A news roundup from the world of print

19 Women in Print hosts Print & Prosecco in Brisbane

Women in Print Australia kicks off 2025 Print & Prosecco networking series

20 E-Bisglobal honours loyalty and legacy at 35-year celebration

E-Bisglobal marks 35th anniversary with celebratory Sydney Harbour cruise

22 Star Business: Mediapoint

Approaching 20 years, MD Jamie Xuereb shares insights on trends, challenges, and the power of pivoting

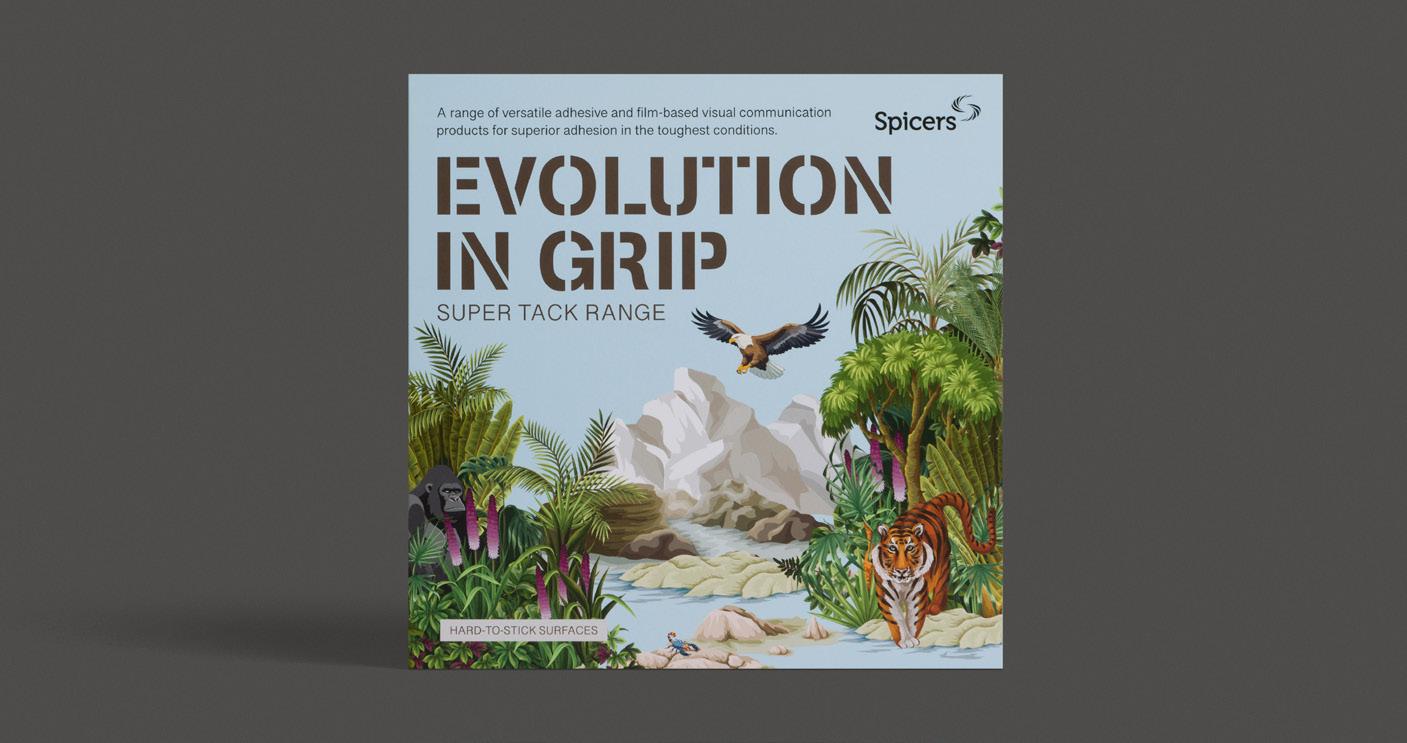

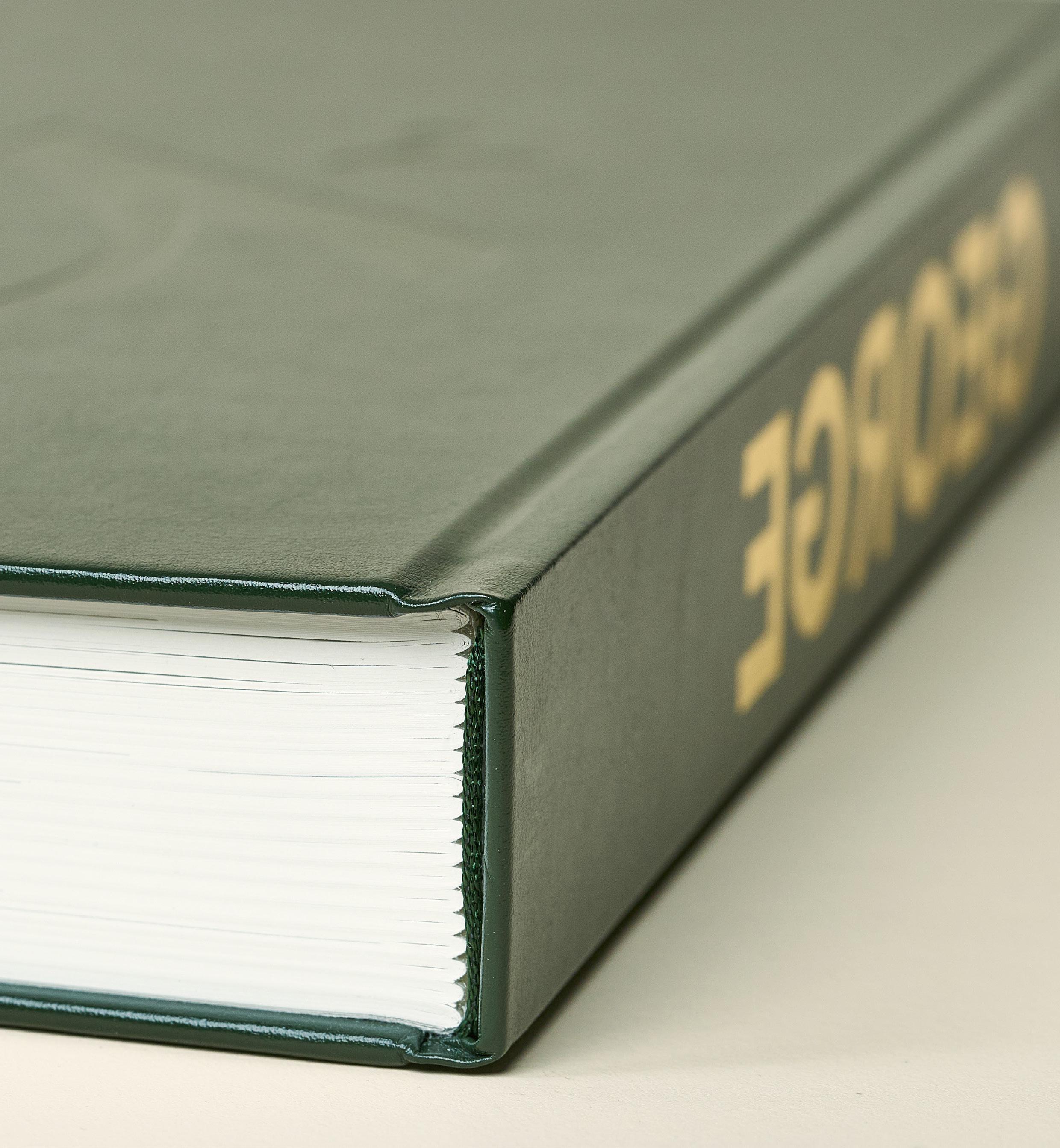

26 Cover story: Engineered to stick

Spicers’ new Super Tack Pack joins the Evolution in Grip series, delivering high-performance adhesive and film solutions for the toughest applications

30 Emerging trends in wide format

New tech, materials, and eco-friendly innovations shaping the future

36 Case study: Elite Printing Studio and Ricoh

Elite Printing Studio powers up production with a second Ricoh L5160

38 Case study: Law In Order and Konica Minolta

How Konica Minolta enables Law In Order to deliver fast, reliable legal document services

39 Case study: Worldwide Carrington Street and Konica Minolta

Worldwide Carrington Street improves efficiency with Konica Minolta’s AccurioPress C14000

40 Comment: Charles Watson

The art of the interview – tips on avoiding common interview mistakes

41 Comment: Andrew Ash

Success through fundamentals – why true success is built on substance, not show

42 ProPrint Diary

Keep up-to-date with the latest industry events

Editor Claire Hibbit, chibbit@intermedia.com.au

Design and Production Manager Sarah Vella, svella@intermedia.com.au

Managing Director James Wells, james@intermedia.com.au

Subscriptions (02) 9660 2113, subscriptions@intermedia.com.au

Printed by Hero Print Alexandria, NSW, 2015

Mailed by D&D Mailing Services Prestons, NSW, 2170

Welcome to the October edition of ProPrint magazine, which examines the everevolving world of wide format printing and signage.

Once limited to traditional signage applications, wide format printing has rapidly expanded its capabilities. Technological advancements have transformed this sector from basic commodity output into one that delivers highvalue, specialised solutions across a wide range of industries. Add to that a growing demand for personalisation, faster turnaround times, and sustainable production practices, and it’s clear the industry is undergoing a significant transformation.

In this issue, we speak with industry leaders to explore how wide format printing is

adapting to these changing demands and what the future of wide format printing might look like.

We also turn the spotlight on Melbourne-based wide-format trade printer Mediapoint, which is gearing up to celebrate its 20th anniversary next year. The journey to this milestone has not been without its challenges for founders and brothers Jamie and Jason Xuereb. Jamie Xuereb shares his insights on evolving industry trends, overcoming key obstacles, and the importance of adaptability.

Also in this edition, we focus on a crucial aspect of any business: hiring. Hiring the right person is vital – but asking the wrong questions can land you in hot water. Charles Watson offers practical advice on how to avoid common interview pitfalls, helping you make smarter recruitment decisions.

Finally, Andrew Ash explores the reality behind business appearances, revealing why genuine success is built on solid fundamentals rather than flashy facades.

EFI and Currie Group have announced a new chapter in their strategic partnership which will see Currie Group become the exclusive distributor for EFI sign and display technologies in Australia and New Zealand.

EFI technologies have been part of the Currie Group product portfolio for the past five years, but this new chapter will see the OEM hand the supply and customer service for its fleet of grand-format equipment exclusively to Currie Group, while it will concentrate on continuing to provide the highest quality technologies for print service providers.

Paul Whitehead, business unit manager – sign and display for Currie Group, said it’s the perfect deal at the perfect time.

“We have been proud to represent EFI’s sign and display portfolio in Australia and New Zealand for the past five years, and we have been delighted with the way our customers have embraced the opportunities those technologies provide,” Whitehead said.

“This latest evolution of the partnership capitalises on the strengths of both companies – EFI in the design and delivery of world-class technologies, and Currie Group in market reach, customer service, and technical support. Most importantly, it provides clarity to the market with one clear channel and one shared strategy based on one strong partnership for the ultimate in customer service and support.”

Rob Pearson, recently appointed as EFI

Aldus Graphics and CS Graphics have announced the successful completion of a management buyout that will see CS Graphics take ownership of the core distributor operations from Aldus Graphics.

CS Graphics partners with global manufacturers including Mark Andy, Rotoflex, GEW, Maxcess, Rhyguan, DYM, Harper, Polywest, JM Heaford, Graymills, and Enercon, to provide equipment, consumables and technical expertise for the label and packaging industries.

The companies said the move marks an “exciting new chapter” with Aldus proud to support the transition and confident that customers will experience minimal

sales development manager for Australia and New Zealand, said the timing of the new agreement could not be better, coinciding with the release of a new generation of energy-efficient UV LED wide-format printers.

“It’s an exciting time to be joining EFI with the opportunity to work in partnership with Currie Group, bringing our latest solutions to the ANZ market,” Pearson said.

“EFI has one of the broadest and most well-regarded ranges of sign and display solutions globally, including the VUTEk Q3h X and Q3h XP 3.3m hybrid roll-fed/flatbed printers, FabriVU 340i+ soft signage solution, the refreshed EFI Pro Series range of entry-level wide format printer solutions, and the brand-new M3h hybrid model.

“Together, we are committed to providing powerful and sustainable solutions that offer the flexibility, variety and quality businesses need to diversify and grow, with the confidence that comes from working with the industry’s largest and most comprehensive service and technical support network,” Pearson said.

For Currie Group CEO, Rob Mesaros, it’s the strategy behind the exclusive distributorship which tells the story.

“It’s a perfect partnership strategy,”

to no disruption during the changeover.

The establishment of CS Graphics ensures continuity of service for existing customers while positioning the company for strategic growth in the evolving print industry landscape.

The newly formed CS Graphics will be led by co-directors and industry veterans Chris Bodger and Sheetal Mishra, who bring decades of combined experience in the narrow web printing and converting sector.

CS Graphics said it will focus on delivering enhanced service and solutions to printing businesses throughout the region.

Aldus Group CEO Frank Floriano said, “At Aldus, we are incredibly proud of what this business has achieved and the strong foundation it has built. We are confident that CS Graphics will continue to deliver the same high levels of service, quality, and innovation that customers have come to expect. We wish the team every success

Mesaros said.

“EFI brings the technology, while we bring unrivalled reach, distribution infrastructure, service, and support. For Currie Group, the exclusive distributorship allows us to confidently pursue our strategy to be the trusted preeminent solution provider for the industrial and production markets in the A/NZ region, while offering our customers access to the world’s leading grand-format technology through EFI’s refreshed product portfolio.

“Most importantly, it demonstrates the strong commitment of both companies to this market. Together, we have the technologies, the strategy, the infrastructure and the support to help industry businesses unlock growth and build success.”

To promote the new partnership, Currie Group plans a series of roadshow events and demonstrations across Australia and New Zealand in the coming weeks.

“We can’t wait to give local businesses a chance to experience the latest solutions in EFI’s refreshed product range, starting with the brand-new M3h hybrid model, which is ideally positioned for the A/NZ ‘sweet spot’ of high productivity combined with an accessible price point,” Whitehead said.

as they begin this exciting new chapter”.

CS Graphics co-director Chris Bodger said, “We’re excited to launch CS Graphics as a dedicated partner for the A/NZ label print and packaging industry.

“This management buyout allows us to focus entirely on what we do best –supporting our customers with the products, expertise, and service they need to succeed. CS is driven by customer service, customer satisfaction and customer success.”

CS Graphics co-director Sheetal Mishra added, “Our transition from Aldus Graphics represents more than just a change of name. It’s our commitment to building a company that truly understands and serves the unique needs of our valued customers”.

Both Aldus and CS Graphics are aligned in ensuring a seamless transition, with all existing customer relationships, contracts, and services continuing uninterrupted.

IVE Group released its FY25 results for the year ending 30 June 2025, reporting a net profit after tax (NPAT) of $52.1 million, up 21.1 per cent from the $43.0 million it recorded in the previous corresponding period.

Its revenue, however, was marginally down by 1.6 per cent – from $969.9 million to $954.8 million and base revenue was down by about 3 per cent relative to the previous corresponding period, which it said was impacted by a softer economy and uncertainty surrounding the federal election.

EBITDA was reported at $136.7 million, up 7.0 per cent from $127.8 million the previous corresponding period, with the company saying that excluding nonoperating items, the group’s underlying result was consistent with guidance with “key profit metrics up significantly”.

The company attributed its strong margin expansion to improved MGM, a full period of Ovato integration benefits, JacPak synergies, as well as ongoing operational efficiencies. In addition, its Brand Activations, 3PL, and Packaging divisions enjoyed new client/business wins including household brands in the FMCG and pharmaceutical sectors.

Commenting on IVE Group’s FY25 performance, IVE Group managing director Matt Aitken said, “Given the somewhat muted economic landscape

including lingering inflation and the uncertainty that surrounded the federal election, I am pleased with the FY25 result which comfortably exceeded the targets set at the beginning of FY25.

“The result was underpinned by a further strong uplift in operating margins reflecting strict cost control coupled with the full emergence of Ovato and JacPak cost synergies.

“Continued strong cash conversion sees the group well placed to deliver continued growth over the medium term with the balance sheet offering significant capacity for both organic and inorganic growth initiatives.”

In addition to the financials, the company provided an update on its growth initiatives including:

• 3PL expansion in Dandenong South, Melbourne – With the strong growth in IVE’s 3PL operations and the upcoming expiry of 3PL’s main warehouse lease

in Braeside, the group is relocating to a brand new, purpose-built facility in nearby Dandenong South. The 33,000m2 facility will become 3PL’s largest site and provide an additional 60 per cent storage capacity for IVE’s Victorian clients (increasing 3PL’s national capacity by 30 per cent to 80,000m² from 62,000m2 currently).

Handover of the site to IVE occurred in late July 2025 with relocation expected to be complete in mid-tolate October. The building has a 5-star green rating, with parking for all staff, solar powered electricity supply with battery storage, and end-of-trip facilities for up to 100 staff. In the initial phase, the warehouse will have state-of-the-art storage systems for more than 25,000 pallets of stock, with plenty of open floor space for future growth and dedicated in-house logistics services for JacPak.

• Sydney supersite at Kemps Creek –This site will consolidate multiple sites for operating efficiencies and capacity expansion, including commercial Print and Packaging from Silverwater, Brand Activations from Granville, CX & Data from Homebush, and Paper storage (for Print Web Offset) from Warwick Farm. This site is said to facilitate the group’s strategy of expanding into horizontal adjacencies such as packaging, to drive revenue growth and operational efficiencies. Groundworks commenced in December 2024 with completion said to be on track for late December 2025, with the site expected to be fully operational by March 2026.

Wildstone has completed the acquisition of nine billboard faces over six billboard structures in metropolitan Melbourne from High Street Media, taking its Australian portfolio to 71 assets – comprising 44 static and 27 digital billboards.

The new additions include three doublesided digital and static structures and three single-sided digital screens. Four of the six are super sites located along major arterial routes including the South Gippsland, Frankston and Princess Freeways. The fifth and sixth are situated on the Metropolitan and Western Ring Roads.

Jonathon Kouvelis, director at High Street Media, said: “I was very happy with the way this transaction progressed with

Wildstone, which handled every aspect of the deal expertly from start to finish. I’m proud of what we’ve achieved with these sites and believe they will continue to

thrive under Wildstone’s ownership”.

All assets are subject to long-term agreements with established billboard operators. ASX-listed oOh!media manages five of the sites, with Civic Outdoor operating the sixth.

Wildstone is the largest owner of outdoor advertising infrastructure in the world, with more than 5,400 assets. It entered the Australian market in May last year and has since completed a number of acquisitions in the country, including Total Outdoor Media’s (TOM) entire portfolio of regional billboards in March this year.

“We’re pleased to have completed another strategic transaction in Victoria as we continue to grow our footprint across the country,” said Noel Cook, managing director of Wildstone Australia.

“Reaching 71 billboard assets in just over a year reflects the strength of our approach and the response from billboard owners and landlords looking for longterm value. We remain focused on further acquisitions in both metropolitan and regional markets.”

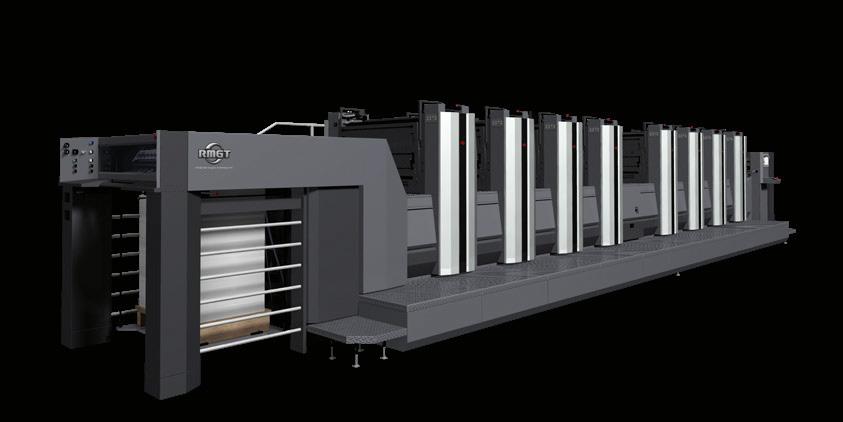

CMYKhub has unveiled its Komori Lithrone GX40RP at the company’s soon to be open, state-of-the-art headquarters in Melbourne.

The Komori Lithrone GX40RP is a twosided press with high productivity, stable printing, no sheet flipping, reduced waste, and eco-conscious functions.

The press is the first of two machines making their debut at CMYKhub’s new 7000sqm purpose-built facility, located in Keilor Park near Tullamarine Airport.

The company has also installed a Canon varioPRINT iX3200 B3 press, which was purchased last year at drupa.

The new premises will represent twice the space of CMKYhub’s current premises, which is currently spread over six locations in Heidelberg, Melbourne. The new headquarters on Wright Road will also feature 500sqm of office space across two levels.

CMYKhub CEO Dayne Nankervis told ProPrint the Komori had been in storage for two years in anticipation of the new facility’s opening.

“Our new Komori replaced an existing machine that will also still be in use at Keilor Park. It’s 30 per cent faster than its

Breen Printing is set to expand its operations with the launch of a second factory located across the road from its current premises.

The Healesville-based company in Victoria, which is led by husband-and-wife team Kirsty and Luke Woodhead, says it is “bursting at the seams” in its current facility following significant growth.

“We’ve seen significant growth over the past few years on the back of COVID, which has been great, but as a result we’ve become a bit strapped for space,” Luke told ProPrint.

A second site has long been part of Breen Printing’s expansion plans. After several years of searching, the company recently secured its new location across the road from its existing facility.

Scheduled to be operational by the end of the year, the new site will allow Breen Printing to split its operations between the two locations. Alongside relocating equipment, Breen will also be investing in new machinery.

predecessor,” Nankervis said.

The area for the new press has been ergonomically designed around the machine, featuring a built-in pit to optimise working conditions for the operators.

“One of the main advantages of the Komori is the elimination of sheet flipping, which significantly reduces downtime,” Nankervis said.

Another feature of the Komori is its advanced camera system, which can detect inconsistencies such as blemishes, or roller marks during production.

“It captures an image of every sheet and compares it directly to the original PDF file. If there are any inconsistencies, the system immediately alerts us. That level of quality control is a major upgrade –something we don’t have on our older presses,” Nankervis explained.

According to Nankervis, the new Komori and its predecessor will both be running at the new Keilor Park site as the company

“We’re planning to move some of our existing equipment across to the new site, as well as purchase additional machinery to expand our product range and introduce new services for our customers,” Luke said.

With fit out work currently underway, the new facility will also support growth in specialised areas such as small-run, large-format packaging and point-of-sale (POS) materials.

The new site is scheduled to be operational by the end of the year.

“We already do some of this type of work, but the new site will allow us to bring more of it in-house and launch new products into the market,” Luke added.

Kirsty confirmed Breen’s wide-format operations will be relocated to the new site.

“We’ll be moving our flatbed and wideformat printer over. We’ve also recently

aims to ensure “100 per cent redundancy into the new facility”.

“While this new press is more advanced and will take on the bulk of the work, the existing press will remain operational and productive. That way, if one press goes down, production doesn’t stop. Both presses use H-UV technology, although the new one runs on LED, which makes it even more efficient.”

Nankervis said the new facility’s layout has been designed for efficient production flow. The factory’s consolidated operations aims to create a purpose-built, climatecontrolled, and sustainable facility.

“We’re entering this new site with a new offset machine, a new digital press, and we’re bringing over all our existing equipment. These additions will increase our capacity and improve our ability to meet turnaround times. We’re also installing a new laminating machine, two new folding machines, several wideformat machines, and a fabric printer,” Nankervis said.

“After 18 years in operation, we’ve taken the opportunity with this new site to redesign the factory layout.

“For the first time, we’ve been able to create designated areas for departments such as digital, offset, bookbinding, labels, and packaging. We’re also adding new departments like fabric printing and soft signage via EFI. Where there’s a value-add for clients, we’ll continue to invest.”

purchased second-hand finishing equipment including a perfect binder, booklet maker, saddle stitcher with threeknife trim, and a large folding machine,” she said.

The company also plans to invest in a large flatbed cutter and is considering a second digital press to increase capacity and improve turnaround times for on-demand jobs.

“While the second press will provide backup, both sites will operate independently,” Kirsty said.

“We’ve also been developing a range of web portals to automate more of our processes.”

This year also marks another major milestone for the business – five years since Kirsty and Luke took ownership of Breen Printing.

“When Kirsty and I first took over the business we had clear plans to grow, employ more people, expand into the online space, and enter the wide-format packaging and POS markets,” Luke said.

“However, when COVID hit, we had to put everything on hold. For three years, like many businesses, we were just focused on getting through. Now, we’re ready to pick up where we left off. The timing of the new factory couldn’t be better, and we’re excited to restart our plans.”

RELIABILITY

•Dependable performance

•Trusted platform

•Easy maintenance

PRODUCTIVITY

•High machine uptime

•High volume label printing

•Consistently high print speed

AUTOMATION

•Seamless integration

• Streamline production

• Maximum efficiency

Adrian Fleming, who previously worked at printIQ before departing in September 2021 following a company restructure, has returned to the business as general manager for Australia and New Zealand, replacing Rachel Davis.

Fleming served as global head of sales at printIQ between August 2015 and September 2021. The business moved its sales and marketing functions to respective target markets overseas, as lockdowns in Australia following COVID-19 made managing marketing and sales out of the country increasingly difficult.

During his tenure at printIQ, Fleming played a pivotal role in the company’s growth, helping drive revenue while significantly expanding its customer base. His leadership was instrumental in printIQ’s successful expansion into North America and Europe, and his strategic vision helped establish the company’s presence in new markets including labels, packaging, promotional products, and office supplies.

Fleming then took a break from work before becoming the CEO of Sourceit, a cloud-based platform that facilitates the

Ball & Doggett has promoted James Merhab as its NSW sign, display and digital sales team lead, reinforcing the company’s ongoing commitment to customer partnerships and regional growth across the signage and visual communications industry.

With more than a decade of experience in the print and signage sector including the last three years at Ball & Doggett, Merhab has developed a strong reputation for building trusted relationships and delivering commercial results.

Prior to Ball & Doggett, Merhab worked at companies including Orafol Australia, Starleaton, and Bus Advertising Australia.

Ball & Doggett said his appointment marks an exciting new chapter for the business as it sharpens its focus on supporting customers

end-to-end procurement process for buyers and suppliers, in March 2022.

Fleming now brings to this role more than 20 years of executive leadership experience in sales, business growth, and transformation across Australia and international markets. His career also includes senior leadership roles at wellknown industry leaders like Kodak, where he managed complex, multi-million-dollar operations across the Asia Pacific region.

According to printIQ, his collaborative approach and proven track record of working effectively across all organisational levels make him ideally suited to drive the company’s continued success in the Australian and New Zealand market. Beyond his corporate achievements, Fleming has been a

dedicated advocate for the printing and graphic communications industry, having served as the president of the Graphic Arts Merchants Association of Australia and being a former executive member of Visual Connections.

“We’re absolutely delighted to have Adrian rejoin our team. His proven track record with printIQ, combined with his deep industry knowledge and exceptional leadership capabilities, makes him the perfect choice to lead our Australia and New Zealand operations into the next phase of growth,” printIQ CEO John Alden said.

Following the COVID period, printIQ brought the management role back in-country in February 2024 with the promotion of Davis from chief operating officer – a role she held from June 2019 –to A/NZ general manager.

After 20 years in the print industry and six years at printIQ, Davis has decided to turn the page and shift sectors, now joining retail drinks and hospitality business Endeavour Group.

“My six years at printIQ were a huge chapter – leading teams, building strong organisational people structures, and embedding systems in A/NZ, while establishing and expanding the UK presence and setting up the structure, systems, and processes in the US to enable its growth,” Davis said.

“Seeing the business positioned for sale in 2022 was a milestone I’m proud of, and I’m grateful for the people I met and the lessons I learned along the way.”

across New South Wales and the ACT.

In his new role, Merhab will focus on expanding Ball & Doggett’s presence in NSW and ACT, strengthening partnerships with signage and display customers, and delivering solutions that help businesses grow and stay competitive in a dynamic market.

“James has consistently demonstrated outstanding leadership, a steadfast commitment to customer excellence, and a strong track record of delivering commercial results,” Ball & Doggett sign, display and digital general manager Rob Brussolo said.

“This promotion underscores our dedication to investing in exceptional talent and driving value for our customers.

With James at the helm, we are confident the NSW team will continue to thrive and inject fresh momentum into the market.”

“I’m incredibly proud to take on this role and lead such a capable team,” Merhab said.

“Our customers are at the heart of everything we do, and I’m excited to build on the strong foundation we have created and expand our footprint, strengthen our relationships, and delivering even greater value.”

MMT Print has made a substantial investment in custom-made finishing equipment with automation to improve its signage manufacturing operations.

Group director, David Walton, told ProPrint the custom-built welder, sourced from American manufacturer Miller Weldmaster, will help the company improve production for fence mesh and billboard fabrication.

“This welder will work with kedder edging, PVC banner, and mesh material and will hem and eyelet in an automated process. This is the first piece of finishing equipment that has been custom built to these specifications anywhere in the world.

“The welder is 3.2m wide, which is larger than other models available that are normally 2.5m, 2.2m or 1.8m as it has been custom-made to our specifications. It will

John Wall has brought to a close two decades of service to the industry as a key member of the Visual Connections board, stepping back at the end of August, when he retired as managing director of leading supplier, Roland DG.

Wall’s career in the industry stretches back more than 40 years, in which time he has not only established himself as an innovator, strategist and commercially astute businessman, but also as a trusted advisor, mentor and friend to many in the industry.

For Wall, business has always been about partnership. During his time with Roland DG, he has developed a reputation for prioritising that two-way relationship with customers, not only delivering astute advice and assistance to them, but also listening to their feedback and suggestions, and ensuring that information is considered in future upgrades and product development.

In a recent profile story, Wall said, “Success is all about the team you build around you to help make your goals possible. Every decision should be treated as if it’s your own business”.

He has brought the same approach to the Visual Connections board, not only providing calm, steady and astute input to board deliberations, but extending support and encouragement to his fellow

do pockets, hemming, webbing and kedder and can be managed by a single operator.

“This is the latest generation of welding equipment with more automation delivering seven lineal metres per minute and will provide us with a huge amount of output at our MMT facility on the Gold Coast.”

Walton said the company plans to install a similar welder in Melbourne.

“As we normally replicate technology across both sites, we would look to install

board members, and to the operational team, first under Peter Harper and, more recently, Karren Challoner-Miles.

Mitch Mulligan, president of Visual Connections, said Wall has made an ‘incalculable’ contribution to the industry through his role on the board, where he has held positions as president, vicepresident and treasurer.

a similar welder into our operations at Omnigraphics in Melbourne – but probably with a five metre width.

“We visited the Miller head office near Cleveland last year after Printing United and after discussing our requirements –they have been building the unit for us ever since. It is a big piece of kit and will be arriving in its own 40-foot container. The designer will be flying out and spending three weeks with us to assist with installation.

“John is not only a valued member of our board, but has become a trusted advisor, supporter and friend,” Mulligan said.

“Sitting on the Visual Connections board is a voluntary role; there is no payment, and little external recognition of the contributions which are made. The fact that John has served the industry in this way for 20 years – in addition to all the many other things he does – attests to his passion and commitment to the sector. The way he has served, with grace, tenacity, wisdom and humour, speaks volumes about the man himself.

“We are incredibly grateful to have had him on our team for so long. We will miss him enormously as we sit around the boardroom table and wish him nothing but good health and happiness as he embarks on his well-earned retirement.”

Karren Challoner-Miles, executive general manager of Visual Connections, said Wall’s support had been pivotal to the association’s successful leadership transition at the end of 2024.

“The start of a new era in any organisation is an exciting time, but periods of change also always bring challenges with them,” she said.

“Having the support of John, and the rest of the board, as we have navigated through those challenges and set the course for the future, has been invaluable.

“I know that our entire team will miss having him around, but we are excited for him to finally have the time and space to realise the exciting plans he has for his own future and look forward to staying in touch.”

Durst Group has announced the full integration of GMG’s spectral colour management technology into its proprietary Durst Workflow software as well as into the open Smart Factory portfolio of the Open Software Initiative.

The official launch of the solution is scheduled to coincide with the presentation of the Open Software Initiative at Printing United 2025.

With this integration, Durst said it is setting a new industry benchmark for automated and colour-consistent production – regardless of printing system or substrate.

From now on, the Durst Workflow will be delivered with fully embedded spectral colour management from GMG. Existing customers with a valid software agreement will receive the new solution at no additional cost.

The integration covers all market segments in which Durst operates labels and packaging, corrugated, and sign and display.

In addition, the GMG solution becomes a key component of Durst’s modular Smart Factory architecture, which is central to the Open Software Initiative –Durst’s vision of an open, fully connected production ecosystem.

“By integrating GMG into our Durst Workflow and open Smart Factory platform, we are delivering a new level of colour consistency – fully automated and highly scalable,” Durst Group software and solutions business unit director

Lamont Print & Sign has introduced a nine-day fortnight work model for its staff, designed to enhance employee wellbeing, and support retention.

Under the new structure, staff will work Monday to Thursday from 7:30am to 4:00pm, and finish at 1:00pm on Fridays, with a 30-minute lunch break each day.

To provide greater flexibility, rostered days off (RDOs) will rotate, with the option for either Mondays or Fridays being scheduled as the additional day off every second week.

The company said this ensures staff maintain full-time hours while benefiting

Michael Deflorian said.

“At the same time, this marks a first realworld example of a true best-of-breed integration in the spirit of our Open Software Initiative. It underlines our ambition to deliver the best software solutions on the market – not just for Durst customers, but for the entire print industry.”

GMG global partnership manager Darrian Young said, “This partnership brings together two companies with

Stephen Lamont

The Durst Workflow will be delivered with fully embedded spectral colour management from GMG

innovation and quality at the core of their DNA. The integration into the Durst Workflow and Smart Factory architecture enables a consistent, media-neutral production process – a real gamechanger for the market”.

With this milestone, Durst Group further strengthens its position as a technology provider for end-to-end production solutions while advancing the open, crosssystem approach of the Open Software Initiative.

from improved work-life balance.

“We know the signage and print industry is in a highly competitive labour market. By giving our people flexible, supportive work structures, we can retain talent, strengthen our culture, and continue delivering the high-quality service our clients expect,” Lamont Print & Sign director Stephen Lamont said.

The initiative is expected to reduce absenteeism, improve morale, and sustain client service through staggered scheduling, ensuring client needs are met even when some staff are on rostered days off.

Lamont Print & Sign will pilot the program before a full rollout, incorporating staff feedback and operational data.

“Flexible work is not just about hours, it’s about building trust, retaining talent, and creating a positive culture,” Lamont said.

GENR8 Printing is gearing up for growth with a new Ricoh Pro C7500 press, featuring a 5th colour, purchased from Pivotal Business Systems for its small format department.

Pivotal Business Systems managing director Gerard Maher said Moratidis closely evaluated Ricoh’s evolving technology through demonstrations and sample testing, particularly around the Ricoh Pro C7100 and 7200 series.

While those models sparked interest, it was the unveiling of the Ricoh Pro C7500 at drupa that ultimately sealed the decision. Its expanded colour capabilities, advanced media handling, and integrated automation aligned perfectly with GENR8’s creative ambitions and operational needs.

“GENR8 Printing was looking for a solution that could elevate its creative output, improve production efficiency, and support growing demand for specialty print applications,” Maher said.

“As a business focused on bespoke, high-quality work, it needed a press that could deliver exceptional detail, handle a wide range of media, and offer advanced colour capabilities beyond CMYK.

GENR8 Printing owner Yianni Moratidis said this is the company’s first deal with Pivotal Business Systems and that it is excited about the possibilities this press presents.

“We’ve been in talks with Pivotal Business Systems since the Ricoh Pro C7100 was launched, but it wasn’t the right time for us to make the investment. When I saw the Ricoh Pro C7500 at drupa, it blew me away. We then made the investment in this machine late last year,” Moratidis said.

“Up until the install of the Ricoh Pro C7500, we’ve been using our Konica Minolta machine. It’s been a great machine, but I’ve been keen to explore what the 5th colour

option can do for our clients.

“The quality that’s coming out of these new Ricoh machines, and especially having the option of the 5th colour, means it’s going to expand our colour gamut. We’re not a high-volume print house, even though we can do it, so we have to focus on bespoke clients as well.”

The Ricoh Pro C7500 digital colour press with 5th colour option delivers true production-level performance. It prints at speeds of up to 95 pages per minute, with a maximum paper capacity of 16,200 sheets.

Automation features include colour calibration, front to back registration, auto duplexing simplified operations, and reduced manual intervention.

“The installation of the Ricoh Pro C7500 at GENR8 Printing highlights Pivotal’s continued commitment to delivering tailored, high-performance solutions to forward thinking print providers,” Maher said.

“With a deep understanding of Ricoh’s technology and a long-standing relationship with the manufacturer,

Pivotal was able to guide GENR8 through the decision-making process with confidence and clarity.

“This install reinforces Pivotal’s reputation for pairing the right technology with the right business goals. It also showcases the team’s consultative approach, technical expertise, and ability to support clients as they expand into new creative and commercial opportunities. For Pivotal, it is another example of helping a growing print business unlock its next chapter.”

GENR8 Printing purchases Plockmatic BM4000 Booklet Maker from Renz

GENR8 also recently purchased a Plockmatic BM4000 Booklet Maker from distributor Renz to offer square edge booklets.

The machine enables the business to produce square edge booklets from A6 to A4 size in landscape, or large format at 300mm by 300mm.

“This makes GENR8 Printing the only one in Newcastle at the moment to offer A4 landscape saddle stitch,” Moratidis said.

“With more people hearing about this purchase, we’ve been getting more enquiries about it, and more new customers, especially corporate clients, are coming through our doors.

“The benefit of this machine is, we can pretty much get it to our customers on the same day – previously, it took us a couple of days as we had to print them, cut them, crease them, then manually staple them and press them together. So, this has been a great investment for us.

“We’ve made investments into our new machines as the quicker we can get jobs out, the more we can service other clients as well. We are a small team, and I like to keep it small, so, speed and less menial tasks go a long way for our team.

“We are starting to see a shift in our clientele – we have more clients come to us today that we’ve never dealt with before. Within the next six to 12 months, we’ll have a better understanding of our growth trajectory and will be making further investments into new machines.”

Women in Print Australia has marked a significant milestone with the formal approval of its new rules of incorporation by the Registrar, with the association saying that the step strengthens its ability to support members and expand reach across the country.

The new framework provides greater flexibility in generating and applying income from activities to benefit members, while also opening access to grants and

Ball & Doggett has reached agreement in principle to acquire flexible packaging supplier Impak Films, with a completion date scheduled for 31 October 2025.

Part of the OVOL, Japan Pulp and Paper Group, Ball & Doggett is Australia’s leading distributor of printable materials and consumables to the print, signage and packaging industries.

Established in 2005 by Andy Newman and Brian Christy, Impak Films specialise in the distribution of a wide range of

Epson has extended its technology and sustainability agreement to support First Nations Fashion + Design (FNFD), the NFP Indigenous Corporation whose goal is promoting the growth of the Indigenous fashion sector and in addition launched the inaugural Epson and FNFD Designerin-Residency Program with its first two awarded recipients.

Epson Australia MD, Craig Heckenberg said, “Our extended relationship with FNFD and the launch of the Designer-inResidency Program is a result of a natural extension of our partnership that allows Epson Australia to play a key role in a number of FNFD strategic initiatives which support and empower emerging First

funding opportunities nationwide. It also gives the association the ability to launch a tiered membership model, so male allies

Nation fashion and textile designers in Cairns and the surrounding regions”.

FNFD founder and chairperson, Grace Lillian Lee said, “The Designer-in-Residency Program is such an important opportunity to provide deep, tailored support for emerging First Nations designers. This year’s recipients bring unique talent and vision to the program and we look forward to walking alongside them as they continue their creative journeys”.

The Designer-in-Residency Program has been created to empower First Nations emerging and established fashion and

can join the association.

The approval followed months of work by the board to simplify and clarify the constitution, ensuring it was both easy to understand and fully compliant with legislative requirements.

“Navigating the technicalities of incorporation can feel daunting, but we were committed to making our rules clear, simple, robust, and futureflexible,” said Stephanie Gaddin, chair of Women in Print Australia.

“That work has paid off, and now we can focus on what matters most, building a strong, equitable and fair community for everyone in industry right across the country.”

The new association rules and constitution are available to download via the Member Portal, or by email request to hello@womeninprint.com.au.

Flexible films into the packaging industry. Ball & Doggett CEO Luke Wilkinson said, “We are delighted to welcome Impak Films into Ball & Doggett, further strengthening our position and commitment to the packaging sector”.

Impak Films managing director Andy Newman said, “This is an exciting next step in the Impak Films journey. Ball & Doggett have the resources, people, and infrastructure to take the business forward which will ultimately provide greater value to our customers, suppliers, and staff. We are excited about what the future holds”.

The business will continue to operate independently from its site in Tullamarine, Victoria with all staff remaining with the business.

textile designers by providing essential resources, mentorship and support from Epson and FNFD to refine their creative practices and grow their businesses.

The program aims to foster cultural expression and sustainability through textile design, build business capacity, production skills and and create opportunities for national exposure through the FNFD Fashion Showcase in 2026.

The first two recipients who have been awarded places on the Designer-inResidency Program are Ivy Minniecon and Lisa Lui.

The Designer-in-Residency Program is funded and fully supported by Epson and includes a broad curriculum of classes, education, mentoring and training in cultural and creative research, digital textile design exploration and printing technical development, textile collection development, and business and branding marketing. This culminates in a midresidency showcase, garment sampling and production, collaboration and innovation and a final collection completion of the 2026 FNFD fashion showcase at the 2026 Cairns Indigenous Art Fair.

oOh!media has officially launched summer, bringing together agencies and brands from across the country to explore how Australians move, spend, and think differently during the warmer months.

The travel-focused event featured a panel of industry leaders including Penny Glasson, CMO of Bundaberg Brewed Drinks; Jodie Teaken, global head of airline marketing at Qantas; and Dan Edgtton, director of data solutions at Westpac Data X.

They explored how Australians move, spend, and make choices over Summer, and shared practical insights on how brands can engage audiences during this period.

Glasson highlighted the power of consistent, strategic OOH investment: “As a brand we mostly advertise over summer, it’s a big recruitment strategy for us. Last summer, we increased brand penetration 7 per cent YoY during this period which reinforces the importance of staying active with consumers. Part of Bundaberg Brewed

Labelexpo has announced it will rebrand to LOUPE – which stands for Labels & OuterPackaging Embellishment.

The change represents a shift in focus for the exhibition to embrace a broader scope of exhibitors including labels, flexible packaging, and folding carton.

The first show under the new branding will be LOUPE Americas to be held in Chicago in September 2026.

“Formerly Labelexpo, LOUPE has evolved with the industry,” the company said in a statement.

“The change is a symbol of LOUPE’s position as a driving force of innovation –ensuring it remains the global home for labels with the widened lens towards package printing sectors.

“LOUPE is the global platform for package printing industries, connecting business professionals in labels, flexible packaging, and folding carton sectors. With a stronger focus, LOUPE delivers the insight, expertise, and innovation to help the industry navigate technology shifts, unlock new capabilities, and drive growth.

“The announcement aligns the show with the evolution of the industry, most notably industry convergence: the package printing

Drinks’ success is that while we’re consistent, we like to tweak what we do each year. For us, It’s evolution, not revolution.

“Using two major platforms, Out of Home and cricket, is testament to how much we back the channels. We are also looking to allocate more focus to reaching regional consumers given the changing patterns of behaviour during this period.”

Edgtton reinforced the scale of the opportunity: “Based on our data, we see a 3 per cent uplift in Victoria, attributed to summer movement and visitation, that’s the biggest of all the states. Three per cent doesn’t sound like a lot, but when you contextualise it, it’s over $350 million

industry is converging around a set of core technologies – digital, digital hybrid, and in-line production – driven by automation, cloud connectivity, and sustainability.

“Market consolidation: the industry is undergoing rapid consolidation and transformation, creating “one-stop” package printing operations that encompass the full range of packaging formats.

“Disruptive technology: label converters have already diversified into flexible packaging and are identifying new opportunities in folding cartons.

“Labelexpo was launched in 1980 with the inaugural Labelex 80 in London, featuring 44 label industry suppliers. Since then, the portfolio has expanded across the globe, supported by influential specialised editorial from Labels & Labeling. In the past two years alone, the combined Labelexpo portfolio of events welcomed more than 125,755 visitors and

more than any other state across that period. So, people are shifting their behaviours and how they’re choosing to spend their money.”

Teaken added a simple but crucial truth: “The best thing you can do is be where your audience is, let audiences tell you where they’re going to be.”

The panel’s insights were backed by fresh data, showing the scale of movement and opportunity for brands over summer.

More than 3.3 million Australians hit the road for regional getaways, fuelling an $8 billion day-trip economy, according to Tourism Research Australia. Westpac Data X revealed this movement drives 3.7 million extra petrol station visits compared to winter, alongside a $76 million surge in coastal spending, with many towns seeing double and even triple-digit growth. For brands, it’s a valuable opportunity to engage audiences who are relaxed, receptive and ready to spend.

The two-day immersive getaway, held at the new Mondrian Hotel on the Gold Coast, saw senior agency and client attendees experience the ‘Great Australian site tour’ from Brisbane to the Gold Coast, including a pit stop at the iconic Yatala Pie Shop. After a night of partying by the five-star Mondrian pool, guests went on a site tour and shopping spree at Pacific Fair, one of oOh!’s busiest and most premium retail centres.

occupied 140,919sqm.

“Today, Labelexpo Europe 2025 in Barcelona welcomes over 650 exhibitors covering a wide spectrum of the labels and package printing sector. Data from Labelexpo Europe 2023 showed 40 per cent of show visitors registered an interest in flexible packaging and 25 per cent in folding cartons. Over 25 per cent of exhibitors at Labelexpo Europe 2025 have portfolios that reach across labels, flexible packaging and folding carton sectors,” the company said.

“Over the decades, Labelexpo has transformed from a narrow web, pressuresensitive-focused show to take in new label formats, then flexible packaging and now folding cartons, all driven by the entrepreneurship, agility and service mentality of label converters. Just as today’s label converters are diversifying and bringing multiple technologies together under one roof, LOUPE mirrors that same spirit, uniting the full spectrum of package printing in one place to inspire innovation, efficiency, and growth for the entire industry,” said Andy Thomas-Emans, strategic director, Labelexpo Global Series and renowned industry expert.

Jade Grace, managing director, Labelexpo Global Series said, “LOUPE will continue to drive the transformation of the labels and outer packaging embellishment industry across all packaging formats. Today, we celebrate a new era with our industry”.

Women in Print Australia launched its Print & Prosecco networking series for 2025 with an intimate and engaging gathering held at the Lina Rooftop in South Brisbane.

Women in Print Australia recently hosted its annual Print & Prosecco networking event in Brisbane, offering a welcoming space for connection, collaboration, and conversation.

Now a much-anticipated highlight on the Women in Print calendar, the Print & Prosecco series brings together women from across the print, sign, display, label, and packaging sectors to build meaningful industry relationships and connect with peers.

Held at the vibrant Lina Rooftop in South Brisbane, the event welcomed around 20 attendees for an evening of relaxed networking and shared insights.

“Print & Prosecco evenings are deliberately informal,” Women in Print Australia chair Stephanie Gaddin said.

“They’re about meeting peers, casual networking, and coming together for a fun evening out. It’s all about creating space for genuine connections, a chance to catch up, share ideas, and nurture your

professional network in a relaxed setting,” said Stephanie Gaddin, chair of Women in Print Australia.

“These evenings remind us how powerful our community is when we come together to support one another.”

More Print & Prosecco evenings are scheduled to take place across the country later this year, continuing Women in Print Australia’s commitment to fostering community and connection within the industry.

E-Bisglobal marked its 35th anniversary with a celebratory Sydney Harbour cruise, honouring the milestone and recognising the contributions of long-serving team members.

NSW Central Coast-based print services, procurement, and software firm E-Bisglobal recently celebrated 35 years, marking the occasion with a celebratory Sydney Harbour cruise with staff, suppliers, business partners, and customers.

E-Bisglobal founder Paul Freeman took the opportunity to reflect on the company’s 35-year history.

“Thank you to everyone for coming along to share in this celebration with us. It’s been a wonderful journey,” said Freeman.

“We wanted today to be about acknowledging all of you – our staff, past and present, our suppliers, business partners, and customers – for the vital role you’ve played in our success. It’s been a combined effort, and I think we’ve had a lot of fun along the way.”

During his speech, Freeman paid tribute to the many people who have helped shape E-Bisglobal.

“Ann [Freeman] and I are proud of the many milestones we have achieved as a group, and we certainly would not be where we are today without your contribution.

“Our current employees are witnessing change like never before – our systems, products, and services and are all being impacted by technology, particularly AI. The executive team of Sean, Catherine, and Will are supported by an experienced management team delivering outcomes throughout the entire company and the future never looked brighter.”

He also acknowledged the contributions of former staff.

“Over the past 35 years we have employed over 400 people, most of them based on the Central Coast, making a substantial contribution to the Central Coast economy. Many of our young employees have benefited from internal and external training programs – whether they be University, TAFE or overseas training and conferences.”

Freeman also expressed appreciation for the company’s suppliers and customers.

“Loyalty is paramount to us. While our clients and business model demand that we stay ahead with technology, we aim to take our suppliers along on that journey with us.”

He highlighted training and development has also been central to the company’s long-term success.

“We’re especially proud of our trainee program which was implemented from day one. It’s always been our goal to employ young people, to invest in their potential, and to help them grow their skills and careers.”

As part of the celebration, E-Bisglobal also recognised the contributions of three long-serving team members: Scott Gibson (20 years), Graeme Wade (25 years), and April Felton (15 years) – each playing a key role in the company’s sustained growth and success.

As Mediapoint nears its 20th year, managing director Jamie Xuereb reflects on evolving trends, key challenges, and the necessity to pivot.

Melbourne-based wide-format trade printer Mediapoint will celebrate 20 years in business next year, but the journey to this milestone hasn’t been without its challenges for the company’s founders, brothers Jamie and Jason Xuereb.

Despite tough market conditions, the company has continued to invest in new equipment and technology over the past 12 months, while also building on its recent success in the packaging sector, which it re-entered two years ago.

“It has been a tough year across the print industry; there’s no hiding from that,”

Mediapoint managing director Jamie Xuereb told ProPrint.

“A lot of our trade partners have felt it. But we’ve been one of those anomaly businesses. When things get tight, more printers tend to outsource, so we’ve seen growth.

“We’ve always taken a long-term approach. Instead of pulling back, we’ve focused on getting more efficient, investing in new gear, and growing the team. So, we are actually expanding right now, not because the market is booming, but because our model helps resellers run leaner and deliver more without overextending.

“Also, we believe in doing things in opposite trends to the market to maintain advantages for our customers. It hasn’t been easy, but it has pushed us to lift our game across the board, and we’re in a stronger position because of it.”

According to Xuereb the biggest challenge in the past 12 months has been the market downturn.

“You can really see the pressure hitting the industry. A lot of companies are struggling with cash flow. Payment times have blown out or, in some cases, customers just haven’t had the funds to pay at all,” he said.

“So, we’ve had to be a bit more cautious and make sure we’re working with trade partners who are stable and will keep running long-term. We have also looked at taking our time to find superstars to join our team, so the challenge has been being there at the right time and place.

“That said, there have still been some big wins. Even in this tough market, we’ve seen solid growth in key product areas, which has helped keep our topline moving in the right direction. At the same time, we’ve taken a hard look at our internal processes – there were a lot of quick wins we could act on, and tightening those up has made a big difference to our bottom line.”

Mediapoint has continued to add to its extensive fleet of machinery, recently installing a Zünd G3 3XL-3200 cutter and a Parkland TC25 Series R semiautomatic core cutting machine.

“We’ve focused our investments over the past year on making what we already do even better,” Xuereb said.

The G3 3XL-3200 is the second Zünd cutter for Mediapoint.

“We’d been running efficiently with just one – and surprisingly, it was keeping up with our Durst D4,” Xuereb explained.

“But we started seeing an increase in the type of work that demanded faster turnaround from our finishing team. So, we added another Zünd to boost our speed and precision, particularly for larger volume jobs.

“Working directly with the brand is always the best experience. For us, partnering with companies like Zünd and Durst –where you have local support and direct contact with the manufacturer – is a huge advantage. When we’re investing in equipment, it’s really important to know we can speak directly with the brand.”

He added that many of Mediapoint’s investments are driven by a philosophy of refining their core offerings rather than expanding too broadly.

“Sometimes the risk is going too wide –trying to do too many things and losing focus. In this industry, everyone has their niche. If you stretch too far, there’s a real danger of neglecting what you do best,” he said.

The newly installed cutter has also brought operational improvements.

“It has helped us speed up turnarounds and added more flexibility to our labelson-rolls offering,” Xuereb said.

One of the biggest upgrades, however, has been behind the scenes.

“Our storage capacity has increased fivefold. That has allowed us to hold more stock and be a lot more responsive to last-minute orders or unexpected volume spikes. So, while we haven’t gone wide into new product lines, we’ve doubled down on the areas we’re strong in and made them more scalable, faster, and reliable for our trade partners,” Xuereb said.

As for expansion, Mediapoint is keeping its focus on maximising existing capabilities.

“At the moment, like many in the industry, we’re focused on getting more out of what we already have. We’re working closely with our trade partners to gather feedback on what stocks and finishes they’d like to see, and that’s shaping our roadmap. So, while we haven’t launched any major new product lines just yet, we’re actively planning for it,” Xuereb added.

He noted that much of Mediapoint’s equipment is now beyond its mid-life cycle, creating more flexibility to explore new areas when the time is right.

“It’s about timing and understanding where demand is heading and making sure we can grow and pivot without losing efficiency,” he said.

The packaging sector is also on Mediapoint’s radar – the company made its return to the labels and packaging market in 2023 after purchasing a Durst Tau RSC E label printer.

Mediapoint had originally entered this sector more than a decade ago but shifted its focus to wide-format printing instead at the time.

Plans to re-enter the market began in 2020, inspired by a 2019 demonstration of the Tau RSC E at Durst’s headquarters in Brixen. However, the company’s expansion was delayed due to COVID.

“We saw the Tau RSC E at Durst headquarters in Brixen in 2019 and recognised that it was a premium machine that was also upgradable to meet our future needs,” Xuereb said.

“The capabilities of the Durst Tau during the demonstration were astonishing. The prints at 1200dpi and a two-picolitre drop were the best I had seen and did not expect from an inkjet UV printer.

“I had not even seen any digital sheetfed prints in the local market that were of that quality. At this point, we knew the print

technology was ready for what Mediapoint wanted to achieve.”

Packaging has now become a major growth market for the company.

“Between our Durst D4 [also purchased in 2023] and Tau, we can cover both board and adhesive-based packaging, and more trade partners are leaning into short-run, custom packaging options. We see that as a space with a lot of upside. It’s an area that’s steadily climbing for us, and we expect it to keep growing as more resellers look for value-add products beyond traditional print,” he said.

“Labels-on-rolls is another area where demand is strong. We’ve built an efficient workflow for it, and resellers are starting to rely on us more as they step away from in-house production or look to offer more without the overhead.

“And honestly, we’re also seeing growth in the overall number of trade partners who want to simplify their outsourcing more. They want reliability, and they’re looking for suppliers who can scale with them. That’s exactly what our model is built for, so we’re feeling confident about what’s ahead.”

According to Xuereb, one of the most significant trends shaping the industry is the changing profile of customers.

“When we started Mediapoint, I was 18 and most of our customers were older than me. Now I’m 37, and a large portion of our trade partners are my age or younger –and that segment is growing fast,” he said.

“The customer landscape is shifting. For nearly two decades, our client base that was made up of mostly older people than me preferred a certain way of doing business. But now, we’re seeing a clear transition. Many of our newer trade partners are younger than I am, and they expect something very different from the print experience.”

Xuereb said this new generation has a digital-first mindset.

“They don’t want to talk to anyone – they want digital tools, self-service options, fast responses, and full transparency throughout the process. It’s not about backand-forth communication anymore; it’s about speed, ease, and autonomy,” he said.

“We’re in a transition phase right now. Half the market still prefers traditional interactions, while the other half wants digital-first solutions. The challenge is finding the right balance. That’s why we’re already thinking ahead about building the infrastructure, technology,

and AI capabilities we’ll need to meet future expectations.”

Sustainability and how to implement it in a practical and meaningful way is also a priority for Mediapoint.

“Sustainability is something we’re always thinking about, but for us, it’s less about big slogans and more about real, day-today improvements,” Xuereb mentioned.

“A big part of our focus has been on reducing waste through leaner processes and automation. Because we run such a streamlined workflow, we minimise overruns, reduce handling, and avoid unnecessary reprints and that’s better for the environment and better for our resellers’ margins.

“Weve also made stock choices that balance performance with sustainability, especially on our labels on rolls and board products. And as we add or upgrade equipment, energy efficiency and material usage are always part of the decision-making.

“Therefore, while we’re not marketing ourselves as an ‘eco printer’, we’re making steady changes that have a real impact.”

Looking ahead, Xuereb says Mediapoint is focused not only on long-term business growth but also on the wellbeing of its team.

“For us, it starts personally. Jason and I work closely with a lot of printers. Many of them are smaller than us and we feel a responsibility to be role models – not just in business, but in how we show up,” he said.

“Therefore, one of our big goals is around family and mental wellbeing. If we’re not in a good space personally, we can’t serve our trade partners properly. And honestly, I hope all our stakeholders, customers, team, and suppliers can get that balance right for themselves too over the next 12 months.

“From a business point of view, the next 12 months are all about laying the groundwork for the next 10 to 20 years. We’ve shifted gears and are currently in the middle of a few key projects that are helping us reshape Mediapoint for the future operationally, strategically, and culturally.

“We’re also building our team. We’re looking for stars in the industry who want

somewhere they can grow long-term. That’s been one of the biggest wins this year bringing in fresh energy and hungry talent, which has made a massive difference to where we’re headed.”

Next year, Mediapoint will celebrate its 20th anniversary. While it’s a major milestone for the brothers, Xuereb says they plan to keep the celebration meaningful and true to the company’s values.

“We’re definitely planning to mark the 20-year milestone; it’s a big one for us. But we’re not looking to do anything over the top or flashy as that is not us,” he said.

“What we really want is to use the moment to thank the people who’ve supported us along the way, our team, our trade partners, and the suppliers who’ve been part of the journey.

“We’re still shaping what that looks like, but it’ll be something meaningful and aligned with who we are as a business. More than anything, it’s a chance to reflect on how far we’ve come and set the tone for where we’re going in the next 20 years.”

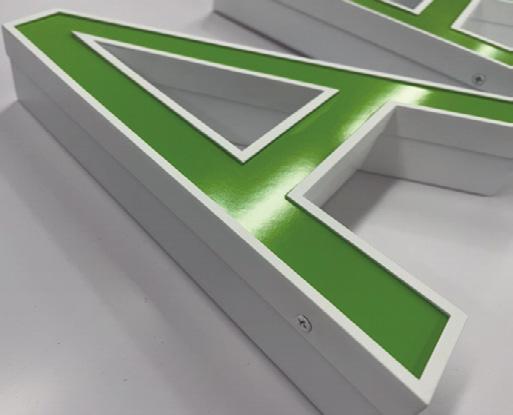

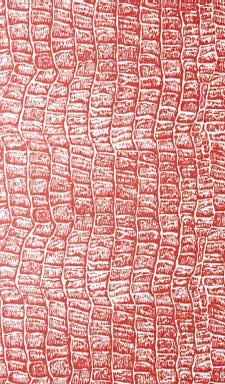

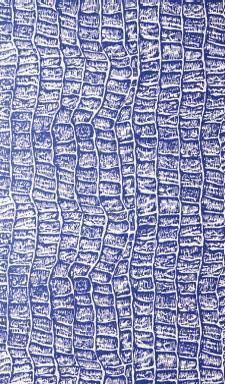

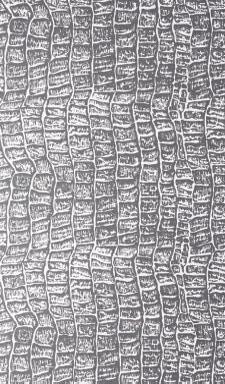

Spicers’ latest addition to the Evolution in Grip series, the Super Tack Pack, combines high-performance adhesive and film-based products designed to tackle the most demanding applications.

In the natural world, survival is not guaranteed by strength alone but by the ability to adapt. The species that thrive are those resilient enough to adjust to change, no matter how harsh the environment. At Spicers, this same principle of adaptation is central to how it approaches its products, customers, and solutions.

Every day, printers, converters, and specifiers face challenges in delivering visual communication projects that don’t just look good on day one but stand the test of time. Whether it’s the shifting demands of a retail campaign, the durability required for outdoor signage, or the difficulty of adhering to

unconventional surfaces, success relies on products that can rise to the challenge.

That’s where Spicers’ Evolution in Grip series comes in. Inspired by resilience in nature, the series brings together highperformance adhesive and film-based products engineered to meet the toughest applications. Each edition in the series builds on the last, offering practical, reliable, and versatile solutions designed to perform on walls, windows, floors, and other hard-to-stick surfaces.

Now, the series has entered its next chapter with the launch of the Super Tack Pack – a carefully selected suite of high-tack solutions engineered

specifically for ultra-challenging environments. This fourth instalment continues Spicers’ mission of providing customers with the tools they need to deliver with confidence, no matter how demanding the brief.

The Super Tack Pack steps up where other products fall short. Imagine applying graphics to a heavily textured wall in a busy laneway, to the rough surface of construction hoarding, or onto low-energy surfaces where adhesion is notoriously difficult. These are exactly the kinds of challenges the Super Tack Pack has been engineered to conquer.

With options for both indoor and outdoor use, the pack’s products deliver uncompromising adhesion, ensuring that campaigns stay put and remain visually striking for their intended lifespan. From short-term activations to long-term signage, these solutions hold fast.

Wayne Hood, Spicers’ visual communications portfolio manager, highlights why this release is so significant, “The Super Tack Pack gives our customers the confidence to deliver – from seasonal retail campaigns through to long-term outdoor signage. In a market where performance and reliability are non-negotiable, this pack is proof of Spicers’ commitment to evolving with our customers’ needs and exceeding expectations”.

The pack is more than a collection of films –it’s a toolbox of solutions tailored for realworld challenges faced daily in the industry.

The Super Tack Pack brings together six proven high-tack performers from trusted international brands:

• 3M IJ180LSE: A premium cast film designed for low-surface-energy substrates, offering exceptional conformability.

• 3M IJ39: A reliable high-tack solution ideal for a variety of surfaces and applications.

• GF 201HTAP: General Formulations’ high-tack option with excellent printability and easy application.

• GF 203HTAP: Another General Formulations film, offering slightly different performance characteristics for broader application flexibility.

• Rocal 5 Year High Tack Series: A durable choice designed for extended outdoor exposure, combining strength with longevity.

• Rocal 3 Year High Tack Series: A shorter-term but highly reliable solution, ideal for temporary campaigns where adhesion cannot be compromised.

Together, these products cover the spectrum of high-tack applications, making the pack a versatile resource for specifiers, converters, and printers alike.

As Hood explains, the strength of Spicers lies in the breadth of its offering, “We are continuously looking at solutions that help our customers achieve results in a range of applications. The Super Tack Pack is the latest example of that commitment”.

The Evolution in Grip series has built its reputation not only on the quality of its product selection but also on the way the range has been presented. Each edition in

the series has been meticulously designed as both a product showcase and a practical decision-making tool.

For many in the industry, choosing the right adhesive film can be complex. Variables such as adhesive type, durability, print compatibility, surface type, and environmental conditions all need to be considered. To make that process easier, each Evolution in Grip pack provides tangible samples alongside clear technical insights.

The entire series features 29 printed samples across the four packs, giving customers a direct, hands-on way to test and compare product performance. This tactile approach ensures specifiers and converters can confidently select the most suitable film for their application.

Cyndi Setia, marketing and design manager at Spicers, underscores the importance of this approach, “Each of the four packs clearly outlines the product features, adhesive type, durability, material, and print compatibility. These are all critical factors when considering stock selection, and the packs are designed to give our audience the information they need to make the right choice for their applications”.

The Super Tack Pack continues this tradition of clarity and usability. It is both a sales tool and an educational resource –

ensuring that customers can approach their projects with knowledge, confidence, and creativity.

The Evolution in Grip series has already made its mark within the visual communications sector, not only in terms of usability but also through industry recognition. Past editions have been finalists at the National Print Awards and winners at the Real Media Awards, reflecting the impact of the series as both a promotional tool and a genuine enabler of better outcomes. The Super Tack Pack

itself was the result of collaboration across Spicers’ network of partners:

• Folders printed by Southern Impact

• Sample inserts printed by Mezographic

• Design by Spicers’ in-house marketing team

As Setia explains, “We wanted to build on a successful series with a pack in high demand, released at the perfect time for seasonal campaigns”.

This collaborative approach not only showcases Spicers’ strong relationships

within the print industry but also ensures the finished pack embodies the same quality and attention to detail as the products it contains.

At the core of the Evolution in Grip series is a line-up of products from some of the world’s most trusted brands. Spicers has partnered with global leaders such as 3M, General Formulations, Neschen, PhotoTex, Rocal, and Yupo – brands known internationally for their performance, reliability and consistency.

By bringing these brands together in one series, Spicers positions itself as a true destination for adhesive films and solutions. Customers don’t need to navigate a fragmented marketplace; instead, they have access to a comprehensive, curated range backed by Spicers’ service and expertise.

While at first glance, the Super Tack Pack may appear to be a collection of product samples, in practice it is much more. It is:

• A problem-solver for difficult applications.

• A confidence booster for printers and converters needing reliable results.

• A time saver for specifiers who want clarity when choosing films.

• A training tool for new staff learning about adhesive films.

• And a creative enabler for designers and marketers who want to push boundaries without worrying about adhesion issues.

By combining innovation with usability, the pack becomes a trusted companion throughout the lifecycle of a campaign –from concept to installation to removal.

The launch of the Super Tack Pack is not just an addition to Spicers’ range; it’s a continuation of a philosophy. A belief that to thrive, businesses – like species in nature – must be able to adapt. The Evolution in Grip series demonstrates how Spicers continues to evolve alongside its customers, anticipating their challenges and providing the solutions they need to succeed.

With the Super Tack Pack, Spicers reinforces its role as a partner in creativity, innovation, and execution. For short-term retail activations, seasonal promotions, or long-term outdoor signage, these products deliver adhesion that can be trusted.

Because when ideas are engineered to stick, they don’t just survive – they thrive.

Committed to growth and innovation, Ball & Doggett offers equipment that empowers its customers to expand their in-house print manufacturing and finishing capabilities.

Wide format printing has evolved far beyond traditional signage applications. Thanks to rapid technological innovations, wide format printers now deliver a much broader range of services, moving away from commodity printing toward high-value, specialised solutions.

According to Tatjana Ferguson, national manager – large format equipment at Ball & Doggett, these advancements have expanded into non-traditional areas such as interior décor, architectural applications, education, manufacturing, and technical printing.

One notable development is Direct-toObject (DTO) printing, where flatbed UV printers apply high-quality images and text directly onto three-dimensional objects, materials, and substrates. Using UV-cured inks that dry instantly, this process ensures durability, a premium finish, and the ability to personalise items such as phone cases, trophies, ceramic tiles, golf balls, bottles, tabletops, and even wheel rims.

According to Ferguson, another major growth area is digital textile printing, particularly for fashion, sportswear, and home décor. This sector continues to drive demand for wide format printers as businesses seek faster, more flexible production methods

“Trends in Direct-to-Garment (DTG) printing include growing demand for personalisation, eco-friendly water-based inks for cotton and blends, and the rise of on-demand printing to reduce waste. Sublimation trends involve increased use for sportswear, gifts, and promotional products on polyester, with advances in productivity and automation,” Ferguson said.

“The demand for sustainable and versatile natural fibre textile printing is being met by Kornit Digital’s direct digital printing on fabrics and Mimaki’s waterless, pigment transfer system, TRAPIS. These methods allow for high-quality printing on a wider range of materials, including cotton and silk, without the significant pre-treatment, water usage, and fabric limitations of traditional sublimation, which is restricted to polyester.”

The increase in on-demand and customised printing has further accelerated interest in Direct-to-Film (DTF) technologies.

“With low equipment investment, easy setup, and broad versatility, DTF offers a cost-effective way to produce highquality, personalised prints across a wide variety of surfaces – enabling businesses to serve niche markets and smaller production runs more efficiently,” Ferguson said.

In response to these shifting industry demands, Ball & Doggett’s extensive range provides customers with equipment designed to expand their in-house print manufacturing and finishing capabilities.

The Ball & Doggett range features:

• Advanced wide-format cutting tables and finishing technology – delivering automated production of complex shapes and sizes with minimal waste, greater speed, and consistent quality.

• Compact, user-friendly equipment for automated carton cutting – ideal for short-run packaging. These systems can cut, crease, and perforate directly from design files, streamlining production for packaging converters, e-commerce brands, and commercial printers. As an accessible entry point into automation, they save time, reduce waste, and unlock new revenue opportunities through fast, flexible packaging solutions.

Looking ahead, Ferguson believes the wide format printing sector is positioned for sustained growth.

“Ongoing advances in print head technology, ink formulations, digital systems, and automation will further improve efficiency while opening new application possibilities,” she said.

Sustainability will also remain a defining priority, driving the development of ecofriendly substrates, low-impact inks, and energy-efficient processes.