8 minute read

1. The Follo Line railway tunnel project – An introduction

from Tunnelling in the Follo Line Project - NFF Norwegian Tunnelling Society publication no 29

by TunnelTalk

Anne Kathrine Kalager, Bane NOR

The Follo Line project

Advertisement

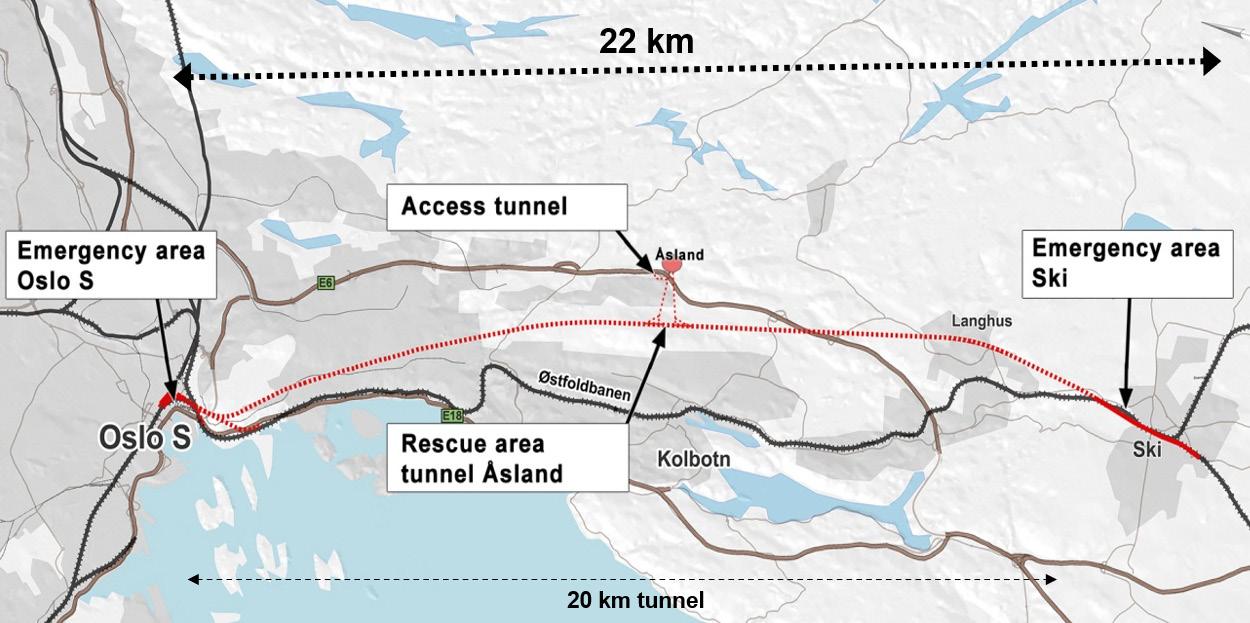

The Follo Line is a new 22 km long double track railway line under construction between Oslo Central station and the city of Ski (Kalager,2016). The Follo Line is built without stations between Oslo Central station and Ski. When the new line is in operation, it will work in interaction with the existing double track Østfold Line, which has 12 local stations between these two cities. The traffic will be divided between the two lines, depending on whether the trains will stop or not. The Follo Line will be a part of the development of the InterCity railway line down to the border of Sweden (the Østfold Line) and is a priority project of the current National Transport Plan (NTP, 2014–2023). The status of the development of the InterCity railway network is shown in figure 1-1 below. The section between Oslo and Ski forms the core part of the line southwards towards Halden to the border of Sweden.

Figure 1-1: Development of the InterCity railway network in the Oslo area.

The project is divided in different sub-projects, as shown in figure 1-2 below. The main part of the project consists of a 20 km long tunnel, which will be the longest railway tunnel in the Nordic countries to date.

The Ministry of Transport and Communications (Samferdselsdepartementet) is responsible for transport of people and goods, telecommunication and postal services and is the “owner” of the Follo Line project. The Norwegian Railway Directorate (Jernbanedirektoratet) is the government’s representative for railway services.

Bane NOR is a state company established to plan, build and operate the railway network. Bane NOR is reporting to a board of directors and to the Norwegian Railway Directorate.

Figure 1-2: The Follo Line (orange) between Oslo Central station and the City of Ski with the 20 km long tunnel.

At the northern end of the tunnel, the Follo Line will be connected to Oslo Central station. A separate contract for the performance of the civil work for connecting the Follo Line to Oslo Central station and a relocation of the existing double-track Østfold Line outside the rock-tunnel section was awarded to the Italian contractor, Condotte in December 2015. At the tunnel portal are the new and existing railway lines going into an approx. 600m long cut-andcover section. To increase the efficiency, the inbound Østfold Line is diverting from the cut-and-cover section of the Follo line tunnels into an approx. 1.5 km long rock tunnel joining the existing line right after the tunnel portal, while the outbound leaves the cut-and-cover section after a short stretch.

After the cut-and-cover section the Follo Line tunnels run in two separate drill-and-blast tunnels until they meet the tunnel section excavated by TBMs. The civil part of the entire northern sections has been divided in various civil contracts. It was one contract for the railway system in the cut-and-cover tunnels as well as in the rock tunnel for the inbound Østfold line, while the railway system for the major part of the drill-and-blast tunnels was added to the scope of work for the TBM section.

The contract for excavating the remaining 18.5 km of the tunnel with TBMs, including installation of the railway systems for the entire 20 km long tunnel, was awarded to the Joint Venture of the Spanish/ Italian contractors Acciona and Ghella, AGJV, in March 2015.

South of the 20 km long tunnel, named The Blix tunnel, the scope of work included both civil work and installation of the railway systems for a new 1.5 km long open section for the Follo Line including a total re-building and extension of the railway station at Ski, and a re-location of the existing Østfold Line in order to prepare for a future efficient utilization of the two lines. Between the portal of the Blix tunnel and the station, two connection-tracks are built to achieve conflict free connections between the two lines. This is shown in figure 1-3 below.

Figure 1-3: The tracks south of the 20 km long tunnel.

Figure 1-4 Two separate tubes with cross sections every 500 meters are chosen for the 20 km long tunnel, The Blix tunnel, at the Follo Line project.

Connection track West will be used for southbound trains that have to switch from the Østfold Line to the Follo Line, and Connection track East will be used for northbound trains that have to switch from the Follo Line to the Østfold Line. A 600 m long tunnel, crossing right over the Blix tunnel, are built for the Connection track East.

The contract for performing the construction work for this section south of the tunnel, including the rebuilding of the station at Ski, was awarded to the Spanish contractor Obrascón Huarte Lain, OHL, in August 2015. The contract strategy will be described in more detail in Chapter 4, “Contract Strategy”.

The tunnel concept

The 20 km long tunnel is, as the first railway project in Norway, built with two separate single-track tubes and in this way comply with inter-European safety requirements for long tunnels with cross passages every 500 meters. Se figure 1-4 below.

The cross passages will be used both for installation of the railway system equipment and as escape routes.

Two access tunnels were built in a pre-work contract to guarantee sufficient logistic capacity for the supply of four TBMs. Right in the middle of the project were for the assembly and logistic supply of the TBMs approx. 500m long tunnels with bigger cross section excavated, which will act as a rescue area for the Follo Line during the operation phase. A more detailed description of this will follow in Chapter 19, “Safety concept for the operation phase”.

When the Follo Line project will go in operation at the end of 2022, it will fulfill safety and maintenance requirements for a densely trafficked high-speed railway line, in addition to strict regularity requirements to ensure reliable traffic handling.

Geological conditions

The rock mass within this project area consists predominantly of Precambrian gneisses with banding and lenses of amphibolite and pegmatite. In addition, some generations of intrusions occur. Sedimentary shale occurs in the northern part of the tunnel, close to Oslo Central station. Se figure 1-5 below. Generally, the rock mass is quite homogenous and competent, with moderate jointing. Laboratory tests show that the rock is abrasive and strong, with uniaxial compressive strength varying between 100 and 300 MPa.

The Precambrian gneisses are folded in sharp isoclinal folds and they expose a clear foliation. Fracture zones in the gneisses have during several glacial periods been more exposed to erosion than the areas with solid rock. The rock surface has therefore been formed as deep valleys in the areas with major fracture zones, and peaks in areas with no or minor fractures. After the last glacier period, 10,000 years ago, these valleys were filled with marine sediments, mostly silt and clay.

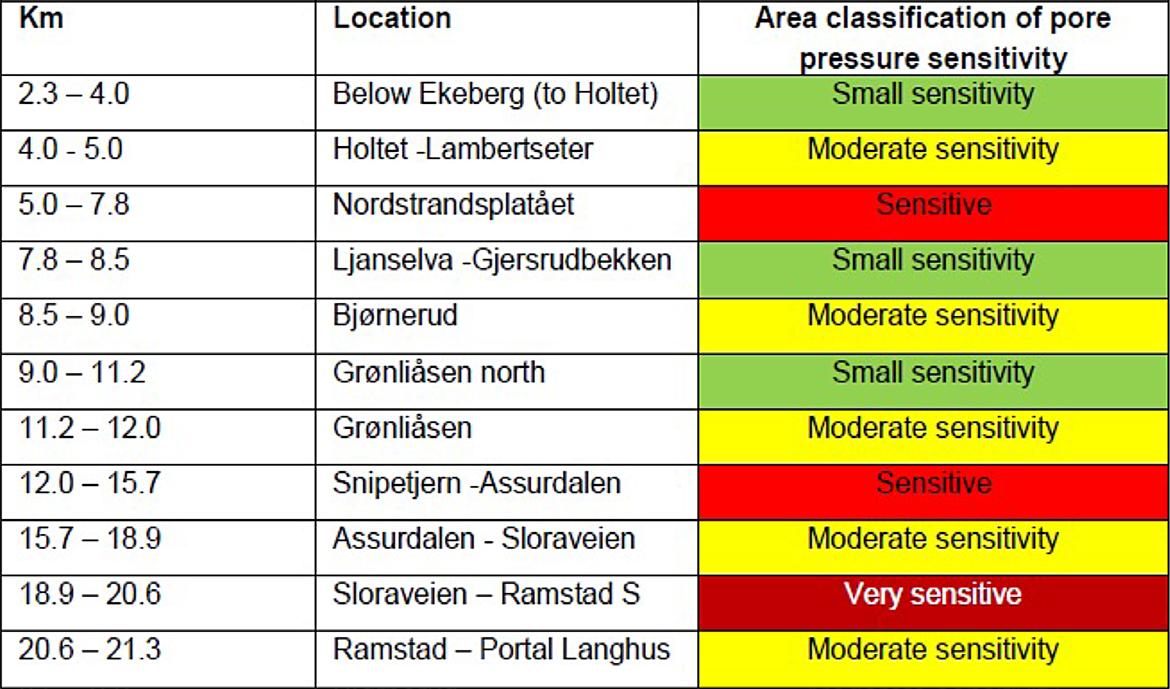

Some of these fracture zones intersect the tunnel alignment, and leakages were expected in these areas during the excavation of the tunnel. In many cases, these zones were connected to each other as a network. Intersecting one fracture zone could therefore influence a large area. This is also illustrated in figure 1-6 below. This is described in more

Figure 1-5: Geological longitudinal profile, which shows some of the intrusions (deep purple and yellow), shale in the north (green) and fracture-zones with a thickness of > 1 meter (blue)

Figure 1-6: The circles represent crossing-points between the tunnels and fractures. The fractures are connected to each other in different networks. The stars illustrate the areas affected by leakages from the crossing of the fractures.

details in Chapter 3, “Pre-construction planning and geological investigation”, Chapter 14, “Geological mapping and following up during the TBM excavation” and in Chapter 15, “Groundwater control and monitoring”.

To avoid settlements and damages on buildings and infrastructure along the tunnel section, the requirements for leakage into the tunnel, both during the excavation and after completion, were very strict. To fulfill the requirements, different mitigations to prevent leakages and development of settlements were an important part of the performance of the tunnel.

The overburden of the tunnel varies between 5 and 170 meters, and the groundwater table is normally located approximately 1 - 2 meters below the surface.

How the contractor prepared for handling of the geological conditions during the performance of the tunnel-excavation and the mitigations to avoid any kind of damages on the surface are described in detail in Chapter 14, “Geological mapping and following up during the TBM excavation”.

In Chapter 15, “Groundwater control and monitoring”, follows a description of how the impact on the water balance and on conditions on the surface were followed up during the excavation phase.

Good cooperation – An important key to success

The main focus of this publication is the technical execution of the Follo Line project, including safety and quality of the performance. The skills and experiences of all the involved parties are therefore an important key to success, but in this respect, there are also other topics which could be mentioned; When the contract was signed in March 2015, the client and the contractor decided to give priority to establish a good relationship for a common performance of this huge and multidisciplined project. Cultural differences were one of the topics that was highlighted. The client is Norwegian, and the contractor is a joint venture between a Spanish and Italian contractor, with subcontractors from even other countries. Workers came from all over the world to contribute to this project, so many nations and many different cultures have been represented on site. In the beginning, the client and the contractor spent time together including special cultural workshops to learn more about each other’s cultures, the way each party think, act and react, which was very valuable.

During the project execution various social events like skiing activities, common celebration of St. Barbara and celebration of achieved milestones were conducted.

The result is that even after 6½ year, the parties still have a good relationship within all levels of the two organizations. Even though there have been, and still are, disagreements between the parties, they have all the time been able to discuss and cooperate in order to find solutions.

Figure 1-7: Attempting to socialize without a frame can be a challenge.