Please contact the TRT service department if you have any questions about your trailer. Please list the model number and Vehicle Identification Number (VIN) in all correspondence.

Manufacturer

TRT - Tidd Ross Todd Ltd 48 Maui Street

Pukete Industrial Estate Hamilton 3200, New Zealand

Phone: +64 7 849 4839

Fax: +64 7 849 3628 trailers@trt.co.nz www.trt.co.nz

Contact your local distributor.

Supplied Trailer Information

Supplied documentation (electronic) comprises the following: Operating Procedure, Risk Analysis, Rated Capacity, Parts Catalogue and Service Manual.

Any modifications made to the Trailer must be approved by manufacturer. Failure to gain written approval will void warranty.

Vehicle Identification Number (VIN)

When corresponding with the manufacturer the VIN should be included, it will be used to identify the trailer. (VIN is located at the front of the trailer.)

TRT Australia 1028 Lytton Road, Murarrie, QLD 4172 Australia

Phone: +61 7 3890 8800

Email: cranesales@trtaust.com.au www.trtaustralia.com.au

4.1.10.

4.1.12.

4.1.13.

4.1.14.

4.1.15.

4.1.21.

4.1.22.

4.1.23.

4.3.

5.6.

5.7.

VIN 7A9NZ0513RH002054

Model HT3H50ABOD

Tare weight 17960kg

ATM rating 50,000kg

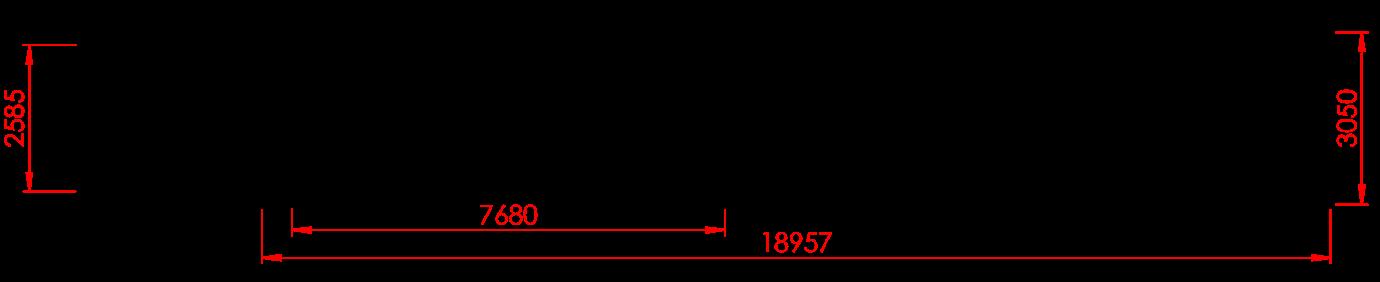

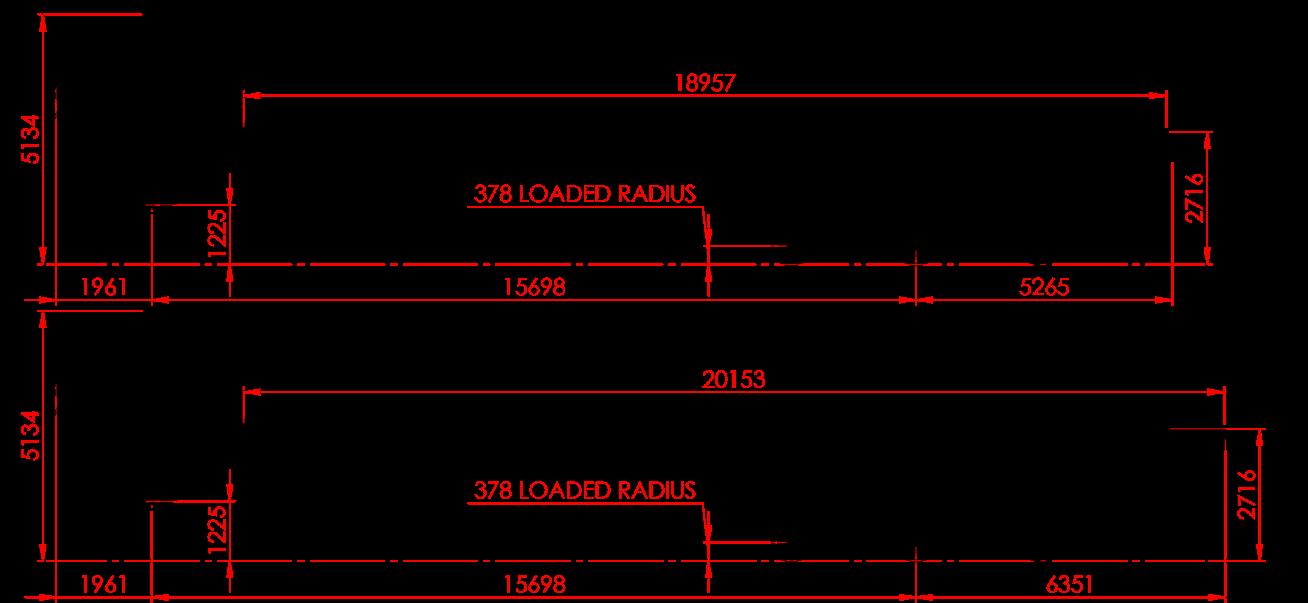

Deck length (behind gooseneck) 11,200mm (Closed) 18,900mm (Open)

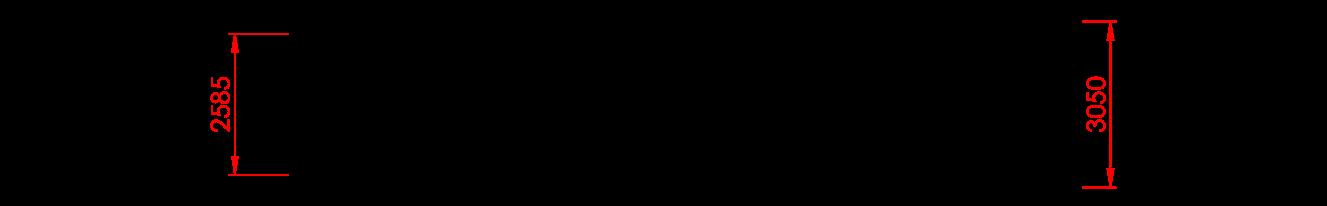

Width 3050mm

Deck height - lowered 880mm

Deck height - raised 2750mm

Axle spacing 2400mm

2.1.

2.3. Suspension Lowered

2.4. Suspension Raised

3.1. Legs

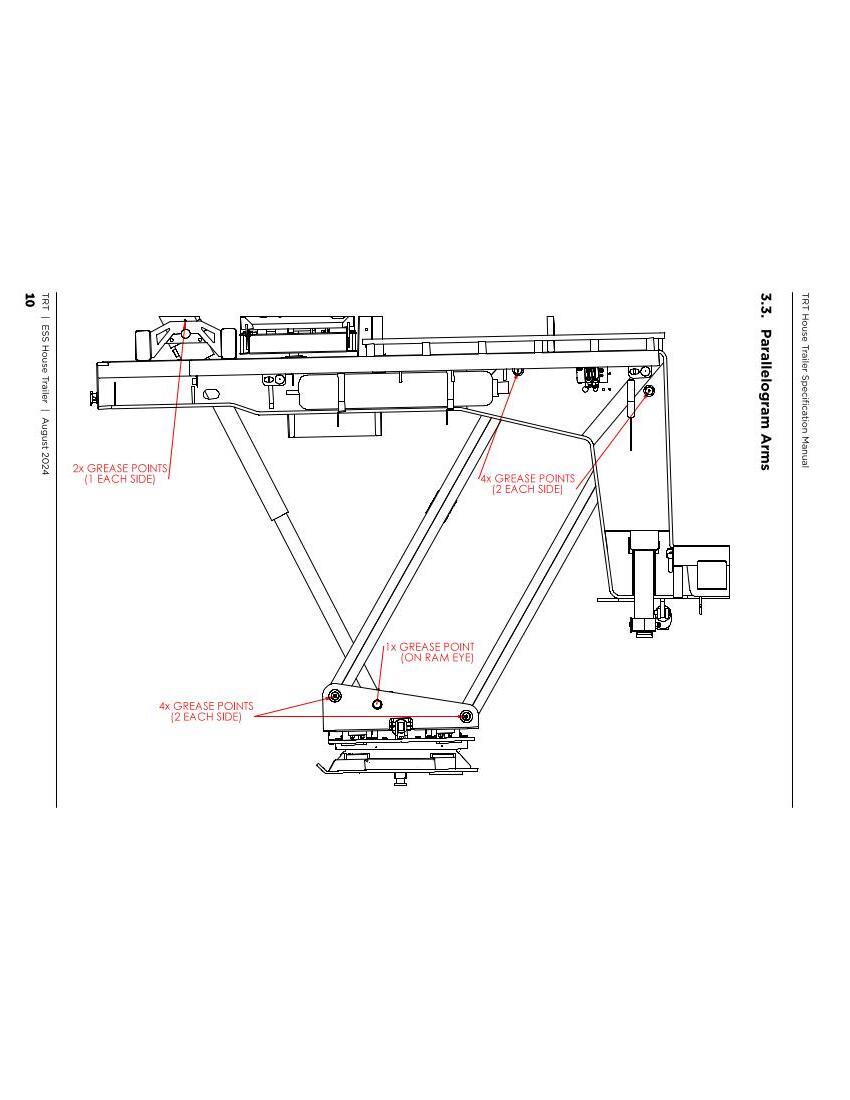

OPERATE LEGS UP AND DOWN THROUGHOUT THE GREASING PROCESS. THIS WILL ENSURE ALL COMPONENTS ARE SUFFICIENTLY LUBRICATED.

SIDES)

GREASE POINT (PIN ON BOTTOM OF RAM) 2x GREASE POINTS (1 EACH SIDE OF RAM PIVOT) GREASE POINTS 2x GREASE POINTS ON STUB AXLE PIVOT BOSS (UNDERSIDE) GREASE POINT

Grease nipple (on Ram eye @ #3)

2 grease nipple / side @#4 (total of 4) 6 grease nipples on slew ring

1 Grease nipple each @ #1 (total of 4)

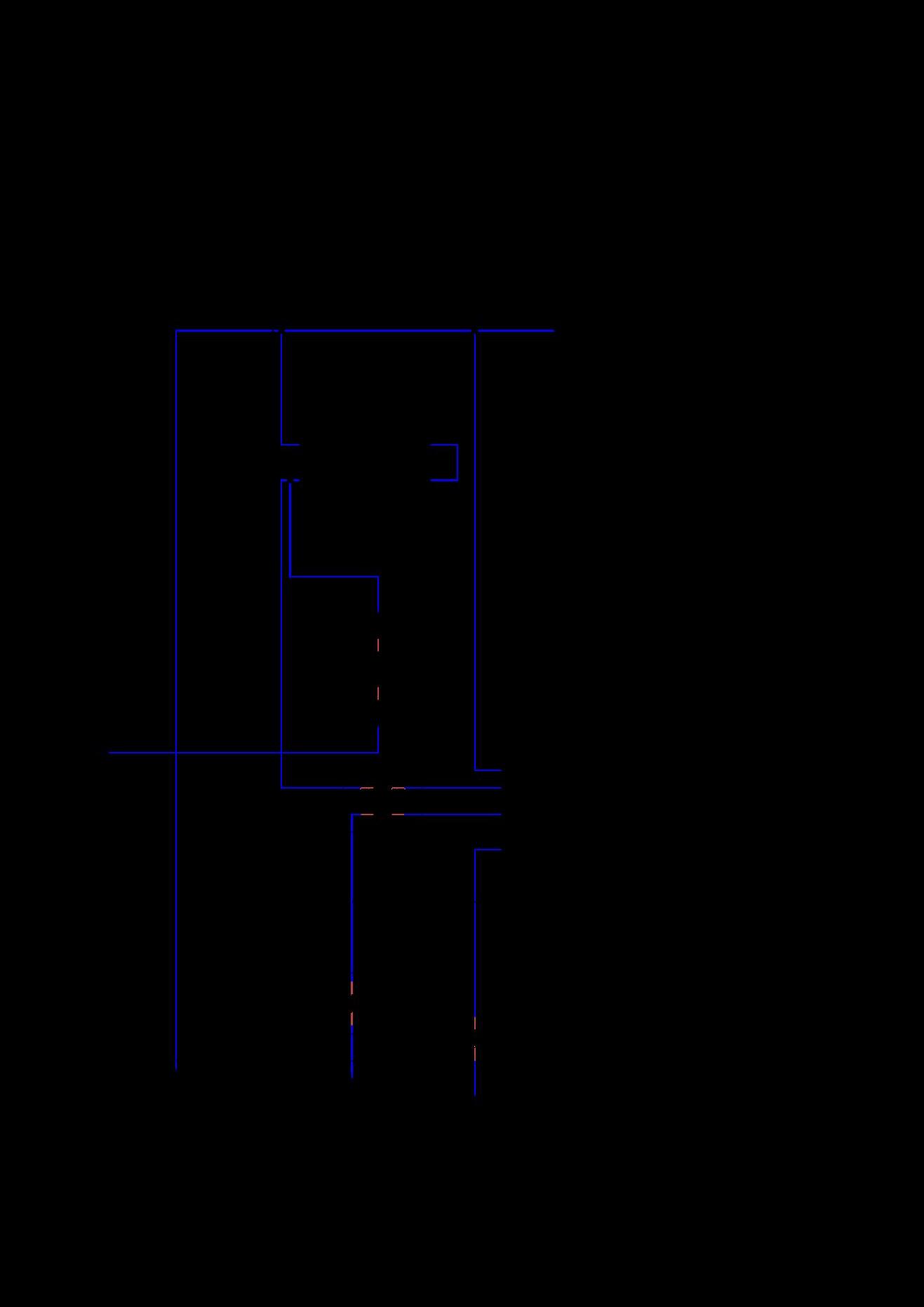

4.1. Electrical

4.1.1. Trailer Plan View

NOTE: **OUT_23 is used to provide power to OUT_41 and OUT_42 only in the House Trailers.** **In Platform Trailers, OUT_23 is used for widening, and power for OUT_41 and OUT_42 are connected directly to battery voltage.***

NOTE: **OUT_23 is used to provide power to OUT_41 and OUT_42 only in the House Trailers.** **In Platform Trailers, OUT_23 is used for widening, and power for OUT_41 and OUT_42 are connected directly to battery voltage.***

A/B Signal C Signal A/B Signal 1 2 3 4 1 2 3 4

RC12-10/30 NPN Inputs

RC12-10/30 NPN Inputs GND Pins GND Pins

RC28-14/30 NPN Inputs

A/B Signal C Signal A/B Signal C Signal A/B Detect 1 C Detect 1 A/B Detect 2 C Detect 2

3-4 Axle Trailer (A&B) 1 2 3 4 1 2 3 4

RC28-14/30 NPN Inputs GND Pins GND Pins

C Signal A/B Detect 1 C Detect 1 A/B Detect 2 C Detect 2

NOTE: Detection pins are used to determine which modules are connected in the front and back of each module. This assists in cross-checking that the correct module IDs were entered by the operator in setting up trailer configuration. E.g. if the trailer configuration was set as ABC, The A-module will detect a B-module behind it (A/B Detect 2). The B-module will detect an A-module in front (A/B Detect 1) and a C-module behind it (C Detect 2). The C-module will detect a B-module in front of it (A/B Detect 1).

*Since both the A & B modules run identical programs, the control system differentiates if an A-module or B-module is connected.

RC28-14/30

RC12-10/30

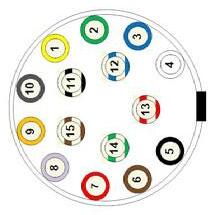

4.1.13. Controller Pin Functions

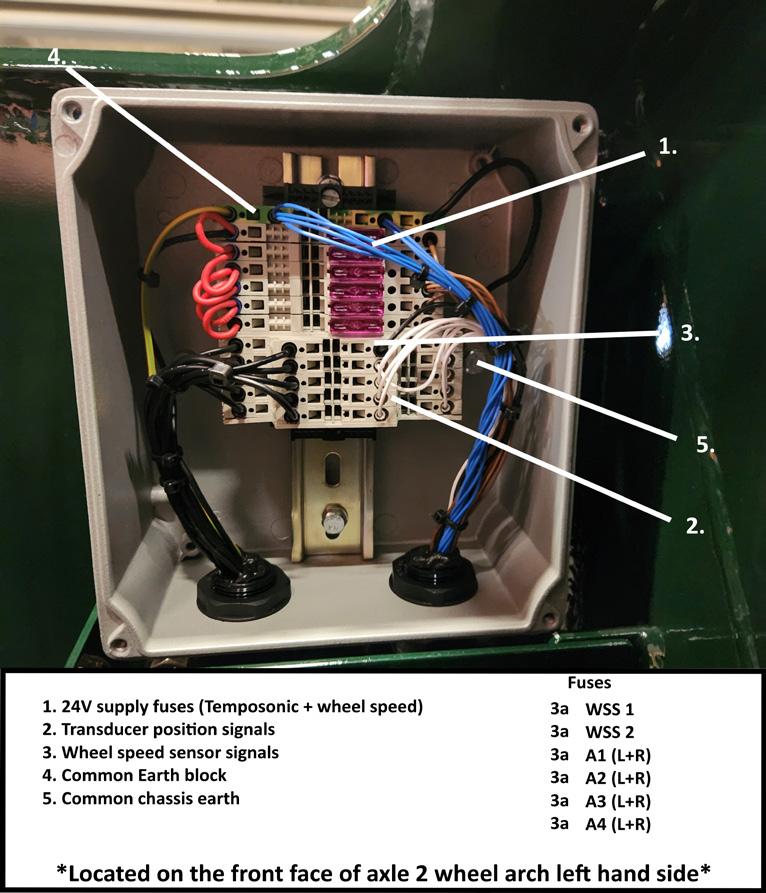

4.1.15. Enclosure Main - DIN Rail

House Trailer Either switch operate both rams Both rams operate at the same time Operating the switch ramps up the pump and gives a direction command to the valve

Pre-Alginment Checks Date: Time: Job#

Encoders Calibrated

Technician Name:

Encoder 1 Reading count:

Encoder 2 Reading count:

NOTE: Some trailers have switches for Left lower and Upper, and Right Lower and upper work lights on the 3-pin [house-lights] box on each side of the gooseneck

the suspension, clip-on rams and other auxiliary functions when specified

tail, Indicators, No.plate lights Feed to 3-pin plug enclosures for House lights (on Brown wire) Feed to beacon switch or socket (when specified)

Function and Notes

Trailer lights, Screen power and CAN,

Charge current from truck to trailer (option)

All gooseneck side lights terminate to BROWN Both Gooseneck 3-pin enclosures terminate to BROWN (option) May require (2mm)blue to main enclosure and (4mm)Blue back again for leg lights

left chassis rail under the powerpack

7-core cable to rear, exits box Powerpack On top of Gooseneck

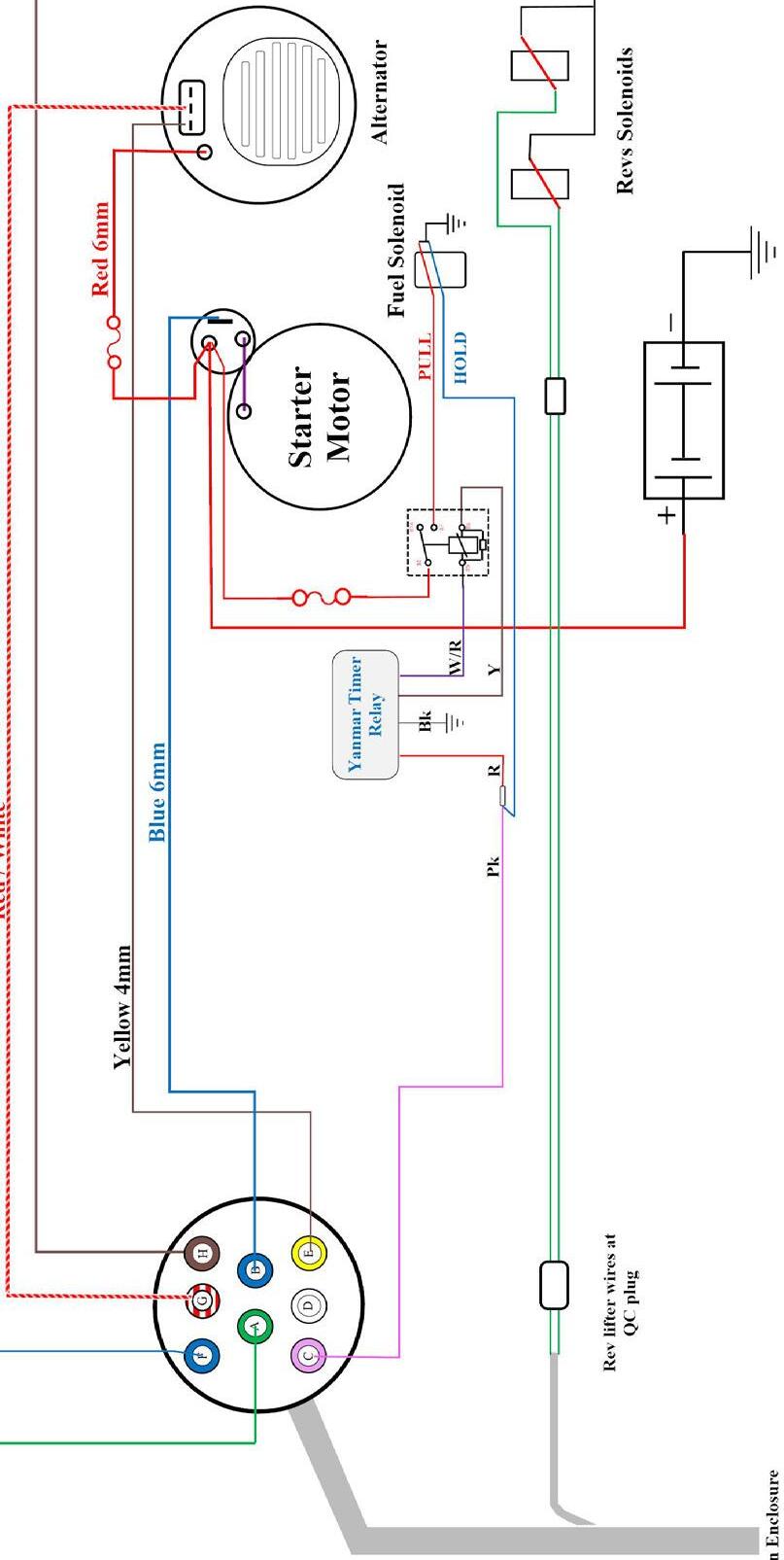

Yanmar 4TNV 98 Revs set at 1800rpm and 2400 rpm. Rexroth 28cc pump with electronic load sense controller 12 volt start and charge Battery isolator on front of powerpack when specified

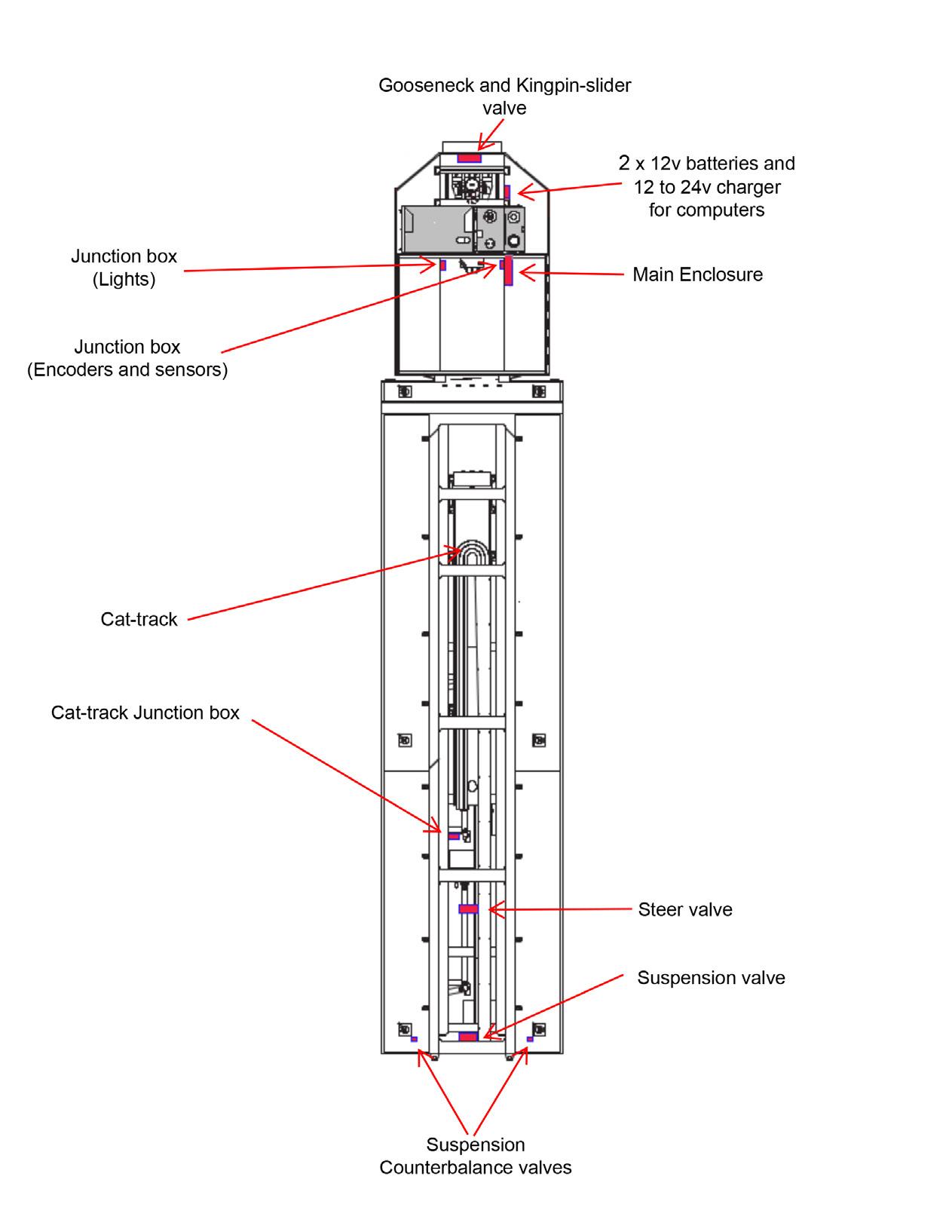

Battery pack for control system Right side of Gooseneck by main enclosure 2 x 12v AGM (Glass-pack) batteries

A 12-24volt charger uses the powerpack battery to charge the control batteries A re-settable circuit breaker controls the out current to the main enclosure 12v fuse for input 24v fuse for charge

Contains trailer ECU's and motor control (start, stop, Charge, revs etc relays)

Termination points for all major data and command supplies Has 12v, 24v and 5v supplies insideuse mustimeters for diagnostic procedures 24v Isolator on rear of box Ignition sw. on rear of box

Receives remote controller commands and send commands to trailer ECU's via the CAN system

Terminate inside main enclosure at lower work-lights switch

Main electrical enclosure Right side of Gooseneck

Remote Receiver Right side of Gooseneck on or in main enclosure

Lower Work lights Under short front deck

4.1.22. Charge

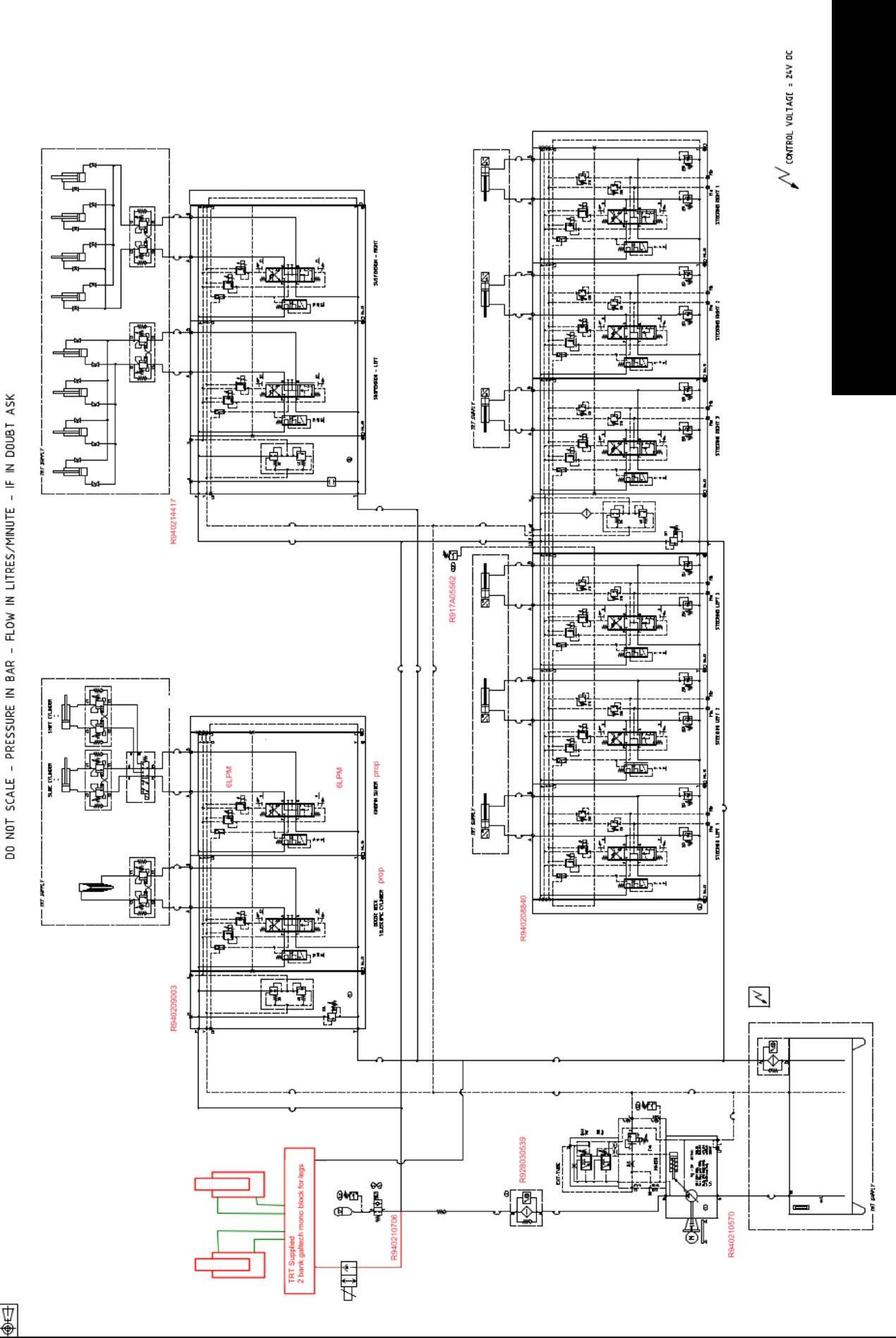

Hydraulic Schematic (Electronic Steering)

Battery (Starter Motor)

Battery (12V 36Ah AGM - Computer Control)

Battery Charger (24V DC 20A - Computer Control)

Coupling between Powerpack and Pump (Yanmar)

Engine (Yanmar)

Engine Mount (Matalastik)

Engine RPM Control Solenoid

Hydraulic Pump (Axial Piston, Variable Pressure)

Inline Filter Element (10Um)

Oil (Yanmar, 15/40W)

Return Filter Element

Rev-lifter Ram (16 Bore, 50mm Stroke)

Sight Glass (Level & Temperature)

Axles (ROR Meritor - Steer L & R Set)

Bearing (BRG Spherical 50mm ID, Suspension Ram)

Bearing (BRG Spherical 70mm ID, Leg Pivot)

Bearing (Spherical 35mm ID, Steer Ram)

Bush (Command Steering, Axle Pivot - Oily)

Bush (Parallelogram Arm, 50.85mm x 40.4mm x 72mm)

Bush (D-Glide - Ram Eye)

Circlip (Leg Pivot)

Tyre 235 70 R17.5 XTE2

Wheels (17.5” x 6.75” 10 Stud Steel Rims)

CBNS70MF

AMREC36-12

ELBCDC2420

AM91/K0203M

AM4TNV98

AMAD6050223

SSA226-02

RXR940206717

RXR928006863

AMYM222240005

TDESS1810E

SMCD85N1650BXC6B

AMLG6-10T

ROCSK2

GE50DO2RS LS

GE70DO2RS LS

GE35DO2RS LS

TDCM013-A041-024

TDCM13-A10-P009

HTCOM-A1-P8

IKIC105

235R17.5

OGAGR365

M16 NYLOCK NUT

CM13-A10-P009

HTCOM-A1-P3

HTCOM-A1-P8 HYD51-001

BRG SPHERICAL GE70 DO

CIRCLIP INT 105mm

HTCOM-A5-P1

CM13-A10-P006

CM13-A10-P005

CIRCLIP INT 105mm

BRG SPHERICAL GE70 DO

CM013-A041-024

CM13-A10-P009

CM087-007-004

CM087-007-005

22295_3.0x1.5x331

CM087-011-001

M24 NUT

CM013-A041-024

Accessory Valves (Rexroth, Gooseneck)

Accessory Valves (Rexroth, Rear of Main Chassis)

Accumulator (AES - 35L/260bar)

Cartridge Valve (Counter Balance)

Cartridge Valve (Counter Balance, Side Step)

Diverter Valve (Electric, 6 port, 3/8”, 24V, King & T Diverter)

Handle (Suspension Lock)

Pressure Sensor (0-280bar)

For repairs, quote serial number on valve as reference.

For repairs, quote serial number on valve as reference.

AM3426010628

HYCBPA-20M

HYCBPA-08

HY4003799

AMDCV40-H

RXR917A05562

Solenoid Valve (N/O, 1-Way Check, for AES System)

Steering Valves (Rexroth)

Suspension Isolation Valve Coupling (Biscuit)

RXR940205272

For repairs, quote serial number on valve as reference.

TDLVC-S753A

Valve Assembly (Suspension Locks with Handle) TDLVASS

Gooseneck Ram (2 Stage, 2300mm Stroke)

Landing Leg Ram

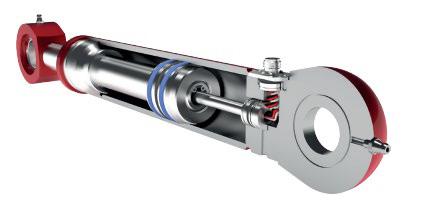

Steering Ram (Victor - 3.0” x 1.50”, 331mm

Stroke, including Transducer)

Steering Ram Transducer (331mm Stroke)

Suspension Ram (6”, 640mm Stroke)

King-pin Slider

Air Toggle Switch

TDHYD36-A1

HYD50-003

TD22295

TDLA4792

TDHYD51-001 REV B

HYD77-A1

SL216050

Brake Chamber AL24SD

Brake Chamber for Deck Locks (T30) AL30RS

Drain Valve (Pull) WH12104

Quick Release Valve (Wabco, 0psi crack) WA973/500/000/0

Spring Brake Chamber (24/30) AL2430SB

Yard Release Valve SL17600B

Cable (Devicenet, DataThick, Purple, PUR Sheath)

Cable (Devicenet, DataThin, Purple, PUR Sheath)

Cable (Olflex Truck Control Cable, 2x6, 3x1.5, 2x1.5)

Controller Plug (154 Pin)

Controller BODAS RC12-10/30

Controller BODAS RC28-14/30

Display Unit

Display Unit Mounts

Display Unit Plugs

Gooseneck Rotary Encoder

Remote Control (Transmitter/ReceiverCustom)

Elbow Connector (Encoder, 5 Pin)

5.5.1. Plugs & Sockets

15-Pin Socket (Round)

Anderson Plug Kit (2 Pole, 350A)

Housing Base Mount (for HD64 Connector)

EL2170344

EL2170345

EL7027093

RXR902603622

RXR917A08181

RXR917A07683

RXR917010009

RXR917010015

RXR917010017

ELRM9000

ELWACA057 (alternitive)

TDDYNAMIC

EL22260128

HA8JB007242-011

ELACX2764

EL79164400

Housing Top Entry (for HD64 Connector) EL19111900

Ignition Switch YANMAR

Insert Female (for HD64 Connector)

Insert Male (for HD64 Connector)

Pin Female (for HD64 Connector)

Pin Male (for HD64 Connector)

Socket (2 Pole, Marine)

Suzi Cable (Spiral, 15 Core, 4m)

15-Pin Plug (Round)

8-Pin HD30 Circular Connector (Motor Plug)

Inclinometer

EL11273000

EL11272000

EL13163300

EL13162300

HA2741

HA8KA007648041

HA8JA007241-021

ELACX2921

ELJD2110

Combination Light (LED Indicator/Stop/Tail, UV resistant) HA2331

Marker Light (Green)

HA95963055

Licence Light (LED) HA2559

Marker Light (Red/Amber) HA2053

Marker Light (White) HA2054

Indicator Light (Amber, Side) HA2031

Indicator Light (Amber, LED, Rear) HA2151

Reflector Circle (60mm, Amber) HA2916

Reflector Circle (60mm, Clear) HA2917

Reflector Rectangle (105mm x 55mm, Red) HA2926

Work Lamp (LED) HA1539

Strobe Beacon 85213A

5.7.

DO NOT OVERTAKE Sign (NZ)

Trailer Decals

TRT Name Plate (AU, Alloy)

5.8.

Kingpin - 2.0" Bolt up

CIXT037/A

TRT Custom

TDTRTPNZ

JTKZ151601 2”

Slew Ring for House Trailer L:VI085A28

TRT can provide a power pack service kit, or any individual components from the kit. The kit includes:

Fuel filter

Oil filter

Air filter (inner element)

Air filter (outer element)

Vee Belt

Yanmar Oil 15/40W - 5 litres

Yanmar Coolant - 5 litres

Pressure filter element, and

Return filter element.

Source: www.assalistefen.com/it/assali

(*) installation length is the distance between the actuator support and the center of the hole on the slack adjuster with the brake at rest. It is good practice, even though not strictly necessary, to install a return spring on the slack adjuster.

3.1 - TM SERIES AXLES

Procedures

Frequency

Specific service and maintenance intervals must be set by the person in charge of the vehicle or vehicle fleet depending on the operating conditions in which these vehicles work. Here, at any rate, are the following minimum conditions which must be complied with.

TM - Disc & Drum BRAKE AND WHEEL TIGHTENING CHECK

TM - Drum

• CAMSHAFT BUSHING AND SLACK ADJUSTER LUBRICATION

• OIL LEVEL CHECK (for oil-lubricated hubs)

TM - Drum COMPLETE BRAKE MAINTENANCE

TM - Disc BRAKE INSPECTION AND MAINTENANCE

TM - Disc & Drum HUB AND BEARING INSPECTION WITH OIL RETAINER REPLACEMENT

TM - Disc & Drum COMPLETE OVERHAUL OF THE HUB

• Before starting to work

• After 150 km

• After 1,500 km

• Every three months

• Every time the wheels are removed

• Every time the brakes are overhauled

• Every three months

NOTE: shorten the interval to six weeks when using brake lubricant other than the recommended lubricant or when the vehicle works in environments with a strong presence of abrasives

• Prior to the second yearly trailer overhaul

• Subsequently every year

• Inspect pads, caliper and disc every 50,000 km or three months

• Carefully clean caliper and rotor every 100,000 km or six months and every time the pads are replaced

• Every time the hub is removed

• Every year after the first complete overhaul

• If faults are found during inspection

• Before the second yearly overhaul or every 200,000 km, whichever comes first

• Subsequently every year or 100,000 km, whichever comes first

Recommended tightening torques in Nm (10 Nm ~ 1 kgm):

4.1 - DISC & DRUM BRAKES Description

Hub cap screws (grease lubrication) 16-30 11-15 11-15

Hub cap screws (oil lubrication) 25-30

Axle end lock nut 350-375

M22x1.5 nut (for steel and alloy wheels)

4.2 - ELSA 195 DISC BRAKES – TM and LM SERIES AXLES

Description

Rotor -

screws

4.3 - ELSA 2 or ELSA 225 L DISC BRAKES –TA and LM SERIES AXLES

Description Torque value

Rotor - hub fastening screws 230-270

Caliper fastening M18 screws 380-420

ABS sensor support screws 20-25

Brake actuator nuts 180-210

The above-mentioned torque values are for dry tightening (with high friction)

5.1 - RECOMMENDED LUBRICANTS FOR HUB BEARINGS

BRAND

GREASE Type

MERITOR Hub Grease Blue lithium EP2

SHELL

Calithia EP2T

Alvania EP (LF) 2

MOBIL Mobilux EP2

CASTROL

TEXACO

Spheerol EPL2

Multifak EP2

TOTAL Multis EP2

B P LS EP2

ESSO Beacon EP2

SILKOLENE G62

EUROL

Universalfett EP2

ELF Lithium EP2

AXLE CHRISTIERNSSON Lithac 162 EP

FINA Marson EPL2

SKF LGEP2

G B

OIL Type

Spirax EP90

Mobilube GX 90

Hypoy EP90

Multigear EP85W/90

Total EP90

Gear Oil 90 EP

GX 85/90

Lithium EP2 ---

5.2 - LUBRICANTS FOR CAMSHAFT BUSHINGS AND BRAKE COMPONENTS

TotalFina CERAN WRC2

5.3 - SPINDLE LUBRICANTS

Optimol Optimoly White Paste T, recommended for application on bearing housings to prevent rust formation and facilitate subsequent hub removals

5.4 - QUANTITY OF LUBRICANT

5.4.1 - Axles with oil lubrication: Fill the hub up to the level marked on the hub cap (about 380 ml ).

5.4.2 - Axles with grease lubrication (quantities in grams )

5.4.1 - Axles with oil lubrication:

Fill the hub up to the level marked on the hub cap (about 380 ml ).

5.4.2 - Axles with grease lubrication (quantities in grams )

BEFORE STARTING TO WORK

- Check the brake system an d suspensions (hoses, fittings, equipment, …)

- Check that brakes and suspensions work properly

- Check the working height of the suspension

- Check any axle lift device and related system

AFTER 1,000 km

- Check the tightening torques of the components of the suspension

- Check air system hoses and equipment

- Check the working height of the suspension

- Check for oil leaks in shock absorbers

- Check that optional equipment works properly (lift unit, lift- lower valves …)

AFTER 10,000 km AND SUBSEQUENTLY EVERY 10,000 km

In addition to the 1,000 km checks:

- Check the shock absorber bushings

- Check tire wear (if tire wear is uneven check the trailing arms elastic bushings for damage and check axle alignment as described in chapter 9)

- Visually check the air springs

EVERY 100,000 km

In addition to the 10,000 km checks:

- Check proper operation of every single component in the air system

- Check the front suspension supports, their inner part and the wear plate near the trailing arm

We particularly recommend checking the tightening torques of suspension components at the first 1,000 and 10,000 km .

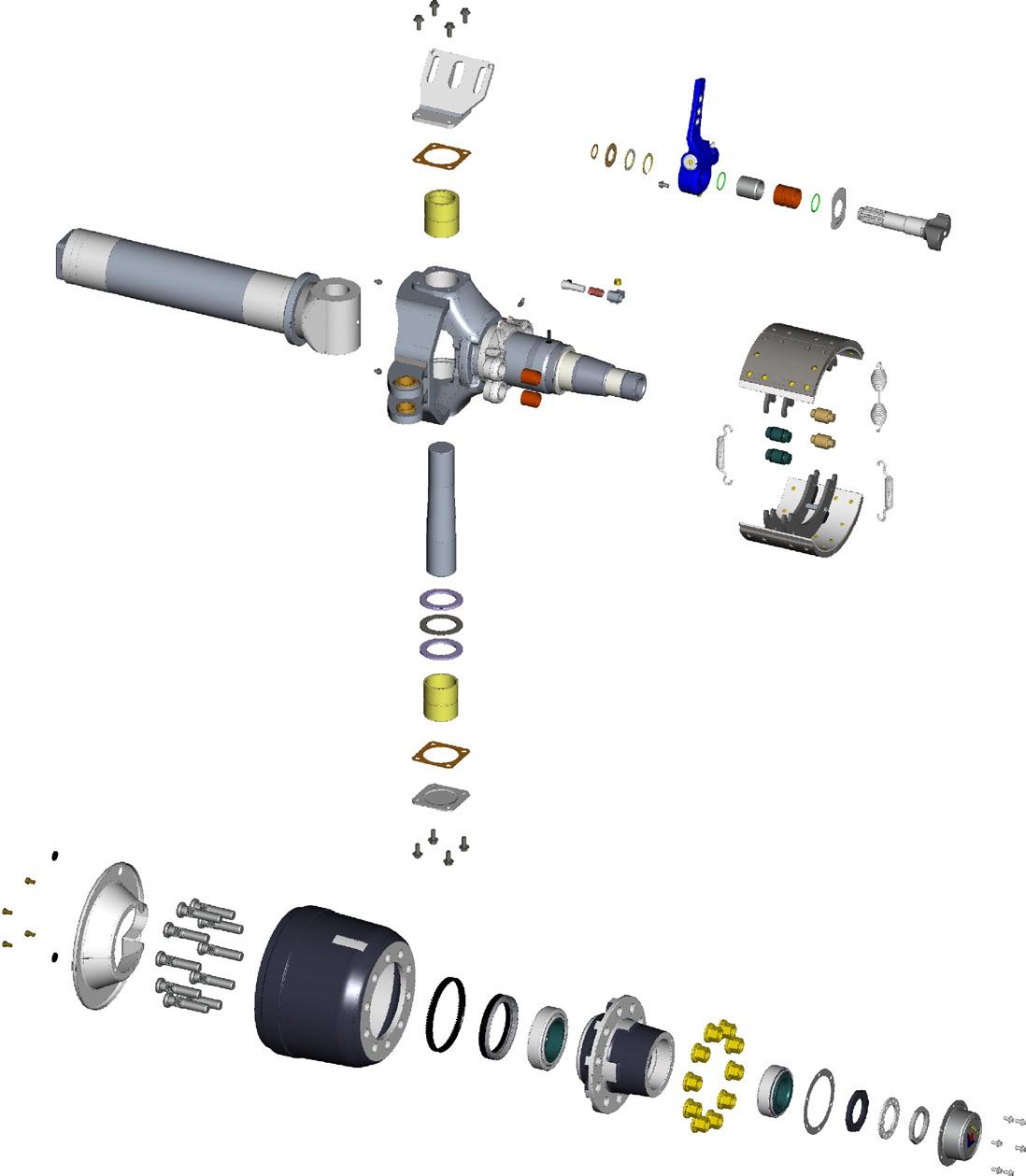

6.2. Axle Parts List

Source: www.assalistefen.com/it/assali

Complete Assembly Axle S121930A001A

& S121930A051A - Rev.0

2

assembly (*)

Brake assembly (***)

S121930A001A & S121930A051A - Rev.0

1 Brake shoe lined assembly M04004A 2 Brake lining, anchor end C09011A

Brake lining, cam end C09012A

Brake shoe C07006A 5 Roll pin C99007A

6 Return spring C05001A 7 Retaining spring C05006A 8 Cam roller C06001A 9 Roller retainer clip C07007A 10 Anchor pin M05001A Rivet (brake shoe) C99001A Brake linings kit K02003A

Descriptions and specifications were in effect at the time of this publication and are subject to change without notice or liability Assali Stefen reserve the right to make design improvements, change or discontinue parts at any time

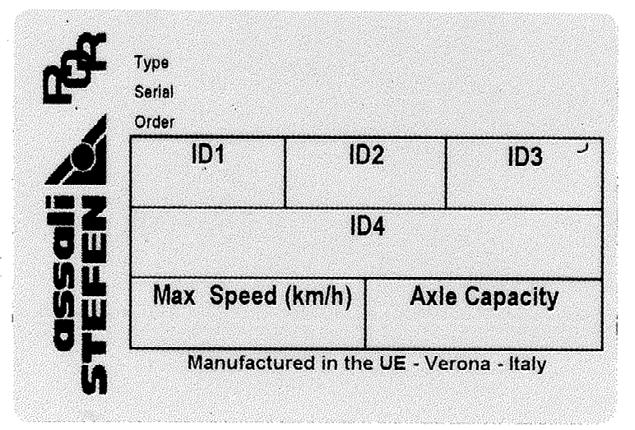

* IMPORTANT: The serial number engraved on the name-plate is input into the manufacturer’s electronic archives. By referring to this number you can, at any time, have information or genuine spare parts.

Component Identification

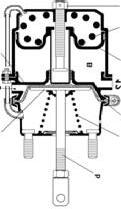

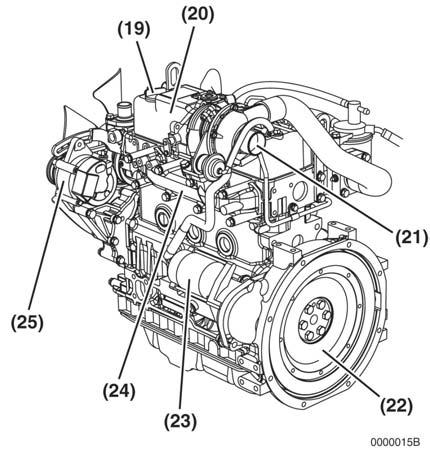

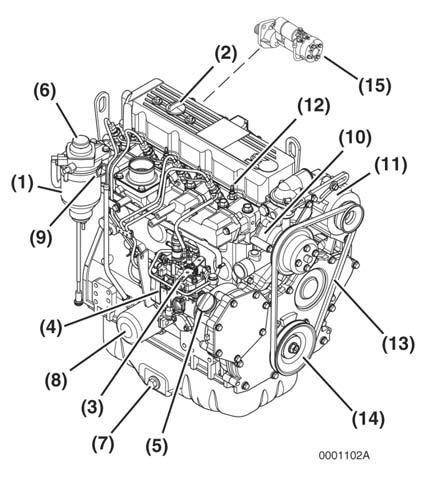

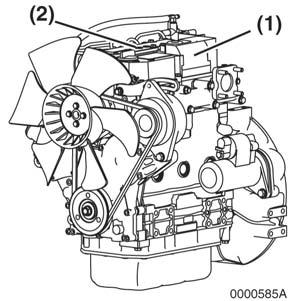

Figure 4-1a, Figure 4-1b shows where the major engine components are located.

4TNV98 ENGINE

Figure 4-1a

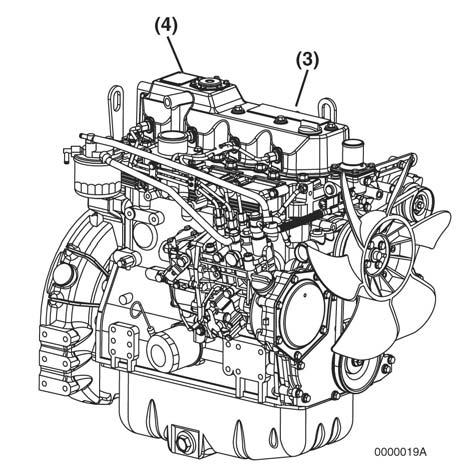

4TNV98 & 4TNE98 Diesel Engine

(1) Lifting Eye (Flywheel End).

(3) Lifting Eye (Engine Cooling Fan End).

(4) Engine Coolant Pump. (5) Engine Cooling Fan.

(6) Crankshaft V-Pulley. (7) V-Belt.

(8) Side Filler Port (Engine Oil). (9) Drain Plug (Engine Oil).

(10) Fuel Injection Pump. (12) Engine Oil Filter.

(13) Dipstick (Engine Oil) (14) Governor Lever. (15) Intake Manifold. (16) Fuel Filter.

(17) Fuel Inlet. (18) Fuel Return to Fuel Tank.

(19) Top Filler Port (Engine Oil). (20) Rocker Arm Cover.

(21) Air Intake Port (From Air Cleaner).

(22) Flywheel. (23)Starter Motor.

(24) Exhaust Manifold. (25) Alternator.

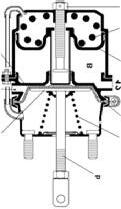

4TNE98 ENGINE

Figure 4-1b

(1) Fuel Filter / Water Separator

(2)Top Filler Port (Engine Oil)

(3) Governor Lever

(4) Fuel Injection Pump

(5) Side Filler Port (Engine Oil)

(6) Fuel Priming Pump

(7) Drain Plug (Engine Oil)

(8) Engine Oil Filter

(9) Dipstick (EngineOil)

(10) Engine Coolant Pump

(11) Alternator

(12) Glow Plug

(13) V-Belt

(14) Crankshaft V-Pulley

(15) Starter Motor

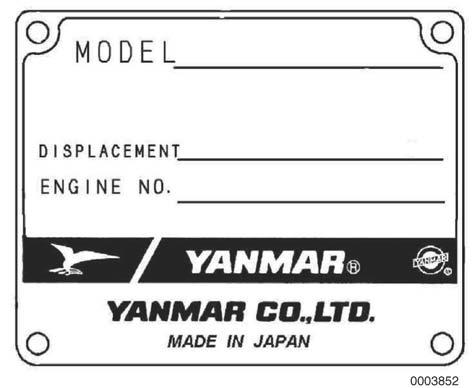

Figure 4-2 shows the location of regulatory and safety labels on Yanmar TNV & TNE series engines.

4TNE98 ENGINE

4TNV98 ENGINE

Figure 4-2

The typical location of the emission control information label shown (Figure 4-2 (2), (3)).

The typical location of the engine nameplate is shown (Figure 4-2 (1), (4)).

EPA / ARB Regulations - USA Only

Yanmar engines meet Environmental Protection Agency (EPA) (U. S. Federal) emission control standards as well as the California Air Resources Board (ARB, California) regulations. Only engines that conform to ARB regulations can be sold in the State of California.

Refer to the specific EPA / ARB installation (page 40) and maintenance (page 40) in the Periodic Maintenance Schedule section of this manual.

4TNV98 & 4TNE98 Diesel Engine

4TNV98 EPA Tier 2

Engine Model

4TNV98

Version VM (SDF)

Type Vertical In-line Diesel Engine

Combustion System Direct Injection

Aspiration Natural

No. of Cylinders 4

Bore × Stroke

Displacement

Idling

Engine Weight (Dry) with Flywheel Housing

3.858 x 4.331 in. (98 x 110 mm)

cu in. (3.319 L)

518.2 lb (235 kg)

PTO Position Flywheel End (Option)

Direction of Rotation

Cooling System

Lubricating System

Counterclockwise Viewed from Flywheel End

Liquid-Cooled with Radiator

Forced Lubrication with Trochoid Pump

Normal Oil Pressure at Rated Engine Speed 42 - 57 psi (0.29 - 0.39 MPa, 2.96 - 3.98 kgf/cm²)

Normal Oil Pressure at Low Idle Speed 8.5 psi (0.06 MPa, 0.6 kgf/cm²)or greater

Electric Starting - Starter Motor: DC12V, 3.1 hp (2.3 kW)**

Alternator: DC12V, 40A** Starting System

Recommended Battery Capacity: 12V, 64 Amp-Hour (5h rating)**

Dimensions (L × W × H)* 28.31 x 19.61 x 29.21 in. (719 x 498 x 742 mm)

Engine Oil Pan 11.1 / 6.3 qt (10.5 / 6.0 L) (Dipstick Upper Limit / Lower Limit)

Engine Coolant Capacity 1.1 gal (4.2 L) Engine Only

Standard Cooling Fan 16.14 in. (410 mm) O.D., 6 Blade Pusher-Type**

* Engine specifications without radiator

** May vary depending on application.

*** Engine oil capacity for a “Deep Standard” oil pan. Refer to the operation manual provided by the driven machine manufacturer for the actual engine oil capacity of your machine.

&

Cooling System

Check and Refill Engine Cool

Check and Clean Radiator Fins

Check Engine Coolant Temp. Indicator

Check and Adjust Cooling Fan V-Belt

Drain, Flush and Refill Cooling System with New Coolant

Adjust Intake / Exhaust Valve Clearance

Cylinder Head Lap Intake / Exhaust Valve Seats

Indicators

Battery

Engine Oil Level

Check Engine Oil Pressure Indicator

Drain and Fill Engine Oil Engine Oil

Replace Engine Oil Filter

and after Engine Speed Control Check and Adjust Governor Lever and Engine Speed Control

Emission Control Warranty Inspect Crankcase Breather System

Inspect, Clean and Test Fuel Injectors

Check and Refill Fuel Tank Level

Check Fuel Filter Indicator

Fuel Tank

Drain Fuel Filter / Water Separator

Check Fuel Filter / Water Separator

Clean Fuel Filter / Water Separator

Replace Fuel Filter

Hoses Replace Fuel System and Cooling System Hoses

Intake and Exhaust

or Replace Air Cleaner Element

or every year whichever comes first

or every 2 years

NOTE: These procedures are considered normal maintenance and are performed at the owner’s expense.

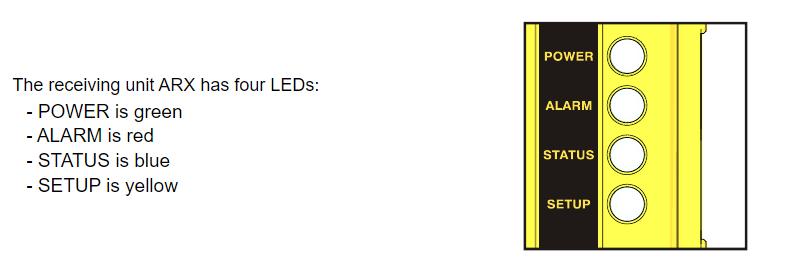

TRANSMITTER

RED LED

Is OFF

Transmitter is working correctly

Blinks The battery is nearly flat

Is ON for 2 seconds

Transmitter not working correctly

Blinks once At power ON – the transmitter has detected that the E-stop is pressed or damaged

Blinks Twice At power ON – the transmitter has tried to start with a safety switch in the ON position

Blinks 3 times When turned on = Battery is flat

Blinks 3 times At power ON – the transmitter has tried to start with a Paddle out of centre or damaged

BEEPS A BEEP will accompany the LED flash pattern

ALARM LED

Is OFF Receiver is working correctly

Blinks once Error on the STOP outputs

Blinks Twice Error on the Safety Outputs

Blinks 3 times Error on commands corresponding to direction

Is ON Configuration fault

SET-UP LED

Is OFF Receiver working correctly

Blinks once Error in Address key

Blinks Twice Error in Memory Board

LastUpdated 01/12/2023

STATUS LED

Is OFF No radio link

Blinks Slow Over voltage at power supply

Blinks Fast Data received from transmitter

Is ON

Over-current at PWM analogue output

P/Design/01 ESS trailers/001 Electrical

Remote Blink and Beep codes Garth Uren

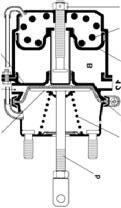

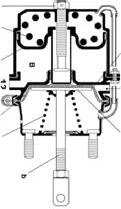

Ram Head-nut

Transducer

Plug and

Spear and Piston

Transducer

Magnet

Transducer

Rod

Transducer O-ring and Locating ring (Grub-screw slot)

1. Remove the ram from the trailer, Clean it and mount it in a vice, or similar, for dismantling

2. Unwind the head-nut and carefully remove the ram spear and piston from the ram Barrel. Take care to keep the Spear etc in line with the barrel as it is being removed as the transducer slides inside the ram spear.

3. Remove the 2 screws that retain the Plug to the barrel

4. Locate and remove the small grub screw that retains the Transducer in the ram

5. Pull the transducer out of the end of the barrel. Take care to thread the wires and plug through the cavity as the transducer is withdrawn from the ram

1. Inspect the ram barrel and spear to ensure it is ok to be re-used

2. Unsure the O-ring on the replacement transducer is lubricated

3. Run a draw-string through the cavity and tie it lightly to the plug.

4. As the transducer is slid into the barrel, draw the plug and wiring through the cavity (Do NOT damage the plug or wires during this process)

5. Push the transducer ‘home’ onto the seal cavity, and refit the grub-screw to hold it in place. Check the transducer is located properly and held in place

6. When the plug is all the way through the cavity, and in the correct position, secure it with its mount plate and screws.

7. Reassemble the ram by carefully sliding the piston and spear over the Transducer as it is inserted into the barrel. Tighten the Head nut

8. Test the ram for function and seal leaks before refitting

9. Test the transducer output is correct and stable as the ram is being tested.

Customer:

Lead Trailer - Module number

Date:

HPU Upper setting

#1 B-Module number 1a Clip-on HPU Stand-by

#2 B-Module number 2a Clip-on

SPEED-THRESHOLD SETTINGS (Shows ring around function as it becomes isolated)

Joystick Override Rear axle straight Crab Auto

Controller Master Switch 24V

Batteries

Switch Isolates all 24V supply

Ignition Switch Key Starts and Stops Motor

E-stop at Main Enclosure

Gooseneck - UP / DOWN

Suspension Left - UP / DOWN

E-stop Button Stops Motor and controllers

Suspension Right - UP / DOWN MANUAL REMOTE (Tethered)

Revs REMOTE / OFF / HIGH

/ Off

Widening Controls Where it plugs in Ramps

Ramp Float

Clip-on ram controls Individual Switches Both sides

Clip-on isolation

Engine start / Stop

Gooseneck UP / DOWN

Suspension Left - UP / DOWN Paddle

Suspension Right - UP / DOWN Paddle

Ramps Switch

Ramp Float Switch

Steer Manual Auto

Steer Direction Paddle

Horn Button

Screen inputs

Diagnostics

Auto steer

Crab Auto

Manual steer

Steer pivot point

Speed cut-out for steer functions

Adjustable using Bodas if customer requires a change

Options go grey and cant be selected

Valves accessible on wheels

Decals Correct

OVERSIZE sign

Steer Alignment

TRAILER CONFIGURATIONS TYPE

Splitting and joining the trailer

Light bars

Push bar

Dolly hook-up and hydraulic supply

Importance of clean couplers

Importance of clean couplers electrical Plugs

DO NOT HOT PLUG!

Screen set-up

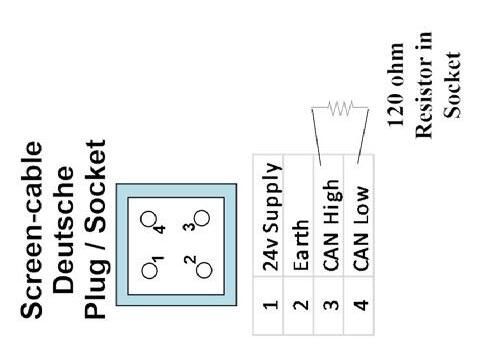

120ohm resistors

TRAINER (Name and Signature)

Acknowledging I/we have run the trainee through the function checks stated above.

Care in moving screen between trucks

Fitted in CAN looms be careful if servicing electrical plugs

TRAINEE (Name and Signature)

Acknowledging I/we have been run through the function checks stated above.

DATE