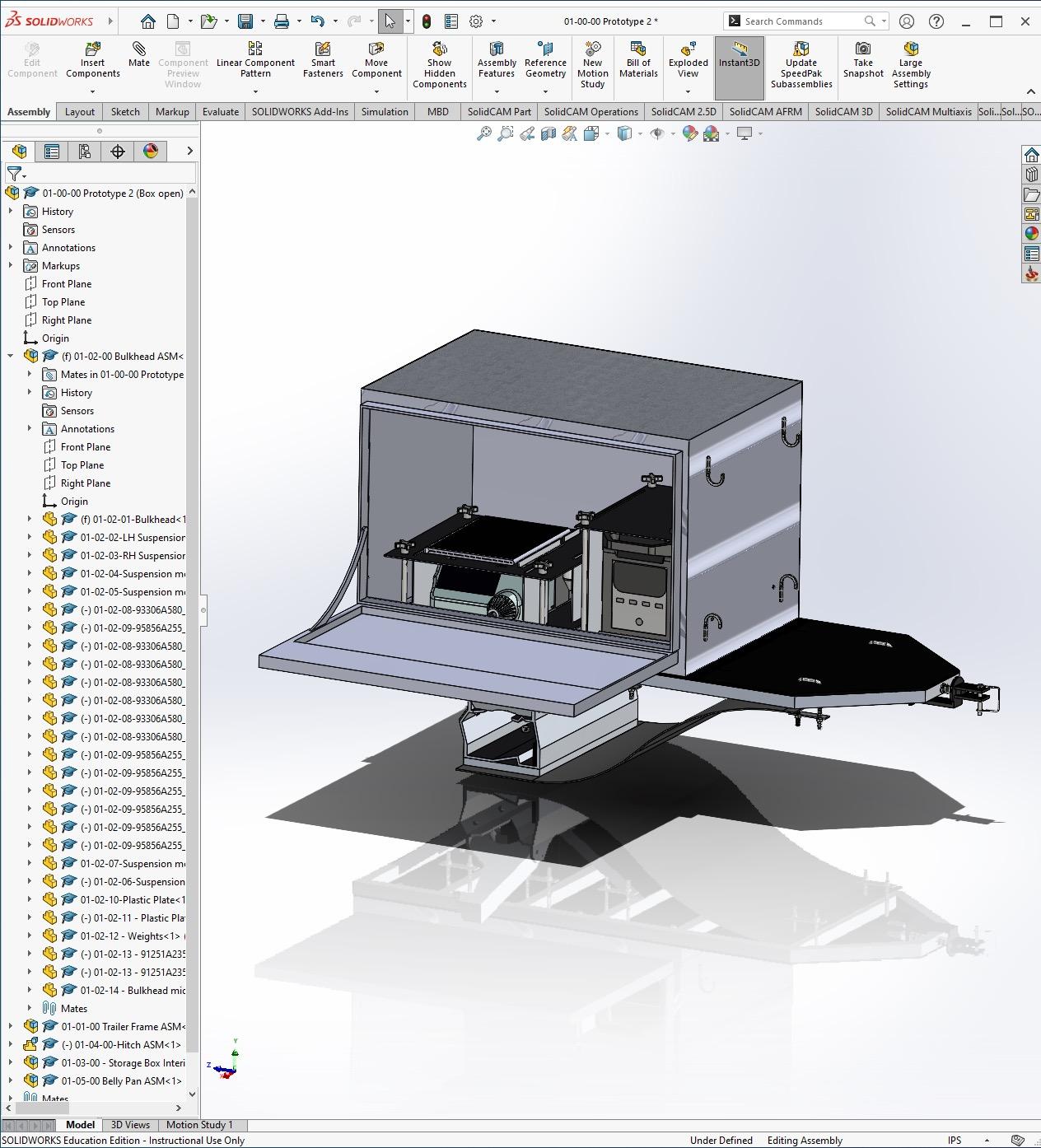

Objective -

Design and manufacture a Tow behind emissions analyzer equivalent to the competition’s trailer.

Weighs 350 lb.-m

Be able to go 45 mph

Measure and record snowmobile emissions

Use pre-existing suspension assembly

Pin-hitch attachment

Weatherproof storage

SNOWMOBILE TOW -BEHIND ANALYSIS TRAILER (TBA)

Members: Brad Henke, McKenzie Reid, and William Thielman

Durable and stable (Left to Right)

Background -

The University of Idaho Clean Snowmobile Challenge team has the goal of designing a cleaner, quieter, and more fuelefficient snowmobile that competes in a nationwide competition.

Value Proposition -

A smarter way to record emissions data: New loaded emissions analysis concept

UICSC emissions research

Potential for industry use

Cheaper solution than dynamometer

Concept Development -

Prototype 1 Analysis

Pros Towed nicely at speed

Recorded emissions data

Waterproof functionality

Electronics worked in weather

Cons

High weight placement

Poor device security

Stiff suspension

Roll- over prevention failed

Solutions adapted to Prototype 2

Weight placement outside of the box without rust corrosion or deterioration

Interior device security approaches

New shocks that can be customized according to weather and landscape conditions

Pin-connection manufacturing and decoupling ideas

Design Validation -

Speed, stability, data acquisition, and usability were categories all scored using the following acceptance systems:

1. Pass or fail

2. Rating system

3. Progressive

Data Acquisition -

Tested Results (2/01/24)

Final Design -

Final Refinements

Relocated weights/altered weight distribution

Redesigned hitch

Redesigned interior lockdown device

Fox float shocks

Additional usability-oriented components (belly pan, wire hooks, reflectors, rubber grommets, decals, RPM cable coupling)

Competition Results for 2023

Our team produced a functional trailer that records emissions and performs on snow to CSC team expectations.

Future Recommendations:

Heated emissions line for accurate THC totals

Can Bus recorder for accurate fuel consumption to convert from %/vol to g/mile

Acknowledgements: Kamal Kumar, Dan Cordon, Alex Fuhrman, Bryan Petty, Charles Cornwall, Miles Pepper, Arctic Cat, Wagstaff, and Horiba

Objective

Design, build and test a portable ember generator for use in wildfire simulations and research

Background

2021 Expo Dragon 1.0 needed improvements

• Leaks embers

• Hopper fires

• Safety concerns

• Poor calibration

• Low ember flux

• Durability issues

Value Proposition

• Wildfires cost $394-893 billion annually in the US alone

• Risk to structures at the wild-urban interface

• Require better ember characterization

• Ember generator will allow for wildfire simulation

Key Design Criteria

• Prevent ember leaking

• Protect hopper from backburn

• Improve the safety of the ignition procedure

• Allow for a greater level of control over propane input

• Run continuously for 15 minutes

• Budget: $2600

Ember Generator for Forest Fire Simulation

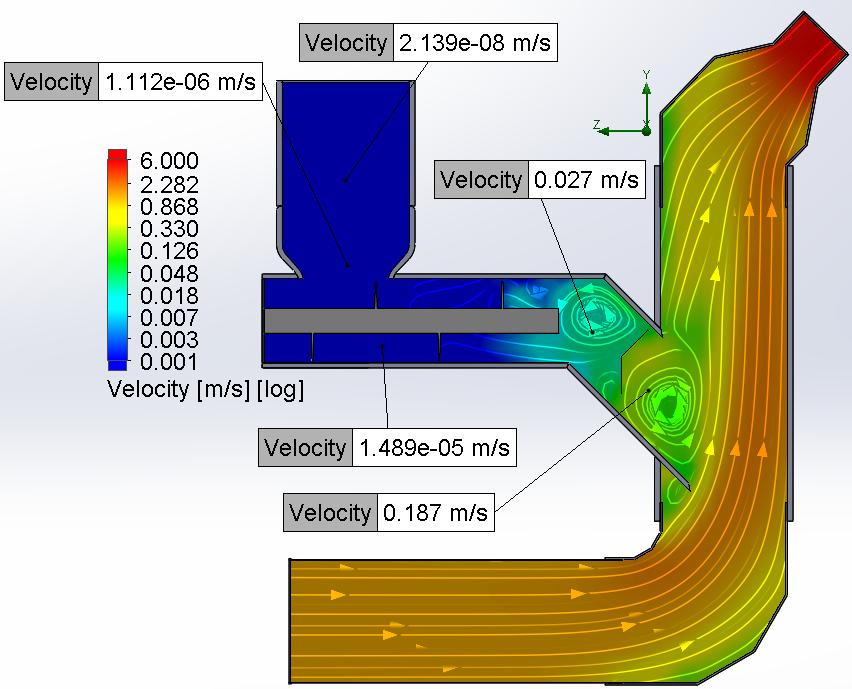

Concept Development

Prevention of backburn

• Reduce airflow in hopper

• Tighter auger clearance

• Damper blocks embers from reaching hopper

• Solidworks Fluid Simulation for validation

• Sloped fuel chute

• Create discontinuity between hopper and torch

• Improved lid seal

• Increase back pressure in the hopper

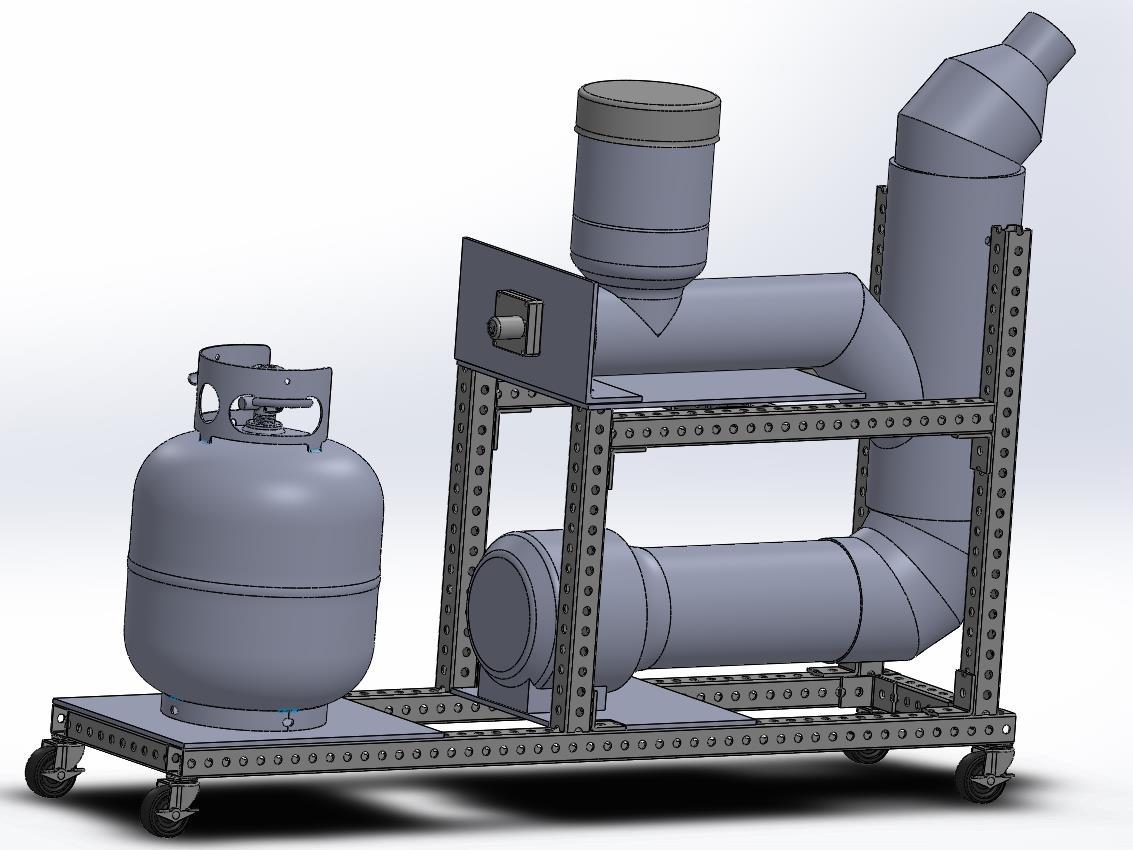

Final Design

Key Features

• Schedule 40 welded design for durability

• HVAC duct to reduce weight

• Thermocouples allow for monitoring of system and data collection

• CO2 suppression system to improve safety

• Spark igniter to simplify ignition procedure

Validation

• Temperatures never exceed 900 °F

• Thermocouples closely aligned with IR

• Hopper temperature stayed under 150 °F

• No back burn during tests

Recommendations

• Improve fire suppression system

• Implement solenoid for remote activation

• Test for system durability

• Quantify ember flux at different wood chip feed rates, fan speeds, and propane flows

Acknowledgements

• Doug Hardman – Client

• Dr. Alistair Smith – Client

• Dr. Mark Roll – Lead Instructor

• Nagendra Tanikella - Mentor

OBJECTIVE

Develop a propulsion system that can fire various 9mm projectiles at consistent velocities, with the ability to adjust such velocities incrementally.

BACKGROUND/VALUE PROPOSITION

Vista Outdoor manufactures defensive ammunition cartridges that are difficult to test due to the variation in the projectile’s velocity, which influences penetration and expansion upon impact

To reduce the extensive testing currently required to isolate the results from these variations, our design will utilize an air propulsion system to provide cheaper and more efficient product design.

KEY REQUIREMENTS

REACH A VELOCITY BETWEEN 900-1200 FT/S

FIRE 100-GRAIN 9MM CALIBER PROJECTILES

ABILITY TO ADJUST EXIT VELOCITY INCREMENTALLY

10 SHOTS WITHIN A 15-MINUTE WINDOW

CONTROLLED VELOCITY PROJECTILE

ACCELERATION USING COMPRESSED AIR