Please contact the TRT service department if you have any questions about your trailer. Please list the model number and Vehicle Identification Number (VIN) in all correspondence.

Contact your local distributor.

Supplied Trailer Information

Supplied documentation (electronic) comprises the following: Operating Procedure, Risk Analysis, Rated Capacity, Parts Catalogue and Service Manual.

Any modifications made to the Trailer must be approved by manufacturer. Failure to gain written approval will void warranty.

Vehicle Identification Number (VIN)

When corresponding with the manufacturer the VIN should be included, it will be used to identify the trailer. (VIN is located at the front of the trailer.)

Manufacturer

TRT Tidd Ross Todd Ltd 48 Maui Street

Pukete Industrial Estate

Hamilton 3200, New Zealand

Phone: +64 7 849 4839

Fax: +64 7 849 3628 trailers@trt.co.nz www.trt.co.nz

TRT Australia 1028 Lytton Road, Murarrie, QLD 4172

Australia

Phone: +61 7 3890 8800

AU Parts: parts@trtaust.com.au

AU Service Group: service@trtaust.com.au www.trtaustralia.com.au

4.3.5

5.

5.8

6.

7.

8.

VIN

5-LINE A TRAILER:

7A9AS0485RH002001 MODEL: PF5H120FOD

3-LINE MODULE:

7A9AS0485RH002002 MODEL: PF3H54FOD

2-LINE MODULE #1:

7A9AS0485RH002003 MODEL: PF2H36FOD

2-LINE MODULE #2:

7A9AS0485RH002004 MODEL: F2H36FOD

TARE WEIGHT: (Incl Ramp)

5-Line (Lead Trailer Only)

7-Line (5+2)

8-Line (5+3)

9-Line (5+2+2)

10-Line (5+2+3)

12-Line (5+2+2+3)

Ramps 2500kg

GVM RATING:

5-Line (Lead Trailer Only) –

7-Line (5+2)

8-Line (5+3)

9-Line (5+2+2)

10-Line (5+2+3)

12-Line (5+2+2+3) 216,000kg

AXLE RATING 16 tonne per line on highway 25 tonne per line below 8kph

DECK LENGTH (Behind Gooseneck): 25.752m

DECK HEIGHT: 865mm Lowered 1000mm Travel Height 1510mm Raised

AXLE SPACING:

5 - Line (A Trailer)

7 - Line (5+2)

8 - Line (5+3)

9 - Line (5+2+2)

10 - Line (5+3+2)

12 - Line (5+3+2+2)

Steer Axis 62% of combined trailer length

3.2 Wheel Assembly

4.1 Electrical

4.1.1 Trailer Plan View

WIRING LOOMCOMPUTER

WIRING LOOMLIGHTS

SUSPENSION & STEERING VALVES

ELECTRICAL ENCLOSUREREMOTE RECEIVER2x COMPUTER

POWERPACK1x 24V BATTERY (COMPUTER)1x 12V BATTERY (MOTOR START)

Inputs

NameAssignmentPin

IN_75

Frequency NPN

A Controller INPUTs and OUTPUTs

RC28-14/30 Controller

109Wheel Speed Sensor #1 Pulses per Rev 80, Wheel Diameter 215/75R17.5, Wabco Sensor Prt No ??

IN_73 Frequency NPN 110Wheel Speed Sensor #2

IN_52 Current 0- 20 mA138A1_LH_Steer_Signal

IN_53 Current 0- 20 mA168A1_RH_Steer_Signal

IN_54 Current 0- 20 mA218A2_LH_Steer_Signal

IN_55 Current 0- 20 mA229A2_RH_Steer_Signal

IN_56 Current 0- 20 mA171A3_LH_Steer_Signal

Pulses per Rev 80, Wheel Diameter 215/75R17.5, Wabco Sensor Prt No ??

IN_57 Current 0- 20 mA227A3_RH_Steer_Signal 4-20 mA Temposonic 220 mm stroke

IN_58 Current 0- 20 mA167A4_LH_Steer_Signal

IN_59 Current 0- 20 mA169A4_RH_Steer_Signal

IN_1 Voltage 0-5 volts 250Hydraulic Pressure Sensor

IN_2 Dig IN 236Local Control Selector

IN_3 Dig IN 209Remote Control Selector

IN_4 Dig IN 147Gooseneck up PB

IN_5 Dig IN 223Gooseneck down PB

IN_6 Dig IN 148Suspension Left Up PB

IN_7 Dig IN 159Suspension Left Down PB

IN_8 Dig IN 158Suspension Right Up PB

IN_9 Dig IN 214Suspension Right Down PB

IN_10 Dig IN 157Widening A Front LHS IN PB

IN_11 Dig IN 252Widening A Front LHS OUT PB

IN_12 Dig IN 238Widening A Rear LHS IN PB

IN_13 Dig IN 222Widening A Rear LHS OUT PB

IN_14 Dig IN 210Widening A Front RHS IN PB

IN_15 Dig IN 136Widening A Front RHS OUT PB

IN_16 Dig IN 137Widening A Rear RHS IN PB

IN_17 Dig IN 135Widening A Rear RHS OUT PB

IN_18 Dig IN 134Spare Input 1

IN_19 Dig IN 211Spare Input 2

IN_20 Dig IN 144Spare Input 3

IN_21 Dig IN 224Spare Input 4

Outputs

NameAssignmentPin Function

OUT_1PWM output for M4-12 Valve Coil153Axle A1, LH Rotate CW

OUT_2PWM output for M4-12 Valve Coil177Axle A1, LH Rotate CCW

OUT_3PWM output for M4-12 Valve Coil154Axle A1, RH Rotate CW

OUT_4PWM output for M4-12 Valve Coil178Axle A1, RH Rotate CCW

OUT_5PWM output for M4-12 Valve Coil151Axle A2, LH Rotate CW

OUT_6PWM output for M4-12 Valve Coil175Axle A2, LH Rotate CCW

OUT_7PWM output for M4-12 Valve Coil152Axle A2, RH Rotate CW

OUT_8PWM output for M4-12 Valve Coil176Axle A2, RH Rotate CCW

OUT_9PWM output for M4-12 Valve Coil149Axle A3, LH Rotate CW

OUT_10PWM output for M4-12 Valve Coil173Axle A3, LH Rotate CCW

OUT_11PWM output for M4-12 Valve Coil150Axle A3, RH Rotate CW

OUT_12PWM output for M4-12 Valve Coil174Axle A3, RH Rotate CCW

OUT_13PWM output for M4-12 Valve Coil130Axle A4, LH Rotate CW

OUT_14PWM output for M4-12 Valve Coil131Axle A4, LH Rotate CCW

mA Temposonic 220 mm stroke

Notes

OUT_01_POH_CL

OUT_02_POH_CL

OUT_03_POH_CL

OUT_04_POH_CL

OUT_05_POH_CL

OUT_06_POH_CL

OUT_07_POH_CL

OUT_08_POH_CL

OUT_09_POH_CL

OUT_10_POH_CL

OUT_11_POH_CL

OUT_12_POH_CL

OUT_13_POH_CL

OUT_14_POH_CL

OUT_15PWM output for M4-12 Valve Coil126Axle A4, RH Rotate CW OUT_15_POH_CL

OUT_16PWM output for M4-12 Valve Coil101Axle A4, RH Rotate CCW

OUT_17

OUT_18

125spare output 1

129spare output 2

OUT_19Digital Output 128Gooseneck Raise

Lower

Output

OUT_21Digital Output 107Suspension LH Raise

OUT_22Digital Output

LH Lower

Output 190Suspension RH Raise

Output 189Suspension RH Lower

Output

A FR LH Open

Output 193Widening A FR LH Close

OUT_27Digital Output 243Widening A FR RH Open

OUT_28Digital Output 241Widening A FR RH Close

Output 242Widening A RR LH Open

Output 256Widening A RR LH Close

Output 244Widening A RR RH Open

Output 257Widening A RR RH Close

IN_52

IN_54

B Controller INPUTs and OUTPUTs

RC12-10/30 Controller

20 mA

20 mA

20 mA

IN_1 Dig IN 250Ramp Up PB

IN_2 Dig IN 236Ramp Down PB

IN_3 Dig IN 209Float Ramp SW

IN_4 Dig IN 147Widening B LHS IN PB

IN_5 Dig IN 223Widening B LHS OUT PB

IN_6 Dig IN 148Widening B RHS IN PB

IN_7 Dig IN 159Widening B RHS OUT PB

IN_8 Dig IN 158Spare Input 1

IN_9 Dig IN 214Spare Input 2

IN_10 Dig IN 157Spare Input 3

IN_11 Dig IN 252Spare Input 4

Outputs

OUT_1PWM output for M4-12 Valve Coil153Axle B1, LH Rotate CW

OUT_2PWM output for M4-12 Valve Coil177Axle B1, LH Rotate CCW

OUT_3PWM output for M4-12 Valve Coil154Axle B1, RH Rotate CW

OUT_4PWM output for M4-12 Valve Coil178Axle B1, RH Rotate CCW

OUT_27Common Supply for M4-12-B2-LH243Axle B1, LH Common

OUT_37PWM output for M4-12 Valve Coil183Axle B2, LH Rotate CW

OUT_38PWM output for M4-12 Valve Coil184Axle B2, LH Rotate CCW

OUT_29Common Supply for M4-12-B2-RH242Axle B2-RH Common

OUT_39PWM output for M4-12 Valve Coil185Axle B2, RH Rotate CW

OUT_40PWM output for M4-12 Valve Coil186Axle B2, RH Rotate CCW

OUT_5

OUT_6

151spare output 1

175spare output 2

OUT_19Dig_Output 128Ramps Up Coil

OUT_20Dig_Output

OUT_21Dig_Output

103Ramps Down coil

OUT_01_POH_CL

OUT_02_POH_CL

OUT_03_POH_CL

OUT_04_POH_CL

OUT_27_DOH

OUT_37_POL_CL

OUT_38_POL_CL

OUT_29_DOH

OUT_39_POL_CL

OUT_40_POL_CL

OUT_19_DOH

OUT_20_DOH

107Ramps Float Coil OUT_21_DOH OUT_22Dig_Output

output 3

B LH Close

AUTHOR

DOCUMENT: Electrical Wiring Drawing

7 23/08/2023 Corrected incorrect drawing for Diverter outputsPg 03 Sakya E Op�onal features that can be enabled through Bodas Service.

DESCRIPTION

VER DATE

1 08/11/2022 Common wiring drawing for all Gen 4 trailers

E 2 11/11/2022 Added Push-Pull Brakes outputPg 03 Added missing pin numbers for ground pins on RC12-10/30Pg 05

3 02/12/2022 Updated pinout for 3-6 Axle Aux RC12-10/30Pg 07 Removed incorrect/extra input pins (SS FRONT LEFT & SS FRONT RIGHT)Pg 06

E 4 06/12/2022 Added Site Manual Lock Switch input pin to PT Clipon (Pg 09) and HT Clipon (Pg 11) Added Sidestep Legs to Aux RCPg 06 Sakya E 5 24/01/2023 Added Sidestep DiverterLegs as a panel input to the Aux RC12-10/30. Pg. 06 Sakya E 6 14/06/2023 Removed Detect Pins input pinsPg 04 / 09 / 11 Corrected Diverter output pins and Axle 6 Power output pinsPg 03 Removed Widening Float output pinPg 07 Added CAN loca�ons for Ride-Height inclinometersPg 05 / 13 Sakya E

NOTE: **OUT_23 is used to provide power to OUT_41 and OUT_42 only in the House Trailers.** **In Pla�orm Trailers, OUT_23 is used for widening, and power for OUT_41 and OUT_42 are connected directly to ba�ery voltage.***

is used to provide power to OUT_41 and OUT_42 only in the House Trailers.**

Pla�orm Trailers, OUT_23 is used for widening, and power for OUT_41 and OUT_42 are connected directly to ba�ery voltage.***

1-2 AxlePla�orm Trailer ClipOnRC12-10/30

4.2.1 Radio Control

CONFIGURATION TRANSMITTERAUTO OFF AFTER MINS WITHOUT D2-D10 OR H/L(1-30 MINS)

WHEN SO1/2ARE CONFIGUREDAS STOP,THEYFORMTHE PRIMARYSAFETYELEMENT,AND WHEN OPEN MUST RENDER THE MACHINE SAFE.

WHEN SO1/2ARE CONFIGUREDAS SAFTHEYPROVIDE PROTECTIONAGAINSTUNEXPECTED MOTION FROM STANDSTILL, ANDARE OPEN WHEN NO MOTION COMMANDSAREACTIVE.THEY MUSTBLOCK POWER FLOWTOTHE MOTION DEVICES WHEN IN THATSTATE.

BOTHTHE HIGHAND LOW OUTPUTS MUSTBE USED IN ORDERTO ACHIEVE SAFETYCATEGORIES HIGHERTHAN CAT1.

DO NOTCONNECTAPOWER SOURCETOANYOUTPUTSAS POWER CAN FLOW BACKTHROUGHTHE SOLID-STATE OUTPUTS WITH UNEXPECTED RESULTS. USE DIODES OR RELAYSTO ISOLATEAS NECESSARY.

LOSS OF EARTHTOTHE RECEIVER CAN POSEAHAZARD IF ALTERNATE EARTH PATHS (THROUGHTHE FLYBACK DIODES AND LOAD)AREAVAILABLE. RUN SEPARATE CABLESTO 0VAND PE. ITIS RECOMMENDEDTHATTHE RECEIVERANDTHE LOAD BE EARTHEDATTHE SAME POINT. SEE INSTALLATION MANUAL.

NOTES ON IMPLEMENTATION Node ID = 10 (0Ah) Baud Rate = 250Kbit/s

4.2.3 Tethered Control

4.2.4 Tethered Control Schematic

4.3.1 5 - Line A Trailer Hydraulic Map

3 - Line Hydraulic Schematic

4.3.6 2 - Line Hydraulic Schematic

5.1 Power Pack

Battery

Battery for Starter Motor

Battery 12V 36Ah AGM (computer controll batteries)

Battery Charger 24V DC 20A (for computer controll batteries)

Coupling between Powerpack and Pump (Yanmar)

Engine Mount (Yanmar / Matalastik Eng mount)

Hydraulic Pump (Axial Piston - Variable Pressure)

Inline Pressure Filter Element (Complete Unit)

Inline Pressure Filter Element 10Um (Complete Unit)

Powerpack Isolator Mounts

Return Filter Element

Rev Lifter Ram(s)

Sight Glass (Level & Temperature)

Yanmar 60hp 4cyl Diesel

5.2 Suspension & Wheels

Axles

Bush - Sus Leg Pivot ACM Tribotex 102 x 85 x 80

Gasket - Platform Suspension Seal

Shim 304 SS 112 OD x 101 ID x 1.5mm Thick

Shim 304 SS 112 OD x 101 ID x 2.0mm Thick

Shim 304 SS 112 OD x 101 ID x 2.5mm Thick

Shim 304 SS 112 OD x 101 ID x 3.0mm Thick

NS70ZZ

CBNS70MF

AMREC36-12

ELBCDC2420

TDSAE4PPD

AD6050223

R940206717

RXR928030539

RXR928022275

IH80445R1 (2/mount)

TDESS1810E

SMCD85N1650BXC6B

AMLG6-10T

4TNV98

TM862660-786.3304

CM045-A3-P7D

TDCM045-A2-P22A

CM045-A1-P10-1.5

CM045-A1-P10-2

CM045-A1-P10-2.5

CM045-A1-P10-3

Spindle nut and Washer (KIT) AU 209325GWDT

Spacer Sleeve (Cone)

Spherical Tie Rod End (Weld-On)

CM045-A1-P6

TDGK35ES

Steering Kingpin Bearing Lower IKGE100SX

Steering Kingpin Bearing Upper IKGE120SX

Steering Kingpin Grease

Steering Ram Bush TRIBOTEX BUSH 70 x 60x 70

Castrol SBX2

TD20523BU1-0B

Steering Ram Bush TRIBOTEX* BUSH 70 x 60x 70

Steer Quadrant Bush 76 x 65 x 108

Tyre (215/75R17.5 135/133 16 Ply)

Thrust Bearing for Axle Pivot

Thrust Washer - Sus Leg ACM TRIBOTEX 132 x 90 x 8

Thrust Washer - Sus LegACM TRIBOTEX

Thrust Washer - ACM TRIBOTEX 100 x 65 x 3

Thrust Bearing for Bottom Suspension Arm

Thrust Bearing for Axle Pivot

Thrust Washer SS 134 x 90.3 x 1.5mm Susp. Leg

Thrust Washer SS 134 x 90.3 x 2mm Susp. Leg

Thrust Washer SS 134 x 90.3 x 2.5mm Susp. Leg

Thrust Washer - Bottom Susp. Arm 1.5mm SS

Tyre (215/75R17.5 135/133 16 Ply)

Vee Ring seal

Wheel (17.5” x 6” 10/225 26mm Stud) ALLOY

TD20523BU2-0B

TD096-A902-P7E

OG215/75R17.6

CM045-A15-P3C

TD CM045-A15-P3C

TD CM045-A15-P4C

TD096-A902-P13B

CM045-A3-P9C

CM045-A15-P3B

CM045-A15-P5-15

CM045-A15-P5-20

CM045-A15-P5-25

CM045-A3-P8-15

OG215/75R17.6

TDVA199N

OGAGR370

Accessory Valves - Gooseneck (see tag on valve)

Accessory Valves - Suspension (see tag on valve)

Accumulator 35L/ 360 bar AES

Accumulator 20L/ Gooseneck

Rexroth custom build

Rexroth custom build

AM3426010628

AM11093201125

Cartridge Valve - Counterbalance (Rexroth) GOOSENECK R940203324

Cartridge Valve - Counterbalance (Rexroth) SUSPENSION R940007048

Cartridge Valve - Relief HYRV1026A0N35

Cartridge Valve N/O Ramp Float HYSV10-24

Check Valve 3/8 Bolster FT260/6-38

Diverter Valve - 3 Port (Electric) 1/2 24vdc Watertable HY1607111

Hydraulic Pump (Axial Piston - Electronoic Variable Pressure)

RXR940206717

Handle for Suspension Locks AMDCV40-H

Manifold - Counterbalance (Steel) (Rexroth) SUSPENSION R940000716

Manifold Ramp Float HYHS1020P6N_B

Manifold for SVC10-22 Bolster HS1020P6_B

Pressure reducing cartridge Bolster PR1032AON08

Pressure reducing cartridge Manifold Bolster HS1030P6

Pressure sensor 0...280 Bar

RXR917A05562

Steering Valves (see tag on valve) Rexroth custom build

Solenoid valve NO 24vdc (one way check) AES

RXR940205272

Solenoid Coil for Ram / Widening Float (flying leads)Ramp Float 6352024

Solenoid cardridge valve Bolster SV 10-22

Valve Assy for Suspension Locks (incl. Handle) PLATFORM TDLVASS0812

24V Coil (flying leads) Bolster 6356024

5.3.1 Hydraulic Rams And Ram Parts/ Platform Specific

Clip-on Lock 125MM x 3.0” x 290mm

Gooseneck Ram 8.0 x 3.5” x 525mm (AU)

Ramps 4’x 2’ x 406MM

TDHYD53-001

TD299-5002

TDRR10050406Z

Steering Ram Position Sensor (220mm Stroke) Inside steer rams TDLA4421

Steering (Inc Tempersonic)

Widening - Front & Rear 100 x 50 x 670

Widening - Front & Rear 100 x 50 x 700

TDPL-22186H

TDPL-304-5001H

TDPL485-100-001-A

Air Toggle Switch SL216050

Check Valve 434/014/000/0

Control line filters

432/500/020/0

Drain Valve (Pull) WH12104

Pressure Limiting Va;lve 0.5bar Brake-by-wire kit

475/015/040/0

Pressure Protection Valve (65PSI) BX277147

Quick release valve MDKN32005

Quick release valve (WABCO) 973/500/000/0

Relay Valve for Service Brakes 2 Port (Sealco) SL110360

Relay Valve for Service Brakes 2 Port (Wabco) 4psi 973/011/006/0

Relay Valve for Spring Brakes 2 Port (Sealco) SL110701

Spring Brake T30/30 w/ Heavy Duty Housing AL3030SBGC-TSE

Slack Adjuster Auto 10spl 16mm Offset LH

Slack Adjuster Auto 10spl 16mm Offset RH

TM8180960

TM8180960

Wabco REV Towing Kit 971 002 150 0

Yard Release Valve SL17600B

12/24v solenoid NC Brake-by-wire kit

5.5

CDisplay Unit

Display Unit Mounts

Display Unit Plug

Controller BODAS RC28-14/30

Controller BODAS RC12-10/30

Controller BODAS RC10-10/31

Controller PLUG 154 PIN

WA4721271400

RXR917010009

RAM (manufacturer)

RXR917010017

RXR917A07683

RXR917A08181

RXR917A10287

RXR902603622

Gooseneck Rotary Encoder ELRM9000

Gooseneck Rotary Encoder (alt supplier - CAN Automotion Pty VIC Au)

WDGA-36J-10-1218-CO-AB-00

Elbow Connector (Encoder - 5 pin)

ELWACA057

EL22260128

Encoder Gear

Remote Control Transmitter / Receiver (Custom built)

Remote Control CAN Wired Handset (Custom built)

Cable - Devicenet DataThick (Purple PUR Sheath)

Cable - Devicenet DataThin (Purple PUR Sheath)

Cable - Olflex Truck Control Cable 2x6 3x1.5+(2x1.5)

5.5.1

ABS/EBS 7-Pin Plug w/ Screw Terminals

E18GB-3-A8-P2

TDDYNAMIC

TDDYNAMIC

EL2170344

EL2170345

EL7027093

HA8JA007644051

EPIC H-B 6 Box Mount Base (with cover) M25 thread CAN tethered remote LAPP-79015600

EPIC H-B 6 Hood M25 thread CAN tethered remote LAPP-19011000

EPIC H-BE 6 BF Female Insert CAN tethered remote LAPP-10401000

EPIC H-BE 6 Male Insert CAN tethered remote LAPP-10400000

Ignition Switch Yanmar

Spiral Cable (Suzie) 15 core 4Mtr

HA8KA007648041

Suzi Cable w/ 7-Pin Trailer Plug AM82524

15-Pin Plug Round

15-Pin Socket Round

8-Pin HD30 Circular Connector (Motor plug)

5.6

Beacon Rotating 12/24V

Combination Light Rear LED (Indicator/ Stop/ Tail) w/ 3m Cable

HA8JA007241-021

HA8JB007242-011

ELACX2921

BCN01A

ELCRL280LED3M

Licence Light (LED) HA2559

Indicator Light (Amber) - Side HA2031

Marker Light (Red / Amber) HA2053

Marker Light (White) HA2054

Marker Light (Red) HA2307

Marker Light (Green) HA95963055

Reflector Rectangle 105mm x 55mm (Red) HA2926

Work Lamp LED HA1539LED

OVER SIZE 2 pce Class 2/ 450x600mm/ Al/SIGN

Rear marker with ‘DO NOT OVERTAKE’ (Au deligniator)

Rear marker with ‘DO NOT OVERTAKE’ (Au deligniator)

SPRING - Oversize Sign & Slack Adjuster

TRT Name Plate (Alloy) AUST

Trailer Decals

CIXT008/A

CIXT028/AL

CIXT028/AR

BW0539726030

TDTRTPAU

TRT Custom

Grease manifolds Alemlube

Kingpin - 3.5” Bolt up

JTKZ1016

Ramp Twitch AM685GHLB

Slew Ring for Platform Trailer E24VI097B

Support Leg Pin

Tool box T-handle

AMS9160

AM10502-CH510

6

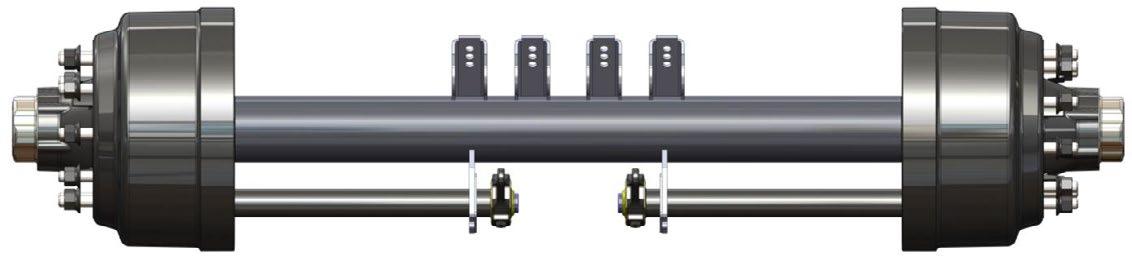

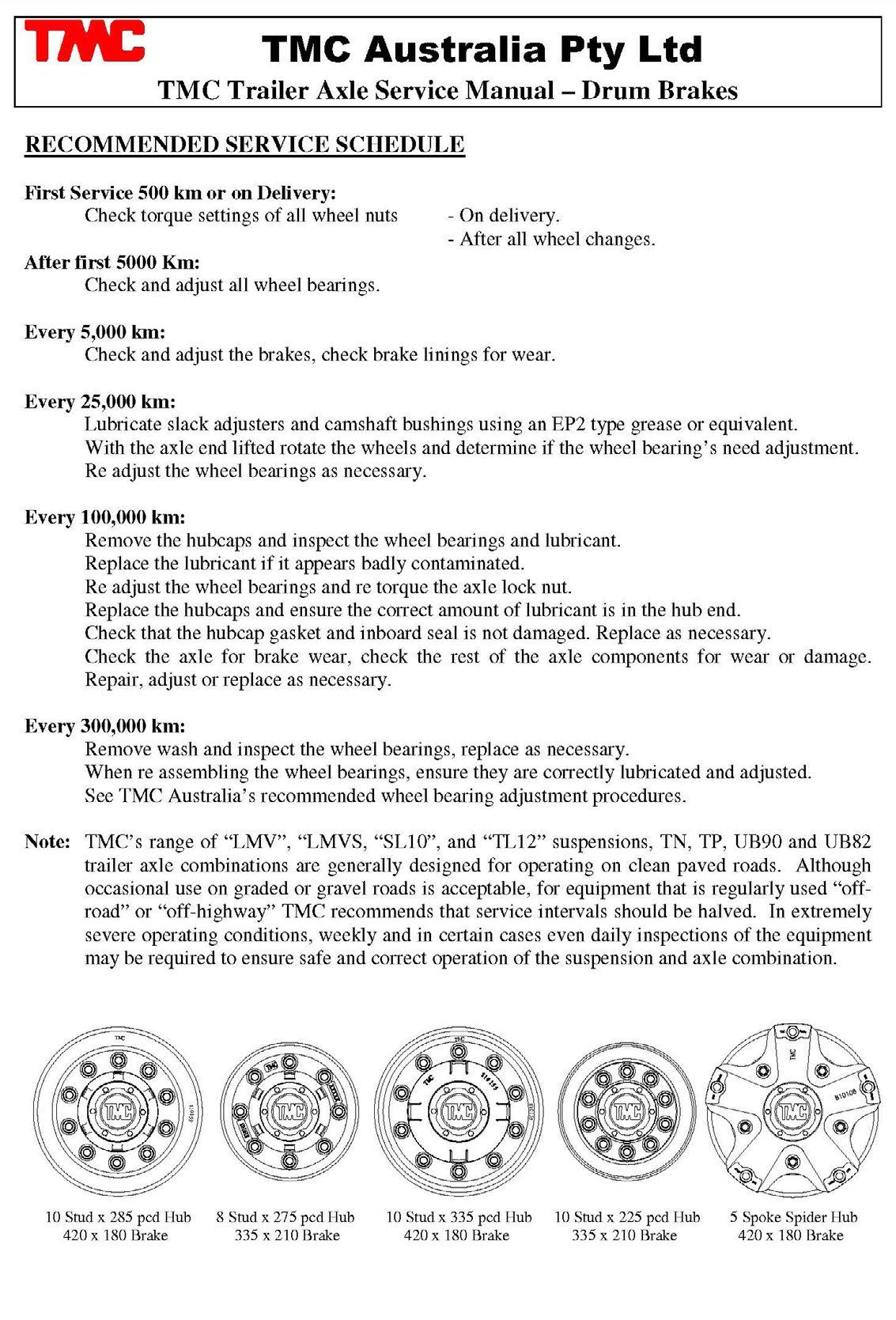

SPARE PARTS - AXLE MODELS PFRD-225-167 and PFRD-245-167

TN and TP Axles with 420 diameter x 180 wide ‘S’ cam brakes (16.5” x 7”).

5

TMC Axle and Suspension Spare Parts Listing

SPARE PARTS - AXLE MODEL PFRD-U82-136S.

Unitised Axles with 335 diameter x 210 wide ‘S’ cam brakes and Axles with 335 diameter x 160 wide ‘S’ cam brakes.

8

9

32 810061 Outer cam bushing

33 810105/616L& R Camshaft 10 spline – 616 long (L&R)

34 810122 Camshaft washer

35 810121 Camshaft circlip

36 810091 Enclosed cam tube assembly

37 810087 Enclosed cam tube support plate

38 810081 Enclosed cam tube seal – inner

39 810082 Enclosed cam tube seal – outer

40 9HNM10 Hex nut M10

41 9FWM10 Flat washer M10

42 SWM10 Spring washer M10

810169 ABS pole wheel – 100 tooth

810169/80 ABS pole wheel – 80 tooth

810300 ABS axle kit – 100 tooth

810300/80 ABS axle kit – 80 tooth

1

Brake chamber Type 16/16 universal 820133

Brake chamber Type 12/16 universal 820138

Brake chamber Type 14/16 universal 820139

Brake chamber Type 14/24 universal 820140

Brake chamber Type 20/16 universal 820149

Brake chamber Type 20/24 universal 22 820132

Brake chamber Type 16 universal 820134

Brake chamber Type 12 universal 820135

Brake chamber Type 24 universal

Brake chamber Type 20 universal 820136

Brake chamber Type 22 universal

(100 tooth optional) **

7. Drum Brake Service Manual

7. Drum Brake Service Manual

7. Drum Brake Service Manual

7. Drum Brake Service Manual

7. Drum Brake Service Manual

# Tapered roller bearings are essentially used in trailer axles because they can sustain large radial and axial (thrust) forces at moderate speeds. The conical geometry gives a larger contact patch and less wear than with other bearings such as spherical, plain, ball and even other roller bearings (needle, cylindrical etc).

# Tapered roller bearings are based on the fact that cones that meet at a point can roll over each other without slipping. In taper roller bearings, the line of action of the resultant load forms an angle or taper with the bearing axis. Taper roller bearings are therefore particularly suitable for carrying combined radial and axial loads. The steeper the cup angle, the greater the ability of the bearing to handle axial loads.

# Tapered roller bearings consist of four parts: inner and outer rings, tapered raceways and tapered rollers and cages. The inner ring and roller assembly is called the cone. The outer ring is called the cup.

# Bearing capacity and life are usually measured as:

• Static load capacity (Co) is the maximim static load (bearing not rotating)

• Dynamic load rating (C10) is that load which will cause 10% of sample of bearings to fail at or before 1 million revolutions. 90% of bearings would achieve at least 1 million revolutions at this load.

# Tapered roller bearing load life is usually measured in the number of revolutions which can then be translated to hours at a known speed.

WHEEL BEARING ADJUSTMENT PROCEDURE – MANUAL ADJUSTMENT

Double Axle Lock Nuts and Lock Washer – TN Wheel Bearings, Suits drum and disc brake axles.

Recommended wheel bearing adjustment procedure:

1. Ensure that the hub rotates freely in both directions. If any brake drag (binding) is felt temporally back off the brake adjustment to ensure free rotation of the hub.

2. Rotate the hub in both directions and at the same time tighten the wheel bearing adjusting nut until a torque setting of 150/180 Nm is reached.

3. Then back off the adjusting nut five (5) holes, use the axle lock washer as a guide. Refit the axle lock washer, taking care that the wheel bearing adjustment is not disturbed. Fit the lock tab washer. Fit the axle locknut and tighten to a torque of 350/400 Nm.

4. Check the bearing end float is 0.08mm to 0.20mm. Finally check that the hub rotates freely. If it does not rotate freely it may be necessary to redo the wheel bearing adjustment procedure. If necessary, now re adjust the brakes.

5. Bend two of the tabs (one on opposite side) on the lock tab washer over to prevent the locknut from coming loose in service.

SPINDLE ADJUSTING NUT

SPINDLE LOCK NUT

WHEEL BEARING ADJUSTMENT PROCEDURE – PRESET

TN Double Axle Lock Nuts and Lock Washer

Recommended wheel bearing end float checking procedure:

1. Ensure that the hub rotates freely in both directions, back off brakes if necessary.

2. Rotate the hub in both directions and at the same time tighten the wheel bearing adjusting nut until a torque setting of 390/410 Nm is reached.

3. TN - Fit the axle lock washer onto the axle. Adjust the adjusting nut TIGHTER if necessary to get the lock washer properly seated onto the adjusting nut. Fit the lock tab washer then the axle locknut and tighten to a torque of 290/310 Nm. Bend two tabs of the lock tab washer against the lock nut to prevent it coming loose in service.

4. Check the bearing end float is 0.08mm to 0.20mm. Finally check that the hub rotates freely. If it does not rotate freely it may be necessary to repeat the wheel bearing adjustment procedure. Re adjust the brakes if necessary.

Axle Spindle Adjusting Nut TN Part No. 810124

TN AXLE SPINDLE NUTS

Axle Spindle Locknut TN Part No. 810125

TN AXLE NUT SPANNERS

Recommended end float procedure (follow below or Timken method):

1. Ensure locknut has been torqued to 350/400 Nm.

2. Before bending the tabs on the lock tb washer, place magnetic base with dial indicator attached to spindle, and then line up dial indicator with the outer hub face so that it just makes contact with the hub.

3. Place pry bar in between the hub and lockwasher and apply a firm and even force to pry bar (up and down). The dial indicator reading (bearing end float) should be no less than 0.08mm and no more than 0.20mm. If the setting is correct, bend the tabs over. If setting is incorrect, readjust the adjusting nut and re -torque the locknut. Repeat process.

AXLE SPINDLE NUT TIGHTENING PROCEDURE – UB82

Double Axle Lock Nuts and Locktab Washer

Recommended wheel bearing end float checking procedure:

1. Apply a light film of anti -seize grease to the spindle bearing surface. Install hub ensuring seal is not damaged during installation. Apply a light film of anti -seize grease to the spindle thread and fit the axle spindle nut (part 812015). Tighten to 1000 Nm.

2. Fit the axle lock tab washer (part 812017) onto the axle spindle.

3. Fit the axle spindle lock nut (part 812016) onto the axle spindle and tighten to 800 Nm.

4. Bend the lock tab washer tabs both inwards over the axle spindle nut and outwards over the axle spindle lock nut to ensure they cannot move. Apply a light smear of grease over all the parts on the axle spindle end to prevent rusting. Finally refit the axle hubcap and gasket onto the axle hub end. Tighten the hubcap studs (M8) to 20 / 25 Nm.

UB82 AXLE SPINDLE NUTS

Axle Spindle Adjusting Nut UB82

Part No. 812015

Axle Spindle Locknut UB82

Part No. 812016

UB82 AXLE NUT SPANNER

1. Clean and inspect the wheel bearings and seal bore each time the hub is removed or when contamination is evident. Replace all damaged bearings and seals as a unit if any of them is damaged.

2. Follow the lubrication and bearing service interval requirements.

1. Separate the hub from the spindle and wheels.

2. Thoroughly clean and degrease the hub with a nonflammable solvent.

3. It is recommended that the hub be heated evenly throughout in an oven or in boiling water to approximately 100 dec C. See below for an alternative method.

4. Remove the hub from the oven or water and quickly press out the bearing cup. Take care to avoid damage to the bearing cup bore and shoulder. (Variations within tolerances of materials and oven temperatures may allow the bearing cup to drop in and out easily).

Alternate Procedure:

Use an electric welder to weld a large bead around the inside surface of the bearing cup.

Do not deposit weld spatter on to the hub. Let the assembly cool or quench in water. The weld will cause the cup to shrink enough to allow it to be easily removed.

5. To replace the bearing cup, heat the hub evenly as in step 3 above.

6. Remove the hub from the oven or water quickly and press in the new bearing cup. Be sure the cup is properly aligned and fully seated. Take care to avoid damage to the bearing bore and shoulder. Be sure both cups are fully seated before installing the hub. If the cup is being pressed into an unheated hub, additional installation force will be required. To reduce the installation force the cup can be put in a freezer for an hour Prior to installation.

1. Thoroughly clean and dry the hub in the bearings cups and hub void area. The cleaning operation should be conducted using a clean solvent damped cloth and then wiped clean with a dry cloth. Inspect for damage to the bearing bore and indication of movement of the bearing cone during service. Replace the hub if there is any evidence of damage.

2. Warm hub in either an oven or by hot water to approximately 100 Deg C.

3. Quickly press in a new bearing cup, using a suitable pressing disc. Make sure the cup is correctly aligned and fully seated in the hub. Take care to avoid damage to the bearing bore and shoulder.

4. If the bearing cup is pressed into an unheated hub, additional Pressure will be required. This can be reduced by placing the cup in the freezer for approximately 1 hour prior to installation.

5. Grease the bearing cones, hub and spindle surface in accordance with the specification. Mobil XHP222 (NLGI Grade 2) or equivalent lithium complex grease is to be used.

6. Fit the pre-greased inner bearing cone inside the hub and cup. Fit the hub seal and drive the seal home against the hub shoulder using the a hammer and seal installation tool. Ensure the seal is free and can move

7. Lift the hub/drum assembly and slide the assembly onto the spindle. Ensure the inside of the drum is clean.

8. Using the inner bearing seating tool, drive the inner bearing cone home against the spindle shoulder. Ensure the bearing is hard up against the shoulder.

9. Fit the pre-greased outer bearing cone using a seating tool, fit the spindle adjuster nut, lock washer, lock-tab washer and spindle adjusting nut.

10. Adjust the wheel bearings in accordance with the specification, and then replace the hub cap with the new gasket.

11. New wheel bearing seals and hubcap gaskets need to be installed during a bearing installation. Seals should be replaced every time the hubs are removed from the spindle. Refer to the seal installation guideline.

UB82 SPINDLE MOUNTED HUB SEAL PRESS TOOL 9. Bearing Adjustment and Seal Installation Guidelines

UB82 BEARING and HUB SEAL INSTALLATION

9. Bearing Adjustment and Seal Installation Guidelines

GREASE IN BEARINGS:

Grease should be applied evenly in the bearings so that the bearings are packed. Traces of grease should appear from the surface of the cone. For proper lubrication, the grease must be packed between the rollers and cage of the bearing cones. A mechanical grease packer will improve the procedure of packing the bearings. Store pre -greased bearings covered and in a clean environment for protection from dust and dirt.

GREASE IN HUBCAPS:

There should be atleast 0.5 to 1 cm high of grease inserted in the grease hubcap.

GREASE IN HUBS:

Grease should be applied evenly around the hub cavity or “hub well” and filled to a line running from inner bearing cup diameter to outer bearing cup diameter. Always ensure that this “packing grease” is distributed evenly around the “hub well”, to ensure satisfactory lubrication of the bearings

GREASE ON SPINDLE

SURFACE:

Grease should be lightly smeared over the complete surface of the spindles.

9. Bearing Adjustment and Seal Installation Guidelines

The recommended grease to be used in our axles is a Lithium Complex type grease NLGI grade 2. Mobil HP 222 is the main Brand, but other brands such as Castrol APXT, Timken AP, or Castrol EPX can all be used.

Grease other the specified type above is not recommended. Grease with traces of Molybdenum Disulphide is not recommended. Molybdenum Disulphide is an extreme pressure additive and is readily used in applications to prevent seizure of components. Moly grease causes the grease to go black and is not recommended for rolling element bearings.

If discoloured bearing grease is observed in the hub, this is often shown by a grease with a thin, dark and muddy complexion. This could indicate that the bearings were exposed to an ingress of water and dirt or other contaminant.

Generally, discoloured bearing grease indicates one of:

(i) Exposure to high levels of heat.

(ii) Improper/Insufficient lubrication.

(iii) Improper bearing adjustment, i.e. excessive preload/end play.

(iv) Excessive wear of the rollers, rings cages etc, causing overheating.

(v) Excessive ingress of water and dirt.

The signs for excessive heat are:

(i) The grease has a decrease in viscosity, solidifies or becomes oily and tacky. It has a tendency to evaporate with increasing temperature. There is a loss in the ability to support the load.

(ii) The grease becomes oily, and has a burnt aroma.

(iii) Overloading the axle, will cause excessive heat to be generated and can cause premature bearing failure.

After the wheel bearing adjustment is carried out, the hub should then spin freely. The bearings would then be considered to be functional.

A premature bearing failure could be due to:

(i) Ingress of water and dirt or other contaminant. Grease becomes discoloured.

(ii) Excessive loads causing brinelling (severe impact to the bearing).

(iii) Manufacturing/Installation defects such as the fit of the bearing cups and cones (tolerances are out of specification etc).

(iv) Improper preload, i.e. due to bearing spacer or axle nut torque out of specification.

Too much end play could result in symptoms of noise, and erratic steering.

(v) Overheating issues.

Look for any scuffing marks, ID/OD wear etc. A premature hub seal failure could be due to:

(i) Inadequate installation, i.e was the seal cocked, or not seated correctly, was the seal installed backwards etc?.

ii) Was any lubrication present on the seal lip on the axle journal?.

(iii) Excessive heat. If the seal looks and feels rough and dry, this could be an indicator of excessive heat.

The recommended axle spindle wear limits, including inner (I) and outer (O) bearing journals and spindle end to bearing shoulder measurement (S). Axle types affected are TN,TP, UB90 and UB82.

Note:

The recommended spindle wear limits are denoted by dimensions shown with *

The recommended Brake Drum Wear Limits used in TMC 335x160, 335x210 and 420x180 drum braked axles.

DRUM SIZE

335x210 (17.5”/19.5”)

PFRD-225-138

PFRD-245-138

PFRD-U82-138

PFRD-225-136

PFRD-U82-136

(20”/22.5”)

PFRD-225-167

PFRD-245-167

PFRD-U90-167

TRT can supply service kits for the ESS Power packs

AMKITESS250 (250 hr service kit)

Fuel Filter

Oil Filter

AMKITESS500 (500 hr service kit)

Fuel Filter

Oil Filter

VEE Belt

Air Filter (inner)

Air Filter (outer)

Pressure Filter

Return Filter

Check Replace Contact your Yanmar service agent

Air Intake

Clean or replace, may need more frequent service in dusty conditions

Cylinder head Intake and Exhaust valve

Electrical

Check Battery water Before operation

Check Charging indicator At start-up

Injectors Inspect spray pattern

Check level Before operation

Drain and refill

Engine Oil

Replace Oil Filter

Check for leaks

Exhaust

Before and after operation

Check Rain flap if fitted

Fuel Fuel level Before operation

Check water trap for water, Drain if present

Replace fuel filter

Check level

Coolant

Inspect hoses

Inspect Radiator mounts

Ram Head-nut

Transducer

Plug and

Spear and Piston

Transducer Magnet

Transducer Rod

Transducer O-ring and Locating ring (Grub-screw slot)

1. Remove the ram from the trailer, Clean it and mount it in a vice, or similar, for dismantling

2. Unwind the head-nut and carefully remove the ram spear and piston from the ram Barrel. Take care to keep the Spear etc in line with the barrel as it is being removed as the transducer slides inside the ram spear.

3. Remove the 2 screws that retain the Plug to the barrel

4. Locate and remove the small grub screw that retains the Transducer in the ram

5. Pull the transducer out of the end of the barrel. Take care to thread the wires and plug through the cavity as the transducer is withdrawn from the ram

1. Inspect the ram barrel and spear to ensure it is ok to be re-used

2. Unsure the O-ring on the replacement transducer is lubricated

3. Run a draw-string through the cavity and tie it lightly to the plug.

4. As the transducer is slid into the barrel, draw the plug and wiring through the cavity (Do NOT damage the plug or wires during this process)

5. Push the transducer ‘home’ onto the seal cavity, and refit the grub-screw to hold it in place. Check the transducer is located properly and held in place

6. When the plug is all the way through the cavity, and in the correct position, secure it with its mount plate and screws.

7. Reassemble the ram by carefully sliding the piston and spear over the Transducer as it is inserted into the barrel. Tighten the Head nut

8. Test the ram for function and seal leaks before refitting

9. Test the transducer output is correct and stable as the ram is being tested.

Customer:

Gooseneck - UP / DOWN

Suspension Left - UP / DOWN

Suspension Right - UP / DOWN

Revs LOW / OFF / HIGH

Widening Controls

Ramps - UP / DOWN

Ramp Float - OFF / ON

Remote(s) Only

Remote(s) Only

Remote(s) Only

Remote(s) Only

Remote(s) Only

Remote(s) Only

Remote(s) Only

Date:

Engine start / Stop Switch

Engine Revs LOW / OFF/ HIGH Switch

Gooseneck UP / DOWN Paddle

Suspension Left - UP / DOWN Paddle

Suspension Right - UP / DOWN Paddle

Ramps - UP / DOWN Switch

Ramp Float Switch

Steer Manual Auto Switch

Steer Direction Paddle

Horn Button

Screen inputs

Diagnostics

Auto steer

Crab Auto

Manual steer

Rear Axle Straight

Steer pivot point

Speed cut-out for steer functions

Valves accessible on wheels

Adjustable using Bodas if customer requires a change

Options go grey and cant be selected

Revs Powerpack to 1800 or 2400rpm

Decals Correct Decal replacements available on request

OVERSIZE sign

Steer Alignment

Grease manifolds

Requires technician to re-set if required

Grease Main Leg pin

Protects the ramps and rams when loading the trailer

TRAILER CONFIGURATIONS

Splitting and joining the trailer

Light bars

Push bar

Dolly hook-up and hydraulic supply

Importance of clean couplers

Importance of clean couplers electrical Plugs

DO NOT HOT PLUG!

Screen set-up

120ohm resistors

TRAINER (Name and Signature)

Care in moving screen between trucks

Fitted in CAN looms

Acknowledging I/we have run the trainee through the function checks stated above.

TRAINEE (Name and Signature)

Be careful if servicing electrical plugs

DATE

Acknowledging I/we have been run through the function checks stated above.