LET’S TALK CLADDING

In association with Let's Talk Cladding is Sponsored by

In association with Let's Talk Cladding is Sponsored by

Let's Talk Cladding is Sponsored by

The built environment landscape has undergone a period of rapid change and improvement since the tragedy of the Grenfell Tower Fire in 2017.

In this new digital publication, we will focus on these changes and the work continuing to be done to raise standards and safety through the work of industry bodies, manufacturers, architects and specifiers and installers.

Starting with Dame Judith Hackitt’s watershed independent review of building regulations and fire safety, ‘Building a Safer Future’, which was commissioned by the UK Government in the aftermath of the tragedy, up to the publication of the Grenfell Inquiry and recommendations now being enacted by Westminster, these changes and improvements remain ongoing.

There are many that regard this as a revolution in building safety and standards, while others maintain that significant steps remain to be taken and regard it as evolution. Either way, change has happened and is happening at a far greater pace than we’ve seen in decades.

Most recently, UK-SPEC HRB was developed, in collaboration with professional engineering institutions

and expert volunteers, to assess the competence and commitment of individual engineers and technicians working on higher-risk buildings in the UK.

Based on the UK Standard for Professional Engineering Competence and Commitment (UK-SPEC) the new Standard is tailored for engineers and technicians working in the built environment, particularly on the design, construction, maintenance, and operation of higher-risk buildings.

At the launch of this new standard, Dame Judith highlighted why it is important to have assured competence of those working on higher-risk buildings and that this must be centred on professionalism: “people who will uphold high standards of professional conduct themselves and call out those who undermine that in any way”.

Dame Judith also emphasised that this launch is very much the end of the beginning of the process. The real work now is for engineering institutions to promote the new Standard with their members and strongly encourage people to go through the process.

She stressed that wider industry must be informed about the new Standard and the

benefits of being able to prove that buildings have been designed and constructed by demonstrably competent people.

Engineering Council CEO, Paul Bailey, said the standard presents yet another significant milestone in the industry’s continuing work to ensure public safety in the built environment.

“We hope the tragedy of the Grenfell Tower fire and the sad loss of 72 lives will never be seen again,” he said.

“UK-SPEC HRB will provide a means for those engineers and technicians working in the built environment, particularly on the design, construction, maintenance, and operation of higher-risk buildings, to become professionally registered.

“This is the first step however and it is our hope that UK-SPEC HRB is embraced and championed by the sector and the wider engineering profession, and that the Standard, and the Register of those individuals assessed against it, will support the continuing improvement of public safety across the sector.”

Such milestones have been hit already and many others are set to be hit in the near future as the industry spearheads a new way of working that is driving an improvement in standards and safety.

In response to the Grenfell Inquiry findings, RIBA Chair of the Board, Jack Pringle said: “What happened at the Grenfell Tower was a tragedy that should never have happened and must never happen again.

“Both the Inquiry Report and the Government have acknowledged the work that we’ve already undertaken to improve the education and training of architects.

“Now the work continues, we are committed to engaging across the sector and with the Government to create buildings and homes that are safe and high quality for all.”

Paul Groves || Group Editor

Let's Talk Cladding is Sponsored by

In accepting 49 of the 58 recommendations in full in the Grenfell Inquiry’s Phase 2 report, published on 4 September 2024, the Government pointed to the significant progress made to improve the safety of buildings since the tragedy of the Grenfell fire. But it made it clear that the response builds on this work and seeks to go further where needed.

The Construction Products Association (CPA) welcomed the Government’s publishing of the Construction Products Reform Green Paper – its ambition, clarity and direction of travel for the construction products sector has been long awaited.

As with the two independent reviews overseen by Dame Judith Hackitt and Morrell/Day, the CPA said it will work with our members and wider industry to provide our full support and response during the Green Paper’s consultation.

“We are already pleased to note in the Paper the recognition and support from Government for our work in developing the Code for Construction Product Information as a positive

industry initiative to raise standards in product information and marketing,” said Peter Caplehorn, CEO of the CPA.

“The Government’s response and the Green Paper mark another key milestone in a continuing series of reforms to our industry’s culture and practices. The CPA remains committed to learning from this tragedy and helping drive meaningful change, particularly toward eliminating unsafe practices and ensuring that safety and accountability become non-negotiable priorities in the industry.”

Mark Reynolds, Co-Chair of the Construction Leadership Council and Executive Chair of Mace, said the aim now is to reverse years of failings from the state and industry, of

deregulation, and of poor practice in the construction sector.

“The Inquiry also highlighted widespread failures by manufacturers, the construction products sector and the institutions that should have been responsible for ensuring high standards and assurance of the system,” he added. “It is incumbent on us all to fully engage with and respond to the proposals for reform set out in the Construction Products Reform Green Paper published alongside the Government’s response. There has been significant progress on building safety made since the Grenfell fire in June 2017, delivered through ongoing collaboration between Government and industry – but we are well aware that there is more we can and must do.

“There must be continued collective responsibility to drive a meaningful and permanent cultural change and enhance the levels of competence in the construction sector. We will continue to work closely with the Government, regulators, industry bodies and businesses to enable the implementation of these further reforms without undue disruption to the vital work of our industry across the country.”

It is a sentiment echoed by Caroline Gumble, CEO at the Chartered Institute of Building (CIOB), who said there remains a significant amount of work to do and the introduction of the Building Safety Act 2022, while a positive step, was only the beginning.

“We are ready to play our part in improving the culture in the sector and ensuring construction professionals are appropriately competent to conduct their roles, not only in the case of high-risk buildings but throughout the wider built environment, ensuring public trust in what we build and maintain.

“Since the Grenfell Tower Inquiry Phase 2 Report was published in September 2024, we have introduced mandatory continued professional development (CPD) on building safety for our members to ensure they remain up to date and relevant with developments in building safety and evolving regulation and legislation, including best practice.

“Additionally, we have launched the Principal Contractor Competency Certification Scheme (PCCCS) to provide Principal Contractors with a route to proving their competency as required by the Building Safety Regulator (BSR). Our intention is also to develop a similar scheme for Principal Designers, which is set to be available later this year.

We are also providing building safety training via our Academy. Our industry still has a long way to go to change its culture and ensure safety is at the heart of everything we do, and this must be fully addressed and delivered.”

Construction Products Association – Enquiry 3

ITP supplied the award-winning breather membrane, Stamisol Safe One, for one of Kent’s most popular heritage destinations as part of new facilities at the National Trust’s Ightham Mote property in Sevenoaks.

WW Martin Ltd was appointed as the main contractor overseeing the construction of a reception building, shop and visitor car park on the site of the Grade I listed medieval moated manor house which dates back to the 14th century and is registered as a Scheduled Monument. The enhanced facilities support the National Trust’s conservation of the historic house and gardens for future generations while enabling the estate to accommodate a projected increase in annual visitor numbers.

Appropriately designed to reflect their surroundings, the buildings will be fully sustainable with the use of hempcrete walling, air source heat pumps, a green roof and sustainable surface water management. Stamisol Safe One was sourced for the project via leading specialist builders merchant, SIG, to protect the long-term condition of the buildings. The membrane prevents the ingress of rainwater while facilitating the release of internal water vapour, preventing the build-up of condensation in the insulation layer.

Winner of Product of the Year in the 2022 Façade Design and Engineering Awards, Stamisol Safe One offers a market-leading range of performance attributes. The product is the first breather membrane in the UK to combine a W1 rating for water tightness, breathability to BS5250 standards, waterproofing of 7,000mm,

UV resistance of 5,000 hours and a Euroclass A2 limited-combustible fire rating. ITP Account Manager, Paul Harrison, said: “Stamisol Safe One is ideal for projects that are designed for longevity in support of conservation. Its combination of fire safety and all-round protection is unrivalled. Unlike other breather membranes on the market, the product is independently age-tested, so it can be specified with confidence in its ability to stand the test of time and maintain the condition of the building envelope in the long-term.”

Stamisol Safe One is one of a wide range of building membranes supplied by ITP. The company’s product range also includes vapour control layers, roofing underlays, house wraps, UV façade membranes and gas barrier membranes. Solutions are available in Euroclass A1, A2 and B ratings, all fully compliant with fire safety regulations on highrise and higher-risk buildings.

For more information visit itpltd.com, call 01347 825200, or email us at info@itpltd.com

ITP – Enquiry 4

NatureClad, a high-definition, wood effect PVC external cladding system, is the latest addition to join Swish Building Products’ extensive cladding range – and it’s already proving exceedingly popular.

Available in Double Shiplap and Double Feather Edge profiles in board lengths of 5 or 6 metres, NatureClad is extremely versatile and can be used in numerous ways, from new build homes and RMI (repairs, maintenance, and improvement) projects to garden rooms, caravans, lodges and holiday homes.

NatureClad’s authentic woodgrain texture has been achieved using premium wood effect foils which guarantee consistency in finish, negating the need for batch matching.

Its super-matt surface is available in six contemporary wood tones; Moonlight Anthracite, a dark grey; Morning Dew Silver,

a light grey; Cumulus Grey, a mid-grey tone; Chimenea Charcoal, a nearly black; Coastal Sand, a nature inspired light brown; and Rich Espresso, a dark brown. The range also features complementary trims and joints, resulting in a seamless, cohesive finish.

NatureClad has been specially designed to combine both style and substance.

It’s PVDF layer and low surface tension provide greater resistance against dirt and chemicals, resulting in a durable, long lasting cladding system. In addition, NatureClad is lightweight, quick to install, and extremely low-maintenance, making it the ideal for installers and property owners alike.

“NatureClad is the next generation of wood-effect cladding”, explains Lewis Litchfield, Product Marketing Manager at Swish Building Products.

“It’s high-definition finish offers arguably the most realistic wood effect appearance on the market and, unlike other systems which are only available with aluminium trims and joints, NatureClad offers complementary wood effect trims and joints which results in a fully cohesive finish.

“NatureClad is durable and easy to maintain, keeping it vibrant and attractive year after year. It also comes with a lengthy 15-year guarantee, which both demonstrates our complete confidence in the product and provides our customers with the peace of mind that they have purchased only the highest quality cladding,” concludes Lewis.

Further information about NatureClad can be found at https://www.swishbp.co.uk/ natureclad or by calling 01827 317200

Swish Building Products – Enquiry 5

Let's Talk Cladding is Sponsored by

Carlton Jones, Director of the MCRMA (Metal Cladding & Roofing Manufacturers Association), explains how the publication of the Building Safety Act 2022 heralded a new era in building safety and it will be a cornerstone of the design and construction process from here on.

Like any new legislation or standards that require change to established ways of working, its publication has also brought a degree of uncertainty and nervousness amongst industry professionals working at all stages of the building envelope supply chain as they seek to ensure that their projects comply with the new requirements.

The process for changing the industry and delivering safer buildings, however, is not going to be completed overnight. We only have to consider the scale of the UK construction industry, which has an estimated value of £168 billion and employs around 2.14 million people – 9% of the country's entire workforce – to understand that change will take time.

That said, there are changes that have already impacted and mean new processes must now be followed by law. For example, buildings that are at least 7 storeys or 18 metres high

and contain two residential units or more, categorised as higher risk buildings (HRBs), as well as some others that fall into the category, need a full application to be submitted and approved before work can commence. This includes the provision of additional information on competence, fire safety, control measures and mandatory reporting.

This has implications for anyone involved in the design and specification of cladding. And, more than anything, it means that following the best practice advocated for many years by the MCRMA, along with other industry associations, can no longer be regarded as optional.

This new approach to working should also be applied to all types of buildings, not only the HRBs which are subject to stricter controls, because the ultimate aim is to increase the safety of buildings across the board, regardless of their size.

How to find the latest best practice guidance

What does metal building envelope design best practice look like? It very much depends on the type of façade or roof selected, the loads it is being subjected to, its form, how it will be used by the occupiers, and the local environmental conditions. However, as with all elements in building design, there are some general principles that can be applied to every project, many of which are explained in the MCRMA’s Guidance Documents.

These Guidance Documents, authored by respected technical specialists from across the industry, many of whom work within member companies of the MCRMA, cover all aspects of metal building envelope design.

A number of the Guidance Documents are also approved online CPDs which have been assessed and certified by the CPD Certification Service to provide additional points.

The topics span design, specification and installation considerations relating to thermal performance, acoustics, air and watertightness, wind loadings, durability, minimising corrosion risks, aesthetics and much more. Fire performance is a factor in all of the Guidance Documents because of the multi-functional role that the envelope plays – i.e. there is never just one design or performance objective.

Several of the Guidance Documents, however, are associated with fire safety more than others and will be of particular interest to anyone seeking to develop or clarify their fire performance knowledge relating to facades. These include GD36 “Cavity barriers for ventilated rainscreen façades” and GD 40 “Understanding membranes in ventilated rainscreen facades”.

All the Guidance Documents are free to access and available to view and download at the MCRMA website – www.mcrma.co.uk

Early consultation with industry specialists

We know that many architects have always valued early consultation with product and system manufacturers and specialist façade consultants when working on client projects. But we also appreciate that can be difficult without established relationships or knowing where to begin in the search for specialist input.

The MCRMA can help here too, with our membership comprising of businesses who may be ideally placed to provide expert guidance,

whether from the perspective of a system or component manufacturer, a designer or independent inspector. Many of the association’s members regularly collaborate with architects to ensure the proposed design is feasible and most appropriate to meet the design objectives.

They can also recommend amendments to the design and specification based on their experience to maximise performance, enhance sustainability – a topic explored extensively in the MCRMA’s eight-part Guidance Document GD39 “Sustainability and Durability” – and even achieve time and cost savings.

Metal Cladding & Roofing Manufacturers Association – Enquiry 7 Let's

The increasing importance of CCPI

One final consideration for working within the new building safety regime is the need to access accurate, trustworthy information from suppliers and manufacturers. One of the ways this is becoming easier is through the CCPI (Code for Construction Product Information) initiative, which the MCRMA is supporting as a CCPI Trade Associate.

The CCPI aims to improve the clarity, accuracy, and accessibility of product information, and the government is actively pushing for increased regulatory oversight of construction products.

Manufacturers who sign up to the scheme have their company and products independently assessed to ensure they comply with the code and that gives an extra layer of assurance to architects, specifiers and clients.

As an emerging scheme, it will obviously take time for all suppliers to the construction industry to get on board with the CCPI, which may become mandatory in future. Aside from looking for CCPI registration, it is crucially important to scrutinise performance claims and the supporting test data and assessments at the specification stage.

If there are any concerns or grey areas relating to the information provided, or if you are seeking an additional review of your proposed design and specification to provide additional peace of mind, an independent façade design consultant or roofing and cladding inspector will be able to assist, and they could be an extremely valuable addition to your project team.

Find out more about the MCRMA at www.mcrma.co.uk.

Richard Owen, Technical Liaison Manager at Colorcoat® - Tata Steel

With sustainability and embodied carbon now core considerations for all buildings, it’s more important than ever to consider the whole lifecycle of a building. It’s essential to look carefully at the longevity and durability of external roof and wall cladding materials, as the areas most exposed to the external elements throughout the building’s lifespan.

Most buildings built today can reasonably be expected to still be in use well beyond 2050 (the UK’s target for achieving net zero) and so specifying a material that can last decades is the only responsible path. For this reason, pre-finished steel products with long term guarantees are an increasingly popular specification.

Pre-finished steel is manufactured with several different layers, including topcoat, primer and pre-treatment, all applied to the steel in a carefully controlled process. The quality, type, thickness and application of these layers is what dictates the product’s durability and resistance to exterior conditions.

Colorcoat Prisma® and Colorcoat HPS200 Ultra®

Offering excellent durability, both pre-finished steel products feature an optimised Galvalloy® metallic coating. Consisting of a special mix of 95% zinc and 5% aluminium for superior corrosion resistance and cut edge protection, it offers a combination of increased barrier and sacrificial protection when compared to

conventional Hot-Dipped Galvanised (HDG) coatings. Both surpass the requirements of RC5+ as per EN 10169:2022 – the highest classification available for corrosion resistance, products meeting this level of performance undergo extensive weathering tests at a C5 exposure site for at least four years.

Manufactured in the UK, they are certified to BES 6001 Responsible Sourcing standard and are BBA certified for durability in excess of 40 years. The products are also independently tested for the liberation of volatile organic compounds (VOC) against EN ISO 16000-9, achieving an A+ rating and are chrome-free and REACH compliant.

Colorcoat Prisma® renowned in the industry for its superior aesthetics, is a 3-layer product with a protective clear layer that provides an additional barrier to enhance UV resistance. With an extensive choice of colours and finishes, including a textured finish that delivers a striking effect for building facades, the colour range includes solid, metallic, matt and unique matt metallic colours, as well as natural metal shades.

Colorcoat Prisma® has even been proven to surpass the requirements of Ruv5, in accordance with EN 10169, which is the highest classification available for UV resistance.

Colorcoat HPS200 Ultra® developed over 60 years, is designed to withstand even the most demanding and aggressive environments.

Its nominal 200-micron structure is up to four times thicker than many other options to deliver enhanced longevity and durability, even when exposed to extreme weather conditions. Colorcoat HPS200 Ultra® has been tried and tested in climates around the world, from coastal locations to extreme environments, with installations ranging from the Middle East to South America.

For peace of mind on the long-term performance, Colorcoat Prisma® and Colorcoat HPS200 Ultra® are supplied with the industry renowned Confidex® Guarantee, offering up to 40 years protection for industrial and commercial buildings when registered online. The most comprehensive guarantee on the market, it covers both inland and coastal environments, with no reduction for the installation of Photovoltaic (PV) frame modules. The Confidex® Guarantee is also offered direct to the building owner with full rectification in the event of a coating failure.

With Colorcoat® built to last and supported by the Confidex® Guarantee for up to four decades, this provides reassurance of the longevity of the products – well in excess of the UK’s Net Zero target - and demonstrates that durability is truly sustainability.

To find out more about Colorcoat Prisma® and Colorcoat HPS200 Ultra® by Tata Steel click here.

Tata Steel – Enquiry 8

Let's Talk Cladding is Sponsored by

For the Building Safety Regulator, the Building Safety Act (BSA2022) has been about turning plans into action. The Grenfell Tower Public Inquiry’s Phase 2 report remains a stark reminder of why this work matters. It challenges the industry to learn from past mistakes and ensure residents’ safety and well-being are at the heart of every decision.

That is the message of Philip White, HSE Chief Inspector of Buildings, in a review of 2024. He says 2024 was a transformative year for building safety in England. It marked the shift from groundwork to meaningful action.

“Think of it like moving into a new home – exploring the space, tackling immediate priorities, and laying the groundwork for improvements, he said. “Since our May conference, which marked a new era for building safety, BSR has become fully operational. This isn’t business as usual – it’s

a generational shift in how the construction industry operates. BSA2022 introduced new frameworks and principles that require fresh thinking and collaboration.

“The post-conference survey reinforced this commitment: 71% of the 1,300 delegates reported a good or full understanding of their responsibilities, and nearly half (47%) said they intended to make significant changes to their practices this year.

“Throughout 2024, we’ve worked to embed these principles. By setting consistent building control standards and holding those managing higher-risk buildings accountable, we’ve laid strong foundations for lasting change.

“July brought one of our biggest challenges when an unexpected surge in applications, driven by external industry issues, caused delays in processing building control applications. We acted quickly to keep things on track, putting contingency measures

in place, such as recruiting additional staff and securing industry support. These steps are already having a positive impact, helping us manage the increased demand.

“We’re committed to overseeing the safety and compliance of higher-risk buildings, while supporting industry to deliver safe and successful projects. The new gateway processes, introduced in response to the Grenfell tragedy, are central to raising safety standards.

“We know that adapting to a new system takes time. That’s why we’re working closely with industry leaders – listening to feedback, strengthening our advice, and providing clearer guidance to help applicants navigate this process with confidence.”

He said building safety is more than meeting regulations – it’s about transforming how we work and think.

At the heart of this shift is competence. It’s not a box to tick but an ongoing responsibility. Professionals must ask themselves:

• Do my teams have the skills and attitudes needed to deliver safe outcomes?

• Am I staying within my expertise and improving my knowledge?

• What more can I do to embed safety into everything we do?

“Building safety isn’t just about technical standards – it’s about people and their homes,” he added. “At BSR, we’re committed to putting residents’ safety at the heart of everything we do. It’s not enough for people to be safe; they also need to feel safe. That means knowing their homes are secure, their concerns are heard, and their voices matter.

“Change isn’t easy, but it’s essential. This year’s challenges have only strengthened our resolve. One clear message has emerged: those who create risks must be held accountable for managing them.

“As Gateway 3 progresses, we’re focusing on verifying compliance during the final stages of construction. Managing design changes to maintain safety standards will be a critical priority.”

In 2025, the BSR will continue strengthening the regulatory framework, improving competence across the sector, and amplifying residents’ voices.

The mission goes beyond compliance -it’s about rebuilding trust and creating a safer future.

“Next year, we’ll work with government, industry regulators, fire authorities, Mayors, and local leaders to accelerate remediation for higher-risk buildings still affected by unsafe cladding,” he said. “Collaboration will be key to driving this critical work forward.

“Another priority will be modernising the Approved Documents framework in particular consulting on a revised Approved Document B, which covers fire safety. By simplifying and clarifying these rules – especially for smaller builders – we aim to make compliance more accessible and straightforward. A public consultation is expected by early autumn.

“The progress we’ve made proves what can be achieved when we work together. But there’s still more to do. Professionals, policymakers, and residents all have a role to play in shaping a safer built environment.”

Health & Safety Executive – Enquiry 10

Euroform’s WeatherClad® wood effect shiplap planks have been selected for Devonshire Homes’ new Ilfracombe development, Mariner’s Haven.

Euroform is supplying the low maintenance, fibre cement planks, which are manufactured according to BS EN 12467: 2012+A2:2018 and have BDA Agrément certification, in six bespoke colours.

Performance and look were key criteria for product selection for Devonshire Homes. Initially, Euroform provided samples of eight bespoke colours from which the housebuilder chose six to depict sand, grass, sea and sky. WeatherClad® is also available in 21 standard colours, plus RAL and NCS colours on request, and Euroform provides a comprehensive range of colour matched profiles and trims.

The natural timber effect of WeatherClad®, with its random embossed grain, and the width of the board will both add to the pleasing look. WeatherClad® boards are 230mm wide, wider than most similar boards on the market.

WeatherClad® carries third party BDA Agrément certification from KIWA, a certification recognised by architects, specifiers, engineers and building control personnel.

Certification confirms the product’s suitability and fitness for purpose in terms of performance and durability. WeatherClad® has a European Classification of A2-s1,d0 for Reaction to Fire in accordance with BS EN 13501-1.

Weatherclad® is part of the range of Euroform’s Code for Construction Product Information (CCPI) assessed products.

Angus Cook of Devonshire Homes commented: “One of our top priorities is to ensure properties are sympathetic to the local environment. This is why we chose Euroform’s WeatherClad® as the colours complimented the countryside and ocean scenery surrounding Mariner’s Haven. We always use high-quality products that will stand the test of time, and WeatherClad® promises to do just that with its strong durability and water vapour resistance.”

Euroform – Enquiry 11

Let's Talk Cladding is Sponsored by

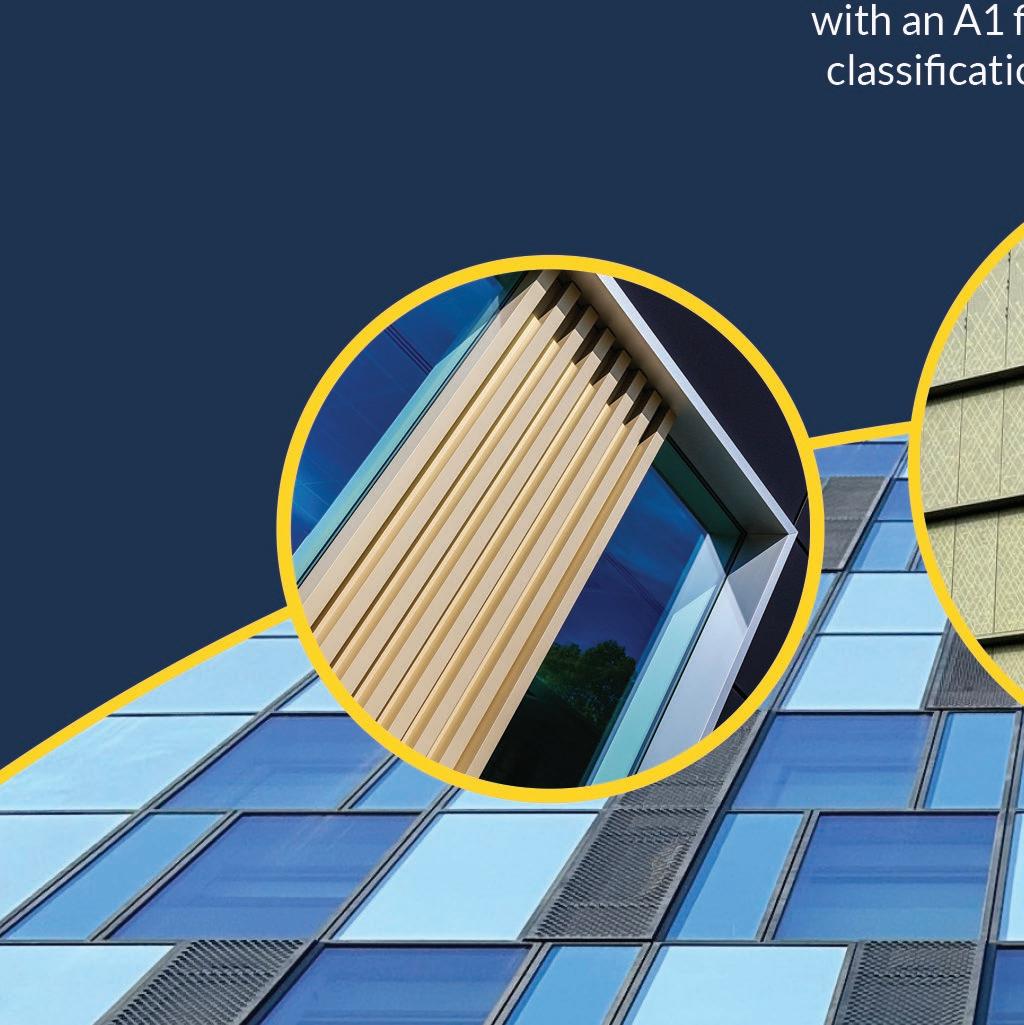

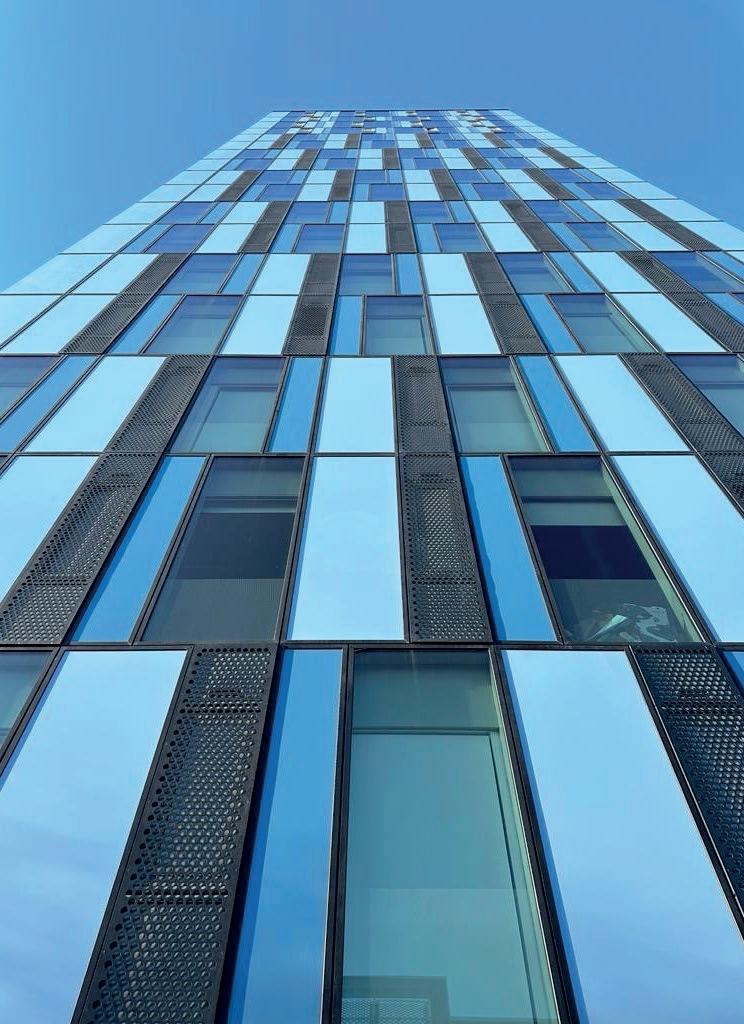

Metalline’s non-combustible ULTIMA Insulated Spandrel Panels were selected to enhance fire performance, improve thermal efficiency, and provide a modern, seamless aesthetic.

The primary goal for this project was to upgrade the existing cladding with a solution that enhanced fire safety with A rated materials, improved long-term durability and thermal performance, and delivered a contemporary aesthetic vision. This included a specially manufactured two-tone colour designed to replicate the existing panels and blend into the London sky. Metalline’s ULTIMA Insulated Spandrel Panels provided the ideal solution, ensuring compliance with stringent fire safety standards while maintaining a sleek, highquality aluminium finish.

Chapter House, Kings Cross, recently underwent vital fire safety remediation to replace the existing spandrel panels into the unitised curtain walling system. This ambitious project involved the removal and replacement of over 5,500 combustible cladding panels across two 16-storey student accommodation towers.

A key challenge in this project was manufacturing bespoke panels that integrated smoothly into the existing building structure without requiring significant structural modifications. The building corners posed particular challenges, requiring precise engineering to ensure a perfect fit.

Given that the two towers were occupied throughout the project, the installation process was carefully planned and executed over a six-month period using both scaffold and cradle access. This ensured minimal disruption to residents while maintaining strict safety measures. Metalline’s ULTIMA Insulated Spandrel Panels were selected for their exceptional fire performance and ease of integration into existing glazing systems.

The ULTIMA Insulated Spandrel Panels offer A1 & A2-s1,d0 fire classification according to BS EN13501-1. They have been tested for impact resistance to CWCT TN75/76 standards and fully tested for wind resistance to CWCT standards. The panels provide limitless colour options, allowing designers aesthetic flexibility while ensuring low maintenance, strength, and durability.

Looking ahead to 2025 and beyond, Metalline continues to drive innovation in architectural façade solutions. The company is actively working towards achieving key third-party certifications, including ISO 14001 & 9001 for environmental and quality management, BBA Certification to reinforce product reliability and compliance, and Environmental Product Declarations (EPDs) to support sustainability initiatives. With nearly 35 years of experience in

the industry, Metalline has established itself as a market leader in the design and manufacture of architectural façade solutions. Renowned for delivering high-quality, innovative products, the company continues to push the boundaries of performance, safety, and aesthetic design, remaining firmly at the forefront of the market.

The Chapter House, Kings Cross project showcases Metalline’s commitment to delivering high-performance, fire-safe, and aesthetically superior façade solutions. With a strong focus on compliance, sustainability, and innovation, Metalline remains at the forefront of the industry, setting new standards for architectural cladding systems.

If you are looking for an innovative, fire-safe, and visually striking façade solution for your next project, Metalline can help. Contact us today to discuss how our ULTIMA Insulated Spandrel Panels can enhance your building’s safety, performance, and aesthetic appeal.

Metalline – Enquiry 12

Let's Talk Cladding is Sponsored by

The publication of the Grenfell Tower Inquiry Phase 2 report in September 2024 was long-awaited and vital for the industry.

The importance of independent and rigorous product testing and certification regimes was reinforced in the report and changes have been happening at a rapid pace.

“Whilst a difficult read – an important milestone for us to reflect on our progress to date and a look to the future on what else needs to be done,” said Hardy Giesler. “Our colleagues have dedicated their careers to contributing to the construction sector in a positive way. Whilst there has been no malicious intent or gain, the findings, of course, cut to the bone – as they have to.

“However, while the content of the report may have been new to some, the BBA has been closely involved since the fire in June 2017. Our learning forms the basis of everything we do, every change we make and every improvement in services that we target. It has formed the basis of our transformation plan and remains core to our business plan.

“The impact of this work is showing in the use of product certification in the construction industry. Since Grenfell, demand for independent, 3rd party certification has more than trebled; a clear sign that the sector continues to embrace independent verification and oversight.

Hardy Giesler

“Apart from the publication of the Grenfell report, 2024 this year also saw more elements of our transformation programme come to fruition.

“The BBA welcomes all and any changes being made to improve product testing and certification. Many of our people are involved in industry forums, committees and working group to influence, contribute and support these changes. It very much meets one of our original objectives, to be more stakeholder, market and industry focused. We have much to contribute and are pleased to be able to do so.

“A market consultation in 2022 identified ways in which the BBA can further improve the performance of products in the built environment, combinations of products and systems. We have shared these with stakeholders and as changes to regulations, approved documents, standards and industry

best-practice are considered, the BBA contributes actively. We actively share the sixty years of experience we have access to, and we contribute our knowledge, and our understanding of best practice and relevant standards.

“The work we do can be complex and will always require a high level of competence to support the users of the information provided. We are trying to simplify this as much as possible to help decision-making across the industry, but equally competence on behalf of the user will always be a necessity.

“We believe in independent oversight, so naturally BBA has is accredited by UKAS, the government-appointed accreditation body for the UK for over 20 years.”

The Government has acknowledged the important role of UK Conformity Assessment Bodies, such as the BBA, and has confirmed

it will work with them as part of the building safety reforms it is considering.

The Government also confirmed that, any changes to the recognition of CE marking would be subject to a minimum 2-year transitional period. It is important to note that CE or UKCA marking do not establish a

product’s fitness-for-purpose for a particular construction application. They simply confirm a product’s characteristics, which are not specific to the UK or use.

Furthermore, over two-thirds of construction products used in the UK are not covered by Harmonised or Designated Standards,

which means that no assessment of them is mandatory before they are sold in the UK. A third-party Agrément Certificate, such as the BBA’s assesses a product’s fitness for purpose for a specific application, is subject to stipulated reviews and is specific to the UK climate and Building Regulations.

The Inquiry report did not identify one single fault that led to the fire, but rather highlighted countless flaws and shortcomings that led to inherent failures in the system to build and maintain safe housing, particularly in high-rise buildings.

FPA Chief Executive, Dr Gavin Dunn said, “It is imperative that everyone involved in all parts of the system reflect on what has happened, what has been done in the past, but most crucially, what needs to now be done differently to enable the change that will ensure a similar tragedy does not reoccur.

“The report is rightly extensive, however a number of the key recommendations as they relate to fire safety can be grouped together. They focus on legislation and regulations, the competency and accountability of professionals, and product fire performance testing and data, all areas that the FPA support change in.”

British Board of Agrement – Enquiry 14

When it comes to industrial and commercial roofing and cladding, Tek Clad is the name you can rely on.

With 15 years’ experience, we’ve built a reputation for excellence and attention to detail, delivering top-tier roofing and cladding solutions across a range of projects, from new builds to refurbishments. Our knowhow and exacting standards can help you extend the life of your buildings and improve their sustainability too.

Based in Weymouth, Dorset, we cover the surrounding counties and beyond, taking on projects as far afield as the West Midlands and London. Whether you're looking for a reliable subcontractor or need a full-service team, Tek Clad can make your project a success, whether it’s a £100k or a £1m+ contract.

Our core services include the design and installation of tailored roofing and cladding systems, and refurbishments, from stripping outdated materials and installing new, energyefficient components, to over-cladding to enhance insulation and appearance without the need for material removal.

Our people are at the heart of our success. We have a directly employed team, and invest continually in training and accreditation, with NVQs, IPAF certificates, and CSCS cards held across our staff.

A recent investment in two telescopic handlers and CPCS qualifications has allowed us to bring lifting capability fully

in-house, ensuring consistency and greater flexibility for our clients.

Get in touch to discover the Tek Clad difference - quality that lasts: email estimating@tekclad.co.uk or call us on 02382 440 956

Tek Clad – Enquiry 15

Despite playing a crucial role in the performance of a metal building envelope, fasteners are an often overlooked component at the design stage.

However, as the construction industry rises to the challenge of creating a safer and more sustainable built environment, one of the ways greater certainty can be provided regarding the quality and performance of the roofing and cladding is to focus on the fastener specification early, and not leave decisions about these tiny components to chance.

Choosing incorrect fasteners can be detrimental to the performance of the envelope. In many cases, however, the issue may not be due to the wrong fastener being used – it could be because a poor quality product has been selected, or that the correct fastener has being incorrectly installed. All these issues can be mitigated with careful specification.

Early consideration of the fasteners is not only about minimising the risks of issues developing. It could actually determine the form that the envelope takes as a whole. In fact, the fastener choice not only influences the aesthetics of the building, but it can even offer a completely different perspective on the proposed envelope design or system choices.

This is the case with the FM Approved EJOT Colorfast range. These self-drilling fasteners feature a head coloured to match the panels providing enormous scope to add interesting creative features and achieve aesthetically original metal building envelopes, without compromising performance goals.

Colorfast fastener heads are completely encapsulated using engineering-grade nylon which is composed to include a colour pigment to match the sheets. It provides a durable, UV-stable and lasting colour with material characteristics that mean it is unlikely to be damaged during installation in the way that powder coated screws can be.

The over-moulded head also offers total protection for the screw’s hex head, thus virtually eliminating the risk of corrosion, and it contributes to an enhanced seal in combination with the integrated washer formed of EPDM bonded to aluminium. This helps to distribute an even clamp load when the fastener is driven into place, ensuring a tight seal can be achieved to a level where it will compensate for moments when installation cannot be 100% perpendicular.

The performance capabilities of Colorfast fasteners are confirmed by globally recognised third party approvals in the form of European Technical Assessments (ETAs) and FM Approvals.

Find out more about EJOT UK at www.ejot.co.uk/colorfast_hub.

Image 1: With over-moulded fasteners, it is possible to match to around 400 colours in line with recognised colour matching systems, such as RAL, NCS, British Steel, and Pantone. Bespoke corporate colour matches can also be achieved.

Image 2: Self-drilling fasteners which feature a coloured nylon over-moulded head provide aesthetic consistency in metal roofing and facades.

EJOT – Enquiry 16

UV stabilized polymer

Provides long-life colour durability, 400 colours as standard.

Ultra-secure EPDM seal

Actively prevents water / air ingress.

Application-specific range

Solutions for the most demanding and challenging environments.

EJOT drill-point technology

Unrivalled self-drilling precision.

Integral over-moulded head

100% encapsulation using high-grade engineering nylon.

EPDM bonded metal washer

Mirrors the fastener head to create a uniform compression.

Choice of fastener materials

Organically coated carbon steel

Stainless / bi-metallic steel, A2 or A4.

Optimised design

Reduced waste during the manufacturing process whilst fully optimising installation.

650 million fasteners worldwide. Speaks volumes!

Now third generation, EJOT Colorfast has been building the future for more than 30 years. This accrued performance data is engineered into every single product, across the entire self-drilling range. For designers and contractors that means total reliability, clean aesthetics and building-life performance that is endorsed by FM Approvals and all leading system OEMs. Call EJOT Customer Service: 01977 687040 E: salesUK@ejot.com

Visit: www.wall-systems.co.uk

A2 Fire Rated EWI System Ideal for Remediation Projects. Superior Impact Resistance. Moisture & Weather Protection. Blends Seamless with Rendered Façades. Below DPC, Base Areas, Balconies, Walkways, and Pla

Wetherby Wall Systems, part of the ROCKWOOL Group, has introduced SOQEL A2, the UK’s first fully fire-tested External Wall Insulation (EWI) system designed specifically for use below the damp proof course (DPC).

This new solution addresses a critical but often overlooked area in building design. In line with updated UK Building Regulations, materials used on buildings over 11 metres must now meet a minimum A2-s1,d0 fire classification. While insulation systems for upper façades have evolved to meet this standard, below DPC treatments have remained largely untested and disconnected from the wider façade system. SOQEL A2 changes that.

Engineered for use at ground level and other vulnerable zones such as balconies, walkways, and plant rooms, SOQEL A2 provides tested performance where it’s needed most. The system uses Coverrock X-2 insulation with a durable factory-applied coating that protects the A1-rated Stone Wool core during application and enhances adhesion for the finishing layers.

It’s reinforced with Heck K+A SL basecoat and Heck CER Mesh to offer lasting resistance to impact, moisture, and weather extremes.

A key benefit of SOQEL A2 is its visual integration. The system includes Heck 4S Silicone Render, which allows for a colourmatched, seamless finish with the upper façade. This avoids the patchy or inconsistent appearance typical of older below DPC solutions, such as bitumen coatings. The result is a cleaner, more unified façade that doesn’t compromise safety or aesthetics.

Joe Ragdale, Technical Director at Wetherby Wall Systems, said: “SOQEL A2 is the first system of its kind to undergo full fire testing for below DPC use.

“Developed with our ROCKWOOL Group partner HECK in Germany, it’s a major step forward in ensuring fire safety compliance across the entire building envelope. It’s a practical, durable, and visually cohesive option for both refurbishment and new build.”

With SOQEL A2, Wetherby extends its portfolio of compliant, high-performance façade solutions into a space where safety, appearance, and durability have often been difficult to balance.

For technical support or project enquiries, visit www.wall-systems.co.uk

Wetherby Wall Systems – Enquiry 19