As the year ends, there is much to look back on and learn from while at the same time there is a bright future to plan for. On page 6 Diane Calabrese has written “What to Expect in 2026.” One of the first realities is the growing impact of AI in all areas, including in the pressure washing industry. Greg Sprunk is president of Superior Cleaning Equipment in Phoenix, AZ, and he expresses cautious optimism that many good things are happening, including on monetary matters.

Bruno Ferrarese is co-owner of Idrobase Group in Italy, and he sees, “There are many factors to weigh and evaluate.” He notes that because of all the economic changes and challenges that have occurred this year, 2026 could be a very exciting and stimulating year. Calvin Rasmussen is president of Royce Industries, and he is very optimistic about 2026. He acknowledges multiple challenges, but he also sees “the outlook for companies that are disciplined, data-driven, and focused on execution is very strong.”

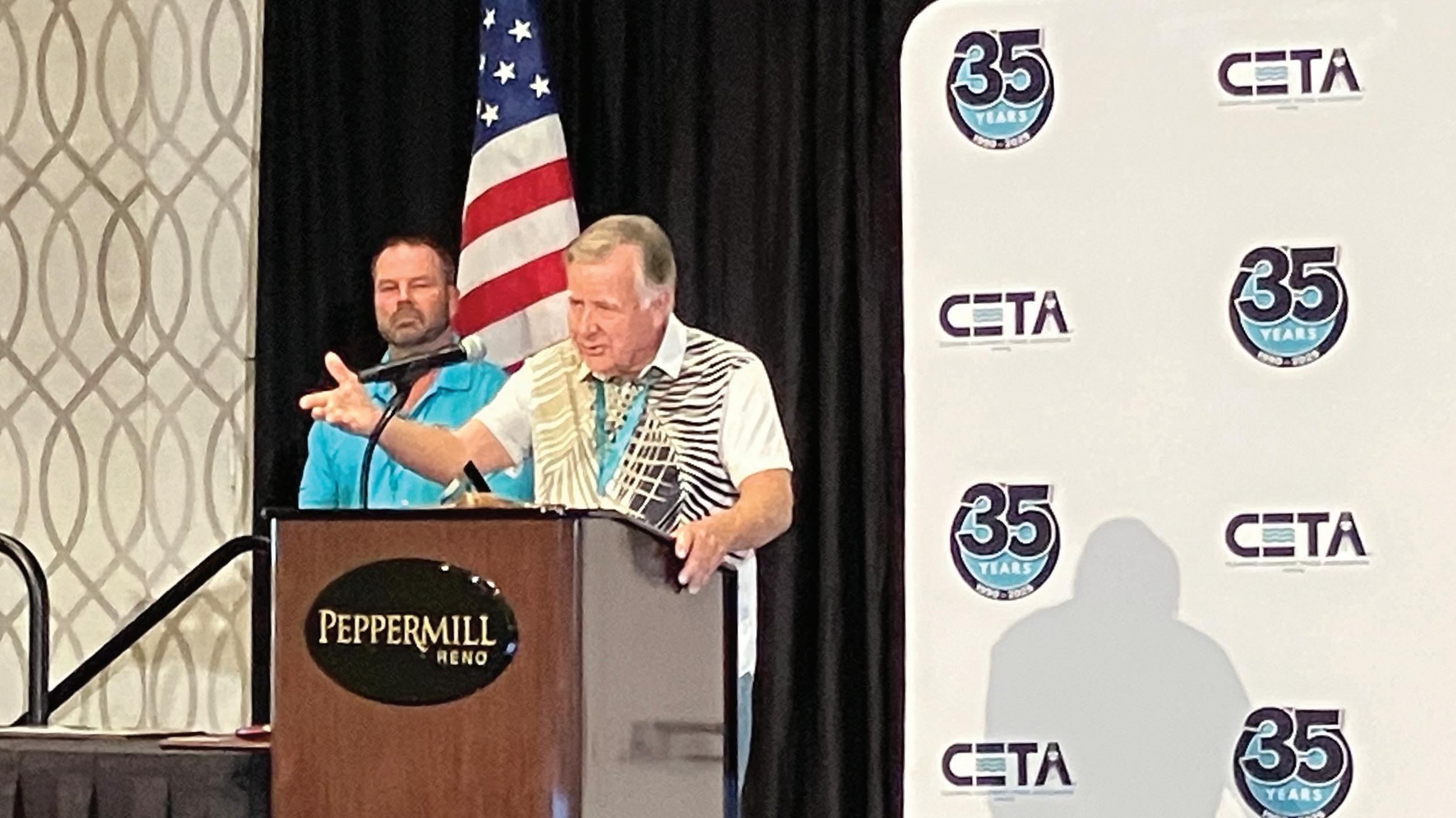

On page 10 there is a focus on multiple awards given at CETA PowerClean 2025 to those devoted to the industry. It’s good to see these folks receive their awards for their devotion to the industry and to anticipate the new group that will be award recipients in 2026.

Turn to page 22 to read about the Power Washers of North America (PWNA) industry event in February 2026. ELEVATE 2026 will be hosted at the DoubleTree SeaWorld in Orlando, Florida, February 18–20. The live demonstrations, certification classes, social events, and vendor exhibits make this an event to attend.

Merry Christmas! Cleaner Times hopes you have a wonderful celebration and enjoy some time away from the normal routines of work.

Michael Hamline

mhamline@cleanertimes.com

800-525-7038

Cleaner Times (ISSN #1073-9602) is published monthly by

True Source Publishing, LLC 1000 Nix Rd, Little Rock, AR 72211 (800) 525-7038 • (501) 280-0007 Fax: (501) 280-9233 www.cleanertimes.com © Copyright 2025

The publisher and editor(s) of this magazine do not accept responsibility for the content of any advertisement, including statements made by advertisers herein, or the opinions expressed by authors of by-lined articles. The publisher and editor(s) also reserve the right to reject any ad or article for objectionable content in verbiage or images. The intent of this publication is to provide general information only and is not intended to provide specific advice or recom-mendations. Appropriate legal, financial, or engineering advice or other expert assistance should always be sought from professionals.

HOW TO REACH US

Times 1000 Nix Road Little Rock, AR 72211 www.cleanertimes.com

SUBSCRIPTION RATES One Year, $24 U.S. and $75 Canada. Back issues are available for $8 each. Reproductions of any part of this publication without the written consent of the publisher is prohibited.

Candor about AI must top the list of expectations for 2026. In fact, make it a certainty instead of an expectation—a certainty that may unfold even before 2025 ends.

It’s becoming increasingly difficult—to the level of silliness—for analysts to continue “hypothesizing” about what AI will do and can do all while AI is already doing.

Debate over such things as legislating guardrails for AI is in the realm of the absurd. So, too, is any discussion of how best to integrate, coexist with, deploy, or slow down AI.

In 2026, if not before, every sphere of society, from commerce and industry to education and healthcare, etc.,

will be forced to acknowledge that AI permeates all interactions, and that its impact grows larger each second. Is there exponential growth? Perhaps not yet, but another overwhelming thing on which to reflect.

Meanwhile, economic activity continues, and business owners, financial experts, and others have a perspective on what that activity will look like in the new year—a year that puts us at the midpoint of the third decade of the 21st century.

Let’s zero in on the outlook for business. Does anyone have ideas?

“I would say I’m cautiously optimistic,” says Greg Sprunk, president of Superior Cleaning Equipment Inc. in Phoenix, AZ. “I think there are a lot

of good things happening; and I think the country is headed in the right direction as long as the policies the current administration wants to enact are enabled and enforced.”

Sprunk holds a generally positive outlook on monetary matters. “I think interest rates are going to be reduced. I think that will reduce some pressure, but I also think there are possible problems as well.”

Issues such as effects from government shutdowns can reduce some of the positives because they lead to conflict, explains Sprunk. And conflict—whatever the source—tends to dampen the spirit of people. Does the outlook for 2026 seem reminiscent of any past year? “No, it

by Diane M. Calabrese

seems like for the last five years we are in unchartered territory every year,” says Sprunk.

The many unexpected happenings that began in late 2019 with the acknowledgement that a new and fast-moving virus was making its way around the world made a memorable beginning to the decade. What followed on were “the stock market resilience, inflation, politics, and many other factors that have made every year since seem unique,” says Sprunk.

There’s an unpredictability about it all. Yes, that’s true as every new year arrives. But business owners are detecting something unusual as well as unpredictable.

“The economic outlook for 2026 is that of a rapidly changing market that is difficult to predict,” says Bruno Ferrarese, co-owner of the Idrobase Group in Borgoricco PD, Italy. “There are many factors that could influence it, such as artificial intelligence, the emergence of new manufacturers, cross-border customs duties, and the needs of end customers.”

There are many factors to weigh and evaluate. “All this will lead to very significant changes that are difficult to interpret and assess at present,” says Ferrarese. “Those who are able to present new communication-focused solutions to the market will be the winners.”

Again, the uniqueness to this time captures attention. “With this out -

look, 2026 promises to be a very exciting and stimulating year,” says Ferrarese. “Never before have the market and the world changed so much, replacing old habits with new ones.”

So unique is this period that Ferrarese sees nothing that’s about to unfold as reminiscent of a year past.

“Absolutely not,” he says. “The year 2026 will certainly not be a continuation of what we have experienced over the last five years.”

What is 2026 likely to bring? “It will be a year of momentous change, and it is difficult to draw up a business plan that can be confirmed in the consolidated financial statements at the end of 2026,” says Ferrarese.

Although it may seem that digital communication occurs at the speed of light, it’s not quite that fast. Under most present conditions (and conveyors), it’s about two-thirds the speed of light.

Still, the speed is fast enough to pull us into the swirl of yet-to-be imagined directions. Before being swept away, however, it’s always a good idea to remember we build on a foundation of knowledge and societal activity. That recollection allows us to temper both our expectations and our concerns.

“In many ways 2026 reminds me of the post-2008 recovery period,” says R. Calvin Rasmussen, president of Royce Industries L.C. in West Jordan, UT. “Back then, companies that survived the downturn emerged leaner, more intentional, and better positioned to gain market share.”

How did they reposition? “The focus was on fundamentals, training teams, tightening financial controls, and strengthening customer relationships,” explains Rasmussen.

“Today feels similar,” says Rasmussen. “Economic uncertainty has prompted companies to examine every operational decision.”

Rasmussen says that it’s likely companies that approach 2026 with “discipline, clarity, and actionable insights” will “outperform their peers” as they did in the years that began with 2010. Indeed, his outlook is positive.

“I’m optimistic about 2026,” says Rasmussen. “While the challenges like rising operating costs, a tight labor market, and ongoing supply chain adjustments remain, the outlook for companies that are disciplined, data-driven, and focused on execution is very strong.”

In fact, Rasmussen explains that his company looks to 2026 as a year for strategic growth. “The demand for cleaning equipment, service, and parts continues to be robust, driven by industries that prioritize compliance, efficiency, and uptime.”

And there’s a corollary to the demand. “Companies that invest in

innovation, including automation, wastewater treatment solutions, and environmentally responsible products, will be best positioned to capture market opportunities,” says Rasmussen.

There’s a question each business should be able to answer, says Rasmussen. “What are you doing to prepare your company and your industry for success in 2026?”

And what is Rasmussen’s company doing? “We are planning with precision and intention.”

By leveraging its CETA [Cleaning Equipment Trade Association] benchmarking PAR [performance analysis report], Rasmussen’s company has identified five top areas on which to focus, areas such as improving gross margin, increasing sales per customer, and optimizing operational efficiency.

The chair of the CETA benchmarking committee, Rasmussen is a forceful advocate for benchmarking as he explains that each participating

company benefits. And so does the entire industry.

“When one company grows smarter and stronger, it helps lift the entire market, truly a case of ‘a rising tide lifts all boats,’” says Rasmussen.

As we write near mid-October 2025, many groups are releasing economic forecasts for 2026. Most begin with tempered optimism, such as “things look better than we feared.” But it’s possible to find data to support almost any outlook from gloomy to giddy.

One recurring theme tossed about is that the pervasiveness (growth) of AI promotes optimism. More on the “why” of the optimism would be welcome, but we infer it’s because so much research and development funding is flowing into AI, which in turn provides a boost to the economy, at least in the short term.

OECD [Organization for Economic Co-operation and Development] issued an interim report in September 2025 suggesting real GDP growth will slow globally (from 3.2 percent in 2025 to 2.9 percent in 2026), and inflation is expected to ease.

Cautious optimism comes from members of our industry as well as analysts. Add Dennis Black, the president of McHenry Pressure Cleaning Systems in Frederick, MD, to the group.

“We do expect an approximately 10 to 15 percent increase by the end of 2025 compared to 2024,” says Black about the picture at his company. Even with myriad variables that will affect 2026, he takes that as a positive indicator.

“Our business and market area are fairly diverse and not dependent on just one segment or industry,” explains Black. “Putting aside all the variables and things we do not have control over, I expect business to continue at a modest rate in 2026.”

What Black would like to see in 2026 is more attention given to focused adaptation. “I feel it is very important that this industry stays somewhat flexible to what the market needs and wants.”

And is there a key to accomplishing that flexibility? “I believe our manufacturers need to be willing to meet additional custom and special needs that the distributor market is going to require,” explains Black.

“I expect to continue to see some eroding on certain markets and types of equipment,” says Black. “Distributors need to be able to adjust and meet the specific applications…Therefore, the manufacturers that support them need to do the same.”

Adjusting quickly to supply chain pulses might be a place that AI could intervene—and no doubt already does. Similarly, predicting what the next pulse will be ahead of its arrival would most definitely make AI formidable— although it is already formidable (just quietly so), and its predictions from aggregated data may be labeled a forte. Overall, what should we expect in 2026? An interesting year, and time will tell in which way(s). CT

by Diane M. Calabrese

hanks for being an example to us. That’s the sentiment embedded in awards of every kind.

We look to awardees, take stock of their accomplishments, and become inspired to do more ourselves. And there is plenty of inspiration to be had from the recipients of awards at PowerClean® 2025.

So much inspiration, in fact, that we offer a recap here of the award recipients. This year in addition to the recognition of individuals, CETA recognized a company for an innovative achievement—the first of what will be an annual award for innovation.

A few words from award recipients and their colleagues follow. Recipients are introduced in alphabetical order.

For Jack Hill the special recognition award took on layers of positives, including the surprise of having his three sons arrive for the presentation—something his wife, who had accompanied him to Reno, arranged. A secret well kept.

No secret around the great affinity and appreciation that Hill has for CETA. The association has “been very helpful in many special ways” to both him and General Pump, he explains.

Hill serves as executive director of sales and marketing/ quality and service at General Pump, a member of the Interpump Group, which is based in Mendota Heights, MN. He credits CETA with strengthening all its members.

“The association and its membership is such a close-knit group and made up of very successful entrepreneurialspirited, hard-working people, which rubs off on you as time goes by,” says Hill.

The co-sponsorship that Hill and his company have provided for the annual reception at PowerClean has been fundamental to its success, says Debbie Murray, managing director of CETA. “Their dedication transformed this event into a cherished tradition.”

The Dual Wash Pro™, a product of the FNA Group in Pleasant Prairie, WI, was voted the most innovative product of the year by PowerClean 2025 attendees. Embodied in the product line are the company’s “ingenuity and passion for new products,” explains Rick Gilpatrick, senior vice president for R&D at the company.

Indeed, customers may not have thought such a power cleaning solution was possible. That is, a single machine built to switch between pressure washer and soft wash capabilities.

How did Gilpatrick’s company arrive at the innovative product? “With the accumulation of more than 150 years of developing exciting new products for the power cleaning industry, we observed, listened to, and took time to read

the stories and testimonies of professionals and consumers about what they liked and wished they had.”

Gilpatrick describes the Dual Wash Pro as a technological wonder. And there is no question that its origin— really its “essence”—derives from the strong legacy of the company.

“The dual-capability machine was spearheaded by our company Delco™,” explains Gilpatrick, “It optimizes the technology of a commercial-grade positive displacement pump, combining unique patent pending methods to manage the flow of water or soft wash chemicals with advanced materials designed to meet the reliability and durability expectations of power washing and protection against the harshness and corrosive environment of soft washing… all into one solution.”

DTX Foundation, which supports organizations such as Hospice of Michigan, marks 10 years in June 2026 and has

roots in the 1990s. One of its founders, Jamie McGoffin, was nominated for the community service award by Chad Reiffer, distribution program manager at Hydro-Chem Systems Inc. in Caledonia, MI.

“I have worked alongside Jamie at our company for nearly 10 years,” says Reiffer. “I have seen him dedicate countless hours to the DTX Foundation’s fundraising and charitable organization involvement. This all takes place along with his commitment to excellence in the power cleaning industry as an account manager and team leader for detergent and pressure washer sales and service.”

Reiffer says observing McGoffin’s work on behalf of the community has been an inspiration to others. They, in turn, have become more involved in community activities.

“I definitely was caught off-guard by the award,” says McGoffin. “I was not informed that I was being nominated, but it was truly a blessing.”

McGoffin says he follows the path of CETA members in his professional and avocational endeavors. “Aside from the helpful business discussions, the members of CETA have shown a desire to help others, and this adds to my drive to further the DTX Foundation’s goals.”

A remarkable career, unwavering dedication, deep expertise, exemplary leadership—quite a list of attributes. And all (and more) were assigned to Jeff Theis, the president and CEO of ProPulse, a Schieffer Company, in Peosta, IA, by Erik Spurling, who nominated the award winner. Spurling serves as director of sales and marketing at Schieffer’s company.

“Theis’ contributions have helped shape and elevate the industry, earning him the respect and admiration of colleagues and peers alike,” says Spurling. As for Theis’ reaction to receiving the award, he was pleasantly surprised.

“Given the caliber of alternatives, I really didn’t know what to expect,” says Theis. “Of course, on hearing the news, I felt greatly honored to be selected.”

In receiving the award, Theis reflects on the group he has joined. “There have been a lot of past recipients whom I have looked up to over the years—Ralph Notch at A.R. North America, Gary Scott of Alkota, and Jack Hill of General Pump, to name a few. All of these are inspirational, with at least four decades in the industry.”

Theis explains that CETA itself has “been a model to emulate both personally and professionally.” And he elaborates, “What has always struck me about CETA is that amidst the rivalries, competitors were able to set aside their parochial interests for the common and greater good.”

Achievements of Dave Wyett, the owner of Always Under Pressure in San Jose, CA, extend to every component of our industry. They include early work on advancing product safety and standardization to strengthening the benchmarking and technical committees at CETA.

“Simply put, the milestones that shaped our industry are inseparable from Dave Wyett’s career,” says R. Calvin Rasmussen, the CEO at Royce Industries L.C., headquartered in West Jordan, UT. Rasmussen nominated Wyett for the award and provided a list of achievements much longer than we can include here.

“Dave has consistently elevated the bar for what professionalism and partnership look like in our field,” says Rasmussen. “He recognized early on that innovation and integrity could coexist, that when manufacturers,

distributors, and service providers share common goals, everyone benefits.”

Receiving the award in 2025, when CETA celebrates 35 years, adds to the honor, says Wyett. “To be recognized by an organization that represents the very best of our industry is both humbling and deeply meaningful.”

To be sure, in reflecting on the award, Wyett expresses an appreciation that illustrates what forms the strong, enduring core of CETA:

colleagues, mentors, and partners contributing to shared success.

“Throughout my career I have had the privilege of working alongside many dedicated professionals who share a commitment to excellence, innovation, and integrity in the cleaning equipment industry,” says Wyett, and he adds, “CETA has played a vital role in fostering that spirit of collaboration and growth, and I am proud to have been part of this community.” CT

by Diane M. Calabrese

If it’s broken, fix it—and get the fix right. That’s the unrelenting goal of service centers.

So how do members of our industry ensure they have the service and repair tools necessary to provide excellent results? They assess and calibrate every dimension of service: tools, training, logistics, parts, etc.

“Making sure each service tech has their own portable workstation [and] toolbox” provides a good foundation,

says Dennis Black, president of McHenry Pressure Cleaning Systems in Frederick, MD. “All common hand tools are available right where they are working—in shop, outside, etc.”

Ease of access expedites work in-house and on mobile calls. “We provide each one of our service techs with their own tool cart,” explains Black. “They are responsible for the box and its contents, and only they use it.”

Careful consideration of ways to expedite work of team members leads to continuous improvements. “We have also found success in providing cordless tools for all our mechanics” says Black. “These include drills, impact wrenches, and cut-off saws. These have increased work efficiency.”

Black adds that his company has multiple sets of cordless tools in his shop. And each service truck has a set for on-site use.

Does Black have any recommendations for contractors regarding the tools they should have on hand while at jobsites? Needs of contractors and technicians who provide in-field service to contractors do overlap in the field.

“Pressure washer techs need a good quality multimeter with the correct functions, such as being able to determine AC and DC volts, AC and DC amps, [and] other readings,” says Black. “Other items include

pressure gauges for oil and gas— natural and LP—and pressure and temperature gauges for output of pressure washers.”

Black proffers, too, that he has a perspective on torque wrenches. “I see some shops may not provide or encourage the use of torque wrenches. Although not always necessary, proper torquing assemblies is the correct and professional way to perform assemblies and rebuilds.”

Is there any priority higher than an excellent result in repairs? Yes, of course there is. That is safety.

Proper tools are essential to worker safety. “Using the wrong or inadequate tool can [result in injuries],” says Black. That’s in addition to the damage to property.

“Using improper tools can also result in breaking or damaging what [a technician is] working on,” explains Black. “In other words, making the

damage worse or breaking parts that originally did not need replacing.”

Distributors and contractors share a vested interest in having the optimal collection of tools, the best tools, and the most up-to-date understanding of tool use. In the next section we get a perspective from the point of view of a distributor. And in the third section we get a perspective from the point of view of a contractor.

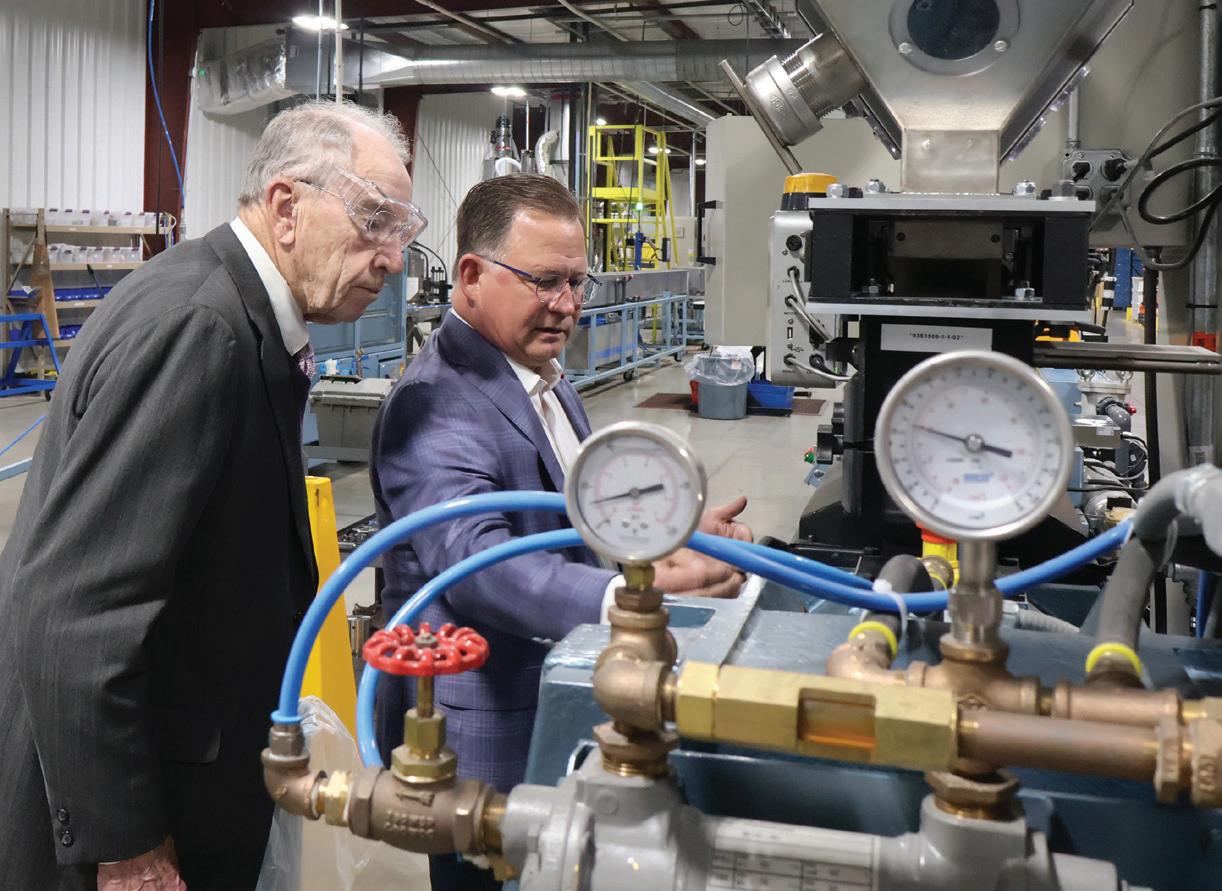

When we put questions about service and repair tools to Aaron Auger with BE Power Equipment, which is headquartered in Abbotsford, BC, Auger reached out to some of his company’s customers. He spoke with Greg Rothbardt and Jacob Hendren at Hanson Industrial Inc. in Moline, IL.

Rothbardt is the owner of the company based in the Land of Lincoln state. And Hendren is a service technician at the company. In the paragraphs that follow, we relate some of the approaches that Rothbardt’s company has taken to ensure

service and repair tools are deployed and exploited to their full advantage.

A system for winterizing pressure washers was added recently. The system makes the process easier and faster.

“We have also recently added a test station including a water tank to our shop for testing equipment,” says Rothbardt. “This eliminates having a lot of standing water due to spraying equipment on the floor of our repair center.”

Rothbardt and Hendren say that the one tool no contractor should be without on a jobsite is a fuel stabilizer. They explain that most of the pressure washers the company sells are gas driven; and when gas sits in the tank, it can separate.

Separation in the fuel tank can lead to issues with starting the pressure washer. “This is very prevalent when a contractor has equipment sit over the winter,” says Rothbardt. “They go to use it in the spring, and the engine won’t start.”

In most cases, Rothbardt and Hendren explain, the fuel stabilizer

prevents the separation and ensures the pressure washer will start. In addition to the fuel stabilizer, they cite a voltmeter as something every contractor should have. The testing and verification of a customer’s voltage verifies that the correct voltage is available for the equipment being used.

Rothbardt and Hendren offer a list of the four top concerns they have about unwise practices that can accelerate the need for major repairs. One is starting a pressure washer with no water. Doing so generally burns the packing/seal kit, and then the washer will not perform properly, they explain.

A second concern surrounds nozzles. Using the incorrect nozzles is common, explain Rothbardt and Hendren. They note that contractors often go to a big box store and pick up nozzles without knowing the correct orifice they need.

A third concern deals with the failure to stay ahead of leaks. As Rothbart and Hendren explain, the stress that leaks put on pressure

washers is avoidable. Repairing them should be a priority.

The fourth concern from our sources in Illinois is that contractors often do not cool down their hot water units before shutting them down.

Tailoring tools to recurring jobsite needs will somewhat depend upon the type of work a contractor does. But there is an overarching axiom contractors should keep in mind: Using the wrong tool inevitably leads to trouble—perhaps not immediately, but soon enough.

“Using the wrong tool to repair a machine would not usually work due to the fact that you’re not using the right tool to do the repair correctly,” says Tom Rice, owner of Island Wide Pressure Washing, which is based in Wantagh, NY, and serves Nassau and Suffolk counties. He takes on residential and commercial jobs.

To assemble the tools of greatest utility, a contractor should ask one

question, says Rice: Which tools are most commonly used?

“A handpick to remove and replace broken O-rings is a valuable tool to have in the field,” says Rice. “O-rings tend to break over a period of time.”

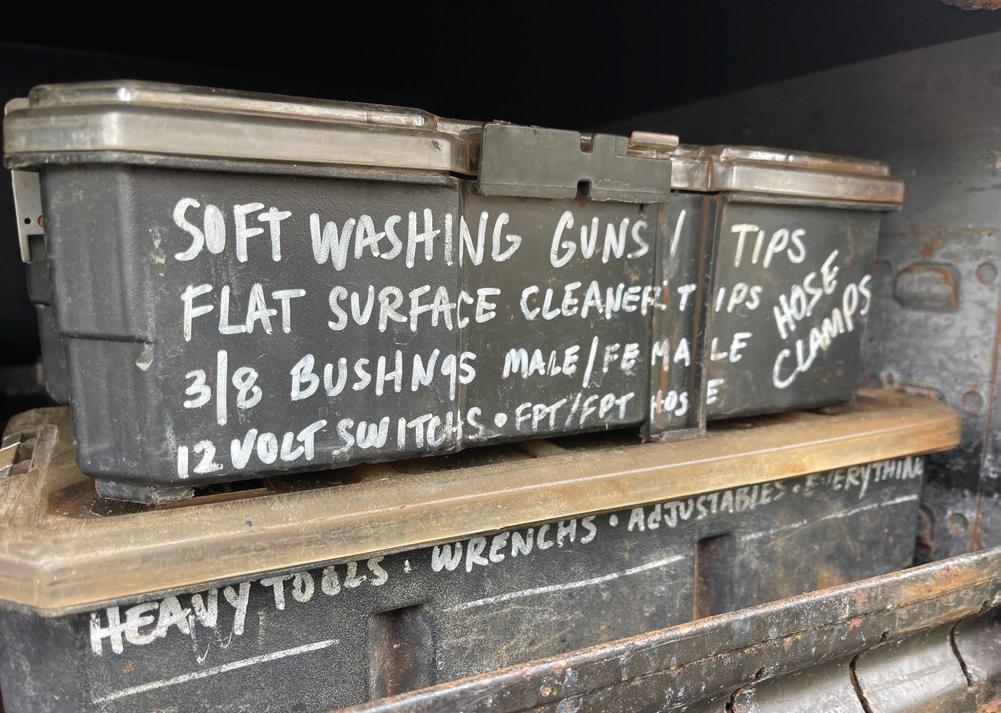

As for what he keeps on his truck, Rice explains that is as comprehensive an array as possible. “I basically have a small mobile mechanic shop on my truck.”

Rice emphasizes that the tools are “very neat and well organized,” or in other words, both accessible and protected from damage in transit. “We keep everything on the truck from new guns—both pressure washing and soft washing—to new swivels for the hose reels, nozzles, and quick connects–male and female, quarter-inch, half-inch; we basically have everything on the truck to do any sort of repair in the field.”

Channel locks and adjustable wrenches “are very useful for a quick fix, whether it be changing out new quick connects on an extension pole or

the end of a lance,” says Rice. So he keeps those tools at the ready onsite too.

“I recently bought a rather unique tool that has been very beneficial and helpful to me [in the field],” says Rice. It is a rigid one-quarter inch handthreader die head.

The hand-threader die head “is very helpful when you need to thread the quarter-inch extension poles,” says Rice. He explains that his company uses five- and six-foot extension poles for difficult to reach and high areas.

“The extension poles are typically aluminum, and the threads sometimes break off,” says Rice. The hand threader enables him to make a fix of new threads within a few minutes.

Rice stresses the importance of being equipped to handle small repair issues at a jobsite. Being able to do so dramatically reduces downtime.

One tool that Rice recommends all contractors consider carrying is a vise. “I would suggest that no contractor should be out on a jobsite without a

vise. Many years ago I took a vise and mounted it on a trailer-hitch tongue, and we keep it on the truck.”

Rice encourages other contractors to think about just how useful a vise might be to them. “This tool is very handy. We work on many different applications, such as replacing a quick-connect from the high-pressure hose or swapping out a broken gun, that the vise makes possible. I would definitely recommend keeping a vise on the truck.”

Whether it’s a tool set that gives a service technician autonomy and a no-wait environment, or a multimeter to ensure that there is no miscommunication between the tool and the power source, distributors and contractors strive for the best repair environment. The standard repertoire of tools is well known.

But it’s subtle configuration modifications (unique to each company) and specialty tool sections (made by each company) that add up to best practices industry wide. CT

by Ryan McGowan

he Power Washers of North America (PWNA) is more than an association. It is a community built on education, safety, and success. Every year contractors, suppliers, and educators gather to share ideas, learn new skills, and celebrate progress at the PWNA Annual Convention. In February 2026 the PWNA will host its biggest event yet—ELEVATE 2026—to be held at the DoubleTree SeaWorld in Orlando, Florida, February 18–20. This event brings together professionals from across North America for three powerful days of learning, networking, and growth. Whether you run a small pressure-washing company or manage a full team of technicians, ELEVATE 2026 offers the training, business classes, and membership benefits that help your business grow stronger and more profitable.

The PWNA Annual Convention is the highlight of the year for the pressure-washing and exterior-cleaning community. It combines live demonstrations, certification classes, and vendor exhibits into one action-packed event. At the convention, attendees can experience the following:

• Earn certifications through hands-on classes taught by industry experts

• See live outdoor demos featuring professional-grade equipment

• Meet vendors and explore new tools, detergents, and safety systems

• Join social events such as the PWNA corn hole tournament, opening reception, and the Women’s Wine & Wash

• Network with other business owners who share the same goals. This year’s event will be co-located with the International Window

Cleaning Association (IWCA), making it an even bigger opportunity to connect with related trades. The PWNA mobile training trailer will be in full use throughout the convention, bringing classroom knowledge to life with hands-on experience. From surface cleaning to water reclamation practices, you will learn how to work smarter, faster, and safer.

The convention also gives members access to exclusive vendor discounts, giveaways, and raffles, making it both an educational and rewarding event.

Before the main convention kicks off, attendees can participate in specialized pre-convention classes on February 17, 2026 (additional cost applies). These advanced trainings are ideal for those looking to expand their services or enter new markets.

• Solar Panel Cleaner & PV Fire Safety Training led by Steve

Williams from the International Solar Cleaning Academy (ISCA)— PWNA Certified Instructor. Learn safe and efficient solar panel cleaning techniques while understanding PV system hazards and fire prevention protocols.

• Niche Market Training led by Carlos Gonzales of Pressure Wash Training—PWNA Certified Instructor. Discover how to develop profitable business models in niche markets such as gas stations, chain accounts, and other high-demand sectors.

ELEVATE 2026 features joint sessions with both PWNA and IWCA, spotlighting two respected industry business minds.

• Brandon Vaughn, Founder & CEO of HireBus and Wise Coatings. Brandon grew up in the home services industry—scaling his own company from “me and a truck”

to a 70+ person operation—and now helps thousands of trade professionals do the same.

• Coach D.J. Carroll, widely known as Coach Carroll, is an entrepreneur and business strategist who has built, scaled, and sold multiple companies. Through his energetic keynotes and coaching, he delivers real-world strategies with an edgy, motivational style that drives growth and action. Their combined insights will inspire attendees to push beyond limits, strengthen leadership, and “elevate” both business and mindset.

Running a power-washing business takes more than strong equipment. It takes strong business knowledge. The PWNA offers business classes at the convention that focus on the real-world topics contractors face every day. These sessions help owners and team leaders improve their operations,

marketing, and finances. The goal is to help every attendee walk away with clear ideas they can apply immediately to grow their company. Here are some of the main topics covered in the PWNA business classes:

• Business Systems and Structure— Learn how to organize your company for efficiency. Discover ways to manage scheduling, payroll, and job tracking so your business runs smoothly.

• Pricing and Profit—Understand how to price jobs fairly and profitably. Classes explain cost analysis, equipment investment, and how to calculate break-even points.

• Marketing and Online Presence— These classes focus on social media, local SEO, and digital branding. Learn how to get found online, attract new clients, and build trust in your community.

• Customer Service and Retention— Discover how communication and professionalism turn firsttime customers into loyal, longterm clients.

• Insurance and Compliance—

Protect your business by learning about the right coverage, documentation, and safety standards to stay compliant with OSHA and EPA guidelines.

Each business class is led by an experienced instructor who understands the challenges that contractors face in the field. Lessons are practical, clear, and designed to help you take immediate action once you return home.

The PWNA believes that knowledge should lead directly to improvement. Whether you are looking to grow your revenue, organize your team, or reduce daily stress, these classes give you the foundation to do it.

While the PWNA offers several membership options, the Enterprise Membership is the most complete package for companies serious about growth and safety. It combines

education, tools, and support into one simple membership plan for both contractors and vendors.

Enterprise Members receive unlimited access to PWNA training and certification classes for the power washing and window cleaning industry. This means every employee can become fully trained and certified without paying per-class fees. It’s an easy and affordable way to keep your entire team educated and consistent.

• Unlimited Education and Training— Members can take all available safety, certification, and continuingeducation courses. Subjects include house washing, roof cleaning, wood restoration, fleet washing, window cleaning, and OSHA 1910 safety.

• Digital Tools for Safety, Compliance, and Technical Training— Enterprise Members gain access

to a mobile app loaded with the following:

Job Hazard Analysis forms

Safety Data Sheets (SDS)

Inspection checklists

Video safety meetings These tools make it easy to manage safety and training in the field.

• Convention Access and Savings— With six months of active membership, Enterprise Members receive one free annual convention pass—perfect for attending ELEVATE 2026. Members also receive special event pricing and discounts all year long.

• Marketing Exposure and SEO Benefits—Each Enterprise Member is listed in the PWNA.org contractor list, helping customers find certified professionals online. The longer your listing is active, the stronger your search visibility becomes.

• Discounts and Business Perks— Enterprise Members save money

on insurance, equipment, and supplies through PWNA’s trusted partners. These savings often pay for the membership itself.

• Community and Networking— Members join the private PWNA Community Connect Facebook Group where contractors and vendors share advice, referrals, and success stories. It’s a direct line to hundreds of industry peers.

• $129 per month or $1,299 per year

• Contractors use code 100DECO for $100 off annual memberships (offer not valid with monthly subscription)

• One membership per location

• Kitchen Exhaust Cleaning (KEC) classes are included with KEC Enterprise Membership, $1500 per year

Becoming an Enterprise Member is simple. Visit PWNA.org, choose your plan, and start accessing unlimited education right away.

The power-washing industry continues to grow across residential and commercial markets. Customers expect professionalism, safety, and quality. The PWNA helps its members meet those expectations through structured education and strong community support.

By attending the convention, enrolling in business classes, and upgrading to Enterprise Membership, contractors can build a safer, smarter, and more profitable company. These programs are proven to improve team performance, reduce liability, and strengthen your brand’s reputation.

PWNA members often report higher customer satisfaction, more referrals, and greater confidence in their daily work. The combination of hands-on training, business knowledge, and community involvement gives members a real advantage.

Education is not just a step forward—it’s the path to long-term success.

This February join hundreds of power-washing professionals at ELEVATE 2026—the PWNA’s Annual Convention at the DoubleTree SeaWorld in Orlando, Florida, February 18–20. Experience the following for three days:

• Live training and certification classes

• Business workshops that help you grow

• The latest equipment and vendor exhibits

• Fun networking events and giveaways

Whether you are attending for the first time or returning as a PWNA member, ELEVATE 2026 is your chance to connect with the best in the industry, learn from experts, and build lasting relationships that help your business thrive.

Learn more and register today at www. PWNA.org. Elevate your knowledge. Elevate your business. ELEVATE 2026 CT

by Diane M. Calabrese

Structural integrity might not be the first thought when coursing through a dirty parking garage, but it’s something to consider. The short of it is that a properly cleaned garage— emphasis on properly—ensures that concrete realizes its full lifespan. And one need not be claustrophobic to want overhead slabs of concrete to stay in place.

Failure of tons of concrete obviously constitutes an undesirable outcome. Yet, there are also quieter sorts of unwelcome events.

the ‘slipperiness’ of a surface, and it is the property manager’s responsibility to ensure the coefficient of friction on all walking surfaces meets insurance requirements.”

What’s the frequency of cleaning required to keep a walking surface safe? “Parking garages should be cleaned as often as needed to prevent dirt and oil buildup,” says Dingler. “Different geographical locations can lead to a variety of contaminants, such as sand and dirt in dry regions and sand, dirt, and organic growth in humid regions.”

The closure of a level and relocation of vehicles also facilitates entry for sweepers, which may be used prior to washing. Once water enters the picture, a contractor must be fully compliant with regulations for handling wastewater that contains oil and other residues.

As for tool of choice, Dingler likes surface cleaners. “Surface cleaners are a go-to for any garage; the bigger, the better.”

Paul Laramee, the owner of Exquisite Finishes in Warwick, RI,

“Oil comes from vehicles and puddles in the middle of each parking space and can be tracked with foot traffic, leading to slip and fall hazards,” says Mike Dingler, owner of Firehouse Pressure Washing LLC in Peachtree City, GA. When a garage user is injured, the garage owner is impacted.

“Oil and dirt can affect the coefficient of friction of the concrete in the parking garage, leading to a potential lawsuit if left unchecked,” explains Dingler. “Coefficient of friction is a measurement used in insurance to rate

There’s a simplicity to the structure of parking garages, but cleaning them can be complicated.

“Many factors contribute to the complexity of cleaning parking garages,” says Dingler. “The work is usually performed when the garage would be most empty.”

Dingler explains that for a commercial garage few vehicles will likely be present at night, whereas a residential garage would be just the opposite; and optimal logistics may require closing one level at a time, moving vehicles, or both.

completed his first parking garage contract for a municipal building owner in 1989, the same year he launched his business. Today most of his work is commercial with only about 10 percent residential.

“Most of the garages we do are twice a year,” says Laramee. Typically, they are jobs obtained by responding to an RFP [request for proposal].

Laramee says he likes the RFP process, which may put his company in contention with six or so other bidders. He appreciates the process because the owner states what’s expected. In ideal

cases, written expectations are amplified during a walk-through.

“I like the walk-through. You can see the obstacles like drainage and pitch,” says Laramee. It’s also a good time to ask questions, too, so that the response to the RFP is realistic.

With any project, Laramee begins with mechanical sweeping. “You want to pick up all the dirt; otherwise you are just pushing mud.”

Requirements for wastewater can vary. Some garages have a drain that can be used. Others have drains that must be covered so that no sand or silt enters them. Some garage owners want all the water picked up.

Laramee has been on the board of directors for the PWNA for more than a decade. And he’s happy to field questions from fellow contractors, which he often gets from states as far away as Florida and Texas.

It’s the details that matter when planning the cleaning. For instance, an awareness of height restrictions is a must, explains Laramee. A sixfoot, nine-inch clearance may actually be only a six-foot, six-inch clearance in some spots because of ancillaries like hanging power strips and camera systems.

Underground parking garages require special attention to exhaust

and ventilation. If hot water is used in the semi-confined space, caution must be taken so that the heat does not set off sprinkler systems or alarms.

Vexing issues vary with the structure of the garage. Above-ground garages built with slabs and deploying expansion joints pose different challenges than underground garages where concrete was poured, explains Laramee.

A pressure washer is Laramee’s tool of choice. “But every garage is a little different. It all depends on what kind of equipment I can get in.”

Care in all things applies. That includes keeping water away from

elevators and at least five feet away from doors, says Laramee.

Moreover, it’s not just about cleaning. Snow on top levels of above-ground structures must be removed for safety.

Garage owners often contract with outside companies for garage management. A contractor who develops a relationship with a management company may secure more work. And it’s possible to contract for add-ons, such as concrete sealing and line striping.

Whichever approach a contractor takes to cleaning, there is one constant. “You need a lot of water flow,” says Laramee.

“A proper-sized surface cleaner is always a good choice to accelerate cleaning and yield a great appearance,” says Bruce Tassone, president of HydraMotion Cleaning Systems in Pottstown, PA. “A large surface

cleaner is helpful, but a contractor should check that their pressure washer flow is sufficient and that there is enough water available to drive the surface cleaner.”

The large surface cleaner is one choice. “Another good option is to use environmentally safe degreasers to pretreat any heavily stained areas or grease buildups,” explains Tassone.

Balance in all things, including the frequency of cleaning parking garages. “The goal is to keep a proper appearance and not allow buildup to accumulate so fast that cleaning becomes more difficult in the future,” says Tassone.

It’s worth repeating that cleaning promotes a safe environment. Yes, cleaning eliminates slip and fall hazards. It also ensures that garage users are not so distracted by grime, startled by rodents, etc. that they walk into a vehicle.

“There are two significant challenges in cleaning a parking garage,”

says Tassone. “One is having sufficient water or a water source available. There must be sufficient water available to drive the pressure washer, particularly when using multiple crews and equipment.”

The second challenge also relates to water. It is meeting local regulatory requirements for water discharge. “The contract cleaner should always check to ensure what the local requirements are,” says Tassone.

“All parking garages present unique challenges,” explains Tassone. “One site may have limited access; another site may have multiple levels.”

Completing the job on time and within budget begins with planning, says Tassone.

Experience is a good teacher. Usually, however, learning from someone who possesses extensive experience is better.

John Tornabene, owner of Clean County Powerwashing in Kings County, NY, brings deep experience to the classes he teaches. In October he offered such a class at the CETA PowerClean® 2025 in Reno, NV.

In class Tornabene covers the full array of relevant topics: how to get jobs, how to clean efficiently, and how to earn a good income. Obtaining excellent results for customers is only half the equation for a contractor. The other half is ascertaining that a profit is made.

The combination of sweeping and washing, if done on a regular schedule, can lengthen intervals between washes. “A parking garage should be swept at least every other month and power washed every one to two years,” says Tornabene.

“Parking garages must be power washed to preserve the integrity of the concrete,” says Tornabene. If tracked-in salts are not washed away, they will begin to soak into the

porous concrete and eventually attack the rebar.

Disintegrating rebar leads to cracks in concrete. A crack in a concrete sidewalk is one thing; a crack in an overhead concrete slab is another thing altogether. Over time, chunks of concrete could fall, or in the worst cases a garage could collapse.

“The most difficult and dangerous part of power washing a parking garage is if it’s done while the garage is open,” says Tornabene. In some cases, such as hospital garages, there is no alternative to working while the garage remains open.

“The most challenging garages to clean are the ones that are below the surface,” says Tornabene. “If the exhaust fans aren’t up to par, then the trucks have to be kept outside so workers are not at risk for carbon monoxide poisoning,” he says.

In the tool-that-works-best category, Tornabene puts riding surface machines. The machines speed up the cleaning process, and the operator doesn’t suffer from fatigue.

A formal class such as Tornabene’s gives a contractor the knowledge required to separate facts from sales techniques. Consider on-site drains. Tornabene explains that certain on-site drains can be used for wastewater. With access to an appropriate drain, the contractor need not invest in an expensive, on-site reclamation trailer.

In the end, maintaining a parking garage is about much more than appearances—it’s a matter of safety, liability, and long-term investment protection. Attention to detail, proper scheduling, and the right tools can make all the difference between a clean, secure structure and one that poses hidden risks. For property managers and contractors alike, a well-maintained garage isn’t just a clean space—it’s a sign of diligence, professionalism, and respect for everyone who drives or walks through it. CT

Voluminous is one way to describe the amount of space, in real and digital realms, that gets filled by analysts of industrial output and trends (past, present, and future). In short, there’s a lot of it.

Is all the analysis helpful? Yes, especially some that comes from decades past or even 100 or more years ago. (We will return to a bit of that later.)

One point of convergence among the many sorts of analysis: There’s a churn to industry.

The churn is the predictable part. The specifics must be taken as they come.

To serve industrial markets is to acknowledge stasis just is not part of the picture. Members of our industry stand ready to respond to the market that exists, not the one that was (even a day or month ago). And they try to anticipate what may be coming.

There’s an expression about the perils of “playing the last hand” that applies in bridge (and poker and more). Of course, it’s a reminder that a static approach—doing what worked before without reassessing variables—is likely to lead to a bad outcome.

The better a business owner can “count cards” (assess variables), the more likely that success will follow. Getting caught up in what was—the last hand— only impedes clear thinking.

Writing in the Journal of Political Economy (April 1919) more than a century ago, H.L Reed of Cornell University made an observation that applies universally to economic endeavors: “Unless the problem of the industrial future is viewed from the standpoint of the entrepreneur, it is difficult to arrive at a pessimistic conclusion.”

Reed was acknowledging the churn. Things change. Although some possibilities or market niches (and individual businesses) disappear, others emerge.

by Diane M. Calabrese

For instance, following World War I in 1919, industrial markets quickly changed from a focus on ship building, weapons manufacturing, and the like to a much broader base. An entrepreneur who had been serving shipyards with ancillaries might have had to quickly change focus to serving farms.

Keeping focus on the customer is one of the time-tested ways to change as industrial markets evolve, coalesce, and emerge. Know what the customer needs. Meet the need.

Even with the intense interest in renewable sources of energy, it is unlikely that oil field customers will suddenly disappear. And the oil field customer is a very interesting one to serve, says Brandon Keilers, the owner of Ramteq Pressure Washers in Houston, TX.

The business-to-business dimension of an industrial market is significant. “Knowing you’re helping other small businesses succeed in most cases is foundational,” says Keilers.

“Meeting the price point to stay competitive with the import manufacturers” is a challenge, says Keilers. And that is a challenge that comes even with close ties.

To be sure, the strongest links can be severed in less-than-stable economic times. And that can be a challenge in industrial markets just as it is in any market. Difficulties arise in every sphere of commerce and industry. And working through them is what it takes.

It’s gratifying in many ways, including overcoming any obstacles that arise, to serve industrial markets. “For me it’s about helping people solve problems they have,” says Delany Johnson, senior manager and sales engineer at Wayne Combustion Systems in Fort Wayne, IN.

Serving within a vast industrial market sphere brings other pluses as well, says Johnson. “It’s great that we are in so many different industrial markets and can see the different issues people have.”

Yes, there are challenges, says Johnson. One is “how different each company is.”

And by differences, Johnson means the way in which each company approaches its interaction with their vendors and suppliers. “Some are easygoing and enjoy your help and ask for it; others only want you around when they have issues.”

There’s a second challenge out there as well. “The other big issue is government regulations,” says Johnson. “They seem to have changed a lot lately.”

Matching the product to the customer’s needs is the essence of maintaining a

robust presence in the industrial market sphere. Take industrial ovens, one of the products that Johnson’s company supplies.

“There are so many different styles of ovens, and they need different heat for all kinds of volumes from small ovens to very large,” explains Johnson. “This market has lots of different ways to create the heat—from direct fire to many different styles of combustion chambers.”

Members of our industry that serve industrial markets find the experience invigorating, even exhilarating. And why not? They are working in multiple ways to assist companies that keep improving living standards across the world.

“What’s most gratifying is knowing that the equipment we build helps keep essential industries running smoothly,” says Curtis Braber, owner of BE Power Equipment in Abbottsford, BC, Canada. “Our engineers [enjoy] developing the larger, high-quality hotwater pressure washers, for example.”

And places of service for the equipment produced by Braber’s company are many and varied. “Whether it’s manufacturing, food processing, or transportation, these businesses depend on reliable, heavy-duty cleaning solutions to maintain safety, efficiency, and compliance.”

The many and varied applications add up to a wide range of requirements. “The challenge lies in the complexity and variety of industrial needs,” says Braber.

“Each facility or application often has unique requirements—from water flow rates and pressure levels to safety regulations and environmental considerations,” explains Braber. “Industrial customers also demand equipment that can withstand tough conditions and operate reliably with minimal downtime.”

The dynamism of industrial customers must be matched by the companies that serve them. And that’s a good thing, says Braber.

“Meeting the expectations of industrial customers means we have to continually innovate, engineer for durability, and provide strong after-sales support,” explains Braber. “It’s challenging, but it also pushes us to be better.”

Each industrial market looked at closely has a way of capturing attention. It also reminds us of the interlocking systems that keep thriving societies strong.

“One example is the food processing industry,” says Braber. “It’s fascinating because the cleaning standards are so rigorous—everything has to meet strict sanitation and regulatory requirements.”

So, what is a must for the machines that serve the food processing sector? “Pressure washers in this environment need to combine high performance with reliability, while often being designed with stainless steel or other materials that can handle wash-down and prevent contamination,” explains Braber.

Again, the rewards for serving industrial markets accrue in many ways. “Serving the food processing market is interesting because it challenges us to think creatively about design and engineering, while also knowing our solutions directly support public health and safety,” says Braber.

The future will be a cleaner one. That’s the prevailing outlook across all sectors of society.

It does not mean the future will be free of industrial processes but simply that the processes will be as clean as possible. Moreover, the water used for industrial cleaning, like the water used in all industrial processes, will be minimized to the fullest extent possible. Our industry, which has long worked in accordance with the objective of doing more with less, will continue to serve using the least amount of water (and energy). Wastewater treatment on site is likely to become the norm.

The push being given to industries to do more with methods that leave the smallest footprint in the environment comes from both consumers and

regulators. But it is also an internal imperative because of the cost savings that can be realized by methods that minimize water and energy use.

Onshoring industry is a focus of the current U.S. administration. The Manufacturing.gov website, which is managed by the National Institute of Standards and Technology (NIST), provides an easy path to the many federal programs that offer incentives to companies that increase production done inside the United States.

The U.S. Small Business Administration (SBA.gov) has established a portal focused on onshoring. Using the tool, businesses that would like to verify which products are U.S. made can easily do so.

There are different philosophies about the importance of domestic production versus global supply chains. Most do not involve an either-or outlook.

Yet industrial markets that source more of their raw materials and/or components close to where final products are manufactured can almost always save energy and time. The savings realized might be an argument for onshoring.

Some look to the health of industrial markets for clues about the near future of the economy. In an admonishment to anyone interested, J. Laurence Laughlin of Washington, D.C. wrote in 1926 this pair of prophetic statements:

In fact, the main function of the industrialist, besides watching costs, is to see that his production is duly adjusted to wants. Starting the presses to work printing money does not increase the volume of salable goods in a well-adjusted production, by which alone does purchasing-power emerge. (“The Industrial Outlook” in The Journal of Political Economy, https://www. journals.uchicago.edu/doi/pdf/ 10.1086/253751.)

As 2026 begins, Laughlin’s assessment three years ahead of 1929 bears reading and heeding. Industrial markets are vital components of economic activity. CT

by Ricardo Smith

There is a particular pride in waking up in the morning with your freshly brewed cup of coffee and sitting on the porch to admire the landscape. Homeowners spend thousands each year on perfectly trimmed bushes and seasonally installed flowers that boost curb appeal.

The problem is when the time comes to get the roof soft washed or finally remove those dirt streaks from the siding with soft washing. While those tasks can make the home more appealing, they also put your carefully curated plants at risk. Too much overspray or chemical exposure from runoff can lead to scorched leaves and weakened roots.

Like any other challenge in life, a little preparation and some quality aftercare go a long way to getting the washing your home needs and keeping your beloved plants in excellent health. You’ll need to develop a complete plant care strategy to make this work.

Both pressure and soft washing often involve cleaning solutions designed to break down dirt, grime, oil, algae, and stains. While that works fantastically on unwanted aesthetic issues, those chemicals are typically not intended for plants.

The most common chemical is sodium hypochlorite (SH). That will strip away organic growth on the siding or shingles but also rob plant life of vital nutrients. Even more ecofriendly detergent-based solutions can be risky if not properly prepped. Surfactants, chemical agents that stick to surfaces, may magnify harmful effects by restricting plant respiration. You have to pay attention to preparation before soft washing.

If you learn nothing else from this article, keep in mind the “core” principles of protecting plant life during pressure washing. Those include the following:

• Divert—Redirecting downspouts or using shields in targeted areas can redirect chemical and water runoff from affecting plants and landscaping.

• Dilute—Pre-wetting sensitive plants with clean water helps because roots and leaves are already saturated, meaning they’ll absorb fewer chemicals.

• Decontaminate—Once the pressure washing is completed, give your plants a final rinse or apply a neutralizing agent for any lingering chemicals so you restore balance to the plant life’s pH.

These three steps are the foundation of your layered strategy. This alone is all you need to shield greenery and get a beautifully cleaned home. Some additional tricks may help if you are extra worried. For instance, if you’re prewetting the plants, be sure to pay more attention to any foliage directly under rooflines or next to siding. That is where runoff will be the most extreme.

When covering plants, don’t use plastic. That will create microecosystems like a sauna, restricting air flow and burning out leaves. You want Tyvek or cloth that allows airflow

without trapping heat. Many professionals only cover the tops of plants for this reason.

As you reroute runoff, pay attention to gutters and downspouts. Bag the ends of downspouts with heavy-duty trash bags or attach extensions and PVC piping to send chemical overflow to the drains instead of your bushes.

Finally, pick up a neutralizing agent like sodium thiosulfate to render any bleach inert. That will basically change harmful chemicals into saltwater. I recommend professional roof washers apply a neutralizer on all plants and greenery as a precaution.

You can save money and feel a sense of accomplishment if you handle the pressure washing on your own. That way you can control how much water or spray reaches your plants. The trouble is that most rental equipment is designed for high-power pressure washing that is likely to damage roof shingles, tiles, or siding.

Soft washing using specific angled nozzles and maintaining a distance from your more sensitive areas helps reduce the risk to sensitive plants like Japanese maples or newly planted shrubs. You want soft washing professionals like Rinse Prince in New Jersey, as they have the local knowledge to manage runoff better, use eco-conscious solutions, and help prep a space before getting to work. That expertise is worth the extra expense.

Even when you hire a pro soft washing team, you can still mitigate much of the risk to your plant life with a bit of preparation. Walk around your property and look at it about 10 feet from the roofline or siding. You’re looking for any sensitive plant life, such as young evergreens or seasonal flowers. Point them out so the workers understand which areas require extra attention. Next, trim back any overhanging branches. You want to reduce exposure

to overspray but also make the pressure washing safer and more efficient. While you’re doing this, give your plants a long soak.

It also helps to pick up some extra mulch and fertilizer once the soft washing is complete. Mulch helps retain moisture after your final rinse and regulates temperature if the water or air is too cold. It will protect the root systems of your plants while you replenish nutrients with fertilizer. Just be sure to use the correct amount for specific plants as overfertilization can stress them further. Remember to manage your expectations. Some plants may take longer than others to recover. If your garden is already struggling with too many pests, powdery mildew, or fungal infections, the soft washing isn’t going to make much of a difference. These plants have limited reserves and are unlikely to recover quickly. You may want to contact a professional landscaper or an arborist. Setting clear expectations early goes a long way to understanding your risk and ensuring

you get the best of both worlds (cleaning and lush gardens).

It really helps to hire a professional pressure washing team. All the techniques of diverting runoff, pre-wetting the garden, carefully covering sensitive plants, and neutralizing after the job sound easy enough, but when grouped, they require careful timing and precision. Experience plays a significant role in reducing missteps.

Professionals know how to get the proper chemical ratio instead of relying on the “rental guy’s” recommendations. They will adjust methods for specific property layouts and maintain the right balance of effective cleaning and plant production.

Lush gardens are common in the Northeast, especially near siding and rooflines. The right crew will work with you to protect delicate landscaping and ensure you have the curb appeal and home pride that will make your neighbors jealous.

Your home deserves a clean, beautifully maintained exterior that makes you smile each time you pull into the driveway or host a backyard barbecue. That perfect living space shouldn’t come at the risk of your landscaping. As long as you go into soft washing the roof or pressure washing the siding with eyes wide open, you’ll be able to enjoy all the benefits of a professional job well done.

Stick to the foundation principles of divert, dilute, and decontaminate. Pre-soak all your sensitive plants and cover the tops with breathable materials. Work with whomever you hire to clean your home and garden, and you’ll be glad you did. That way, when the work is done, your morning stroll involves pristine siding, clean roofs for winter, and a relaxing green space to clear the mind and soul. CT

Award-Winning System Delivers Both Pressure Washing and Soft Washing in One Professional-Grade, Space-Saving Machine

Delco, a leading brand within the FNA Group, today announced the launch of its latest innovation—the Dual Wash Pro™, a revolutionary cleaning system that combines pressure washing and soft washing capabilities in one engineered unit. Designed for professionals who demand efficiency, versatility, and performance, Dual Wash Pro eliminates the need for multiple machines, saving users time, space, and money.

Recognized as the First Place Winner of the CETA® 2025 Innovation Award, the Dual Wash Pro has already earned industry-wide acclaim for its breakthrough engineering and productivity-enhancing design. With a simple lever flip, operators can instantly switch between high pressure and soft wash modes—with no downtime, extra equipment, or wasted motion.

• Industrial Pump: Options between a nickel-plated or stainless-steel manifold

• Durable Design: Chemical-resistant components, stainless-steel fittings, and anodized die-cast housing

• Easy Integration: Compact, installer-friendly design for trailers, trucks, or fixed setups

“The Dual Wash Pro is engineered from the ground up to integrate two distinct cleaning processes into one unified platform,” said William Alexander, EVP for the FNA Group. “By combining soft wash and pressure washing capabilities through a single mechanical control system, professionals gain precise flow management, reduced equipment footprint, superior field efficiency, and, of course, a financial benefit. This recognition underscores the engineering innovation and operational value it brings to our customers every day.”

Built for demanding residential, commercial, and agricultural applications, the Dual Wash Pro offers the following:

• Soft Wash: Up to 10 gpm at 300 psi

• Pressure Wash: Up to 4,000 psi at 8 gpm

• Commercial-Grade Power: Choose from premium CRX® or Honda® engines

Proudly made in the USA* and backed by Delco’s bestin-class warranty (including a lifetime pump manifold warranty), Dual Wash Pro redefines what professionals can expect from a single cleaning system.

*Made in the USA with domestic and global components. Delco is a trusted name in industrial-grade cleaning systems and a division of the FNA Group, a leading manufacturer of pressure washers, pumps, and outdoor power equipment. With decades of engineering experience and a commitment to reliability, Delco continues to set new standards for performance and value in the cleaning industry.

Note: Product News submissions should be emailed to jkidder@cleanertimes.com. Please be sure that your product announcement is accompanied by a high-resolution photo of the product. CT

by Diane M. Calabrese

Does it hum, whir, or spin? Then “it” likely has an electric motor.

Electric motors keep devices—and their components—moving. The hush that comes over a home or workplace when there’s a gridlevel power failure signals motors that were keeping refrigerators cold, desktops cool, and buildings ventilated have stopped.

True battery backup and generators (gas, diesel, and solar) may take over, but even the switch will probably be noticed. Why would we notice? We are inured to the sounds emanating from the motors in our life, including traffic, and thus instinctively notice when the sounds disappear or change.

In just about every setting, an abrupt change in sound—including motors powering equipment on jobsites—indicates a problem. A problem that should not be ignored, however inconvenient.

Many parties have vested interest in promoting understanding of electric motors. Among them are manufacturers of the motors, motor repair technicians, makers of equipment that incorporates electric motors, the U.S. Department of Energy (Energy.gov), and environmental groups promoting clean energy.

As such, the parties make available a huge amount of information easily found in the digital world and, of course, quickly collected and aggregated by AI searchers. Let’s approach it all a bit differently to start, and then return to some of the best basic resources for those wanting to learn more, resources that happen to be at Energy.gov.

Pete Gustin is a product manager for Comet/HPP with Valley Industries— Comet Pumps in Paynesville, MN. He kindly answers a few fundamental questions regarding the relation of electric motors to equipment.

Cleaner Times (CT): Which are the essentials that you wish every powerwashing contractor knew/understood about an electric motor?

Gustin: There are way fewer moving parts, and an industrial-grade electric motor will outlast a gas engine by a long shot.

That the comparison between electric and gas is very seldom apples to apples. An electric motor allows for so many dynamic behaviors that can save energy, costs, materials, etc. It is very important to do a proper analysis with a professional to truly understand the cost savings and dynamic opportunities that an electric system can provide.

The normal limitations of 120-volt systems don’t exist when using a hybrid AC/DC motor. With these motors, a battery can act as a buffer so that amperage limitations are much, much higher, albeit for a limited amount of time.

CT: In the course of the workday, a power-washing contractor encounters/relies upon perhaps many electric motors. Which among the possible motors encountered is most interesting or concerning to you and why? [We note that home and day-beginning tools, such as a Braun electric toothbrush, have an electric motor, and welcome comments beyond the worksite—e.g., a vehicle.]

Gustin: The most interesting category of electric motors going forward will be battery-powered motors between 1.5 and 5 hp. This power range will experience a revolution over the next few years, and the days of gas engines in this range are numbered. Batteries have reached high capacities, and the cost and size are both shrinking exponentially. Almost every manufacturer of power equipment in this range is considering all battery-powered options.

CT: Concerns about the meaning attached to “motor” range from emphatic concern (motors are electric and engines are combustion) to no concern at all. If you would like to comment on the dichotomy, please do.

Gustin: Electric motors are cleaner and quieter. They require less maintenance and present less risk of fire if designed properly, and they offer enormous returns on investment. Look for

financing options and government incentives to overcome the hurdle of upfront costs that contractors and homeowners face in converting to battery electric. And study the comparisons carefully as battery-powered machines offer hundreds of advantages in equipment design, work hours, mounting options, RPM adjustments, etc.

LIFE ACCRUES TO ELECTRIC MOTORS COMPARED TO COMBUSTION ENGINES, THANKS TO FEWER PARTS. BUT AS CONTROLS (SEE STEPPER MOTORS) ARE ADDED, THE NUMBER OF PARTS REQUIRING ATTENTION MAY INCREASE. AND THERE ARE STILL SITUATIONS— LONG DISTANCE FROM THE GRID, TOO MUCH POWER REQUIRED, ETC.—IN WHICH ELECTRIC MOTORS WILL NOT BE A MATCH FOR THE APPLICATION.

In deftly handling our question about the difference between electric motors and internal combustion engines, Gustin reminds us of the many important comparisons that deserve to be made between electric motors and gas engines.

(Note: We understand the serious concern some members of our industry have about using the term motor for an internal combustion engine [ICE]. But we will not delve into it here except to acknowledge that many

thoughtful people consider the term “electric motor” redundant because motor should not be used to label an internal combustion engine.)

The Energy.gov website is an excellent starting point for members of our industry who want to learn more about motors. Technical publications, tip sheets, case studies, and energy assessment tools regarding motors can be perused by title and linked to instantly. The offerings from the

energy department include an energy assessment tool.

For example, an older (2014) Tech Brief from the energy department provides an excellent introduction to the reasons motors fail. See “Why do motors fail?” (https://www.energy. gov/sites/prod/files/2014/04/f15/tech_ brief_motors.pdf).

Here are the basics of what the brief just cited tells us. Motors fail because of heat, power supply

anomalies, humidity, contaminants, improper lubrication, and unusual mechanical loads.

The heat that leads to failure can be produced by overloading, frequent starts, high ambient temperature, low or unbalanced voltage, high-altitude operation, and inadequate ventilation. Temperatures that exceed the range for optimal performance can cause problems in multiple ways, such as contributing to the deterioration of insulation and changing the consistency of lubricants, leading to bearing failure.

There are voltage variations in the electricity supplied by the grid. Power companies strive to keep them in a narrow range, but if a significant voltage imbalance occurs (more than one percent), it can cause problems for a motor.

With grid suppliers being expected to interface with renewable (home) generation from solar and wind, voltage fluctuations are not unusual. A voltage regulator is a good idea, even though it may only be needed occasionally.

The technical brief goes into much more detail on each of the banes to a motor. And it’s a good instructional tool to use directly or as a template for training purposes. A more succinct— and more basic still—resource comes from the Energy Efficiency and Renewable Energy Advanced Manufacturing Office at the Department of Energy. It is Motor Systems Tip Sheet #3 titled “Motor Systems.”

See the motor systems tip sheet via (https://www.energy.gov/sites/prod/ files/2014/04/f15/extend_motor_ operlife_motor_systemts3.pdf). The tip that’s emphasized at the onset concerns the longevity of a motor. The more carefully a motor’s owner follows a maintenance schedule, the longer the motor will last. The caveat is that in harsh environments motors will deliver fewer hours of service before they must be replaced or refurbished.

According to the tip sheet, bearing failures, which can be precipitated by a harsh environment, account for

two-thirds of motor failures. This is where responding quickly to changes in a familiar sound can prevent a motor from incurring damage that cannot be repaired.

If something seems to be unusual about a motor—a new sound, an unexpected wobble—check out what’s going on. Vibration often signals trouble.

NEMA [National Electrical Manufacturers Association] establishes the standards for protecting motors. It sets the limits for ambient temperature, voltage variation, frequency of starts, etc. The limits, which will be conveyed with the motor, should not be exceeded.

Electric motors are daily fixtures for members of our industry. They power pumps, compressors, vehicles, fans, and drills.

Obviously electric motors can provide power in environments where safety would be compromised by a combustion engine. In parking garages, using a diesel-powered

pressure washer with insufficient ventilation is hazardous.

Ventilation through partially open garage walls—and augmented by fans—is not enough. Contractors opt to run long hoses from washers running outside the garage to avoid risk of exposure to elevated carbon monoxide levels, but the longer hoses diminish the efficiency of the job.

The potency of combustion engines— higher energy output per unit of fuel— is attractive, but the interest in finding ways to switch more functions to electric motors continues to grow.

Continuous improvement in direct current (DC) motors, such as brushless DC motors, is allowing for longer service and greater efficiency. (As a nice aside, many notice the lower noise level with brushless DC motors.)

The types of electric motors go well beyond the simple AC versus DC divide. But that divide is generally the first subdivision made. Because rectifiers can be deployed to change AC to

DC and then feed a device as a battery would, the division gets murky right from the start.

General subdivisions for AC motors are induction (asynchronous) and synchronous. General subdivisions for DC motors are brush, as well as brushless, and stepper [moving in discrete steps rather than a continuous rotation].

Stepper motors may be either DC brushless, or DC achieved through a rectifier. A stepper yields precision in movement in rotation and angularity. The stepper is a crucial player in medical applications and in robotics.

Longer life accrues to electric motors compared to combustion engines, thanks to fewer parts. But as controls (see stepper motors) are added, the number of parts requiring attention may increase. And there are still situations—long distance from the grid, too much power required, etc.— in which electric motors will not be a match for the application. CT

In November 2025 the CETA Edge column focused on “Plans and Perspectives 2026” and had comments from the new CETA president, Gus Alexander.

Several of the new CETA board of directors shared their comments in the article and are serving on the board now. We wanted to introduce you to them:

by Diane M. Calabrese

usiness as a garden works well as metaphors go.