1.

Specifiers Guide to Render Solutions

A general introduction into specifying and using rendered finishes

Specifiers Guide to External Wall Insulation (EWI)

Reviewing the process of specifying the right EWI solution

A general introduction into the benefits of using lime render and plaster

Anew economic report exploring the construction industry’s capacity to deliver on key targets and meet demand for new homes and infrastructure in the UK has been published by the Chartered Institute of Building (CIOB).

The report, Capacity Constraints in Construction: Rethinking the Business Environment, looks at some of the industry’s biggest challenges including recruitment, training and retention and the volatile nature of the sector, which results in hundreds of construction businesses collapsing each year, and the impact this has on the wider UK economy.

CIOB says it wants to drive policy makers and industry leaders to look beyond short-term fixes and explore longerterm solutions that not only alleviate immediate challenges but also shift the sector towards being more resilient, more progressive and more productive in the future.

CIOB worked with experienced economist Brian Green to compile the report, he said: “Construction is regarded as the most volatile major sector of the economy and it repeatedly faces capacity challenges. This means firms within the sector shape themselves to withstand swings between having too much work and too little resource and having too little work and too much resource. It is inefficient and debilitating to the industry.

“This report takes a different tack. It assumes firms are likely to be responding rationally to their business environment. So it argues that rather than simply seeking to force changes on the industry we should look to change the environment within which it operates. The industry and its firms would inevitably adapt of their own accord.

“These changes should include seeking ways to reduce the volatility and improvements to the institutional framework that determines what gets built where and when. Underpinning this, there should be greatly enhanced information to help steer decision-making.”

The CIOB maintains the report is crucially important as it seeks to shift the dialogue from aspirational targets to understanding and analysing the deep and often challenging structural issues faced by the sector which make it volatile and unstable.

• 60 years of independently certified test data

• Dedicated project support team

• Project specific solutions

• Dedicated training and onsite support

• Digital convenience inc. Product Passports, EPDs, DigiTrace

Issues with paving jointing are the primary cause of delays and of premature paving failure. This includes site delays due to jointing material restrictions against installation in wet weather, but then when this is not prevented, not so well understood is the subsequent premature breakdown and failure of the joints leading to overall failure of the paved surfaces.

The good news is that ALL these issues can be solved using the ‘Stateof-the-Art’ paving jointing, GftK vdw 850 plus from NCC Streetscape, who also provide full technical and practical support to do this throughout the UK, from the design office, right though to completion on site.

See pages 16-17 for the details.

Enquiry - 9

TSP Media Ltd, Grosvenor House, Central Park, Telford, TF2 9TW

T: 01952 234000

E: info@tspmedia.co.uk www.tspmedia.co.uk

The Built Environment Committee has published its report, ‘New Towns: Laying the Foundations’, following its inquiry into new towns.

Strong and dedicated central government leadership is essential if the next generation of new towns is to succeed.

This will not be possible without the Government being able to communicate its overall vision for the new towns programme in terms that resonate with the public, parliamentarians, local authorities, and the built environment sector. And for this, the Government needs to be clear about what it is aiming to achieve through the programme.

So says the cross-party House of Lords Built Environment Committee in its report, New Towns: Laying the Foundations.

The key findings from the report are:

• The necessary leadership and long-term stewardship of the programme and of each individual new town will not be achieved through existing structures.

• The original post-war new towns programme received very significant public funding in the shape of longterm loans, with the Treasury acting as a patient investor, underwriting the programme for decades, from planning, through construction, and on until maturity. In the current fiscal context, the ability of the Government to provide funding at this level is significantly reduced, meaning that alternative funding models will be needed to plug the gap.

• One clear route to encouraging and supporting the provision of this kind of funding from the private and alternative sectors is by delivering the infrastructure first – for example, building the public transport links, schools, and hospitals –before breaking ground on new housing.

• Delivery of the new towns should, in almost all cases, be through development corporations. A number of possible models are available, but the Committee recommends that democratic accountability should be ensured through local authority

Foster + Partners is designing the second phase of the Ellison Institute of Technology (EIT) campus, which will extend the interdisciplinary research and development facility in Oxford.

The second phase encompasses the western part of The Oxford Science Park and features a state-of-the-art auditorium and autonomous and purpose-built laboratories, including those for generative biology, plant sciences, robotics, and AI, as well as other dynamic spaces for research

and education. Gerard Evenden, Head of Studio, Foster + Partners, said: “We are delighted to be designing the extended Ellison Institute of Technology campus, which will strengthen the Institute’s presence in Oxford and facilitate its groundbreaking research.

“Our design for the second phase builds upon and consolidates our work for phase one. Greenery knits together both parts of the site – directly connecting people with nature to foster wellbeing and enhance outcomes.”

representation within those delivery and governance structures.

Lord Gascoigne, Chairman of the Committee, said: “The Government’s new towns programme is a once-in-a-lifetime opportunity to build genuinely affordable, high-quality homes and to create communities where people want to live.

“Public support is fundamental to the success of the programme. The Government needs to work hard, day in and day out, to articulate a clear and ambitious vision for its programme. A key element of this must be to inspire developers and planning authorities to use the new towns as a model for future development.

“But a vision alone will not be enough to get these new towns built: the Government needs to show that it has the grip necessary to drive the programme forward and make it happen. Now that the New Towns Taskforce has published its shortlist of locations for 12 new towns the Government needs to set out, in explicit terms, how it is planning to fund and deliver them.”

Morgan Sindall Construction has successfully completed the first phase of transforming Gloucester's iconic Art Deco Debenhams building, creating a sustainable new City Campus for University of Gloucestershire.

Designed by ADP Architecture and delivered through the Pagabo Major Works framework, the adaptive reuse of the former department store offers a state-ofthe-art centre for teaching, learning, and community services. The scheme is set to be a major catalyst in the reinvigoration of Gloucester's high street and its wider city centre regeneration.

The City Campus in Kings Square is home to University of Gloucestershire’s Education, Psychology and Social Work programmes, forming a new city-centre base for 1,200 students and staff.

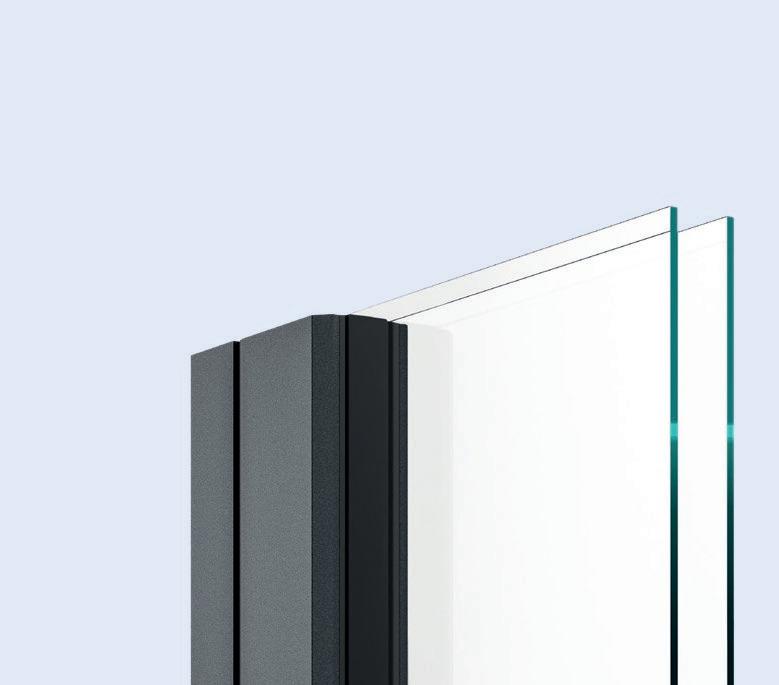

Fassacouche Kiwa BDA certified for ‘very severe’ wind-driven rain conditions in the UK

Through-coloured render

High aesthetic value

Good water repellency

Excellent breathability

Excellent workability

1 FASSACOUCHE Semi-lightweight through-coloured render for protecting and decorating facades. Available in 23 different shades.

2 FASSANET MAXI* Alkali-resistant fibreglass reinforcing mesh, 160 g/m².

* FASSANET MAXI is recommended to be applied where stress is concentrated or on irregular substrates.

IS 510 Siloxane water-repellent.

PX 505 Acrylic-siloxane filling finish for exteriors.

TO FIND OUT MORE about Fassa Bortolo and its range of render systems and building products. Visit www.fassabortolo.co.uk or call 01684 218 305

The Royal Institute of British Architects (RIBA) has named Appleby Blue Almshouse, a social housing complex for over-65’s, by Witherford Watson Mann Architects, as the winner of the RIBA Stirling Prize 2025.

Replacing an abandoned care home, Appleby Blue radically reimagines the traditional almshouse, flipping the centuries-old typology by placing shared spaces at its heart to foster community and reduce isolation among residents. The development contains 59 bright, spacious flats arranged in a U-shape around a central garden courtyard.

Inside, generous homes with discreet accessibility features offer an aspirational living environment, standing in stark contrast to the institutional atmosphere often associated with older people’s housing. Large kitchen windows draw in natural daylight and provide residents with uninterrupted views of the garden courtyard. A variety of plants, trees and a gentle water feature, that echoes throughout the building, gives a sense of a woodland oasis, allowing residents a constant connection to a green space in the heart of London.

Light-flooded, terracotta paved hallways connect the flats and contain customisable planters and benches, forming a “social corridor” that encourage spontaneous

interaction among residents. Cleverly designed automated vents alongside the double-glazed windows allow the corridors to collect heat in the winter to create a warm winter-garden for residents, and release heat to stay cooler in the summer.

Above, a generous roof terrace provides a colourful, transportive communal space for residents, where the planting beds have been raised to accommodate accessibility needs.

At street level, floor-to-ceiling bay windows create a strong social connection between residents and the surrounding community. A direct view of the bus stop on the main street allows for chance interactions and residents to observe the daily bustle of city life. A varied public calendar of events also helps draw people inside to the warm, timber-clad shared spaces. The generous double-height public “garden room” and community kitchen provide spaces for everyone to come together and socialise, offering residents a form of co-living centred around communal spaces.

Remarkable collaboration and meticulous attention to detail between Witherford Watson Mann Architects and the client, United St Saviour’s Charity, has created a serene, social and profoundly transformational environment for the users of Appleby Blue, where the importance of the resident's mental and physical wellbeing are each treated with equal significance and priority.

Appleby Blue gently reimagines later living as a collective experience, drawing its residents together in spaces that elevate the everyday. The result is a pioneering model for designing high-quality housing for later living, where care and dignity are embedded into the design throughout.

Stephen Witherford, on behalf of Witherford Watson Mann Architects and United St. Saviour’s Charity, said: “Appleby Blue is a contemporary almshouse on a busy London high street, designed to address the social and economic challenges faced by many older people in our inner cities. Working closely and imaginatively with United St. Saviour’s Charity, we’ve created an environment that reduces loneliness, encourages connection, and supports a good later life. The charity has made social housing aspirational, enabling people to grow old locally with the right support, benefiting both residents and the wider Southwark community. We’re honoured that the RIBA Stirling Prize recognises the power of architecture to create places that genuinely transform lives.”

The ceremony also included the announcement of four RIBA Special Award-winning schemes:

• United St Saviours Charity, winner of the RIBA Client of the Year Award 2025 for Appleby Blue Almshouse

• Appleby Blue Almshouse by Witherford Watson Mann Architects, winner of the RIBA Neave Brown Award for Housing 2025

• Sheerness Dockyard Church by Hugh Broughton Architects, winner of the RIBA Reinvention Award 2025

• St Mary’s Walthamstow by Alex Spicer at Matthew Lloyd Architects, winner of the RIBA Stephen Lawrence Prize 2025

Hardie ® Plank by James Hardie:

• 21 colours & two finishes available

• Low maintenance & easy to install

• A2 fire rated & BBA certified

Available nationwide though Brickability Brick & Building Materials. Speak to our teams for take-o services, technical advice, and local supply.

Neil Turner, UK Technical Sales Manager at Ecological Building Systems, looks at why insulating a warm pitched roof with natural insulation is becoming an increasingly popular option.

With around 25% of heat from a home lost through the roof, fitting effective roof insulation at new build stage or when upgrading a property, is an effective way to improve energy efficiency and reduce heating bills. When a warm pitch roof is insulated correctly, it has a lifespan of around 60 years, so it can pay for itself many times over.

Unlike cold roofs, where insulation is placed at ceiling level, hybrid warm pitch roofs use insulation both between and above the rafters, with ventilation above the top layer. This design maintains a consistent temperature throughout the roof structure while creating a thermal barrier that minimises heat loss and enhances energy efficiency. By insulating above the rafters, hybrid warm pitch roofs offer improved thermal performance and reduce the risk of thermal bridging, which can lead to significant heat loss.

Natural insulation materials are derived from renewable resources, such as wood fibre, grass, sheep's wool, hemp and

cellulose. These materials are valued for their sustainability, thermal performance and moisture-regulating properties. However, not all natural insulation products behave in the same way. Differences in density, thermal conductivity and vapour diffusion characteristics mean that careful material selection is essential for pitched roof applications.

These natural materials are not only environmentally friendly but also offer excellent thermal performance and moisture management properties. In addition, many natural insulation products provide high thermal resistance (U-value), which is crucial for meeting stringent building regulations. They also contribute to better indoor air quality by minimising the release of harmful chemicals and Volatile Organic Carbon (VOC’s). This is particularly important for maintaining a healthy living environment.

Renowned for their effective moisture control, natural insulation materials absorb and release moisture, helping to regulate humidity levels within the building and reducing the risk of interstitial condensation. To support this function, these materials should be used in combination with vapour open, windtight membranes on the outside, such as Pro Clima Solitex Plus or Pro Clima Intello membrane on the inside. These layers help manage moisture flow safely while contributing to overall airtightness.

This insulation is typically more moisture vapour diffusion open than synthetic alternatives, allowing moisture to escape while preventing the ingress of external dampness. This characteristic helps to maintain a balanced indoor environment, reducing the risk of mould and mildew.

Correct installation of natural insulation is important for optimal performance, but achieving airtightness requires a comprehensive approach involving the use of intelligent vapour control membranes and airtightness tape. When used together, these components help prevent unwanted air movement and ensure long-term energy efficiency. Natural insulation supports this system by fitting snugly around the structure, but it must be combined with the correct layers and detailing to be effective.

Working with a high-quality natural insulation distributor is essential as they can advise on insulation choice and installation to meet regulatory requirements. Natural insulation offers an effective solution for warm pitch roofs, particularly as thermal performance requirements become increasingly stringent. Its sustainability, thermal efficiency and moisture management properties make it an ideal choice for modern building designs.

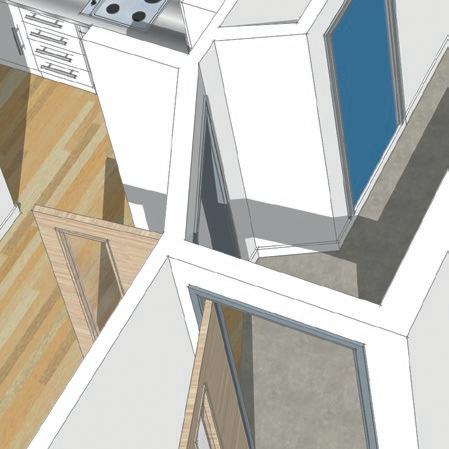

Project: Gap House for Bristol City Council

Architects: BDP

Suppliers: Etopia

A council-owned, disused garage plot in Bristol has been revitalised to create affordable housing thanks to the innovative Gap House concept. The nine onebedroom, two-storey sustainable homes on Bell Close, Horfield, for social rent, are now complete, with the first residents beginning to move in.

Designed by architects and landscape architects at multidisciplinary design practice BDP and built by contractor Beard and SIP (structural insulated panel) specialist Etopia, the homes were commissioned and funded by Bristol City Council.

BDP originally showcased its Gap House concept design at the Housing Festival Expo in Bristol in 2018, as a proposed way of helping to address the city’s need for housing and revitalising neighbourhoods.

The homes have been built using modern methods of construction (MMC), with factory-made panels used to create the external walls of the homes. The use of MMC helped overcome the challenge of building on a tight, urban site with limited access.

Councillor Barry Parsons, chair of the Homes and Housing Delivery Committee at Bristol City Council, said: “Creating safe and healthy neighbourhoods, with affordable, high-quality homes is one of the council’s key priorities,

and working with partners is key to helping us achieve these goals. These nine new homes will be a real asset to the council’s housing stock and allow us to make a real difference to the lives of nine households in need of an affordable home.

“Using innovation and MMC, the Gap House concept has allowed us to build vital homes on a difficult site with limited access. I am also delighted that the new homes are low energy and sustainable, which will result in cheaper energy bills for future tenants.”

Each home will be energy efficient, cheap to run and have a low environmental impact, thanks to low energy lighting, high levels of insulation, minimal heating requirements and renewable energy generated by solar PV panels and air source heat pumps.

The homes include an open-plan kitchenliving area and a bathroom on the ground floor, with a bedroom and storage on the first floor. Large windows allow for maximum natural light.

The entrance to each property has been designed to promote a ‘front porch culture’ with green space and outdoor seating in front of each home to encourage social interaction and community cohesion. >>

>> Nick Fairham, Chief Executive at BDP, said: “The Gap House showcases a huge potential to transform the thousands of disused garage plots across the country into much-needed, sustainable and affordable housing. It shows the power of thinking innovatively about how we repurpose small pockets of derelict brownfield land to help create thriving cities and communities that benefit all.”

Local ward councillors and Labour Group Leader Councillor Tom Renhard, and Deputy Group Leader Councillor Carole Johnson, said: “We are delighted to see new innovative, environmentally friendly council homes completed. Bristolians are now living in

places that provide security, warmth and a better future.

Bristol desperately needs more council housing; these are the exact sort of homes that need to be built at scale across the city if we are to make progress tackling the housing crisis.

“Our thanks go to partners: Etopia, BDP and Beard for their exemplary work on this highquality scheme. Providing sustainable social housing built on under-utilised land for those most in need is to be commended. As local councillors, we are pleased to have played a role in making these homes a reality.”

The Gap House concept was refined as part of an Innovate UK programme supported by the Housing Festival, designed to explore

the potential for MMC housing. Last year, it featured in the Housing Festival’s Social Rent Housing: The MMC Playbook, a guide for local authorities, which highlighted Gap House as “an innovative approach to successfully unlocking land and overcoming challenges for successful creation of new housing”.

Images by: Kathy Coley

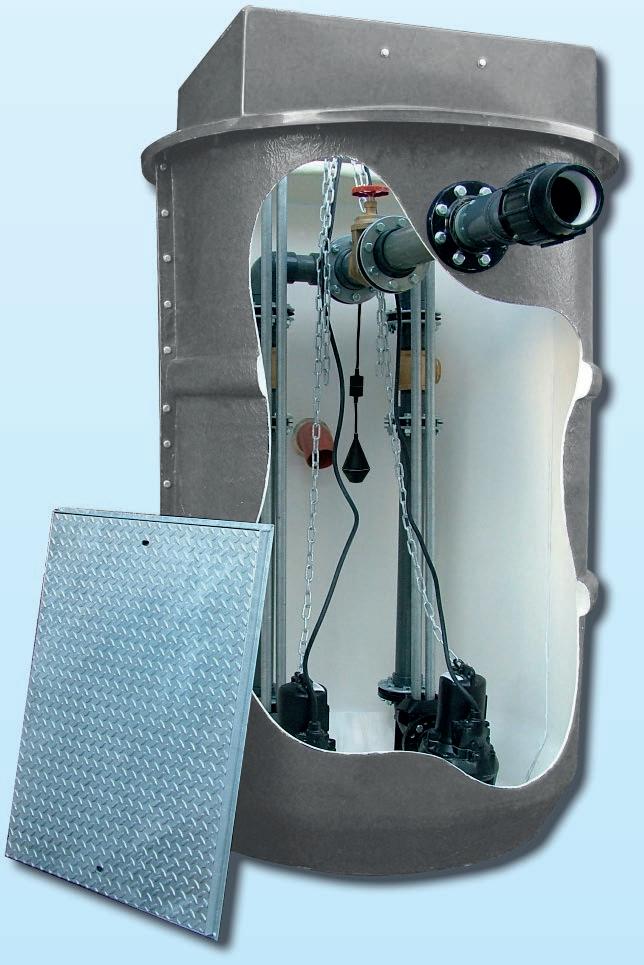

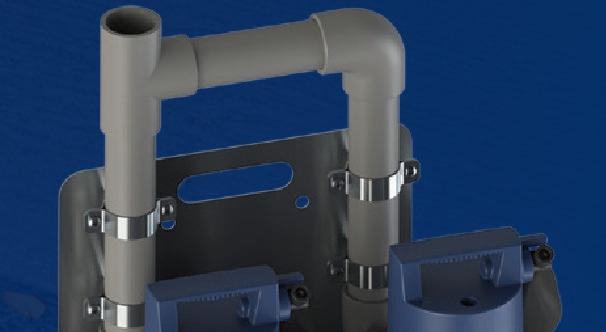

Extensions that flow without fail

No worries about potential basement flooding

Larger projects command bigger solutions

For the precise solution... Go with the Saniflo

Over 60 years experience lift water up to 11 m

2 year warranty

If you're looking for underground solutions for removing waste water from extensions or buildings, clearing flood water from car parks or adding extra toilets to offices, Saniflo have the ideal product.

Our macerators and pumps open up more opportunities and help you find the perfect solution to get the job done.

“Do it Once - Not Every Year”

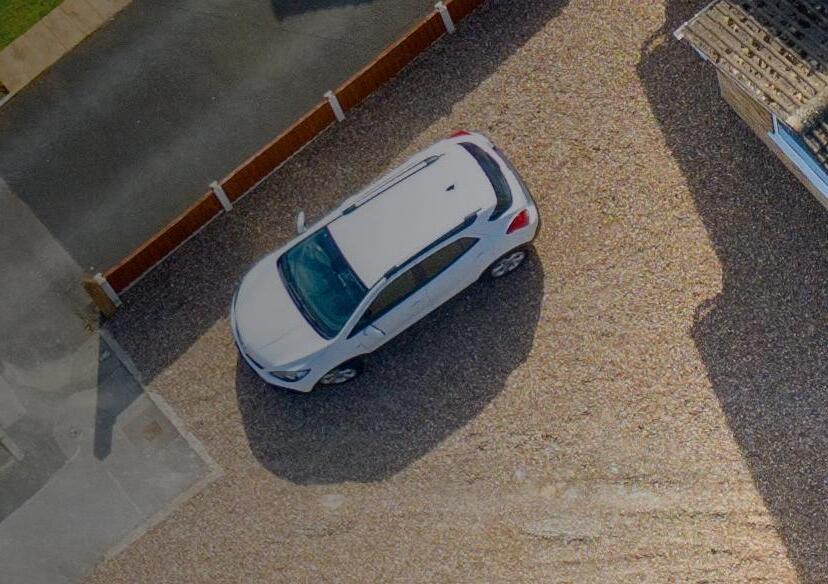

For all types of bonded paved surfaces in the UK, from domestic patios and driveways to the paving around retail and other commercial premises, and paving in the public domain, including pavements, highways and market squares, issues with paving jointing are the primary cause of delays and of premature paving failure.

This includes site delays due to material limitations and restrictions for secure installation and completion, but then not so well understood is premature breakdown of the joints leading to overall failure of the paved surfaces.

Site delays are frequently due to the limitations and necessary restrictions on using paving jointing materials, usually cement-based, in wet weather, or even when rain is forecast in the next 24 hours. This then delays completion, which delays getting the areas open for service.

Secondly, when these limitations and restrictions are not strictly observed, this leads to more serious premature breakdown of the joints, followed by failure of the overall paved surfaces. Due to time and cost pressures to meet schedules and opening dates, the critical jointing restriction that jointing must only take place with no residual water in the joints, and with no rain in the immediate forecast, which can get overlooked in the rush to completion.

Technically, any residual water in the joints, or added water during rainfall, will significantly change and disrupt the water to cement ratio (W:C) of ALL and

ANY cement-based jointing materials. This change increases both short and long-term shrinkage cracking, as well as increasing the permeability and reducing the strengths of the hardened material in the joints.

Unfortunately, these defects are generally NOT visible at the time and go unnoticed, but the properties of the product in the joints, will be very different and much lower than those in the specification or Product Data Sheet. Though any retained site samples will be correct, because they are poured into moulds, maintaining the w:c ratio. The extent of the joint material inadequacies only becomes apparent after a year or so, when the joints start to visibly degrade and are progressively damaged much more easily than they should be in service.

This means by any combination of exposures to water ingress, frost attack, traffic and cleaning regimes, especially in areas cleaned by high pressure jet-washing, or with the use of mechanical streetcleaning machines. As a result, all over the UK there is an abundance of premature paving joint breakdown taking place.

The good news is that ALL these issues, for ALL types of paving, in ALL types of areas, can be solved using the ‘State-ofthe-Art’ paving jointing, GftK vdw 850 plus from NCC Streetscape, who also provide full technical and practical support to do this throughout the UK, from the design office, right though to completion on site.

GftK vdw 850 plus is unique and unrivalled, it is the second-generation of epoxy paving jointing technology. All around the UK there are now extensive references, including major public projects now more

than 15 years old, looking good, and good for many more years’ service.

The GftK vdw 850 plus can be applied quickly and easily in dry, damp or wet weather, even in the pouring rain, and with no worries about residual water in the joints, and no wet-weather delays, plus no risk with water: cement ratios.

GftK vdw 850 plus is also very easy and fast to apply by wet-slurry techniques, it has very high flow properties and selfcompacts into the joints, so there is no additional tooling or finishing required.

Additionally, it is non-staining, does not leave a ‘sheen’, and unlike cement or ordinary resin products, there is no waiting to clean-off, and no ‘washboy’ or special cleaning equipment required, with no annoying residual cement haze or efflorescence.

GftK - The Only Truly Wet-Weather Paving Jointing

• No delays - No waiting to joint

• No concerns over water in joints

• Keep jointing in cold (> 3oC)

• Easy wet-slurry application

• Very high flow & self-compacting

• No tooling or finishing required

• No waiting to clean off

• No washboy required

• No haze & No efflorescence

• Fast curing & hardening

• No shrinkage cracks

• Highest joint performance

• Optimum strengths & flexibility

• Fully resistant to traffic, de-icing salts, and jet-washing

GftK vdw 850 plus hardens quickly to a tough, very durable joint that resists heavy pedestrian and vehicular traffic, plus it is fully resistant to de-icing salts in winter, and to frequent machine cleaning.

Use GftK vdw 850 plus for your paving jointing and/or repointing (if you did not use it first time), and ensure your paving is durable and a truly sustainable choice.

Visit our website for more information on GftK vdw 850 plus paving jointing: https://www.nccstreetscape.co.uk/pavingjointing/vdw-850plus.html

And for more information on Paving Repointing: https://www.nccstreetscape.co.uk/type-ofarea/paving-repointing.html

NCC Streetscape – Enquiry 9

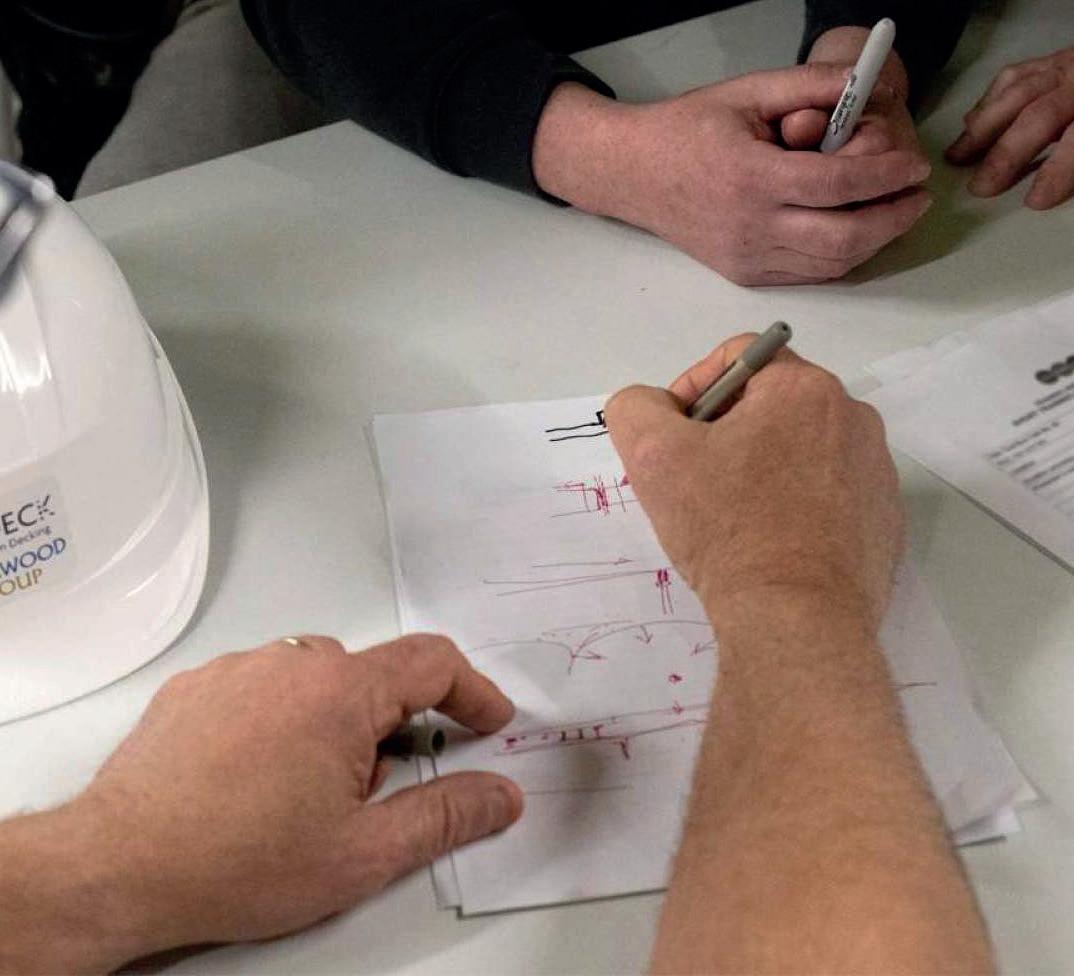

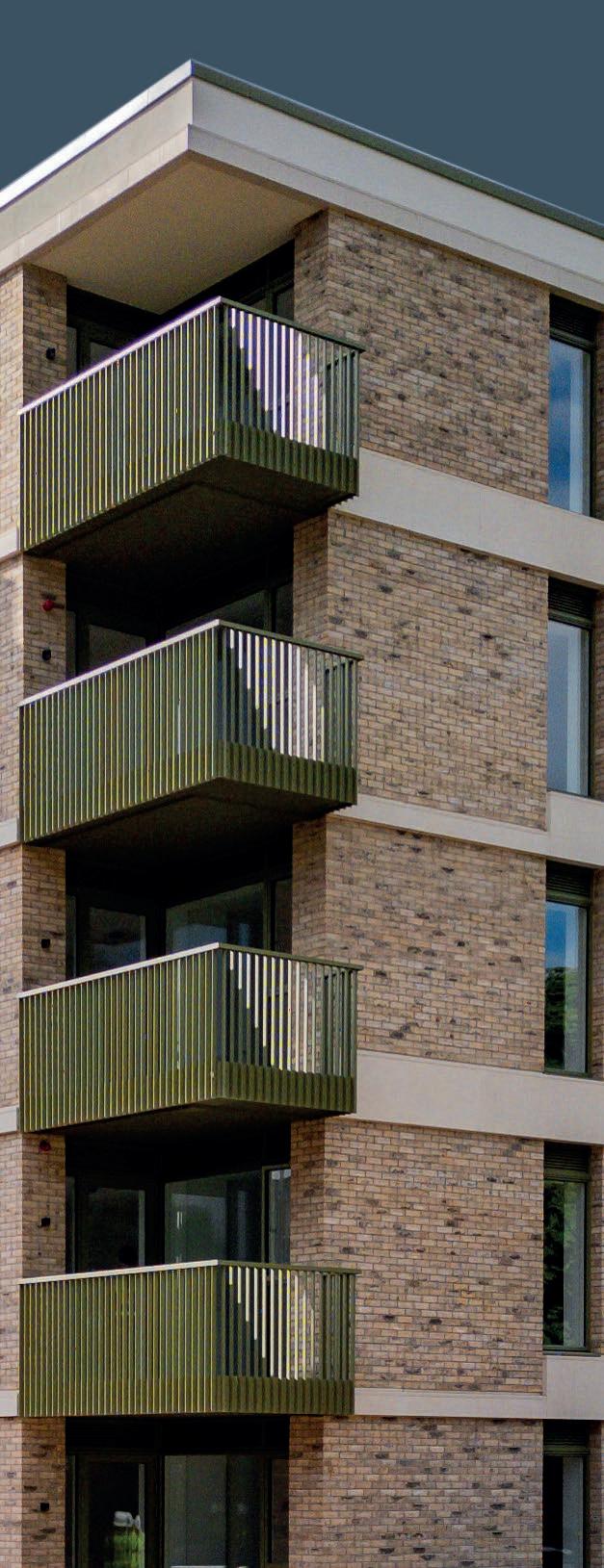

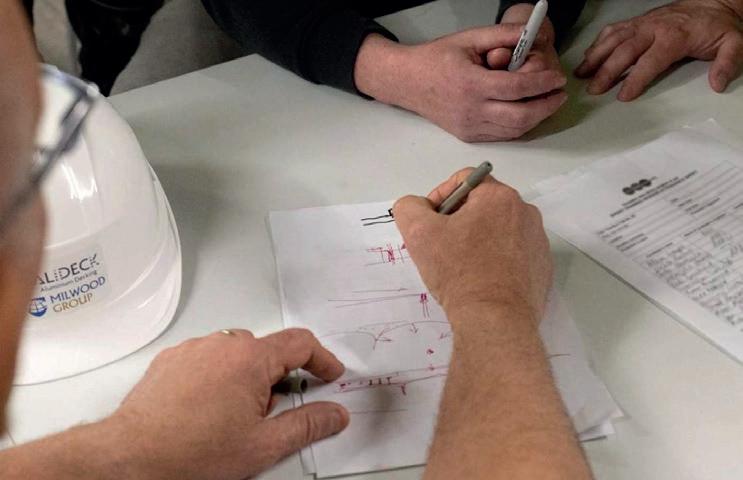

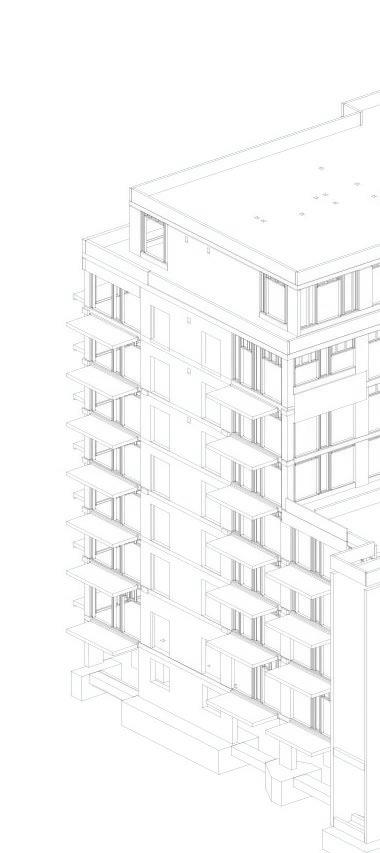

Since the Building Safety Regulator (BSR) came into force, the way balconies are designed and specified has changed dramatically. For architects, specifiers, and developers, getting a project over the line is no longer straightforward. Every decision is under the spotlight, every material must be proven, and every detail has to be backed up with evidence.

We know how challenging this can feel. Projects stall, paperwork piles up, and deadlines get tighter. That’s why at AliDeck, we’ve made it our role to be more than just a supplier. We’re here as a partner — helping to guide projects through the process so they don’t just meet the new standards, but move forward with confidence.

The BSR asks for a huge amount of detail, from fire test results and CAD drawings to full compliance packs. Pulling this together can be daunting, especially when time is short.

Our technical team works directly with specifiers to make it easier. We prepare the documents, drawings, and evidence needed so nothing gets missed. This level of support has already helped several projects gain BSR approval — showing that with the right expertise behind you, the process doesn’t have to be a roadblock.

Balcony systems are about much more than the boards and balustrades you see on site.

They’re safety-critical parts of a building — and they need to be right first time. That’s why we stay involved throughout the project, not just at the point of supply.

• Design support: We sit down with specifiers early to shape compliant, practical solutions that work in the real world.

• Installation training: We provide hands-on training so contractors can fit our systems correctly, avoiding mistakes and delays.

• CPD sessions: For architects, our CPDs cut through the complexity of the regulations, turning technical requirements into clear, practical steps.

This joined-up approach means fewer surprises, smoother progress, and safer outcomes.

One of the things that sets AliDeck apart is our supply chain. All of our aluminium is extruded here in the UK and our systems are Made in Britain certified. By keeping production local, we remove the risks and delays that come with overseas supply. We also powder-coat everything in-house, giving us full control over quality. And with our new Qualicoat accreditation, specifiers can be confident that our finishes are built to last — tested and proven for performance in even the toughest environments.

Our focus has always been on raising standards in balcony design. The BSR has only reinforced that mission. Today, it’s about offering specifiers more than just compliant products — it’s about providing reassurance, guidance, and proof at every stage. When you work with AliDeck, you’re choosing a partner who:

• Has already helped projects secure BSR approval.

• Offers design input, CPDs, and installation training to support the whole team.

• Manufactures here in Britain with complete quality control.

• Delivers in-house, Qualicoat-accredited powder coating for lasting performance.

The BSR has raised the bar for everyone, but it doesn’t need to hold projects back. With the right partner, compliance becomes something you can manage, not something you fear. At AliDeck, we’re proud to be that partner. By combining proven balcony systems with UK manufacturing, accredited finishes, and real project support, we’re helping specifiers move forward with clarity and confidence. When compliance matters most, you don’t have to face it alone.

AliDeck – Complete Balcony Solutions. Complete Compliance.

AliDeck – Enquiry

Shoreham Beach House is a private residential development at Shoreham-by-Sea in Sussex. Jim Miller Design, a leading architectural practice based in Hove, has designed the project using Passivhaus principles. One of the challenges involved the extensive number of connections between the internal and external steel frames at the various overhangs. To minimise thermal bridging issues at these connectivity points, the Schöck Isokorb T type S was incorporated throughout.

The house faces south with the main living space on the second floor, which enjoys a large terrace providing superb views along the coast. Architecturally, the form of the building is roughly cuboid, resulting in a good volume-to-surface area ratio (form factor). This results in reduced energy for heating and cooling, making it easier to achieve high performance targets.

With the house being located on the beach, there is a calculated risk of flooding, so the site was raised 300mm, with the ground floor walls constructed of waterproof concrete. However, the upper floors switch to steel frame and timber with natural insulation, to reduce the carbon footprint.

Overall the main technical criteria is to provide a low energy, comfortable and healthy indoor environment all year round.

Extensive steel frame connectivity

Given the technical criteria, the need to manage solar control drove the overall aesthetics of the project, especially to the south, with southerly overhangs to all three floors being achieved through the balcony, terrace and second floor overhangs wrapping around the building. The extensive overhangs limit overheating and provide architectural interest, but also created 48 connections between the internal and external steel frames; and these thermal bridges needed addressing.

Practice owner, Jim Miller, comments “I chose the Schöck Isokorb T type S because it reduced heat loss by about twice that compared to the other manufacturers that we considered. Additionally – and

critically – the Isokorb clearly demonstrated that there would be no condensation risk to the inner steels, which was not the case with some alternatives”.

Minimal thermal bridging with the Isokorb T type S

The Schöck Isokorb T type S is a load bearing thermal insulation element that reliably separates and minimises thermal bridges at the connections to steel structures (such as canopies, frame systems or balconies) and is designed for both new build and renovation projects. Consisting of modules T Type S-N for tensile forces and T Type S-V for transferring shear and normal forces, it can be adapted for any profile size and structural load. The unit is able to withstand extremely demanding loads and its stainless steel components mean complete corrosion protection.

The dependable Schöck Isokorb range offers the widest selection of structural thermal break solutions from any European supplier; and in the UK enables projects to meet full compliance with the necessary Building Regulations. There are solutions for concrete-to-concrete, concrete-to-steel and steel-to-steel. All products have the security of independent BBA Certification.

Contact Schöck on 01865 290 890; or for full details of the Isokorb range, visit the solutions page on the website at www.schoeck.com/en-gb/solutions

1. Shoreham Beach House - Jim Miller Design Ltd

2 & 3. Isokorb T type S in position

Schöck – Enquiry 12

When it comes to balcony safety, there’s no room for compromise.

The Building Safety Regulator (BSR) is setting a new benchmark for accountability, compliance, and long-term performanceand AliDeck is leading the way.

We’re proud to be the only UK balcony manufacturer with QUALICOAT accreditation, the global quality mark for aluminium powder coating. This certification confirms that our in-house finishes meet the highest international standards for durability, corrosion resistance, and weather protection.

It’s proof of our commitment to quality — not just in words, but in verified performance.

✔ Only balcony manufacturer with QUALICOAT accreditation

✔ BSR-compliant non-combustible systems

✔ Made in Britain certified

✔ 30-year product warranty

AliDeck - where compliance meets quality. LEARN MORE about our Qualicoat process - SCAN HERE!

In the fast-paced world of construction, time is often the most valuable resource. Delays can cascade through a project, impacting budgets, client satisfaction, and downstream trades. That’s why innovative materials like fermacell® fibre gypsum boards are transforming how architects approach internal wall construction, offering a smarter, faster alternative to traditional blockwork and plasterboard systems without sacrificing strength or performance.

One of the most compelling advantages of fermacell® fibre gypsum boards are their installation flexibility. Unlike blockwork, which typically requires the building envelope to be sealed before internal walls can be constructed, fermacell® fibre gypsum boards can be installed before the envelope is closed. This shift in sequencing has a profound impact on programme time. By enabling earlier commencement of internal works, fermacell® helps compress the overall schedule, allowing multiple trades to work in parallel and reducing idle time on site.

Speed is another critical factor. fermacell® fibre gypsum boards are quicker to install than blockwork, thanks to its dry construction method and ease of handling. There’s no need for wet trades, curing times, or complex logistics around mortar and mixing. Installers can move swiftly, and the boards can be cut and fixed with standard tools, streamlining the process even further. For architects working on tight deadlines or fast-track projects, this speed translates directly into time saved and milestones met. When compared with traditional plasterboard systems its reduction

in layers including pattress and small component lists offer a time reduction.

Yet speed alone isn’t enough - performance matters. fermacell® fibre gypsum boards deliver the strength and durability of blockwork, making them suitable for high-impact areas, crowd loading applications and demanding environments. Its dense composition provides excellent acoustic insulation, fire resistance, and robustness, meeting the rigorous standards architects expect from traditional masonry. This means you don’t have to compromise on quality to gain time.

Another often-overlooked benefit is the reduction in enabling works. Blockwork typically requires foundations, lintels, and other structural supports, adding complexity and cost. fermacell® fibre gypsum boards, by contrast, offer a lightweight system that

can be installed without these additional elements. This not only simplifies design and coordination but also reduces material usage and site disruption, contributing to a more sustainable and efficient build.

From a design perspective, fermacell® fibre gypsum boards offer versatility. They support direct finishes such as paint, tiles, or wallpaper, and can be used in curved or complex layouts that would be challenging with blockwork. This opens up creative possibilities while maintaining practical advantages.

In summary, fermacell® fibre gypsum boards are more than just a building material, they are a strategic tool for architects looking to accelerate project delivery without compromising on performance or design integrity. By enabling earlier installation, reducing enabling works, and offering the strength of blockwork with the speed of drywall, fermacell® helps architects stay ahead of schedule and deliver smarter, more efficient buildings.

For practices focused on innovation, sustainability, and time-sensitive delivery, fermacell® fibre gypsum is a material worth specifying. It’s not just about building fasterit’s about building better. Discover now: www.fermacell.co.uk/sustainability-meetssimplicity

From wellness suites, water features, saunas, steam rooms and swimming pools to spas, hot tubs, ice baths and enclosures, the BIG 30th anniversary edition of SPATEX has the lot!

The UK’s only dedicated water leisure show is free to attend, and open to all, and runs from Tuesday 3rd to Thursday 5th February at the Coventry Building Society Arena.

1. It’s the BIGGEST showcase of water leisure in the UK to date

See hot tubs, swimming pools, spas and ice baths water-filled and in action. View and compare a host of new innovations, products and services in a fast-moving market. With over 125 exhibiting companies, including all the leading water leisure manufacturers and suppliers from around the world, the glittering showcase will include every aspect of water leisure, and all the ancillary equipment (eg chemicals, lighting, heating, and ventilation) for both the commercial and domestic sectors.

2. Design inspiration

SPATEX is bursting with trends and ideas. The BSPF (the British Swimming Pool Federation) will be hosting the SPATA and BISHTA Awards, showcasing the best examples of design, construction, and installation. Photos of the winning projects will all be on display, providing excellent design inspiration.

3. Sustainability and energy saving are top of the agenda at SPATEX 2026

Reducing energy consumption is a consideration that is often better factored in at the design stage, making this show of vital importance for planners and designers. View the latest energy saving products from variable speed pumps, heat retention covers and LED lighting to air source heat

pumps and super insulated one-piece pools and discuss how they can be incorporated into your designs.

4. A powerhouse of knowledge

SPATEX will host a free-to-attend double seminar programme with a diverse range of topics, including the design and build of commercial pools, up-to-the-minute health and safety legislation, safeguarding against waterborne bacteria, such as Legionella. The programme includes the ISPE (Institute of Swimming Pool Engineers) workshop programme in Arena 1 where CPD points and certificates of attendance are issued to all attendees.

5. Industry Hub

2026 sees the introduction of an exciting new initiative –esteemed industry associations, such as the BSPF (British Swimming Pool Federation) and RLSS UK (Royal Life Saving Society UK) will all be conveniently situated on one large stand (adjacent to seminar Arena 2).

Representatives from each association will be on hand to offer visitors a plethora of information and guidance specific to each of their specialisms.

6. Expert advice

Bring your plans with you – there’s no better place to seek impartial advice from a variety of specialists, and all for free.

SPATEX provides free car parking for its visitors and Coventry Building Society Arena is within two-hour drive time of 75 per cent of the population. Register for free here: www.spatex.co.uk

SPATEX – Enquiry 15

Home life safety leaders Aico are bringing back their biennial Community Awards, set to take place at The International Convention Centre in Birmingham on 16th April 2026. The event celebrates excellence and inspirational achievements from across the UK housing industry, honouring those making a real difference in their communities.

Open to all, Aico’s Community Awards provides entrants the opportunity to showcase inspirational colleagues, projects and innovations from the housing sector.

The last awards, held in 2024, raised over £9,000 for the Electrical Industries Charity (EIC), with Aico matching the donation to result in a total contribution of £18,000 to this worthy cause. Since 1905, the charity has offered vital support to those who work within the electrical and energy industries.

Next year’s ceremony will welcome over 450 guests, including the inspirational finalists from all award categories. Continuing its support for the EIC, the evening will feature a formal dinner, influential guest speakers, and live entertainment, all hosted by Carl Jones from SBLTV.

“We’re proud to bring the Community Awards back for 2026,” said Neal Hooper, Managing Director at Aico. “These awards are about recognising the real difference individuals and organisations make every day in improving lives and communities across the UK.”

New for 2026, the People’s Choice Award introduces an exciting interactive element to the evening. This special category will be voted for exclusively by attendees on the night, giving guests the chance to play a direct role in recognising excellence.

The 13 other award categories outlined below are now open to enter by either groups or individuals from across the UK. All entries must be submitted by 20th of February 2026.

• Corporate Social Responsibility Initiative

• Neighbourhood Transformation

• Resident Engagement

• Lifetime Achievement Award

• Woman in Fire Safety Award

• College Initiative of the Year

• Rising Star Award

• Electrical Contractor of the Year

• Inspirational Colleague of the Year

• Sustainability Project of the Year

• Best Distributor Community Initiative

• Collaborative Partnership

• Apprentice of the Year

Previous Woman in Fire Safety Award winner Georgina Homer from Wolverhampton Homes, was commended for her passion and

dedication to resident engagement. Georgina commented: “I am thrilled to win this award and incredibly humbled to be in this position. A moment I’m going to remember for a very long time.”

Marc Redfern, Managing Director of Service Electrical Distributors and winner of Best Distributor Community Initiative, added: “We don’t do social value to win awards; we do social value to give back to people who are less fortunate. To get recognised for what we do is probably one of my proudest moments in business.”

Don’t miss the chance to be a part of this inspiring celebration of excellence, community spirit and innovation. Submit your entries by 20th February 2026 and join Aico alongside professionals from across the housing industry for an unforgettable evening.

Find out more and access entry forms here: www.aico.co.uk/news-and-events/aicocommunity-awards-2026

Aico – Enquiry 16

A selection of Glidevale Protect’s products has been specified and installed offsite by Oakworth Timber Engineering for an exclusive residential development in Derbyshire, demonstrating how a fabric first approach can enhance energy efficiency and control the risk of condensation in new homes. Read more on page 26

A selection of Glidevale Protect’s products has been specified for an exclusive residential development at Matlock Road in Wessington, Derbyshire, demonstrating how a coordinated approach to the design of the building envelope can enhance the energy efficiency of new homes.

Developed by Oakworth Construction for AG Properties (UK) Ltd, the scheme comprises nine individually designed, four-bedroom family homes set in the picturesque Derbyshire countryside. Constructed offsite using pre-insulated panels at Oakworth’s timber frame division – Oakworth Timber Engineering’s Sheffield factory, the homes benefit from precisionengineered offsite construction techniques to improve thermal performance and reduce carbon emissions.

Protect TF200 Thermo, a high-performance reflective external wall breather membrane, has been integrated into Oakworth Timber Engineering’s Varytherm timber frame system, ensuring excellent thermal performance and contributing to improved energy efficiency. Protect TF200, a nonreflective breather membrane has been applied to the spandrel panels, providing weather protection during the construction phase and reducing the risk of interstitial condensation. In addition, Protect VP200,

a high-performance, vapour permeable pitched roofing underlay, has been installed across all roofs to minimise the risk of roof space condensation in line with BS 5250.

The new build project follows a fabric-first approach, with the timber frame construction designed to deliver exceptionally low U-values. By using the reflective TF200 Thermo wall membrane with a strong aged thermal resistance, this helps the performance of the overall wall build up, with Oakworth Timber Engineering achieving an average throughwall U-value of 0.16 W/m²K. Combined with air-source heat pumps as the primary heating source, the development prioritises low-carbon, energy-efficient living. Designed to exceed Parts F, G, L, and O of the Building Regulations, the homes are also expected to deliver carbon emissions at least 35% lower than notional regulatory requirements, reinforcing the project’s commitment to sustainability.

Liberty Roofing, a long-standing Glidevale Protect supply chain partner, has been

appointed as the roofing contractor on the scheme, specifying Protect VP200 for its durability and proven performance in wind uplift zones 1 and 2, covering the majority of England. With the Matlock Road site located close to Glidevale Protect’s manufacturing facility in Pinxton, Nottinghamshire, this allowed for roofing membrane materials to be efficiently sent to site on a timely basis.

Jon Rees, Operation Director at Oakworth Constuction, commented: "Working with Glidevale Protect and specifying the right reflective membrane product for this project has been instrumental in helping us achieve the high standards of energy efficiency required for this development. Protect TF200 Thermo integrates seamlessly into our timber frame wall system, supporting our commitment to sustainable, low-carbon construction."

John Curley, Product Manager at Glidevale Protect, commented “Through our involvement at the Matlock Road development, we have been able to demonstrate our commitment to delivering innovative, high performance solutions that meet market demands and stringent industry standards, positioning us as a trusted partner in modern housing development.”

To find out more, visit www.glidevaleprotect.com, call 0161 905 5700, or email info@glidevaleprotect.com Follow Glidevale Protect on LinkedIn.

Protect – Enquiry

Demonstrated

Meeting Housing Demands Without Limitations

Combining

Building

BOPAS

As the new academic year gets underway, firms involved in building accommodation to house the growing number of students in the UK are becoming busier. Meanwhile some schools and universities are seeing building innovation as the key to progress.

The value of project starts on student accommodation schemes rose to £849 million in the three months to July, double the value in the same period a year earlier, according to recent Glenigan data. In all, student homes accounted for 7% of total housing projects getting underway.

A series of factors is driving up activity in the sector. Today, student numbers are on the rise, and there is a growing shortage of places in purpose-built student accommodation (PBSA) schemes.

Applicant numbers through the UCAS university admissions agency were up by 1.3% compared with the same point last year, with notably healthy growth amongst UK 18-year-olds (+2.2%) and overseas students (+2.2%).

Demand for new student accommodation is strongest in cities with highly regarded Russell Group universities. Today, London, Nottingham, and Leeds are expected to see the largest increases in supply, according to a recent report from agents Knight Frank. Glenigan data (see below) details

opportunities in all these centres.

For now, demand for student accommodation continues to exceed supply. This year, just 1,609 new student beds had been added by the end of July, with 17,802 set to be delivered in time for the start of the 2025/26 academic year in October.

Unite, the largest owner and developer of UK student accommodation, said earlier this year that the new supply of PBSA was down 60% on pre-pandemic levels, as high construction costs, planning backlogs, and building safety approvals take their toll.

Meanwhile, private landlords who have traditionally rented homes to students in university cities are retreating from the sector, deterred by high mortgage costs and tighter regulations. But against a background of supply shortages,

investment in the sector is growing. Knight Frank notes that £1.6 billion was invested in UK PBSA in the first half of this year, well above the long-run average of £1.1 billion. Today, Unite has a fully funded pipeline of off-campus accommodation, worth £925 million and concentrated around Russell Group universities.

Unite also has an on-campus pipeline of 4,300 beds for delivery over the next three to five years. In May, the group unveiled a second university joint venture with Manchester Metropolitan University for 2,300 new beds in the city centre. This follows a similar partnership with Newcastle University, and the group is in talks on accommodation JVs with other academic institutions. >>

BUILD COMMISSIONING

MAINTENANCE

From primary schools to university campuses, our integrated lowcarbon technologies are designed to meet the unique demands of the education sector, keeping students comfortable, costs under control, and sustainability targets on track.

With expert support every step of the way, from consultation and system design to commissioning and ongoing aftercare, we’ll work with you to create the right solution for your learning environment, now and for the future.

>> Refurbishment is also thriving. Morgan Sindall Construction has officially commenced works to renovate the three accommodation blocks of Claycroft Residences at the University of Warwickone of the largest banks of accommodation on the University's main campus in Coventry.

The 17,000m² development comprises three individual accommodation blocks, providing 679 bedrooms arranged into eight-person flats. The scheme will look to breathe new life into the halls, built between 1994 and 1997, providing students with modern, highquality living facilities.

The scope of works, which took 14 months to design and plan, includes replacement of the existing roof coverings along with a general upgrade of the buildings to continue to comply with safety standards. This will involve a full rewire and the renewal of all fire safety systems.

Elegant engineered timber excels B&K Structures has played a fundamental role in the construction of the new SciTech Centre at Haileybury School in Hertfordshire, an ambitious and trailblazing project which fully embraces the aesthetics of engineered timber.

Offsite manufactured timber technology has contributed to the fast and flawless delivery of this complex and beautiful Education facility, which meets the highest environmental standards.

Hopkins Architects led the design team, which included Integral Engineers, Atelier Ten, Adrian James and Kier Group. B&K Structures (BKS) was appointed to design, manufacture and erect the cross laminated timber (CLT) and glulam elements for the structural frame of the new teaching block, research block and a light filled cloister designed to establish a focus for the square. The new development integrates the old and new buildings and draws on the experience of this expert project team, including BKS’ supply chain partners Derix and Stora Enso who supplied the glulam and CLT elements respectively.

The three-storey teaching block adopts a hipped roof form with a series of pitched glulam beams, clear spanning at regular centres with stainless steel ties. Linked via the cloister, the two-storey research block has a central spine wall, supporting the first floor and roof, and a feature CLT stair, which extends from ground to first floor, trimmed with glulam beams. The roof forms a truncated pyramid featuring a central butterfly roof, while glulam beams cantilever from the spine wall, propped at each end by hip beams, extending down to the perimeter ring beam. The elegant design of the connections between the hip members and the tension and compression rings was key to the success of the final design, requiring strong timber knowledge and innovation by B&K Structures – who

brought over 20 years of timber design and erection experience to the project team. BKS coordinated the intricate design via its supply chain partner Engenuiti and their own inhouse team of skilled structural engineers.

A mixture of non-visual and visual grade CLT was specified to optimise use of raw materials as well as harness the aesthetic and biophilic benefits of exposed timber –which has proven advantages for students in education settings.

Speed of delivery was a key factor, to coincide with term times. Prefabrication of details within the factory, rather than on site, helped to achieve an impressive12-week build schedule for the structural works, delivering rates of progress on site of 90 m3 per week.

Finally, alongside utilising low carbon structural timber, the SciTech Centre also features solar panels, green roofs and ground-source heat pumps. Now open, the unique facility features state-of-the-art laboratories, IT and robotics suites and 20 inter-connected seminar spaces. The project has doubled the size of the school’s previous provision, while supporting its Net Zero sustainability goals.

A major milestone in Scottish education has been achieved with the opening of the Dunfermline Learning Campus in West Fife. Purpose-built to inspire learning, the state-of-the-art facility spans 26,666 m² and accommodates 2,700 pupils and 246 staff, making it the UK’s largest building constructed to Passivhaus standards.

Gerflor has played a key role in the project’s success, supplying over 14,000 m² of high-performance flooring solutions including Taraflex® sports flooring, DLW Marmorette Linoleum, Tarasafe Safety flooring, and Powershock 300 rubber tiles. Alongside this, Gradus accessories including stair nosings and a variety of trim finishes were also supplied, the combined package of products from both Gerflor and Gradus were specified for their exceptional durability, safety, and style to meet the needs of the various areas across the facility.

Maggie Smith, Scotland Team Leader at Gerflor, said, “we were able to offer a comprehensive flooring and accessories package that not only met the project’s functional and aesthetic requirements but also delivered significant cost efficiencies. By tailoring our solution to align with the budgetary goals without compromising on quality, we demonstrated the value of working with a supplier who can provide both innovation and cost-effectiveness.”

Installation was managed by Veitchi Flooring, renowned for their expertise in large-scale projects. Jamie Cargill, Contracts Supervisor at Veitchi, commented, “We recommended Gerflor and Gradus products because of their exceptional design appeal, durability, performance, and competitive price point, key factors in delivering an effective overall solution. The project was completed on schedule, maintaining the highest standards of workmanship.”

Cabinet Secretary for Education and Skills, Jenny Gilruth, commented, “This is an important milestone for the Dunfermline Learning Campus, and I know that the new school building will be of significant benefit to pupils, teachers and the local community.” Her statement reflects the broader impact of the project, highlighting its long-term value to the educational experience and for the area as a whole.

The campus is now a modern hub for education and community activity, with

sports facilities accessible to pupils, staff, and the wider public. Maggie Smith added, “The client is delighted with the finish and overall performance of our world-class products.”

Gerflor – Enquiry 22

Taraflex® is the most widely specified indoor sports surface in the world. Its’ unique construction and technical performance is unrivalled, it has been fitted at every Olympic Games since 1976.

Taraflex® delivers optimum safety and comfort for all users, and is widely recognised and installed in the education sectors. Over 8 million pupils everyday enjoy the benefits of Taraflex® sports flooring.

If you have an education facility and require more than just sports flooring, Gerflor also have other resilient floor coverings for your project, including Tarasafe Safety Flooring, Powershock Rubber Tiles, and DLW Linoleum.

(0) 1625 428 922 contractuk@gerflor.com www.gerflor.co.uk

We provide a complete, sustainable and manageable pathway to fire safety compliance and resilience. Our technical expertise, transparent processes and deep sector knowledge make us a trusted partner across healthcare, education, commercial, industrial and public sector environments.

Our experience spans a wide range of building types and operational settings. We recognise the unique challenges faced by sectors such as education and healthcare, where the safety of vulnerable occupants is critical.

Our approach is built on three core pillars: strategic planning and prioritisation, delivery and monitoring and reviewing and improving.

RECOM Fire Solutions stands at the forefront of passive fire protection, offering a robust, client-led approach that helps organisations safeguard their people, property and operations.

Through close engagement with stakeholders and a detailed understanding of each client’s estate, we develop risk-based programmes tailored to their operational and compliance needs.

During the delivery phase, all works are carefully managed to ensure the highest standards of quality, traceability and minimal disruption. Whether supporting commercial clients with complex estates or public sector organisations responsible for critical infrastructure, we align every intervention with operational priorities and financial considerations. Our scalable delivery model enables us to move seamlessly from single-

site projects to estate-wide programmes, providing flexibility and consistency regardless of size or sector.

Central to our service is the golden thread of information — a structured approach to data management and reporting that ensures clients maintain an “audit-ready” level of evidence and compliance.

We are committed to open communication and collaborative working, ensuring all stakeholders remain informed and engaged throughout every stage of the process. By combining technical expertise with a proven

risk-based methodology, we deliver fire safety solutions that achieve immediate compliance goals and support long-term business continuity.

With every engagement, RECOM Fire Solutions helps clients meet their legislative responsibilities, protect their assets and create safer environments for all.

To arrange a visit from our team, call us on +44 (0) 161 478 1200 or drop us an email info@recomsolutions.co.uk

RECOM – Enquiry 24

Hunter Douglas provided bespoke ceiling and wall solutions for the ambitious €65 million Deloitte University EMEA building, near Paris, France.

Designed by Dubuisson Architecture, the international training campus for Deloitte embodied a strong commitment to sustainability, well-being and high-quality design, taking its inspiration from grand French estates. Hunter Douglas, the global architectural products company, supplied more than 6,500m2 of Derako® Solid Wood Linear

systems crafted from Iarch and European pine. Finished in a mix of terracotta varnish, oak and white-stain, the wall and ceiling systems were installed in key zones such as the main entrance hall, circulation areas and auditorium.

A further 2,500m2 of Tavola™ aluminium baffles finished in RAL 9003 were installed in the “Town Square” relaxation zone and surrounding corridors that connect to the restaurant, classrooms and auditorium.

Hunter Douglas Architectural – Enquiry 26

Modern efficiency meets heritage at Corpus Christi College

Hamworthy Heating, a trusted British manufacturer and supplier of commercial heating and hot water products, has supplied its Modumax mk3 modular condensing boilers and Powerstock calorifiers to Corpus Christi College, University of Cambridge.

Installed within a Grade I Listed building; the new system delivers an efficient heating and hot water solution tailored to the unique challenges of the site. The chosen system features four Modumax mk3 floor-standing condensing boilers (196 / 392V) delivering 1,532 kW total across eight modules. These are integrated with two Hamworthy Heating Powerstock PS500 indirect calorifiers to provide domestic hot water for the college.

Hamworthy Heating – Enquiry 28

Quieter classrooms with Optimise 70

Modern school classrooms are a tough place for any floor, but the IVC Commercial Optimise 70 range might well be the perfect solution.

Affordable, tough, easy to maintain, it upgrades any classroom floor in need of replacement. Made in Europe by IVC, Optimise 70 is a heavy-duty (0.70mm wear layer) heterogeneous vinyl floor that delivers more than just outstanding wear characteristics. With a choice of 40 designs, including everything from wood plank and herringbone to terrazzo and bright colours, it can certainly create an inspiring classroom setting while supporting pupil concentration thanks to its 19dB of impact sound reduction.

IVC Commercial – Enquiry 27

Altro adhesive-free flooring and recofloor are top class

Bedford Academy has chosen eco-friendly flooring for its new-build school extension, opting for Altro Cantata adhesive-free and using the Recofloor vinyl take-back scheme on a project where sustainability considerations were a top priority.

The new two-storey extension at Bedford Academy was a £12m project for Bedford Borough Council in 2025.

The extension features Altro Cantata adhesivefree throughout the main areas and Altro

Aquarius in the bathrooms and shower spaces. These floors are designed for durability, low maintenance, and sustainability, making them an ideal fit for a high-traffic educational setting.

Keen to minimise waste and carbon during construction and beyond, main contractor Ashe Construction asked Altro for sustainable flooring ideas for the build. This led both to a change in product specification and to implementing post-installation waste collections through Recofloor, the commercial vinyl take-back recycling service. In total, 0.85 tonnes of vinyl offcuts were collected for recycling. Recycling this quantity gives an estimated carbon saving of 1 tonne compared to manufacturing new materials.

For this project, Recofloor bins were deployed on site at Bedford Academy. Once the project started, fitters were able to dispose of the growing amount of offcut waste as they went along, without filling up site skips.

Altro – Enquiry 29

When Skypoint School, part of Spark of Genius’ UK network of specialist education providers, relocated to a striking 19th Century building, it marked more than just a change of address.

As part of the move, the interiors had to be transformed into a welcoming environment tailored to young people with additional support needs – with Valspar Trade Tough Matt playing a key role in making this vision a reality.

Speaking about the project, Scott Wilson, Project Manager at Spark of Genius, said: “Working with the school maintenance team,

we’ve used Valspar Trade products for years. For this project, we chose Valspar Trade Tough Matt for the walls and ceilings. Durability was a must when it came to choosing the paint. With capacity for 50 students, it was essential that the paint could stand up to the school’s daily wear and tear, especially within high traffic areas.”

Valspar Trade Tough Matt is a water-based, stain resistant and scrubbable formulation, giving long-term performance, while its high opacity and superior covering power ensures excellent application.

Scott continued: “Our local Valspar Trade representative was on hand throughout, including carrying out site visits and supporting with estimated paint quantities.

He also helped us with the colour scheme specification. As such, we chose a variety of calming, pastel shades for the internal walls, including Blush Wash, Dusky Sand and White Moss.

“The site team have been really pleased with the paint’s opacity, saving them valuable time.”

From Sherwin Williams, Valspar Trade offers a range of high-quality paint essentials for all interior and exterior applications.

Learn more about Valspar Trade, here: www.valspartrade.co.uk.

Valspar Trade – Enquiry 30

Moveable partitioning experts Style worked with Todd Architects and contractor Felix O’Hare & Co, to divide the Student Hub at Queen’s Business School, Belfast. An impressive 290-seat tiered lecture theatre like this demands an equally remarkable movable wall solution — which is why Style recommended the fully automatic Skyfold Classic 60 system.

This pioneering operable wall is discreetly concealed within the ceiling cavity and descends gracefully at the push of a button, seamlessly dividing the stepped auditorium.

With an outstanding 59dB Rw acoustic rating, Skyfold enables two independent teaching spaces to be quickly created, with no risk of sound interference.

Style is the exclusive UK distributor for Skyfold movable walls, including the Mirage glass system and the Zenith, featuring a narrow descent path that is ideal for restricted spaces.

Founded in 1845 as Queen's College Belfast, Queen’s University Belfast became an independent university in 1908. Today, it is ranked as one of the top 200 universities in the world and is a member of the Russell

Group of UK research-intensive universities. University lecture theatres are often under-utilised, but the stepped flooring makes it challenging to divide the space into two functional rooms using traditional solutions. Skyfold overcomes this problem, offering a fast, safe, and efficient way to partition the facility while providing exceptional acoustic separation. For easy movement between the two areas, an access door can be incorporated.

efficiently. We were very proud to have been involved in the Student Hub, which was named Northern Ireland’s Building of the Year 2025 by the Royal Society of Ulster Architects (RSUA).”

“This is a unique and impressive moveable wall solution,” said Michael Porter, Style’s group managing director.

“When the Skyfold descends from the ceiling it creates real ‘wow’ factor, sub-dividing this very high-ceilinged lecture quickly and

“Skyfold’s innovative design and seamless functionality ensure that Queen’s University Belfast now has a flexible, future-ready lecture theatre that combines acoustic excellence with striking visual impact.”

Style Partitions – Enquiry 31

The Pledge is an international commitment calling on governments, organisations, and businesses to take practical action to ensure that every person has access to healthy indoor air. It highlights indoor air quality (IAQ) as a fundamental human right and a critical component of public health, education, and economic productivity.

The pledge, which was launched at the Healthy Indoor Air: A Global Call to Action conference attended by political leaders, policymakers, scientists and health experts, states: “We declare, for the first time as a global community, that clean indoor air is a fundamental human right for protecting health and safeguarding well-being.

By signing, BESA joined a growing coalition of global partners who commit to:

• Monitor and improve indoor air quality in buildings they influence.

• Apply science-based standards and share best practice openly.

• Collaborate across sectors to accelerate innovation and investment in healthier indoor environments.

• Report transparently on progress to maintain public trust and accountability.

BESA and its members have long campaigned for IAQ to be treated with the same urgency as outdoor pollution, warning that poor ventilation and exposure to indoor pollutants contribute to respiratory illnesses, lost productivity, and reduced wellbeing.

The World Health Organisation (WHO) states that IAQ is directly linked to 3.8 million

premature deaths worldwide every year and BESA members are central to efforts to improve building ventilation that can reduce exposure to air pollutants and infectious diseases, aid human productivity, and improve sleep.

“Signing the Global Pledge was a natural step for BESA,” said technical director Kevin Morrissey. “Our members are at the forefront of designing, installing and maintaining the systems that determine the quality of the air we breathe. This commitment sends a clear signal: we will work with clients, policymakers, and partners worldwide to make clean indoor air the norm, not the exception.

“These tools help building owners, FM providers and contractors take practical steps to assess, monitor, and improve indoor environments,” said the group’s chair Adam Taylor (left). “The pledge will also help us in our ongoing efforts to champion IAQ in regulatory debates, industry standards, and client education.”

The Global Pledge also aligns with several UN Sustainable Development Goals, including Good Health & Wellbeing (SDG 3)

and Sustainable Cities & Communities (SDG 11), reinforcing BESA’s role in supporting healthier indoor spaces as part of the wider effort to create more sustainable built environments worldwide.

Louvres for pioneering learning community IKON Aluminium Systems (IKON) has supplied Duplus Architectural Systems (Duplus) with aluminium louvred products for Phase 2 of the Northstowe Learning Community expansion project.

Northstowe Learning Community is an all-through education campus delivering nursery, primary, secondary, and sixth form learning within one integrated site. Phase 2 expands education capacity in Northstowe, one of the most significant new communities under construction in the UK. >>

>> “Ventilation, natural daylight, acoustic comfort, and indoor air quality are critical to student wellbeing, concentration, and learning outcomes – especially in education environments,” comments Claire Mills, Principal of Northstowe Learning Community. To realise this, project architect and lead designer, Frank Shaw Associates designed in a wide range of ventilation solutions, including glazed in louvres supplied by IKON.

“We have worked with IKON previously and know them to be reliable; they have never let us down, comments, Ben Roberts, Contracts Department Manager, Duplus Architectural Systems Ltd. “They also make a really good, high quality louvre. We chose IKON for Phase 2 of the Northstowe project based on price and a competitive lead time.”

For this project IKON recommended its IKL302-PFA50 glazed in louvre which complies with BS EN 13030:2001 and provides ventilation to help regulate indoor temperature and air quality without letting rain or debris in. This louvre features a blade centre of 30mm and blade

angle of 59 degrees and offers 58% visual free area and 50% physical free area, and achieves the required airflow rate of 50%.

Many of the 101no. supplied were fitted directly into the curtain walling made by Duplus. Visually, the louvres blend seamlessly with the curtain walling maintaining the aesthetic of the modern building design.

limited such as narrow hallways. For awkwardly shaped rooms or for those with limited wall space, the Ellipsis vertical model works great.

For higher heat outputs in larger spaces, a double configuration – where there are two layers of tubes – will still take up less wall space whilst also providing more heat.

Ellipsis range expands Manufacturer of designer radiators and towel rails, The Radiator Company, has expanded its popular Ellipsis range, with a 30mm tube size option.

The new model is available in both horizontal and vertical designs and provides even more choice.

Distinctly smaller than the original 50mm model, the 30mm Ellipsis offers much smaller tubes for a sleek unobtrusive design without compromising on performance, making it ideal where space is tight or

Additionally, the new Ellipsis 30mm range is also available in a matching heated towel rail option, perfect for kitchens and bathrooms as well as utility and boot rooms. Available in four height options and four widths, the Ellipsis 30mm Towel Rail makes achieving design continuity across heat emitters in one property very simple. The Ellipsis 30mm Towel Rail is also available from stock in White (RAL 9016) and is ideal for those seeking a more personalised aesthetic, as the made-toorder service offers an impressive palette of 188 RAL colours, 31 specific finishes and 6 exclusive feature finishes.

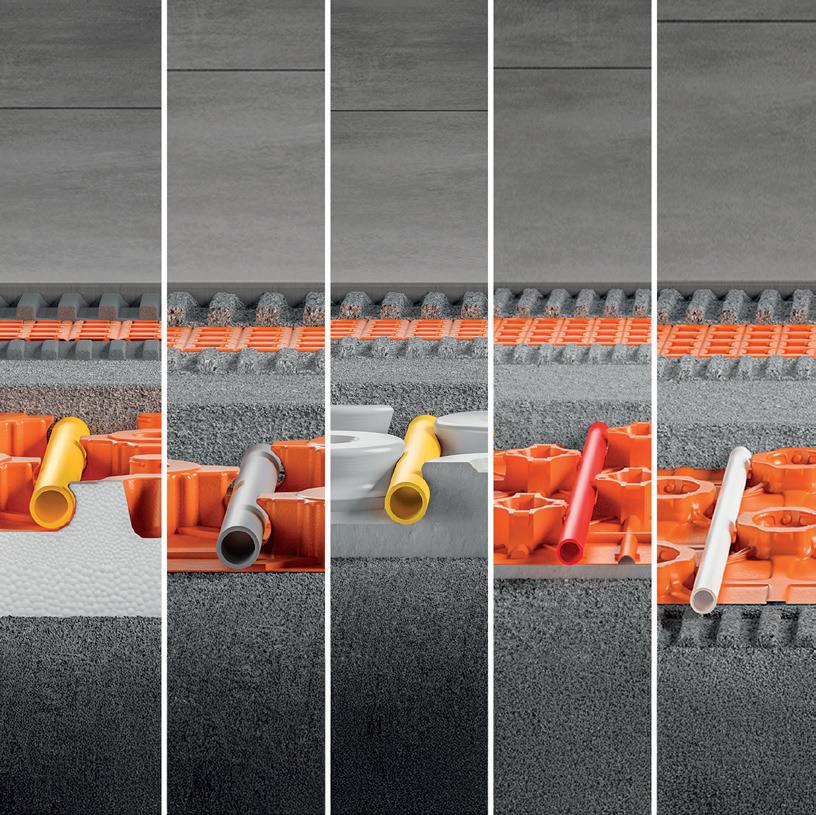

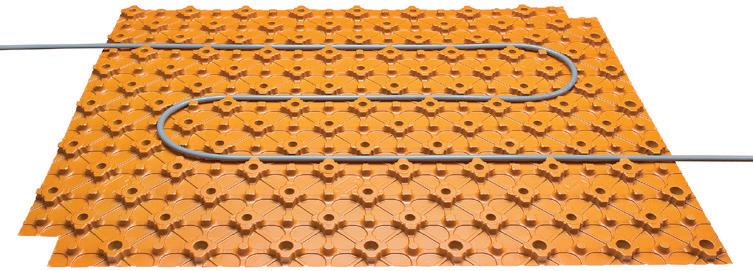

Schlüter-Systems, as a leading manufacturer of tile installation products, also offers both conventional underfloor heating (UFH) and an electrical undertile heating alternative suitable for diverse applications: the manufacturer’s two CAD-enabled options for the 21st century - BEKOTEC-THERM and DITRA-HEAT E.

The first is a hydronic system that can be installed in the traditional way beneath different floor finishes throughout the home or in commercial buildings. But unlike many rival UFH systems, BEKOTEC-THERM is based on studded modular panels which are quick and easy to install and offer a low build height with rapid warm up times.

A screed is laid across the pipe runs and, rather than waiting weeks for it to cure, tiling operations can commence as soon as the surface is hard enough to walk on by using Schlüter-Systems’ DITRA uncoupling mat which means BEKOTEC-THERM is ideal for time-critical refurbishment contracts such as in shops and offices.

Then, as an electric powered undertile solution, applications for DITRA-HEAT E are only limited by the imagination: they encompass demisting mirrors, warming walls or seats in spas and showers, and vanity areas or countertops.

DITRA-HEAT further finds applications for flooring and plant shelving in conservatories while the system has been specified widely in prestigious locations such as The Lanesborough Hotel and Langham’s in London.

Schlüter-Systems’ Technical Specifications Consultant, Tony Taylor-Sheriff, commented: “UFH technology has progressed enormously since the Roman Hypocaust, but there is still much that is not understood across the wider construction industry regarding relevant efficiencies and potential problems such as the importance of uncoupling layers, load distribution and vapour management. Our solutions have been developed to help professionals achieve quick and energy efficient installations, with BEKOTEC-THERM,

for example, being able to offer the benefit of low temperature flow which makes it ideal for use with heat pumps or other renewable sources of heat. DITRA-HEAT E likewise offers rapid response and is very flexible in use.”

For specifiers and architects, as well as installers of flooring finishes wishing to increase their knowledge of underfloor heating technology, SchlüterSystems also offers a CPD seminar entitled Specifying Integrated Underfloor Heating Systems which can be delivered online or in person.

With more than 2,300 employees and seven offices across Europe and North America, SchlüterSystems is the world’s largest and most innovative manufacturer of system solutions for the function, protection and decoration of tiles and natural stone flooring. Schlüter-Systems in the UK offers a very wide

product portfolio including the SchlüterKERDI range waterproofing membranes, the versatile tile backerboard KERDI-BOARD and its underfloor heating solutions.

Schlüter Systems – Enquiry 32

Schlüter®-BEKOTEC-THERM

Modular underfloor heating system for tile, stone and other floor coverings

The focus on a low-carbon future and improved energy efficiency is leading to an everincreasing demand for underfloor heating systems. Schlüter-BEKOTEC-THERM offers modular heating with lower supply temperatures, low construction height, and shorter construction times. Learn more about the many benefits of Schlüter-BEKOTEC-THERM.

DID WE PIQUE YOUR INTEREST?